Patents

Literature

317results about How to "Continuous discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

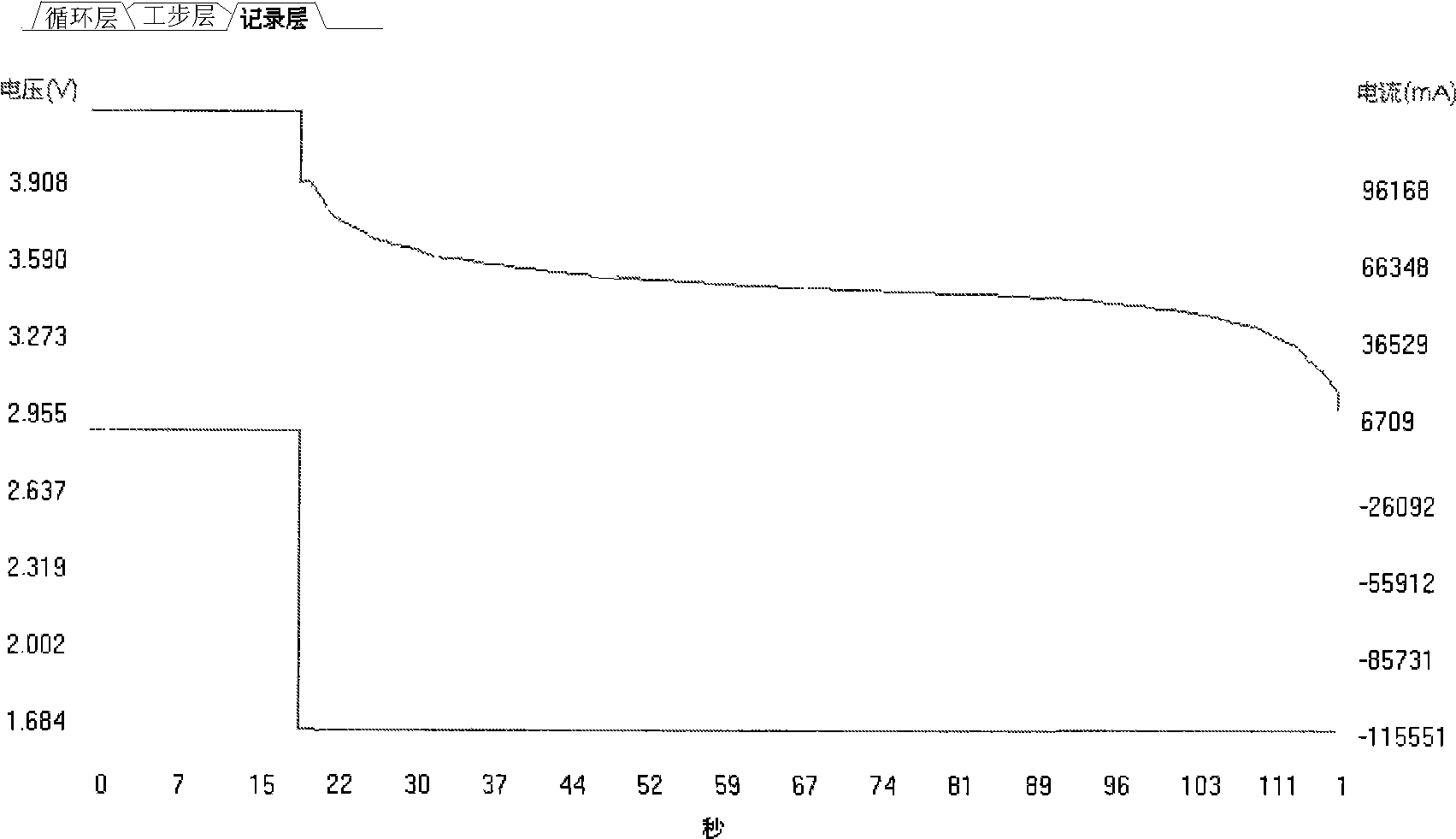

Ultra-high magnification lithium ion battery

The invention discloses a lithium ion battery with superhigh multiplying power, which comprises a positive plate, a negative plate, a membrane, an electrolyte solution, a plate lug and a packing shell. The positive plate is manufactured by coating the mixed slurry of a positive active material, a conducting agent and a cementing agent on both sides of an aluminium foil; the negative plate is manufactured by coating the mixed slurry of a negative active material, the conducting agent and the cementing agent on both sides of a copper foil; and the electrolyte solution is a mixed solution of lithium and an organic solvent. The lithium ion battery is capable of discharging continually at a superhigh multiplying power and the discharge multiplying power can reach 35C-50C. The discharge capacity of the discharge multiplying power at 35C, 40C, 45C, 50C can respectively reach 96.3 percent, 95.6 percent, 95.1 percent and 94.5 percent of the discharge capacity at 1C.

Owner:XIAN SAFTY ENERGY TECH

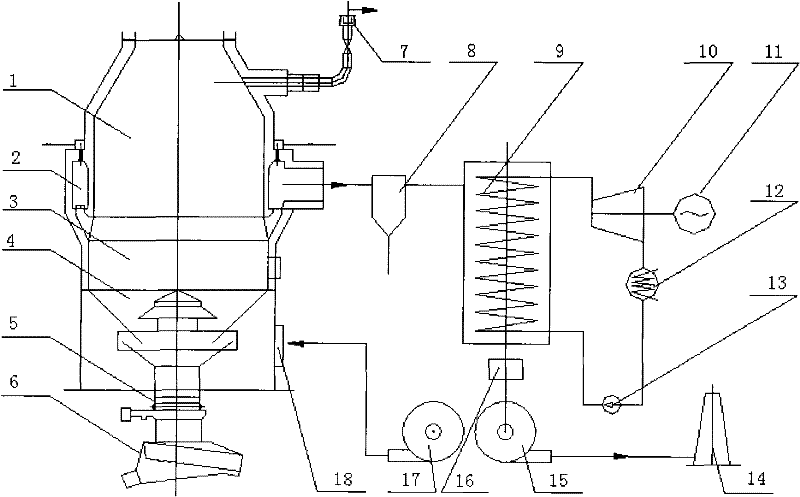

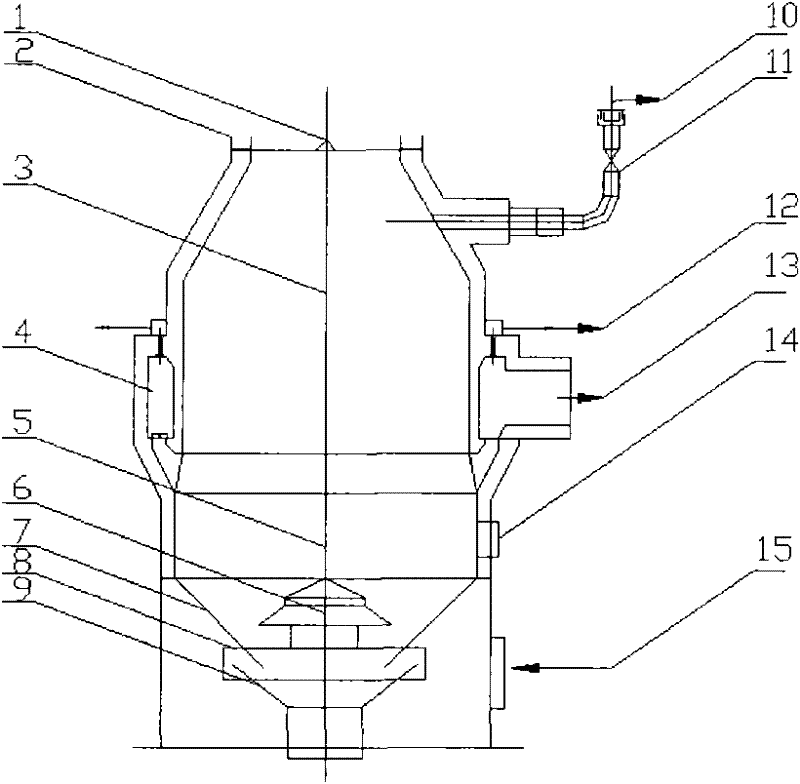

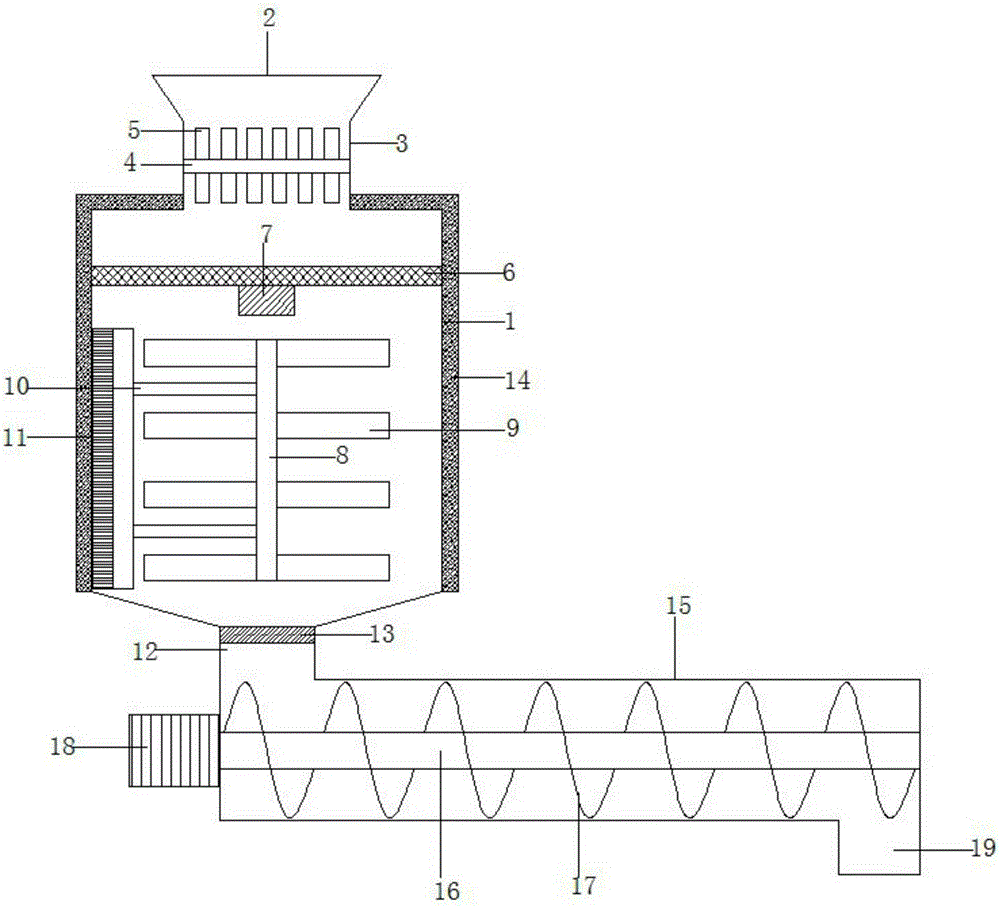

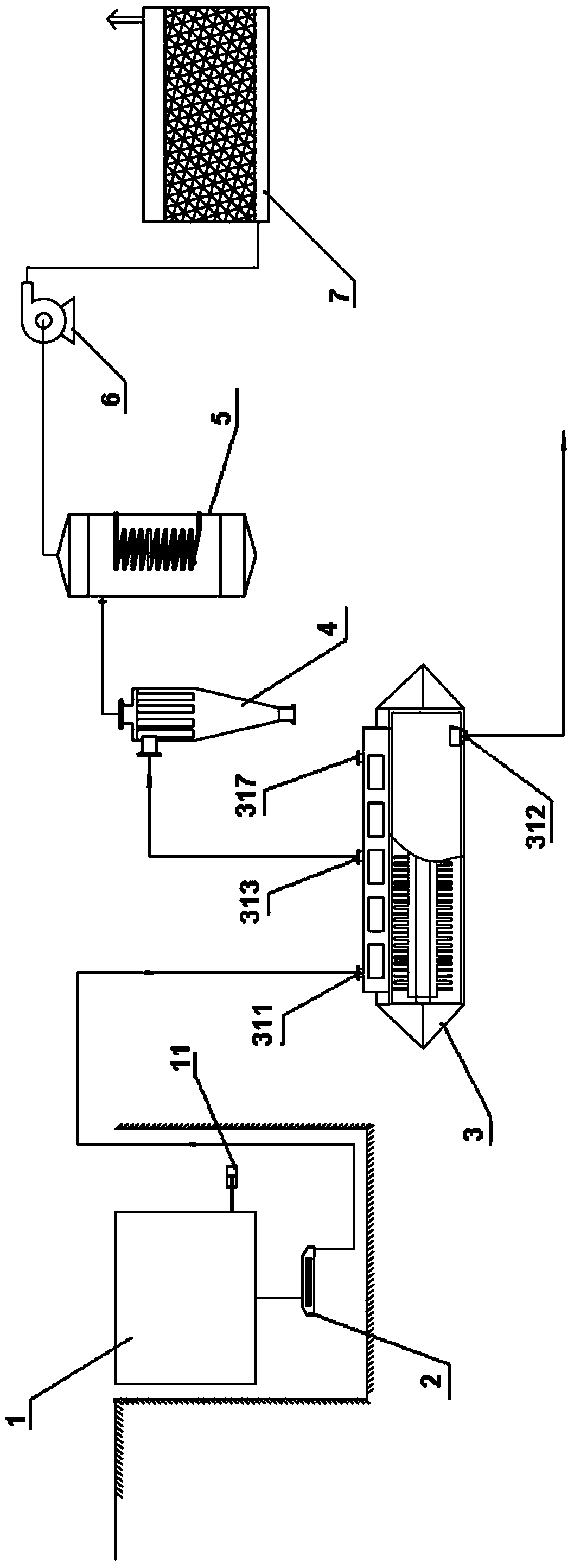

Sintering ore cooling device and waste heat recovery system thereof

InactiveCN102345981AImprove cooling effectEnsure safe and continuous productionIncreasing energy efficiencyHandling discharged materialCold airAir blower

The invention relates to the physical heat recovery field of solid high temperature materials. The system can be applied in the waste heat recovery of extra-large high-temperature particles such as high-temperature sintering ore and the like and the process is as follows: the high-temperature sintering ore from a sintering machine falls into a cold sinter furnace through a feeding system, gradually falls with ore discharge and enters a cooling section to radiate heat. The cooled sintering ore enters a vibrator feeder discharging system through a blanking hopper and a regulating gate. The process can be adopted to cool the sintering ore from about 700-800 DEG C to about 100 DEG C. Cold air provided by an air blower enters the cold sinter furnace through an air inlet and a blast cap, absorbs heat in the cooling section and then enters an annular channel, the high-temperature gas from the annular channel enters a waste heat boiler through a dust remover, the heat is transferred to a working medium and then pumped by the draft fan through the dust remover, and the gas is discharged in a chimney when reaching the dedusting standard. The heat-absorbing working medium (usually water) is converted to superheated steam with a certain parameter in the waste heat boiler to do work in a turbine and drive a generator to generate power. Dead steam after doing work enters a condenser and is sent back to the waste heat boiler through a circulating water pump, thus, a thermal cycle is completed.

Owner:刘柏谦

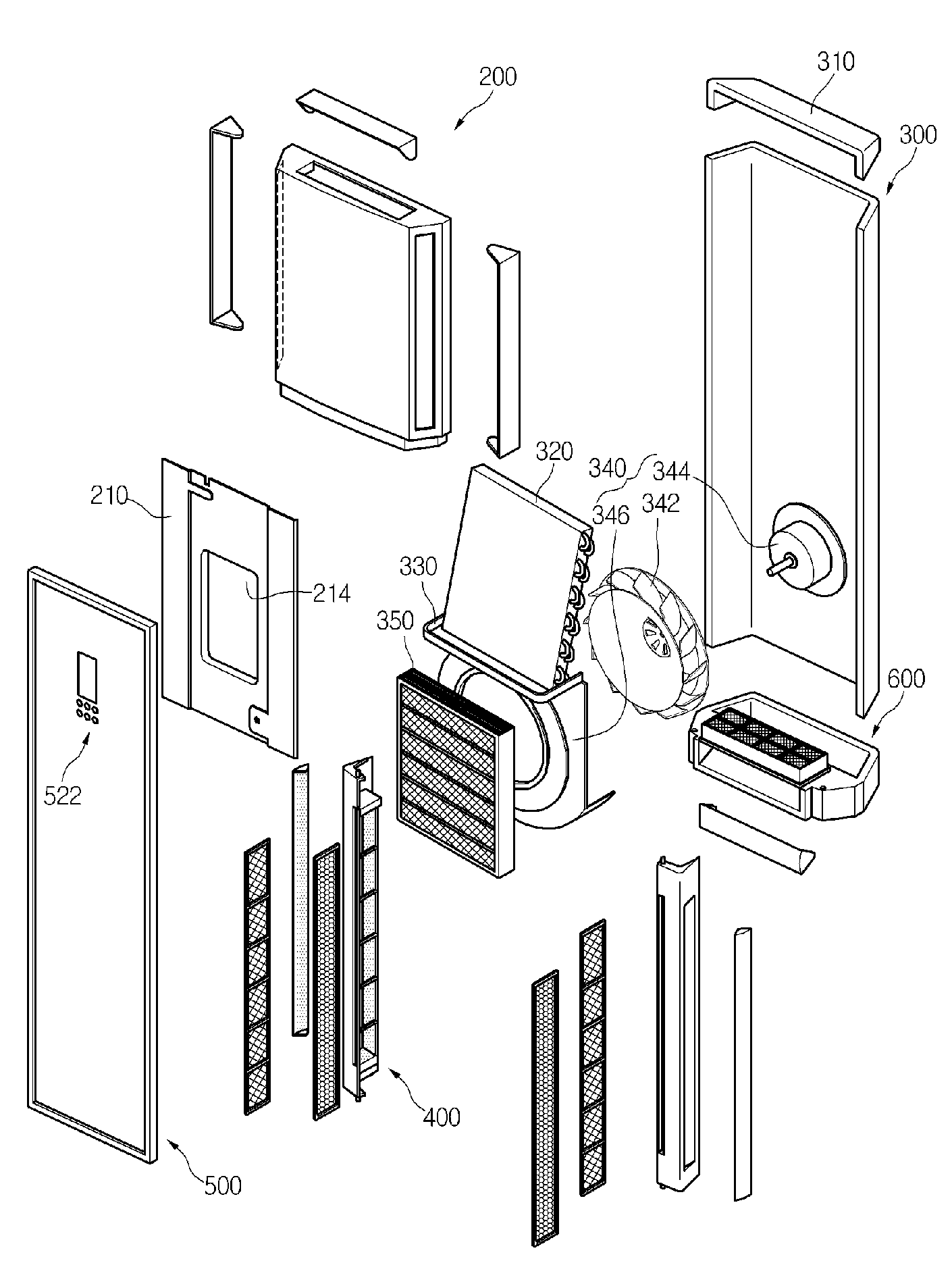

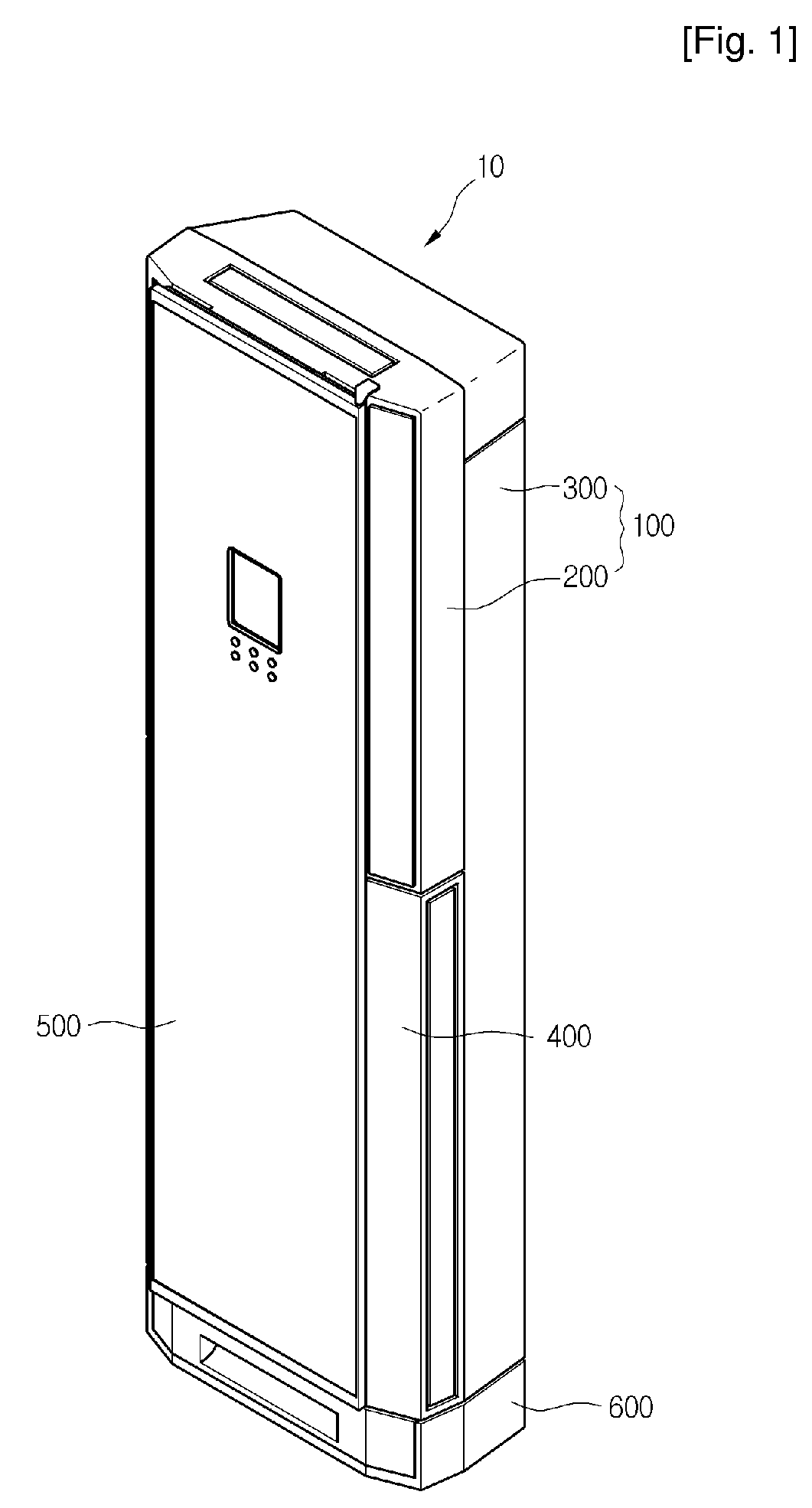

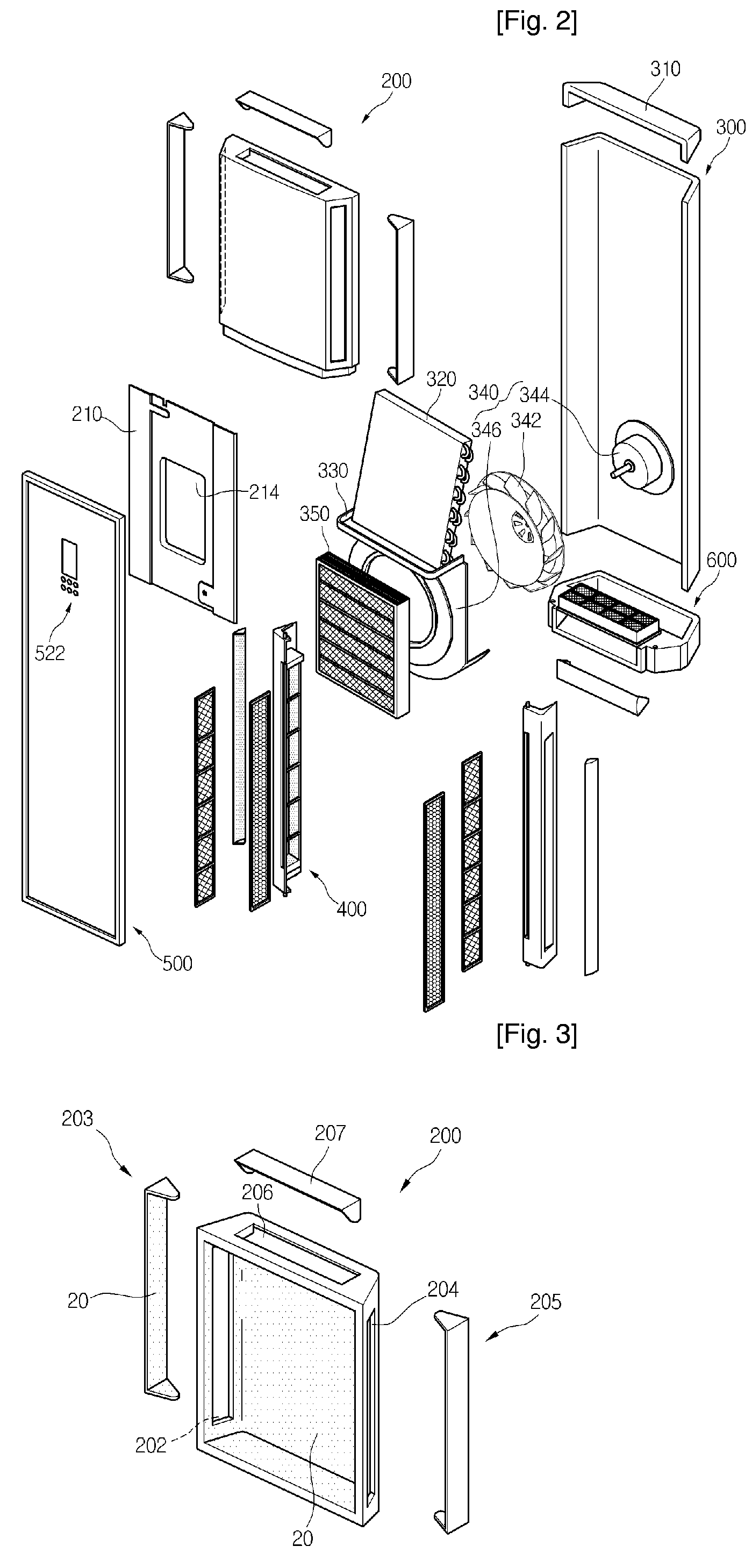

Air conditioner

InactiveUS7934387B2Excellent anti-virus activationHinders its propagationBioreactor/fermenter combinationsMechanical apparatusEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

