Patents

Literature

161 results about "Electrode corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

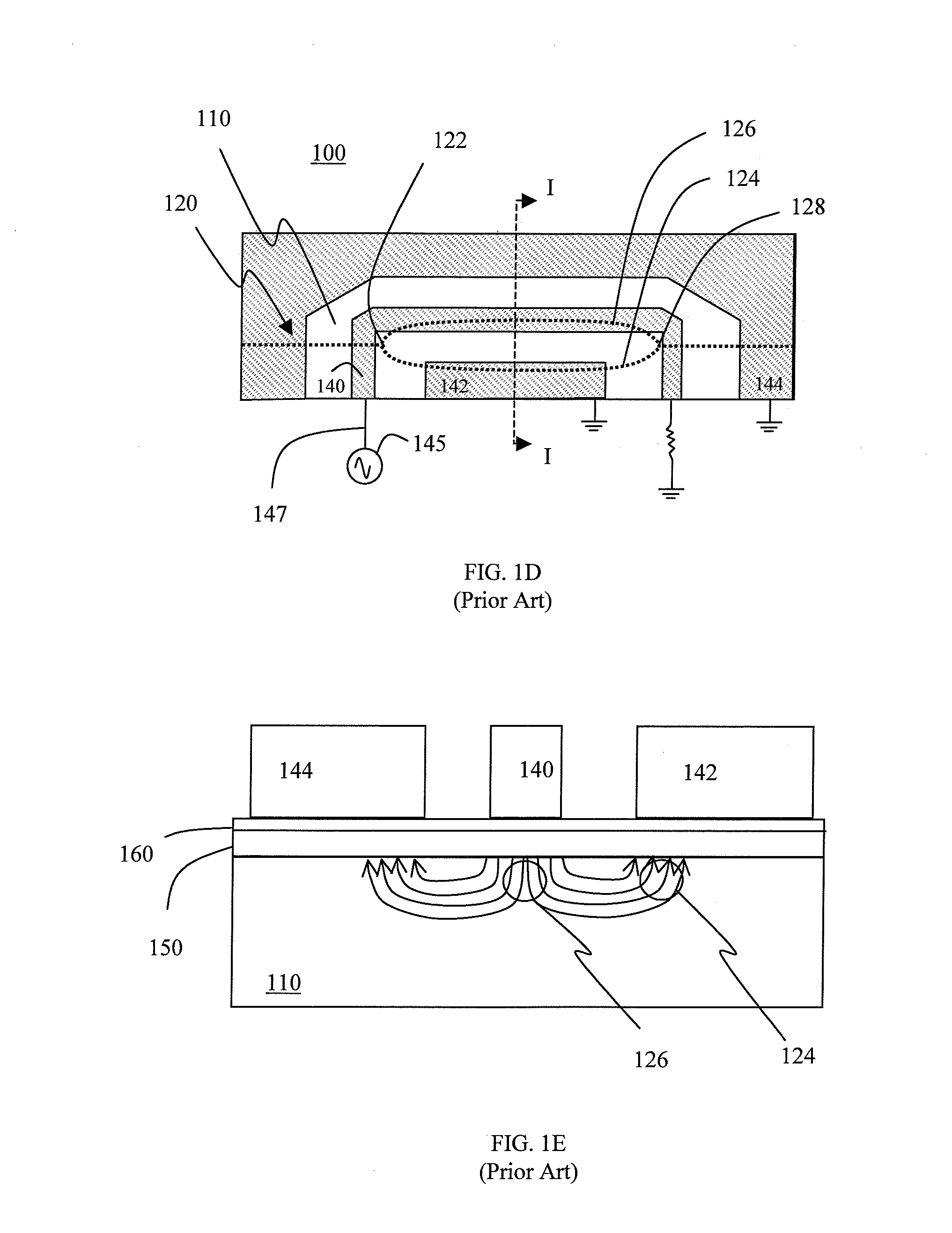

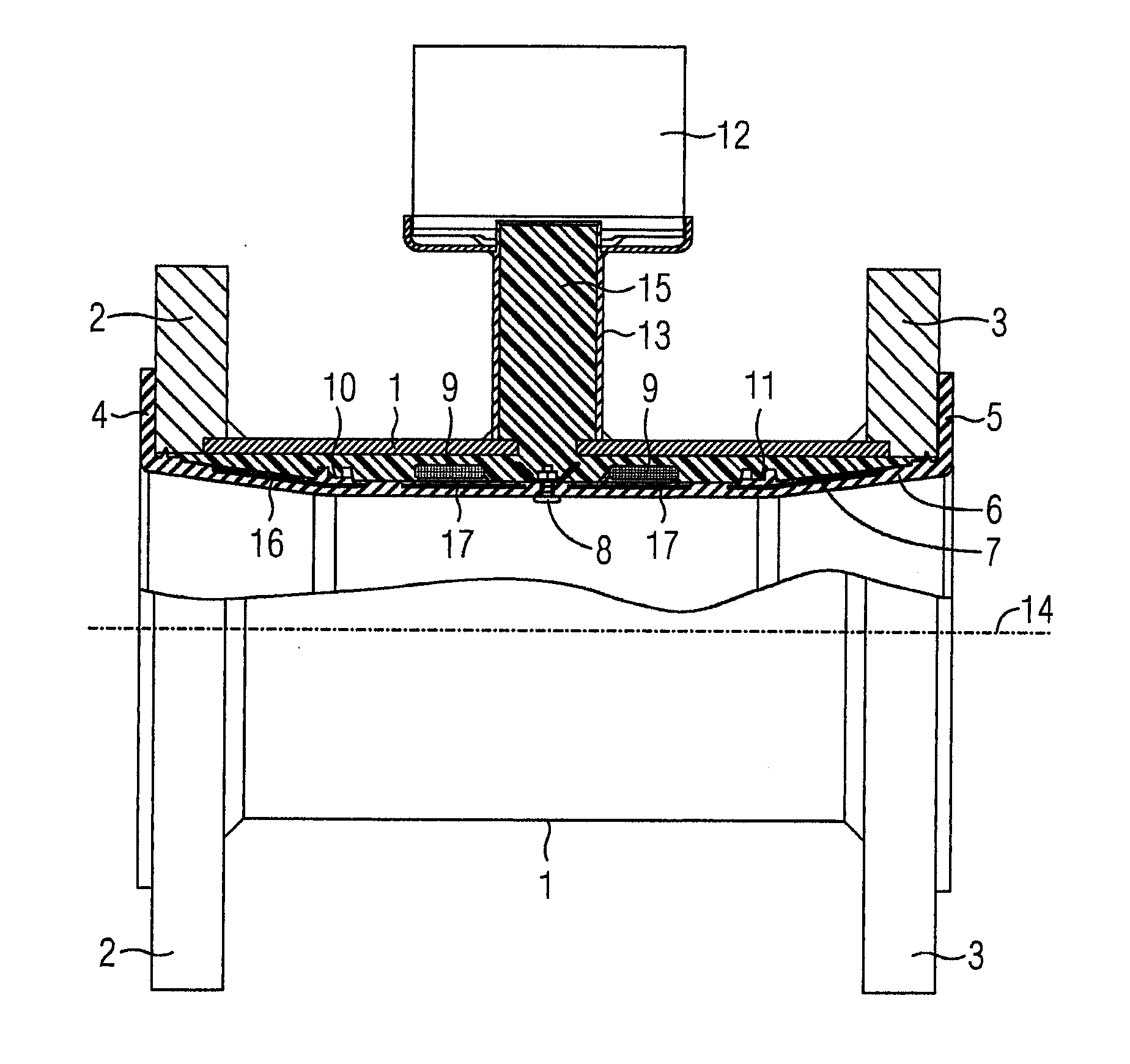

Method and apparatus for sensing a time varying current passing through an ion channel

ActiveUS7622934B2High sensitivityLess dependentCapacitance measurementsCurrent/voltage measurementCapacitanceIon current

A capacitive sensing system is used to measure a time-varying ion current through a channel, such as an ion channel or protein pore. Such a capacitive system does not suffer problems of electrode corrosion and, when used with methods to control a build up of ion concentration, allows the use of measurement volumes around the channel with dimensions on a scale of nanometers.

Owner:ELECTRONICS BIOSCI

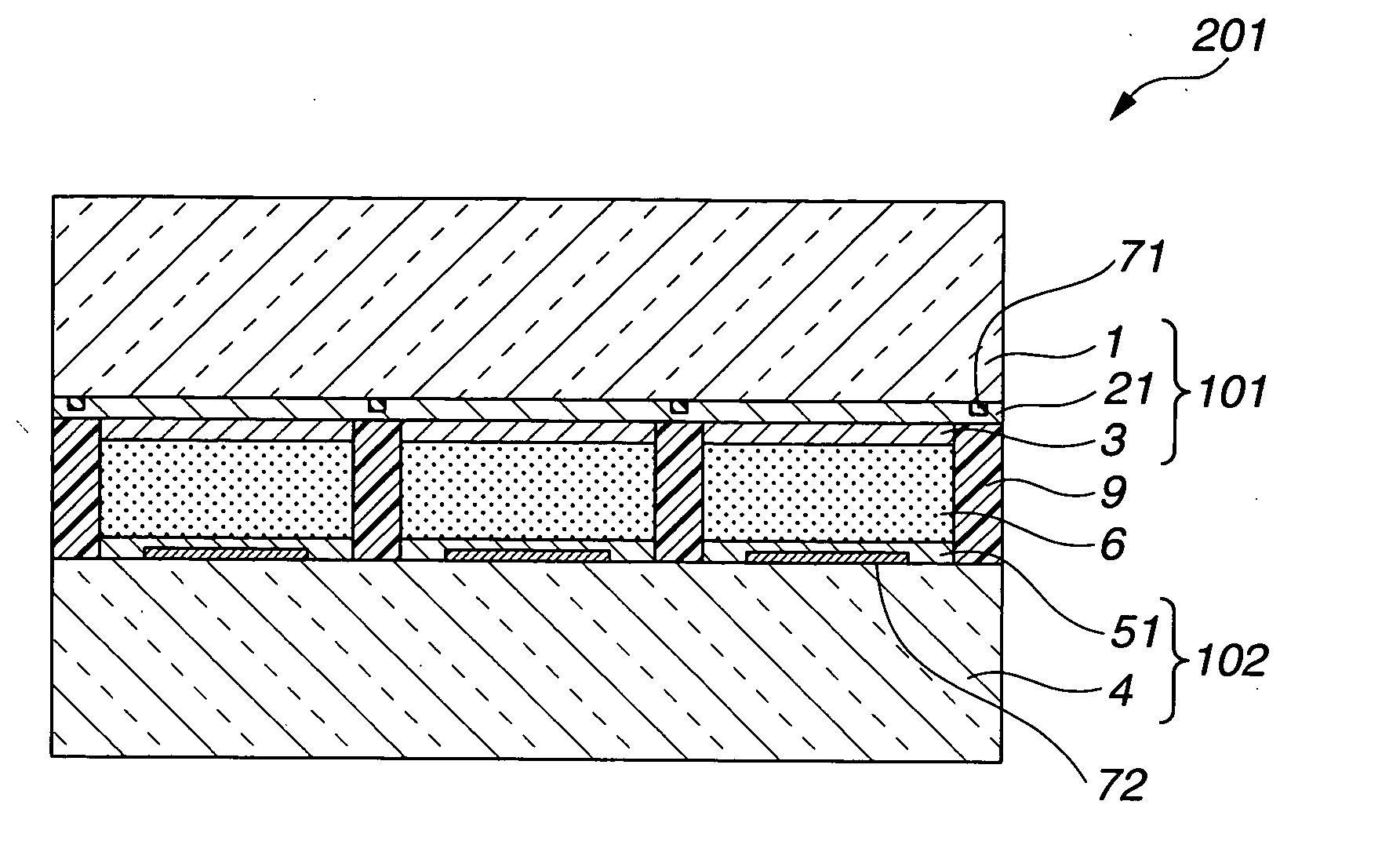

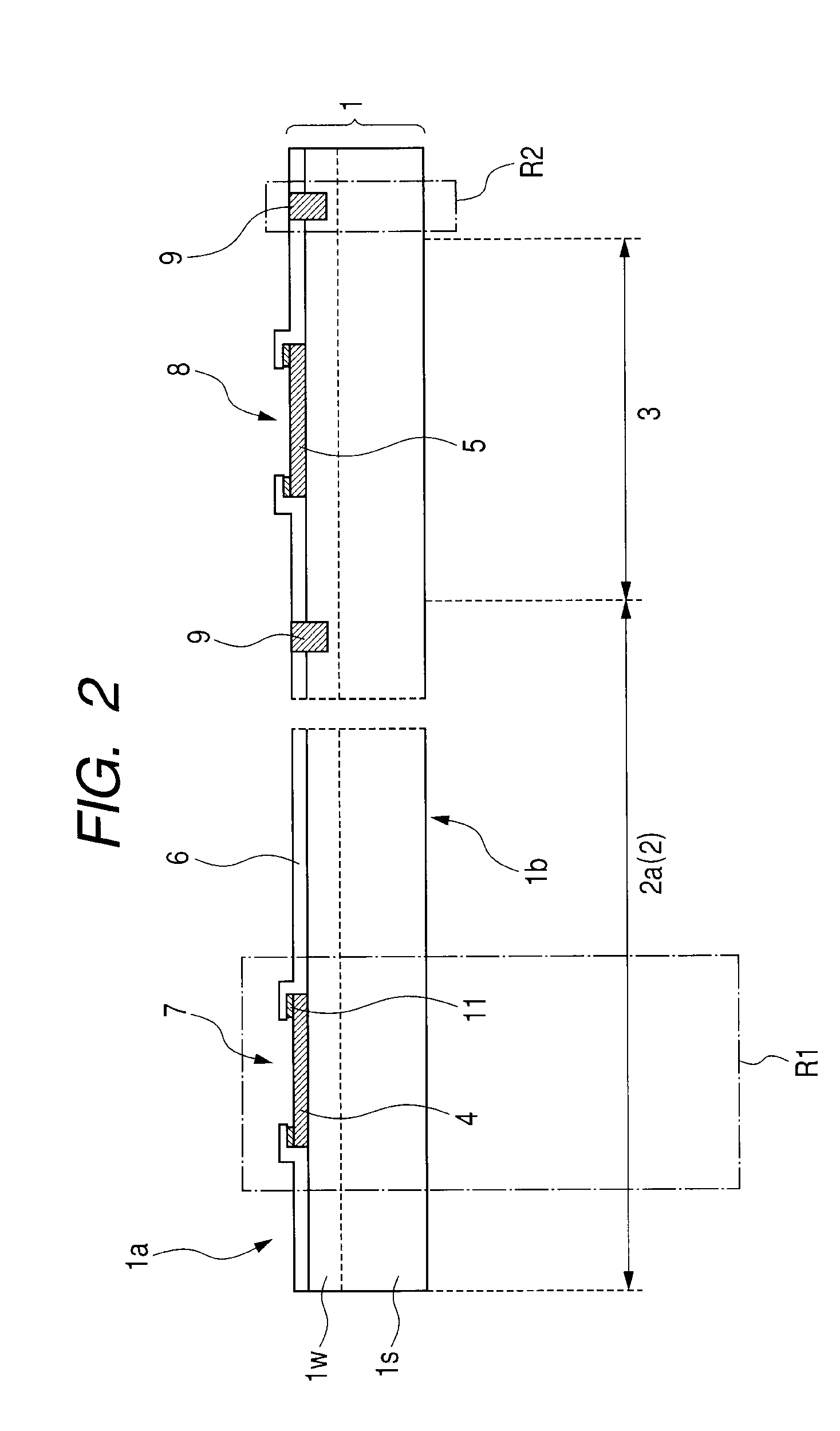

Dye-sensitized solar cell

InactiveUS20070163645A1Increase resistancePrevent collector electrode corrosionLight-sensitive devicesPhotovoltaic energy generationSemiconductor electrodeEngineering

A dye-sensitized solar cell according to one aspect of the present invention includes: a first base member having a first substrate provided with a light-transmitting property, a light-transmitting conductive layer formed on a surface of the first substrate and a semiconductor electrode formed on a surface of the light-transmitting conductive layer and containing a sensitizing dye; a second base member having a second substrate and a catalyst layer formed on a surface of the second substrate in such a manner that the catalyst layer faces the semiconductor electrode; an electrolyte layer formed between the semiconductor electrode and the catalyst layer; and either a collector electrode containing tungsten or a pair of collector electrodes, at least one of which contains tungsten, to collect charge from the semiconductor electrode. The dye-sensitized solar cell of this aspect of the present invention not only shows a sufficient photoelectric conversion efficiency but attains excellent durability by prevention of corrector electrode corrosion.

Owner:NGK SPARK PLUG CO LTD

Semiconductor integrated circuit device and a method for manufacturing a semiconductor integrated circuit device

InactiveUS20100181650A1Avoid corrosionIncrease widthSemiconductor/solid-state device detailsSolid-state devicesWaferingEngineering

With a general wafer level package process, in order to prevent corrosion of an aluminum type pad electrode in a scribe region in a plating process, the pad electrode is covered with a pad protective resin film at the same layer as an organic type protective film in a product region. However, this makes it impossible to perform the probe test on the pad electrode in the scribe region after rewiring formation. The present invention provides a method for manufacturing a semiconductor integrated circuit device of a wafer level package system. The organic type protective films in the chip regions and the scribe region are mutually combined to form an integral film pattern. In a pelletization step, the surface layer portion including the organic type protective film at the central part of the scribe region is first removed by laser grooving, to form a large-width groove. Then, a dicing processing of the central part in this groove results in separation into the chip regions.

Owner:RENESAS ELECTRONICS CORP

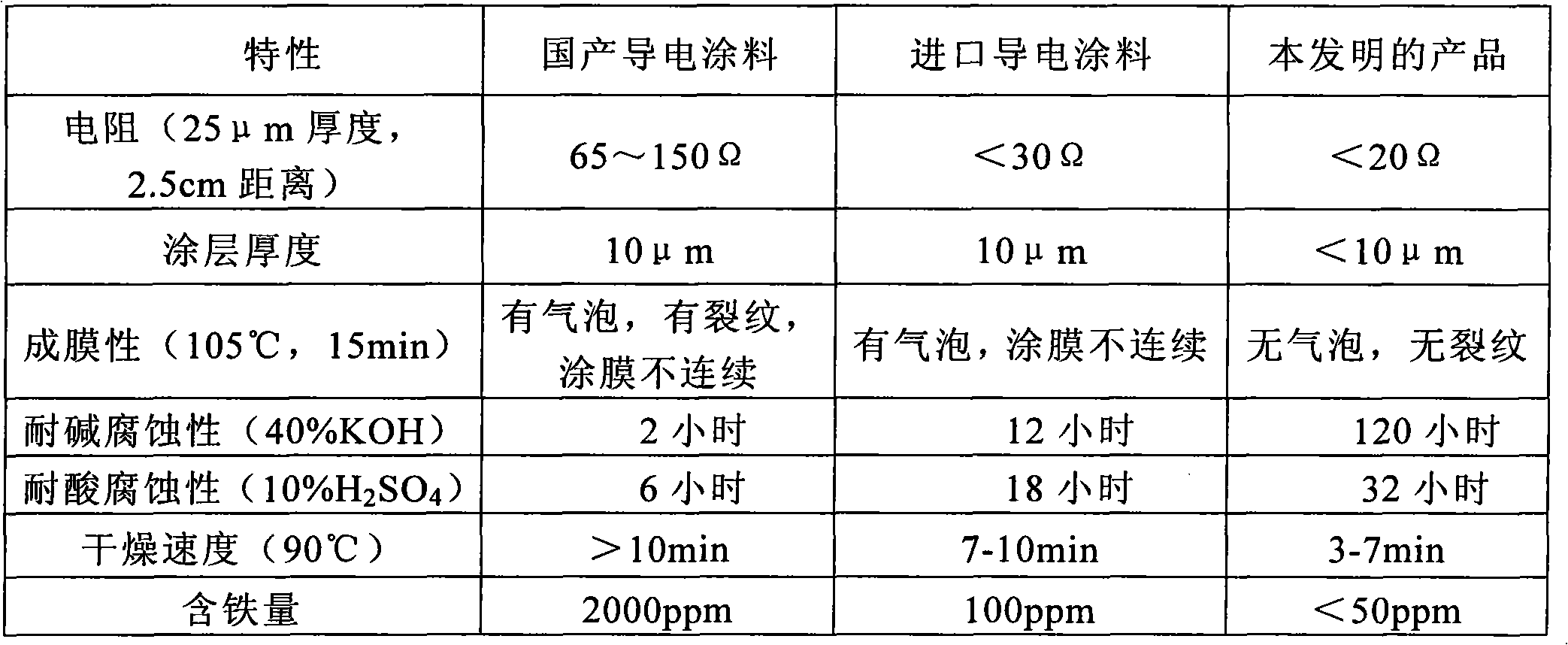

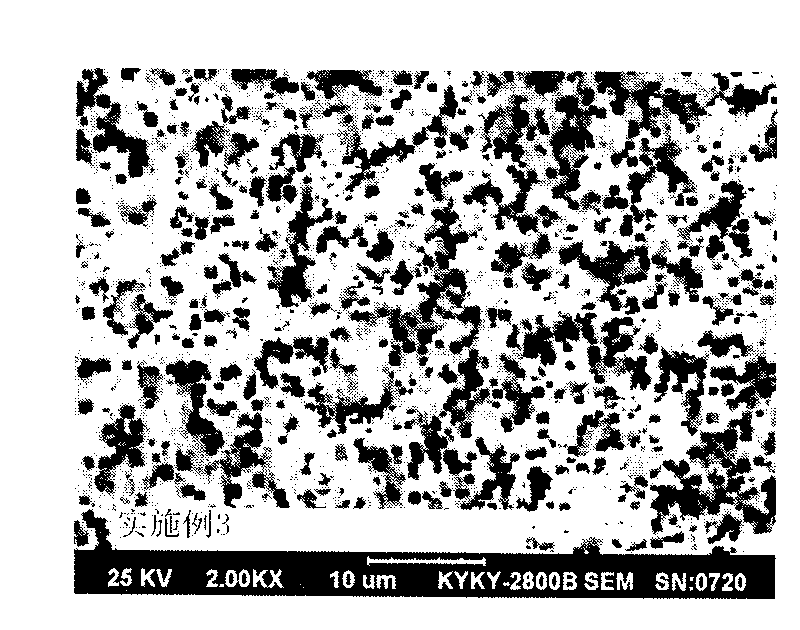

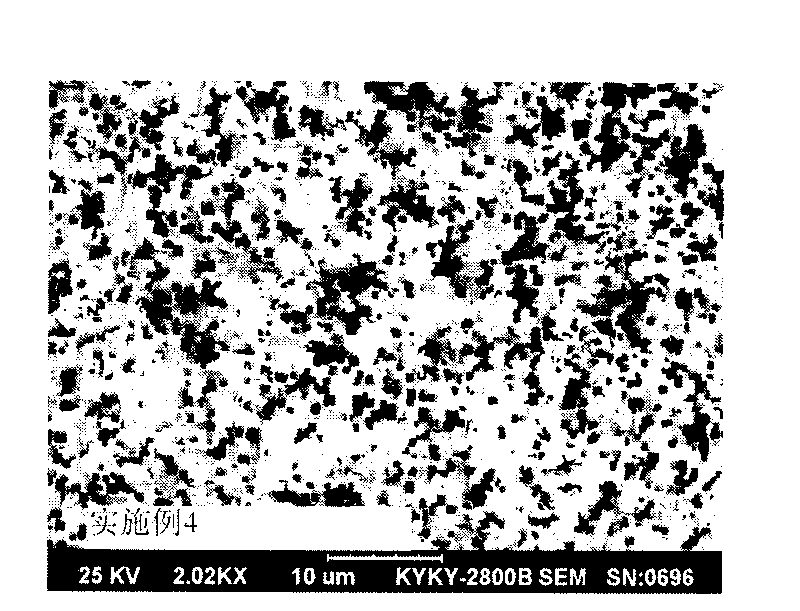

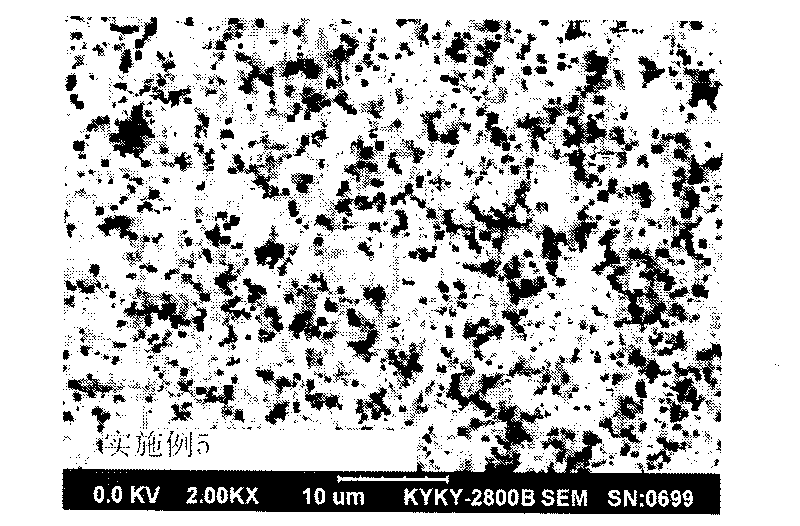

Supercapacitor electrode corrosion-resistant conductive coating

ActiveCN101899233AImprove conductivityReduce volumeAlkali metal silicate coatingsElectrolytic capacitorsConductive coatingSupercapacitor

The invention discloses a supercapacitor electrode corrosion-resistant conductive coating, which comprises the following components in percentage by weight: 10 to 35 percent of conductive agent, 0.1 to 3.5 percent of dispersing agent, 2.0 to 15 percent of binder, 0.1 to 8.0 percent of pH regulator, and 50 to 70 percent of pure water. The supercapacitor electrode corrosion-resistant conductive coating is prepared by the following steps of: fully mixing and uniformly stirring the components, adding the components into a ball mill for peptizing and dispersing, and discharging to obtain the supercapacitor electrode corrosion-resistant conductive coating. Compared with the conventional like products at home and abroad, the supercapacitor electrode corrosion-resistant conductive coating has the advantages of greatly improving the acid and alkali corrosion resistance, having no bubbles, falling off, corrosion and other phenomena after being soaked in alkaline solution for 120 hours and in acid solution for 32 hours, and improving the conductivity, adhesiveness and drying speed. The product can be diluted and adjusted according to need during use.

Owner:SHANGHAI HANBO ENTERPRISE +1

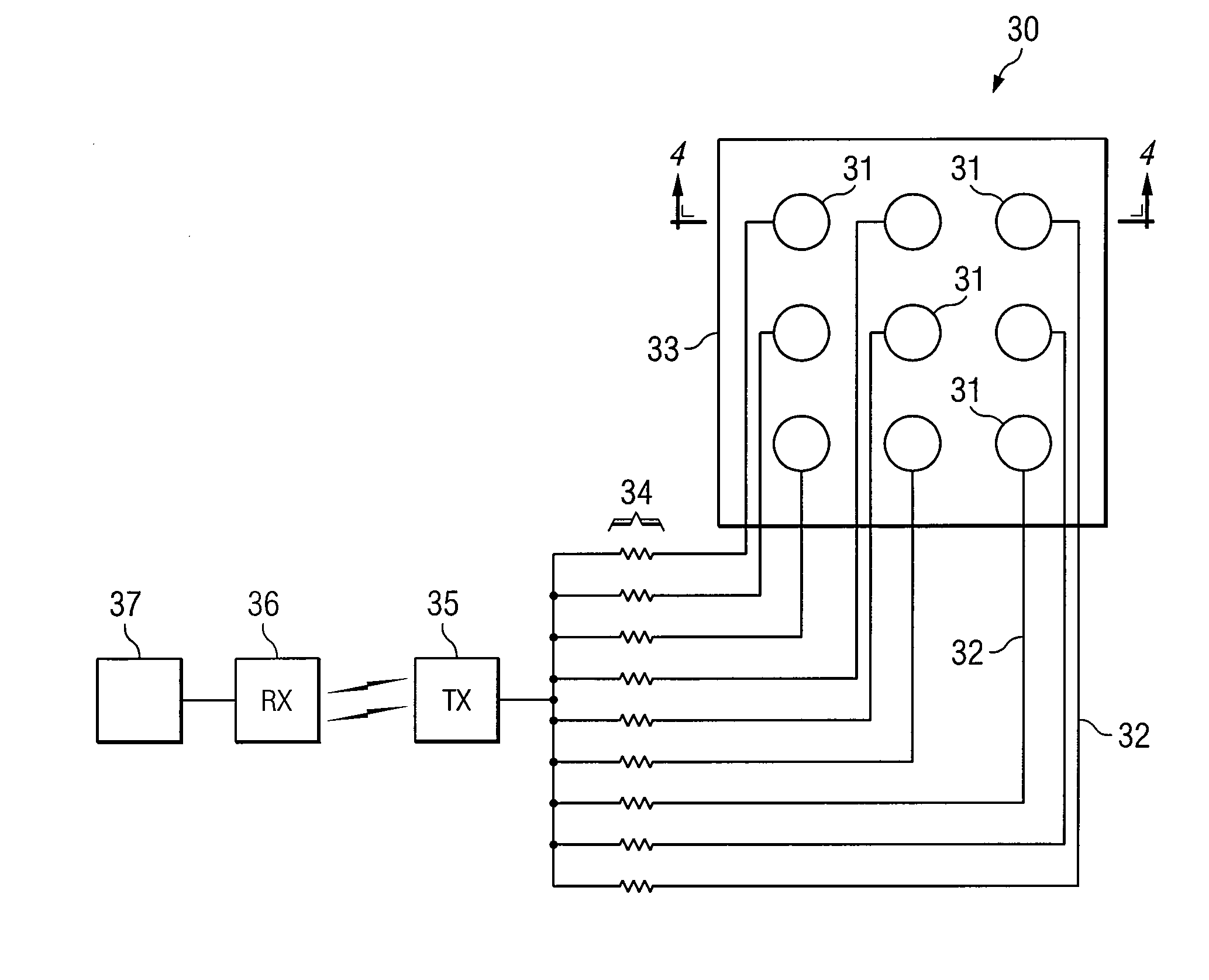

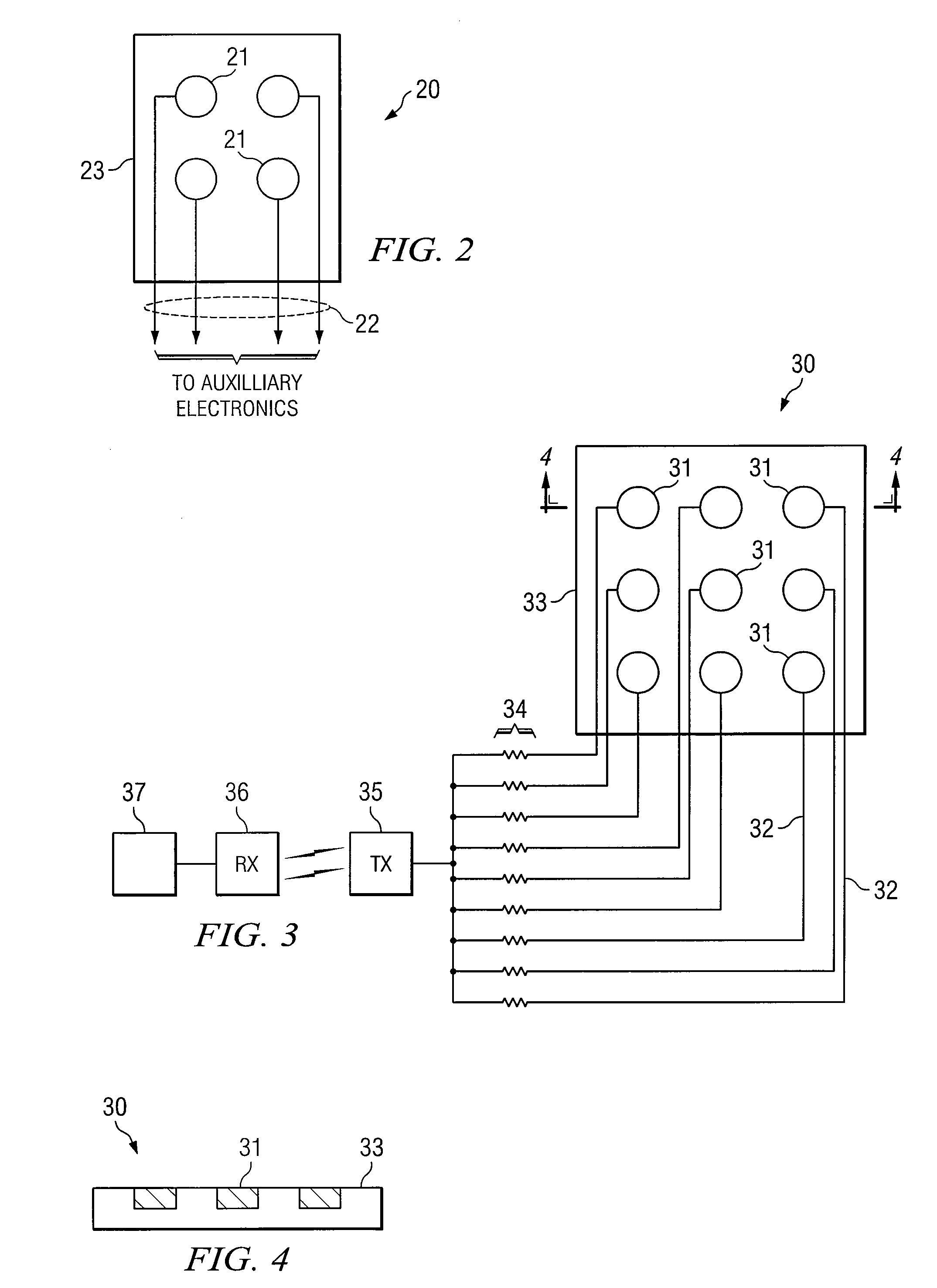

Planar multi-electrode array sensor for localized electrochemical corrosion detection

ActiveUS20070193887A1Easy to useReliable measurementCellsWeather/light/corrosion resistanceEngineeringElectrode array

A planarized type of coupled multi-electrode corrosion sensing device. Electrode pads are fabricated on a thin backing, such as a thin film. Each pad has an associated electrical lead for connection to auxiliary electronic circuitry, which may include a resistor associated with each electrical pad. The design permits the device to be easily placed in small crevices or under coatings such as paint.

