Patents

Literature

391results about How to "Good viscosity stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot Melt Adhesive Based on Olefin Block Copolymers

ActiveUS20110021103A1Improve spray characteristicsGood viscosity stabilityPersonal careLayered product treatmentCardboardCrystallinity

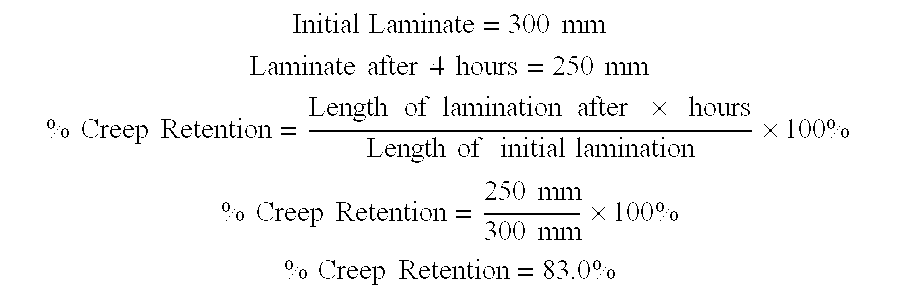

A hot melt adhesive composition, comprising a blend of components including about 5% to about 50% by weight of an olefin block copolymer; about 10% to about 70% by weight of a first tackifying resin having a softening point of at least about 95° C.; about 0 to 65% of a second tackifying resin that is different than the first tackifying resin; about 0% to about 60% by weight of a plasticizer; about 0% to about 20% by weight of an aromatic reinforcing resin having a softening point equal to or higher than 115° C.; about 0.1% to about 5% by weight of a stabilizer; and about 1% to about 40% by weight of a secondary polymer that is different from the olefin block copolymer, the first and second tackifying resins and the reinforcing resin, having relatively low crystallinity, which low crystallinity is equal to or less than 250 Joules / gram, wherein the components total 100% by weight of the composition, and the viscosity of the composition is equal to or less than about 20,000 mPa·s at 163° C. Laminates, especially those used in disposable soft goods, and methods of making such laminates using the hot melt adhesive composition are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

Polymer-pigment composites

InactiveUS6214467B1Good viscosity stabilityEnhanced resistance to flocculation during preparationSynthetic resin layered productsCellulosic plastic layered productsOligomerPigment

Owner:ROHM & HAAS CO

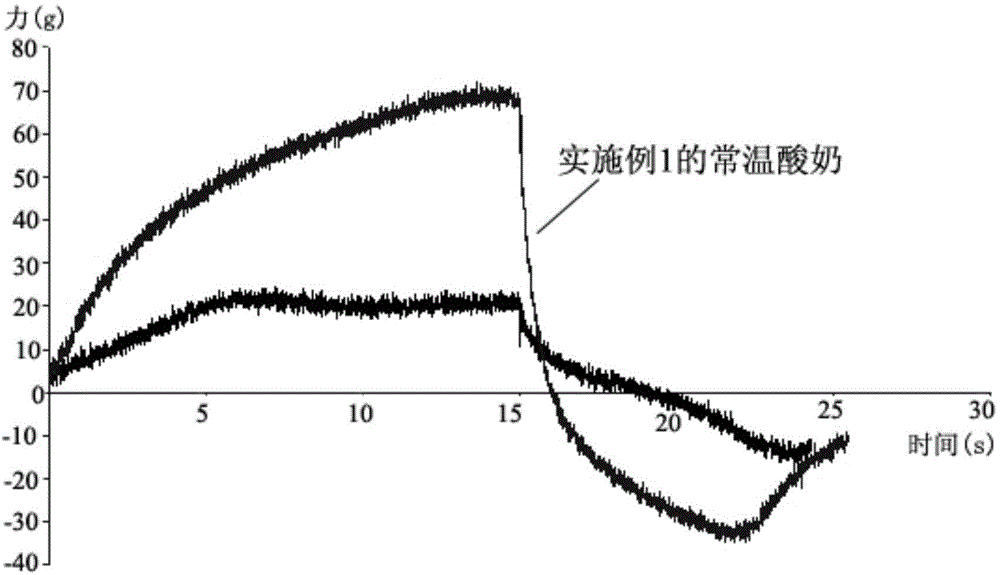

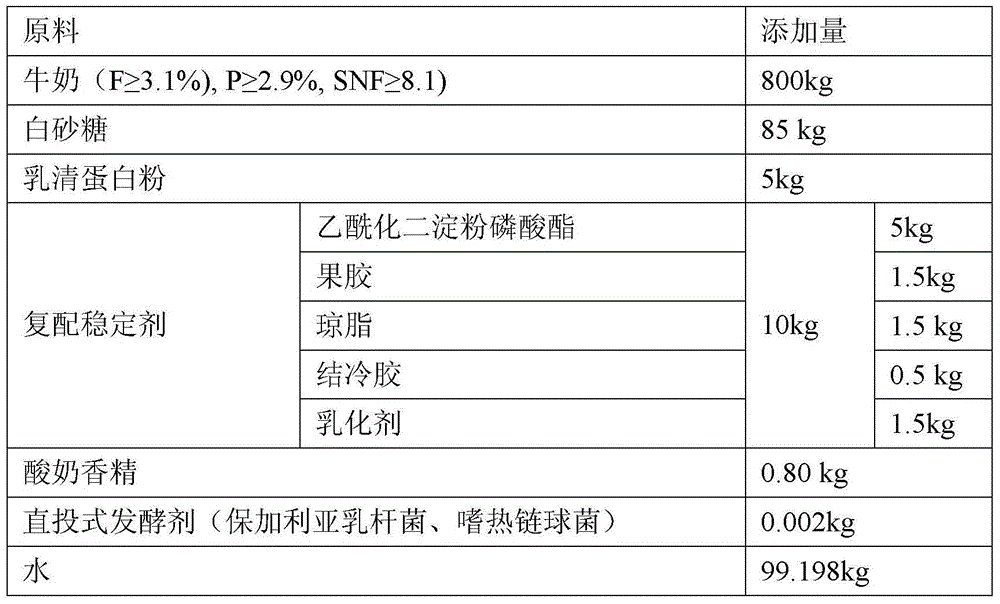

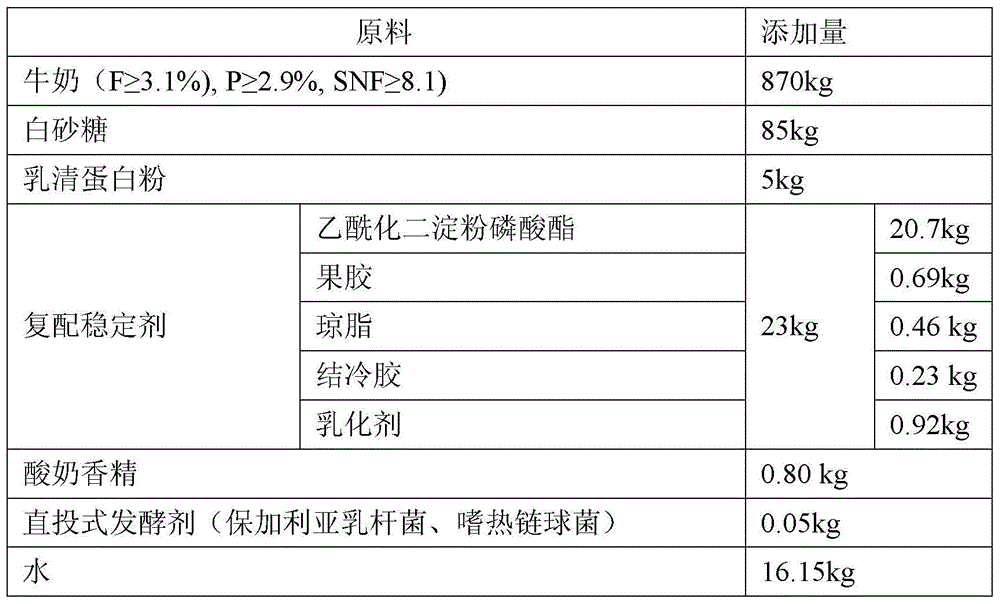

Compounded stabilizer, normal temperature yoghurt containing compounded stabilizer, and preparation method of yogurt

The invention relates to a compounded stabilizer, normal temperature yoghurt containing the compounded stabilizer, and a preparation method of the yogurt. The compounded stabilizer comprises, by mass, 50-90% of esterified modified starch, 3-15% of pectin, 2-15% of agar, 4-15% of an emulsifier and 1-5% of gellan gum. The invention also provides normal temperature yoghurt containing the compounded stabilizer, and a preparation method of the yogurt. The compounded stabilizer has good process tolerance, improves the viscosity stability of a technology processed normal temperature yoghurt system and the viscosity recovery stability of a subsequent product, and allows the viscosity of yogurt at normal temperature of 20-40DEG C to be similar or greater than the viscosity of yogurt refrigerated at normal temperature of 3500-5000cp. The normal temperature yogurt prepared in the invention can be stored at normal temperature of 20-40DEG C for 4-6 months, and allows high quality yogurt to be drunk in remote cold chain lacking places.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Use of converted low-viscosity, high solids starch in foods

InactiveUS6896915B2Stable and low viscosityHigh glossDough treatmentConfectioneryViscosityFood products

Owner:CORN PROD DEV INC

PVC (polyvinyl chloride) coated fabric paste and preparation method thereof

The invention discloses a functional PVC (polyvinyl chloride) paste. The functional PVC paste comprises the following components: PVC paste resin, PVC doped resin, a plasticizing agent, a filling agent, a heat stabilizer, a light stabilizer, an antioxidant, a mildew-proof antibacterial agent, a gas-phase silicon dioxide and the like. A preparation method of the functional PVC paste comprises the following steps of: (1) stirring: firstly mixing and stirring a part of the plasticizing agent and a liquid component uniformly, then adding a solid component, stirring uniformly, finally adding coloring stock and the remaining plasticizing agent, and stirring uniformly, so as to obtain plasticized paste; (2) grinding: grinding the plasticized paste on a three-roll grinding machine; and (3) defoaming and ageing. The paste has the advantages that the viscosity stability is good; and the paste can remain low viscosity under the action of the shearing force of a scraper in the process of producing PVC coated fabric, so that the normal production of the PVC coated fabric is guaranteed, and the surface of the prepared PVC coated fabric is smooth without the phenomena of pin holes and the like.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

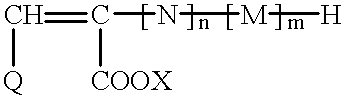

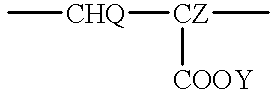

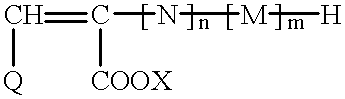

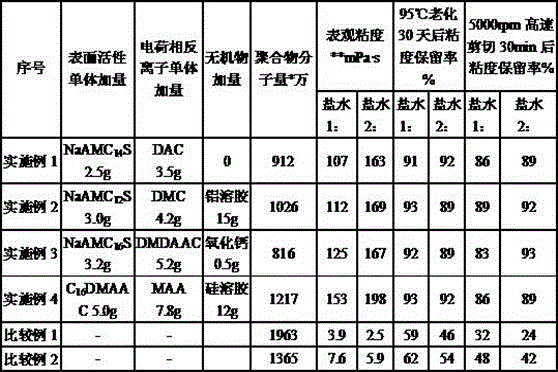

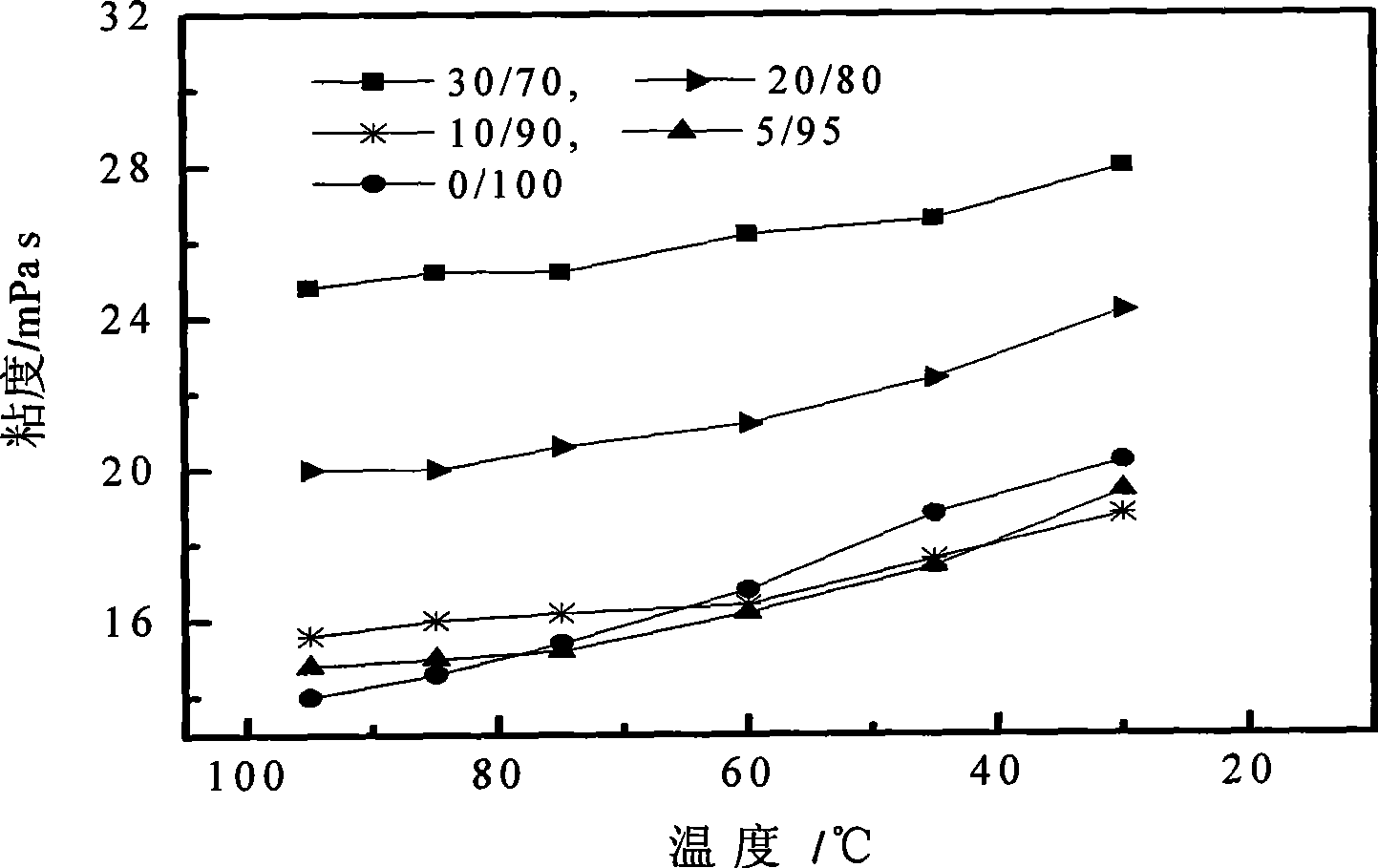

Polymer mobility control agent suitable for ultrahigh-salinity oil deposit and preparation method thereof