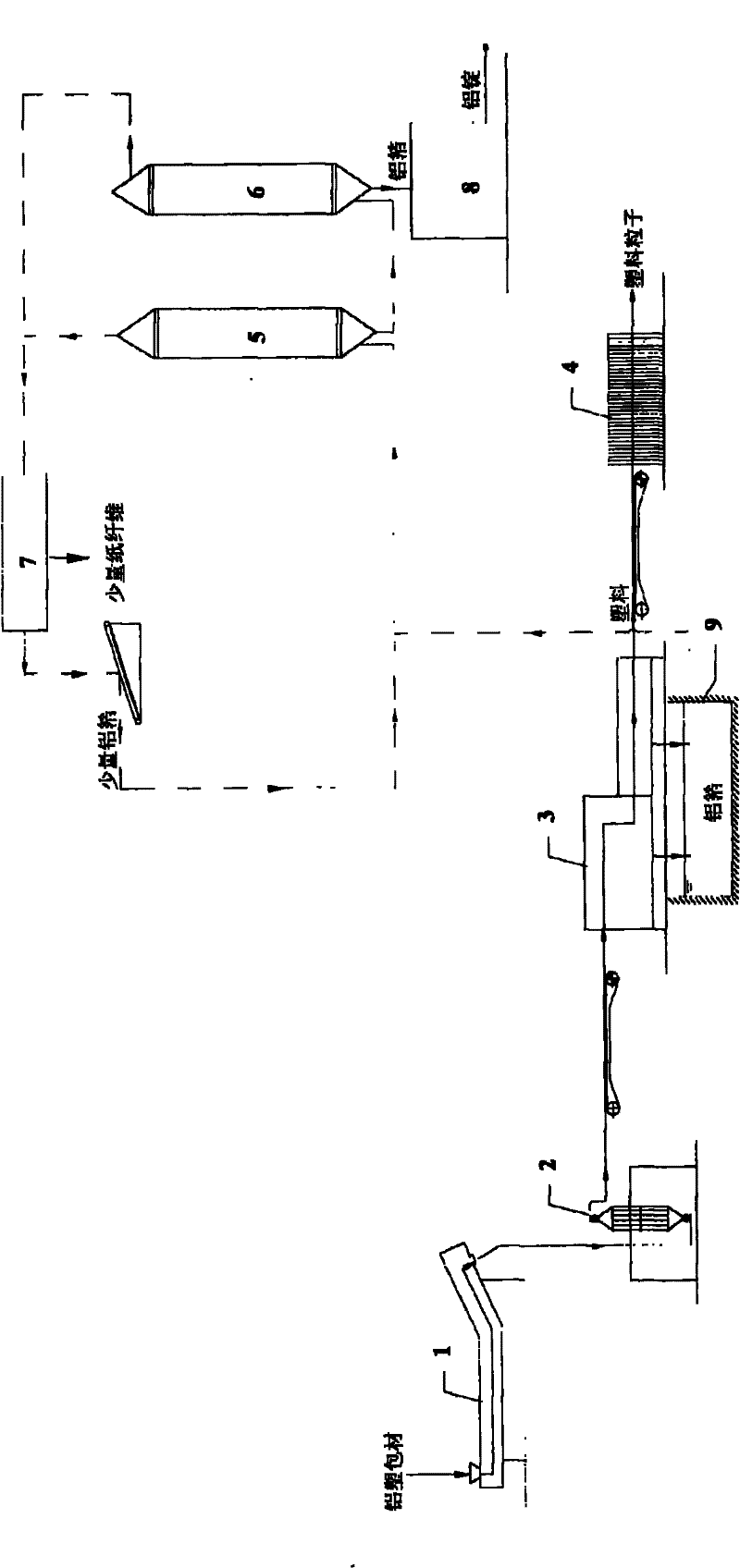

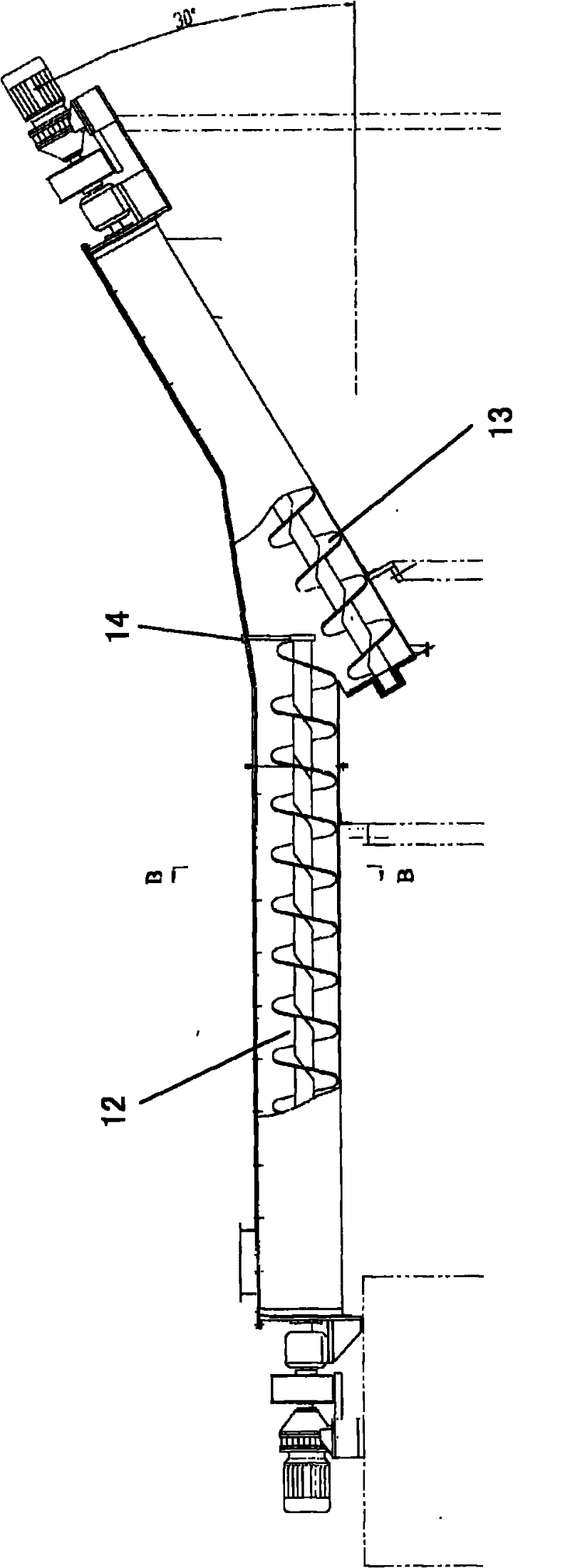

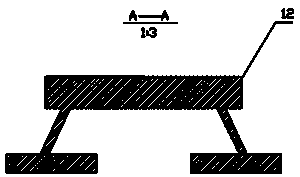

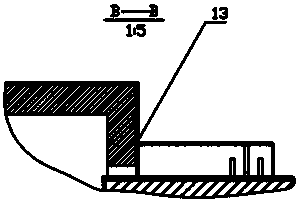

Successive separation method of aluminum-plastic composite packaging materials and device thereof

InactiveCN102206359ASmooth feedingContinuous dischargePlastic recyclingProcess efficiency improvementFormic acidSeparation method

A successive separation method of aluminum-plastic composite packaging materials comprises the following steps of: A) immersing the aluminum-plastic composite packaging materials in a formic acid remover, wherein the formic acid concentration of the formic acid remover is 2-6 mol / L; B) drying the separated aluminium foils and plastic to remove the residual remover; C) centrifuging and sifting thedried aluminium foils and plastic to spall and separate the plastic and aluminium foils, followed by collecting the plastic and aluminium foils. The invention also provides a device to accomplish theabove method. The method provided by the invention accomplishes the purpose of successive feeding and successive discharging with high separation efficiency and high separation speed, saves costs andis of economic and valid industrial value.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Efficient energy-saving feedstuff stirring machine

InactiveCN105169993AFalling smoothlyDrop savingsRotary stirring mixersMixer accessoriesBristleEngineering

The invention discloses an efficient energy-saving feedstuff stirring machine. The efficient energy-saving feedstuff stirring machine comprises a stirring barrel, an iron removing cavity and a spiral conveying barrel. A feeding hopper is arranged on the upper side of the stirring barrel, the lower side of the feeding hopper is connected with the iron removing cavity, a rotating shaft is horizontally arranged inside the iron removing cavity, magnetic iron pieces are symmetrically arranged on the outer wall of the rotating shaft in the vertical direction, and the seven pairs of magnetic iron pieces are arranged in the left-right direction. The bottom end of the iron removing cavity is connected with a feeding port in the lower side of the stirring barrel, a sieve is horizontally arranged on the upper side inside the stirring barrel, and the periphery of the sieve is installed on the inner wall of the stirring barrel through bolts. The magnetic iron pieces are rotated to remove iron of feedstuff sufficiently, the vibration sieve can make the feedstuff evenly fall, and therefore the stirring effect and efficiency are improved; a scraping cleaning bristle brush can scrap off the feedstuff adhering to the inner wall, waste of the feedstuff is avoided, a solar cell panel converts solar energy into electric energy so that the electric energy can be used for the stirring machine, in this way, energy is saved, continuous and even automatic discharging can be achieved, and the working efficiency of the stirring machine is improved.

Owner:林桂清

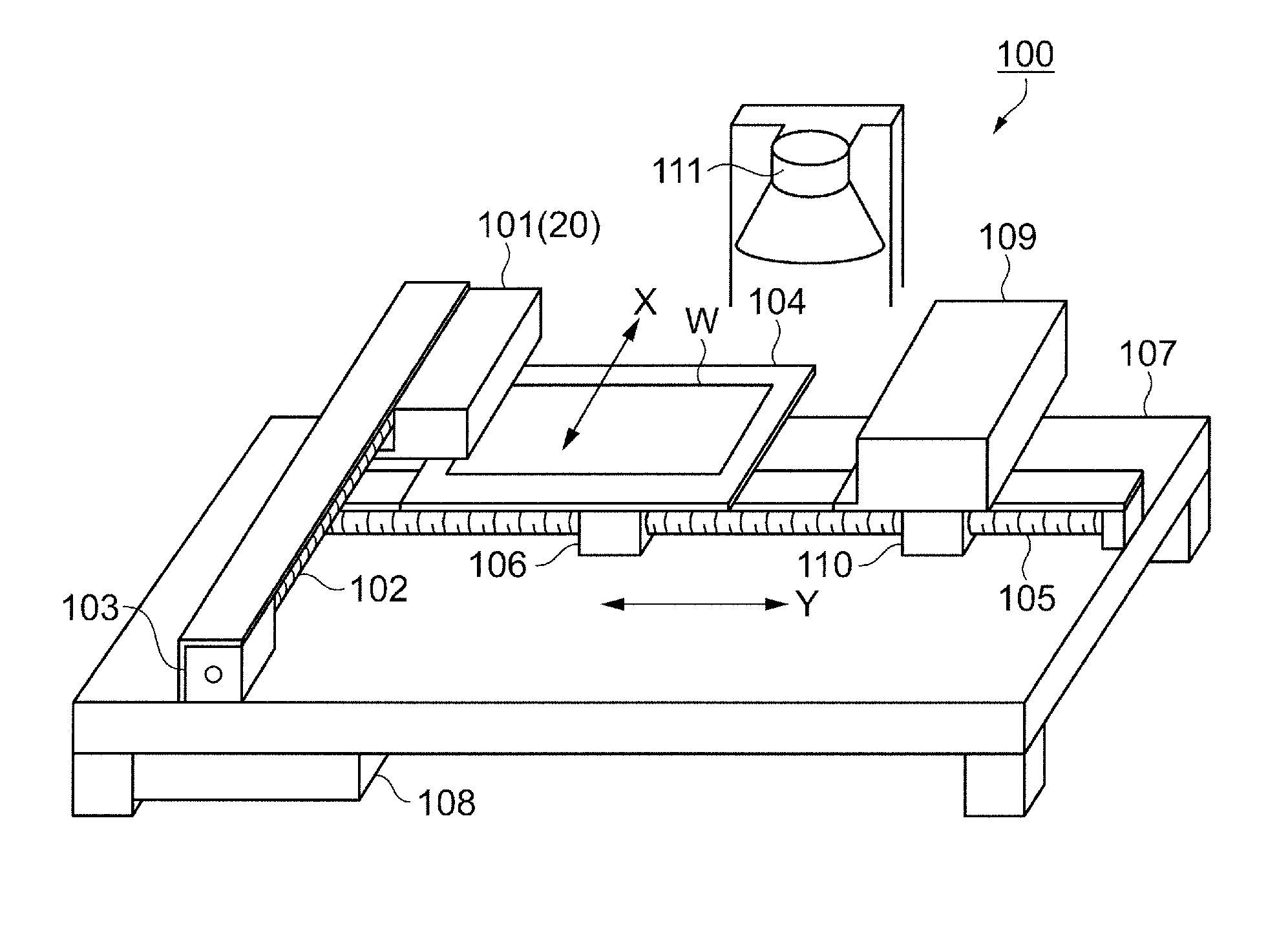

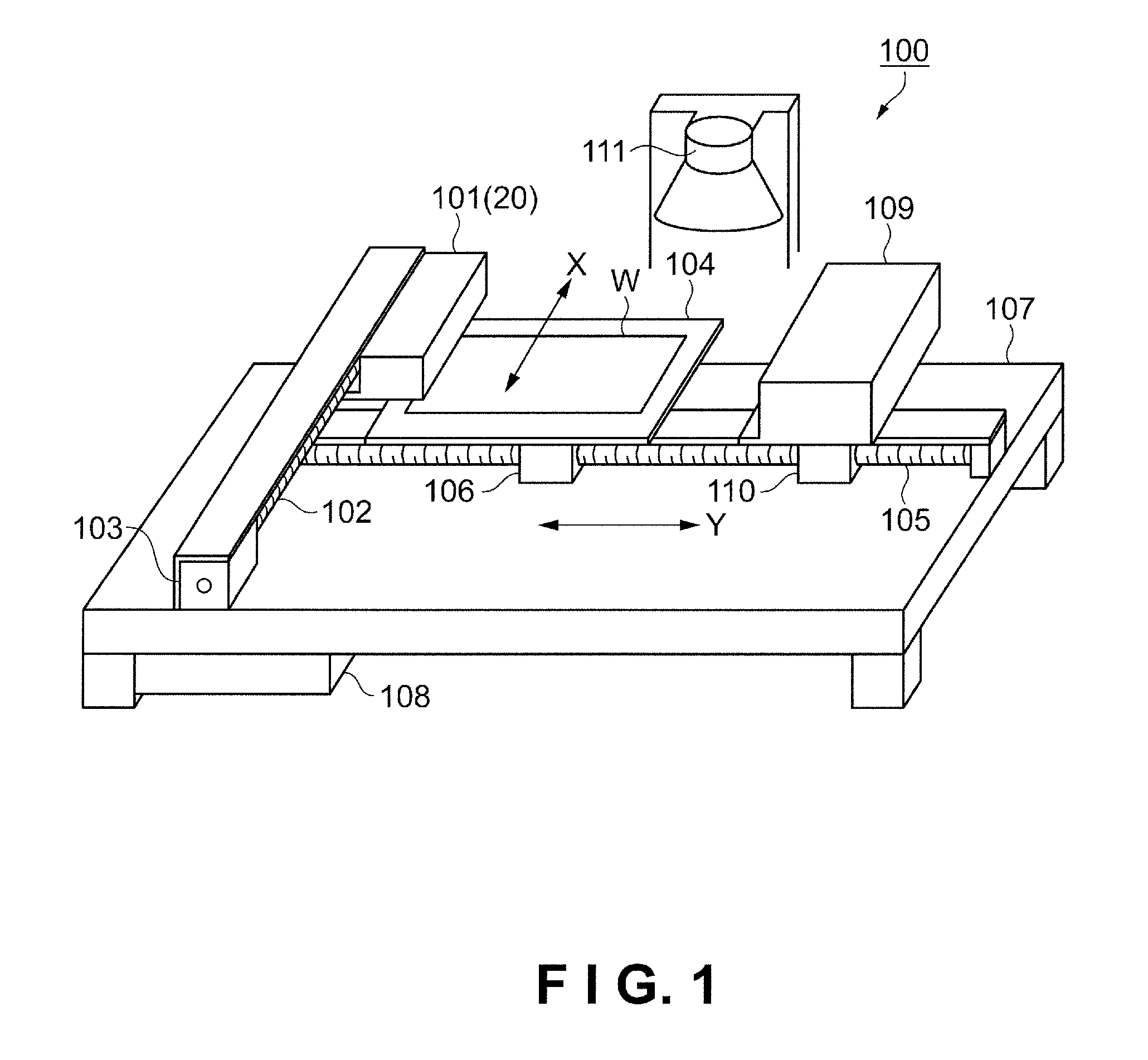

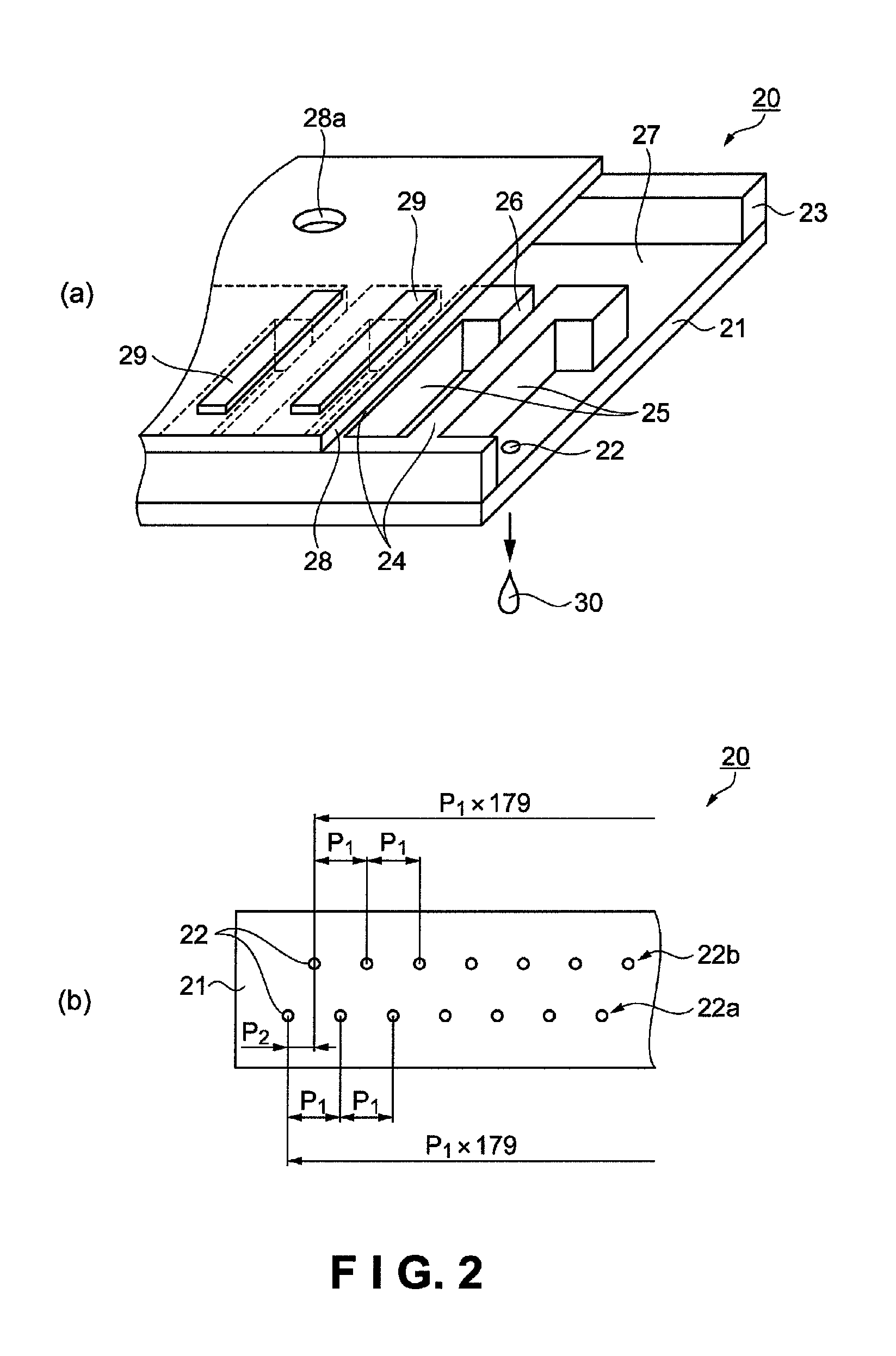

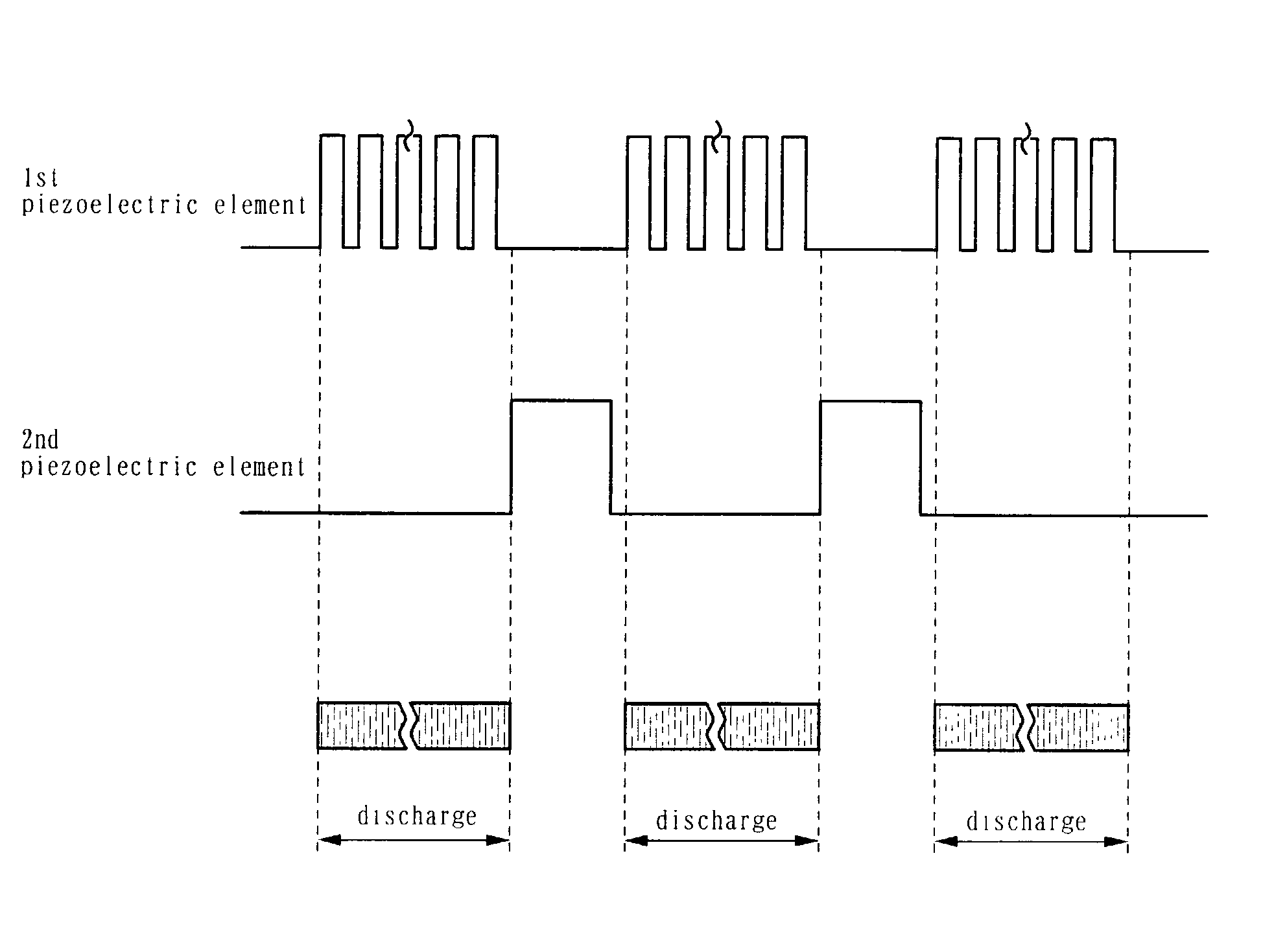

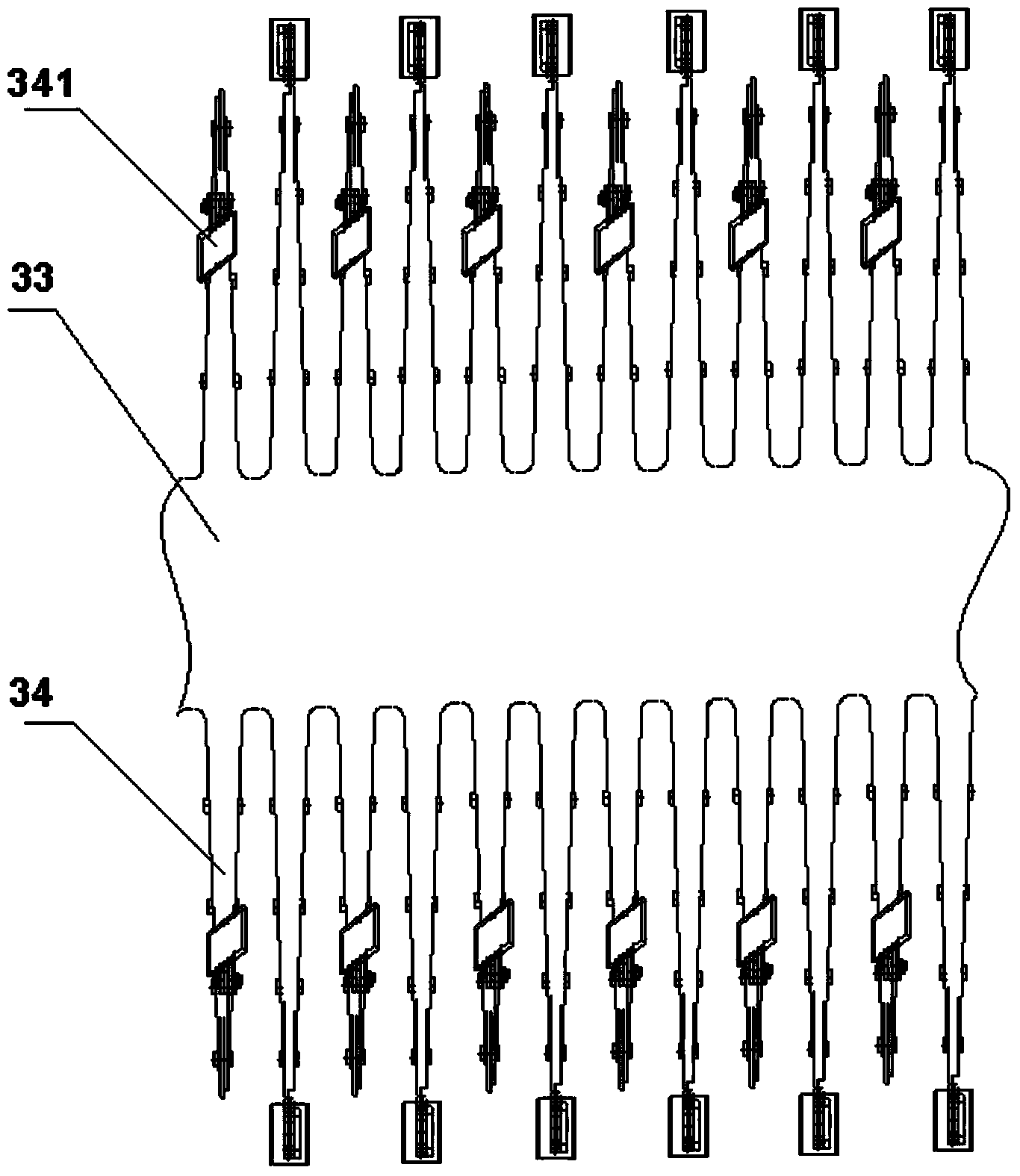

Method for discharging liquid material, method for manufacturing color filter, and method for manufacturing organic EL element

ActiveUS8124190B2Easy dischargeContinuous dischargeInking apparatusElectroluminescent light sourcesEngineeringLiquid drop

A method for discharging a liquid material includes performing a scan by moving a discharge target having a film formation area and a plurality of nozzles forming a nozzle row with respect to each other, and discharging a liquid material as droplets from the nozzles onto the film formation area by selectively applying one of drive waveforms generated using time division to an energy generation element of each of the nozzles in synchronization with the scan. The discharging of the liquid material includes applying a first drive waveform to a first nozzle of the nozzle row and a second drive waveform having a different discharge timing from the first drive waveform to a second nozzle of the nozzle row with the second nozzle being adjacent to the first nozzle, and changing a combination of the first and second drive waveforms selected from the drive waveforms at least once.

Owner:TOKYO ELECTRON LTD

Method for producing acrylic acid from glycerol

InactiveUS7910771B2Thermal equilibriumGood reaction selectivityPhysical/chemical process catalystsOrganic compound preparationGas phaseGlycerol

The invention relates to a method for producing acrylic acid in one step by an oxydehydration reaction of glycerol in the presence of molecular oxygen. The reaction preferably carried out in gaseous phase in the presence of a suitable catalyst.

Owner:ARKEMA FRANCE SA

Cereal vacuum storage device

ActiveCN101185462AQuality is not affectedDoes not reduce moistureEdible seed preservationVacuum pumpingSocial benefits

The invention discloses a set of vacuum storage equipment of a grain: an inner cavity of a hollow grain storage silo body is sleeved with a flexible bag body, the size and shape of which are matched with the inner cavity of the hollow grain storage silo body. A bag inlet and a bag outlet arranged on the flexible bag body are corresponding to a silo inlet and a silo outlet arranged on the hollow silo. The bag inlet and the bag outlet are respectively provided with a sealing mechanism. The upper part at the outer surface of the flexible bag body is connected with the upper part of the inner cavity of the hollow grain storage silo body by a flexible cable; furthermore, a flexible vacuum-pumping pipe is arranged on the flexible bag body and the inner end of the vacuum-pumping pipe is communicated with the flexible bag body and the outer end thereof is communicated with a set of vacuum-pumping equipment. The invention has simple structure, novel design, convenient use and wide application range, can effectively keep the quality of the grain stored in a long term, reaches environment friendly standard as well and is beneficial to the health of eaters, thus having good economic and social benefits.