Owner:SOUTHWEST RES INST

Electro-optic device

The invention relates to an electro-optic modulator structure containing an additional set of bias electrodes buried within the device for applying bias to set the operating point. Thus the RF electrodes used to modulate incoming optical signals can be operated with zero DC bias, reducing electrode corrosion by electro-migration, galvanic, and other effects that can be present in non-hermetic packages. The RF electrodes are supported by a first surface of the electro-optic substrate, while the bias electrodes are supported by a second opposite surface.

Owner:LUMENTUM OPERATIONS LLC

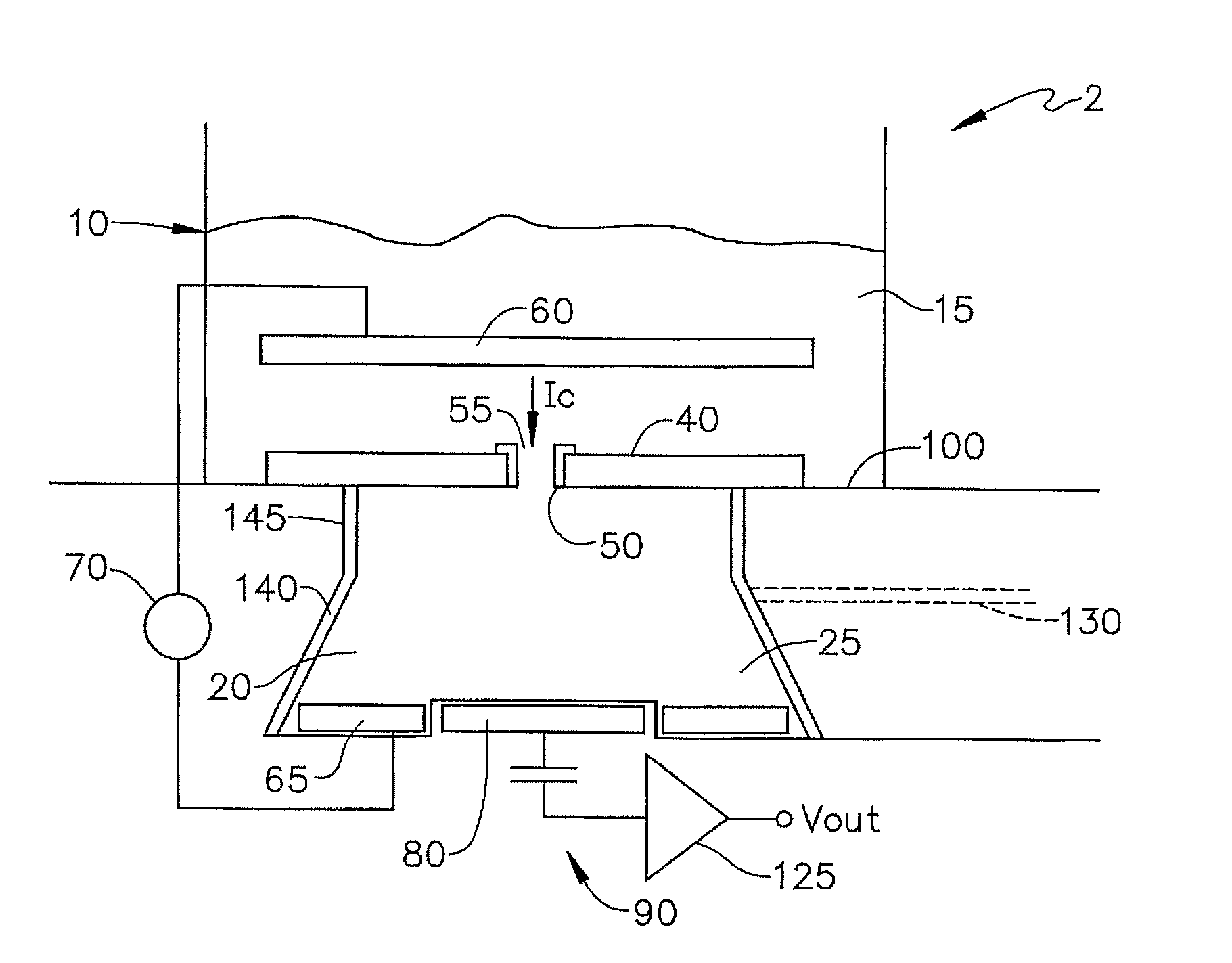

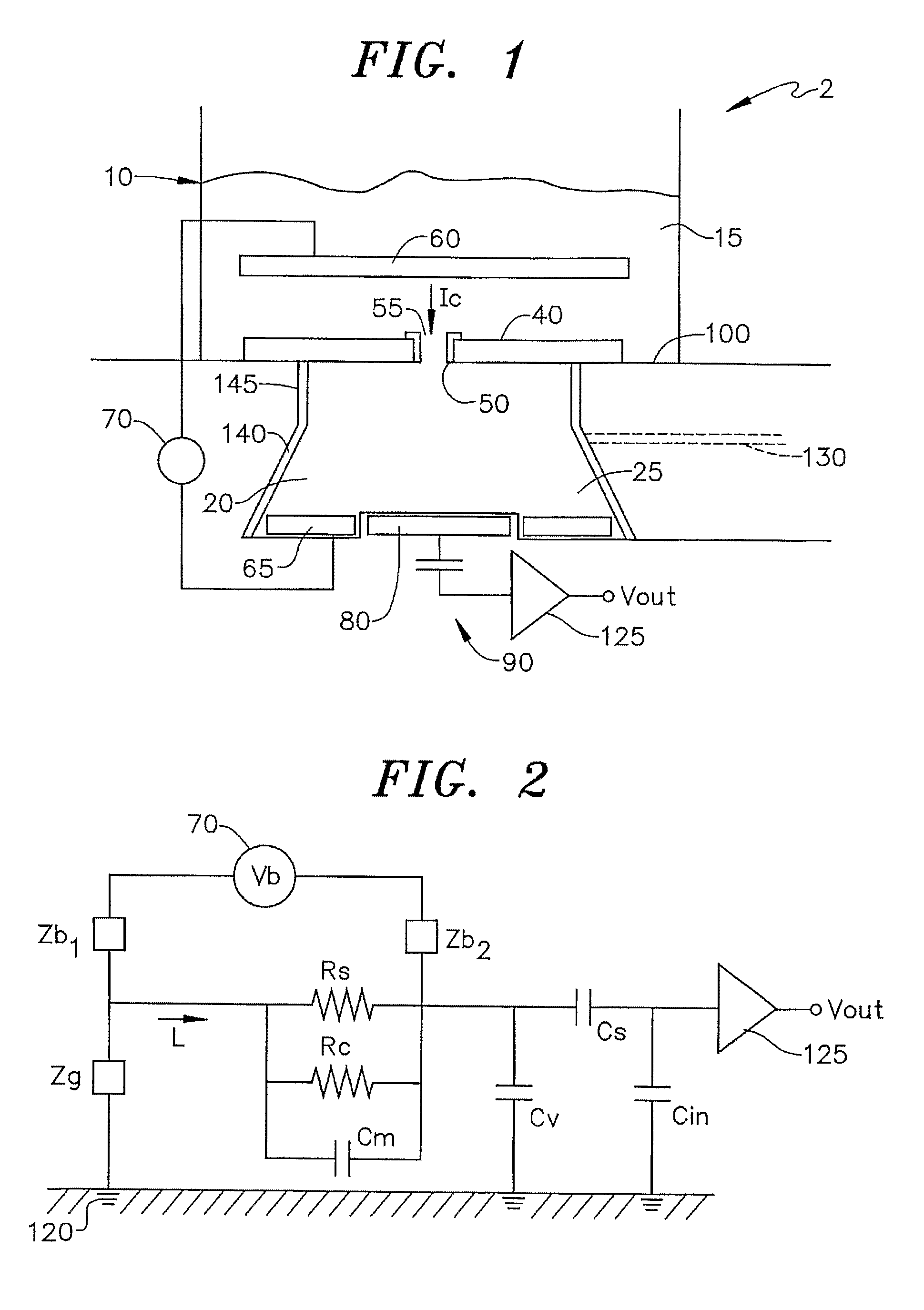

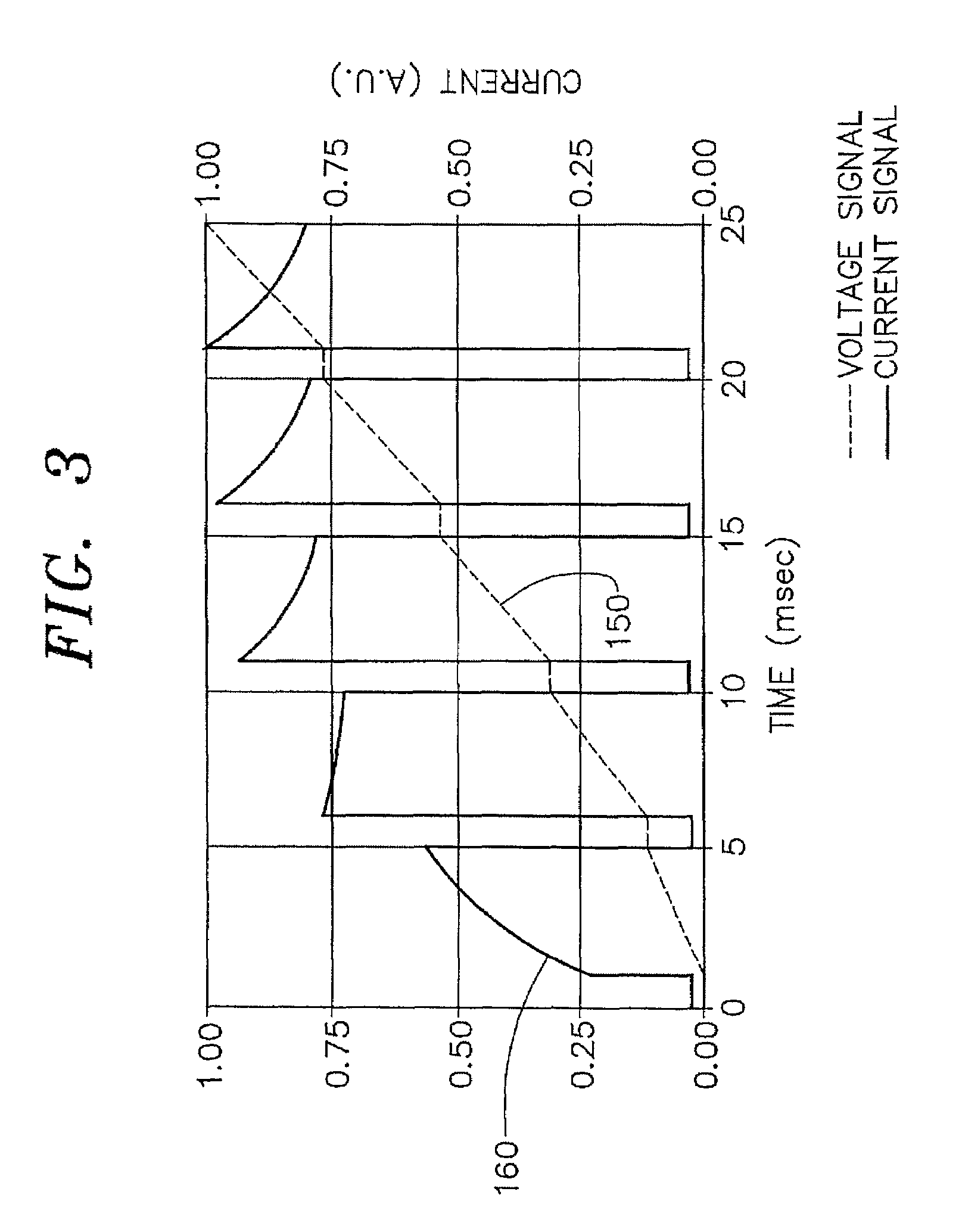

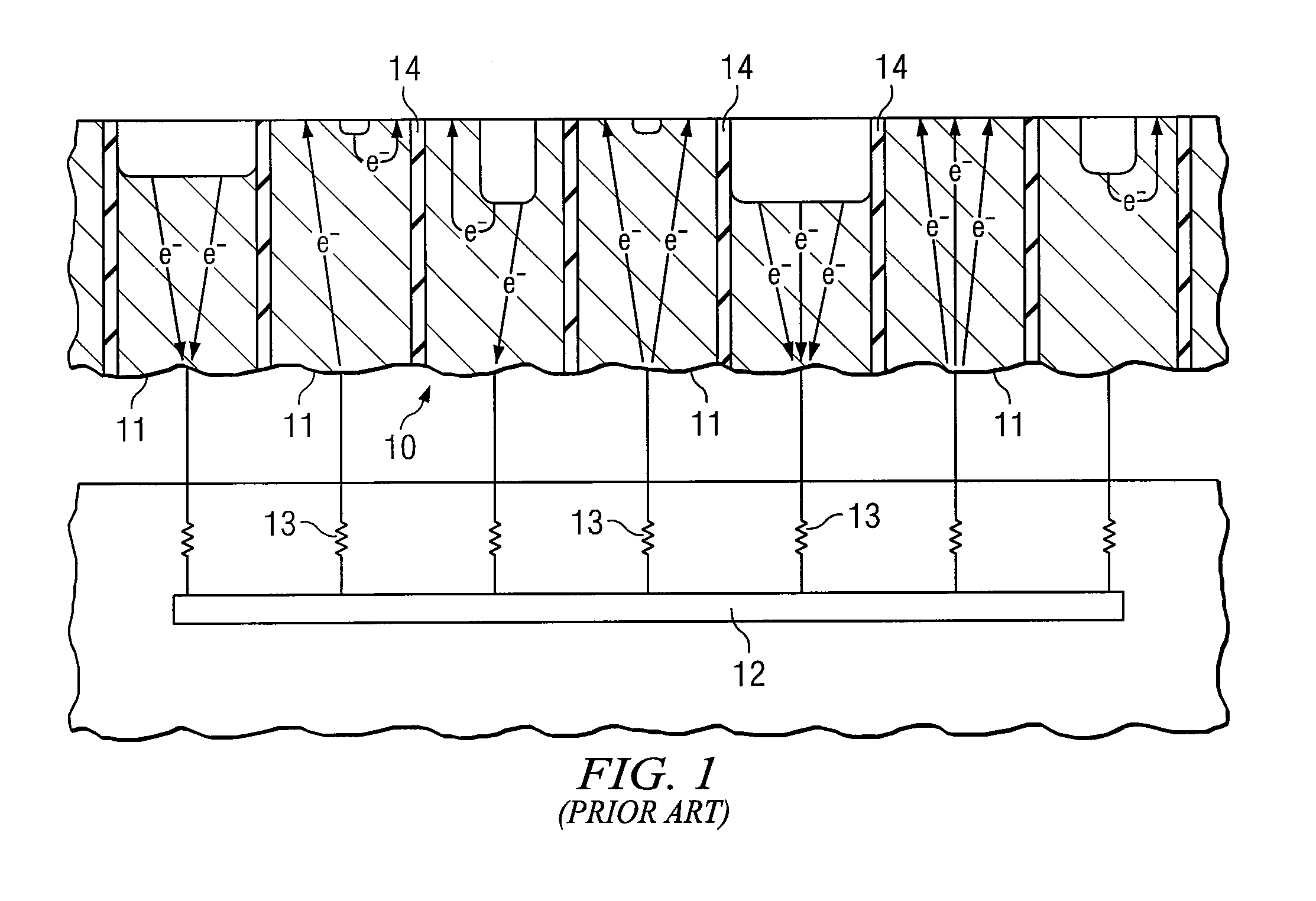

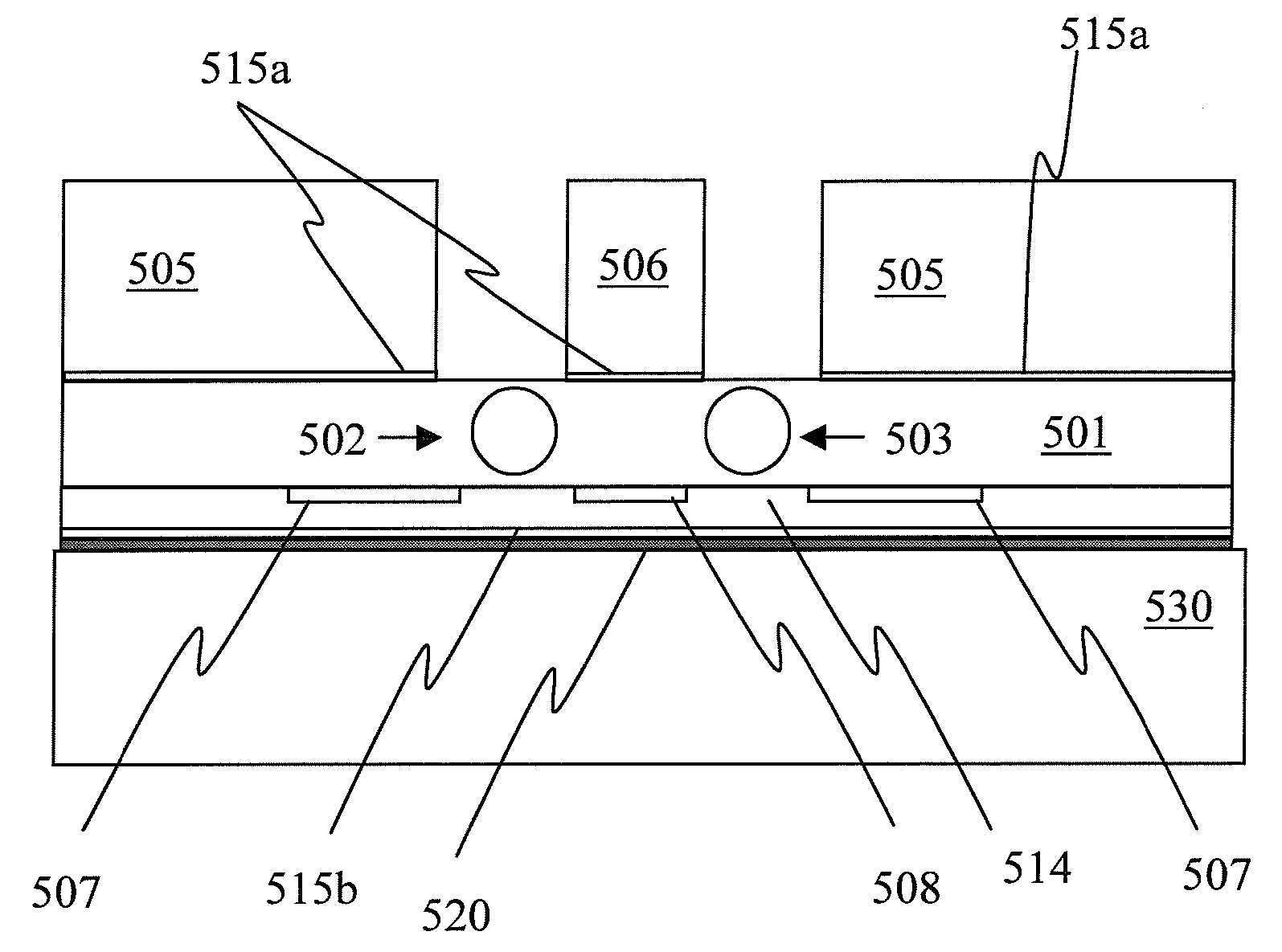

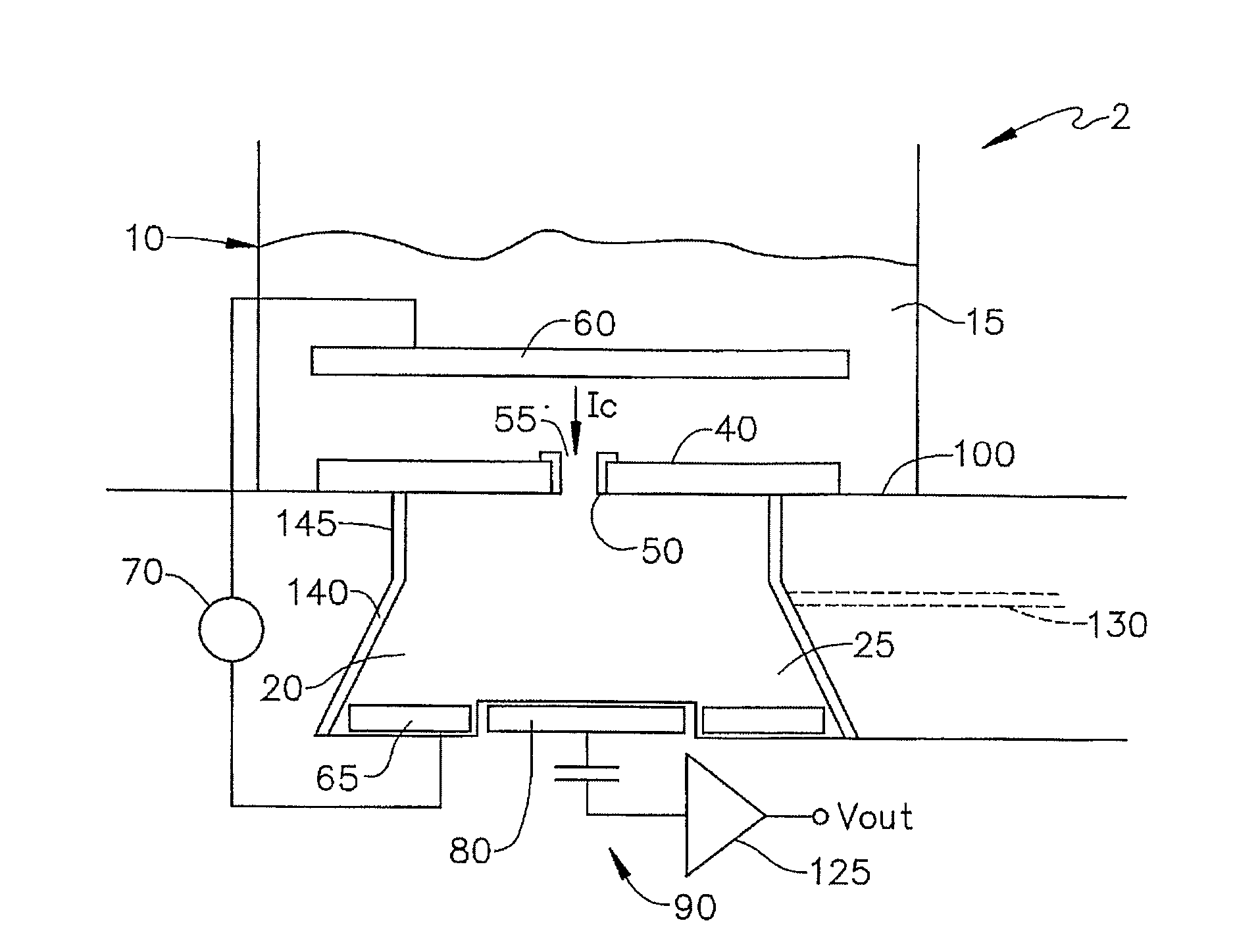

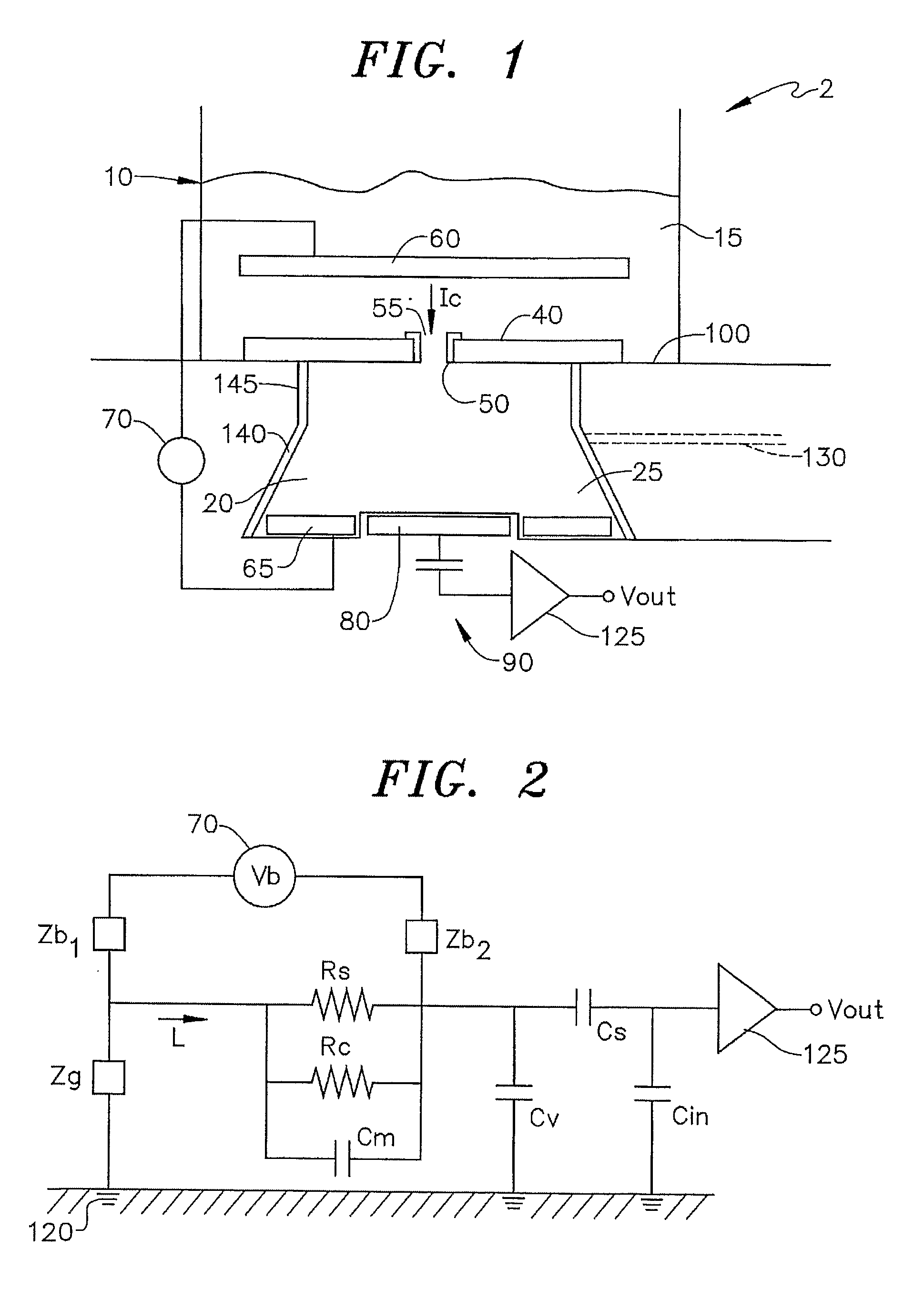