ActiveCN104448127AGood temperature and salt resistanceGood thermal stabilityDrilling compositionPolymer scienceWater soluble

The invention relates to a polymer mobility control agent suitable for an ultrahigh-salinity oil deposit and a preparation method thereof, and the polymer mobility control agent is mainly used for solving the problem that a polymer can not meet the requirement for tertiary oil recovery due to poor temperature resistant property, salt resistant property and shearing resistant property in the prior art. In order to better solve the problem, the technical scheme adopted by the invention is as follows: the control agent for an amphoteric hydrophobic associated polymer comprises the following components in parts by weight of the amphoteric hydrophobic associated polymer: 5-99.9 parts of nonionic water-soluble monomers, 0-50 parts of anionic monomers or / and cationic monomers, 0.1-10 parts of hydrophobic monomers with surface activity, 0.1-5 parts of inorganic substances and 1-20 parts of surface active agents. The preparation method disclosed by the invention can be used for the industrial production of the polymer mobility control agent suitable for the ultrahigh-salinity oil deposit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Compound type cleaning solution

InactiveCN102559406AExcellent decontamination synergisticGood thickeningAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsLiquid stateWater soluble

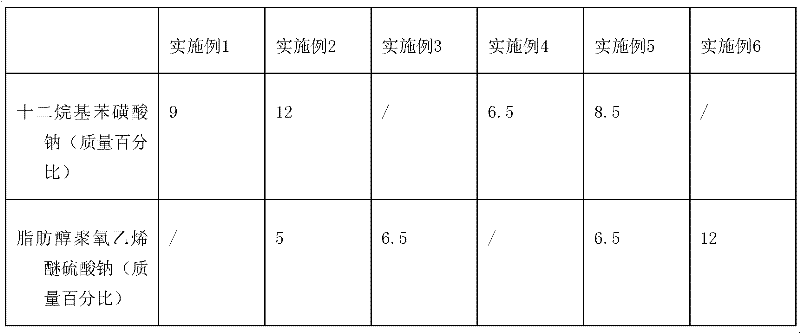

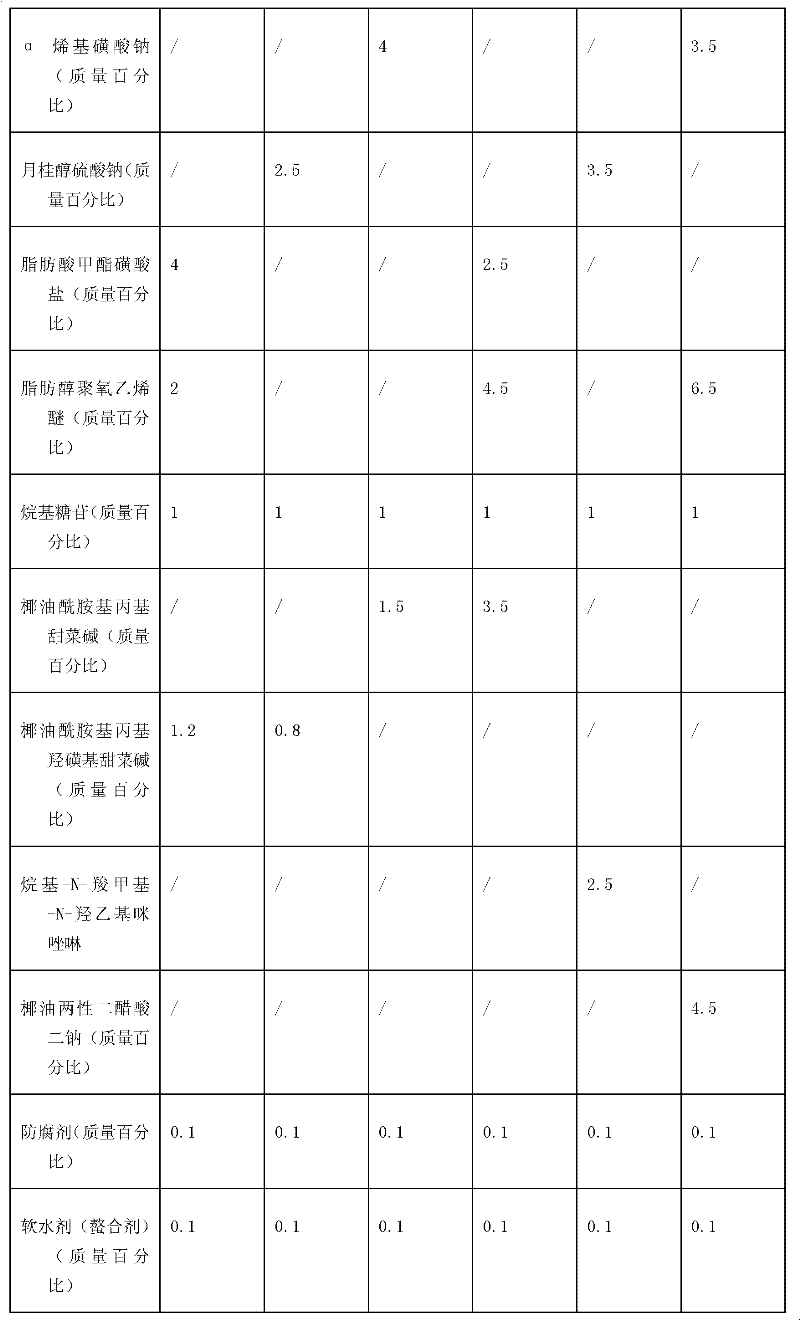

The invention relates to a compound type cleaning solution which comprises a component A, a component B and pure water, wherein the component A is composed of at least one amphoteric surfactant with 8 or more carbon atoms, and accounts for 0.1-15% of the cleaning solution by mass; the component B is at least one anionic surfactant, non-ionic surfactant or cationic surfactant with 8 or more carbon atoms, and accounts for 1-30% of the cleaning solution by mass; and the balance is pure water. In the invention, the amphoteric surfactant and other surfactants are compounded to prepare a dish hand-washing detergent which has excellent functions of cleaning, efficacy enhancing, thickening, foaming, foam stabilizing and the like and is very favorable for improving the performance of the product such as detergency, viscosity, storage stability and the like. Moreover, the amphoteric surfactant is generally in a water-soluble liquid state and can be easily mixed in a formula solution, thus the industrialization of the product provided by the invention can be easily realized.

Owner:WALCH GUANGZHOU COMMODITY

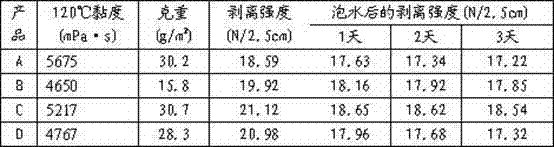

Preparation method of wet curing reaction-type polyurethane hot melt adhesive for textile

ActiveCN103497725AHigh initial bond strengthGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a preparation method of a wet curing reaction-type polyurethane hot melt adhesive for a textile. The preparation method mainly comprises the following steps: (1) stirring and mixing polyether polyol 4000E, polyether polyol 3000H and an antioxidant, heating and warming to about 120 DEG C, dewatering for 0.5 hour when the vacuum degree is smaller than 100Pa; (2) adding a tackifying resin, continuing to warm to 135-140 DEG C, dewatering for 1.5 hours when the vacuum degree is smaller than 100Pa; (3) cooling to 87 DEG C, adding 4,4'-diphenyl methane diisocyanate and a catalyst, stirring and reacting for 2 hours when the vacuum degree is smaller than 100Pa; (4) relieving a vacuum state, adding white carbon black, quickly stirring and evenly mixing, and continuing to stir for 10 minutes when the vacuum degree is smaller than 100Pa; and (5) keeping the discharge temperature at 85-100 DEG C, quickly discharging and encapsulating, and then curing for 4 hours under the condition of 80-85 DEG C, so as to obtain a target product. The product is applied to compounding of the textile, and has excellent peel strength, short opening time, good hydrolysis resistance and good storage stability.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

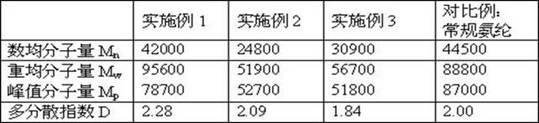

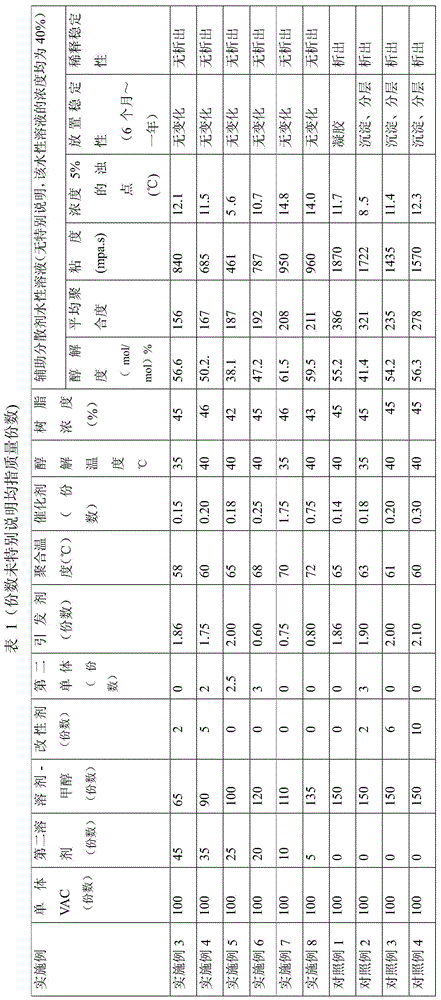

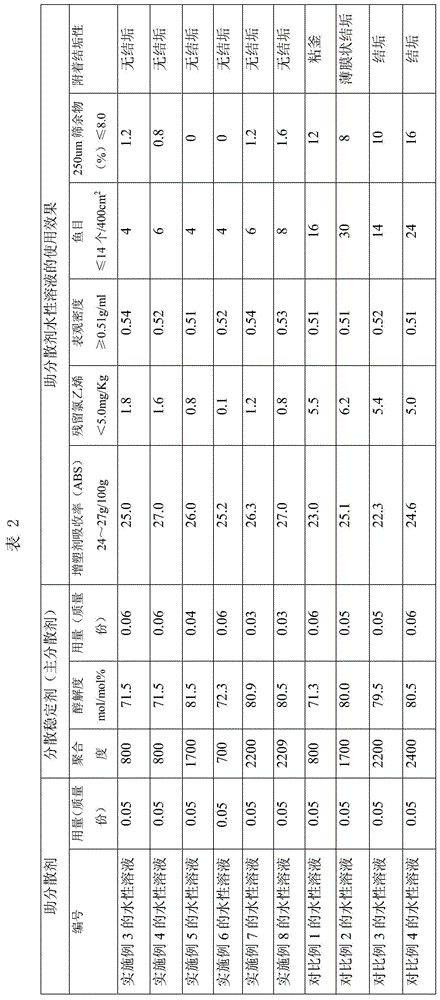

Polyvinyl alcohol, preparation method and applications

The invention provides polyvinyl alcohol. The polyvinyl alcohol is characterized in that the average polymerization degree is no higher than 500, the blocking degree is 0.50-0.85, and the alcoholysis degree is 35mol%-65mol%. The provided polyvinyl alcohol with a low polymerization degree, a low alcoholysis degree and a low viscosity has especially excellent viscosity stability. When the provided polyvinyl alcohol is used for a vinyl polymer suspension polymerization reaction, the monomer droplet disperse dispersion capability is strong, the dispersion stability is good, and the provided polyvinyl alcohol is free from vinyl polymer polymerization conditions. The pores of the prepared vinyl polymers are distributed uniformly and the porosity is high. The removal performance of reaction residual monomers is good, the absorption capability of added plasticizers is excellent during the subsequent processing process, the processing properties are excellent, plasticizing time can be shortened, and the fisheye number is decreased.

