Electrode material preparation method, electrode material and battery

An electrode material and a technology for preparing electrodes, which are applied in the field of materials and can solve problems such as the easy pulverization of silicon negative electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

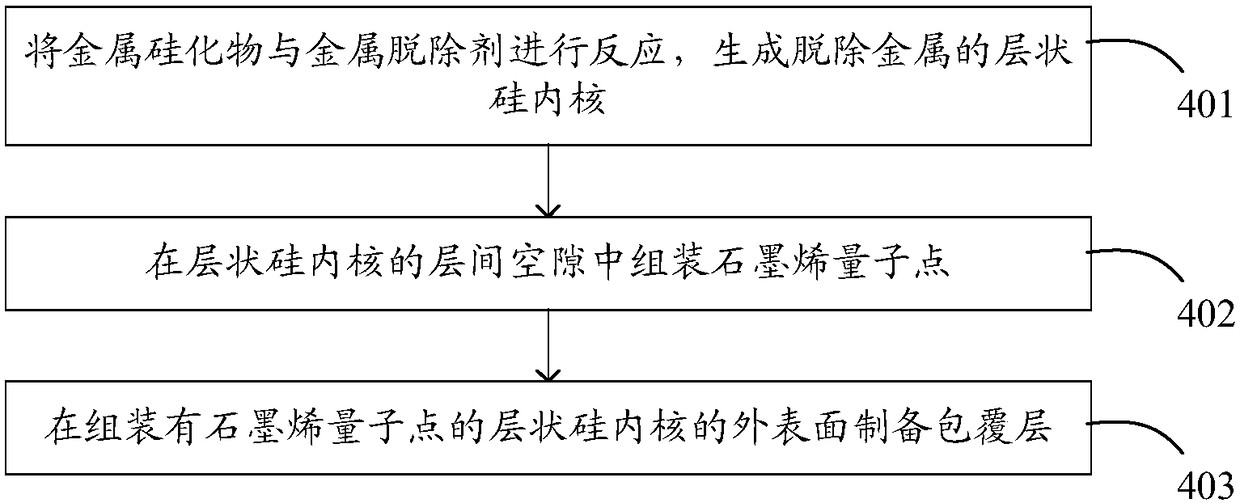

[0040] figure 1 Shown is the schematic flow chart of the method for preparing the electrode material of the present application, including:

[0041] Step 401 , reacting the metal silicide with a metal-removing agent to form a metal-removed layered silicon core. The layered silicon core includes at least two layers of silicon-based materials with interlayer gaps between adjacent two layers of the at least two layers of silicon-based materials, and the silicon-based materials include at least one of silicon or silicon oxides, for example, silicon The base material may be any one of silicon, silicon dioxide, and silicon monoxide, or the silicon-based material may include two of silicon, silicon dioxide, and silicon monoxide, or all three of them.

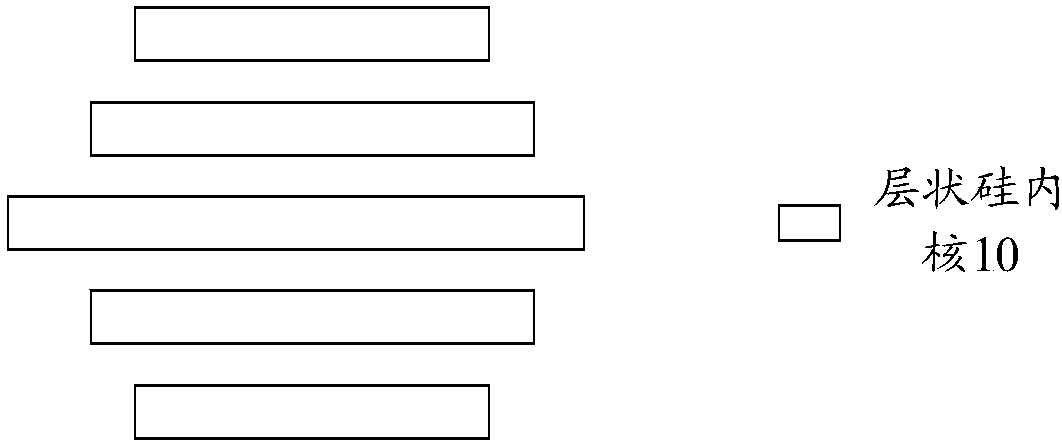

[0042] Figure 2a It is a schematic diagram of the layered silicon core. It should be noted that in the technical solution of the embodiment of the present application, although there is an interlayer gap between two adjacent layers ...

Embodiment 2

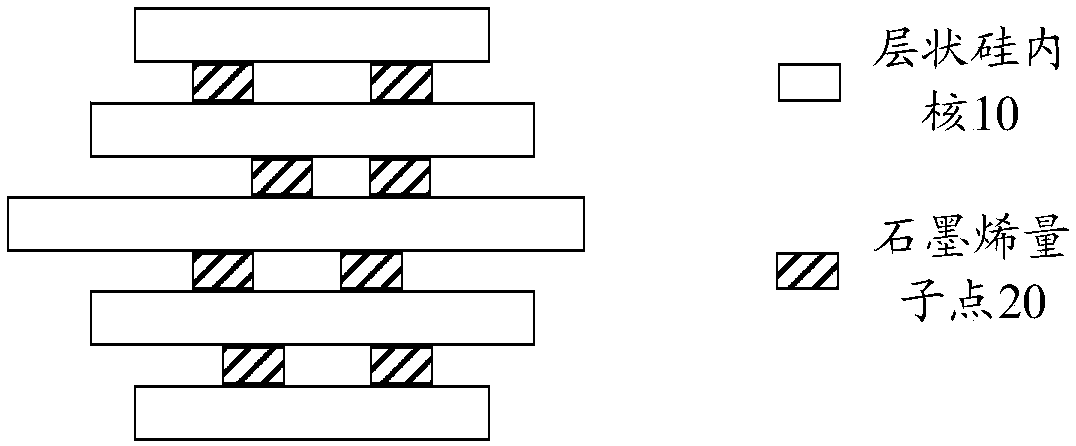

[0099] In the method for preparing an electrode material provided in Example 2 of the present application, after the layered silicon core is obtained according to step 401, graphene quantum dots are modified on the outer surface of the layered silicon core, Figure 2f Schematic diagram of the layered silicon core of surface-modified graphene quantum dots. The way of forming graphene quantum dots on the surface of the layered silicon core can be in-situ growth of graphene quantum dots on the surface of the layered silicon core, such as growing graphene quantum dots by CVD process. In addition, it is also possible to migrate the prepared graphene quantum dots to the outer surface of the layered silicon core.

[0100] When the layered silicon core is used as the negative electrode material of the battery, a large number of interlayer gaps in the layered silicon core can slow down the expansion pressure of the negative electrode in the state of intercalating lithium (or other ions...

Embodiment 3

[0103] refer to Figure 2h , in the method for preparing the electrode material provided in Example 3 of the present application, after the layered silicon core is obtained according to step 401, a cladding layer is prepared on the outer surface of the layered silicon core, and the formation implementation has been described in detail in step 403 , which will not be repeated here.

[0104] In the above technical solution, when the layered silicon core is used as the negative electrode material of the battery, a large number of interlayer gaps in the layered silicon core can slow down the expansion pressure of the negative electrode in the state of intercalating lithium (or other ions released by the positive electrode of the battery), reducing the The volume change of the battery negative electrode material during charging and discharging can effectively avoid the pulverization of the battery negative electrode material and improve the service life of the battery negative elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com