Patents

Literature

1268 results about "Acid corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CMP method utilizing amphiphilic nonionic surfactants

InactiveUS6936543B2Other chemical processesSemiconductor/solid-state device manufacturingOrganic acidCopper

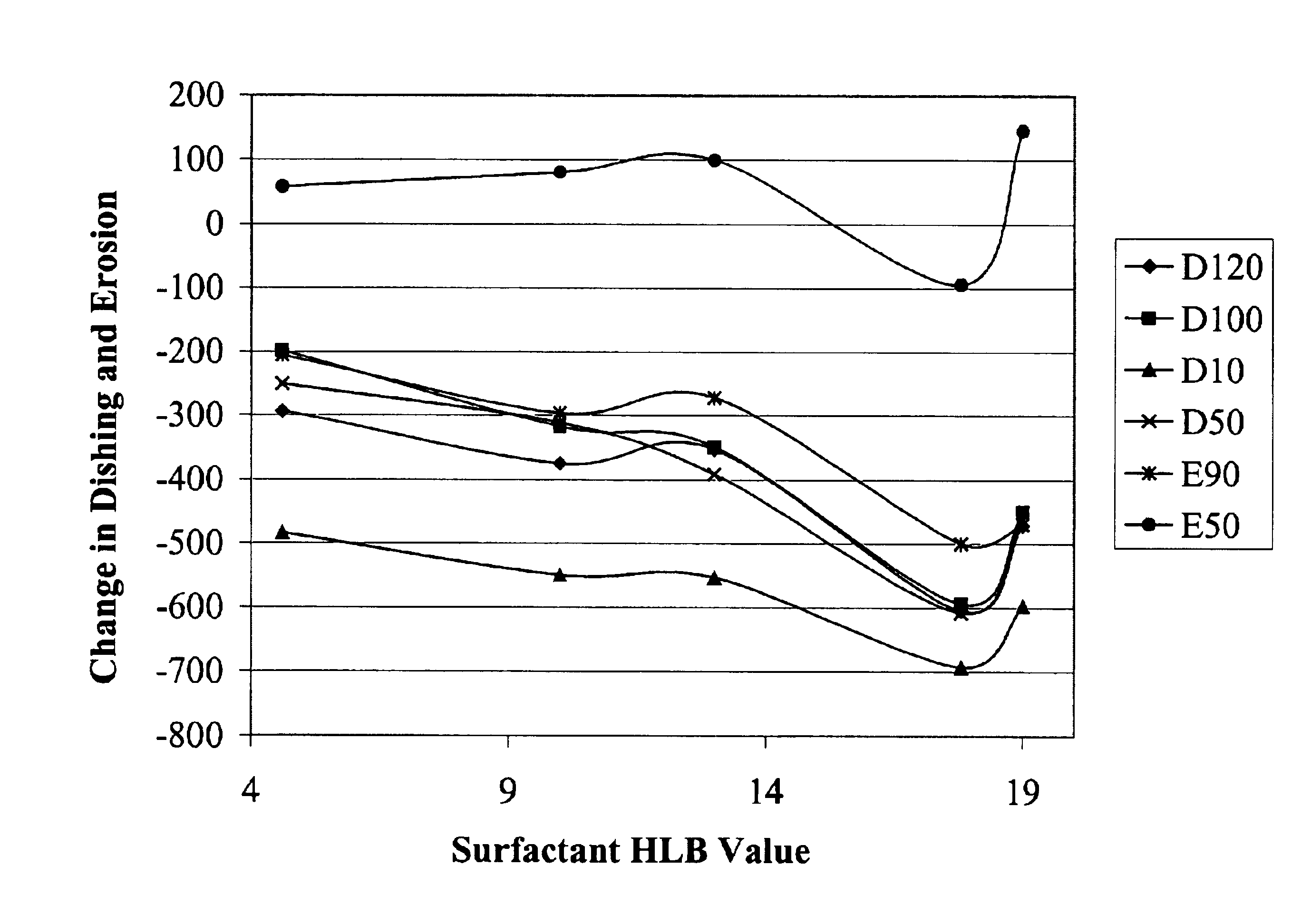

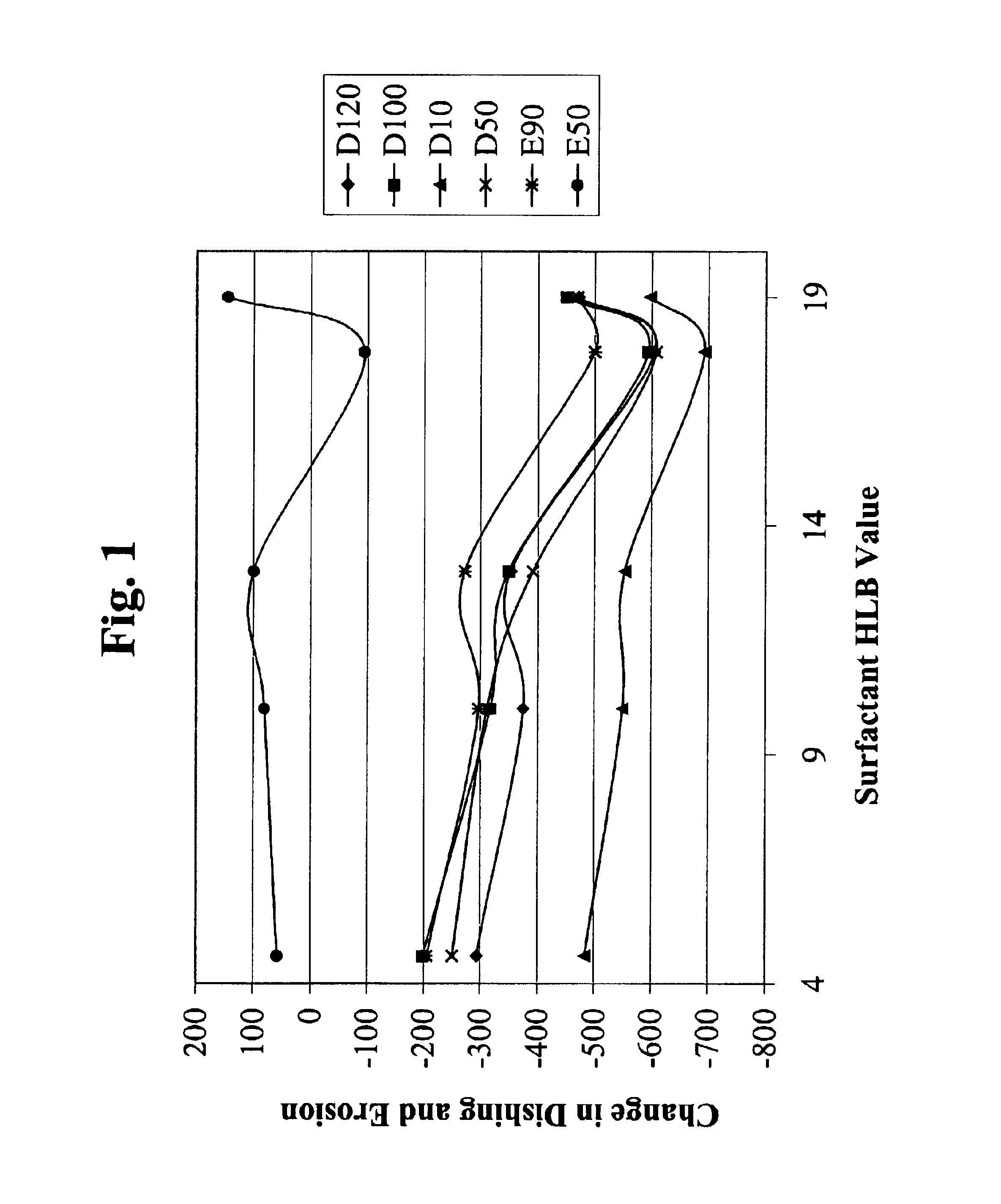

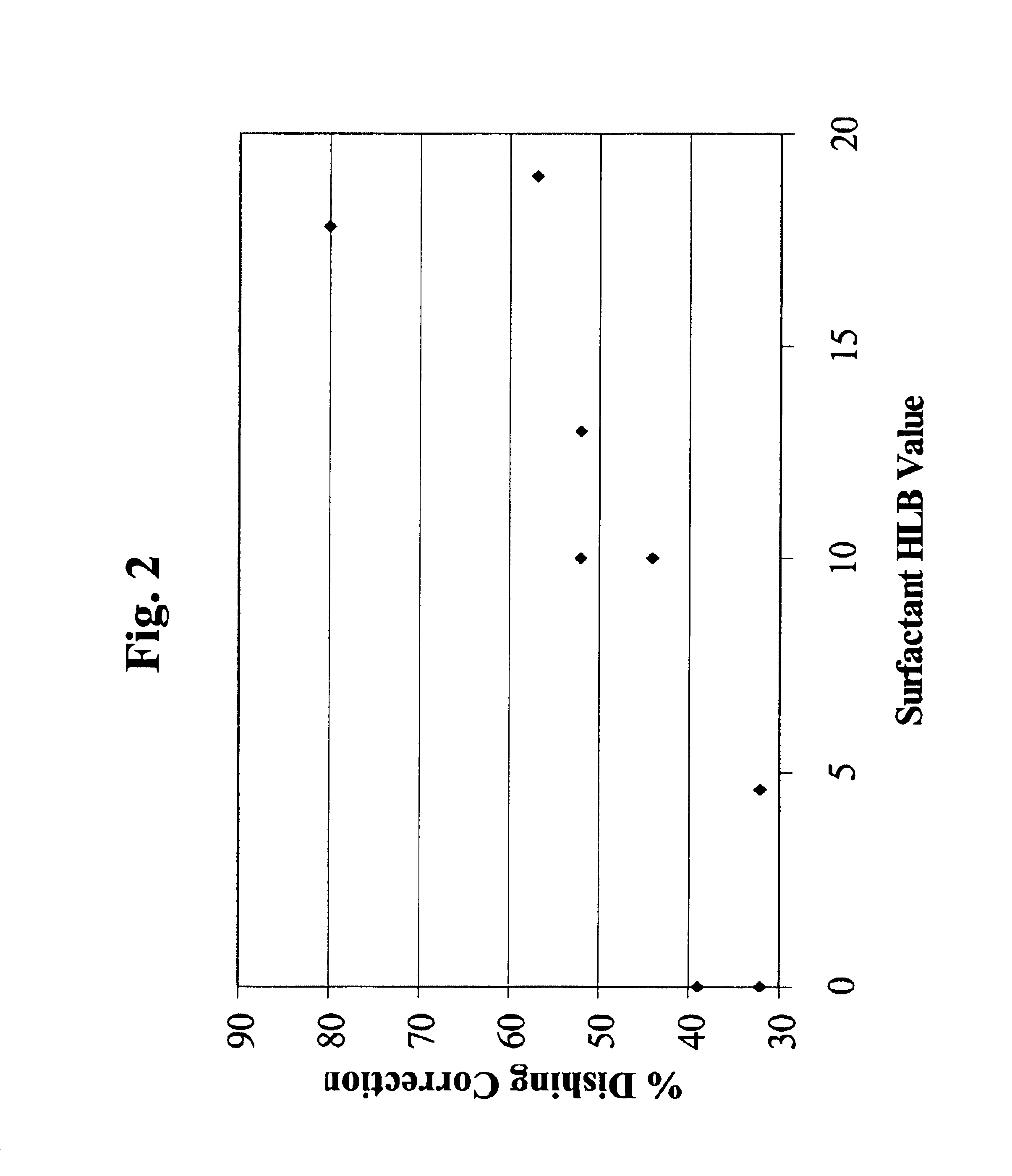

The invention provides methods of polishing a substrate comprising (i) contacting a substrate comprising at least one metal layer comprising copper with a chemical-mechanical polishing (CMP) system and (ii) abrading at least a portion of the metal layer comprising copper to polish the substrate. The CMP system comprises (a) an abrasive, (b) an amphiphilic nonionic surfactant, (c) a means for oxidizing the metal layer, (d) an organic acid, (e) a corrosion inhibitor, and (f) a liquid carrier. The invention further provides a two-step method of polishing a substrate comprising a first metal layer and a second, different metal layer. The first metal layer is polishing with a first CMP system comprising an abrasive and a liquid carrier, and the second metal layer is polished with a second CMP system comprising (a) an abrasive, (b) an amphiphilic nonionic surfactant, and (c) a liquid carrier.

Owner:CMC MATERIALS INC

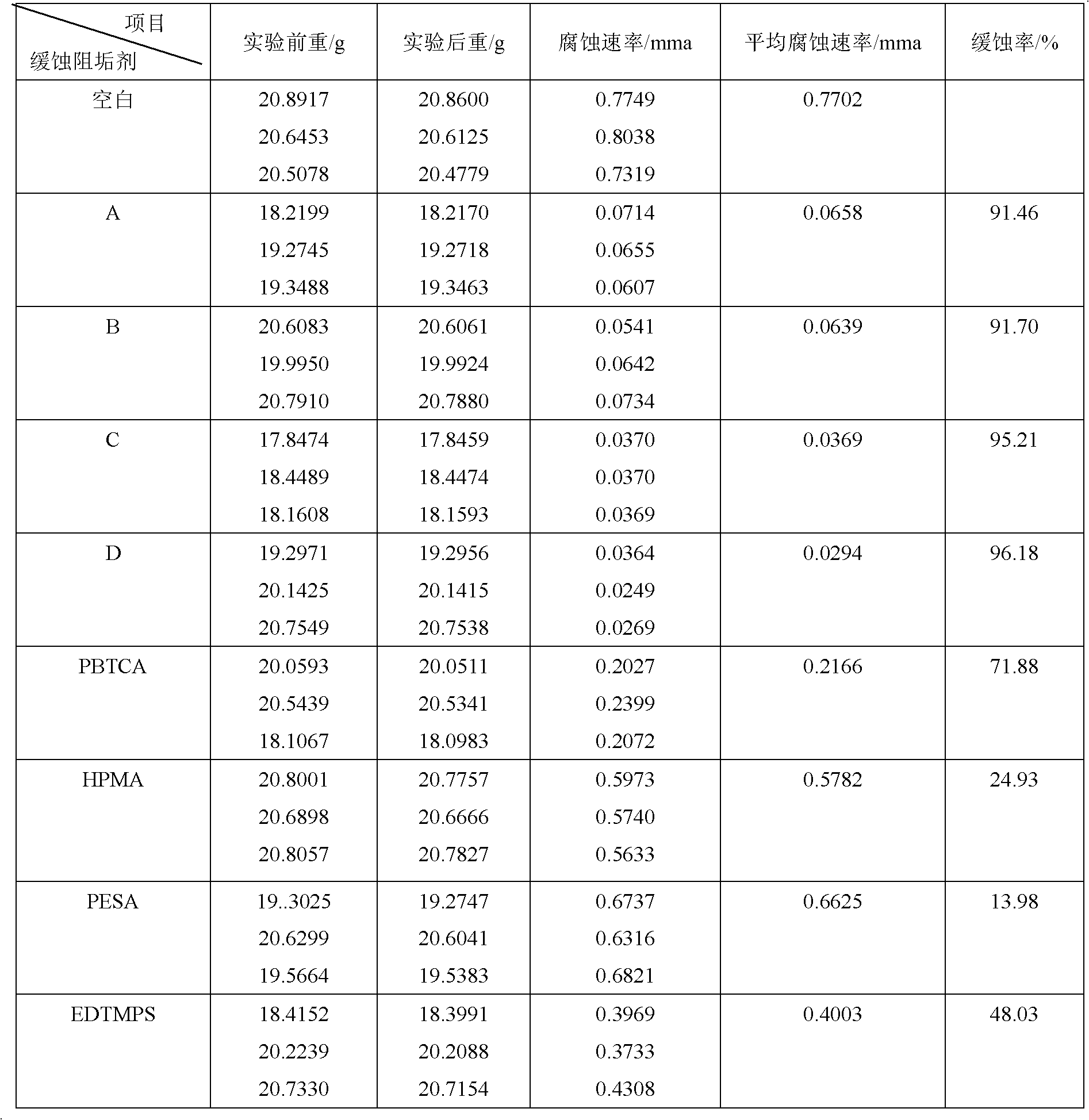

Corrosion and scale inhibitor for cooling water in petrochemical industry

ActiveCN102603086AStrong targetingLow phosphine contentScale removal and water softeningChemical industryPetrochemical

The invention belongs to the technical field of chemical industry, and relates to a cooling water corrosion inhibitor, in particular to an efficient composite corrosion and scale inhibitor which can remarkably reduce corrosion and scaling phenomena of the cooling water of a petrochemical system. The corrosion and scale inhibitor is prepared by evenly mixing organic phosphine carboxylic acid corrosion inhibitor, organic multi-element phosphine acid corrosion and scale inhibitor, polymer scale inhibitor, metal ion succimer, surface active agent, zinc salt, functionality additive and water. The corrosion and scale inhibitor prepared from the components has low phosphine content and excellent corrosion and scale inhibition performance, can prolong the service life of devices, improve the repeated utilization rate of cooling water and reduce the water resource consumption.

