Patents

Literature

138results about How to "Solve the discharge problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

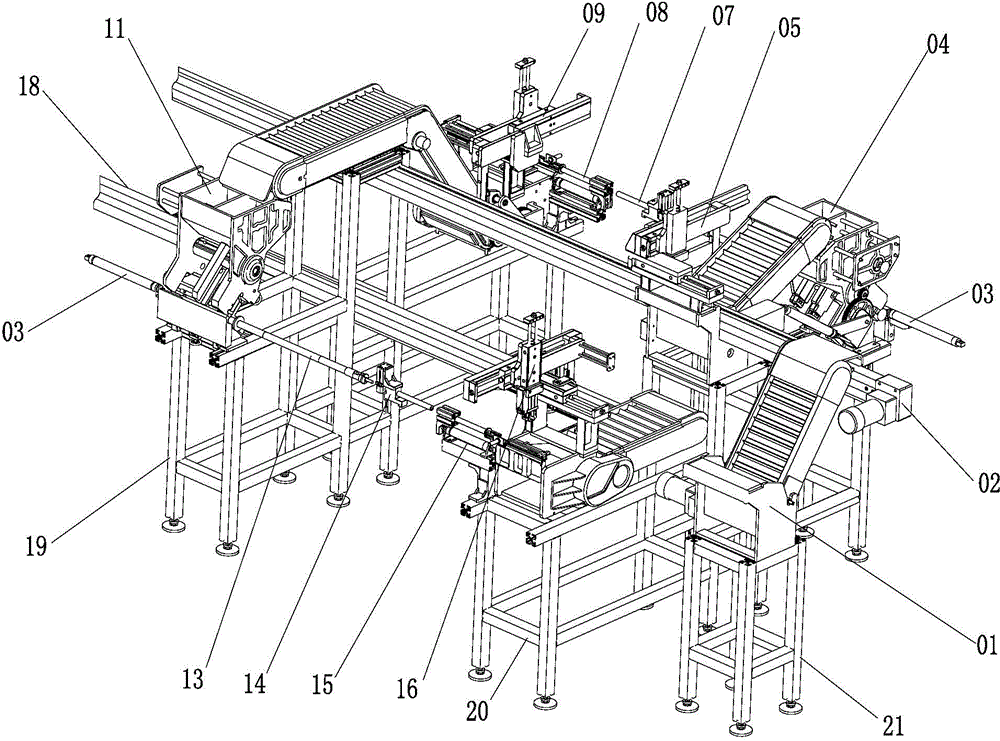

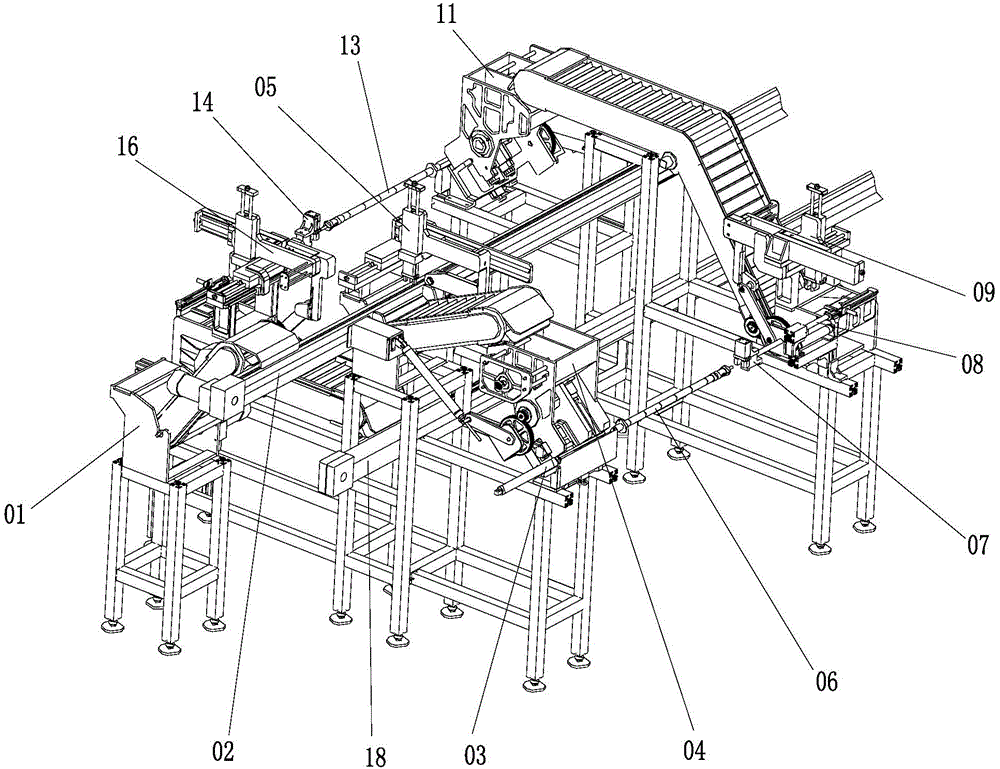

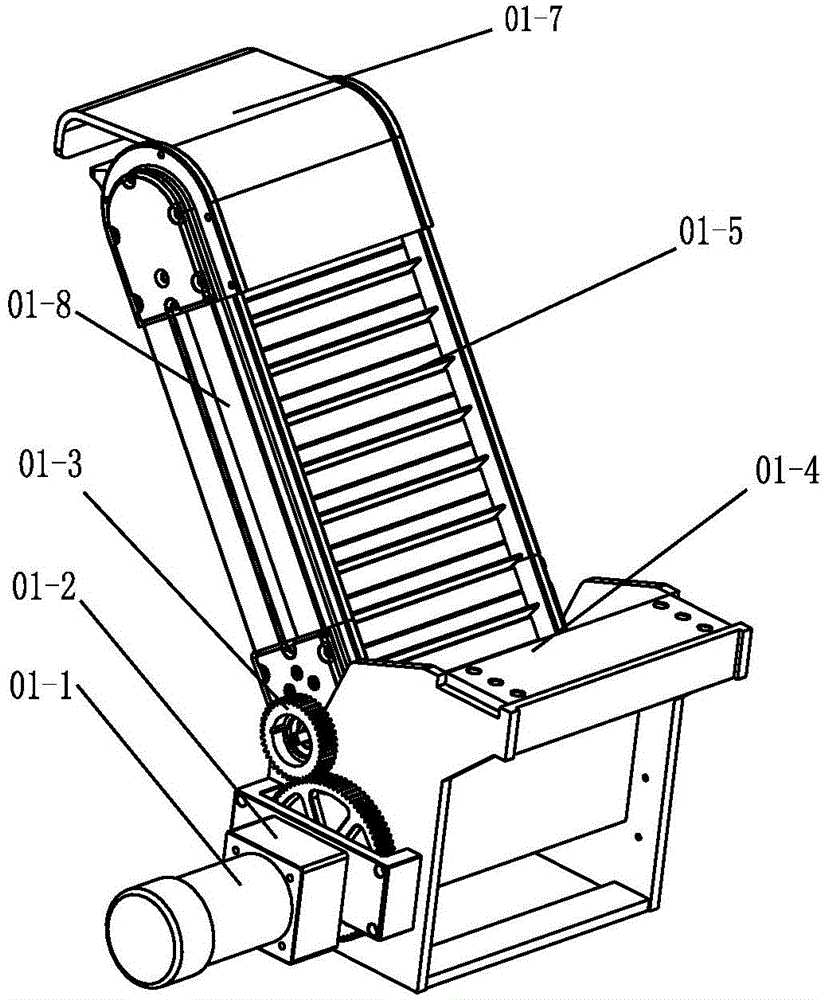

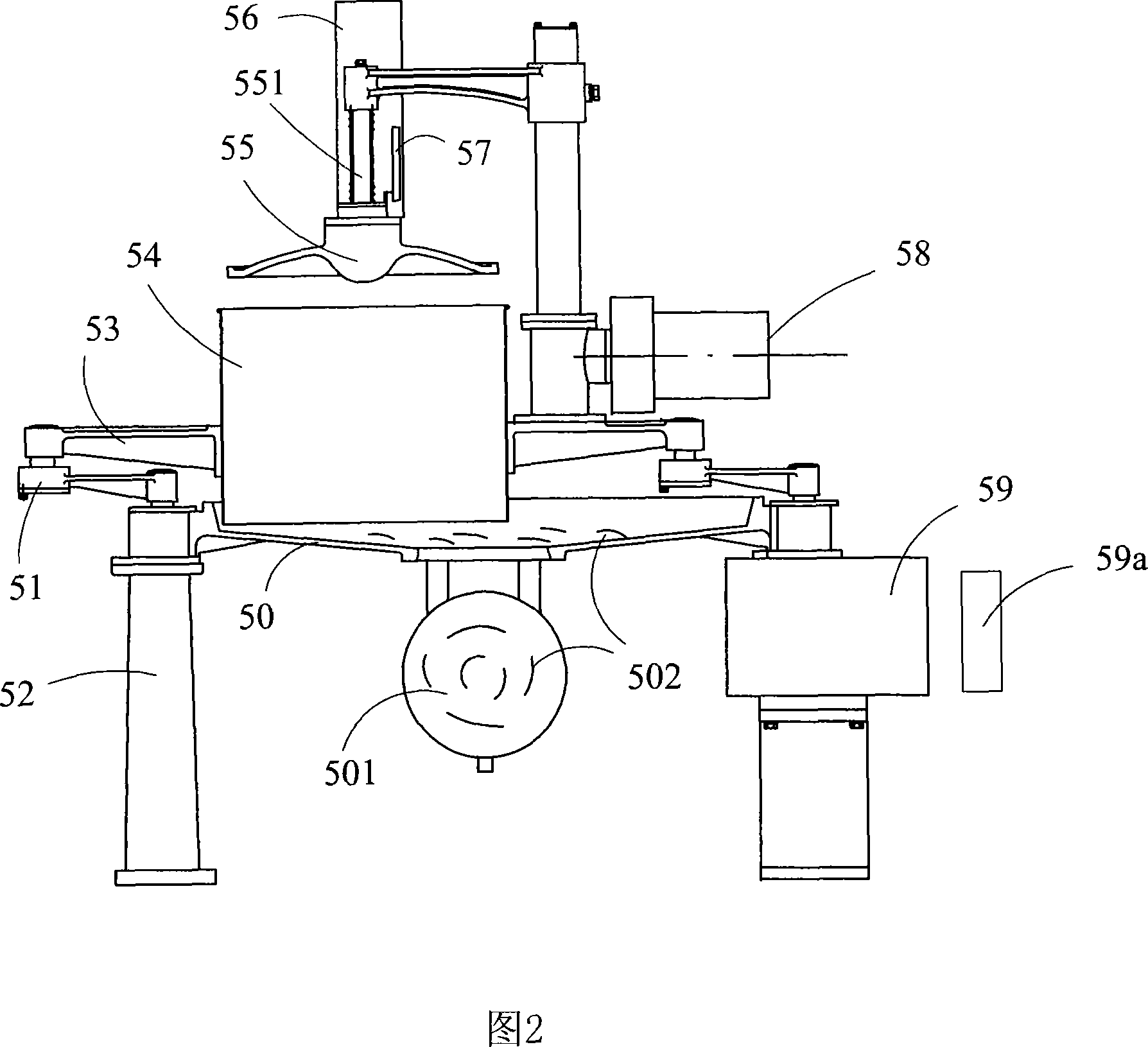

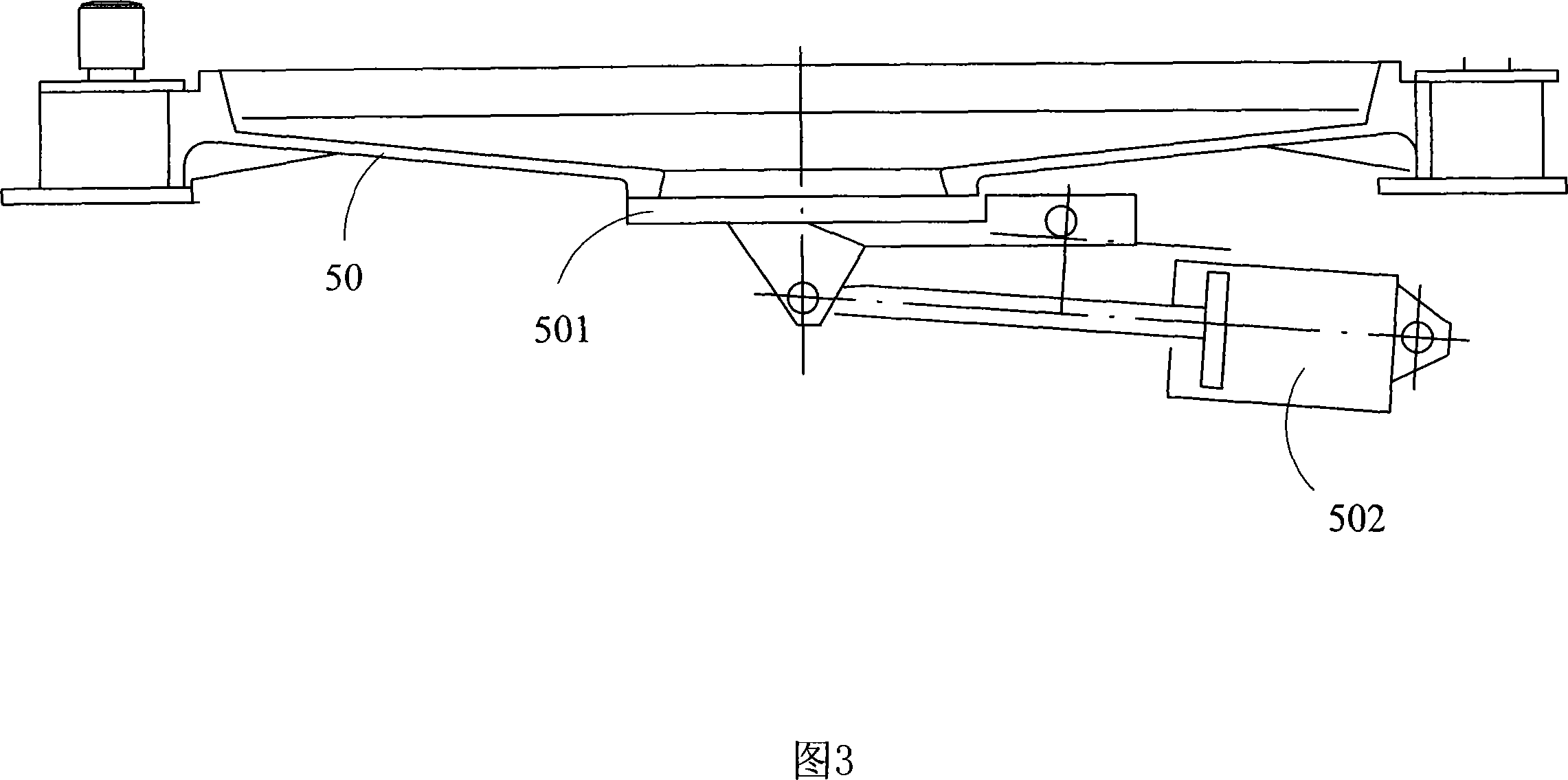

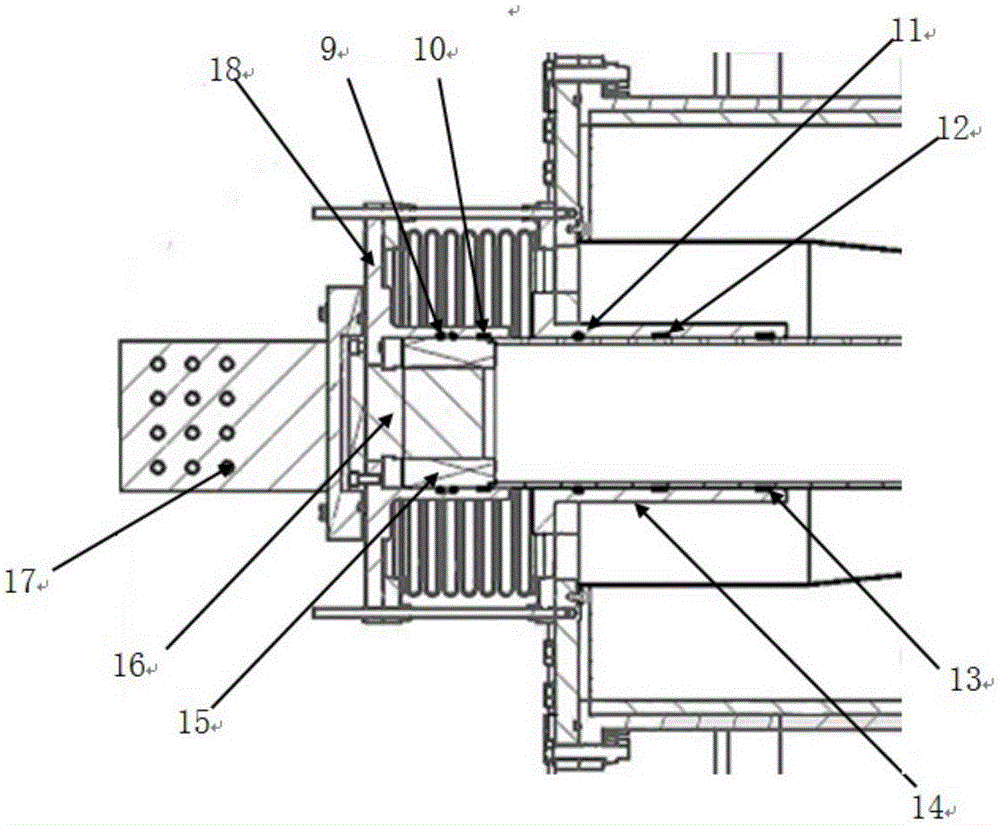

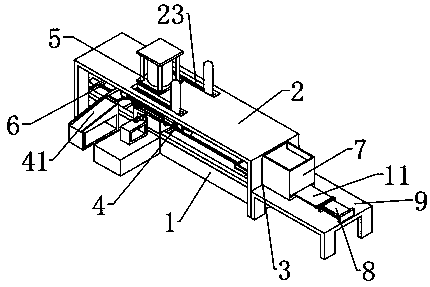

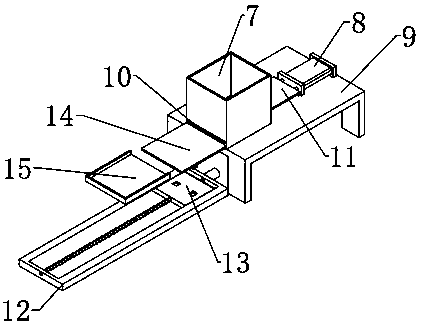

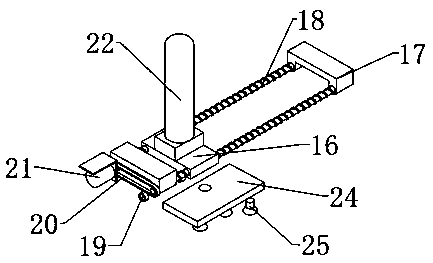

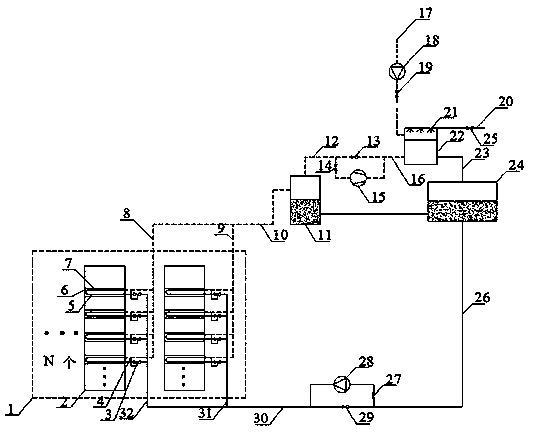

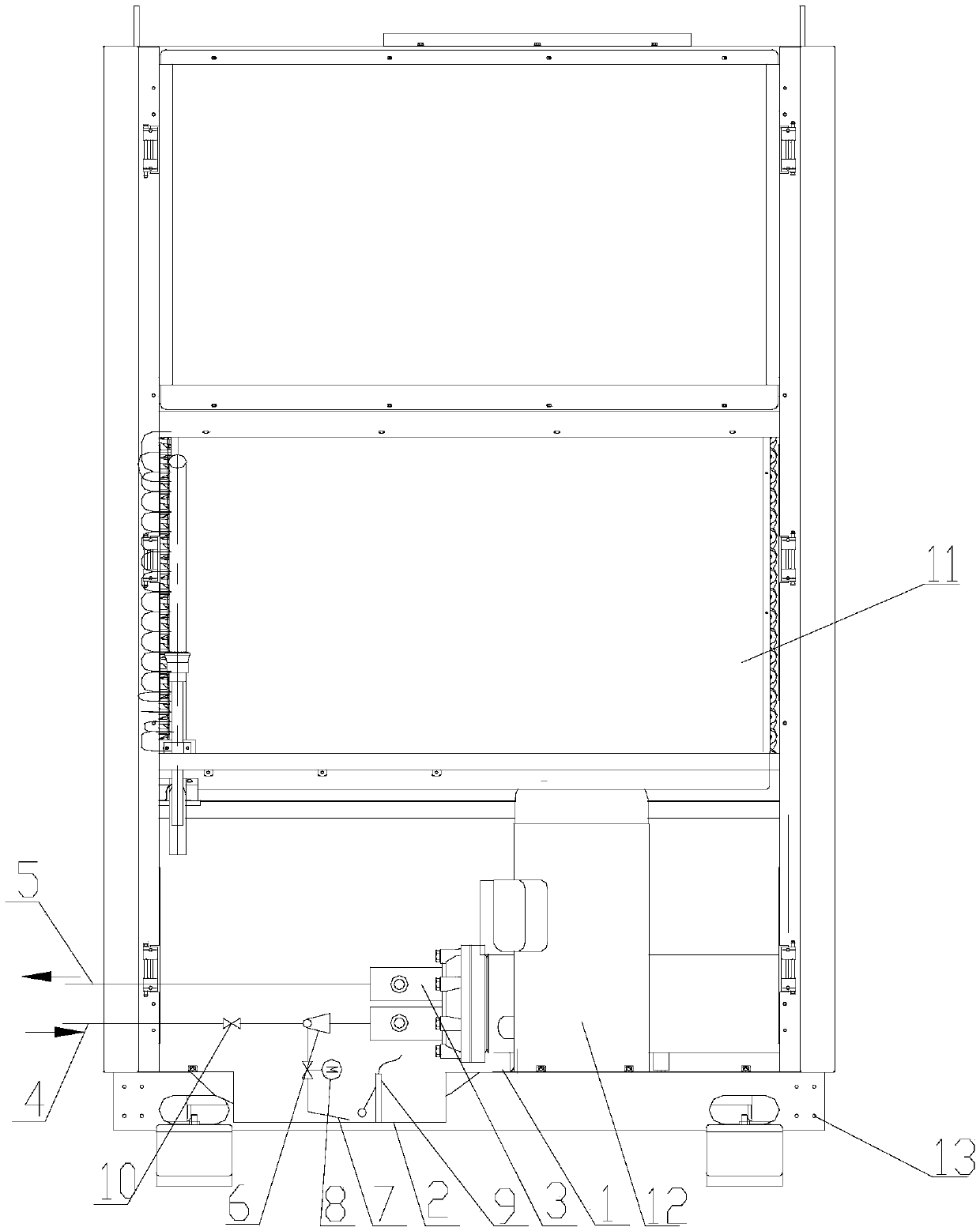

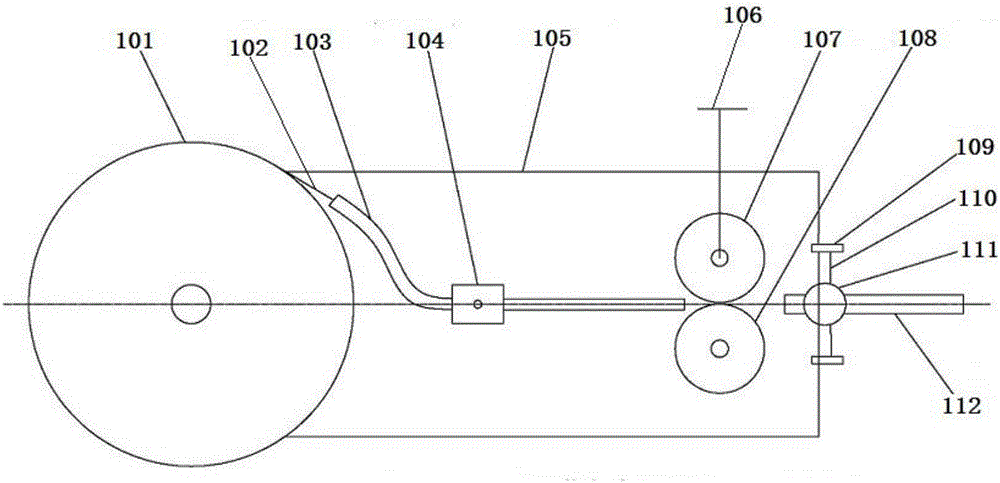

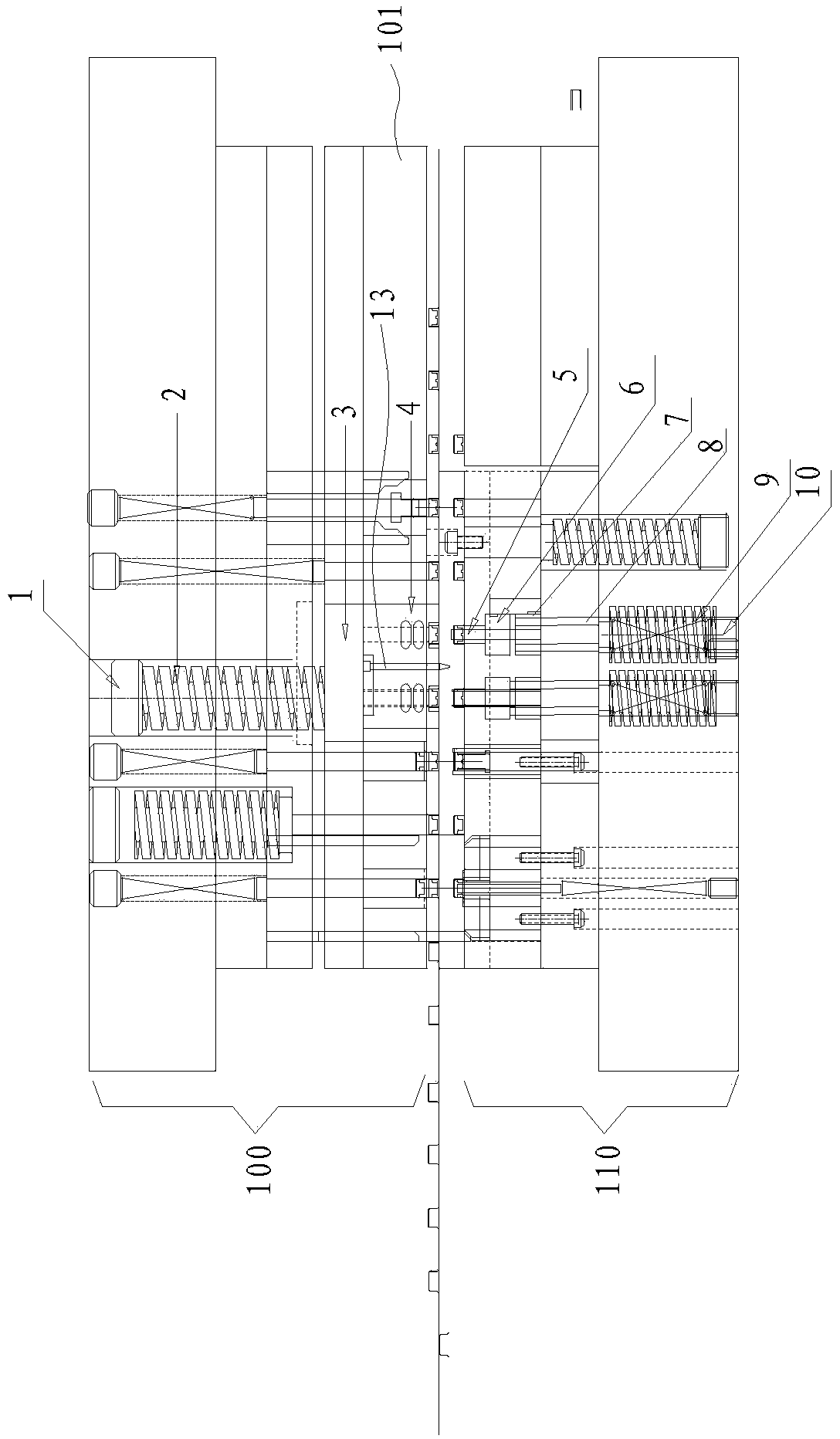

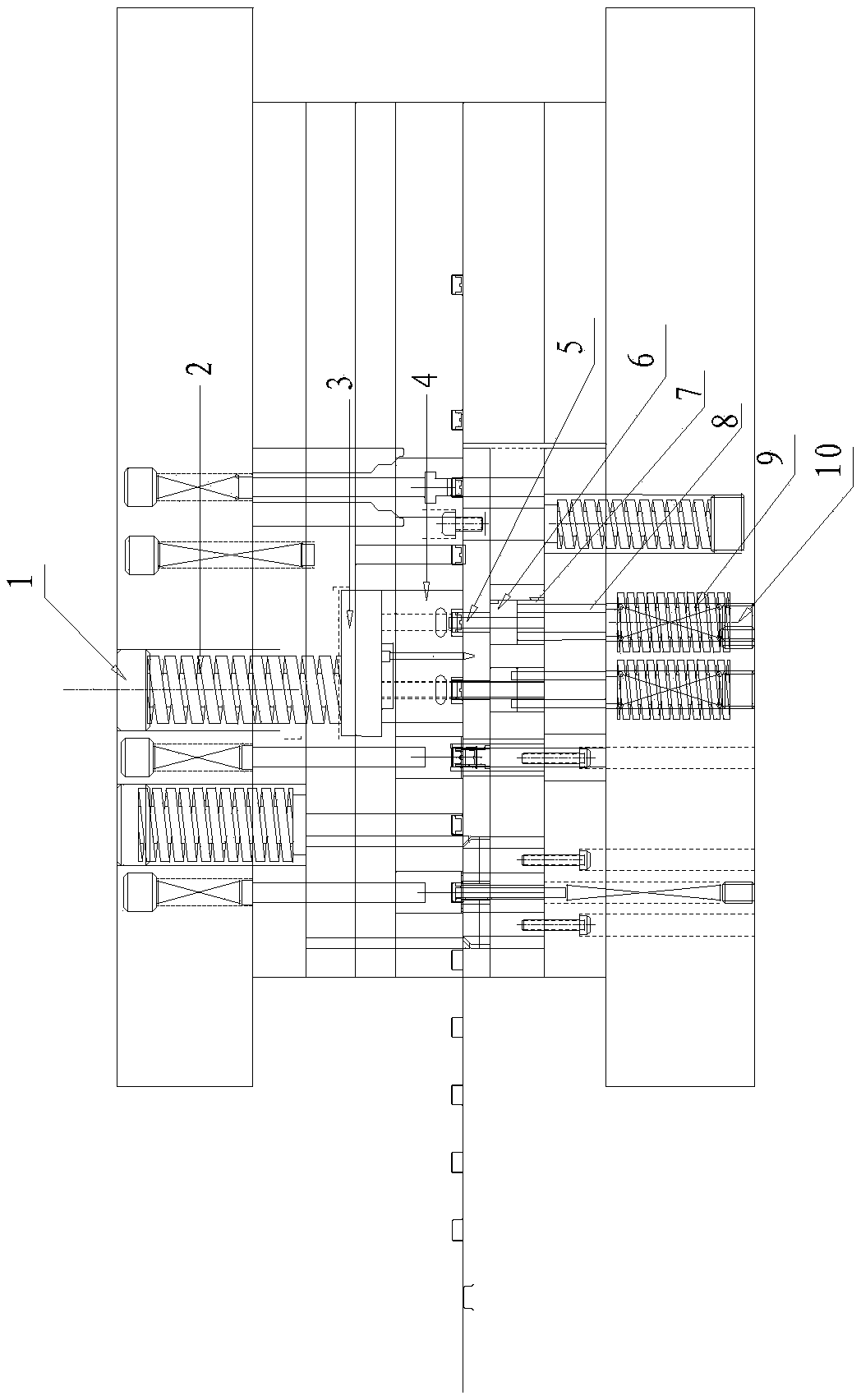

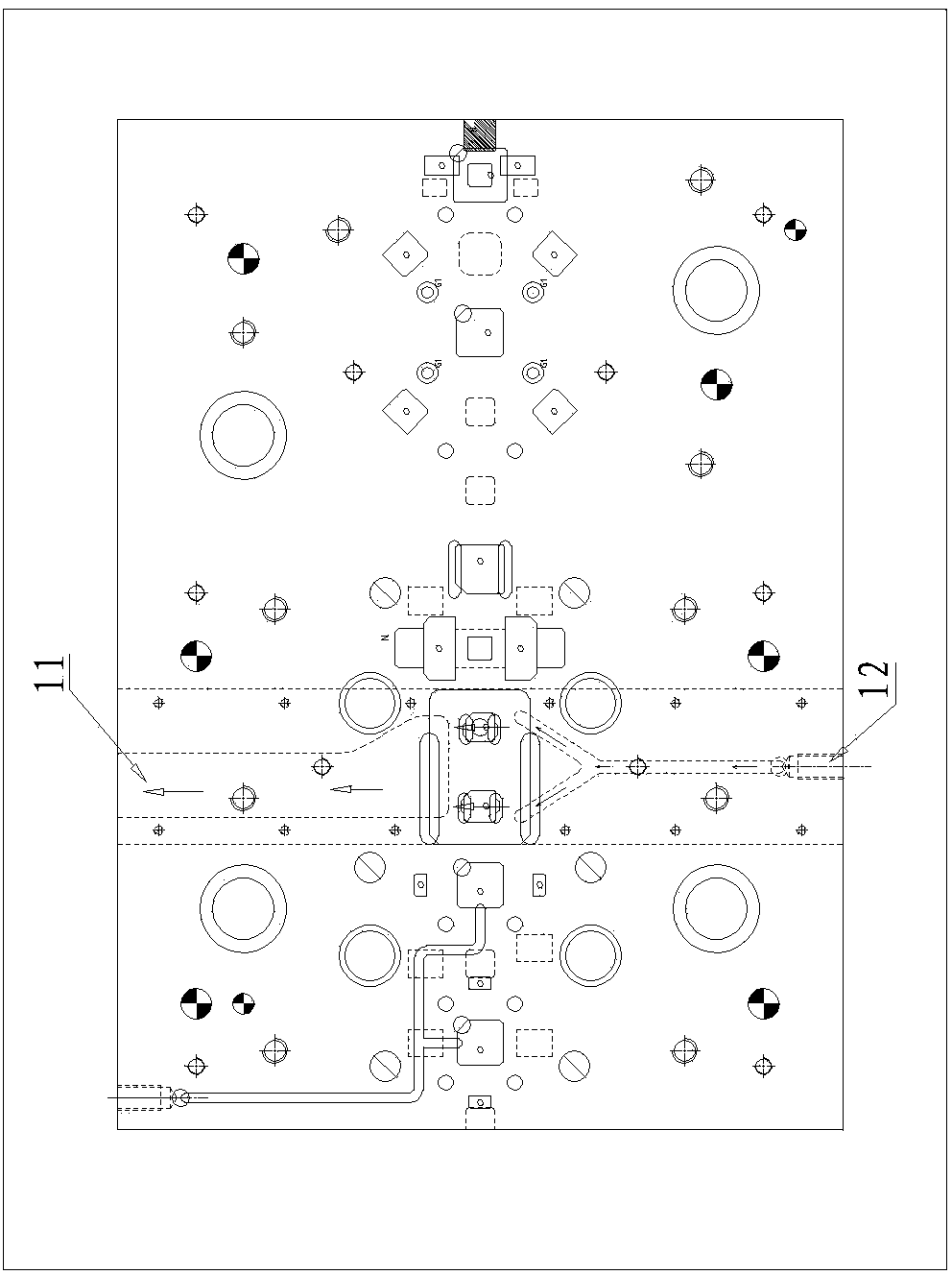

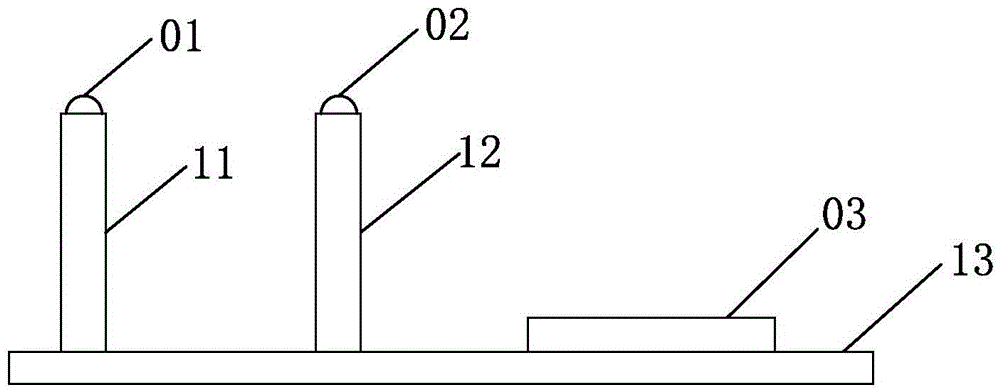

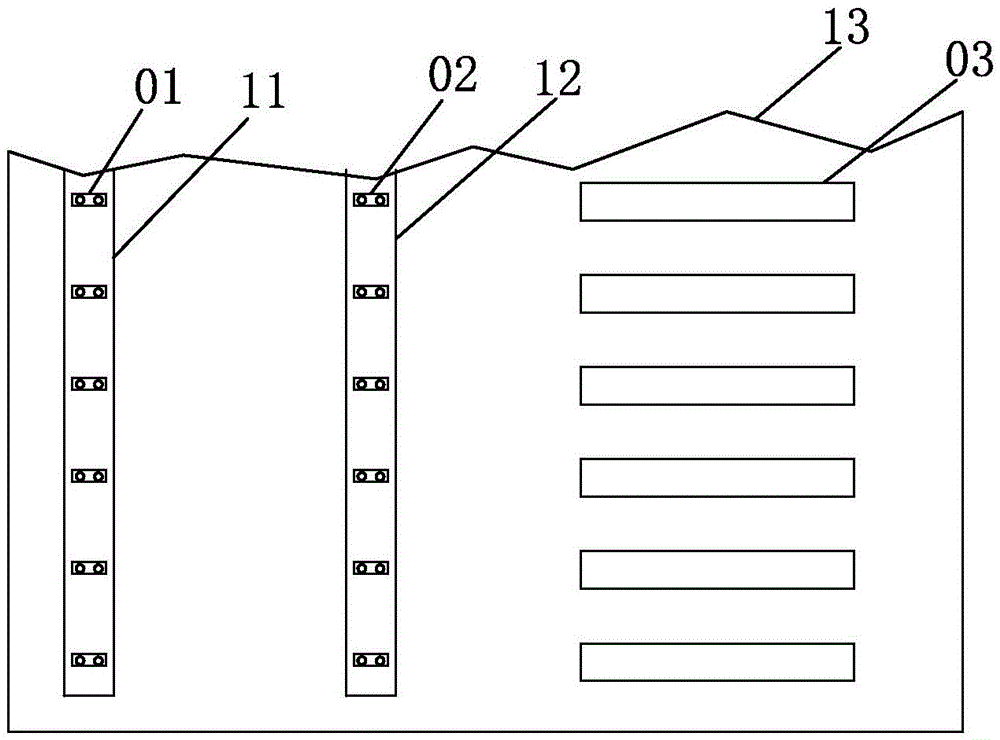

Automatic modularized turning assembly line

ActiveCN103817351ASolve the discharge problemSolve the problem of interference with the carriage of the lathe tool holderMetal working apparatusEngineeringAssembly line