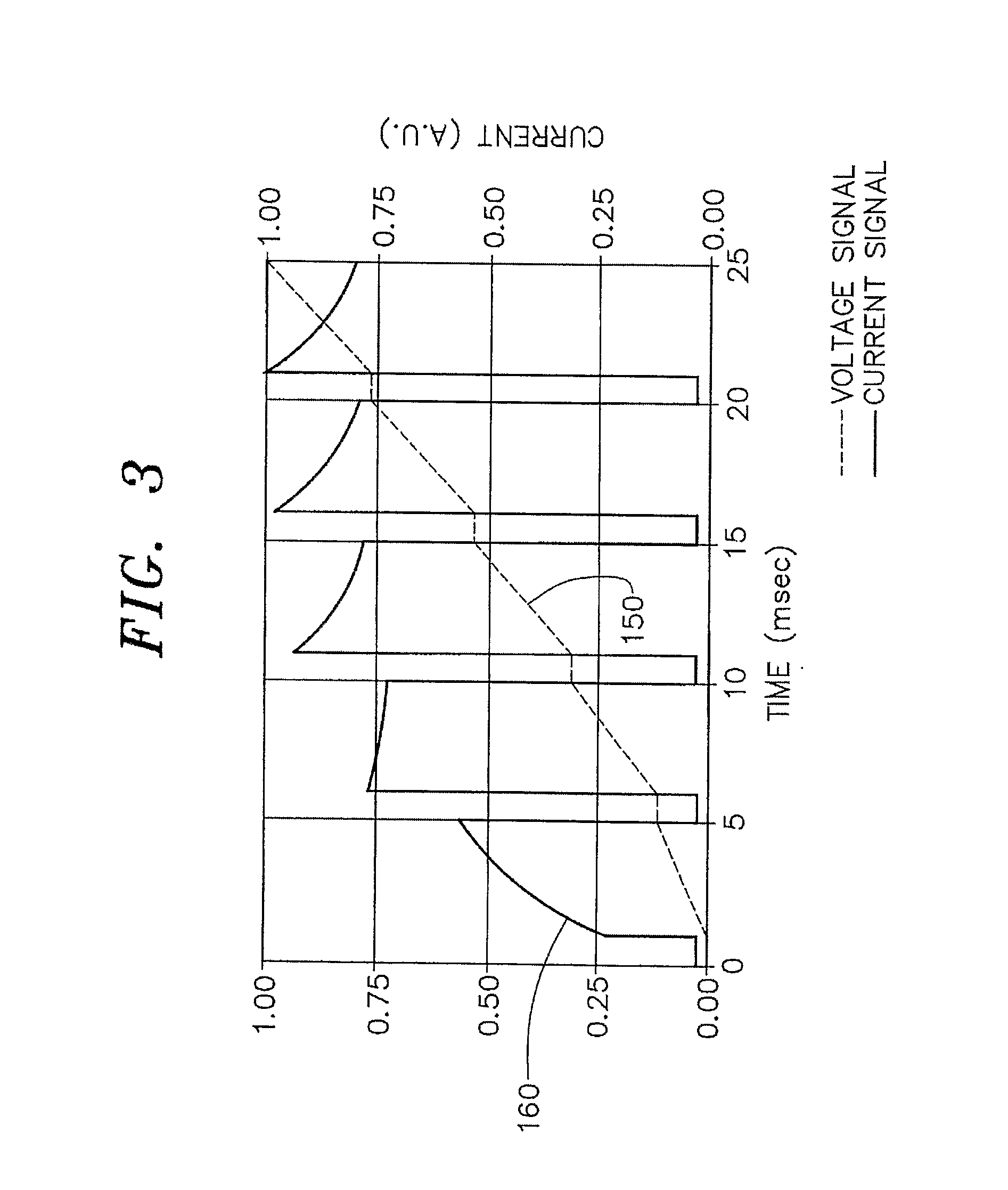

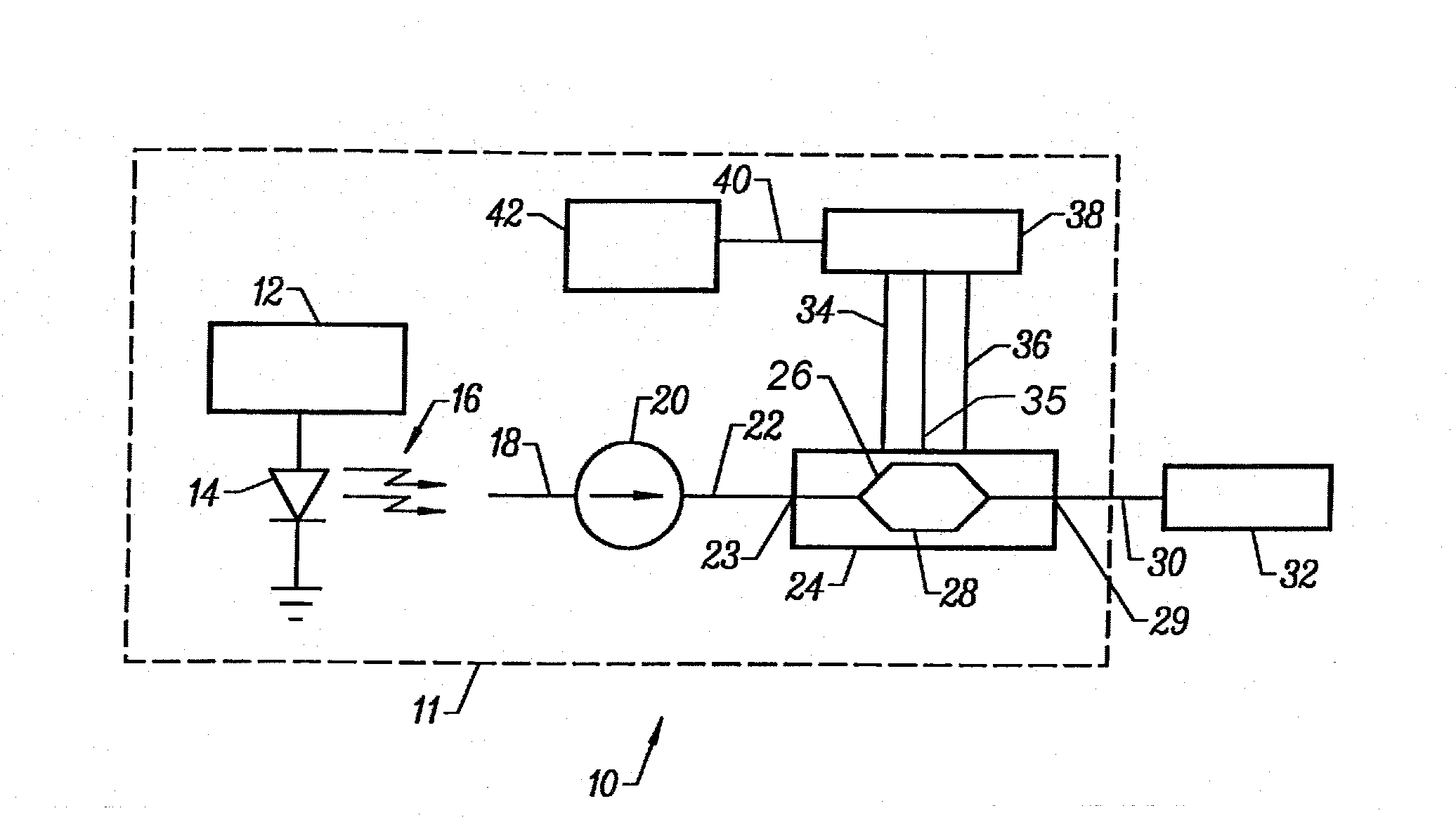

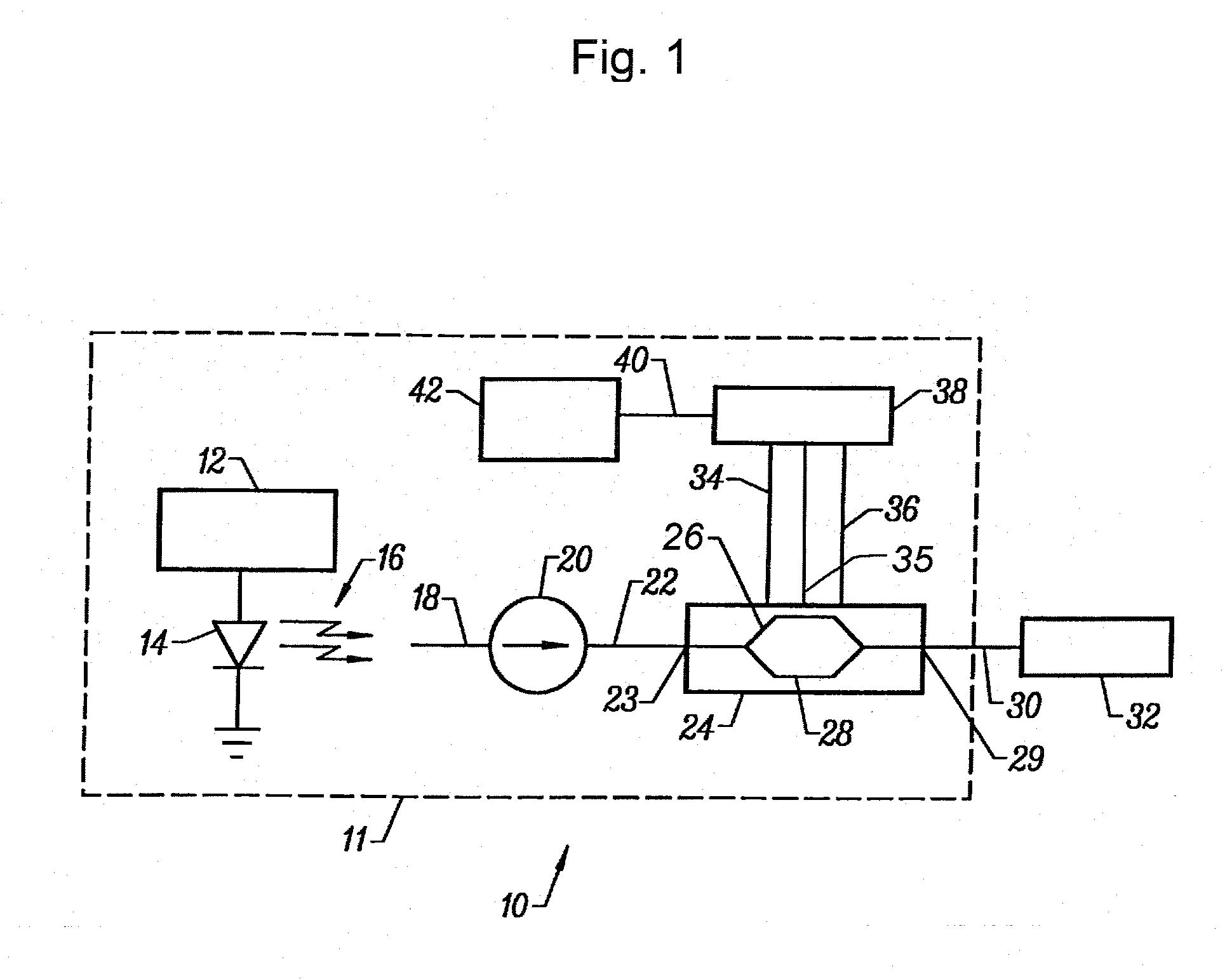

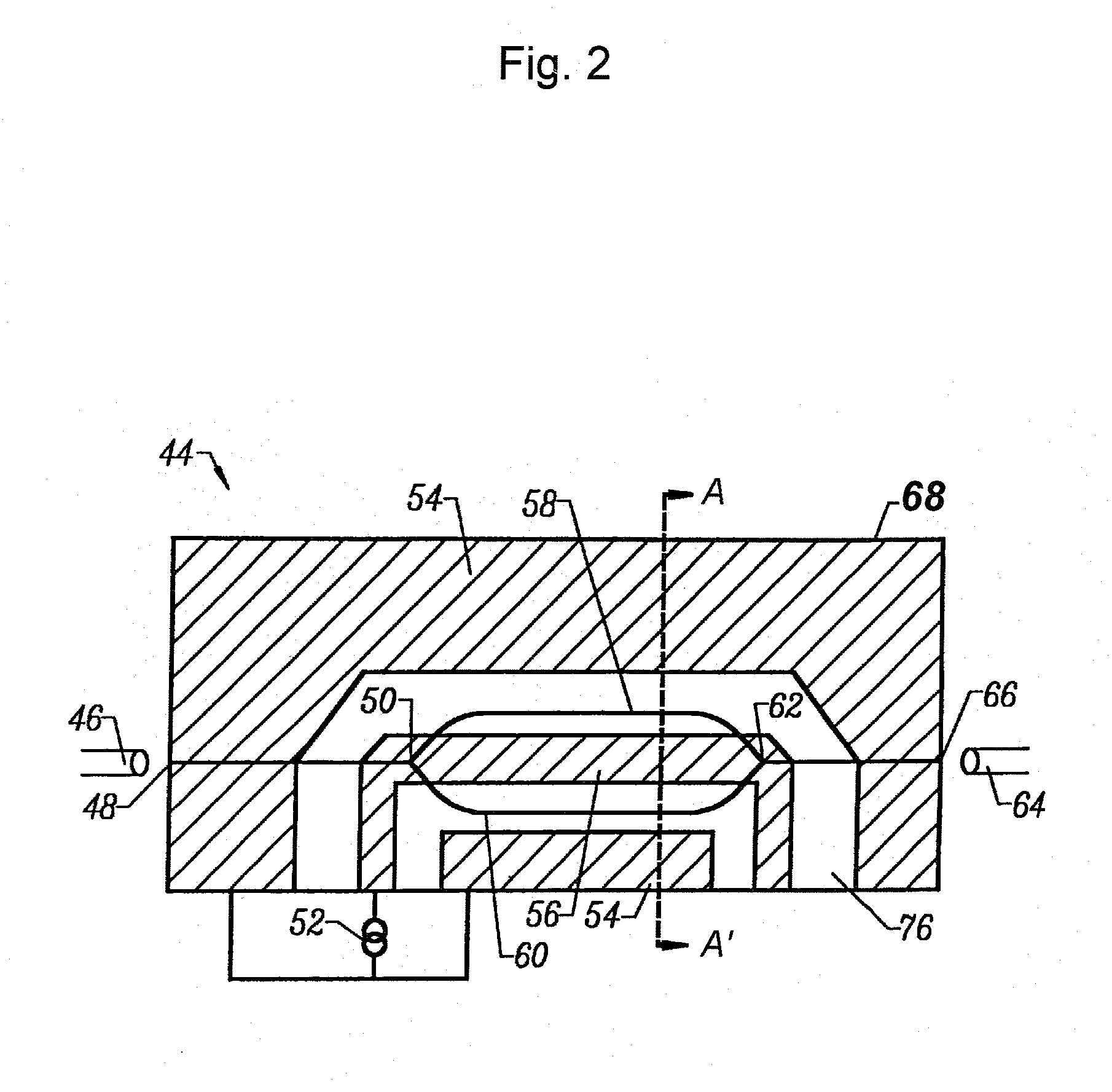

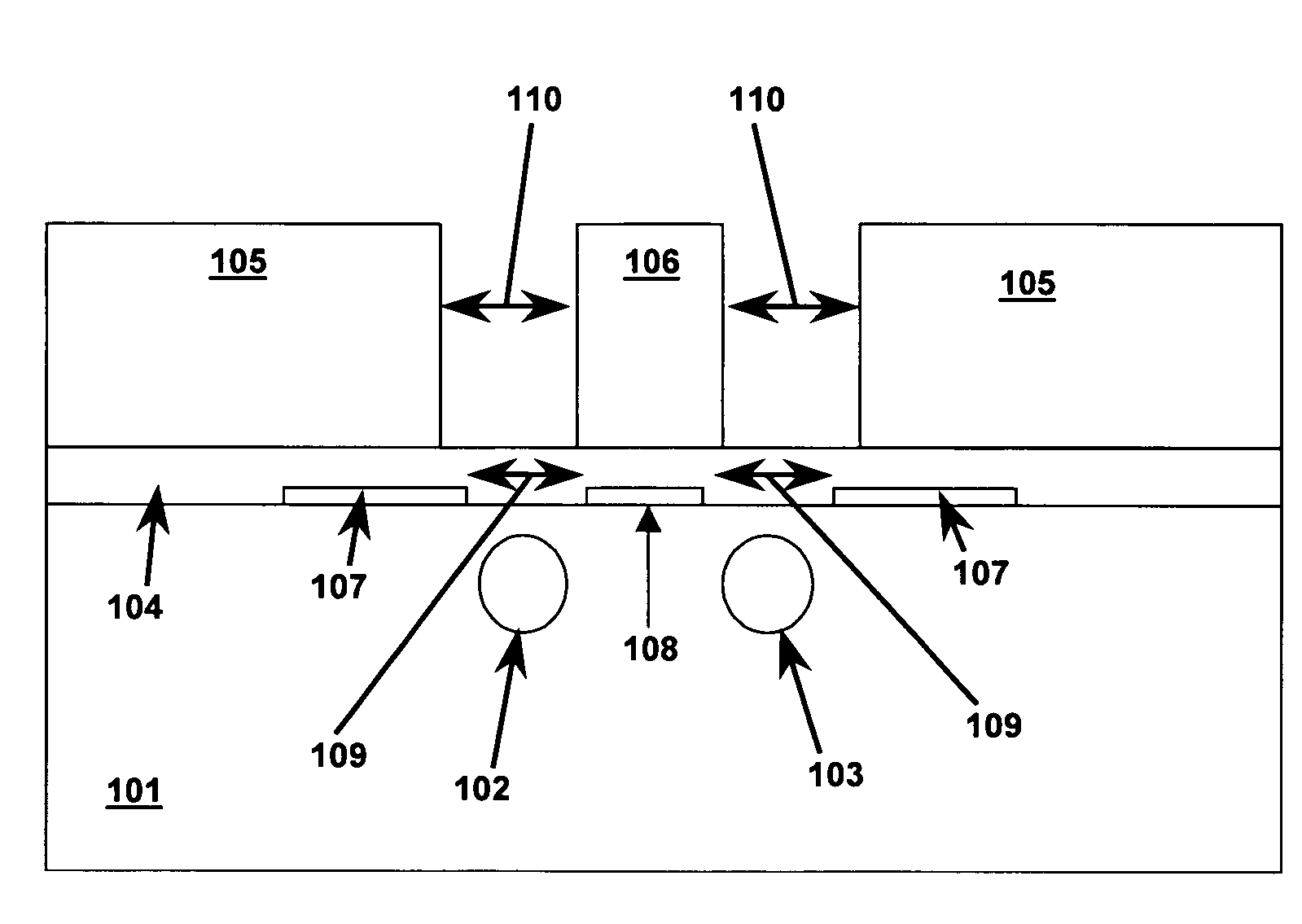

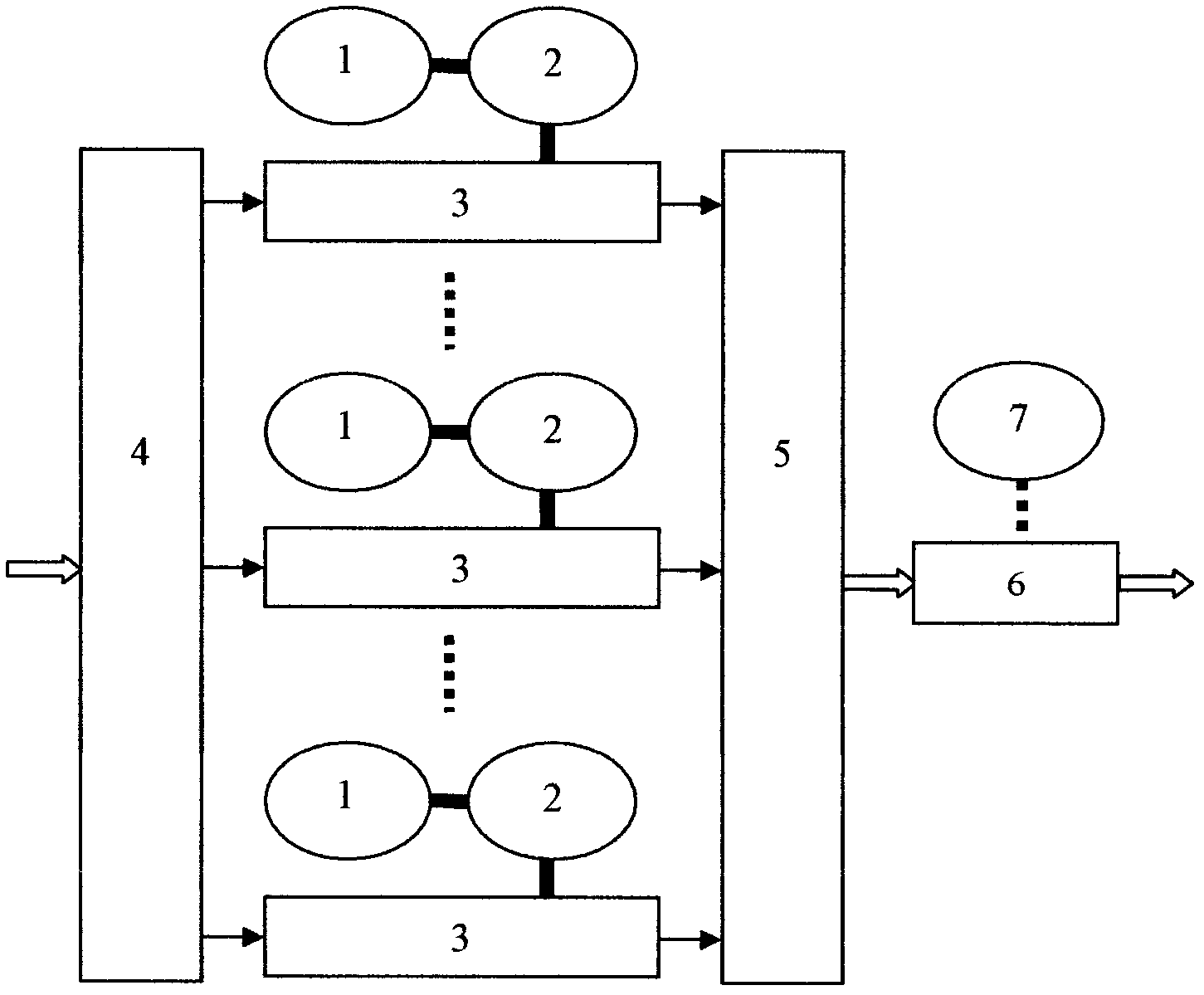

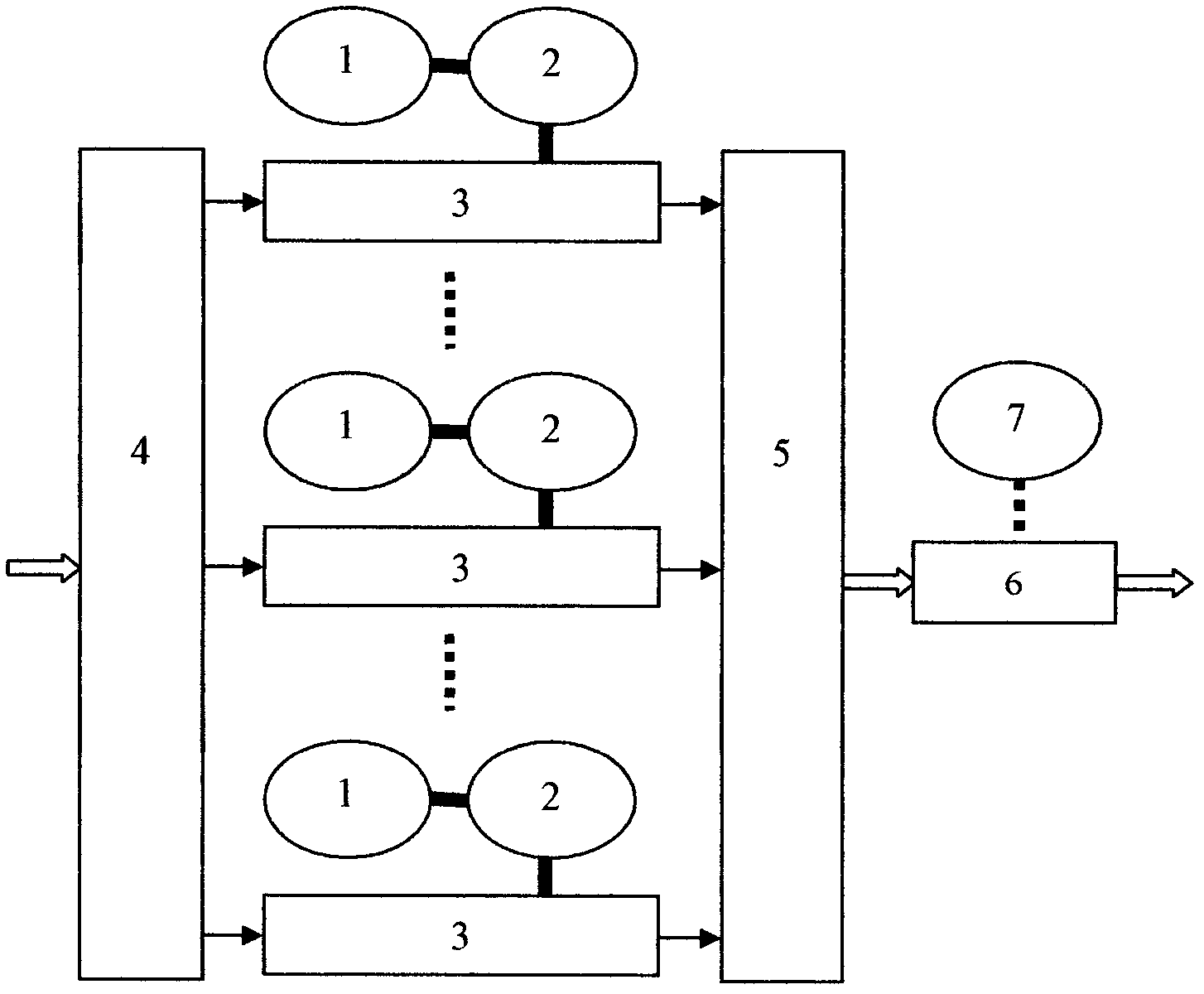

Method And Apparatus For Sensing A Time Varying Current Passing Through An Ion Channel

ActiveUS20080094076A1Less effectLess dependentCapacitance measurementsCurrent/voltage measurementCapacitanceIon current

A capacitive sensing system (2, 2′, 2″) is used to measure a timevarying ion current through a channel (50), such as an ion channel or protein pore. Such a capacitive system (2, 2′, 2″) does not suffer problems of electrode corrosion and, when used with methods to control a build up of ion concentration, allows the use of measurement volumes (10, 20) around the channel (50) with dimensions on a scale of nanometers.