Owner:郑州中粮科研设计院有限公司 +1

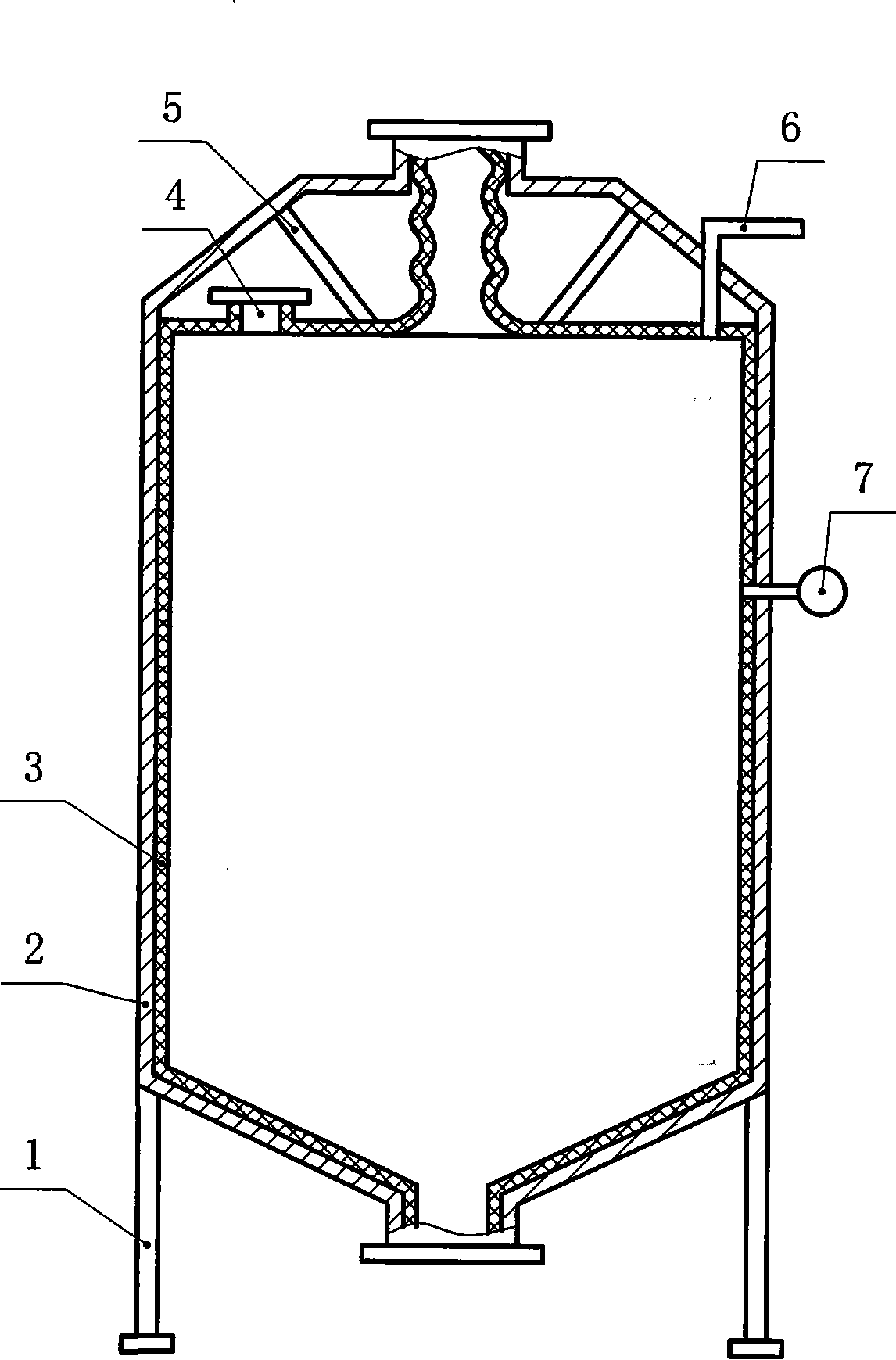

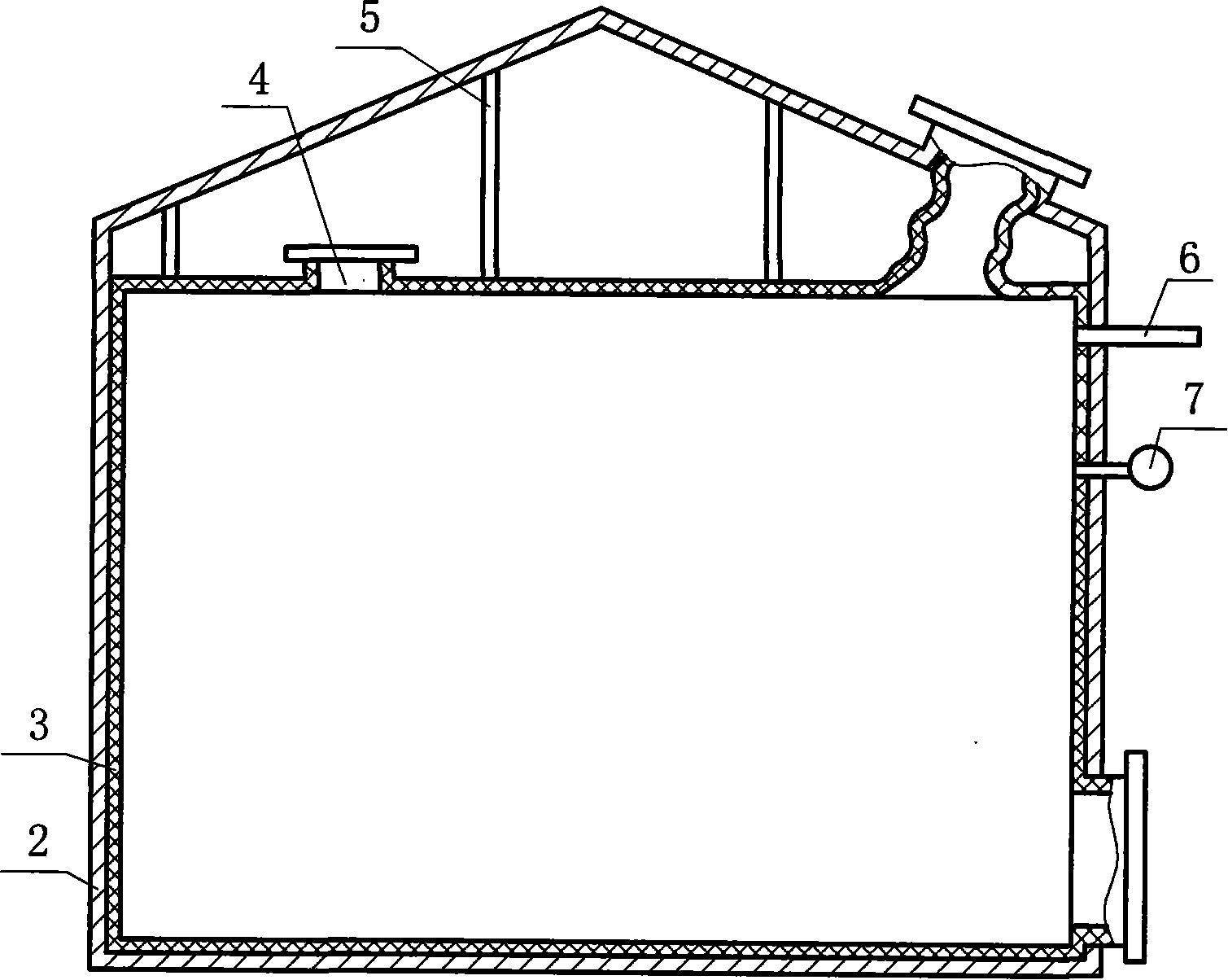

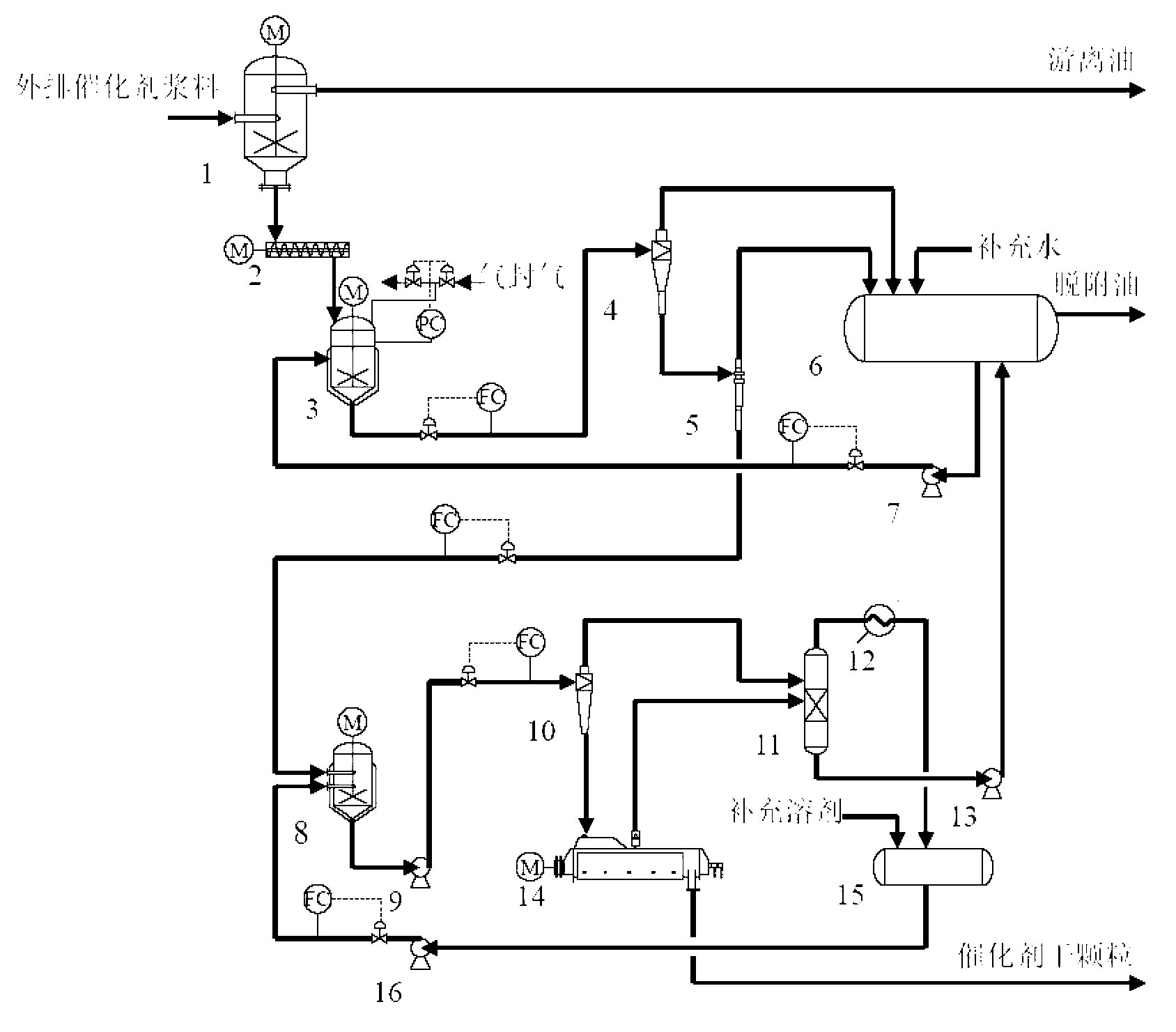

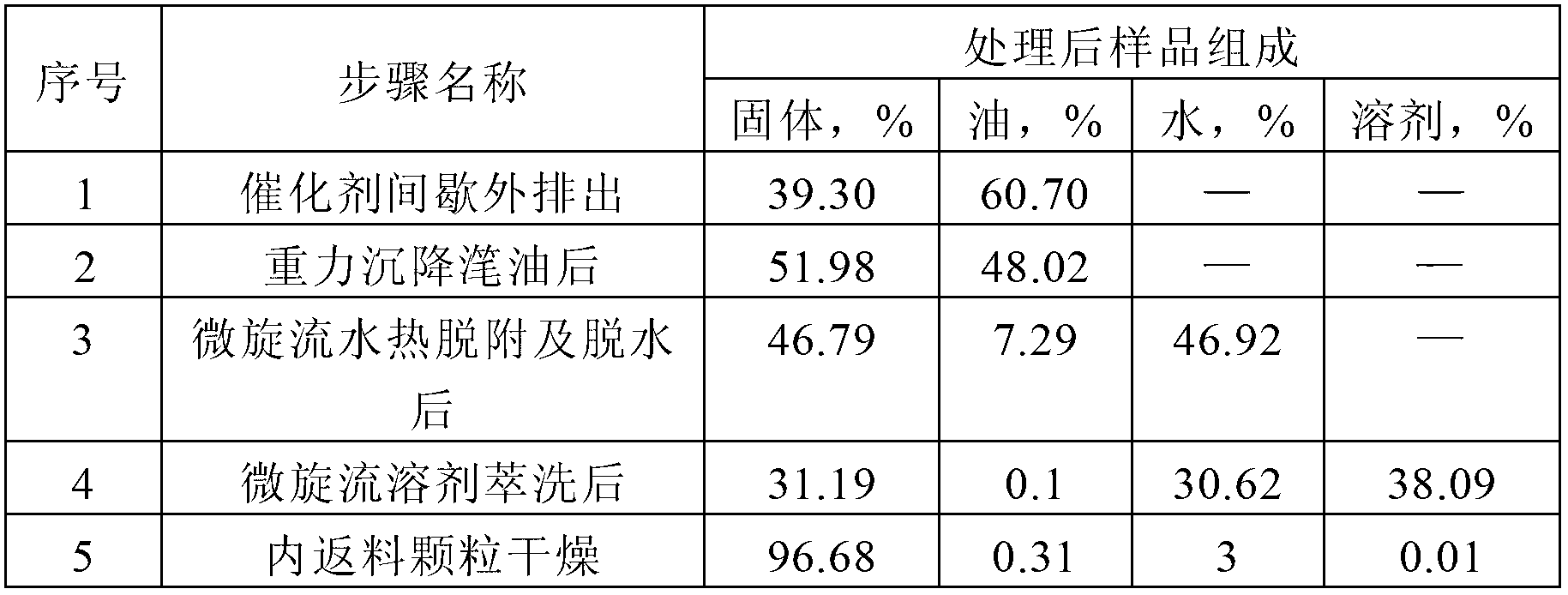

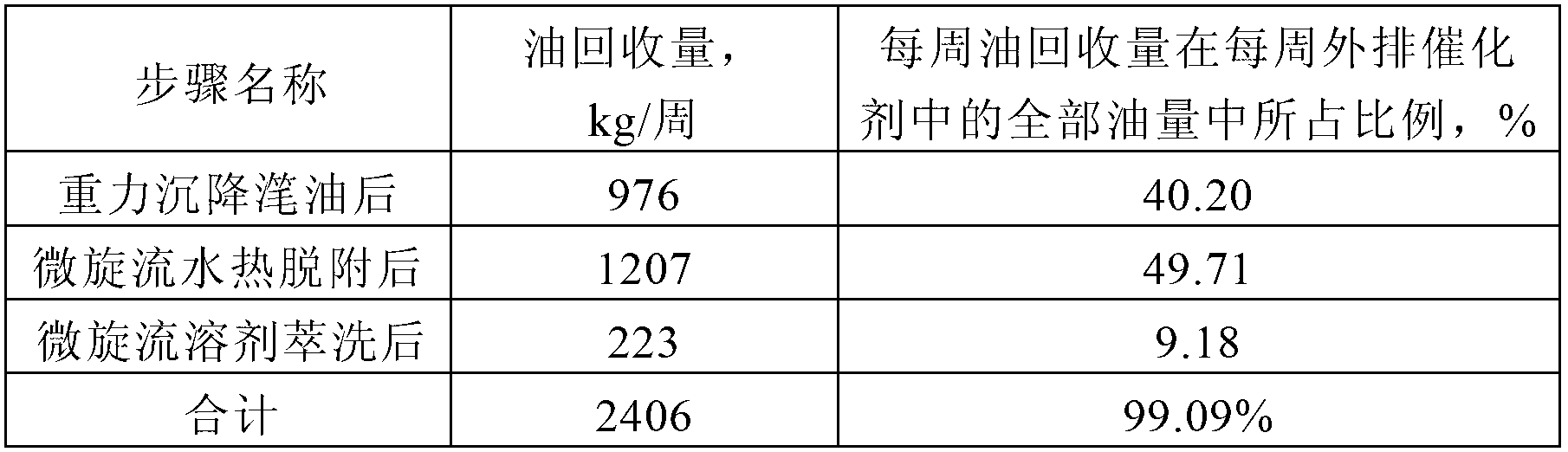

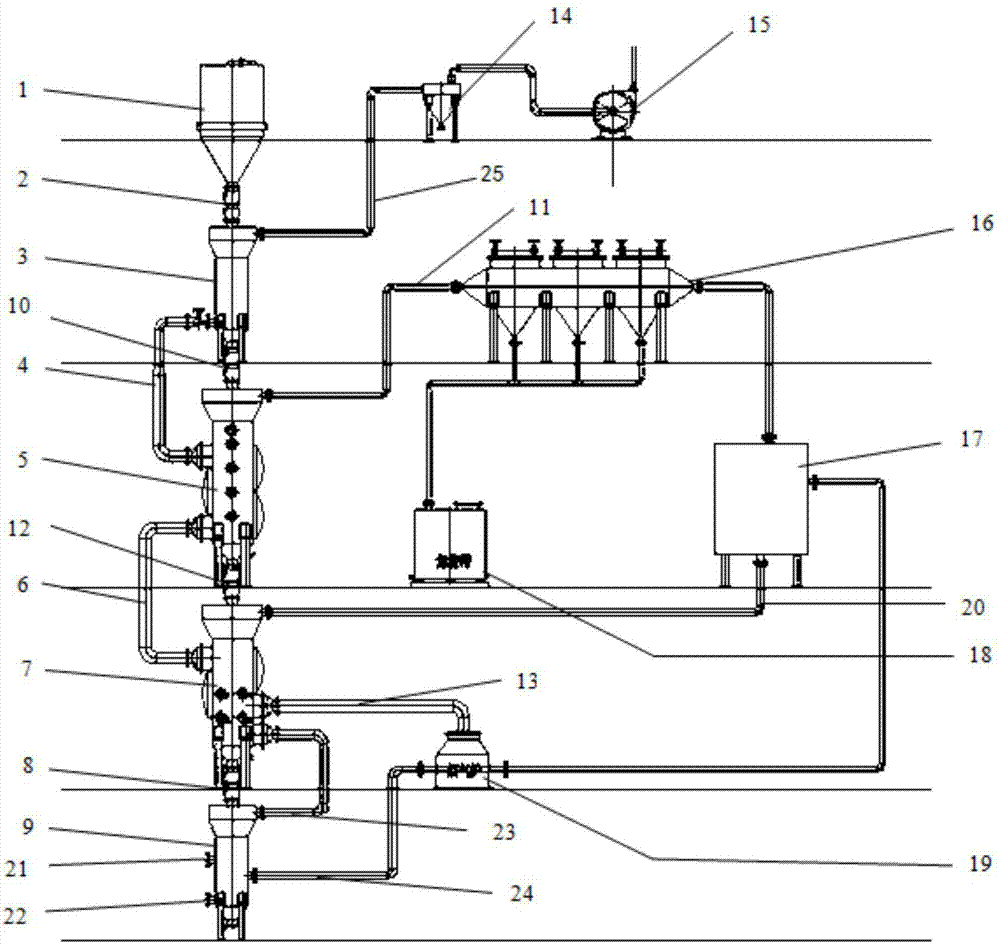

Processing method and processing device for graded desorption of residue hydrotreating excretion catalyst in ebullated bed

ActiveCN102698818AContinuous dischargeContinuous processingCatalyst regeneration/reactivationLiquid carbonaceous fuelsDesorptionWater circulation

The invention relates to a processing method and a processing device for graded desorption of residue hydrotreating excretion catalyst in an ebullated bed, and provides the processing method for the graded desorption of the residue hydrotreating excretion catalyst in the ebullated bed. The processing method comprises the following steps: (A), decanting oil due to gravitational settling, storing, and regulating; (B), carrying out hydrothermal micro-swirling desorption and hot water circulation; and (C) carrying out micro-swirling resolvent extraction and cleaning, as well as resolvent circulation. The invention further provides the processing device for the graded desorption of the residue hydrotreating excretion catalyst in the ebullated bed.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

