Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Lower coefficient of thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

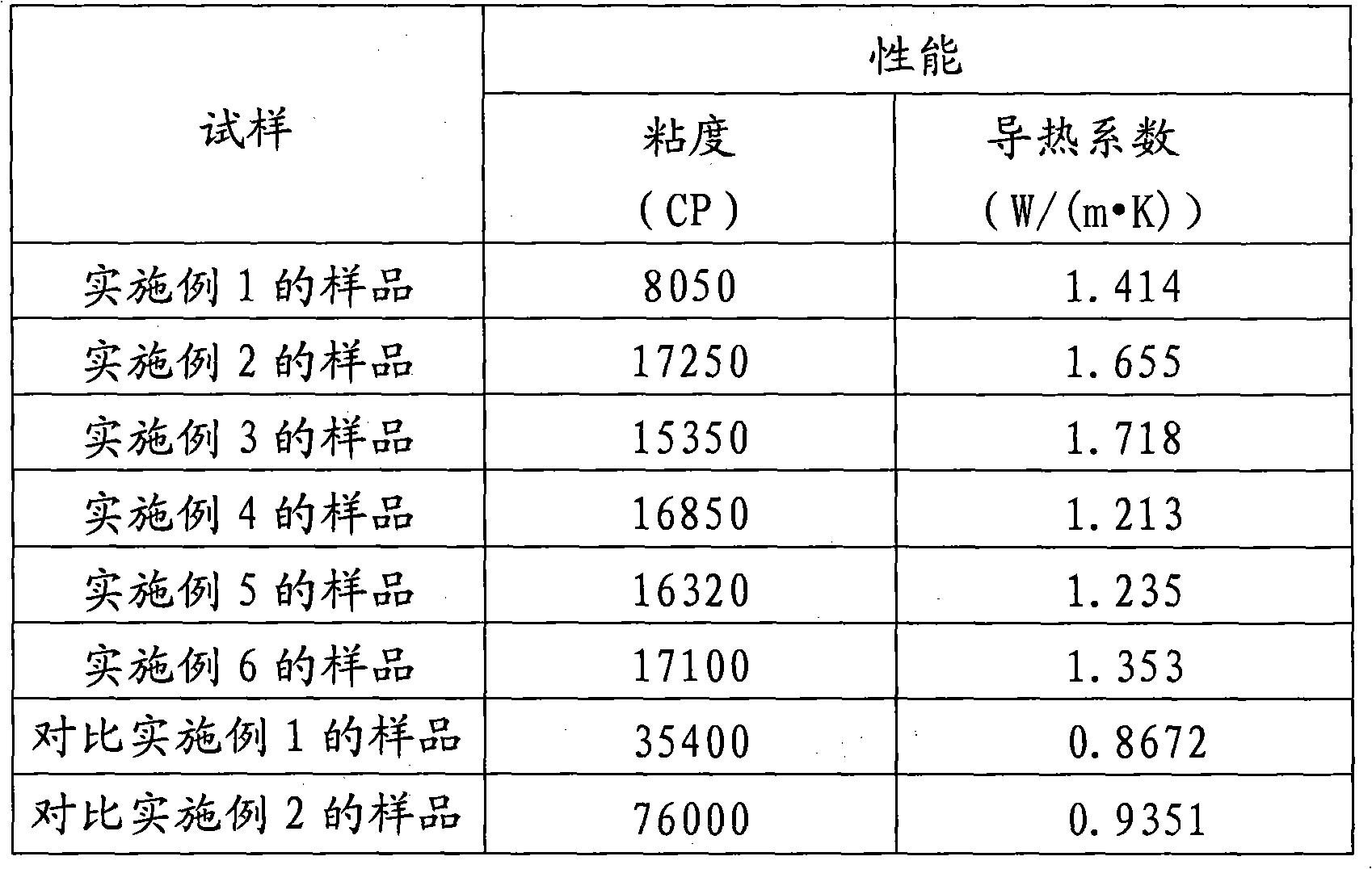

Low-viscosity and high-heat conduction epoxy resin electronic potting adhesive

InactiveCN101974302AImprove thermal conductivityRapid heat buildupNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

The invention relates to a low-viscosity and high-heat conduction epoxy resin electronic potting adhesive which is formed by mixing a component A with an amine curing agent according to the weight ratio of 100:5-12, wherein the component A comprises the following raw materials in weight ratio: 70-85 parts of spherical alumina powder, 10-20 parts of epoxy resin, 2-4 parts of active thinner, 2.5-5 parts of toughening agent and 0.1-0.5 parts of coupling agent. The invention has the advantages that the spherical alumina of the potting adhesive has higher filling amount compared with non-spherical alumina, the viscosity is less affected, the fluidity is favorable and the construction is convenient; the potting adhesive has good dispersibility and is difficult to sedimentate; a condensate has high heat conductivity and can quickly dissipate accumulated heat of heating parts and components; a high-filling filler can reduce a thermal expansion coefficient and a volumetric shrinkage rate and is very suitable for potting parts and components; and the price is cheaper compared with boron nitride and aluminum nitride, and the cost is low.

Owner:YANTAI DARBOND TECH

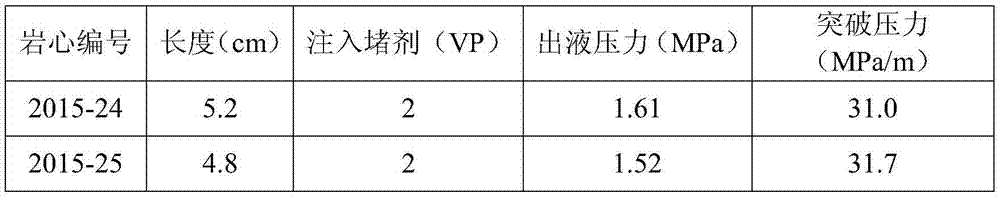

Fireflooding channeling sealing agent and preparation method thereof

ActiveCN105440233AHigh chemical activityHigh bonding strengthDrilling compositionNano al2o3Oleoresin

The invention provides a fireflooding channeling sealing agent and its preparation method. Raw materials for preparing the fireflooding channeling sealing agent contain, by weight, 0.5-3% of a melamine substance, 0.2-1% of phenol, 2-8% of aldehyde, 0.5-2% of a pH regulator, 0.2-1.2% of a nano-alumina oleoresin liquid XZ-LY102, 10-20% of ultrafine silicon dioxide and the rest of water. Sealing rate of the fireflooding channeling sealing agent can reach 93%; temperature resistance reaches 300 DEG C; the highest salinity tolerance reaches 150,000 mg / L; expriation data can reach 6 months and above under the steam condition of 300 DEG C; viscosity of a profile control agent before gel forming is 150-1,500 mPa.S; sealing strength can reach 31 MPa / m; and gel forming time can be controlled within 12-36h. By the use of the fireflooding channeling sealing agent, deep profile control of an oil layer can be realized.

Owner:PETROCHINA CO LTD

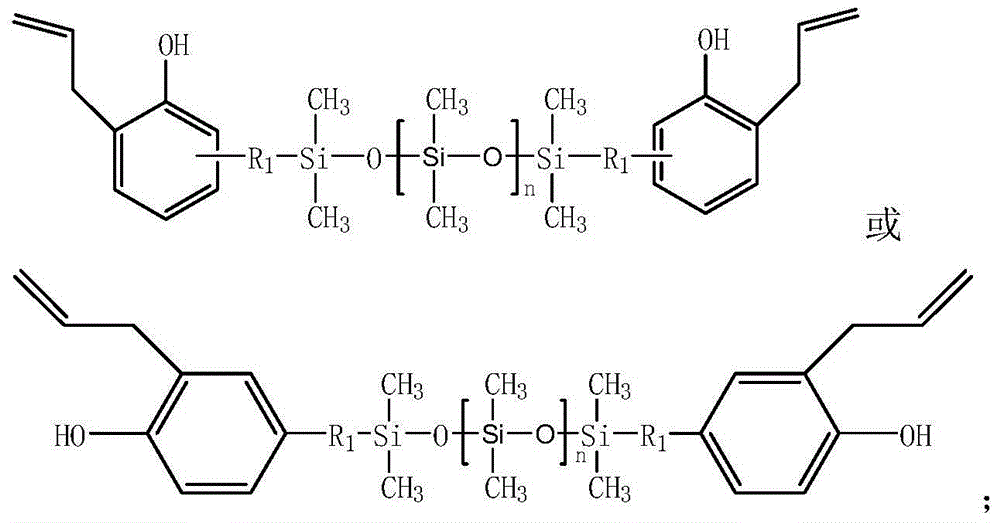

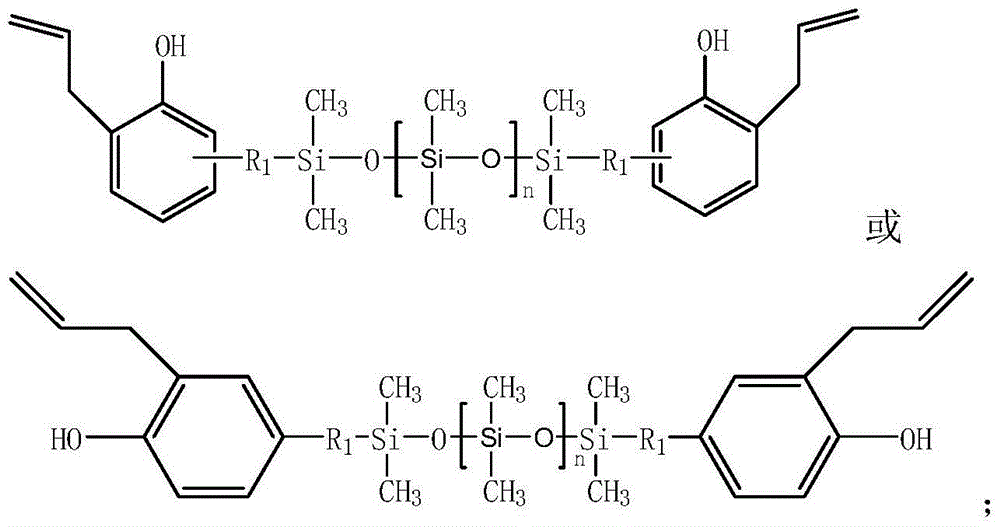

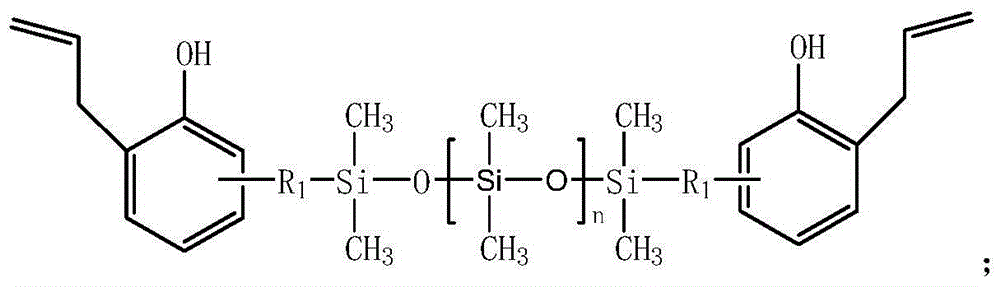

Resin composition and prepreg laminated board manufactured by employing same

InactiveCN104830059AImprove performanceGood thermal expansion performanceSynthetic resin layered productsMetal layered productsThermal expansionSilorane Resins

The invention discloses a resin composition which comprises the following solids by weight: (a) 100 parts of a bismaleimide resin prepolymer, (b) 5-80 parts of cyanate ester, (c) 0-50 parts of a flame retardant and (d) 0-65 parts of inorganic filler, wherein the bismaleimide resin prepolymer is obtained by carrying out reaction on an allyl compound and bismaleimide resin and the ratio of bismaleimide resin and allyl compound by weight is 100: (10-120). According to the resin composition disclosed by the invention, by adopting siloxane containing allyl at the tail end as a modifier of bismaleimide resin and limiting the content of siloxane in the modifier, unreacted siloxane resin is not generated in reaction, so that the advantages and characteristics of siloxane resin can be fully exerted and the interlaminar adhesive force at the high temperature is greatly improved. Moreover, the thermal expansion properties of the solids are optimized, so that the resin composition satisfies the requirements on high precision electronic substrate materials.

Owner:SHENGYI TECH SUZHOU

Superhigh-thermal-conductivity continuous diamond skeleton reinforced composite material and preparation method

ActiveCN105695831AHigh thermal conductivityImprove mechanical propertiesChemical vapor deposition coatingHeat conductingGas phase

The invention provides a superhigh-thermal-conductivity continuous diamond skeleton reinforced composite material and a preparation method. The composite material is composed of a continuous diamond reinforced body and a base material. The continuous diamond reinforced body is prepared by depositing diamond films or diamond compound films on diamond particle preforms through a CVD method. The diamond compound films are graphene-wrapped diamond films or carbon-nanotube-wrapped diamond films. The base material is made of metal or polymer. Diamond powder is prepared into the performs, then the diamond films deposit on the surfaces of the performs through the CVD method, the diamond films are formed at the contact positions of adjacent diamond particles, and accordingly continuous heat conducting channels are formed between the isolated diamond particles. The deposited diamond films can serve as heat conducting bridges between the diamond particles, so that the dispersed diamond particles form a connection structure, accordingly high heat conductivity of diamond is fully used by the composite material, and the heat conductivity of the composite material is greatly improved.