The invention relates to the technical field of equipment part processing equipment, in particular to an automatic modularized turning assembly line which comprises a height-adjustable support. A rod lifting mechanism assembly, a rod longitudinal-conveying mechanism, a rod taking and transverse-conveying manipulator assembly, an adjustable buffer feed hopper assembly, a lathe spindle rear-feeding and positioning device, a lathe tool rest dragging manipulator, a pneumatic lathe discharging and collecting device assembly, a three-shaft automatic taking and transverse-feeding manipulator assembly, a second circulating rear-feeding buffer feed hopper assembly, a second circulating lathe spindle rear-feeding and positioning device, a second circulating lathe tool rest dragging manipulator device, a second pneumatic circulating lathe discharging and collecting device assembly, a third circulating three-shaft automatic taking and transverse-feeding manipulator assembly and a turning finished product longitudinal-conveying mechanism. The automatic modularized turning assembly line is reasonable in structural arrangement, and production efficiency is greatly improved.

Owner:宁波精益微型轴有限公司

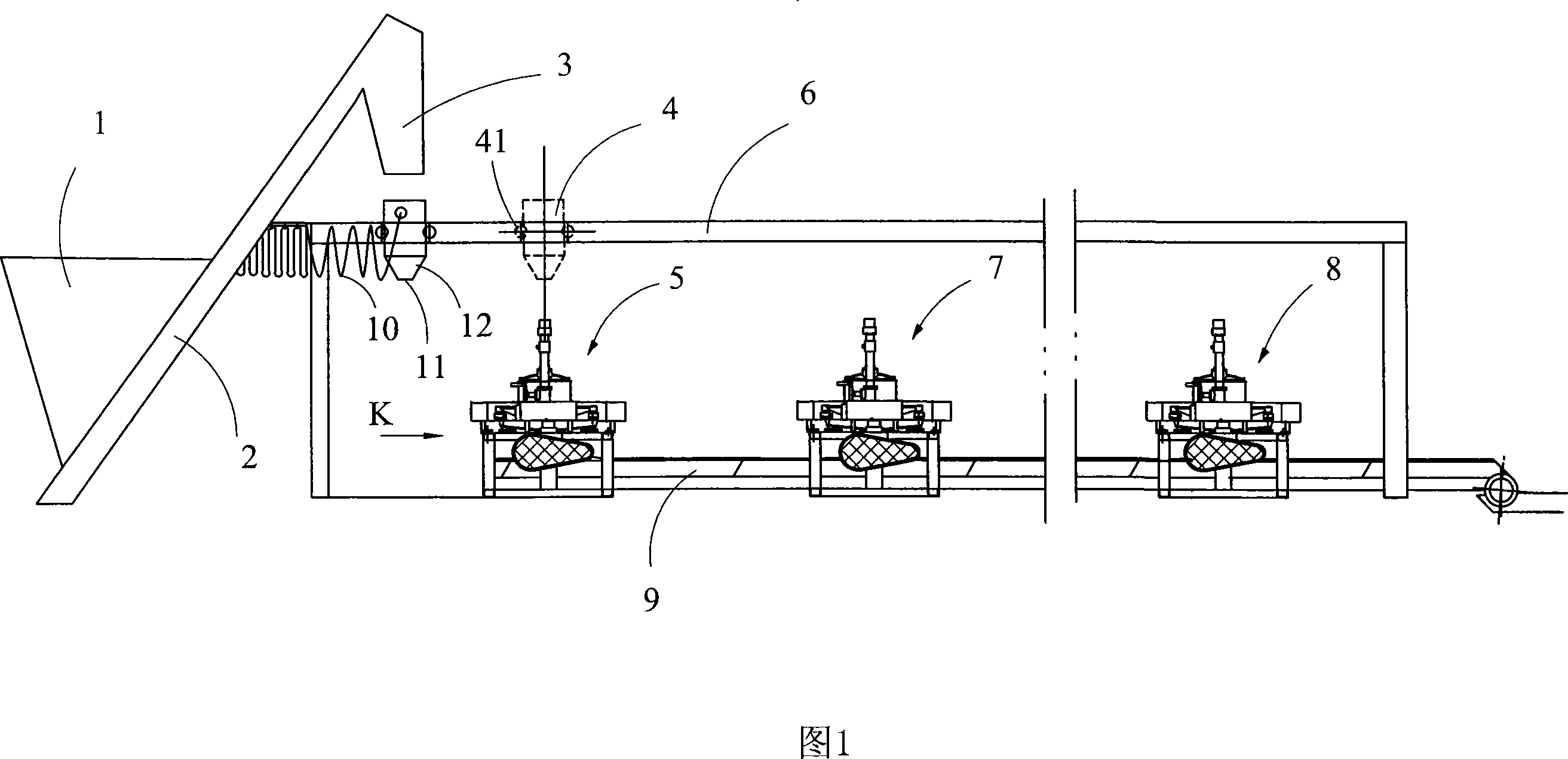

Equipment for automatic and continuous rubbing tea-leaves

InactiveCN101044876ASimple structureMature technologyPre-extraction tea treatmentElectric machineryTea leaf

An automatic continuous kneading apparatus for preparing tea leaves is composed of machine frame, two or more kneading units serially arranged on said machine frame and consisting of kneading pot, kneading tray and pressing module composed of motor and force measuring device, reciprocating feeder with controllable feeding gate, and automatic belt conveyer under the discharge gates of said kneading trays for discharging the kneaded tea leaves.