Owner:CHINA PETROCHEMICAL CORP +1

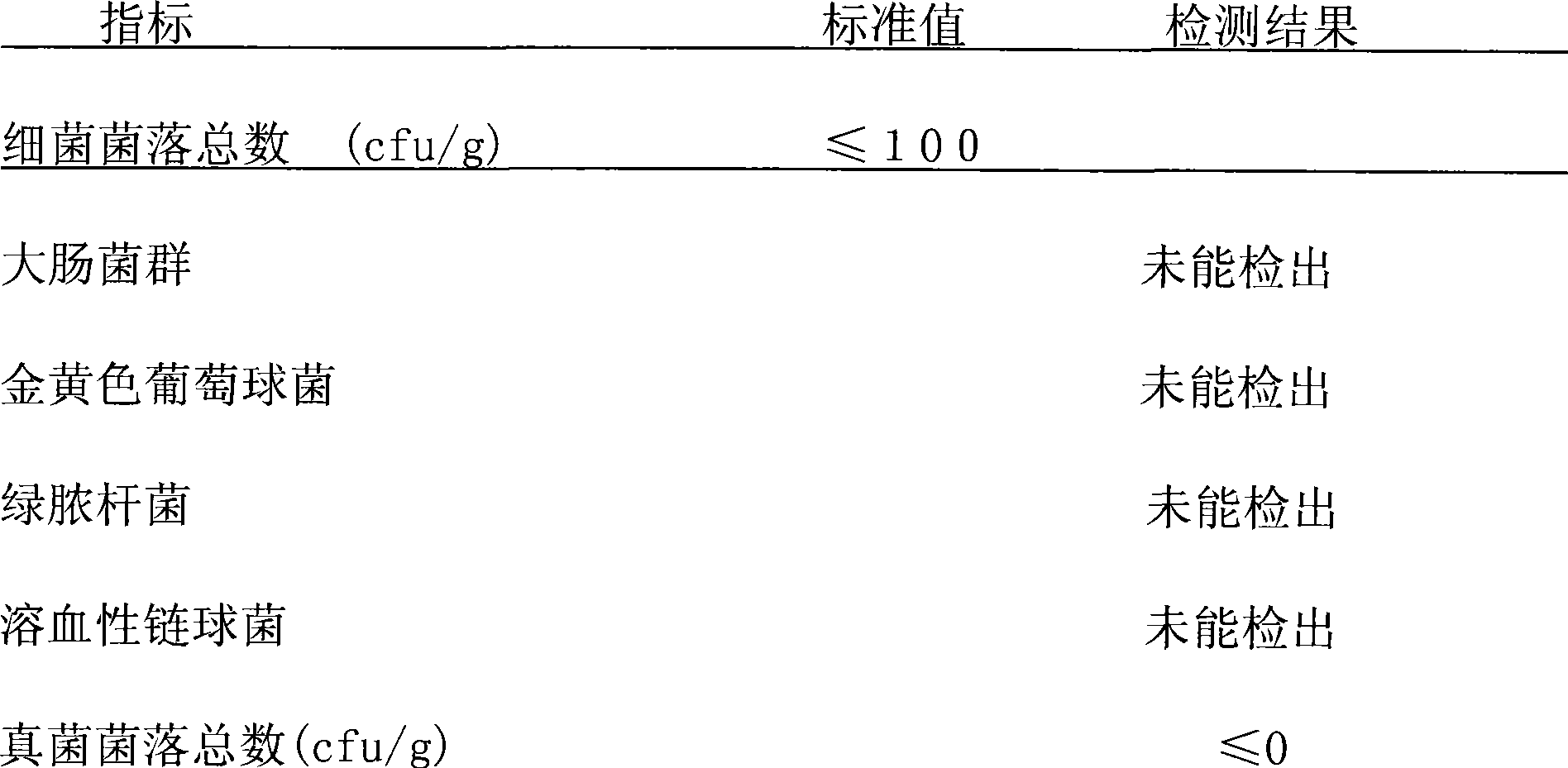

Moisture-absorbing and bacteriostatic base cloth of beauty mask made of spunlace non-woven fabric and preparation method thereof

ActiveCN108166157AImprove the problem of viscosity instabilityGood viscosity stabilityNon-woven fabricsArtifical filament manufactureYarnViscose

The invention discloses moisture-absorbing and bacteriostatic base cloth of a beauty mask made of spunlace non-woven fabric and a preparation method thereof, relating to the technical field of non-woven fabrics. The moisture-absorbing and bacteriostatic base cloth is composed of following fibers, by weight, 40-60% of sodium alginate viscose fibers and 40%-60% of chitosan viscose fibers. The preparation method comprises the following steps: firstly preparing the sodium alginate viscose fibers and the chitosan viscose fibers; next, respectively opening and carding the chitosan viscose fibers; then, netting in an intersected manner; reinforcing a fiber net that is laid well by spunlace, drying the fiber net so as to obtain the base cloth. Sodium alginate and chitosan are respectively added into viscose primary liquid to spin viscose yarns. Epichlorohydrin is utilized such that sodium alginate and chitosan are closely combined with viscose. Sodium alginate viscose fibers and chitosan viscose fibers produced show great air permeability, water retention and moisture absorption capabilities and are capable of eliminating bacteria and inhibiting bacteria. Then, non-woven fabric made by intersecting netting and spunlace reinforcement can be used for material of base piece of the mask. The moisture-absorbing and bacteriostatic base cloth is comfortable and skin-friendly and capable of diminishing inflammation and inhibiting bacteria. Skin can be cleaned and effectively protected. The damage of cosmetics to the skin is minimized.

