Intelligent coated high-frequency copper clad laminate with high flame-retardant function and preparation method of copper clad laminate

A high flame-retardant, copper-clad laminate technology, applied in the field of communication materials, can solve the problems of reducing thickness, increasing the thickness and thermal expansion rate of high-frequency copper-clad laminates, and achieving the effects of improving toughness, ensuring solvent leaching resistance, and strong reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

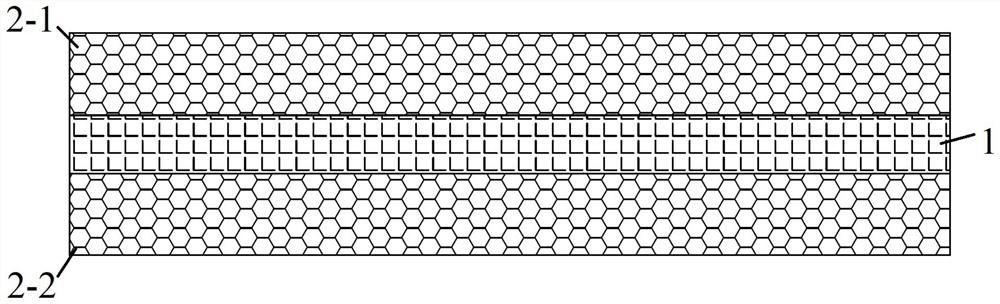

[0046] A high-flame-retardant smart coated high-frequency copper-clad laminate provided in this embodiment includes a prepreg 1 located in the middle, a first coated resin glass fiber cloth-based copper foil 2-1 located on the upper side of the prepreg, and a first coated resin glass fiber cloth-based copper foil 2-1 located on the lower side of the prepreg The second resin-coated glass fiber cloth-based copper foil 2-2; the prepreg 1 is a phosphate-modified polyimide film, and the coating resin is a bio-based dimer acid glycidyl ester modified epoxy resin.

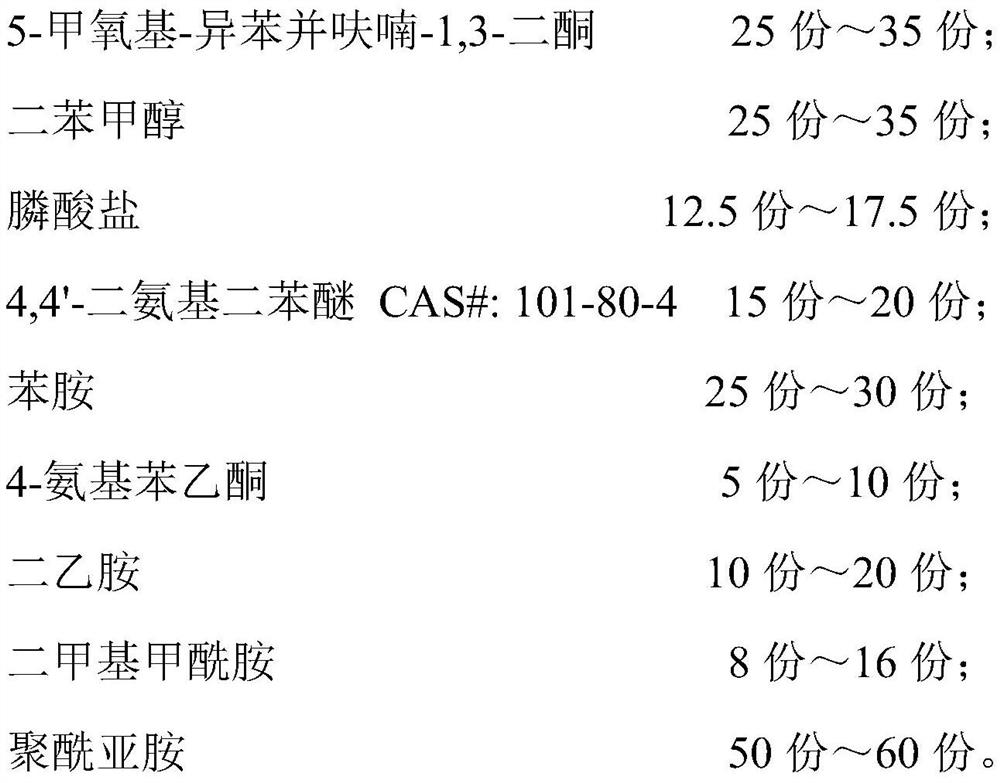

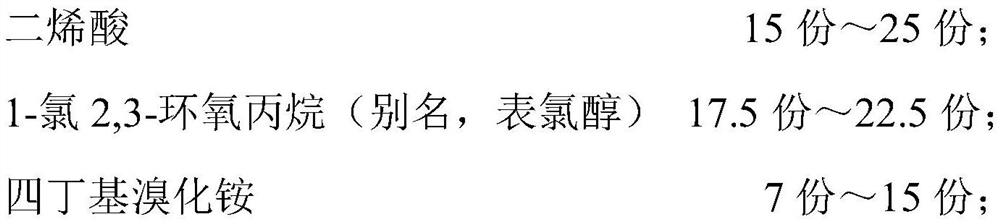

[0047] Among them, the phosphating modified polyimide film, by weight components, includes the following components:

[0048]

[0049] The preparation method of phosphating modified polyimide film comprises the following steps:

[0050] A1: Mix 25 parts of aniline, 5 parts of 4-aminoacetophenone, and 10 parts of diethylamine, stir in a nitrogen atmosphere at 120°C at 200 rpm for 2 hours, filter the obtained mixture, an...

Embodiment 2

[0071] A high-flame-retardant smart coated high-frequency copper-clad laminate provided in this embodiment includes a prepreg 1 located in the middle, a first coated resin glass fiber cloth-based copper foil 2-1 located on the upper side of the prepreg, and a The second coated resin glass fiber cloth-based copper foil 2-2 on the underside of the prepreg; the prepreg 1 is a phosphating modified polyimide film, and the coating resin is modified by bio-based dimer acid glycidyl ester. permanent epoxy resin.

[0072] Phosphating modified polyimide film, by weight component, includes the following components:

[0073]

[0074] The preparation method of phosphating modified polyimide film comprises the following steps:

[0075] A1: Mix 27.5 parts of aniline, 7.5 parts of 4-aminoacetophenone, and 15 parts of diethylamine, stir in a nitrogen atmosphere at 135°C at 225rpm for 2.5h, filter the obtained mixture, and use Methanol recrystallized and dried in vacuum at 115°C;

[0076]...

Embodiment 3

[0095] A high-flame-retardant smart coated high-frequency copper-clad laminate provided in this embodiment includes a prepreg 1 located in the middle, a first coated resin glass fiber cloth-based copper foil 2-1 located on the upper side of the prepreg, and a The second coated resin glass fiber cloth-based copper foil 2-2 on the underside of the prepreg; the prepreg 1 is a phosphating modified polyimide film, and the coating resin is modified by bio-based dimer acid glycidyl ester. permanent epoxy resin.

[0096] Phosphating modified polyimide film, by weight component, includes the following components:

[0097]

[0098]

[0099] The preparation method of phosphating modified polyimide film comprises the following steps:

[0100] A1: Mix 30 parts of aniline, 10 parts of 4-aminoacetophenone, and 20 parts of diethylamine, stir in a nitrogen atmosphere at 150°C at 250 rpm for 3 hours, filter the obtained mixture, and use methanol to obtain the precipitate Recrystallize a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com