Patents

Literature

1166 results about "Aluminium foil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium foil (or aluminum foil in North America), often referred to with the misnomer tin foil, is aluminium prepared in thin metal leaves with a thickness less than 0.2 mm (7.9 mils); thinner gauges down to 6 micrometres (0.24 mils) are also commonly used. In the United States, foils are commonly gauged in thousandths of an inch or mils. Standard household foil is typically 0.016 mm (0.63 mils) thick, and heavy duty household foil is typically 0.024 mm (0.94 mils). The foil is pliable, and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimes laminated to other materials such as plastics or paper to make them more useful. Aluminium foil supplanted tin foil in the mid 20th century.

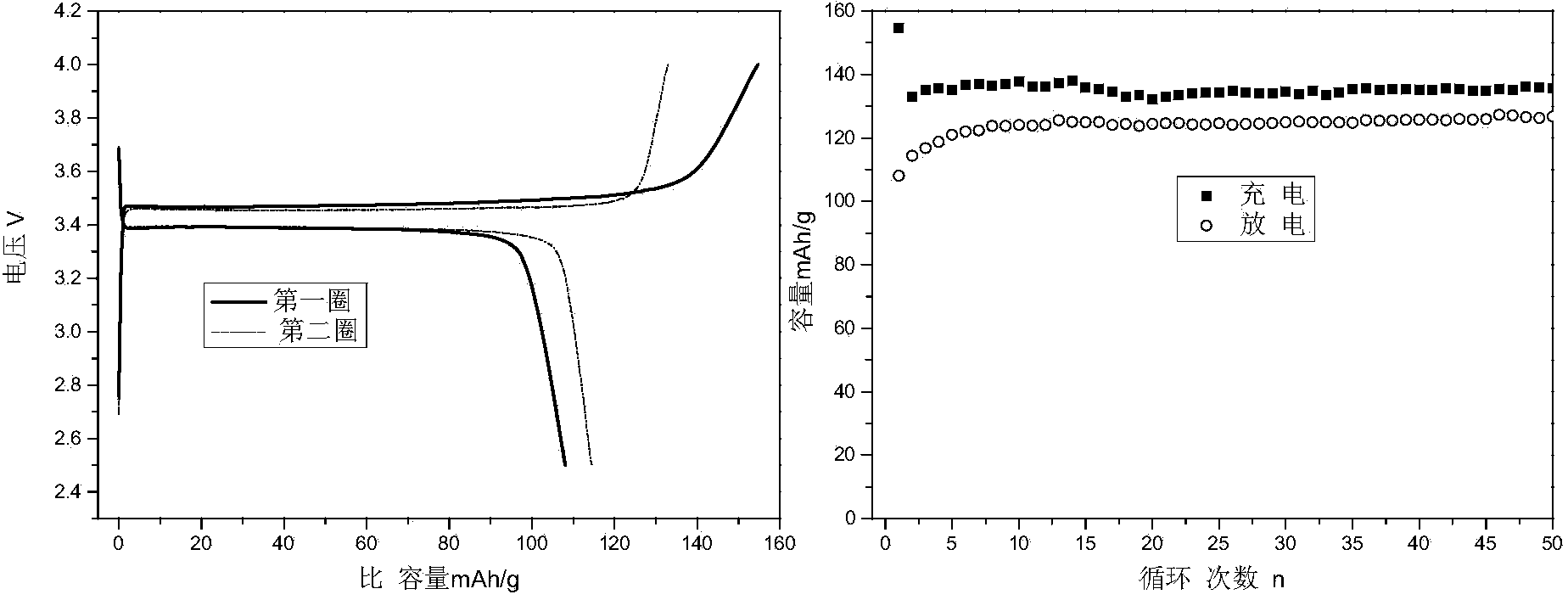

High-performance lithium ion battery and preparation process thereof

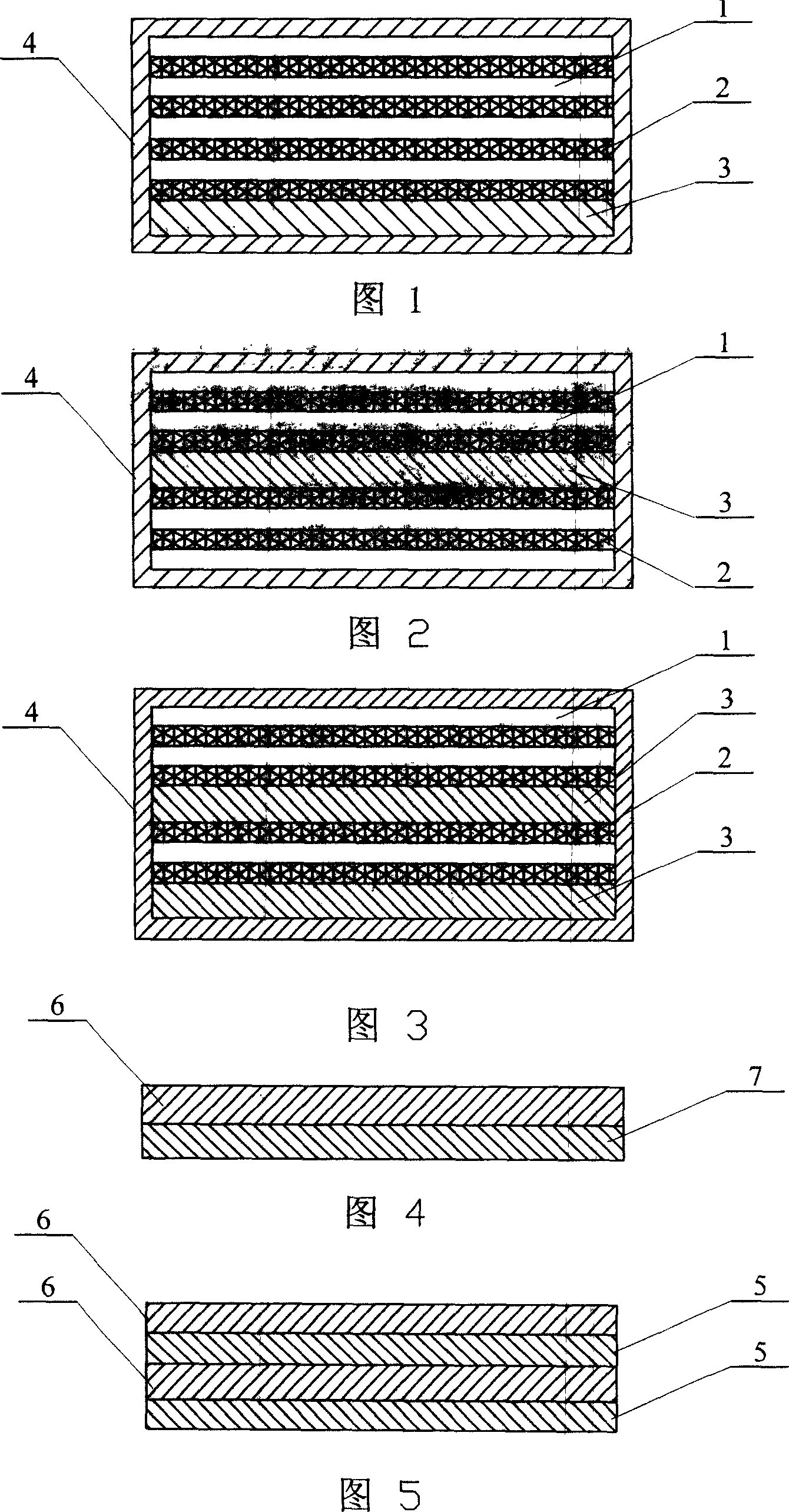

InactiveCN102347475AImprove electronic conductivityImprove charge and discharge performanceCell electrodesSecondary cellsAluminium foilCopper foil

The invention relates to a high-performance lithium ion battery. According to the battery, an electrode material is subjected to a nano-composite treatment of grapheme and polyaniline; an anode current collector comprises aluminium foil; a cathode current collector comprises copper foil; a conductive agent comprises superconducting carbon black, conductive graphite or acetylene black; a binding agent comprises styrene butadiene rubber, carboxymethylcellulose sodium, polytetrafluoroethylene, polyvinylidene difluoride or hydroxy propyl methylcellulose; a electrolyte comprises liquid electrolyte or a polymer electrolyte containing a conductive polymer, a nano-material, or a mixture comprising the conductive polymer and the nano-material; a membrane is subjected to a high temperature resistant insulation coating treatment, or directly adopts a high temperature resistant insulating porous polymer matrix. A preparation process for the high-performance lithium ion battery comprises: material preparing, coating, drying, rolling, slicing, coil winding or sheet stacking, assembling, liquid injecting, formation and capacity distributing. The lithium ion battery provided by the present invention has characteristics of excellent charge and discharge performance at the large rate, small capacity fading, good heat stability, good safety performance and long electrode cycle life, and can be widely applicable for the fields of electric bicycles, electric motorcycles, electric cars and the like.

Owner:LUNAN RES INST OF COAL CHEM

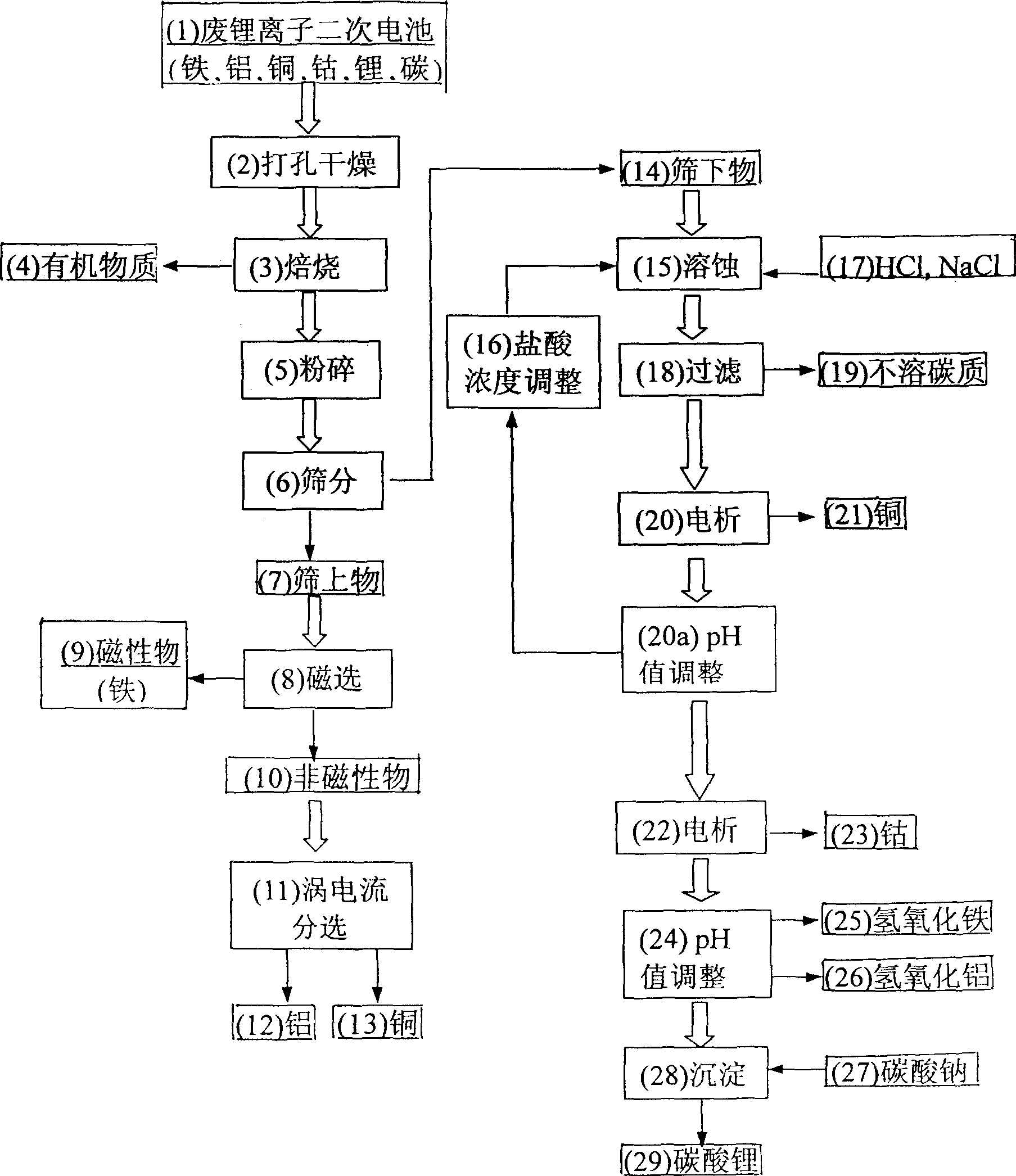

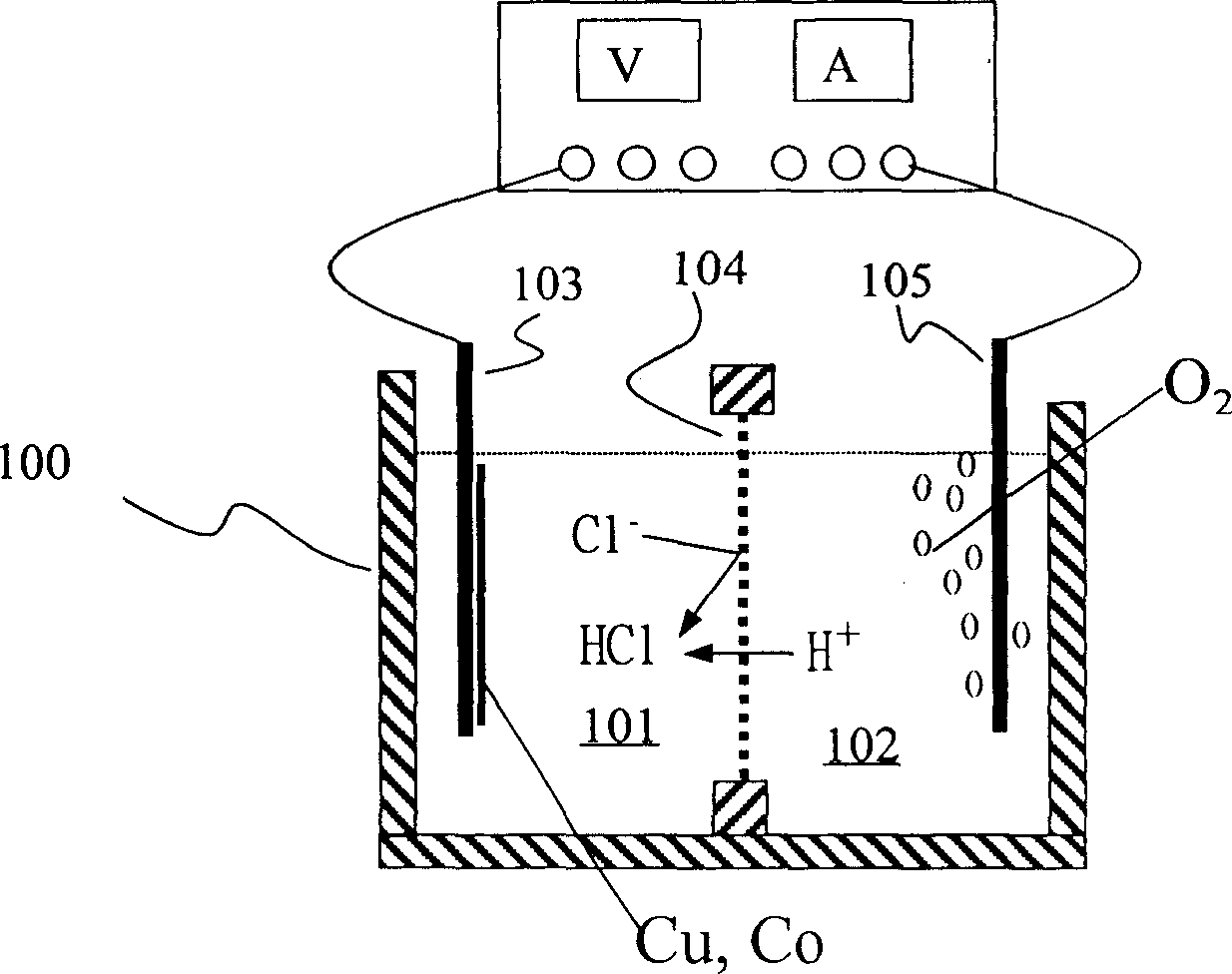

Method for recovering metal from used Li ion cell

InactiveCN1402376ATo achieve the purpose of separationReduce lossWaste accumulators reclaimingBattery recyclingDielectricCopper foil

The invented method includes the physical separation method combining with the preparation procedure of the cleaning wet recycle, providing the features of simple and high purity of the recovered metal. The invention includes following steps. With the disused lithium ion cells being burned in the high-temperature furnace, the organic dielectric is removed. After the smashing and sieving treatment, the oversize material is processed through the magnetic separation and the eddy current sorting so as to obtain the iron case, copper foil and aluminium foil etc. The undersize is processed through the steps of corrosion, filtering and electrolysis so as to obtain copper and cobalt. With carbonic acid radical being added to the solution richen in lithium ion, the high purity carbonate of lithiumis formed so as to recovery lithium.