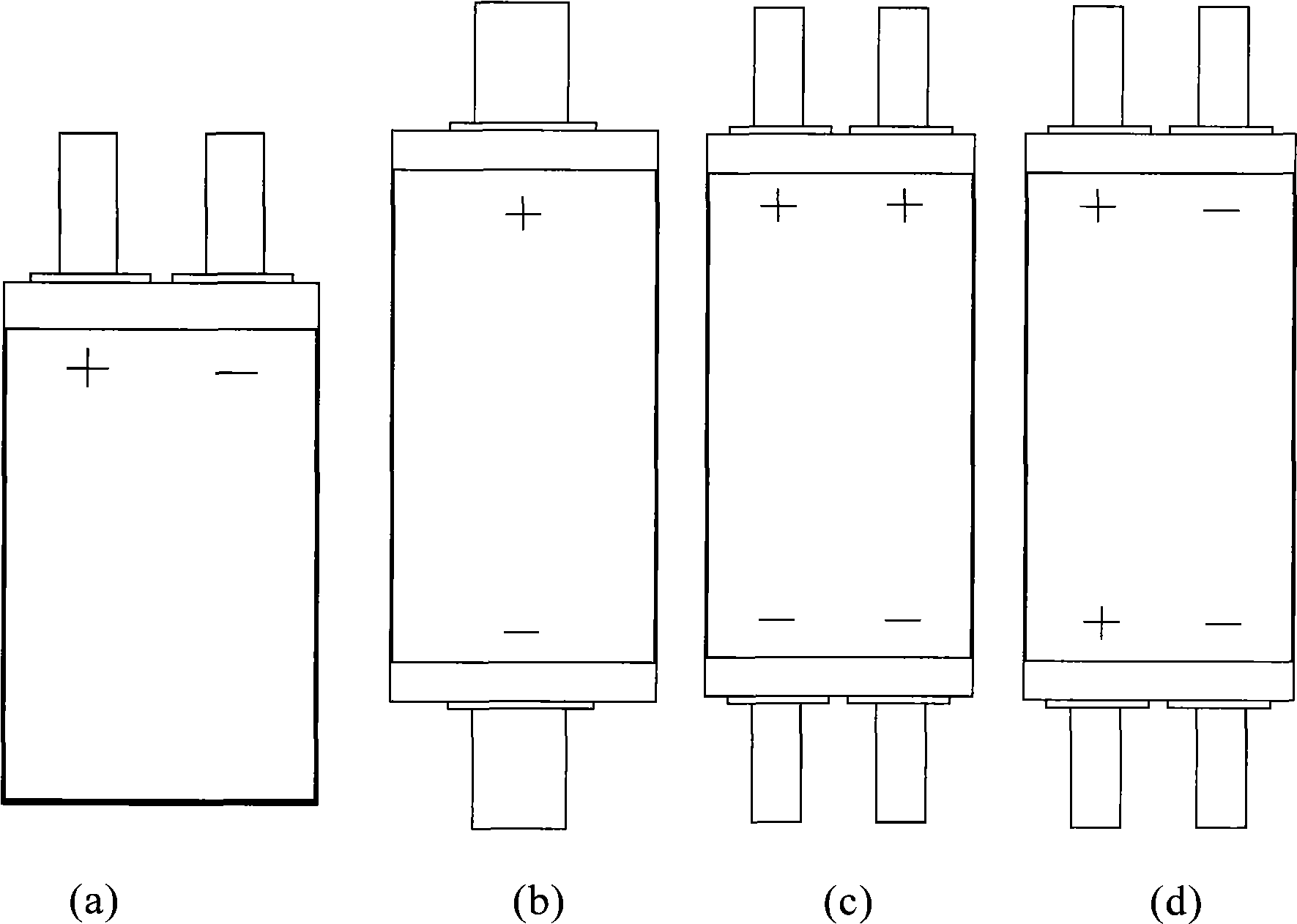

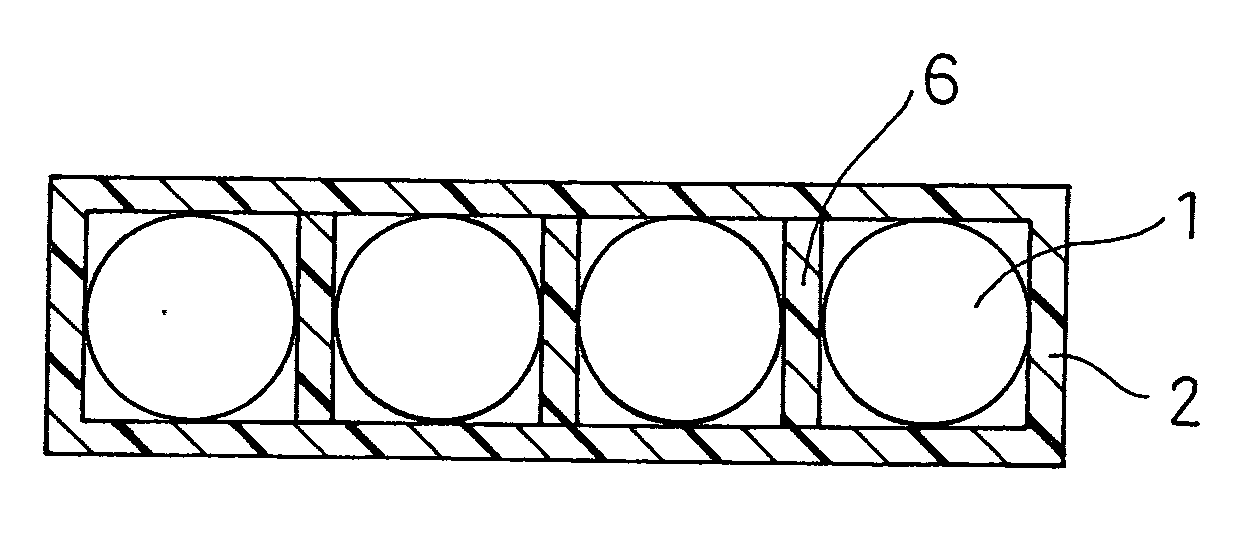

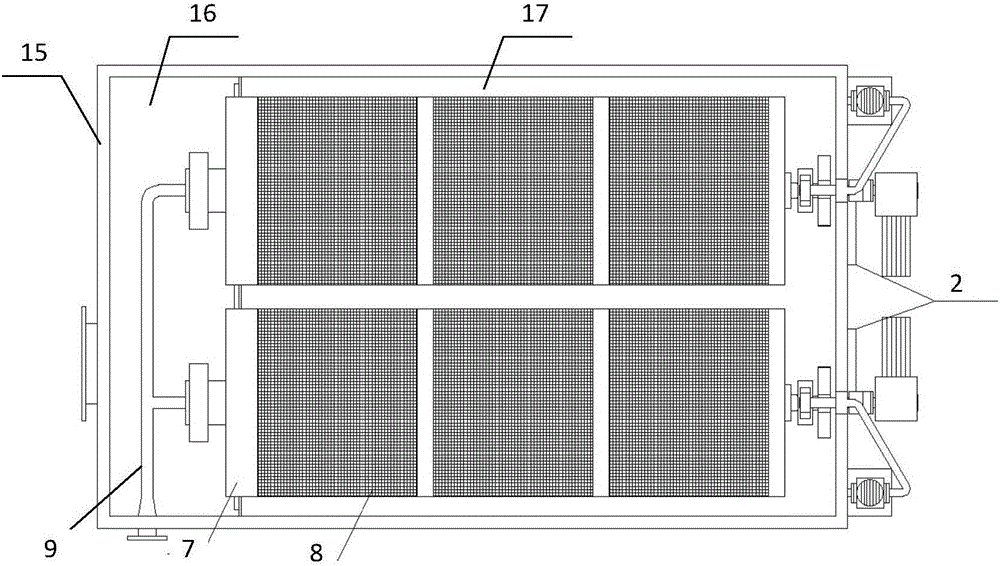

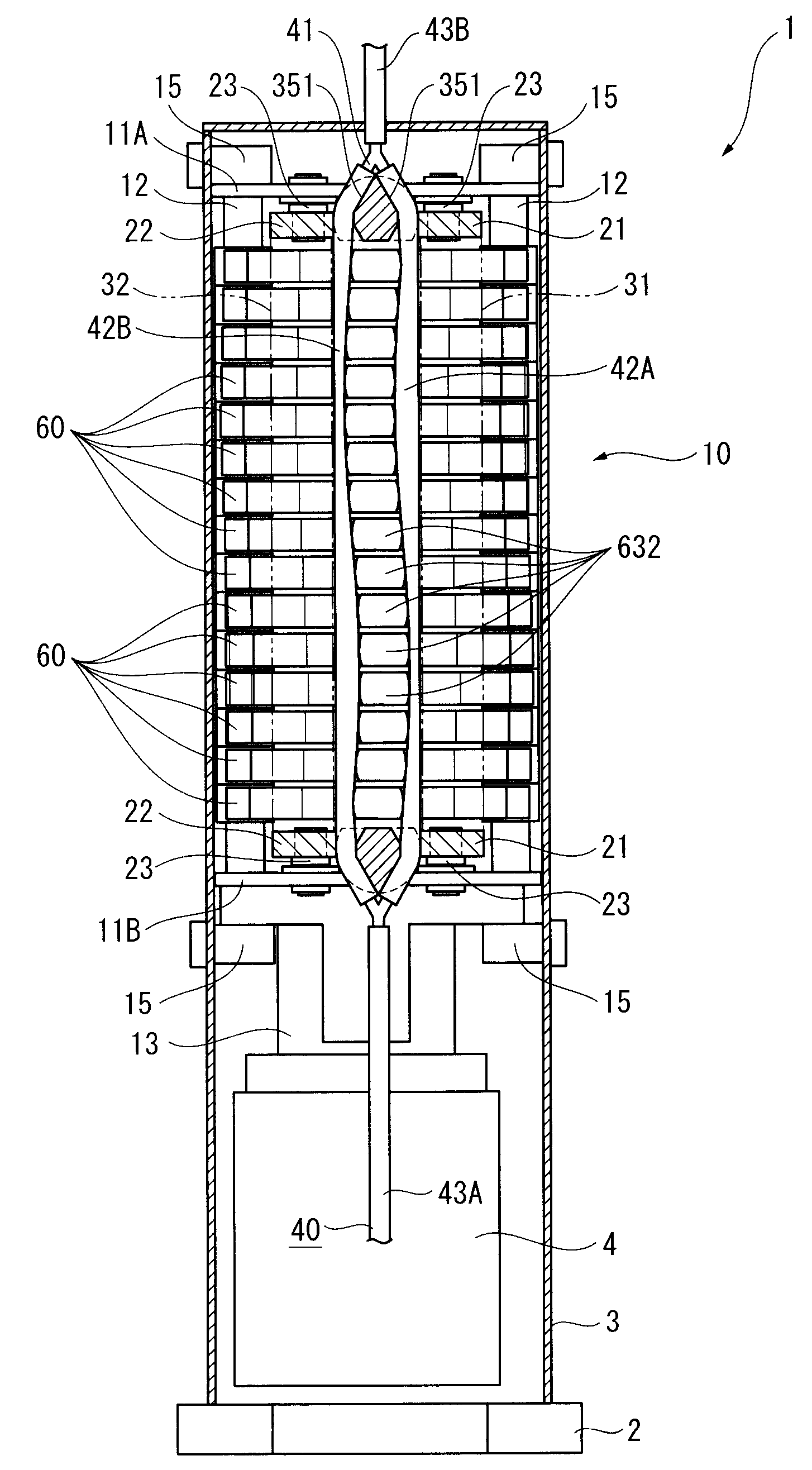

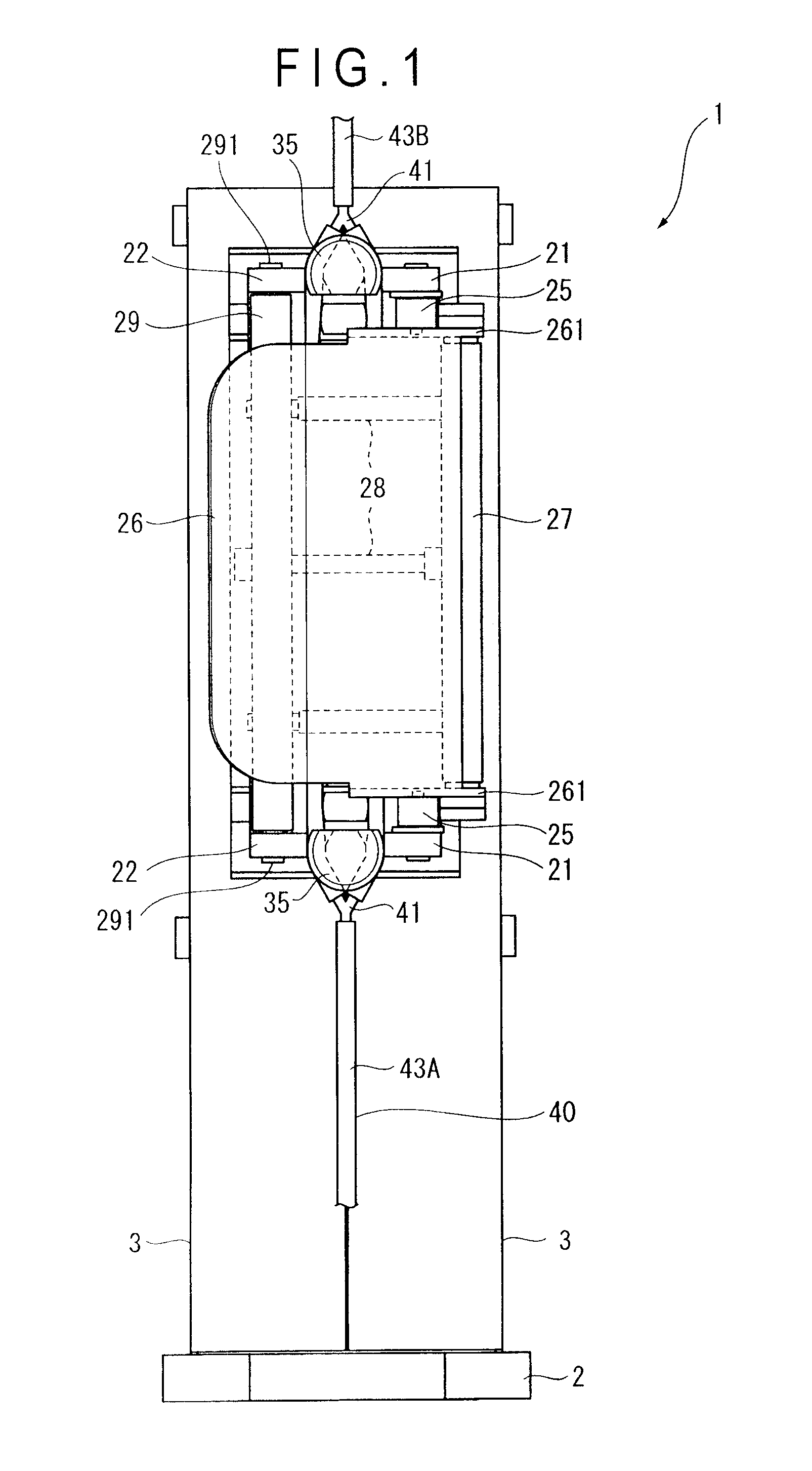

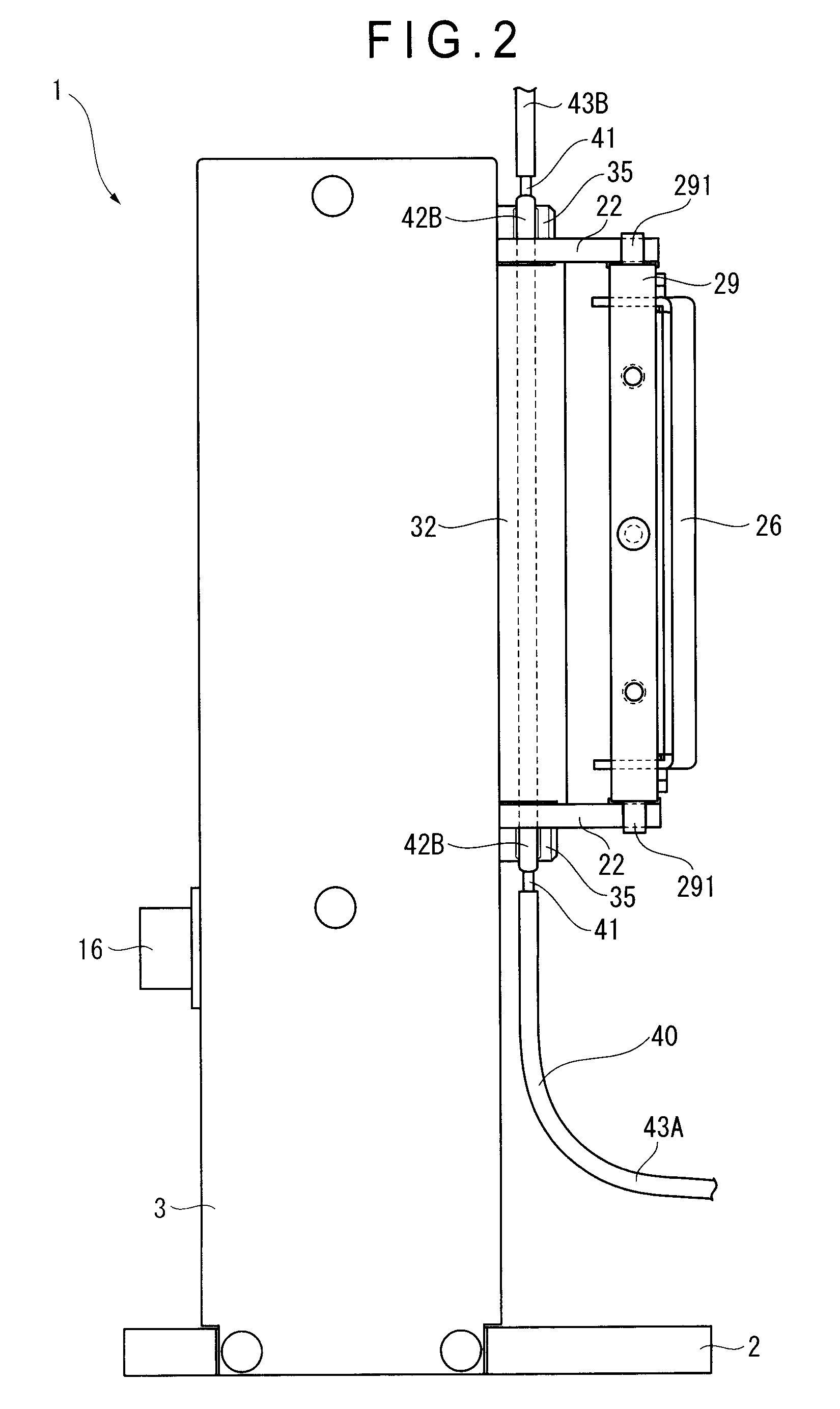

Non-aqueous electolyte battery pack

InactiveUS20060159984A1Reduce resistanceIncrease in battery temperaturePrimary cell to battery groupingCell temperature controlElectricityRechargeable cell

A non-aqueous electrolyte rechargeable battery pack is provided, which includes a measuring unit for measuring a battery voltage and a battery temperature and a control unit for controlling charge and discharge based on a measuring result of the measuring unit. A plurality of cylindrical non-aqueous electrolyte rechargeable batteries each having positive and negative terminals at a cover and a bottom are accommodated in a battery housing in such a manner that side faces of adjacent non-aqueous electrolyte rechargeable batteries face each other. All the cylindrical non-aqueous electrolyte rechargeable batteries are electrically connected to one another. B / A is set to be in a range between 0.02 and 0.2 where A is a diameter of each cylindrical non-aqueous electrolyte rechargeable battery and B is a distance between the side faces of the adjacent batteries. Due to this, it is possible to realize the non-aqueous electrolyte rechargeable battery pack having a structure suitable for outdoor use as a power source for an electric tool.

Owner:PANASONIC CORP

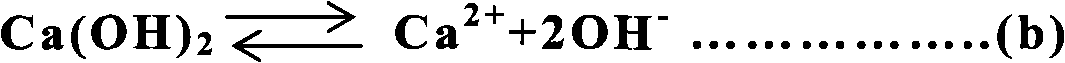

Method for treating acidic fluorine-containing waste water

ActiveCN101823799AGood defluoridation effectNo secondary pollutionWater contaminantsMultistage water/sewage treatmentCalcium hydroxideSludge

The invention relates to a method for treating acidic fluorine-containing waste water. The method comprises the following steps sequentially: (1) adding calcium-containing substance into the fluorine-containing waste water to be treated and adjusting the pH value of the waste water to be about 4.0 to 9.0; and (2) adding water-soluble gamma-polyglutamic acid serving as a biologic capturing agent into the mixture, fully stirring and standing the mixture, separating the supernatant and collecting the precipitated sludge after the mixture is precipitated and demixed, wherein the calcium-containing substance at least comprises one of calcium hydroxide, calcium oxide or calcium salt. The method overcomes the technical disadvantages in the prior art; the high molecular water-soluble gamma-polyglutamic acid with a molecular weight between 500,000 and 1,500,000 is used in the treatment of the acidic fluorine-containing waste water; and repeated experiments show that the fluorine removing effect is excellent and the treated waste water can meet the national first-class discharge standard; moreover, the method has the advantages of low treatment cost, high efficiency for the treatment process, environment friendliness and no secondary pollution.

Owner:江西爱地生生物高分子材料有限公司

Method and device for removing alga by means of micro-filtration by aid of drums for ships

InactiveCN105664567AHigh trafficReduce energy consumptionWater cleaningWaterborne vesselsFiltrationSpray nozzle

The invention discloses a method and a device for removing alga by means of micro-filtration by the aid of drums for ships. The method includes steps of A, drawing the alga, and to be more specific, mounting a micro-filtration algae removing machine with the drums on a photon; B, filtering water, to be more specific, covering the drums with filter screens, filtering the water in algae water by the aid of gravitational force and centrifugal force; C, retaining the alga in the algae water by the filter screens; D, flushing the alga from the filter screens by the aid of backwash water from filtered clear water; E, collecting the flushed alga by algae collecting tanks arranged in barrels and discharging the alga via an algae discharge pipe. A water inlet is formed in the lower side of a water inlet zone at the front end of a tank, a clear water outlet is formed in the rear end of the tank, inlet water and filter water are partitioned by a water partition plate, the filter water is pumped into a backwash pipe by backwash water pumps, backwash spray nozzles are arranged on the backwash pipe, and maintenance windows are mounted at two edges of the upper portion of the tank; frequency converters and air switches are mounted in an electric control box and are connected with a touch screen by electric wires. The method and the device have the advantages that good algae removal effects can be realized, and the method and the device are applicable to collecting and removing blue-green alga with different concentrations in lakes; the alga in water can be quickly and efficiently harvested by the aid of the method and the device on a large scale.

Owner:INST OF AQUATIC LIFE ACAD SINICA +1

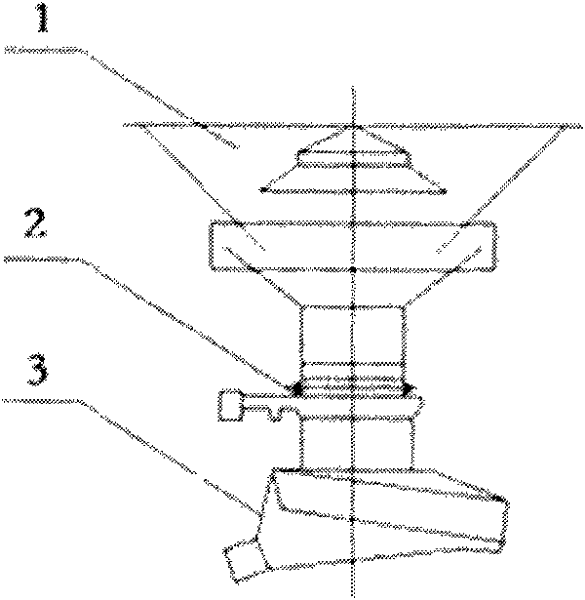

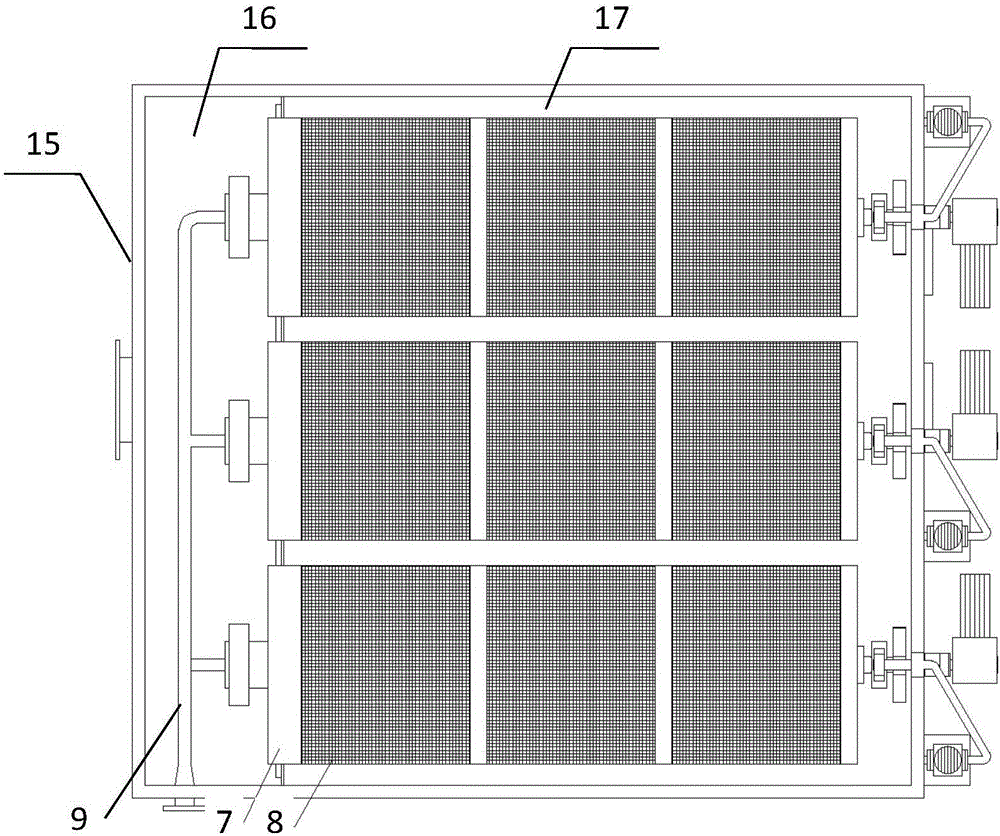

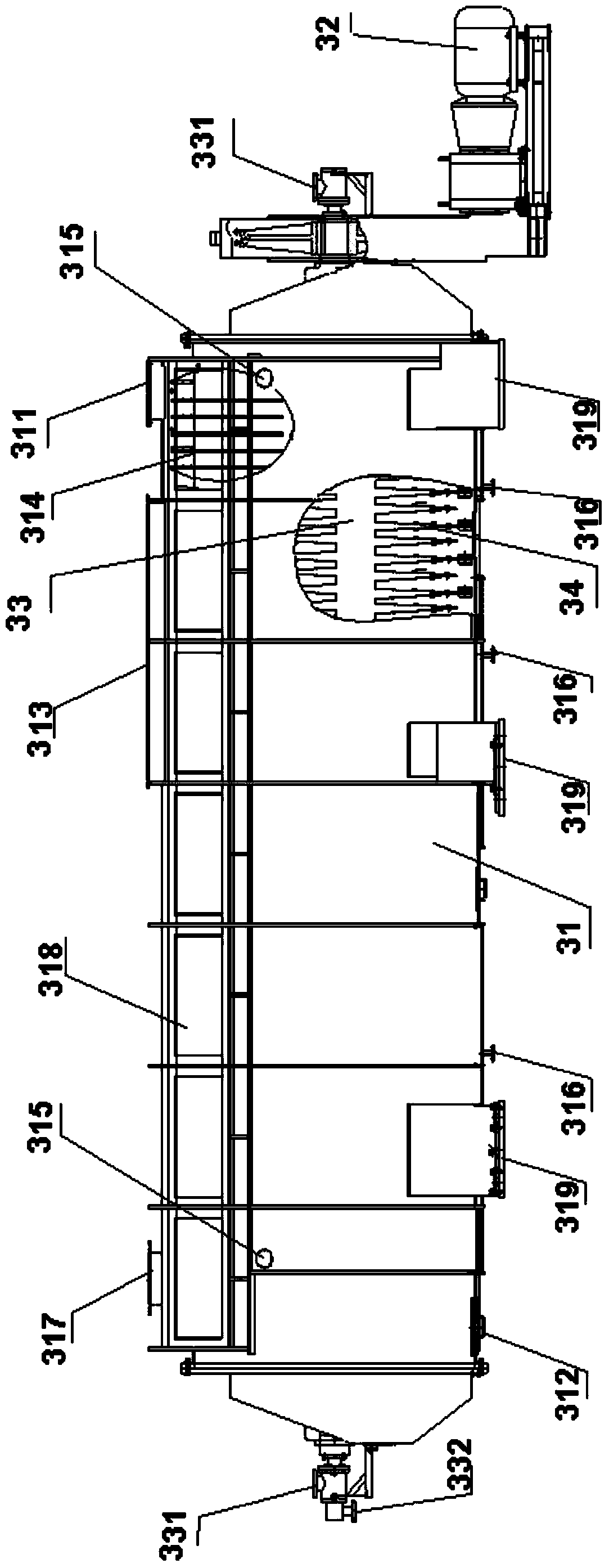

Fermentation tank

ActiveCN103667015AImprove discharge efficiencySave powerBioreactor/fermenter combinationsBiological substance pretreatmentsRadial motionAgricultural engineering

The invention discloses a fermentation tank which comprises an upper cover, a feeding device, a tank body, an air blasting device, an air extracting device, a stirring device and a discharging device, wherein the upper cover is arranged at the upper end of the tank body, a sealing device is arranged between the upper cover and the tank body, the feeding device is mounted on the upper cover, and the discharging device is arranged at the bottom of the tank body; the upper cover can rotate within a certain angle in a reciprocating manner and / or rotate for 360 degrees; the rotation of the upper cover drives the stirring device to rotate; and a slide track is mounted on the upper cover, and the stirring device can move in the radial direction of the slide track. According to the fermentation tank, rotation of the upper cover and the stirring device as well as the radial motion of the stirring device are driven with smaller power consumption, comprehensive stirring without dead angle of a fermented material in the fermentation tank is achieved under the condition of small power consumption; the discharging device is improved scientifically, with the combination of the improvement of the discharging device, the power consumption is reduced more comprehensively, and power required by discharging is reduced remarkably; and the fermentation tank is particularly suitable for vertical stirring of large-scale and supersized solid material fermentation tanks.

Owner:麦行

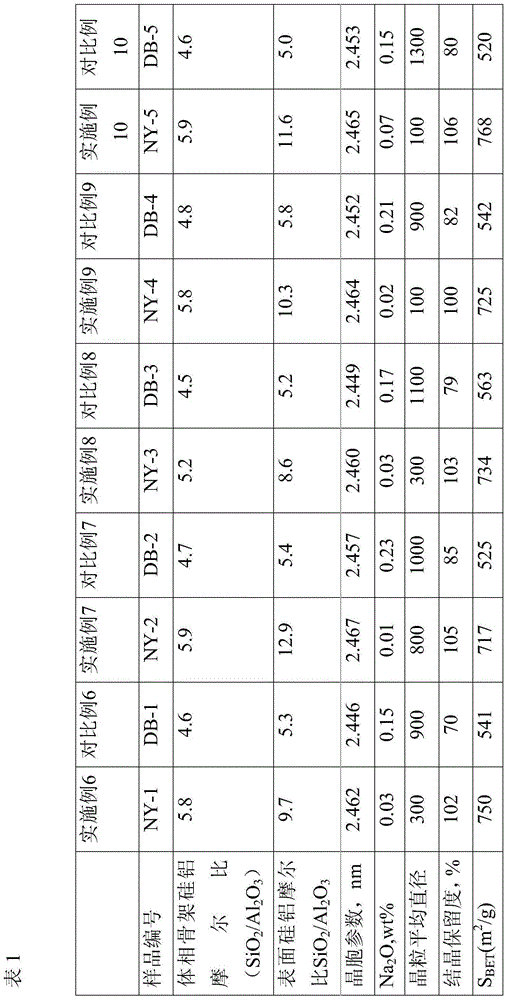

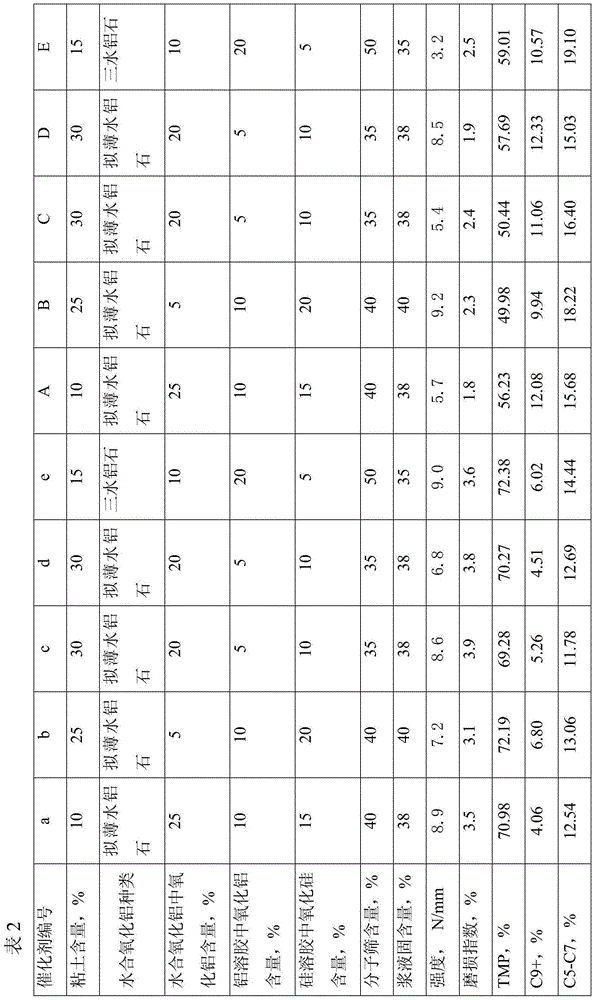

Catalyst containing Y-type molecular sieve and preparation method therefor

ActiveCN105080589AContinuous dischargeFlat surfaceMolecular sieve catalystsAlkyl transferMolecular sieve

The present invention provides a catalyst containing a Y-type molecular sieve. The catalyst comprises a small grain Y-type molecular sieve, aluminium oxide, oxide silicon and clay. The catalyst is characterized in that silicon is rich on the surface of the small grain Y-type molecular sieve, the molar ratio of a molecular sieve body phase skeleton SIO2 / AI2O3 is 5.0-6.0, the molar ratio of surface SiO2 / AI2O3 is 8.0-13.0, a unit cell parameter is 2.460-2.468 nm, the content of sodium oxide is less than or equal to 0.1% by weight, and the average diameter of a grain is 50-800 nm. The catalyst provided by the present invention shows better selectivity of trimethyl pentane in an alkylation reaction of isobutane / butene.