Owner:山东京博众诚清洁能源有限公司

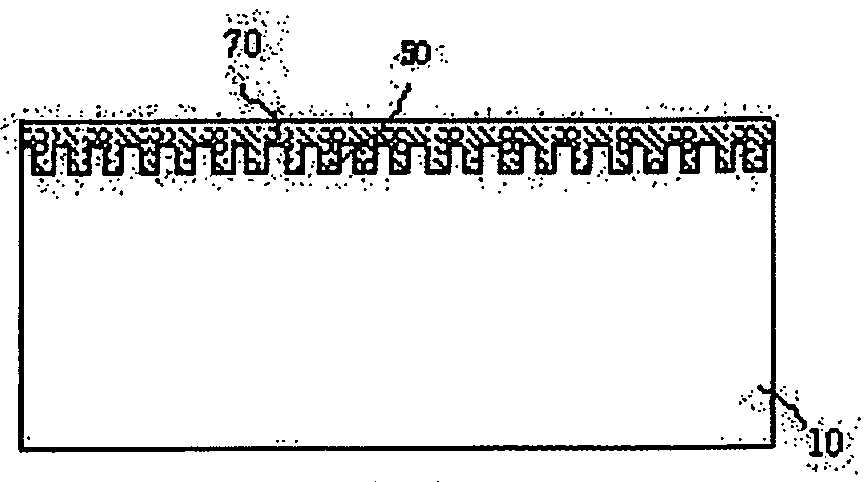

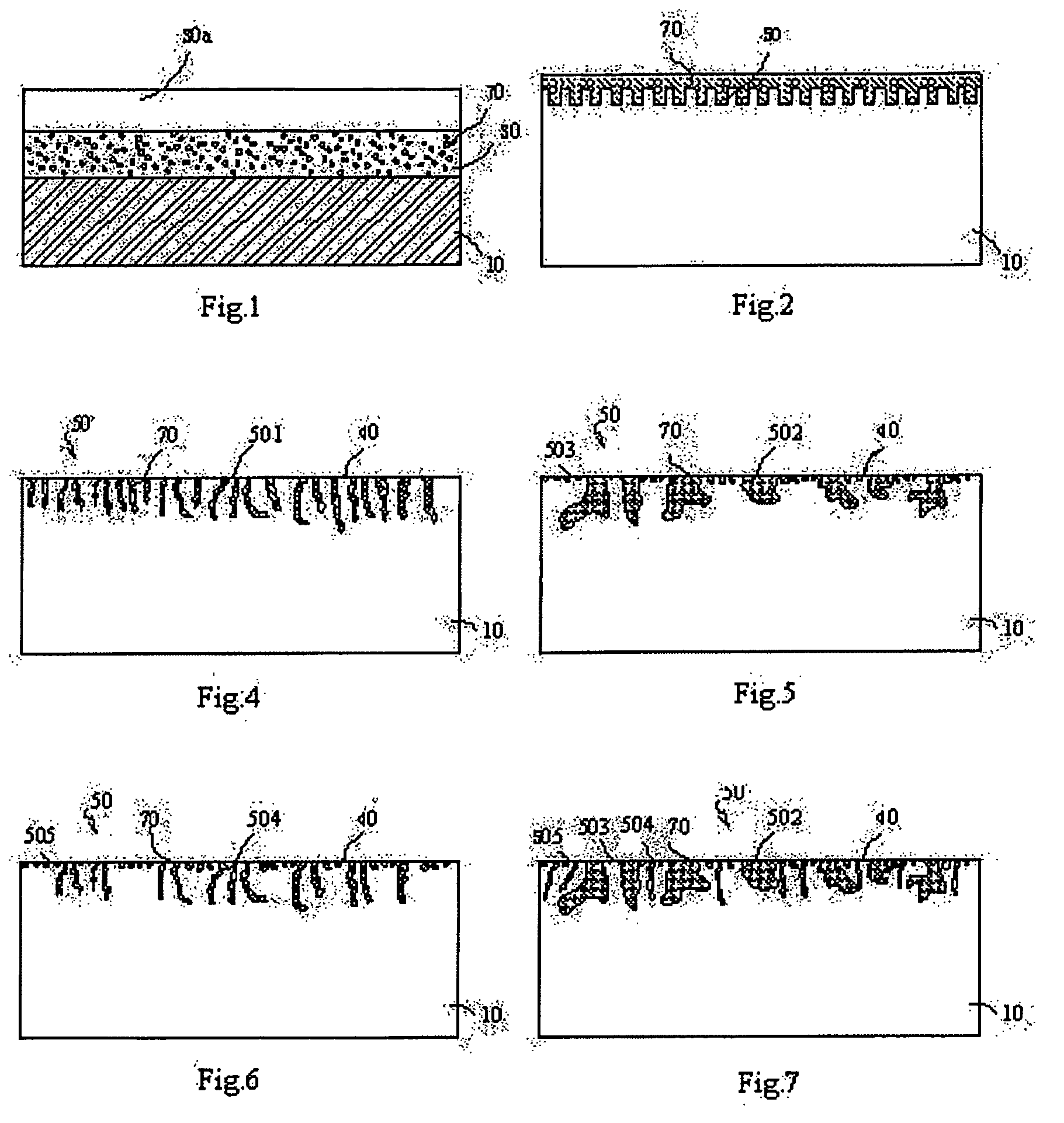

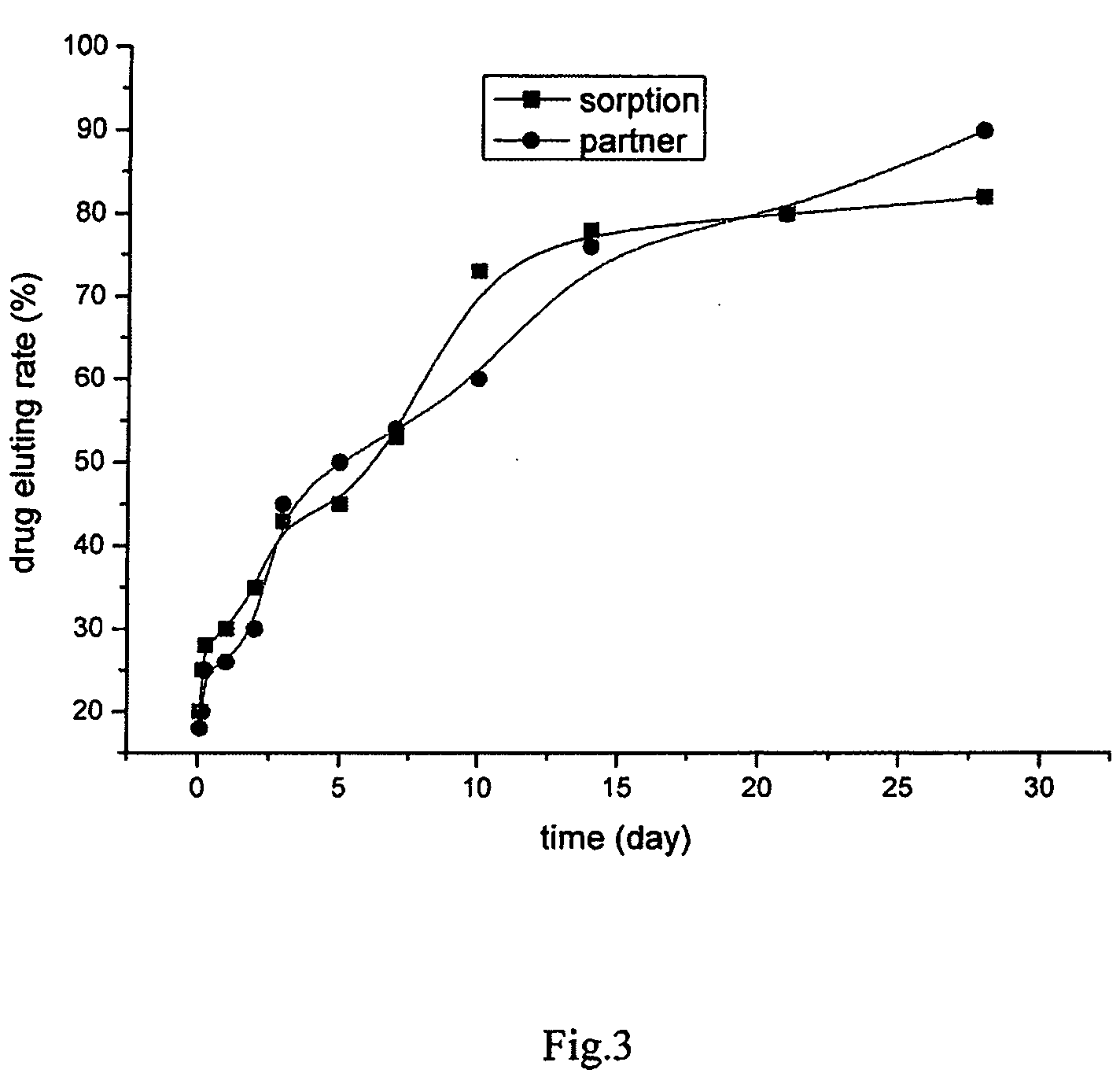

Nanoporous Drug Release Structure for Drug Elute Instruments and the Preparation Method Thereof

InactiveUS20090112310A1Reduce riskNo effect on mechanical propertySurgeryPharmaceutical delivery mechanismMicro arc oxidationPercent Diameter Stenosis

The present invention relates to a nanoporous configuration for drug release used in a drug-eluting device and its preparation, employing acid corrosion or anode oxidation to prepare pores, or employing acid corrosion to prepare pores firstly, then employing anode oxidation or micro-arc oxidation combined with micro-arc nitridation to prepare single sized or two sized or multiple sized nanopores, as well as a uniform size distributed or two or more nonuniform size distributed in pore diameter or pore depth h nanopores on the raw material of device body directly. The preparation process includes: ① Pre-treating the surface of the device body, ② Preparing pore, ③ Post-treating the surface of the device body, ④preparing drug, ⑤ Spraying drug etc. The nanoporous configuration lowers the risk of forming thrombus after the drug-delivery device with polymer carrier is implanted into the tissue. The device also controls the release rate of drug efficiently and lowers the incidence of restenosis significantly.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

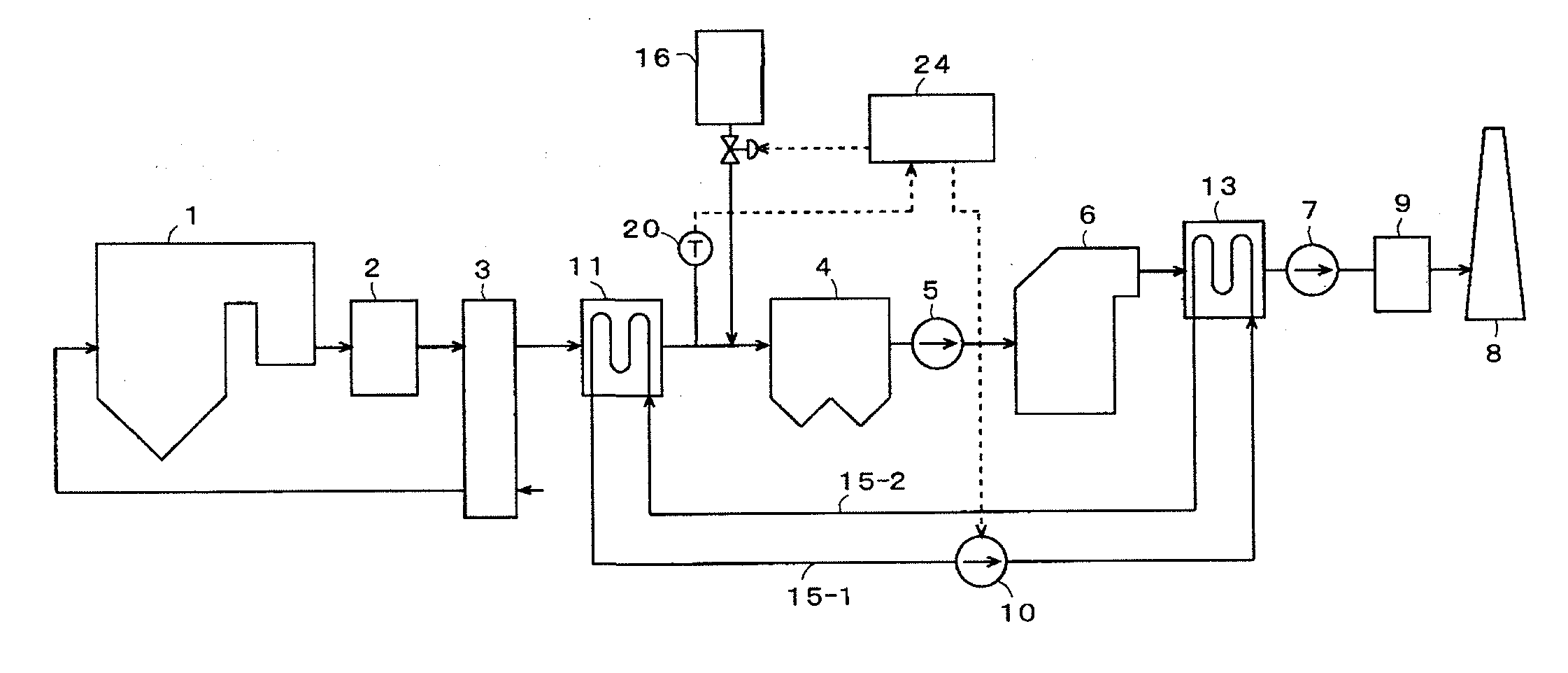

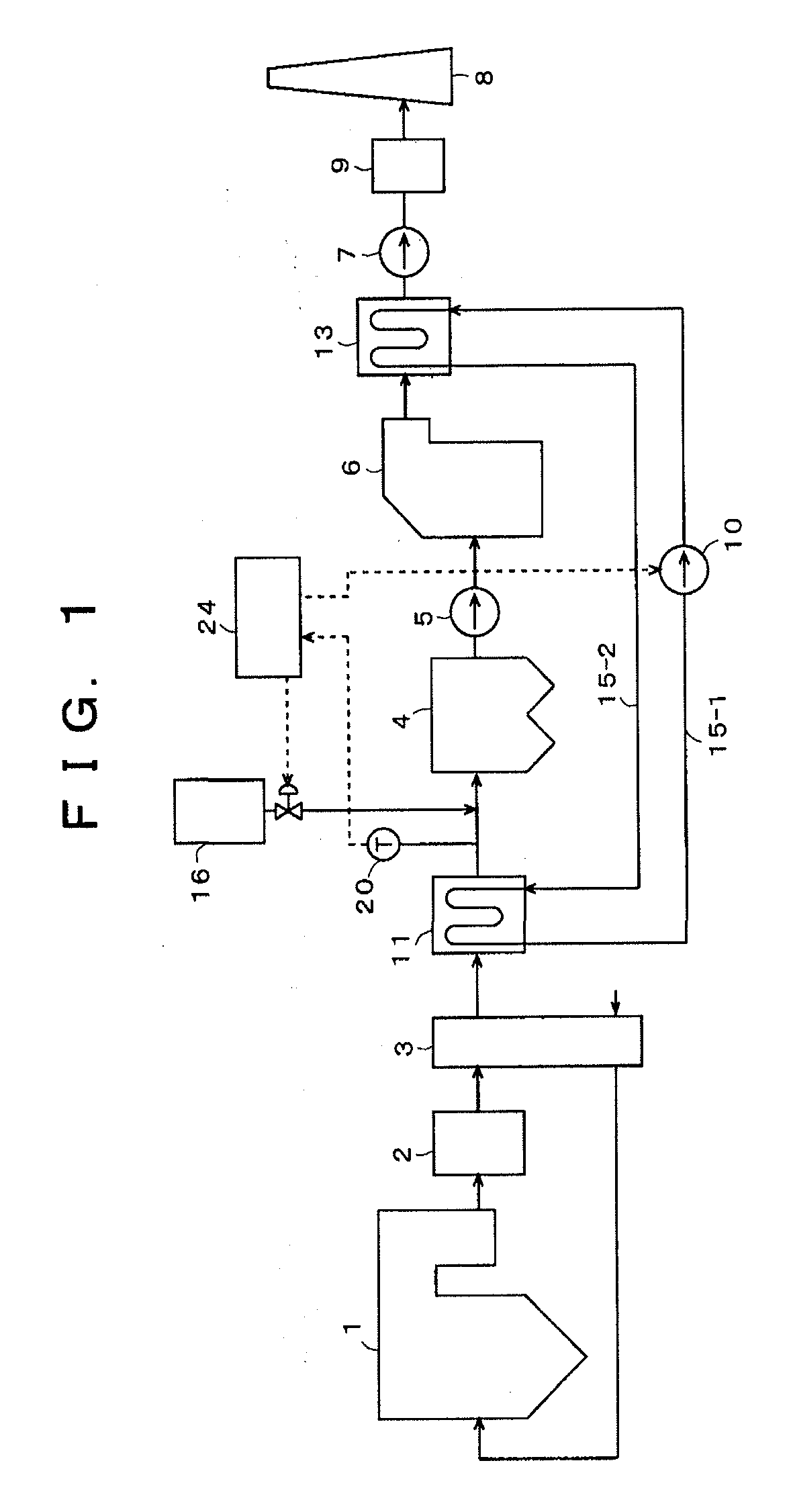

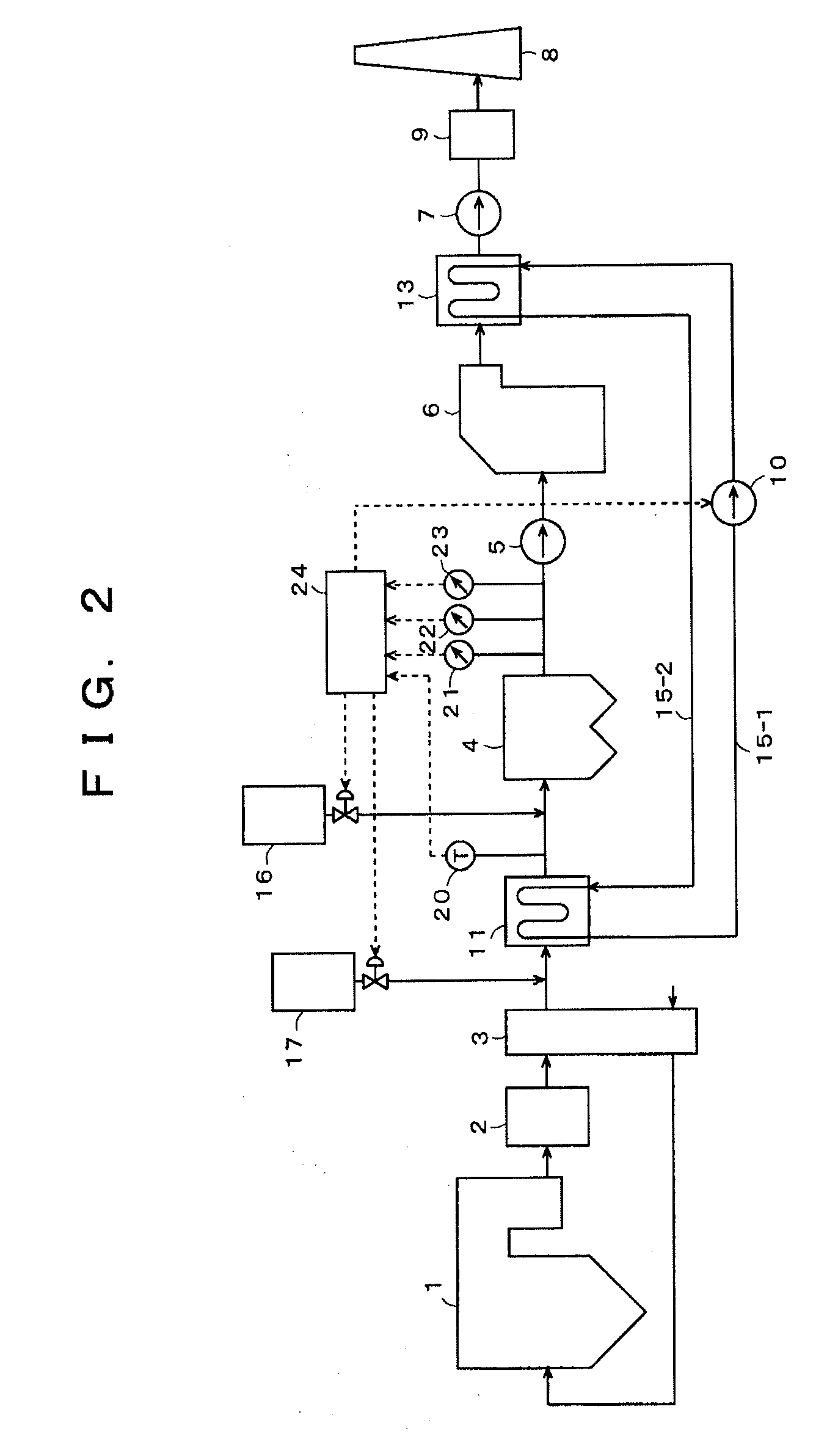

Exhaust gas treating method and apparatus

ActiveUS20100071348A1Easy to adjustReduce concentrationCombination devicesNitrogen compoundsSorbentAcid corrosion

After adjusting an exhaust gas temperature at an exit of a heat recovery unit (11) of an exhaust gas treating apparatus to not more than a dew point temperature of sulfur trioxide (SO3), a heavy metal adsorbent is supplied from a heavy metal adsorbent supply unit (16) disposed in an exhaust gas at an entrance of a precipitator (4) or an intermediate position within the precipitator (4), and the exhaust gas containing the heavy metal adsorbent is supplied into the precipitator (4). Preferably at this stage, the heavy metal adsorbent is supplied into the exhaust gas at the entrance of the precipitator (4) 0.1 seconds after the exhaust gas temperature at the exit of the heat recovery unit (11) has been adjusted to not more than the dew point temperature of SO3. Further preferably, in order to prevent acid corrosion of equipment, the heavy metal adsorbent is supplied after spraying an alkali into the exhaust gas at the entrance or exit of the heat recovery unit (11) and adjusting the exhaust gas temperature at the exit of the heat recovery unit to not more than the dew point temperature of SO3. Accordingly, even when coal with a high sulfur content is used as fuel, heavy metals in the exhaust gas can be removed effectively.