Owner:IND TECH RES INST

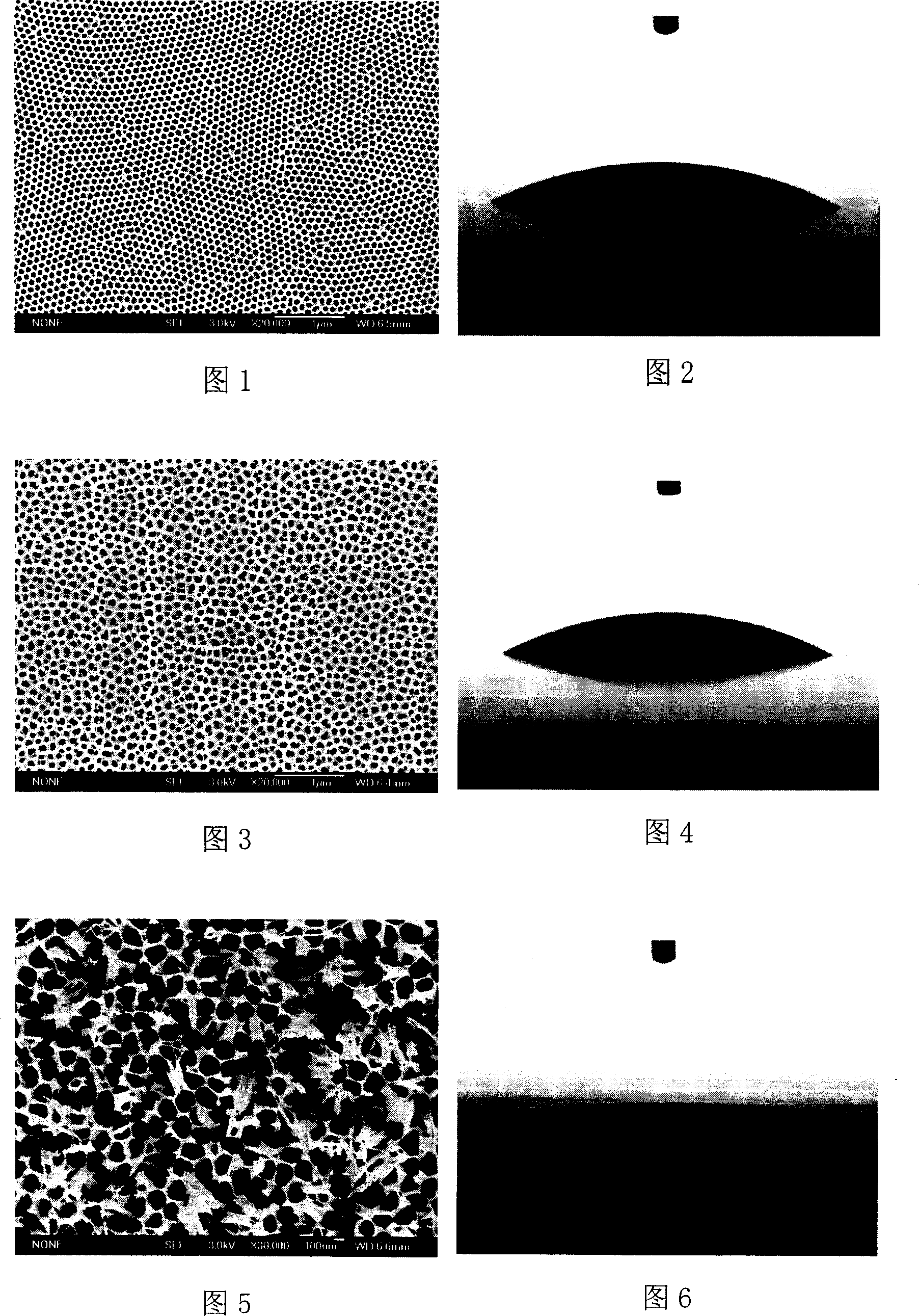

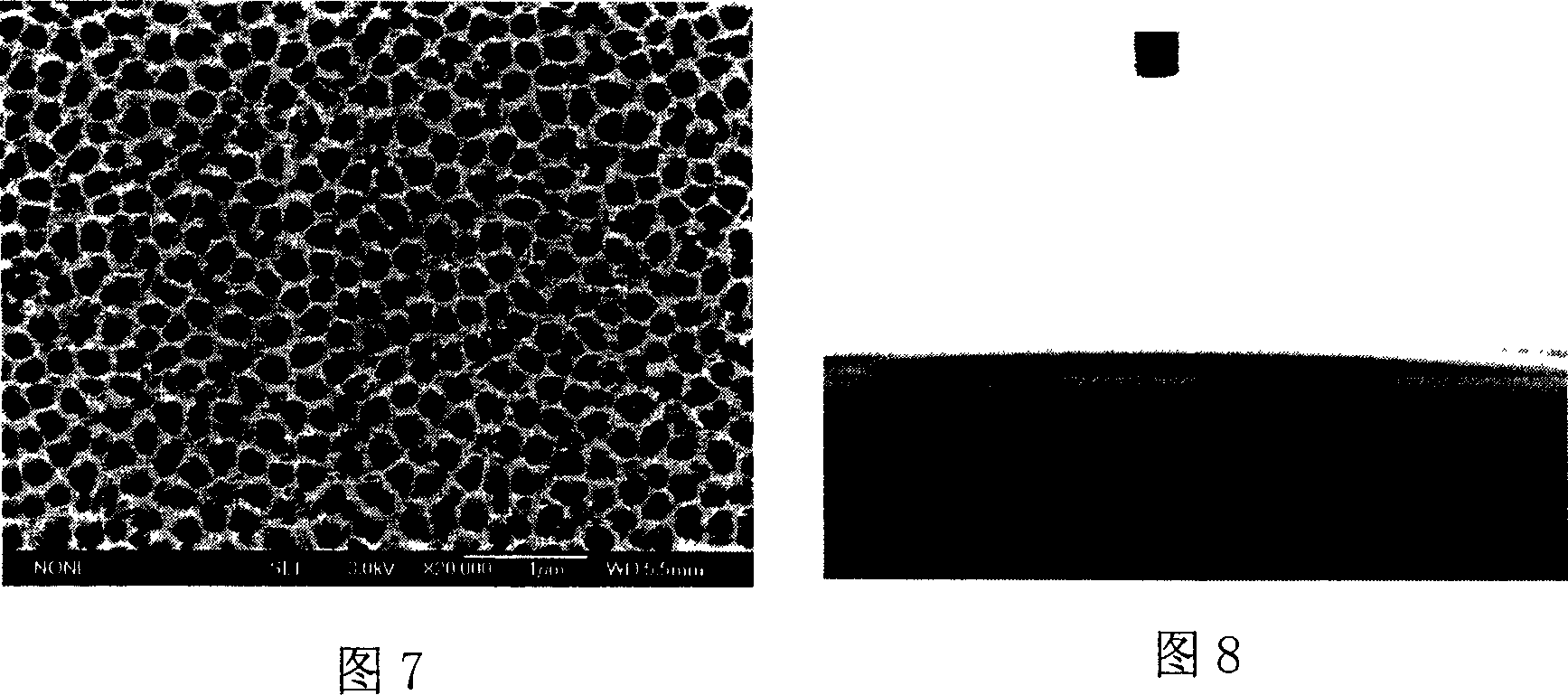

Process for preparing highly-hydrophilic alumina film material

InactiveCN101007645AImprove stabilityShape is easy to controlAluminium oxide/hydroxide preparationPhosphoric acidElectrochemistry

The invention discloses a making method of high-hydrophilicity alumina film, which comprises the following steps: adopting electrochemical polished aluminium foil as anode and platinum piece as cathode; selecting one of sulfuric acid, oxalic acid phosphoric acid with water or poor water (the composite solution of oxalic alcohol and water) as electrolyte solution; using electrochemical oxidizing method to strip aluminium base; removing damping layer; obtaining the product with different shapes and areas.

Owner:BEIJING ZHONGKE NANO THINK PRINT TECH

Method for composite preparation of Ti alloy/TiAl alloy composite plate material by using laminated rolling-diffusion method

InactiveCN101011706AReduce manufacturing costThe preparation method is simpleTemperature control deviceFurnace typesDiffusion methodsAlloy composite

The invention discloses a making method of titanium alloy / TiAl composite board, which is characterized by the following: overlapping A (titanium foil) and C (aluminium foil); placing at least one layer B (titanium or titanium alloy foil, titanium or titanium alloy board) on the upper and lower surfaces of overlapped layer or among overlapping layer; setting adjacent layer C to B; adopting three layers or more of A or B as the most outer layer; jacketing; rolling under 20-750 deg.c and 750-1300 deg.c.

Owner:HARBIN INST OF TECH

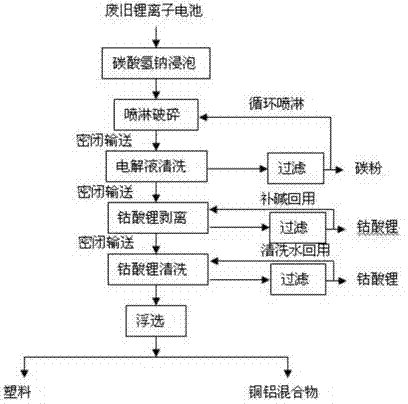

Method for comprehensively recycling waste lithium ion batteries

ActiveCN103943911AAccelerated corrosionAffect healthWaste accumulators reclaimingBattery recyclingSocial benefitsEconomic benefits

The invention discloses a method for comprehensively recycling waste lithium ion batteries, and belongs to the field of recycling of regeneration resource. The method comprises the following steps: a, performing discharging processing on waste lithium ion batteries; b, fragmenting waste lithium ion batteries into sheets with a diameter of 10-20 mm in a closed shearing-type crusher, and spraying during fragmentation to dissolve lithium hexafluorophosphate in the waste lithium ion batteries into a spraying solution; c, peeling carbon powder on the surface of aluminium foils through stirring, dissolving electrolyte into the spraying solution, and recovering carbon powder; d, sending the sheets into a sodium hydroxide solution, peeling lithium cobalt oxide powder on the surface of aluminium foils through stirring, and recovering lithium cobalt oxide powder; e, cleaning the sheets, and recovering lithium cobalt oxide powder; and f, separating and recovering plastic and a copper-aluminium mixture. The method realizes recovery of carbon powder, lithium cobalt oxide powder, the copper-aluminium mixture and plastic through a simple environment-friendly process, and has certain economic benefit and social benefit.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

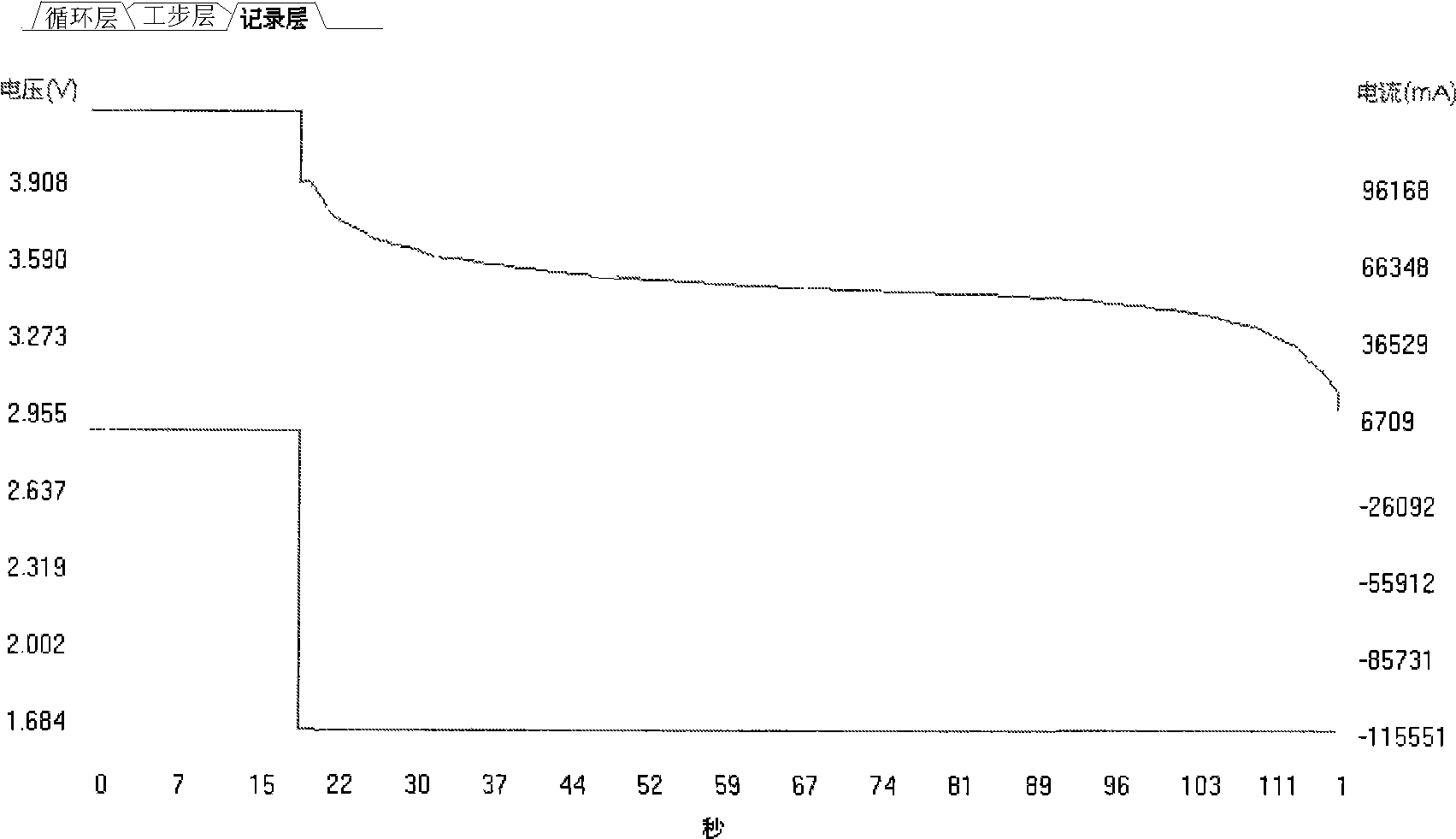

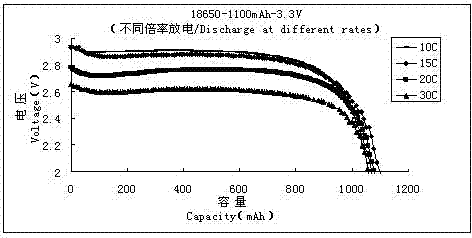

Ultra-high magnification lithium ion battery

The invention discloses a lithium ion battery with superhigh multiplying power, which comprises a positive plate, a negative plate, a membrane, an electrolyte solution, a plate lug and a packing shell. The positive plate is manufactured by coating the mixed slurry of a positive active material, a conducting agent and a cementing agent on both sides of an aluminium foil; the negative plate is manufactured by coating the mixed slurry of a negative active material, the conducting agent and the cementing agent on both sides of a copper foil; and the electrolyte solution is a mixed solution of lithium and an organic solvent. The lithium ion battery is capable of discharging continually at a superhigh multiplying power and the discharge multiplying power can reach 35C-50C. The discharge capacity of the discharge multiplying power at 35C, 40C, 45C, 50C can respectively reach 96.3 percent, 95.6 percent, 95.1 percent and 94.5 percent of the discharge capacity at 1C.

Owner:XIAN SAFTY ENERGY TECH

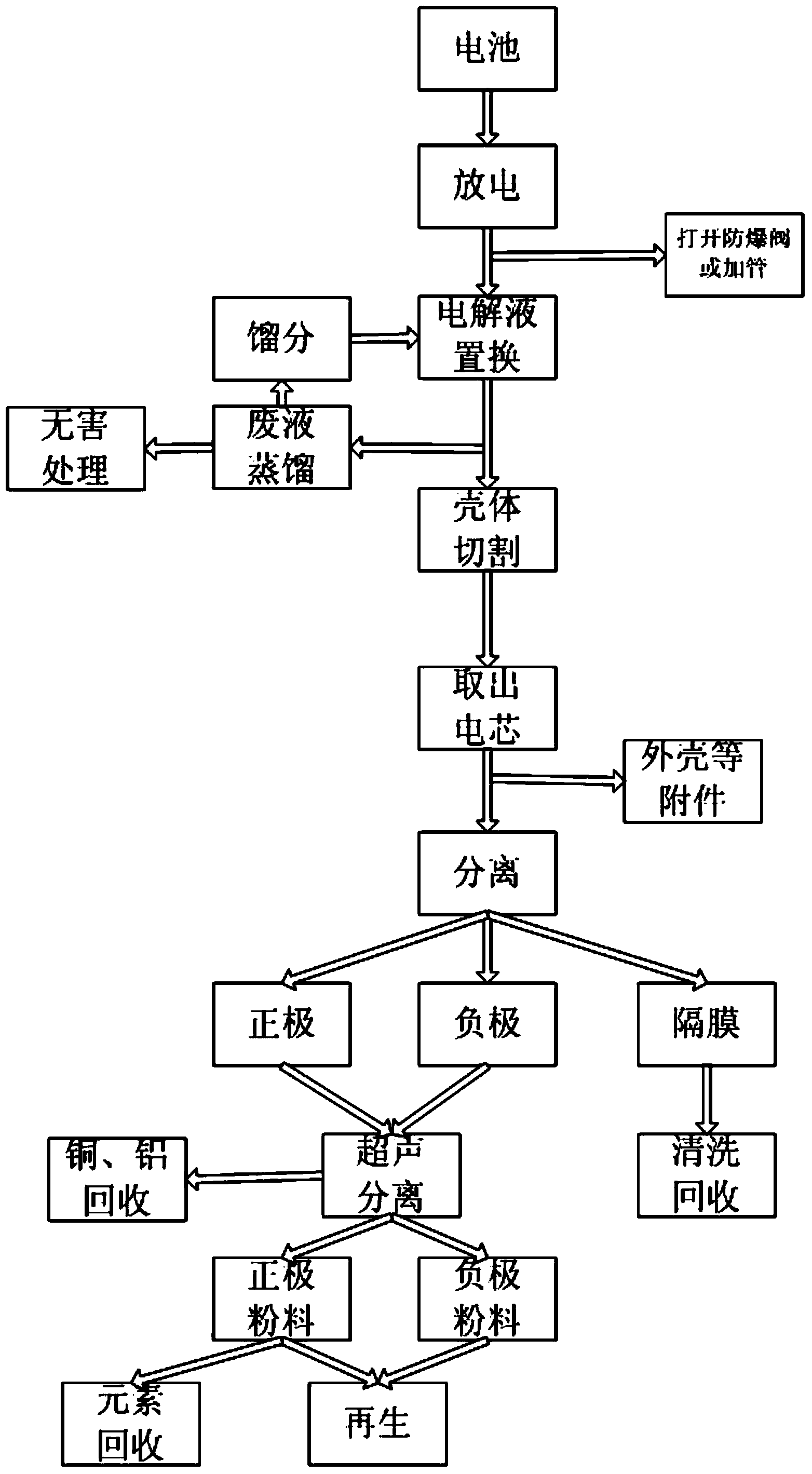

Demonstration process for recovering waste and old dynamic lithium iron phosphate cell in environmental protection mode

InactiveCN103825064AHarm reductionAvoid it happening againWaste accumulators reclaimingCell component detailsLithium iron phosphateSolvent

The invention relates to a demonstration process for recovering a waste and old dynamic lithium iron phosphate cell in an environmental protection mode, which belongs to the technical field of recovery of the power lithium iron phosphate cell. The method comprises the following steps: completely discharging the cell, extracting an electrolyte in the cell, adding a certain amount of solvent or displacement liquid, standing for 30 minutes and extracting the inner liquid of the cell, and distilling the extracted electrolyte to obtain the liquid for cycle usage when the electrolyte is displaced. According to the invention, the cell is cut by 1cm at the position along the cell top through a water jet, an electrical core is taken, wherein the steel casing, or aluminium casing or a PP plate can be directly recovered for usage. The anode, the cathode and a diaphragm are separated, and the diaphragm can be directly recovered through cleaning by ethanol. After the anode and the cathode are separated through physical methods such as ultrasound, a copper foil and an aluminium foil can be directly recovered, anode and cathode powder can be reused to be a cell material through high temperature treatment, and the purposes of no waste and no pollution can be reached by recovering the elements through a chemical method.