Owner:ELECTRONICS BIOSCI

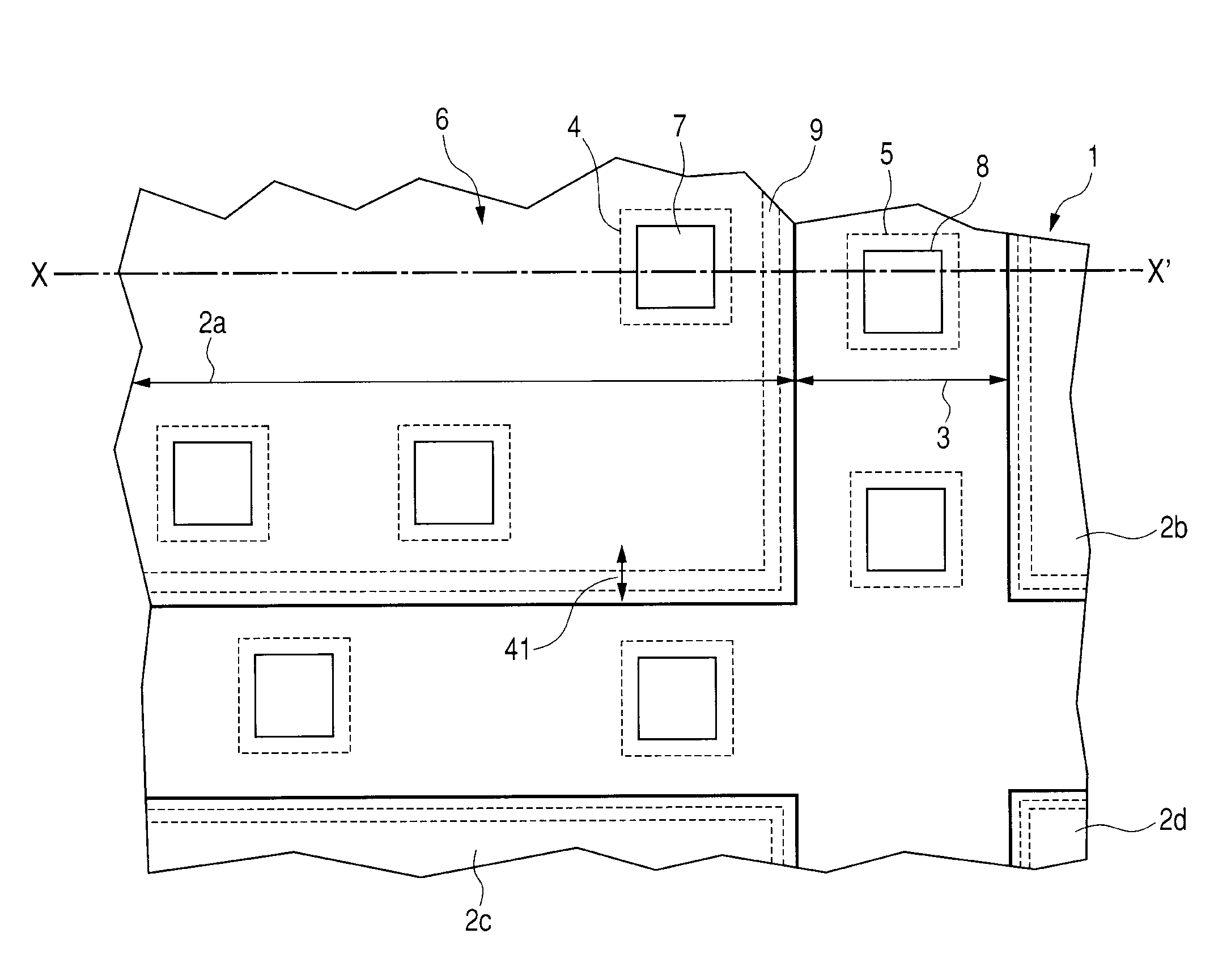

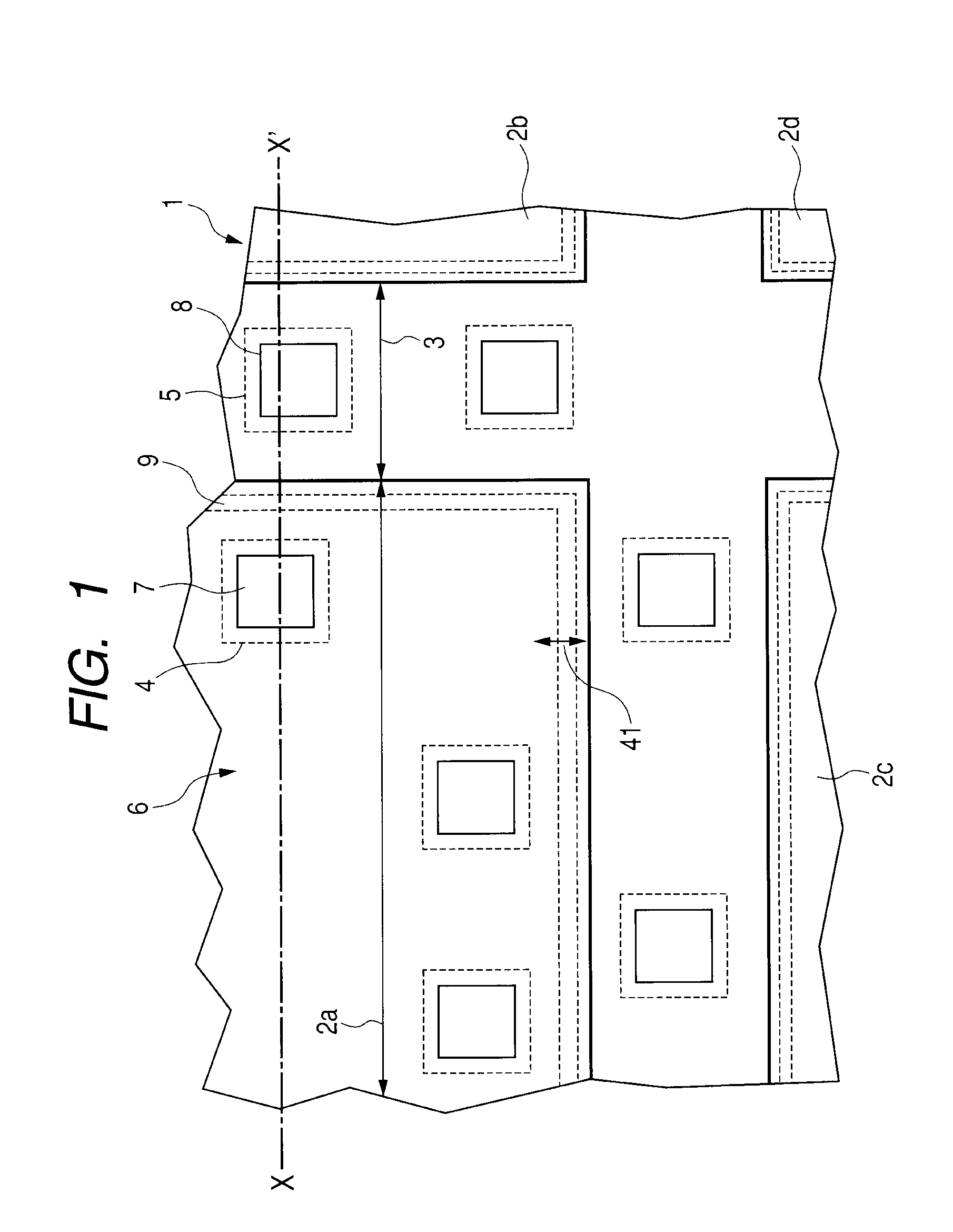

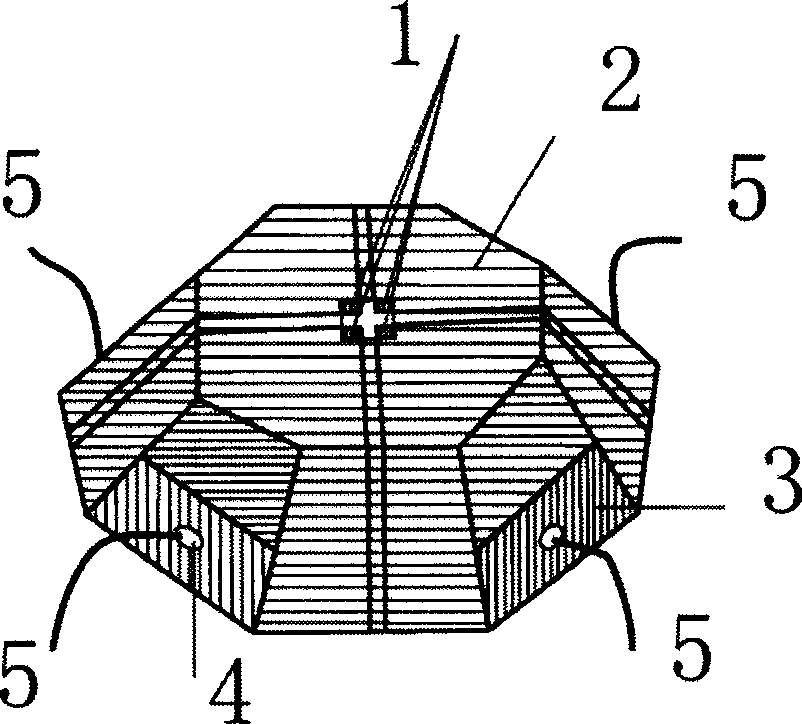

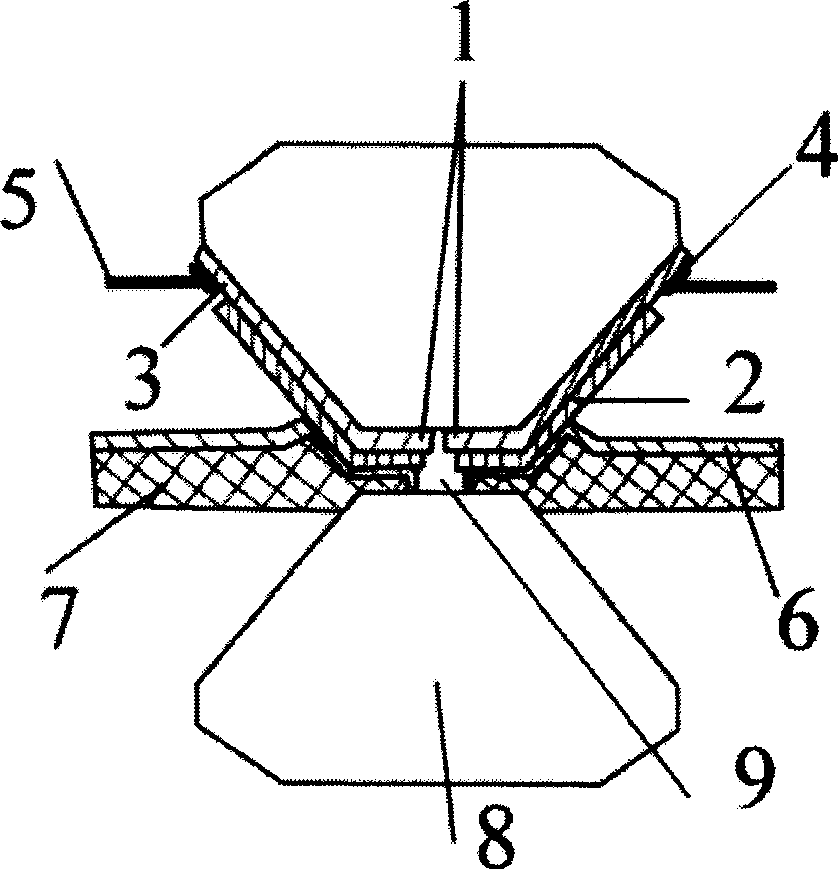

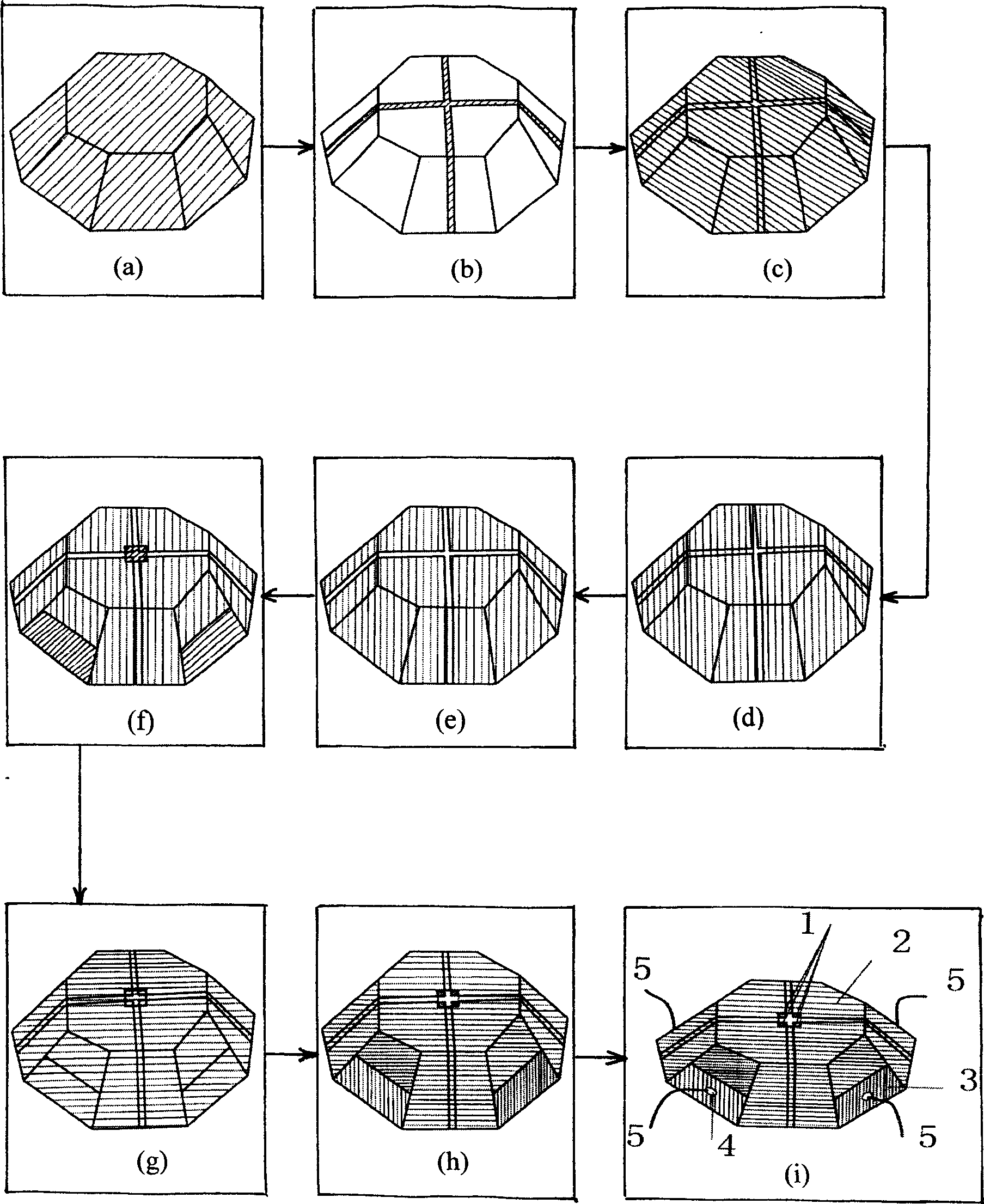

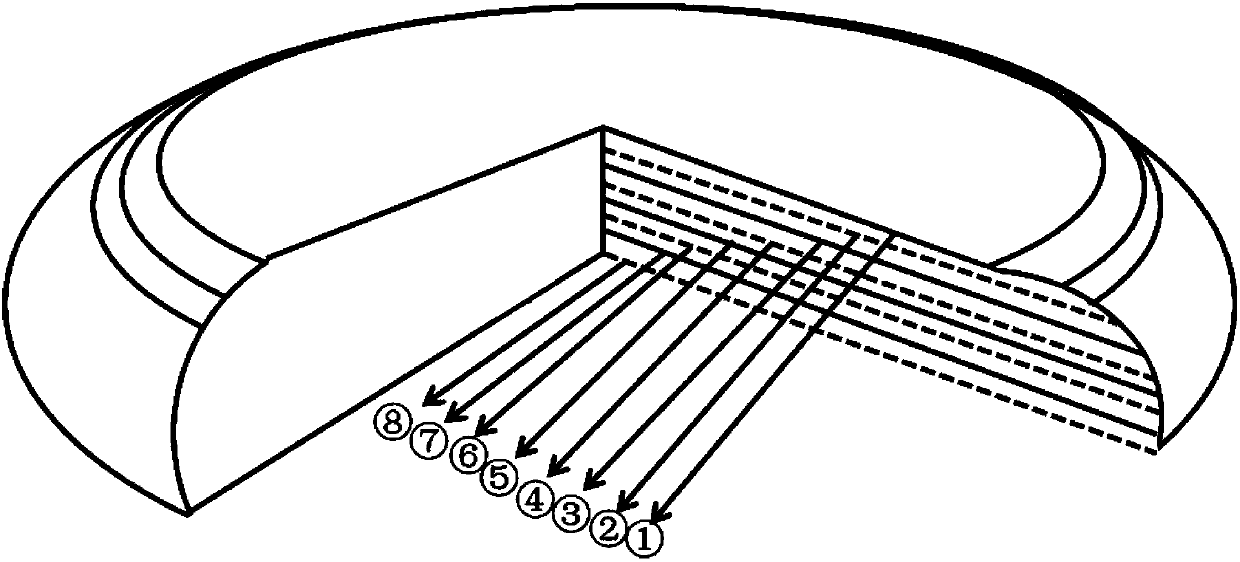

Electrode for in-situ electrical measurement for diamond anvil cell and method for producing the same

InactiveCN101509947ANo breakage problemGood chemical stabilityMaterial analysis by electric/magnetic meansElectrical testingBoronDiamond thin film

The invention discloses an in-situ electrical measuring electrode that is used in diamond-pair anvil cells and a manufacturing method thereof, and belongs to the technical field of high-temperature and high-voltage devices. Four electrodes (1) are deposited on the surface of a diamond anvil cell (8) and distribute from an anvil surface to a lateral surface of the diamond anvil cell (8); the electrodes (1) are diamond films doped with boron; a diamond insulating layer (2) covers the anvil surface and the lateral surface of the diamond anvil cell (8) as well as the electrodes (1) thereof; the electrodes (1) are exposed at one end of the anvil surface, the exposed position lies inside a sample cavity (9), and the electrodes (1) are exposed at one end of the lateral surface and connected with an electrode lead (5). A diamond film microcircuit and the diamond insulating layer are simultaneously integrated onto the surface of the diamond anvil cell by utilizing the film deposition technique, the nanometer seeding technique, the masking technique and the photolithographic method. The manufacturing method of the in-situ electrical measuring electrode prevents the electrode from being destroyed by transverse shearing force and overcomes the electrode corrosion by samples under the high-voltage condition, thus widening the research field of electrical in-situ measurement under high voltage.

Owner:JILIN UNIV

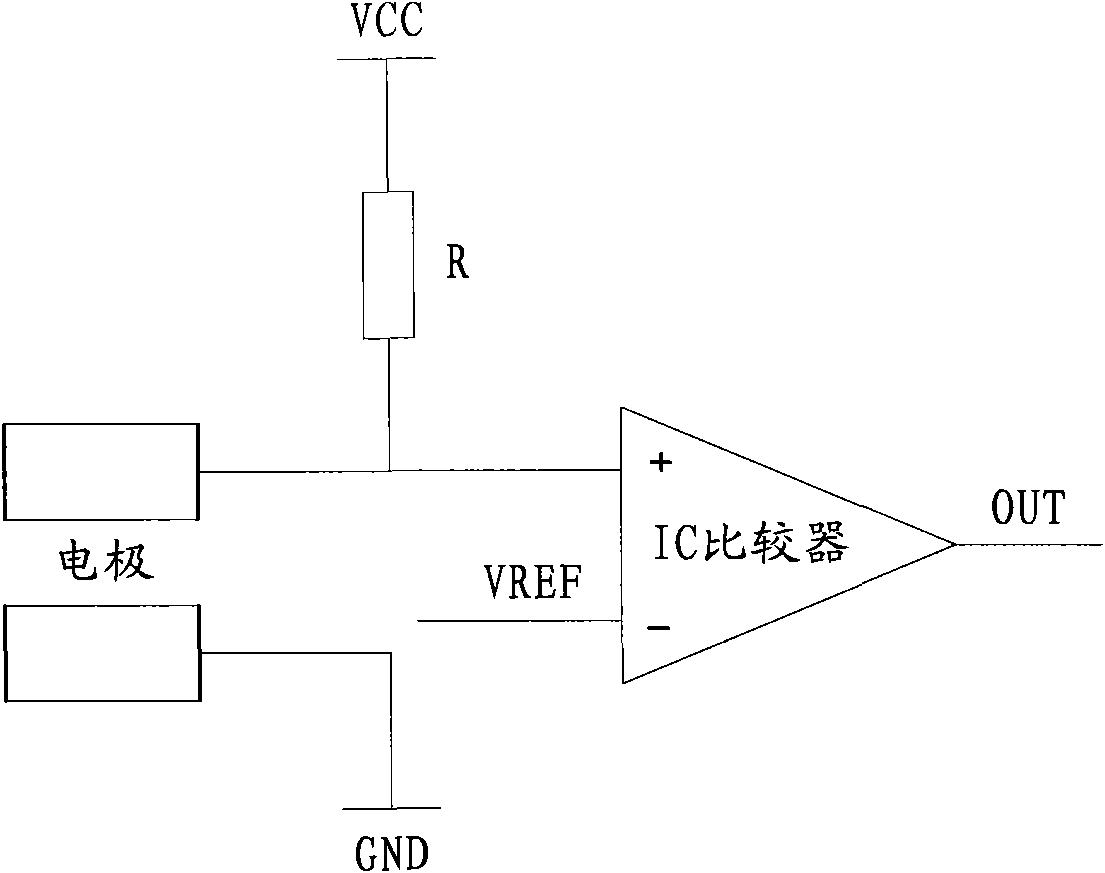

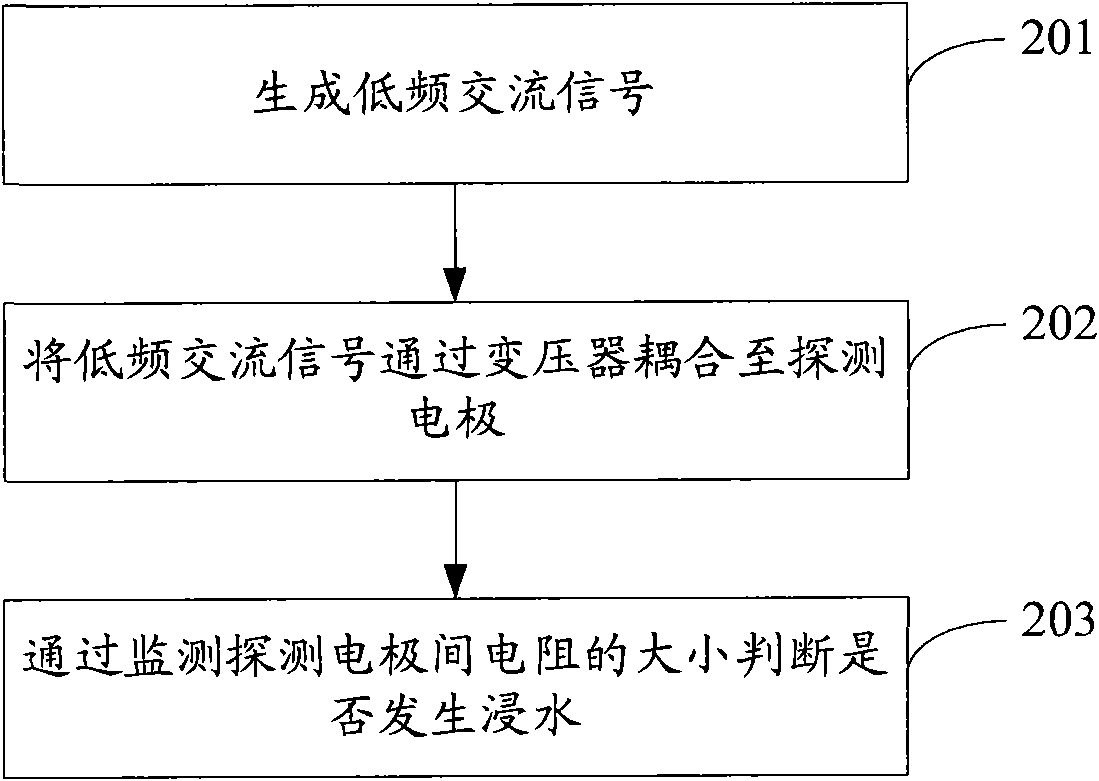

Soaking monitoring method, device and equipment

ActiveCN101614573AIncrease lead-out distanceNot corrosiveLevel indicators by physical variable measurementElectrical resistance and conductanceEngineering

The embodiment of the invention discloses a soaking method, a device and equipment, wherein, the method comprises: generating low frequency alternating current signal, coupling the low frequency alternating current signal to a sounding electrode through a transformer; judging whether soaking occurs by monitoring the size of resistance between sounding electrodes. As the embodiment of the invention adopts low frequency alternating current sounding signal, electrode corrosion and polarization do not occur on the sounding electrode, thus the monitoring result is correct with no false alarm, and the leading-out distance of the sounding electrode can be effectively increased; the low frequency alternating signal and the monitored medium can be separated by a transformer, thus improving monitoring safety and reliability.

Owner:山东宝力马传感技术有限公司

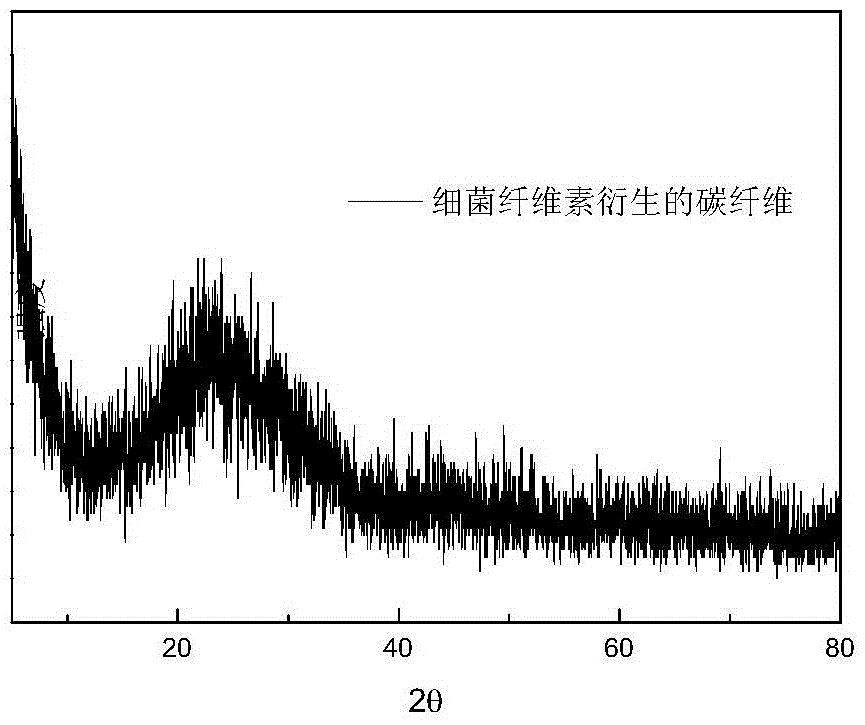

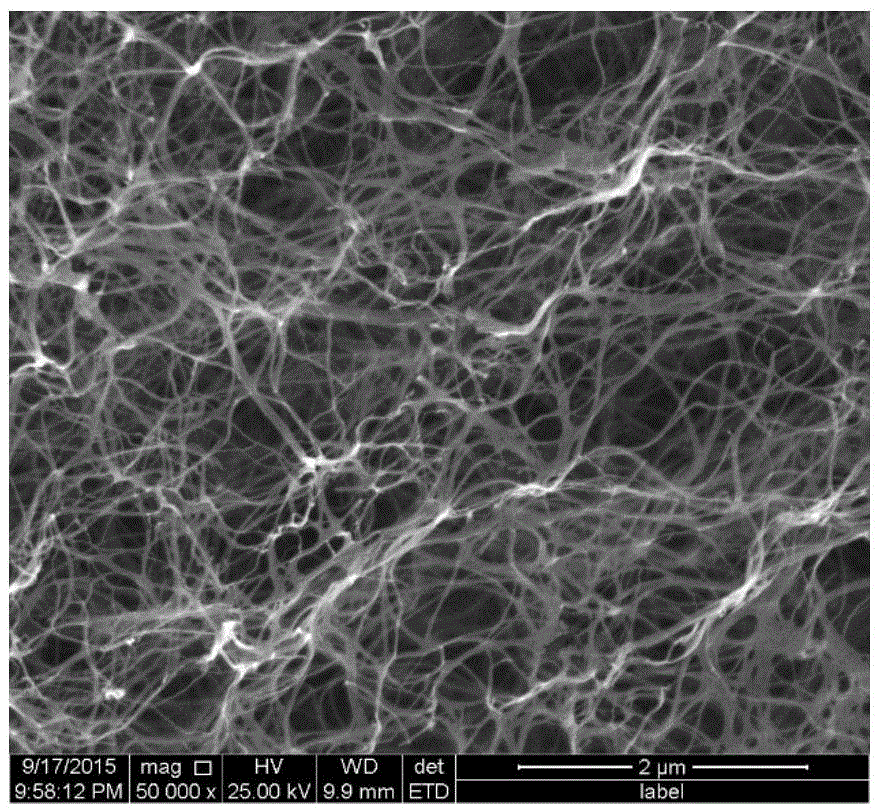

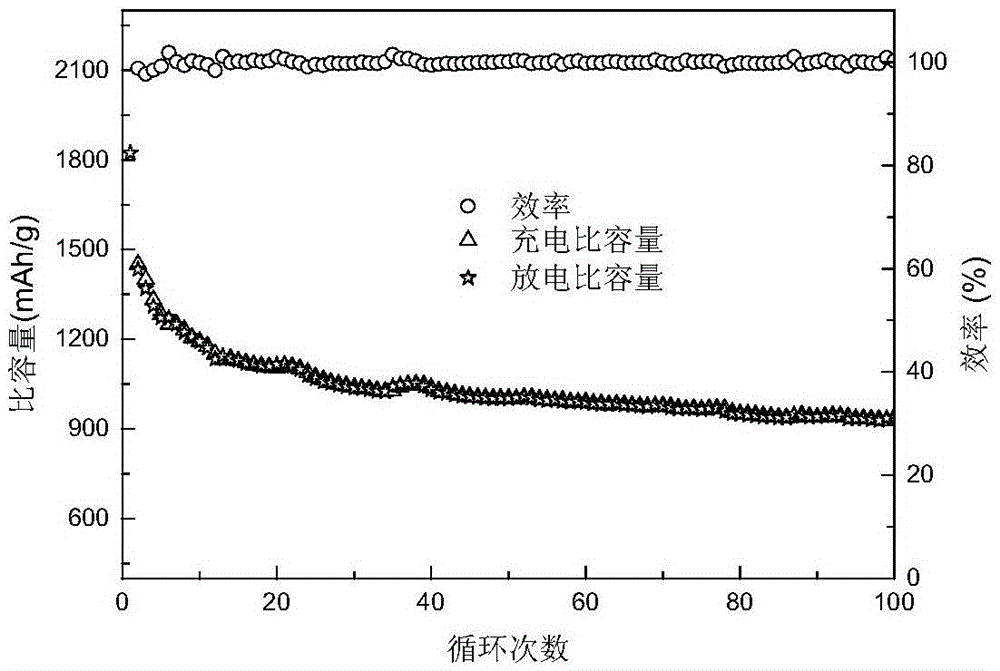

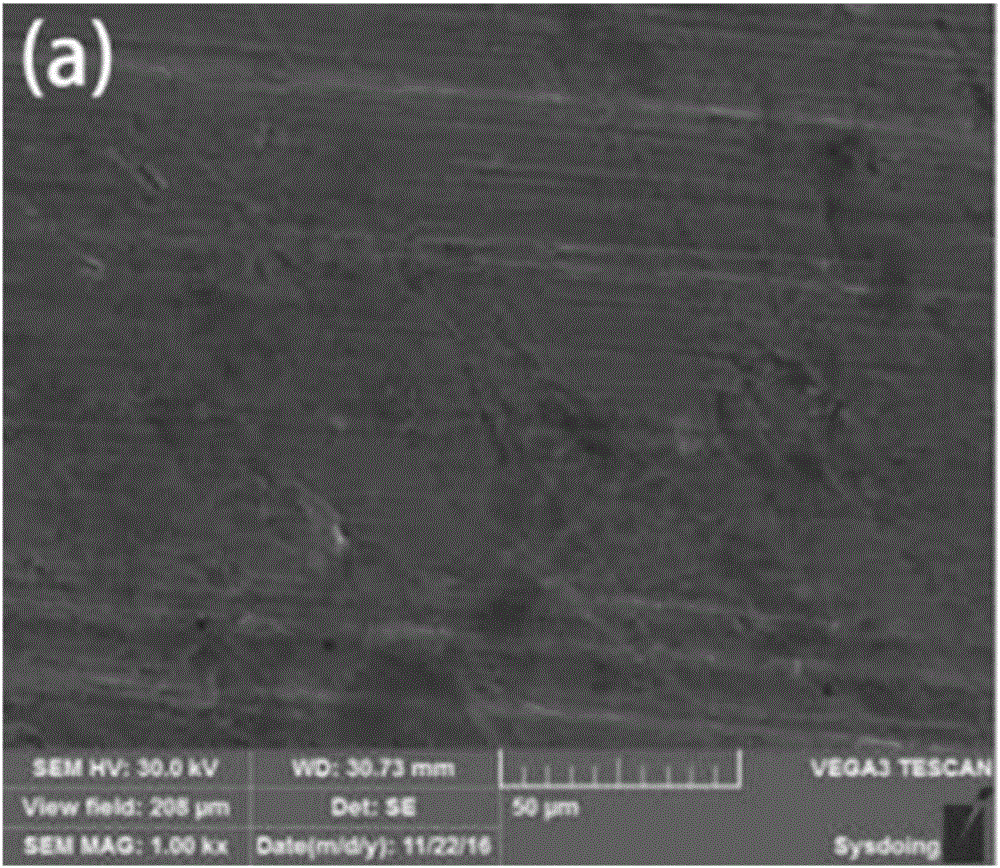

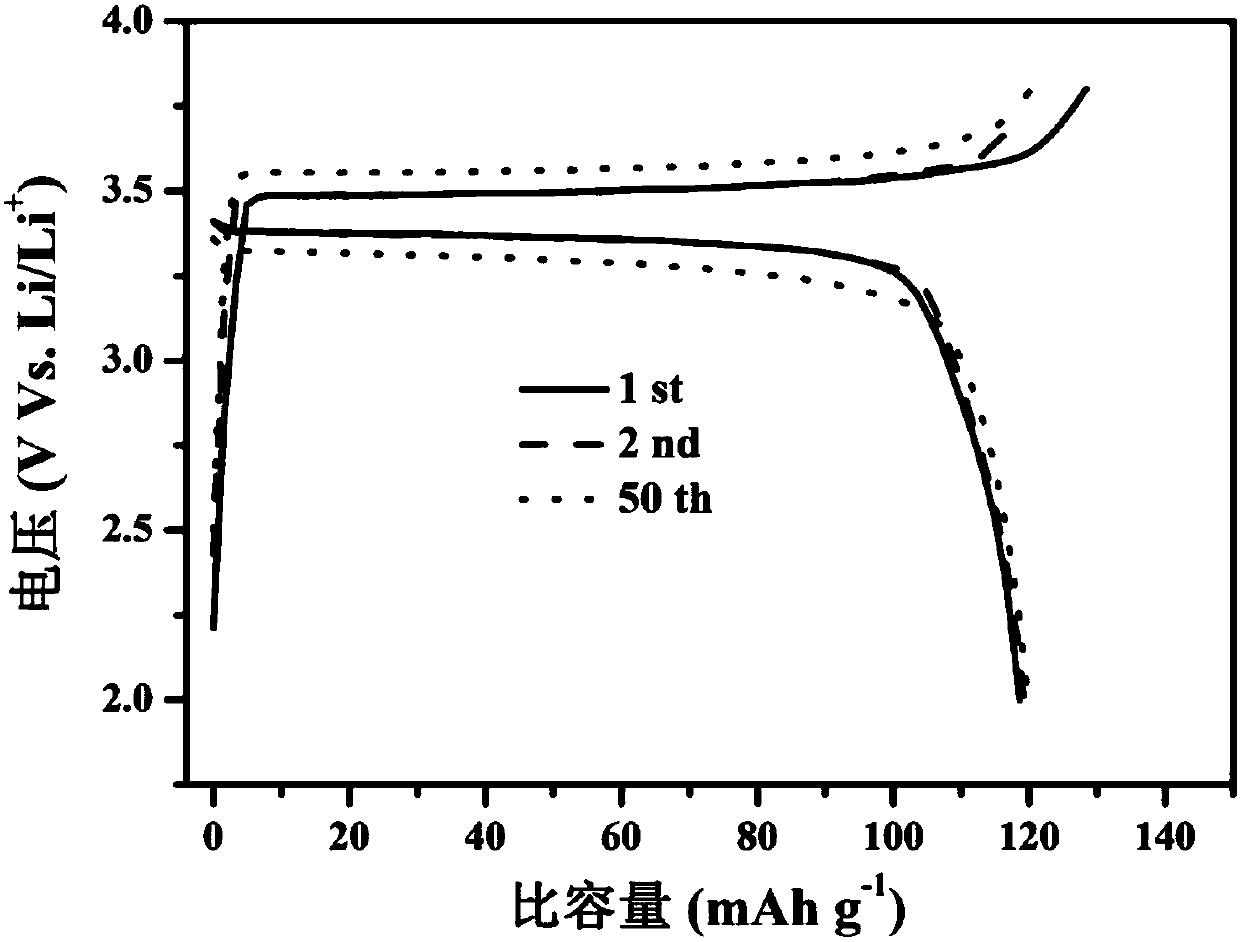

Lithium-sulfur battery containing barrier layer

InactiveCN105428616AImprove electrochemical performancePrevent collapseCell electrodesSecondary cellsFiberCarbon fibers

The invention relates to a lithium-sulfur battery containing a barrier layer, and belongs to the field of electrochemical batteries. The surface of the positive electrode of a conventional lithium-sulfur battery is coated with a bacterial cellulose derived carbon fiber barrier layer, so that the dissolution, shuttling and battery negative electrode corrosion of polysulfide in an electrolyte solution of the lithium-sulfur battery during charging / discharging are inhibited. According to the lithium-sulfur battery containing the barrier layer, a carbon material is directly pressed on the surface of a membrane by utilizing external pressure through using an ultra-filtration cup, and the membrane is directly used after being dried without the need for stripping the carbon-containing barrier layer, so that the material waste is avoided and the effectiveness and completeness of the barrier layer are ensured. The bacterial cellulose derived carbon fiber barrier layer improves the conductive problem of sulfur as an active substance of the positive electrode of the lithium-sulfur battery, and the three-dimensional space structure of carbon fibers also provides a buffer space for volume expansion during charging / discharging, so that the electrode collapse is prevented and the electrochemical performance of the lithium-sulfur battery is improved. Under the current density of 0.5C, the initial discharge specific capacity of the battery is 1,823.2mAh / g, and the specific discharge capacity of the battery after being cycled for 100 times is 939.4mAh / g.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

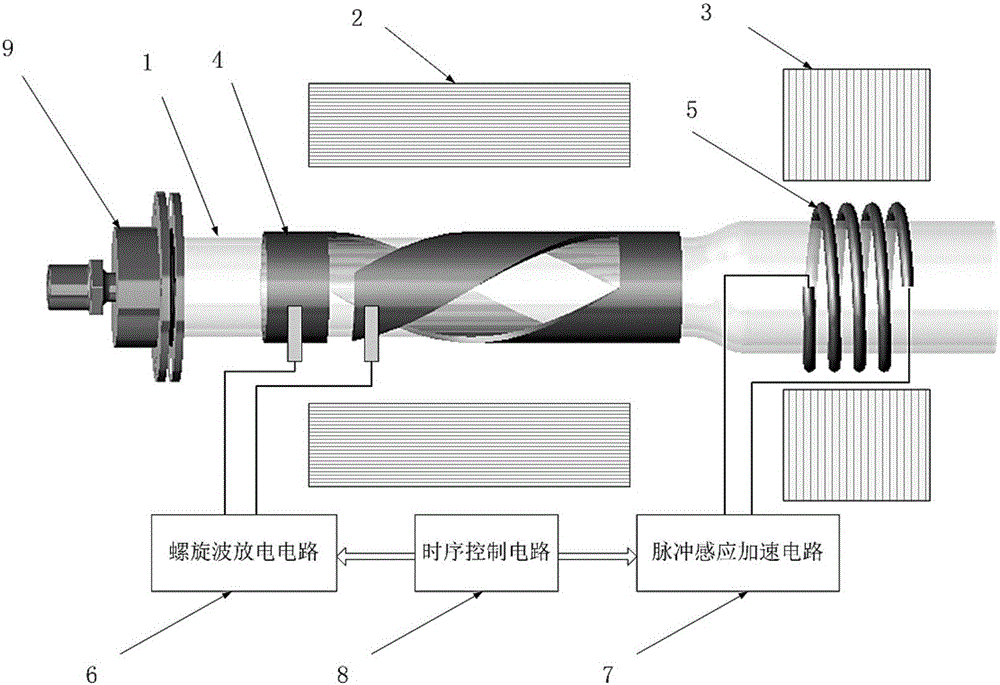

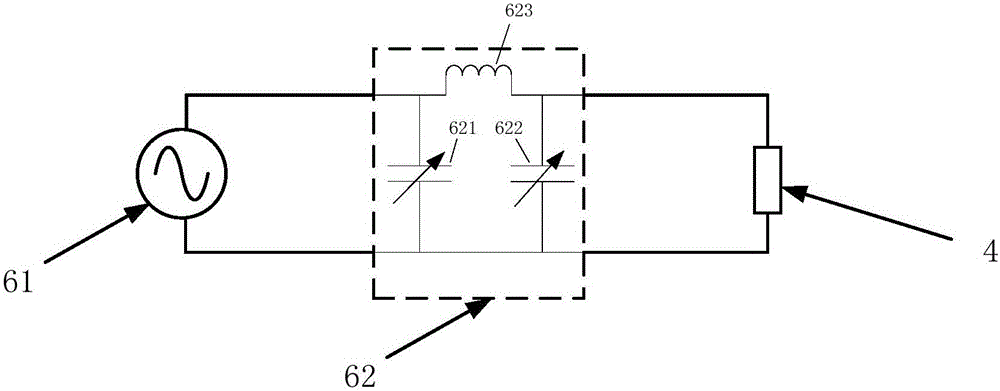

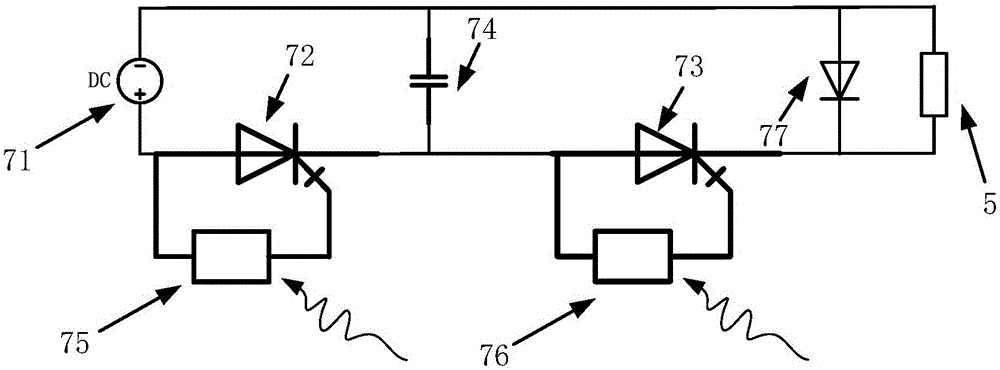

Helicon plasma induction thruster

ActiveCN106014899AMiniaturizationConducive to solidificationMachines/enginesUsing plasmaCapacitanceMiniaturization

The invention discloses a helicon plasma induction thruster. The helicon plasma induction thruster comprises a discharge cavity, and first magnets and second magnets are sequentially arranged on the outer portion of the discharge cavity; a helicon discharge antenna and an induction acceleration coil are sequentially arranged on the outer wall of the discharge cavity in the axial direction; and the thruster further comprises a helicon discharge circuit, a pulse induction discharge circuit and a time sequence control circuit, wherein the helicon discharge circuit provides a work power source for the helicon discharge antenna. The pulse induction discharge circuit is connected with the induction acceleration coil and provides a pulse discharge voltage for the induction acceleration coil so as to drive helicon plasmas to be pushed out in an accelerated manner, and the time sequence control circuit is connected with the helicon discharge circuit and the pulse induction discharge circuit. The helicon plasma induction thruster has the beneficial effects of being free of electrode corrosion, large in ionization density and long in service life. Through efficient decoupling of the ionization level and the acceleration level, efficient separation of the ionization level and the acceleration level is achieved, voltage needed by a capacitor of the acceleration level is reduced, the system size and the system weight are greatly reduced, and miniaturization, lightweight and the solid state of the thruster are facilitated.

