A preparation method of graphene-based button-type supercapacitor with low internal resistance and high specific energy

A supercapacitor, graphene-based technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor separators, hybrid capacitor electrodes, etc., can solve the problems of high contact resistance, limited cycle life, low specific energy, etc., to achieve high Effects of specific capacity, low internal resistance, and reduced internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

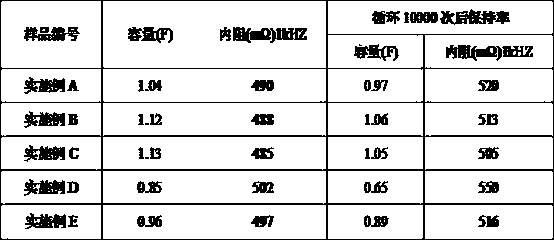

Examples

Embodiment A

[0025] A kind of preparation method of low internal resistance, high specific energy graphene-based button type supercapacitor, it is characterized in that, described preparation method adopts the following steps:

[0026] 1. Electrode preparation

[0027] ①. Taking materials: weighing activated carbon, graphene a, conductive carbon black, and binder a according to the mass ratio of 80:10:5:5, and mixing after weighing to obtain mixed raw materials;

[0028] ②. Dispersion: Put the mixed raw materials in a high-speed powder shear disperser, and uniformly mix them at a temperature of 60°C and a shear speed of 4000 rpm to obtain mixed particles;

[0029] ③.Rolling: Roll the mixed particles at 100°C, control the thickness of the electrode sheet by controlling the gap between the rollers, and obtain the electrode sheet after two times of horizontal and vertical rolling;

[0030] ④. Stamping: Die the obtained electrode sheet to obtain positive and negative electrode sheets.

[003...

Embodiment B

[0044] A kind of preparation method of low internal resistance, high specific energy graphene-based button type supercapacitor, it is characterized in that, described preparation method adopts the following steps:

[0045] 1. Electrode preparation

[0046] ①. Taking materials: weighing activated carbon, graphene a, conductive carbon black, and binder a according to the mass ratio of 75:15:3:7, and mixing after weighing to obtain mixed raw materials;

[0047] ②. Dispersion: Put the mixed raw materials in a high-speed powder shear disperser, and uniformly mix them at a temperature of 90°C and a shear speed of 5000 rpm to obtain mixed particles;

[0048] ③.Rolling: Roll the mixed particles at 120°C, control the thickness of the electrode sheet by controlling the gap between the rollers, and obtain the electrode sheet after two times of horizontal and vertical rolling;

[0049] ④. Stamping: Die the obtained electrode sheet to obtain positive and negative electrode sheets.

[005...

Embodiment C

[0063] A kind of preparation method of low internal resistance, high specific energy graphene-based button type supercapacitor, it is characterized in that, described preparation method adopts the following steps:

[0064] 1. Electrode preparation

[0065] ①. Taking materials: weighing activated carbon, graphene a, conductive carbon black, and binder a according to the mass ratio of 70:20:5:5, and mixing after weighing to obtain mixed raw materials;

[0066] ②. Dispersion: Put the mixed raw materials in a high-speed powder shear disperser, and mix them uniformly at a temperature of 60°C and a shear speed of 5000 rpm to obtain mixed particles;

[0067] ③.Rolling: Roll the mixed particles at 130°C, control the thickness of the electrode sheet by controlling the gap between the rollers, and obtain the electrode sheet after two times of horizontal and vertical rolling;

[0068] ④. Stamping: Die the obtained electrode sheet to obtain positive and negative electrode sheets.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com