Welding wire suitable for welding low-strength H2S-corrosion-resistant pipeline steel in submerged arc mode

A technology of submerged arc welding and pipeline steel, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of easy increase of hardness, easy segregation of weld seam, limited resistance to stress corrosion, etc., and achieve excellent low temperature impact performance, The effect of low weld metal hardness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below:

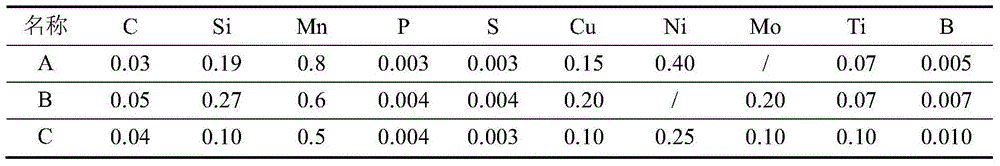

[0022]A type suitable for low-strength (360Mpa ~ 420Mpa) H-resistant 2 Welding wire for submerged arc welding of S corrosion pipeline steel, the welding wire is composed of the following weight percentages: C: 0.03-0.05%, Mn: 0.5-0.8%, Si: 0.1-0.22%, P≤0.005%, S≤0.004%, Cu: 0.1-0.2%, Ti: 0.06-0.15%, B: 0.005-0.012%, one or both of Ni: 0.2-0.5%, Mo: 0.1-0.2%, and satisfy C% +Si% / 30+Mn% / 20+Cu% / 20+Mo% / 15+Ni% / 60≤0.15, and the rest is Fe.

[0023] According to weight percentage, Mn: 0.5%-0.8%.

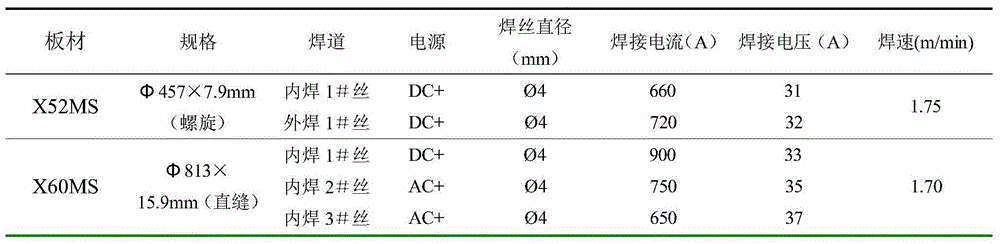

[0024] The welding wire and BG-SJ101G flux are used together for H 2 Submerged arc welding of S corroded pipeline steel.

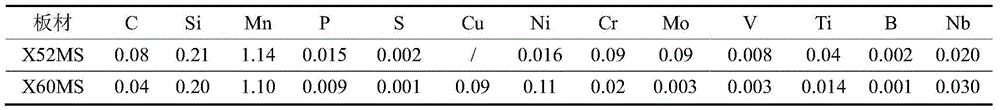

[0025] The low strength (360Mpa ~ 420Mpa) resistant to H 2 The corresponding pipeline steel grades of S corrosion pipeline steel are X52MS~X60MS.

[0026] The acid-resistant submerged arc welding wire of the embodiment of the present invention is used to weld with high-purity BG-SJ101G flux to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com