Preparation method of porous oxide-coated battery silicon anode material

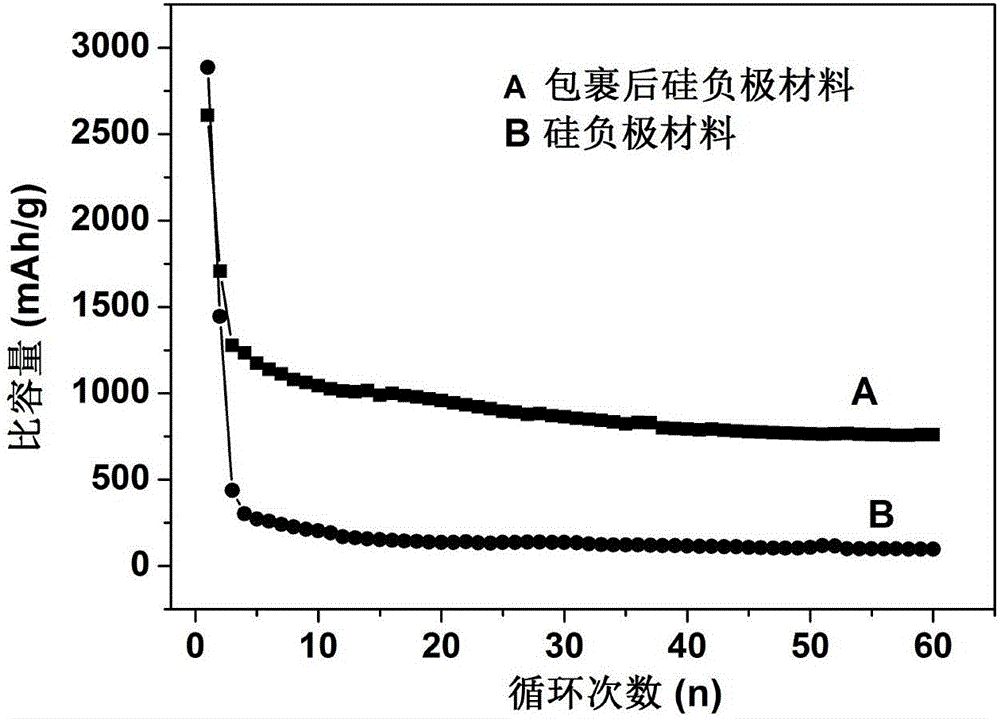

A porous oxide, silicon anode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem that the expansion control silicon anode material cannot take into account the large specific capacity and other problems, achieve good charge-discharge cycle performance, inhibit expansion, large ratio The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