Owner:CENT SOUTH UNIV

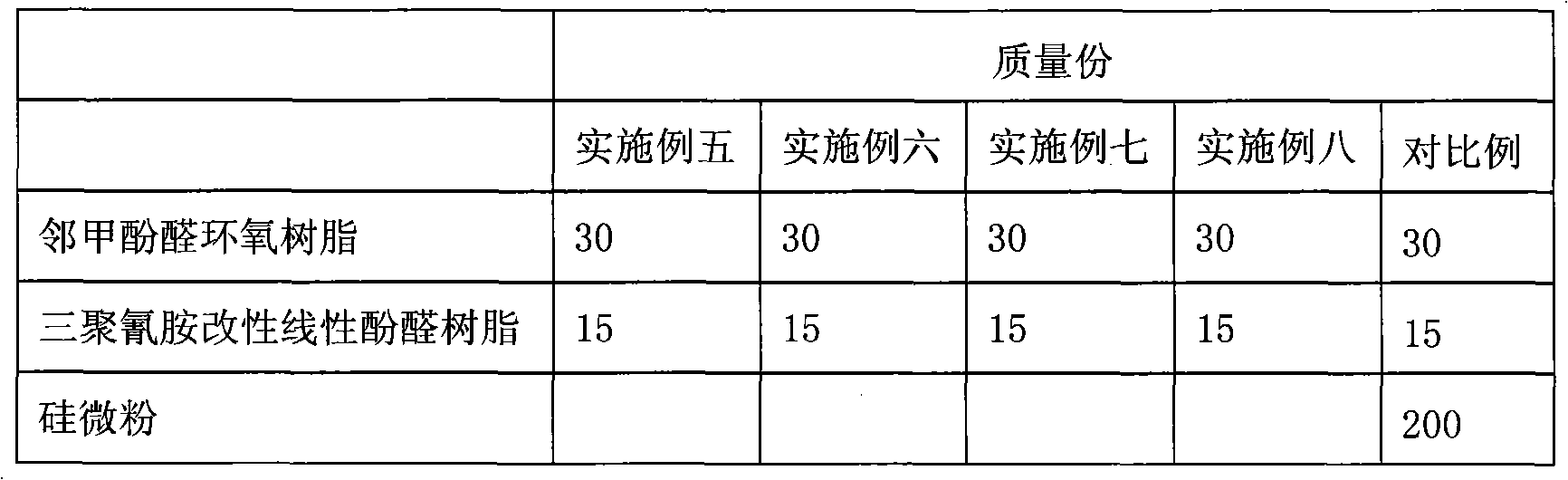

Casting mixture for epoxy casting transformer and preparation method thereof

The invention discloses a casting mixture for an epoxy casting transformer, which comprises the following raw materials in part by weight: 1 part of epoxy resin, 2.5 to 3.1 parts of silicon micropowder, 0.1 to 0.2 part of toughening agent, 0 to 0.02 part of color paste, 0.6 to 0.7 part of curing agent, and 0.001 to 0.003 part of accelerating agent. The preparation method for the casting mixture comprises the following steps: melting the materials; adding the silicon micropowder, the toughening agent, the color paste, the curing agent, and the accelerating agent in the melted epoxy resin in turn under the conditions of heating and stirring; and then performing vacuum defoamation. Due to the adoption of mixed glue prepared from the components of the casting mixture by the preparation method thereof, the crack ratio of a cast casting body can be reduced, and the quality of the product can be improved.

Owner:PINGGAO GRP +2

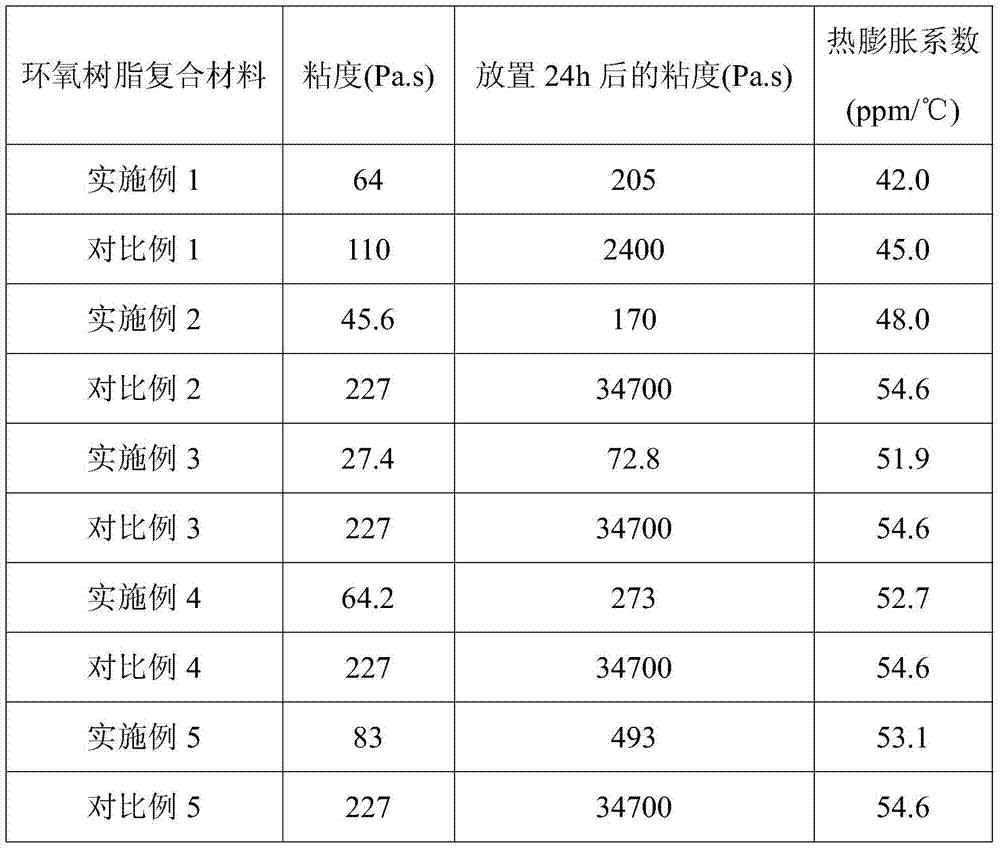

Silica filler, surface treatment method of silica filler and epoxy resin composite material

The invention relates to silica filler. The silica filler has a core-shell structure, wherein an inner core is silica and an outer shell is a coating layer formed by polymers. The silica filler provided by the invention is characterized in that the surface of silica is coated with the coating layer formed by the polymers, and the coating layer can improve the compatibility and the interface bonding force of the silica filler with epoxy resin, so as to reduce the viscosity and coefficient of thermal expansion of an epoxy resin composite material.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

Alumina-titanium calcium aluminate-silicon carbide multiphase refractory material and preparation method thereof

The invention relates to an alumina-titanium calcium aluminate-silicon carbide multiphase refractory material and a preparation method thereof. According to a technical scheme in the invention, 40 to 45 wt% of special alumina particles, 20 to 30 wt% of fine special alumina powder, 10 to 20 wt% of titanium calcium aluminate particles, 4 to 9 wt% of silicon carbide particles, 4 to 9 wt% of fine silicon carbide powder, 1 to 2 wt% of elemental silicon, 2 to 5 wt% of fine powder of active alpha-Al2O3, 2 to 6 wt% of fine powder of white clay produced in Guangxi Province and 0.5 to 1.5 wt% of fine Y2O3 powder are used as raw materials, a binder accounting for 3 to 4 wt% of the raw materials is added, and mixing and milling are carried out so as to obtain a mixture; and then the mixture is subjected to ageing, mechanical pressing, demoulding, standing, drying, retention at 1400 to 1530 in an air atmosphere in a muffle furnace for 180 to 240 min, and cooling in the furnace successively so as to prepare the alumina-titanium calcium aluminate-silicon carbide multiphase refractory material. The preparation method provided by the invention is low in cost, simple in process and high in yield; and the prepared alumina-titanium calcium aluminate-silicon carbide multiphase refractory material has great volume density, great flexural and compression strength, low heat conduction coefficient and excellent thermal shock resistance.

