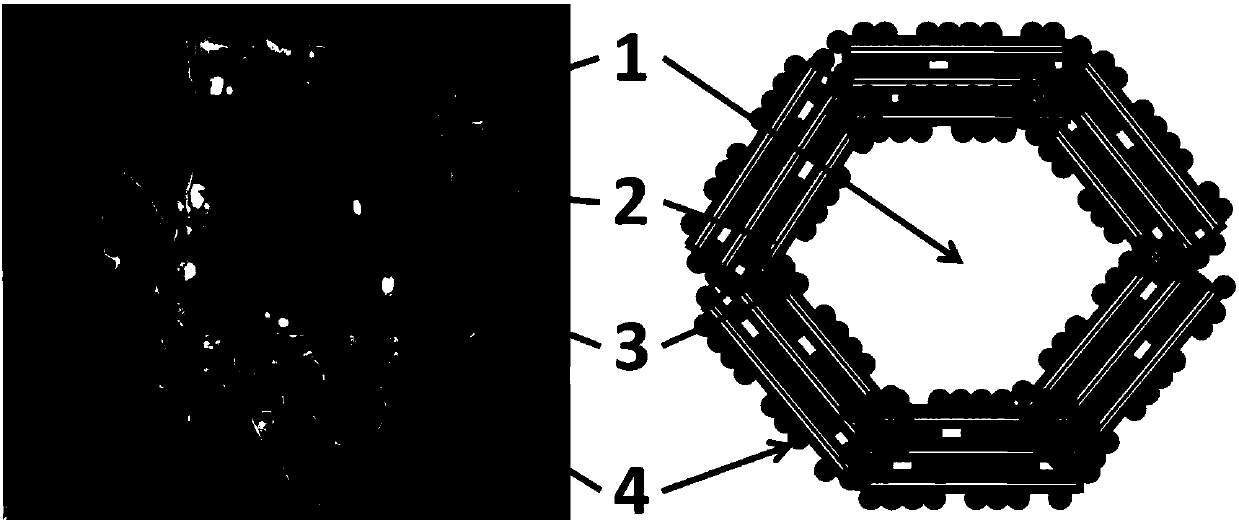

Hollow silicon-carbon composite material for lithium-ion batteries, and preparation method thereof

A technology of silicon carbon composite material and carbon composite material, which is applied in battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve the practical application of difficult lithium-ion batteries, the decline of material cycle performance, and the low battery cycle efficiency. , to achieve the effect of low cost, small expansion and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