Owner:CHINA PETROLEUM & CHEM CORP +1

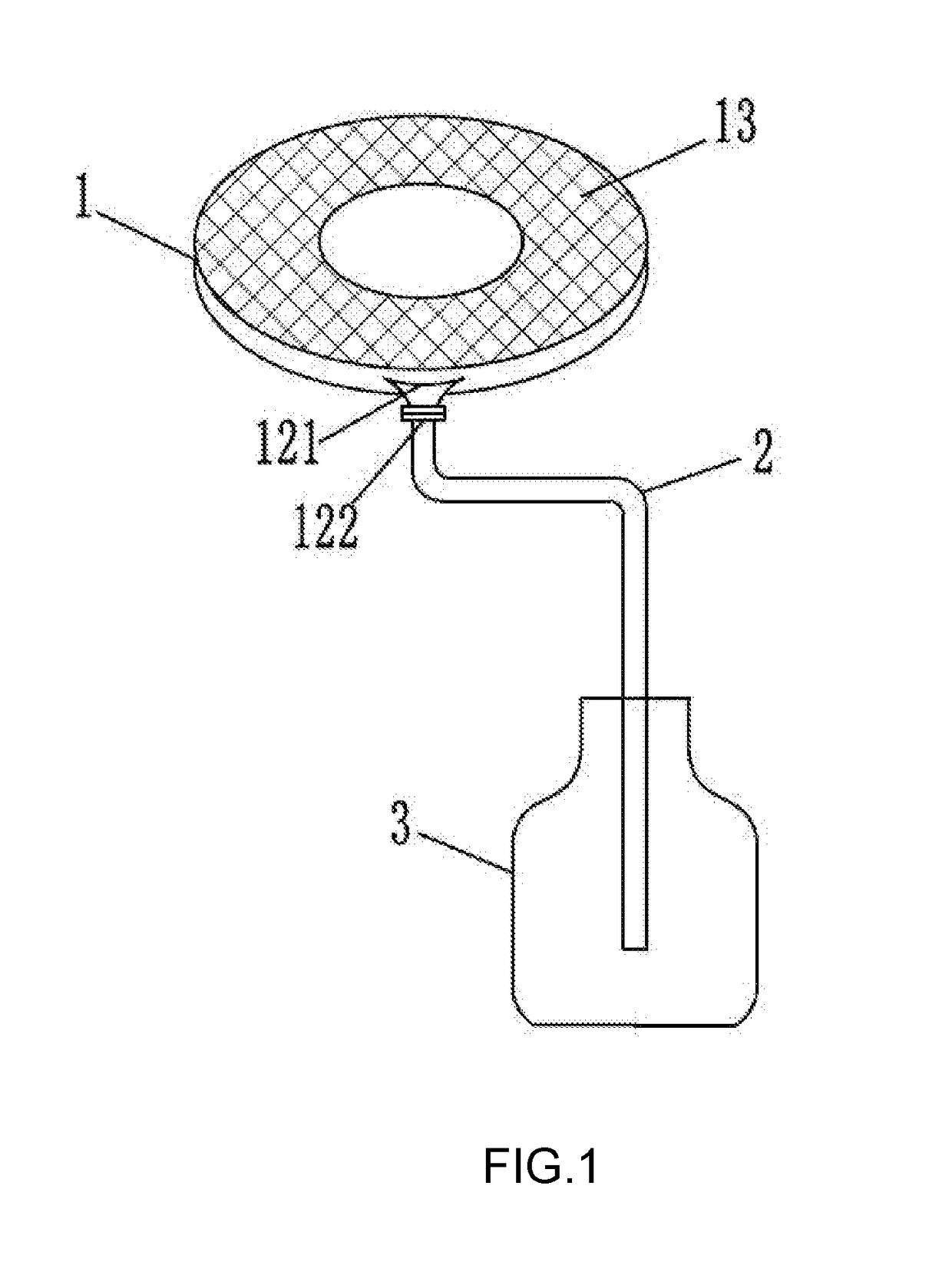

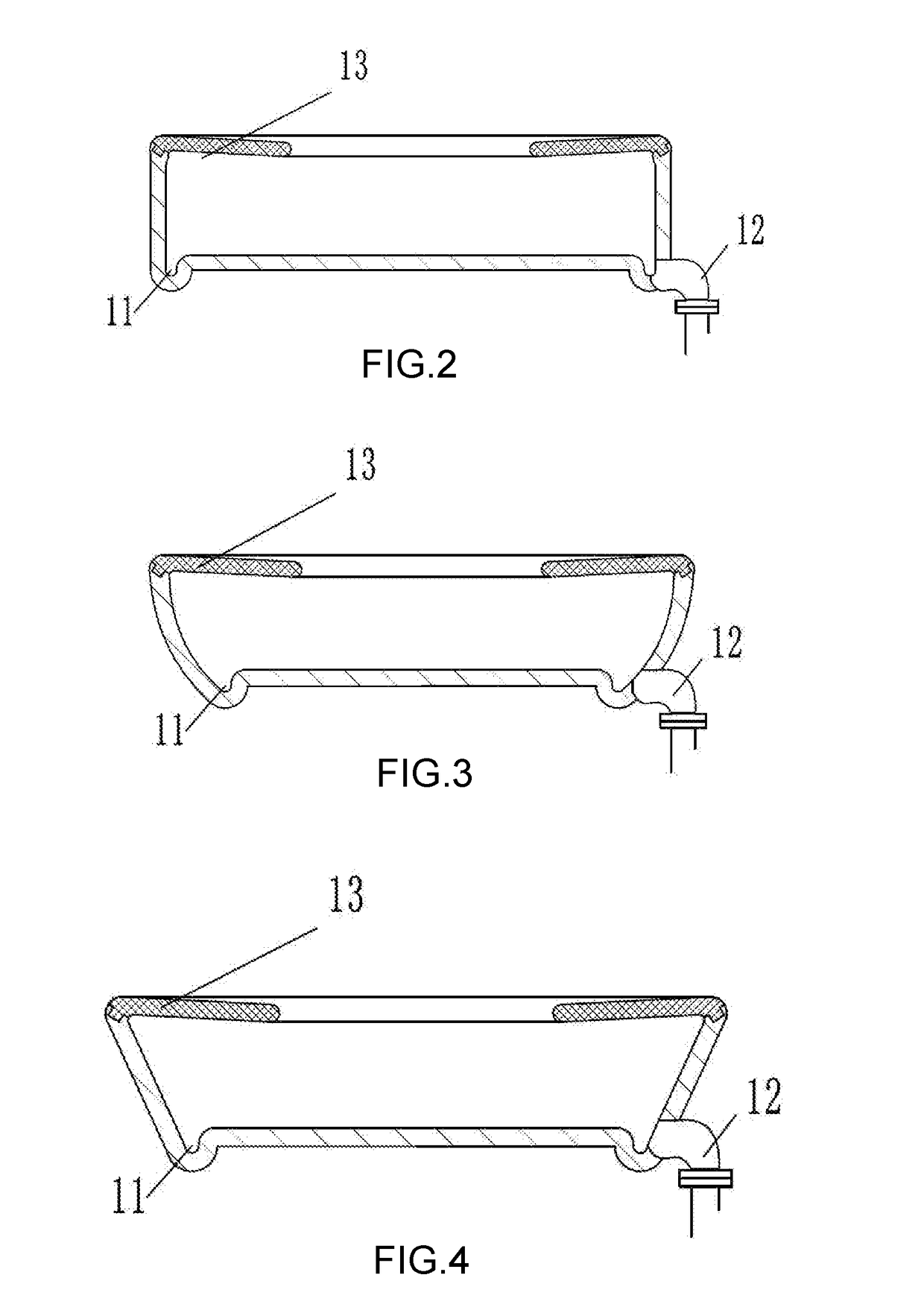

Urine Collector

A urine collector for collecting urine for a user includes a basin which includes a collector including a bottom wall and a surrounding wall upwardly extended therefrom to define a cavity and a top opening, and a top cover supported on the top opening of the collector; and a urine guider provided at the bottom wall of the collector for collecting urine at a peripheral portion thereof for collecting the urine at the urine guider within the cavity of the collector, wherein the bottom wall of the collector further includes an enlarge bottom base defining a circular guiding slot, and an inner concave guiding bottom extended inward and upward from the enlarge bottom base, so that the enlarge bottom base enhances a stabilization of the collector, wherein the urine guider is provided at the inner concave guiding bottom.

Owner:SU SOPHIA HAI YUN

Device and method for preparation of liquid smoke and co-production of activated carbon by pyrolysis of Chinese hawthorn seeds

PendingCN107032351AExpand the scope of useBroaden the fieldCarbon compoundsFood thermal treatmentLiquid smokeWater vapor

The invention discloses a device and a method for preparation of liquid smoke and co-production of activated carbon by pyrolysis of Chinese hawthorn seeds. The device comprises a feed hopper, a drying chamber, a pyrolyzing furnace, an activating furnace, a gas condensation system, a gas cabinet, a combustor, an activated carbon cooling discharge system and a tail gas treatment device. According to the device, co-production of activated carbon can be realized while the liquid smoke is prepared, comprehensive utilization of the resources is realized, the phenomenon that attention is only paid to production of single product while the economic value of byproducts is neglected is avoided, pollution to the environment is avoided while energy is saved, heat required for the processes of drying, pyrolysis, carbonization, activation and the like of the Chinese hawthorn seeds is supplied by combustible gas of non-condensable gas, activating reaction gas and the like obtained by pyrolysis of the Chinese hawthorn seeds, self-sufficiency of the heat can be realized; according to the system, heat exchange is realized by low temperature air used for combustion of the combustor, vapor required for activation and high temperature activated carbon, each takes what it needs, at the same time, high temperature flue gas is exhausted after passing by the high temperature section and the low temperature section sequentially, gradient utilization of different layers of energy is realized, and the energy utilization efficiency is high.

Owner:SHANDONG UNIV +1

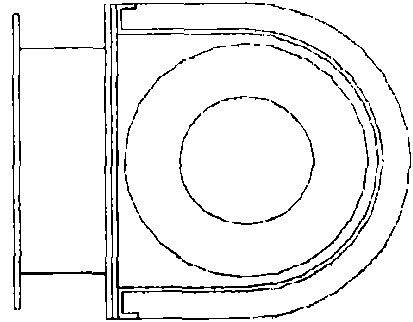

Tube pump

InactiveUS7854600B2Suppress pulsationContinuous dischargeFlexible member pumpsPositive-displacement liquid enginesReciprocating motionEngineering

Owner:NOIBERUKU

Method for producing glucose bulk drug for injection by using rice

ActiveCN102703547AHigh biological potencyImprove saccharification puritySugar derivativesFermentationIon exchangeChemistry

The invention provides a method for producing a glucose bulk drug for injection by using rice. The method comprises the following steps of: soaking and defibrination, size mixing, liquefaction and slag removal, saccharification, primary decoloration and filtration, secondary decoloration and filtration, ion exchange, concentration and refining, primary crystallization, primary centrifugation, sugar solution, sugar concentration and decoloration, secondary sugar boiling and crystallization, secondary centrifugation, drying, packaging and the like. The method has the following advantages: (1), a two-time crystallization process is adopted, the quality is high, and a filtration speed is quick; (2), the problem that a raw material for producing an injection glucose in the south does not existis solved by using the rice as the raw material, and the blank of the production of a crystalline glucose in the south is filled; (3), the crystalline glucose produced by using the rice as the raw material has low-irritability in absorption property and is high in biological value; and (4), a breeding fermentation problem in a production procedure is solved successfully, the sugar concentration and the filtration are added, the quality of a finished product is greatly improved, and the clarity and the filtration speed of the product are guaranteed. The continuous feed and the continuous discharge can be carried out; the crystallization and fermentation contamination is stopped; the quality can be guaranteed; and the continuous production is guaranteed.

Owner:北京佳沃臻诚科技有限公司

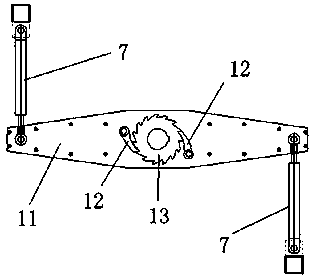

Microwave-assisted dynamic continuous calcining device and method for lithium-ion battery material

PendingCN108759459AExcellent consistency of propertiesImprove production efficiencyRotary drum furnacesCharge treatment typeMicrowave powerLithium-ion battery

The invention relates to microwave-assisted dynamic continuous calcining device and method for a lithium-ion battery material. The device comprises a rotary kiln body, a transmission device and a power device, wherein the power device is connected with the rotary kiln body through the transmission device; the rotary kiln body comprises a rotary kiln tube body; independent microwave emitters are continuously arranged on a rotary kiln body shell; waveguide tubes are connected onto the microwave emitters and are connected with the rotary kiln tube body; the temperatures of different temperature areas of the rotary kiln body are controlled through adjusting microwave powers of the microwave emitters; a discharging device is arranged on a kiln head of the rotary kiln body; a feeder is arrangedon a kiln tail of the rotary kiln body; an air supply gun is arranged on the kiln head of the rotary kiln body and communicates with the rotary kiln tube body; an air discharge flue is arranged on thekiln tail of the rotary kiln body; and a sintering atmosphere in the rotary kiln body is controlled through the air supply gun on the kiln head. The microwave-assisted dynamic continuous calcining device and the method for the lithium-ion battery material provided by the invention have high heat utilization ratio, and is particularly good for preparing a nanometer material; continuous feeding anddischarging can be realized, so that the preparation efficiency of the lithium-ion battery material is greatly improved; and the generated greenhouse gas is less so as to have low effect on the environment.

Owner:CENT SOUTH UNIV

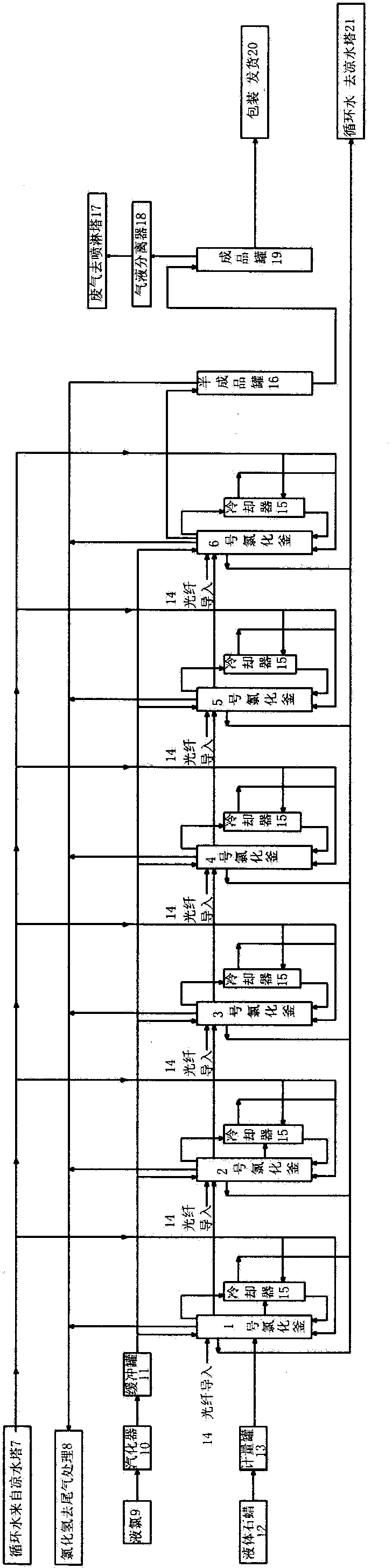

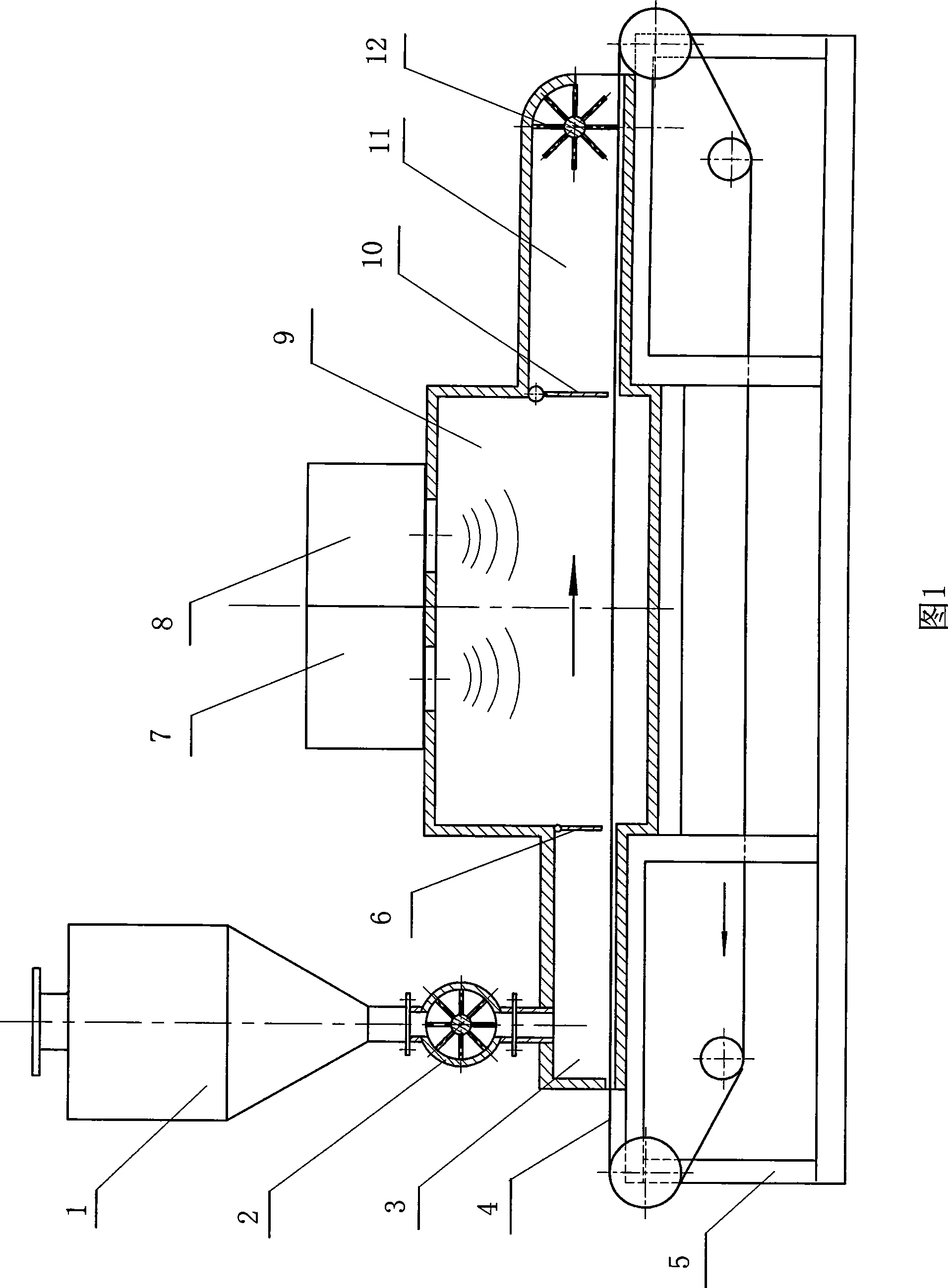

Automatic production technology of chlorinated paraffin

InactiveCN103849433ALower conversion rateImprove conversion ratePetroleum chemical modificationAutomatic controlUltraviolet lights

The invention relates to an automatic production technology of chlorinated paraffin. A continuous kettle type chlorinating technology production control process combining a thermal chlorination process with a photo-chlorination process is adopted, the automatic production technology of the chlorinated paraffin is that the traditional intermittent production process is changed into a continuous production process, forced circulation is changed into natural circulation, and the photo-chlorination process is that an optical fibre technology is adopted for introducing ultraviolet light for replacing an incandescent tube and a distributed automatic control production system is used for replacing manual operation. According to the technical scheme, the automatic production technology of the chlorinated paraffin has the advantages of high chlorine conversion rate, continuous production, safety, low energy consumption and automatic operation.

Owner:LUOYANG OUKEMAI AUTOMATIC CONTROL ENG

Microwave continuous graphite expansion apparatus

A microwave continuous graphite puffing device comprises a hopper; the lower part of the hopper is connected with a rotary feeder which is provided with a drive shaft and a rotary drum; a rotary vane is fixed on the rotary drum; the lower end of the rotary feeder is connected with a microwave feeding absorption chamber, the right end of which is connected with a microwave heating puffing chamber; a left microwave generator and a right microwave generator are arranged on the upper part of the microwave heating puffing chamber, the right end of which is connected with a microwave discharging absorption chamber; and the right end of the microwave discharging absorption chamber is provided with a rotary discharger. The conveyor belt of a belt conveyor respectively passes through the microwave feeding absorption chamber, the microwave heating puffing chamber, and the microwave discharging absorption chamber. The left end of the microwave heating puffing chamber is rotatablely connected with a feeding absorption chamber microwave baffle-board and the right end thereof is rotatablely connected with a discharging absorption chamber microwave baffle-board. The invention has the advantages of easy control, reliable operation, large material treatment quantity, can effectively prevent microwave leakage, and can realize continuous feeding and discharging as well as continuous microwave heating puffing graphite.