Owner:NAT UNIV OF DEFENSE TECH

Low Bias Drift Modulator With Buffer Layer

ActiveUS20070116475A1Guaranteed uptimeLow costElectromagnetic transmissionNon-linear opticsManufacturing cost reductionSignal routing

Owner:LUMENTUM OPERATIONS LLC

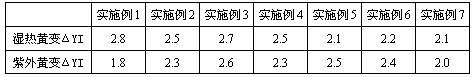

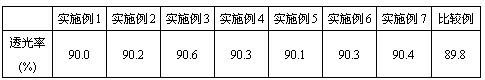

Sealing adhesive film for solar cell

ActiveCN102250554AGood optical performanceCounteracts the disadvantage of reduced light transmittanceNon-macromolecular adhesive additivesFilm/foil adhesivesInorganic particleRefractive index

The invention discloses a sealing adhesive film for a solar cell, comprising a functional compound with the refractive index n of not less than 1.55. The functional compound accounts for 0.009-0.988 percent of total weight of the adhesive film and is sulfur-containing resin containing a reactive functional group or resin containing a delocalization electronic conjugated system. According to the sealing adhesive film disclosed by the invention, the defect that the light transmittance of the adhesive film is reduced because acid absorbent inorganic particles are added is overcome and the light transmittance of the adhesive film is improved, so that the EVA (Ethylene Vinyl Acetate) adhesive film has the characteristics of durability, electrode corrosion inhibition, stable optical performance, and the like; and the photoelectric conversion efficiency and the service life of a solar battery assembly are ensured.

Owner:乐凯胶片股份有限公司

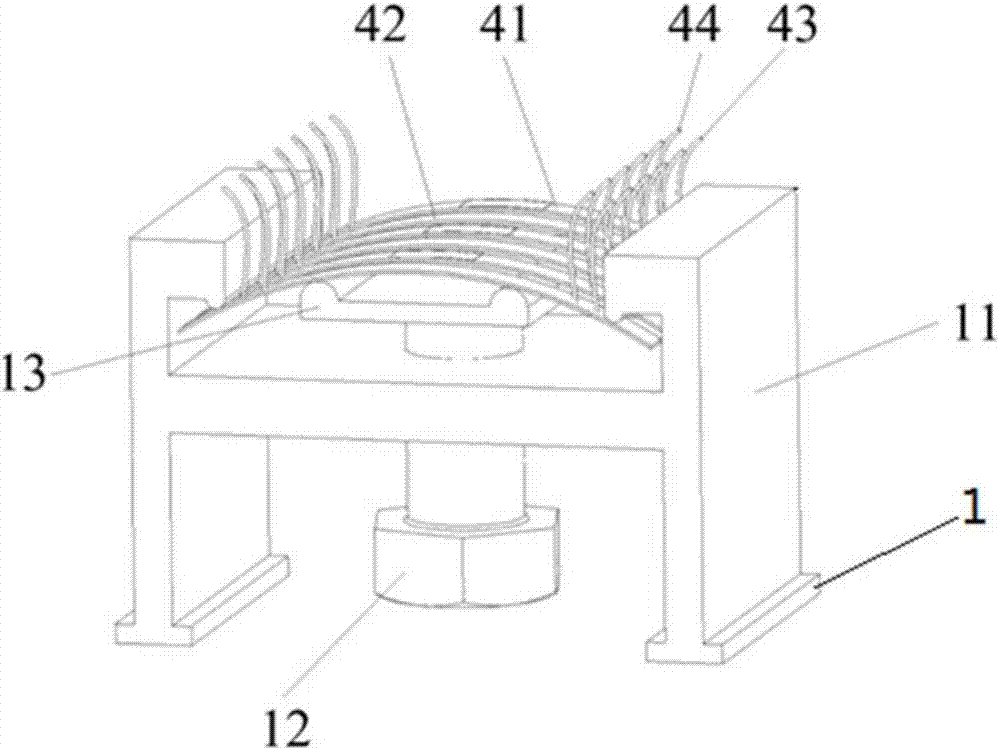

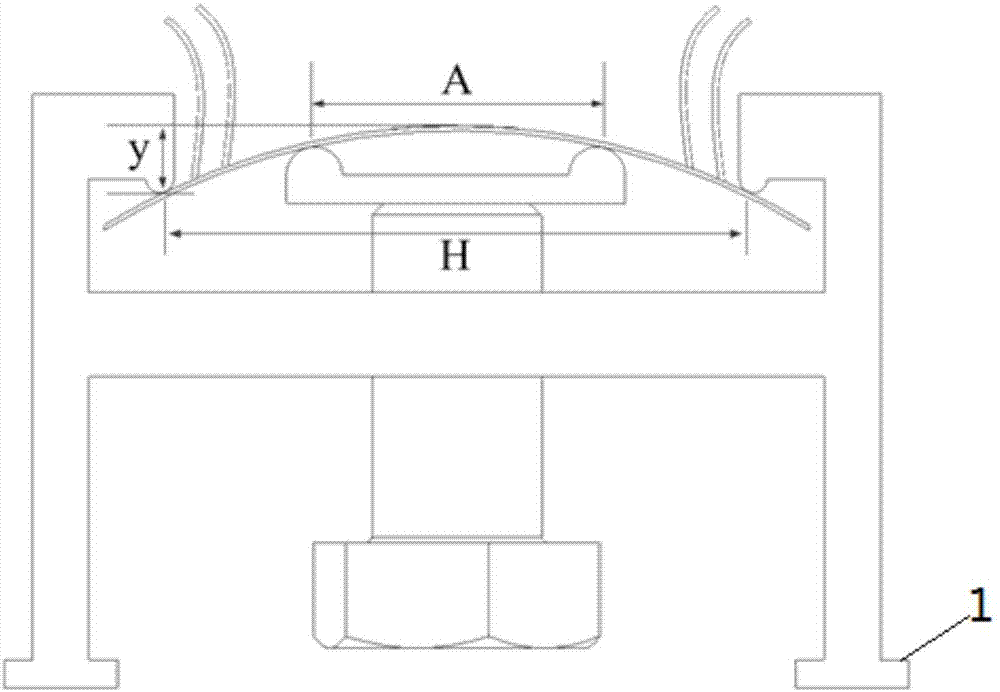

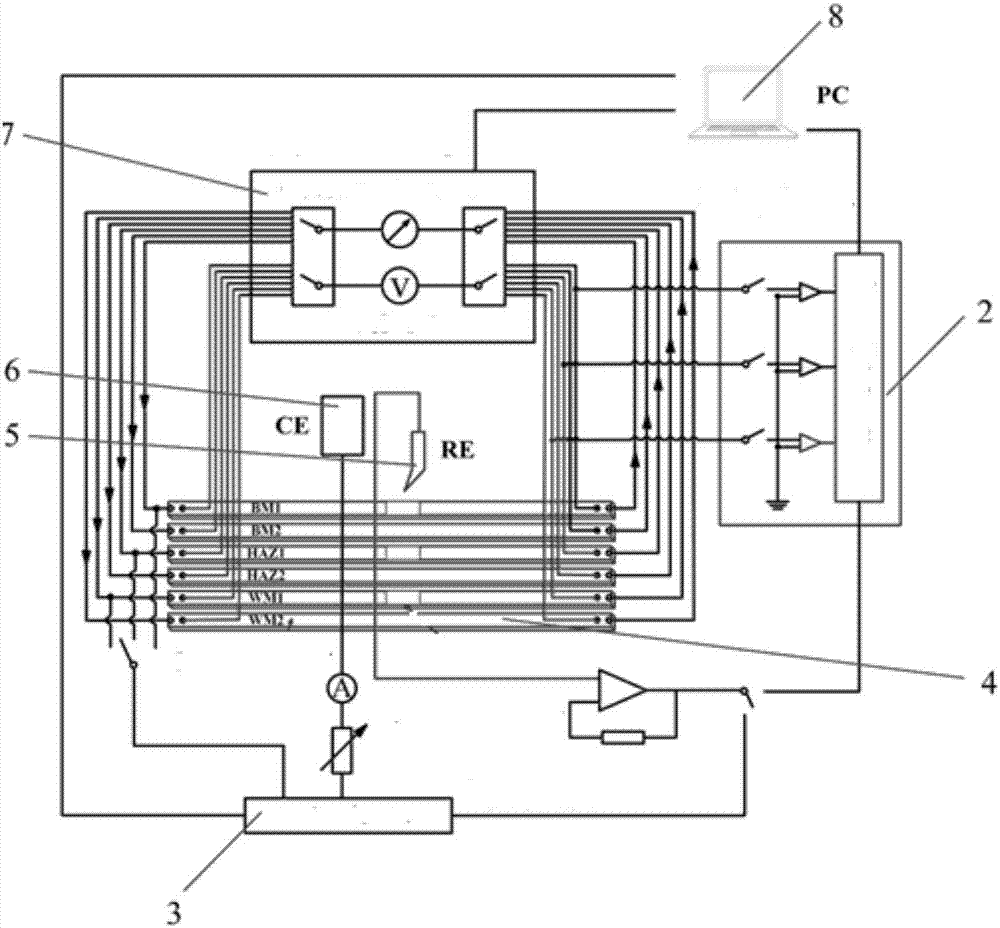

Monitoring device and monitoring method for simulating welding joint corrosion in stress state

ActiveCN107505256AMonitoring for localized corrosion problemsSimulate the realWeather/light/corrosion resistanceAuxiliary electrodeEngineering

The invention relates to a monitoring device and a monitoring method for simulating welding joint corrosion in a stress state. The device comprises a four-point bending augmentor, a zero resistance galvanometer, an electrochemical workstation, a welding resistance-multi-electrode corrosion sensor, a reference electrode, an auxiliary electrode, a microhmmeter and a signal acquisition control system, wherein the welding resistance-multi-electrode corrosion sensor comprises a corrosion element and a reference element; the corrosion element is adapted with a relay switch, and is coupled by the zero resistance galvanometer; the electrode element is connected to the microhmmeter; the stress level of the four-point bending augmentor is changed by adjusting the deflection of a long-strip electrode specimen; the signal acquisition control system is used for acquiring and storing data measured by the zero resistance galvanometer and the microhmmeter, and controlling the action of the relay switch. The monitoring device and the monitoring method disclosed by the invention have the advantages that the corrosion condition of a welding joint area of a pipeline can be comprehensively and accurately monitored, and the total corrosion depth and the corrosion rate of the welding joint area and the electrochemical corrosion rate are measured; in addition, the cathode and anode current in different regions of the welding joint is monitored, and the stress condition of a welding joint node is simulated.

Owner:DALIAN UNIV OF TECH

Anode aluminium foil after treatment method for aluminium electrolytic capacitor

InactiveCN101740227AHigh capacitanceReduce the problem of broken foil caused by riveting instabilityCapacitor electrodesCleaning using liquidsPressure riseAfter treatment

The invention relates to an anode aluminium foil after treatment method for an aluminium electrolytic capacitor, comprising the steps: pretreatment, first-grade corrosion A, second-grade corrosion B1, second-grade corrosion B2, after treatment and drying of corrosion foil, wherein the after treatment comprises the steps of chemical cleaning and ultrasonic cleaning; the after treatment comprises the steps of: putting aluminium foil processed by the second-grade corrosion B2 into 0.3-5wt% nitric acid solution at the temperature of 30-85 DEG C, and performing ultrasonic treatment for 5-60s at the ultrasonic frequency of 1-50KHz and the power of 0.5-5KW. Compared with the electrode corrosion foil prepared by the original technique, the electrostatic capacity of the cleaned anode aluminium corrosion foil is increased by 1-3%, and the pressure rising time is shortened by 6-12%.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

Humidity Tolerant Electro-Optic Device

ActiveUS20080170821A1Improve performanceCoupling light guidesSpecial surfacesOperating pointEngineering

The invention relates to an electro-optic modulator structure containing an additional set of bias electrodes buried within the device for applying bias to set the operating point. Thus the RF electrodes used to modulate incoming optical signals can be operated with zero DC bias, reducing electrode corrosion by galvanic and other effects that can be present in non-hermetic packages. The bias electrodes are at least partially separated from the substrate with a buffer layer, which in one embodiment has a small amount of conductivity. This conductive buffer layer reduces optical loss from the bias electrodes and also reduces DC drift.