Owner:HEFEI C&P NONWOVEN PROD

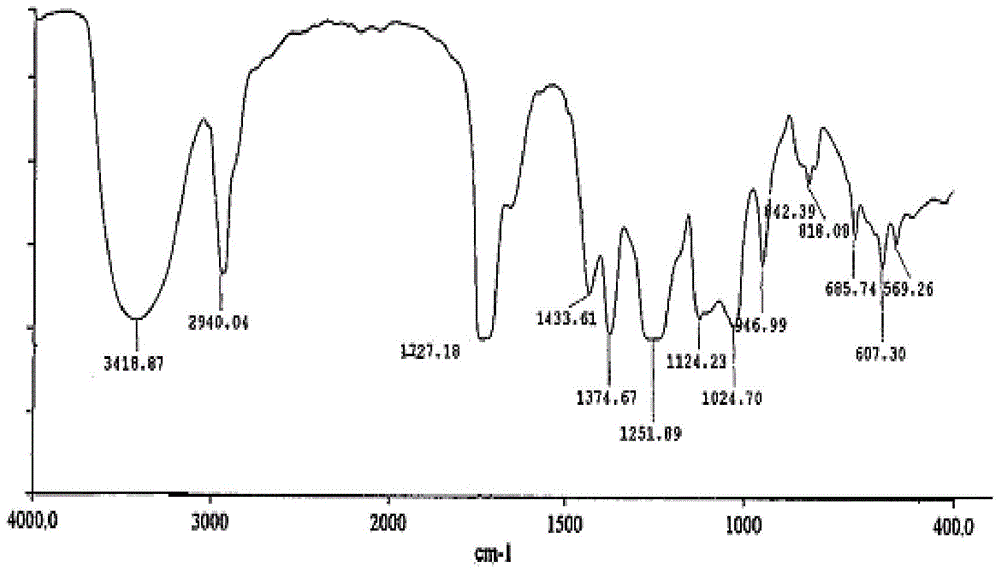

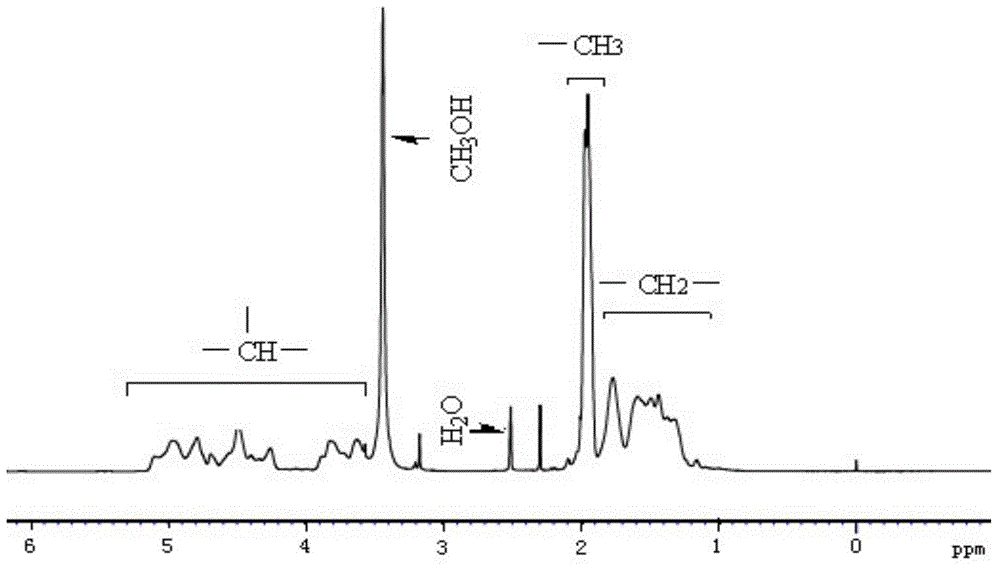

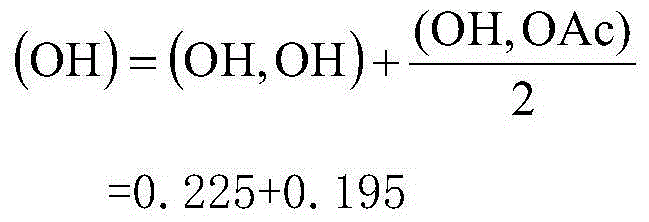

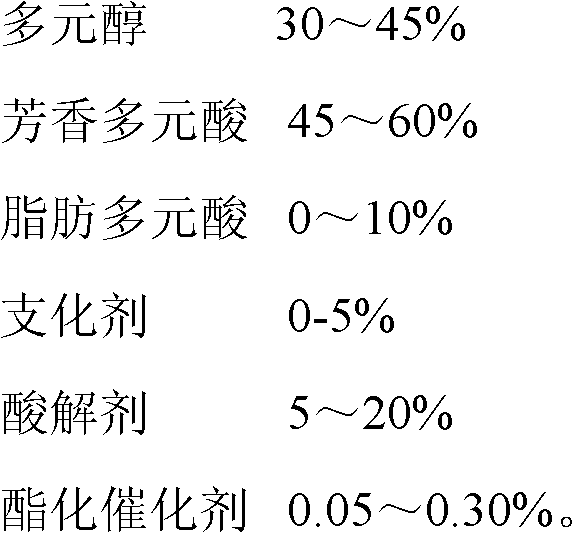

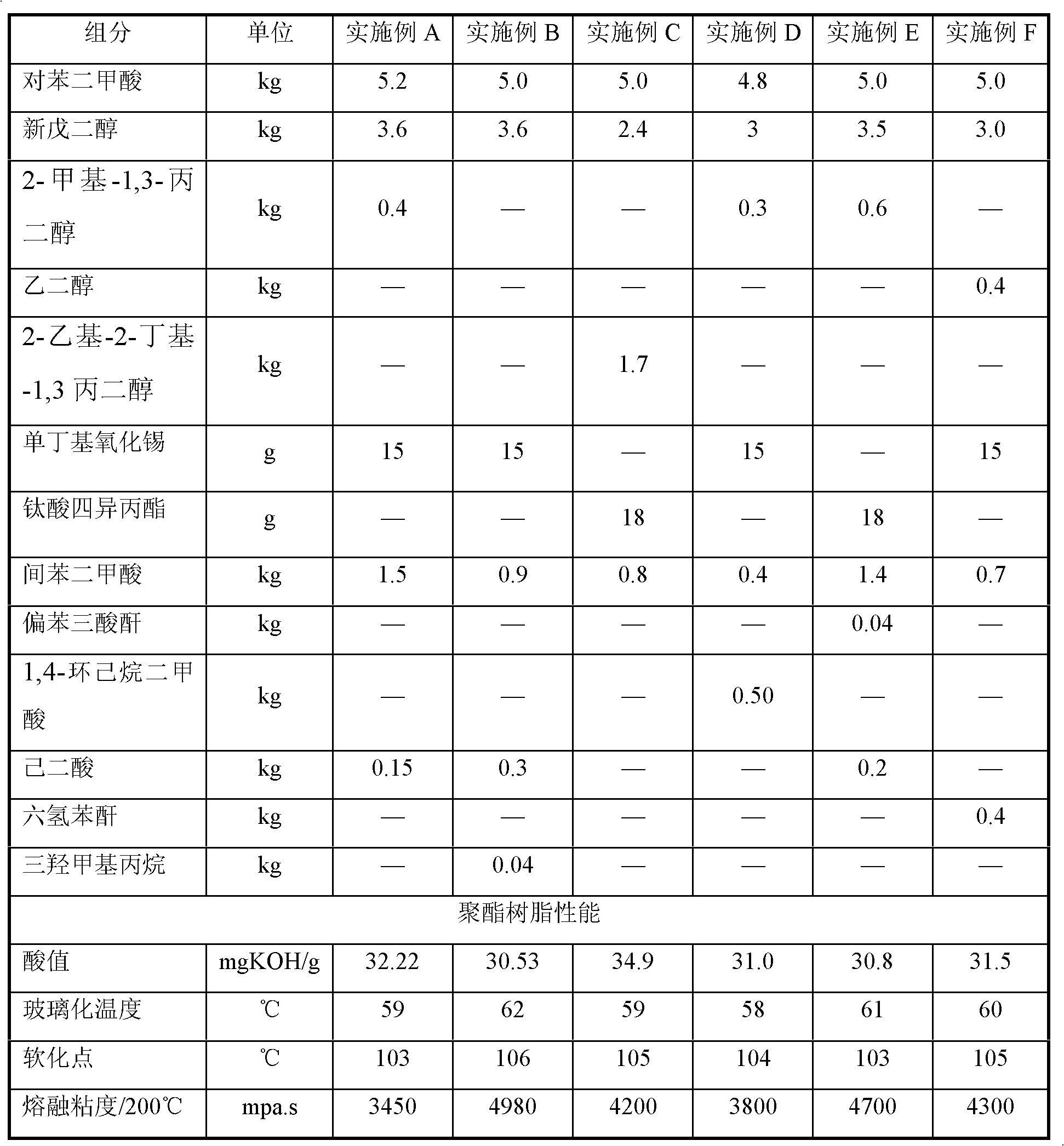

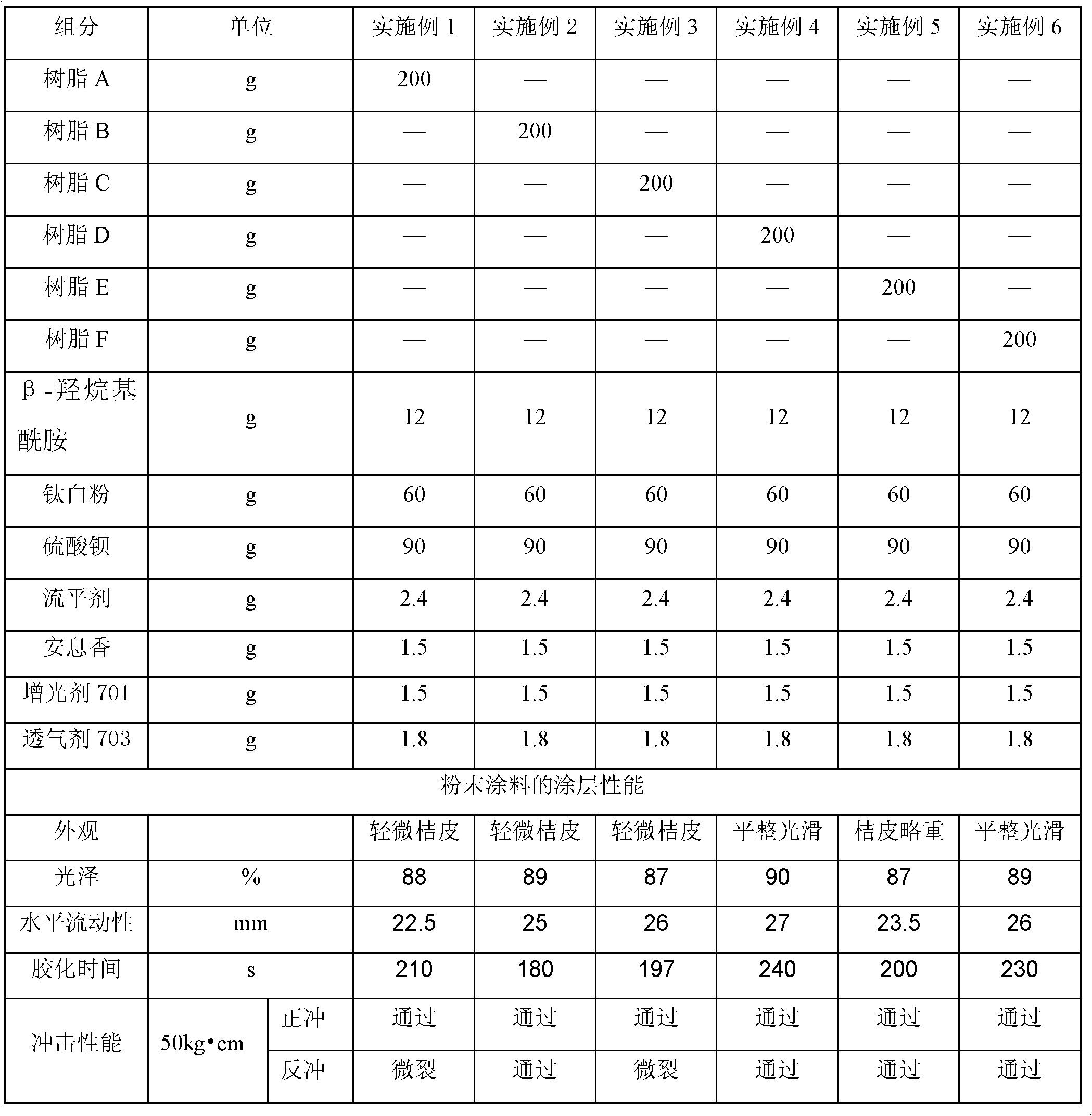

Polyester resin for rapid curing of weather-durable powdery paint by beta-hydroxyalkylamide and preparation method thereof

InactiveCN102443148AHigh glass transition temperatureGood storage stabilityPowdery paintsPolyester coatingsChemistryPowder coating

The invention discloses a polyester resin for the rapid curing of a weather-durable powdery paint by a beta-hydroxyalkylamide. The polyester resin is obtained through carrying out a melting polycondensation reaction on the following components, by weight, 30-45% of a polyol, 45-60% of an aromatic polyprotic acid, 0-10% of an aliphatic polyprotic acid, 0-5% of a branching agent, 5-20% of an antiacid and 0.05-0.30% of an esterification catalyst. The invention also discloses a preparation method of the polyester resin. The polyester resin provided in the invention has the advantages of high glass-transition temperature and softening point, and appropriate melting viscosity and storage stability; and powdery paints prepared with the polyester resin have the advantages of excellent levelability, excellent mechanical performance, good thick film pinhole resistance and the like.

Owner:GUANGZHOU QINGTIAN INDAL

Moisture cured reaction type polyurethane hot melt adhesive and preparation technique thereof

InactiveCN106433540AImprove regularityExtend the usable timePolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolyesterPolyol

The invention relates to a moisture cured reaction type polyurethane hot melt adhesive and a preparation technique thereof. The moisture cured reaction type polyurethane hot melt adhesive mainly contains polyester polyol, polyether polyol, thermoplastic polymer resin, isocyanate MDI, tackifying resin, padding, catalyst and coupling reagent. The components can have a polymerization reaction under a specific technical condition, so as to generate the moisture cured reaction type polyurethane hot melt adhesive with excellent performance. The moisture cured reaction type polyurethane hot melt adhesive is characterized in that the components by weight percent are as follows: 25%-35% of polyester polyol, 25%-35% of polyether polyol, 25%-35% of thermoplastic polymer resin, 10%-20% of isocyanate MDI, 1%-3% of tackifying resin, 1%-5% of padding, 0.5%-1% of catalyst and 0-3% of coupling reagent. Compared with the same formula under different reaction technical conditions, the moisture cured reaction type polyurethane hot melt adhesive generated under the technical condition provided by the invention has the advantages of tiny difference between different batches, performance stability, strong adhesive force and excellent viscosity stability in a gluing process.

Owner:苏州孚霖工业品科技有限公司

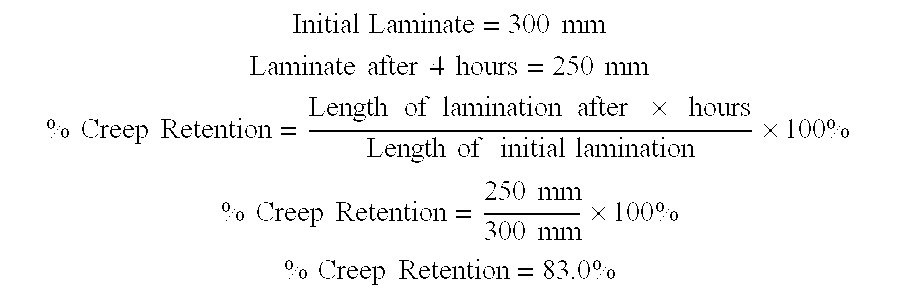

Hot melt adhesive based on olefin block copolymers

ActiveUS8921474B2Improve spray characteristicsGood viscosity stabilityPersonal careLayered product treatmentCardboardCrystallinity

A hot melt adhesive composition, comprising a blend of components including about 5% to about 50% by weight of an olefin block copolymer; about 10% to about 70% by weight of a first tackifying resin having a softening point of at least about 95° C.; about 0 to 65% of a second tackifying resin that is different than the first tackifying resin; about 0% to about 60% by weight of a plasticizer; about 0% to about 20% by weight of an aromatic reinforcing resin having a softening point equal to or higher than 115° C.; about 0.1% to about 5% by weight of a stabilizer; and about 1% to about 40% by weight of a secondary polymer that is different from the olefin block copolymer, the first and second tackifying resins and the reinforcing resin, having relatively low crystallinity, which low crystallinity is equal to or less than 250 Joules / gram, wherein the components total 100% by weight of the composition, and the viscosity of the composition is equal to or less than about 20,000 mPa·s at 163° C. Laminates, especially those used in disposable soft goods, and methods of making such laminates using the hot melt adhesive composition are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

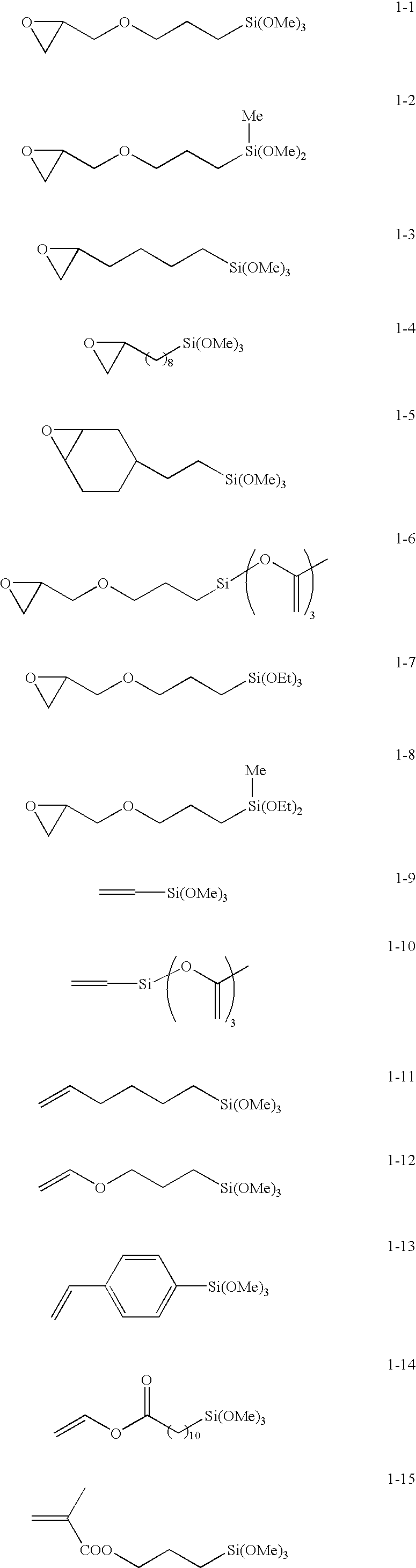

Inorganic fine particle dispersion, method for forming same, ink jet recording medium and method for manufacturing same

InactiveUS20070196597A1High viscosityStability is deterioratedSynthetic resin layered productsCellulosic plastic layered productsInorganic saltsWater soluble

The invention provides an inorganic fine particle dispersion having at least an inorganic fine particles, a silane coupling agent, and at least one member selected from the group consisting of a basic inorganic salt and ammonium, the inorganic fine particle dispersion having a pH of 5.0 or less, and a method for forming thereof including at least adjusting the pH by using the basic inorganic salt and / or the ammonium. The invention further provides an ink jet recording medium and a method manufacturing thereof including at least applying an ink-receiving layer coating liquid formed by mixing the inorganic fine particle dispersion and a water-soluble resin onto a support.

Owner:FUJIFILM CORP

Method of stabilizing fabric softening compositions

InactiveUS6303565B1Good viscosity stabilityCationic surface-active compoundsOrganic detergent compounding agentsPolymer scienceActive agent

The invention provides a process of improving the viscosity stability upon storage at temperatures of 25° C. or more but below 40° C. of a fabric softening composition comprising:(a) a 8 to 50% by weight of a cationic fabric softening agent; and(b) perfumeby the inclusion of 3.5% to 15% by weight of an emulsified silicone, based upon the total amount of the composition, which has been emulsified with one or more cationic surfactants. In one aspect, the viscosity of the silicone before emulsification is from 10,000 cSt to 400,000 cSt, preferably from 20,000 cSt to 350,000 cSt, more preferably from 25,000 cSt to 250,000 cSt and the emulsion is a macro-emulsion. In another aspect, the median emulsified silicone droplet size is at least 0.2 mum, preferably at least 0.25 mum, more preferably at least 0.39 mum, preferably also no greater than 25 mum.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Amphoteric guar gum, preparation method and application thereof

ActiveCN101514233AImprove dry strengthDoes not reduce softnessNon-fibrous pulp additionPaper/cardboardSolventAqueous solution

The invention discloses amphoteric guar gum, a preparation method and application thereof. The preparation method comprises the following steps: (A) adding guar gum raw powder into a low-polar or non-polar solvent at normal temperature, and adding a basic catalyst aqueous solution into the solvent for soaking and basifying; (B) adding a cationic etherifying agent into the mixture under the pressure of between 0.05 and 0.3 Mpa; and (C) adding an anionic etherifying agent into the mixture to react, and adding a neutralizing agent to neutralize the mixture until pH is between 7 and 8, and collecting the amphoteric guar gum from reactant. The prepared product has excellent viscosity stability and higher transparency. As a thickening agent, the amphoteric guar gum can be applied to paper making, foods, textile and other fields; and as a reinforcing agent, the amphoteric guar gum can be applied to the field of paper making, and can obviously improve the baked strength of paper without reducing the softness of the paper.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

