Patents

Literature

206 results about "Silicon anode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

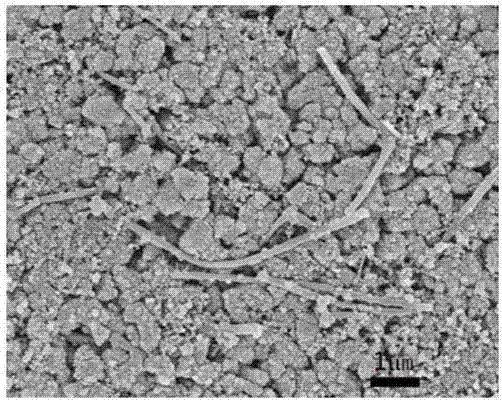

Anode active material hybridizing carbon nanofiber for lithium secondary battery

InactiveUS20090053608A1Material nanotechnologyNon-aqueous electrolyte accumulator electrodesFiberCarbon nanofiber

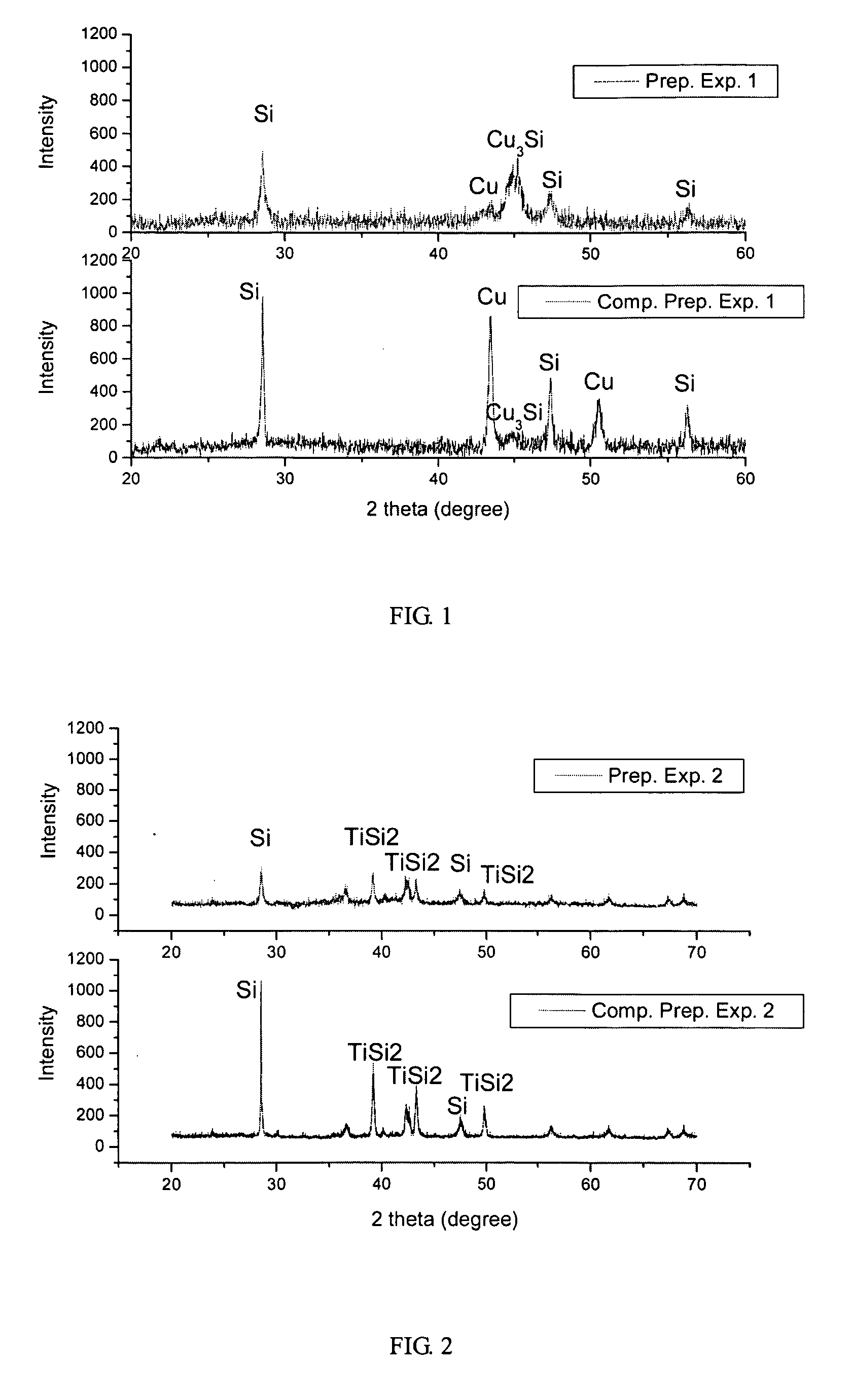

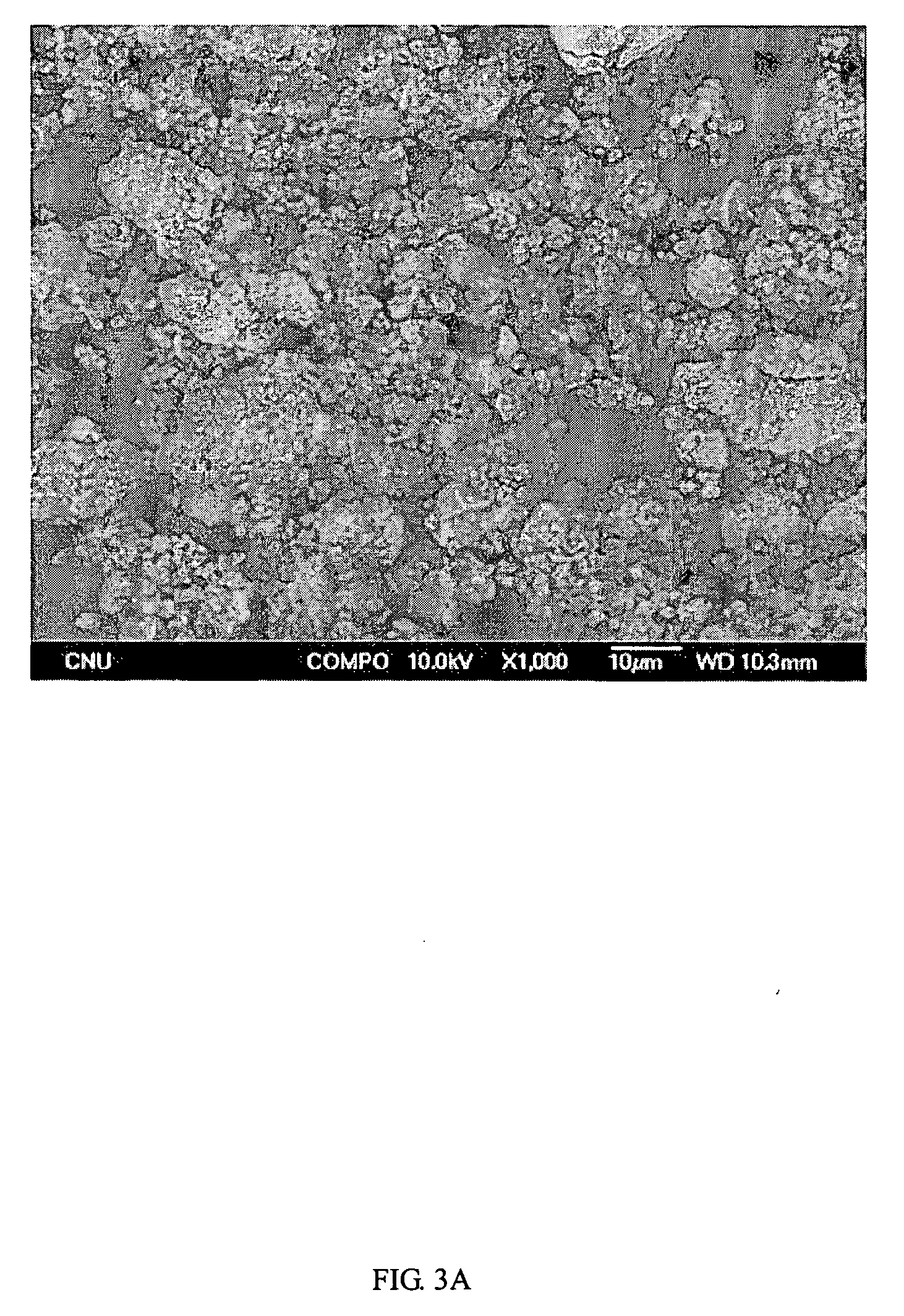

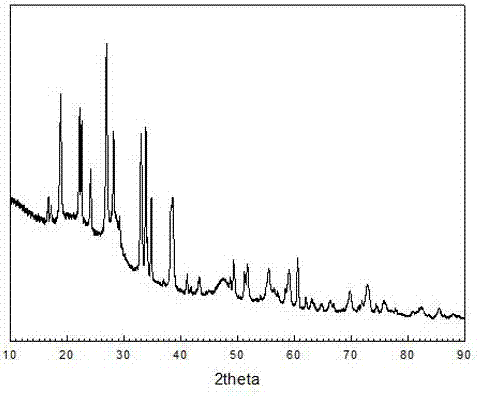

The present invention provides a composite silicon anode material hybridizing carbon nanofiber for lithium secondary battery prepared by the steps comprising: i) preparing a support made by amorphous silicon alloy after processing amorphous silicon and metal; ii) dispersing the catalyst selected from Fe, Co, Ni, Cu, Mg, Mn, Ti, Sn, Si, Zr, Zn, Ge, Pb or In on the surface of said support made by amorphous silicon alloy; and iii) growing the carbon nanofiber using a carbon source selected from carbon monoxide, methane, acetylene or ethylene on said support by a chemical vapor deposition method, wherein the amount of grown carbon nanofiber is 1˜110 wt % of the amount of said support.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Tin silicon anode active material

Owner:STOREDOT

Method of making silicon anode material for rechargeable cells

ActiveUS20120129049A1Excellent cast-abilityExcellent weld-abilityElectrolysis componentsElectrode manufacturing processesRechargeable cellSilicon

Owner:NEXEON LTD

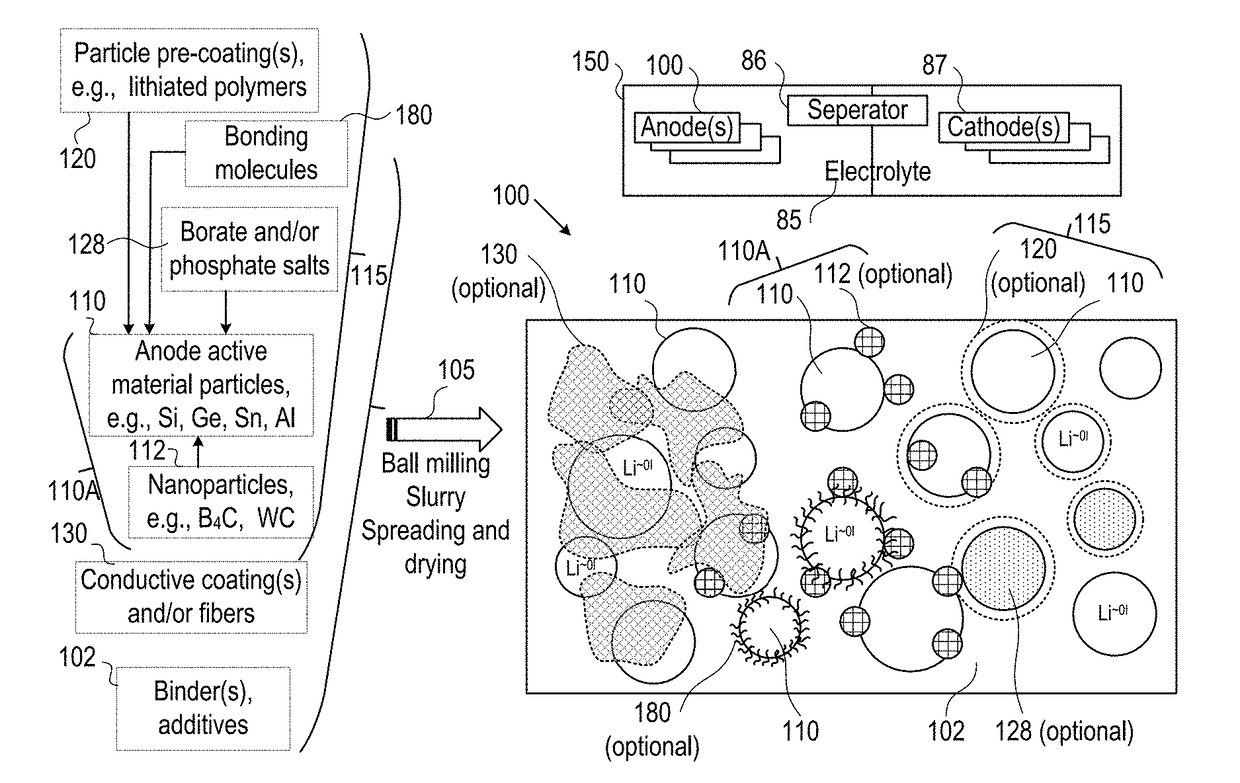

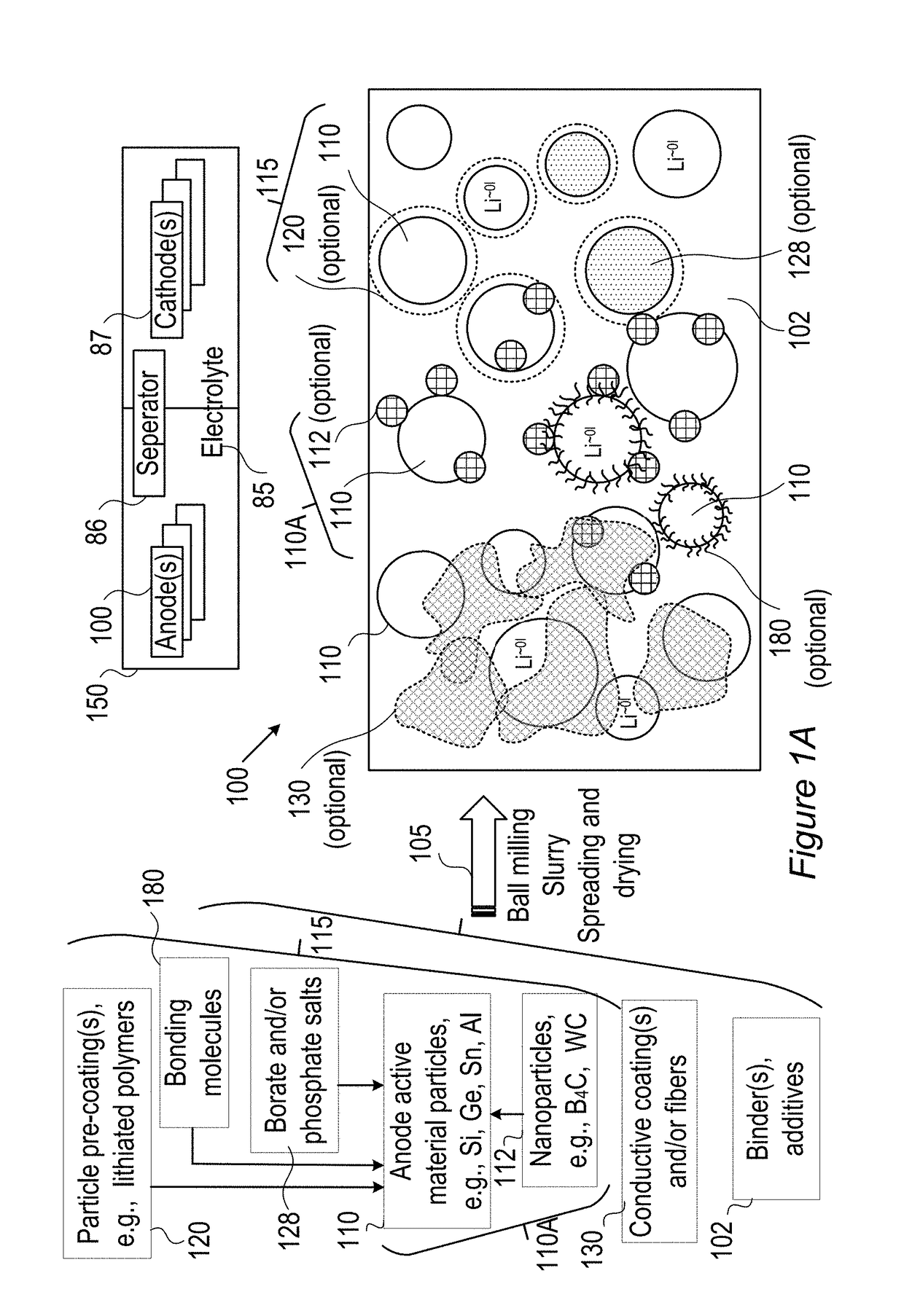

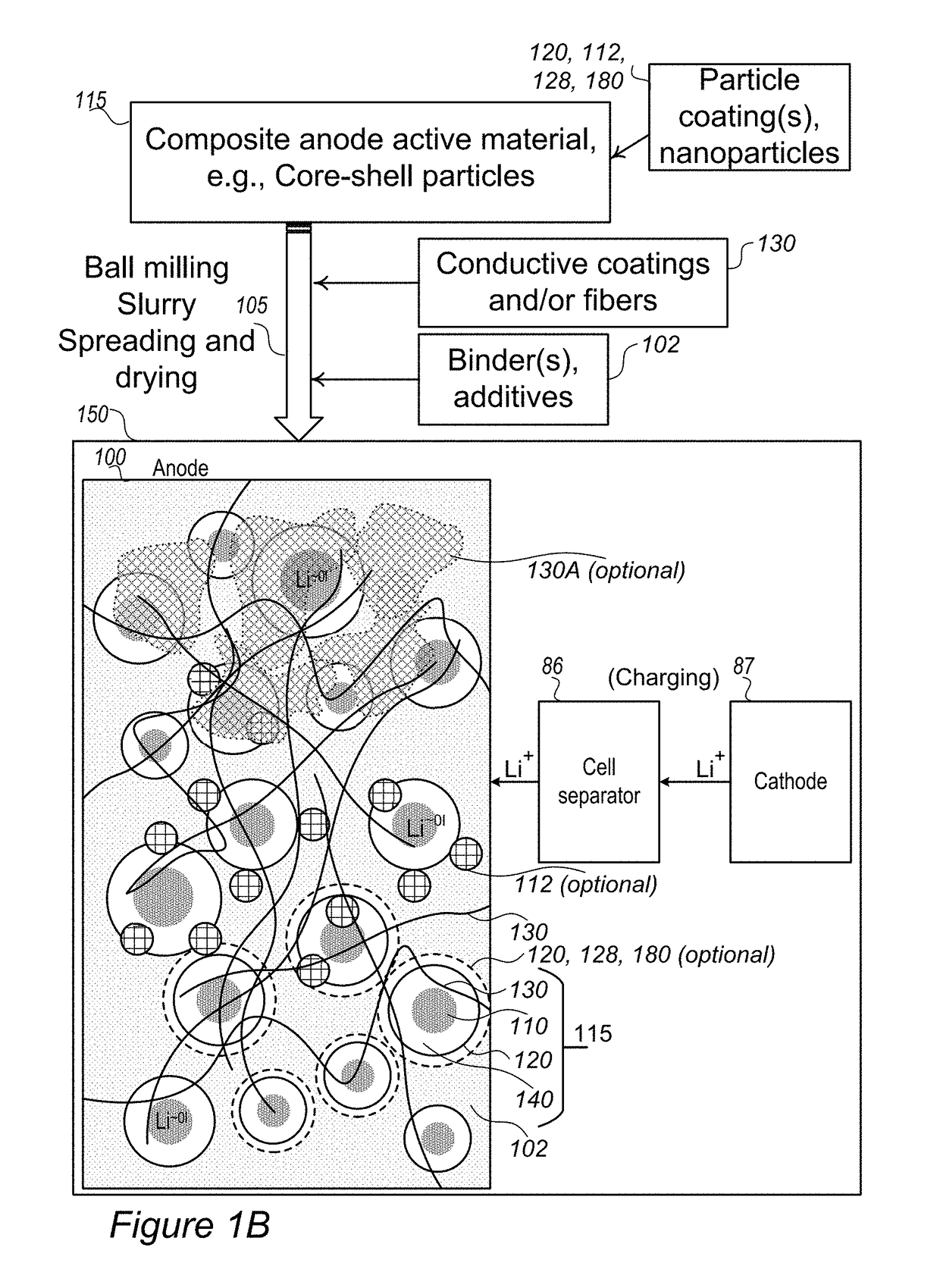

Prelithiated and methods for prelithiating an energy storage device

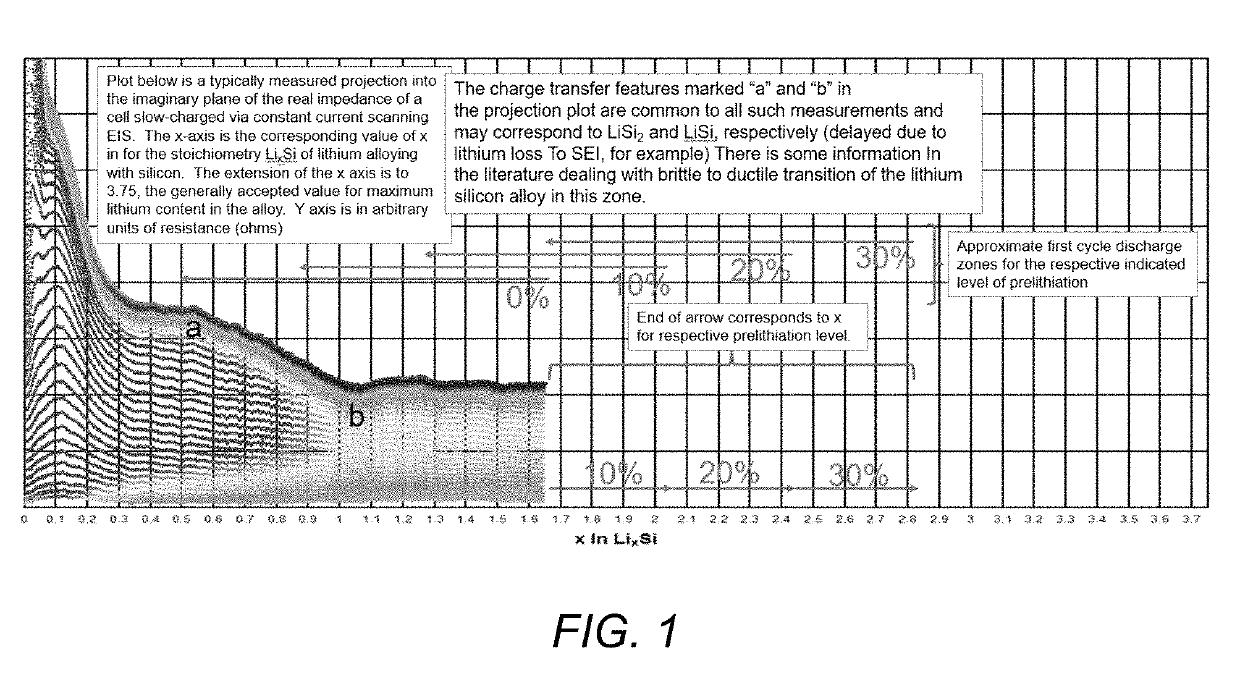

The present disclosure relates to prelithiated Si electrodes, methods of prelithiating Si electrodes, and use of prelithiated electrodes in electrochemical devices are described. There are several characteristics of electrode prelithiation that enable the superior battery performance. First, a prelithiated silicon anode is already in its expanded state during SEI formation, and therefore less of the SEI layer breaks down and reforms during cycling. Second, the prelithiated anode has a lower anode potential, which may also help the cycle performance of an electrochemical device.