Owner:LUMENTUM OPERATIONS LLC

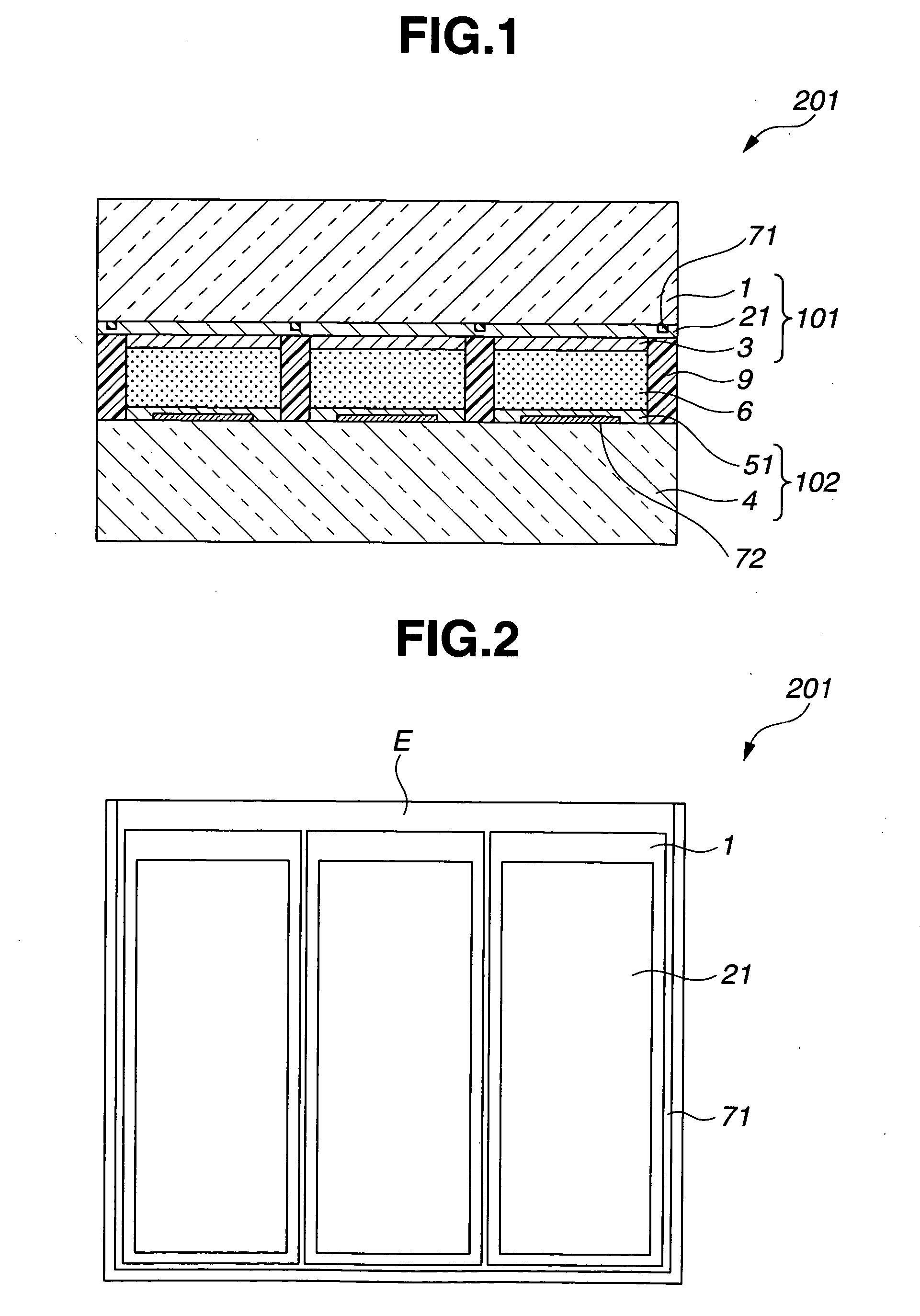

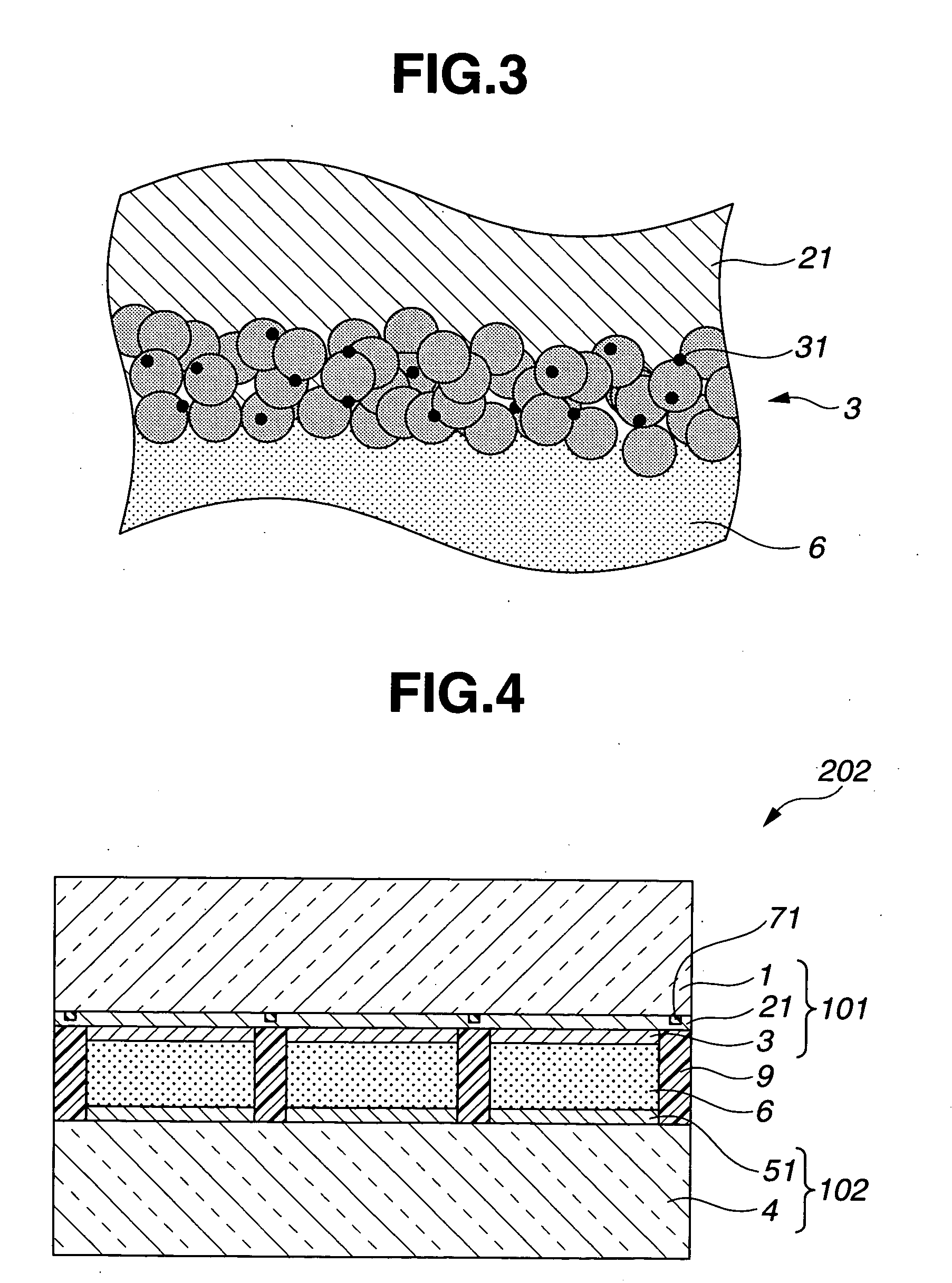

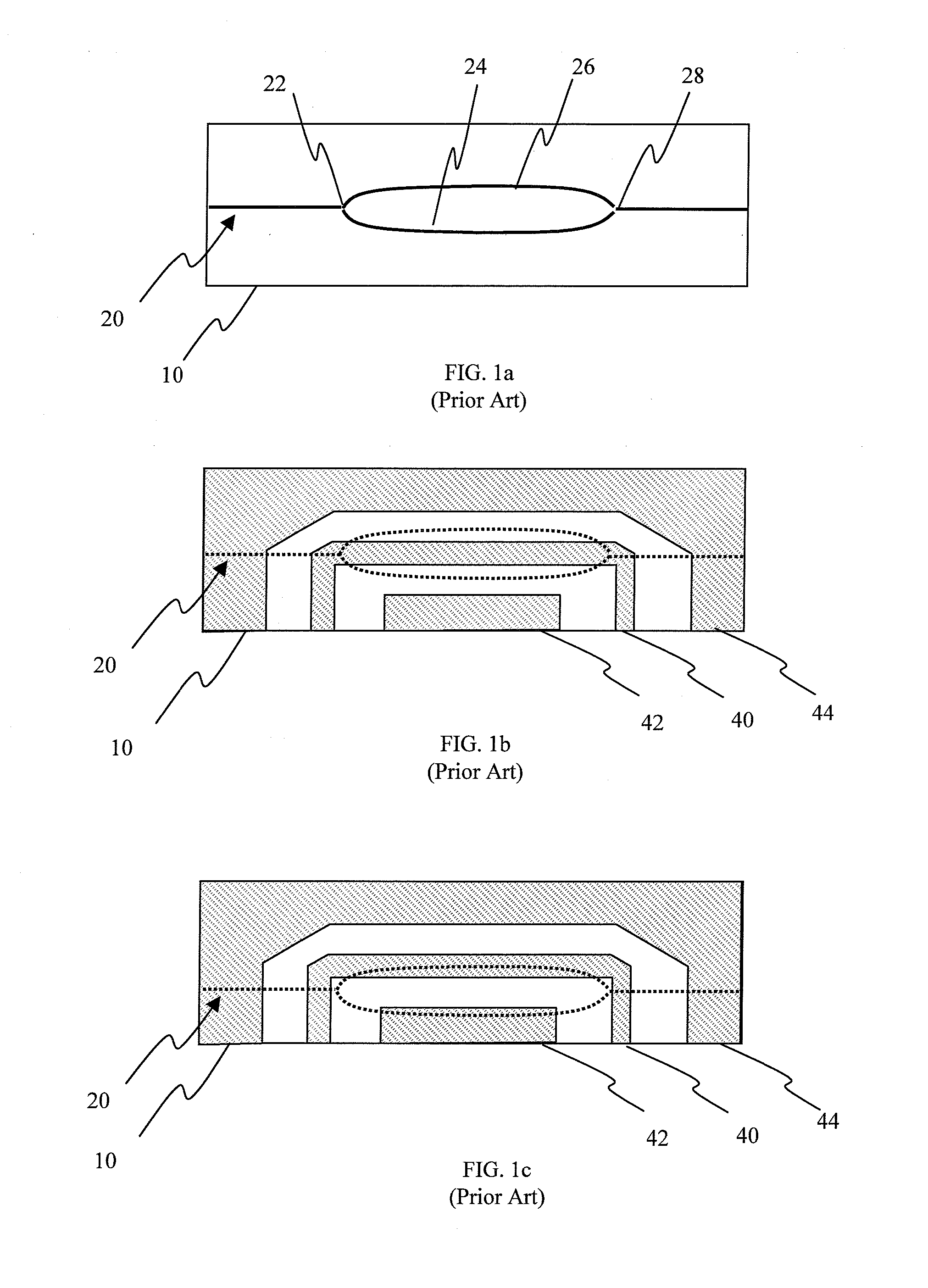

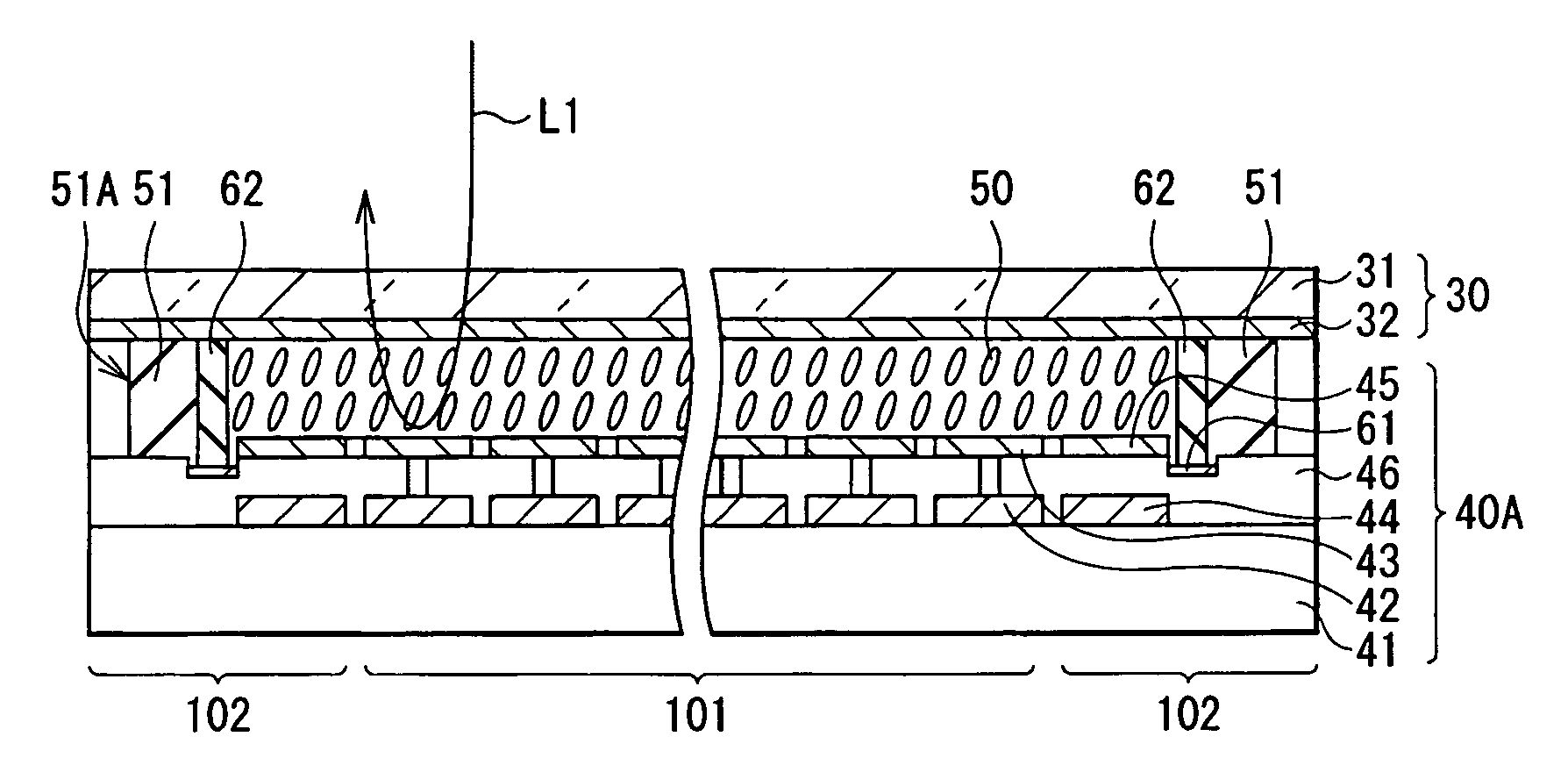

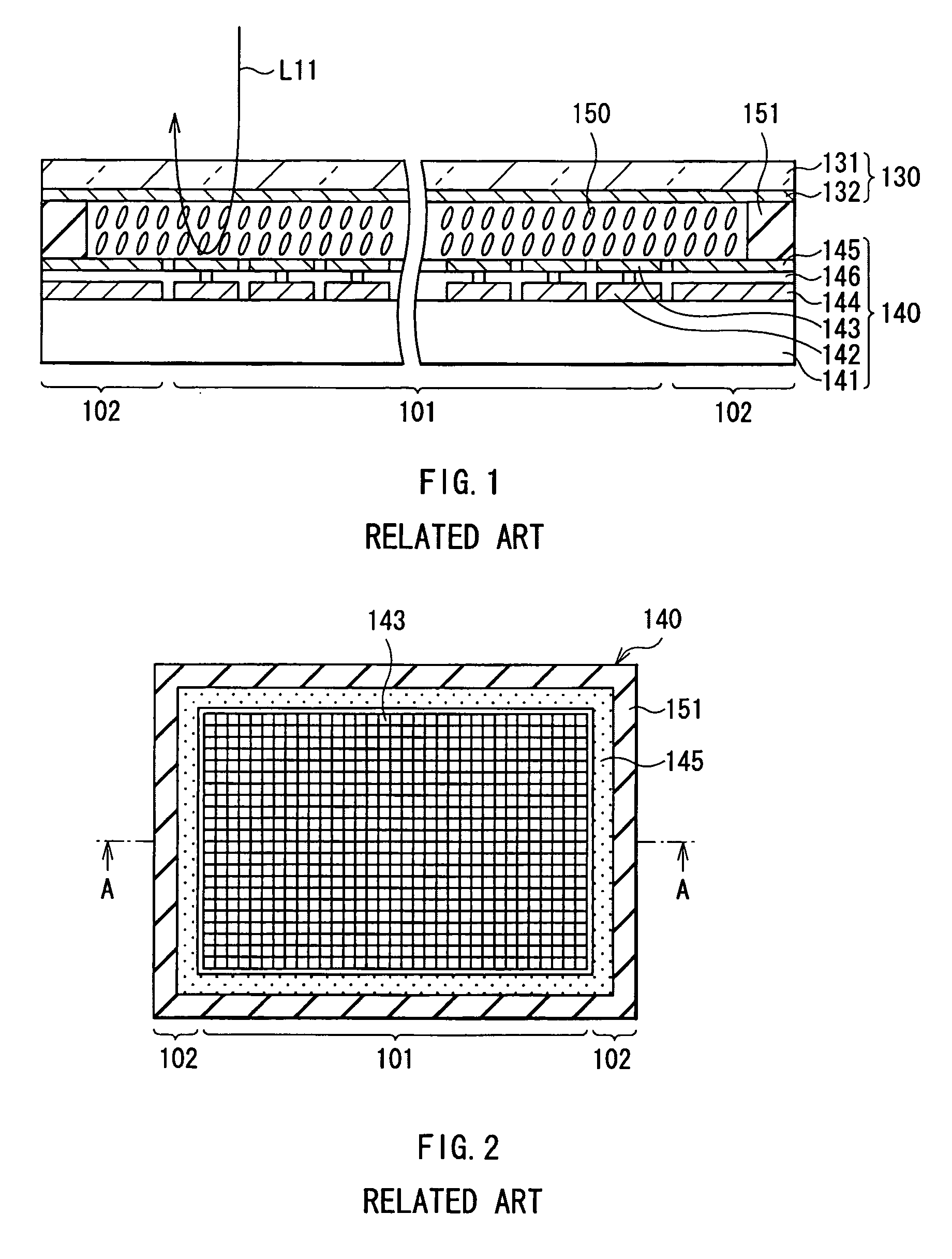

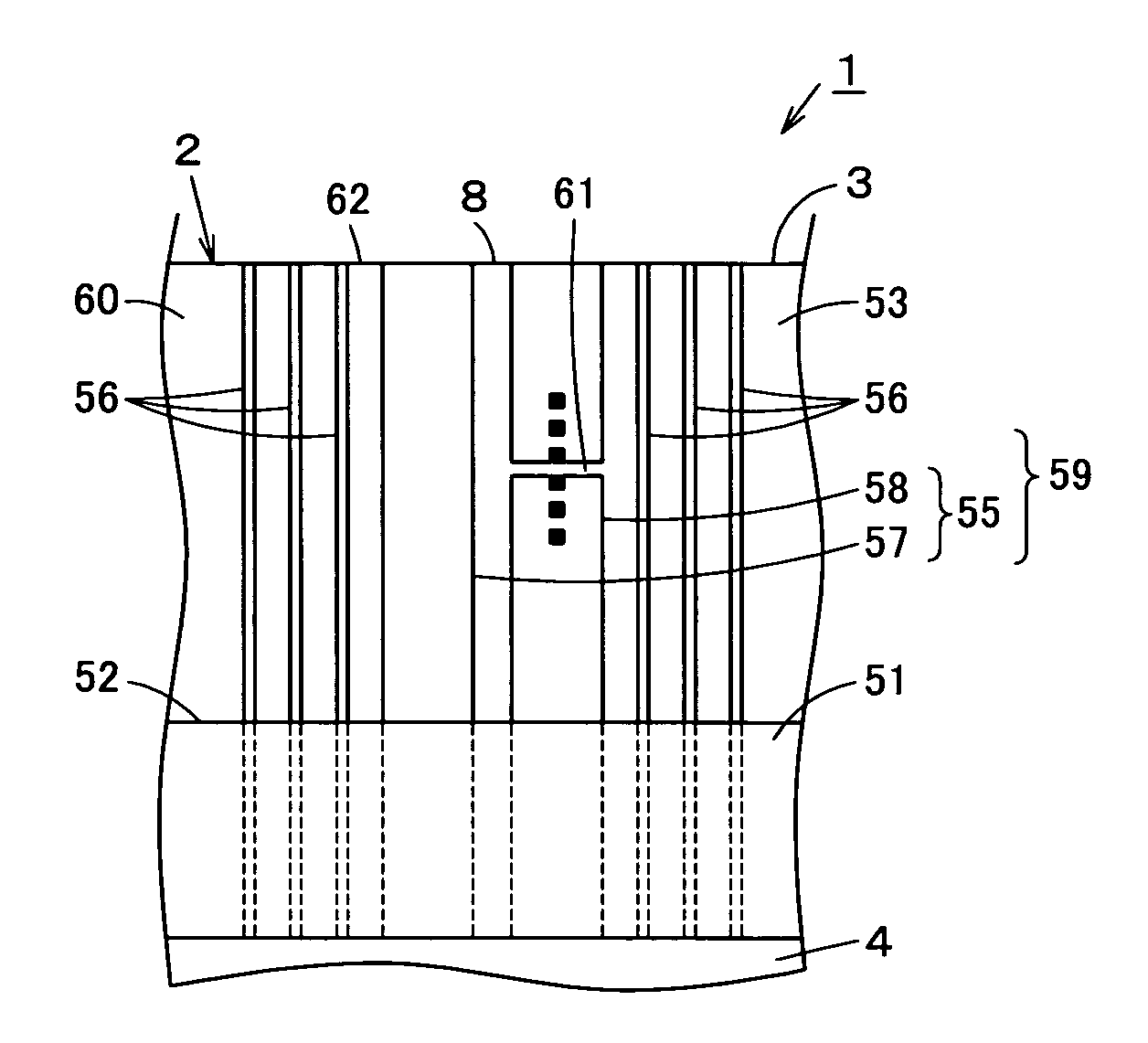

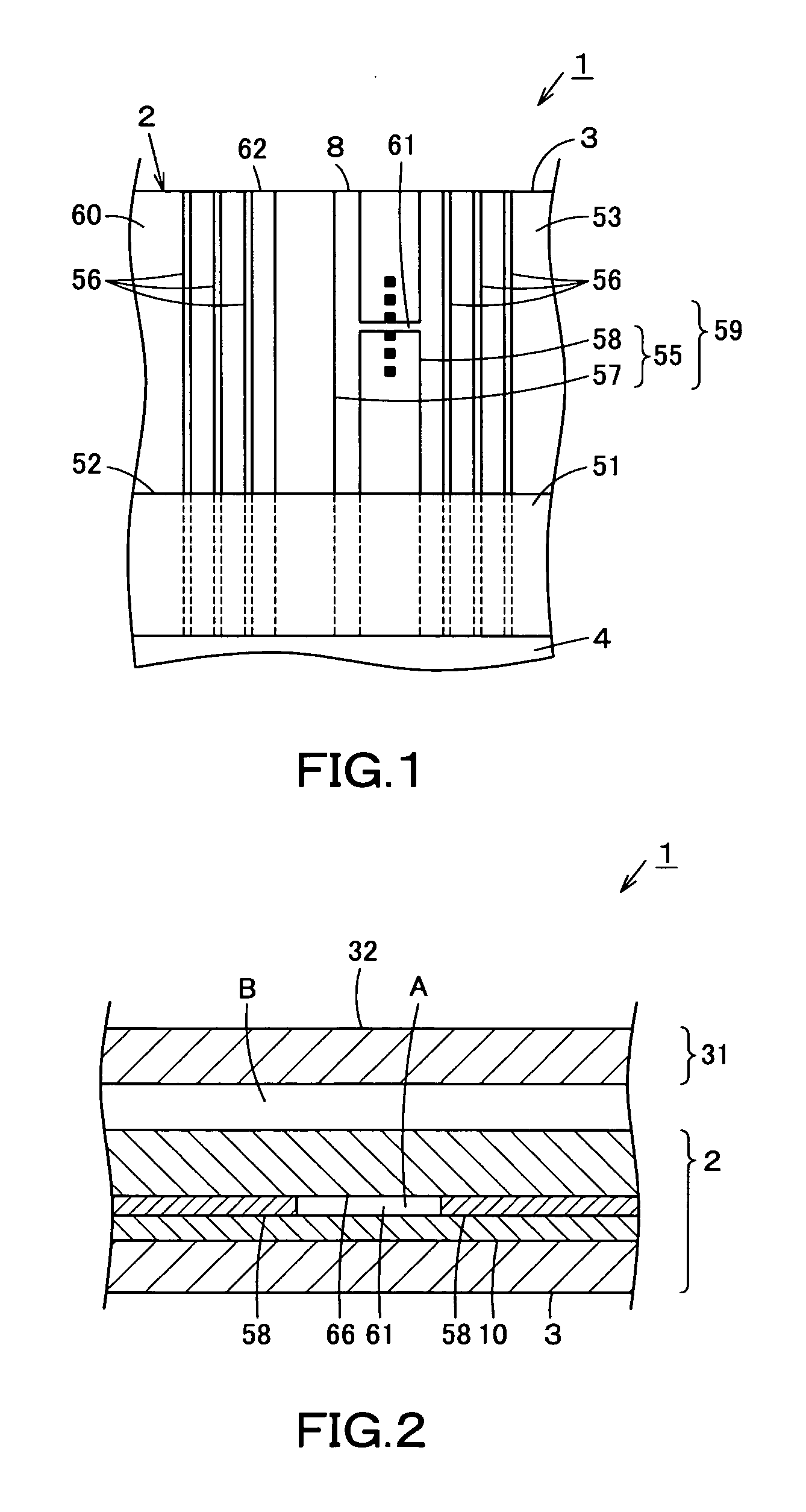

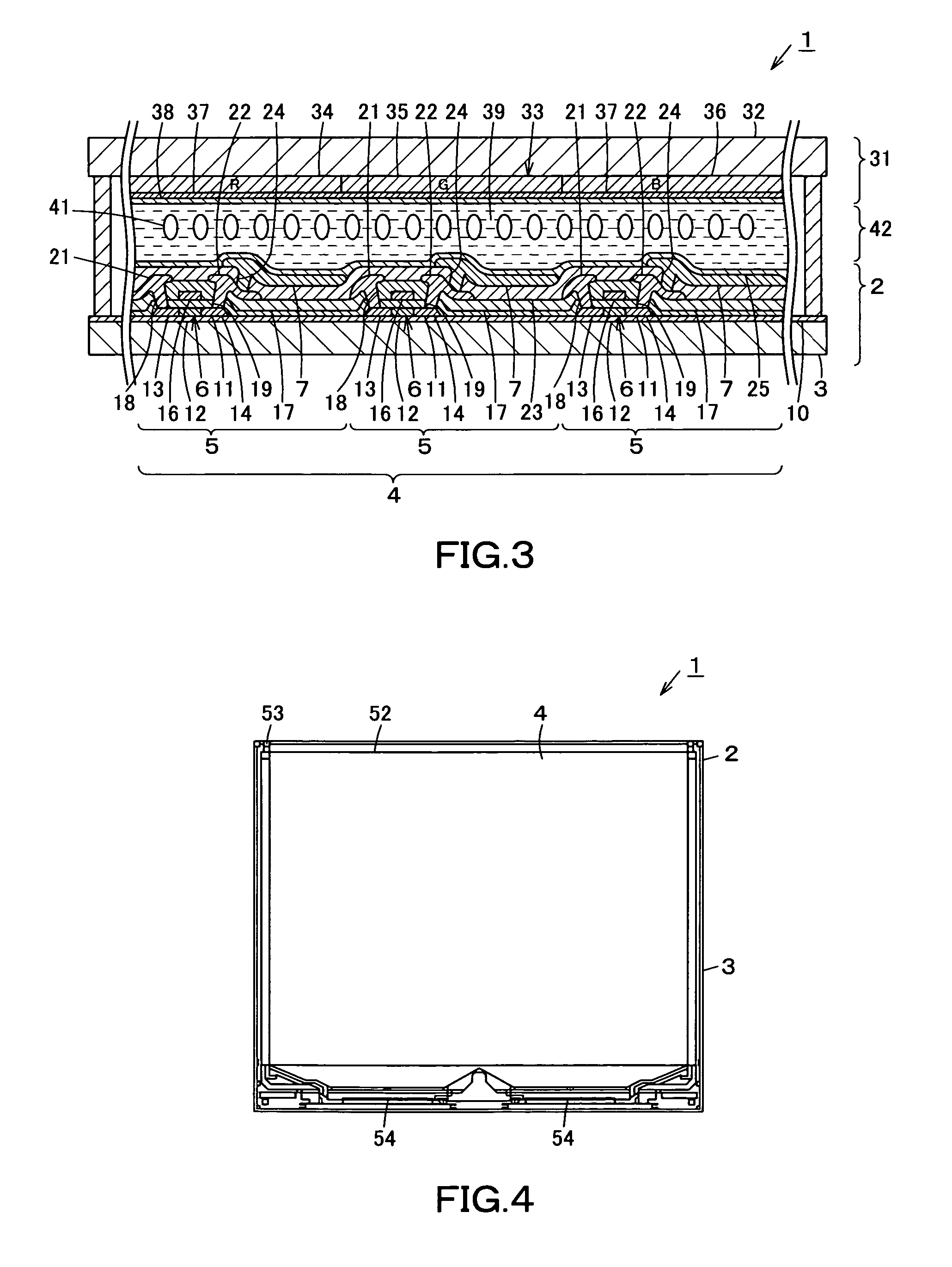

Reflective liquid crystal display device and liquid crystal display unit

A reflective liquid crystal display device and a liquid crystal display unit capable of achieving high moisture resistance and securing long-term reliability through specifically preventing electrode corrosion in a surface portion of a pixel electrode substrate are provided. A seal portion bonds a pixel electrode substrate and a transparent electrode substrate together with a predetermined spacing in between. In this case, the pixel electrodes and a metal film are formed inside an outer surface of the seal portion on the pixel electrode substrate. Thereby, the pixel electrodes and the metal film are not exposed to air, and the moisture resistance can be secured, and electrode corrosion can be prevented. Moreover, as an adhesive surface of the seal portion is a substrate surface, compared to the case where peripheral end sources of the whole device are coated, sufficient adhesion can be secured for a long term.

Owner:SONY CORP

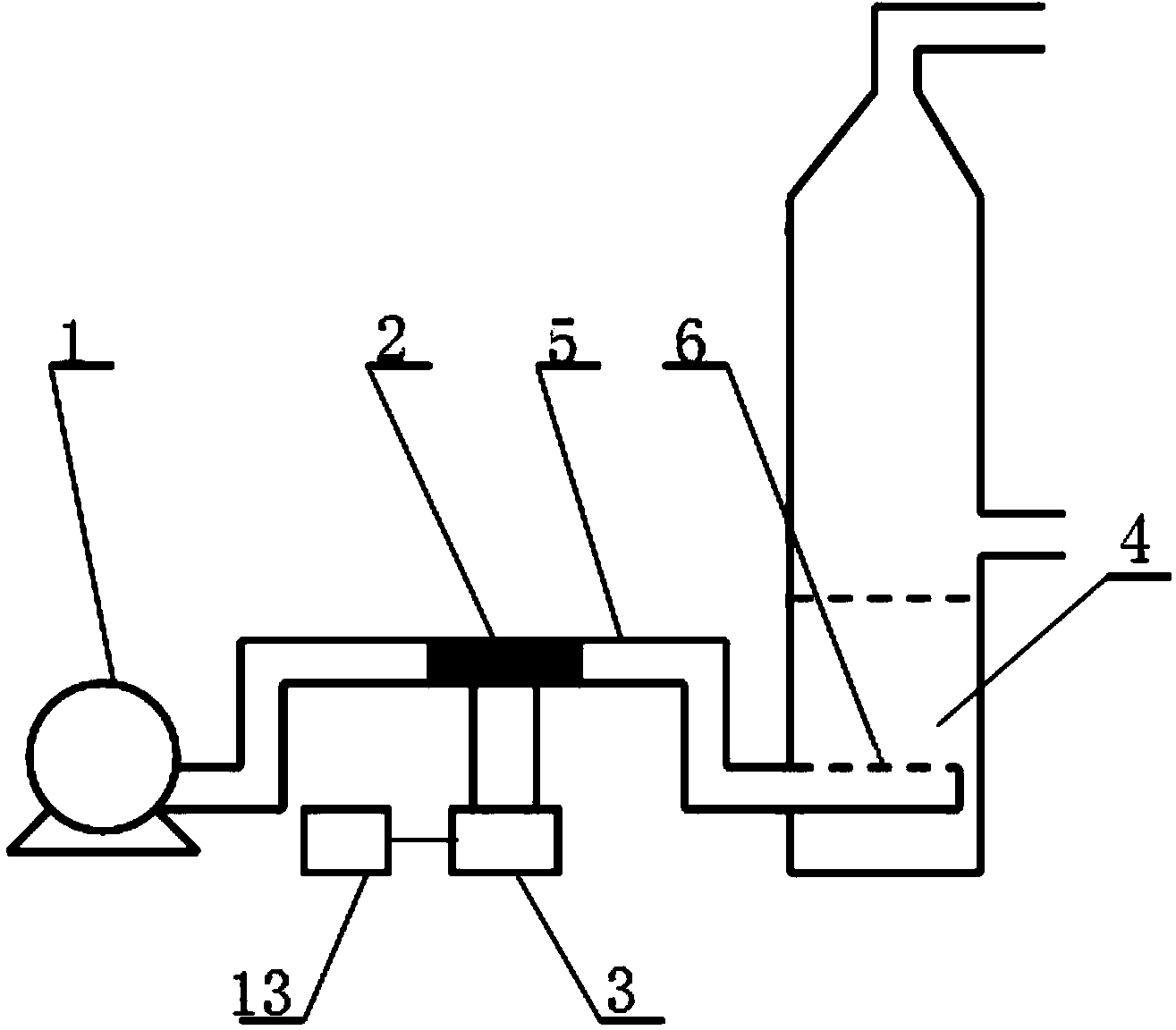

Method and device for oxidizing sulphite grout in wet flue gas desulfurization process

ActiveCN103768902AExtended service lifeAvoid the phenomenon that is easy to be corrodedCalcium/strontium/barium sulfatesDispersed particle separationSlurryOxygen

The invention discloses a method and a device for oxidizing sulphite grout in a wet flue gas desulfurization process. The method comprises the following steps: (1) collecting the sulphite grout generated due to the absorption of alkali liquid at an upper section of a desulfurization tower into a grout tank at a lower section of the same desulfurization tower; (2) introducing oxygen-containing gas into a creeping discharge reactor outside the desulfurization tower, and converting the oxygen-containing gas into active gas containing oxygen active substances; (3) injecting the active gas as an oxidizing agent into the sulphite grout, and oxidizing the sulphite grout to form sulfate grout. According to the device, the creeping discharge reactor is arranged outside the grout tank, so that the oxidation rate is increased, the use amount of the oxygen-containing gas is reduced, meanwhile, phenomena of electrode corrosion and grout backflow are avoided, a wet desulfurization absorption process and an oxidation process are integrated and are finished in the same desulfurization tower, an additional oxidation reactor is omitted, the process is simplified, and the cost is lowered.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL +1

Electrolytic solution used in electrolysis of acrylonitrile for preparing adiponitrile and method

InactiveCN105543888AReduce consumptionElectrode corrosion is smallElectrolysis componentsElectrolytic organic productionPhosphateAcrylonitrile

The invention discloses an electrolytic solution used in electrolysis of acrylonitrile for preparing adiponitrile and a method. The electrolytic solution consists of the following components in percentage by mass: 1%-5% of acrylonitrile, 0-10% of adiponitrile, 8%-15% of phosphate, 0.1%-2% of EDTA or EDTA salt, 1%-10% of borax, 0.1%-5% of biquaternary ammonium salt and the balance of water. The electrolytic solution is added into a non-membrane electrolytic cell, so that the adiponitrile is prepared by electrolysis. The biquaternary ammonium salt and the borax are added into the electrolytic solution, so that electrode corrosion during electrolysis is reduced, and the selectivity and the current efficiency of the acrylonitrile are higher than 90%; and moreover, the consumption of the biquaternary ammonium salt is reduced, so that the content of the propionitrile is kept at a relatively low level while the propionitrile is continuously used for 400 hours without being supplemented.

Owner:CHONGQING UNISPLENDOUR INT CHEM

Application and preparation of Zn-C secondary battery composite material

InactiveCN106784688AHave diversitySimple structureCell electrodesSecondary cellsMaterials preparationShielding gas

The invention relates to a Zn-C secondary battery composite material preparation method. The method includes steps: preparing Zn-based ZIF; pre-carbonizing the obtained Zn-based ZIF in a shield gas atmosphere to obtain pre-carbonized Zn-based ZIF; carbonizing the obtained pre-carbonized Zn-based ZIF in the shield gas atmosphere, and cooling to obtain the Zn-C composite material. The method has advantages that a Zn-C structure is completely replicated from ZIF, uniformity in zinc and carbon distribution is realized, and electrode powdering caused by electrode corrosion in charging and discharging processes is avoided; Zn-C porous structure richness is realized, rich transmission passages are provided for Zn ions, and Zn dendritic crystal generation can be effectively inhibited; due to large Zn-C specific surface area, a large quantity of deposition sites can be provided for Zn or Zn(OH)2, electrode passivation is reduced, and cycle performance is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

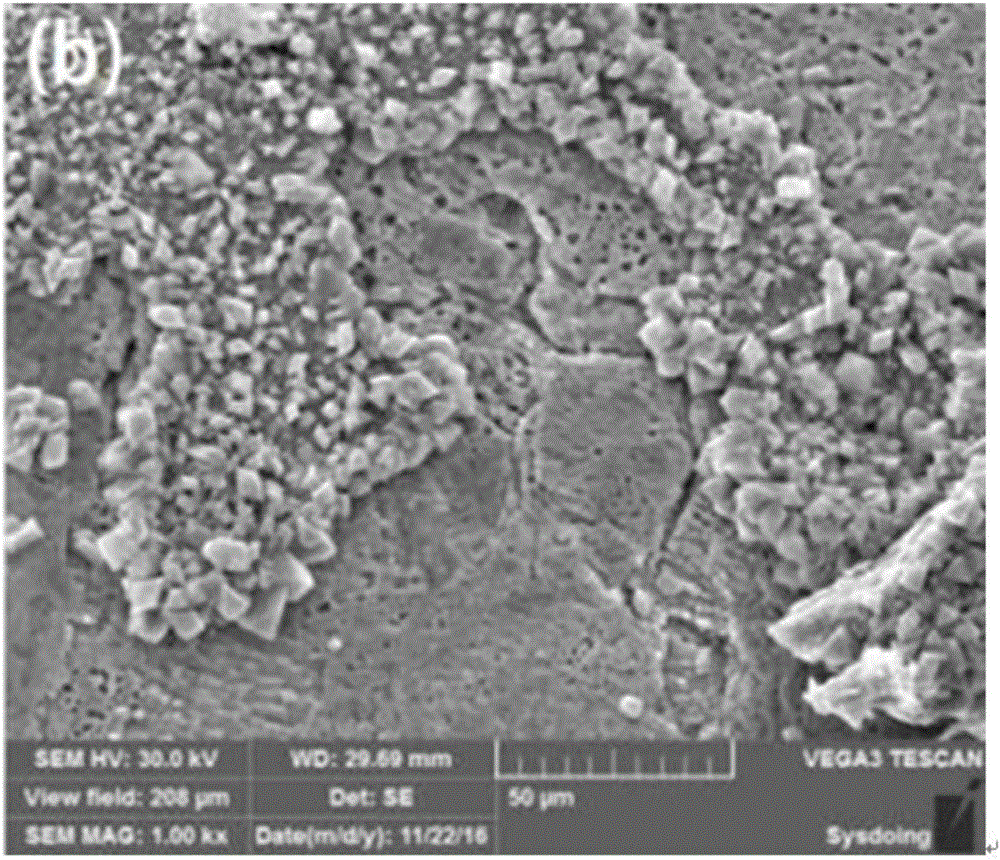

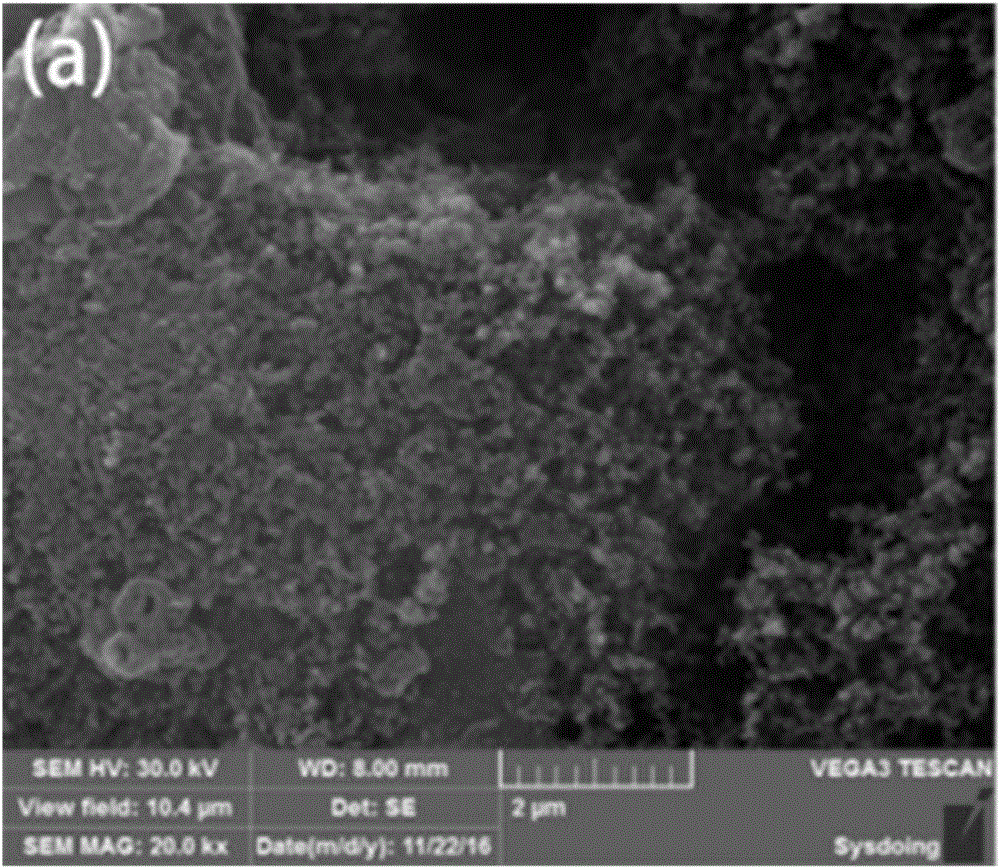

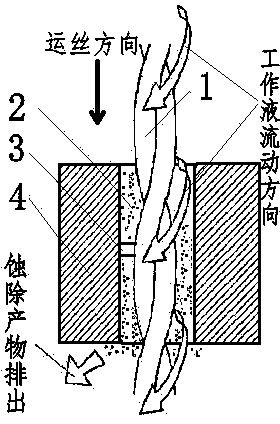

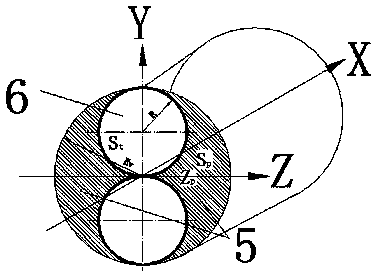

Efficient long-service-life stranded electrode wire for EDM wire

ActiveCN103990877AImprove cutting efficiencyHigh-speed reciprocating wire EDM and low cutting efficiencyElectrical-based machining electrodesCooling effectElectrical and Electronics engineering

An efficient long-service-life stranded electrode wire for an EDM wire is characterized by being formed by stranding at least two electrode wire bodies. Concave cavity grooves and convex discharging joint points are formed on the surfaces of the stranded electrode wire bodies. The concave cavity grooves are not only containing spaces for a working solution but also discharging spaces for inter-electrode corrosion removal products. In addition, feeding of the working solution and the discharging of the corrosion removal products are respectively performed in a spiral mode, and then the inter-electrode cooling effect and the deionization ability are improved. The discharging joint points can form regular discharging, and a discharging pulse interval can be indirectly prolonged. As the surfaces of the electrode wire bodies are provided with the concave parts which serve as the chip containing spaces, the working solution can be fed into inter-electrode in a promoted mode; meanwhile the discharging of the inter-electrode corrosion removal products is accelerated, so that the inter-electrode discharging conditions are improved; due to the regular convex points on the surfaces of the stranded electrode wire bodies, the discharging rule is easier to control. Accordingly, machining efficiency can be enhanced, and surface quality can be improved. Besides, the volume of the chip containing spaces of the stranded electrode wire bodies can be controlled according to the diameter of the electrode wire bodies and the pitch of the stranded wire bodies.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

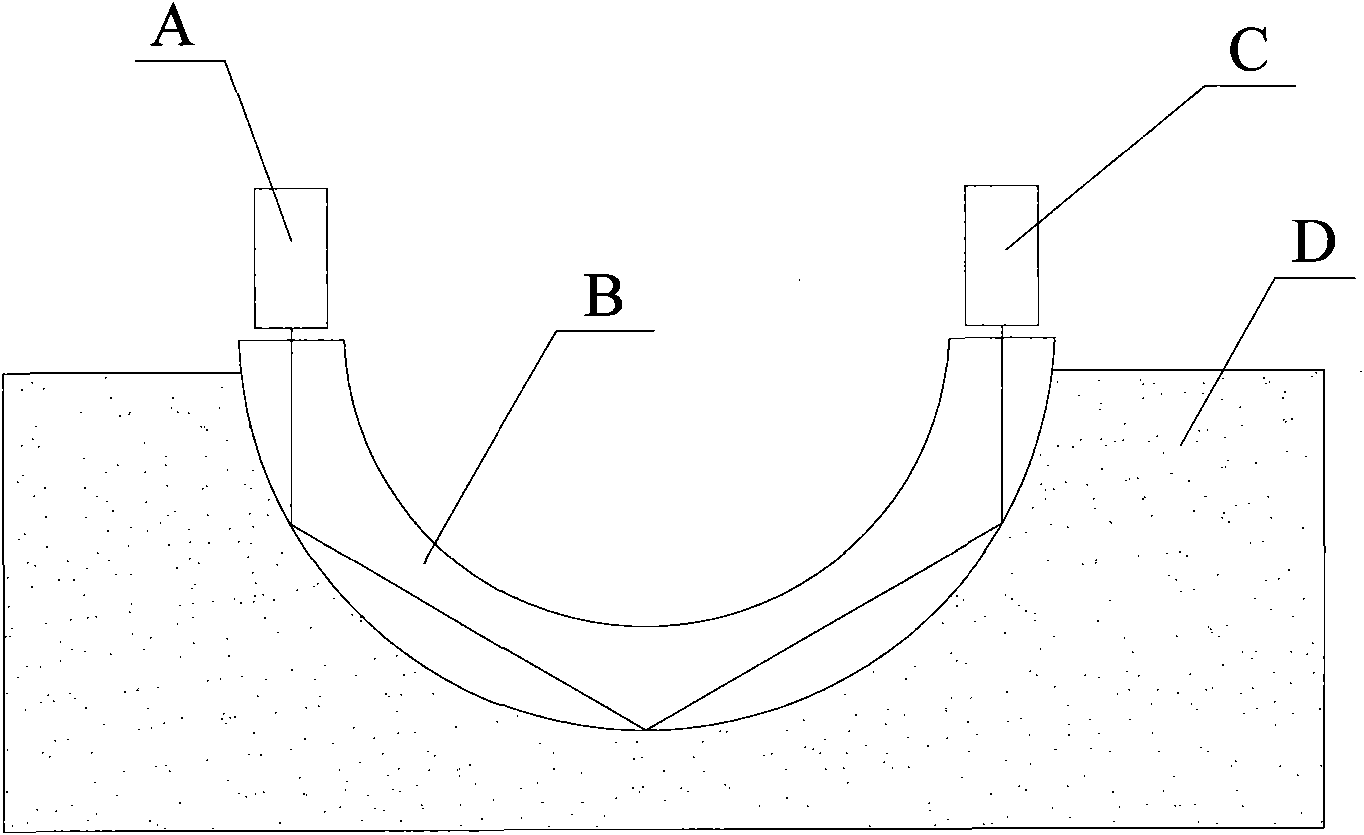

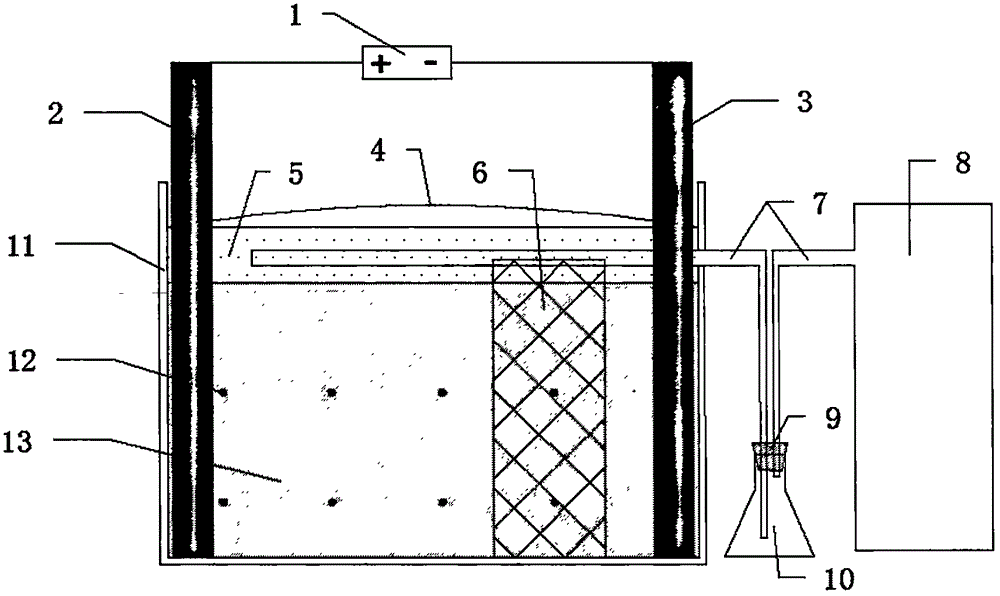

Vacuum pre-loading combined electric process test apparatus and test method thereof

InactiveCN105929132ALow costEasy to operateEarth material testingSoil preservationEngineeringGraphite

The invention relates to a vacuum pre-loading combined electric process test apparatus and a test method thereof, and belongs to the field of geotechnical engineering foundation treatment. The apparatus comprises a power supply part, a vacuum pump part and a box body part. The box body part is a transparent toughened glass box, soil in the box body is coated with a sand cushion, and the front side of the box body is provided with equidistant electric potential monitoring point hole sites. Cylindrical hollow graphite rods are inserted to two sides of the box body as a cathode and an anode, and the anode is a salt solution injection channel. A plastic water draining plate is inserted to a position close to the cathode, the top end of the water draining plate is positioned in the sand cushion and is connected with a conical flask through a rubber tube, and a vacuum pump is connected with the conical flask through the rubber tube. The invention also provides a method for carrying out vacuum pre-loading combined electric process test by using the apparatus. The apparatus can simulate vacuum pre-loading combined electric process soft soil reinforcement indoors, can guarantee test sealing and prevent electrode corrosion, and can be used to accurately measure the water draining effect, the settlement consolidating effect and the vacuum pre-loading combined electric process energy consumption ratio of soil.