Owner:MITSUBISHI POWER LTD

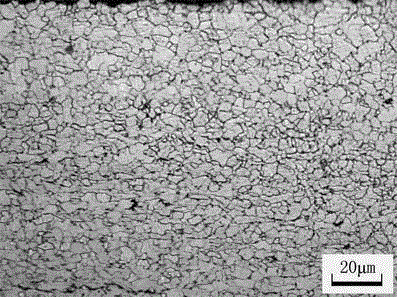

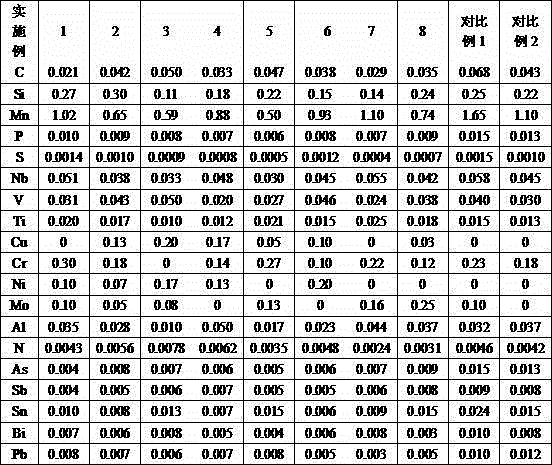

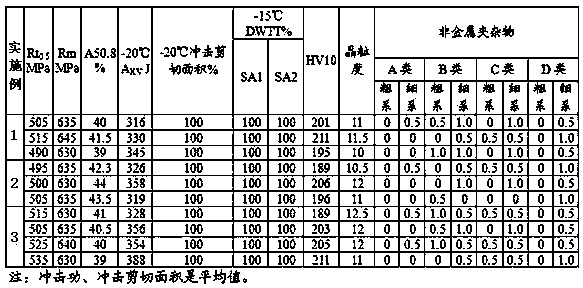

Pipeline steel excellent in acid corrosion resistance on seabed and production method

The invention discloses pipeline steel excellent in acid corrosion resistance on the seabed. The pipeline steel comprises, by weight, 0.020-0.050% of C, 0.10-0.30% of Si, 0.50-1.10% of Mn, 0.012% of P or less, 0.0015% of S or less, 0-0.20% of Cu, 0-0.30% of Cr, 0-0.20% of Ni, 0-0.25% of Mo, 0.030-0.055% of Nb, 0.020-0.050% of V, 0.010-0.025% of Ti, 0.010-0.050% of Al and 0.008% of N or less. A production method comprises the steps of heating after continuous casting and blank forming, rough rolling, precise rolling, cooling, reeling and cooling to indoor temperature. By means of the pipeline steel and the production method, an ideal complex-phase structure containing ultra-fine grain polygonal ferrite and a small number of methyl acrylate (MA) components which are distributed dispersively can be obtained, the Rt0.5 is equal to or higher than 485 MPa, the Rm is equal to or higher than 570 MPa, -20 DEG C KV2 is equal to or higher than 250 J, and -15 DEG C DWTT SA is equal to or higher than 85%. A hydrogen induced crack j (HICj) test and a sulfide stress corrosion cracking (SSCC) test indicate that no fracture or crack occurs.

Owner:武汉钢铁有限公司

Method for preparing lead-aluminum composite anode plate

The invention relates to a lead and aluminum compound anode plate material and the preparing method, which belongs to the field of electrolysis technology. The invention adopts purified aluminum plate or aluminum alloy plate, purified lead or lead and silver alloy and copper electric conducting beam as raw materials. The invention later adopts acid corrosion operation to the purified aluminum plate or the aluminum alloy plate so as to remove an oxide film. And then the surface of the aluminum plate is plated with a layer of other metals such as Ag, Mg, Sr, Zn or Sn, and the processed purified aluminum plate or aluminum alloy is placed into a mould so as to be evenly poured with a purified lead or lead and silver alloy fluid to make out the lead and aluminum compound cathode plate blank. Finally, the lead and aluminum compound cathode plate blank is milled into the lead and aluminum compound cathode plate. The lead and aluminum compound anode plate has the advantages of fine electric conduction, possible groove voltage reduction, electric energy conservation and high intensity of the compound anode plate as well as impossible deformation.

Owner:YUNNAN METALLURGICAL GROUP

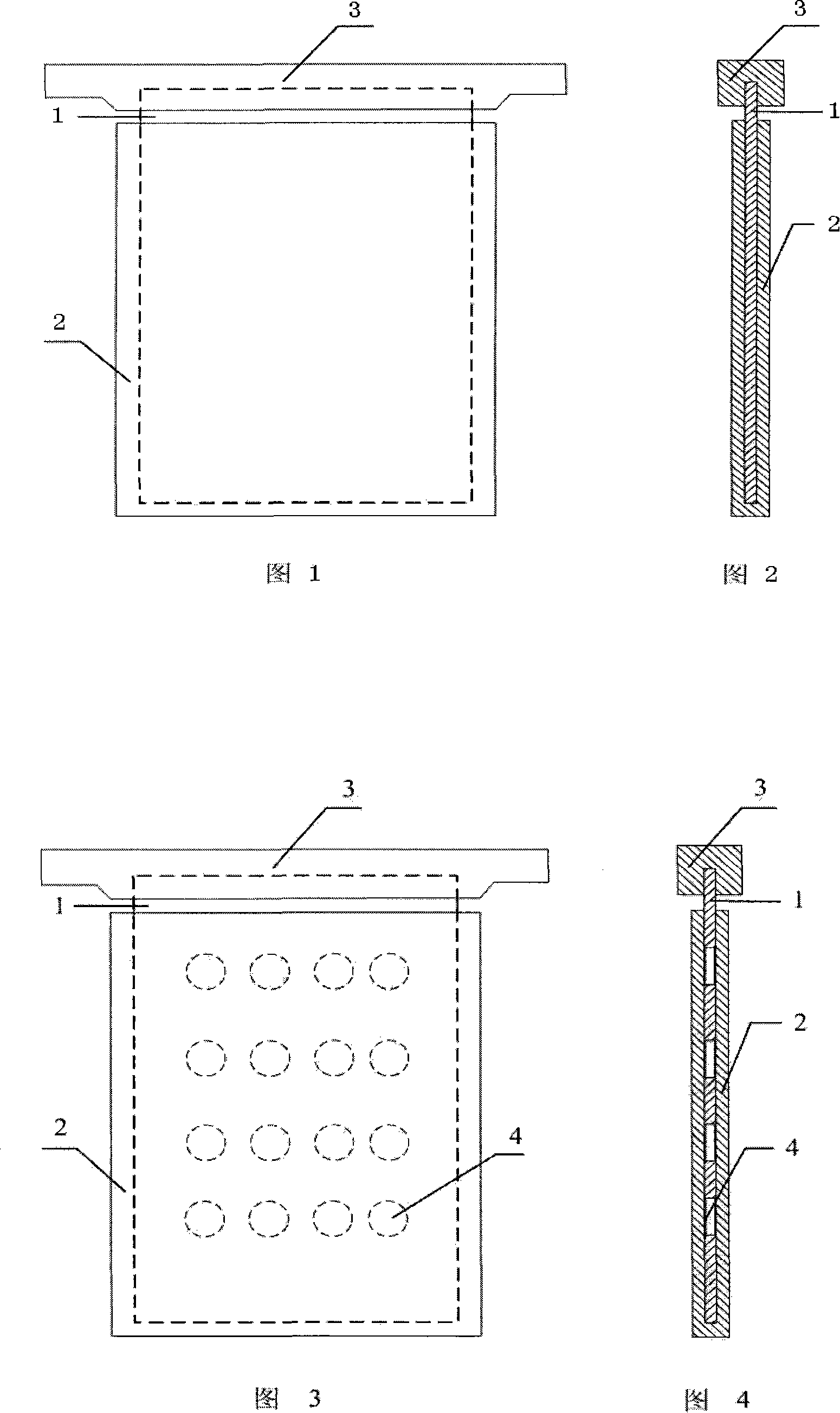

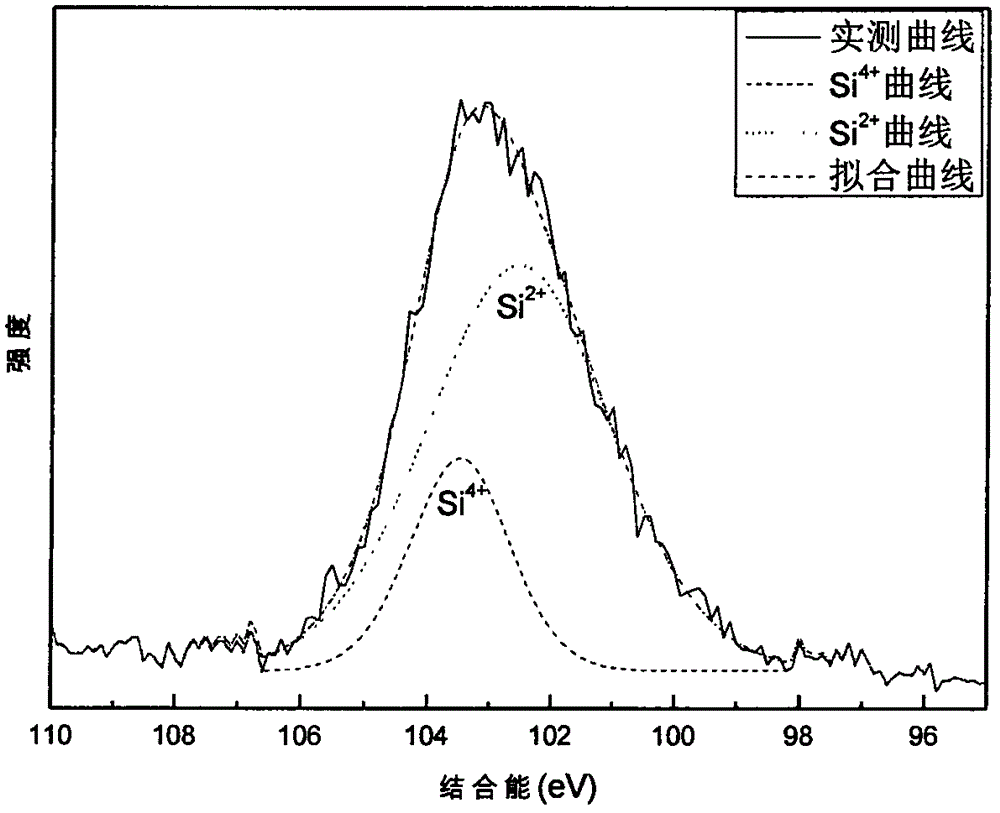

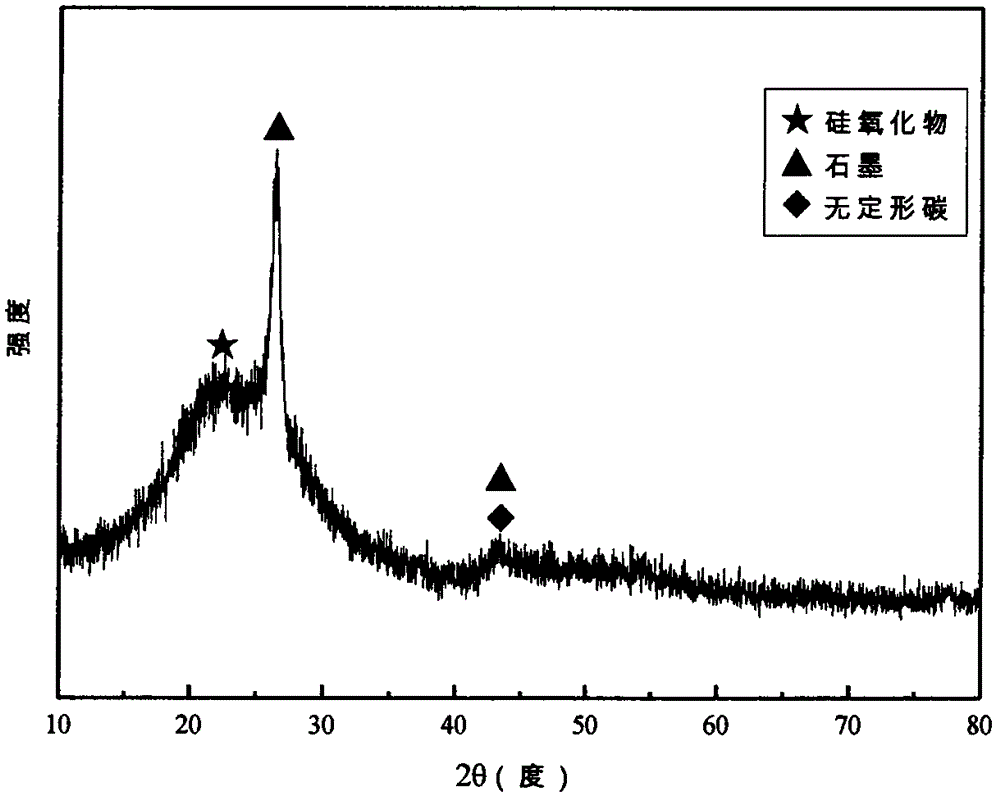

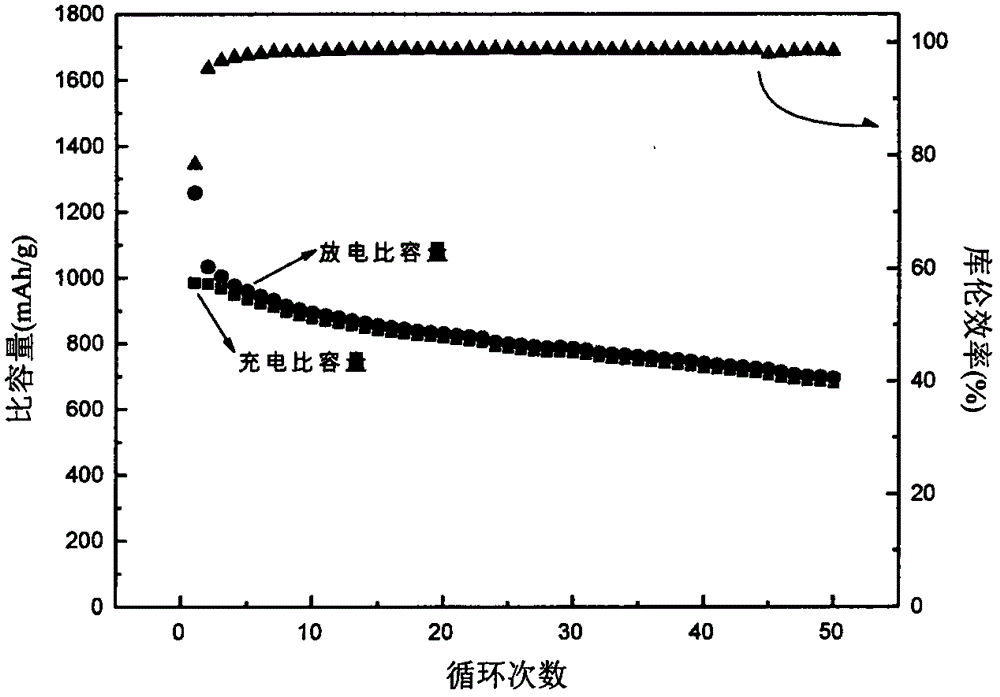

Silicon oxide composite negative pole material for lithium ion secondary battery and preparation method thereof

ActiveCN104577066AReduce manufacturing costImprove the first Coulombic efficiencyCell electrodesFiltrationSilicon oxide

The invention relates to a silicon oxide composite negative pole material for a lithium ion secondary battery and a preparation method thereof. The composite material consists of silicon oxide, graphite type carbon materials and amorphous carbon materials. The preparation method comprises the following steps: performing magnesiothermic reduction on silicon dioxide so as to generate the silicon oxide by using alkaline(soil) metal chloride as a heat absorbent; after performing acid corrosion, sucking filtration, washing and vacuum drying on the silicon oxide, performing pre-ball milling on the dried silicon oxide and graphite; then complementing an organic carbon source, performing secondary ball milling, and then performing high-temperature heat treatment so as to obtain the silicon oxide composite negative pole material. The oxygen content of the silicon oxide is controlled by regulating the proportion of the silicon dioxide to magnesium, and then the silicon oxide is uniformly mixed with the graphite type carbon materials and the organic carbon source. The silicon oxide composite negative pole material disclosed by the invention has the characteristics of a higher first-time Kulun efficiency, a high specific capacity, a better cycle performance and the like; the preparation method adopted by the invention is easy in operation, simple in technology, low in cost and suitable for the industrial mass production.