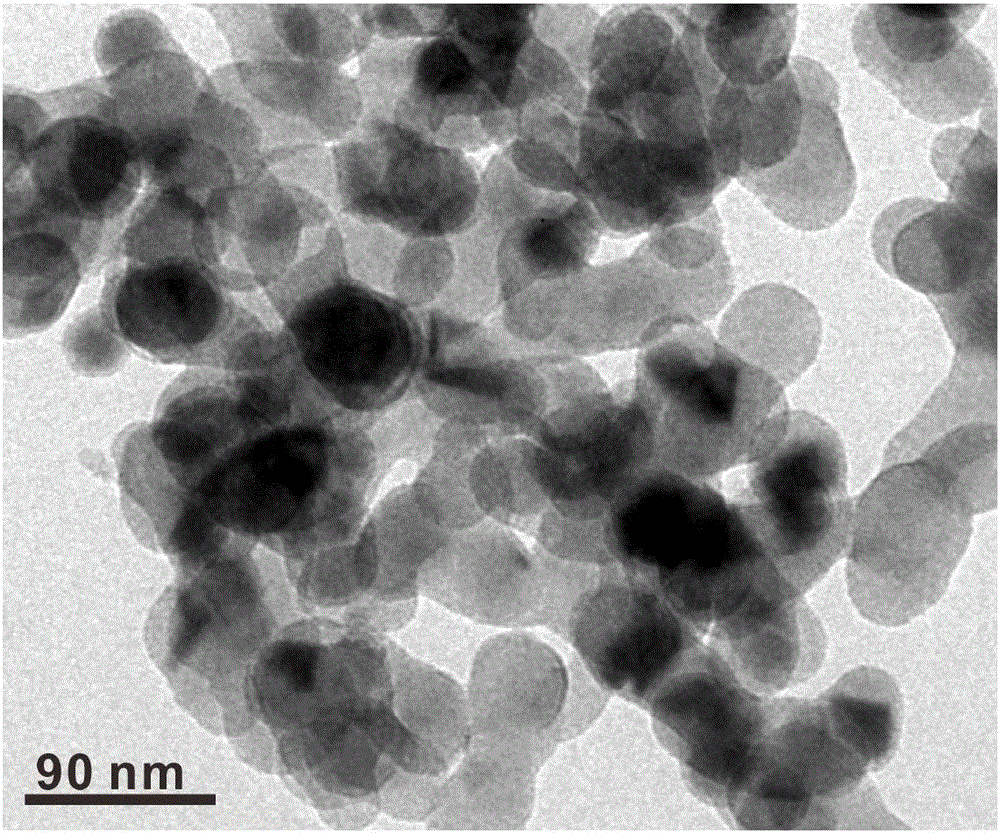

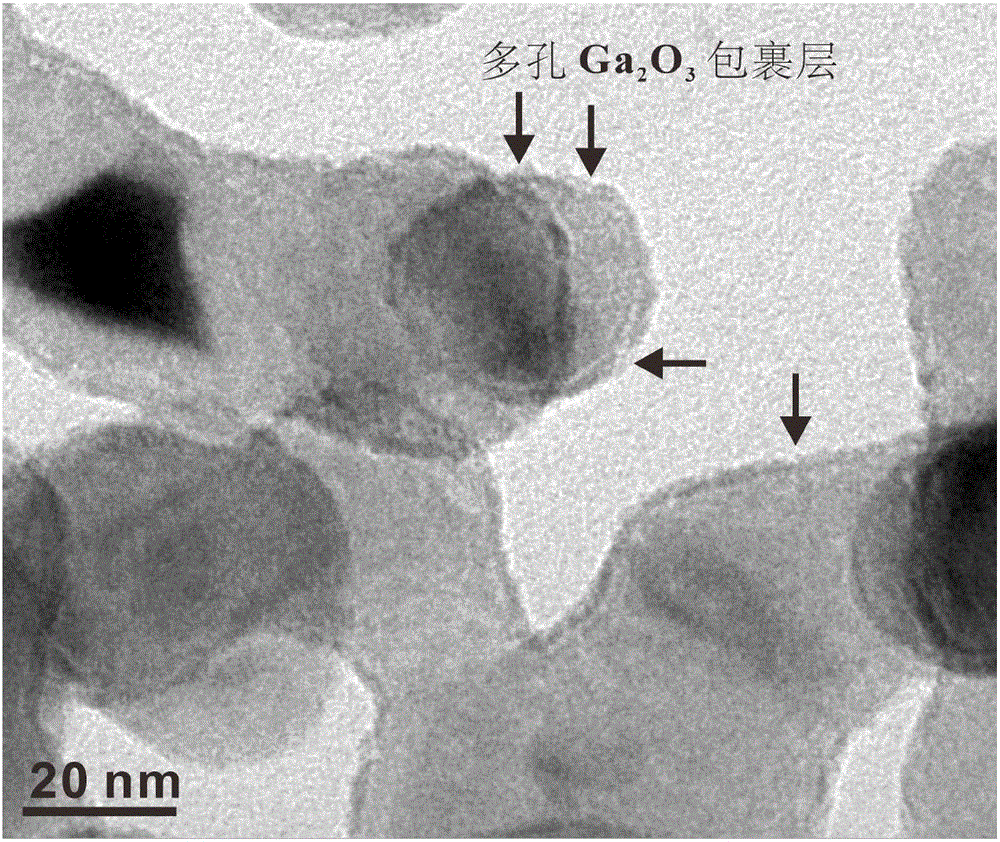

[0027] The preparation method of porous oxide-wrapped battery silicon negative electrode material in this embodiment, the preparation of porous gallium trioxide-wrapped battery silicon negative electrode material in this embodiment, includes the following steps:

[0028] S1. Put the silicon anode material in an oven at 70°C for 8 hours, then put it into a reagent bottle and seal it for later use;

[0029] S2. Put the silicon anode material obtained in step S1 into the gas phase atomic layer deposition chamber, the temperature of the chamber is 120°C, ethanol is used as the pulse precursor, high-purity nitrogen is used as the carrier gas, the pulse time of ethanol is 30s, and then Use high-purity nitrogen to blow off excess ethanol to obtain a silicon negative electrode material with surface passivation treatment;

[0030] S3. Raise the temperature of the gas-phase atomic layer deposition chamber carrying the surface-passivated silicon negative electrode material to 200°C, add ...

Embodiment 2

[0035] The preparation method of porous oxide-wrapped battery silicon negative electrode material in this embodiment, this embodiment prepares niobium pentoxide-wrapped battery silicon negative electrode material, includes the following steps:

[0036] S1. Put the silicon anode material into an oven at 60°C and bake for 6 hours, then put it into a reagent bottle and seal it for later use;

[0037] S2. Put the silicon anode material obtained in step S1 into the gas phase atomic layer deposition chamber, the temperature of the chamber is 130°C, using ethanol as the pulse precursor, using high-purity nitrogen as the carrier gas, and the pulse time of ethanol is 30s, and then Use high-purity nitrogen to blow off excess ethanol to obtain a silicon negative electrode material with surface passivation treatment;

[0038] S3. Raise the temperature of the vapor phase atomic layer deposition chamber carrying the surface passivated silicon negative electrode material to 200°C, add pentae...

Embodiment 3

[0041] The preparation method of the porous oxide-wrapped battery silicon negative electrode material in this example, the preparation of the tantalum pentoxide-wrapped battery silicon negative electrode material in this example, includes the following steps:

[0042]S1. Put the silicon anode material in an oven at 75°C and bake for 10 hours, then put it into a reagent bottle and seal it for later use;

[0043] S2. Put the silicon anode material obtained in step S1 into a gas-phase atomic layer deposition chamber with a chamber temperature of 150° C., using ethanol as a pulse precursor, high-purity nitrogen as a carrier gas, and a pulse time of ethanol for 50 s, and then Use high-purity nitrogen to blow off excess ethanol to obtain a silicon negative electrode material with surface passivation treatment;

[0044] S3. Raise the temperature of the vapor phase atomic layer deposition chamber carrying the surface passivated silicon negative electrode material to 300°C, add tantalu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com