Owner:WUHAN UNIV OF SCI & TECH

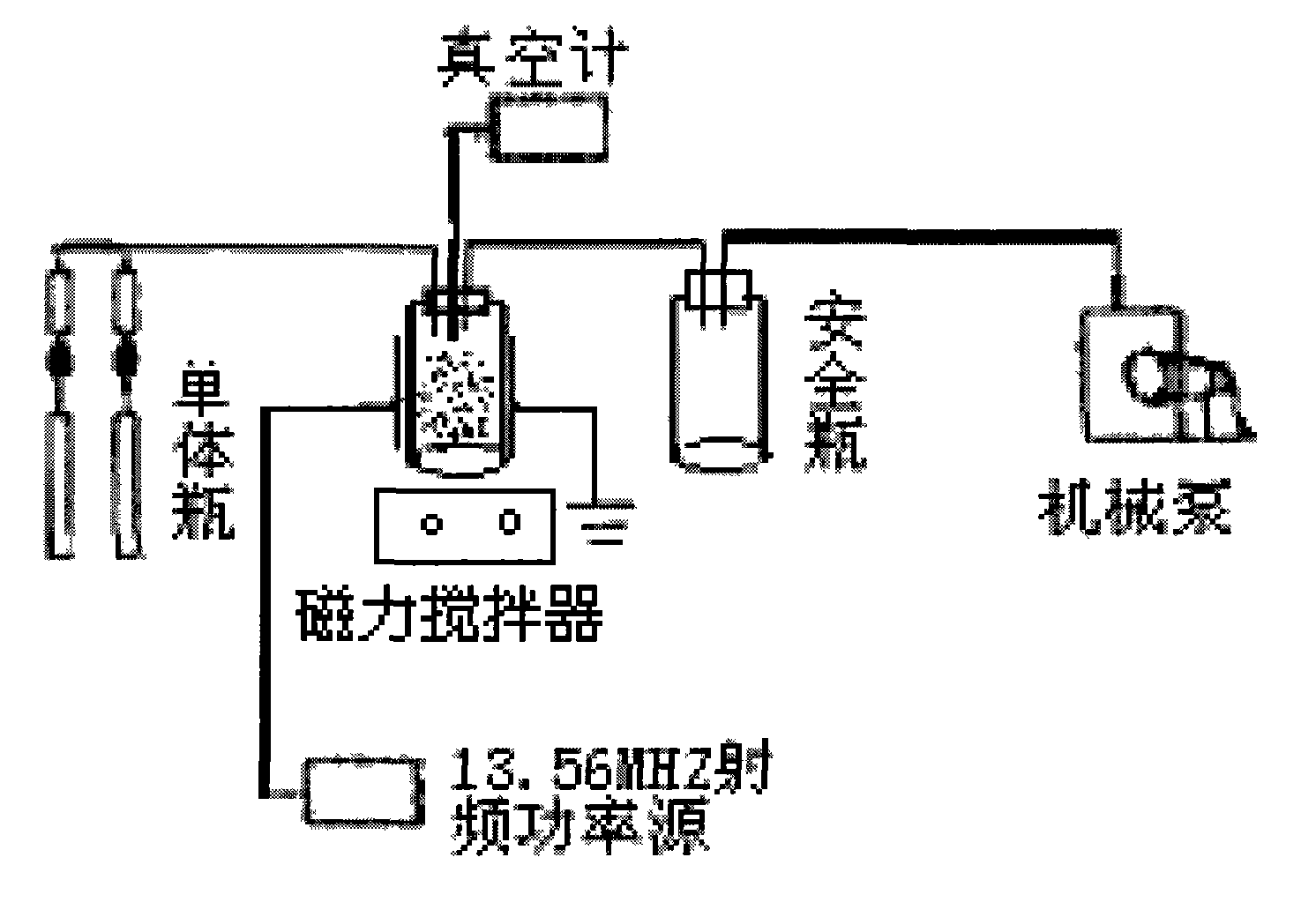

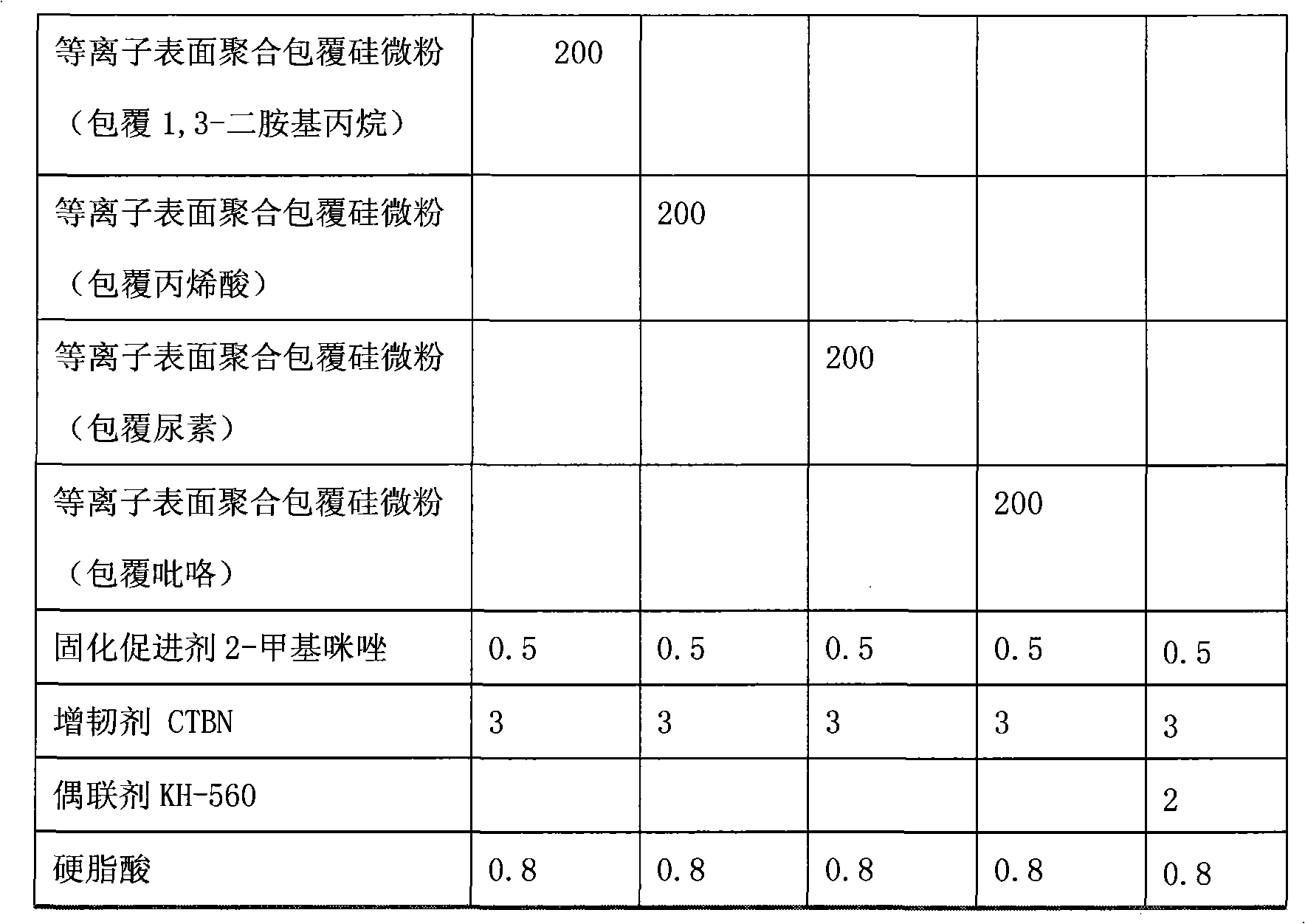

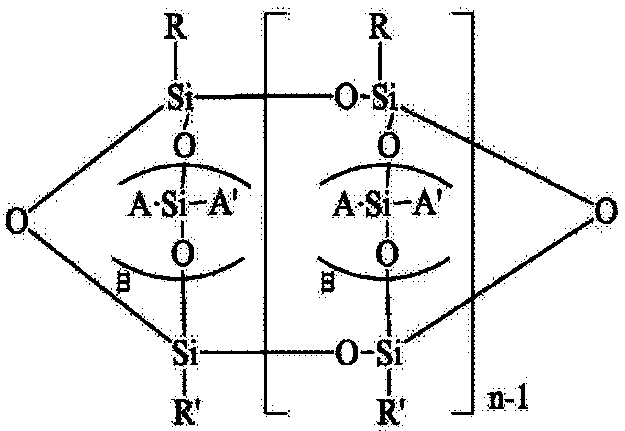

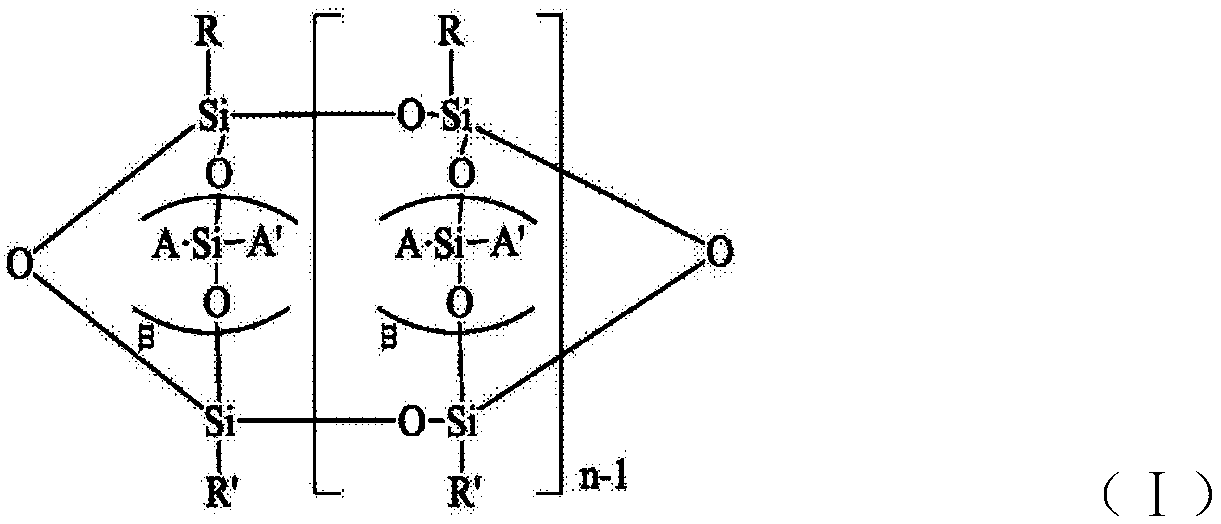

Silicon tiny powder surface treating and modifying method, epoxy resin combination and preparation method thereof

InactiveCN101597436AIncrease filling volumeImprove interfacial bond strengthPigment treatment with macromolecular organic compoundsFirming agentFlexural strength

The invention discloses a silicon tiny powder surface treating and modifying method, epoxy resin combination and a preparation method thereof. The method comprises the following steps: using radio frequency plasma with the radio frequency of 13.56MHz for discharging so as to lead monomer to polymerize and encapsulate on the surface of the processed silicon tiny powder, thus obtaining the plasma polymerization and encapsulation modified silicon tiny powder. The method for preparing epoxy resin combination by the modified silicon tiny powder comprises the following steps: mixing the modified silicon tiny powder, epoxy resin, firming agent, benzimidazoles curing accelerator, lubricant, flexibilizer and the like, then milling, pulverizing, demagnetizing to obtain the epoxy resin combination. The epoxy resin combination prepared by the method in the invention can be used for preparing encapsulation moulding compound (EMC) for large scale integrated circuits, thus greatly improving the bend strength and impact strength, lowering CTE and water absorption rate and enormously enhancing the comprehensive performance of the EMC.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

An iolite porcelain electronic flat-irons soles with low hot expansion factor

InactiveCN101161603ALower coefficient of thermal expansionReduce intensityHand ironTextiles and paperStrontium carbonateSurface finish

The invention discloses a steinheilite ceramic bottom plate of electric iron with low heat expansion coefficient. The invention takes the steinheilite (2MgO.2Al 2 O 3.SiO2) as a principal crystalline phase and is added with industrial alumina, titanium dioxide, strontium carbonate, yttrium oxide and silicon dioxide as auxiliary materials; the weight percentage of the materials are as follows: 82 to 88 percent of steinheilite, 3 to 6 percent of alumina, 2 to 3 percent of strontium carbonate, 3 to 6 percent of titanium dioxide, 0 to 2 percent of yttrium oxide, and 1 to 3 percent of silicon dioxide; when the ceramic material is produced, the raw materials are weighed according to the formula to be made dry grinding and mixing, then are molded and incinerated according to the hot pressure casting production process, finally the ceramic bottom plate of the electric iron can be produced by grinding and polishing the working surface of the ceramic bottom plate. The invention can effectively improve the rigidity and the surface finish of the bottom plate of the electric iron, and contribute to the ironing of high-grade cloth.

Owner:湖南省新化县鑫星电子陶瓷有限责任公司

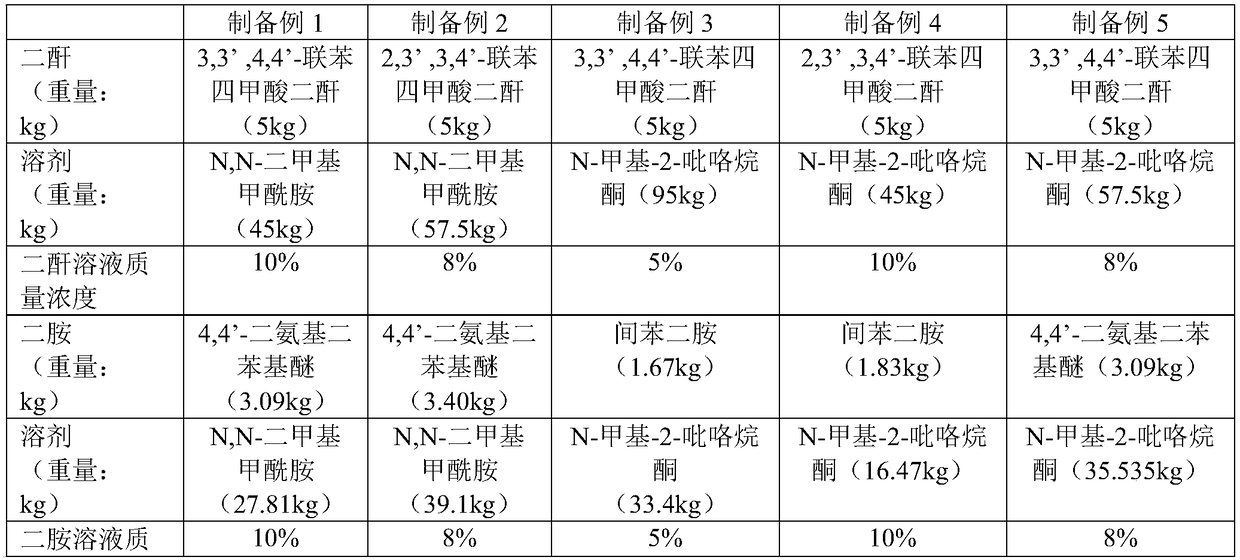

High-performance asphalt composition and preparation method thereof

InactiveCN109251543AImprove high temperature resistanceImprove stabilityBuilding insulationsCrack resistanceAsphalt

The present invention relates to a high-performance asphalt composition and a preparation method thereof, wherein the high-performance asphalt composition comprises petroleum asphalt and polyimide powder accounting for 5-15% of the weight of the petroleum asphalt, and the polyimide powder has a particle size of 400-500 mesh, and is self-end-capping trapezoidal polysiloxane modified polyimide powder. According to the present invention, the high-performance asphalt composition has advantages of crack resistance, rutting resistance and flame retardancy, and cannot produce penetration or crackingin a low temperature and humid environment.