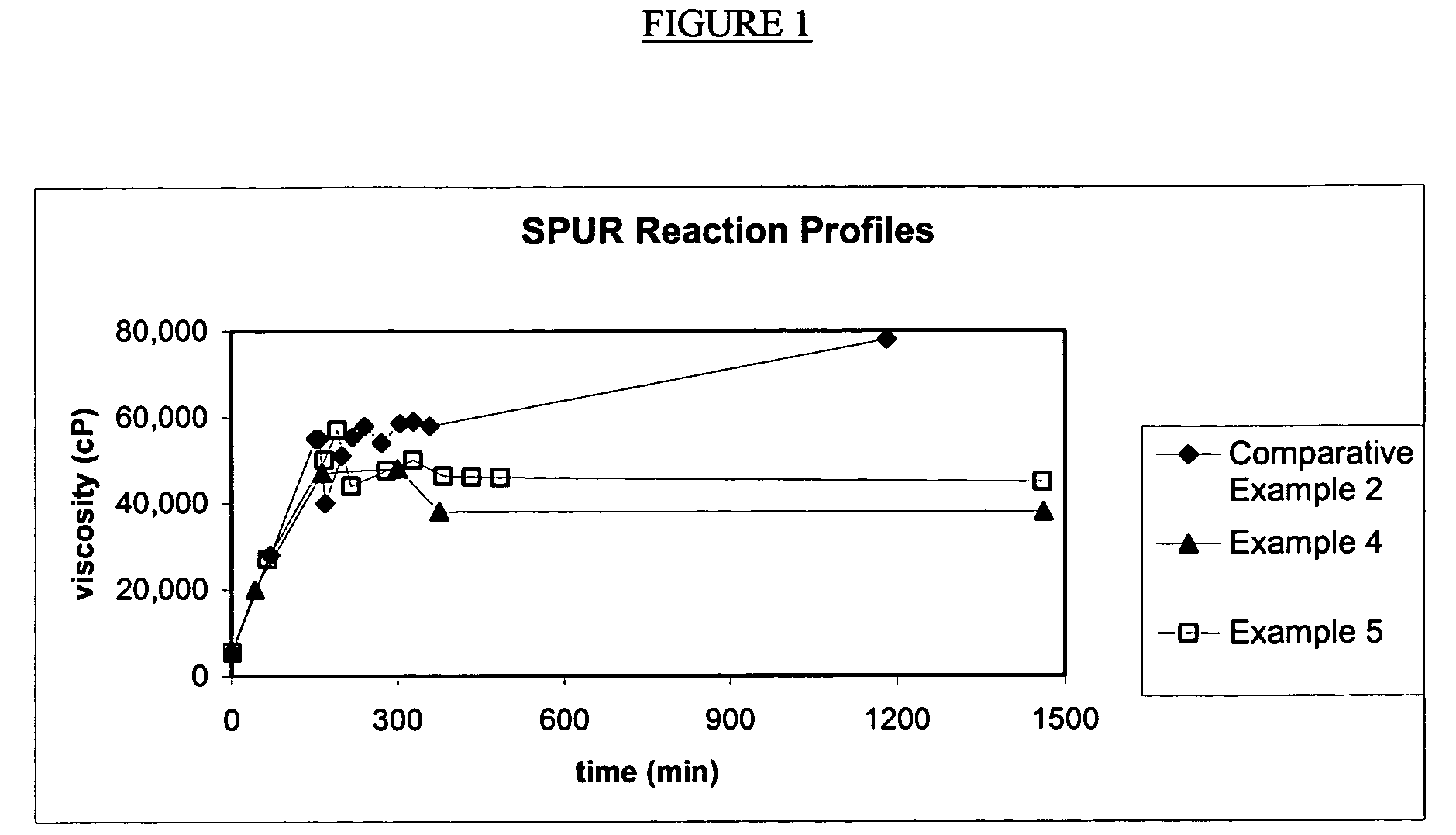

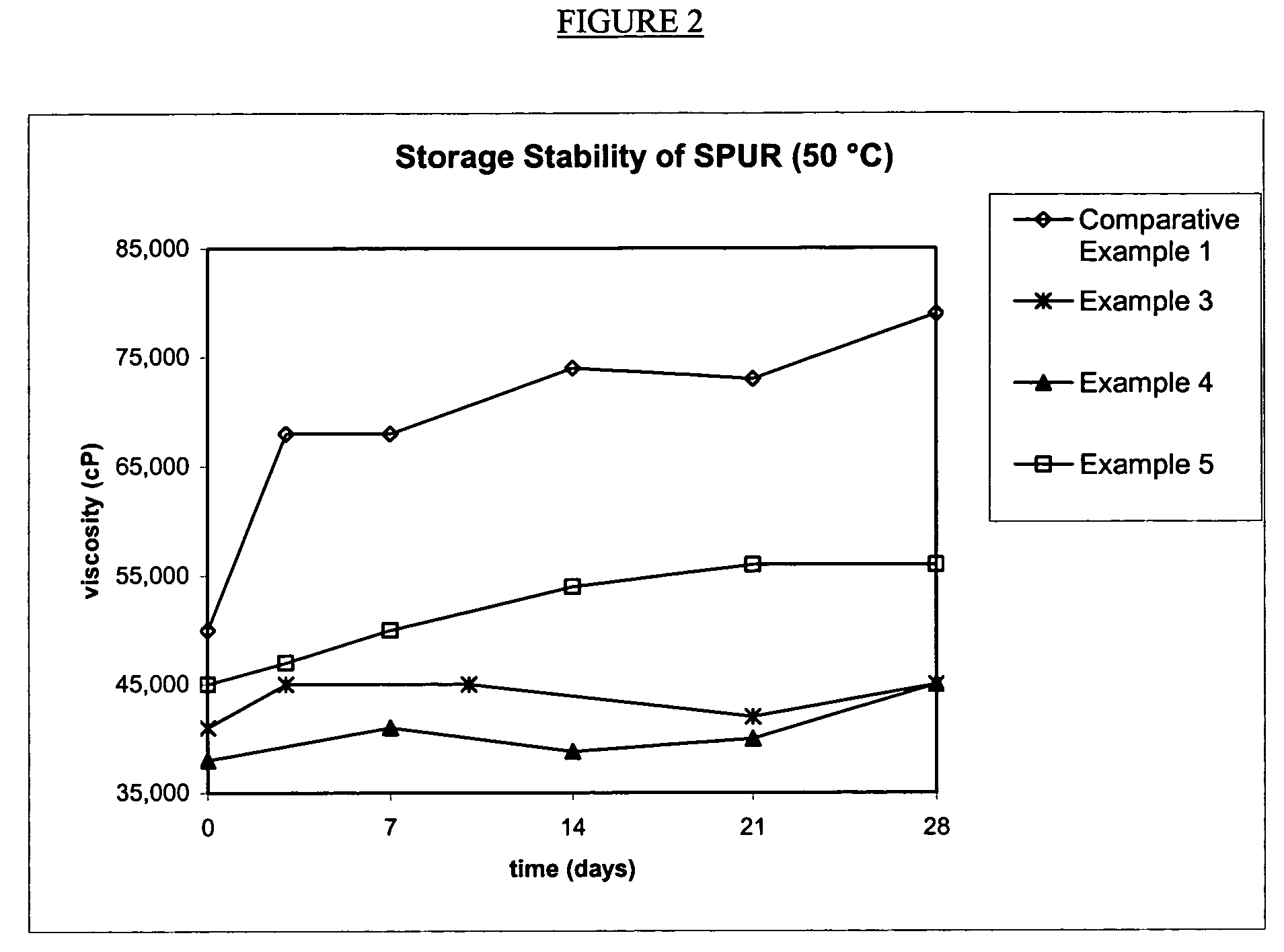

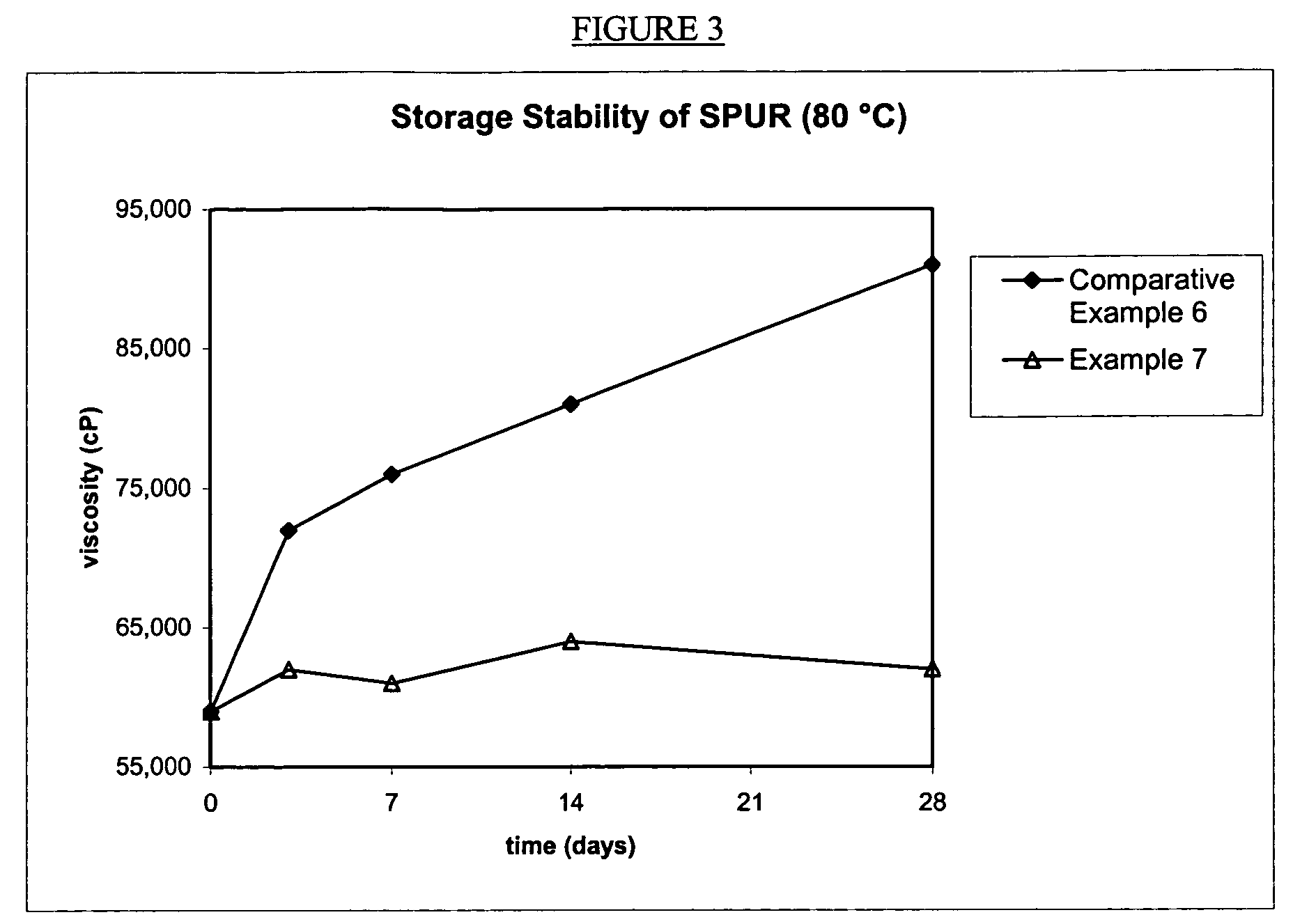

Process for preparing a curable silylated polyurethane resin

The present invention relates to a process for the production of silylated polyurethane resins free of unreacted residual isocyanate possessing consistent viscosity and stability and products therefrom.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

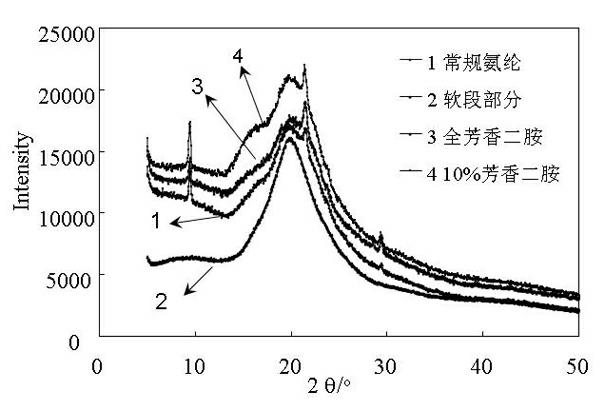

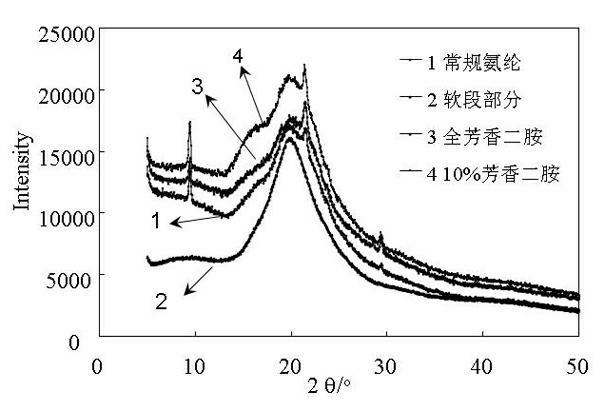

Preparation method of heat resistant spandex fiber

ActiveCN102220653AImprove heat resistanceGood lifting effectMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a preparation method of heat resistant spandex fiber, belonging to the technical field of polymer textile material and preparation thereof; the preparation method comprises the following steps of: (1) mixing polyoxytetramethylene and 4,4'-methylenebis(phenyl isocyanate) according to a mole ratio of 1 / 1.4 to 1 / 2.5 for reaction to obtain a prepolymer; (2) adding non-protonicpolar solvent to the prepolymer prepared in the step (1) so that the prepolymer is dissolved in the non-protonic polar solvent to obtain prepolymer solution; (3) adding a chain extender in the prepolymer solution obtained in the step (2) to obtain spandex spinning fluid with a molecular weight of 20-300 thousands after polymerization reaction, wherein the chain extender is aromatic diamine or themixture of aromatic diamine and aliphatic diamine; (4) using the spandex spinning fluid prepared in the step (3) to obtain the heat resistant spandex fiber with a solution spinning method. Compared with conventional spandex, the product has obviously improved resistance to heat; moreover, the viscosity stability of the polymer is good.