Owner:BEIJING UNIV OF TECH +1

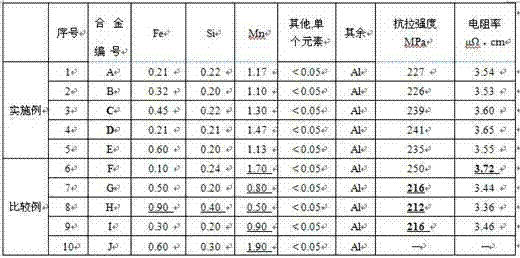

Aluminum alloy material and manufacturing method for dual-zero aluminium foils

The invention belongs to an aluminum alloy material and manufacture technology of aluminum foils, in particular to an aluminum alloy material and a manufacturing method for dual-zero aluminium foils. The aluminum alloy material comprises the following components in percentage by weight: 0.2 to 0.35 percent of Si, 0.70 to 0.90 percent of Fe, 0.10 percent of Cu, 0.05 percent of Mn, 0.05 percent of Mg, 0.05 percent of Cr, 0.10 percent of Zn, 0.05 percent of Ti, and the balance of Al; and the components are smelted into an alloy. The manufacturing method orderly comprises the following steps: smelting the components into the alloy; carrying out casting and rolling on the alloy; carrying out cold rolling, intermediate annealing and second cold rolling on the rolled alloy; carrying out aluminum foil rolling; and carrying out final annealing on the finished product. The dual-zero aluminium foil product prepared from the materials by the method integrates the respective advantages of an alloy 1235 and an alloy 8011, has a few pinhole, high surface quality and good rolling stability, and can effectively improve the production efficiency and finished product ratio. The finished product quality and the rolling performance can be comparable with those of the hot-rolled aluminum-foil sheet.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

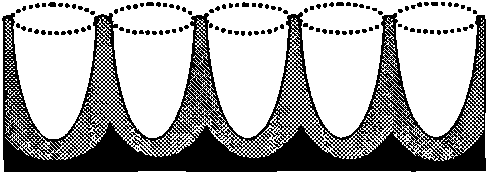

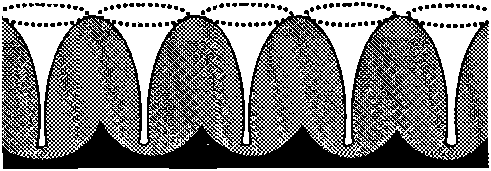

Modulation method for shape morphing of hole of anodic aluminum oxide template

The invention discloses a modulation method for shape morphing of a hole of an anodic aluminum oxide template, which comprises the following steps: I. removing grease and dirt of the surface of annealing-treated or untreated aluminium foil, and then carrying out electrochemical polishing treatment on the aluminium foil for later use; II. forming pit patterns on the surface of the aluminium foil by adopting an electrochemical oxidation method or a hard template mechanical pitting method; and III. carrying out noncontinuous oxidation and chambering on the aluminium foil the surface of which is provided with the pit patterns in an acid electrolyte to form various three-dimensional morphing-type aluminum oxide nanopore array structures by the combination control of electrolyte composition, electrolyte temperature, oxidation voltage, oxidation and chambering frequency and oxidation and chambering time. The modulation method uses existing equipment, has simple implementation and can manufacture various three-dimensional morphing shape-adjustable porous anodic aluminum oxide templates in manner of low cost and big area.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Environmental protection type laser transfer composite aluminium foil paper and its preparation technology

InactiveCN1724811AGood printabilityMeet environmental protection requirementsNon-fibrous pulp additionPaper coatingSolventMaterials science

The invention relates an environmental protection laser transferred composite aluminum foil paper and the preparing technique, mainly solving the problems of the environment pollution and complicated technique caused by separant coating and laser layer protection coating of the existing commonly used solvent laser transferred composite aluminum foil paper. Its mixing proportion (by weight) of the raw materials is: water soluble amino resin 1-20 (or water soluble polyurethane resin 1-30, or water soluble alcohol acid resin 1-30, or water soluble acrylate resin 1-40, or cellulose resin 1-20), assistant 1-10, pigment 0-10, auxiliary solvent 1-30, and water 30-80, or their arbitrary combination, through synthesizing and wet-dispersing to mix into a water laser transfer coating, coating the transfer coating on a carrier thin film, drying, cross-linking curing, laser-mould pressing, and aluminizing to obtain the laser composite aluminum foil paper. It has the characters of improving environmental protection performance, simplifying producing process, saving energy sources, reducing production cost, stable production quality, etc.

Owner:张学毅

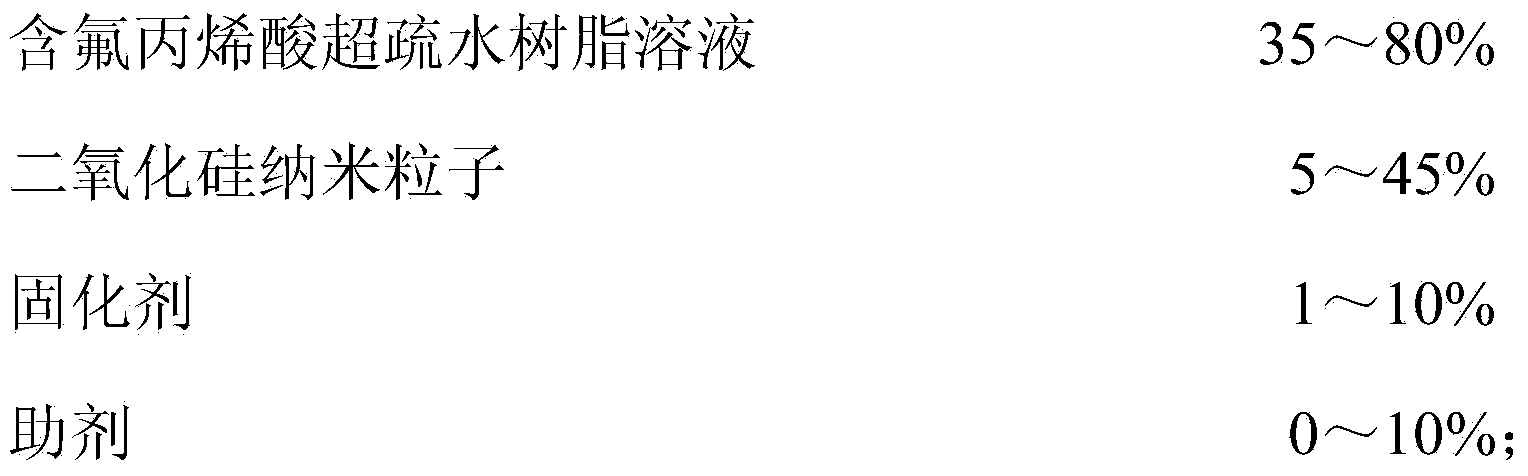

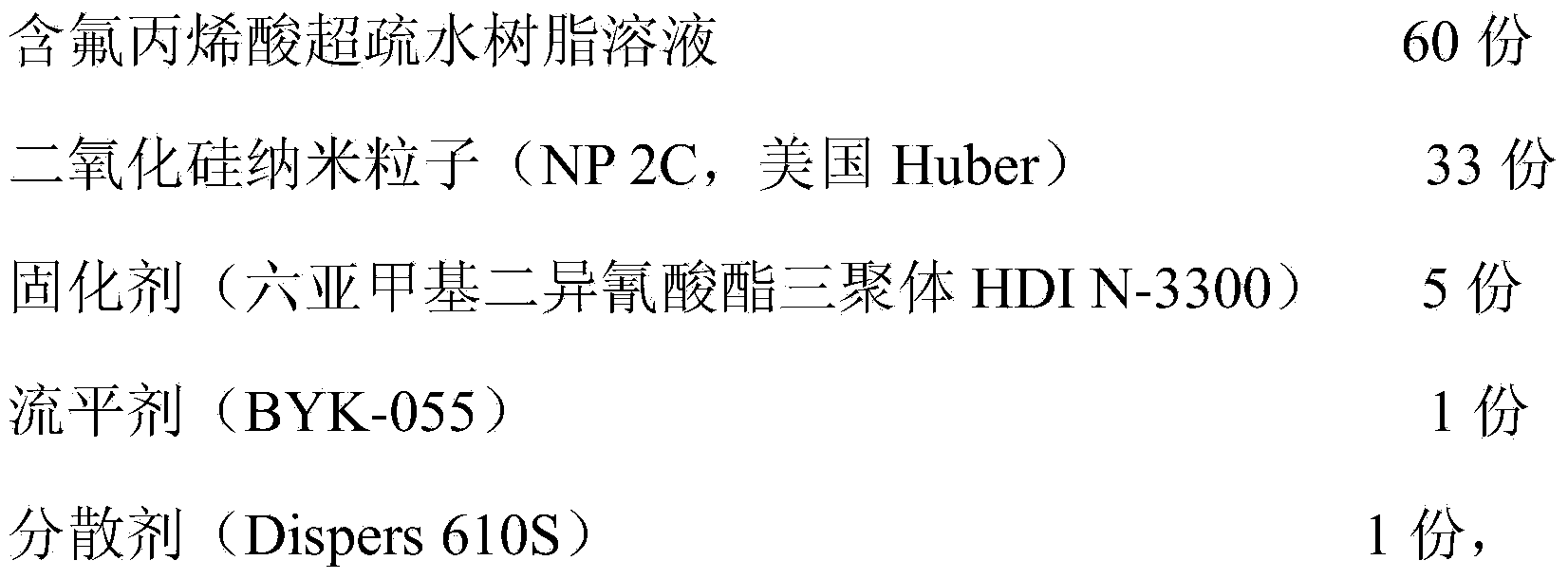

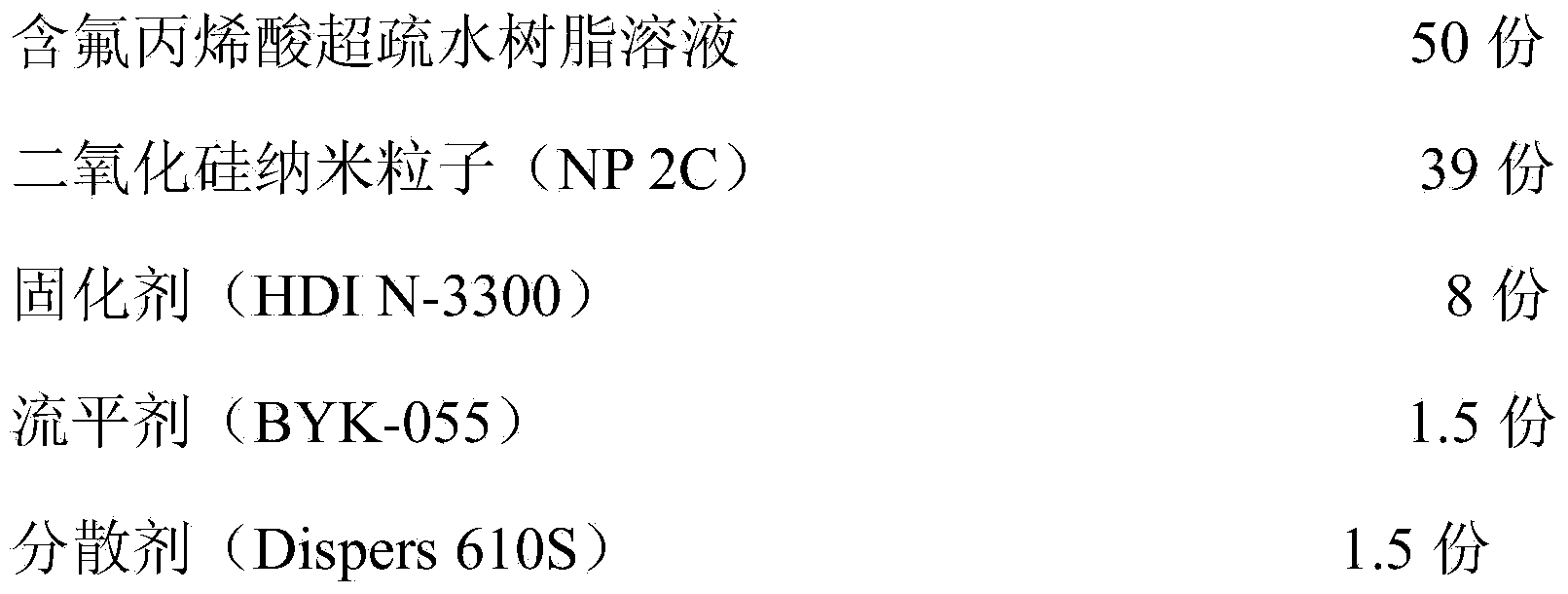

Preparation method of fluorine-containing acrylic acid super-hydrophobic coating

InactiveCN103865372ALower surface energyImprove hydrophobicityPolyurea/polyurethane coatingsNanoparticleSilicon dioxide

The invention discloses a preparation method of a fluorine-containing acrylic acid super-hydrophobic coating. The fluorine-containing acrylic acid super-hydrophobic coating disclosed by the invention is prepared from the following raw materials in weight percentage: 35-80% of fluorine-containing acrylic acid super-hydrophobic resin solution, 5-45% of silicon dioxide nanoparticle, 1-10% of curing agent, and 0-10% of auxiliaries. The prepared super-hydrophobic coating has good super-hydrophobic performance and other application performances and is particularly applied to anti-corrosion and waterproof occasions on the surfaces of air conditioner aluminium foils; related products imported from the abroad in the current market can be replaced; the fluorine-containing acrylic acid super-hydrophobic coating disclosed by the invention is very wide in application prospect and potential.

Owner:ZHONGSHAN POLYTECHNIC

Air insulating structure of vacuum insulation panel and packaging method thereof

InactiveCN101963267AReduce the number of heat-sealed edgesSave on packaging costsThermal insulationPipe protection by thermal insulationVacuum pumpingThermal bridge

The invention provides an air insulating structure of vacuum insulation panel, which is formed by composite material. The composite material does not contain aluminium foil layer; therefore, the heat bridge effect of seal edge during heat seal is avoided. The packaging method of the air insulating structure comprises the following steps of: folding a single piece of composite material to form a bag shaped air insulating structure having a size consistent with that of adiabatic core material according to the specification of the core material and form three seal edges; sealing part of sealing edges with heat, and keeping an opening for placing the adiabatic core material inside; filling the adiabatic core material in the air insulating structure, performing heat seal on the remained opening and keeping a vacuum pumping opening; and placing the air insulating structure, which is filled with the adiabatic core material and has a vacuum pumping opening, in a vacuum room and pumping to produce vacuum, and performing heat seal on the preserved vacuum pumping opening to form a vacuum thermal insulation panel. The air insulating structure has three seal edges, which are fewer than those of the conventional method; therefore, the integral heat bridge effect is reduced, the operation is simple, the appearance planeness of the vacuum insulation panel is improved, and the fold and air leakage of the air insulating structure in convention manufacturing process are avoided.