Owner:SUN YAT SEN UNIV

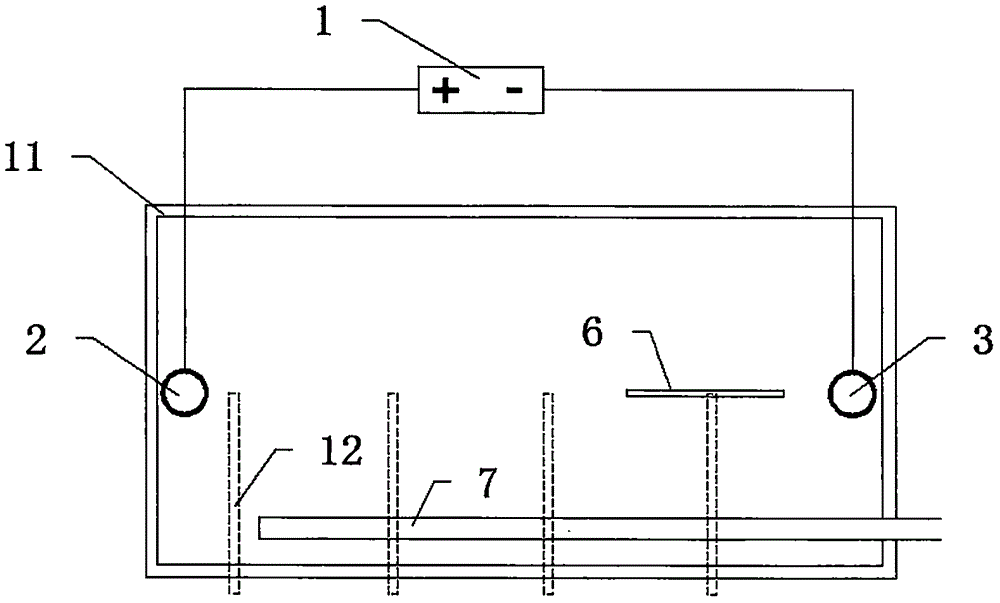

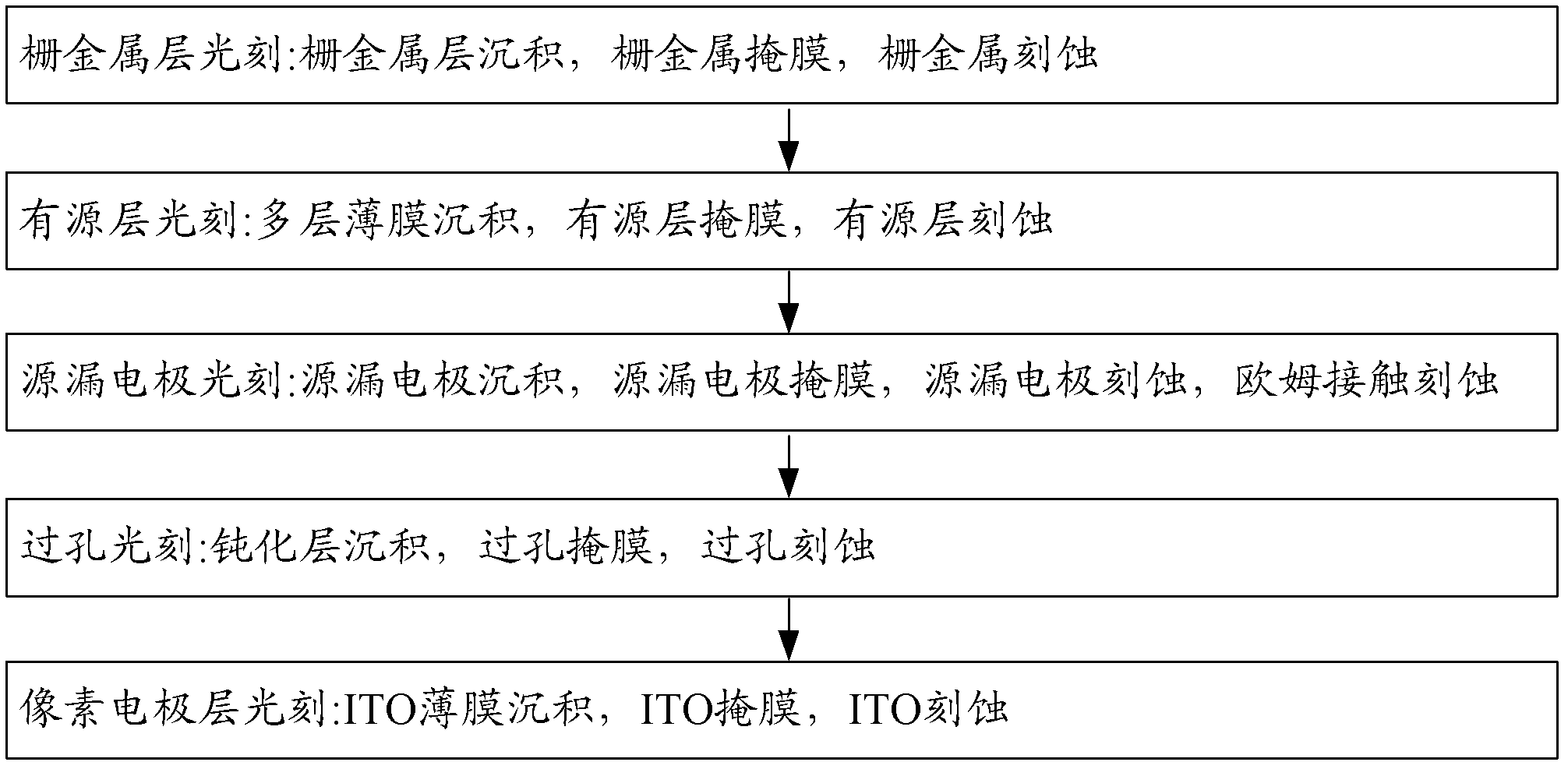

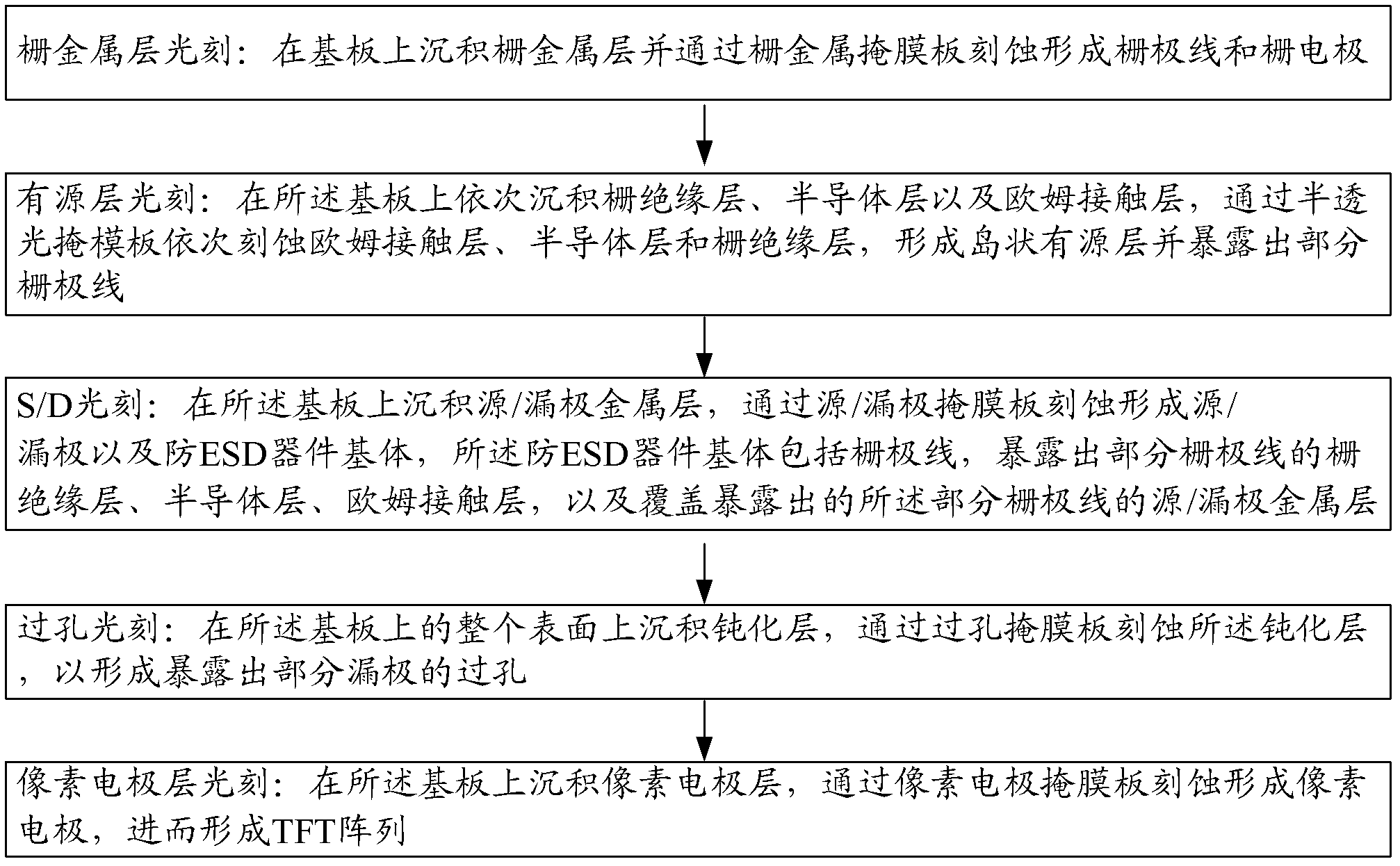

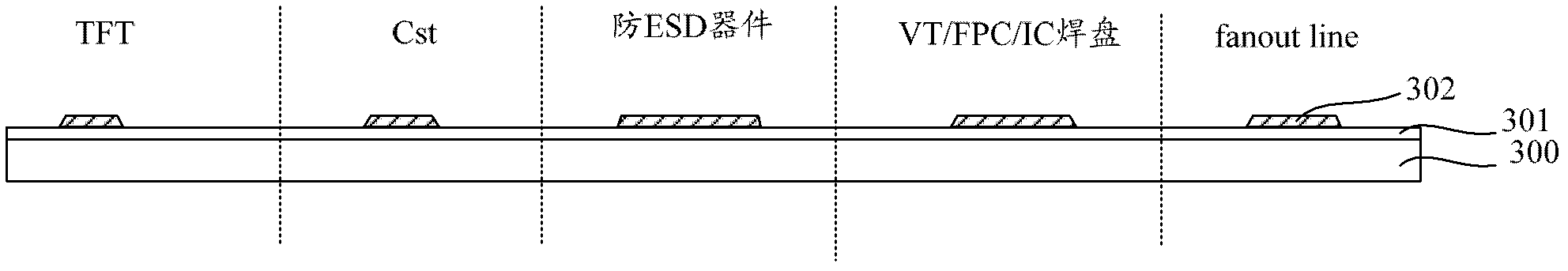

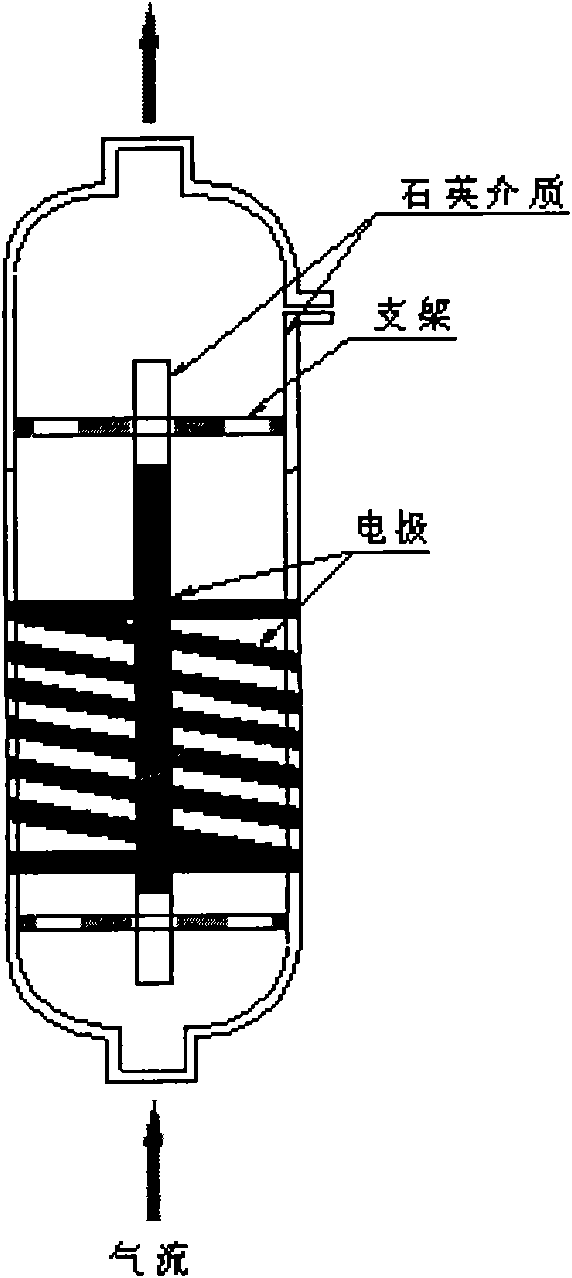

TFT-LCD (thin film transistor-liquid crystal display) array panel structure and production method thereof

ActiveCN103280428AElectrode corrosion is smallPrevent static electricitySolid-state devicesSemiconductor/solid-state device manufacturingLine resistanceLiquid-crystal display

The invention provides a TFT-LCD (thin film transistor-liquid crystal display) array panel structure and a production method thereof. An anti-ESD (anti-electrostatic discharge) element of which a gate metal layer is in direct contact with a source / drain metal layer is produced outside a TFT array in order to prevent each process station after source / drain metal deposition from being injured by static electricity, so that the product percent of pass can be increased; meanwhile, by correspondingly changing active mask, silicon islands are formed in the process of via-hole mask, consequently, the process steps are simplified, and the production cost is reduced; meanwhile, by correspondingly changing gate mask, active mask and source / drain mask, the gate metal is covered by the source / drain metal in the area of a VT / FPC / IC pad, consequently, the electrode corrosion of the gate metal layer can be reduced, and in the extending area of a fanout line, the line resistance can be decreased; and furthermore, before the deposition of the gate metal layer, a silicon nitride layer is first formed, so that the injuries of a substrate caused by dry etch can be reduced.

Owner:CHENGDU TIANMA MICROELECTRONICS

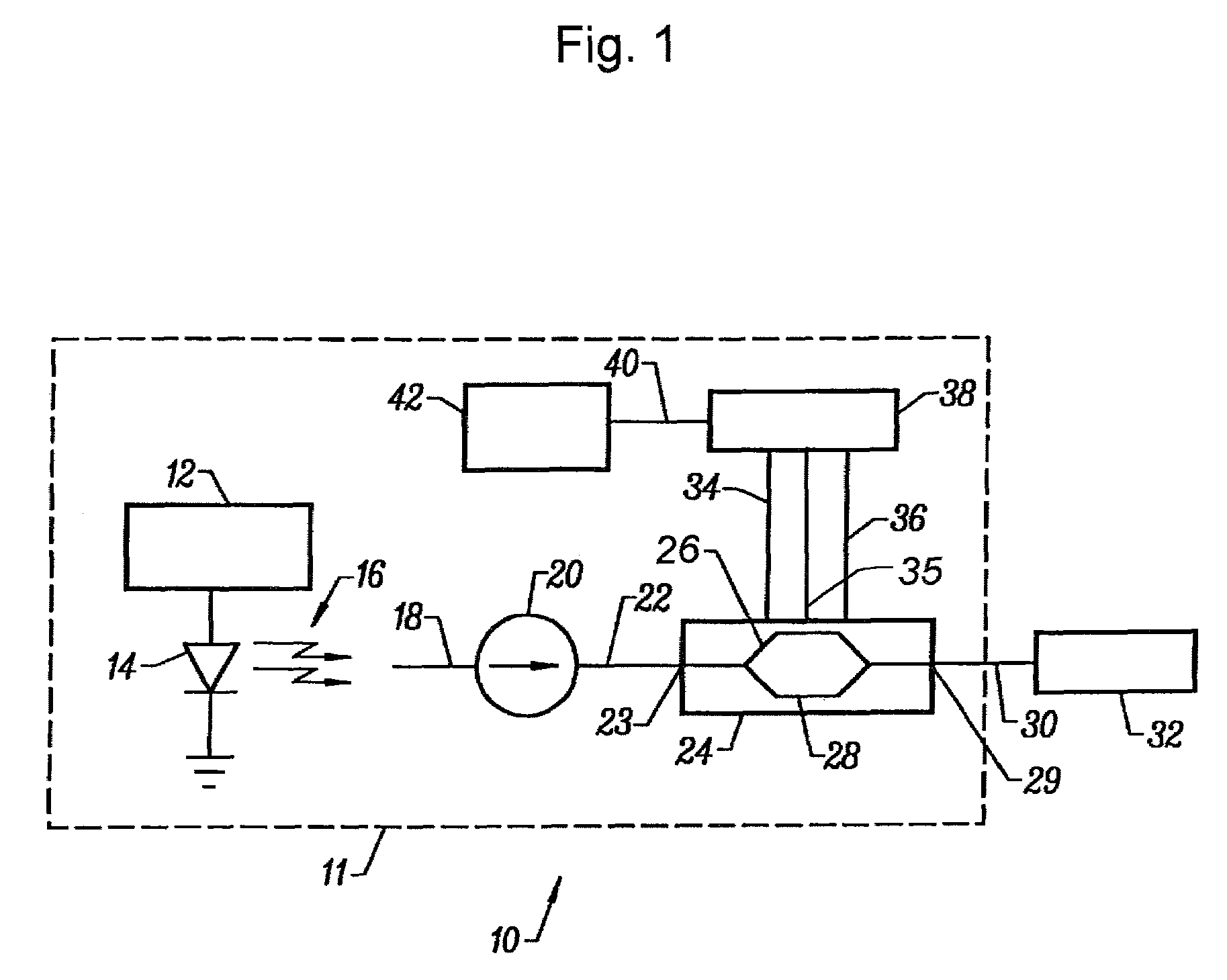

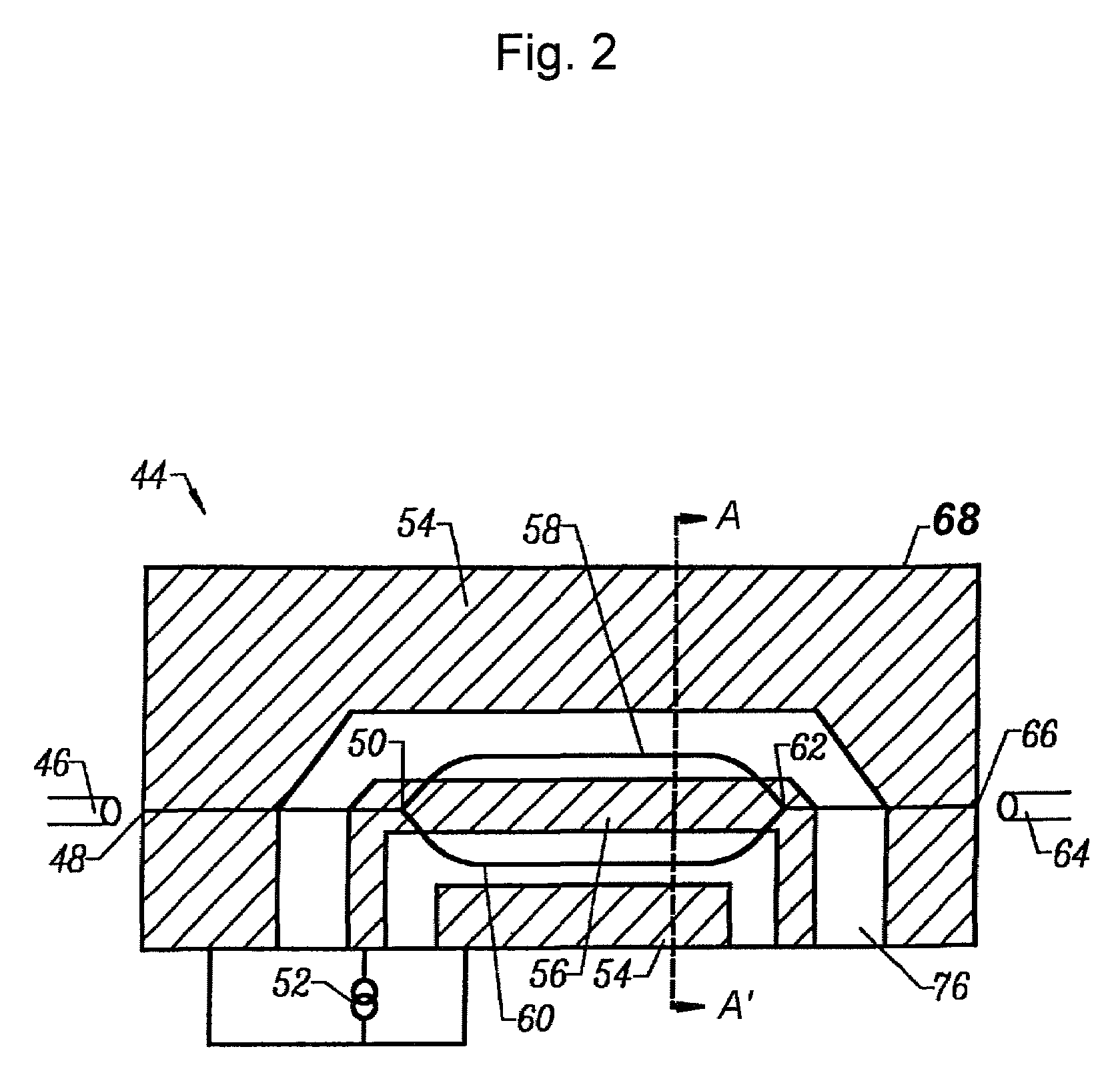

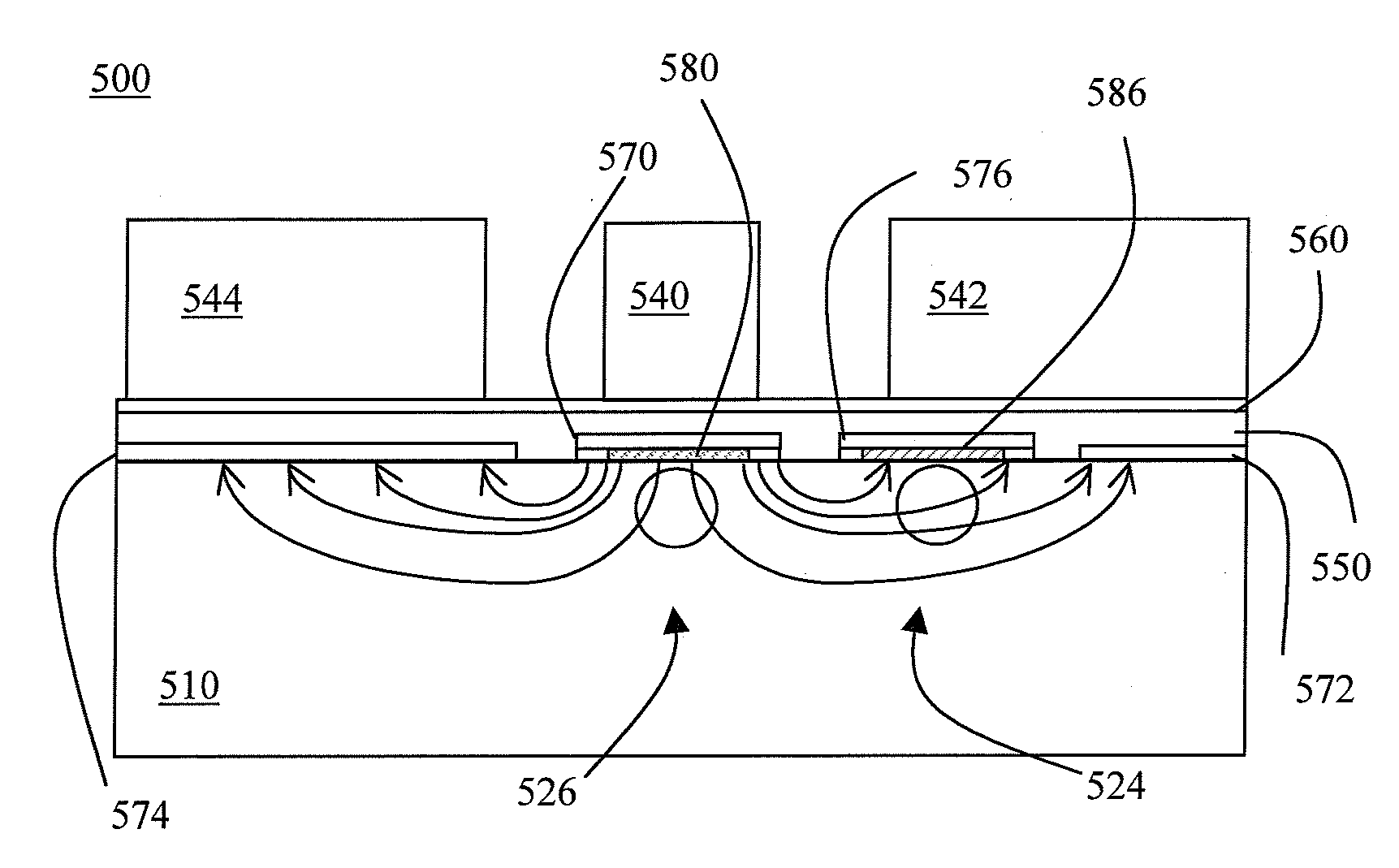

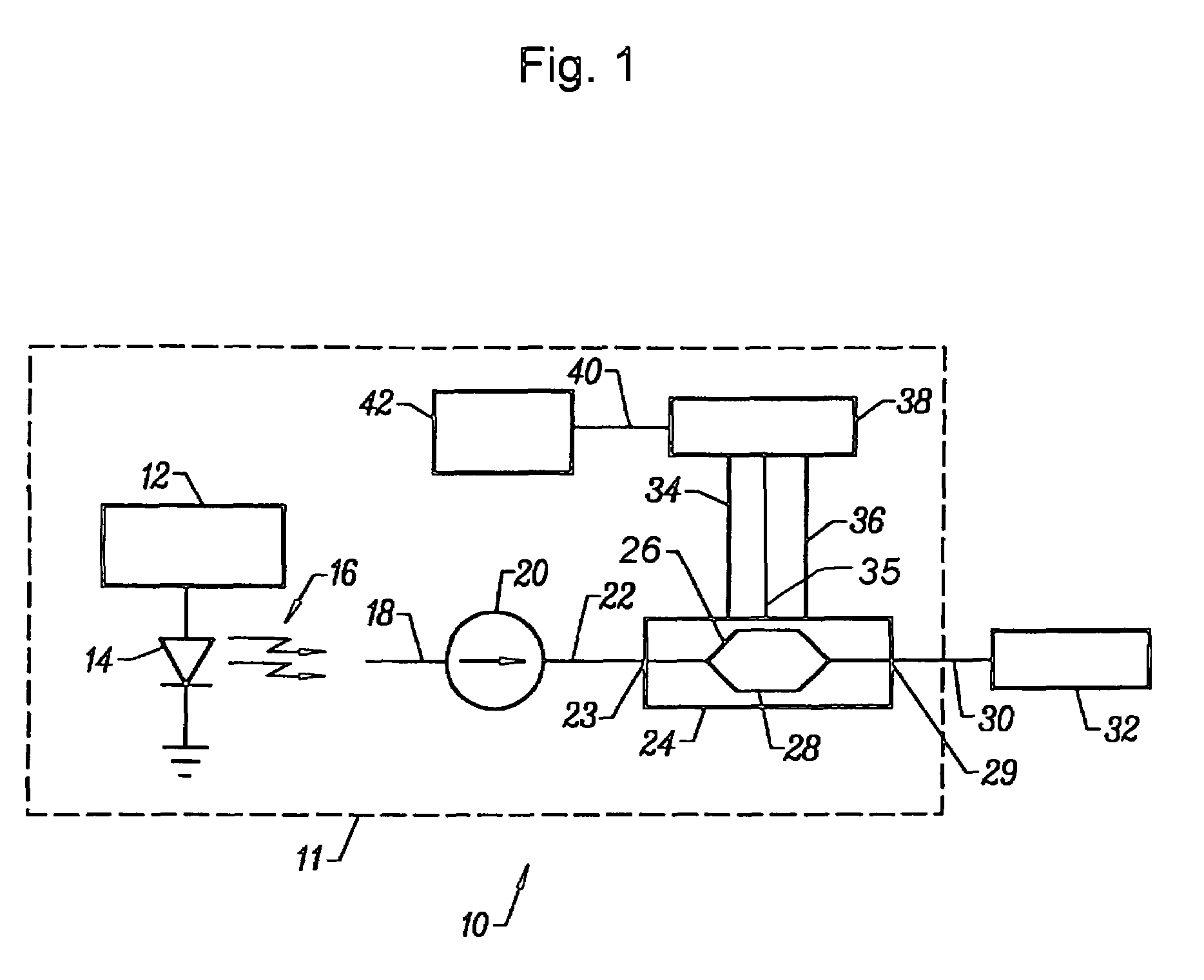

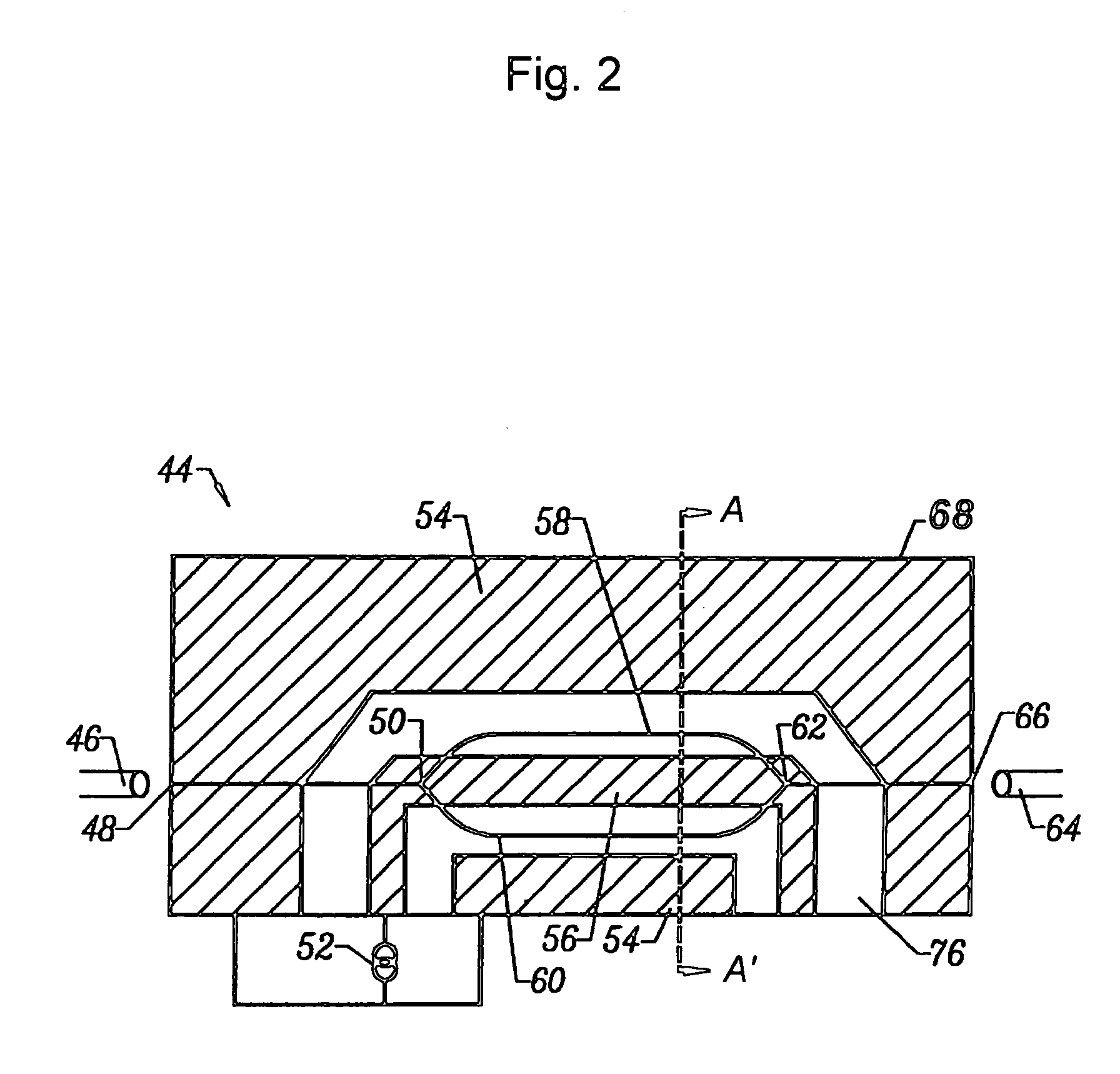

Low bias drift modulator with buffer layer

ActiveUS7324257B2Guaranteed uptimeLow costNon-linear opticsManufacturing cost reductionOperating point

The invention relates to an electro-optic modulator structure containing an additional set of bias electrodes buried within the device for applying bias to set the operating point. Thus the RF electrodes used to modulate incoming optical signals can be operated with zero DC bias, reducing electrode corrosion by galvanic and other effects that can be present in non-hermetic packages. The buried bias electrodes are also advantageous in controlling charge build-up with consequent improvement in drift characteristics. The bias electrode material is useful for routing bias signals inside the device, in particular to external terminals, as well as forming encapsulating layers to permit operation in non-hermetic environments, thereby lowering manufacturing costs. Embodiments using both X-cut and Z-cut lithium niobate (LiNbO3) are presented. For the latter, the bias electrodes can be split along their axis to avoid optical losses.