Owner:任崇桂

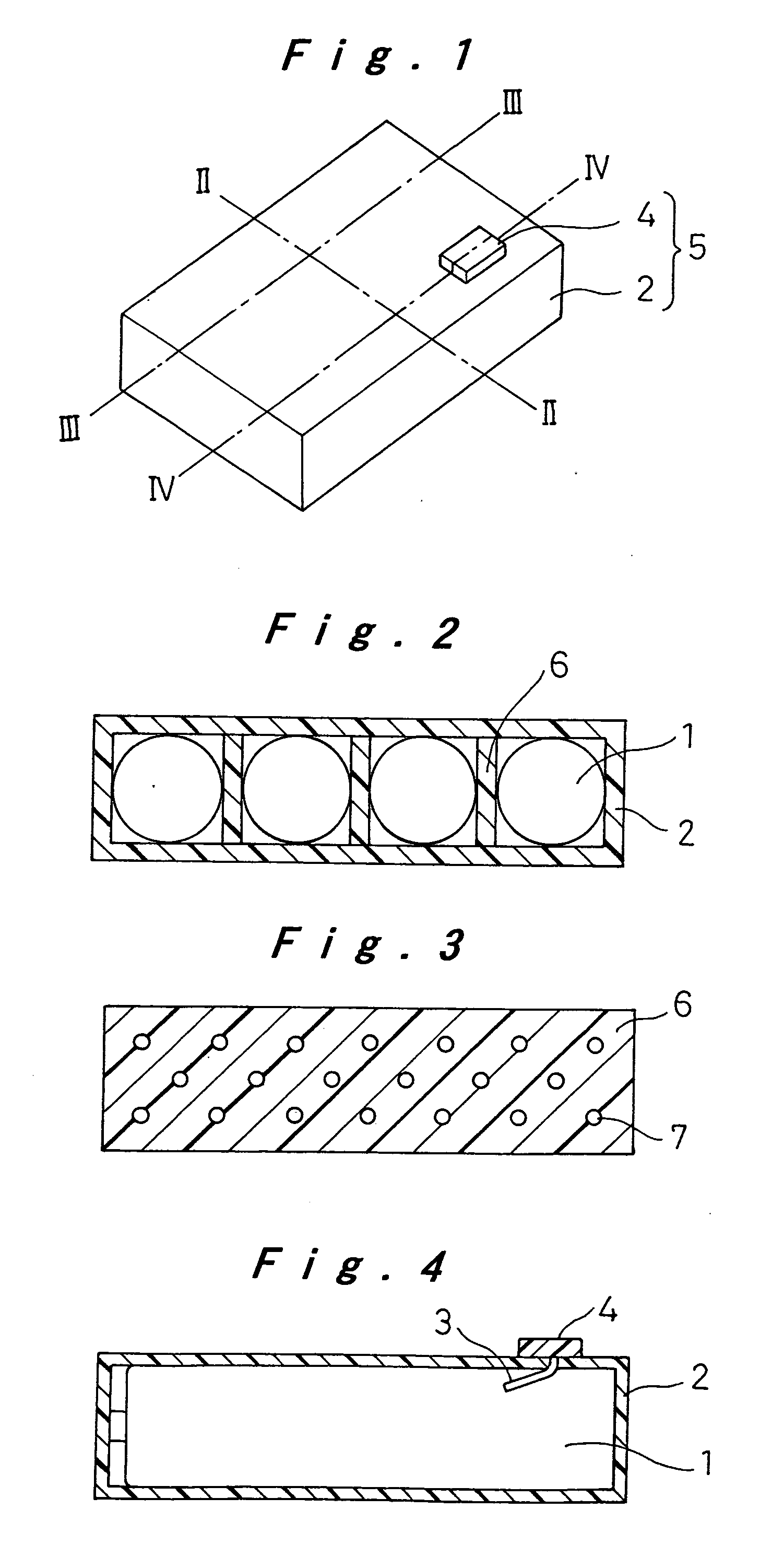

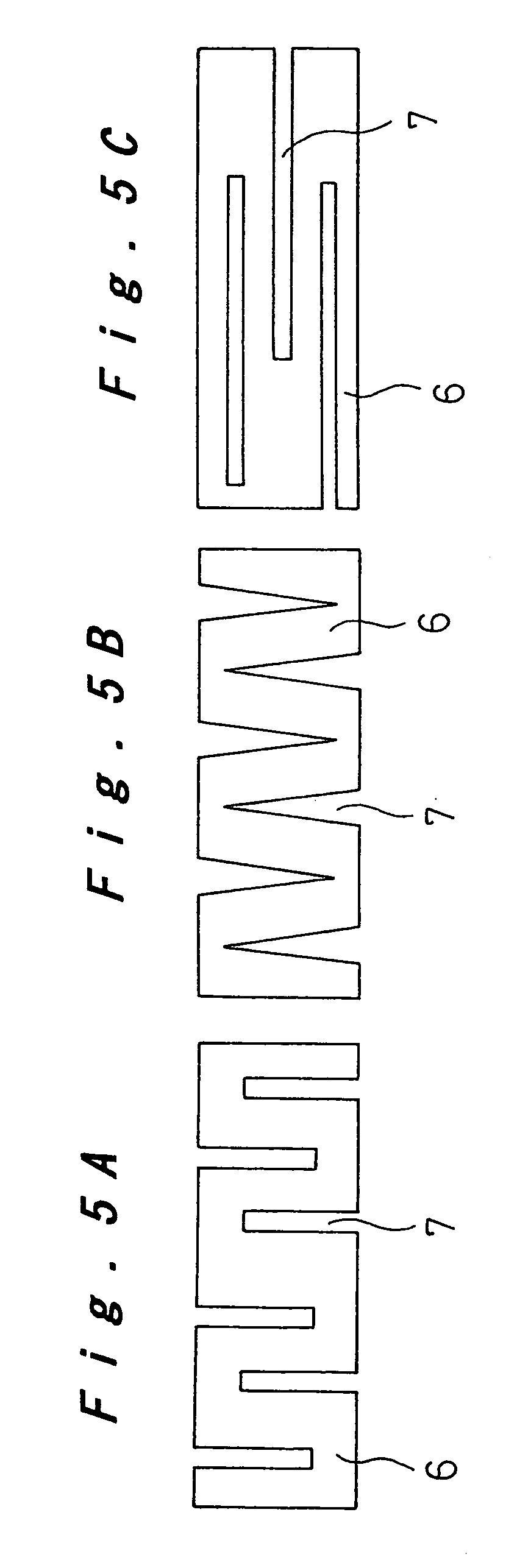

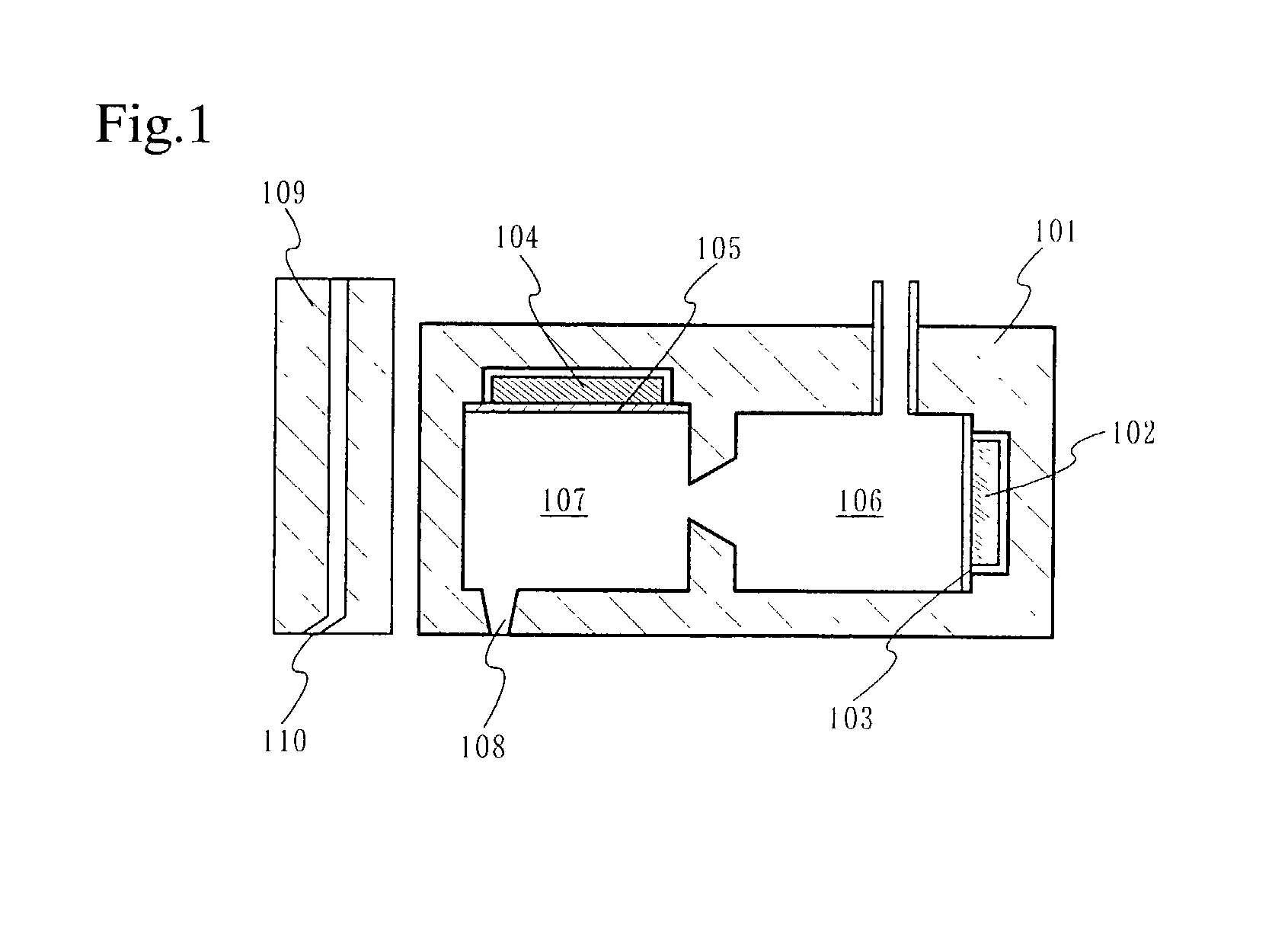

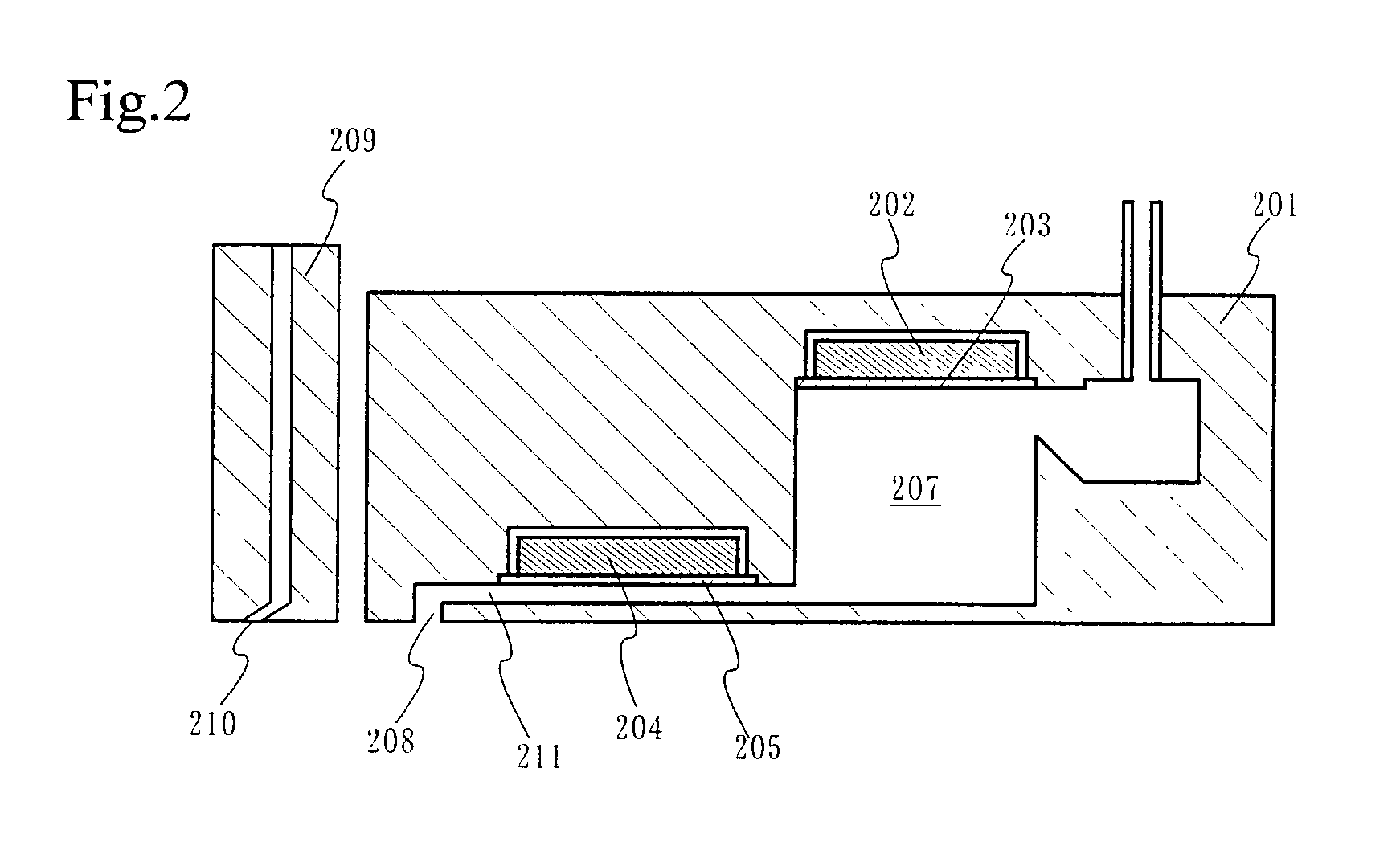

Printing device and method of manufacturing a light emitting device

InactiveUS7063869B2Simple and easy mannerIncrease speedInking apparatusElectroluminescent light sourcesEngineeringLight emitting device

A first pressure generating chamber, which is sealed by a first elastic plate mounted with a first piezoelectric element at one surface, and a second pressure generating chamber, which is sealed by a second elastic plate mounted with a second piezoelectric element at one surface are formed in a casing. The second pressure generating chamber is formed with an opening which is a discharge port. A mixture is discharged from the discharge port. A nozzle formed with an opening jets gas toward a substrate surface, and is provided in the vicinity of the discharge port of the ink head.

Owner:SEMICON ENERGY LAB CO LTD

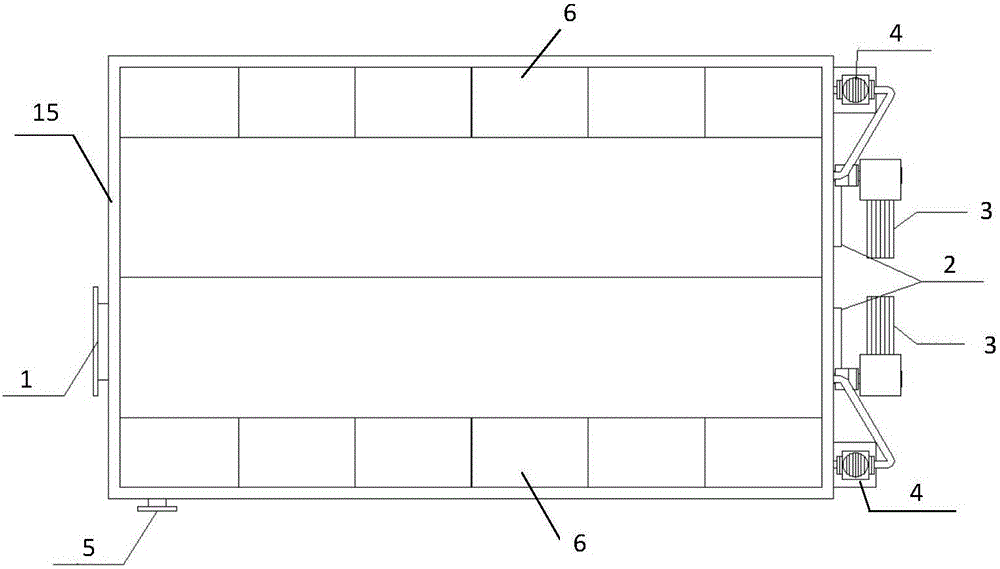

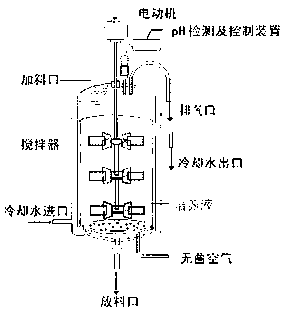

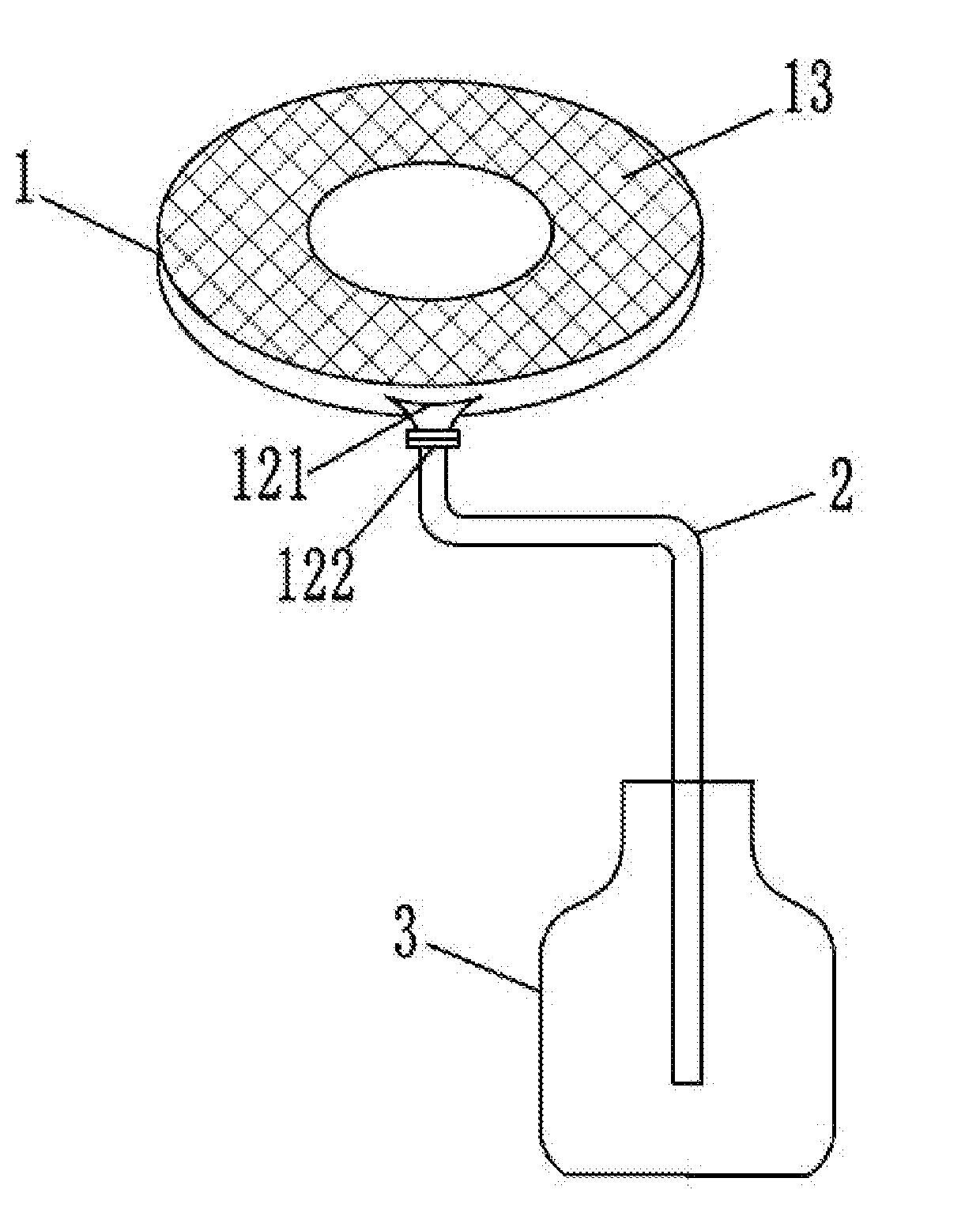

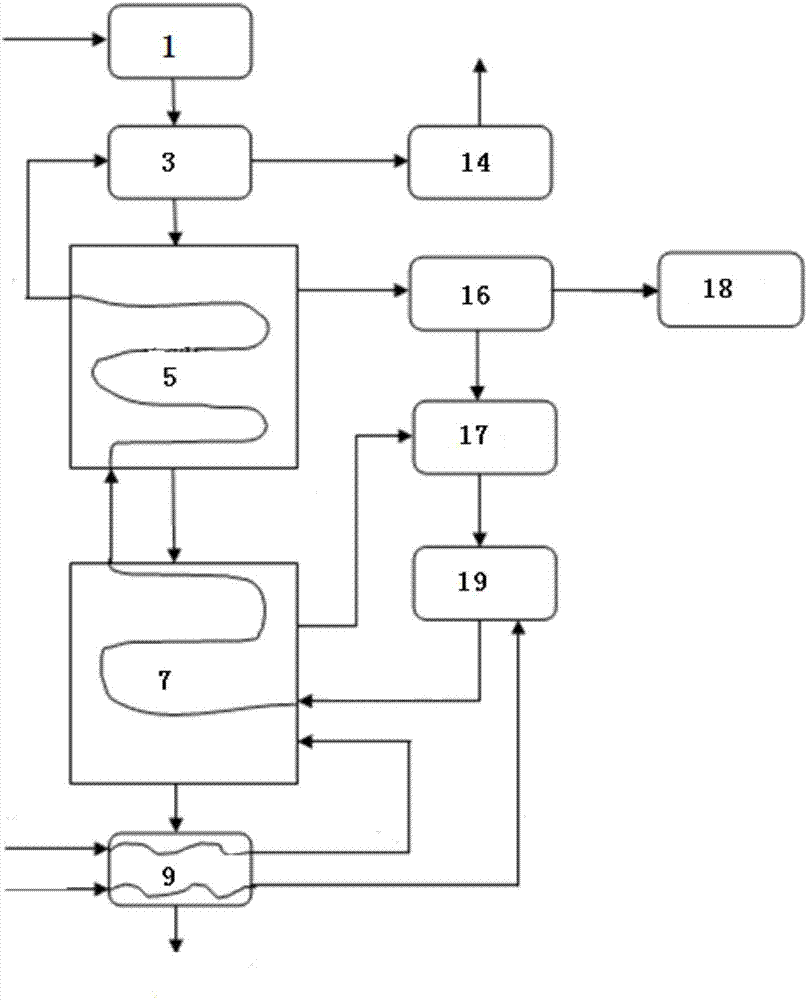

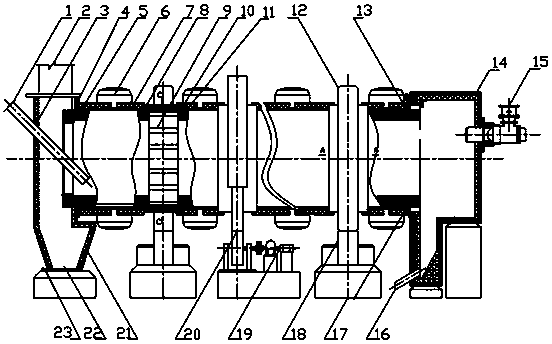

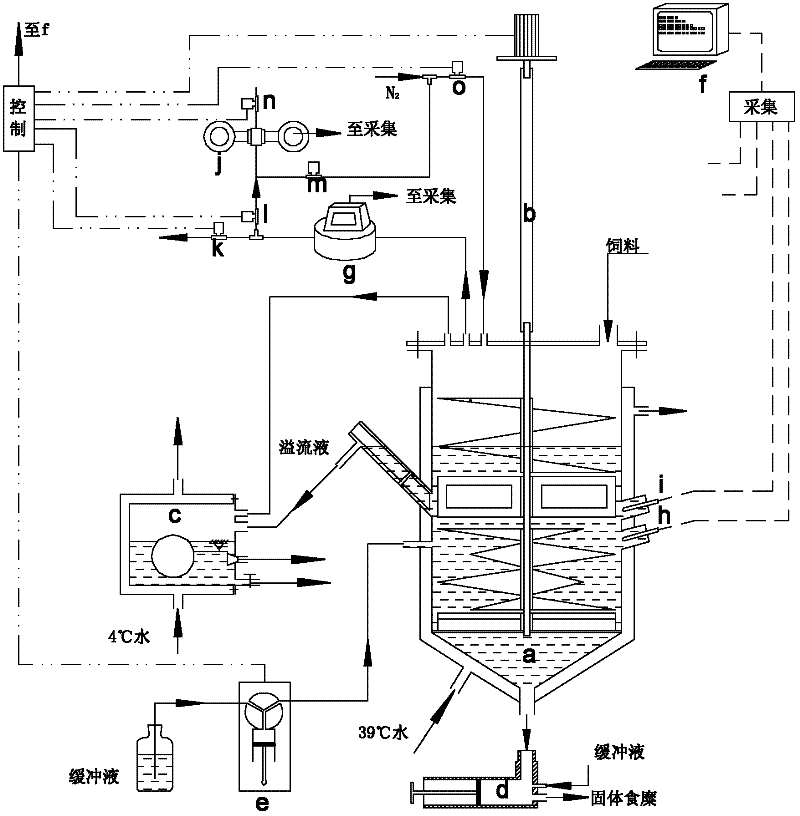

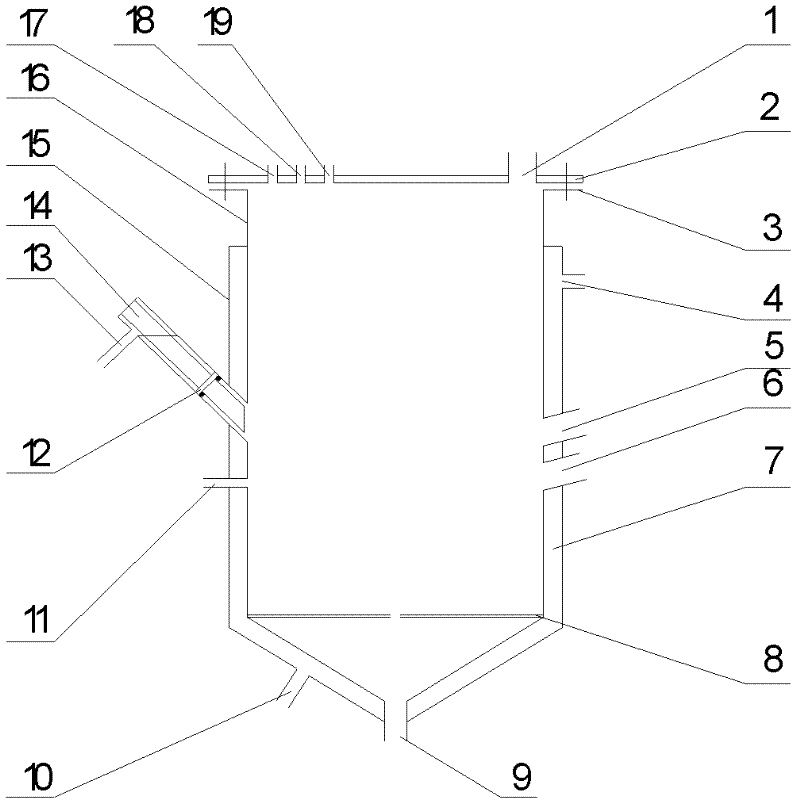

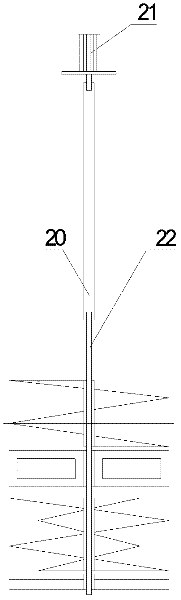

A solid-liquid-gas three-phase split rumen simulation continuous fermentation system and method

ActiveCN102286359ACan not be collectedSolve the disadvantages of metering the gas produced in the fermentation processBioreactor/fermenter combinationsBiological substance pretreatmentsGas phaseEngineering

The invention provides a solid-liquid-gas three phase flow-dividing rumen imitation continuous fermentation system, which is characterized by comprising a fermentation tank body (a), a stirring device (b), a liquid discharging valve (c), a solid discharging device (d), an injection pump (e), a computer (f) and a CH4 and CO2 detector (j). By using the fermentation system, the solid-phase, liquid-phase and gas-phase products produced by fermentation in the fermentation tank can be separated with high efficiency and delivered to the solid discharging device, the liquid discharging valve and the CH4 and CO2 detector respectively. The products in three phases discharged from reaction can be measured accurately by corresponding measuring means, so that deep study on fermentation reaction effectof different kinds of feed can be facilitated. Meanwhile, as an injection pump for supplying buffer solution into the fermentation tank constantly is designed, the drawback that a static fermentationdevice cannot realize continuous fermentation is overcome. In addition, the whole control process of the system can be implemented by high-automation control of a computer.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