Owner:ENEVATE CORP

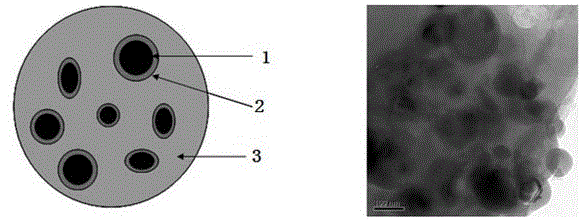

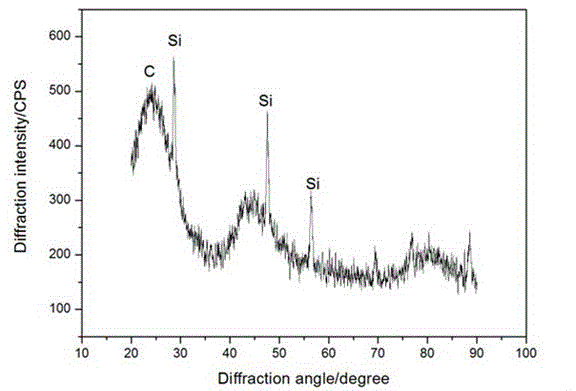

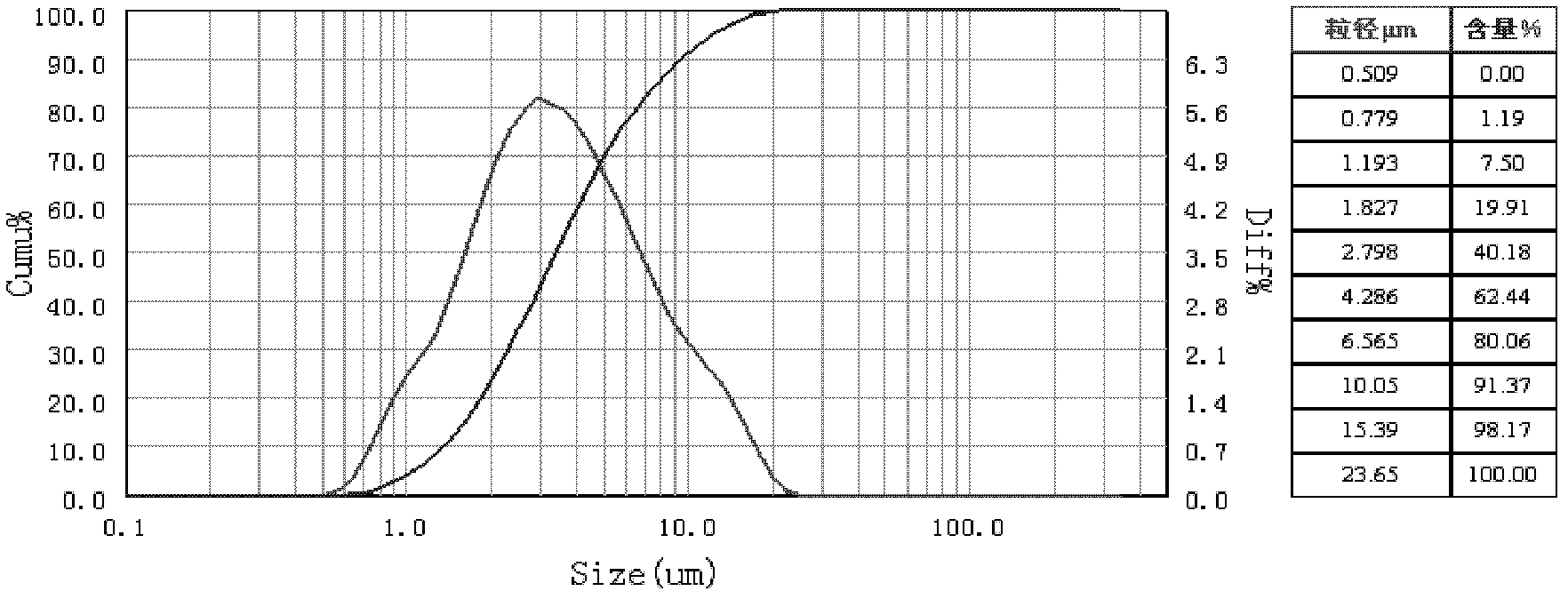

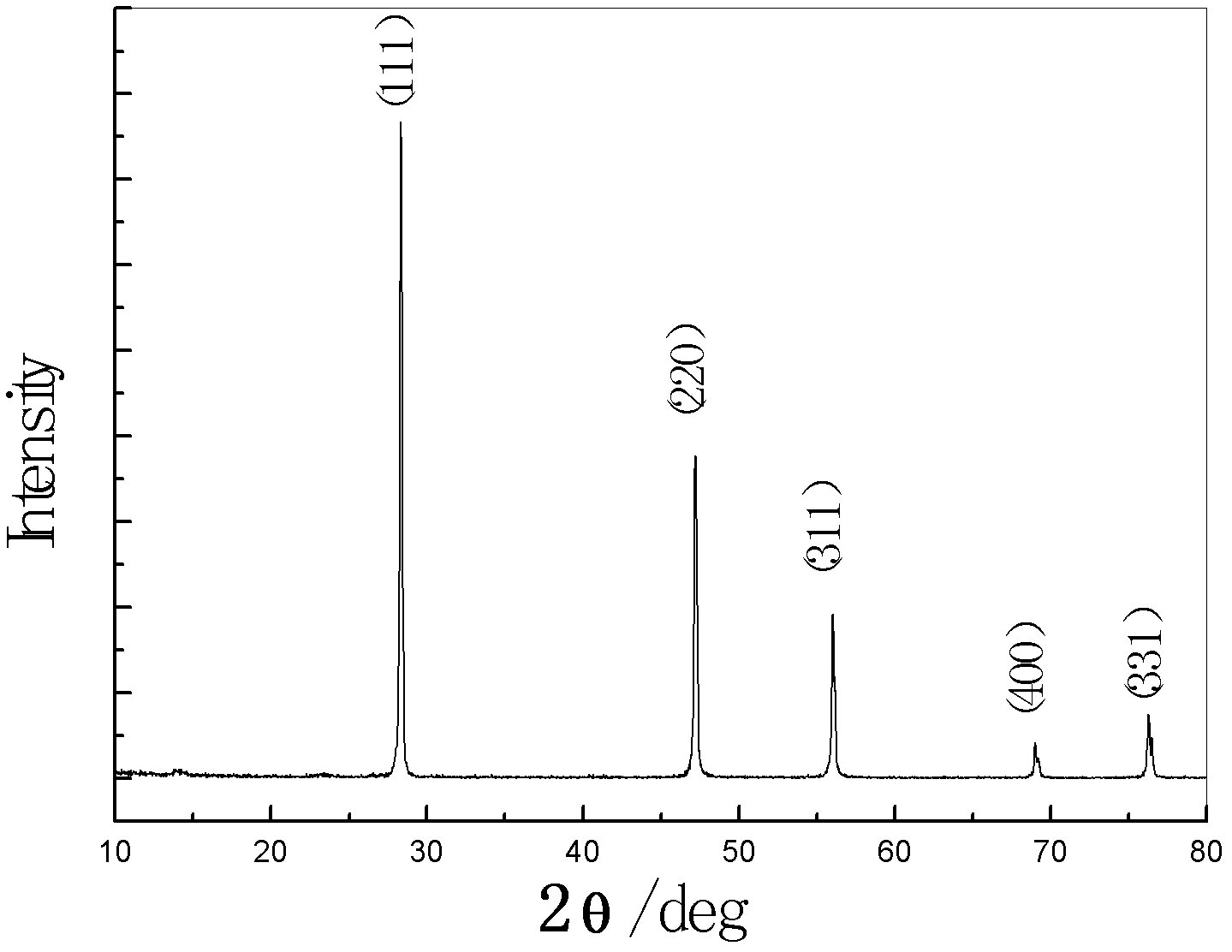

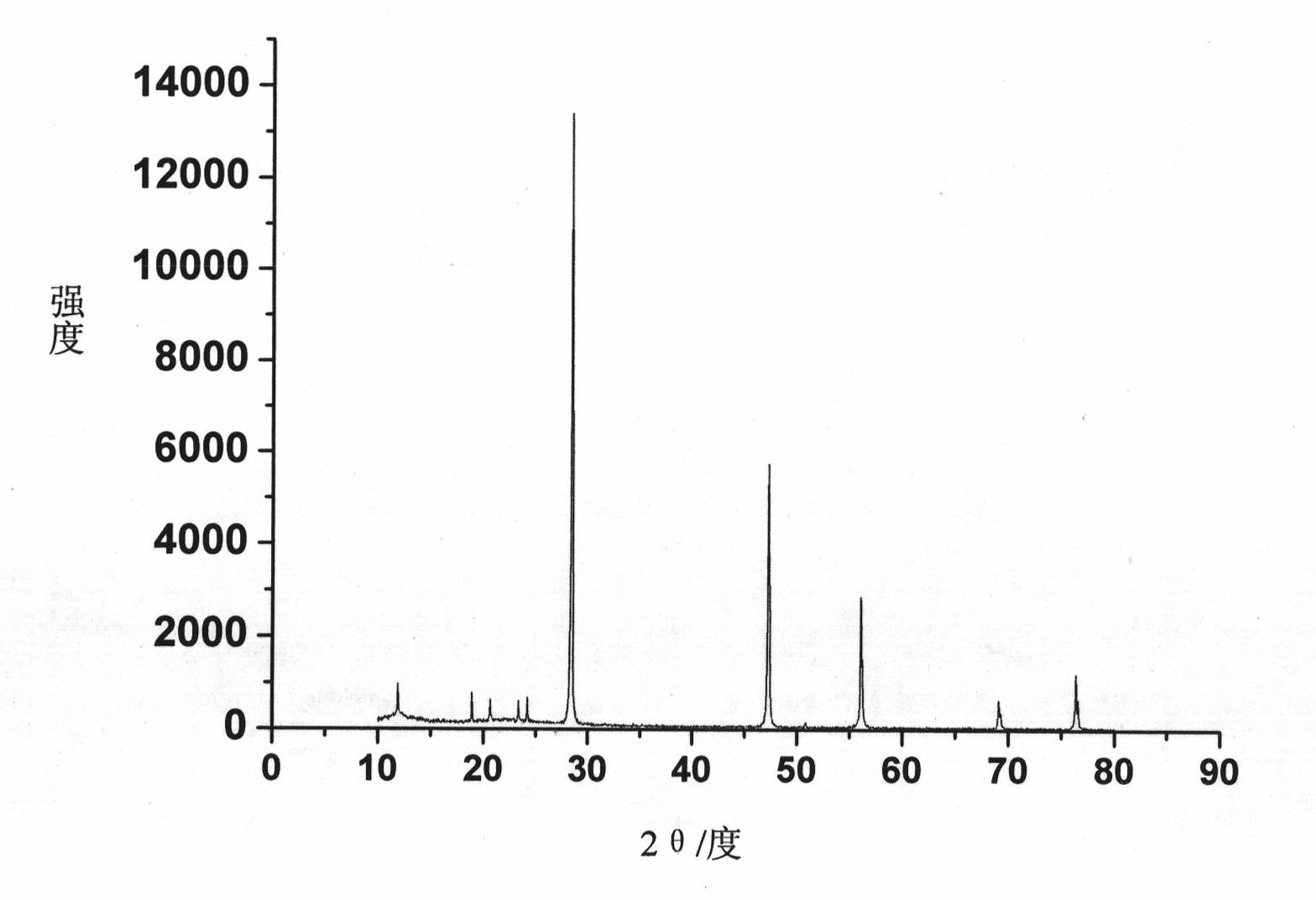

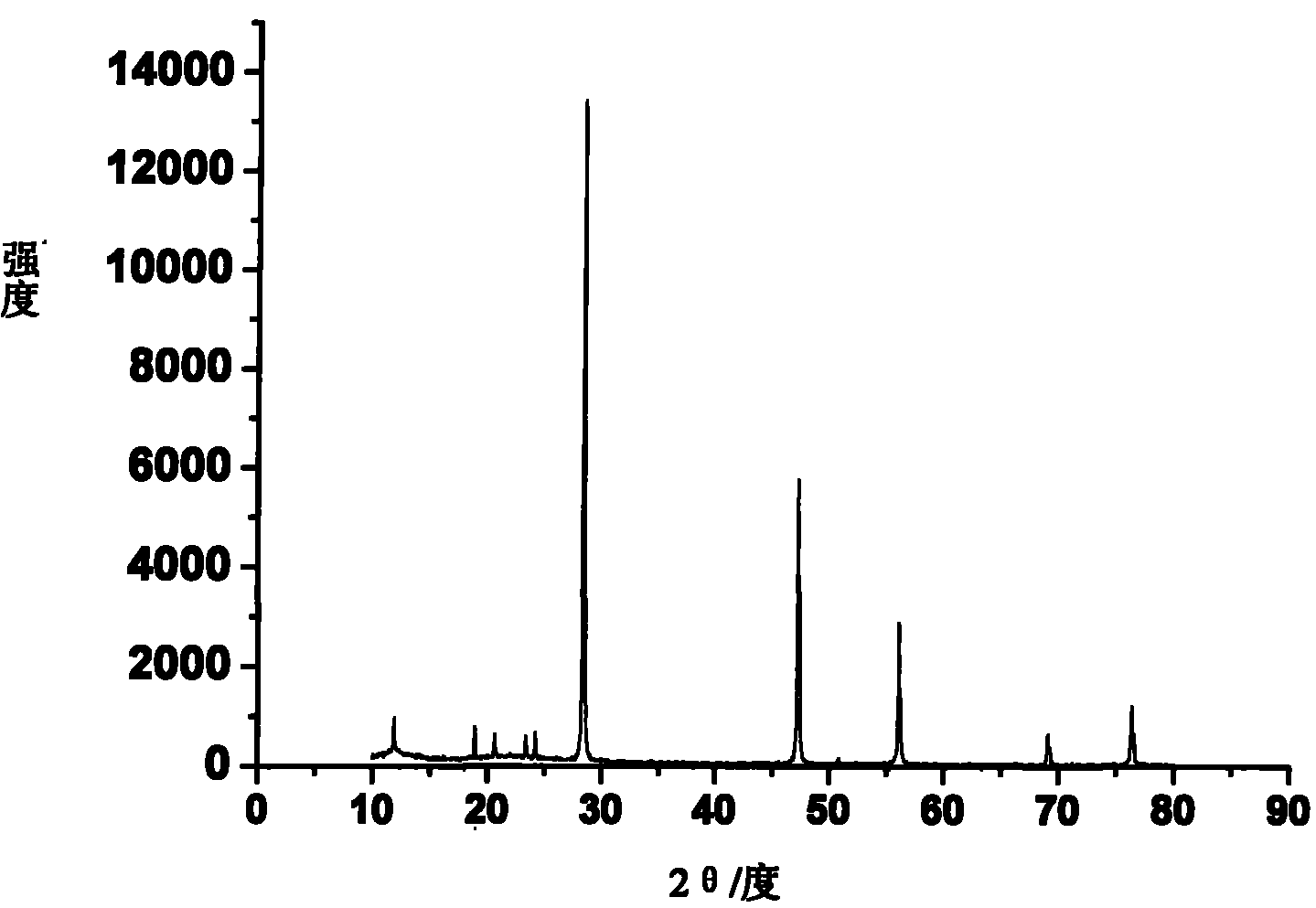

Silicon-carbon composite negative electrode material and preparation method thereof

ActiveCN102509781BHigh specific capacityImprove cycle performanceCell electrodesBatteries manufactureCarbon compositesPorous carbon

The invention provides a silicon-carbon composite anode material, which comprises a nuclear shell structure and a support substrate, wherein particle size of the silicon-carbon composite anode material is 1-200 micrometers, and porous carbon serving as the support substrate is obtained through decomposition of biomass materials. The invention further provides a preparing method of the silicon-carbon composite anode material, which includes the following steps: 1 reaming the biomass materials in physical activation or chemical activation mode to prepare the porous carbon, or preparing small molecular organics serving as a precursor of the porous carbon in hydrolyzing mode; 2 mixing silica particles and the obtained porous carbon or the precursor of the porous carbon in solution and performing ultrasonic treatment; 3 evaporating the solution mixture to dry so as to obtain solid-state powder; and 4 drying the solid-state powder, and performing thermal treatment, crushing and sieving on the solid-state powder to obtain the silicon-carbon composite anode material. The silicon-carbon composite anode material and the preparing method thereof are simple in process, short in flow path, easy to operate and low in cost, and lithium ion batteries manufactured by the silicon-carbon composite anode material are suitable for various mobile electronic equipment or devices driven by mobile energy.

Owner:SHANGHAI JIAOTONG UNIV

Method for preparing lithium ion battery carbon silicon anode material

The invention relates to a method for preparing a lithium ion battery carbon silicon anode material. The method includes that a sol formed by resorcinol and formaldehyde is used for mixing and coating nano silicon powders and superfine graphite powders to obtain a mixture, and the mixture is subjected to a carbonization. Compared with methods in prior art, by means of the method, the circularity of the carbon silicon anode material can be remarkably improved, and the specific capacitance of the carbon silicon anode material is improved.

Owner:TONGJI UNIV

Anode material of lithium-ion battery and method for preparing anode material

InactiveCN102544461AHigh specific capacityInhibition internal resistanceCell electrodesAdhesiveCrystalline silicon

The invention discloses an anode material of a lithium-ion battery and a method for preparing the anode material, belongs to the technical field of the lithium-ion batteries, and aims to solve the problems of poor volume effect caused in the electrochemical lithium de-insertion process of a high-capacity silicon anode material of the lithium-ion battery and low electric conductivity of the material. The anode material of the lithium-ion battery is high in coulombic efficiency and high in cycle performance. The anode material of the lithium-ion battery is formed by adding a carbon element and an adhesive into N-type or P-type doped crystalline silicon active powder which serves as a main material and then laminating a mixture. By adoption of the anode material of the lithium-ion battery, high capacity can be realized, and the electric contact performance of a microcrystal active lithium insertion center can be improved, so that the volume of a silicon micro crystal is slightly changed, the cycle stability is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

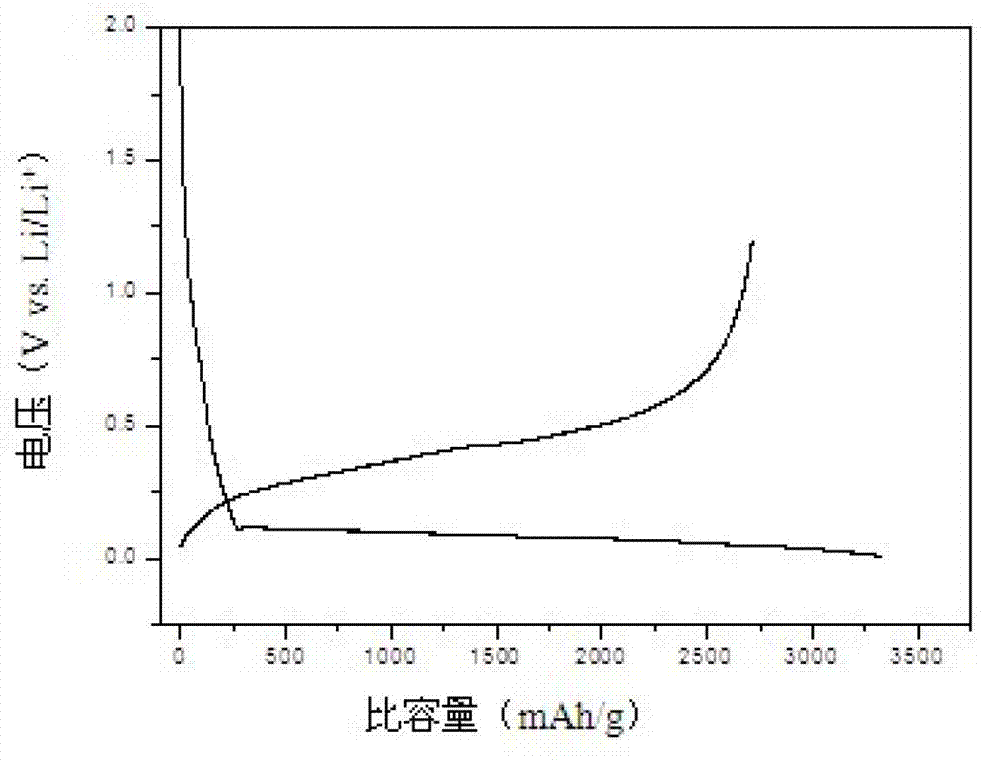

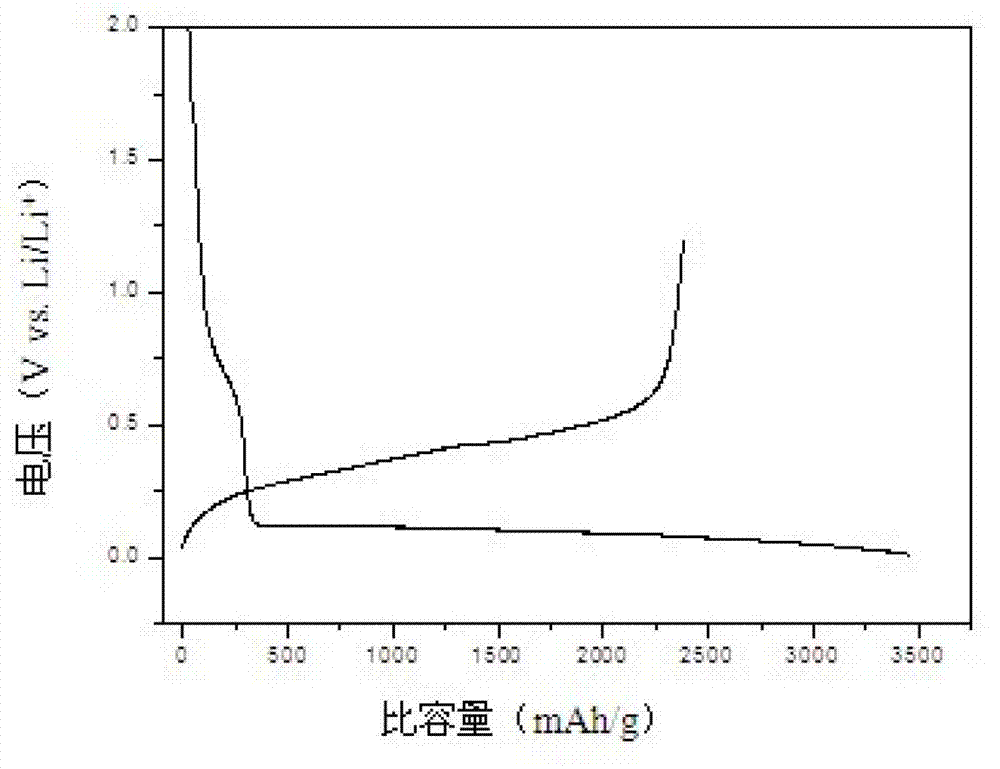

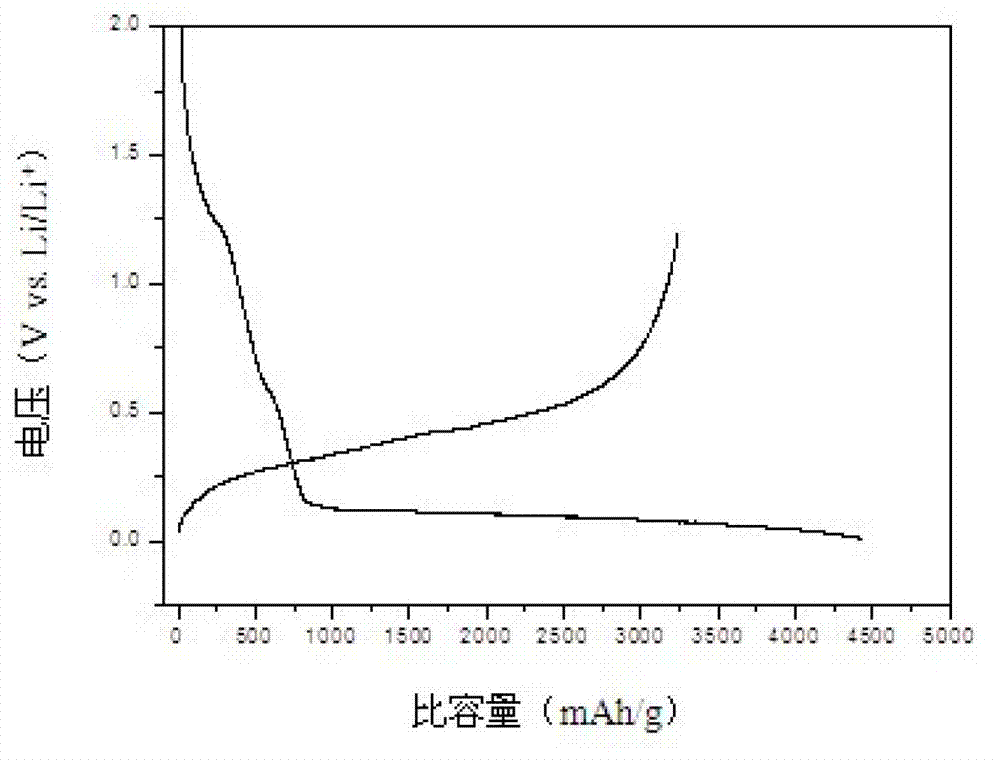

Water-based adhesive used in silicon anode of lithium ion battery and preparation method of silicon anode

ActiveCN103074007AImprove conductivityIncrease contactCell electrodesCyclodextrin adhesivesSolubilityWater based