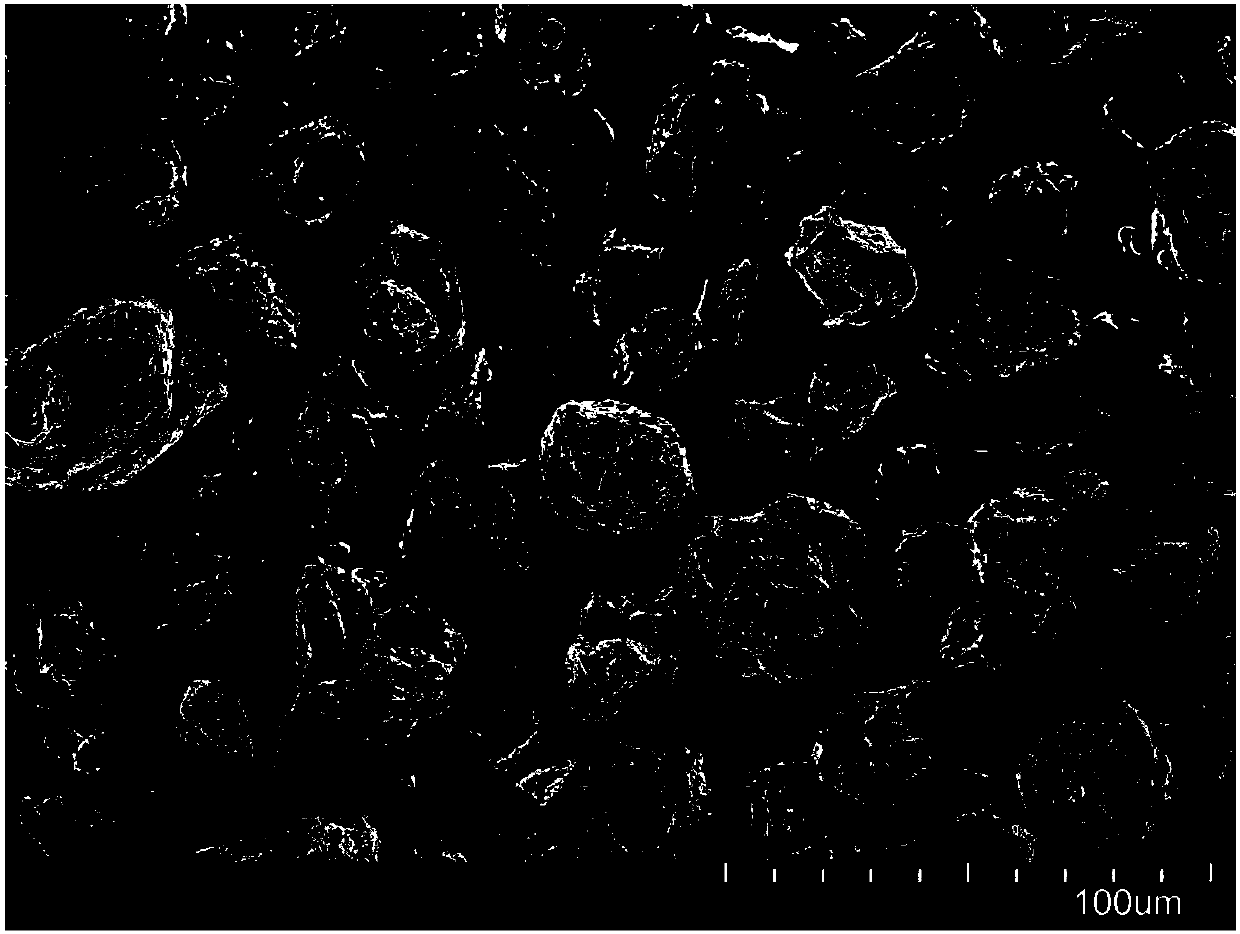

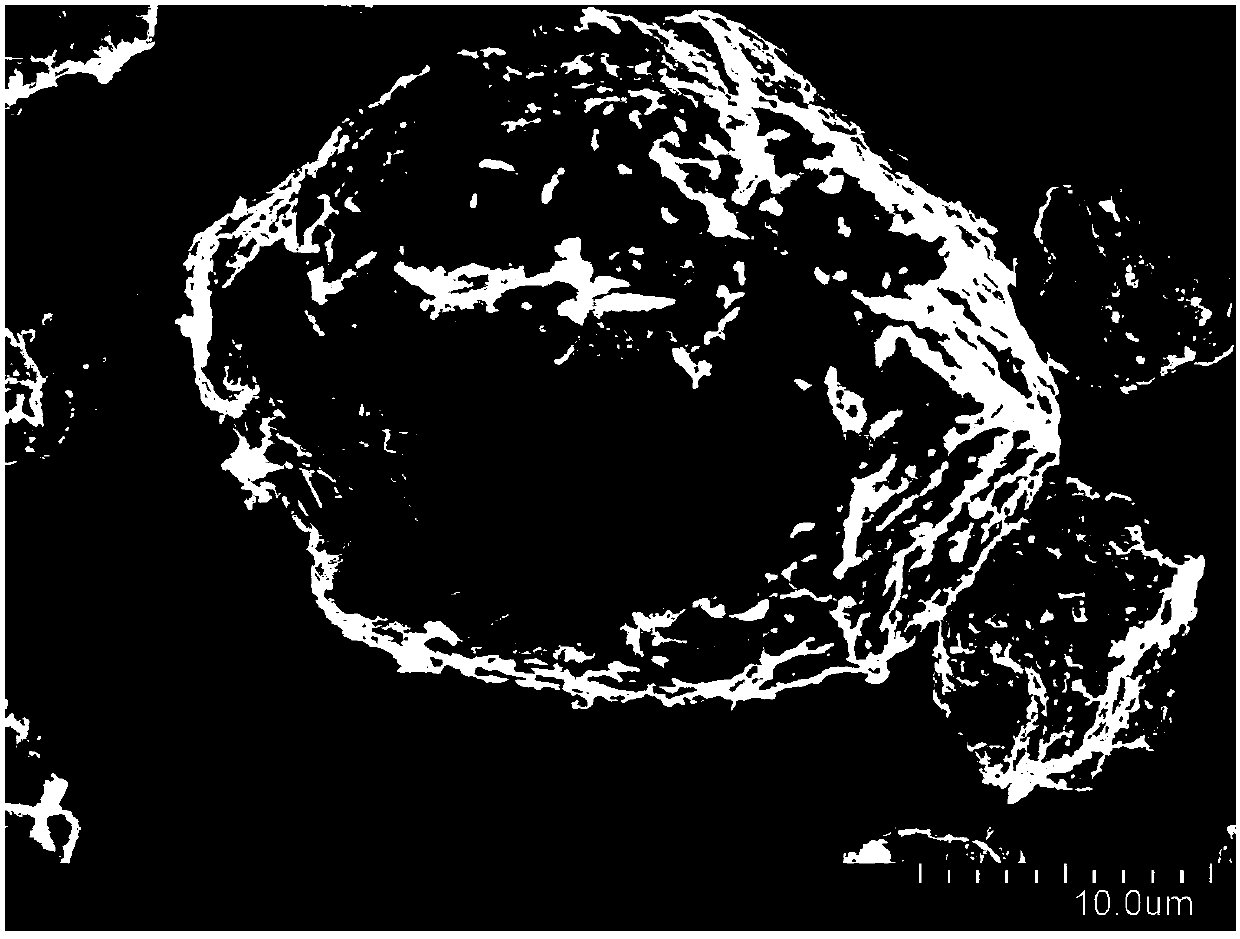

[0049] Take 500g of natural graphite with a median particle size of 22 μm and 4500 g of dimethylacetamide, and grind them with 0.4 mm zirconia beads for 3 hours in a sand mill to obtain a graphite flake slurry with a median particle size of 6 μm. stand-by. Observing the graphite flakes with an electron microscope, the length of the graphite flakes is between 0.1-15 μm and the thickness is between 0.01-0.5 μm. Take 500g of secondary particle median particle size of 2 μm, primary particle median particle size of 0.2 μm nano silicon powder and 4500g of dimethylacetamide, sand mill with 0.4mm zirconia beads for 2 hours in a sand mill, A silicon nanoparticle slurry with a median diameter of 0.3 μm was obtained. Mix 150g of petroleum pitch with 1350g of dimethylacetamide to form a suspension. Pour the above-mentioned graphite flake slurry and petroleum pitch suspension into a sand mill, and fully mix with the silicon nanoparticle slurry for 30 minutes. The dimethylacetamide slurr...

Embodiment 2

[0055] Get 600g of natural graphite with a median particle size of 22 μm, 5400g of absolute ethanol, and 18g of polyvinylpyrrolidone, and grind for 4 hours with 0.4mm zirconia beads in a sand mill to obtain a graphite flake slurry with a median particle size of 5 μm material, take it out and set aside. Observing the graphite sheet with an electron microscope, the length of the graphite sheet is between 0.1-13 μm and the thickness is between 0.01-0.5 μm. Take 300g of secondary