Molten salt for chemical strengthening of glass and application process thereof

A chemical tempering and glass technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high energy consumption, lack of outstanding improvement in the mechanical properties of tempered glass, and accelerated ion exchange speed, etc., to achieve reduction Energy consumption, large-scale production and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Put the glass plate into the chromic acid washing solution and ultrasonically clean it for 10 minutes, and then ultrasonically clean it in deionized water and absolute ethanol respectively to obtain a clean glass plate and dry it for storage.

[0017] The preparation ingredients include a mixed salt of main salt and auxiliary salt, wherein the main salt component KNO 3 100 parts by weight, auxiliary salt component: Al 2 o 3 3 parts by weight, KCl 0.3 parts by weight, K 2 CO 3 4 parts by weight, KOH 0.7 parts by weight.

[0018] Grind the prepared mixed salt until fine and mix well.

[0019] The prepared and ground mixed salt is put into a temperature-controlled electric furnace, and the electric furnace is heated from room temperature to 400° C. within 30 minutes, and then kept for 30 minutes to obtain molten salt. The pre-etched glass plate is preheated, and the specific treatment method is: heating from room temperature to 400° C. within 30 minutes, and then k...

Embodiment 2

[0023] Put the glass plate into the chromic acid washing solution and ultrasonically clean it for 15 minutes, and then ultrasonically clean it in deionized water and absolute ethanol respectively to obtain a clean glass plate and dry it for storage.

[0024] The formulation contains a mixture of primary and secondary salts. Among them, the main salt component KNO 3 100 parts by weight, auxiliary salt component: Al 2 o 3 4 parts by weight, KCl 2 parts by weight, K 2 CO 3 2 parts by weight and 0.9 parts by weight of KOH.

[0025] Grind the prepared mixed salt until fine and mix well.

[0026] The prepared and ground mixed salt is put into a temperature-controlled electric furnace, and the electric furnace is heated from room temperature to 400° C. within 30 minutes, and then kept for 30 minutes to obtain molten salt. The pre-etched glass plate is preheated. The specific treatment method is: put the glass plate into a temperature-controlled electric furnace, and the elect...

Embodiment 3

[0030] Put the glass plate into the chromic acid washing solution and ultrasonically clean it for 15 minutes, and then ultrasonically clean it in deionized water and absolute ethanol respectively to obtain a clean glass plate and dry it for storage.

[0031] The formulation contains a mixture of primary and secondary salts. Among them, the main salt component KNO 3 100 parts by weight, auxiliary salt component: Al 2 o 3 3 parts by weight, KCl 1 part by weight, K 2 CO 3 2 parts by weight, KOH 0.3 parts by weight.

[0032] Grind the prepared mixed salt until fine and mix well.

[0033]The prepared and ground mixed salt is put into a temperature-controlled electric furnace, and the electric furnace is heated from room temperature to 400° C. within 30 minutes, and then kept for 30 minutes to obtain molten salt. The pre-etched glass plate is preheated. The specific treatment method is: the glass plate is placed in a temperature-controlled electric furnace, and the electric ...

PUM

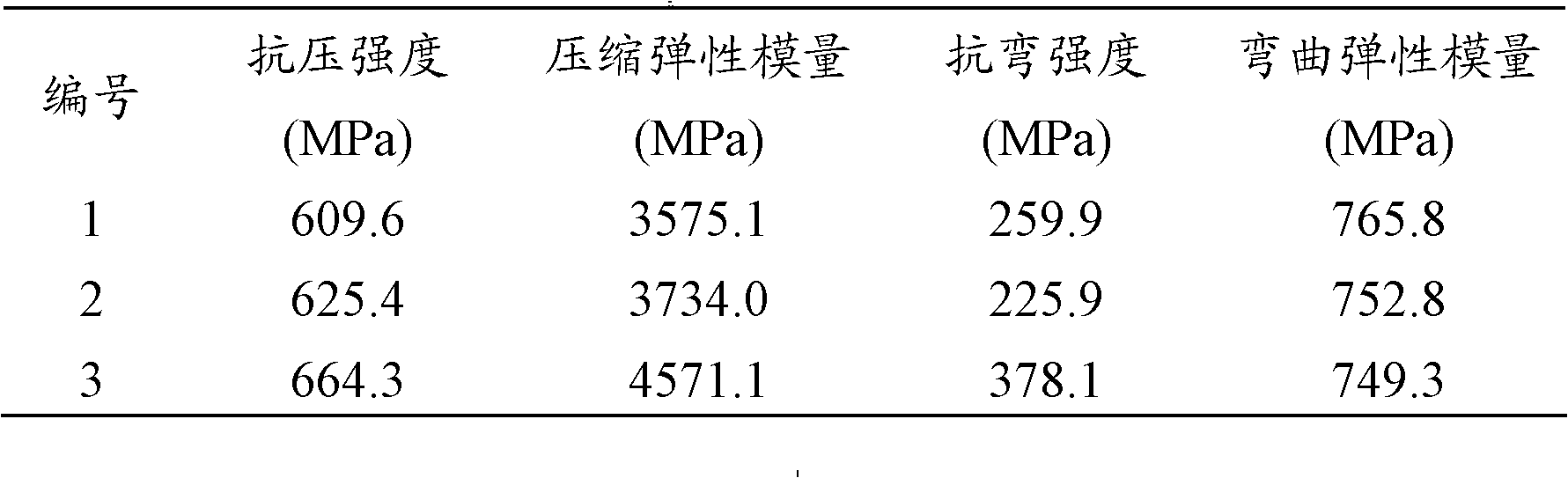

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com