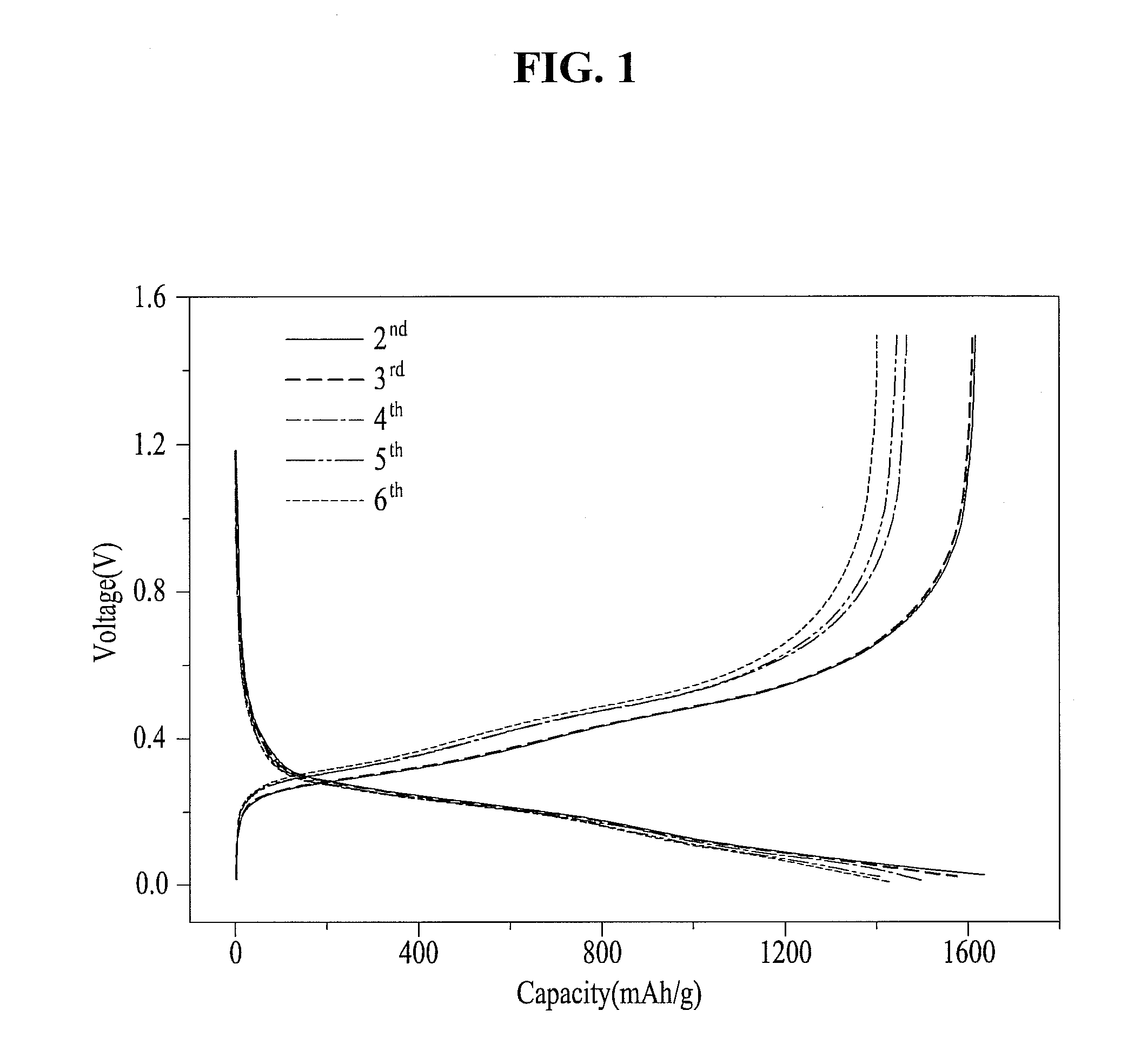

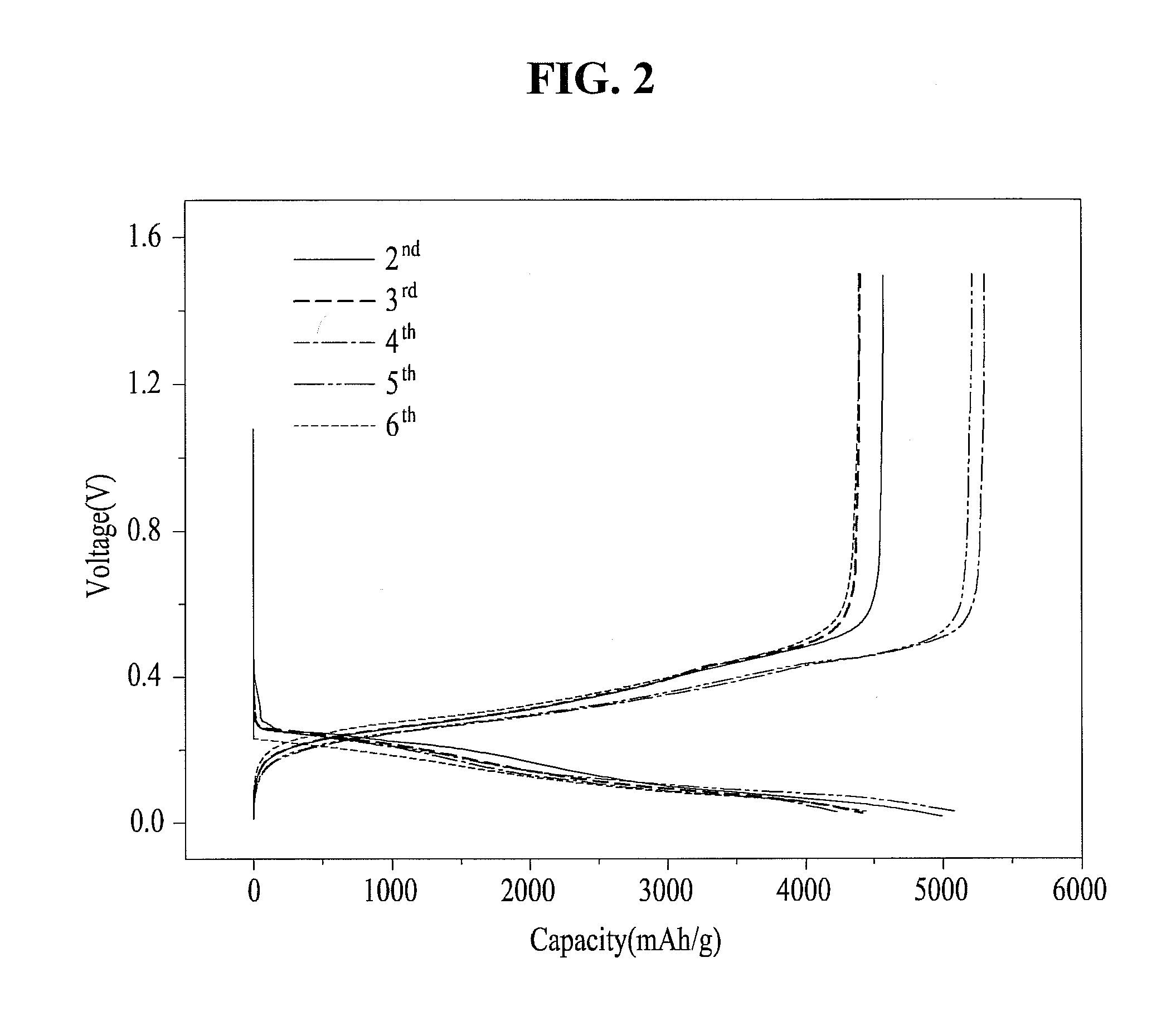

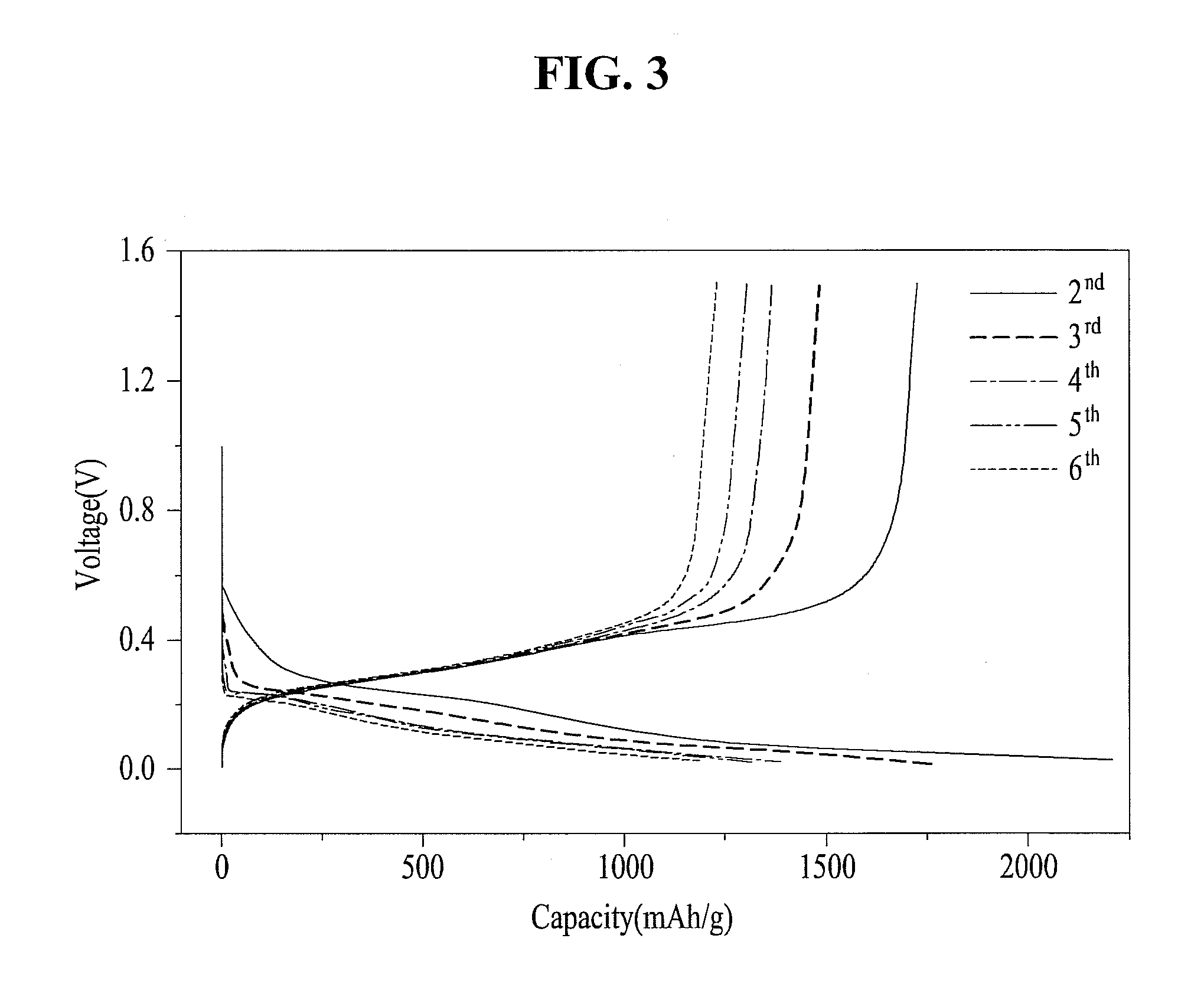

The invention discloses a water-based adhesive used in a silicon anode of a lithium ion battery and a preparation method of the silicon anode. The adhesive is one or more than one mixture of carbonylation Beta-cyclodextrin, poly 3 and 4-ethylene dioxy thiophene, polystyrene sulfonate and gum arabic. The invention further relates to the preparation method of the silicon anode. The preparation method comprises the following steps: firstly uniformly dispersing a silicon material, the adhesive and conductive carbon in water; and then coating the mixture on a copper collector to obtain a final product of the silicon anode of the lithium ion battery after drying. According to the adhesive, Beta-cyclodextrin is adopted, so that the solubility of the adhesive in water can be improved after the carbonylation treatment of the Beta-cyclodextrin; at the room temperature and under the condition of 0.05 C, the silicon anode starts to charge and discharge, the first time discharge specific capacity can reach up to 4440.2 mAh / g, the charging specific capacity can reach up to 3238.7 mAh / g, the charge and discharge efficiency is 72.9 percent, the charge and discharge specific capacity in one hour is 1770 mAh / g, and the cycle performance is very stable. The water-based adhesive and the silicon anode provided by the invention have the advantages of low costs, environmental friendliness, obvious effects, good conductivity, good recycling and good application prospects.

Owner:SHANGHAI JIAO TONG UNIV

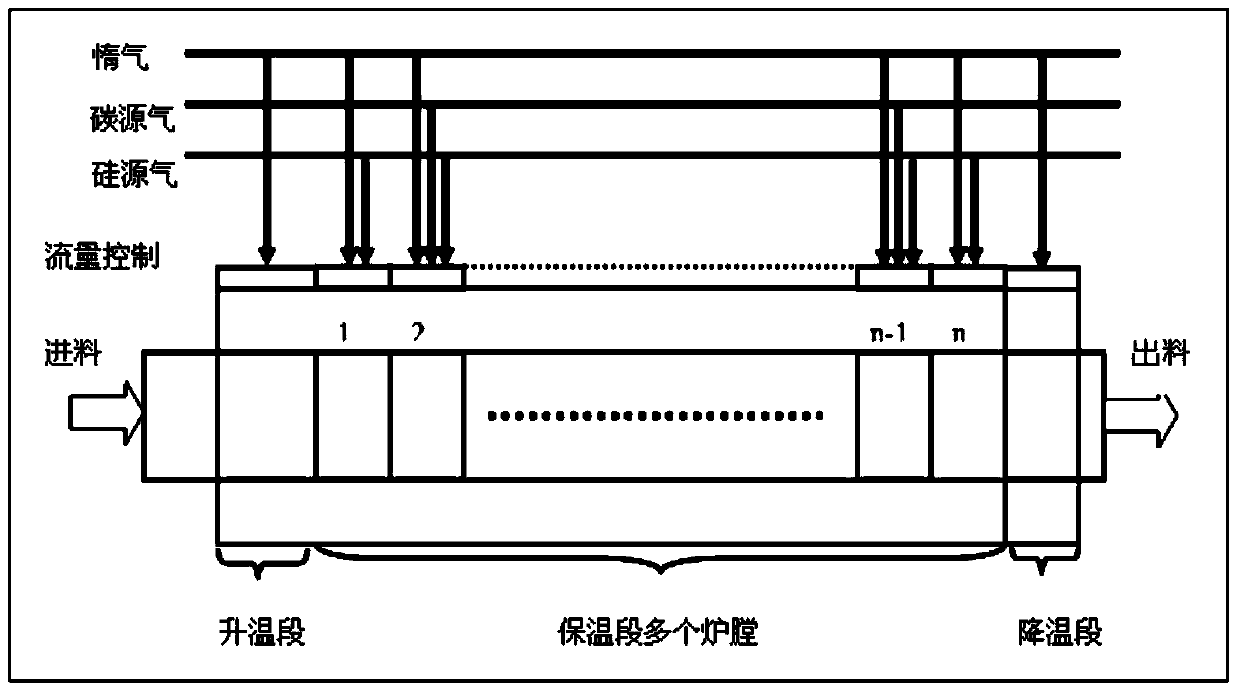

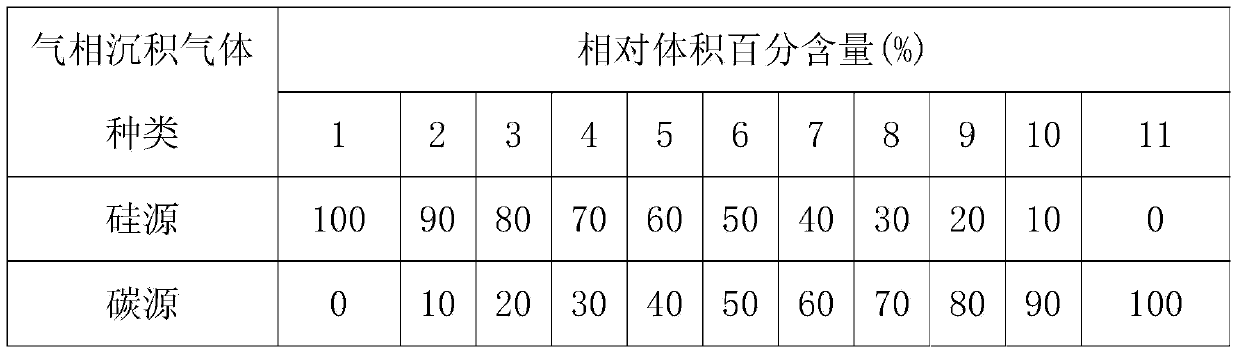

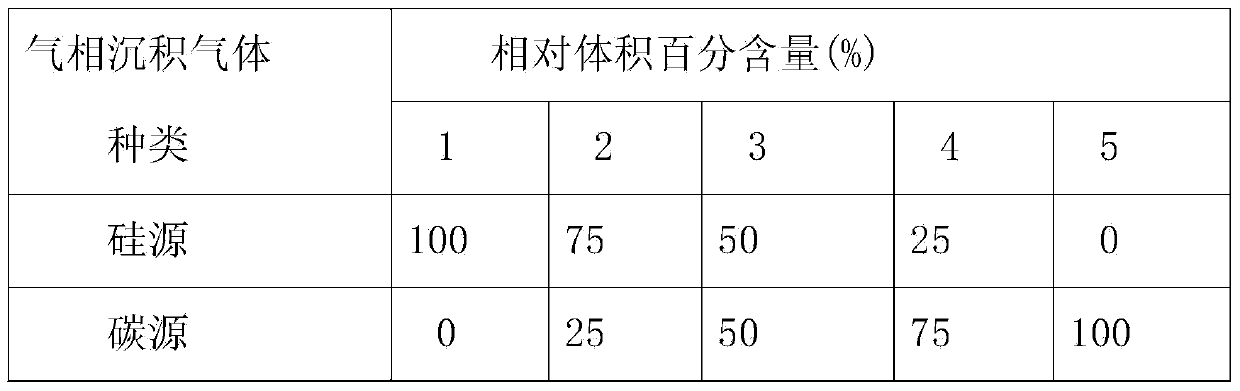

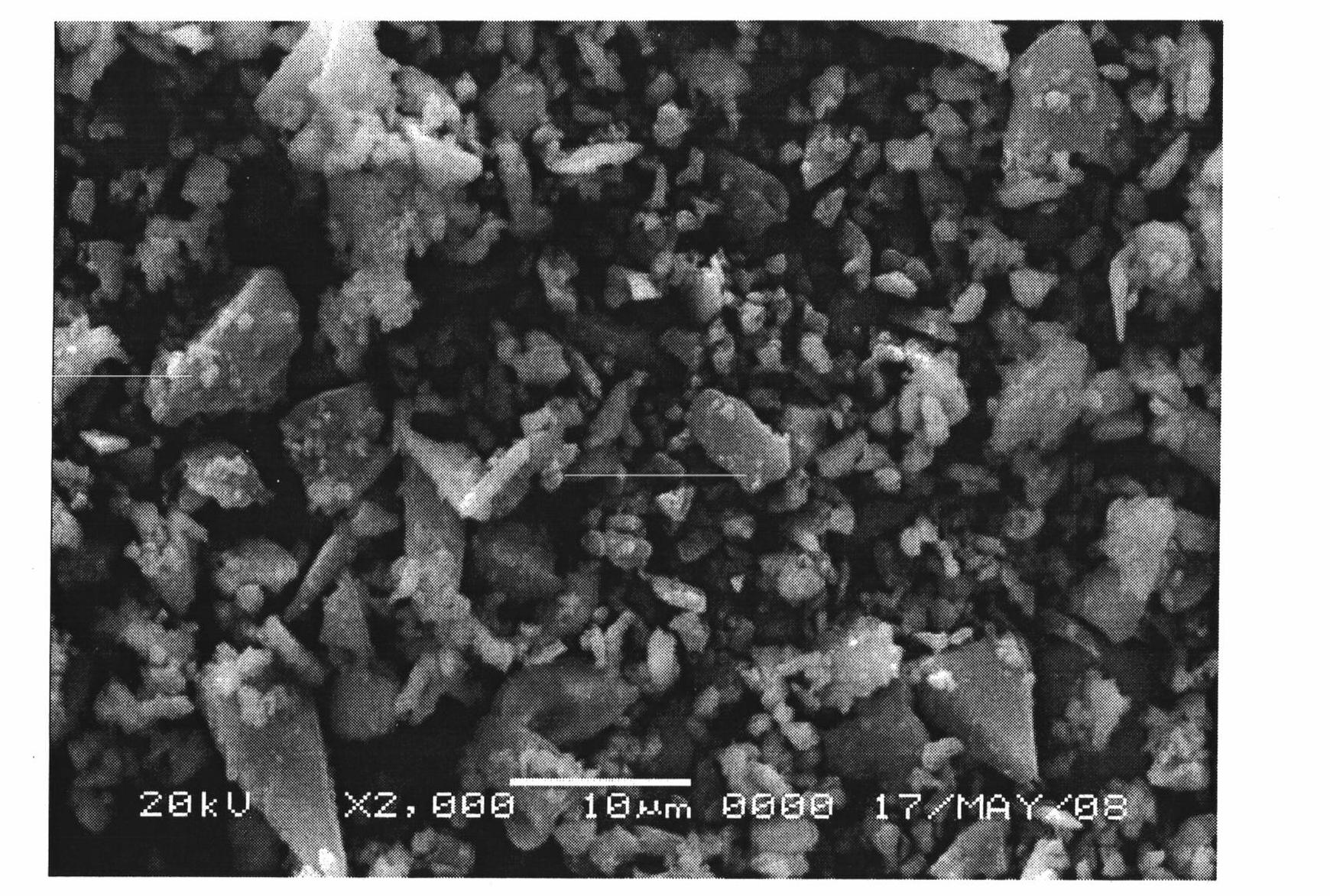

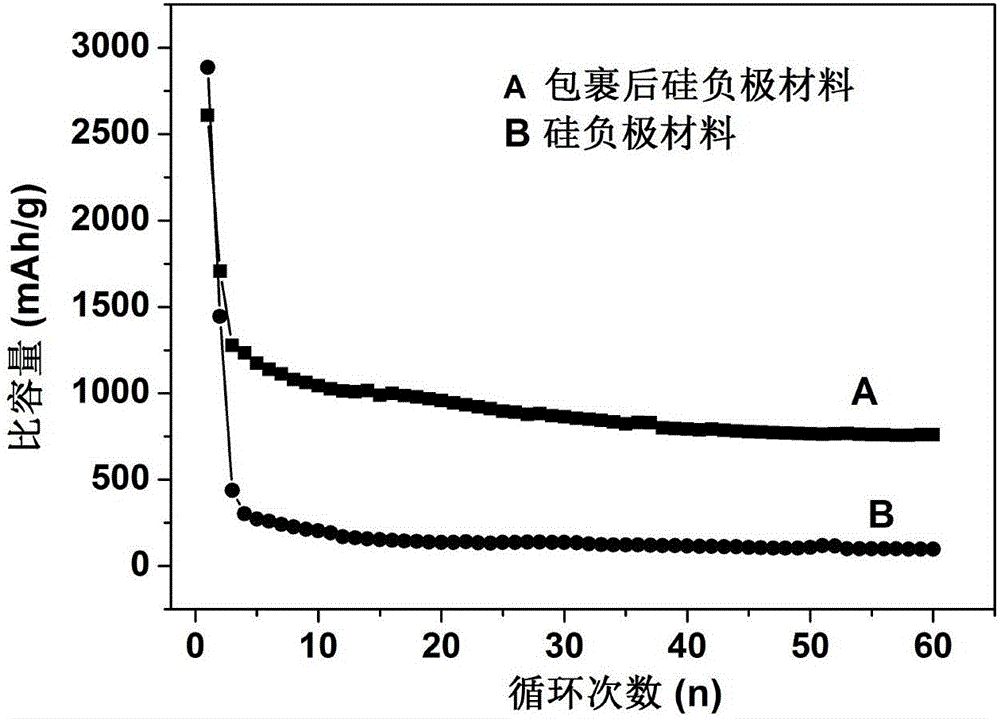

Preparation method of silicon composite anode material provided with gradient change coating layer on surface

ActiveCN103700819AControl heat treatment timeImprove cycle stabilityCell electrodesGas phaseChemical vapor deposition

The invention discloses a preparation method of a silicon composite anode material provided with a gradient change coating layer on the surface, and aims to overcome conventional modification defects of a silicon anode material. According to the preparation method, a porous silicon material is prepared firstly, and on the basis, a chemical vapor deposition method is adopted to uniformly deposit a coating layer on the surface of the porous silicon material, wherein the coating layer adopts an elemental Si-SiC-C transition structure. A test is performed in a vapor deposition reacting furnace provide with segmented temperatures, independently controllable atmosphere and a plurality of furnace chambers. Compared with the prior art, a gradient change process is achieved through the surface coating layer, an obvious interface structure is not formed, the coating layer is tight, so that a volume effect and electric conductivity of the silicon-based anode material in a battery charge-discharge process are inhibited effectively, and the cycling stability of the material is improved greatly. The preparation method is simple in technology and suitable for large-scale industrial production, and has wide application prospect in the field of lithium ion batteries.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Silicon anode material and preparation method thereof and lithium battery using silicon anode material

ActiveCN101777651AImprovement of chalking and shedding problemHigh specific capacityElectrode manufacturing processesFinal product manufacturePre treatmentSilicon dioxide

The invention provides an anode material of a lithium battery, which comprises an active substance and a volume buffering agent. The active substance is coated or partly coated on the surfaces of the particles of the volume buffering agent. The active substance is silicon. The volume buffering agent is silicon dioxide. The invention also provides a preparation method for the anode material, wherein silicon dioxide of powder and powder of a carbon reducing agent which are subjected to pretreatment are subjected to vacuum high temperature sintering; and based on the total weight of the silicon dioxide and the carbon reducing agent, the weight of the carbon reducing agent occupies 16.67 to 35.8 percent of the total weight. The anode material provided by the invention has good cycle performance and high capacity.

Owner:BYD CO LTD

Surface-modified silicon anode active material, method of preparing the same, and anode and lithium battery employing the same

InactiveUS20120121977A1Alkaline accumulatorsNon-aqueous electrolyte accumulator electrodesCycle efficiencySilicon particle

An anode active material comprising silicon particles with an interfacial layer formed on the surface of the silicon is provided. The interfacial layer has good electron conductivity, elasticity and adhesion among anode materials, thereby enhancing anode capacity and reducing stress caused by expansion of silicon particles during charge and discharge cycles. Direct contact between silicon particles and electrolyte is remarkably reduced as well. In addition, anodes and lithium batteries including the anode active material exhibit excellent capacity and cycle efficiency.