Owner:程玉明

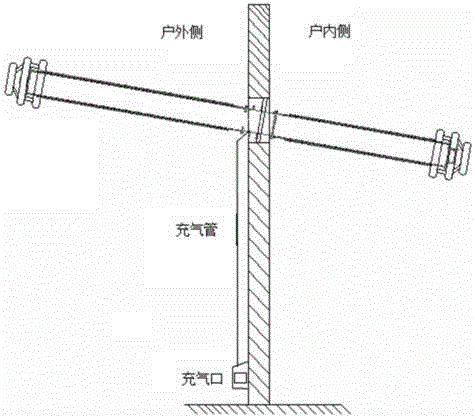

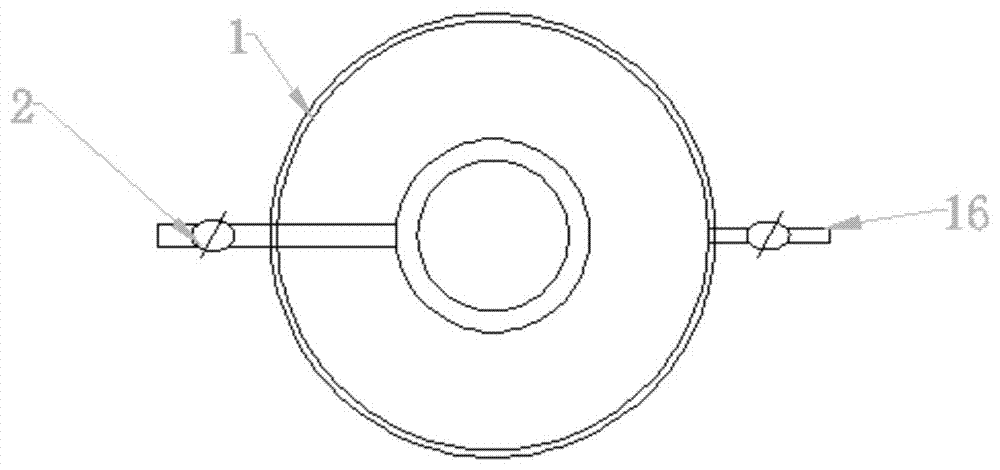

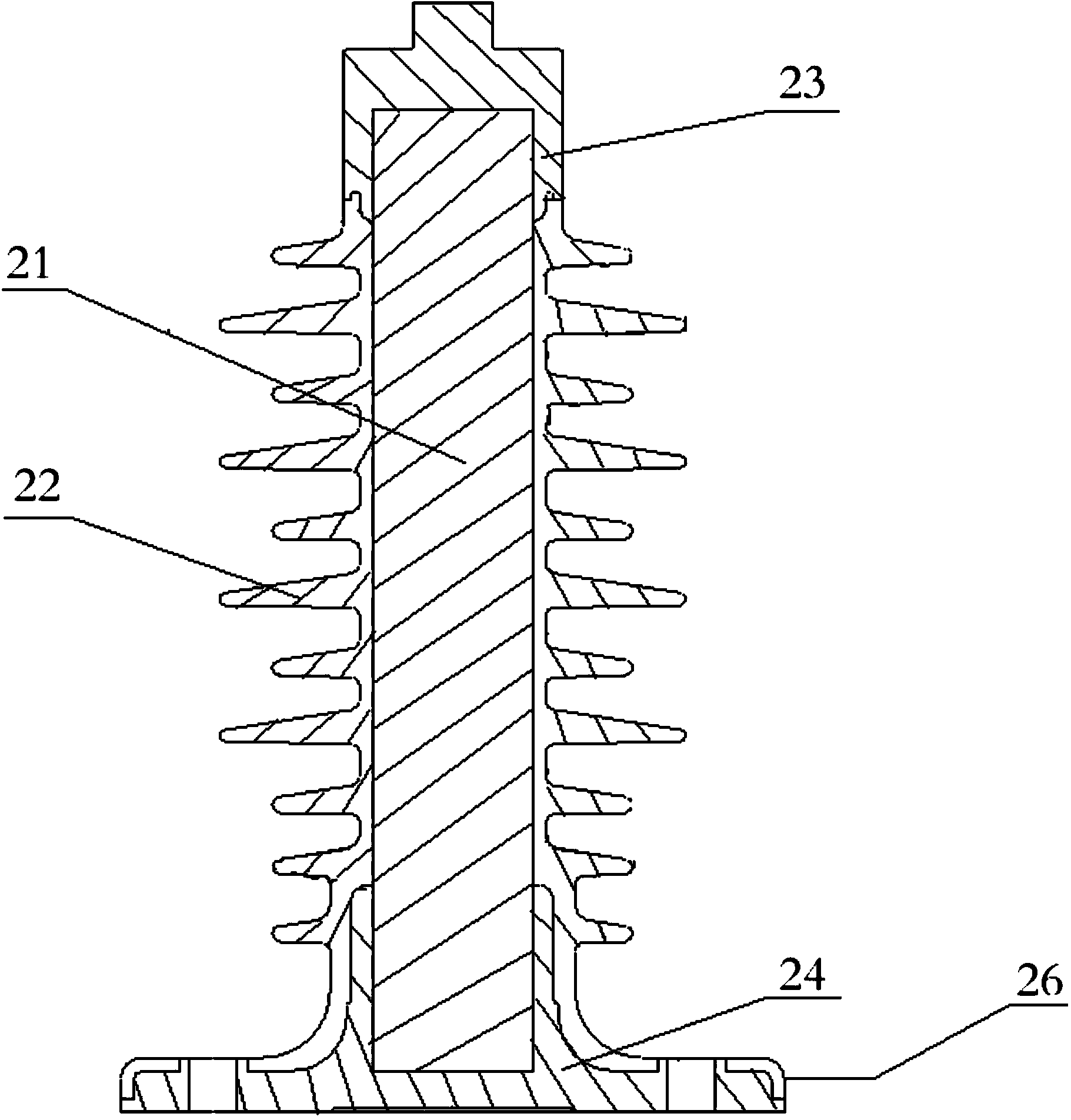

Inflatable extra-high voltage direct current through-the-wall bushing

ActiveCN105977887AOvercome saggingSolve the discharge problemInsulating bodiesElectrical conductorHigh-voltage direct current

The invention discloses an inflatable extra-high voltage direct current through-the-wall bushing comprising an insulation sleeve and a central conductor penetrating the insulation sleeve. One end of the central conductor is fixedly connected with an outdoor side sleeve pipe end cover on one side of the insulation sleeve, and the other end is connected with a T-shaped bellows end cover on the other side of the insulation sleeve in a sealed manner. A stretching device is disposed between the bellows end cover and the central conductor, which are cooperated with each to perform the single-side stretching on the central conductor. The inflatable extra-high voltage direct current through-the-wall bushing has advantages of simple structure, strong discharge capability, reliable performance, and ability of facilitating safe and stable operation of direct current power transmission system.

Owner:CHINA XD ELECTRIC CO LTD

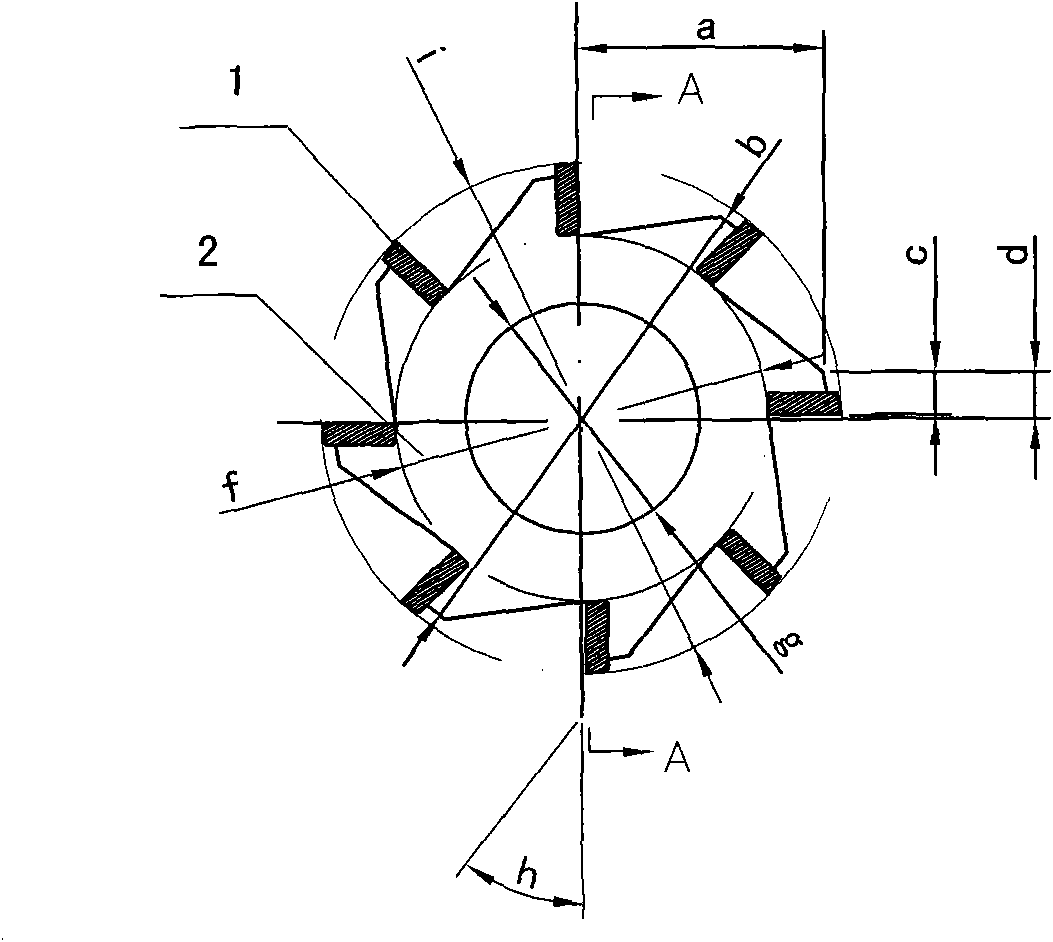

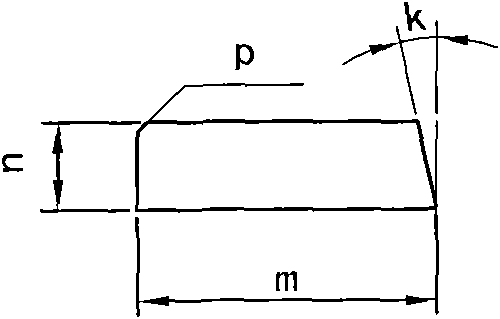

Oil groove milling cutter of hard alloy cold-working mould pressing blank

InactiveCN101637829ASolve the discharge problemDischarge in timeMilling cuttersMilling equipment detailsMilling cutterMachined surface

The invention discloses an oil groove milling cutter of a hard alloy cold-working mould pressing blank, which comprises a steel basal body (2) and a PCD blade (1), wherein the steel basal body (2) isprovided with 6-12 saw teeth, the number of PCD blade (1) is the same with the number of saw teeth, the back of the saw teeth of the steel basal body (2) is designed into an inclined flat bottom shape, and the PCD blade (1) is welded on the saw teeth of the steel basal body (2). Aiming at the difficult problems of low integrated intensity, hard grains and easy machined surface collapse in the processing process of a hard alloy pressing blank, the invention concretely limits multiple items of geometric parameters of the milling cutter, particularly a geometric angle. When the milling cutter isused for processing an oil groove of the hard alloy cold-working mould pressing blank, the edge of the oil groove can be kept integrated, and the machined surface roughness is kept to be not more thanRa 0.8, solving the difficult problem that the quality of the machined surface can not be ensured when the existing milling cutter is used for processing the hard alloy pressing blank.

Owner:FUJIAN JINXIN TUNGSTEN

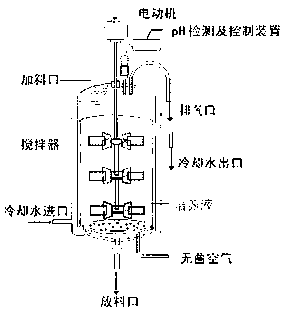

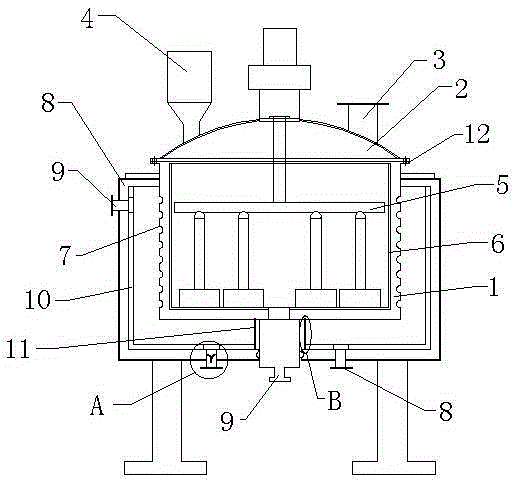

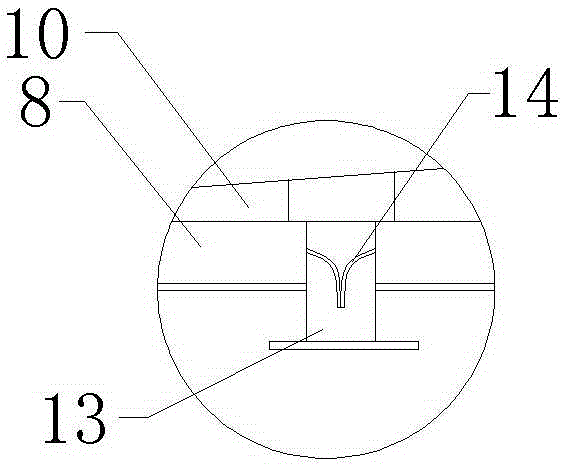

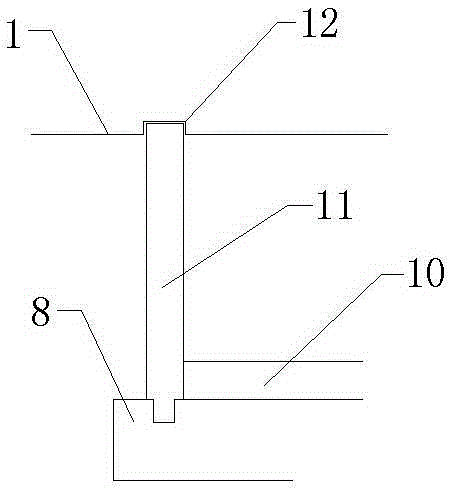

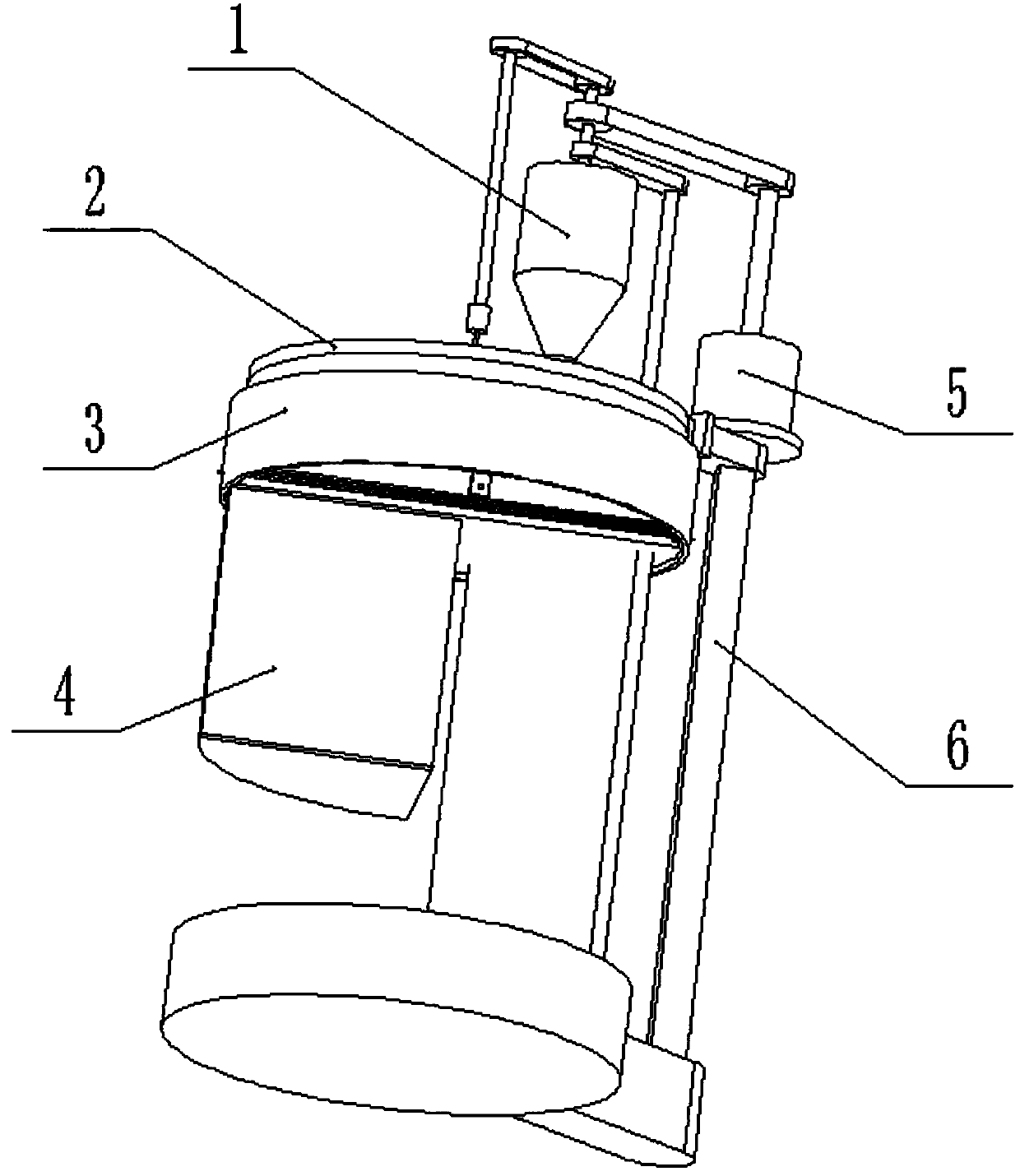

Fermentation tank

ActiveCN103667015AImprove discharge efficiencySave powerBioreactor/fermenter combinationsBiological substance pretreatmentsRadial motionAgricultural engineering

The invention discloses a fermentation tank which comprises an upper cover, a feeding device, a tank body, an air blasting device, an air extracting device, a stirring device and a discharging device, wherein the upper cover is arranged at the upper end of the tank body, a sealing device is arranged between the upper cover and the tank body, the feeding device is mounted on the upper cover, and the discharging device is arranged at the bottom of the tank body; the upper cover can rotate within a certain angle in a reciprocating manner and / or rotate for 360 degrees; the rotation of the upper cover drives the stirring device to rotate; and a slide track is mounted on the upper cover, and the stirring device can move in the radial direction of the slide track. According to the fermentation tank, rotation of the upper cover and the stirring device as well as the radial motion of the stirring device are driven with smaller power consumption, comprehensive stirring without dead angle of a fermented material in the fermentation tank is achieved under the condition of small power consumption; the discharging device is improved scientifically, with the combination of the improvement of the discharging device, the power consumption is reduced more comprehensively, and power required by discharging is reduced remarkably; and the fermentation tank is particularly suitable for vertical stirring of large-scale and supersized solid material fermentation tanks.

