Silica filler, surface treatment method of silica filler and epoxy resin composite material

A technology of silica and epoxy resin, applied in the field of silica filler and its surface treatment, and epoxy resin composite materials, can solve the problem of reducing the processability and operability of epoxy resin, increasing the viscosity of epoxy resin, Particles are prone to agglomeration and other problems, so as to improve compatibility and interfacial bonding force, reduce viscosity and thermal expansion coefficient, and reduce thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

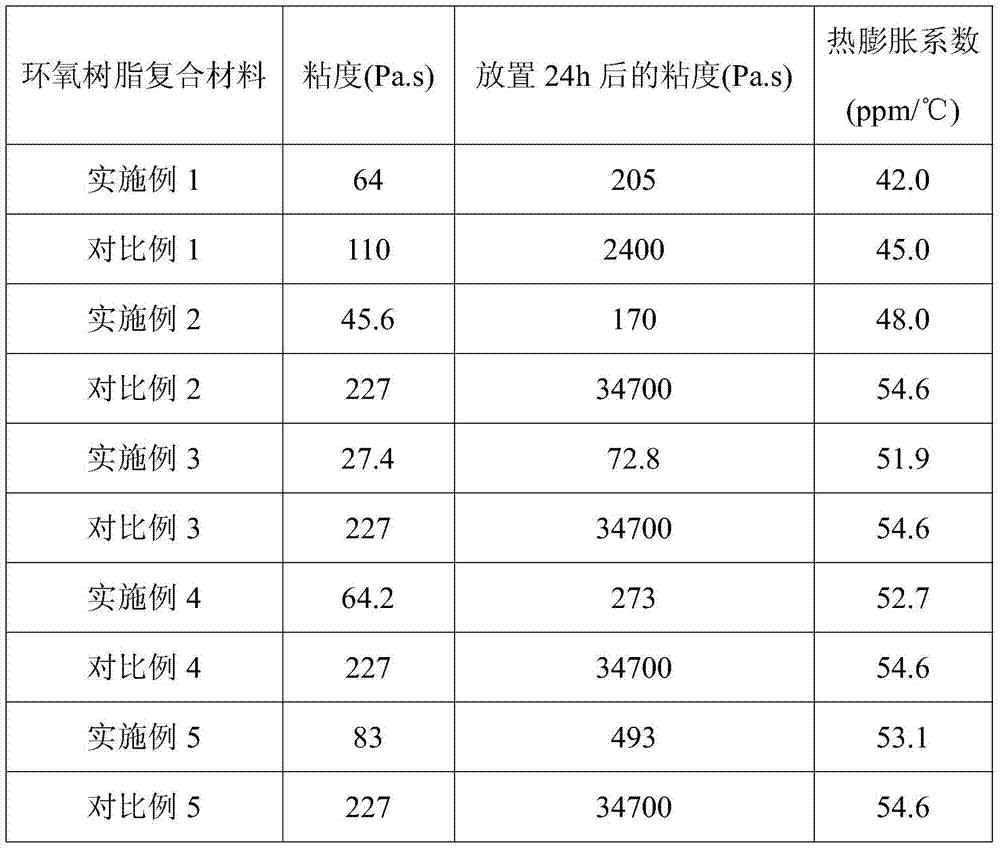

Examples

Embodiment 1

[0037] The surface treatment method of silica filler of present embodiment, comprises the steps:

[0038] (1) Disperse 2 g of silicon dioxide particles in 400 ml of aqueous solution by ultrasonic to prepare a silicon dioxide dispersion;

[0039] (2) 0.2g relative molecular mass is 10000 polyvinyl alcohol is dissolved in the water of 100ml, the obtained mass concentration is the polyvinyl alcohol aqueous solution of 2g / L;

[0040] (3) Mix the above-mentioned silicon dioxide dispersion liquid with polyvinyl alcohol aqueous solution, and the obtained mixed liquid is ultrasonically reacted at room temperature for 5 hours, separated and washed to obtain silicon dioxide filler.

[0041] The silica filler prepared in this example has a core-shell structure, wherein the inner core is silica particles, and the outer shell is a coating layer made of polyvinyl alcohol; wherein, the thickness of the coating layer is 5 nm.

[0042] The polyvinyl alcohol-coated silica nanoparticles prepare...

Embodiment 2

[0044] The surface treatment method of silica filler of present embodiment, comprises the steps:

[0045] (1) Disperse 5 g of silicon dioxide particles in 450 ml of aqueous solution by ultrasonic to prepare a silicon dioxide dispersion;

[0046] (2) 0.025g molecular weight is 70000 polyethyleneimine dissolved in the aqueous solution of 50ml, the obtained concentration is the polyethyleneimine aqueous solution of 0.5g / L;

[0047] (3) Mix the above silicon dioxide aqueous solution and polyethyleneimine aqueous solution, and the obtained mixed solution is ultrasonically reacted at room temperature for 2 hours, separated and washed to obtain the silicon dioxide filler.

[0048] The silica filler prepared in this example has a core-shell structure; wherein, the inner core is silica particles, and the outer shell is a coating layer composed of polyethyleneimine; the thickness of the coating layer is about 10 nm.

[0049] The polyethyleneimine-coated silica particles prepared in this ...

Embodiment 3

[0051] The surface treatment method of silica filler of present embodiment, comprises the steps:

[0052] (1) Disperse 5 g of silicon dioxide particles in 450 ml of aqueous solution by ultrasonic to prepare a silicon dioxide dispersion;

[0053] (2) 0.05g molecular weight is 70000 polyethyleneimine dissolved in the aqueous solution of 50ml, the obtained concentration is the polyethyleneimine aqueous solution of 1g / L;

[0054] (3) Mix the above-mentioned silicon dioxide dispersion liquid with polyethyleneimine aqueous solution, and the obtained mixed liquid is ultrasonically reacted at room temperature for 2 hours, separated and washed to obtain a silicon dioxide filler.

[0055] The silica filler prepared in this example has a core-shell structure; wherein, the inner core is silica particles, and the outer shell is a coating layer composed of polyethyleneimine; the thickness of the coating layer is about 20 nm.

[0056] The polyethyleneimine-coated silica particles prepared i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com