Owner:SHANGHAI MARITIME UNIVERSITY

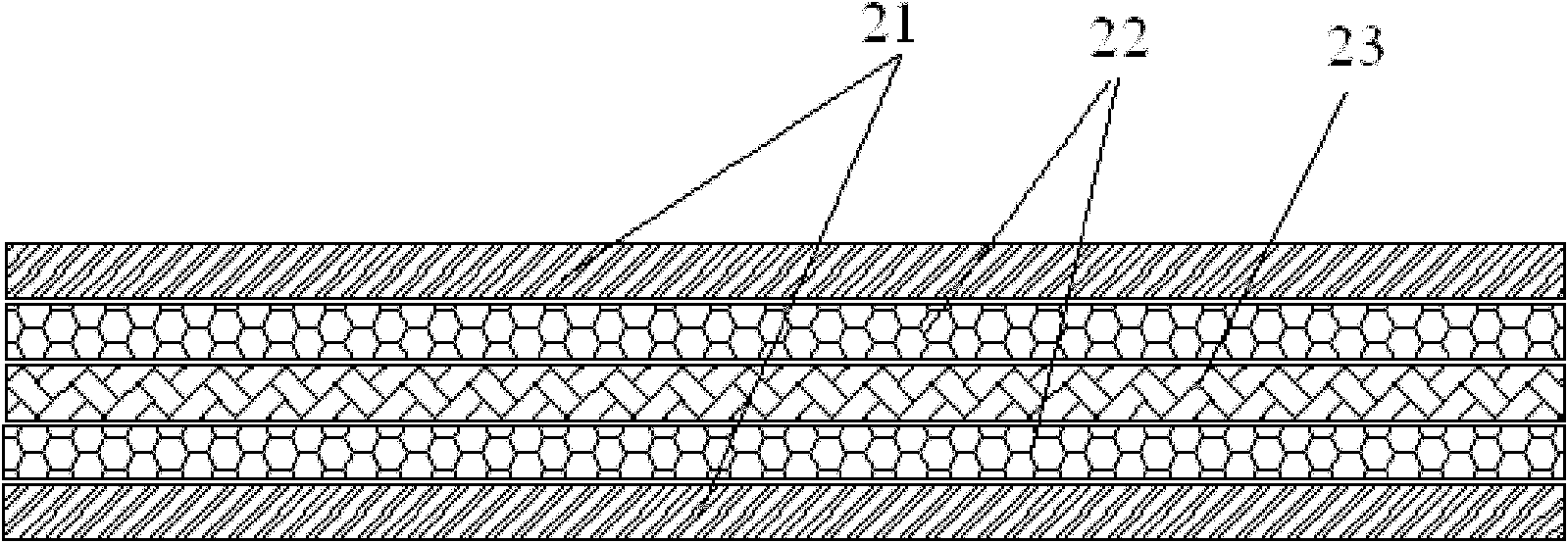

Anti-corrosion high-temperature-resistance thermal-insulation composite fabric for protective clothing

InactiveCN102499501AFeel goodHigh strengthWoven fabricsProtective garmentThermal insulationTemperature resistance

The invention discloses an anti-corrosion high-temperature-resistance thermal-insulation composite fabric for protective clothing. The composite fabric comprises base fabric, wherein a metal aluminium foil layer is arranged on the outer surface of the base fabric; a coating layer is arranged on the metal aluminium foil layer; the base fabric is formed by interweaving of warps and wefts; the warps and the wefts are covering yarns; the covering yarns comprise core yarns and covering fiber; the core yarns are glass fiber filaments or chemical fiber filaments; the covering fiber comprises one or more of flame-retarding acrylic fiber, flame-retarding viscose, aramid fiber, flame-retarding cotton, PBI (polybenzimidazole) fiber and lenzing fiber. With the adoption of the method, the anti-corrosion high-temperature-resistance thermal-insulation composite fabric has good handfeel, high strength, wear resistance, corrosion resistance, high temperature resistance, good thermal-insulation performance and long service life; the surfaces of the yarns of the base fabric do not contain glass fiber, therefore, the health of people wearing the protective clothing is furthest protected.

Owner:SUZHOU CHUANGYU WEAVING

Recovery method for leftover and residue of positive electrode of lithium ion battery

InactiveCN1453897AEfficient recyclingCause secondary pollutionSolid waste disposalWaste accumulators reclaimingRecovery methodOrganic solvent

The leftover and residue of positive electrode of lithium ion battery is crushed mechanically; its active positive electrode material, additive and adhesive attached to the aluminium foil base are separated through ultrasonic vibration, mechanical stirring or other process inside water or some organic solvent at certain temperature; and the active positive electrode material are then separated, washed, dried and high temperature processed to obtain positive electrode material, which has excellent performance and may be used directly. The present invention is significant to lowering battery producing cost and preventing environmental pollution.

Owner:NANKAI UNIV

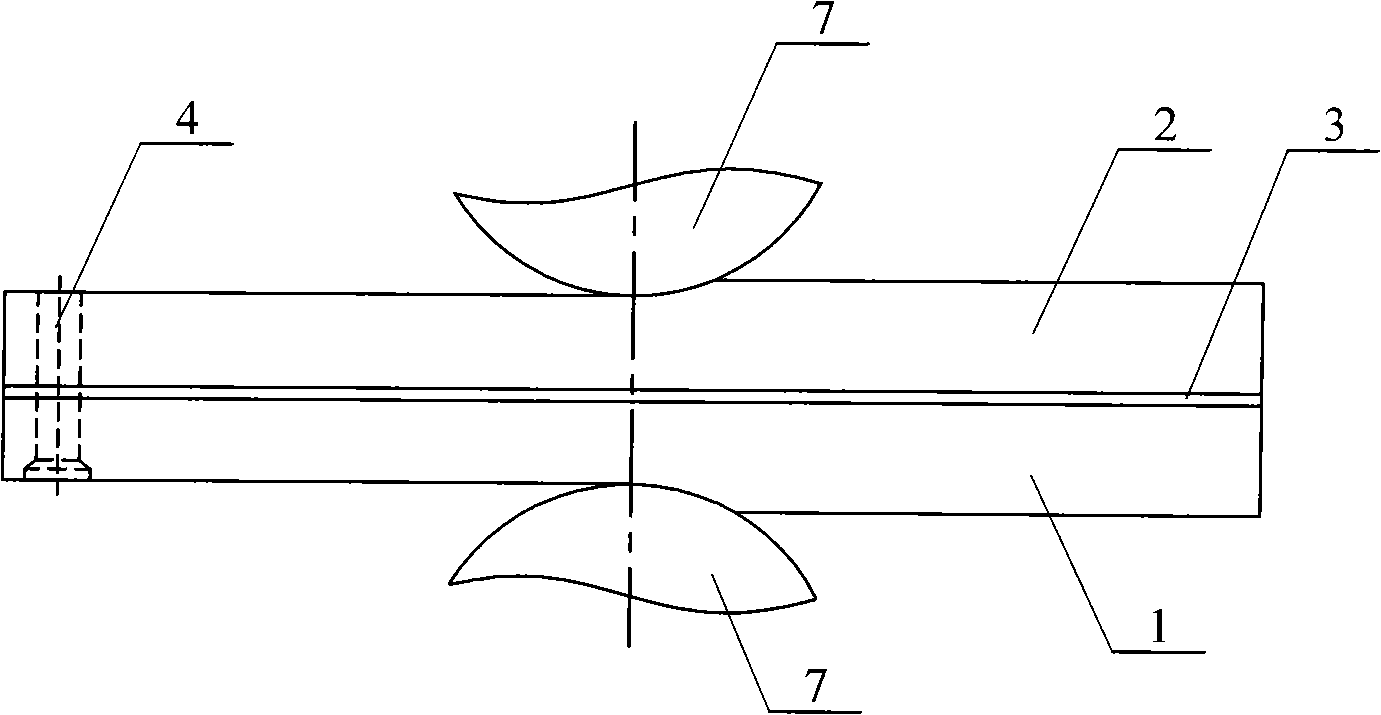

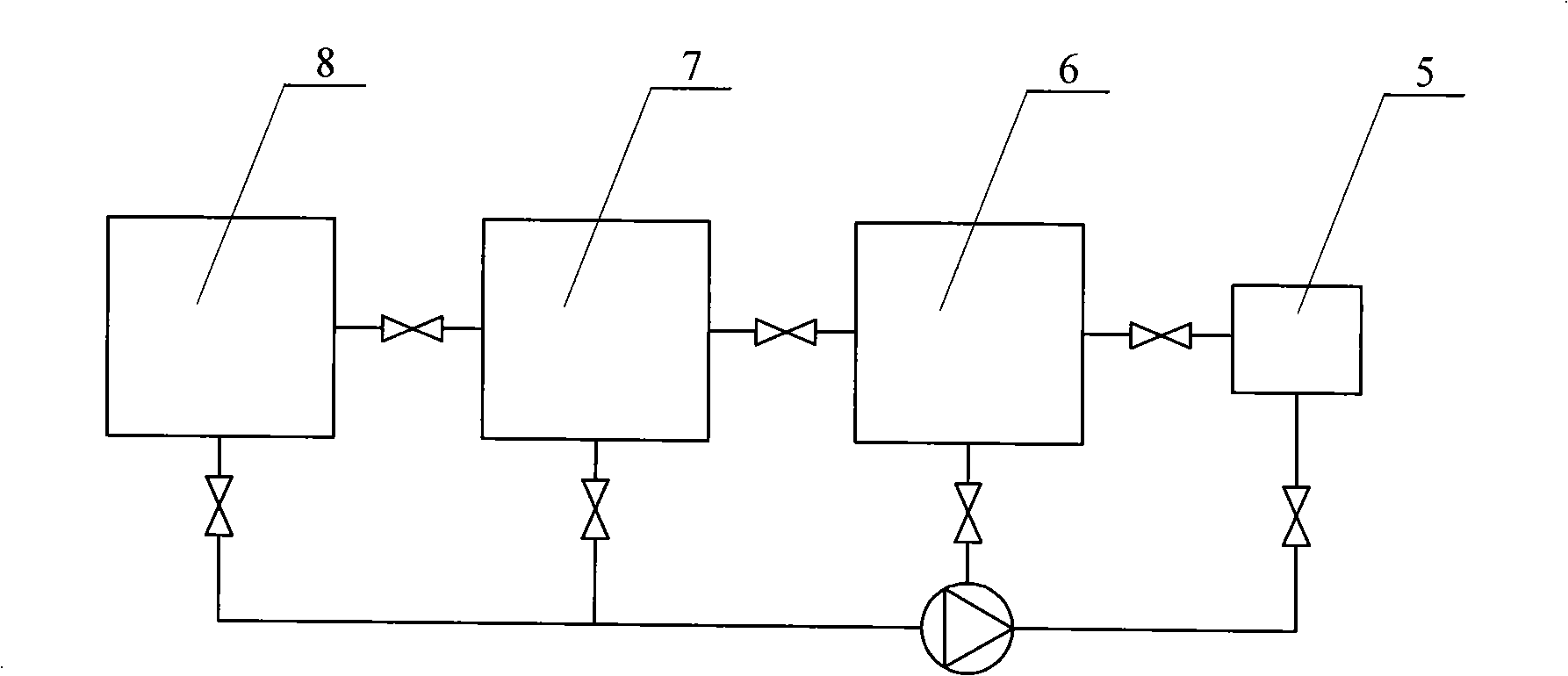

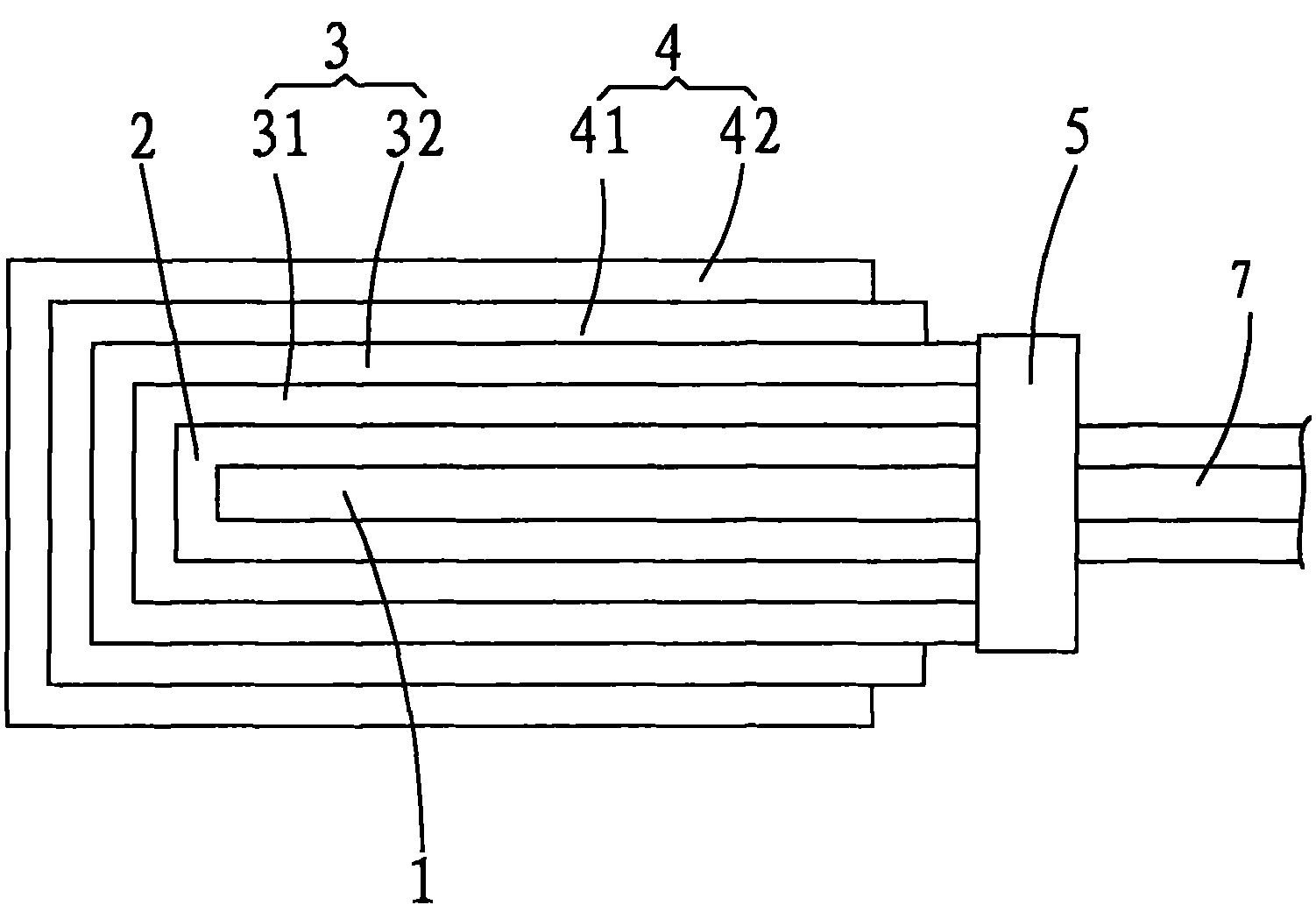

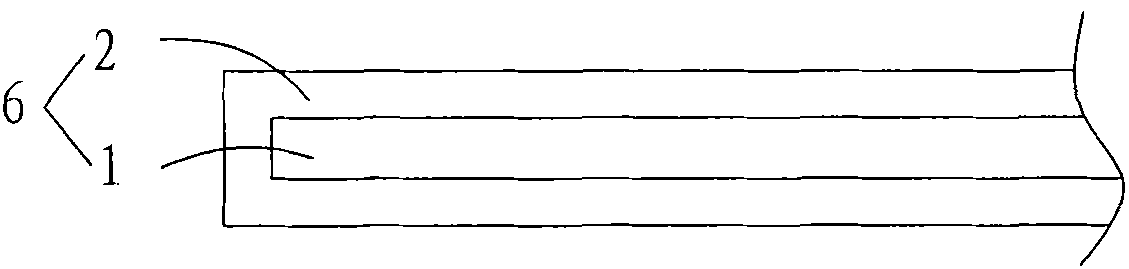

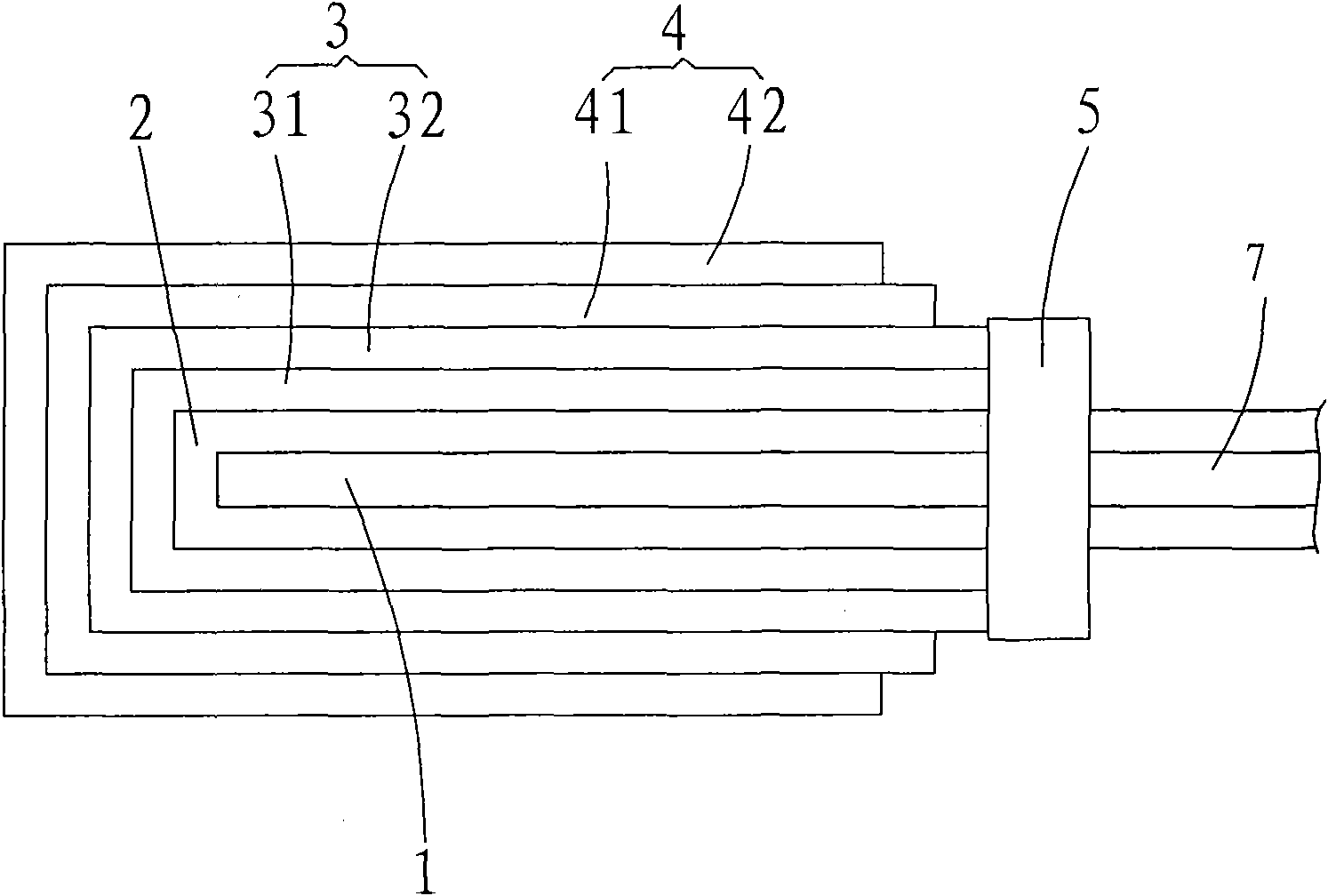

Vacuum hot rolling compounding method of titanium alloy plate and stainless steel plate

InactiveCN101288877AAvoid the problem of severe embrittlementReduce the degree of diffusionTemperature control deviceWork treatment devicesLiquid metalCopper foil

The invention provides a vacuum hot-rolled composite method of a titanium alloy plate and a stainless steel plate, which relates to a composite method for the titanium alloy plate and the stainless steel plate. Aiming at the problems that intense mixing of liquid metal and high welding stress are generated during the melt welding of the titanium alloy plate and the stainless steel plate, the contradiction between the diffusion and the controlling of volume fraction of compounds in connection interface metals is boosted to ensure the connection during the vacuum diffusion welding and the explosion weld joint is difficult to be applied to high-temperature and corrosive temperature, the method is characterized in that the stainless steel plate (1) and the titanium alloy plate (2) are used; furthermore, a copper foil or aluminium foil (3) is used; the surfaces of the two plates are milled flatly and the copper foil or the aluminium foil (3) is laminated and fix between the two plates, so as form a specimen; the specimen is arranged in a vacuum loading chamber (5); when the vacuum degree in a vacuum heating furnace (6) is (1-3)*10<-3> Pa and the temperature is 600-1100 DEG C, the specimen is delivered into the vacuum heating furnace for heating and heat preservation, and then welded by a roller (7) and cooled. The method of the invention has small welding stress, can control the volume fraction of compounds in the metals with high hardness and large brittleness; furthermore, the weld joint can be applied to the high-temperature and corrosive environment.