Owner:WUXI CHUANGCAI OPTICAL MATERIALS

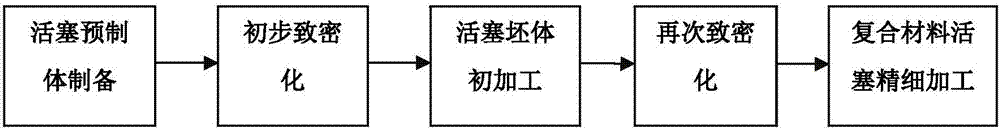

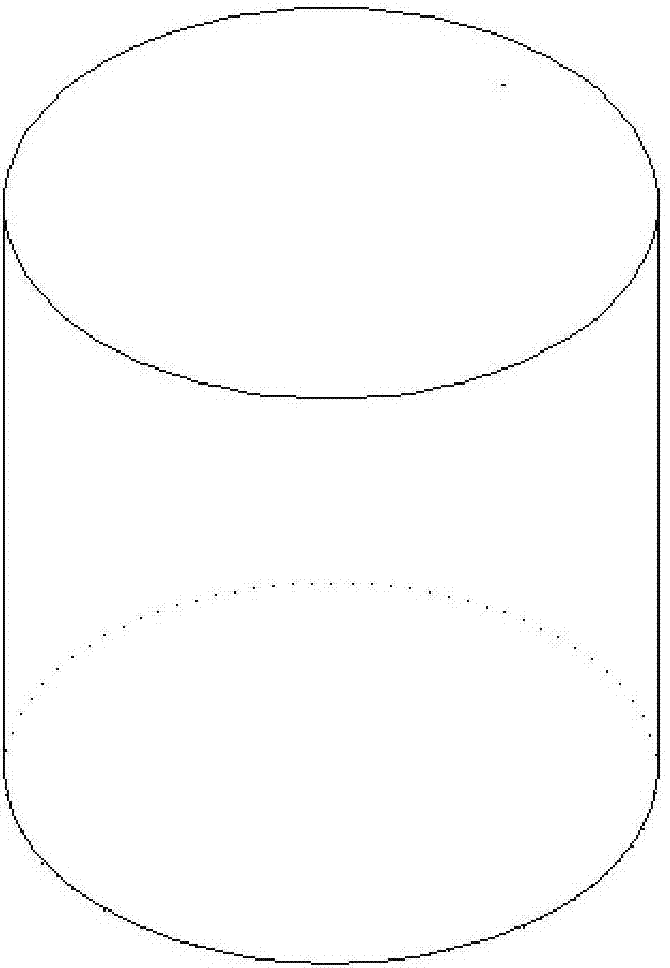

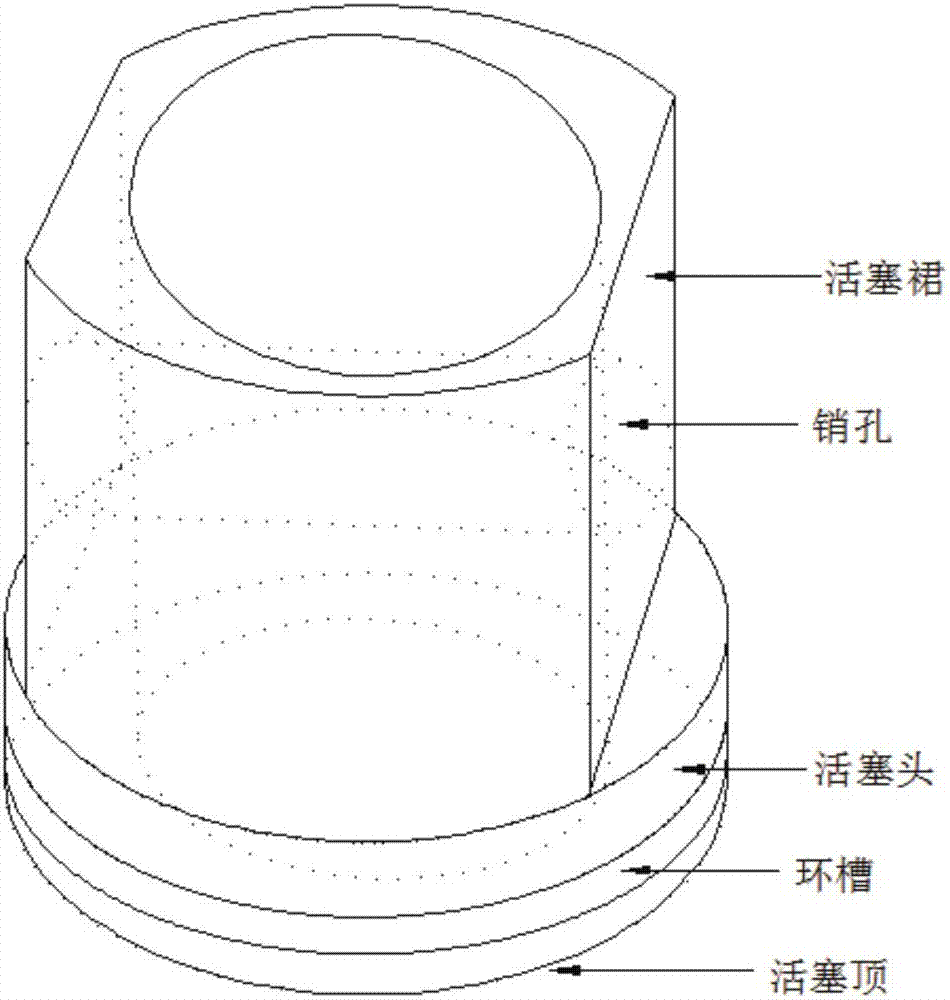

Multiple carbon and ceramic base composite material piston and preparation method and application thereof

ActiveCN106977218AReduce quality problemsLower coefficient of thermal expansionPlungersTrunk pistonsCarbon fibersVolumetric Mass Density

The invention relates to a multiple carbon and ceramic base composite material piston and a preparation method and application thereof. The preparation method is as follows: using carbon fiber or polyacrylonitrile based preoxidized silk to prepare a piston preform; using a chemical vapor infiltration method and / or precursor infiltration and pyrolysis method for preliminary densifying of the piston perform, using the chemical vapor infiltration method for further densifying of the obtained product to obtain a composite piston with the density of 1.74-2.0g / cm<3>; machining the obtained composite piston into final size design to obtain the composite piston finished product. The piston mass and the thermal expansion coefficient of the piston are reduced, the mechanical strength of the piston is improved, heat loss is effectively reduced, and noise and hydrocarbon and nitrogen oxide emissions can be reduced to achieve energy saving and environmental protection.

Owner:BEIHANG UNIV

Method for preparing prebaked anode by using aluminum electrolytic waste cathode carbon blocks

The invention discloses a method for preparing prebaked anodes by using aluminum electrolytic waste cathode carbon blocks. The method includes the following steps of (1) burdening, (2) kneading forming, (3) primary roasting, (4) primary, (5) secondary firing, (6) secondary impregnation and (7) third-time roasting, and prebaked anode carbon blocks are obtained. Harmless treatment and comprehensiveutilization of the aluminum electrolytic waste cathode carbon blocks are realized, the problem of environmental pollution is solved, and petroleum coke is saved. The anode carbon blocks prepared by the method has excellent performance, good oxidation resistance and low resistivity, and is conducive to energy conservation in the aluminum electrolytic process.

Owner:CENT SOUTH UNIV

Friction-resistant plastic and preparation method thereof

InactiveCN104788853AImprove high temperature resistanceImprove thermal shock resistancePolyvinyl chlorideBisphenol

The invention discloses a friction-resistant plastic and a preparation method thereof. The friction-resistant plastic comprises the following components in parts by mass: 90-92 parts of polyvinyl chloride resin, 6-8 parts of silicon carbide, 1-3 parts of talcum powder, 5-7 parts of graphite powder, 50-55 parts of bisphenol A epoxy resin, 5-10 parts of sodium tripolyphosphate, 3-5 parts of mineral oil, 7-9 parts of polyvinylidene chloride, 7-9 parts of sodium tripolyphosphate, 6-8 parts of hydroxypropyl methacrylate, 1-3 parts of titanium dioxide, 5-7 parts of iron powder, 30-40 parts of deionized water, 3-5 parts of a silane coupling agent KH560 and 2-4 parts of auxiliaries.

Owner:SUZHOU JIN YUAN OIL MACHINERY

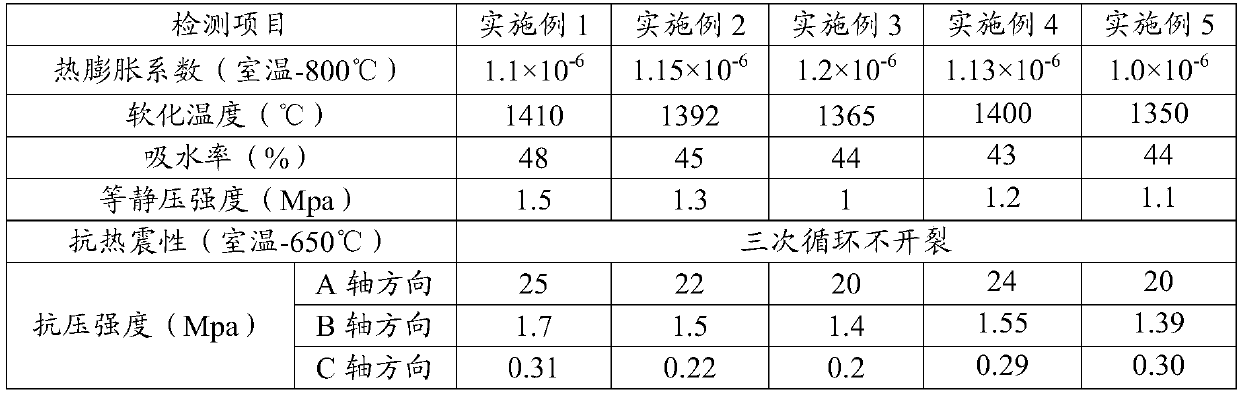

Large-size diesel oil particulate filter with low pressure drop and low expansion coefficient and preparation method thereof

ActiveCN108439967ASmall pressure dropSmall expansion coefficientGas treatmentDispersed particle filtrationAdhesiveThermal expansion

The invention discloses a large-size diesel oil particulate filter with low pressure drop and a low expansion coefficient and a preparation method thereof. The filter is prepared from the following raw materials: an inorganic component, a graphene precursor, starch, polymer resin and an adhesive, wherein the inorganic component is prepared from the following components by mass: 30 to 50 percent oftalcum, 5 to 30 percent of kaolin, 10 to 25 percent of aluminum oxide, 5 to 30 percent of hydrated alumina and 5 to 25 percent of silicon dioxide; the amounts of the graphene precursor, the starch and the polymer resin respectively account for 2 to 15 percent, 5 to 10 percent and 5 to 15 percent of the mass of the inorganic component; the amount of the adhesive is 2 to 10 percent of the total mass of the inorganic component, the graphene precursor, the starch and the polymer resin. The filter provided by the invention can be used for purifying automobile tail gases, in particular to particulate matters in tail gases of diesel vehicles, so that the problems of high pressure drop and high thermal expansion coefficient in an existing filter are solved; meanwhile, the problem of lower qualification rate in the preparation process of the filter is solved, the production cost is reduced, and the production efficiency is improved.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

Method for preparing ramie-form SiC ceramic/Al-based composite material

InactiveCN102212763AImprove impregnation uniformityImprove impregnation rateThermal expansionWear resistance

The invention discloses a method for preparing a ramie-form SiC ceramic / Al-based composite material, comprising the following steps of: firstly, pre-treating ramie fibers; then performing vacuum and pressure impregnation of SiO2 sol on the pre-treated ramie fibers so as to obtain a ramie / SiO2 precursor; then performing anoxic and aerobic compound calcination on the ramie / SiO2 precursor so as to obtain ramie-form porous SiC ceramic precast body; and finally, performing vacuum and pressure impregnation on the ramie-form porous SiC ceramic precast body so as to obtain the ramie-form SiC ceramic / Al-based composite material. The ramie-form SiC ceramic / Al-based composite material prepared with the method in the invention has the advantages of light weight, shock absorbability, sound absorbability and good antifriction wear resistance and can be used for reducing thermal expansion coefficient and density, thereby having a wider application prospect.

Owner:XI'AN POLYTECHNIC UNIVERSITY

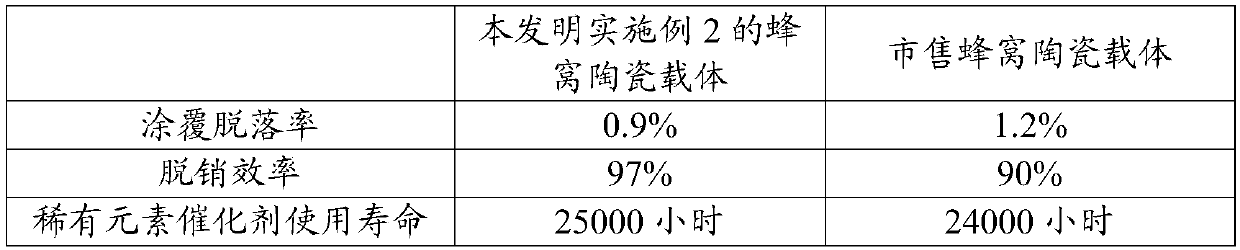

Honeycomb ceramic support and preparation method thereof

ActiveCN109534804AImprove thermal shock resistanceImprove mechanical propertiesCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsAdditive ingredientPlasticizer

The invention relates to the field of environmental protection and particularly relates to a honeycomb ceramic support and a preparation method thereof. The honeycomb ceramic support is prepared through burning the following ingredients in parts by weight: 5-30 parts of illite functional powder, 35-50 parts of Al2O3, 10-30 parts of MgO, 0-5 parts of pore former, 0-5 parts of binder, 0-0.5 part ofsurfactant, 0-2 parts of lubricant, 0-1 part of plasticizer and 20-35 parts of water. According to the honeycomb ceramic support and the preparation method thereof, through cooperation among all the ingredients, the disadvantage that the temperature range of burning is narrow is changed, a burning temperature and a coefficient of thermal expansion are reduced, the thermal shock resistance of the honeycomb ceramic support is improved, and the effects of light weight and high strength are achieved. The strength of a denitration catalyst is enhanced, the catalysis performance of the catalyst is improved, the consumption of the catalyst is lowered, the service life of the catalyst is prolonged, and the cost of denitration treatment is reduced.