Owner:NANKAI UNIV

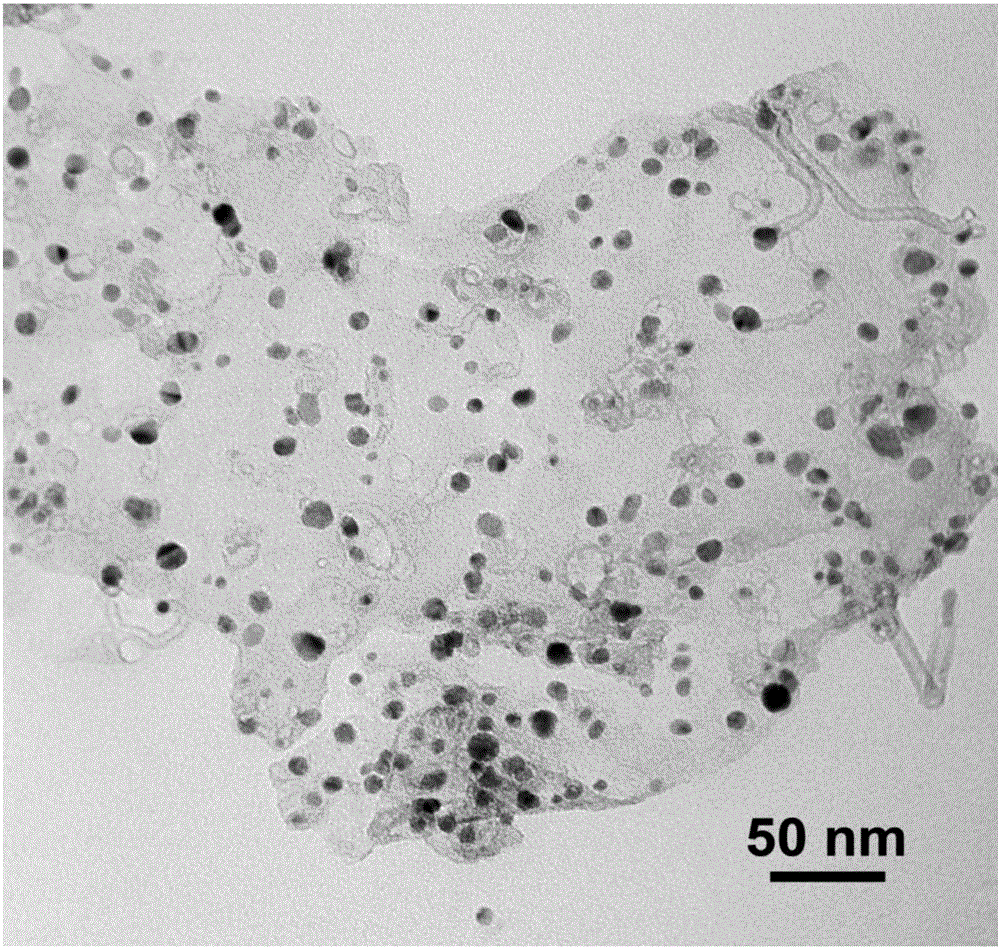

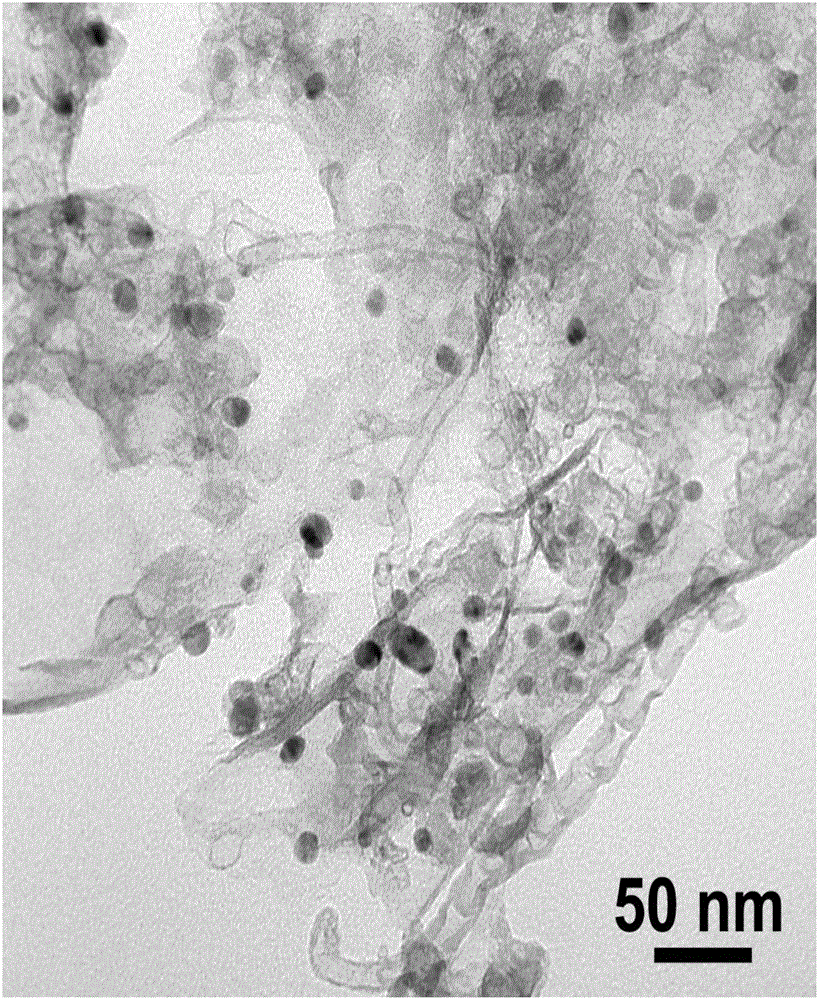

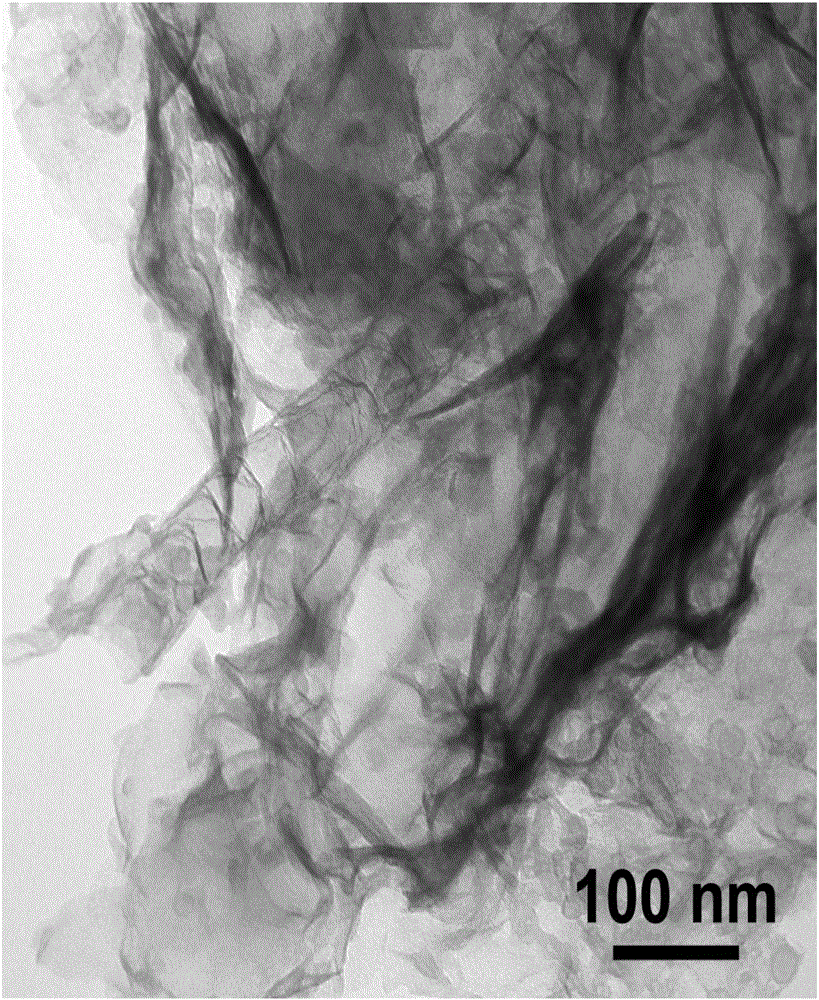

Preparation method of flaky nanoholes carbon and carbon nanotube composite

InactiveCN105776181AShorten the diffusion distanceImprove conductivityMaterial nanotechnologyChemical compositionNanohole

A preparation method of a flaky nanoholes carbon and carbon nanotube composite belongs to the technical field of new materials. The flaky nanoholes carbon and carbon nanotube composite is obtained based on intercalation growth of a metal-organic framework compound in two-dimensional nanoholes of a lamellar inorganic template, confinement carbonization and template removal by acid corrosion. The method is simple and reliable, the large-scale production of two-dimensional nanoholes carbon flake material and one-dimensional carbon nanotube composite is easy to implement. The obtained nanoholes carbon flake and carbon nanotube composite has highly controllable chemical composition and pore structure height and has a promising application prospect in the catalysis field, the energy storage and conversion field and other fields.

Owner:DALIAN UNIV OF TECH

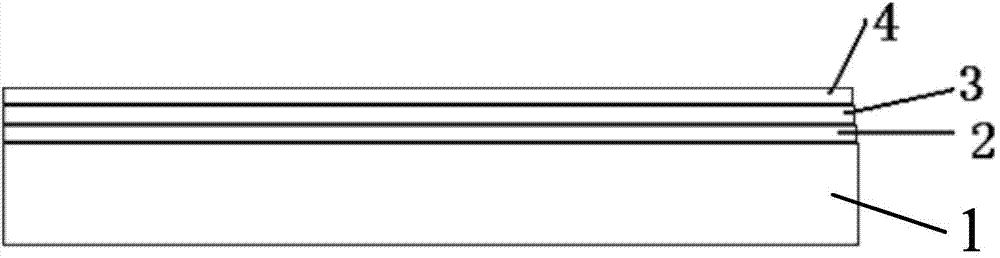

Dual-function film coated glass capable of realizing anti-dazzle performance and visible light antireflection and preparation method of glass

ActiveCN103921487AImprove transmittanceReduce transmittanceGlass/slag layered productsGlass coverAcid corrosion

The invention provides dual-function film coated glass capable of realizing the anti-dazzle performance and the visible light antireflection and a preparation method of the glass. A film layer structure of the film coated glass is composed of a glass substrate, a separation layer, a concave-convex nano-micron compound hole structure film layer and a visible light antireflection film layer which are arrayed in sequence, and is obtained by coating a film by adopting a magnetron sputtering method and treating an anti-dazzle light film layer by adopting a weak acid corrosion method; the total thickness of the film layer is 145-270nm; in a spectral wavelength range of 380nm-1100nm, the transmittance of the dual-function film coated glass is increased by 2.5-4.5 when being compared with that of a glass raw sheet which is not coated with the film; the reflectivity is reduced by 3.5%-5.5% when being compared with that of the glass raw sheet (5%); the rigidity of the film layer is 5.0H-6.5H; the haze of the film coated glass is increased by 3.5-6.5% from 0.2% of the raw sheet. The obtained film coated glass can be used in fields of electronic display panels, packaging glass cover plates, showcases, lens frames, locomotives, steamship window glass and the like.

Owner:WUHAN UNIV OF TECH

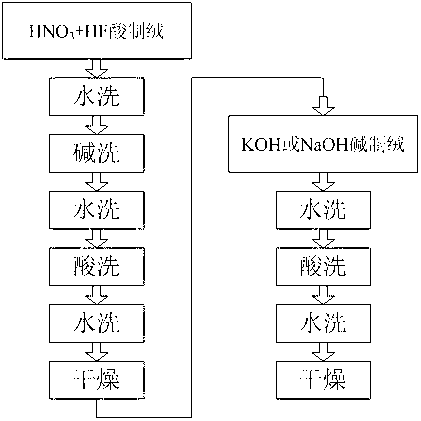

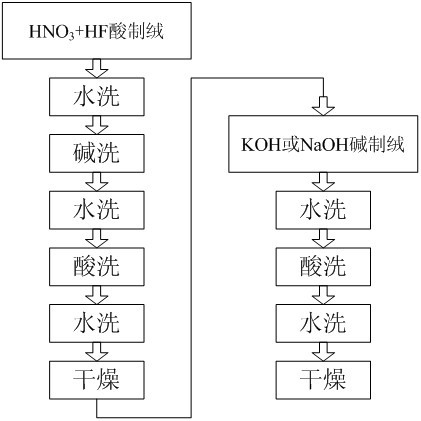

Monocrystal-like solar battery texturing process

InactiveCN102703989AReduce appearanceLow efficiencyAfter-treatment detailsFinal product manufactureElectrical batteryMicrometer

The invention discloses a monocrystal-like solar battery texturing process which comprises the following steps: placing a silicon wafer into a HNO3 and HF mixed acid solution for corrosion; taking out the treated silicon wafer from the mixed acid solution when the corrosion depth of the silicon wafer is up to 2-5 micrometers; carrying out water washing and drying treatment on the silicon wafer after acid corrosion; placing the dried silicon wafer into KOH or NaOH aqueous alkali with a single crystal for corrosion; taking out the silicon wafer from the aqueous alkali when the corrosion depth of the silicon wafer is up to 2-5 micrometers; and carrying out water washing and drying treatment on the silicon wafer after alkali corrosion. According to the process, the texturing treatment is carried out on the silicon wafer, a battery piece which is manufactured by the silicon wafer treated by using the process is small in reflectivity difference rate among crystalline grains with different sizes, and has better anti-damping performances.

Owner:TIANWEI NEW ENERGY HLDG +1

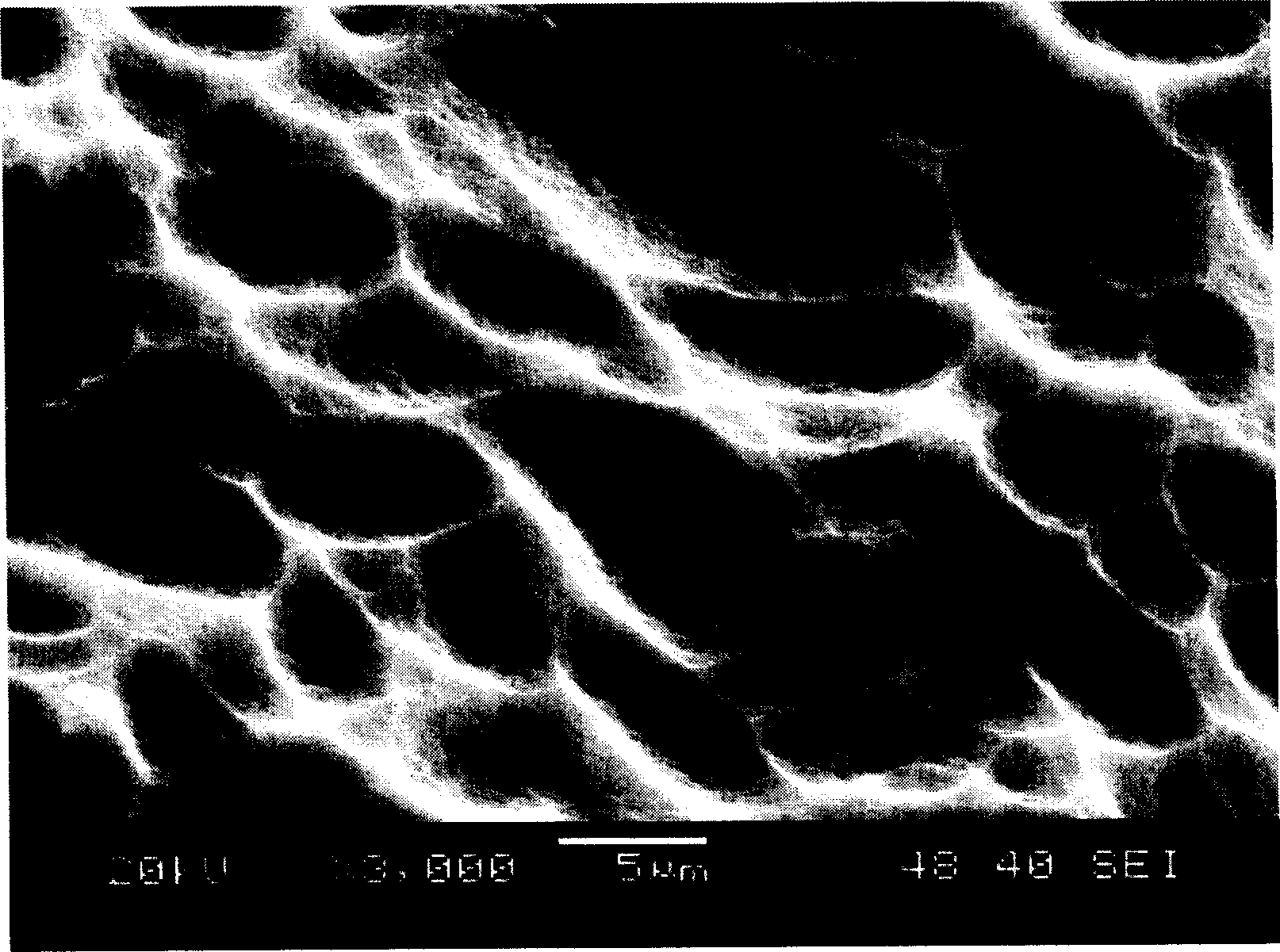

Acid corrosion solution for preparing multicrystal silicon pile surface and its using method

ActiveCN1821446AEliminate hazardsSuitable for mass productionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationCorrosion reactionHydrofluoric acid

The present invention discloses acid corrosion solution for preparing polycrystalline silicon pile surface and its usage. The solution is compounded with oxidant and hydrofluoric acid and through mixing, and the oxidant is nitrate or nitrite. During use, the cut polycrystalline silicon chip is set inside the corrosion solution for corrosion at the temperature of -10 to +25 deg.c for 0.5-20 min to eliminate damage surface caused by wire electrode cutting, with the acid corrosion time and temperature being dependent on the solution concentration. The present invention is suitable for both intermittent production and continuous production, and has easy treatment of the produced waste acid.

Owner:WUXI SUNTECH POWER CO LTD

Molten salt for chemical strengthening of glass and application process thereof

InactiveCN101921054AStrong absorption capacityStrong reflexesGlass tempering apparatusFlat glassMolten salt

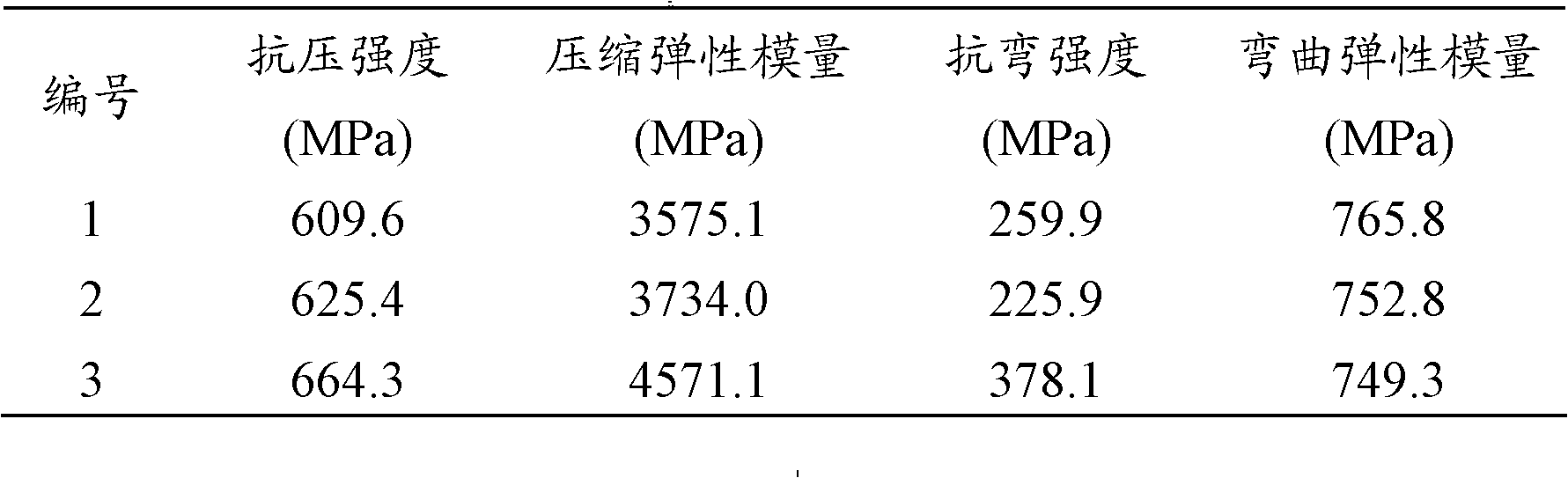

The invention provides molten salt for chemical strengthening of glass. The molten salt comprises main salt KNO3 and auxiliary salts Al2O3, KCl, K2CO3 and KOH mixed proportionally. The invention also provides a process of applying the molten salt to the chemical strengthening of common Na-Ca-Si flat glass. The technological conditions of ion exchange reaction temperature, time and the like are controlled, and a specific acid corrosion strengthening process is introduced before the ion exchange reaction to be combined with the ion exchange reaction to realize chemical strengthening. When the molten salt and the strengthening process of the invention are applied to the chemical strengthening of the common Na-Ca-Si flat glass, the compressive strength, the compression elastic modulus, the bending strength and the bending elastic modulus of the glass are greatly improved, the chemical strengthening time is remarkably shortened, the chemical strengthening temperature is reduced, the energy consumption for production is obviously reduced and the efficiency is increased.

Owner:ZHEJIANG UNIV

Tooth cosmetic veneering method

The invention provides a tooth cosmetic veneering method, which comprises the following steps that: spinels are adopted for porcelain laminate veneering, wherein the veneer thickness can be controlled between 0.5 and 0.8; tooth surfaces are free from being processed, so that painless cosmetology is realized; temporary teeth are free from being worn, so that inconvenience of a person being subject to cosmetology can be reduced; and the tongue side parts of teeth are free from being processed, so that jaw teeth can be effectively protected, and 'foreign body feeling' is free. In the invention, a compound material prepared by a special glass permeation method is adopted, the strength can reach over 400 Mpa after bonding, the durability of the prepared spinel porcelain laminate tooth veneer can reach over 10 years; the prepared spinel porcelain laminate tooth veneer has the optical speciality being the same as that of natural tooth tissues, and has a simulation cosmetic effect; the material has good mechanical and physical properties so as to bear high stress, high acid corrosion resistance, and low heat conduction property so that the tooth body can not be irritated by heating, and no stimulation is caused to teeth pulp when people eat cold and hot food; the material has a self-cleaning capability, so that bacteria are difficult to grow; the X-ray transmission property is good; and the cost is low.