Owner:HARBIN INST OF TECH

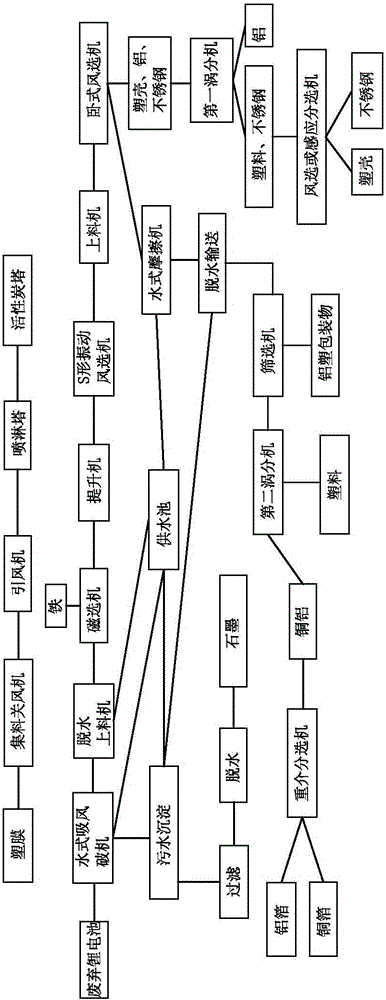

Method for smashing, detaching and recycling lithium battery

ActiveCN105811040AAvoid it happening againImprove processing efficiencyWaste accumulators reclaimingBattery recyclingCyclic processWater source

The invention relates to a method for smashing, detaching and recycling a lithium battery. Plastics, diaphragms, stainless steel, aluminium plastic films, aluminium, plastics, copper foils, aluminium foils, graphite and other materials are sorted from waste lithium batteries through a water type air-suction smashing machine, a magnetic separator, a horizontal type winnowing machine, a water-type friction machine, a first vortex separator, a second vortex separator and the like; the sorting purity can reach 94-99%; various kinds of harmful gases generated in the production process of the lithium batteries are processed by spray towers and activated carbon, and then the standardized gases are discharged; all the water required in the production process is recycled without an externally-discharged water source; and in addition, the water is precipitated, filtered and added with chemical drugs in the cycle process to carry out water treatment. According to the method, the waste batteries are not required to be pre-processed; instead, the waste batteries can be smashed, detached and recycled directly; therefore, the processing quality and processing efficiency of the waste batteries can be greatly improved; and in addition, pollutant emissions in the processing process can be effectively controlled.

Owner:哈尔滨巴特瑞资源再生科技有限公司

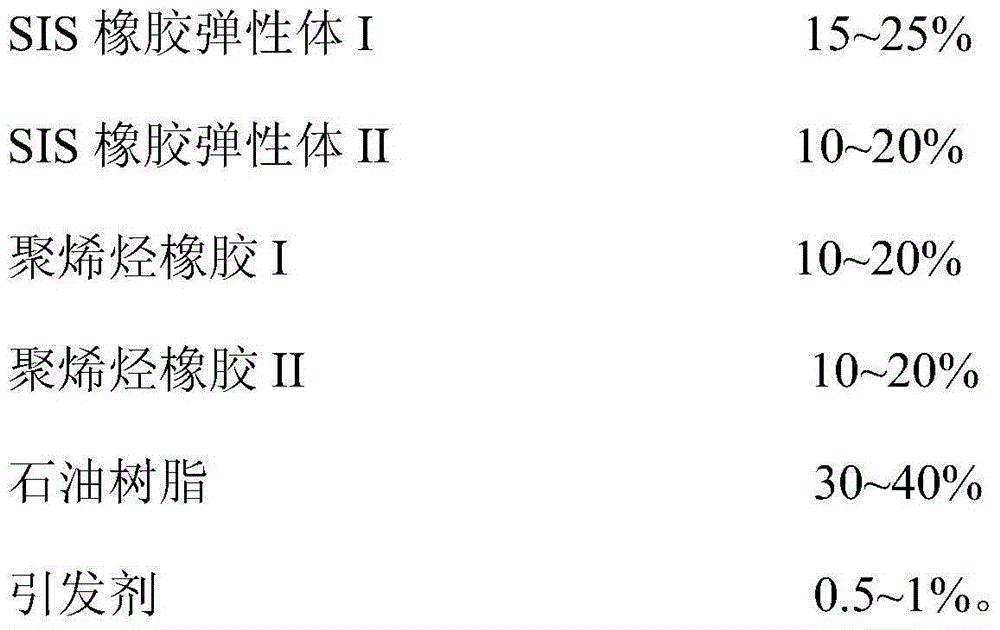

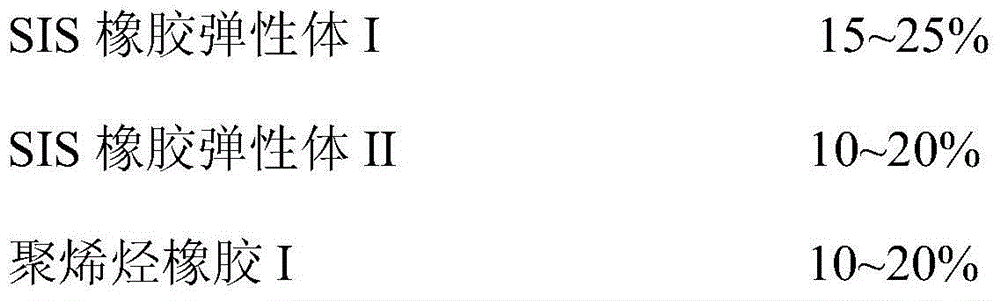

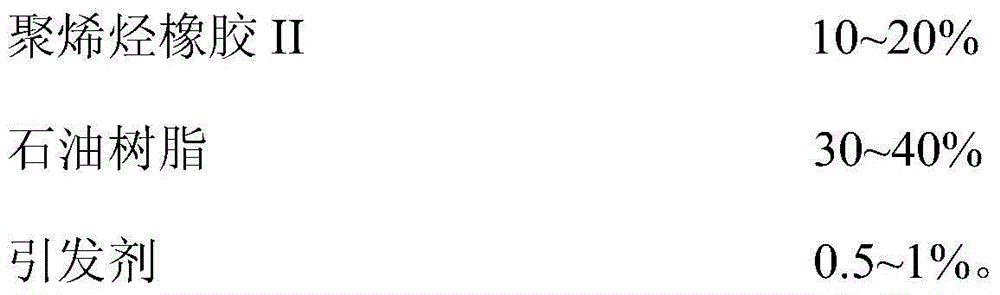

Double sticky tape for lithium battery and preparation method for double sticky tape

ActiveCN104610883AMeet the production process requirementsGuaranteed performanceMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesElectrochemical responseLithium-ion battery

The invention relates to a double sticky tape for a lithium battery. The double sticky tape comprises a first sealed hot-melting pressure-sensitive adhesive layer, a basic film layer, a second sealed hot-melting pressure-sensitive adhesive layer, a normal temperature cohesion-less sealed adhesive layer, and a two-sided silicon-free release film layer, which are sequentially connected from top to bottom, wherein one side of the double sticky tape for the lithium battery has the cohesiveness to an aluminium foil and a polyethylene film at normal temperature, and the other side is free of cohesiveness to the polyethylene side when the temperature is 80 DEG C or below, so that the double sticky tape meets the requirement on production technology of the lithium battery; the adhesive layers of the double sticky tape are free of release agent and other impurities, so that the purity of the adhesive layers can be kept; when the adhesive layers are immersed in electrolyte, the double sticky tape is still high in stability, good in corrosion resistance against the electrolyte and free of electrochemical reaction, so that the performance of the lithium battery can be maintained, and the service life of the lithium battery can be prolonged.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

Waterborne anticorrosive primer acrylic resin composition and preparation method thereof

InactiveCN102167947AImprove anti-corrosion performanceImprove stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyEmulsion

The invention discloses a waterborne anticorrosive primer acrylic resin composition, the component and content (weight percentage) of which are as follows: 78.2 to 85.6% of 40% acrylic acid emulsion, 0.08 to 0.86% of waterborne epoxy resin, 0 to 1.7% of waterborne polyurethane resin and 14.3 to 19.4% of deionized water. The composition is applicable to anticorrosive paint of air-conditioning aluminium foil. The waterborne acrylic resin composition comprises functional groups of phosphate ester, acrylic acid ester and epoxy, with increased wet adhesiveness with aluminium base and remarkable anticorrosion effect.

Owner:SNTO TECH GRP

Stable general-purpose type laser stamping foil of electrified aluminuim and its technique

InactiveCN1480324AStable production processImprove stabilityCoatingsMetal layered productsCelluloseGeneral purpose

A stable and universal process for preparing the laser thermoprinted electrochemical aluminium foil includes mixing parting material, assistant and cosolvent to obtaining the parting material, preparing color material from isocyanate, cellulose resin, diallyl titanate resin, pigment, assistant, mixed solvent and resin, preparing cementing material from acrylic resin, cellulose resin, ethylene-vinyl acetate resin, filler, pigment, assistant, and mixed solvent, sequentially coating them on PET carrier film, laser die pressing and vacuum aluminizing.

Owner:张学毅

Waterborne aluminium foil adhesive and preparation method thereof

InactiveCN102153971AGood adhesionHigh peel strengthMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesFunctional monomerPolymer science

The invention discloses a waterborne aluminium foil adhesive and a preparation method thereof and belongs to the field of adhesives. The aluminium foil adhesive is a composite adhesive with solid content of 40 to 50 percent, which is prepared by using monomers, an emulsifier, protective colloid, an initiator, a buffer, a pH (potential of hydrogen) regulator, a plasticizer, a waterborne assistant and deionized water as the raw materials through pre-emulsification, seed reaction, polymerization reaction and compounding. The monomers in the raw materials comprise hard monomers, soft monomers andfunctional monomers, wherein the hard monomers adopt vinylacetate and methyl acrylate; the soft monomers adopt ethyl acrylate and butyl acrylate; and the functional monomers adopt any one of acrylic acid or methacrylic acid and N-hydroxymethyl acrylamide. The waterborne aluminium foil adhesive has the advantages of low cost, high stripping strength and good leveling property and is simple and convenient to operate.

Owner:BEIJING COMENS NEW MATERIALS

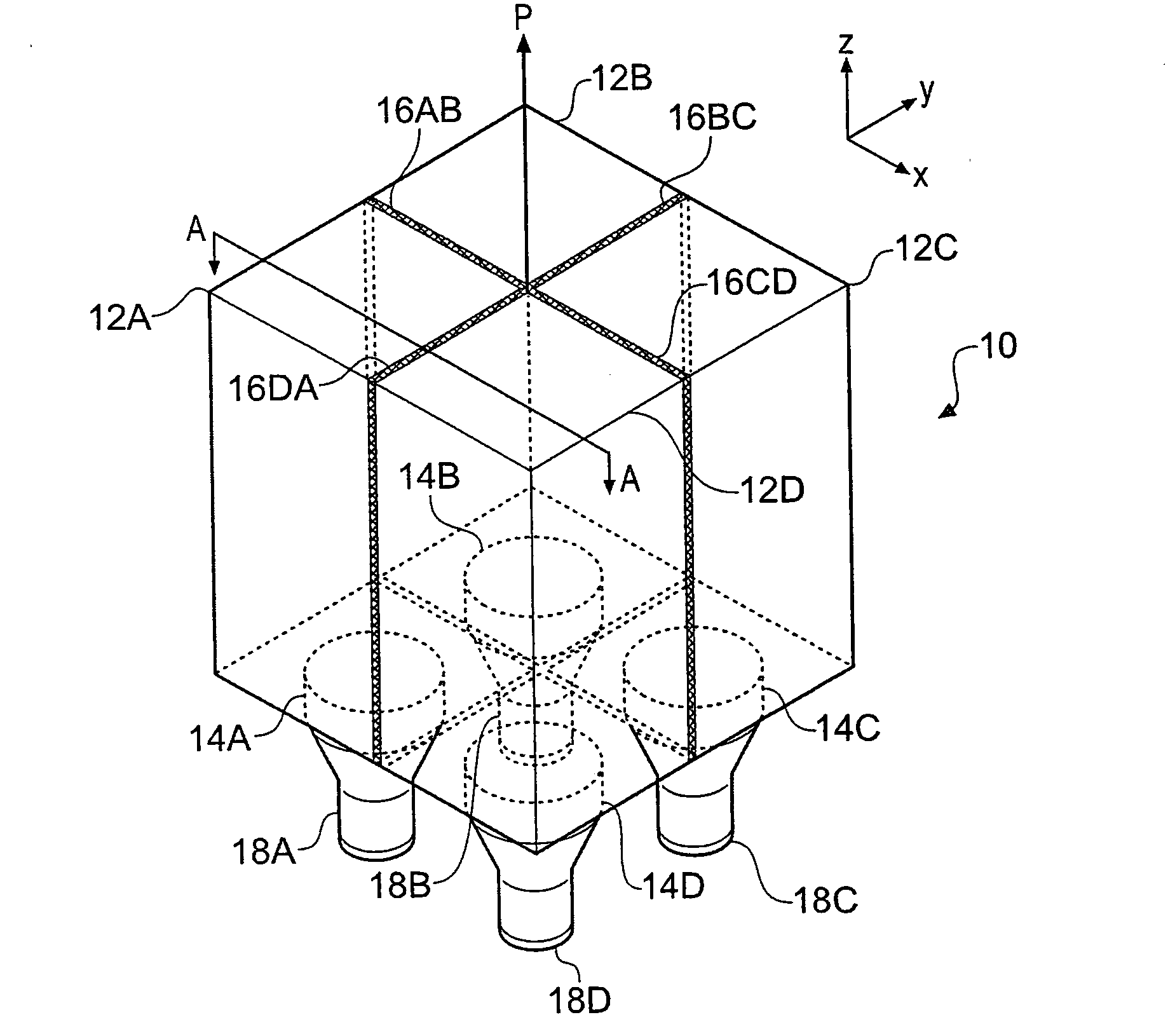

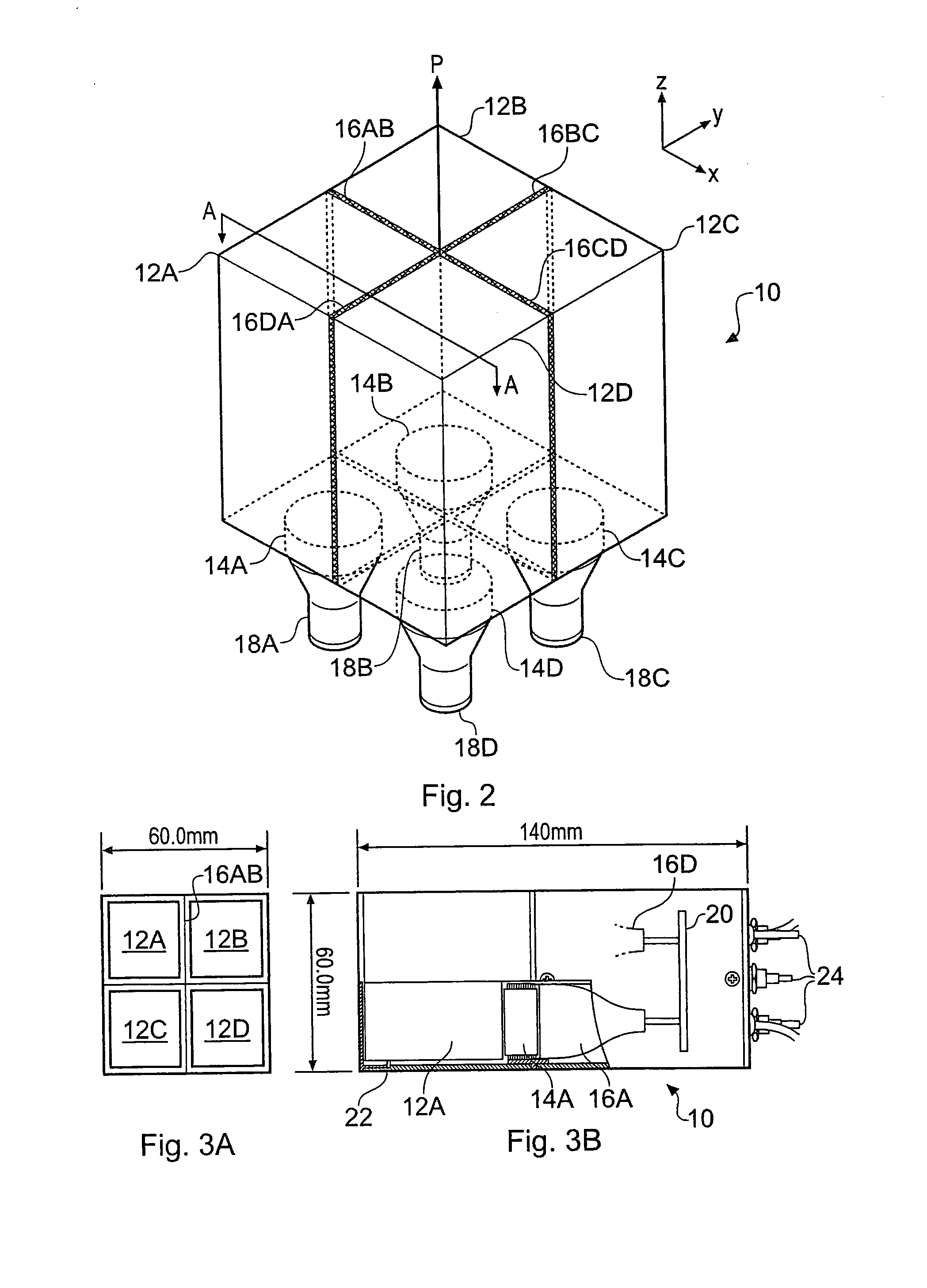

Gamma-ray detector

ActiveUS20090309032A1Quickly and fully assess riskEasy to identifySolid-state devicesMaterial analysis by optical meansPhotovoltaic detectorsFrequency spectrum

