Grading method of lithium ion battery

A lithium-ion battery and capacity-division technology, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries, can solve the problems of inaccurate capacity of lithium-ion batteries and large temperature effects, and achieves short capacity separation time and reduced capacity. Temperature influence, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

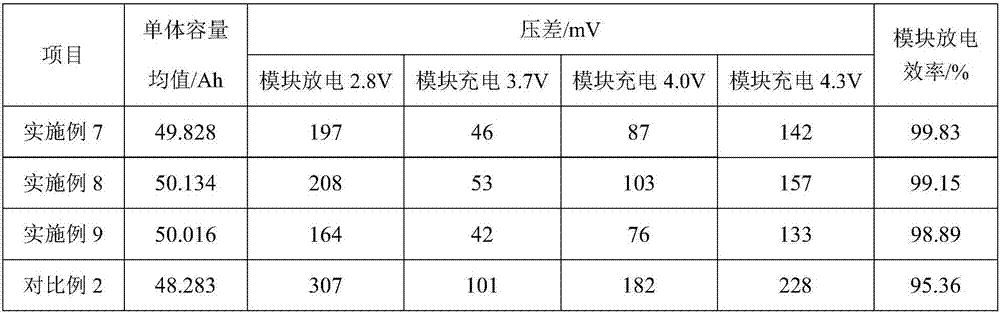

Examples

Embodiment 1

[0023] The capacity division method of the lithium-ion battery of the present embodiment may further comprise the steps:

[0024] 1) Charge the lithium-ion battery to full charge at 20°C in three stages:

[0025] In the first stage, the lithium-ion battery is charged to 3.65V at a constant current of 0.5C and left for 5 minutes;

[0026] In the second stage, the lithium-ion battery is charged to 3.65V at a constant current of 0.1C and left for 5 minutes;

[0027] In the third stage, the lithium-ion battery is charged to 3.65V at a constant current of 0.05C;

[0028] 2) Discharge the fully charged lithium-ion battery at 20°C:

[0029] Discharge the fully charged lithium-ion battery to 2.5V at a constant current of 0.5C, and record the discharge capacity C 1 , placed for 10min;

[0030] Then discharge to 2.5V with a constant current of 0.1C, and record the discharge capacity C 2 ;

[0031] 3) Calculate the split capacity of the lithium-ion battery:

[0032] Add the discha...

Embodiment 2

[0034] The capacity division method of the lithium-ion battery of the present embodiment may further comprise the steps:

[0035] 1) Charge the lithium-ion battery to full charge at 25°C in three stages:

[0036] In the first stage, charge the lithium-ion battery with a constant current of 1C for 1h and leave it for 1min;

[0037] In the second stage, the lithium-ion battery is charged to 3.65V at a constant current of 0.1C and left for 1min;

[0038] In the third stage, charge the lithium-ion battery with a constant current of 0.05C to 3.65V, and let it stand for 10 minutes;

[0039] 2) Discharge the fully charged lithium-ion battery at 25°C:

[0040] Discharge the fully charged lithium-ion battery to 2.5V at a constant current of 1C, and record the discharge capacity C 1 , placed for 5min;

[0041] Then discharge to 2.5V with a constant current of 0.1C, and record the discharge capacity C 2 ;

[0042] 3) Calculate the split capacity of the lithium-ion battery:

[0043...

Embodiment 3

[0045] The capacity division method of the lithium-ion battery of the present embodiment may further comprise the steps:

[0046] 1) Charge the lithium-ion battery to full charge at 30°C in three stages:

[0047] In the first stage, the lithium-ion battery is charged to 3.65V at a constant current of 0.5C and left for 10 minutes;

[0048] In the second stage, the lithium-ion battery is charged to 3.65V at a constant current of 0.1C and left for 10 minutes;

[0049] In the third stage, charge the lithium-ion battery with a constant current of 0.05C to 3.65V, and let it stand for 1min;

[0050] 2) Discharge the fully charged lithium-ion battery at 30°C:

[0051] Discharge the fully charged lithium-ion battery to 2.5V at a constant current of 0.5C, and record the discharge capacity C 1, place for 1min;

[0052] Then discharge to 2.5V with a constant current of 0.05C, and record the discharge capacity C 2 ;

[0053] 3) Calculate the split capacity of the lithium-ion battery:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com