Owner:CHENGDE RENHE MINING CO LTD

High-temperature-resistant plastic and preparation method thereof

InactiveCN104788861AImprove high temperature resistanceImprove thermal shock resistanceGlass fiberCarbide silicon

The invention discloses a high-temperature-resistant plastic and a preparation method thereof. The high-temperature-resistant plastic comprises the following components in parts by weight: 85-88 parts of PVDF, 3-5 parts of silicon carbide, 1-3 parts of silica micropowder, 1-3 parts of graphite powder, 40-42 parts of bisphenol A epoxy resin, 10-12 part of sodium tripolyphosphate, 3-5 parts of mineral oil, 7-9 parts of polybutadiene rubber, 7-9 parts of acrylic resin, 2-4 parts of glass fibers, 1-3 parts of ceramic powder, 60-80 parts of a phosphoric acid solution, 50-60 parts of deionized water, 1-2 parts of a silane coupling agent KH560 and 1-3 parts of auxiliaries.

Owner:SUZHOU JIN YUAN OIL MACHINERY

Method for preparing gasoline vehicle particle catcher by using fumed silica

The invention relates to the technical field of exhaust pollutant post-treatment of gasoline vehicles, and particularly relates to a method for preparing a low-pressure drop and low-expansion coefficient cordierite gasoline vehicle exhaust particle catcher by using fumed silica. The method comprises the following steps: (1) mixing inorganic raw materials by a dry method, and adding a binder; (2) kneading; (3) practicing; (4) extruding, microwaving and drying; (5) cutting and sintering; (6) punching holes, blocking the holes and then putting the holes into a kiln for back burning. The fumed silica material is adopted as the raw material catcher, the pore-forming effect is remarkable, and the micro-pore connectivity is good, so that the pressure drop and the thermal expansion coefficient ofthe catcher can be reduced; meanwhile, the fumed silica can replace common silica, thereby not only achieving the function of serving as an inorganic component, but also achieving the pore-forming effect and reducing the adding amount of the organic pore-forming agent; the use of the fumed silica not only can meet the use requirements, but also reduces the production cost and improves the production efficiency.

Owner:CHONGQING AOFU FINE CERAMICS CO LTD

Method for preparing zirconia sizing nozzle by adding magnesium-rich spinel micropowder

The invention discloses a method for preparing a zirconia sizing nozzle by adding magnesium-rich spinel micropowder. The method includes the steps that magnesium-rich spinel micropowder, a binding agent and powder are subjected to wetting granulation to obtain granules, and the granules are fired at 1710-1720 DEG C to obtain the zirconia sizing nozzle, wherein the powder includes partially-stabilized zirconia micropowder, monoclinic zirconia micropowder and magnesium-rich spinel micropowder, and the use level ratio of partially-stabilized zirconia micropowder to monoclinic zirconia micropowder to magnesium-rich spinel micropowder is (45-50):(45-50):(4-6). Compared with a common sizing nozzle obtained through a preparation process of adding magnesia micropowder, the volume density of the zirconia sizing nozzle obtained through the method is increased by 3-5% or so, and the porosity of the finished product is reduced by 5.0-6.5%; besides, the phenomenon of magnesia hydration caking does not occur in the granulation process, and the service life of the zirconia sizing nozzle can reach 40 h or longer. The method solves the problem that in the process of adding a magnesia micropowder stabilizer into monoclinic zirconia for wetting granulation, magnesia hydrated particles are caked.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Archaized brick

InactiveCN106007667AImprove plasticityImprove fire resistanceCeramic materials productionClaywaresBrickCrushed stone

The invention discloses an archaized brick and relates to the technical field of ceramic tiles. The archaized brick is prepared from raw materials in parts by weight as follows: 25-32 parts of kaolin, 16-22 parts of quartz sand, 12-18 parts of fly ash, 8-14 parts of clay, 4-6 parts of cement, 4-6 parts of talc powder, 6-12 parts of crushed stone, 10-20 parts of water and 12-20 parts of a glaze. Compared with the prior art, the strength of the archaized brick can be improved.

Owner:岑溪市新建球陶瓷有限公司

Archaized brick and preparation method thereof

The invention provides an archaized brick and a preparation method thereof. The archaized brick is at least prepared from raw materials in parts by weight as follows: 100-200 parts of cement, 100-260 parts of diamond, 80-160 parts of potash feldspar and soda feldspar, 80-120 parts of bentonite, 3-10 parts of titanium dioxide, 1-6 parts of copper sulfate, 6-12 parts of silicon dioxide and 10-40 parts of vinyl ester resin. All the components are well compatible, and the prepared brick has high structural density and has the advantages of improved tensile strength, shear strength and pressure intensity as well as reduced deformation, elongation and thermal expansion coefficient.

Owner:贞丰县恒山建材有限公司

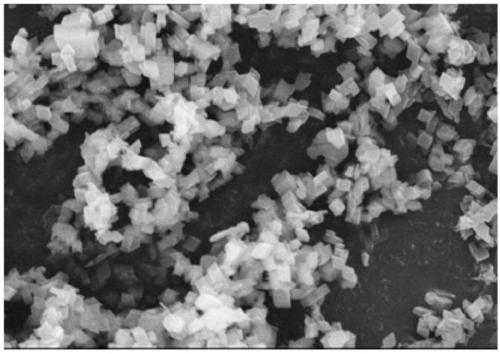

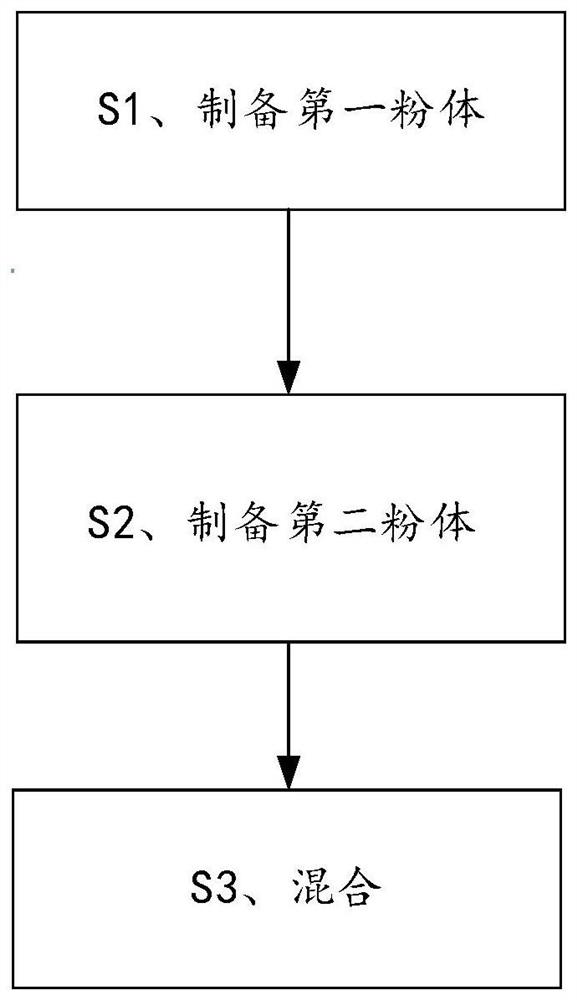

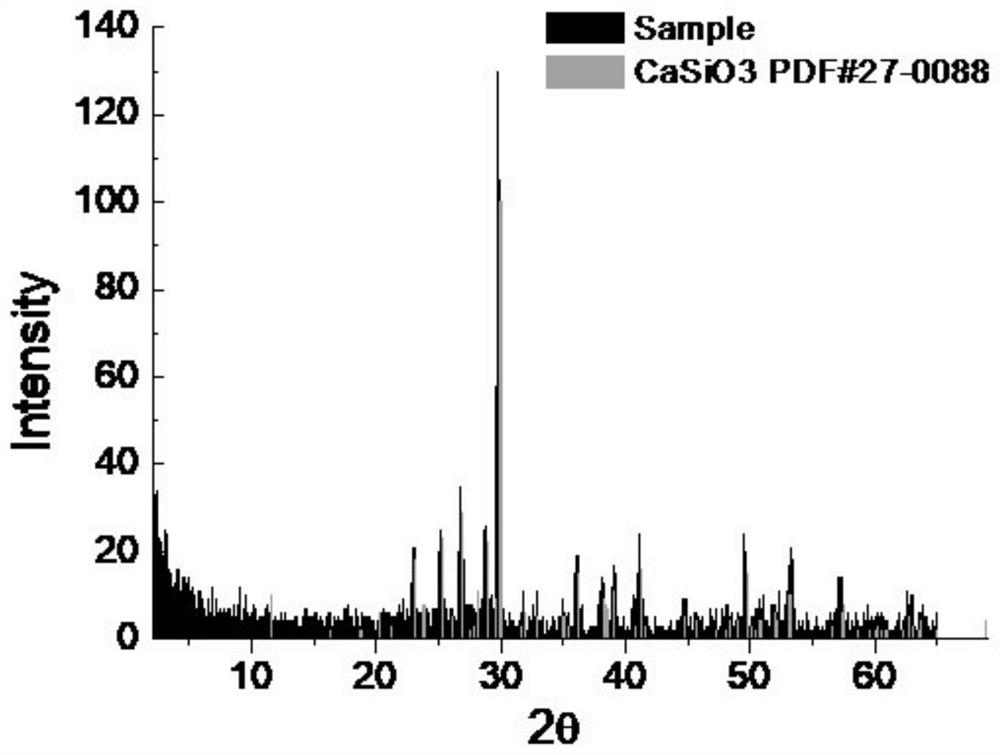

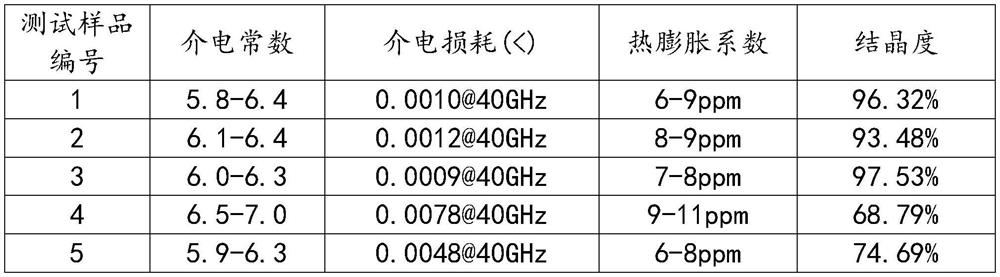

Low-temperature sintered glass ceramic powder as well as preparation method and application thereof

ActiveCN113754409AReduce the problem of high frequency lossHigh crystallinityThermal dilatationSpray Granulation

The invention provides low-temperature sintered glass ceramic powder, which is prepared by compounding the following components in parts by mass: 3 to 10 parts of first powder and 1 part of second powder. The first powder is prepared from the following raw materials in parts by mass: 1 to 50 parts of B2O3, 35 to 65 parts of CaO and 10 to 65 parts of SiO2. The second powder is prepared from the following raw materials in parts by mass: 1 to 50 parts of H3BO3, 35 to 65 parts of CaO and 10 to 65 parts of C8H20Si. The invention also provides a preparation method of the low-temperature sintered glass ceramic powder. The preparation method comprises the following steps: mixing the raw materials of the first powder, smelting, quenching, drying, grinding and carrying out heat treatment; and allowing raw materials of the second powder to be dissolved and subjected to spray granulation. The invention also provides application of the low-temperature sintered glass ceramic powder in a low-temperature co-fired ceramic substrate. According to the low-temperature sintered glass ceramic powder as well as the preparation method and the application thereof, the high-frequency loss, the dielectric constant and the thermal expansion coefficient of a dielectric material are effectively reduced, so that the dielectric material has better comprehensive performance.

