Preparation method of negative electrode of metal lithium secondary battery

A secondary battery and metal lithium technology, applied in secondary batteries, electrode manufacturing, battery electrodes, etc., can solve problems such as weakening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of metal lithium secondary battery that aluminum foil is used as negative electrode protection, the steps are as follows:

[0032] 1) Weigh 32mg LiFePO 4 The powder is used as the positive electrode active material, 4mg Ketjen black is used as the conductive agent, and 80uL, the concentration is 50mg mL -1 The polyvinylidene fluoride (PVDF) solution (solvent is N-methylpyrrolidone (NMP)) is used as a binding agent, and 3ml NMP is added dropwise as a dispersant, and ball milled in a ball mill tank for 5h to make a slurry one;

[0033] 2) Apply the slurry evenly on the front of the scrubbed clean current collector (that is, the matte surface of the single-sided glossy aluminum foil with a thickness of 16±2um, purchased from Kejing Company) with a doctor knife. Make electrode sheets with a coating thickness of 200 μm, vacuum dry overnight at 90°C and cool down naturally;

[0034] 3) Cut the dried and naturally cooled electrode sheets into ele...

example 1

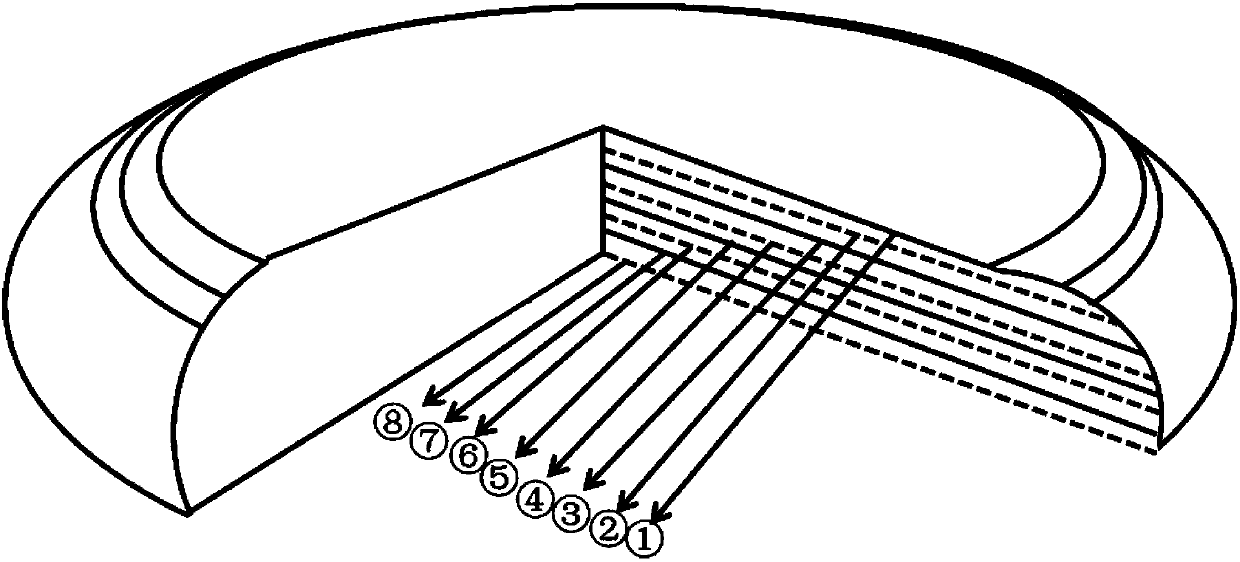

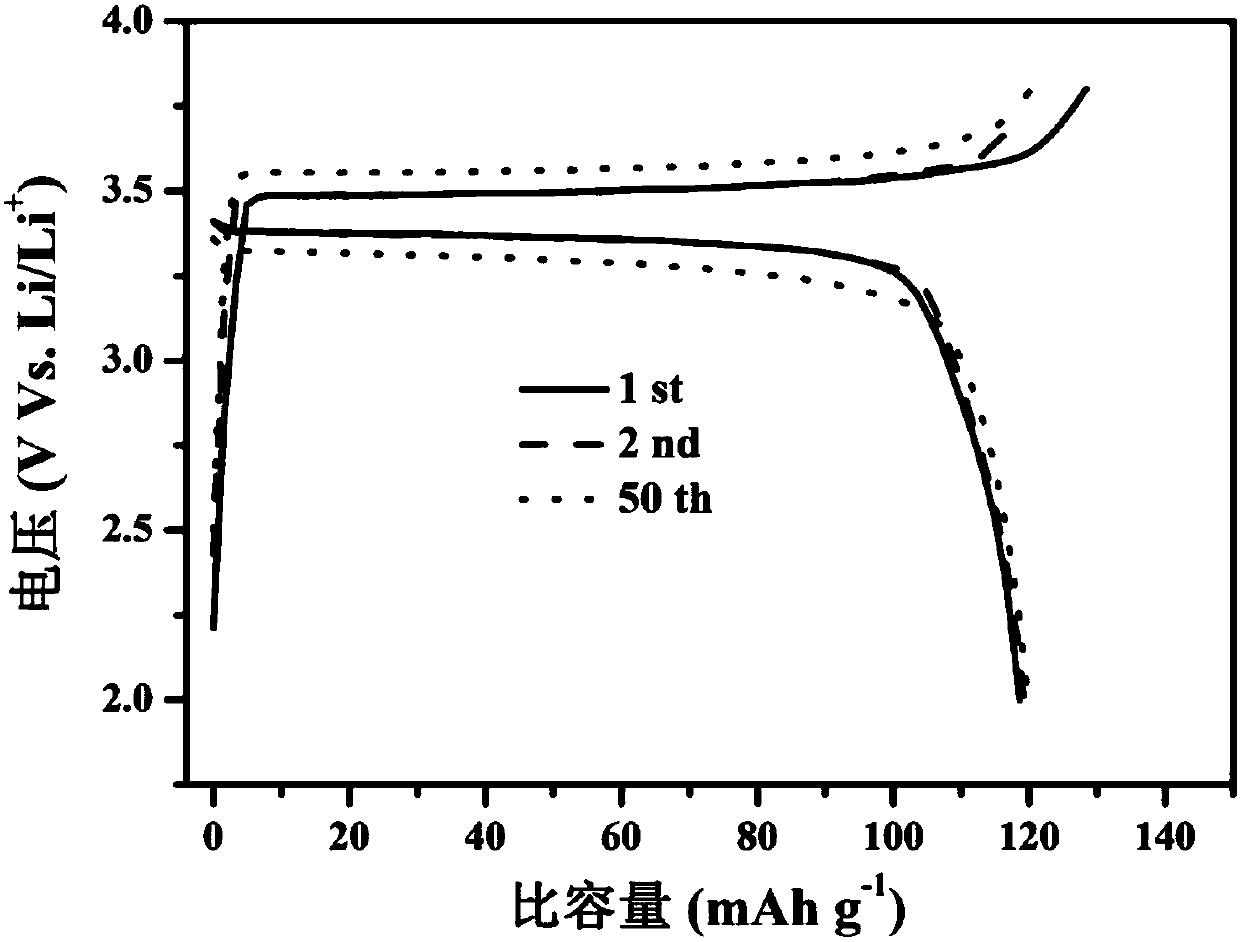