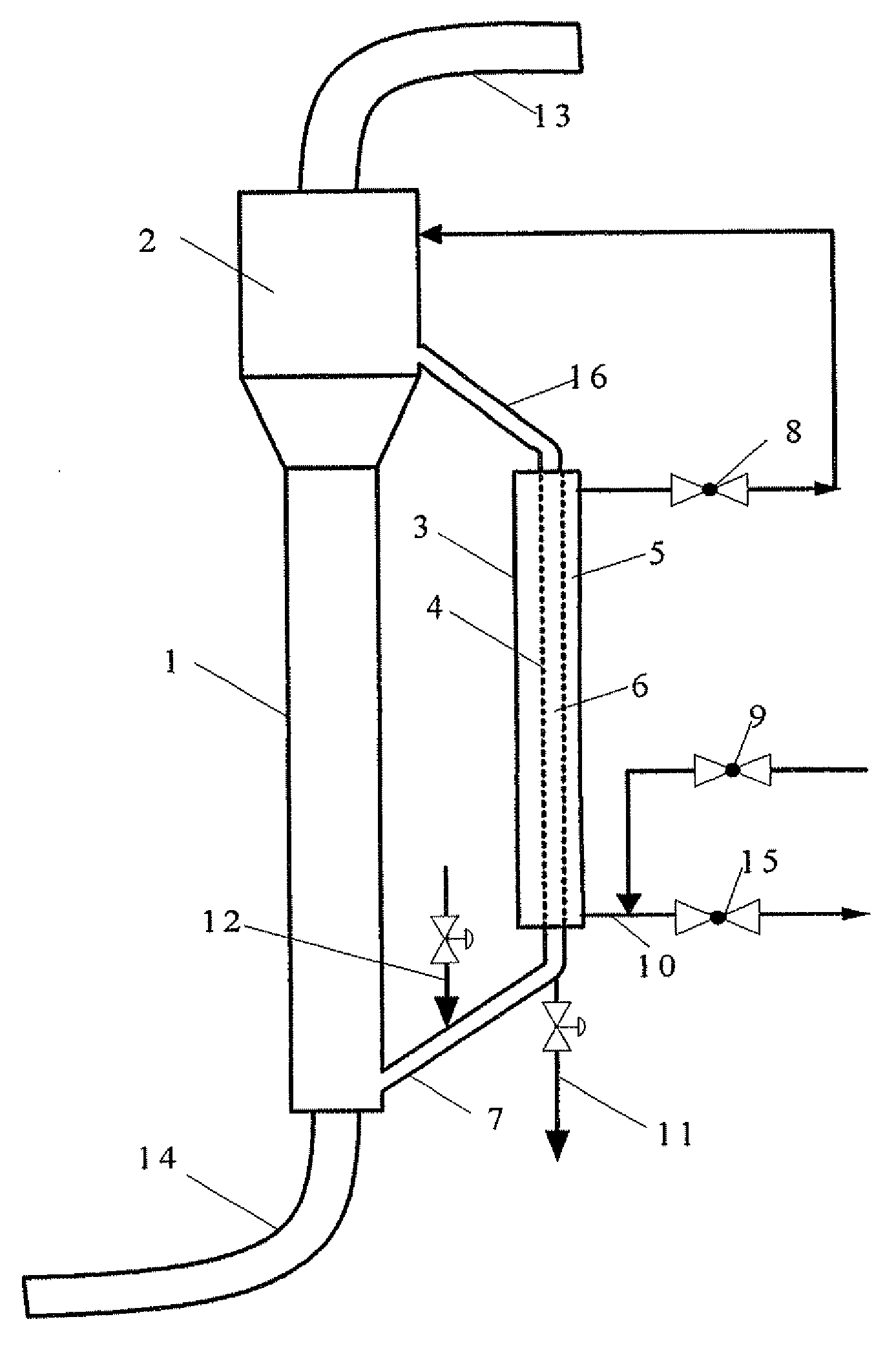

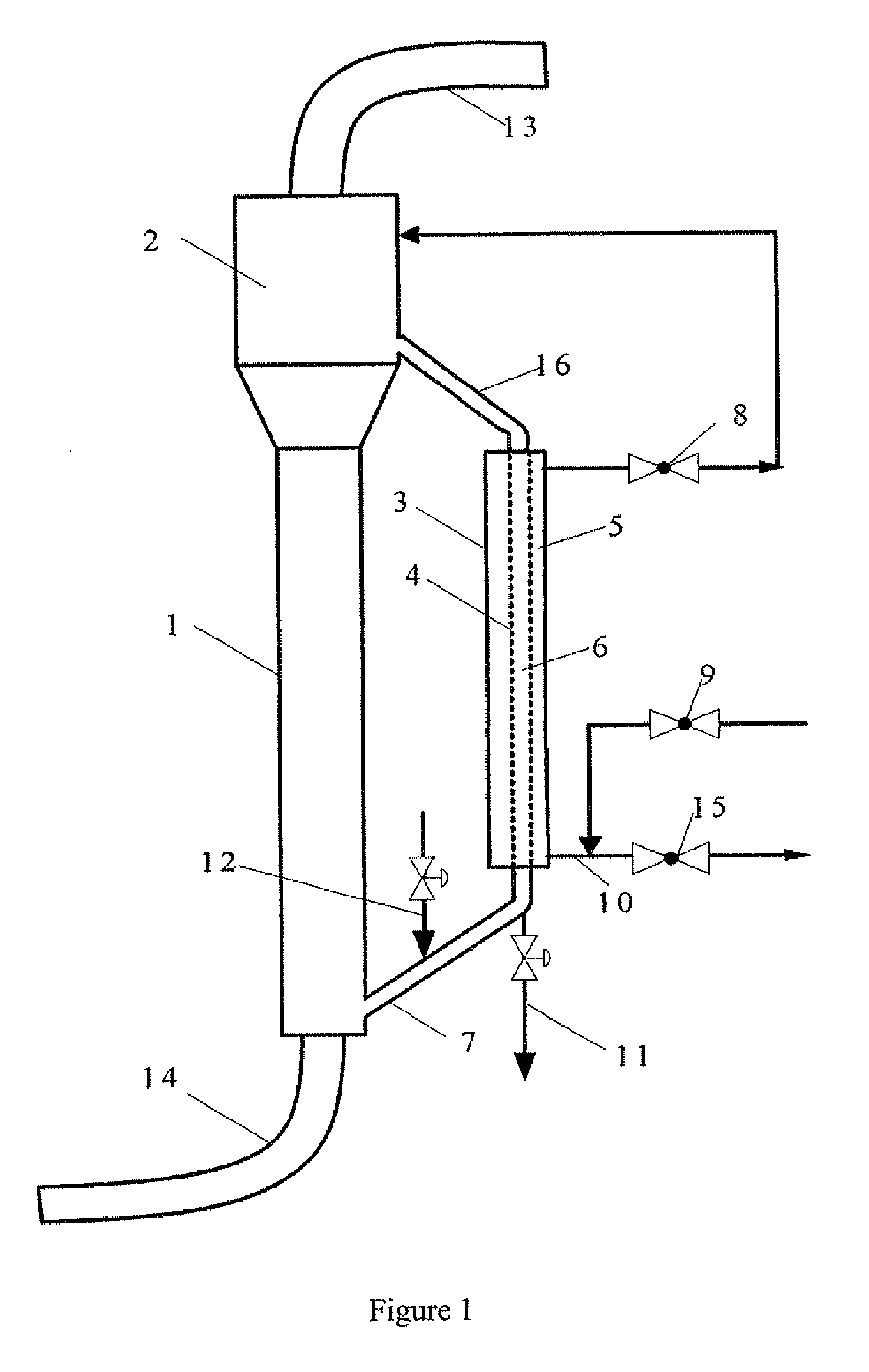

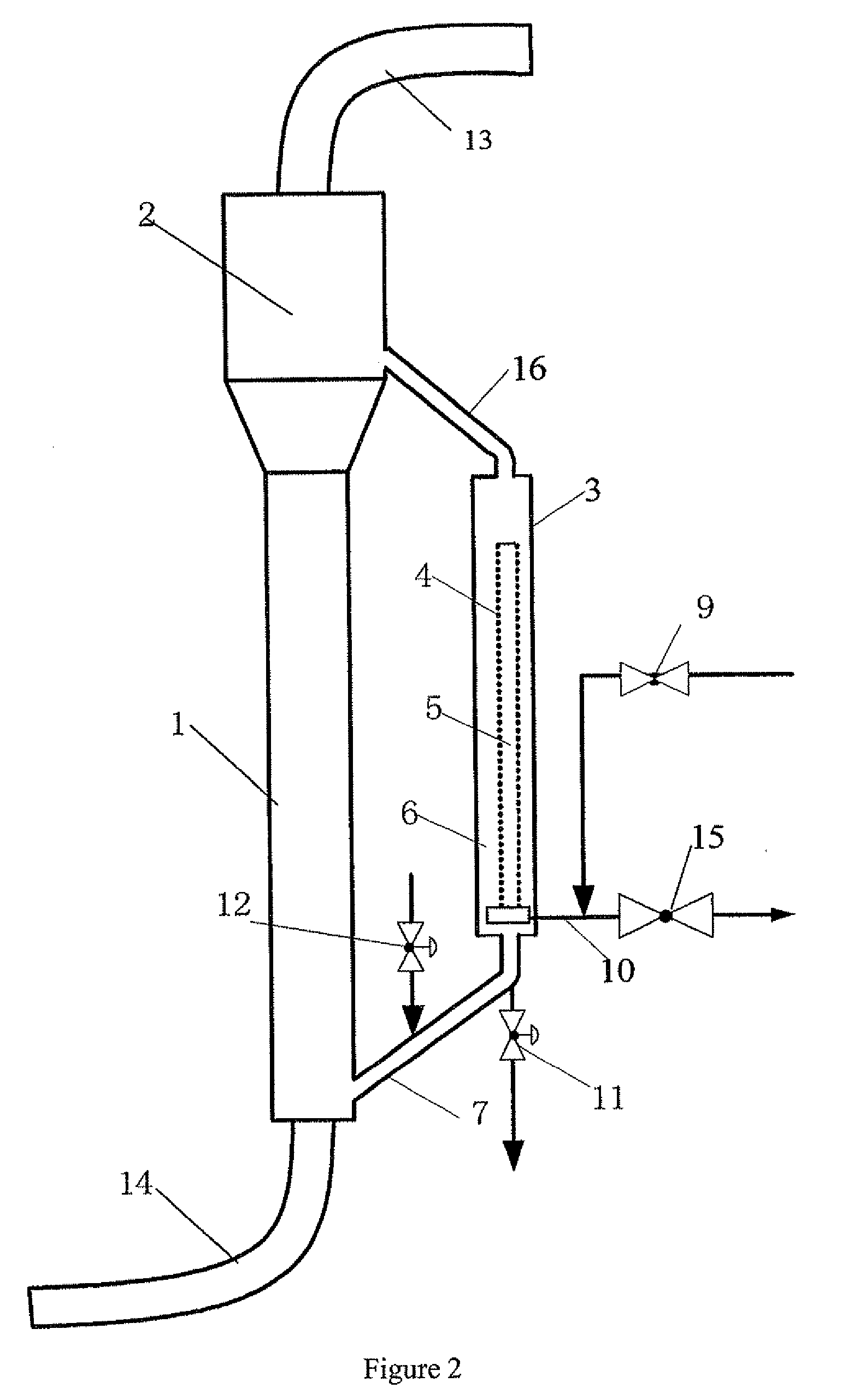

Slurry bed loop reactor and use thereof

ActiveUS20090197979A1High efficiencyFlexibly operateOrganic compound preparationOxygen compounds preparation by reductionSettlingThree-phase

The present invention relates to a slurry bed loop reactor comprising a riser and at least one downcomer (3), wherein two ends of the riser are connected to two ends of the downcomer (3) via lines (16) and (7), respectively. The riser comprises a reaction section (1) and a settling section (2) with an increased tube diameter disposed on the reaction section (1). A gas outlet (13) exists at the top of the settling section (2). Each of the downcomers (3) is divided into a filtrate section (5) and a slurry section (6) by filter medium (4), wherein the filtrate section (5) is connected to a liquid outlet (10); two ends of the slurry section (6) are respectively connected to two ends of the riser, and the filtrate region (5) may further be connected to a back purging system. When used in a gas-liquid-solid three phases reaction system, the reactor can realize successive separation of gas, liquid and solid particles in slurry, and realize the back purging regeneration of filter tubes without influencing the reaction processes. In addition, said reactor has the advantages of high separation efficiency, simple structure, flexible and easy operation

Owner:CHINA PETROCHEMICAL CORP +1

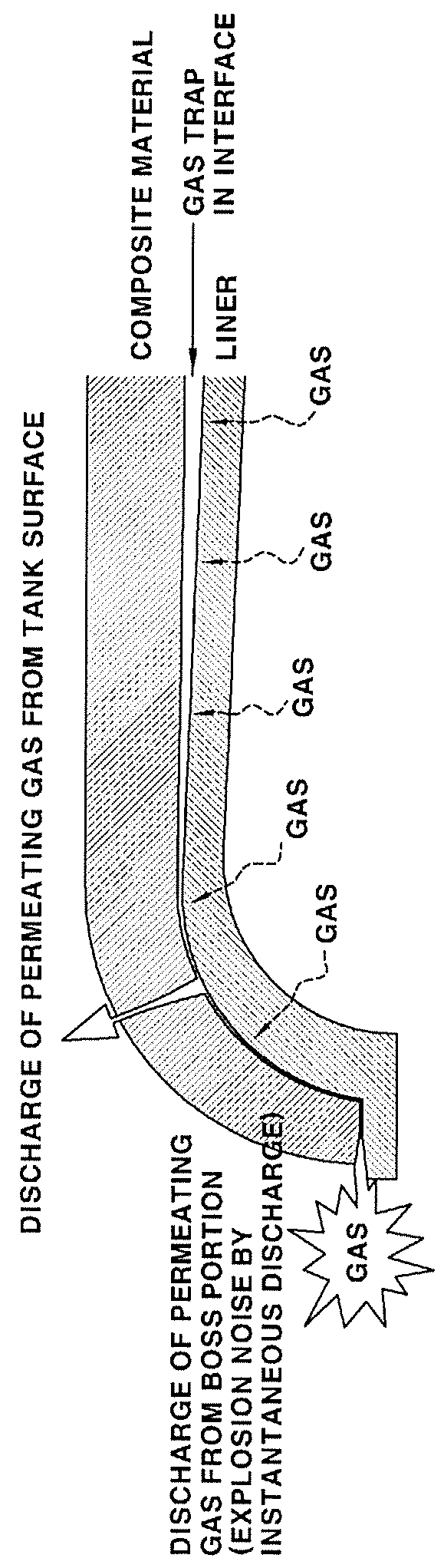

High-pressure tank having structure for radiation of heat and discharge of remaining gas and method of manufacturing the same

InactiveUS20180274725A1Continuous dischargeAvoid overdoseReactant parameters controlFinal product manufactureHigh pressureElectrical and Electronics engineering

A high-pressure includes a liner; a composite material surrounding an outer circumferential surface of the liner; a heat-transfer sheet formed on the outer circumferential surface of the liner; and a spacer disposed between the heat-transfer sheet and the composite material. The heat-transfer sheet and the spacer have a gap therebetween.

Owner:HYUNDAI MOTOR CO LTD +2

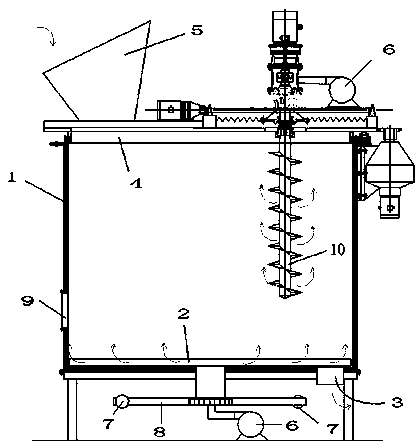

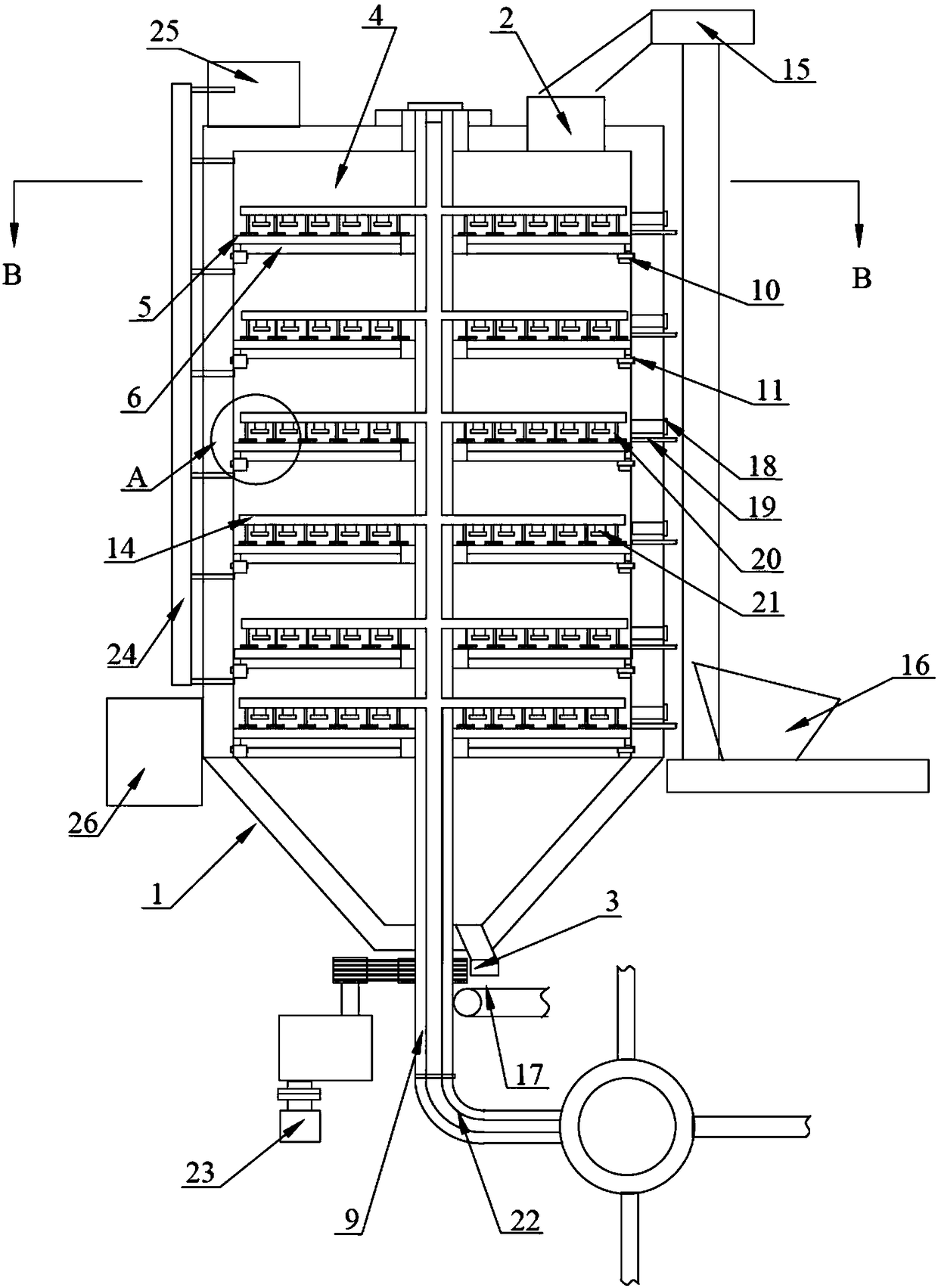

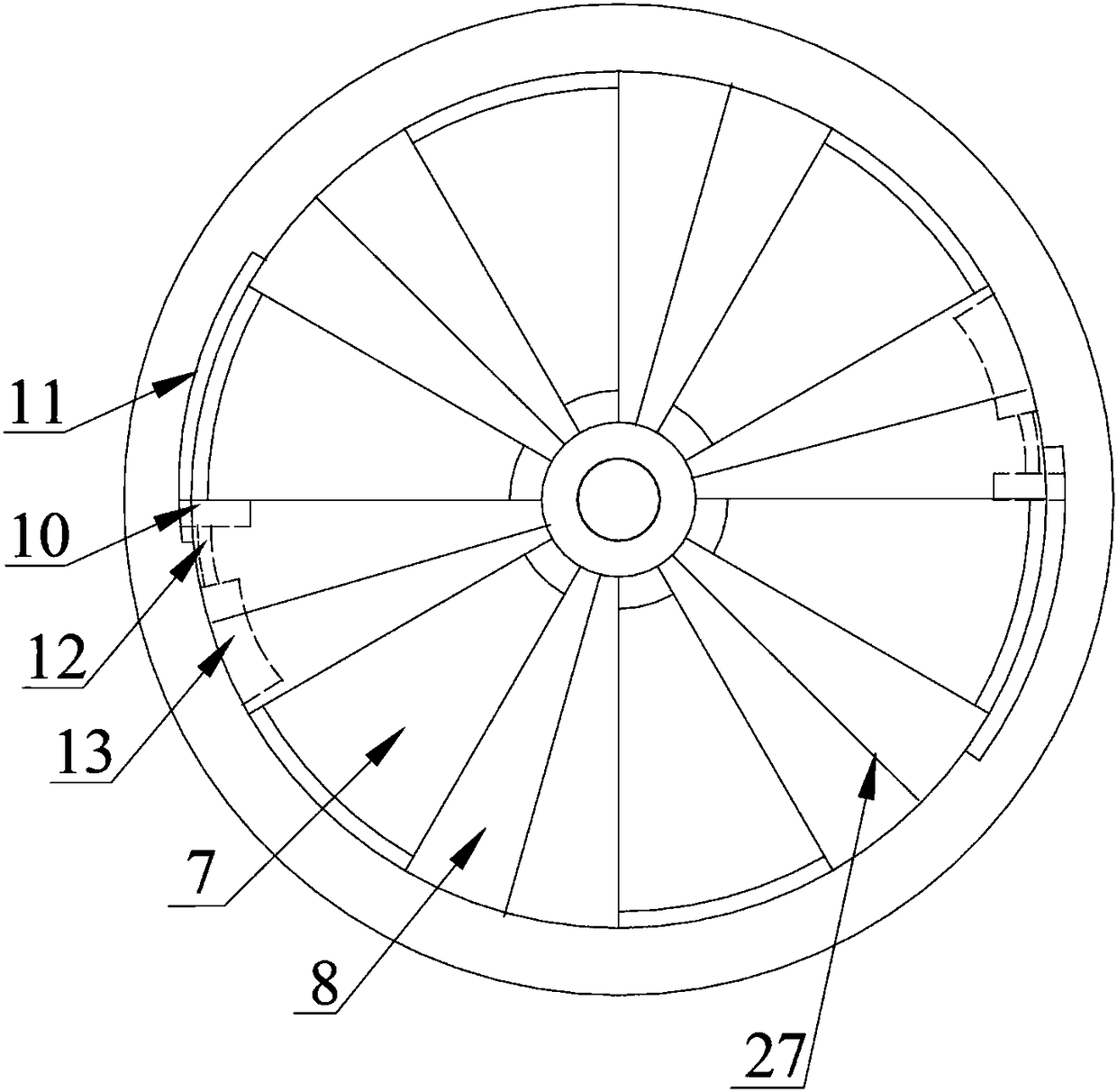

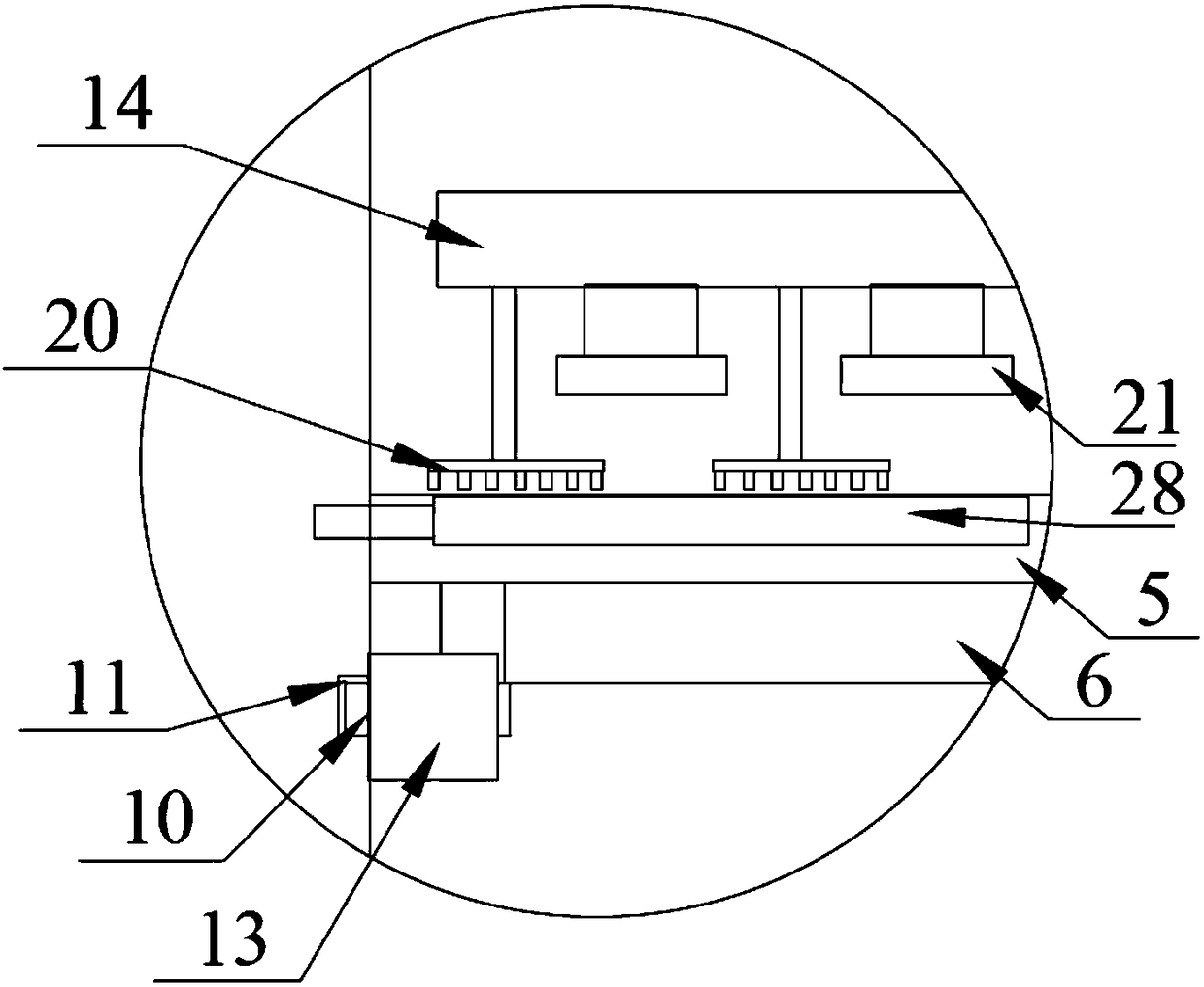

Automatic environmentally friendly livestock and poultry manure high temperature aerobic fermentation facility

ActiveCN108164289ASimple structureEasy to useClimate change adaptationExcrement fertilisersAgricultural engineeringPoultry manure

The invention discloses an automatic environmentally friendly livestock and poultry manure high temperature aerobic fermentation facility. The facility comprises a fermentation tank arranged on a base. The top of the fermentation tank is provided with a feed inlet. The bottom of the fermentation tank is provided with a discharge outlet. The interior of the fermentation tank is divided into a plurality of fermentation chambers from top to bottom. Between the uppermost fermentation chamber and the lowermost fermentation chamber, multiple fixed partition plates and rotary partition plates are arranged. The fixed partition plates are fixedly connected to the inner wall of the fermentation tank. The fixed partition plates and the rotary partition plates are provided with a plurality of hollowed-out grooves. The surface, which is between neighbored hollowed-out grooves, of a fixed partition plate is in an inverted V shape structure and projects upwards. A vibration rod is arranged under thesurface. A hollow rotation shaft is arranged on the center of the fermentation tank. The hollow rotation shaft goes through the fixed partition plates and the rotary partition plates. The edges of rotary partition plates are connected to slide blocks. One side of each slide block is slidingly matched with a chute arranged in the inner wall of the fermentation tank. One end of each slide block is connected to one end of an arc piston rod. The other end of the arc piston rod is connected to a piston in an arc driving cylinder.

Owner:江苏仁康蛋业有限公司

Wet sludge treatment method and equipment thereof

InactiveCN103524013AReduce speedRealize integrationSludge treatment by de-watering/drying/thickeningDeodrantsLand resourcesMunicipal sewage

The invention relates to a wet sludge treatment method and equipment thereof. Wet sludge is conveyed into sludge drying and forming equipment to be dried and formed through a wet sludge conveying pump from a wet sludge cabin; generated tail gas is sucked out through a draught fan, is fed into a dust collector for dust removal, and subsequently is fed into a condenser for condensation; uncondensed gas is fed into a deodorization device for smell gas removal, and is discharged until the gas meets the discharge standard. The wet sludge treatment method has the advantages that the heat conduction efficiency is high, the energy consumption is small, the process is simple, the reliability is high, a land is saved, the operation cost is low, and the like; municipal sewage and sludge can be treated in scale; a land resource is saved; the great significance in energy conservation is achieved.