A portable gamma-ray detector for indicating the intensity of a source of gamma-rays, the nature of the source, and the direction to the source relative to an axis of the detector. The detector comprises a plurality of scintillation bodies arranged around the pointing axis, for example four scintillation bodies in a two-by-two array and separated from each other by aluminium foil. Thus gamma-rays from different directions are shielded from different ones of the scintillation bodies by the other scintillation bodies. The scintillation bodies are coupled to respective photo-detectors and a processing circuit is configured to receive output signals from the photo-detectors and to provide an indication of the direction to a source relative to the pointing axis of the detector based on the relative output signals from the different photo-detectors. The processing circuit is further operable to determine the intensity of the source from the magnitudes of the output signals, and the nature of the source from a spectral analysis of the output signals.

Owner:SYMETRICA

Preparation method for three-dimensional carbon nanotube/nitrogen-doped graphene/sulfur electrode slice

InactiveCN105609736AReduce Shuttle EffectImprove cycle lifeCell electrodesLi-accumulatorsSulfur electrodeCarbon nanotube

The invention provides a preparation method for a three-dimensional carbon nanotube / nitrogen-doped graphene / sulfur electrode slice. The preparation method comprises the following steps of (1) adding the carbon nanotube, graphite oxide and polyacrylonitrile to N-methyl pyrrolidone, performing an ultrasonic reaction, coating an aluminium foil with mixed paste, and performing vacuum drying to obtain the electrode slice; (2) putting the obtained electrode slice into a muffle furnace under ammonia gas protection, heating to 400-500 DEG C, and naturally cooling; and (3) enabling the electrode slice obtained in the step (2) to be fully inserted into a Na2S2O3 solution, and slowly adding hydrochloric acid to the solution in a dropwise manner until the PH value of the solution reaches 6.5-7.5, taking out the electrode slice, and drying the electrode slice to obtain a positive plate. The electrode slice prepared by the invention can be directly used for the positive electrode of a lithium-sulfur battery without requiring a conductive agent and a binder, so that the cost of the electrode is greatly lowered.

Owner:钟玲珑

Aluminium foil base material producing process

ActiveCN101066576AImprove rolling effectQuality improvementFurnace typesOther manufacturing equipments/toolsHigh surfaceAluminum foil

The aluminum foil base material producing process includes the following steps: smelting aluminum alloy in a smelting furnace, casting and rolling in a double roller continuous casting and rolling to produce blank material of 5.0-10.0 mm thickness, cold rolling, heat treatment, finishing, etc. The aluminum foil base material thus produced has excellent rolling performance, high surface quality, excellent internal structure, well dispersed intermetallic compound, and capacity of being rolled to thickness smaller than 0.01 mm while maintaining less pin holes.

Owner:CHINALCO RUIMIN

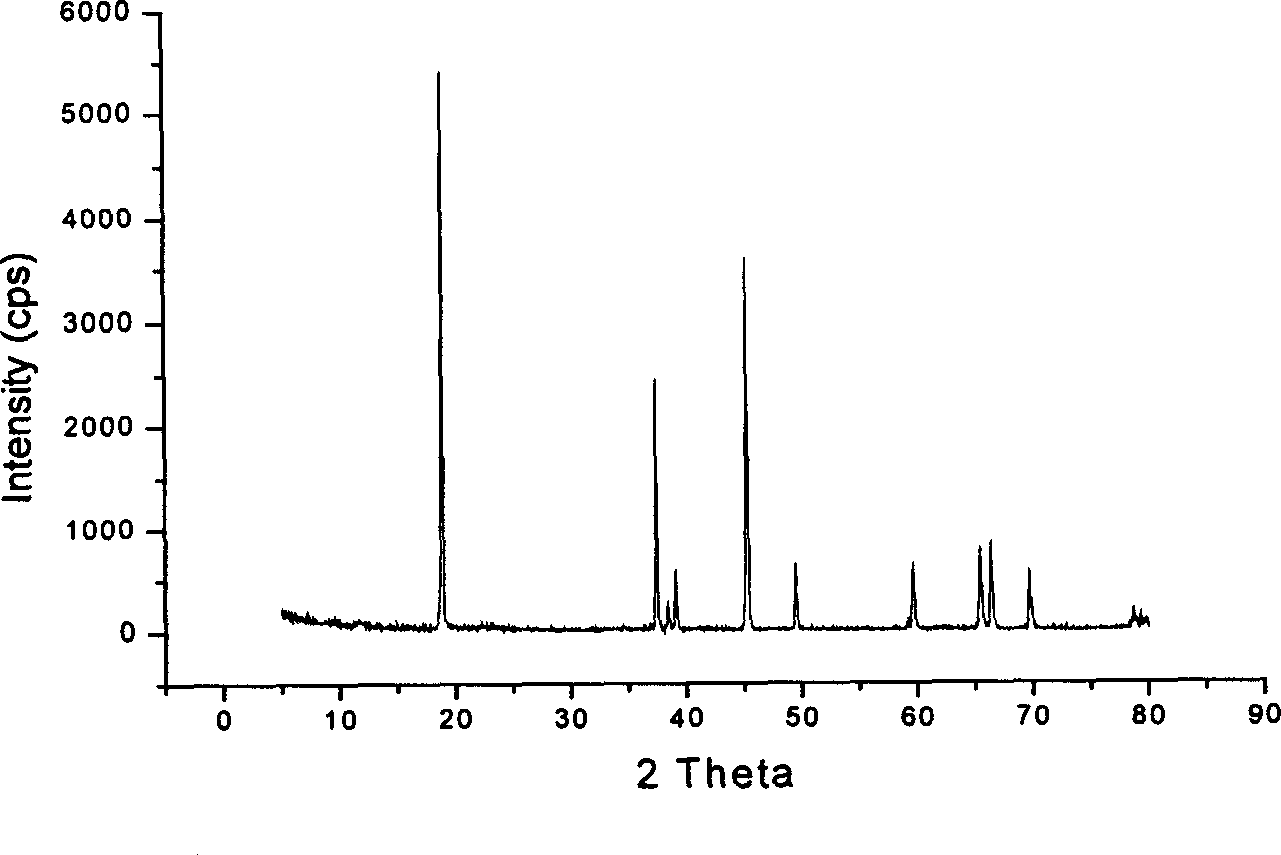

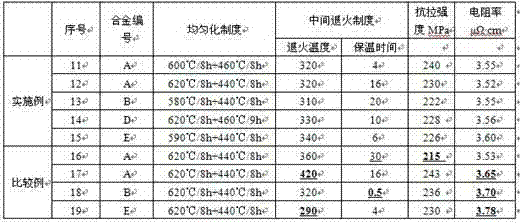

Aluminium alloy foil for lithium ion battery positive current collector and manufacturing method thereof

ActiveCN102787259AHigh strengthLow resistivityElectrode carriers/collectorsPositive currentLithium-ion battery

The invention relates to an aluminium alloy foil for a lithium ion battery positive current collector and a manufacturing method thereof. The aluminium alloy foil comprises 0.1-0.7wt% of Fe, 1.1-1.6wt% of Mn, less than 1.8wt% of Fe+Mn, 0.1-0.3wt% of Si, less than 0.02wt% of Ti, less than 0.004wt% of B, and the balance consisting of Al and inevitable impurities. The manufacturing method comprises conducting alloy smelting, melt purification, casting, carrying out face milling and uniformization treatment on keelblook, conducting hot rolling and cold rolling, conducting intermediate annealing and aluminium foil rolling to obtain a hard aluminium foil with the thickness of 5-30 mum, wherein two-stage uniformization system at high temperature and low temperature can be used, the corresponding intermediate annealing temperature of the cold-rolled sheet is 300-340 DEG C, and the temperature is kept for 1-25 h; or single-stage uniformization system at high temperature is used, the corresponding intermediate annealing temperature of the cold-rolled sheet is 340-400 DEG C, and the temperature is kept for 1-40 h. According to the invention, the resistivity is reduced while the high intensity is guaranteed.

Owner:CHINA ALUMINUM INT ENG CORP

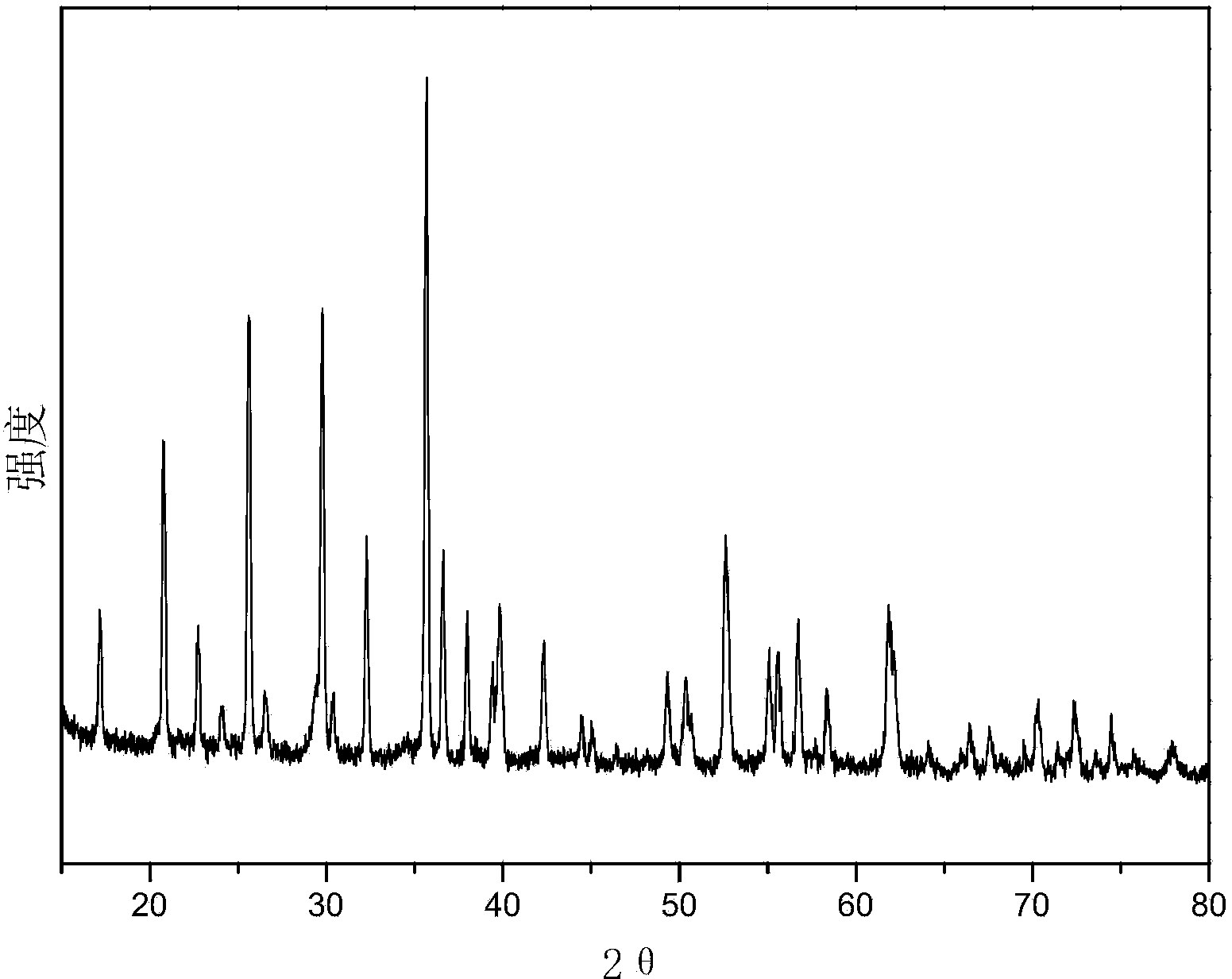

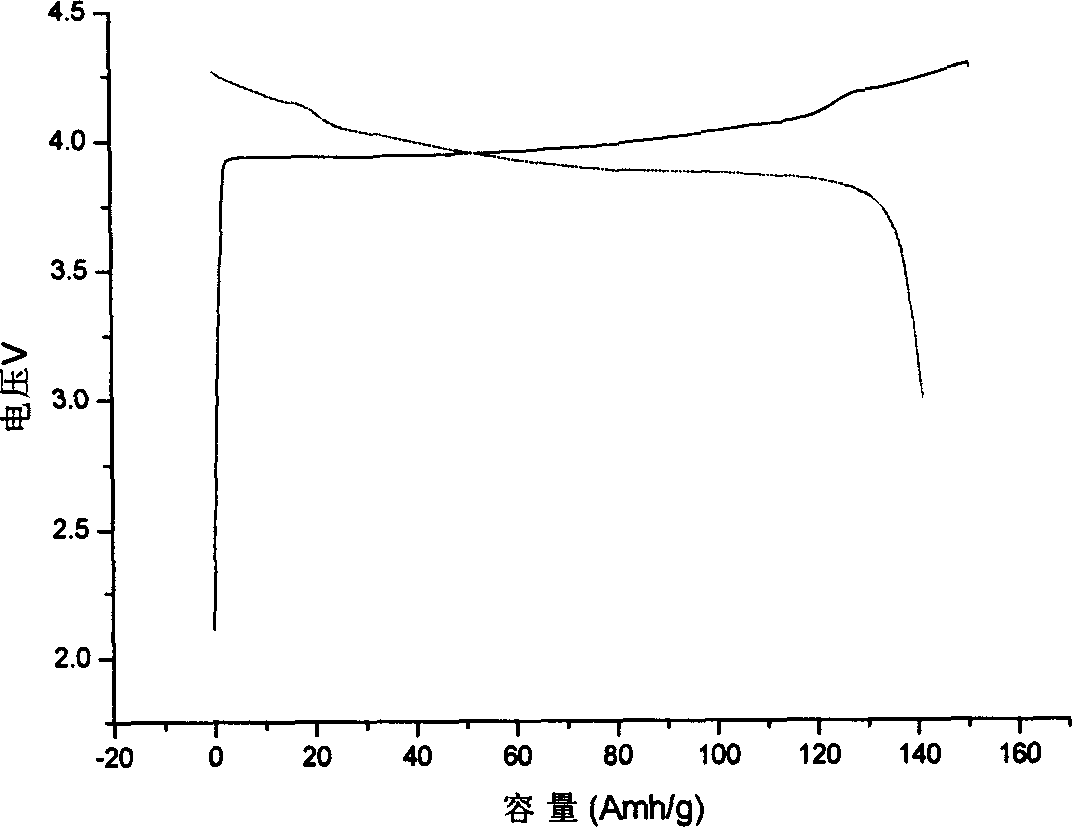

High rate lithium iron phosphate cell and preparation method thereof

ActiveCN102403531AImprove uniformityImprove consistencyFinal product manufactureCell electrodesHigh rateLithium iron phosphate

The invention discloses a high rate lithium iron phosphate cell and a preparation method thereof. The method comprises steps of preparation of an anode slurry and a cathode slurry, design of an anode sheet and a cathode sheet and design of cell safety, and aims to improve rate performance of a lithium iron phosphate cell and enhance cell safety. The preparation of the anode slurry and the cathode slurry employs a method combining ultrasonic mixing and mechanical stirring to enhance slurry disperse effect. The anode is prepared by pulping a lithium iron phosphate active material, a conductive agent and a binder according to a certain ratio and coating on an aluminium foil. The cathode is prepared by pulping graphite (or intermediate phase carbon microballoon), a conductive agent and butadiene styrene rubber (SBR) according to a certain ratio and coating on a copper foil. The anode and the cathode are prepared into a cylinder cell; an electrical core is assembled under an atmosphere protection environment; and a cap deflation apparatus is used to enhance safety of the cell. The lithium ion cell of the invention has good safety and can realize high rate 30 C continuous discharge.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