Owner:SHENZHEN TAOTAO TECH CO LTD

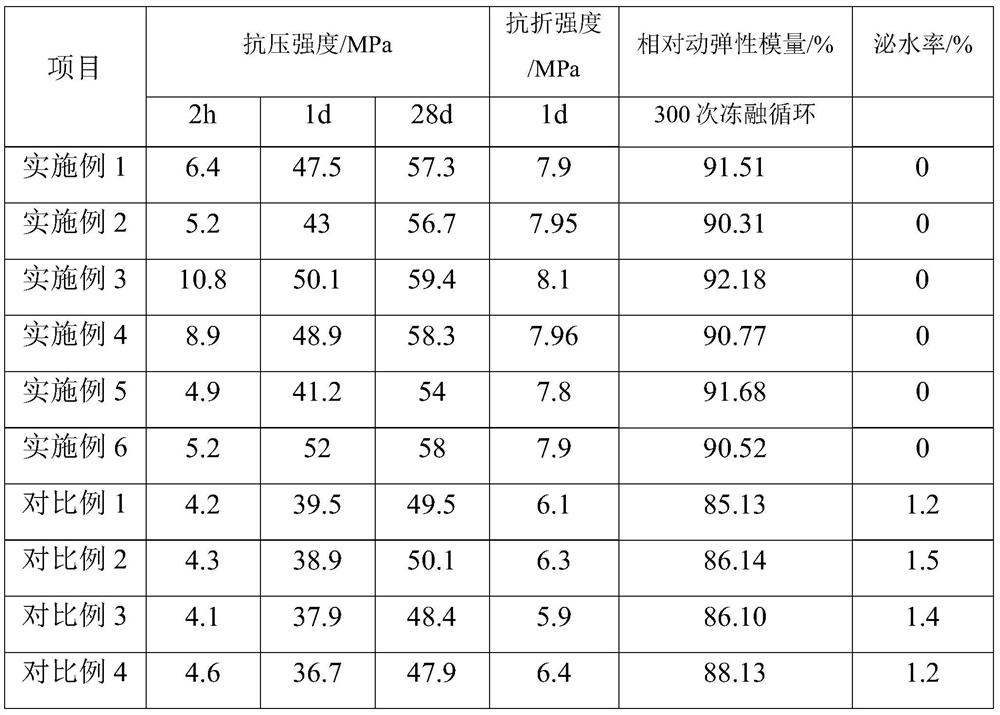

Grouting material for large bridge support and preparation method thereof

The invention relates to the technical field of building materials, and particularly discloses a grouting material for a large bridge support and a preparation method of the grouting material. The grouting material comprises the following raw material components in parts by mass: 20 to 40 parts of cement, 30 to 60 parts of stone, 20 to 45 parts of natural sand, 3-6 parts of fly ash, 0.3 to 2 partsof a polyacrylate-polyurethane copolymer emulsion, 1 to 4 parts of gypsum, 0.4 to 0.8 part of a hardening accelerator, 0.08 to 0.2 part of a retarder, 0.02 to 0.08 part of a defoaming agent, 0.1 to 0.4 part of a water reducing agent, and 6 to 12 parts of water. The grouting material provided by the invention has the characteristics of high hardening speed, good early strength, high compactness, good anti-freezing durability and the like.

Owner:SHIJIAZHUANG TIEDAO UNIV

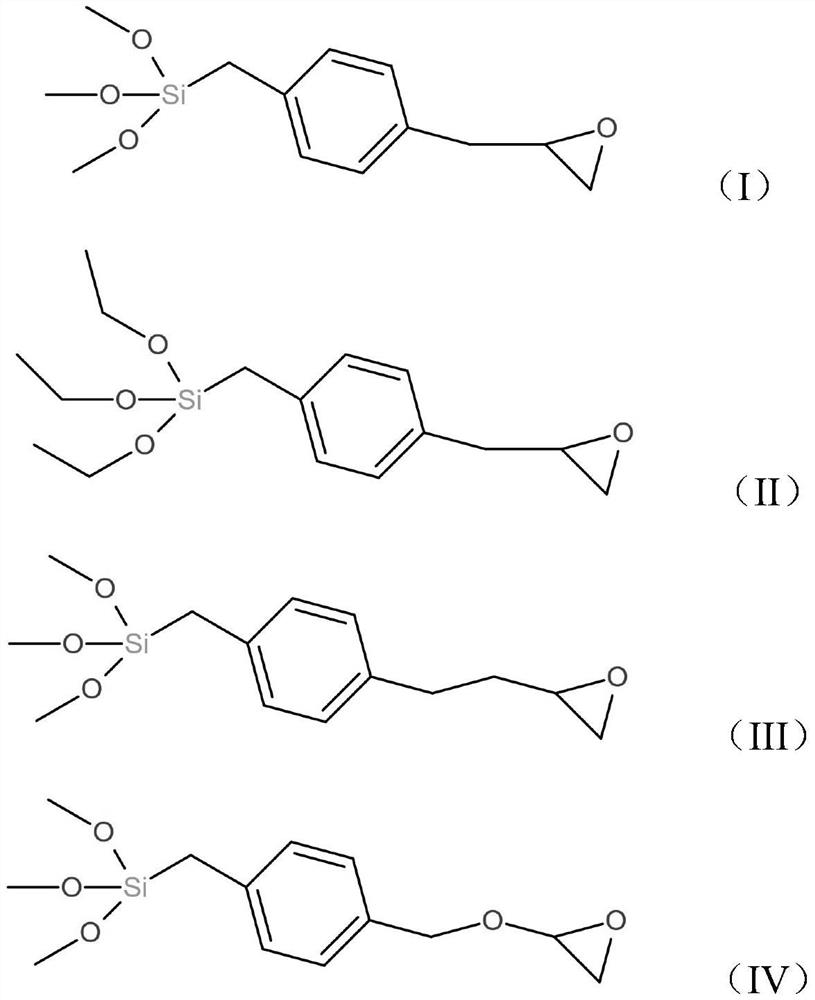

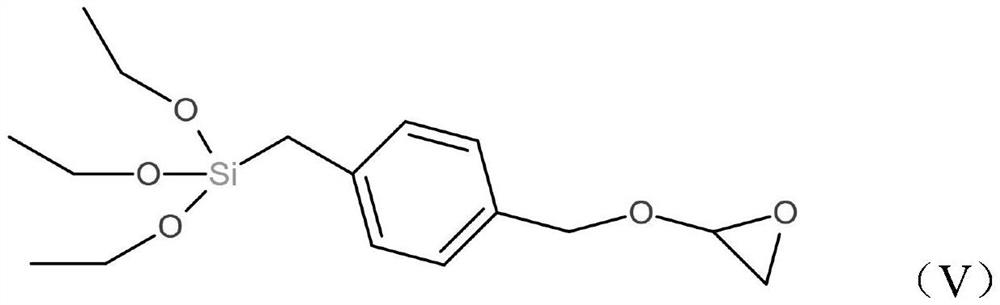

Surface modification method and application of silicon dioxide

ActiveCN114262528AImprove rigidityLower coefficient of thermal expansionPigment treatment with organosilicon compoundsEpoxyThermal dilatation

The invention discloses a surface modification method and application of silicon dioxide. The modified silicon dioxide is obtained by carrying out surface grafting modification on silicon dioxide by adopting an epoxy silane modifier containing an aromatic ring. The invention also discloses an epoxy resin composition containing the modified silicon dioxide. According to the epoxy silane containing the aromatic ring, due to the fact that the aromatic ring in the silane structure is large in rigidity and small in molecular motility, in the electronic packaging process, modified silicon dioxide is added into epoxy resin, the thermal expansion coefficient and viscosity of the packaging material can be reduced, and the elastic modulus can be increased.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

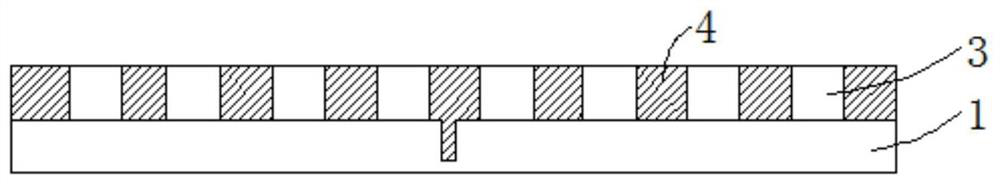

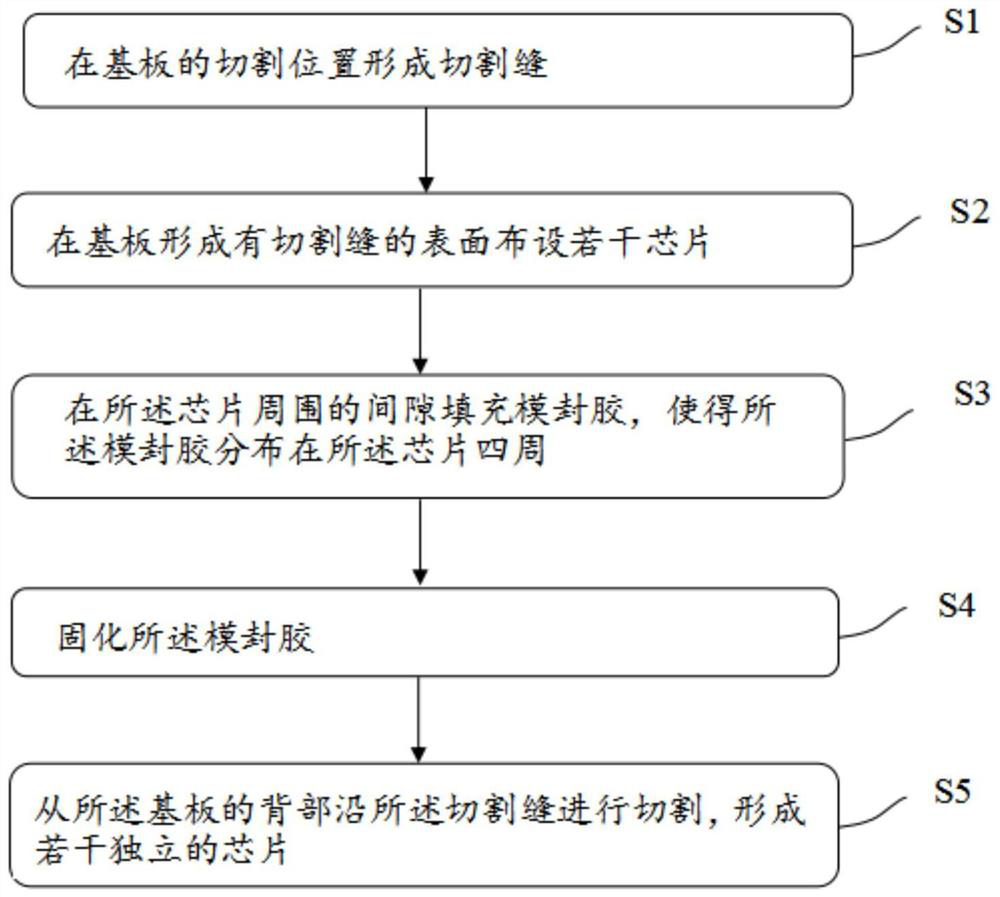

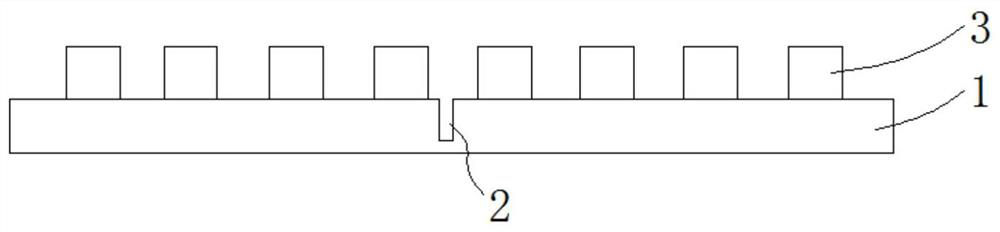

Dimer acid epoxy resin composition for chip packaging, application of dimer acid epoxy resin composition and cutting method of chip

PendingCN113278253AImprove the cushioning effectReduce warpageSemiconductor/solid-state device detailsSolid-state devicesEpoxyThermal dilatation

The invention discloses a dimer acid epoxy resin composition for chip packaging, application of the dimer acid epoxy resin composition and a cutting method of a chip. The dimer acid epoxy resin composition provided by the invention can be matched with an inorganic filler to form a mold sealing compound for chip packaging, and the warping and thermal expansion coefficient of the mold sealing compound can be effectively reduced. The mold sealing compound is uniformly formed on a cofferdam around the chip, so that the cushioning performance of the chip is improved, impact caused by mismatching of overall temperature expansion characteristics between the chip and the substrate or cutting external force of the chip can be effectively reduced, and meanwhile, welding spots can be prevented from being oxidized.