Owner:麦行

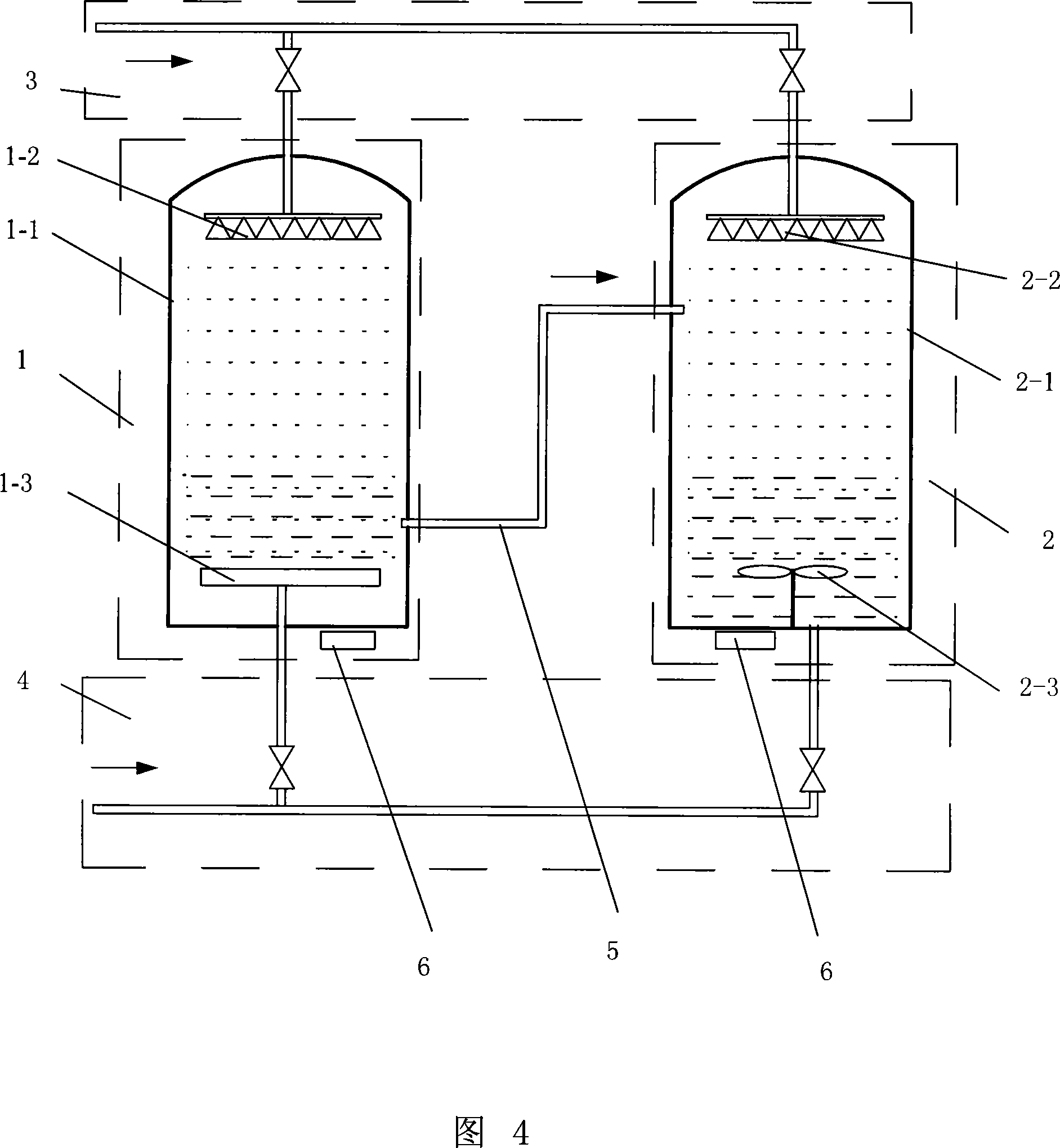

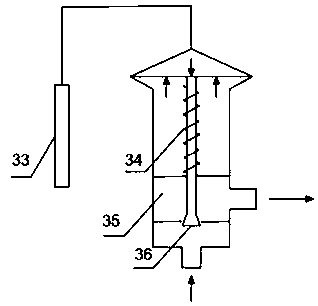

Two-stage series reactor for synthesis of natural gas hydrates

InactiveCN101113379AIncrease contact areaPromote generationGaseous fuelsVena contracta diameterProcess engineering

The invention relates to a double-stage and serial connection reactor synthesized by natural gas and hydrate relating to a synthesized reactor of natural gas and hydrate. The invention overcomes the defectiveness of the existing reactors of bubbling type that the hydrate is easily iced and blocked on the surface of an orifice plate and the defectiveness of the existing reactor of spraying type that the hydrate heat of reaction is difficult to be drained away. The double-stage and serial connection reactor consists of a No.1 reactor, a No.2 reactor, a water inlet pipe, a natural gas inlet pipe and a transfusion pipe. The No.1 reactor comprises a No. 1 autoclave body, a No. 1 spray device and an orifice plate device, with the No.1 spray device being arranged at the top of the inner chamber of the No.1 autoclave body and communicated with the water inlet pipe and the orifice plate being arranged at the bottom of the inner chamber of the No.1 autoclave body and communicated with the natural gas inlet pipe; the No.2 reactor comprises a No.2 autoclave body, a No.2 spray device and a stirring device, with the No.2 spray device being arranged at the top of the inner chamber of the No.2 autoclave body and communicated with the water inlet pipe and the stirring device being arranged at the bottom of the inner chamber of the No.2 autoclave body and the bottom of the No.2 autoclave body being communicated with the natural gas inlet pipe. The side wall of the No.1 autoclave body is communicated with that of the No.2 autoclave body.

Owner:HARBIN INST OF TECH

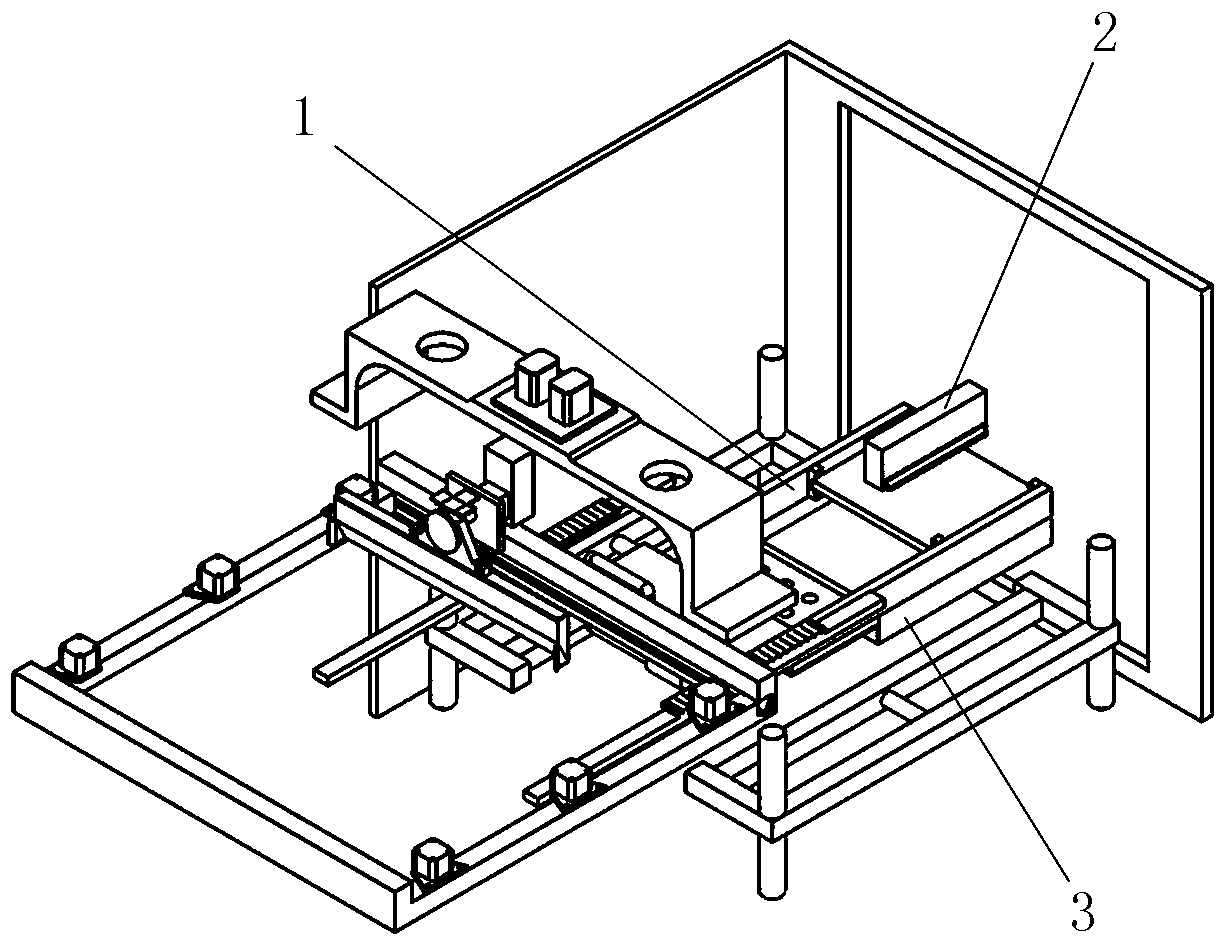

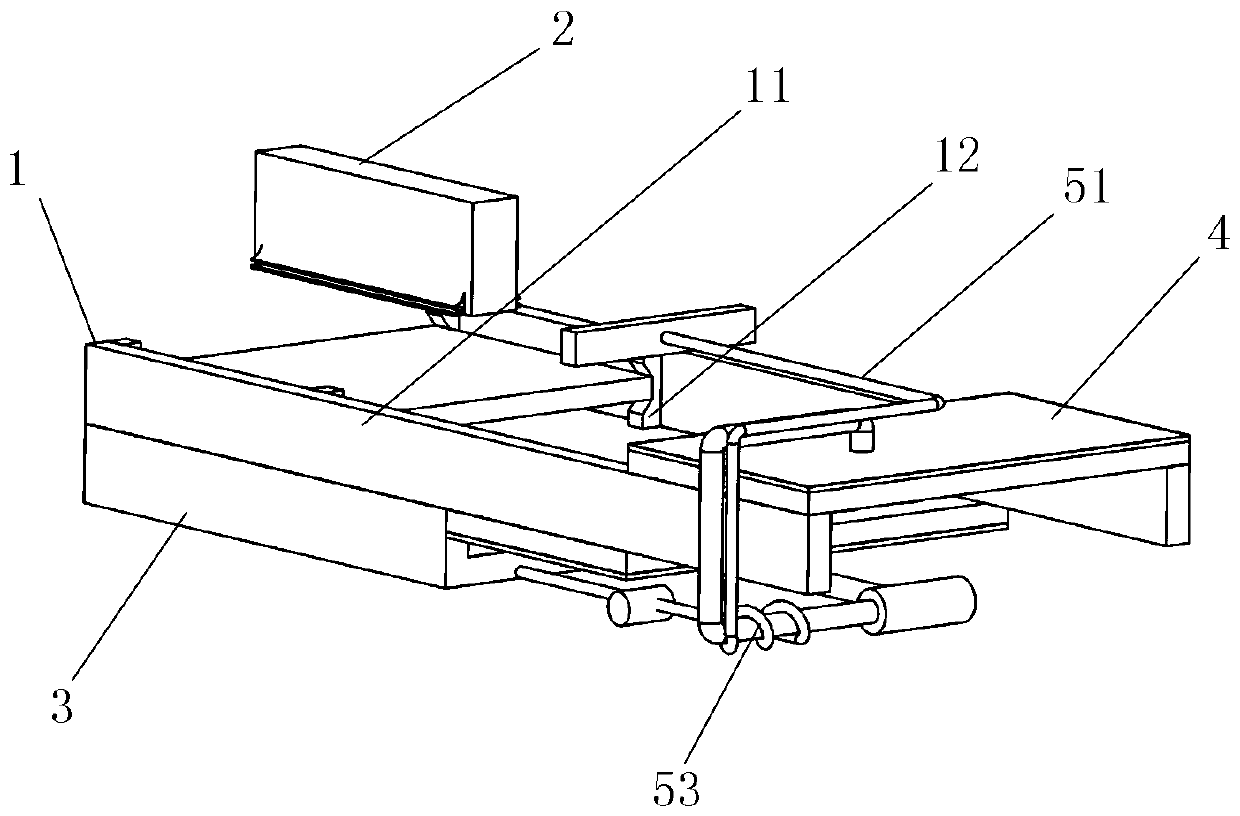

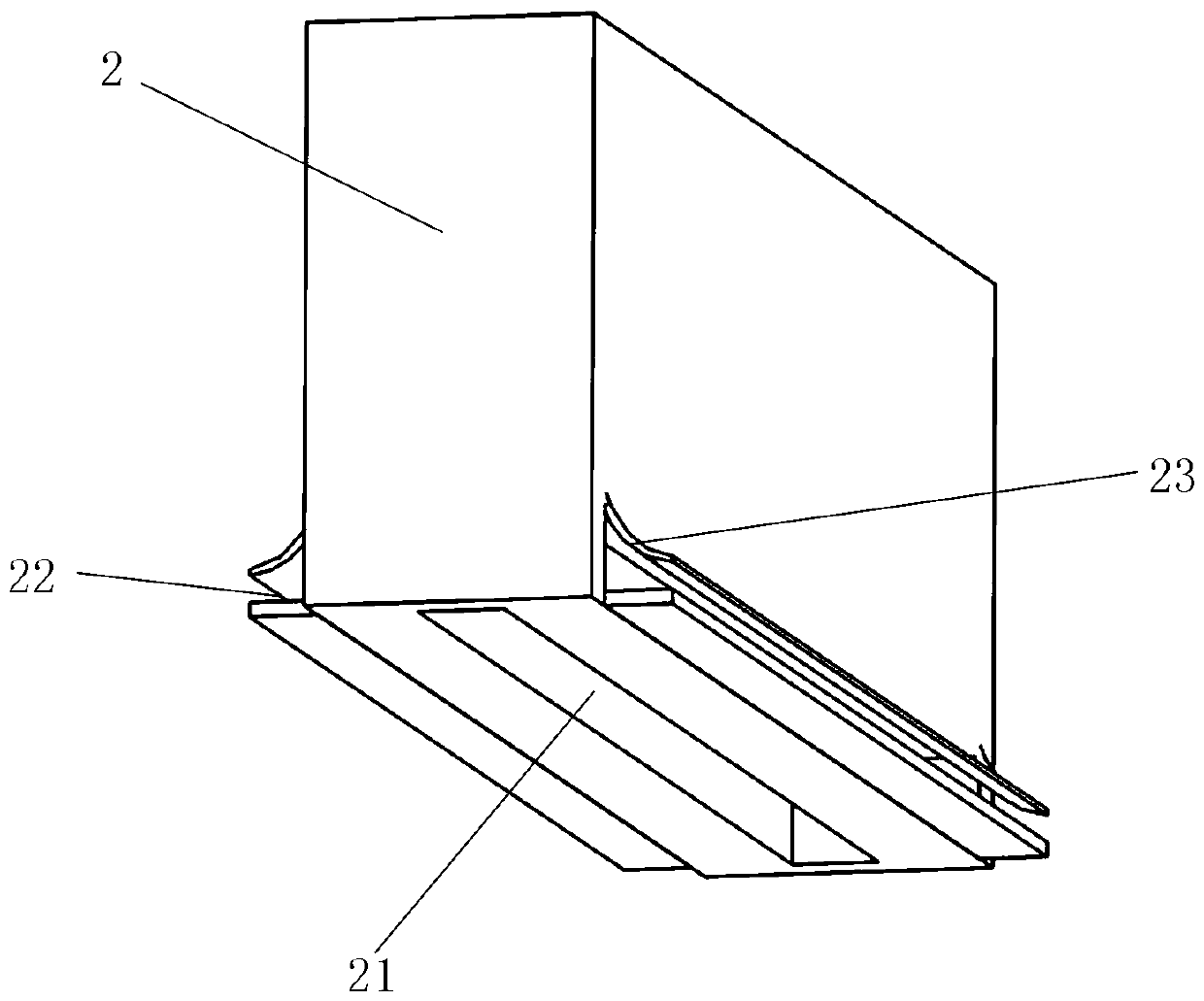

Guide rail punch forming device

ActiveCN110743951ASolve the discharge problemPrevent movementMetal-working feeding devicesMetal working apparatusPunchingStructural engineering