Owner:郑雷

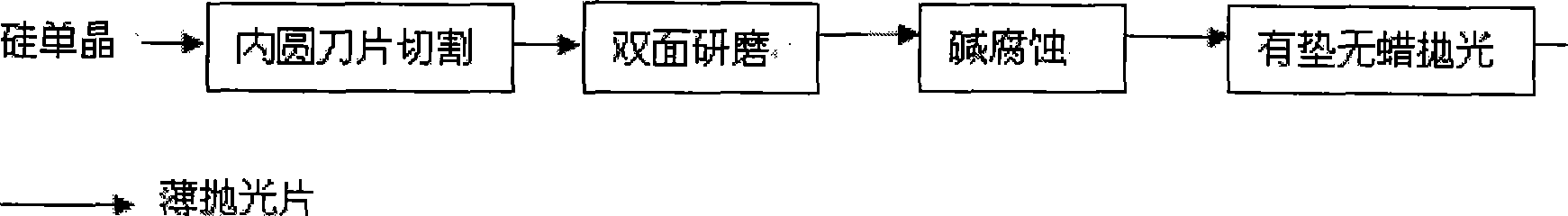

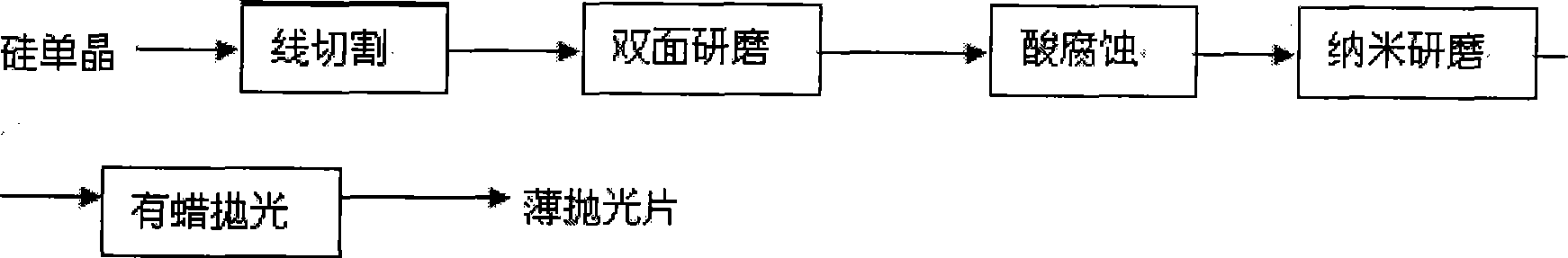

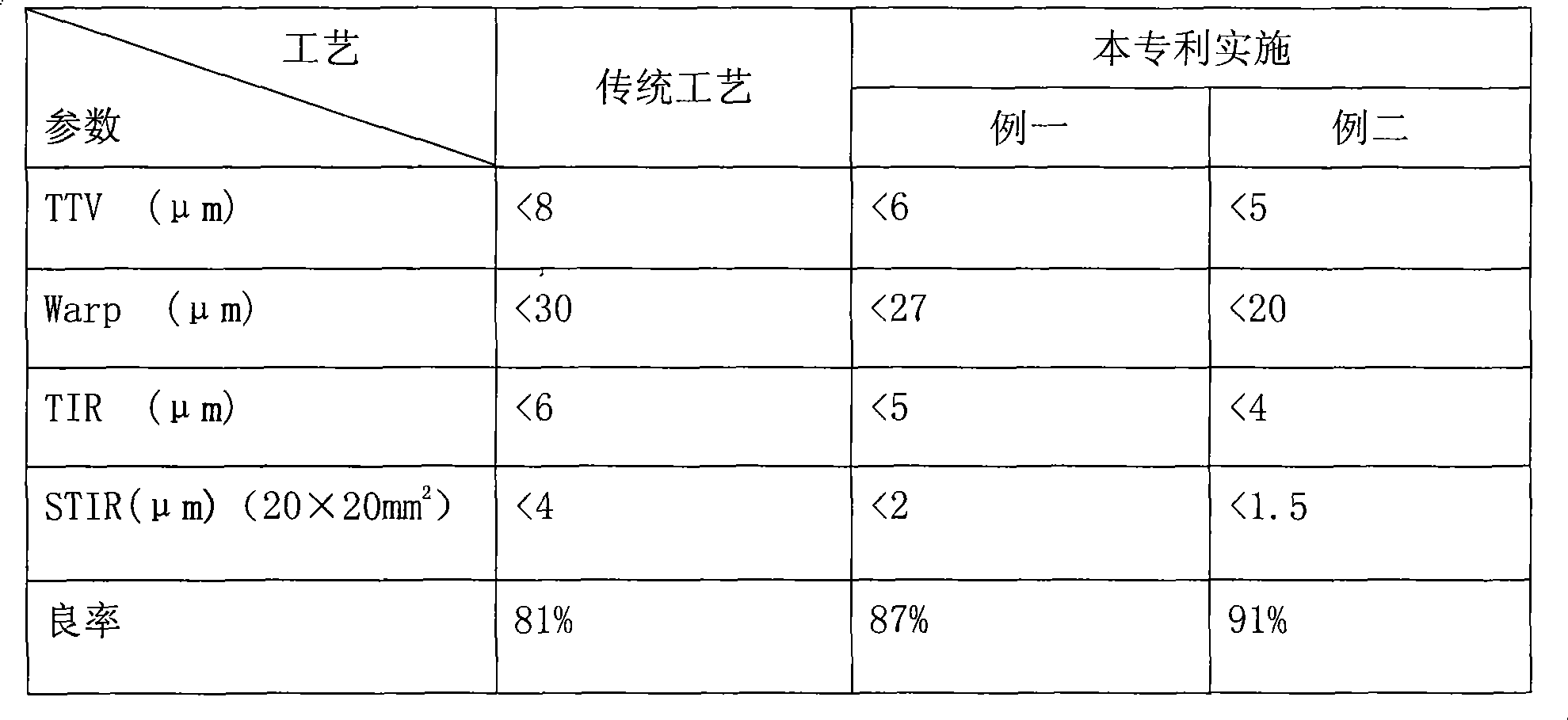

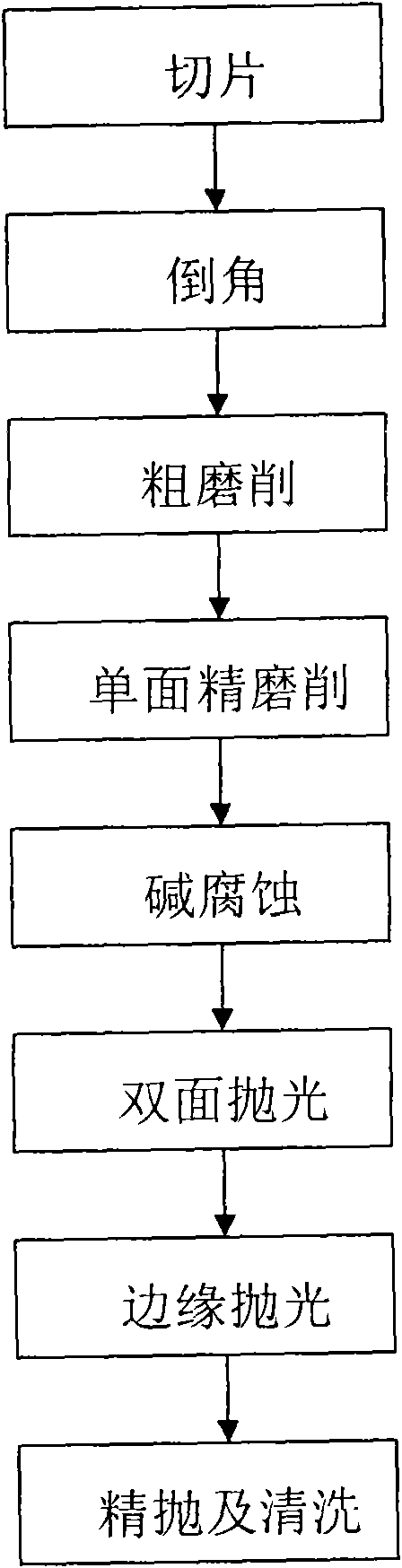

Processing method of thin silicon monocrystal polished section

ActiveCN101431021AImprove productivityImprove qualitySemiconductor/solid-state device manufacturingRubber ringWax

The invention relates to a method for producing thin monocrystalline silicon polished wafer. The method comprises the following steps: Step 1, monocrystalline silicon is sliced up by adopting wire cutting; Step 2, a slotting double-face grinder which adopts a stainless steel planetary sheet with an internal circle inlaid with a soft rubber ring is adopted to carry out double-surface grinding on the sliced monocrystalline silicon; Step 3, a technique of acid corrosion thinning is adopted, wherein, the removal amount resulted from acid corrosion is 10 micrometers to 60 micrometers; Step 4, a nanometer grinding technique is adopted, wherein, the removal amount resulted from nanometer grinding is 1 micrometer to 25 micrometers; and Step 5, a wax polishing technique is adopted, wherein, the removal amount resulted from wax polishing is 5 micrometers to 30 micrometers. By adopting a new technical route and a new technical procedure for producing new thin monocrystalline silicon polished wafer, the invention effectively improves TTV level, WARP level, TIR level, STIR level and other levels as well as the finished product rate of the thin monocrystalline silicon polished wafer.

Owner:JINGHUA ELECTRONICS MATERIAL

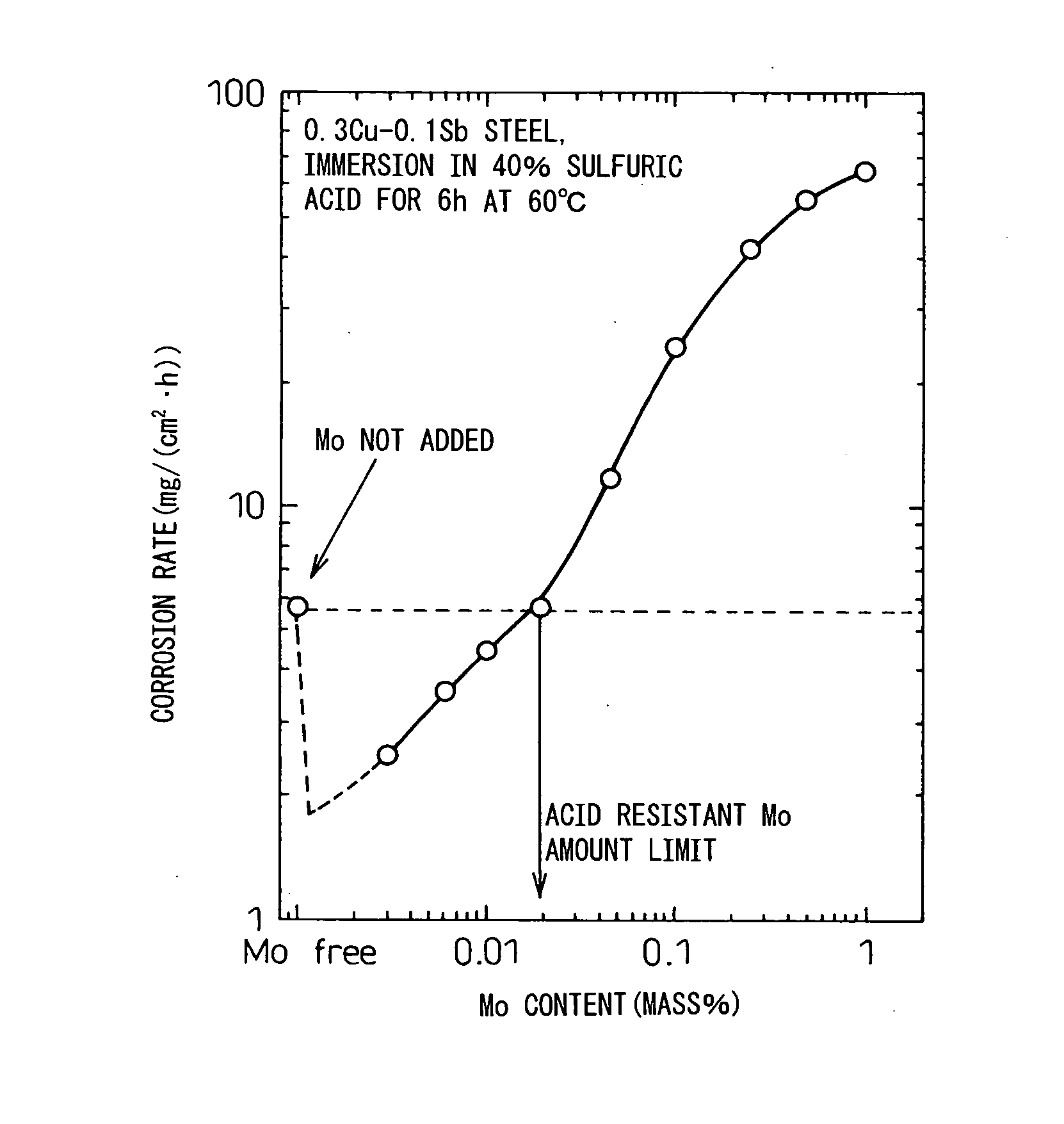

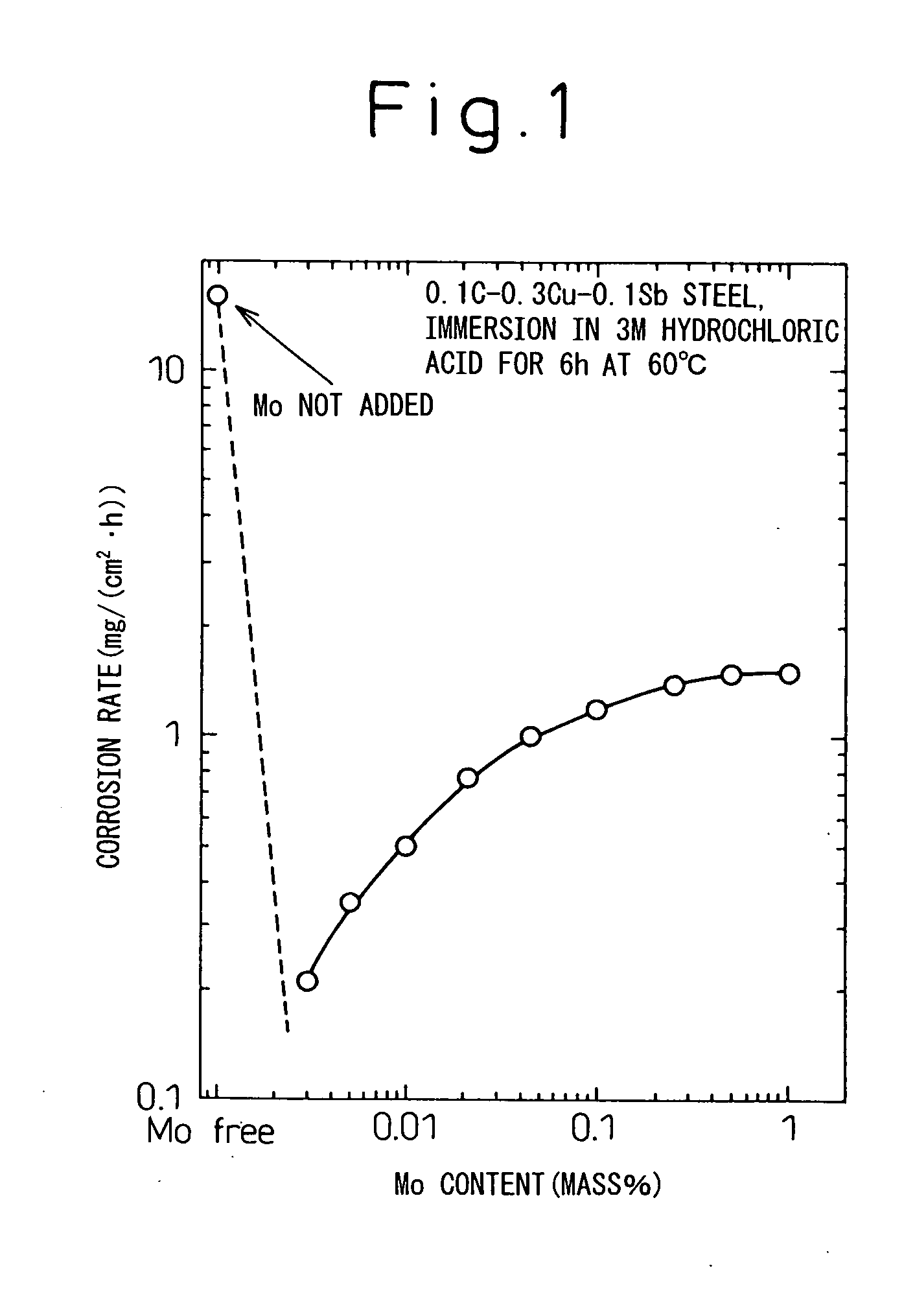

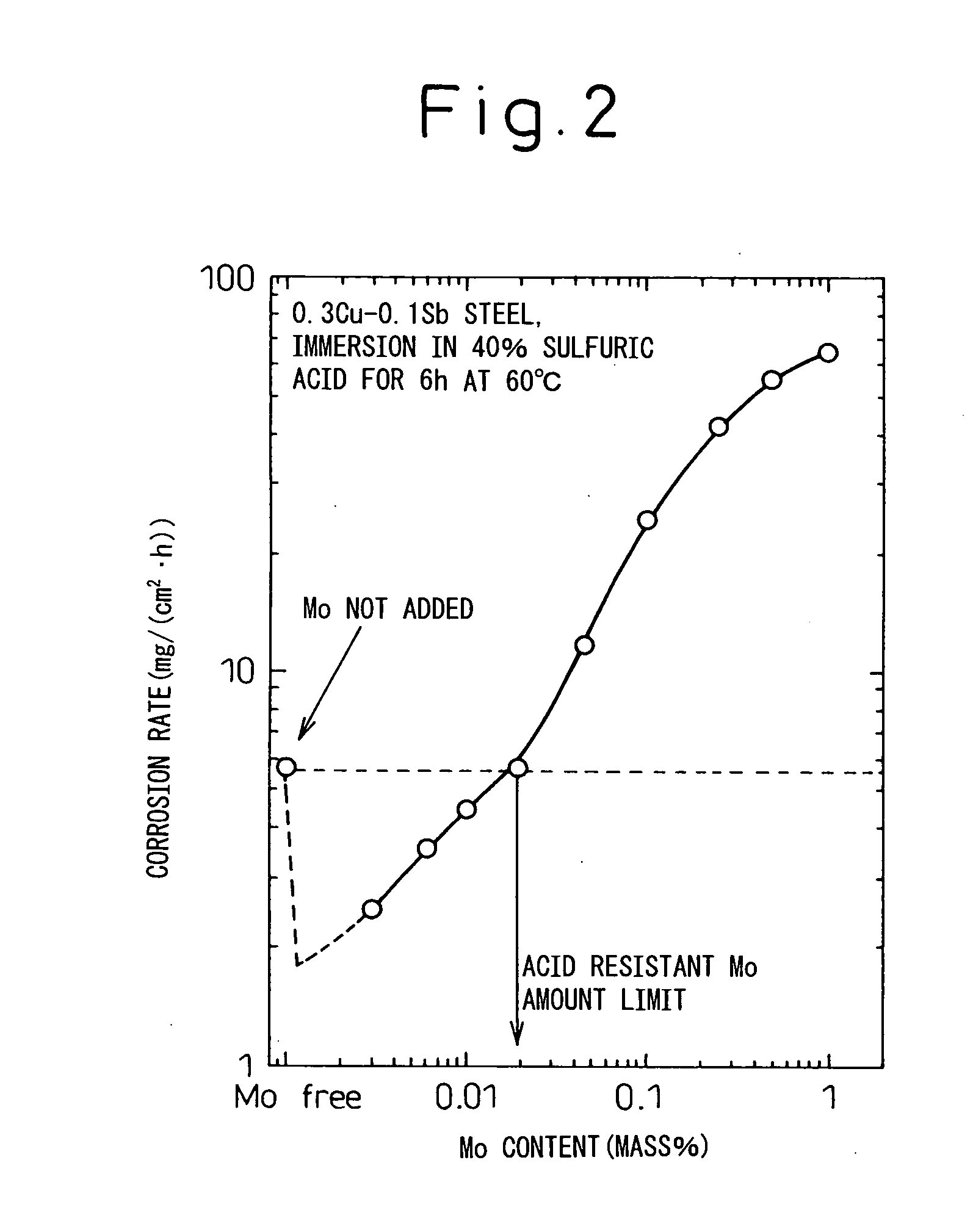

Low alloy steel excellent in resistance to corrosion by hydrochloric acid and corrosion by sulfuric acid and weld joint comprising the same

ActiveUS20050013722A1Improve economyImprove the immunityArc welding apparatusFurnace typesAcid corrosionImpurity

The present invention provides a low alloy steel and a weld joint thereof excellent in hydrochloric acid corrosion resistance and sulfuric acid corrosion resistance, said low alloy steel containing, in mass, C: 0.001 to 0.2%, Si: 0.01 to 2.5%, Mn: 0.1 to 2%, Cu: 0.1 to 1%, Mo: 0.001 to 1%, Sb: 0.01 to 0.2%, P: 0.05% or less, and S: 0.05% or less, with the balance consisting of Fe and unavoidable impurities; and the acid corrosion resistance index AI of said low alloy steel being zero or positive. Here, said AI is given by the following expression, AI / 10,000=0.0005+0.045×Sb %−C %×Mo %, where % means mass %.