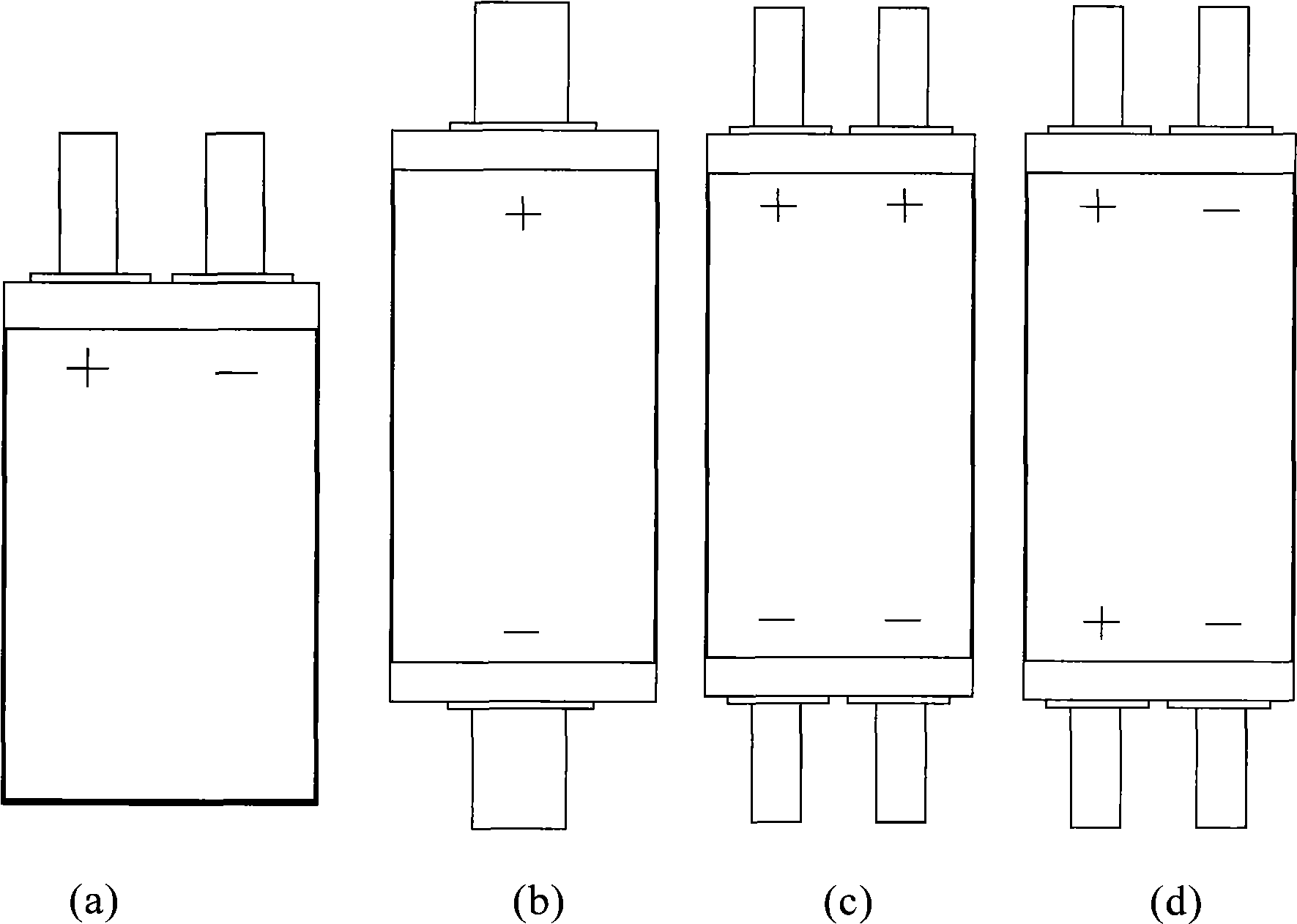

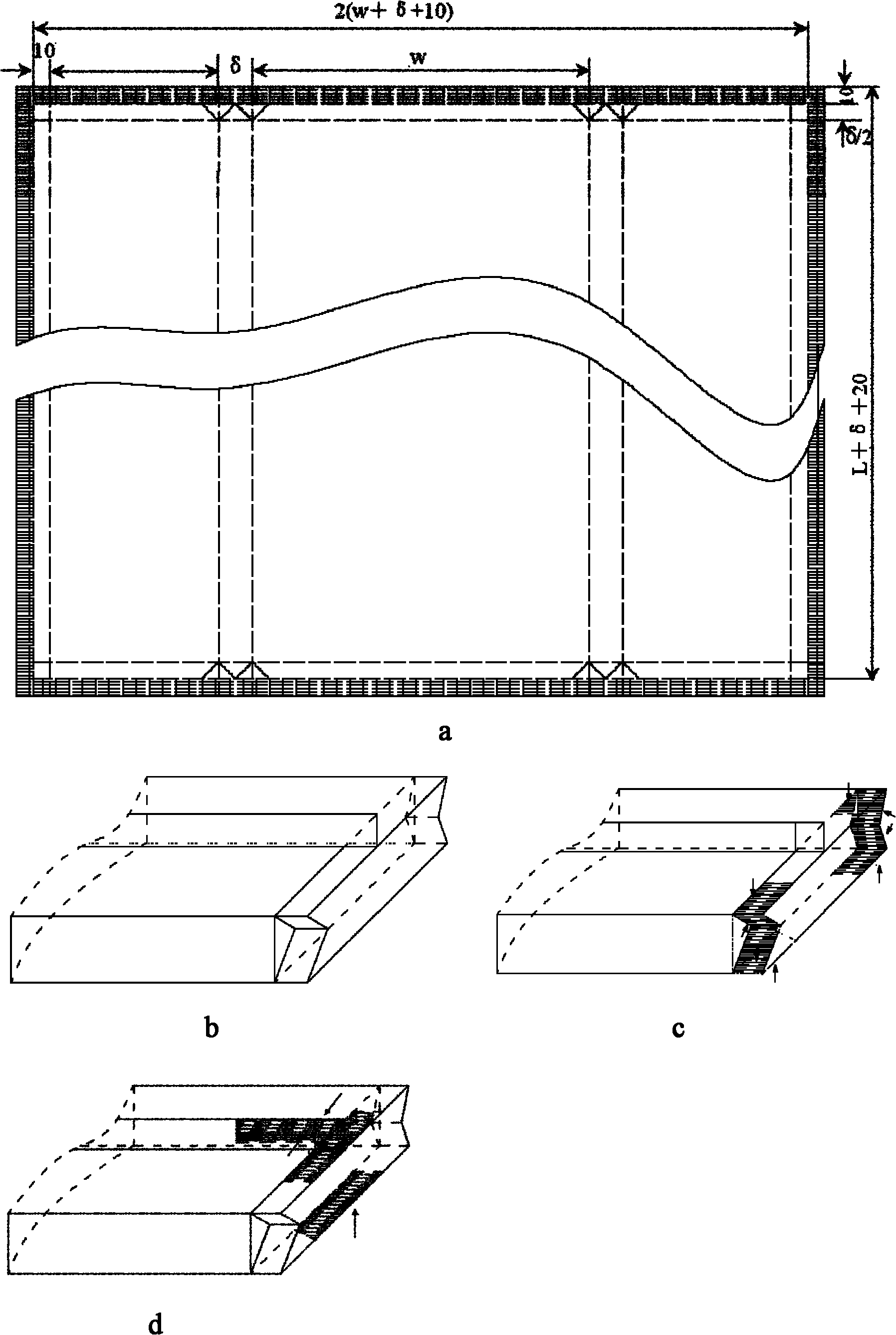

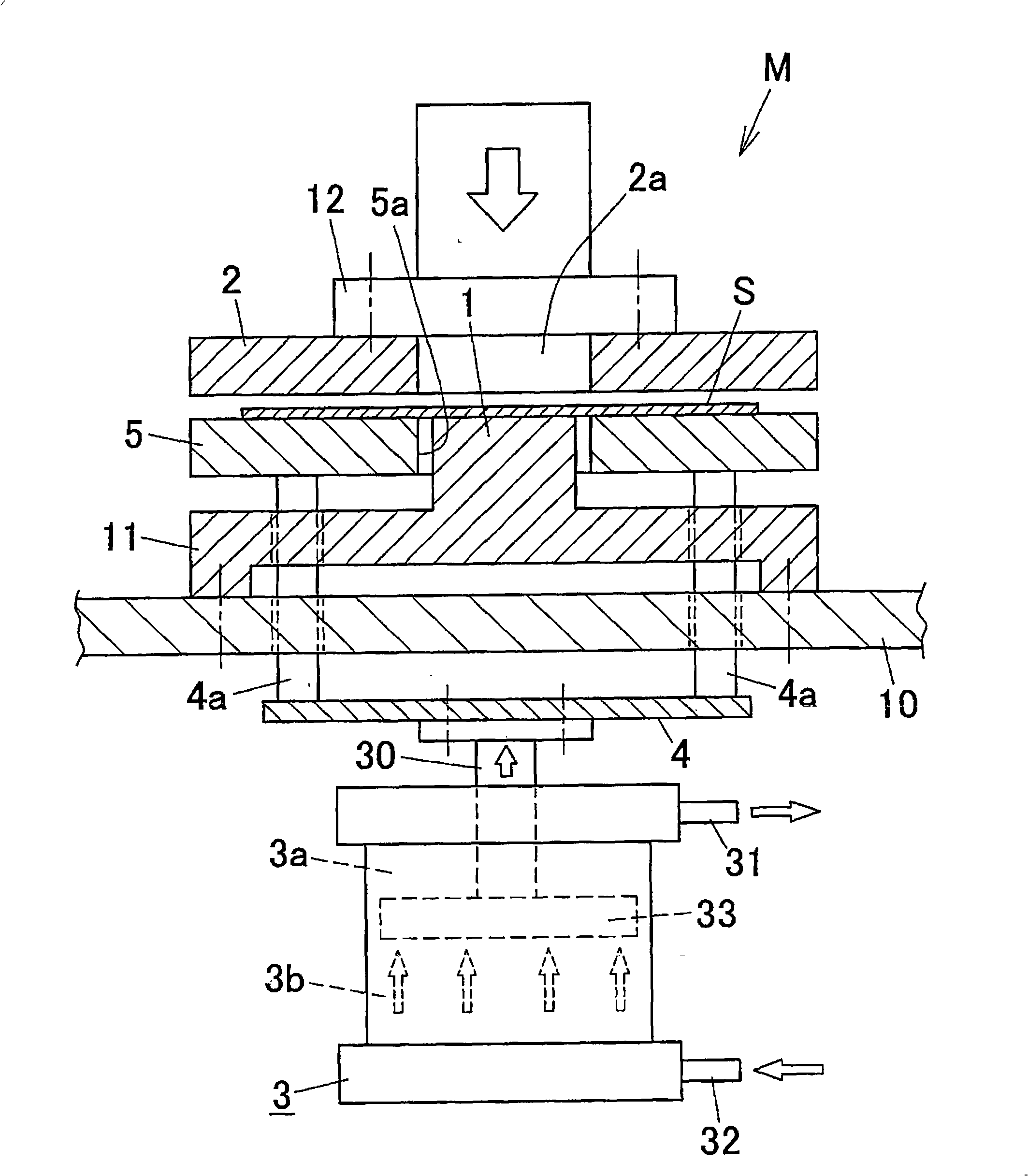

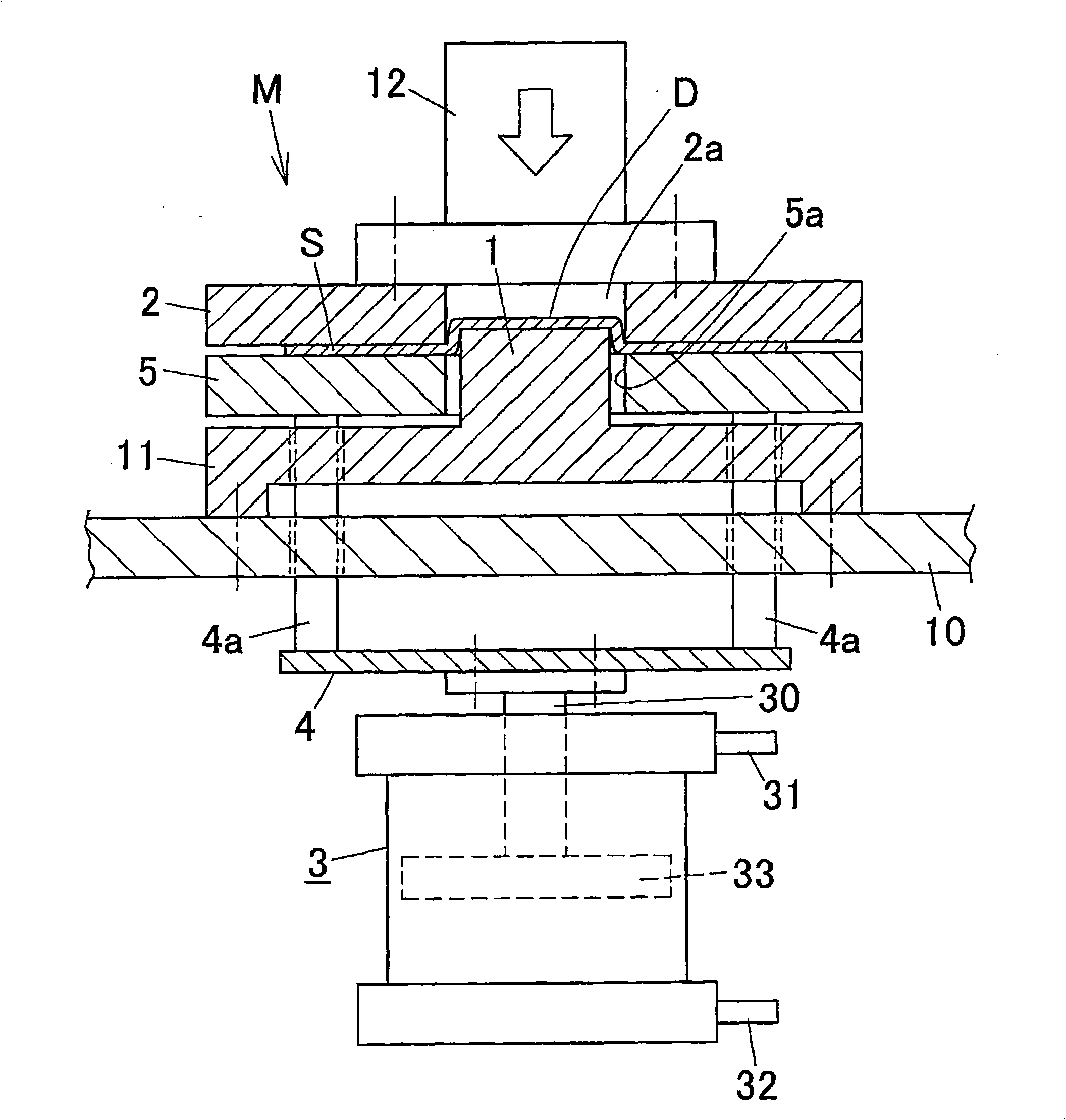

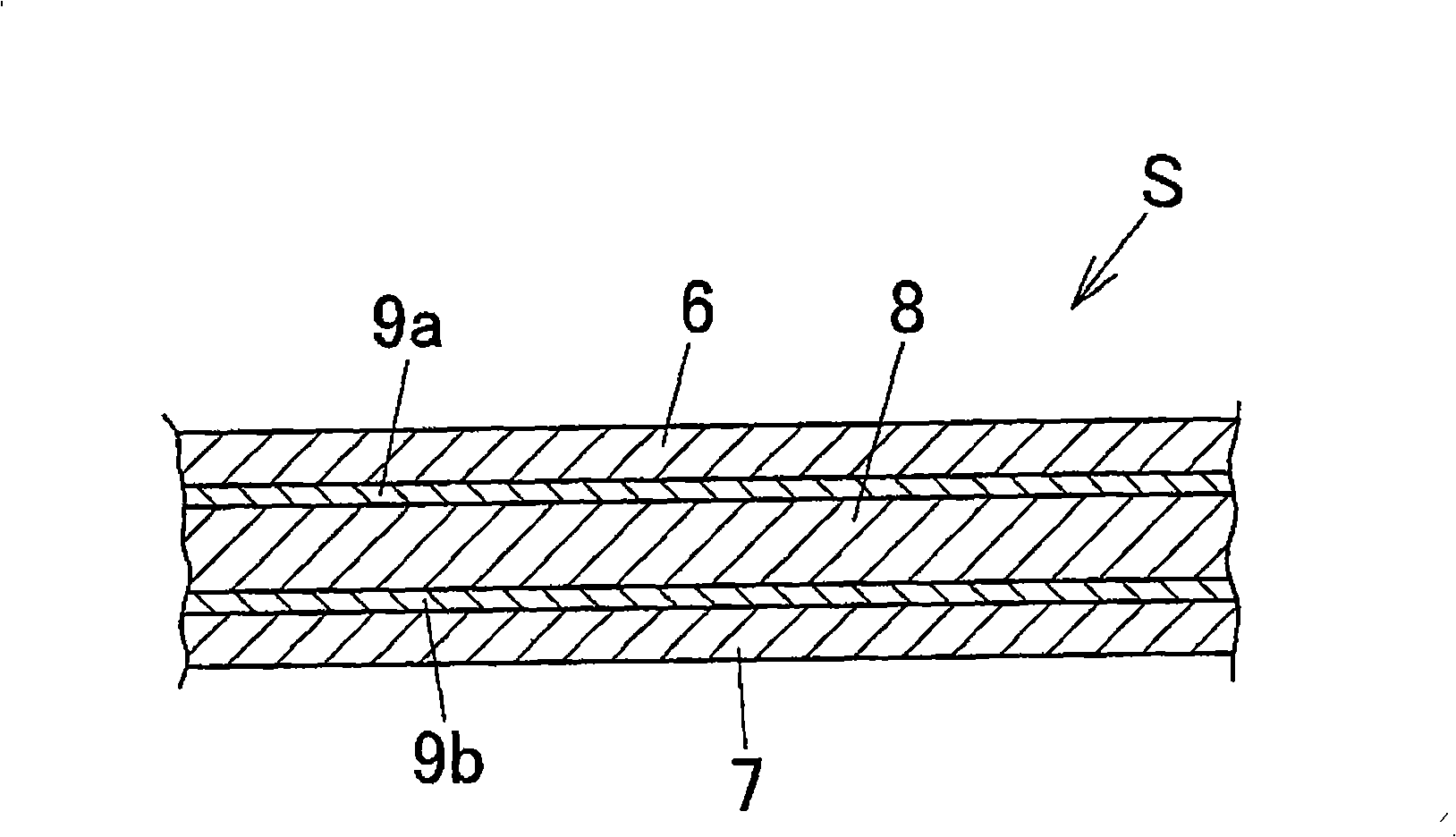

Forming method and forming device for battery shell

ActiveCN101259498AImprove yieldReduce sizeLamination ancillary operationsSynthetic resin layered productsResistElectrical battery

The invention provides a forming method of battery shell which is charactered in that: a forming sheet (S), which includes a resin film layer as an outside layer, a resin film layer as an inner layer and an aluminium foil layer between two film layers, is punch formed to required shape by a punch forming mould composed of a die (2), a former block (1) and a crease-resist pressure pad component (5). According with the forming method, in a deep pulling / processing process that punch forming is realized by the forming sheet with special lamination structure used as forming material, the crease-resist pressure pad pressure generated by the crease-resist pressure pad can be adjusted suitably according with forming shape size, deepness also likes. Consequently, more deep process can be processed easily and suitable range of forming shape is enlarged, and a deep pulling process without crease is processed.

