Silicon battery anode material, anode plate for lithium battery and lithium battery prepared thereof

A technology of negative electrode material and carbon negative electrode material, applied in the field of electrochemistry, can solve the problems of short cycle life and low initial efficiency, and achieve the effects of improving electrical conductivity, high charging and discharging efficiency, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The used silicon negative electrode material Li of the lithium battery of the present embodiment 0.8 SiO 1.2 / C, the specific composition is Li 0.8 SiO 1.2 for 96 copies by Li 4 SiO 4 , Li 2 SiO 3 Composed of LiSi and 4 parts of amorphous carbon layer. Li 0.8 SiO 1.2 / C anode material. The preparation steps are as follows:

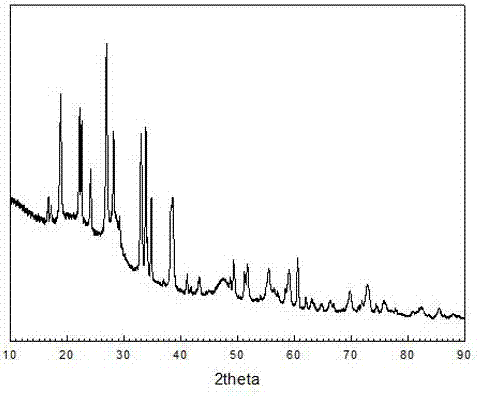

[0025] First, weigh and mix spherical silicon, lithium carbonate, lithium iodide, and glucose with a stoichiometric ratio of about 20 nm, and then weigh the ethanol solution according to the mass ratio of the mixed material to the dispersant ethanol of 1:25. After mixing evenly by ball milling, stir and dry, and finally put the dried powder in a tube furnace, roast at 600°C for 12 hours under argon, and cool naturally to obtain the desired Li 0.8 Si / C anode material. figure 1 gives Li 0.8 SiO 1.2 / C XRD patterns.

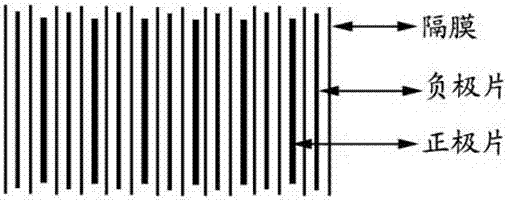

[0026] The negative electrode sheet used in the lithium battery of this embodiment is composed of a copper foil current c...

Embodiment 2

[0029] The used silicon negative electrode material Li of the lithium battery of the present embodiment 0.6 SiO / C, the specific composition is Li 0.6 SO is 98 parts by Li 4 SiO 4 , Li 2 SiO 3 Composed of LiSi and 2 parts of amorphous carbon layer. Li 0.6 SiO / C anode material. The preparation steps are as follows:

[0030] First, weigh and mix spherical silicon, lithium acetate, lithium iodide, and Tween 80 of about 50nm according to the stoichiometric ratio, and then weigh the ethanol solution according to the mass ratio of the mixed material to the dispersant ethanol of 1:50. After mixing evenly by ball milling, stir and dry, and finally put the dried powder in a tube furnace, roast at 800°C for 6 hours under argon, and cool naturally to obtain the desired Li 0.6 SiO / C anode material.

[0031] The negative electrode sheet used in the lithium battery of this embodiment is composed of a copper foil current collector and a negative electrode layer coated on the current ...

Embodiment 3

[0034] The used silicon negative electrode material Li of the lithium battery of the present embodiment 3 SiO 4.5 / C, the specific composition is Li 3 SiO 4.5 for 96 copies by Li 4 SiO 4 , Li 2 SiO 3 Composed of LiSi and 4 parts of amorphous carbon layer. Li 3 SiO 4.5 / C anode material. The preparation steps are as follows:

[0035] First, weigh and mix silica hollow spheres of about 30nm, lithium hydroxide, and Tween 80 according to the stoichiometric ratio, and then weigh the ethanol solution according to the mass ratio of the mixed material to the dispersant ethanol of 1:10. After mixing evenly by ball milling, stir and dry, and finally put the dried powder in a tube furnace, roast at 1400°C for 1 hour under argon, and cool naturally to obtain the desired Li 3 SiO 4.5 / C anode material.

[0036] The negative electrode sheet used in the lithium battery of this embodiment is composed of a copper foil current collector and a negative electrode layer coated on the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com