Owner:ELECTROCHEM MATERIALS

Silicon anode active material and preparation method therefor

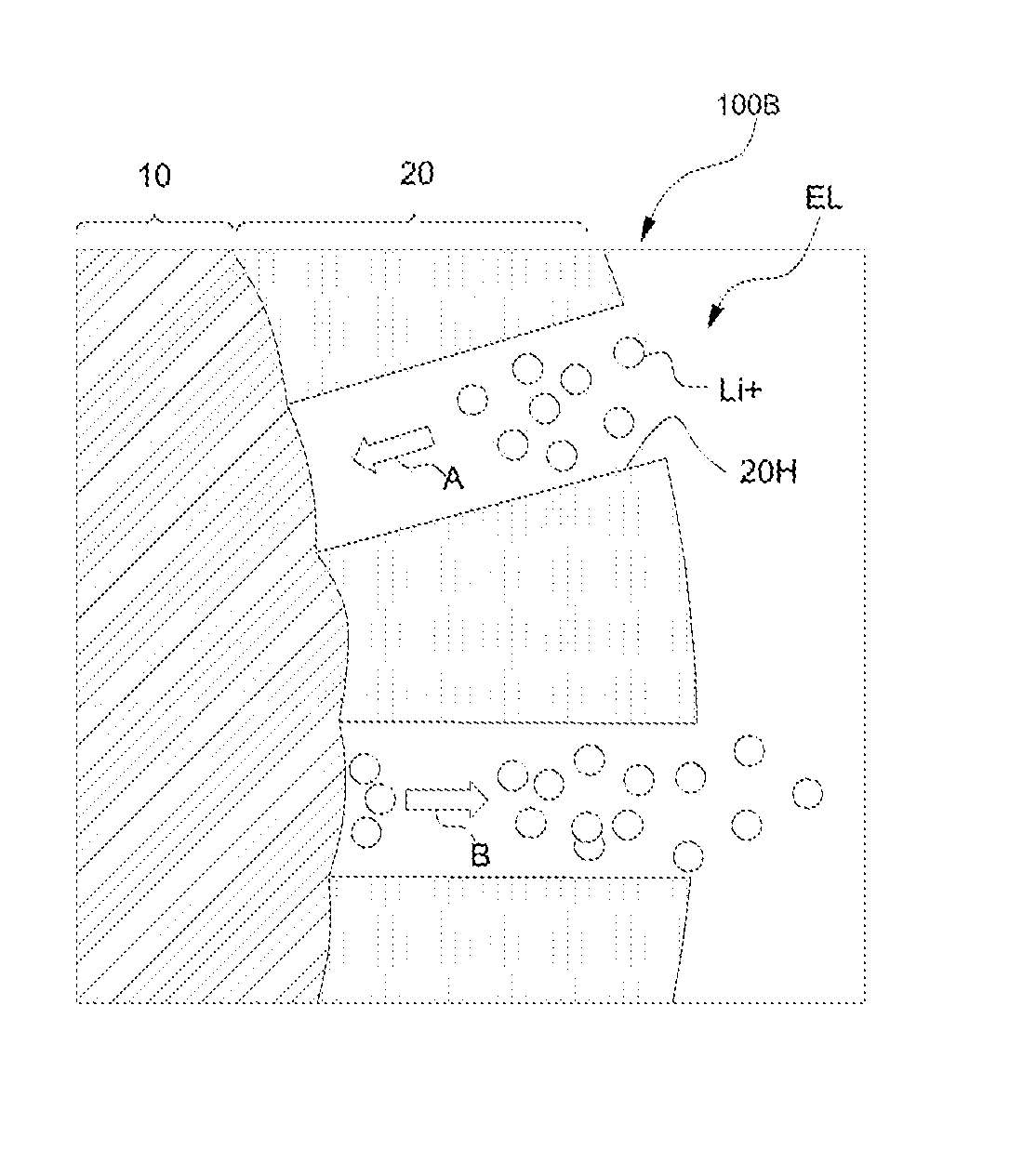

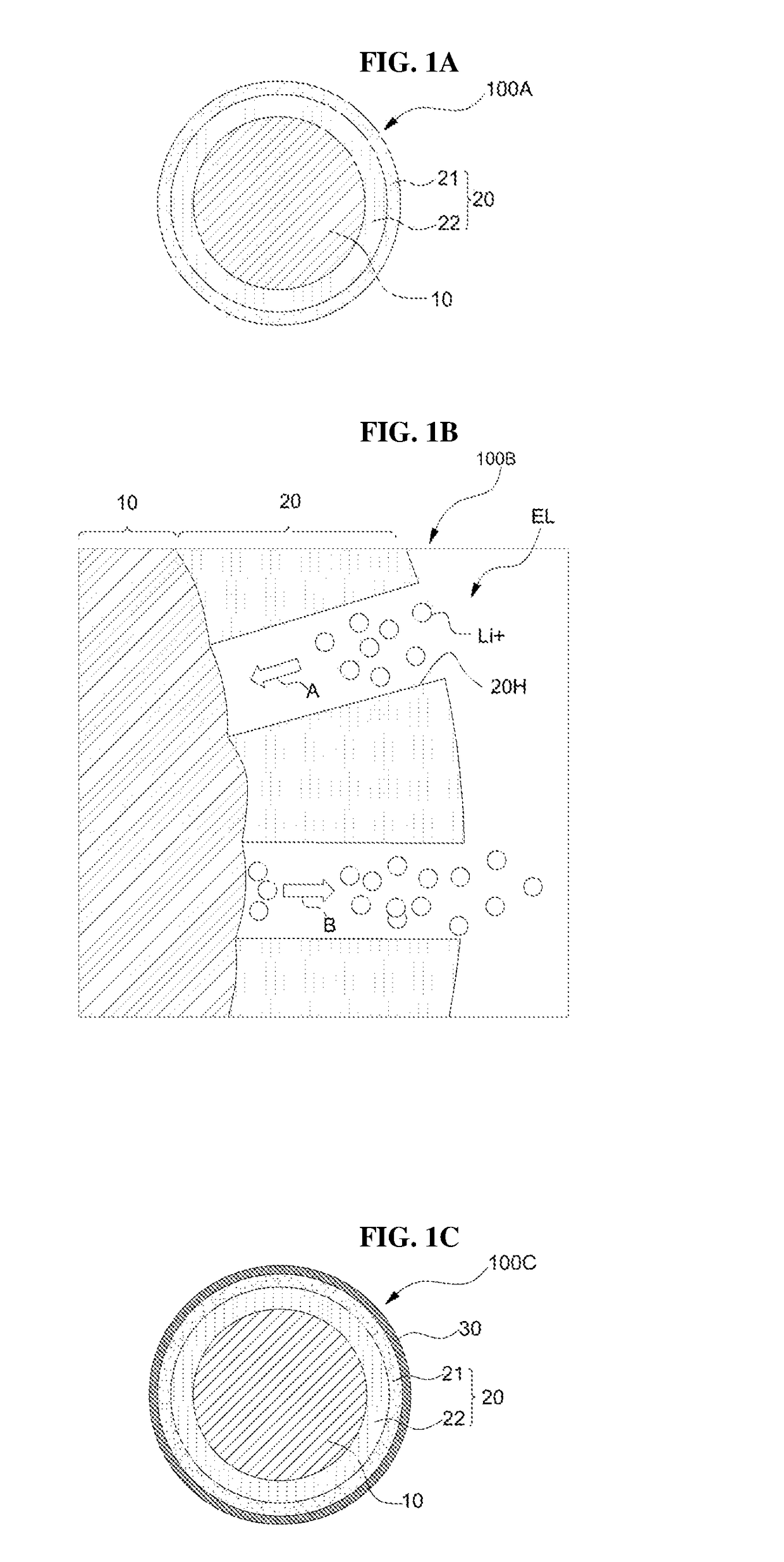

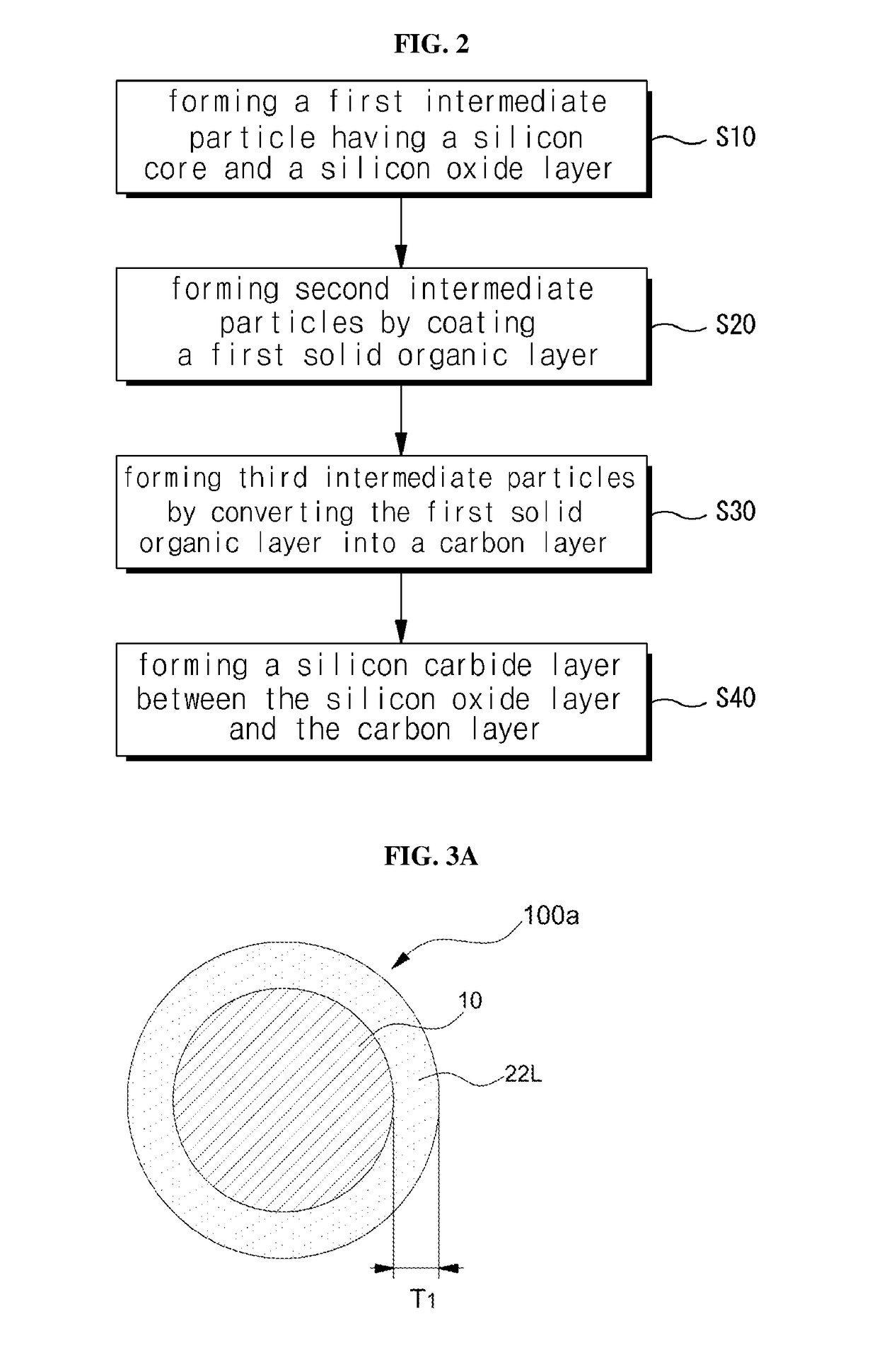

ActiveUS20180034056A1Large capacityExtend your lifeElectrode thermal treatmentNegative electrodesSilicon oxideSilicon particle

The present invention relates to a silicon anode active material capable of high capacity and high output, and a method for fabricating the same. A silicon anode active material according to an embodiment of the present invention includes a silicon core including silicon particles; and a double clamping layer having a silicon carbide layer on the silicon core and a silicon oxide layer between the silicon core and the silicon carbide layer.

Owner:NEXEON LTD

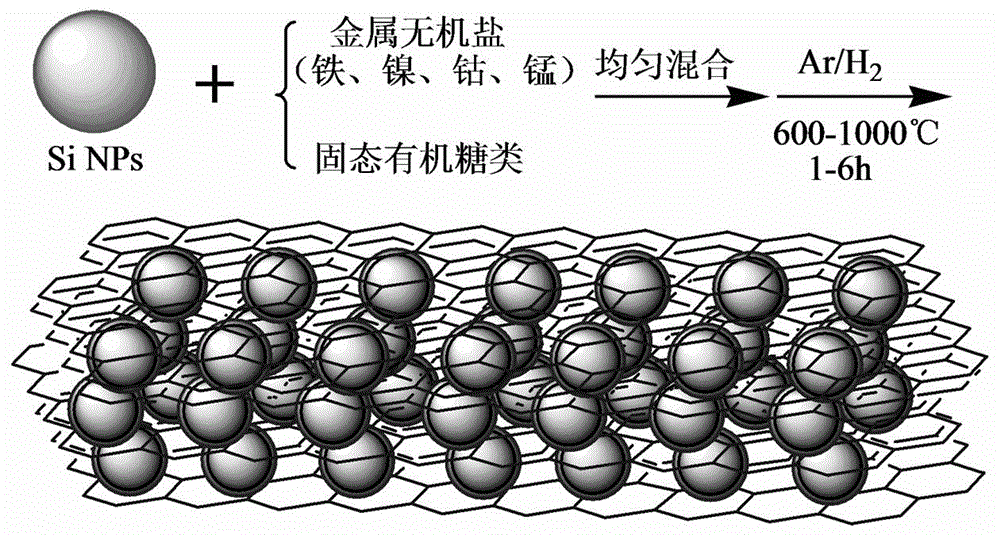

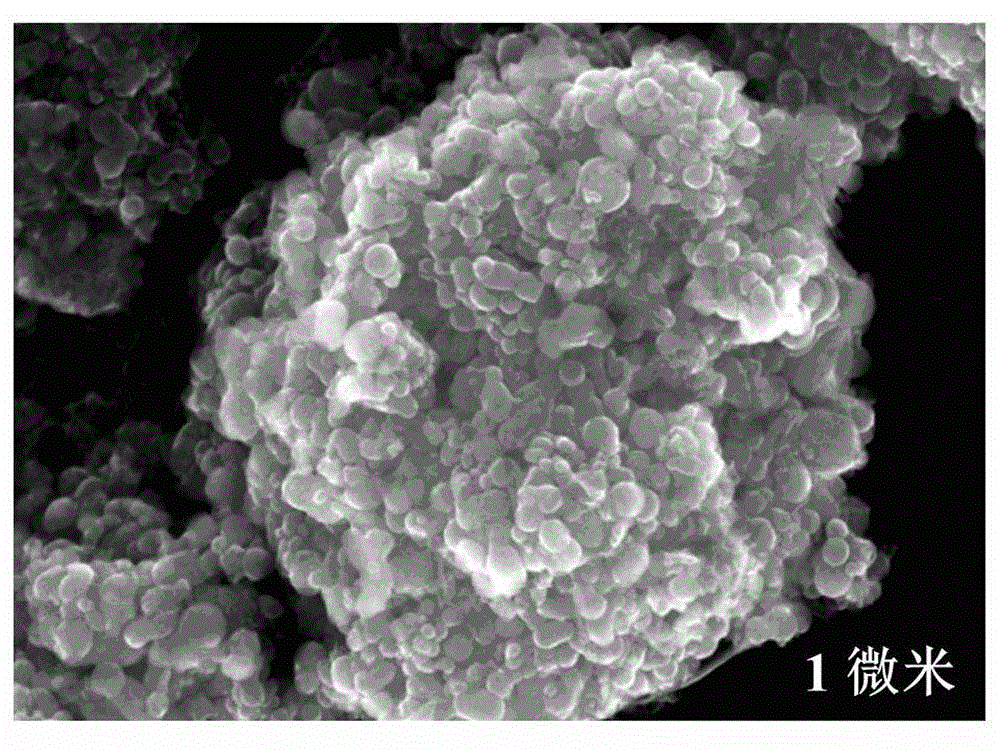

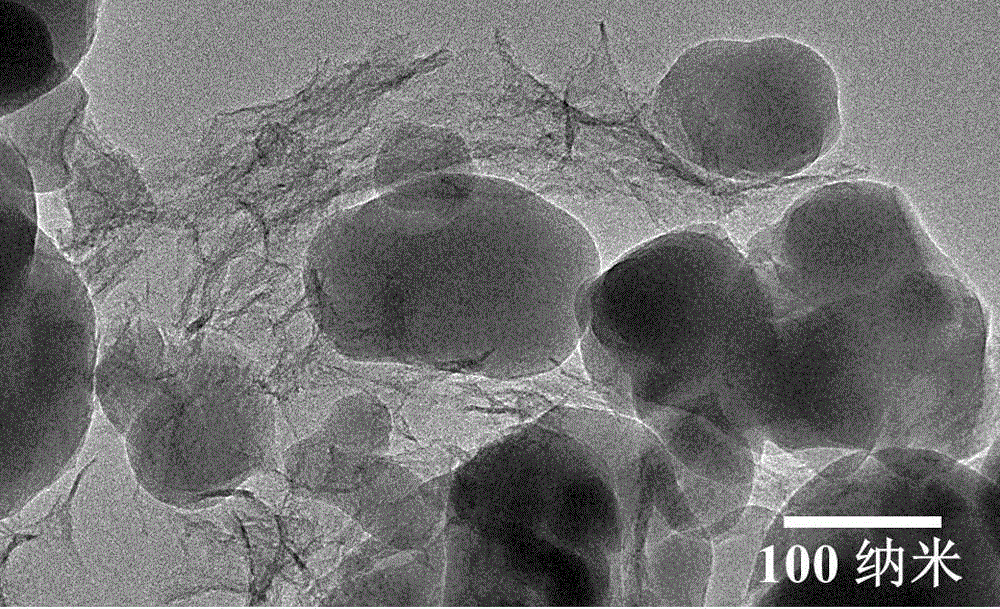

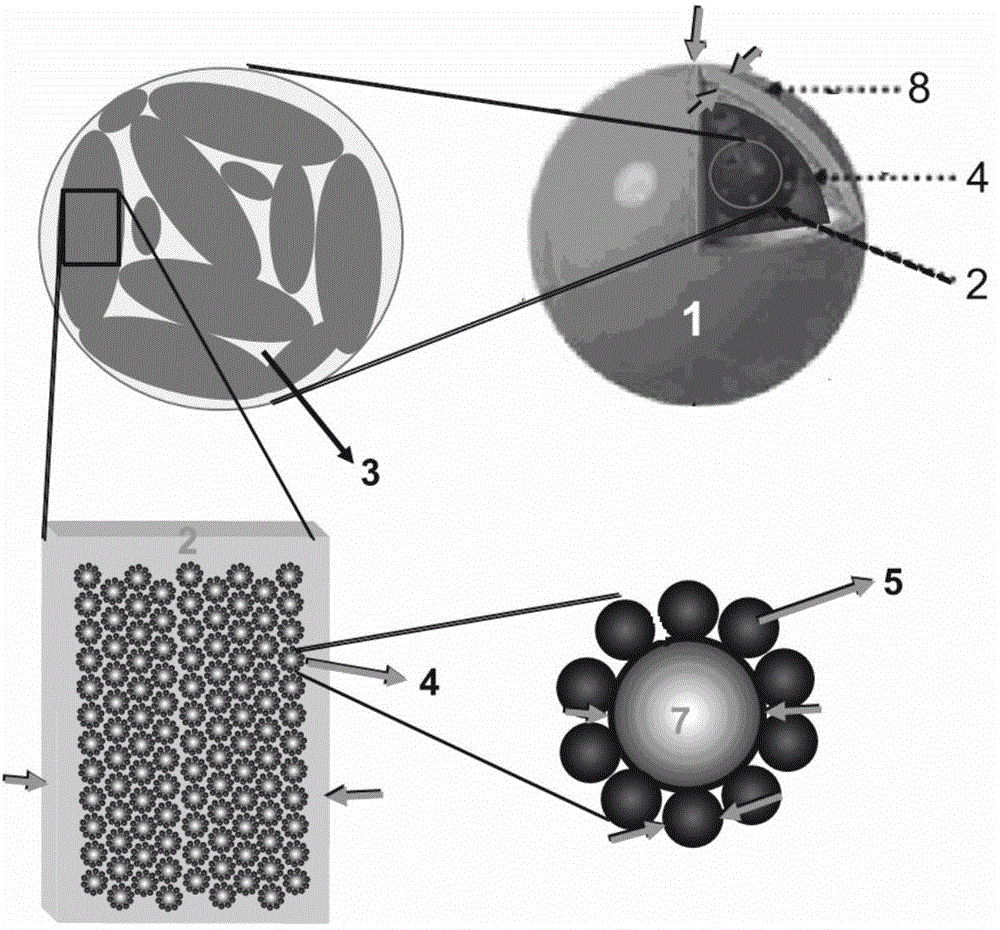

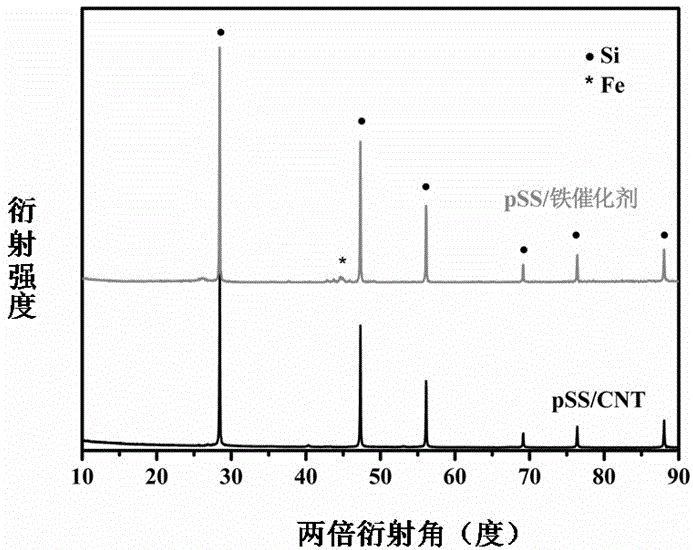

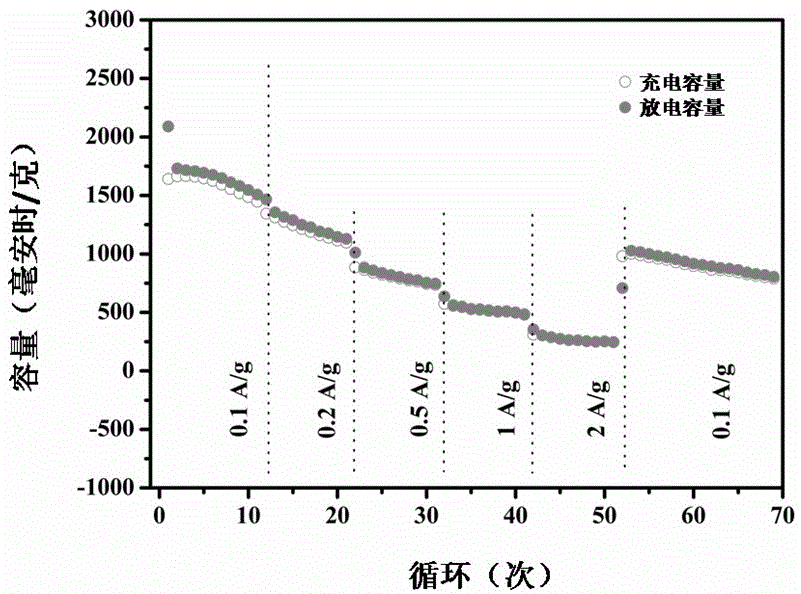

In-situ solid-phase synthesis method of silicon-graphene spheroidal composite material with multilevel structure and application thereof

InactiveCN104934573AAvoid volume effectImprove electronic conductivityCell electrodesFinal product manufacturePtru catalystElectronic conductivity

The invention brings forward a novel low-cost in-situ solid-phase preparation method. By the method, a silicon-graphene spheroidal composite material with a multilevel structure can be synthesized by one step. The composite material can be used as a high specific energy anode material to be applied in a lithium ion battery. Low-cost organic carbohydrate and inorganic transition metal salt which are respectively used as a carbon source and a metal catalyst precursor are selected to be uniformly mixed with a silicon nano-material; by a tube furnace heating method, in-situ catalytic growth of a graphene coated network happens on the surface of silicon nano-particles; and through the bridging effect of the graphene network, spheroidal micro-scale particles with a nanometer fine structure is self-assembled. The silicon-graphene spheroidal composite anode material with the multilevel structure has an advantage of high specific capacity. In addition, two main bottleneck problems such as poor electronic conductivity of a silicon anode material and severe volume effect during the cyclic process can be overcome simultaneously, and multiplying power and cycle performance of silicon anode can be raised greatly.

Owner:SUZHOU GREEN POWER TECH CO LTD

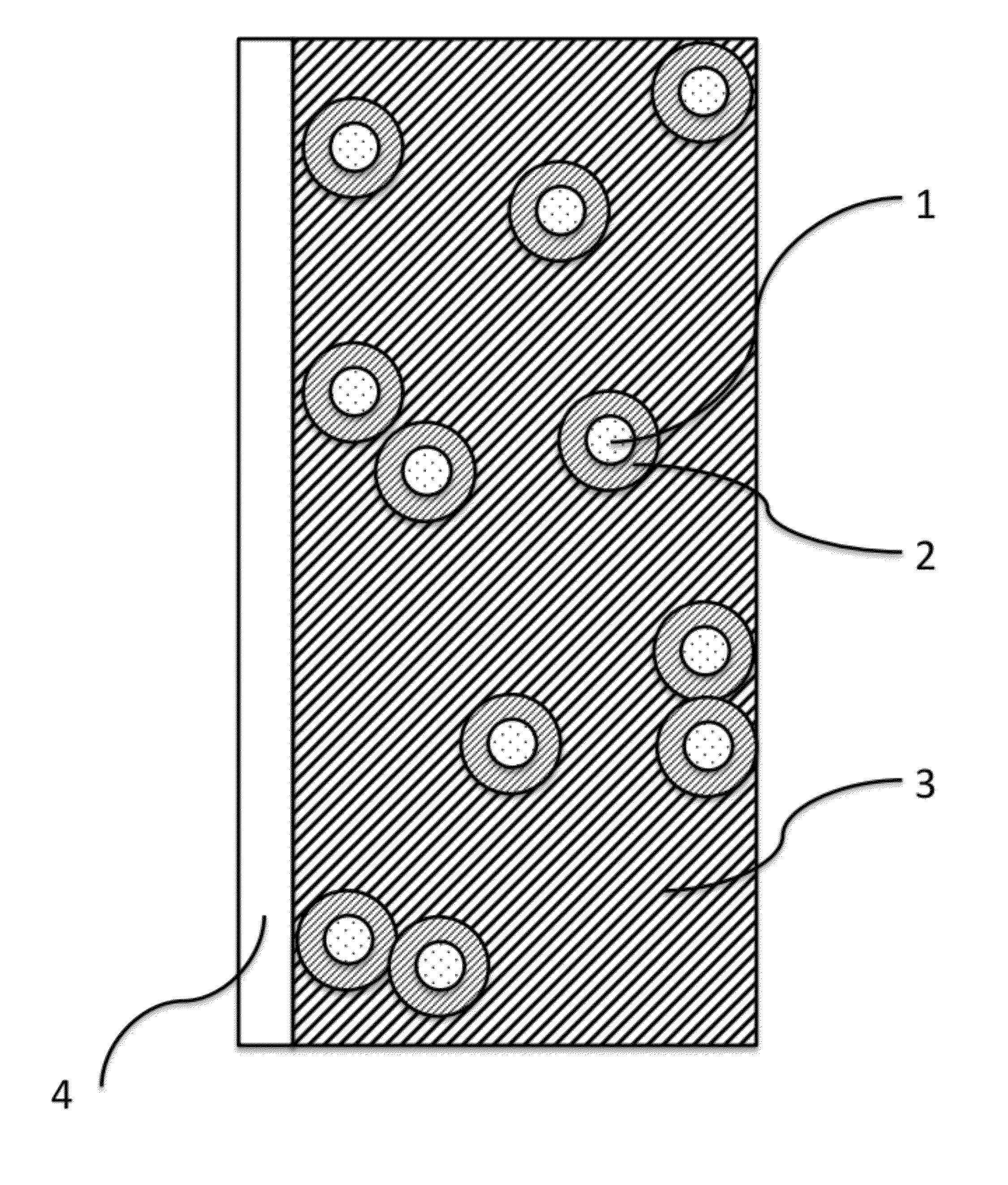

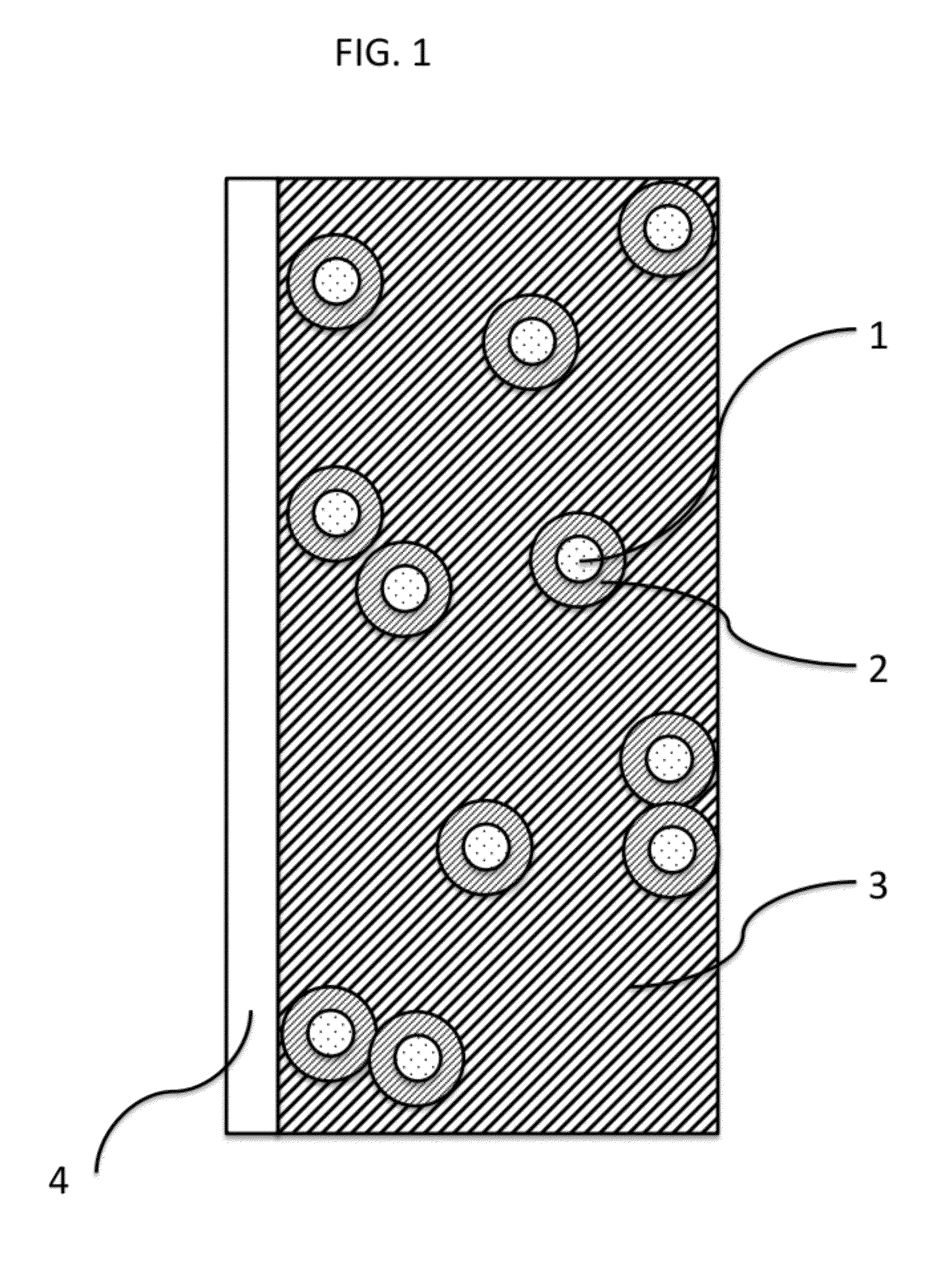

Silicon-based composite anode material for lithium ion battery and preparation method thereof