The invention relates to the field of guide rail production, in particular to a guide rail punch forming device. The device comprises a workbench and further comprises a support, a feeding assembly, aloading assembly, a punching assembly and a discharging assembly. The feeding assembly is arranged on the workbench. The loading assembly is arranged on the support and located on one side of the upper portion of the feeding assembly. The punching assembly is arranged at one end of the feeding assembly. The discharging assembly is arranged at the end, away from the feeding assembly, of the punching assembly. The feeding assembly comprises a pushing mechanism and a delivering mechanism. The pushing mechanism is arranged at one end of the workbench. The delivering mechanism is arranged on the workbench and located between the pushing mechanism and the punching assembly. The pushing mechanism, the delivering mechanism, the punching assembly and the discharging assembly are arranged linearlyin the length direction of the workbench in sequence. By means of the guide rail punch forming device, the problem that automatic loading and discharging fail to be performed during guide rail punch forming is solved, the human cost is lowered, and the production efficiency is improved.

Owner:平湖市晨丰五金有限公司

Cooling system of data center machine room

ActiveCN111479441ASolve the discharge problemHigh strengthCooling/ventilation/heating modificationsEnergy consumption minimizationData center

The invention provides a heat dissipation system of a data center machine room. The heat dissipation system comprises heat collection modules, a gas-liquid separator, a liquid storage tank, a heat dissipation device and a fluid working medium, wherein the heat collection module, the gas-liquid separator, the liquid storage tank and the heat dissipation device form a heat dissipation circulating pipeline, the fluid working medium flows in the heat dissipation circulating pipeline, and the collection module comprises an evaporation section, a fluid inlet pipeline, a fluid outlet pipeline, a control mechanism, an induction mechanism and a steam branch pipeline. According to the invention, the data center machine room automatically switches the heat dissipation mode and the working mode to take away the heat generated by the evaporation end of the heat collection module according to the outdoor temperature condition and the thermal load condition of the machine room by taking energy consumption minimization as a target during operating; the flow is automatically adjusted through the flow self-strain mechanism of the heat collection module so as to solve the problem of heat production difference between the heat collection modules in the cabinet; and the refrigeration cycle, the gravity-driven self-cycle and the pump-driven two-phase flow cycle share a radiator array.

Owner:南京艾科美热能科技有限公司

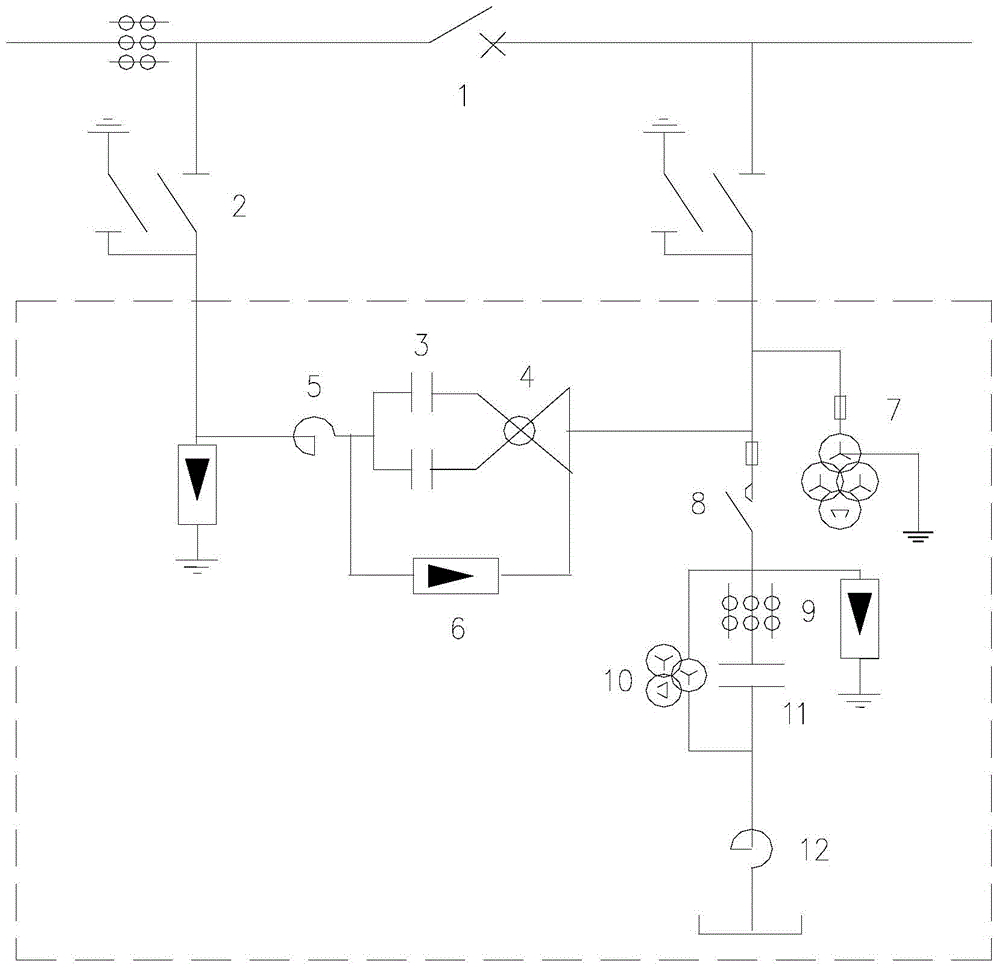

Series-parallel connection comprehensive compensation device for power distribution network low-voltage treatment

ActiveCN105226657AChange reactanceSolve long linesReactive power adjustment/elimination/compensationReactive power compensationElectricityPower flow

The invention relates to a series-parallel connection comprehensive compensation device for power distribution network low-voltage treatment. The series-parallel connection comprehensive compensation device comprises a series connection compensating module, a parallel connection compensating module, and a controller. The series connection compensating module is disposed in a main loop circuit and is connected with a rapid vacuum switch in the main loop circuit. The parallel connection compensating module is connected with the main loop circuit through a vacuum contactor. The controller is connected with the rapid vacuum switch and the vacuum contactor and is used for controlling the operation of the series connection compensating module and the parallel connection compensating module via the rapid vacuum switch and the vacuum contactor according to the voltage and the load at the tail end of a power distribution network system. Compared with a product in the prior art, the series-parallel connection comprehensive compensation device is simultaneously provided with the series connection compensating module and the parallel connection compensating module, comprehensively controls a series capacitor loop circuit and a parallel capacitor loop circuit according to a system requirement, may change circuit reactance and system reactive power flow, and may absorb harmonic waves so as to greatly enhance the voltage regulating capability and range of a device.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

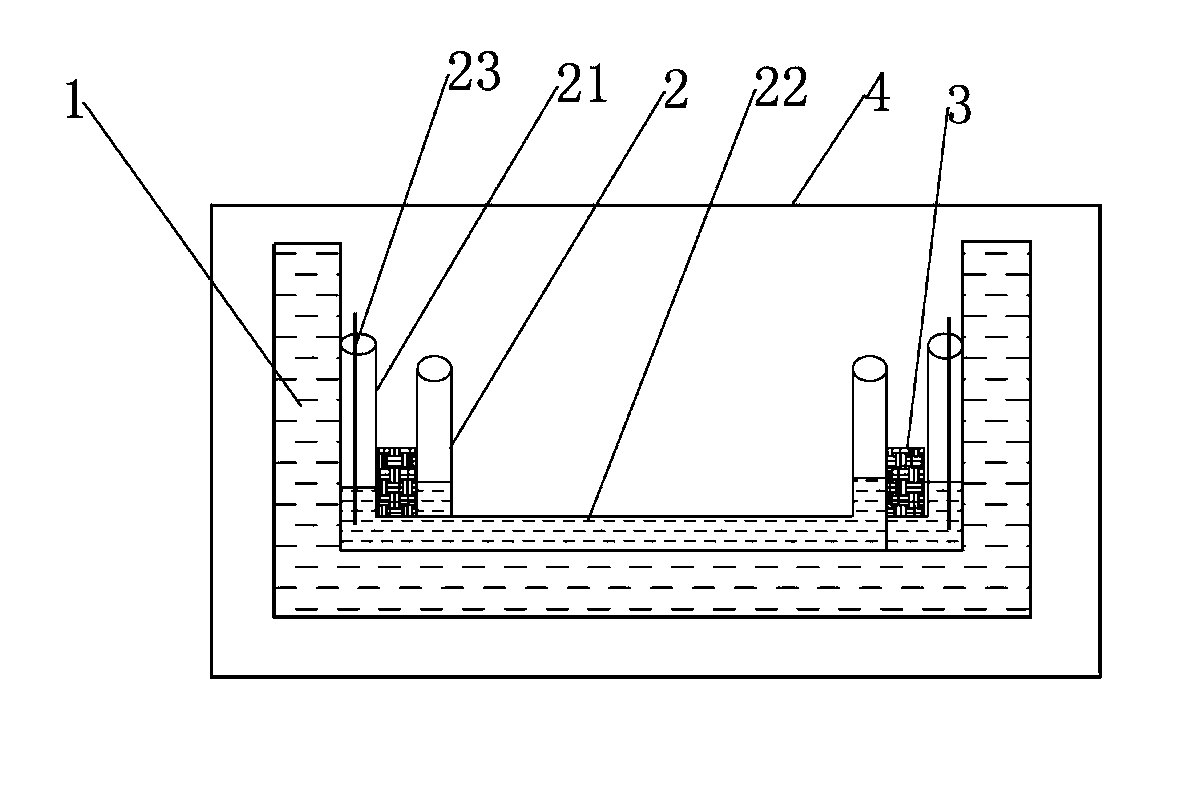

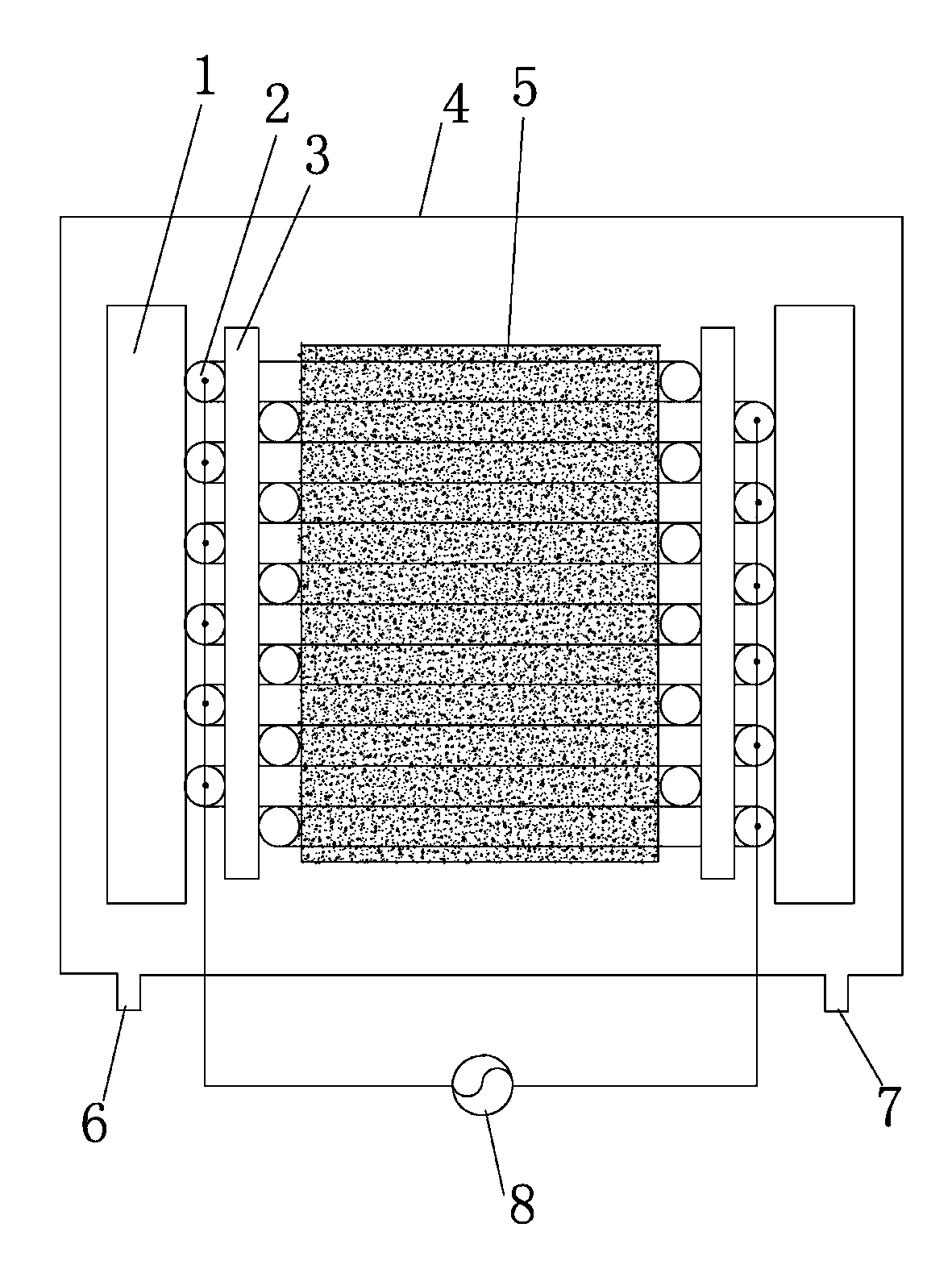

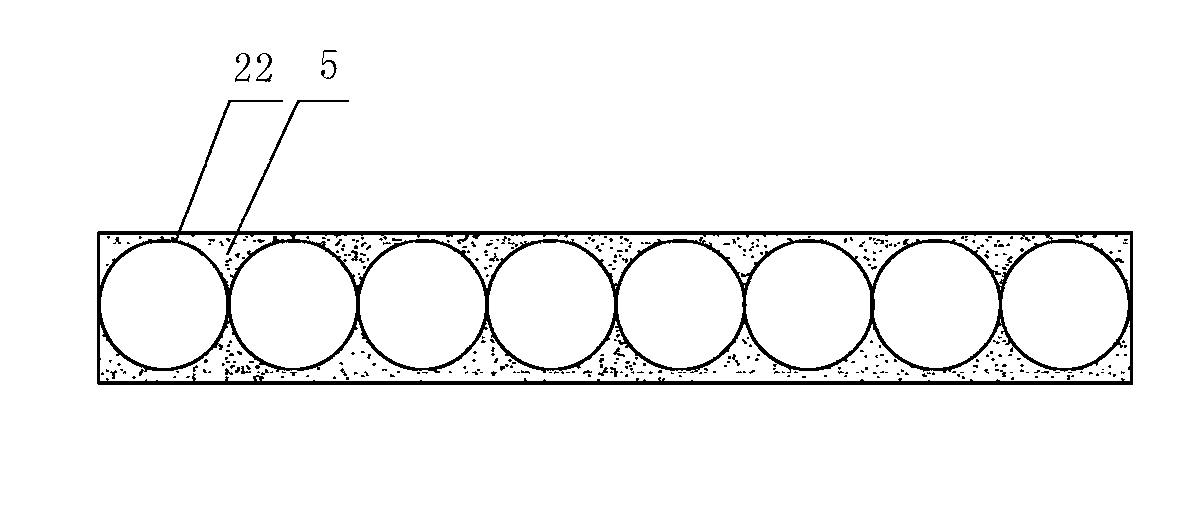

Device for producing large-area surface discharge by utilizing water electrodes

InactiveCN103025040ASolve the discharge problemEasy dischargePlasma techniqueDischarge efficiencyVertical tube