Owner:天通新环境技术有限公司

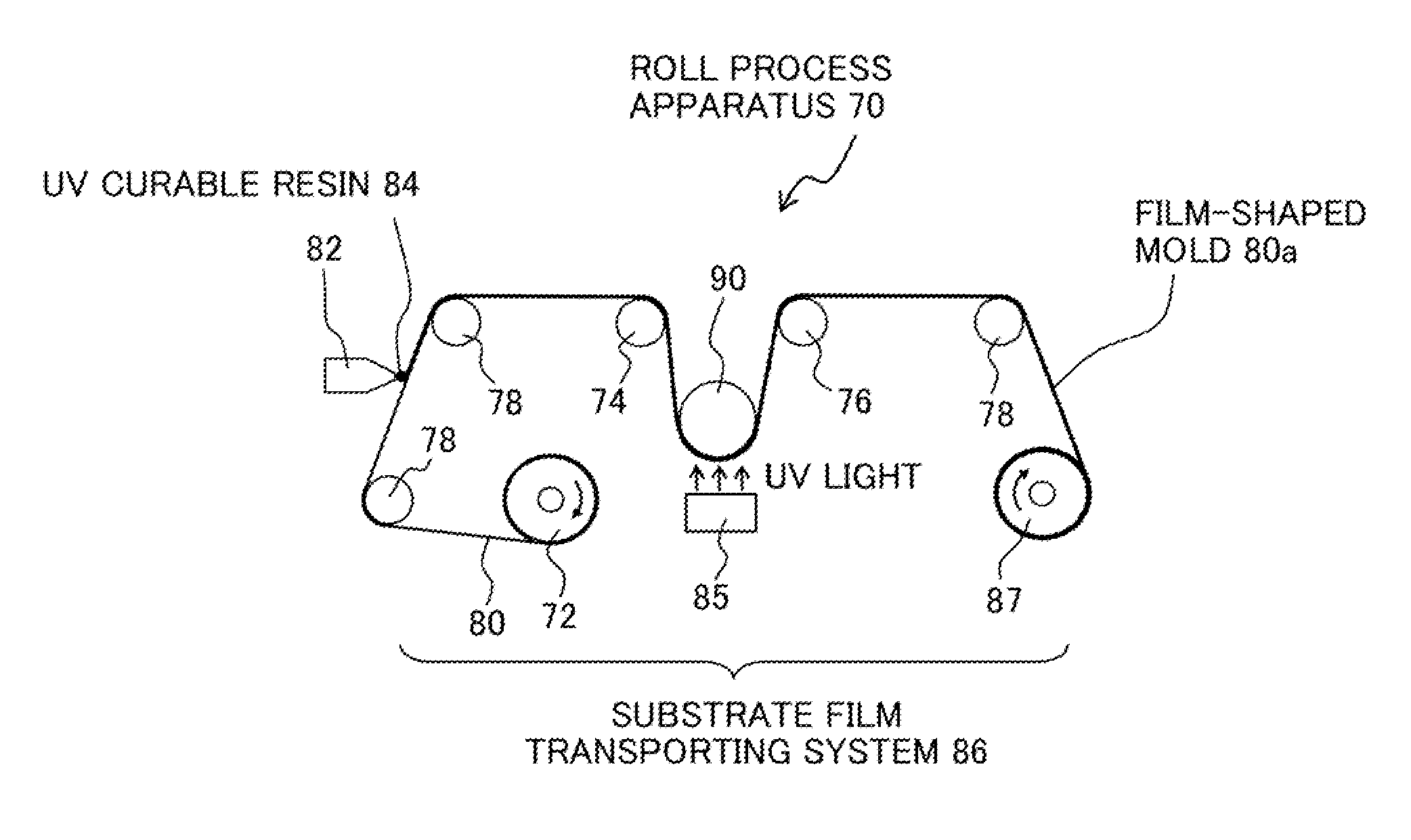

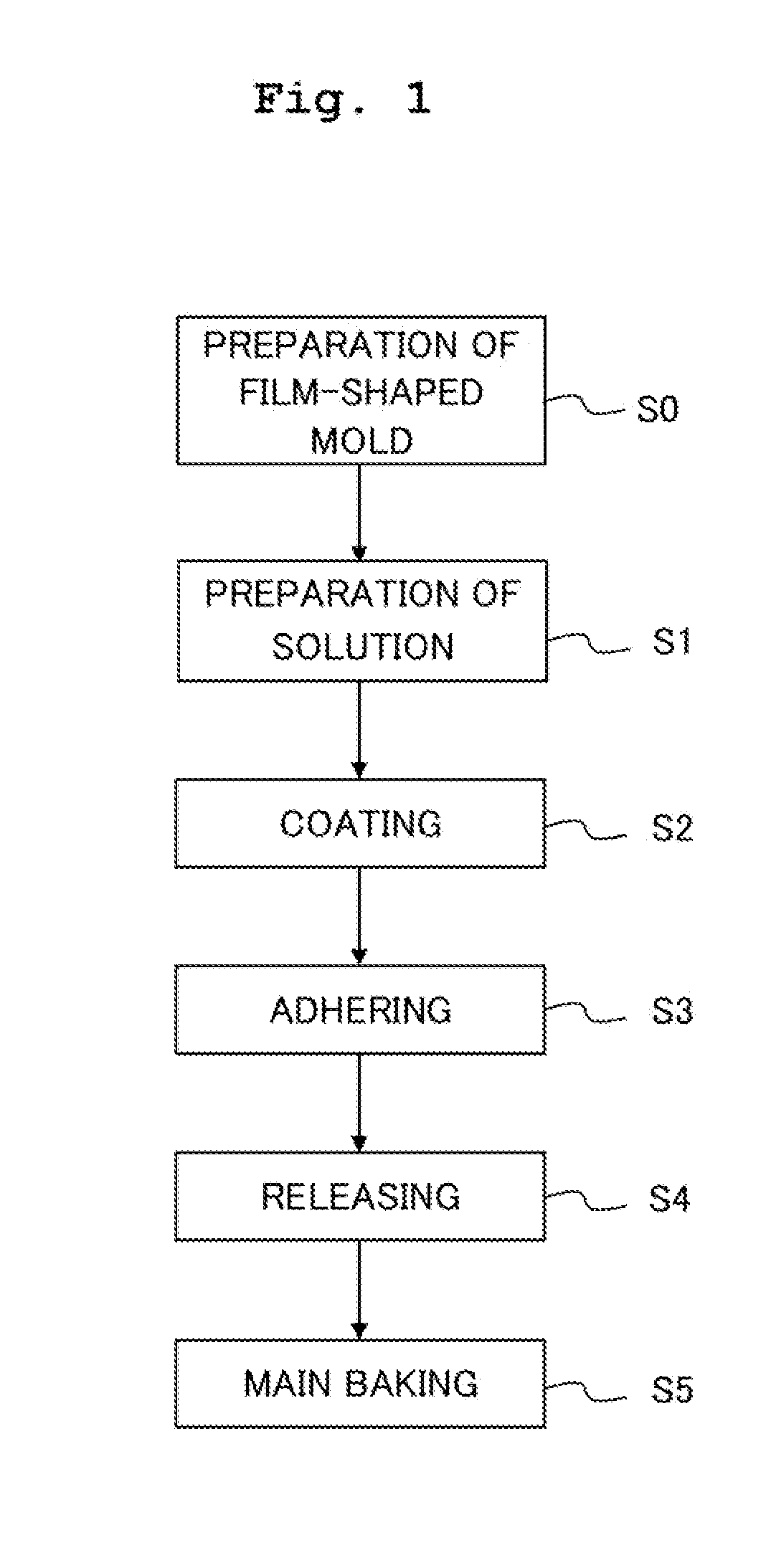

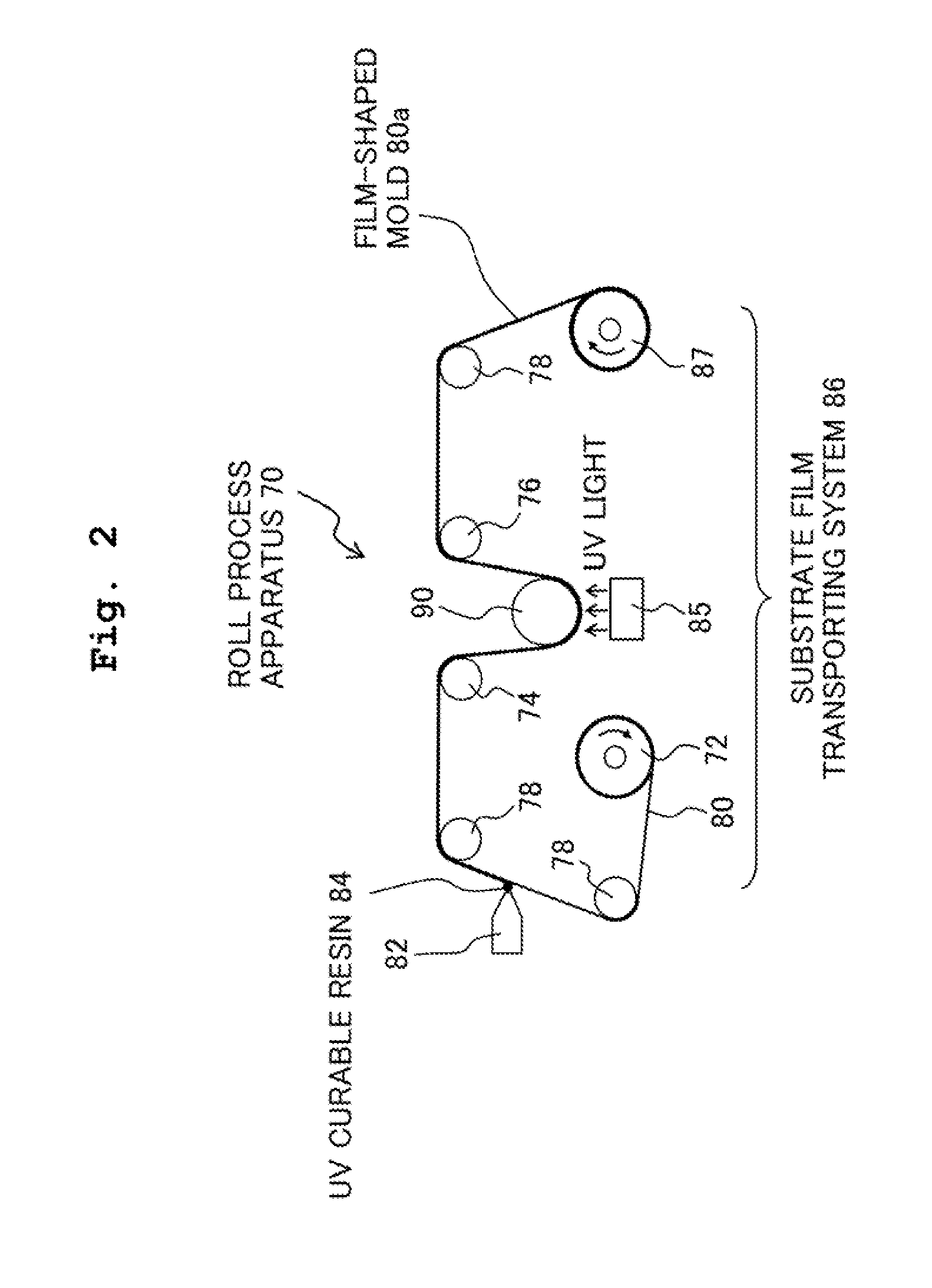

Manufacturing method for optical substrate using film shaped mold, manufacturing device, and optical substrate obtained thereby

InactiveUS20150202829A1Improve throughputImprove heat resistanceDiffusing elementsLayered productsSol-gelCoating

A method for producing an optical substrate includes: a step of preparing a long film-shaped mold having a concave-convex pattern surface having a concave-convex pattern; a step of forming a coating film made of a sol-gel material on the concave-convex pattern surface of the film-shaped mold; a step of adhering the coating film, which is formed on the concave-convex pattern surface of the film-shaped mold, to a substrate by arranging the concave-convex pattern surface of the film-shaped mold on which the coating film made of the sol-gel material is formed to face the substrate and by pressing a pressing roll against a surface of the film-shaped mold on a side opposite to the concave-convex pattern surface; a step of releasing the film-shaped mold from the coating film; and a step of curing the coating film adhered to the substrate.

Owner:JX NIPPON OIL & ENERGY CORP

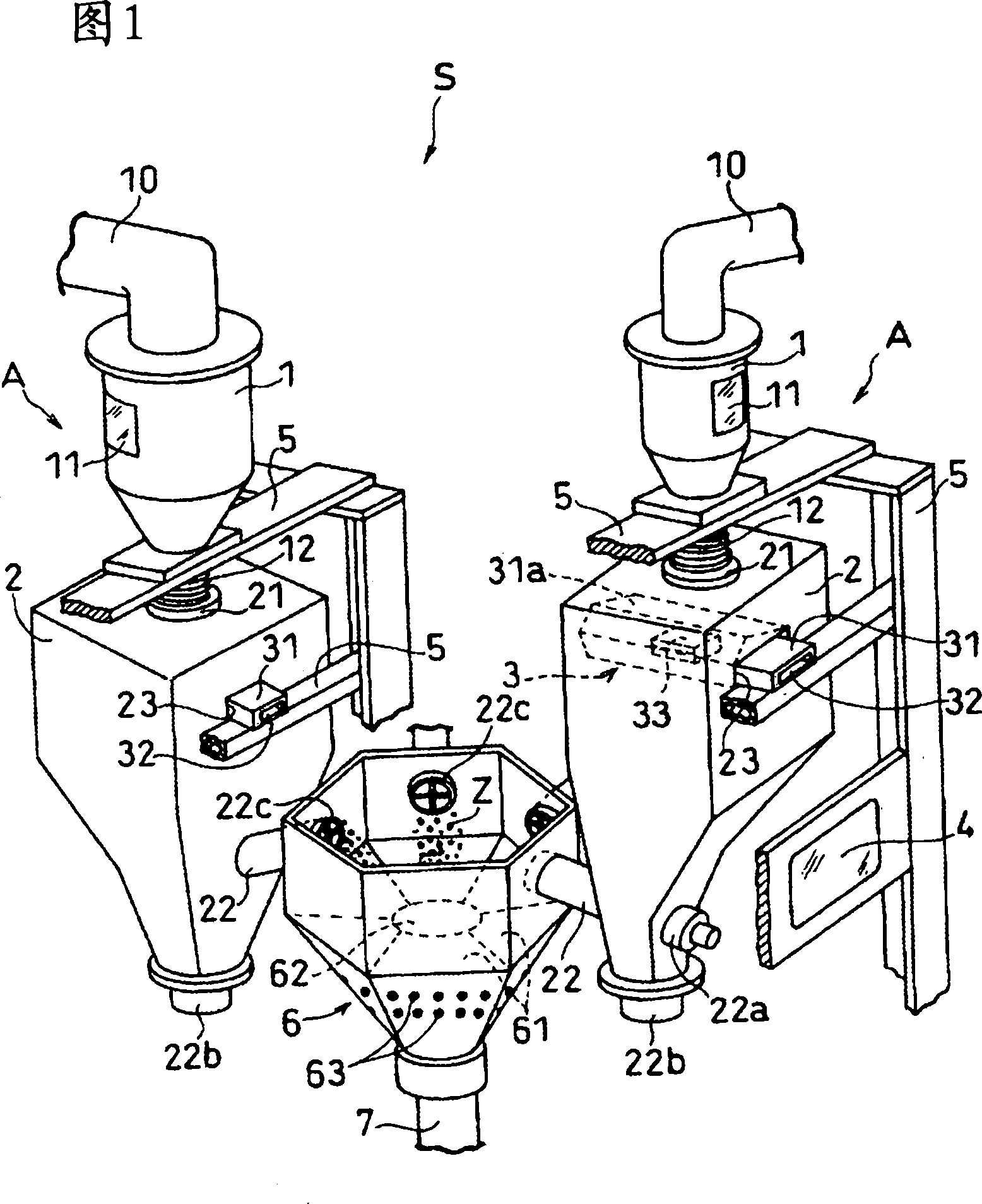

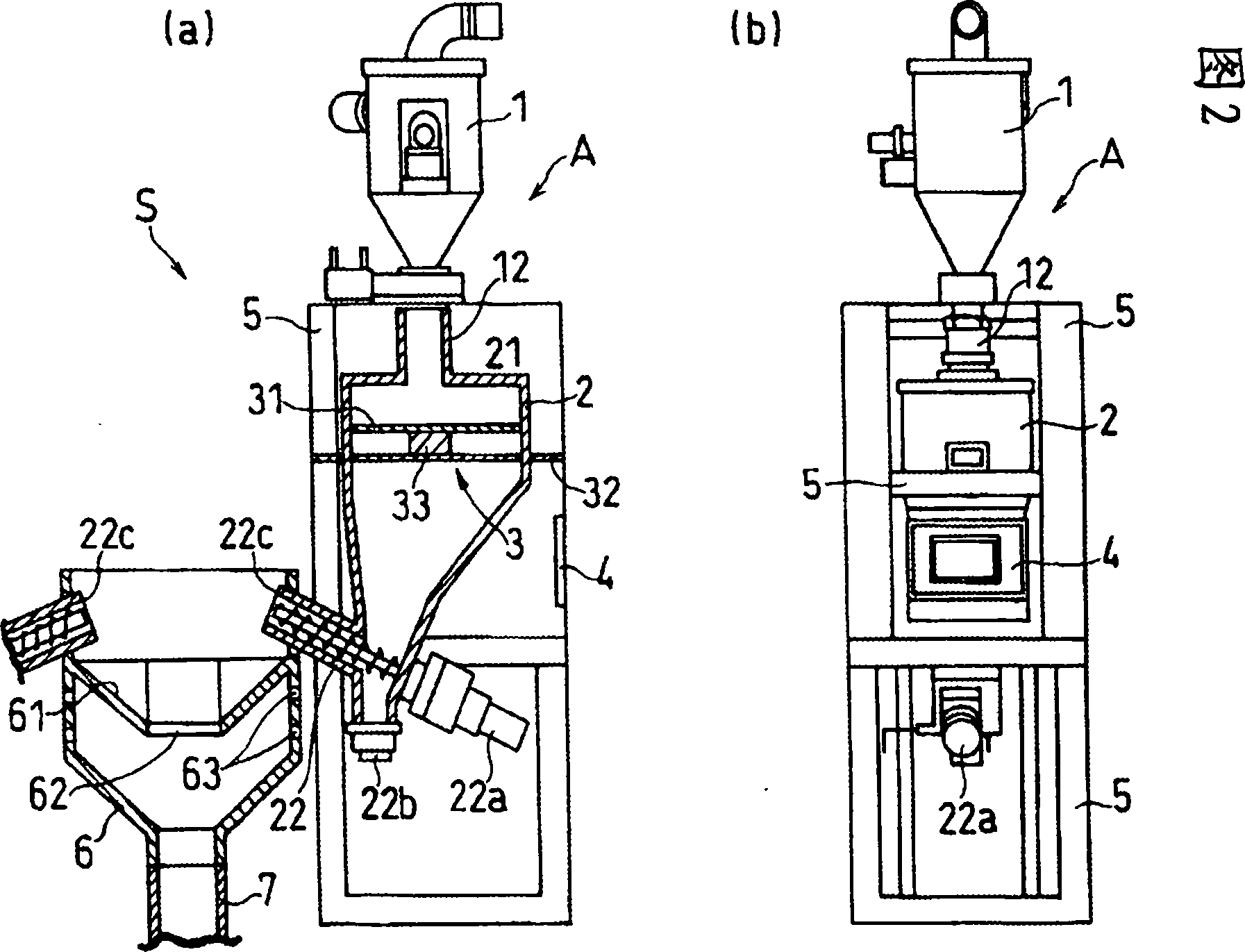

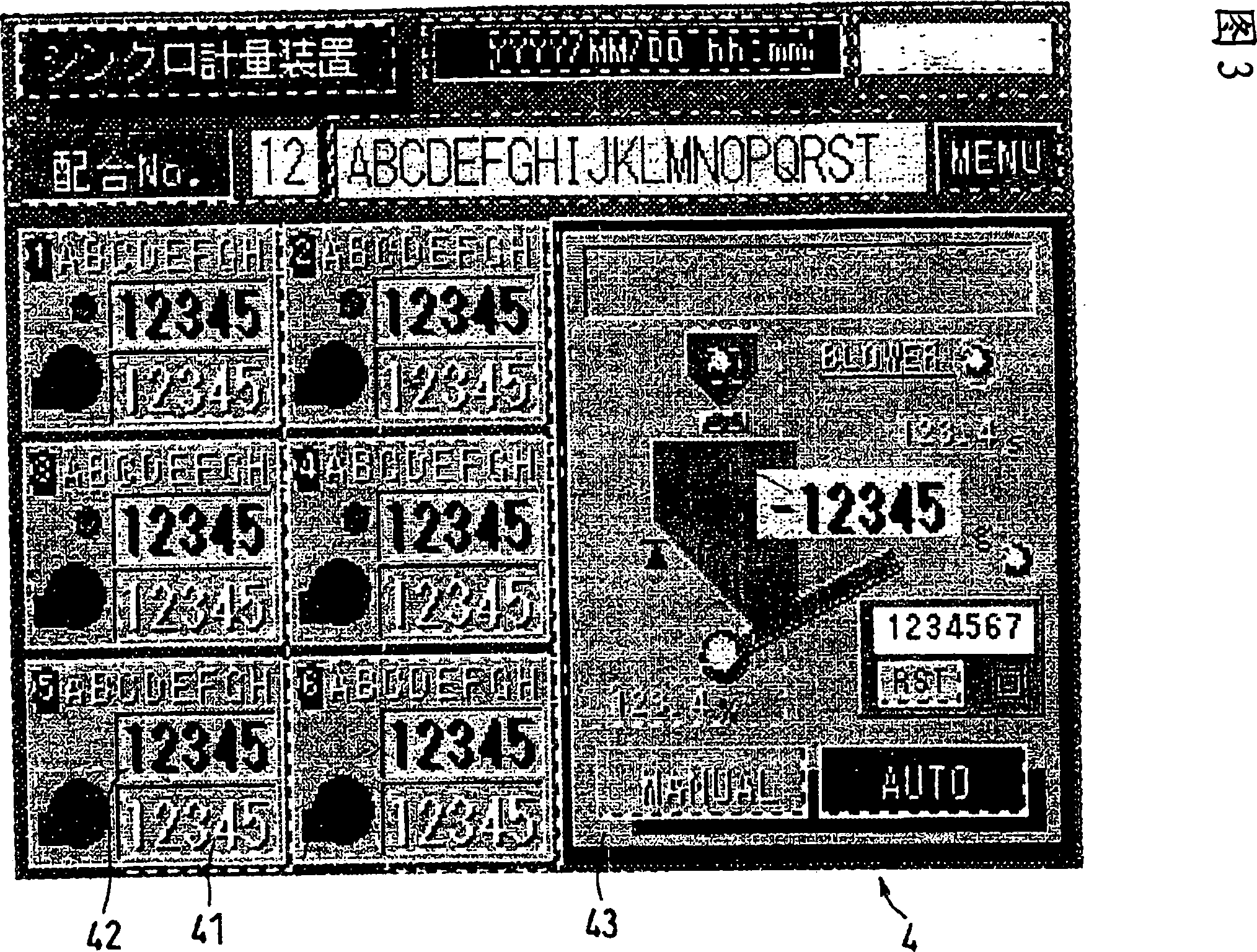

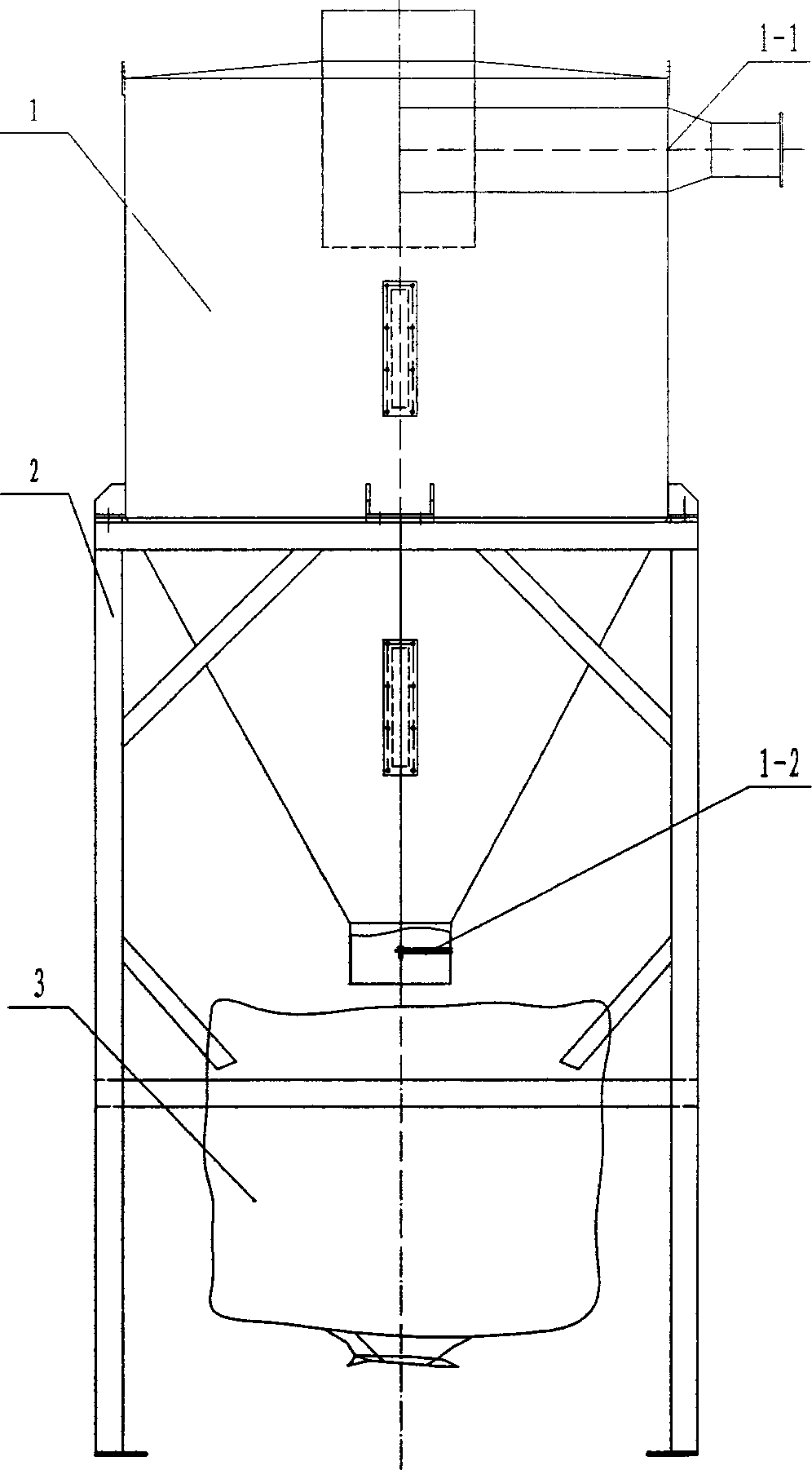

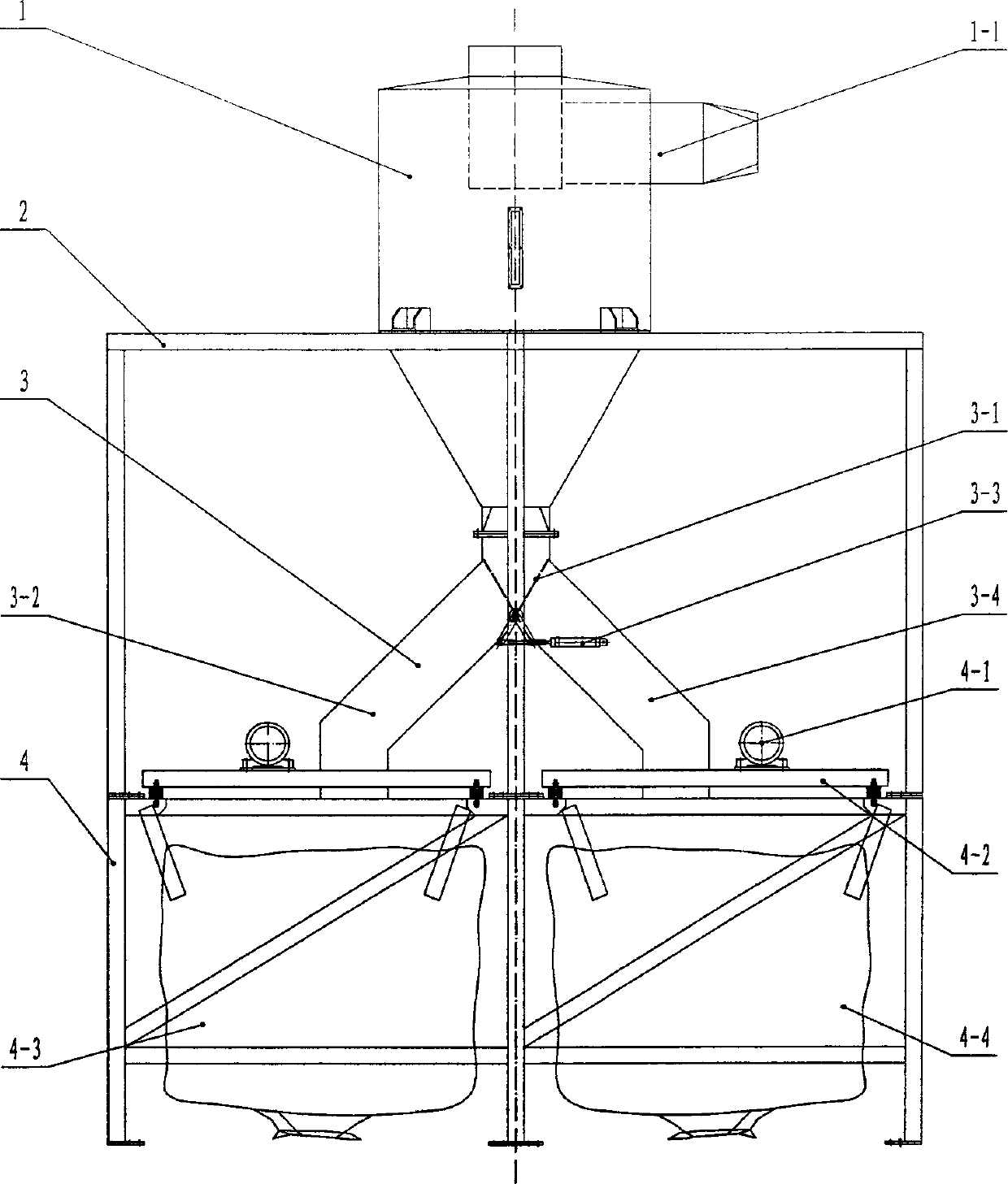

Continuous fixed quantity discharging device and material blending system using the same

InactiveCN1977151AContinuous dischargeGuaranteed continuous supplyFlow mixersMixer accessoriesMaterial storageMixing ratio

To provide a continuous fixed quantity discharging device and a material blending system using the device reduced in overall size and capable of accurately, smoothly, and continuously discharging a fixed quantity of material and mixing the discharged material at a uniform mixing ratio. This continuous fixed quantity discharging device comprises a material reserving tank (1) for reserving the material (Z) continuously fed by a supply means (10), a material storage tank (2) having a material inlet (21) separated from the material reserving tank (1) formed at the upper part, storing the material (Z) fallen from the material reserving tank (1), and having a discharge device (22) capable of continuously discharging the fixed quantity of the reserved material (Z) formed at the lower part, a load cell type mass weighing part (3) formed by installing a carrying arm (31) connected to only the material storage tank (2) in the material storage tank (2) and supporting the carrying arm (31) by a load cell (33) installed on a support frame (32) separated from the material storage tank (2) in a non-contact state, and a control part (4) monitoring the values weighed by the load cell (33) and controlling the discharge of the material by the discharge device (22) and / or the supply of the material into the storage tank (2) by the discharge device.

Owner:MATSUI MFG

Pneumatic reversing jolt compacting packing machine

InactiveCN104210679AContinuous dischargeIncrease productivitySolid materialEngineeringMechanical engineering

The invention discloses a pneumatic reversing jolt compacting packing machine, which is structurally characterized in that a bin barrel is arranged on an upper bracket; a feeding hole is formed in the upper right part of the bin barrel; a splitting box is connected below the bin barrel; a closure plate is arranged in the splitting box to divide the splitting box into a left box and a right box; the closure plate extends out of the splitting box so as to connected with a cylinder; the closure plate is driven by the cylinder to swing; the upper bracket is connected with a lower bracket; a platform is arranged above the lower bracket; a vibrating motor is arranged above the platform; packing bags are hung below the platform.

Owner:江苏美星大地环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com