Owner:ZHEJIANG KAIPUTE SPANDEX +1

Air-activated organotin catalysts for polyurethane synthesis

InactiveUS20050282700A1Good viscosity stabilityHigh catalytic activityTin organic compoundsMolecular sieve catalystsLow activitySolvent based

This invention relates to an organotin-based catalyst system for polyurethane synthesis that is useful in coatings applications. The catalyst has low activity in the absence of oxygen. When a coating mixture comprising the catalyst is sprayed and / or applied to a substrate as a thin film in air, the catalyst is activated. For solvent-based refinish systems comprising hydroxyl and isocyanate species at high solids levels, the catalyst system therefore provides extended viscosity stability, i.e., pot life.

Owner:AXALTA COATING SYST IP CO LLC

Polyvinyl alcohol, and preparation method and application thereof

The invention provides polyvinyl alcohol, which is characterized by having the average degree of polymerization in a range of 50-500, the alcoholysis degree in a range of 30-65 mol%, and the viscosity no more than 1500 mPa*s. Polyvinyl alcohol is prepared into an aqueous solution, which is taken as an auxiliary dispersant for suspension polymerization of vinyl polymers. The cloud point of an aqueous solution, the concentration of which is 5 wt%, (that is, a polyvinyl alcohol aqueous solution of 5 wt%), is no less than 1 DEG C and less than 15 DEG C. The viscosity measured at 25 DEG C of an aqueous solution, the concentration of which is 40 wt%, is no more than 1500 mpa*s. Gel and layering don't appear in an aqueous solution, the concentration of which is in a range of 30wt%-50wt%, in at least one year, so that the aqueous solution is extremely excellent in stability.

Owner:CHINA PETROCHEMICAL CORP +1

Liquid crystal sealing agent, method for manufacturing liquid crystal display panel using the liquid crystal sealing agent, and liquid crystal display panel

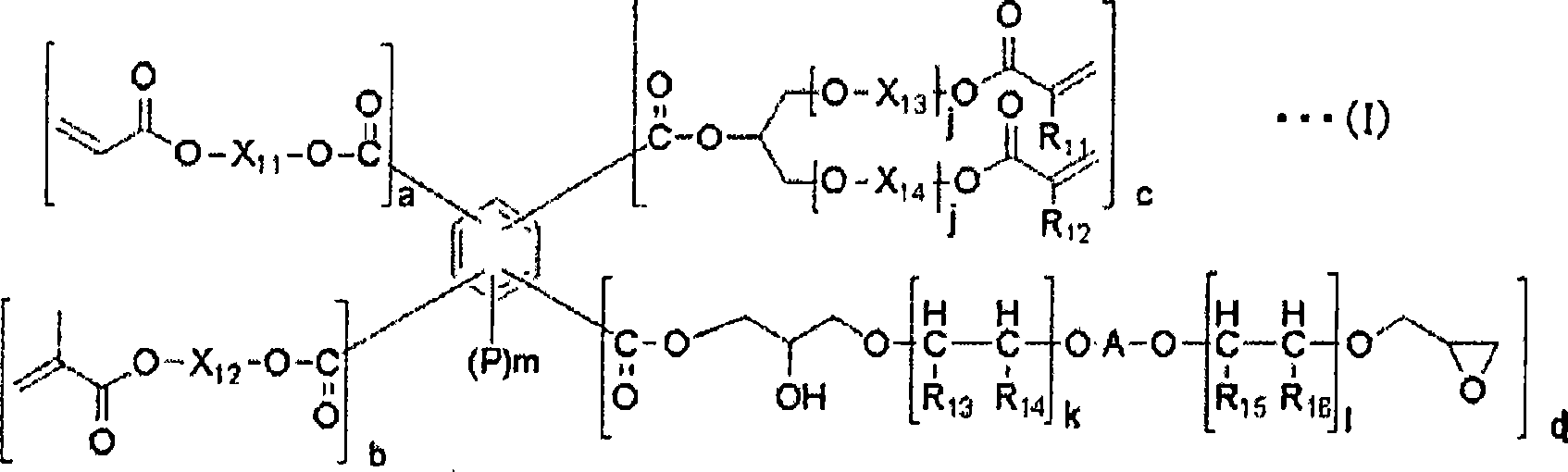

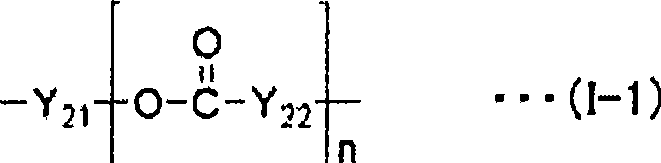

ActiveCN101512421AHigh bonding strengthImprove qualityOrganic chemistryOther chemical processesSolubilityCrystallography

This invention provides a liquid crystal sealing agent which can be applied to liquid crystal display panels. The liquid crystal sealing agent comprises (a) a compound containing a (meth)acryloyl group and a glycidyl group in its molecule and having a number average molecular weight of 500 to 2000, (b) a heat latent curing agent, (c) a radical polymerization initiator, and (d) a filler. The component (a), despite its high molecular weight, has high reactivity and latent curability, and thus simultaneously has a low level of solubility in liquid crystals, a high level of curability, and a high level of viscosity stability. Accordingly, the manufacture of a liquid crystal display panel using the liquid crystal sealing agent is advantageous in that, while maintaining the high level of productivity, the strength of adhesion between a substrate and a cured product of the liquid crystal sealing agent is high and the contamination of the liquid crystal can be suppressed on a low level, resulting in the manufacture of liquid crystal display panels which can realize a high level of display and a high quality.

Owner:MITSUI CHEM INC

Special corn biomass-based adhesive and method for preparing same

InactiveCN101831262AHigh transparencyImprove corrosion resistanceGraft polymer adhesivesWaxy cornPolymer adhesive

The invention relates to a special corn biomass-based adhesive, and belongs to the field of deep processing of corn starch. The adhesive is prepared from the following components in part by mass: 80 to 120 parts of waxy corn oxidized-hydroxypropyl starch, 150 and 250 parts of deionized water, 3 to 4 parts of sodium hydroxide, 10 to 15 parts of vinyl acetate, 4 to 8 parts of polyvinyl alcohol, 0.5 to 1 part of boric acid, 3 to 5 parts of urea and 2 to 3 parts of preservative. The method for preparing the adhesive comprises pulp blending, gelatinization and graft copolymerization. The adhesive of the invention has the advantages of good viscosity stability, long shelf life and high fluidity and transparency. In the adhesive produced by the method, 90 percent of solids are degradable, and if the special corn biomass-based adhesive of the invention is used for replacing the polymer adhesive, pollution can be greatly reduced, and the environmental protection requirements on the production process and the using process are met.

Owner:吉林省轻工业设计研究院

Technology for producing degradable and edible film by utilizing corn composite modified starch

ActiveCN102311554AGood viscosity stabilityImprove strength propertiesFlexible coversWrappersCarrageenanPhosphate

The invention provides technology for producing a degradable and edible film by utilizing corn composite modified starch, belonging to the technical field of food processing. The technology comprises the following main production processes: firstly gelatinizing the corn hydroxypropyl-phosphate monoester composite modified starch; then adding glycerin, sorbitol, sodium alginate, carrageenan and other components which improve the film performance; carrying out tape casting on the film solution on a copper plate after homogenization and degasification; adopting a copper plate film forming conveyer belt to firstly pass through steam drying pipeline equipment and then pass through cooling pipeline equipment with relative humidity being about 50% to form a film; and finally adopting mechanical film rolling equipment to roll the film, thus producing a degradable and edible film with high strength. The film material has good mechanical performance and oil, moisture and oxygen resistance. The film can be applied to packaging of various materials such as food, health products, drugs, feed and the like.

Owner:活泼

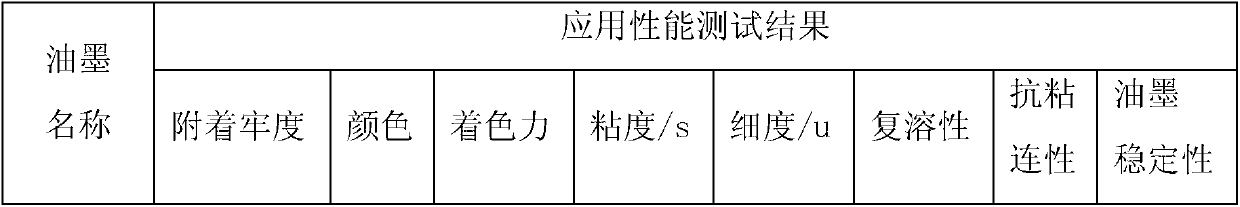

Environment friendly bacteriostatic water color ink for tipping paper

ActiveCN101429364ABacteriostaticEnhance the antibacterial effect of the mediumInksWater basedCalcium bicarbonate

The invention provides an environment-friendly bacteriostatic water-based ink for tipping paper, which is characterized by consisting of the following raw materials in mass percentage: 45 to 55 percent of water, 3 to 10 percent of ethanol, 1 to 3 percent of antibacterial agent, 2 to 4 percent of anti-settling agent, 9 to 15 percent of titanium dioxide, 4 to 6 percent of calcium bicarbonate, 1 to 3 percent of GR organic dye, 5 to 10 percent of GR organic dye yellow, 1 to 3 percent of GR organic dye black, and 18 to 25 percent of binder. The environment-friendly bacteriostatic water-based ink can greatly reduce usage amount of ink and contents of arsenic, mercury and lead, prevents heavy metals such as the arsenic, the mercury, the lead, cadmium, nickel and chromium in a print from causing harm to human body, improves working environment, delays dispersing time of the antibacterial agent, increases antibacterial effect, has better viscosity stability and low inflammability, can simplify workload for printing and washing, and improves production efficiency.

Owner:楚雄市华丽包装实业有限责任公司

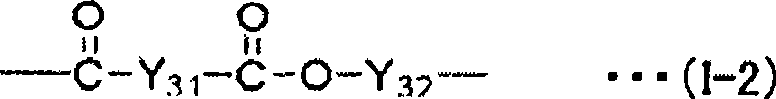

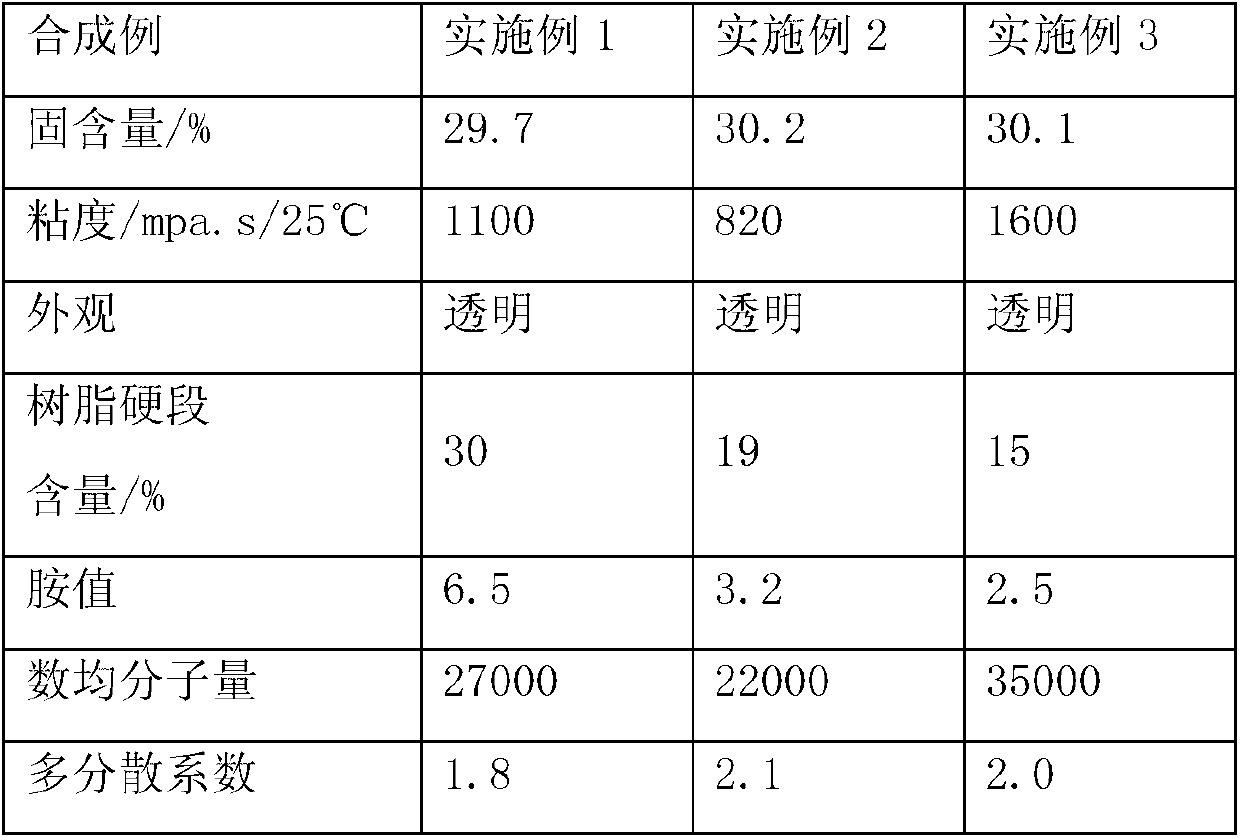

Preparation method of polyurethane resin for gravure composite ink

ActiveCN103012724AMild responseThe chain extension process is stable and controllableInksEnd-groupPolyethylene glycol

The invention discloses a preparation method of polyurethane resin for gravure composite ink, wherein the polyurethane resin is alcohol ester-soluble polyurethane resin not containing free cyanate ester radicals. Large amounts of allophanate radicals are introduced into the resin so that the ink prepared from the resin has excellent adhesion fastness to substrates such as PET (Polyethylene Glycol Terephthalate), NY (Nylon) and PP (Polypropylene) and the like. The preparation method is characterized in that diisocyanate is reacted with high-molecular polyol to generate NCO-terminated prepolymers, and then the prepolymers are added into a solvent containing an amine chain extender to achieve the polyurethane resin for the ink. The soft and hard segment of the resin has the advantages of wide adjustable range, large cohesive energy, good anti-aftertack property and good heat resistance; and the prepared ink has high binding strength to various printing substrates and has high composite strength. The preparation method provided by the invention has obvious characteristics of stable reaction in the synthesis process of the resin, easiness in control of the preparation process, narrow distribution of the molecular weight and good dissolubility of the resin.