ActiveCN105762329AAdjustable capacityStable structureElectrode manufacturing processesInsulation ProblemSodium-ion battery

The invention discloses a silicon-based composite anode material for a lithium ion battery and a preparation method thereof. The anode material comprises a graphite skeleton and an amorphous carbon layer which coats the graphite skeleton. The graphite skeleton is filled with a silicon material coated with a carbon-containing structure. The silicon material and the graphite skeleton are combined through a loose carbon material. The preparation method at least comprises the following steps: (1) preparing the silicon material coated with the carbon-containing structure; (2) preparing spherical particles with graphite as the main body; (3) coating the spherical particles with the amorphous carbon layer; and (4) granulating. According to the invention, the electric insulation problem of silicon anode due to its volume change can be solved, and it can be guaranteed that silicon active component can always be electrically contacted with a current collector during the charge-discharge cycle process. Meanwhile, huge stress effect caused by volume expansion / shrinkage of the active material silicon is further buffered. Then, the composite material has characteristics of high electrochemical cycle stability and regulable specific capacity.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

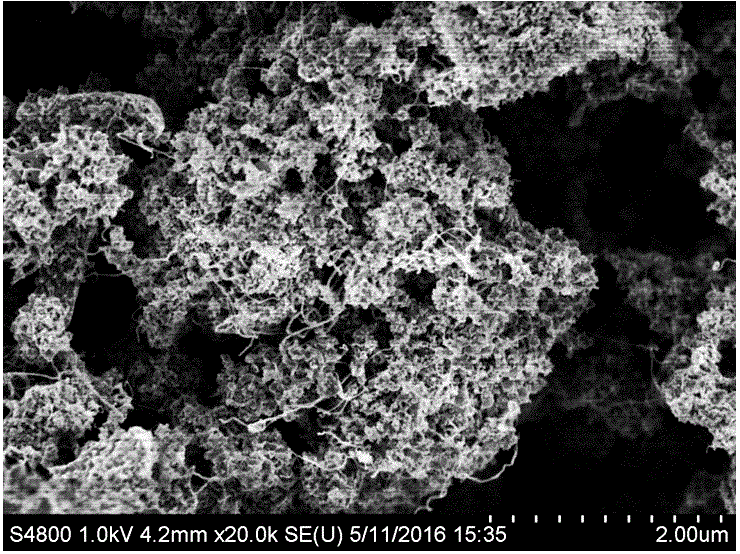

Preparation method of carbon nanotube composite porous silicon anode material for lithium ion battery

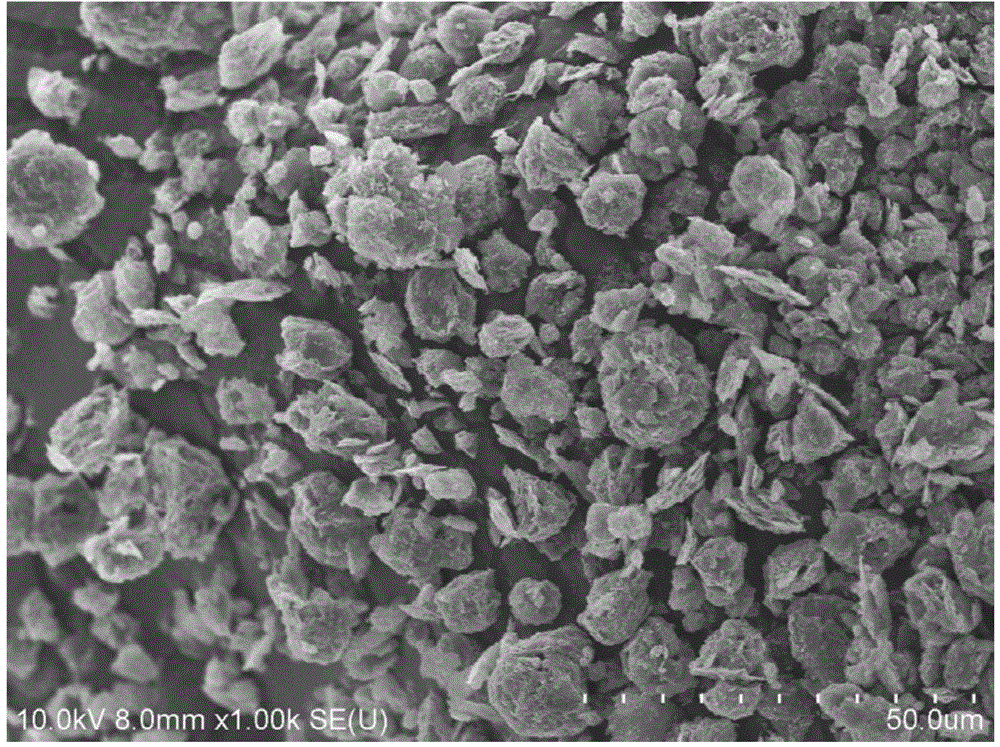

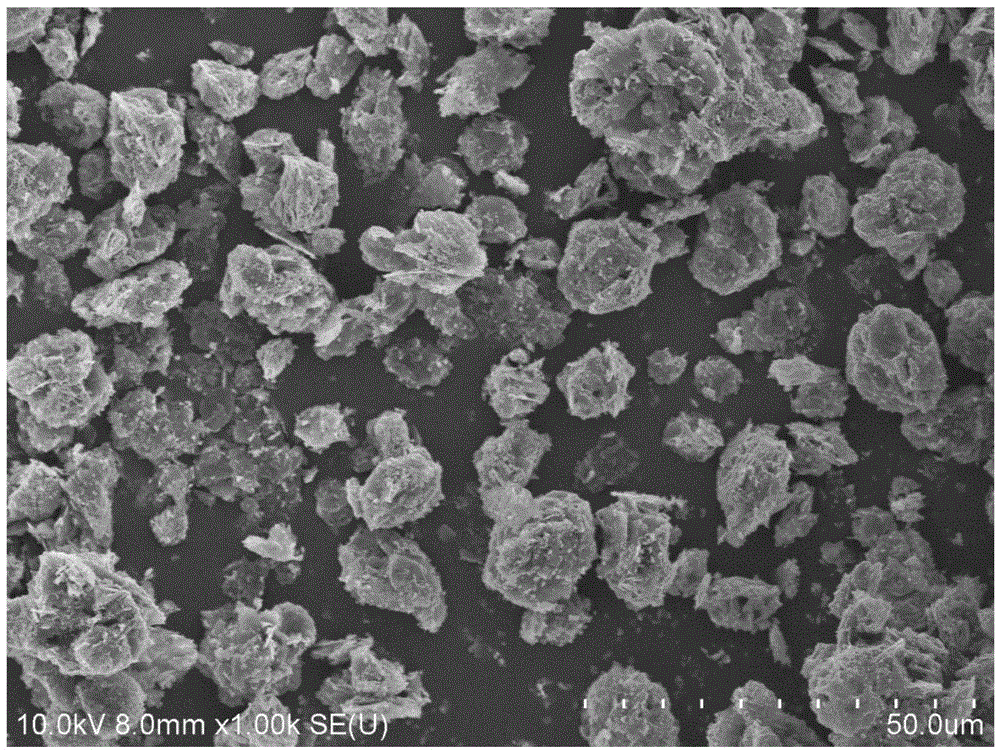

InactiveCN106058256AAlleviate volume changesLow costCell electrodesSecondary cellsCarbon layerCarbon nanotube

The invention belongs to the technical field of preparation of lithium ion batteries, and particularly relates to a preparation method of a carbon nanotube composite porous silicon anode material for a lithium ion battery. The preparation method mainly comprises the following steps: preparing porous silicon by thermal reduction; coating the porous silicon with carbon by chemical vapor deposition and compounding carbon nanotubes; removing an iron catalyst by acid treatment. The preparation technology is low in energy consumption and cost, reversible capacity of the silicon anode material is increased effectively, the rate capability is improved, and the cycle life is prolonged. Primary particle sizes of the prepared porous silicon are 50-500 nm, a uniform carbon layer with the thickness range of 2-50 nm is deposited on the surface of the porous silicon, and the carbon nanotubes are distributed inside and outside particles, so that overall electronic conductivity of the porous silicon is improved.

Owner:FUDAN UNIV

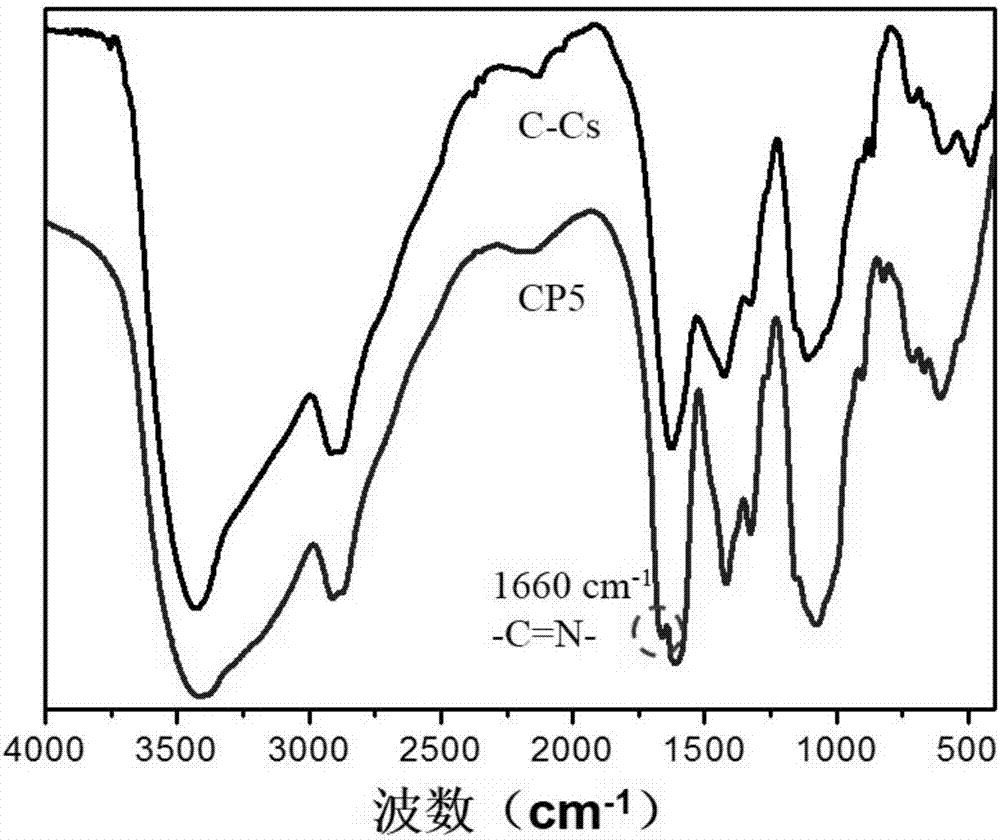

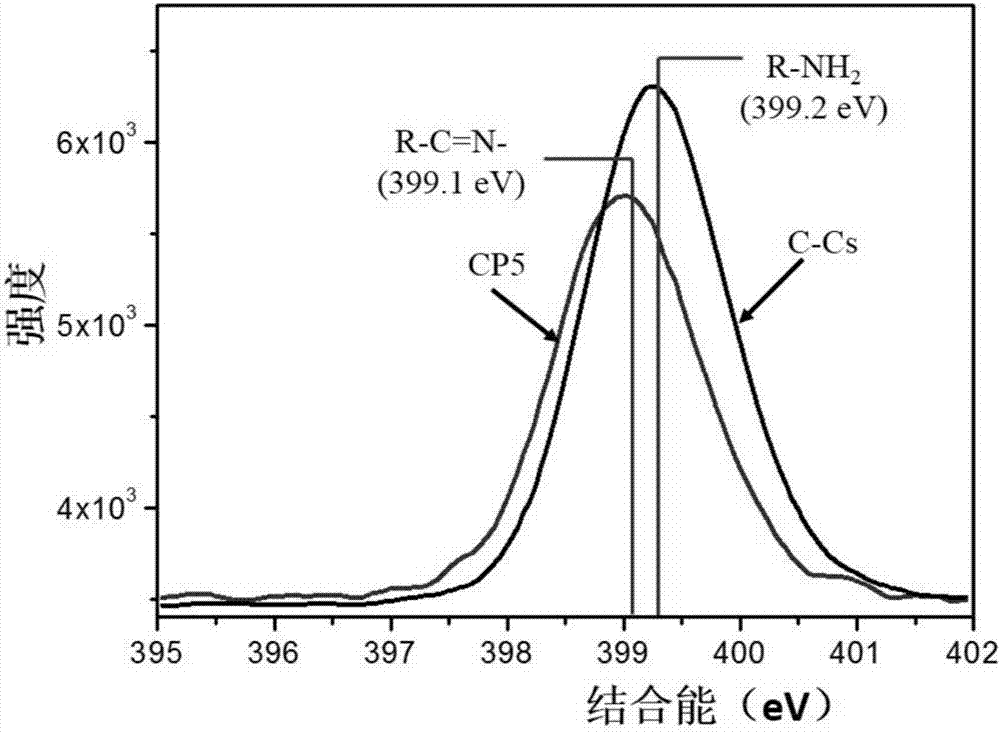

Polymer crosslinked binder, preparation method and application thereof

ActiveCN107482221AImprove mechanical propertiesBoth ionic conductivityCell electrodesSecondary cellsSolubilityPolymer science

The invention discloses a polymer crosslinked binder, a preparation method and application thereof. The polymer crosslinked binder is prepared by adopting double end group substituted polyethylene glycol as the crosslinking agent for crosslinking reaction with a water-soluble linear polymer binder. The invention verifies the feasibility of preparation of a three-dimensional polymer binder through crosslinking reaction. The polymer modified binder takes natural biologically modified macromolecule as the raw material, the sources are wide, the cost is low, and also the water solubility is good. The polymer reaction is carried out through Schiff base reaction, high temperature or a catalyst is unnecessary, and the implementation process is simple and feasible. Testing representation of the performance of a silicon anode prepared from the binder finds that crosslinking modification of the binder not only improves the binding performance of the binder, but also improves the ionic conductivity of the electrode, improves the electrochemical properties of the battery material, and enhances the battery comprehensive performance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Lithium ion battery

ActiveCN102315422AEasy accessAvoid the problem of full releaseSecondary cellsNon-aqueous electrolyte accumulator electrodesAlloyMaterials science

The invention aims at providing a lithium ion by a compensation lithium cathode to compensate the loss of battery cathode capacity by an alloy anode. The characteristic of a silicon anode causes the low efficiency for compensating lithium to the lithium ion battery in a system for the first time which has large loss to the cathode capacity. The advantage of high energy density of the silicon anode battery can be highlighted by using the lithium ion provided by the compensation lithium cathode to compensate the loss of battery cathode capacity. Through the method of compensating lithium, lithium can be respectively compensated for twice to a cathode pole and an anode pole, thereby the method is capable of raising the capacity and performance of the battery.

Owner:DONGGUAN AMPEREX TECH

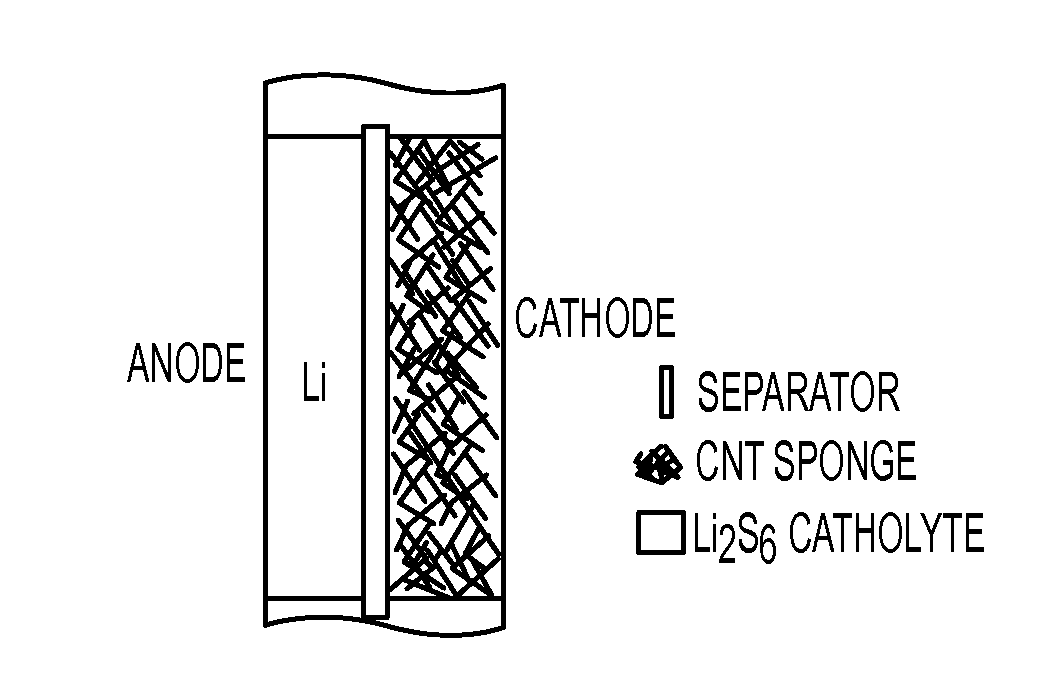

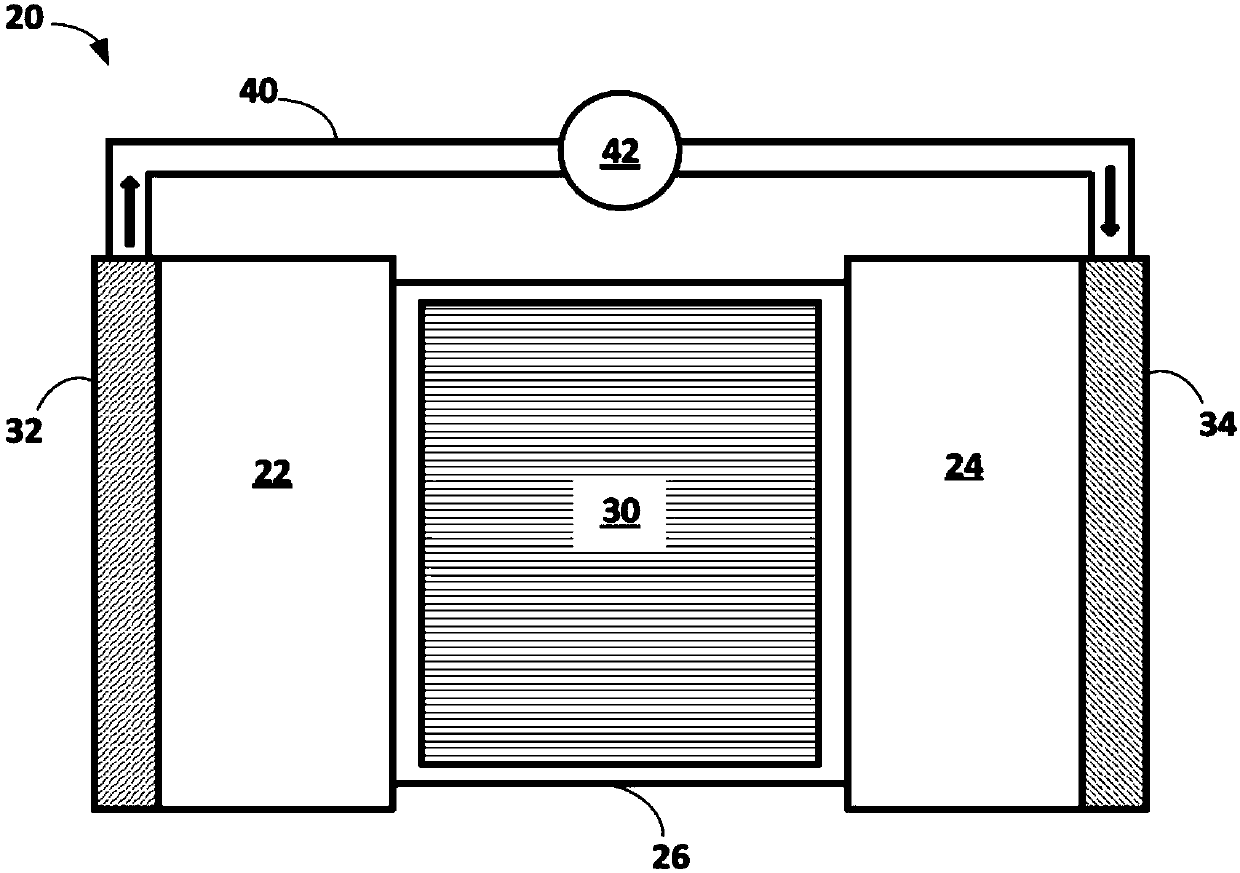

Large energy density batteries

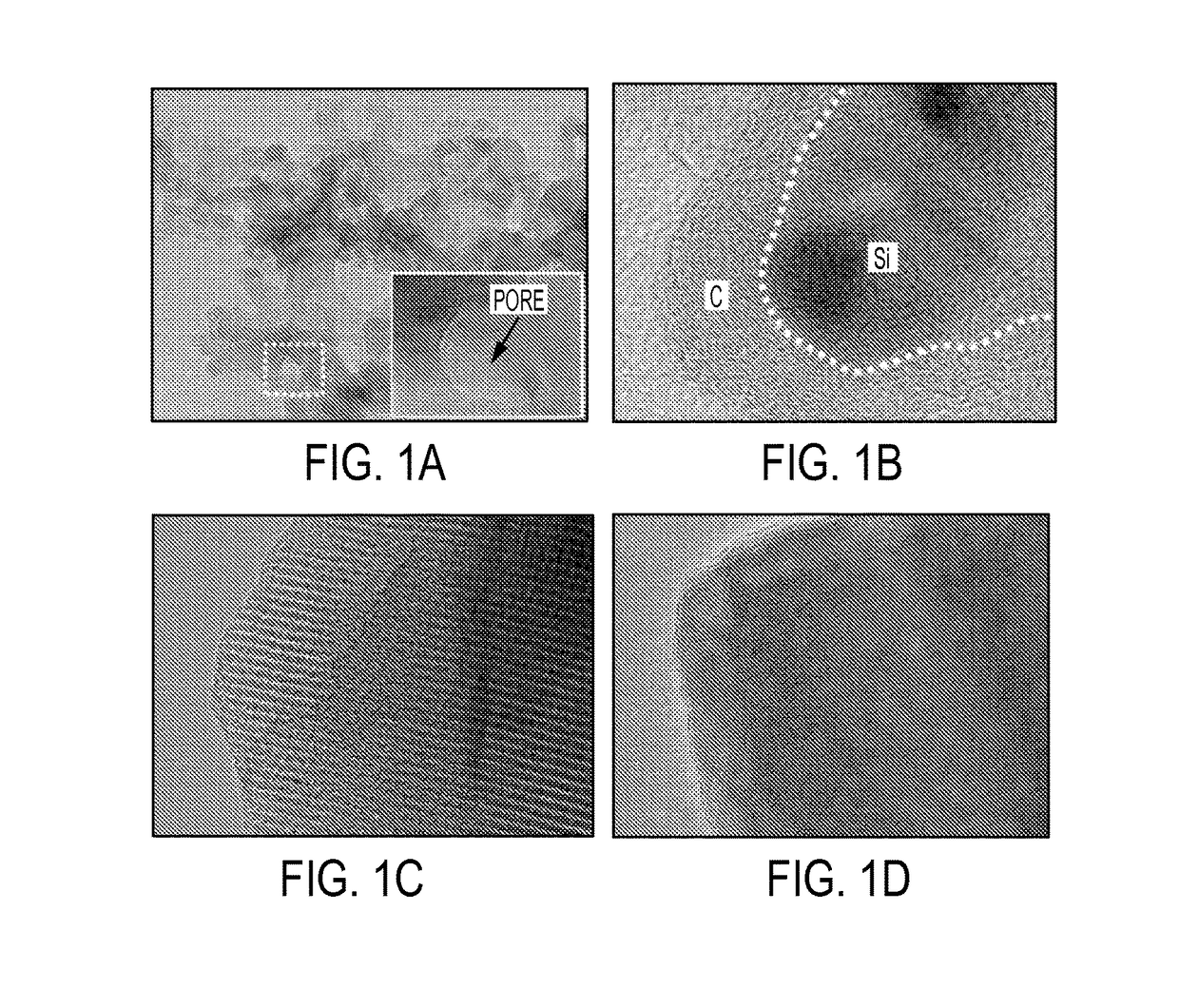

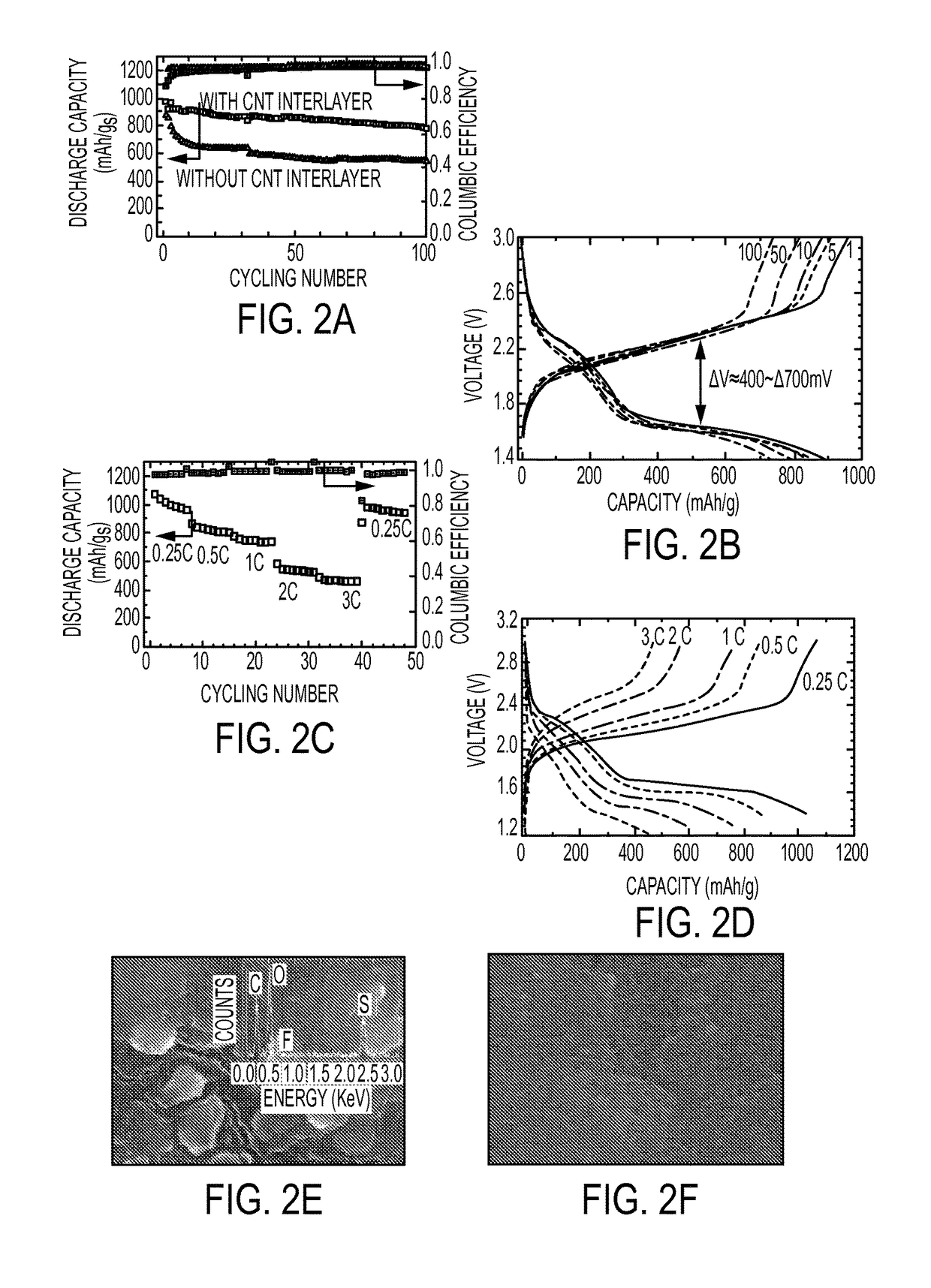

Embodiments of the claimed invention are directed to a device, comprising: an anode that includes a lithiated silicon-based material and a sulfur-based cathode, wherein the anode and the cathode are designed to have mesoporous structures. In certain embodiments, the sulfur-based cathode is a mesoporous carbon structure comprising sulfur within the mesopores. A further embodiment of the invention is directed to a device comprising a semi-liquid lithium-sulfur battery comprising a lithium anode and a sulfur cathode. In certain embodiments, the sulfur cathode comprises a liquid catholyte, which is housed within a reservoir that is a carbon nanotube sponge. An additional embodiment of the invention is directed to a method for producing a lithiated silicon anode and a sulfur-based cathode.