[0040] The assembly of lithium metal battery described in example one is as follows figure 1 As shown, the method is to assemble a button-type lithium metal battery with a battery model of CR 2032 in a glove box filled with an argon atmosphere. This method is a known technology, briefly described as follows: in a glove box full of argon atmosphere, according to figure 1 ① Negative shell, ② shrapnel, ③ spacer (16mm in diameter), ④ lithium sheet (16mm in diameter), ⑤ 600nm aluminum foil, ⑥ separator (Celgard 2400, 19mm in diameter), here the separator should completely separate the positive and negative electrodes. Therefore, it must be larger than the diameter of the lithium sheet, which is 19mm), ⑦ positive electrode material (LiFePO 4 ), ⑧ Assembling button batteries in the order of the positive shell, wherein, before and after placing the separator, 2-3 drops of electrolyte (LiPF 6 (EC:DEC=1:1)) On the surface of the aluminum foil, the in-situ alloying reaction between the...

Embodiment 2

[0043] A kind of preparation method of metal lithium secondary battery that aluminum foil is used as negative electrode protection, the steps are as follows:

[0044] Step 1) is identical with embodiment 1;

[0045] 2) Change the thickness of the coating film to 300 μm, and keep other conditions unchanged;

[0046] 3) same as embodiment 1;

[0047] 4) Select the electrode sheet to control the active material loading to about 3.0 mg cm -2

[0048] 5) The remaining steps are similar to those in the embodiment, and the obtained charge-discharge cycle curve is similar to that in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Charging capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com