Owner:NANTONG GAOMENG NEW MATERIAL

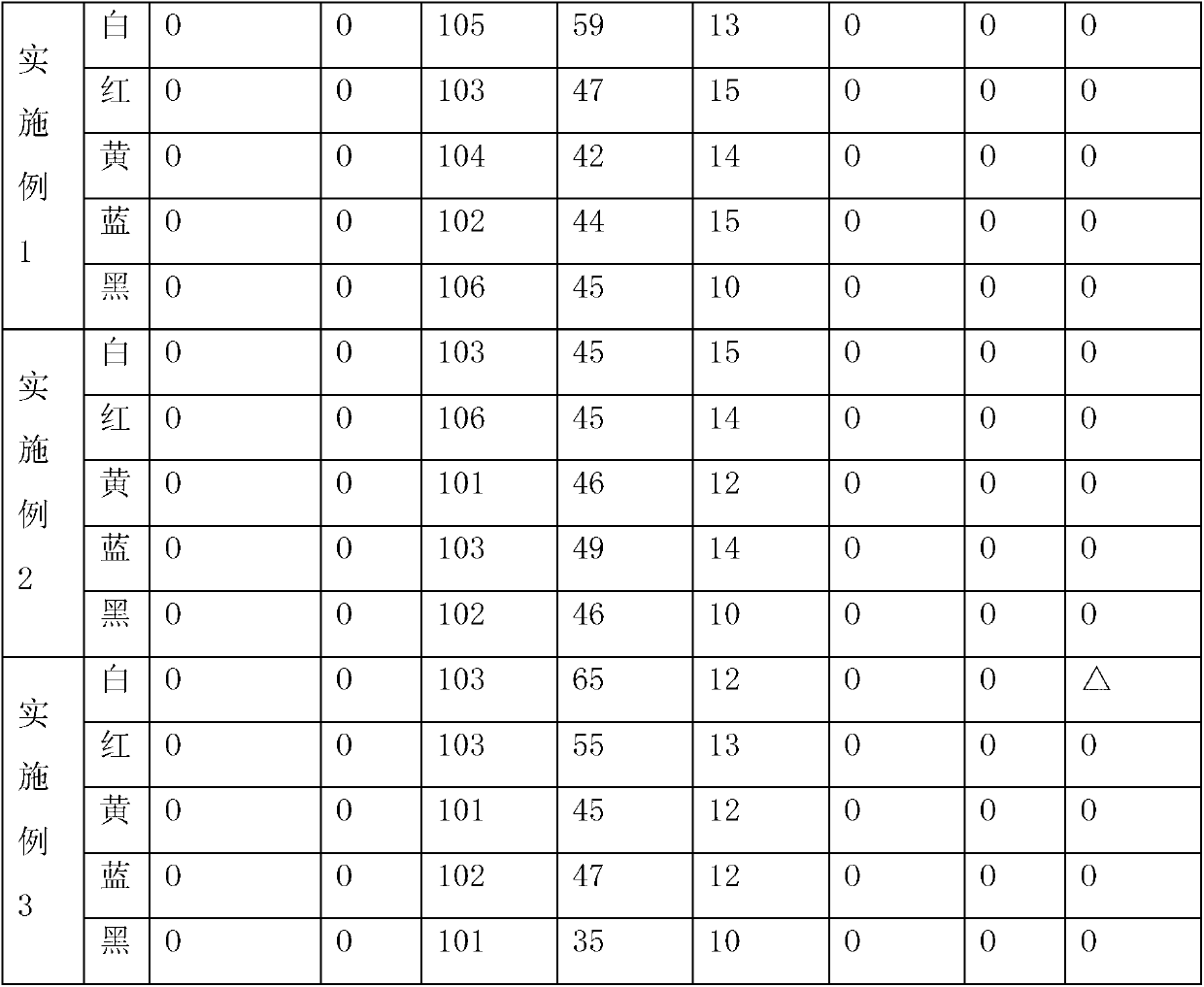

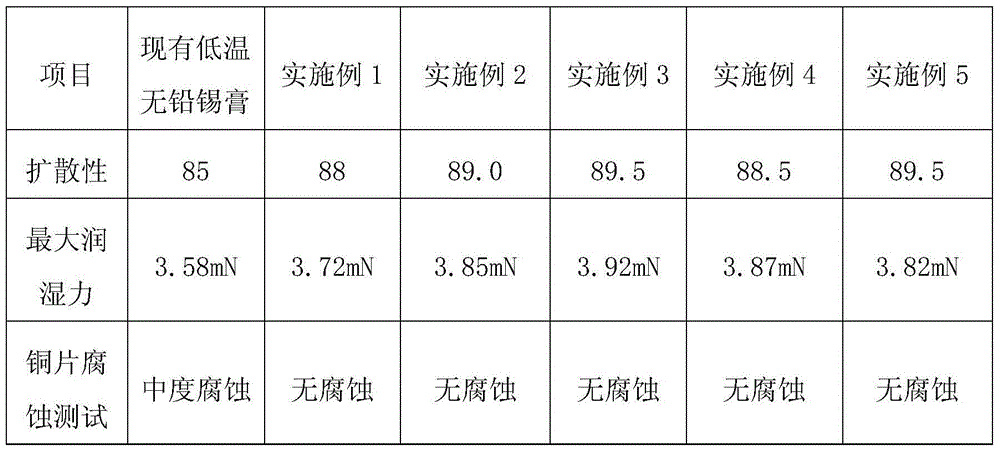

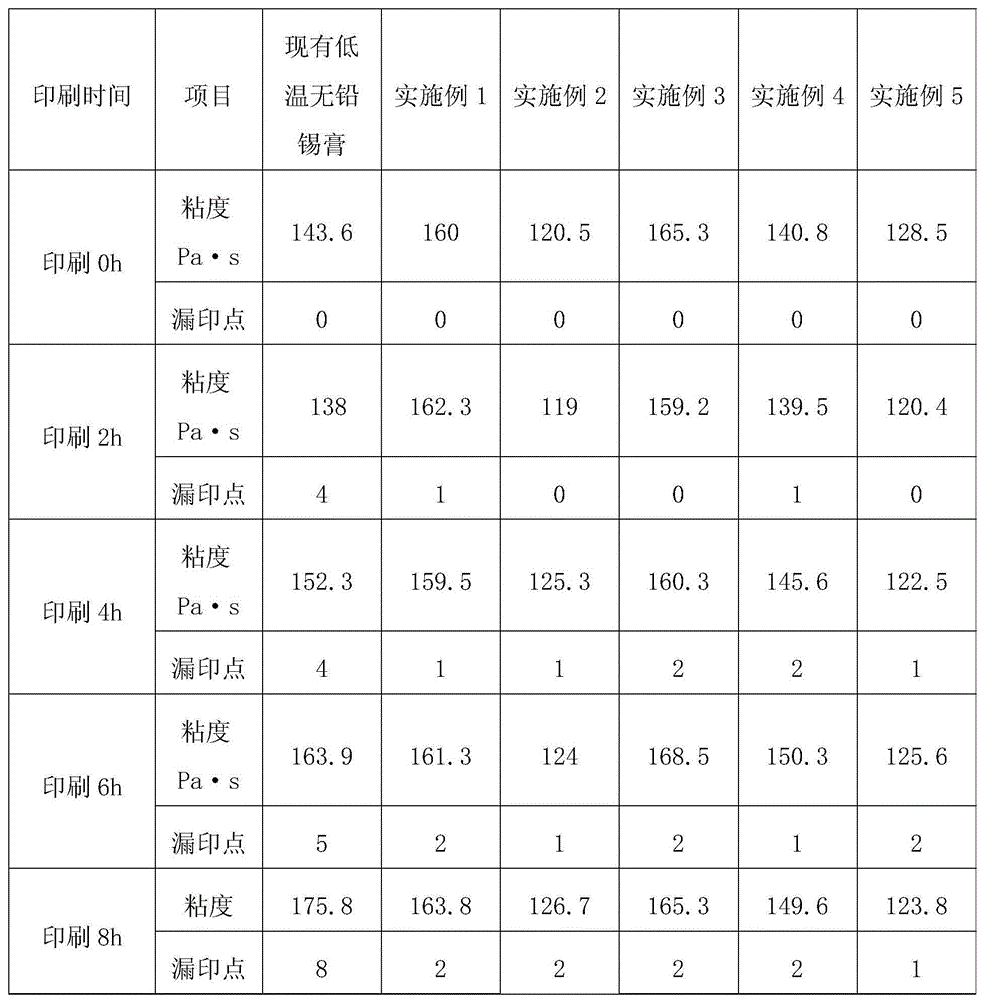

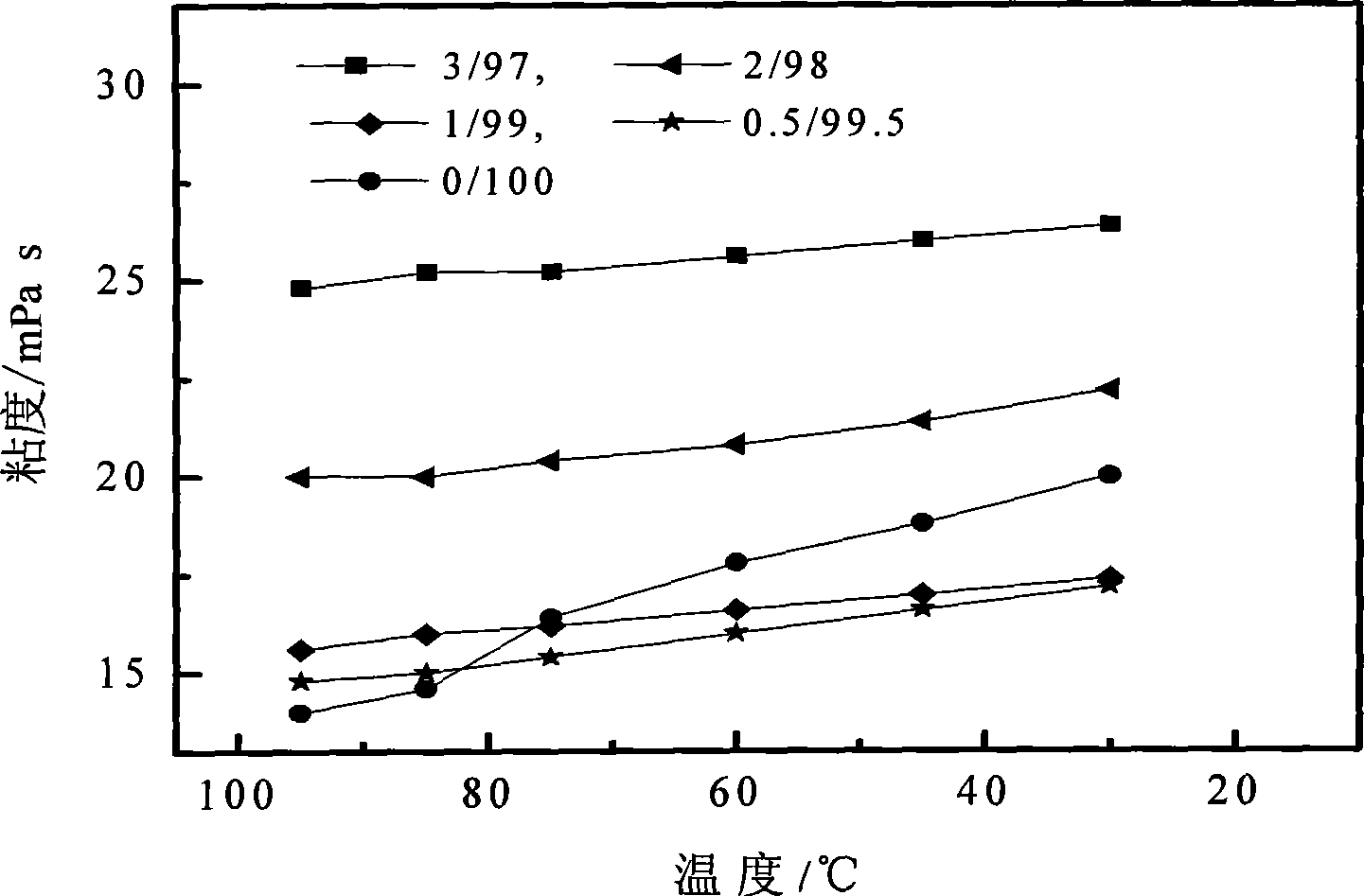

Low-temperature lead-free tin paste and production technique for paste flux thereof

ActiveCN104889596AImprove liquidityHigh activityWelding/cutting media/materialsSoldering mediaActive agentPolyamide

The invention relates to the technical field of electronic welding, in particular to low-temperature lead-free tin paste and a production technique for paste flux thereof. The low-temperature lead-free tin paste includes 87-90% of tin powder and 10-13% of paste flux by weight; the tin powder is tin bismuth base, tin bismuth copper base and tin bismuth silver base alloy, and the paste flux is composed of 35-45% of rosin, 40-48% of solvent, 5-12% of thickening agent, 4.5% of thixotropic agent and 5-8% of active agent by weight; the solvent is low-boiling point solvent; the thixotropic agent is composed of modified hydrogenated castor oil and modified polyamide wax, and the best weight ratio is 1: 2; the active agent is mainly composed of 3-6% of organic acid, 0.5-1.5% of surface active agent and 1-2% of organic amine; the paste flux is prepared according to a special technique. The low-temperature lead-free tin paste is excellent in activity, suitable for welding bonding pads with different kinds of clad layers, excellent in viscosity stability and excellent in printing property, and the welding spot corrosion is avoided.