Owner:NIPPON STEEL CORP

Composite acupuncture filter bag used for smoke treatment of ceramic kiln

ActiveCN101695615AShort production processHigh porosityDispersed particle filtrationFiltration separationYarnAlkali free

The invention discloses a composite acupuncture filter bag used for smoke treatment of a ceramic kiln. Short fibers and base fabrics are acupunctured by adopting non-woven acupuncture technology to form a composite acupuncture plain felt, the plain felt is soaked and coated by adopting a surface chemical treatment agent, and then the plain felt is dried and cured at a high temperature and is tailored and sewn to form the filter bag, wherein the base fabrics adopt 30-count alkali-free glass fiber woven fabrics; the short fibers for acupuncture comprise polypropylene fibers, polyphenylene sulfide fibers and 80-count short glass fiber yarns; and the surface chemical treatment agent comprises polytetrafluoroethylene emulsion, polyacrylic ester emulsion, coupling agent, antistatic agent and water. The invention provides the composite acupuncture filter bag used for the smoke treatment of the ceramic kiln, which has the advantages of moisture resistance, good acid corrosion resistance, long service life, high strength of the base fabrics and lower production cost. The problems of poor moisture resistance, poor corrosion resistance, low strength, short service life and high production cost of the filter bag in the prior art are solved. The filter bag is suitable for dust removal and purification treatment for the smoke of the ceramic kiln.

Owner:山东兴国新力环保科技股份有限公司

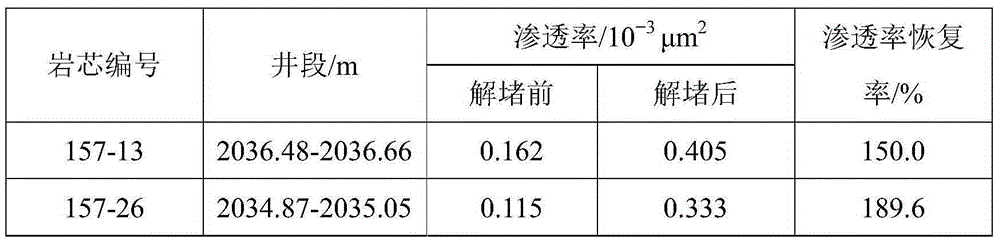

Slow blockage removing agent for oil well and blockage removing method

ActiveCN105255466AUnblock pollutionFree from secondary injuryDrilling compositionClay mineralsFluoboric acid

The invention discloses a slow blockage removing agent for an oil well and a blockage removing method, and belongs to the technical field of oil field exploitation. The slow blockage removing agent is prepared from prepad fluid, main fluid and post-pad fluid, the prepad fluid and the post-pad fluid both take hydrochloric acid as the main component of acid fluid for removing inorganic scale precipitation and dissolving reaction residues, and the main fluid takes glacial acetic acid and fluoboric acid as the main components of acid fluid for stabilizing clay mineral of a reservoir stratum, decreasomg the acid rock reaction speed, enlarging the blockage removing radius and increasing the blockage removing depth. For a fracturing production horizontal well, the treatment fluid is injected into the reservoir stratum in the former stage, the intermediate stage and the later stage, and liquid nitrogen is simultaneously injected, so that residual reaction fluid can be quickly drained after blockage removing construction is performed; pollution blockage near a well bore of the oil well can be effectively removed, the effective permeability near the well bore is increased, the individual-well producing rate is increased, damage caused by excessive acid corrosion to the rock framework of the reservoir stratum can be avoided, and therefore the reservoir stratum can be prevented from being subjected to secondary damage.

Owner:CHINA PETROLEUM & CHEM CORP +1

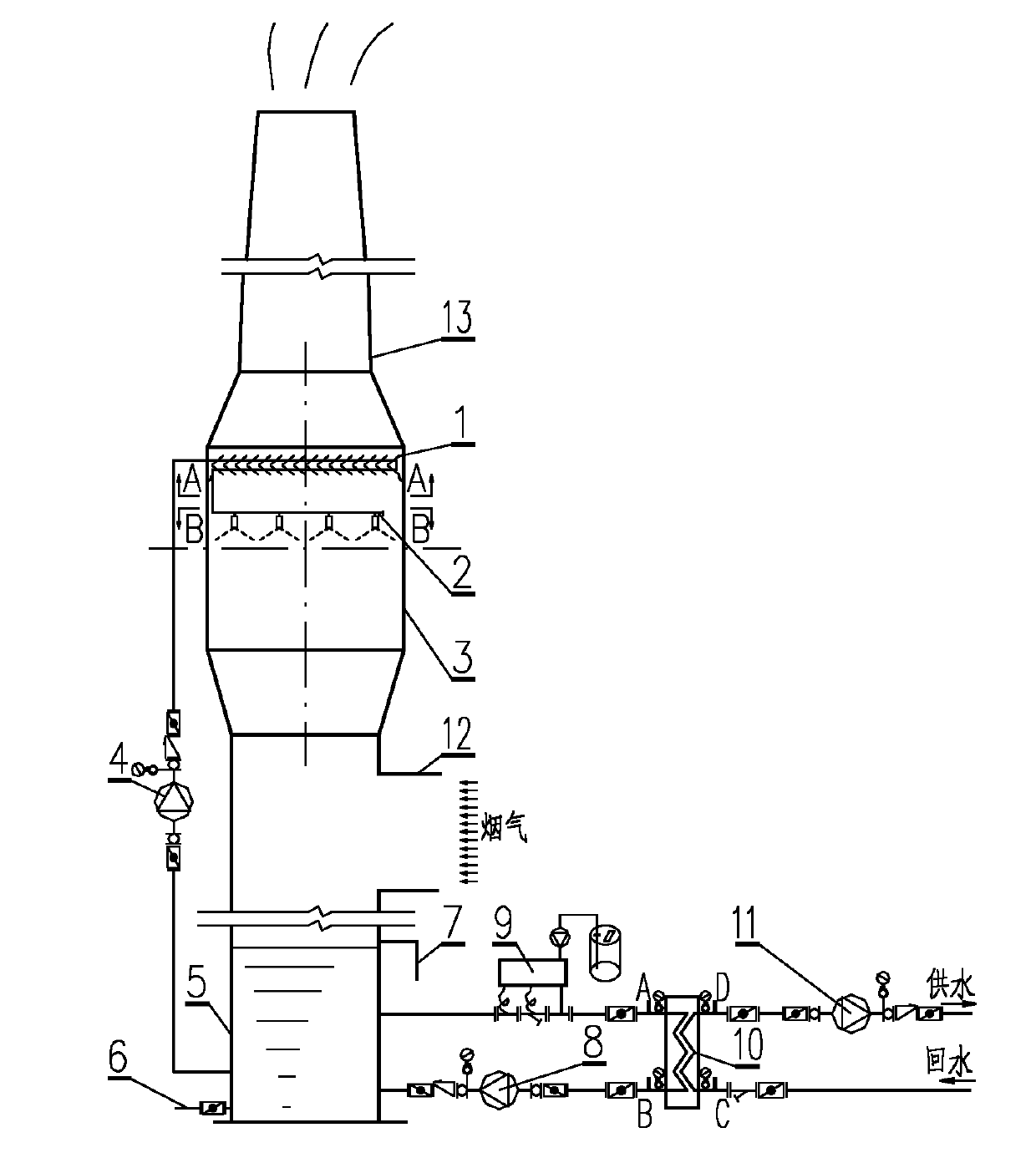

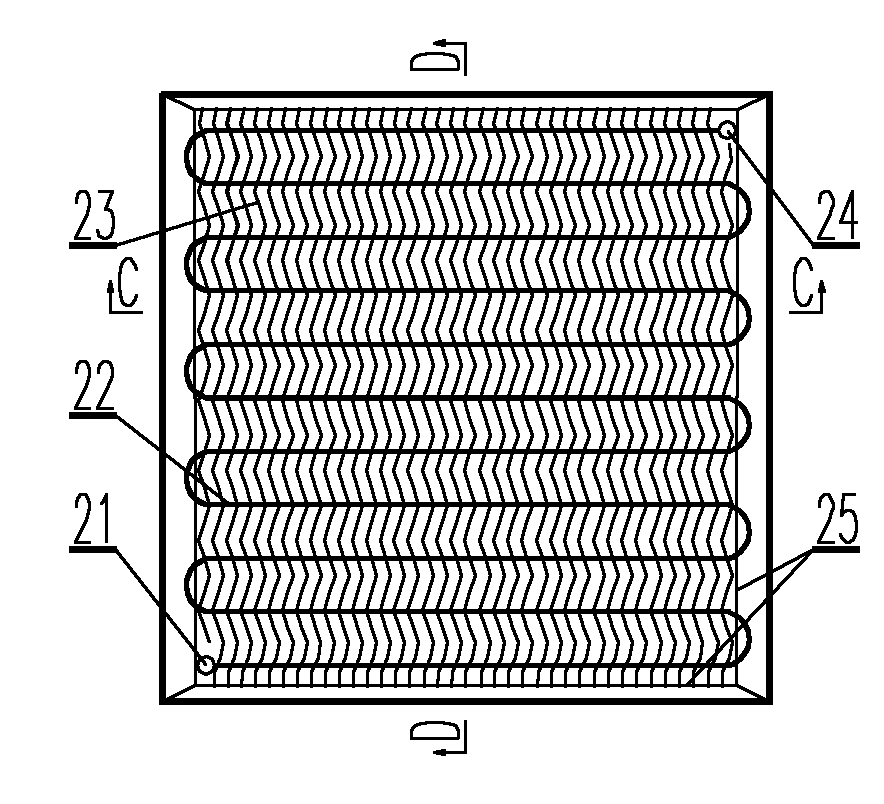

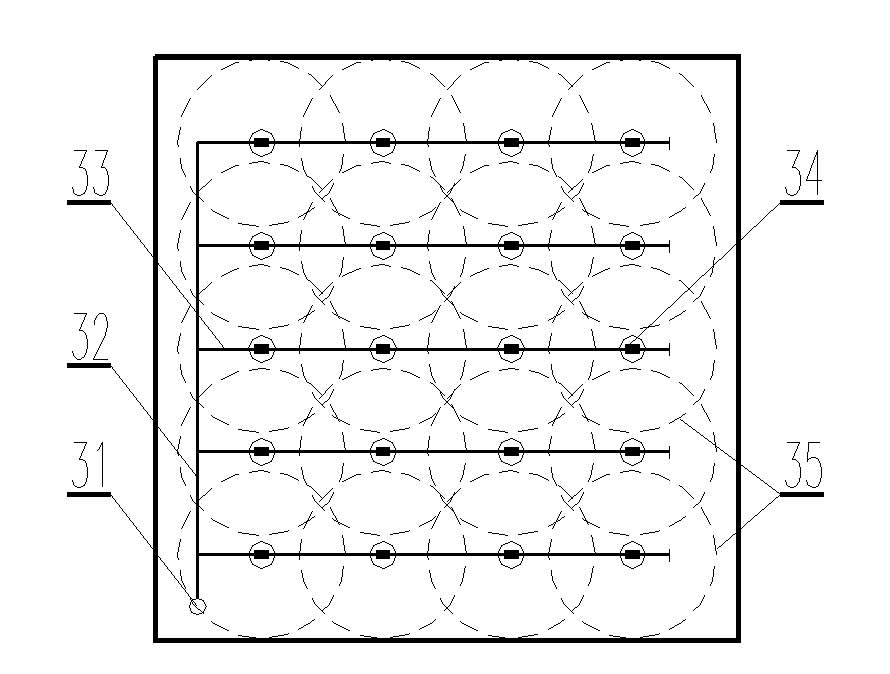

Contact-type advanced recycling system for waste heat of low-temperature flue gas

InactiveCN102168888AIncrease surface areaReduce volumeUsing liquid separation agentEnergy efficient heating/coolingWater vaporWater storage tank

The invention relates to a contact-type advanced recycling system for the waste heat of low-temperature flue gas, and belongs to the technical field of the advanced recycling of the waste heat of the flue gas. The system comprises a contact-type advanced recycling subsystem for the waste heat of the low-temperature flue gas, a heat storage and water quality maintaining purification subsystem and a waste heat output utilization subsystem, wherein the contact-type advanced recycling subsystem for the waste heat of the low-temperature flue gas mainly comprises a water retaining condenser with a multifunctional fin, a water distributor, a contact-type spray tower and a spray pump; the heat storage and water quality maintaining purification subsystem mainly comprises a hot water sedimentation water storage tank, a drainage pipe, an overflow pipe, a circulating pump and an full-automatic water quality measuring control maintainer; and the waste heat output utilization subsystem mainly comprises a plate-type heat exchanger and a water feeding pump. By utilizing the contact-type advanced recycling system, the sensible heat of the flue gas is recovered, and a large amount of water vapor latent heat in liquid and gas fuel flue gas is also recovered; therefore, the contact-type advanced recycling system has the effects of washing and purifying the flue gas and the effects of washing and weakening acid corrosion on equipment and flues.

Owner:TSINGHUA UNIV +1

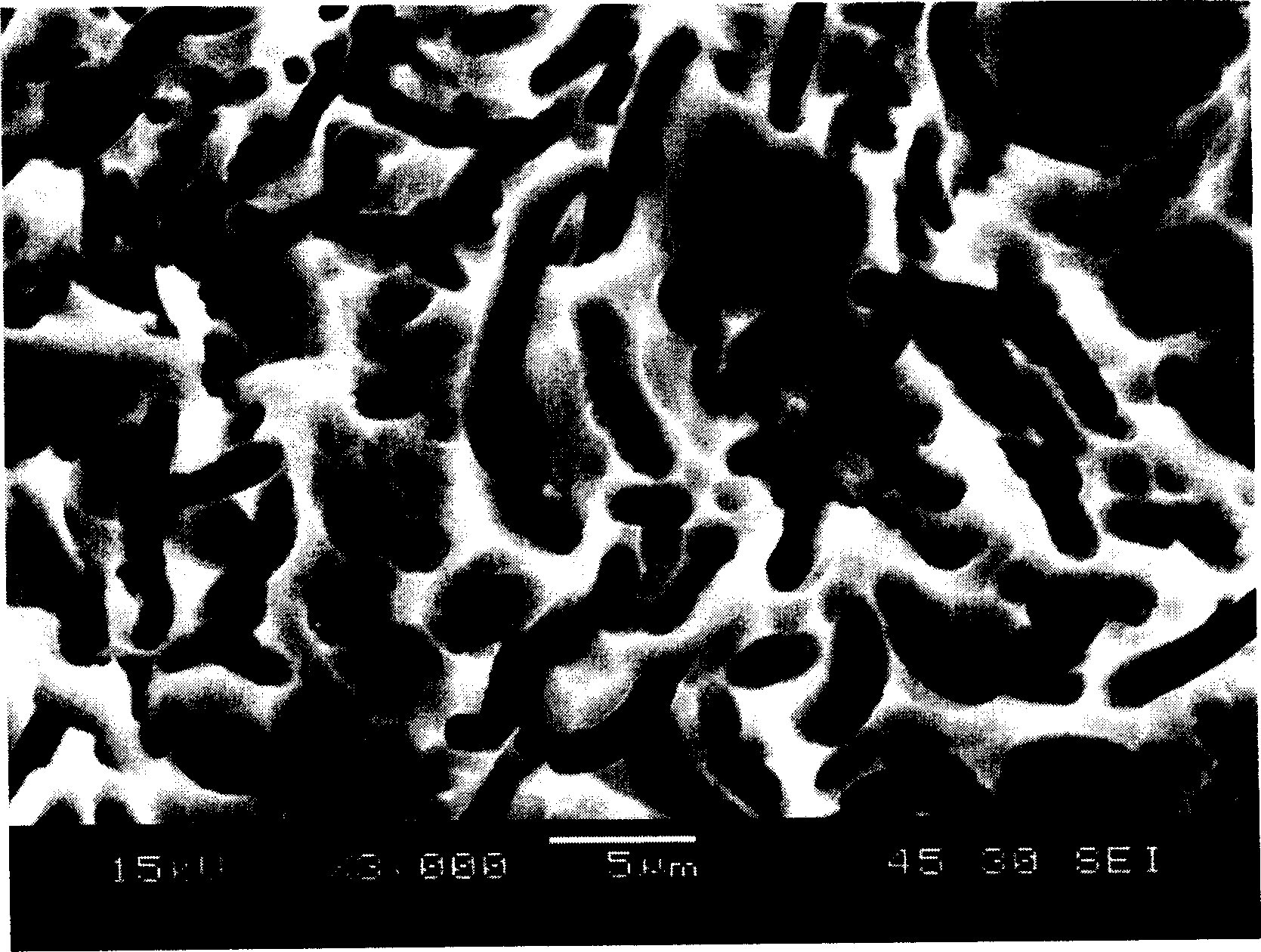

Method for preparing textured polycrystalline silicon wafer

ActiveCN101935884AReduce reflectivityExtend your lifeAfter-treatment detailsFinal product manufactureAcid corrosionSolar cell

The invention provides a method for preparing a textured polycrystalline silicon wafer, which comprises the following steps of: performing alkaline corrosion on the polycrystalline silicon wafer in alkaline corrosion solution to ensure that the corrosion amount of the polycrystalline silicon wafer is 0.01 to 0.1mg / cm<2>; and performing acid corrosion on the cleaned polycrystalline silicon wafer under the acid corrosion condition to ensure that the corrosion amount of the polycrystalline silicon wafer is 0.5 to 5mg / cm<2> so as to obtain the polycrystalline silicon wafer subjected to the acid corrosion. By the method for preparing the textured polycrystalline silicon wafer, the reflectivity of the texture can be lower than 18 percent when the wavelength is between 300 and 1,100nm; meanwhile, part of damaged layers left when the polycrystalline silicon wafer is cut can be removed, so the life of a minority carrier can be prolonged to increase the optical conversion efficiency of a solar cell.