Owner:HUBEI CHOICE TECH CO LTD

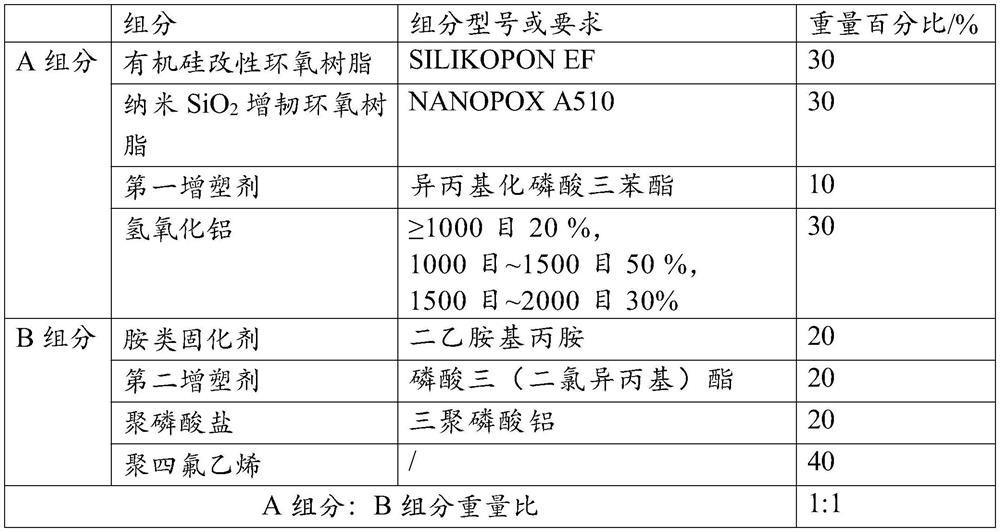

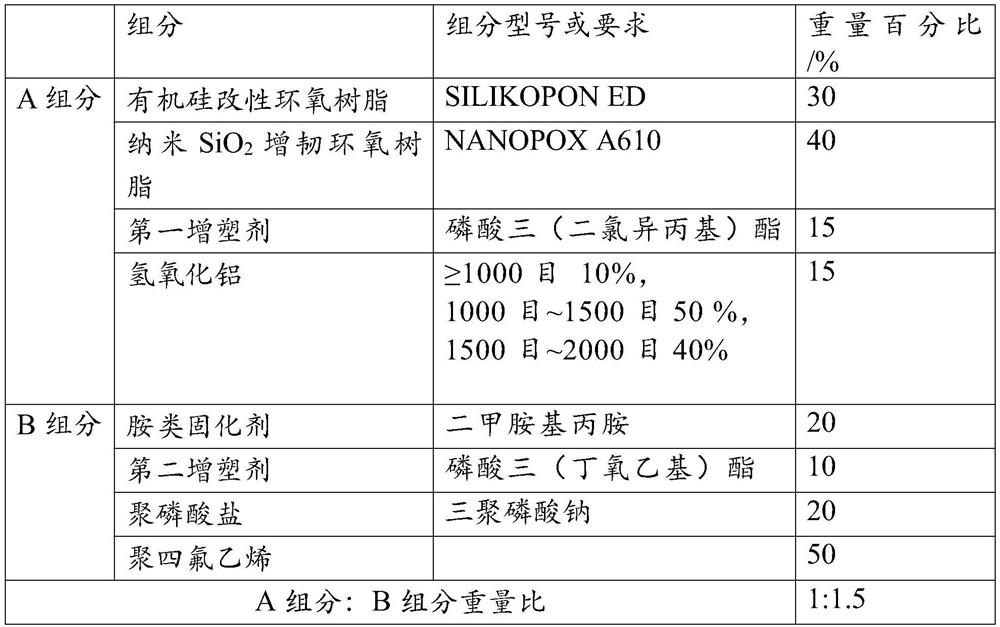

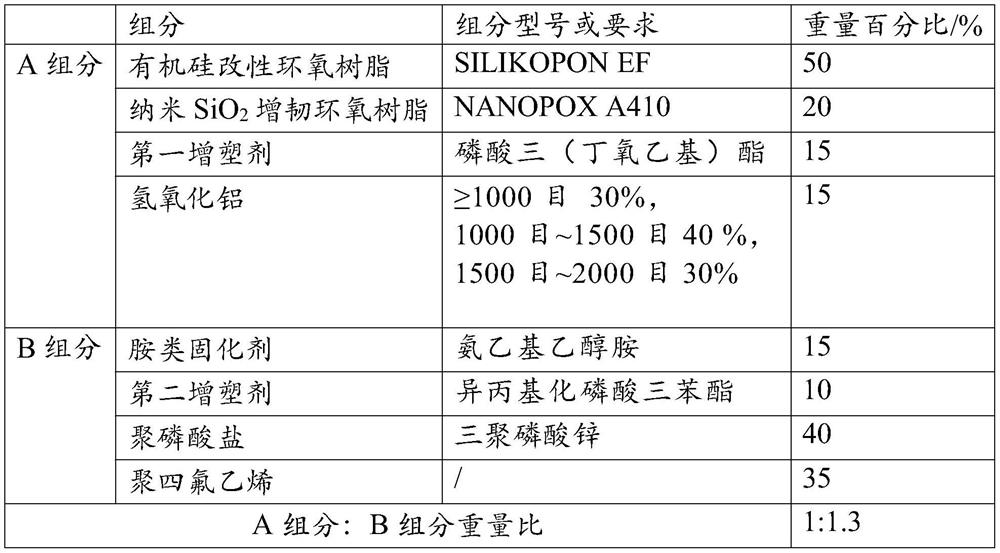

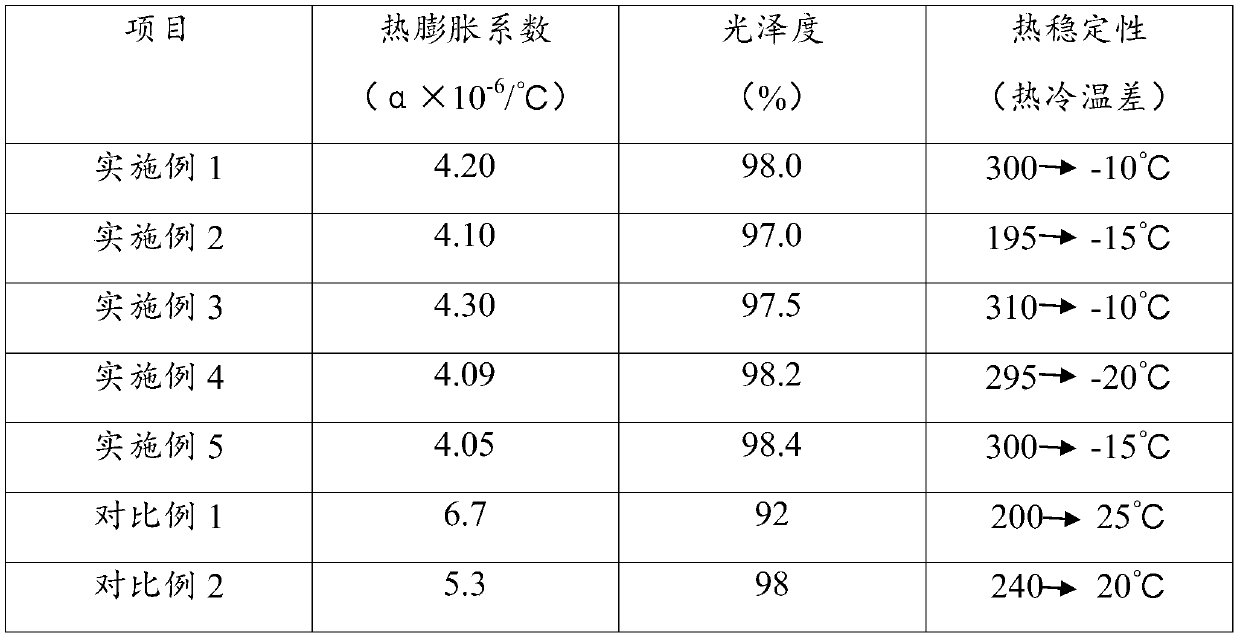

High-insulation high-flame-retardant double-component epoxy coating and preparation method thereof

ActiveCN112322098AImprove insulation performanceHigh electrical insulationFireproof paintsEpoxy resin coatingsPolymer sciencePlasticizer

The invention relates to a high-insulation high-flame-retardant double-component epoxy coating. The coating is characterized by being formed by mixing and curing a component A and a component B according to a weight ratio of 1: 1 to 1: 1.5 during use, wherein the component A is mainly prepared from the following components in percentage by weight: 10.0%-50.0% of organic silicon modified epoxy resin, 15.0%-40.0% of nano-SiO2 toughened epoxy resin, 10.0%-20.0% of a first plasticizer and 15.0%-40.0% of aluminum hydroxide; and the component B is mainly prepared from the following components in percentage by weight: 5.0%-25.0% of an amine curing agent, 10.0%-20.0% of a second plasticizer, 20.0%-50.0% of polyphosphate and 20.0%-50.0% of polytetrafluoroethylene. The coating has good insulating and flame-retardant properties.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +2

High-temperature-resistant glaze

The invention provides high-temperature-resistant glaze. The glaze is prepared from the following raw materials: silicon dioxide, nano yttrium oxide, modified glass fibers, a rheological agent, kaolin, lithium oxide, sodium carboxymethyl cellulose and nano neodymium oxide. The nano yttrium oxide, the modified glass fibers, the lithium oxide and the nano neodymium oxide in the high-temperature-resistant glaze can enhance the heat resistance of the glaze, tiny gaps are formed in the glaze so that glaze shrinkage is reduced, cracking is not caused under a relatively large temperature difference,the melting temperature and the thermal expansion coefficient of the glaze are also reduced, thermal stability is improved, the fired ceramic glaze has few pinholes, is fine and smooth and has good glossiness, the rheological agent and the sodium carboxymethyl cellulose are added so that the fluidity and thixotropy of the glaze can be improved, the binding force of the glaze and a green body is effectively improved, and the smoothness of a glaze layer is increased, so that the high-temperature-resistant glaze disclosed by the invention not only has very good thermal stability, but also the glaze layer formed on ceramic has very good glossiness, and the surface smoothness can be kept.

Owner:FOSHAN UNIVERSITY

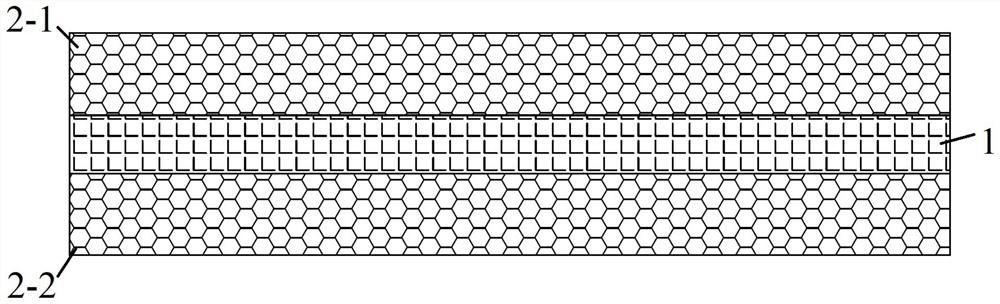

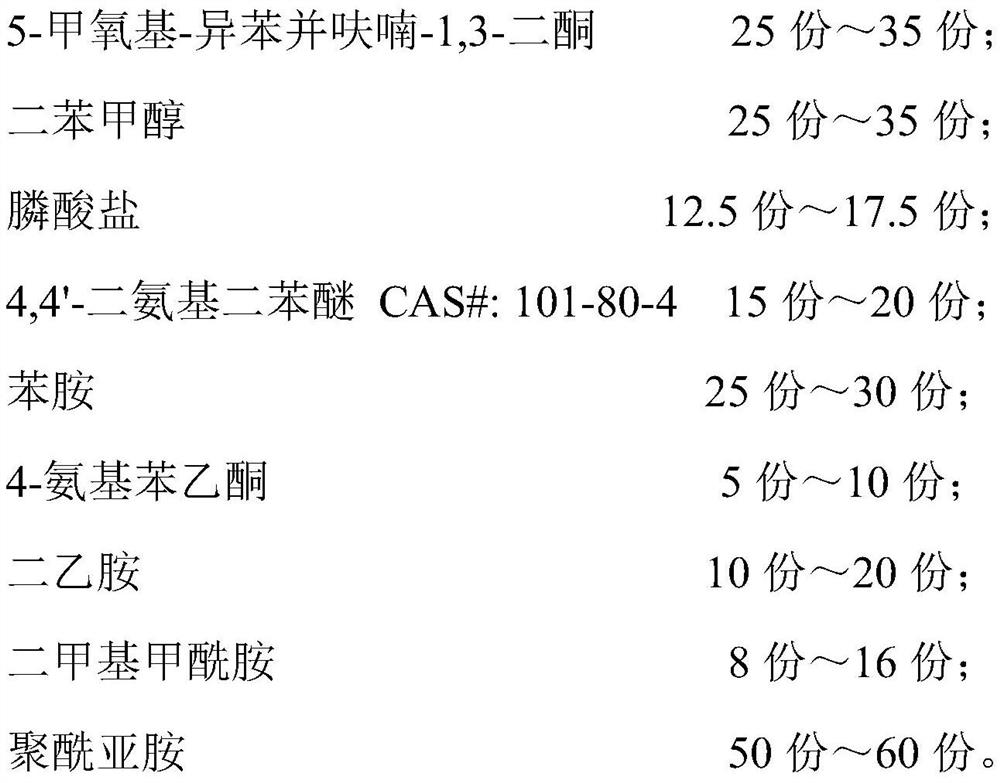

Intelligent coated high-frequency copper clad laminate with high flame-retardant function and preparation method of copper clad laminate

ActiveCN111976246AExtensive sources of raw materialsStrong renewable capacityLamination ancillary operationsSynthetic resin layered productsEpoxyThermal dilatation

The invention provides an intelligent coated high-frequency copper clad laminate with high flame-retardant function and a preparation method of the copper clad laminate. The copper clad laminate comprises a prepreg in the middle, a first resin-coated glass fiber cloth-based copper foil on the upper side of the prepreg, and a second resin-coated glass fiver cloth-based copper foil on the lower sideof the prepreg; and the prepreg is a phosphating modified polyimide film, and the coating resin is a bio-based dimer acid glycidyl ester modified epoxy resin. The high-frequency copper clad laminateprovided by the invention is double-layer direct metallization without bonding layer, meets the requirements of high miniaturization of electronic devices, has high glass transition temperature, low thermal expansion coefficient and dielectric constant, and then has high flame retardancy performance and high rigidity. Both the phosphating modified polyimide film and the bio-based dimer acid glycidyl ester modified epoxy resin glass fiber cloth do not need to be filled with inorganic fillers, so as to reduce the occurrence of agglomeration which leads to uneven microstructure of the copper cladlaminate, and avoid the defects of low transparency and reducing light transmittance of the copper clad laminate.