Owner:深圳海诚锡元科技有限公司

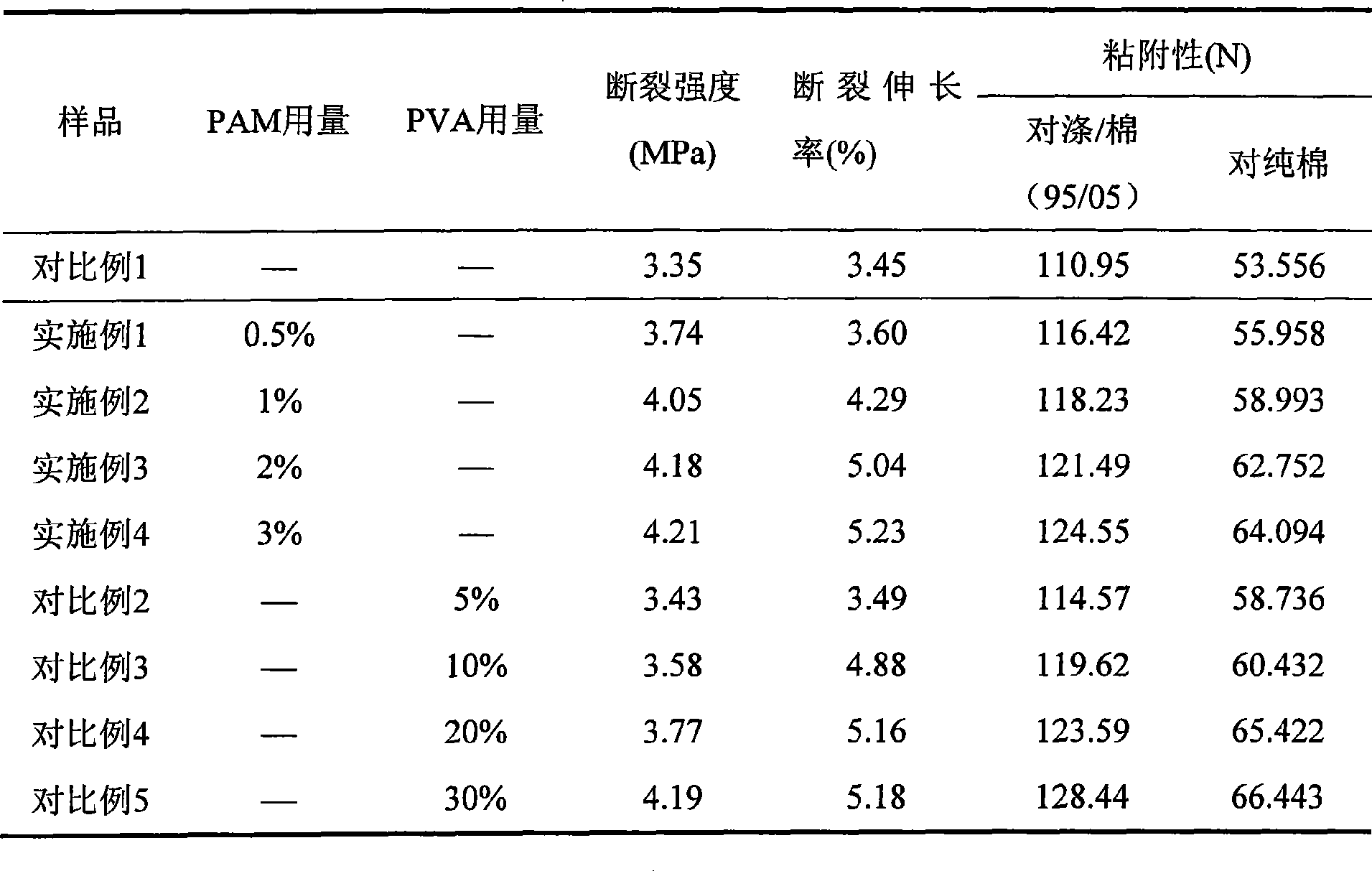

Modified starch/polyacrylamide textile slurry composition and preparation thereof

The invention discloses a modified starch / polyacrylamide textile size composition and a preparation method thereof. The invention is characterized in that 95.0-99.9 parts of the modified starch and 0.1-5.0 parts of the polyacrylamide are physically mixed under the state of dry powder, after 625-1667 parts of de-ionized water are added into the mixture and evenly stirred, 0-5 parts of sizing grease, 0-5 parts of hygroscopic agent and 0-20 parts of other sizing materials are added and the mixture is heated to boil for 1-1.5h and lasts 5-10min for heat preservation, and the modified starch / polyacrylamide textile size composition is prepared, with the solid content of the serosity standing at 6%-16%. The sizing materials have obviously improved the mechanical property, can replace the environment-polluting PVA sizing material in large quantity and reduce the cost of the sizing materials; after the PAM and the modified starch are mixed together, the compatibility is good and the viscosity stability is excellent, the film forming of the sizing materials is intact, the surface of the sizing film is level and smooth, and the adhesion property and the sizing property of the serosity to the yarns are improved.

Owner:SICHUAN UNIV +1

Hot-melt adhesive composition for non-wovens

InactiveUS7307124B2Improve spraying effectImprove creep resistanceFilm/foil adhesivesAbsorbent padsPolymer scienceAntioxidant

Hot-melt adhesive compositions used in non-woven assemblies, comprising:(a) 100 parts by weight of a block copolymer of the formula S-(I / B)-S, wherein S represents a predominantly poly(styrene) block and (I / B) represents a polymer block obtained by at random copolymerization of a mixture of predominantly isoprene and butadiene in a weight ratio in the range of from 70:30 to 30:70, wherein the total block copolymer has a melt flow index measured at 200° C. / 5 kg in the range of from 0.1 to 12 g / 10 min. and has a poly(styrene) content of from 28 to 50 wt % and a coupling efficiency of from 50 to 100%,(b) from 250 to 300 parts by weight of a tackifying resin,(c) from 50 to 150 parts by weight of a plasticizer, and(d) from 0 to 3 parts by weight of auxiliaries, such as stabilizers and / or antioxidants,and disposable articles, comprising at least a non-woven element and assembled by the use of said hot-melt adhesive compositions.

Owner:KRATON POLYMERS US LLC

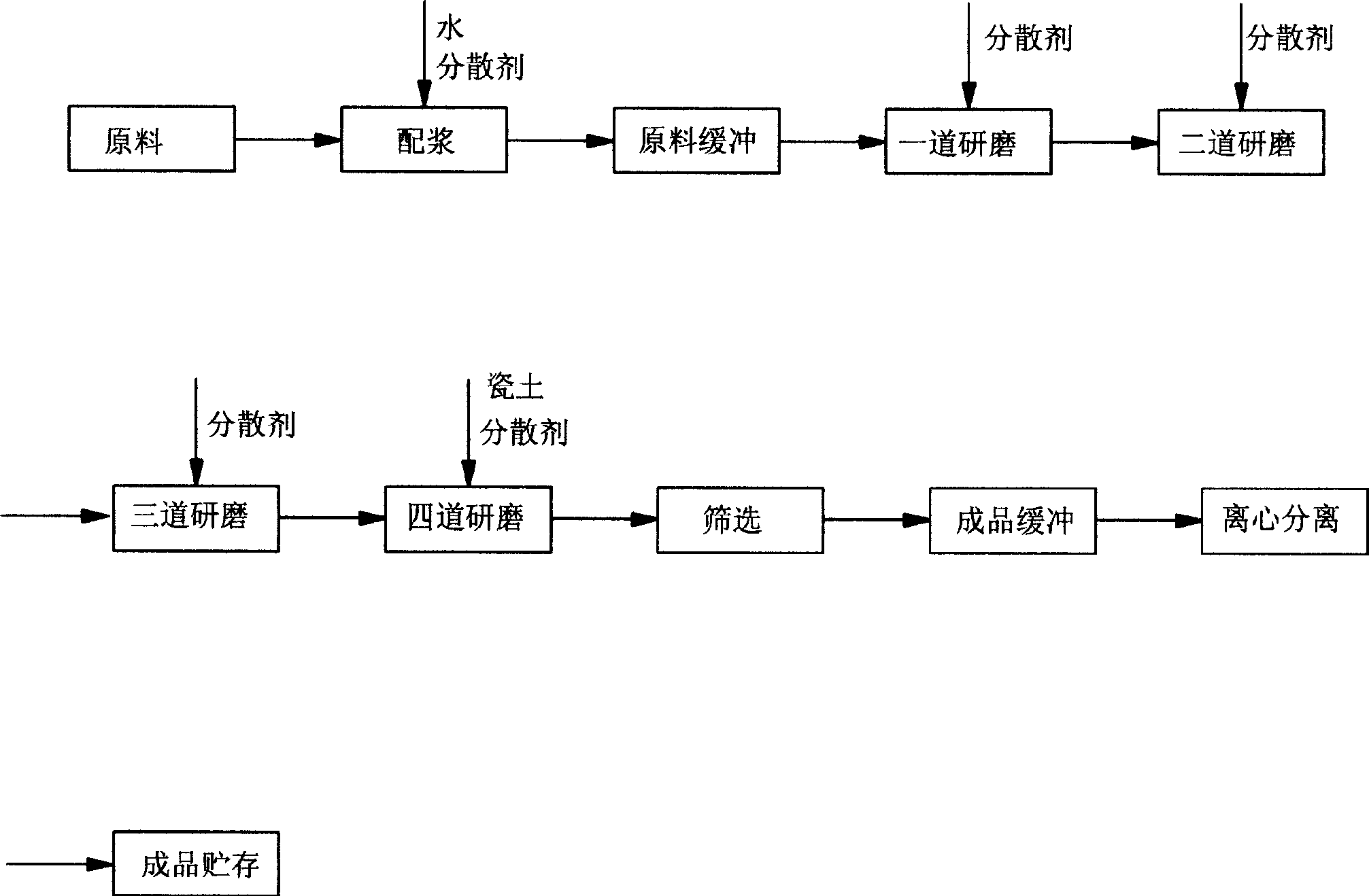

Slurry type heavy calcium carbonate of added porcelain clay for making paper and its preparing method

InactiveCN101050610AHigh solid contentImprove stabilityCoatings with pigmentsClay processing apparatusSlurryMaterials science

The present invention discloses a kind of paste natural calcium carbonate into which a porcelain clay is added for making paper and its preparation method. It is made up by using (by weight portion) 720-850 portions of natural calcium carbonate, 14-18 portions of dispersing agent sodium polyacrylate, 180-300 portions of porcelain clay and proper quantity of water as raw material through the processes of mixing, buffering, grinding, screening and separation, etc.

Owner:寿光德圣造纸化工有限公司

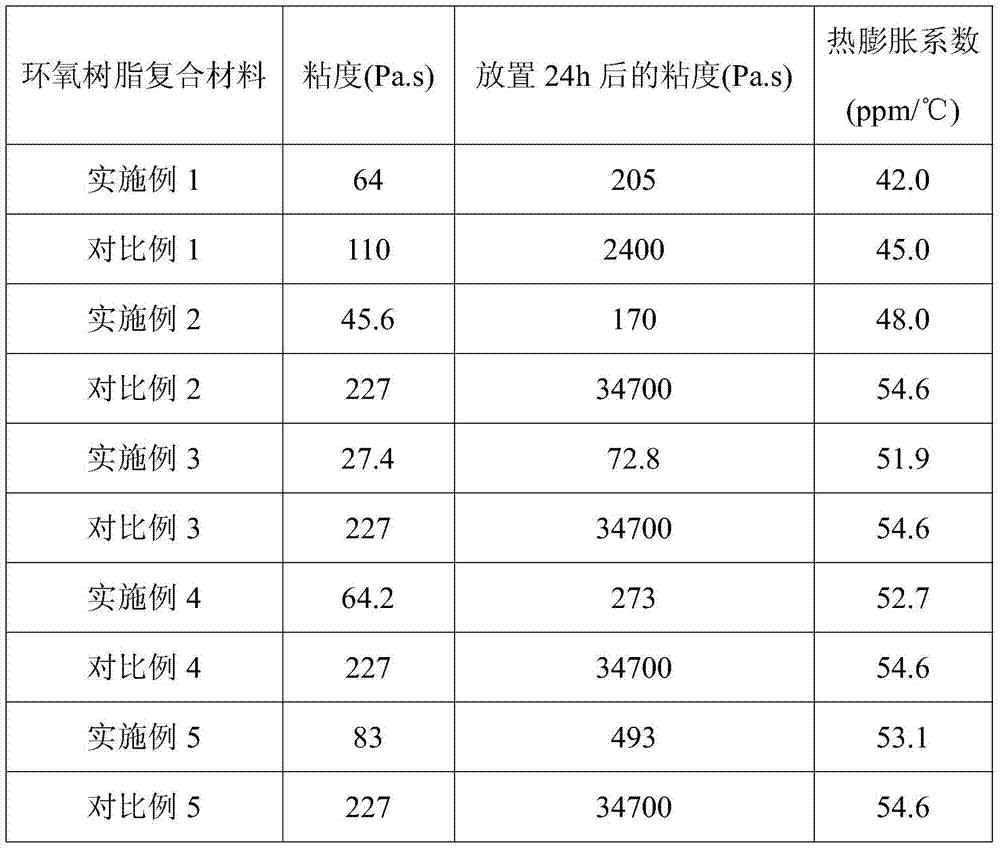

Silica filler, surface treatment method of silica filler and epoxy resin composite material

The invention relates to silica filler. The silica filler has a core-shell structure, wherein an inner core is silica and an outer shell is a coating layer formed by polymers. The silica filler provided by the invention is characterized in that the surface of silica is coated with the coating layer formed by the polymers, and the coating layer can improve the compatibility and the interface bonding force of the silica filler with epoxy resin, so as to reduce the viscosity and coefficient of thermal expansion of an epoxy resin composite material.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com