particles with a median particle size of 2 μm, nano silicon powder with a primary particle median size of 0.2 μm, 2700g of absolute ethanol, and 9g of polyvinylpyrrolidone, and sand them with 0.4mm zirconia beads in a sand mill After 2 hours, a silicon nanoparticle slurry with a median diameter of 0.2 μm was obtained. Dissolve 250g of glucose in 2250g of deionized water to make glucose aqueous solution. The graphite flake slurry and the aqueous glucose solution were poured into a sand mill, and thorough...

Embodiment 3

[0059]Get 240g of artificial graphite with a median particle size of 19 μm, 1360g of isopropanol, and 5g of polyvinylpyrrolidone, and grind for 2 hours with 0.4mm zirconia beads in a sand mill to obtain a graphite flake slurry with a median particle size of 6 μm material, take it out and set aside. Observing the graphite flakes with an electron microscope, the length of the graphite flakes is between 0.1-15 μm and the thickness is between 0.01-0.5 μm. Take 900g of polysilicon powder with a median particle size of 5 μm, 5100 g of isopropanol, and 18 g of polyvinylpyrrolidone, and grind them with 0.4 mm zirconia beads in a sand mill for 3 hours to obtain silicon nanoparticles with a median particle size of 0.4 μm. granular slurry. Dissolve 150g of glucose in 2850g of deionized water to make glucose aqueous solution. The graphite flake slurry and the aqueous glucose solution were poured into a sand mill, and thoroughly mixed with the silicon nanoparticle slurry for 30 minutes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com