Owner:TEXAS A&M UNIVERSITY

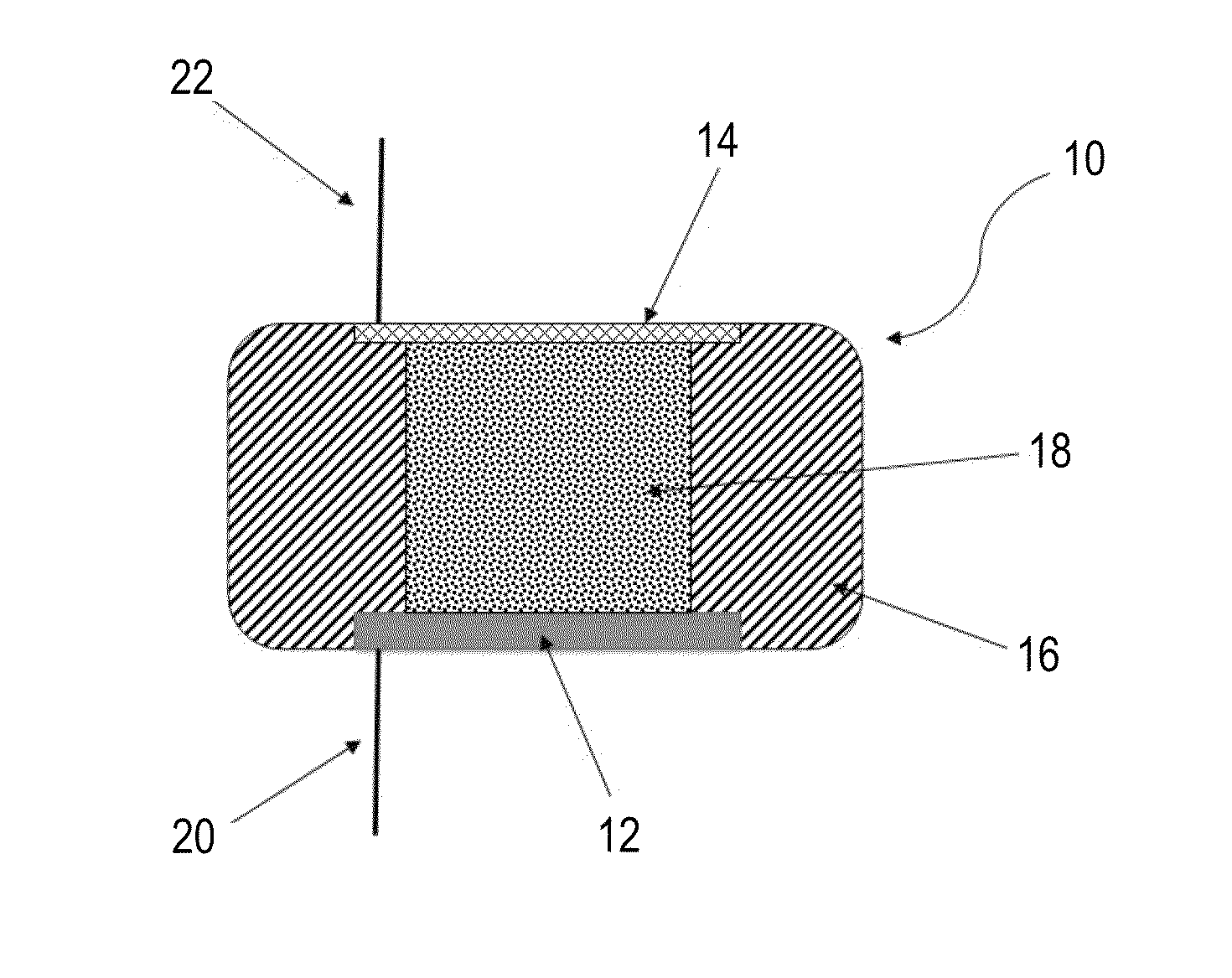

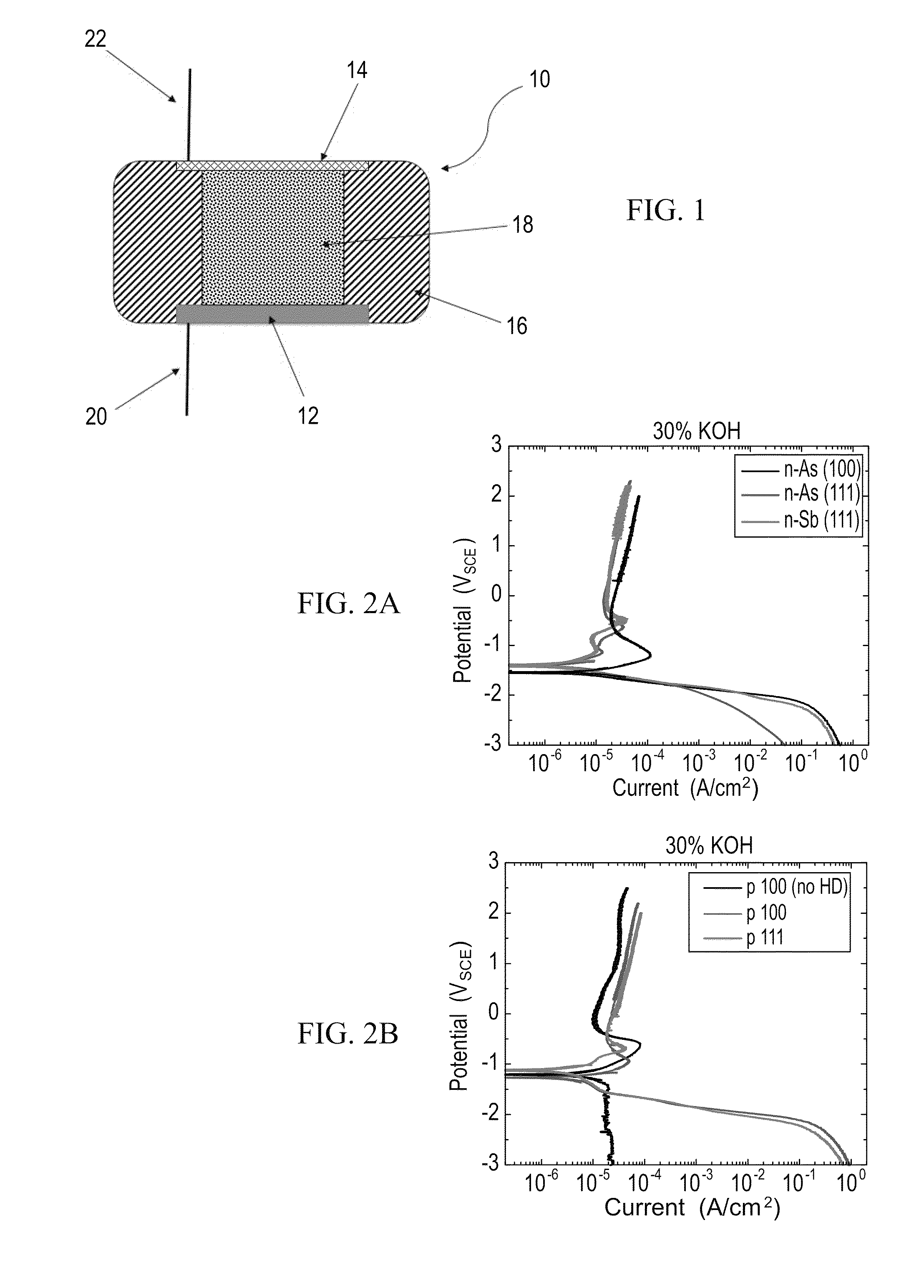

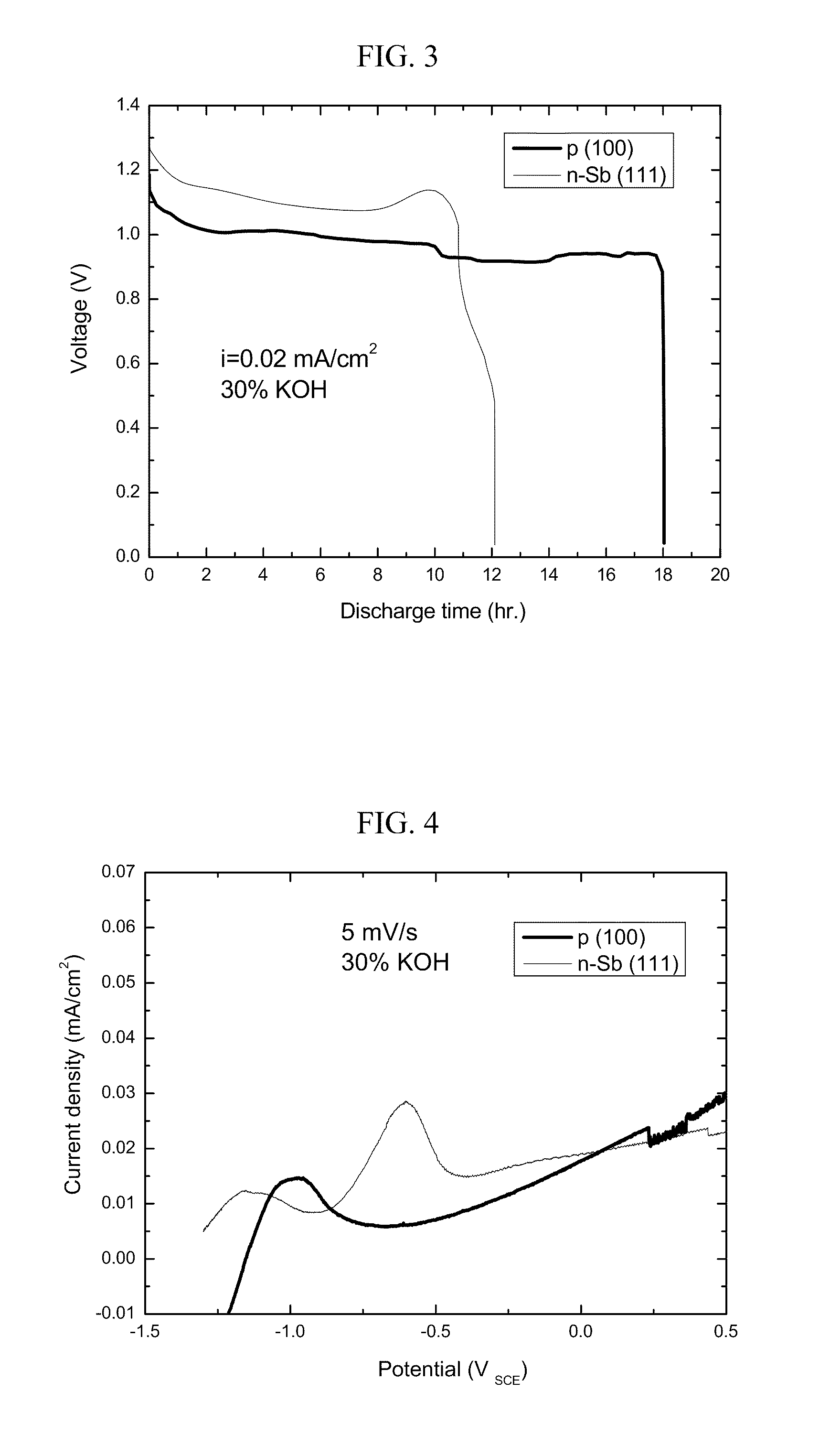

Silicon-air batteries

ActiveUS20110318657A1Increase oxygen flowFuel and primary cellsCell electrodesSilicon–air batterySilicon oxygen

Owner:PENN STATE RES FOUND +1

Lithium ion battery

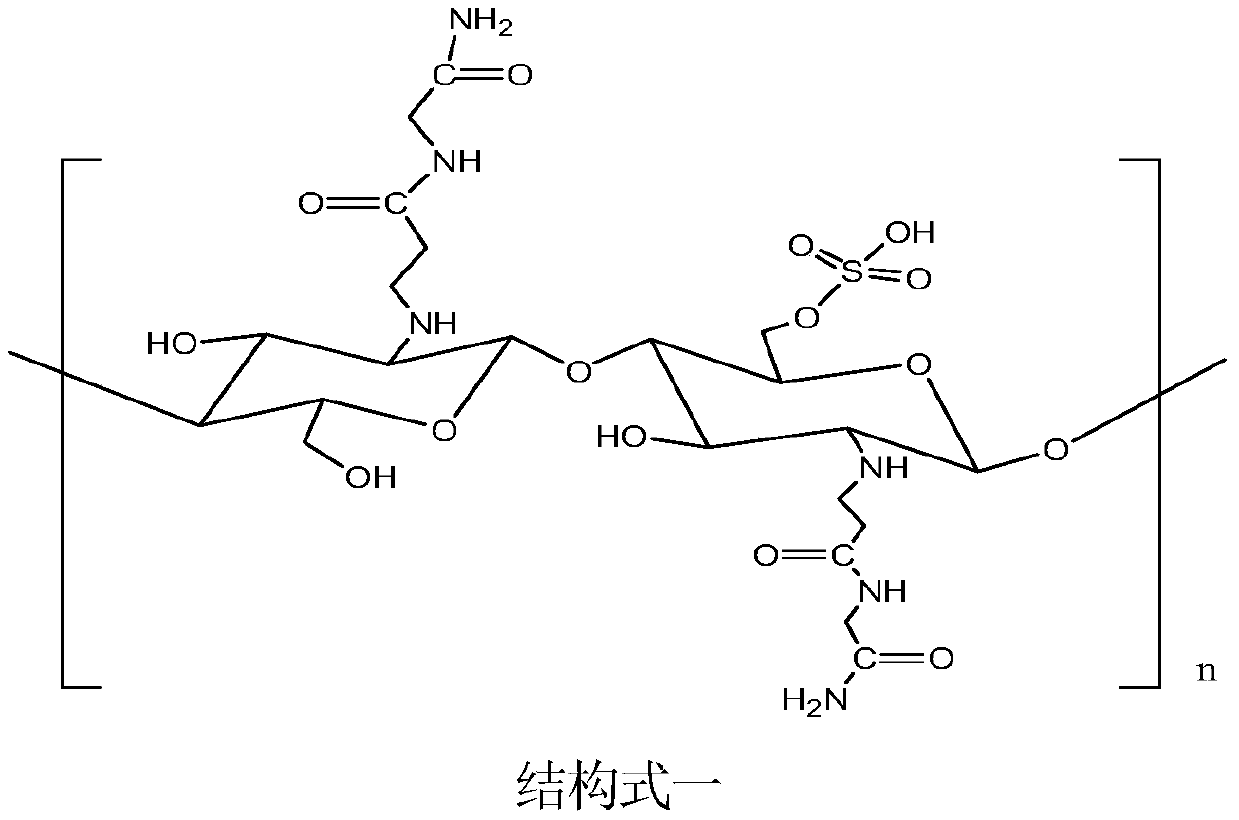

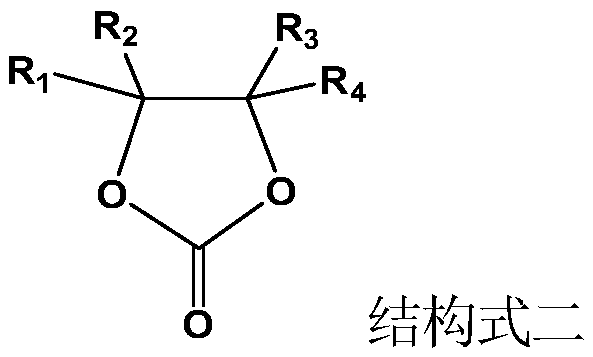

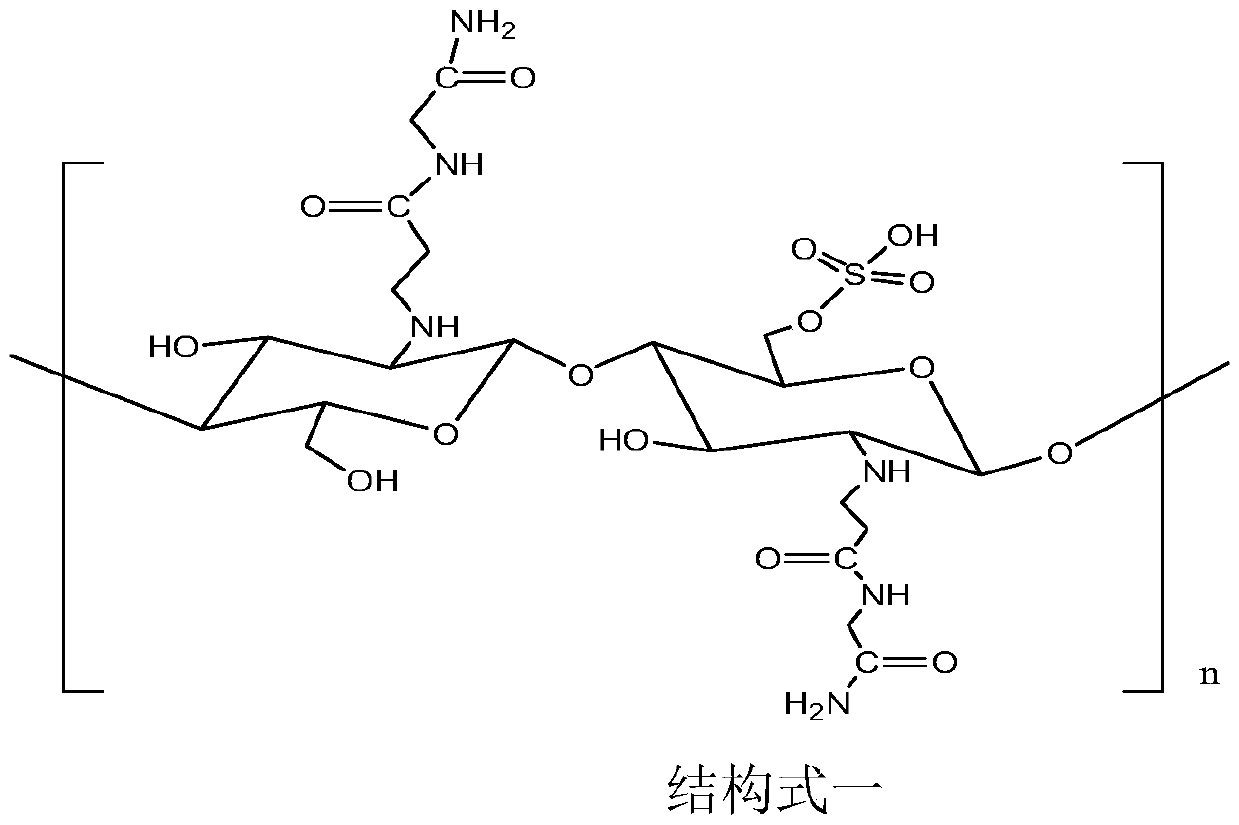

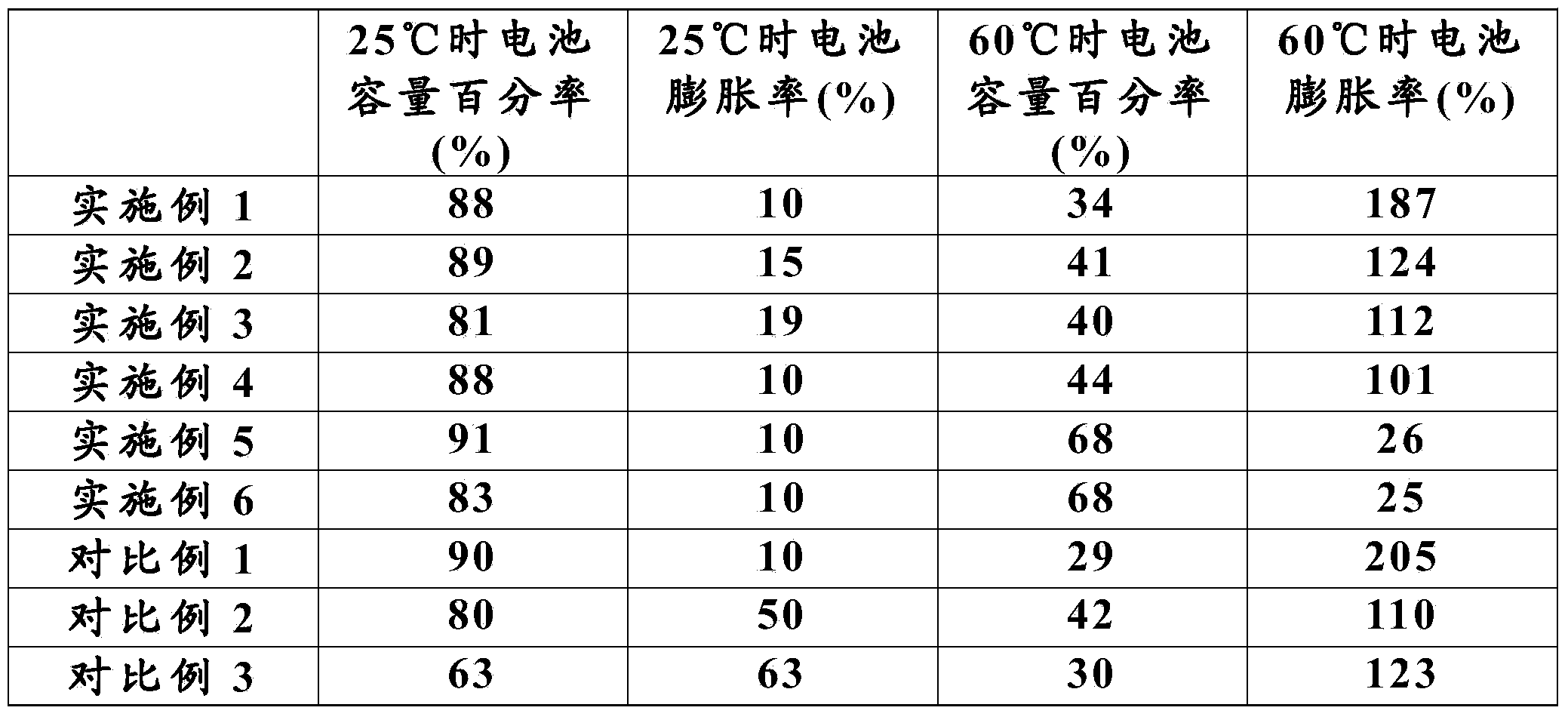

InactiveCN109768278AInhibit internal resistance growthImprove cycle performanceCell electrodesFinal product manufactureInternal resistanceAdhesive

The invention discloses a lithium ion battery and relates to the technical field of batteries. The lithium ion battery prepared by using a binder provided by the invention can more firmly adhere a silicon negative material, a conductive agent and a current collector together during the charging and discharging process of the silicon anode, which can suppress the increase in internal resistance inthe battery cycle and improve the cycle performance of the battery. In addition, the fluorinated cyclic carbonate in the electrolyte can form a SEI film with good mechanical properties on the surfaceof the negative electrode, which can well adapt to the volume expansion-shrinkage change of the silicon negative electrode without being destroyed, and has a better effect than using alone in combination with the adhesive of the structural formula 1.

Owner:SOUTH CHINA UNIV OF TECH

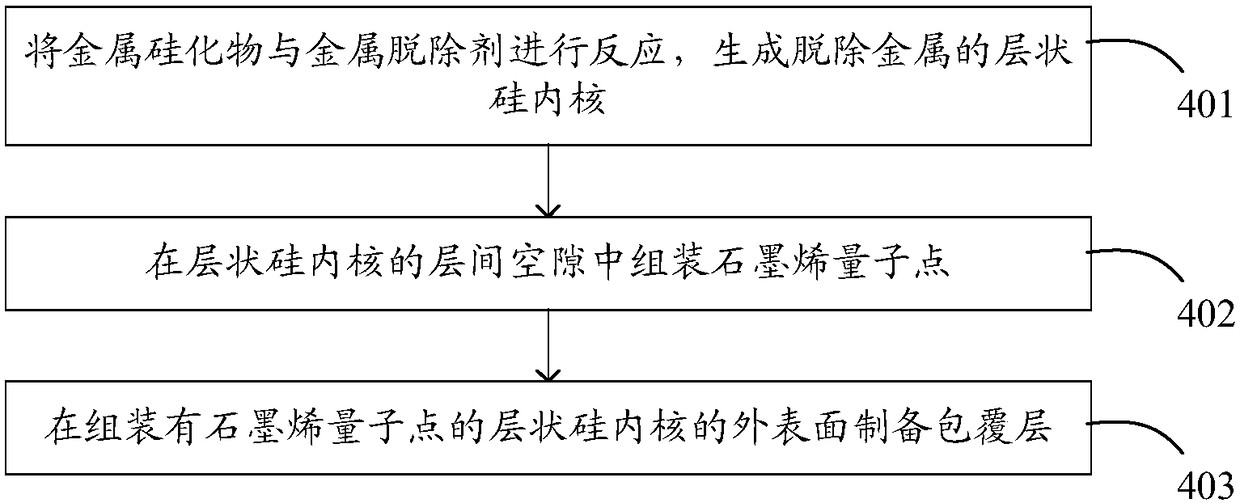

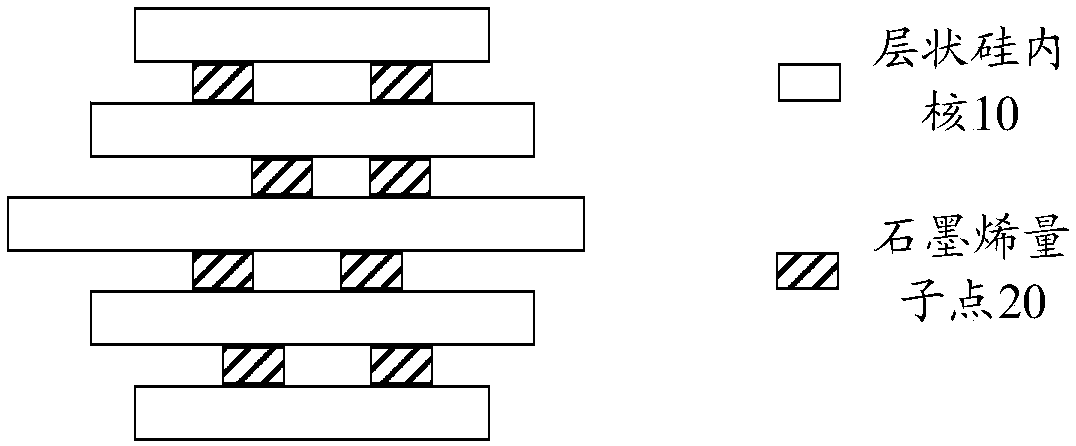

Electrode material preparation method, electrode material and battery

The application provides an electrode material preparation method, an electrode material and a battery, used to solve the problem existing in the prior art that the silicon anode material in the battery can be easily pulverized in a full-embedded state. The electrode material comprises: a layered silicon core and graphene quantum dots; wherein the layered silicon core comprises at least two layersof silicon based material; an interlayer gap between the adjacent two layers of the at least two layers of silicon based material; wherein the silicon based material comprises at least one of siliconor oxide of silicon; and wherein the graphene quantum dots are located in the interlayer gap of the at least two layers of silicon based material.