The invention discloses a device for producing large-area surface discharge by utilizing water electrodes. The device structurally comprises a sealing tank and a discharge device installed in the sealing tank, wherein the discharge device comprises a plurality of sequentially arranged U-shaped tubes. Vertical tubes on each side of the U-shaped tubes are aligned at intervals, adjacent vertical tubes are staggered and arranged in two rows, and an insulating dielectric plate is placed between two rows of adjacent vertical tubes on each side. Horizontal base tubes of the U-shaped tubes are embedded into an insulating rubber layer side by side. The water electrode is placed into one vertical tube of the U-shaped tubes, water electrodes placed in the aligned vertical tubes are jointly connected to one output end of a high-voltage alternating current power supply, and the water electrodes placed in other row of aligned vertical tubes are jointly connected to the other output end of the high-voltage alternating current power supply. Compared with a solid electrode dielectric barrier surface discharge device embedded in an insulating dielectric through metal strips, the heat dissipation problem of a discharge electrode is solved fundamentally, the discharge duration and the service life are prolonged, the discharge efficiency is improved, the manufacture process technological requirement is reduced, and the discharge device manufacture cost is reduced. The device for producing the large-area surface discharge by utilizing the water electrodes has wide application prospect in the fields of ozone synthesis, sterilization and disinfection, material processing, aircraft cloaking and the like.

Owner:HEBEI UNIVERSITY

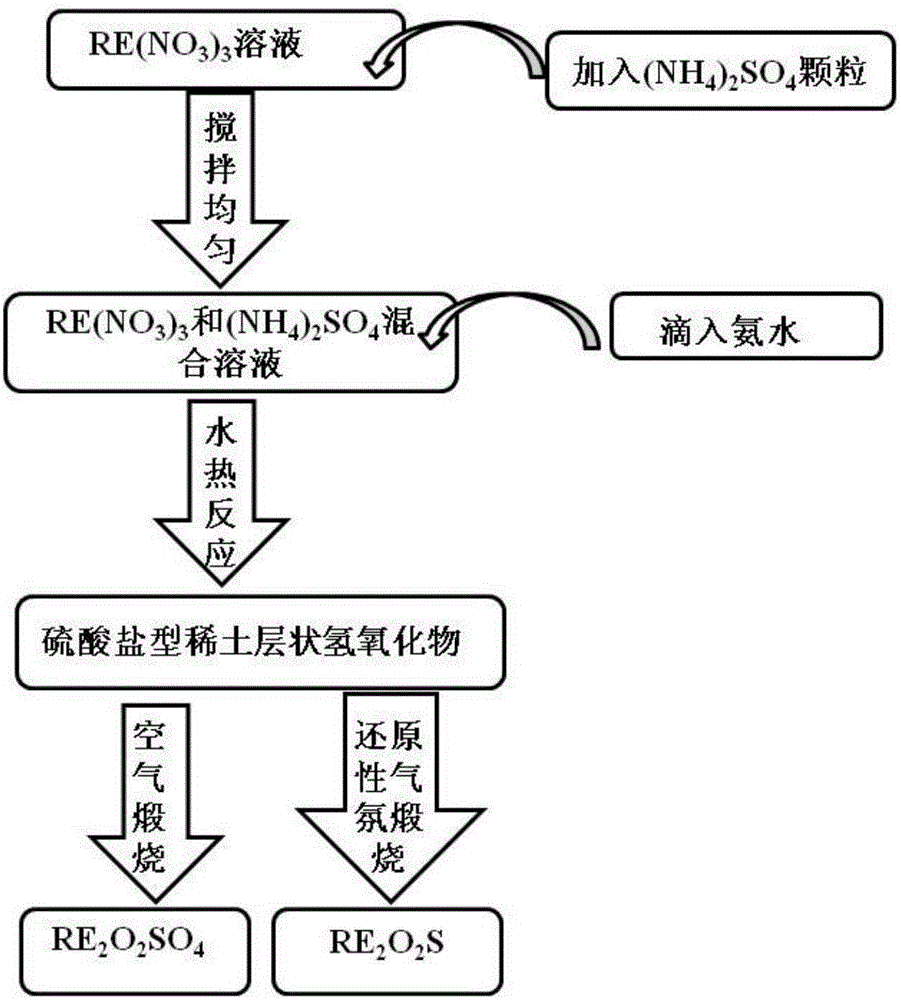

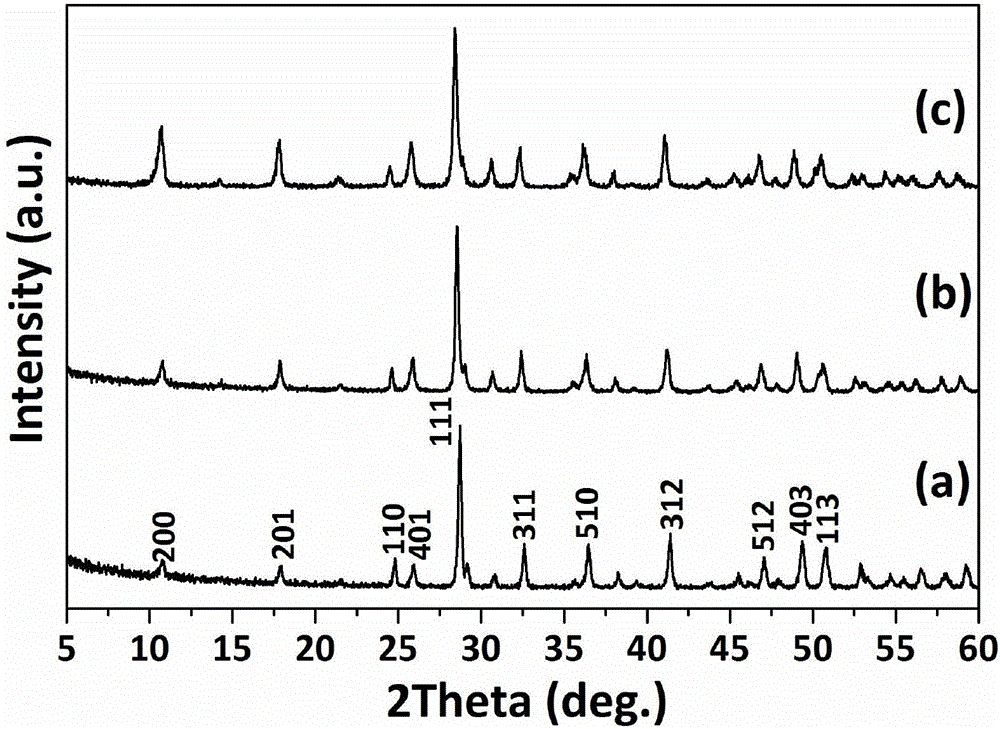

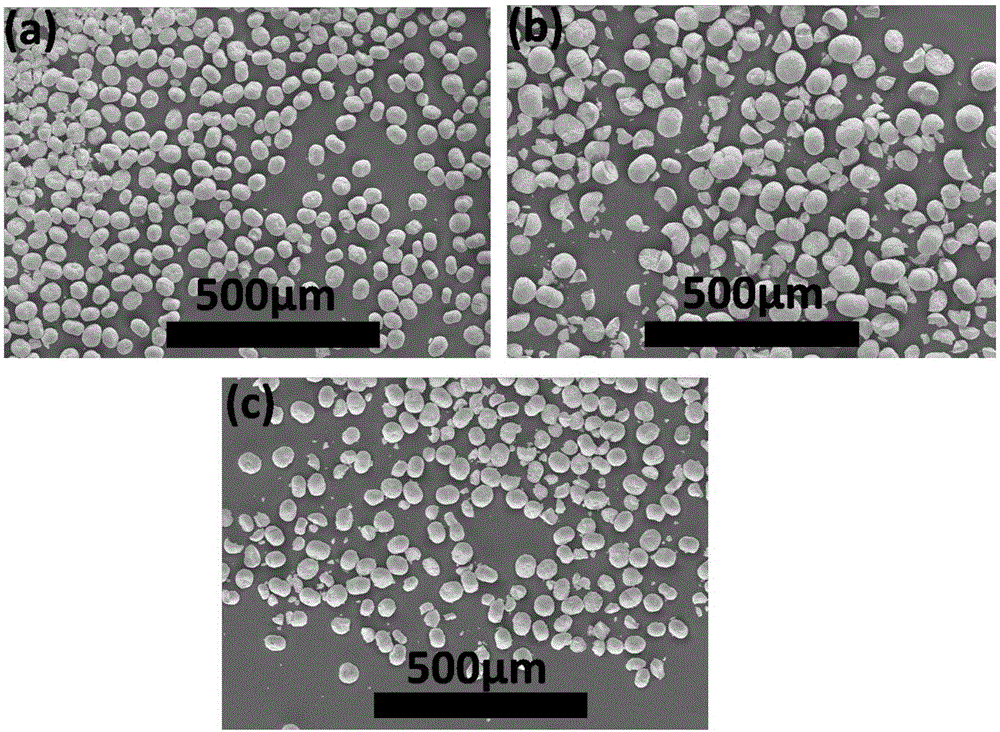

Preparation method of rare earth-doped gadolinium oxysulfide and oxygen-containing gadolinium sulphate up-conversion phosphor

ActiveCN106520121ASolve the discharge problemRealize green manufacturingLuminescent compositionsOxygenUp conversion

The invention provides a preparation method of rare earth-doped gadolinium oxysulfide and oxygen-containing gadolinium sulphate up-conversion phosphor, and belongs to the field of material science. The method comprises the following steps that 1, Gd(NO3)3.6H2O, Yb(NO3)3.6H2O and Ln(NO3)3.6H2O are mixed, deionized water is added, and a RE(NO3)3 solution is obtained; 2, ammonium sulfate is dissolved into the RE(NO3)3 solution, stirring is conducted, stirring continues, ammonia water is added, the pH value is regulated, and suspension is obtained; 3, the suspension is subjected to a hydrothermal reaction for 1-72 h at the temperature of 100 DEG C to 150 DEG C and then naturally cooled to room temperature, and a reaction product is obtained; 4, the reaction product is centrifugally separated, washed and dried, and a white powder precursor is obtained; 5, the white powder precursor is calcined, and the rare earth ion-doped Gd2O2S or Gd2O2SO4 up-conversion phosphor is obtained. According to the method, the problems of usage of sulfur-containing raw materials and discharge of harmful by-products in a conventional method are effectively solved, and the method is a green and environment-friendly preparation technique.