Owner:BYD CO LTD

Method of Mitigating Corrosion Rate of Oilfield Tubular Goods

Acid-soluble cupric acetate may used in conjunction with potassium iodide to generate cuprous iodide (CuI) as an acid corrosion inhibition aid. A suitable corrosion inhibitor together with the aid protects steel surfaces in an acid environment, for instance, while acid fracturing or matrix acidizing subterranean formations. Cupric acetate monohydrate may be used with an alkali metal iodide salt such as potassium iodide or sodium iodide to generate cuprous iodide in situ in aqueous acid solutions. Use of cupric acetate provides a somewhat delayed reaction rate with potassium iodide to generate the desired product, cuprous iodide, which has very low solubility in acid systems. The method includes delayed and in situ production of cuprous iodide for enhancing performance of commercially available corrosion inhibitors, commonly referred to as intensifying the effect of the corrosion inhibitor (corrosion inhibitor intensifier or simply an intensifier).

Owner:BAKER HUGHES INC

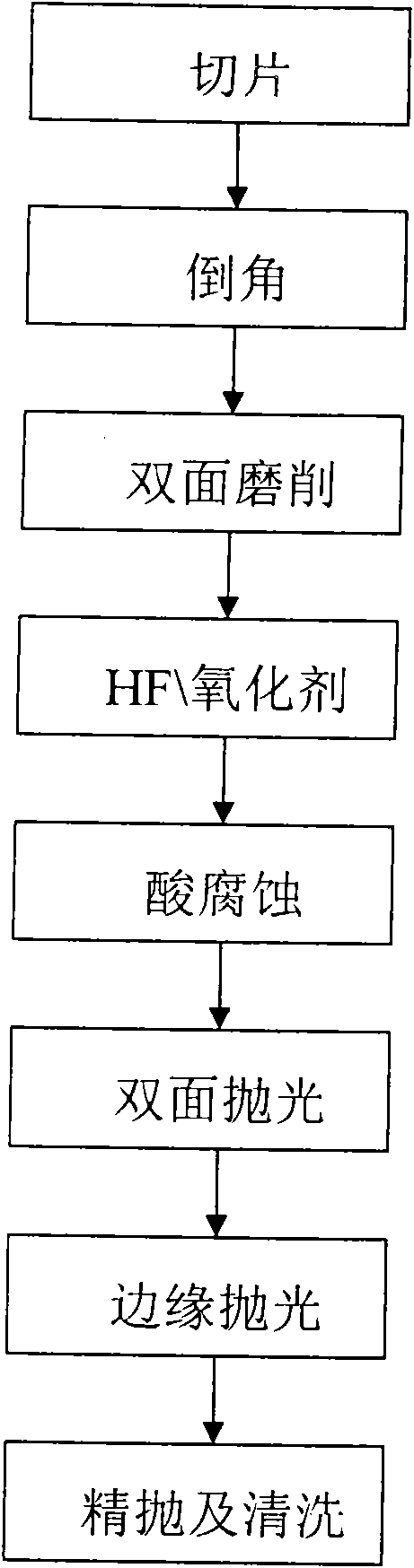

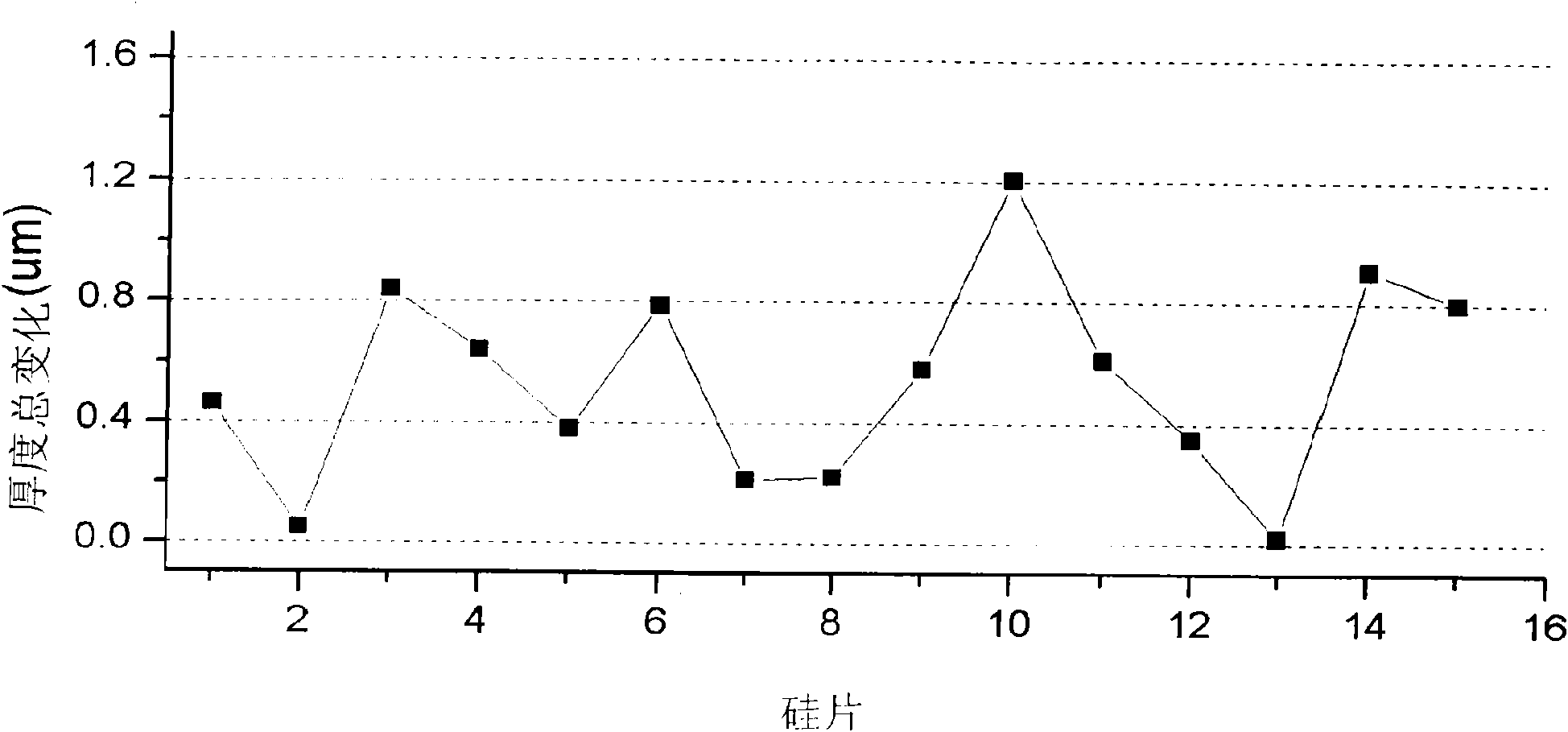

Technique for processing silicon chip

ActiveCN101656193AUniform acid corrosion rateReduce removalSemiconductor/solid-state device manufacturingAcid corrosionSilicon chip

The invention discloses a technique for processing a silicon chip, which comprises the following steps: (1) performing double-sided grinding on the chamfered silicon chip by a double-sided grinding machine; (2) removing micro-convex parts on the silicon surface with mixed solution combined by HF solution and either H2O2 or O3; (3) performing conventional acid corrosion on the silicon chip; and (4)performing conventional double-sided polishing on the silicon chip after the acid corrosion, and performing single-sided fine polishing and cleaning on the silicon chip. The technique for processingthe silicon chip has the advantages of capability of obtaining the silicon chip with high flatness and capability of reducing the removal amount in the whole manufacturing process about 20 microns which is equivalent to the removal amount in single-sided polishing.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

Acid-corrosion-resistant X70 pipeline steel plate and manufacturing method thereof

The invention belongs to the technical field of smelting, in particular relates to an acid-corrosion-resistant X70 MS pipeline steel plate, and further relates to a manufacturing method of the steel plate. The steel plate comprises the following ingredients in percentage by weight: 0.03-0.06 percent of C, 0-0.04 percent of Si, 1.30-1.70 percent of Mn, at most 0.008 percent of P, at most 0.0010 percent of S, 0.030-0.050 percent of Nb, 0.010-0.025 percent of Ti, 0.10-0.35 percent of Mo, 0.10-0.35 percent of Cu, 0.15-0.35 percent of Cr, 0.15-0.30 percent of Ni, 0.020-0.035 percent of Al, at most 0.0045 percent of N, at most 0.00015 percent of H, at most 0.0025 percent of O and the balance of Fe, wherein H+O+N+P+S is at most 150ppm. The manufacturing method overcomes the problems of poor dynamic tearing toughness at low temperature and poor uniformity of thickness and structure of thick pipeline steel and can manufacture the X70 MS pipeline steel plate which is stable in performance and has HIC and SSCC resistance and low-temperature dynamic tear resistance. The steel plate is good in cold formability and good in wild weldability and is suitable for construction of conveying pipelines for petroleum and natural gas which are not dehydrogenized and contain a hydrogen sulfide medium.

Owner:SHANDONG IRON & STEEL CO LTD

Thick-specification acid-corrosion-resisting X65 pipeline steel plate and manufacturing method thereof

The invention discloses a thick-specification acid-corrosion-resisting X65 pipeline steel plate and a manufacturing method thereof. The yield strength of the steel plate is level 450MPa, a low-carbon and low-alloy composition design concept is adopted, the molten steel purity is improved through refining, the balled impurity form is processed through calcium, and production is performed through a controlled rolling and controlled cooling technology, so that the steel plate has the excellent HIC (hydrogen induced cracking) and SSCC (sulfide stress corrosion cracking) acid-corrosion resistance, and meanwhile, the steel plate is a product with excellent comprehensive properties such as the high strength, the high anti-crack toughness, the good weldability and the like.

Owner:JIGANG GRP

Reinforcing material of permeable hydraulic degraded unconsolidated rock and reinforcing method thereof

The invention discloses a reinforcing material of a permeable hydraulic unconsolidated rock. The reinforcing material comprises the following components: low carbon alcohol solution A with a phosphorus source substance as a main solute, wherein, a mineralized coupling agent is dissolved; polyhydroxy low carbon alcohol solution B with a calcium source substance as a main solute, wherein, a hardener and a dispersant are dissolved; and aqueous solution C with ammonium salt as a solute. Penetration operation is performed on the unconsolidated rock by natural flow, spraying, brush coating, soaking or applying methods. The alcohol solution A and the solution B can be mixed and permeated or sequentially permeated respectively, and then the aqueous solution C is permeated after permeation is finished. The reinforcing material has the advantages of easily available raw materials, mild preparation conditions, simple use method, good compatibility with the rock, acid corrosion resistance, obvious reinforcing effect, water soak resistance, no pollution and environmental protection.

Owner:ZHEJIANG UNIV

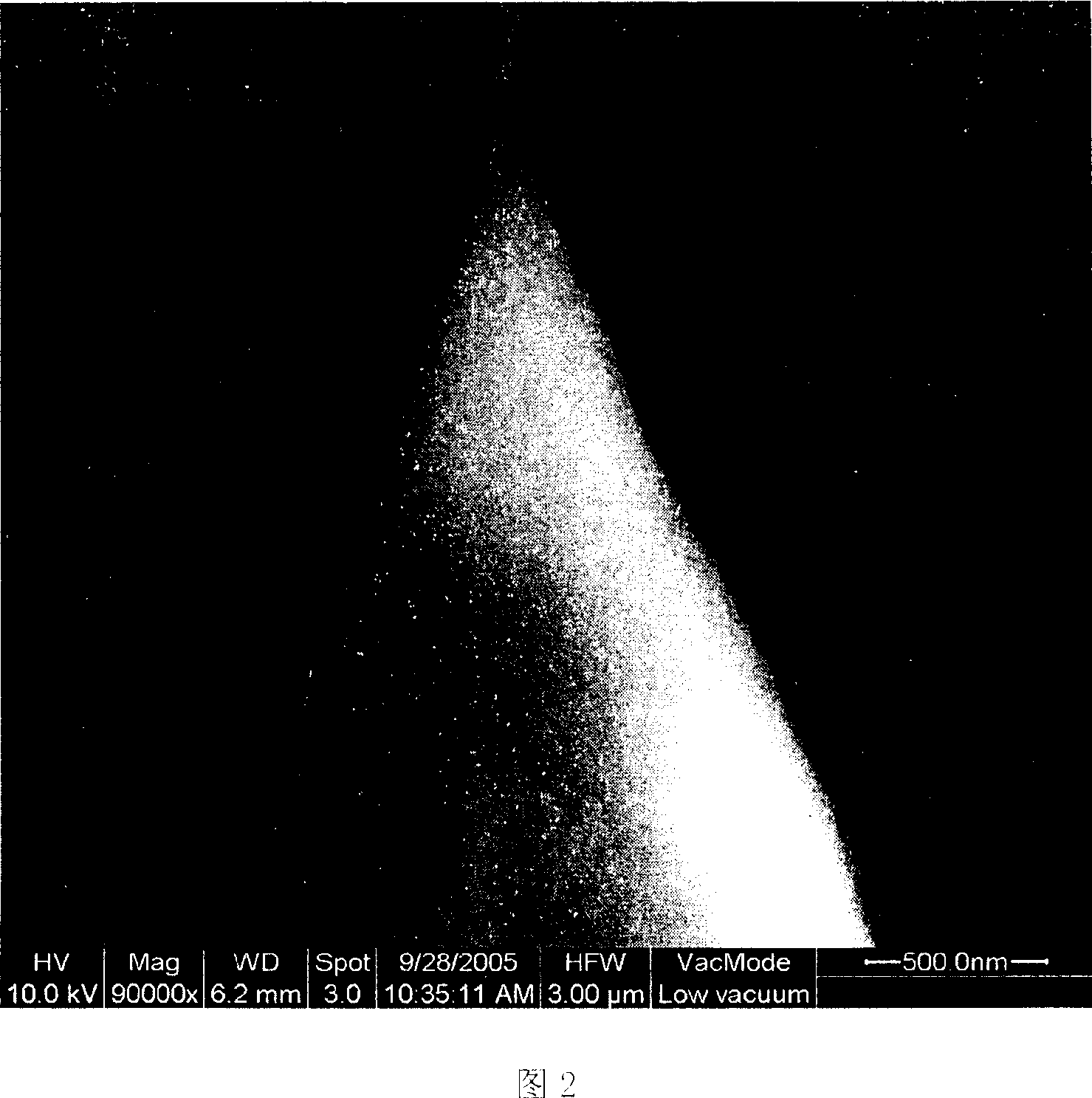

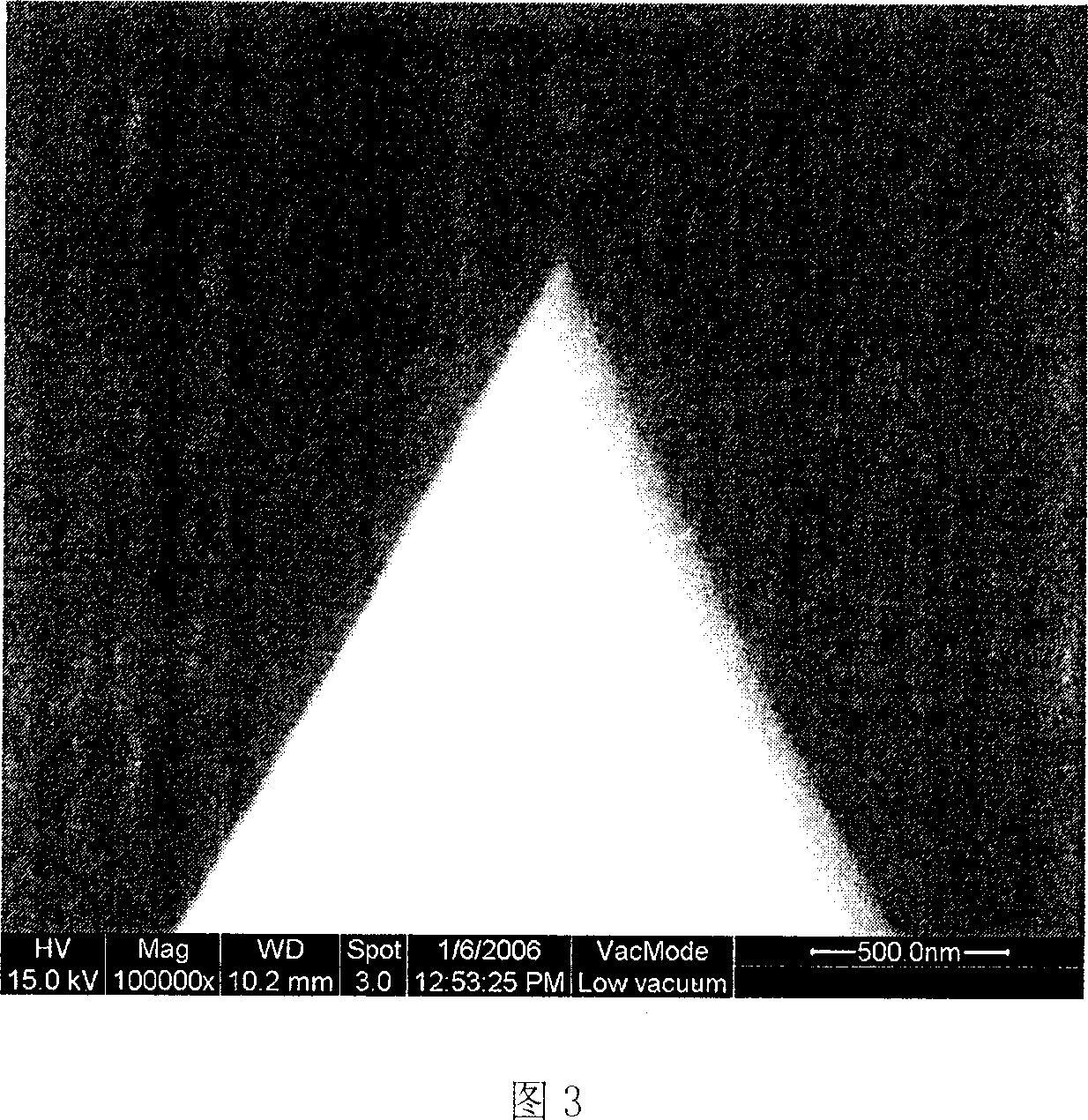

Field optical fibre probe and its production

InactiveCN101030455ARealize industrial preparationQuality improvementSurface/boundary effectInstrumental componentsOrganic solventAcid corrosion

A method for preparing near-field optical fiber probe includes using HF acid corrosion to process optical fiber to form reduced front-end diameter in certain conical angle, using plastic solution to clad said conical unit of optical fiber and curing plastic solution to form plastic film on surface of optical fiber, inserting prepared optical fiber HF acid with oil protection for corroding said optical fiber and using organic solvent to remove off plastic film on surface of said optical fiber to obtain near-field optical fiber probe.