Owner:HUAWEI TECH CO LTD

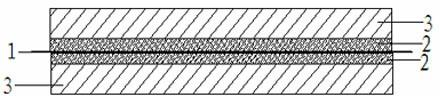

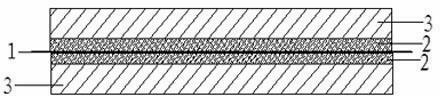

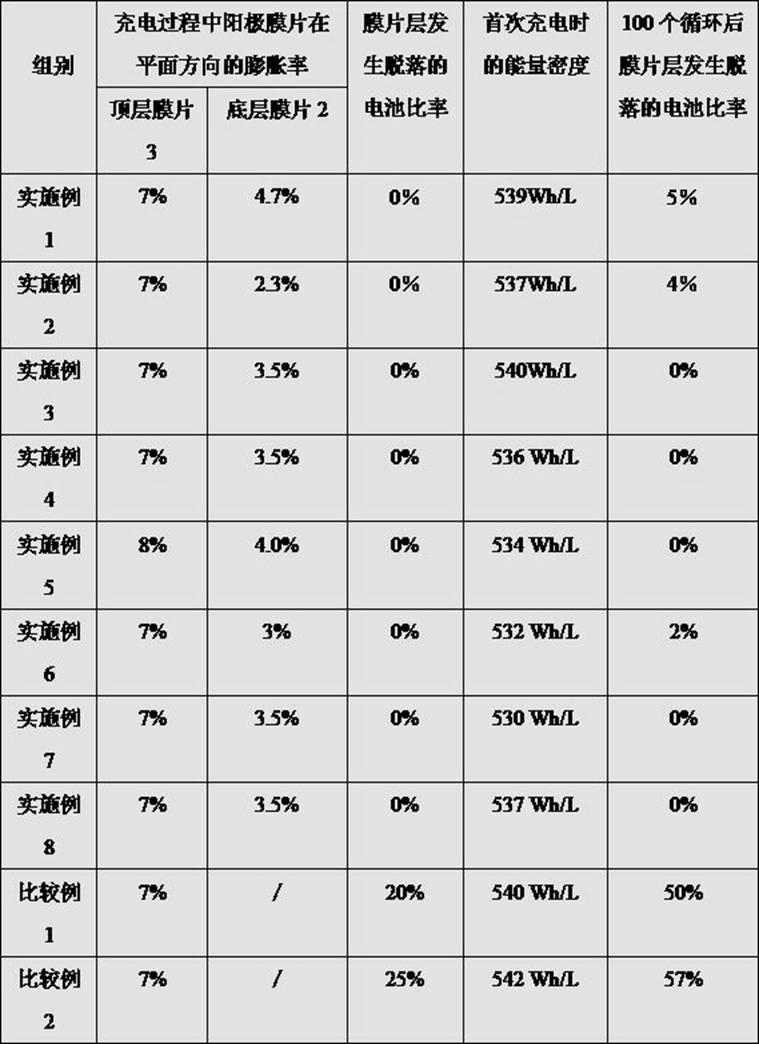

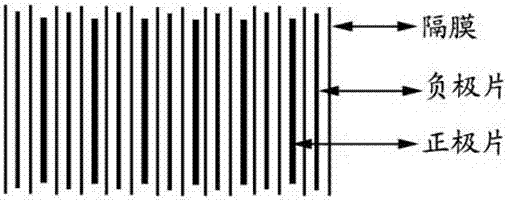

Lithium ion battery anode pole piece

InactiveCN102694145AIncrease energy densityEnergy Density ImpactSecondary cellsNon-aqueous electrolyte accumulator electrodesAdhesiveSilicon alloy

The invention belongs to the technical field of lithium ion batteries and in particular relates to a lithium ion battery anode pole piece comprising a current collector, bottom layer film pieces arranged on the surface of the current collector and top layer film pieces arranged on the surface of the bottom layer film pieces. The bottom layer film pieces and the top layer film pieces all comprise active substances, adhesives and conductive agents. The active substances in the bottom layer film pieces are graphite, and the active substances in the top layer film pieces are at least one of silicon, silicon alloy and tin alloy. Compared with the prior art, in the lithium ion battery anode pole piece, the graphite anode bottom layer film pieces having a buffering action are arranged between the top layer film pieces having large expansion trends and the current collector, a part of the large expansion trends of the top layer film pieces are offset by the bottom layer film pieces so as to solve the problem of expansion demoulding of a silicon anode and an alloy anode in the charging process, and silicon anode and alloy anode materials can be adopted for preparing the batteries to improve the energy density.

Owner:DONGGUAN AMPEREX TECH +1

ELECTRODE BINDING MATERIAL WITH Li, Na, K SUBSTITUTED FOR POLYACRYLIC ACID FUNCTIONAL GROUP (COOH) AND A LITHIUM SECONDARY BATTERY USING THE SAME

InactiveUS20130236778A1Maintain good propertiesImprove propertiesConductive materialActive material electrodesALLYL SUCROSESide reaction

The present invention is based on an electrode binding material including polyacrylics and a functional group substituent(Li, Na, K) as a binder of an electrode. The present invention provides a polyacrylic acid an electrode binding material including a polyacrylics mixture having a high degree of polymerization and a functional group with Li, Na or K being substituted and high efficiency Lithium secondary battery utilizing a silicon anode active material etc. using the same. Therefore, the electrode binding material of the present invention has an excellent binding force, and can reduce side reactions in reactions of a secondary battery, and maintain a stable cycle property, and also enhance electric performance.

Owner:KOREA INST OF CERAMIC ENG & TECH

Silicon-anode lithium battery electrolyte and silicon-anode lithium battery

InactiveCN104241684AImprove charge and discharge performanceReduce flatulenceSecondary cellsOrganic electrolytesOrganic solventPhysical chemistry

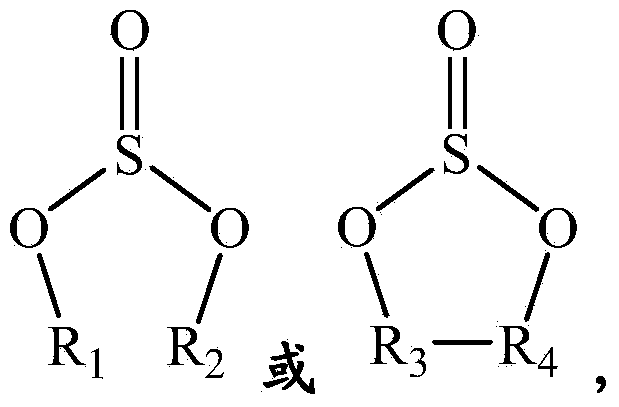

The invention relates to silicon-anode lithium battery electrolyte. The silicon-anode lithium battery electrolyte consists of an organic solvent, a lithium salt and additives, wherein the concentration of the lithium salt is 0.001-2 mol / L; the additives consist of an additive A and fluorinated ethylene carbonate; the mass of the additive A accounts for 0.1-20% of the mass of the electrolyte; the mass of the fluorinated ethylene carbonate accounts for 0.1-10% of the mass of the electrolyte; the additive A is a sulfite compound. In a silicon-anode lithium ion battery, in non-aqueous electrolyte, the sulfite compound and the FEC (fluorinated ethylene carbonate) are used, and in EC (ethylene carbonate)-based electrolyte, electrochemical improvement effect on a silicon anode is good, and a formed SEI (solid electrolyte interface) film is thicker, so that the defect that the silicon anode has large volume expansion change in the cycle is made up, the charge and discharge performance of the silicon-anode lithium ion battery can be improved more effectively, side reactions can be reduced, thereby reducing battery expansion and improving the cycle life of the battery, and thus the room temperature performance and the high temperature performance of the battery are very good.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

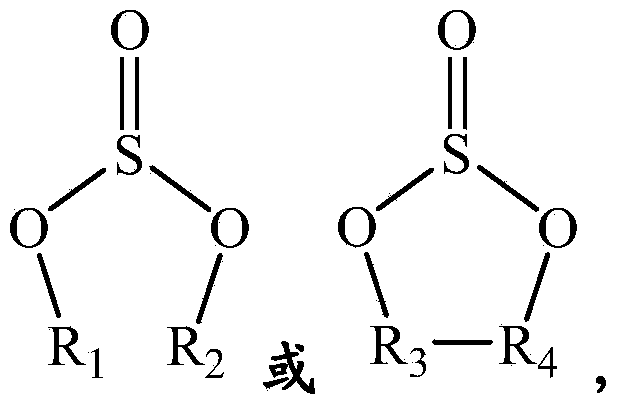

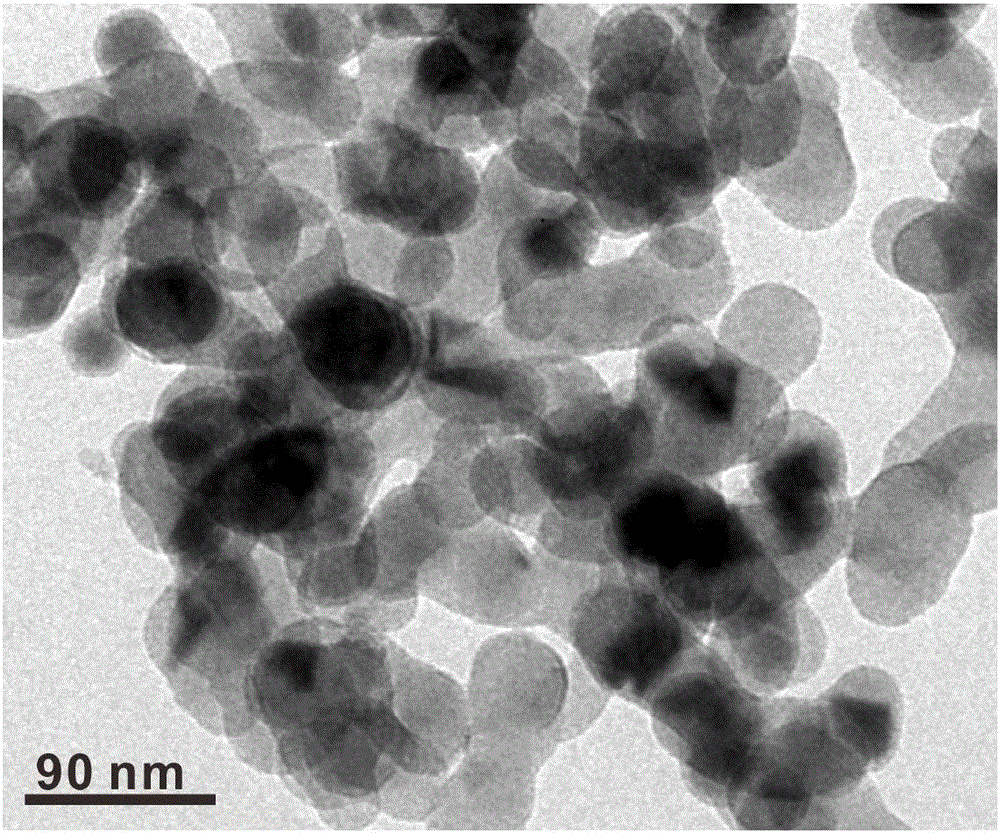

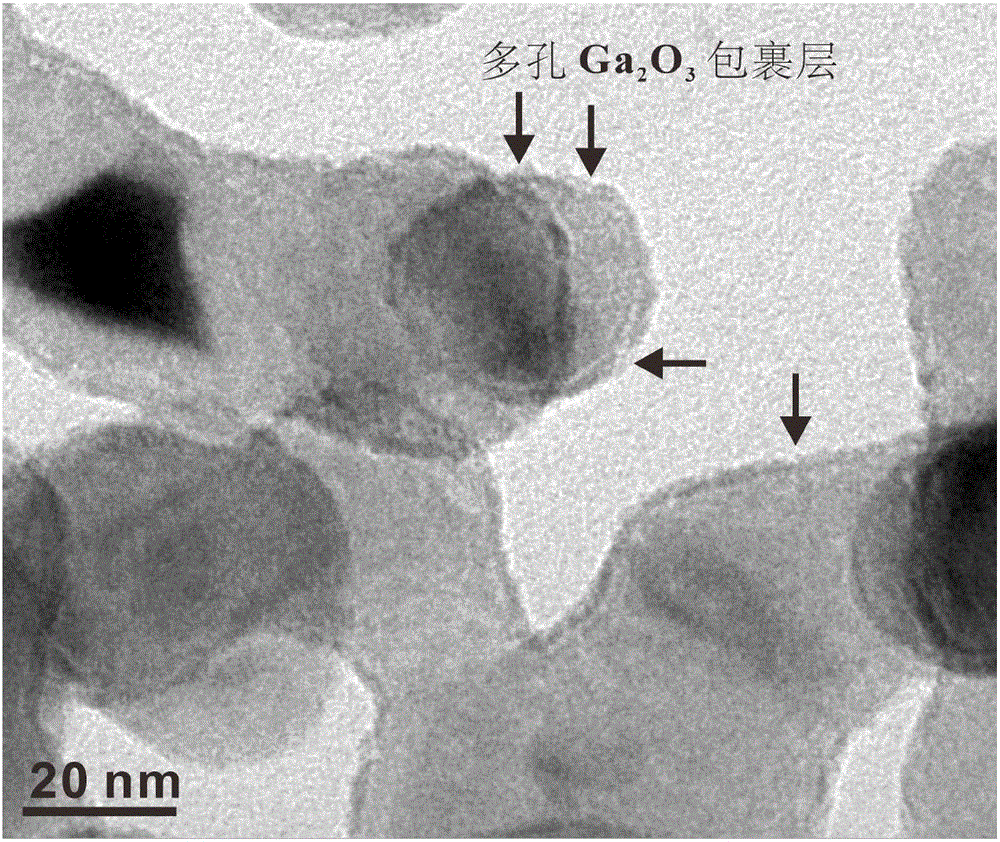

Preparation method of porous oxide-coated battery silicon anode material

ActiveCN106784763ALower specific capacityReduce the numberCell electrodesGas phaseSodium-ion battery

The invention provides a preparation method of a porous oxide-coated battery silicon anode material and relates to the technical field of preparation of lithium ion battery anode materials. The preparation method provided by the invention comprises the following steps: performing silicon anode material drying treatment; performing surface passivation treatment on a silicon anode material with ethyl alcohol; performing set cyclic cycle deposition in a gas-phase atomic layer deposition chamber to obtain the porous oxide-coated battery silicon anode material. The preparation method provided by the invention is simple and good in repeatability; the prepared lithium ion battery silicon anode material not only has large specific capacity, but also can inhibit the expansion of the silicon anode material in the charting and the discharging processes of a lithium ion battery, so that the lithium ion battery silicon anode material has good charging and discharging cycle performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