Owner:株式会社力森诺科包装

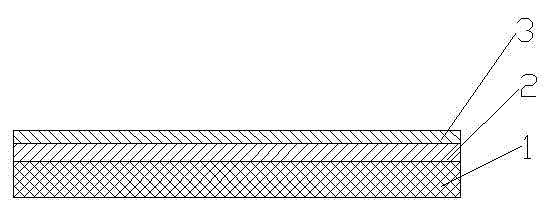

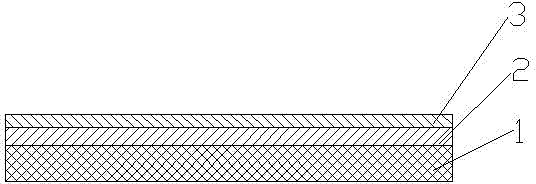

Laminated adhesive aluminium foil band and it mfg. process

ActiveCN1693400AImprove anti-corrosion performanceImprove tensile propertiesFilm/foil adhesivesMetal layered productsPlastic filmAluminium foil

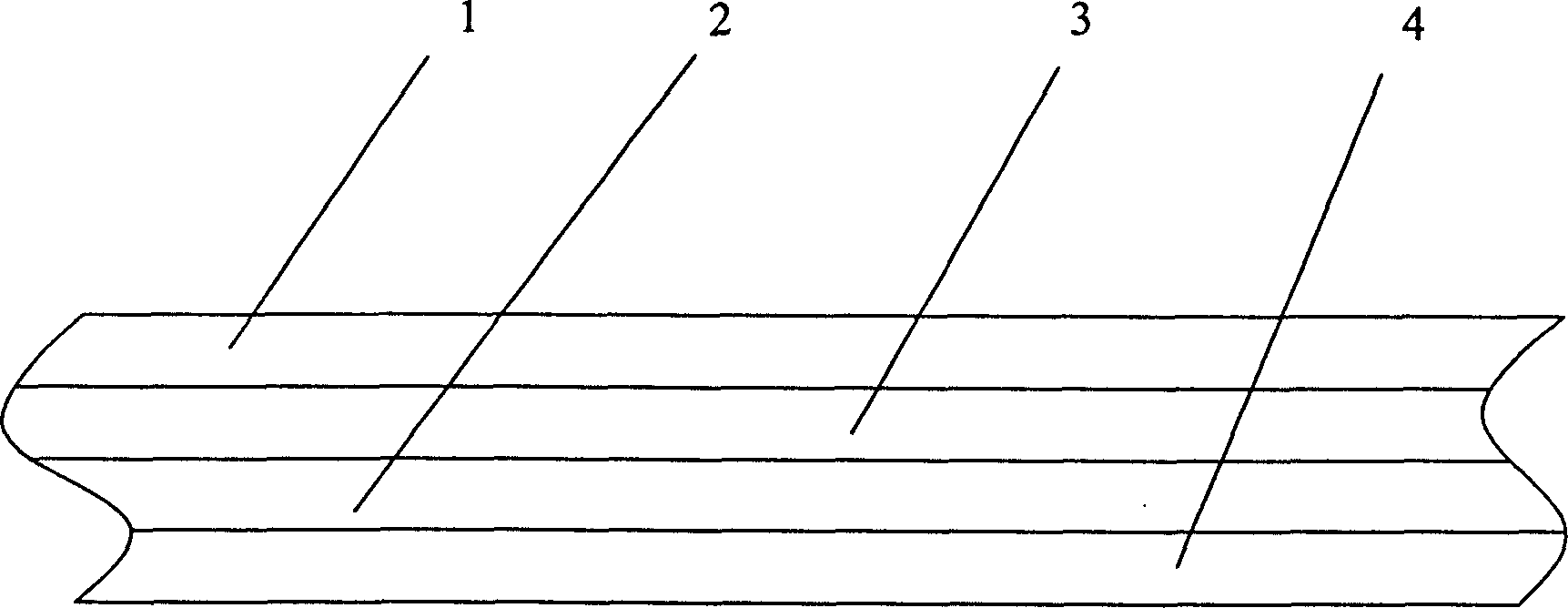

A laminated adhesive aluminium foil band is composed of plastic film layer, aluminium foil layer, central adhesive layer and adhesive bottom layer. Its preparing process includes such steps as coating adhesive on top surface of plastic film, attaching aluminium foil to it, and coating adhesive on the bottom surface of aluminium foil. Its advantages are high anticorrosion performance, adhesion and tension strength, and easily tearing off.

Owner:FENGYOU ADHESIVE PROTECTS XIAMEN

Electrochemical polishing method for high purity aluminum under ultrasonic agitation

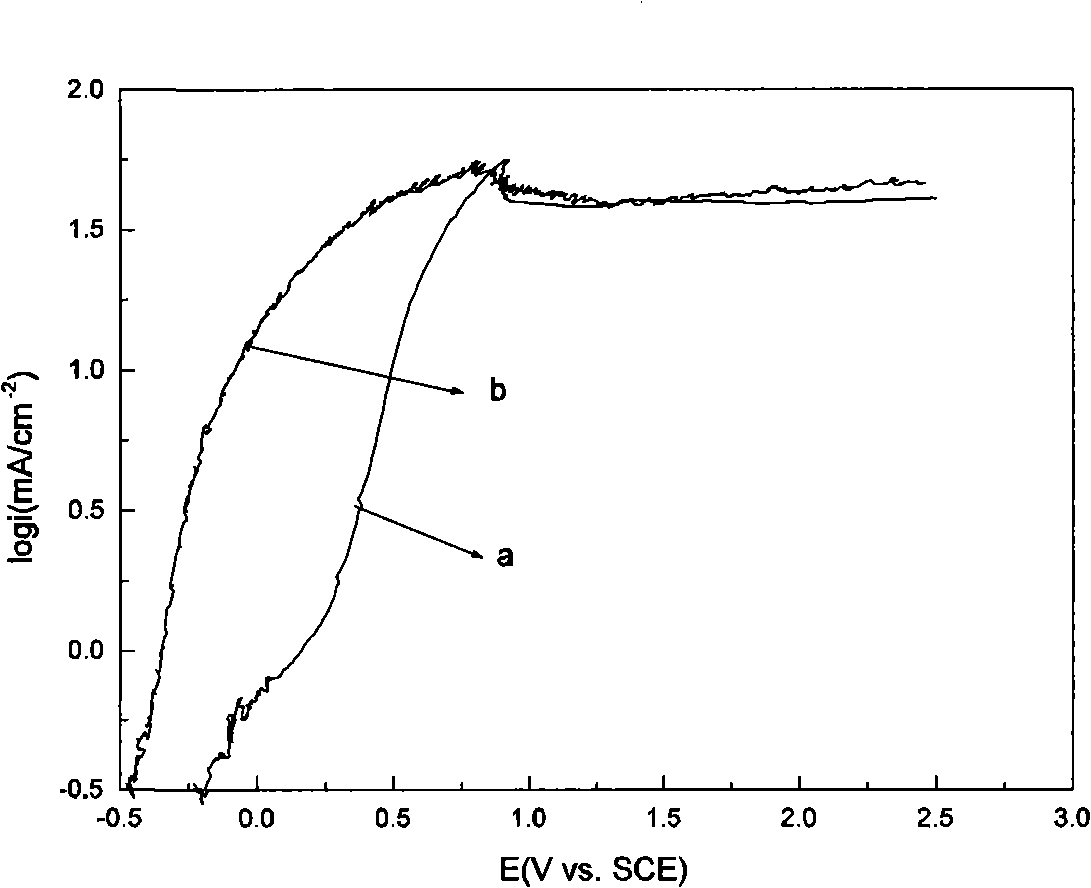

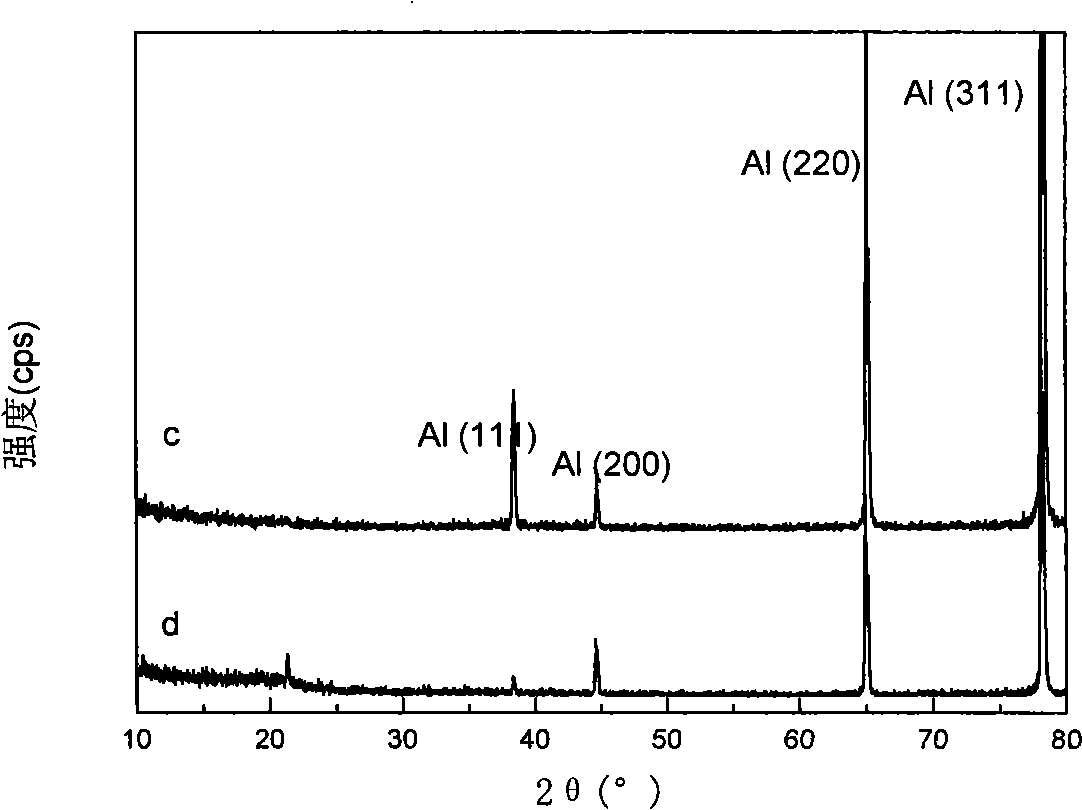

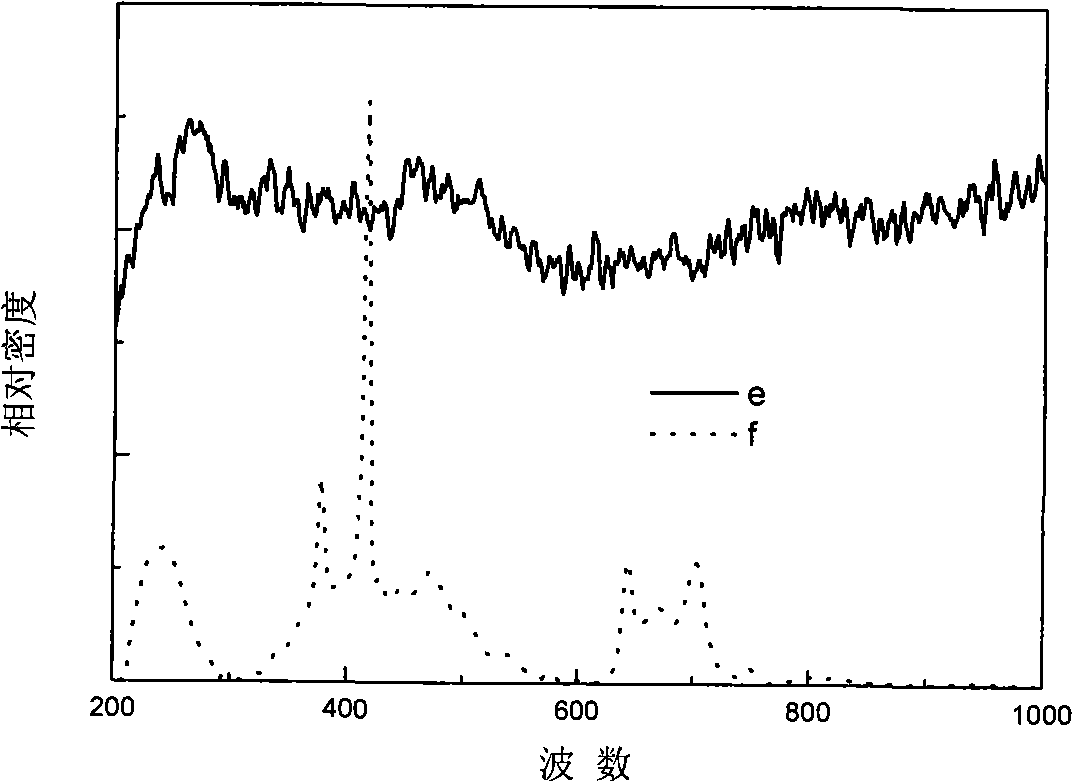

The invention relates to an electrochemical polishing method for the high purity aluminium under ultrasonic agitation, which belongs to the fields of the material chemistry and the electrochemistry. The electrochemical polishing method under the ultrasonic agitation comprises the following steps: high purity aluminium foil is added in absolute ethyl alcohol, so as to be cleaned with deionized water and through ultrasonic oscillations, and the natural oxide film in sodium hydroxide is removed; the aluminium foil after being pretreated is used as an anode, the platinum sheet is used as the cathode, the reference electrode is saturated calomel electrode, and the electropolishing solution is the mixed liquor composed of absolute ethyl alcohol and perchloric acid; the electrolysis vessel is positioned in an ultrasonic wave cleaner, and electrochemical polishing is performed on a constant potential rectifier. The self-organizing structure with nanoscale stripe shape is formed on the aluminium surface, the structure is observed by adopting the atomic force microscopy, and the size of the stripe-shaped nanostructure changes under the ultrasonic agitation; the composition of the polishing surface is analyzed through the Raman spectrum and the X-ray diffraction, so as to indicate that the composition of the polishing surface is amorphous aluminum oxide.

Owner:DALIAN UNIV OF TECH

Electrolyte used for treating aluminium foil in aluminium electrolytic capacitor

InactiveCN101871115AImprove leakage currentImprove reliabilityAnodisationSolid electrolytic capacitorsElectrolysisSURFACTANT BLEND

The invention provides an electrolyte used for treating an aluminium foil in an aluminium electrolytic capacitor. A surfactant used for reducing surface tension of the electrolyte and improving infiltration of solution on the surface of the aluminium foil is added into the electrolyte, and is at least one of an anionic surfactant, a cationic surfactant, an ampholytic surfactant and a nonionic surfactant. The surfactant can obviously reduce the surface tension, improve the infiltration of the solution on the surface of the aluminium foil, and greatly improve the capacity of the electrolyte of reaching the surface of the aluminium foil to corrode hole walls and hole bottoms, so an oxidation film on the surface of the aluminium foil is fully repaired, and the leakage current and the reliability of the electrolytic capacitor are greatly improved. The electrolyte has the advantages of readily available raw materials and strong operability in the preparation process, and is suitable for large-scale technological improvement and promotion.

Owner:FUJIAN GUOGUANG ELECTRONICS SCI & TECHCO

Iron-phosphate-based lithium-ion battery positive plate and preparation method thereof

InactiveCN101867037AIncrease contact areaGood adhesionElectrode carriers/collectorsMicron scaleAdhesive

The invention provides an iron-phosphate-based lithium-ion battery positive plate and a preparation method thereof. The iron-phosphate-based lithium-ion battery positive plate comprises an anode current collector, iron-phosphate-based lithium-ion particles, conducting solvent and adhesive and is characterized in that the anode current collector is an aluminium foil which forms pores by corrosion, the grain diameter of the iron-phosphate-based lithium-ion particle is from nanometer to micron scale, and the adhesive is the mixture of organic conducting high polymer adhesive and the non-conducting high polymer adhesive. The iron-phosphate-based lithium-ion battery positive plate of the invention improves the bonding performance between an anode material and the anode current collector aluminium foil, improves pole piece conducting performance and improves the situation of uneven pole piece impedance.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com