Owner:LUMENTUM OPERATIONS LLC

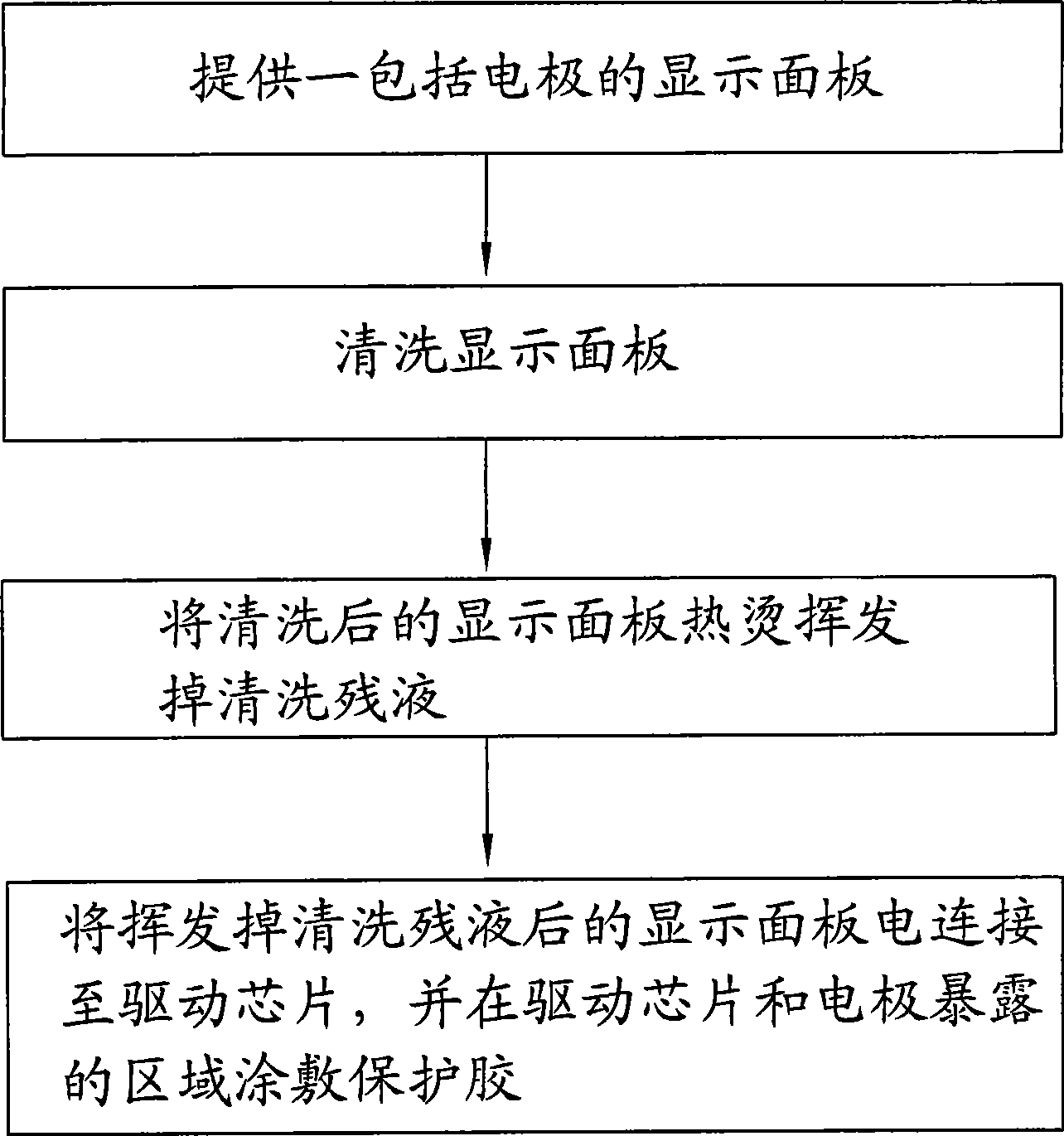

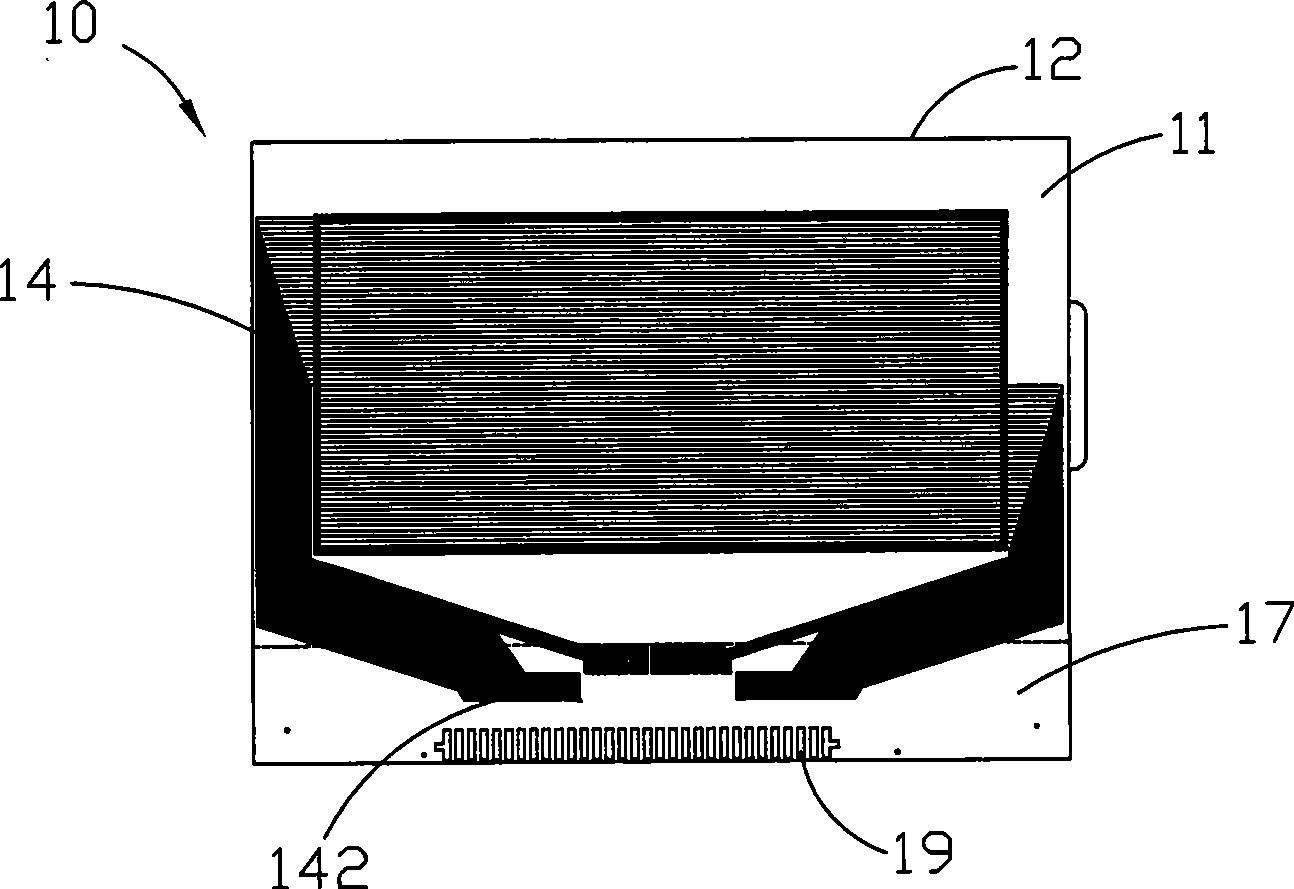

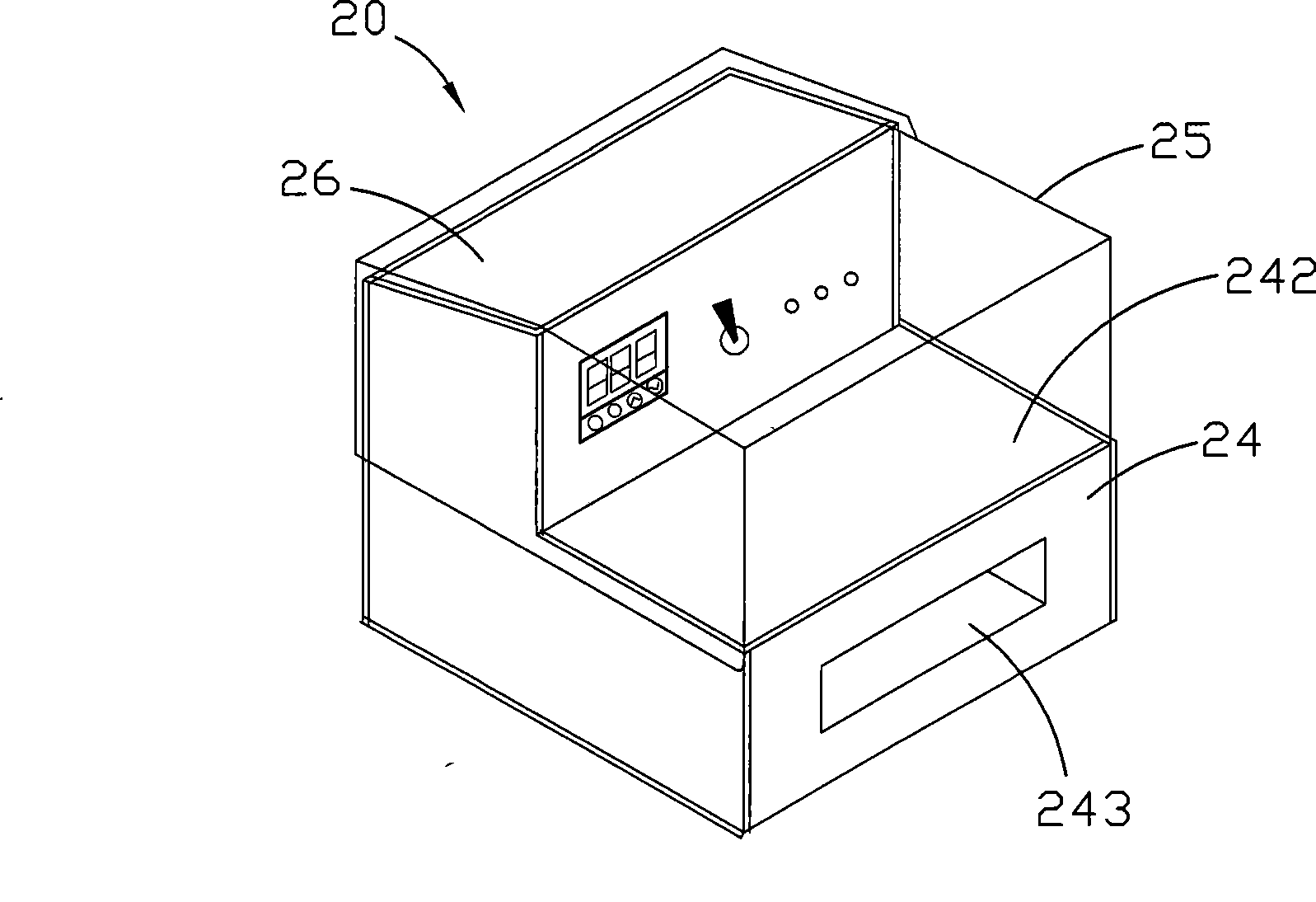

Corrosion preventive method and corrosion preventive blanching device for display panel electrode

InactiveCN101458414AReduce corrosionImprove efficiencyOhmic-resistance heatingNon-linear opticsElectricityEngineering

The invention discloses a corrosion protection method for display panel electrode and a corrosion protection hot iron device for preventing the display panel electrode from being corroded, and the method comprises the following steps: washing a display panel with an electrode, heating the washed display panel to volatilize the residual liquid, then electrically connecting the electrode of the display panel to a driving chip, and finally coating protection glue on the driving chip and the exposed area of the electrode. In the process of the corrosion protection method for display panel electrode, the display panel is heated by the hot iron device before connecting the electrode with the driving chip, in order to volatilize the residual liquid completely and avoid the washing liquid retaining on the electrode, thus preventing the corrosion of the electrode.

Owner:深圳市合力泰光电有限公司

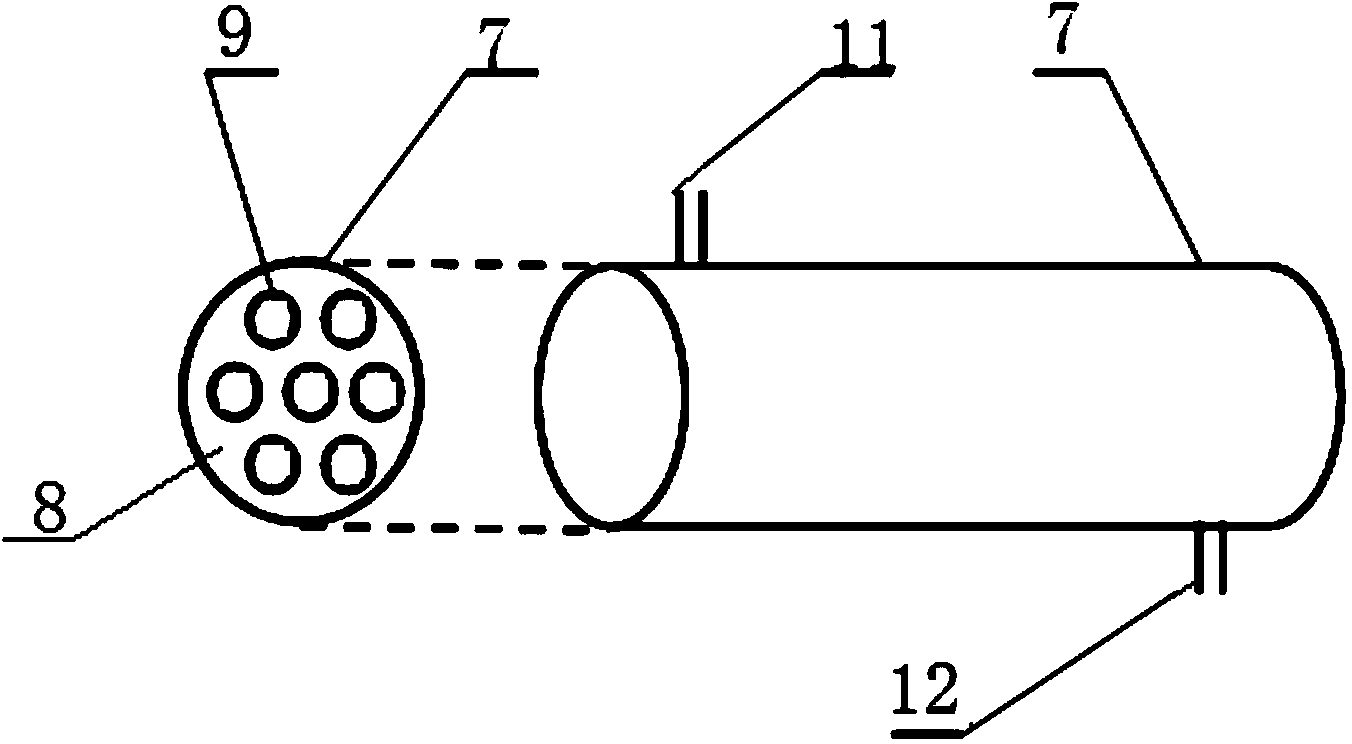

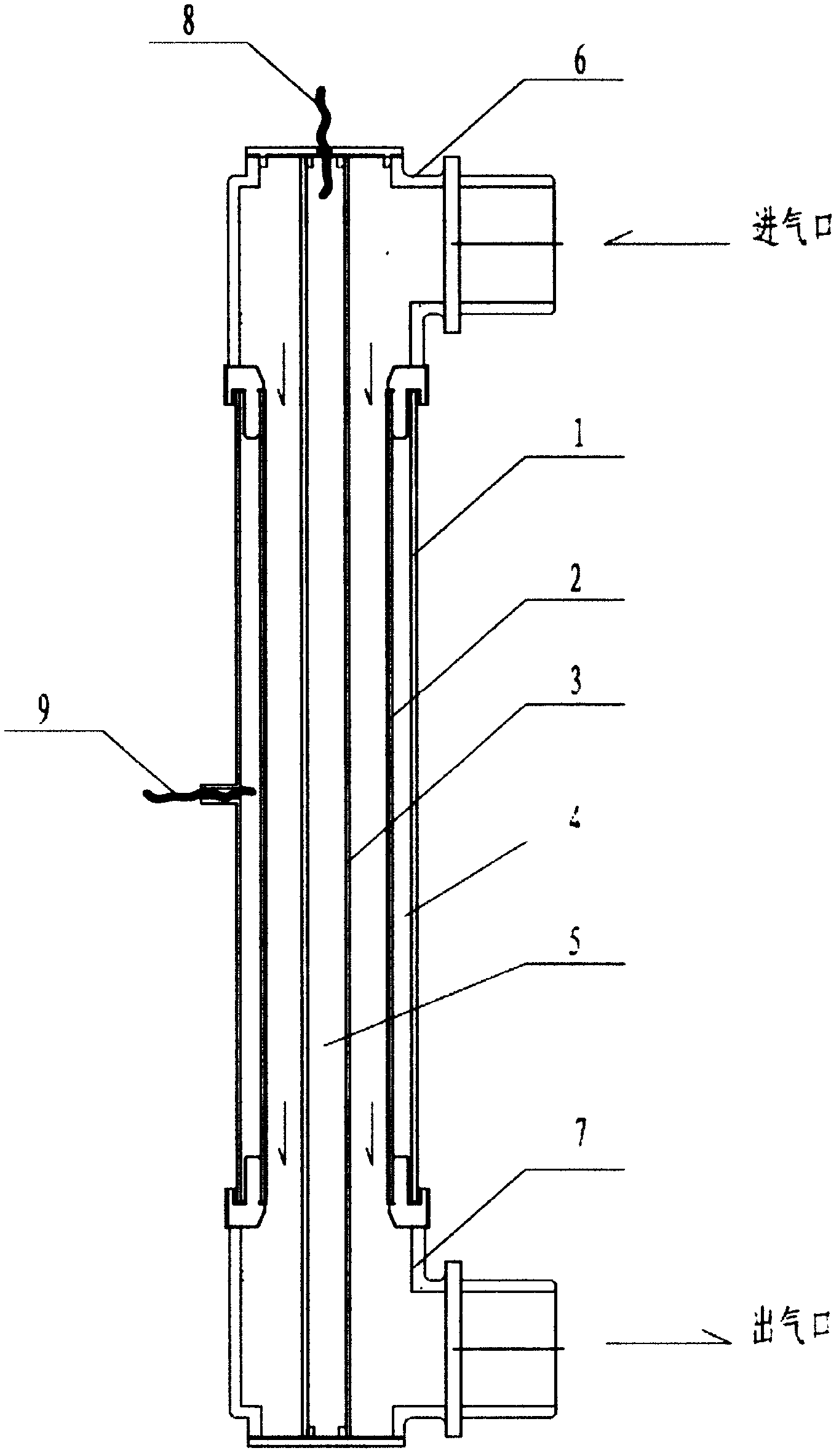

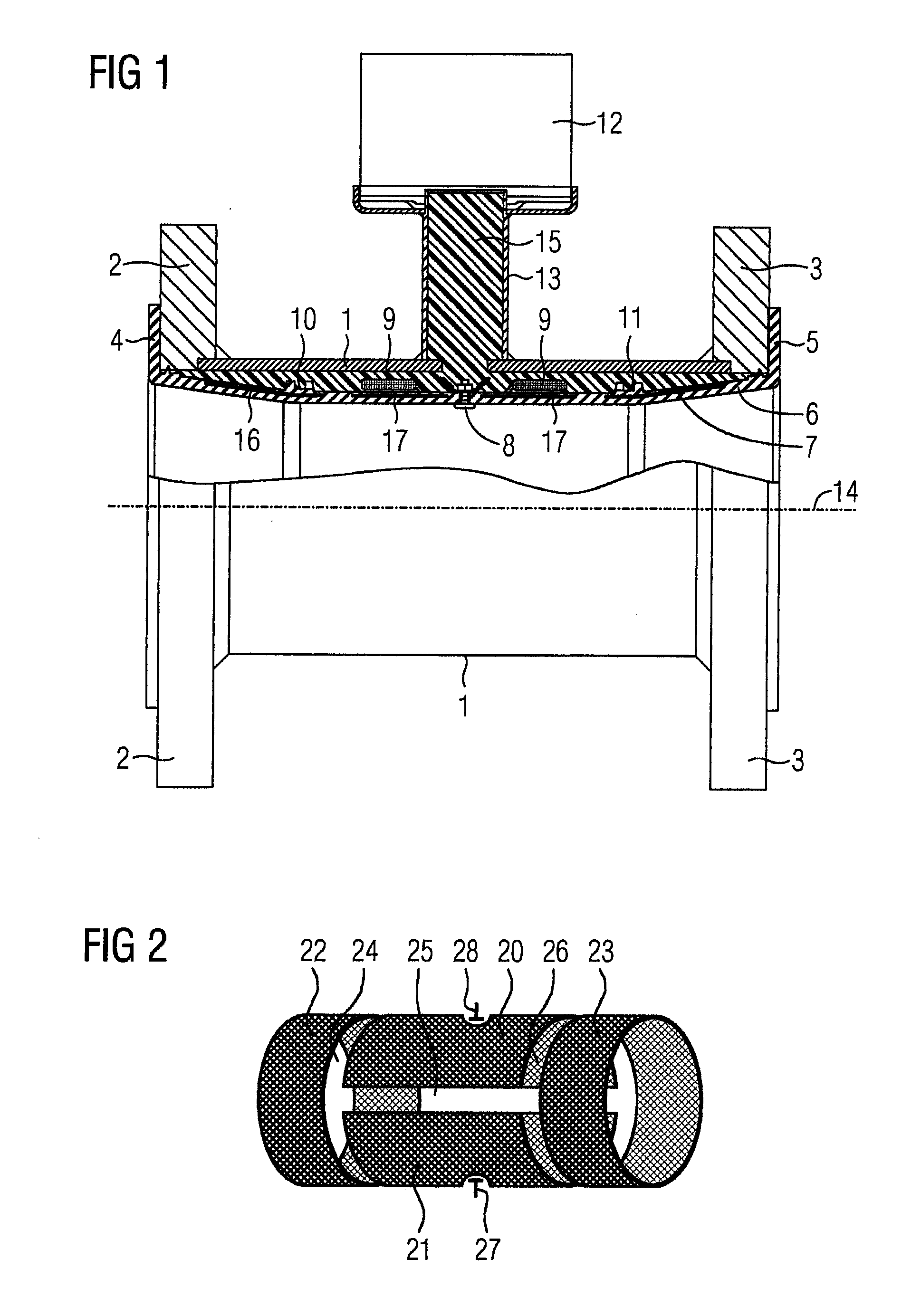

Plasma generation system by tubular dielectric barrier discharge and application thereof

ActiveCN102612250ASolve the problem of poor contactSolving Corrosion ProblemsDispersed particle separationPlasma techniqueDistribution systemEngineering

A plasma generation system by tubular dielectric barrier discharge belongs to the technical field of environmental protection and is characterized by comprising discharge tubes, plasma power supplies, high-tension transformers and a gas delivery and distribution system. The discharge tubes comprise three medium tubes with identical center, wherein a closed cavity formed by external medium tube and middle medium tube is filled with conductive metal powder so as to serve as an external electrode, a gas passage is formed in an open area formed by the middle medium tube and internal medium tube, and a closed cavity in the internal medium tube is filled with the conductive metal powder so as to serve as an internal electrode. The plasma generation system is capable of avoiding the problem of electrode corrosion, generating high power and large volume plasma stably, is even in gas flow distribution, stable in discharge, and is applicable to purification treatment of waste gas pollution.

Owner:SHANDONG PALLET ENVIRONMENTAL ENG

Display device

InactiveUS20070195217A1Display in display region can be preventedIncrease distanceNon-linear opticsElectricityLow voltage

An intermediate portion of a low voltage power supply wire is extinguished by irradiation of a laser beam to form a wire cut portion. A different potential portion serves as the wire cut portion of the low voltage power supply wire. The distance between the end portions of a high voltage power supply wire and the low voltage power supply wire between which the potential is different is increased. An electrical short-circuit between the high voltage power supply wire and the low voltage power supply wire hardly occurs. Even when impurities invade into the gap between an insulating layer on the high voltage power supply wire and the low voltage power supply wire and a glass substrate, electrode corrosion of the high voltage power supply wire and the low voltage power supply wire can be prevented. A display failure can be prevented.

Owner:TOSHIBA MATSUSHITA DISPLAY TECH

Magnetically inductive flow meter

InactiveUS20150300851A1Production outlay is smallLess sensitiveVolume/mass flow by electromagnetic flowmetersElectricityGas bubble

A magnetically inductive flow meter including a first electrode arrangement for galvanically contact detection of an induced voltage dependent on the flow velocity of the medium as a first measurement signal, and a second electrode arrangement for capacitive detection of an induced voltage as a second measurement signal, wherein by determining and evaluating characteristic parameters of the first and second measurement signals, diagnostic messages on the status of the medium and / or the flow meter are obtained, such as the content of gas bubbles in the fluid, electrode corrosion, electrical conductivity of the medium, damage to the electrically insulating interior lining of the measuring tube, deposits on electrodes, magnetic interference fields, electrode short-circuits and / or the fill level of the measuring tube.

Owner:SIEMENS AG

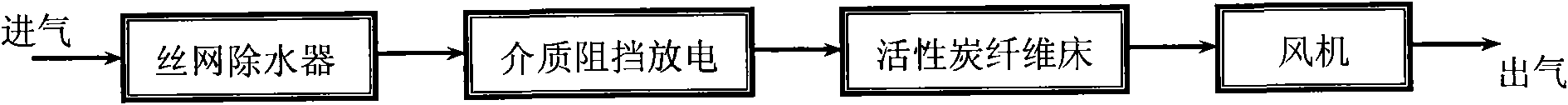

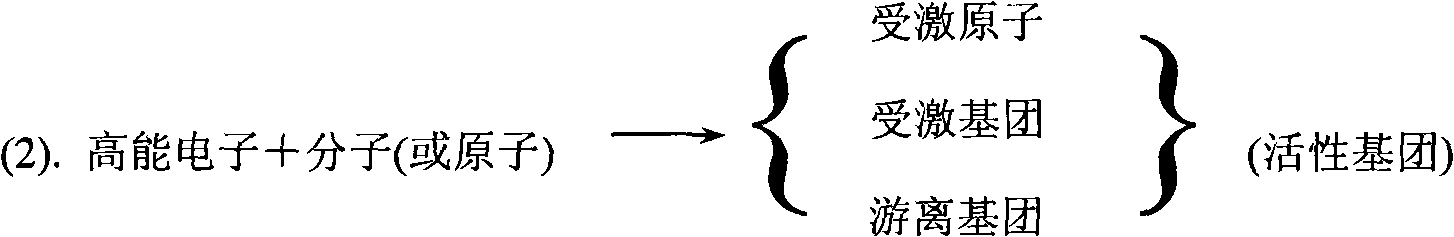

Method for treating industrial organic waste gases

InactiveCN101664626ASolving Corrosion ProblemsNo need for regular replacementDispersed particle separationFiberCarbon fibers

The invention belongs to the technical field of waste gas treatment and relates to a method for treating industrial organic waste gases. In the method, a combination of screen mesh water removal, dielectric barrier discharge plasma and activated carbon fiber adsorption is adopted to treat the industrial organic waste gases, a screen mesh water remover removes liquid drops from the waste gases to ensure the normal operation of the following dielectric barrier discharge plasma, a double dielectric barrier discharge plasma reaction tube is adopted to solve the problem of electrode corrosion by allowing the treated gases to pass through between inner and outer tubes, and high-activity groups generated in reaction, undecomposed organic matters and oxygen in the gases are absorbed in the microporous structure of activated carbon fibers under the absorption and medium actions of the activated carbon fibers to ensure the activated carbon fibers is always in an activated state. The method has the advantages that: the treatment system is compact in structure; the energy efficiency is high; the treatment effect is desirable; and the application prospect is wide.

Owner:FUDAN UNIV

Preparation method of negative electrode of metal lithium secondary battery

ActiveCN107565088AImprove cycle lifeReduce adverse reactionsElectrode manufacturing processesElectrode carriers/collectorsLithiumIon deposition

The invention discloses a preparation method of a negative electrode of a metal lithium secondary battery. According to the method, the surface of the original metal lithium negative electrode is coated with a layer of aluminum foil with thickness of about 600nm; and in a battery assembling process, an electrolyte is dropwise added to the aluminum foil, and the electrolyte and the aluminium foil react quickly to form lithium aluminium alloy. By virtue of the preparation method, an adverse reaction generated by direct contact between metal lithium with overhigh activity and the electrolyte canbe prevented, and lithium dendrites formed by the uneven lithium ion deposition process can be reduced, thereby greatly relieving the problem of constant electrolyte consumption and severe lithium negative electrode corrosion to a certain degree, and further prolonging the cycle life of the battery.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com