Owner:PEKING UNIV

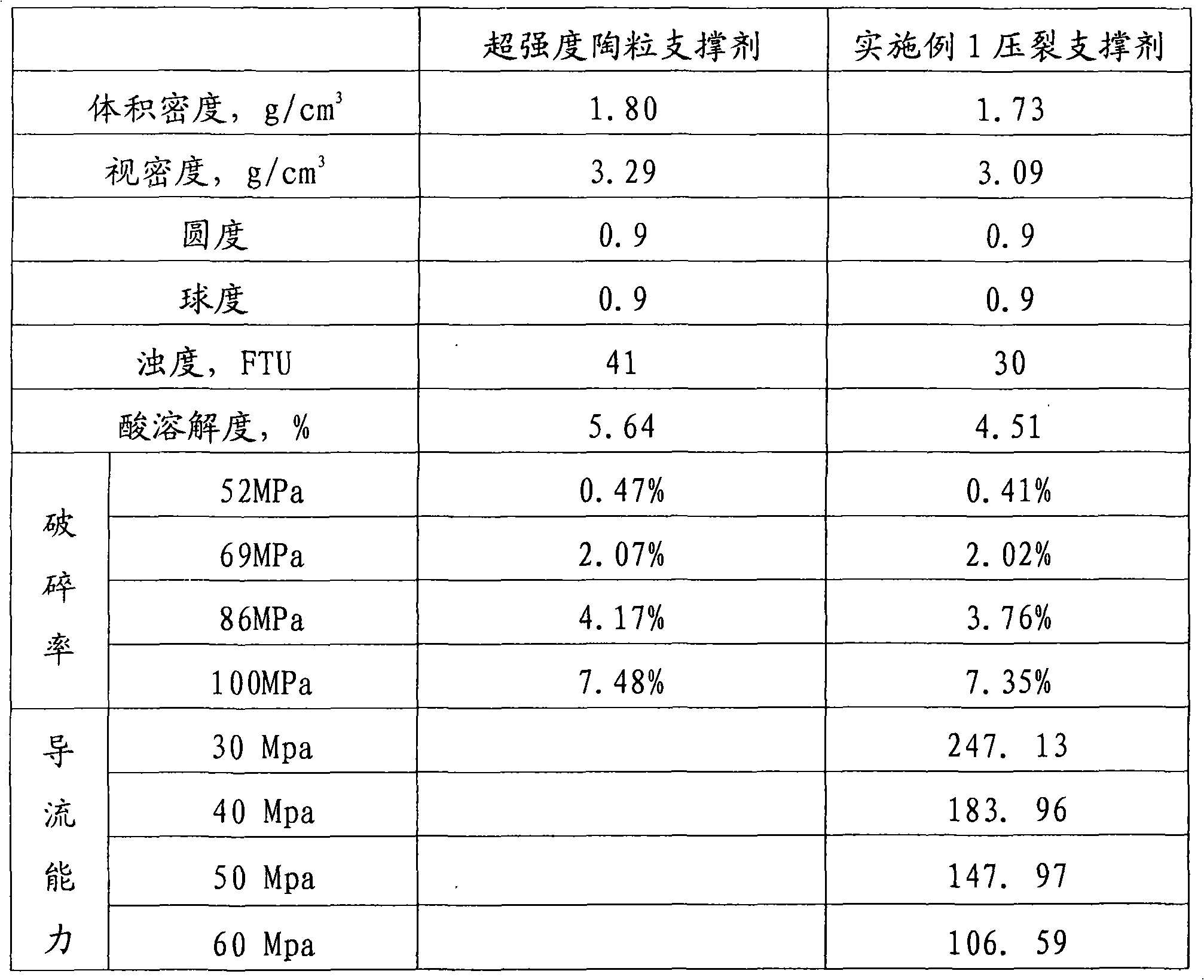

Fracturing propping agent for oil gas well and preparation method thereof

ActiveCN101270280AImprove product qualityHigh breakage resistanceFluid removalSoluble glassAcid corrosion

The invention relates to a fracturing proppant used for oil and gas wells, which is prepared with the following materials by weight: 80 to 88 portions of low content bauxite, 1 to 4 portions of manganese ore, 2 to 3 portions of potash feldspar, 2 to 4 portions of solid soluble glass, 1 to 5 portions of calcium mountain meal, and 1 to 5 portions of French chalk. The quality of the fracturing proppant is stable; the break resistance is high; the acid corrosion resistance is high; the volume density is low; the fracturing proppant can effectively prop up fracture, and significantly improve the permeability in the fracture so that oil and gas flow smoothly, and the oil productivity is improved. In addition, the raw materials and the preparation method are simple, and low requirements are proposed about the raw materials, and the fracturing proppant is prepared simply.

Owner:XINMI WANLI IND DEV

Biodegradable anionic acid corrosion inhibitor comprising sarcosines

ActiveUS20090247431A1Reduce and eliminate needReduce surface tensionCleaning apparatusFluid removalMedicineAcid corrosion

An acid treatment composition is provided including a corrosion inhibitor and an optional corrosion inhibitor intensifier in an acidic solution. More specifically, the composition includes an anionic surfactant. Methods for treating wells with these acid treatment compositions are also provided that help control corrosion of the steel used in the wells during the acid treatment.

Owner:BAKER HUGHES INC

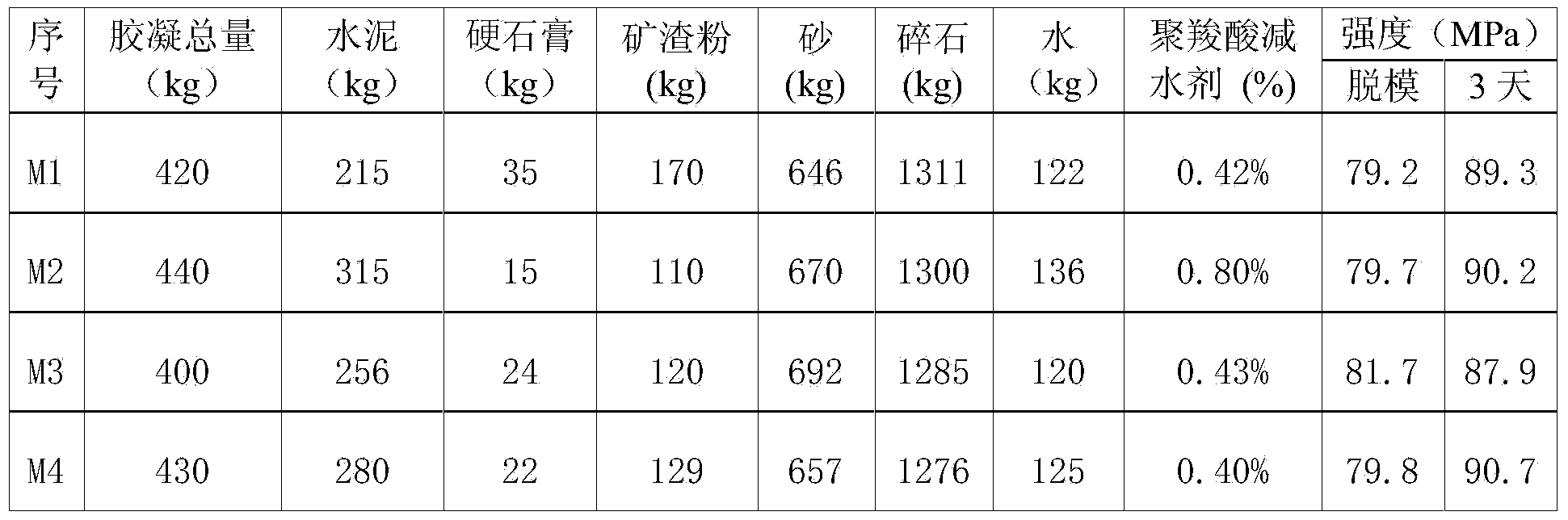

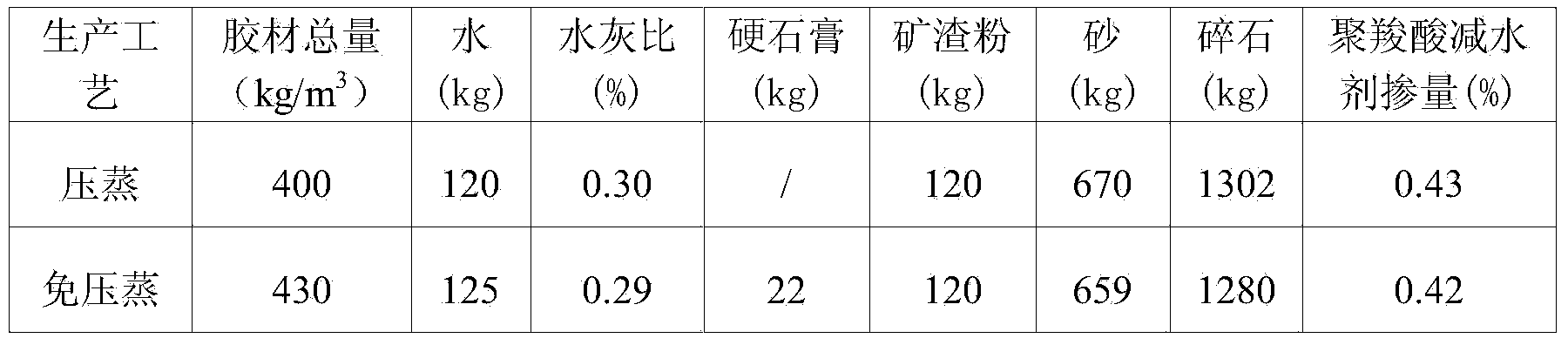

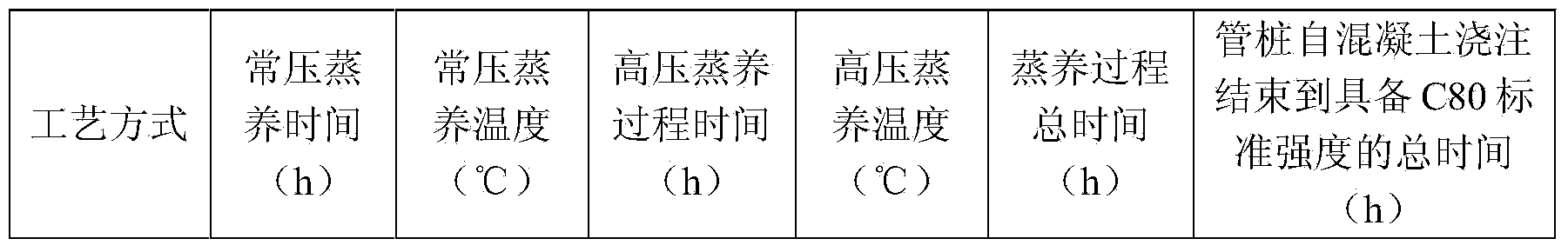

Non-autoclave primary health care (PHC) pipe pile concrete containing early strength composite mineral material and preparation method thereof

The invention relates to non-autoclave primary health care (PHC) pipe pile concrete. The concrete is characterized by being prepared from the following raw materials: a binding material, a water reducing agent, water, coarse aggregate, and fine aggregate, wherein the binding material is prepared from the following raw materials by mass ratio: 3.0-8.0% of rich calcareous material, 25-40% of rich siliceous material and the balance of cement; the water reducing agent accounts for 0.4-0.8% of weight of the binding material; the water cement ratio of the concrete is 29-31%; the sand ratio is 33-35%; the volume-weight is 2480-2500kg / m<3>. The rich calcareous material and the rich siliceous material are compounded at a ratio of 1:4 or 1:6; the cement is excited to hydrate for the second time; the early strength is improved; the C80 strength grade requirements can be met by one-time atmospheric pressure steam maintenance for 6 hours; the performances, such as the volume stability, the carbonizing resistance, corrosion of reinforcement, the chloride penetration resistance, the freeze-thaw resistance, the acid corrosion resistance, the salt corrosion resistance and the like of the PHC pipe pile concrete are improved and changed, and the late durability of the concrete is improved.

Owner:安徽省恒泰新材料有限公司

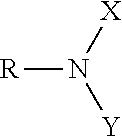

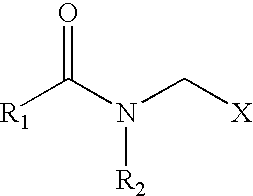

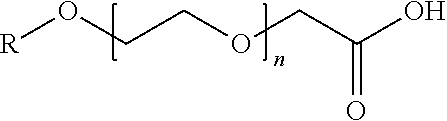

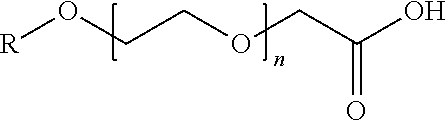

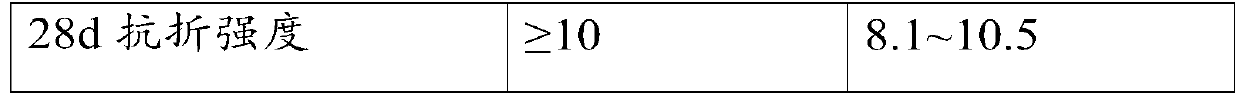

Lubricant composition

A lubricant composition includes a base oil and one or more alkylethercarboxylic acid corrosion inhibitor(s) having the formula;In this formula, R is a straight or branched chain C6-C18 alkyl group and n is a number of from 0 to 5. The lubricant composition can be utilized in a method for reducing corrosion of a steel article. The method includes the steps of providing the base oil and providing the one or more alkylethercarboxylic acid corrosion inhibitor(s). The method also includes the step of combining the base oil and the one or more alkylethercarboxylic acid corrosion inhibitor(s) to form the lubricant composition including less than about 0.1 weight percent of the one or more alkylethercarboxylic acid corrosion inhibitor(s). The method further includes the step of applying the lubricant composition to the steel article wherein the steel article passes corrosion testing according to ASTM D 665 B.

Owner:BASF AG

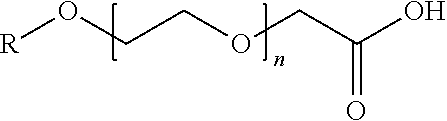

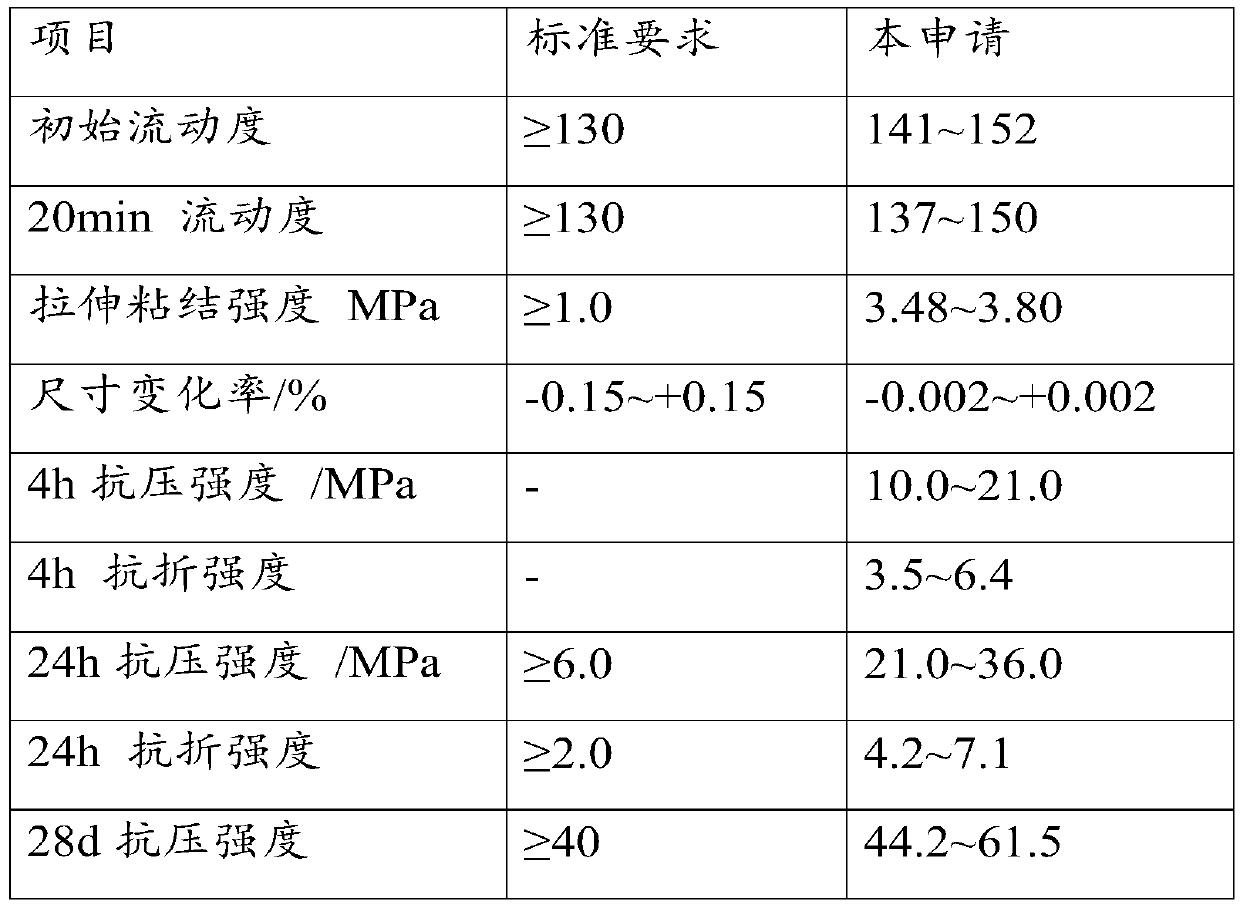

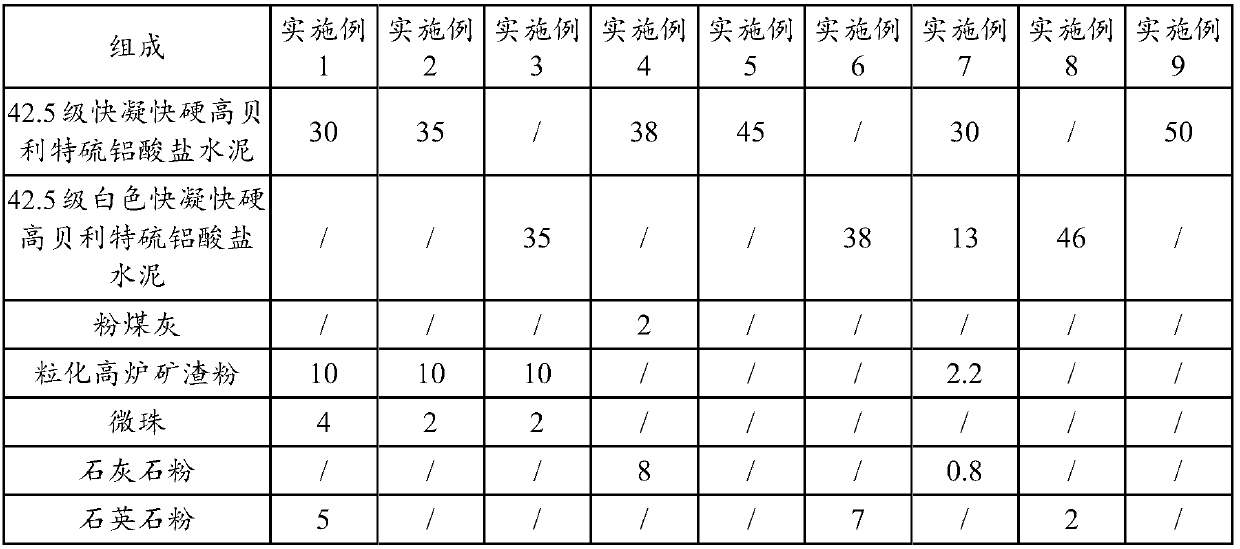

Quick-hardening anti-cracking cement-based self-leveling mortar powder, slurry, mortar and preparation method thereof

PendingCN109836106AImprove initial fluidityNo significant decrease in fluidity after 20 minutesAcid corrosionSlurry

The invention provides quick-hardening anti-cracking cement-based self-leveling mortar powder, slurry, mortar and a preparation method, and relates to the field of building materials. The mortar powder comprises the following raw materials in percentage by weight: 30%-50% of quick-cementing and -hardening high-belite sulphoaluminate cement, 46.19%-51.97% of a fine aggregate, 0.15%-0.3% of a waterreducing agent, 0%-0.04% of a thickening agent, 0.05%-0.2% of a defoaming agent, 0.5%-3.5% of latex powder, 0.075%-0.25% of a retarder and 0.15%-0.3% of a coagulation accelerator. The self-leveling mortar has the excellent properties of acid corrosion resistance, small shrinkage, high tensile bonding strength, high setting and hardening speed and the like, and is suitable for self-leveling floors,industrial floors, civil floors, artistic floors and the like in an acid salt environment.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com