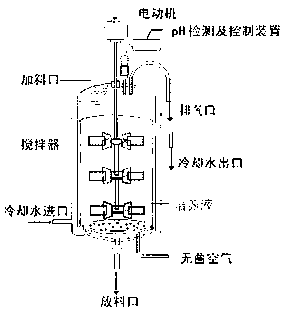

Fermentation tank

A fermenter and tank technology, applied in the field of fermenter, can solve the problems of large mechanical agitator resistance, large and complex reducer, difficult to mix evenly and thoroughly, etc., achieve uniform and thorough stirring, improve discharge efficiency, and realize vertical stirring up and down Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

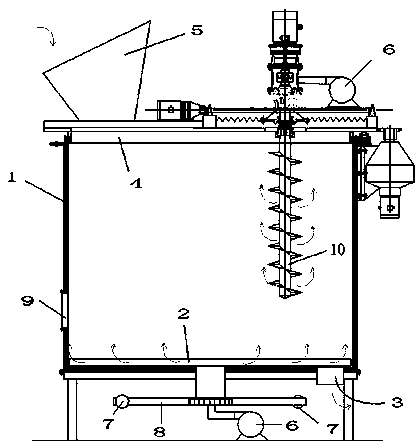

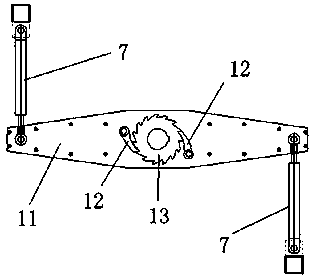

[0041] This embodiment provides a vertical stirring fermenter, the structure schematic diagram, as attached figure 1 As shown, it includes a tank body 1, a discharge device, a stirring device and a feed device 5, and a control sensor (detection sensor, conventional technology, which can realize automatic control and detection, not shown in the figure); the upper end of the tank body 1 is provided with The upper cover 4, a sealing device is installed between the upper cover 4 and the tank body 1, and the upper cover 1 is equipped with a stirring device, a blowing device and an air exhausting device.

[0042] The bottom of the tank body 1 is flat, with a discharge port, a switch gate, a discharge device, and a wind net. The tank body can adopt a double-layer material structure, and the middle of the double-layer material is filled with thermal insulation material. The tank body 1 is provided with a manhole 9 that allows people to pass through, which is convenient for repair.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com