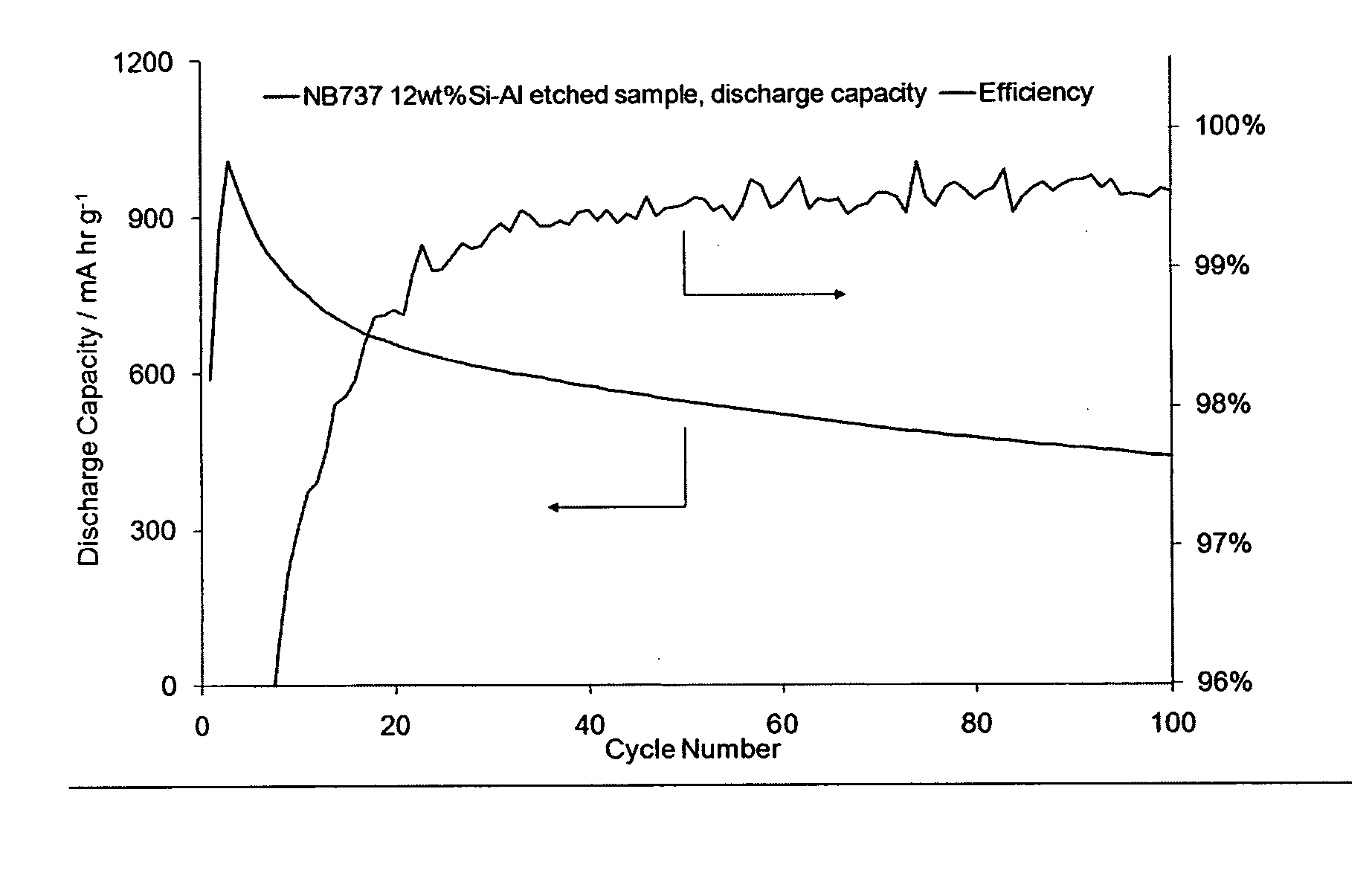

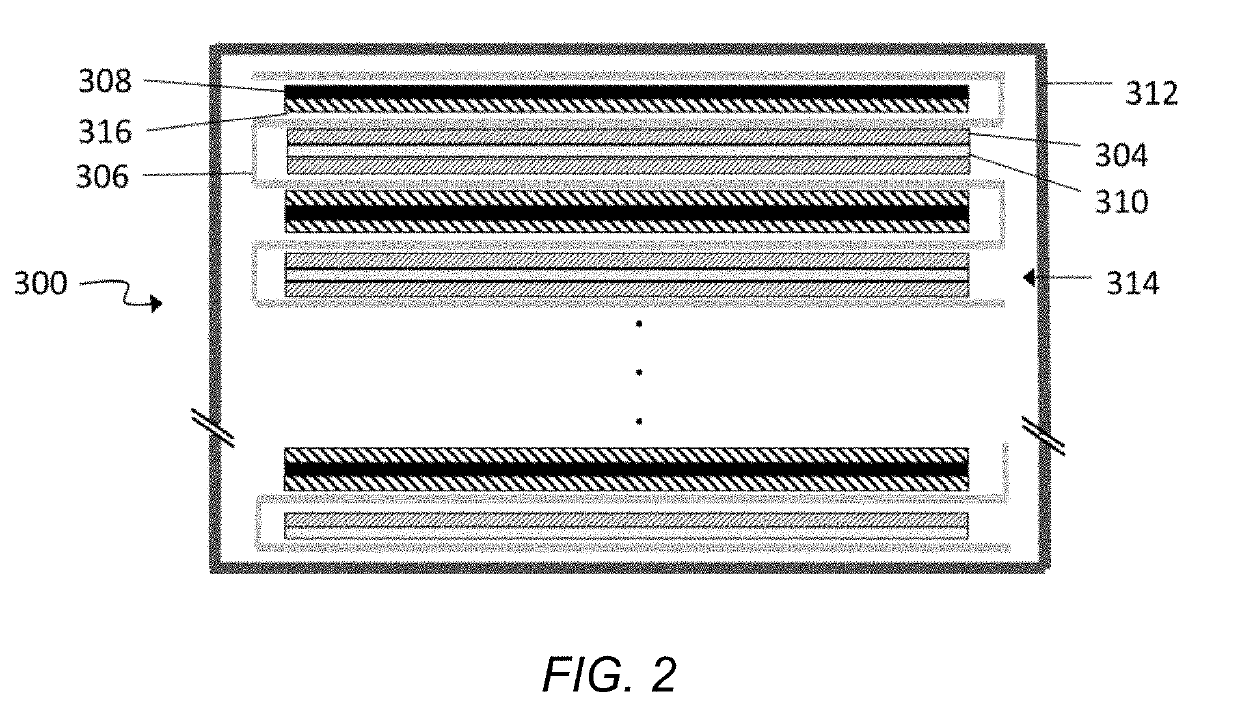

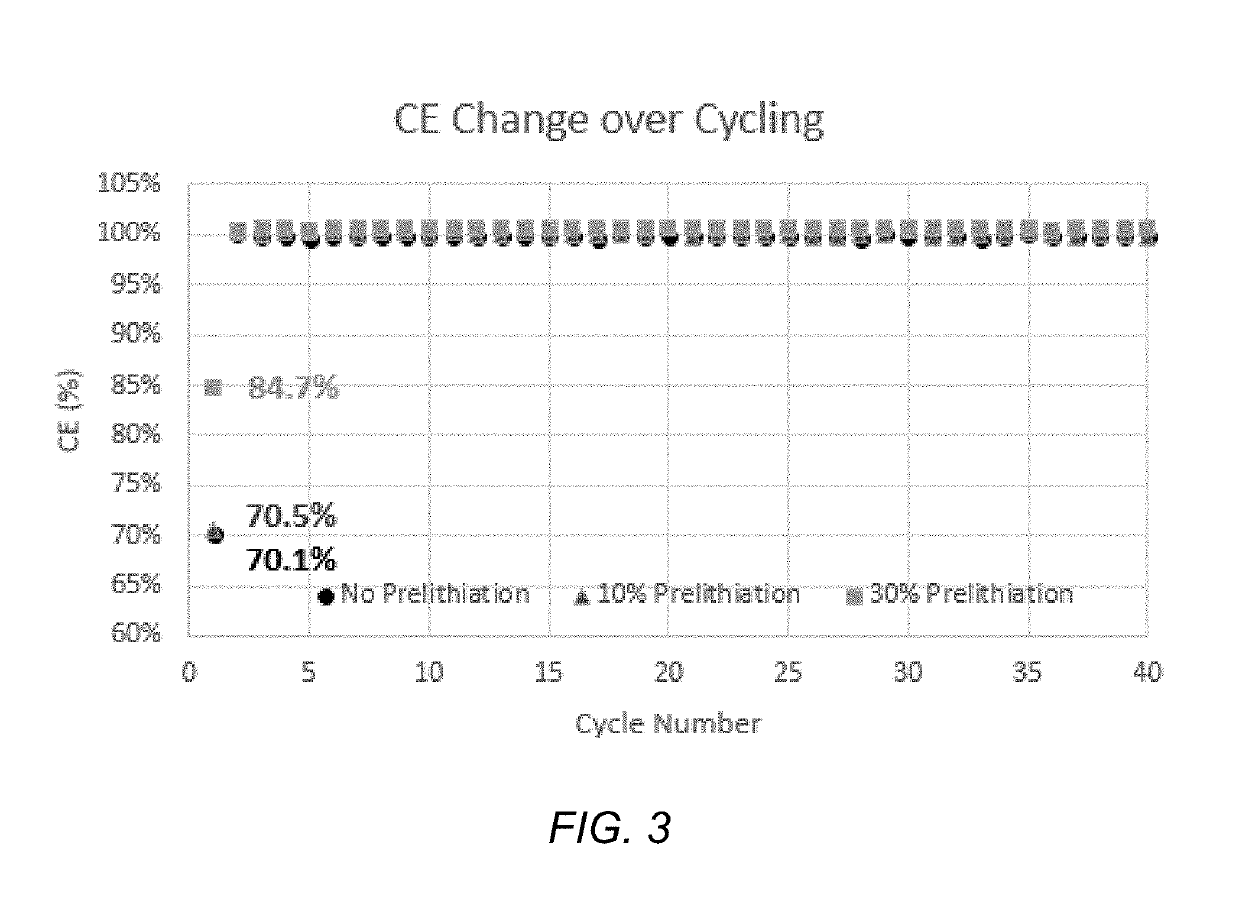

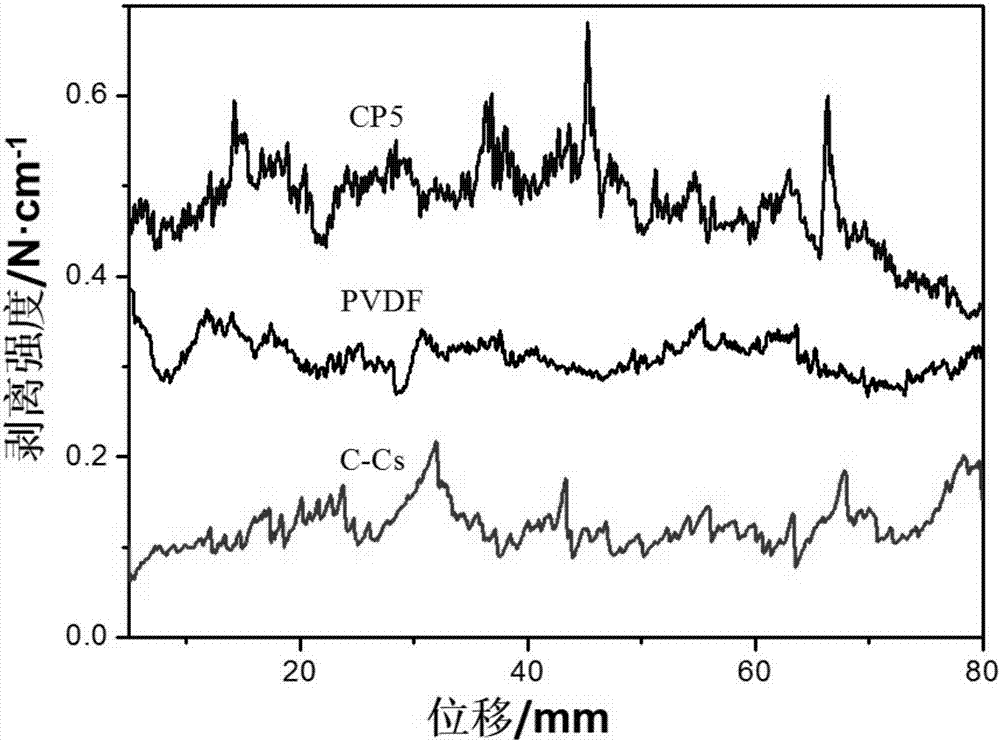

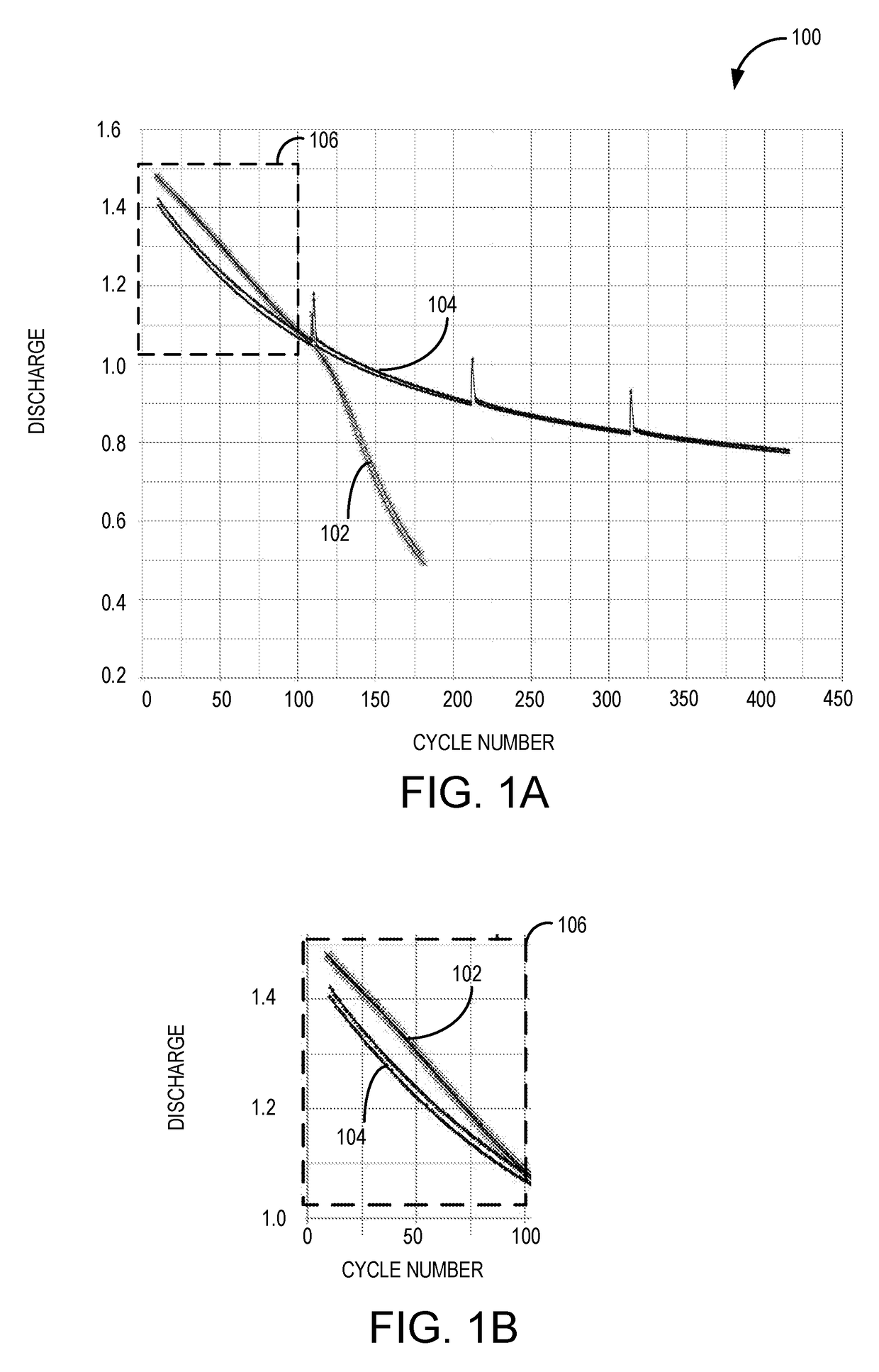

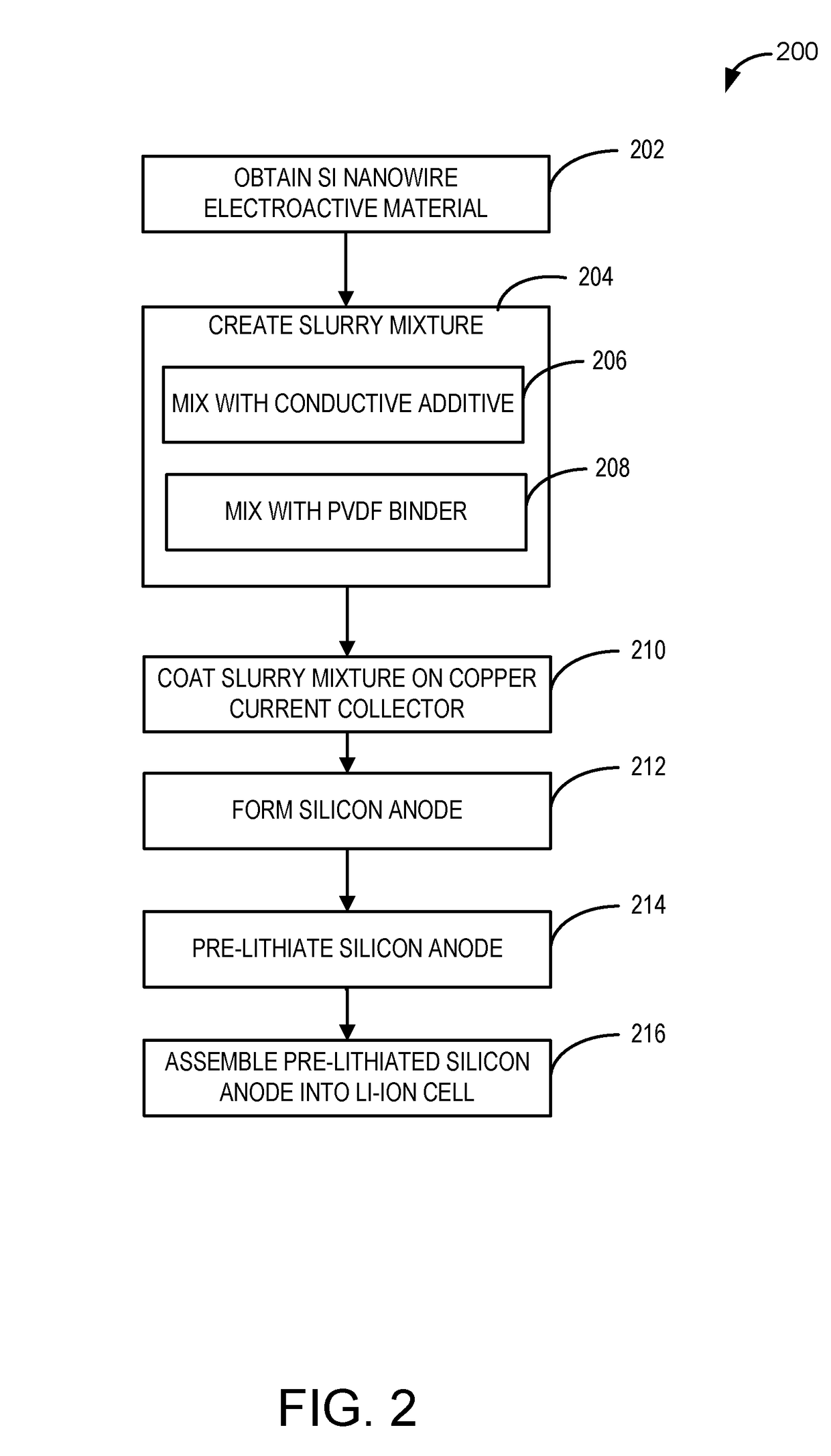

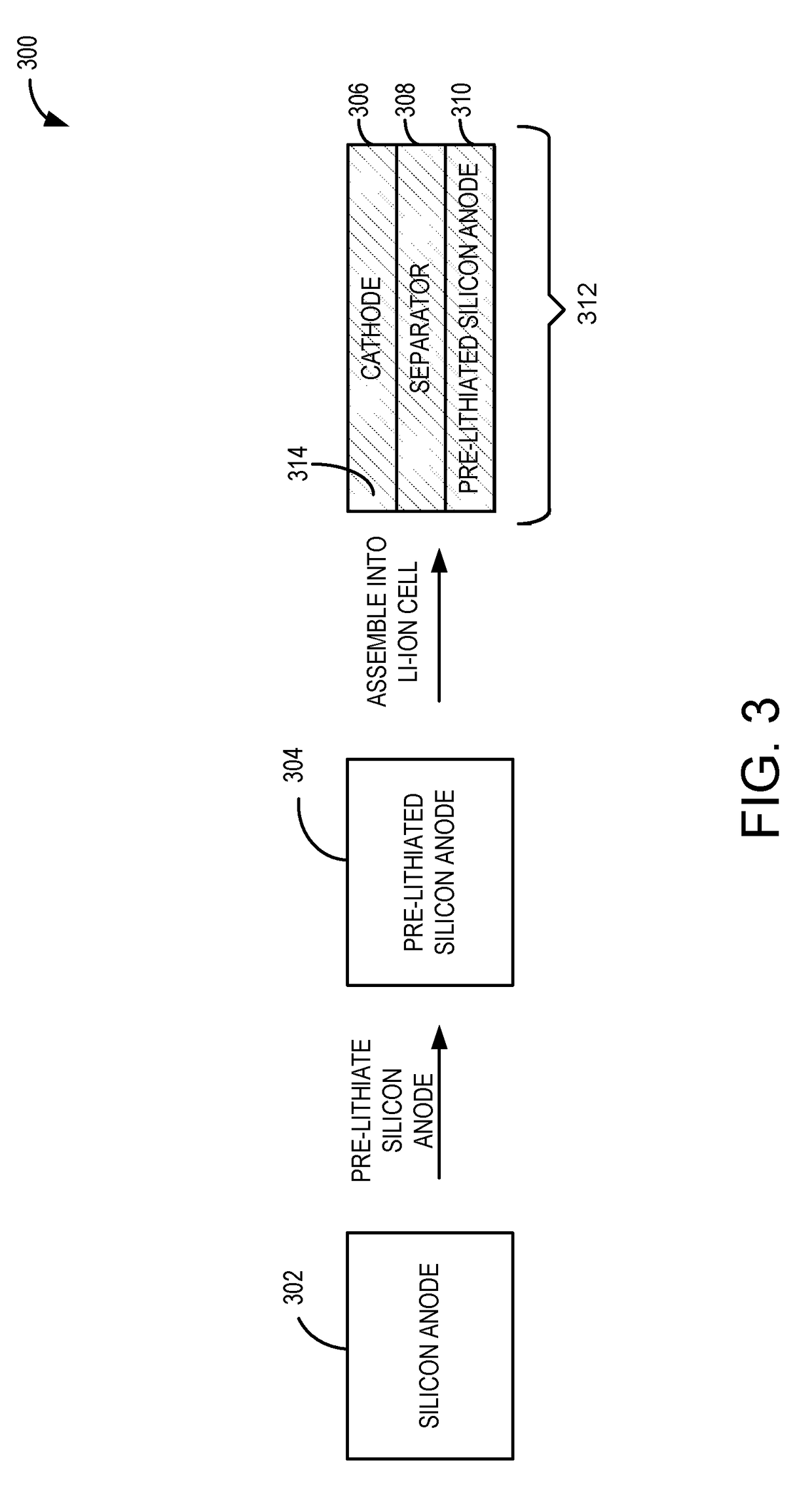

Pre-lithiated silicon anodes with pvdf binder

InactiveUS20170301910A1Influence cycling stabilityHigh strengthFinal product manufactureElectrode carriers/collectorsCell assemblySilicon

A pre-lithiated silicon anode comprising a PVDF binder at 5-12 wt. % for use in a Li-ion cell is provided. In particular instances, a conductive additive may be added at less than 5 wt. %. The Si anode with PVDF binder is pre-lithiated prior to cell assembly and following Si anode fabrication. The combination of pre-lithiation and PVDF in the Si anode for use in a rechargeable Li-ion cell shows the unexpected result of extending the cycle life.

Owner:A123 SYSTEMS LLC

Method of improving performance of lithium ion battery silicon anode material

InactiveCN108682803AImprove the first Coulombic efficiencyImprove other performanceCell electrodesSilicon monoxideAdhesive

The invention discloses a method of improving the performance of a lithium ion battery silicon anode material. The method comprises following steps: (1) preparing an anode material made of a silicon monoxide (SiO) composite material: (a) weighing a certain amount of SiO powder, pouring SiO powder into deionized water, wherein the mass ratio of SiO powder to deionized water is 1:10, and then addinga certain amount of graphite and glucose; (b) filling the obtained solution into a high energy ball milling machine, and carrying out ball milling; (c) after ball milling, placing the obtained precursor in a tubular furnace; and (d) mixing the prepared SiO / C composite material with a conductive agent (acetylene black) and an adhesive (PVDF) according to a certain ratio; and (2) carrying out a pre-lithiation treatment on an electrode. At first, a SiO material is compounded with a carbon material, then lithium is added into the composite material to carry out pre-lithiation modification, aftermodification, the modified SiO composite material is taken as a negative electrode, for the first time, the Coulomb efficiency is increased to 81% from 77%, and other performances of the SiO compositematerial are also greatly enhanced.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

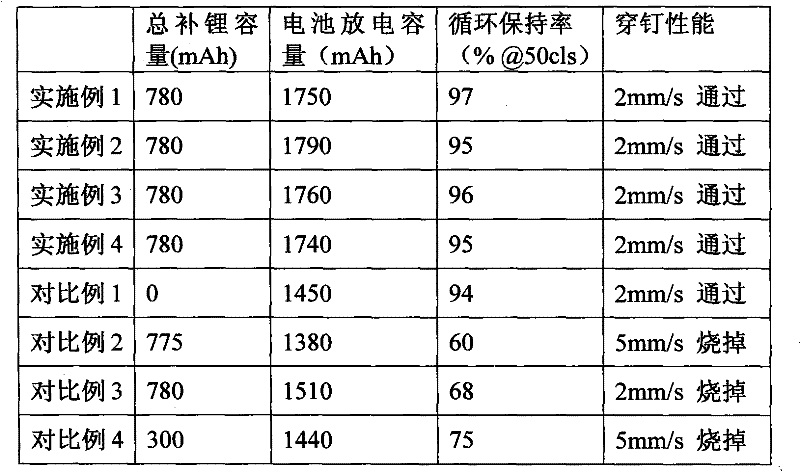

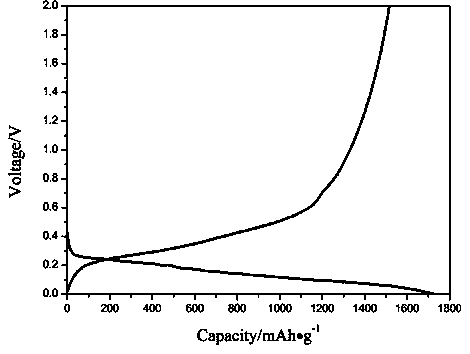

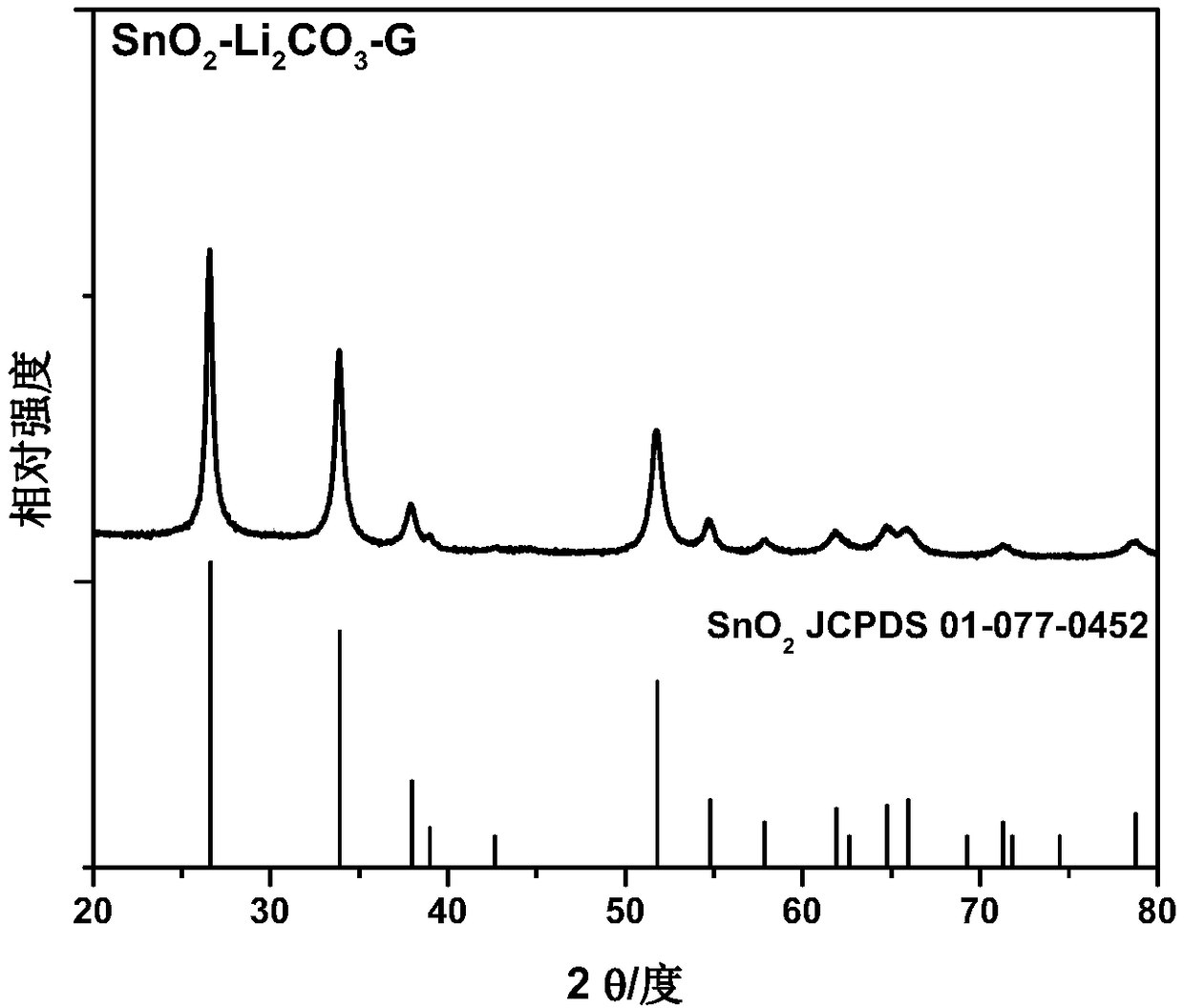

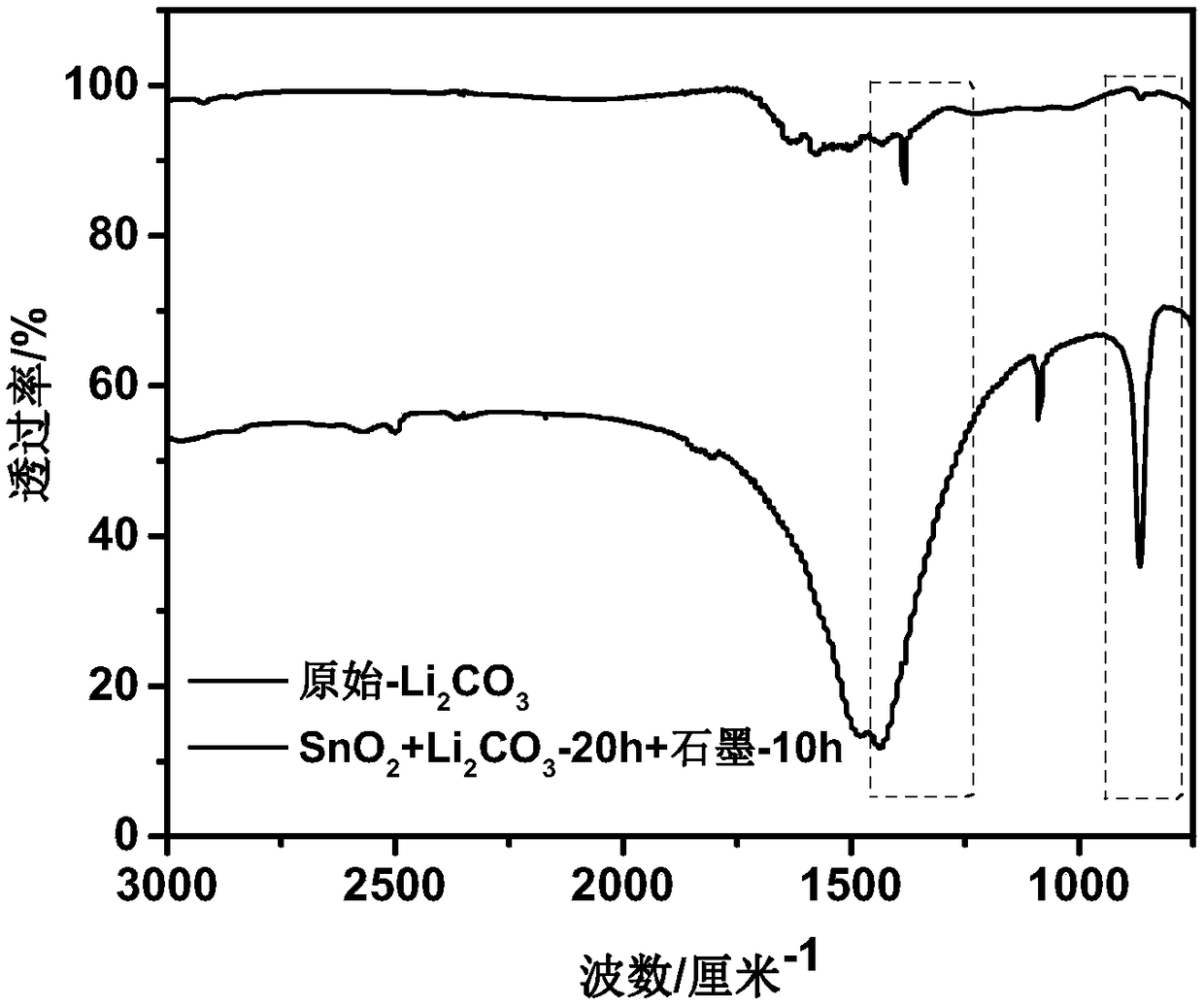

Pre-lithiatedanode material with high reversible capacity and preparation method of pre-lithiatedanode material

InactiveCN109411717AEasy to separateGood effectNegative electrodesSecondary cellsLithium carbonateGraphite

The invention relates to a pre-lithiatedanode material with the high reversible capacity and a preparation method of the pre-lithiatedanode material. The pre-lithiatedanode material comprises a graphite-like carbon material, metallic oxide or silicon uniformly distributed on the pre-lithiatedanode material, and lithium carbonate; the first coulomb efficiency of the anode material is 5%-10% higherthan that of the corresponding pure metallic oxide or silicon anode material, and the capacity retention rate of the anode material is no less than 85% after cycling for 100-350 times. The preparationmethod includes the steps that the metallic oxide or silicon powder, lithium carbonate powder, the graphite-like carbon material and a grinding agent are stirred,mixed and subjected to ball-milling.According to the pre-lithiatedanode material with the high reversible capacity and the preparation method of the pre-lithiatedanode material, by adding the lithium carbonate, the irreversible capacityof the anode material in the initial charging and discharging process is lowered, and thus the first coulomb efficiency is improved; by adding the graphite-like carbon material, structural stabilityof the material in the reaction process and conductivity of an electrode material are improved; and according to the ball-milling method, the size of the anode material particlescan be refined in a short time, and the volume change of the anode material is buffered.

Owner:SOUTH CHINA UNIV OF TECH

Silicon battery anode material, anode plate for lithium battery and lithium battery prepared thereof

InactiveCN106876684AImprove conductivityImprove efficiencyCell electrodesSecondary cellsCore shellLithium intercalation

The invention relates to a lithium battery anode material, a lithium battery anode plate and a preparation process of a lithium battery. The silicon anode material has a structural formula of LixSiOy / C and has a core-shell structure composed of a central LixSiOy material and an amorphous carbon layer on the surface, wherein x is 0.05 to 3. The lithium battery anode and the lithium battery provided by the invention are prepared from the LixSiOy / C material as an active material of the anode plate. The LixSiOy / C material prepared by the invention has the advantages of stable structure, high conductivity, excellent reversibility of lithium intercalation and deintercalation, and excellent first efficiency. The lithium battery prepared according to the invention has high discharge capacity and cycling stability.

Owner:四川国创成电池材料有限公司

High performance silicon electrodes having improved interfacial adhesion among binder, silicon and conductive particles

Methods for making a negative electrode material for use in an electrochemical cell, like a lithium ion battery, are provided. The electroactive material includes a functionalized surface having a grafted reactive group (e.g., an amino group, a carboxyl group, an anhydride group, and the like). The electrically conductive material includes a functionalized surface having a grafted reactive group (e.g., an amino group, a carboxyl group, and the like). The functionalized electroactive material and the functionalized electrically conductive material is admixed and reacted with at least one binderprecursor having a reactive group (e.g., an amino group, an anhydride group, and the like). A porous solid electrode material is thus formed. Negative electrodes are also provided, which provide significant performance benefits and reduce the issues associated with capacity fade, diminished electrochemical cell performance, cracking, and short lifespan associated with conventional silicon anode materials.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com