Owner:无锡睿龙新材料科技有限公司

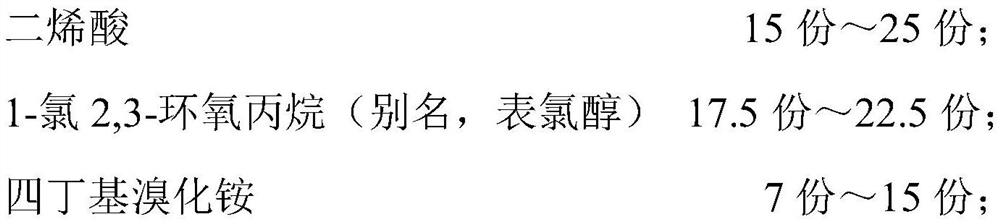

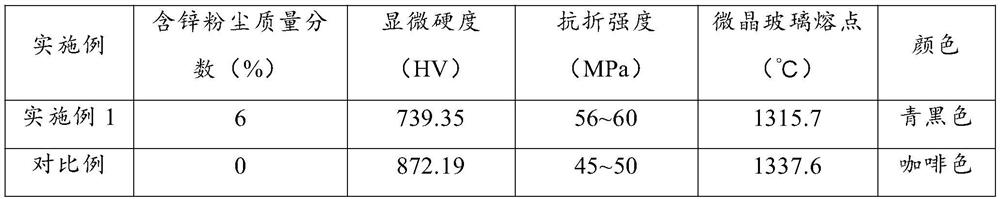

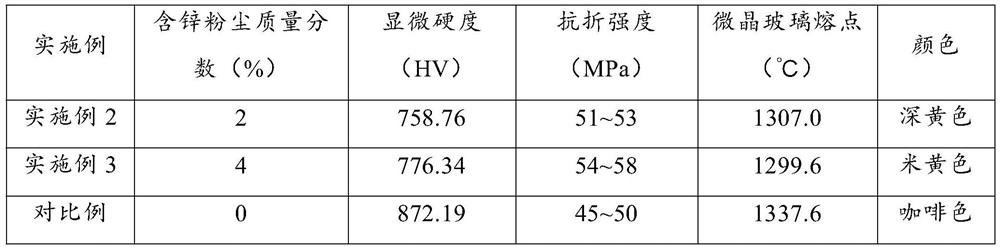

Preparation method of low-cost glass ceramic

ActiveCN113845308AReduce performanceImprove performanceGlass shaping apparatusProcess efficiency improvementGlass-ceramicNatural stone

The invention provides a preparation method of low-cost glass ceramic. Copper slag and high-temperature molten converter slag are mixed, molten reduction tailings generated after iron is reduced and recovered and zinc-containing dust serve as base materials of the low-cost glass ceramic, and a one-step heat treatment process is carried out to prepare the low-cost glass ceramic. The process can be arranged near a high-temperature converter, the solid copper slag and the reducing agent are poured into the liquid converter slag after deslagging and are heated to be completely molten, glass ceramic is prepared from generated secondary tailings, and iron in the glass ceramic is recycled. According to the method, waste of the recovery process can be completely utilized, the economic additional value of the waste is improved, solid waste is reduced, the effect of protecting the environment is achieved, and the purpose of efficiently utilizing the waste heat of the molten converter slag is achieved; and meanwhile, the technological process is simplified. The secondary tailings obtained after reduction of the copper slag and the molten converter slag are used as the base material of the glass ceramic, the preparation cost is low, the price advantage is great, the economic benefit is good, the performance of the prepared glass ceramic is superior to that of natural stone, and the application range is wide.

Owner:WUHAN UNIV OF SCI & TECH

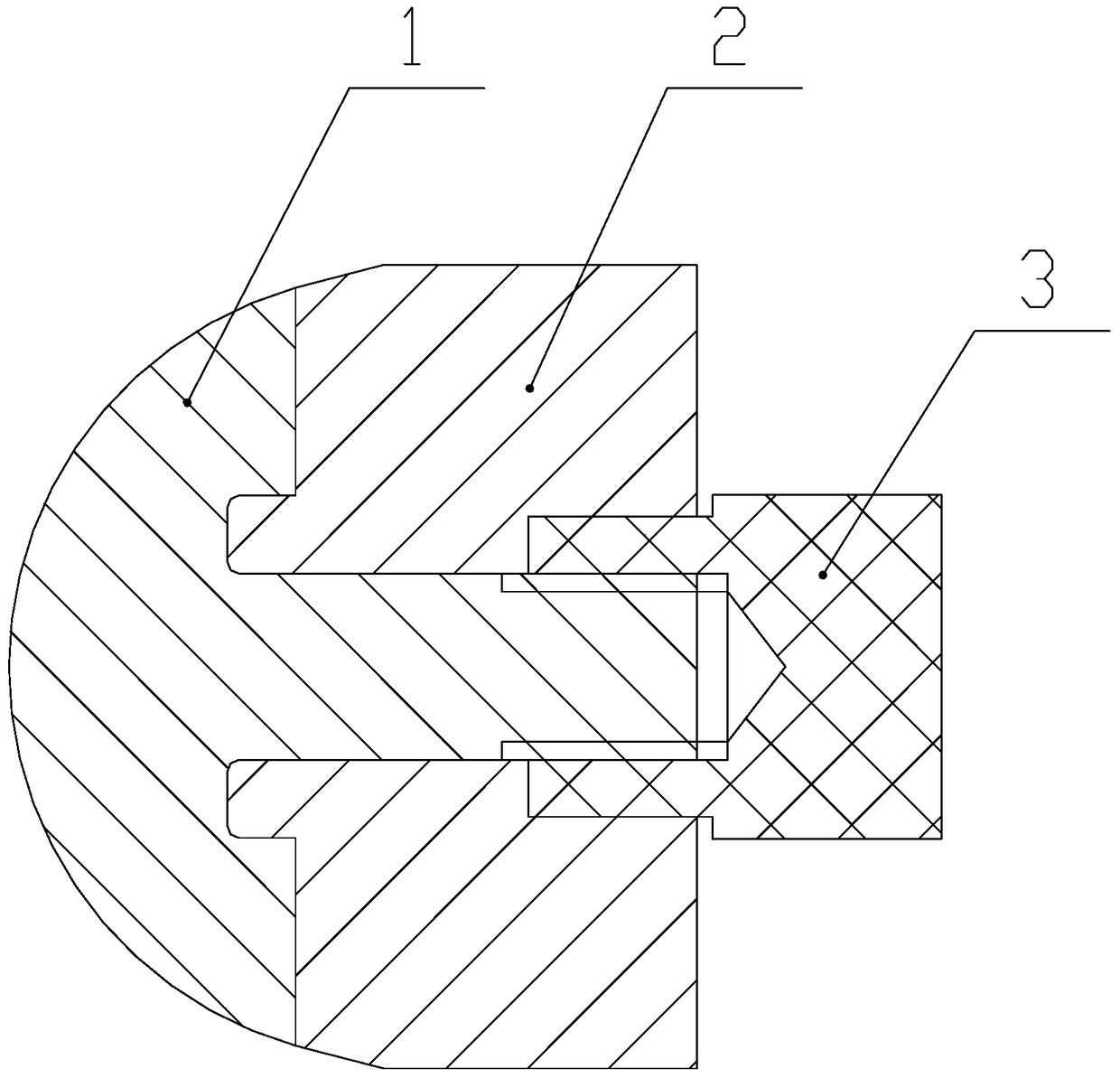

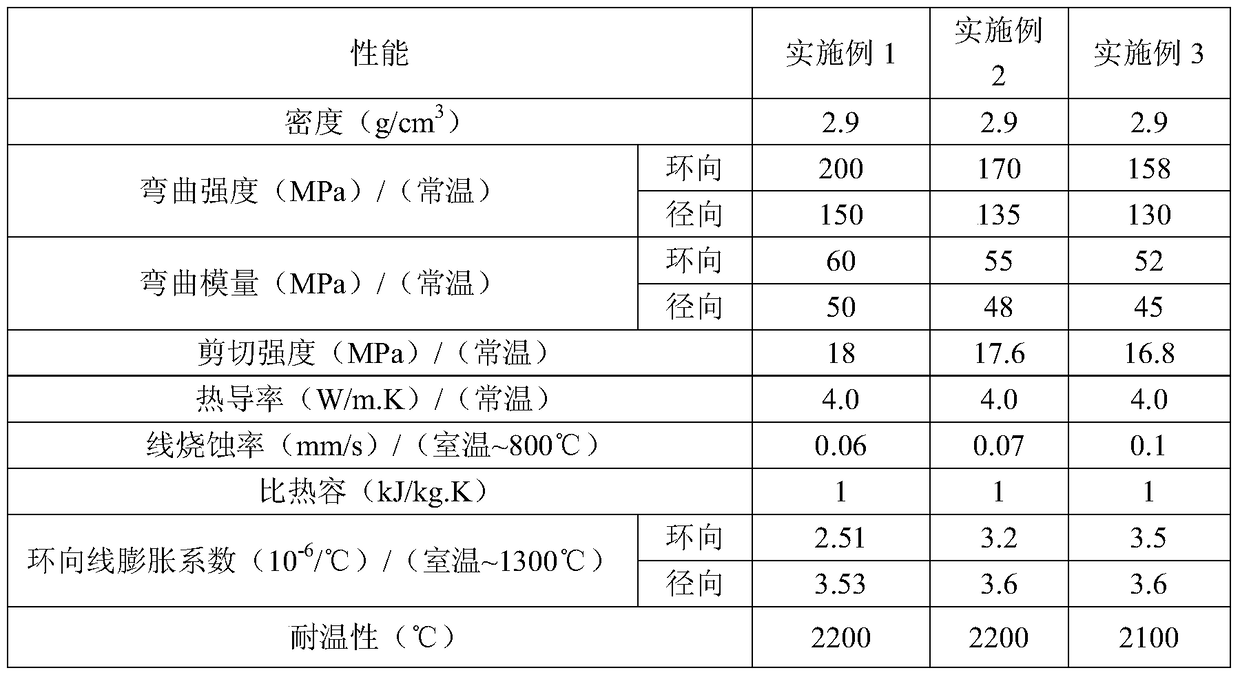

Method for manufacturing ultra-high temperature ceramic matrix composite material ablation head radome body

ActiveCN105742810BImprove high temperature resistanceEasy to useRadiating element housingsCarbon fibersComposite ceramic

The invention discloses a fabrication method for a cover body of a superhigh temperature ceramic matrix composite material ablation head antenna cover. The method comprises the following steps of weaving an ablation head flat plate fabric by a carbon fiber three-phase orthogonal mode to obtain an ablation head woven fabric; immersing and compounding to obtain C / SiC-ZrC composite ceramic ablation head rough blank, and carrying out profiling weaving on the cover body fabric by a needling mode to obtain a cover body woven fabric; mechanically processing the cover body woven fabric to required product sizes to obtain an ablation head and the cover body; and connecting and forming the ablation head and the cover body by nuts, thereby obtaining the cover body of the ablation head antenna cover. According to the method, the C / SiC-ZrC composite material and a C / SiC-HfC composite material which have excellent temperature resistance reaching 2,000 DEG C and ablation resistance are used; and through optimal design on a prefabricated element of the ablation head and control on volume content of annular fibers, zero expansion of the ablation head composite material in an annular direction can be achieved, and thus, the obtained cover body of the antenna cover can be applied to intermediate and remote land attack cruise missiles with high mach (greater than 10Ma), long endurance (greater than 1,000 seconds) and high accuracy.

Owner:湖北三江航天江北机械工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com