Owner:NORTHEASTERN UNIV

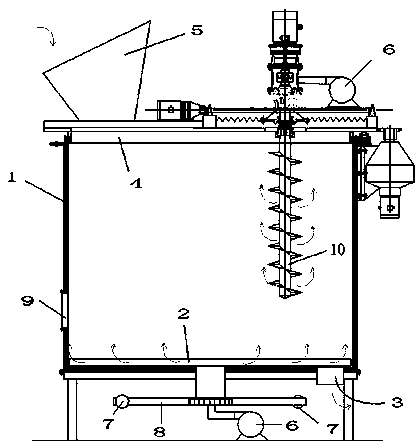

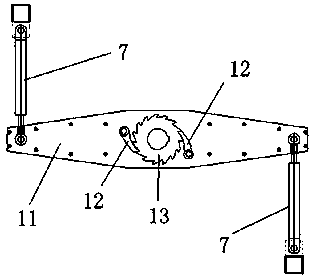

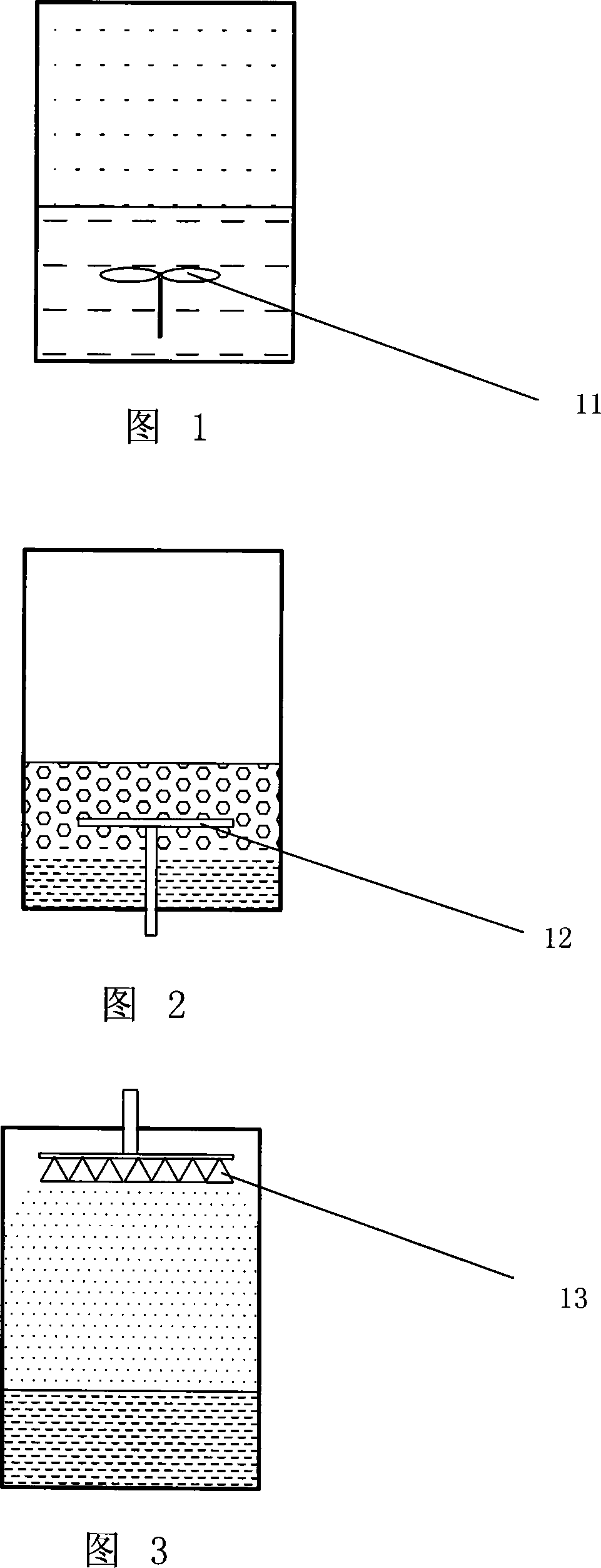

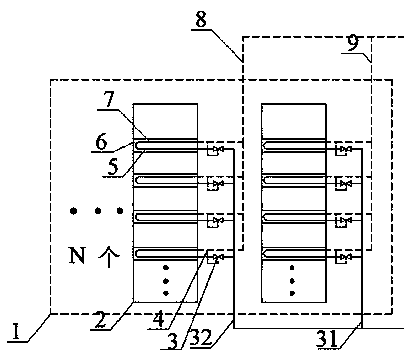

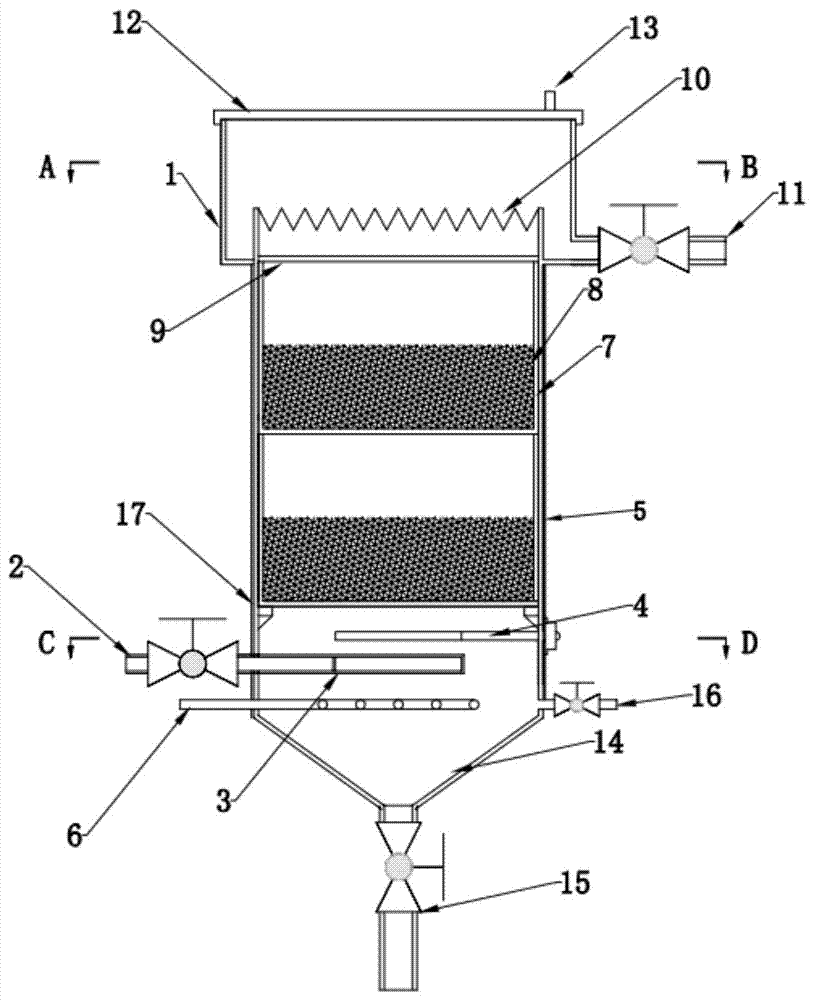

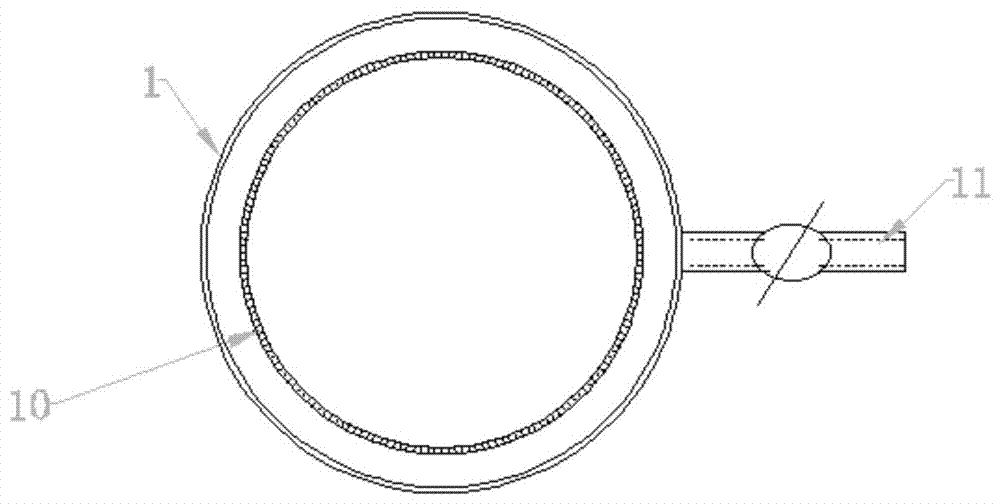

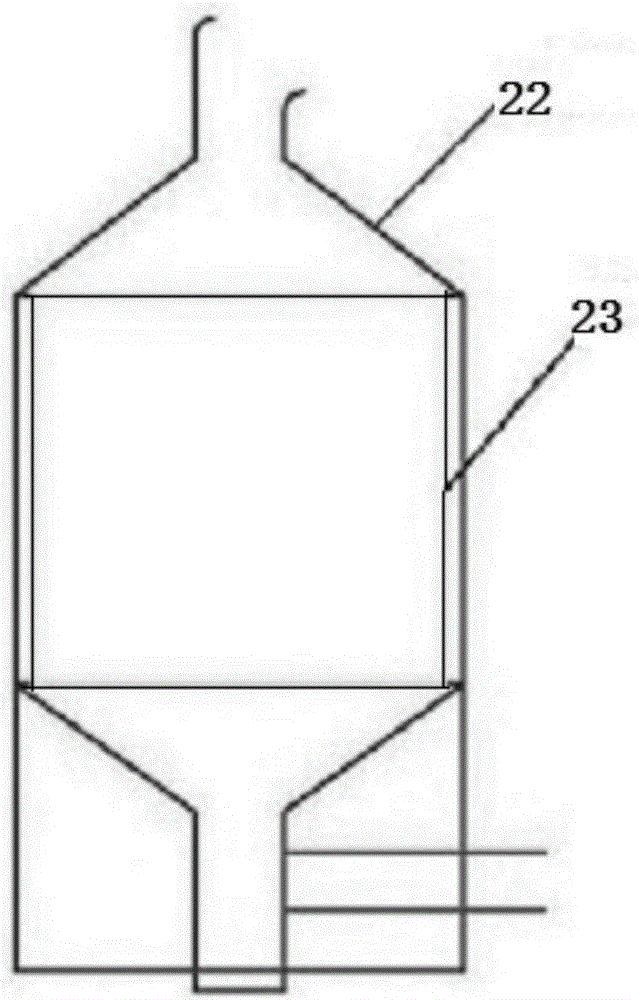

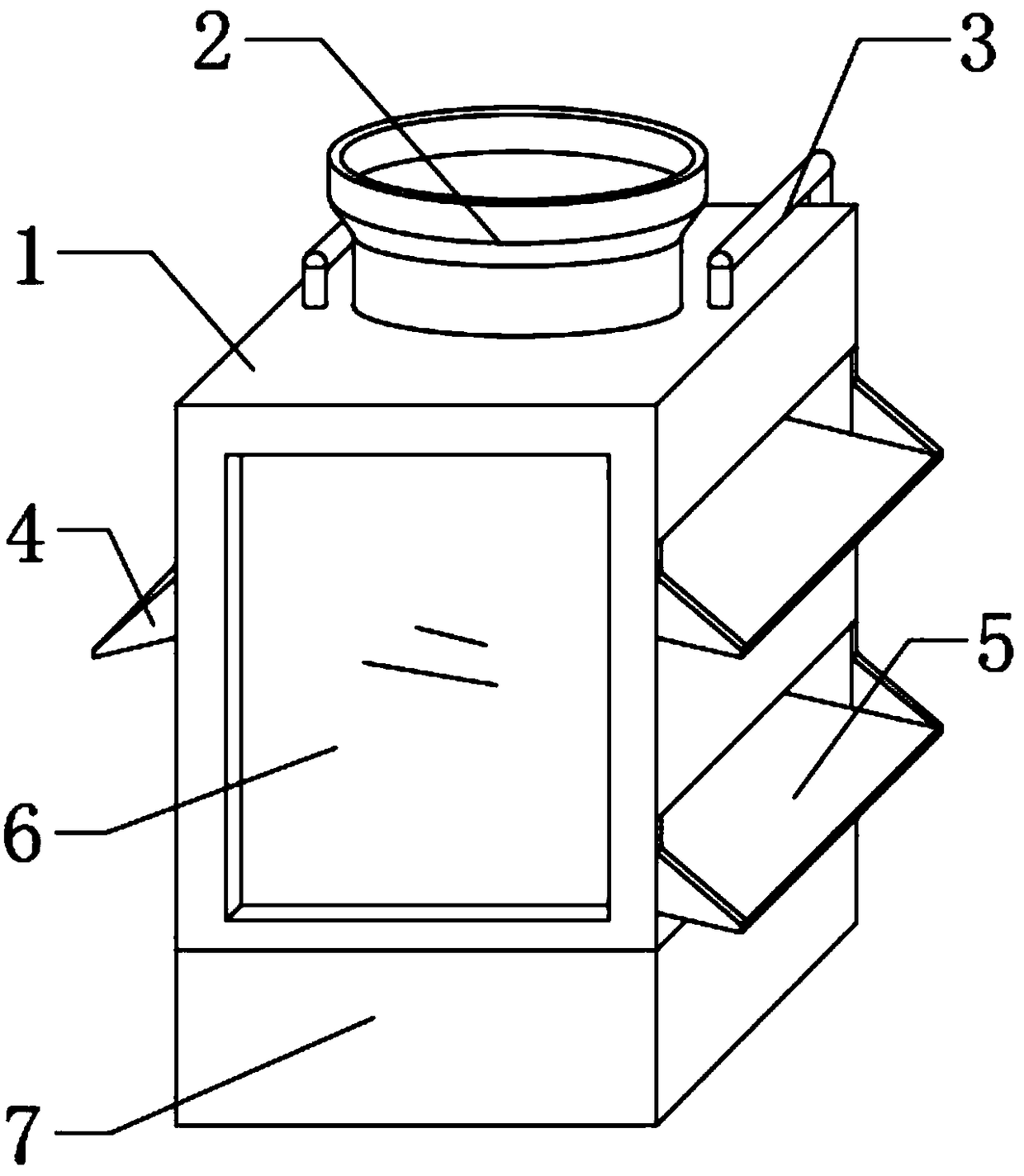

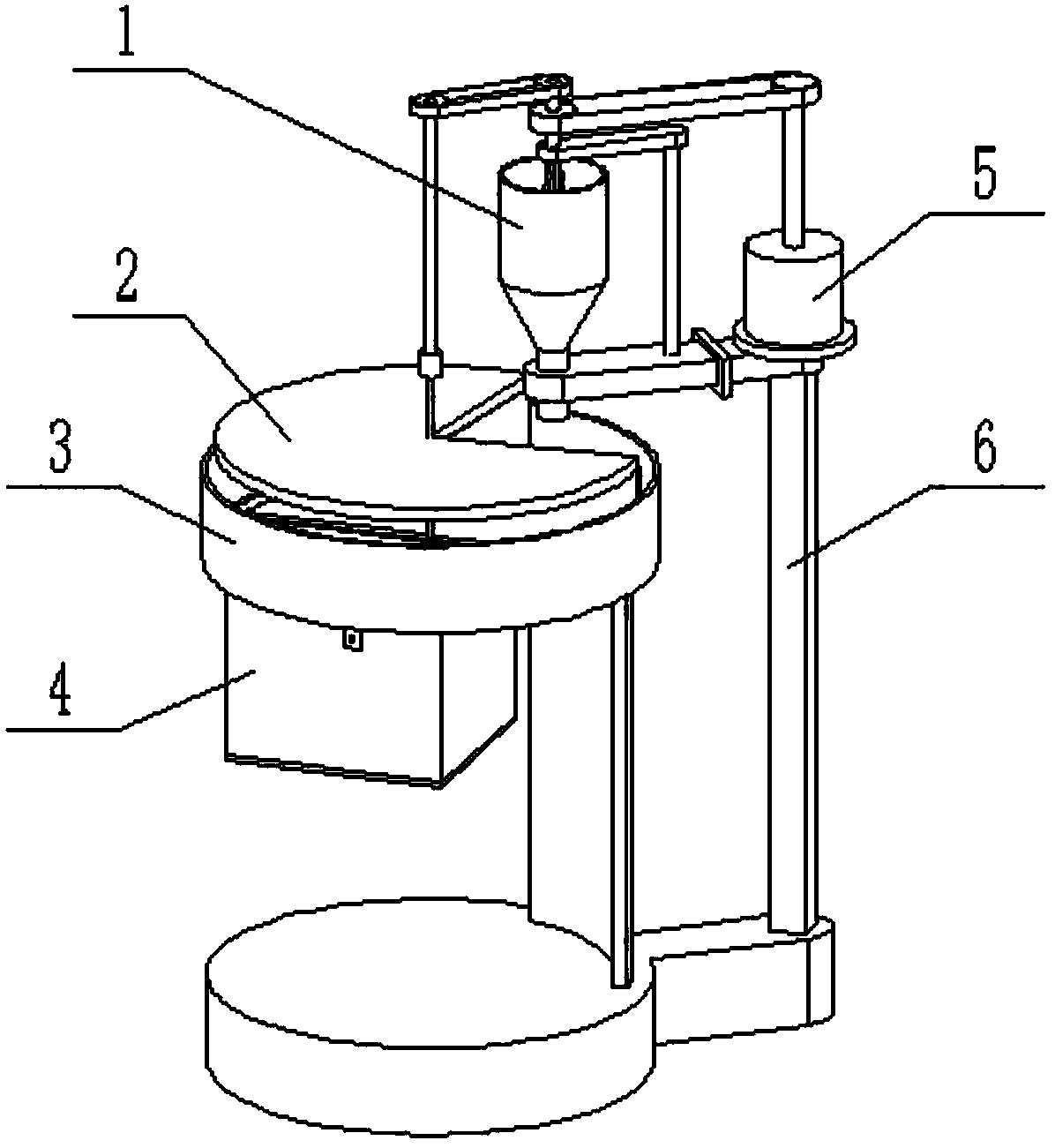

Continuous enlarging cultivation device and method for mineral-bioleaching microorganisms

ActiveCN107881081ACompact structureImprove cultivation efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationMicroorganism

The invention discloses a continuous enlarging cultivation device for mineral-bioleaching microorganisms. The cultivation device comprises a cylinder which is formed by sequentially connecting an upper cylinder body, a middle cylinder body and a lower cylinder body, wherein the upper cylinder body can collect feed liquid which is discharged due to overflowing, the middle cylinder body can continuously cultivate the microorganisms in an enlarged mode, and the lower cylinder body can collect discharged precipitates. A detachable multi-layer filler assembly is arranged in the middle cylinder body, the multi-layer filler assembly is composed of a multi-layer filler box and filler which is arranged in the filler box, a heater, a nutrient solution distributing plate and an aeration device are arranged below the multi-layer filler assembly, and the aeration device is arranged below the nutrient solution distributing plate. The cultivation device is simple in design, continuous cultivation canbe achieved, the concentration of the microorganisms in a mature bacteria solution can be improved, and while continuous production of the high-concentration bacteria solution is maintained, the problem about the loss of strains in a reactor is effectively eased. The cultivation efficiency of the mineral-bioleaching microorganisms is improved, and the device has the advantages of being safe, efficient, low in space occupation, low in power consumption, simple and easy in operation and capable of achieving combined cultivation of a plurality of cultivation devices.

Owner:CENT SOUTH UNIV

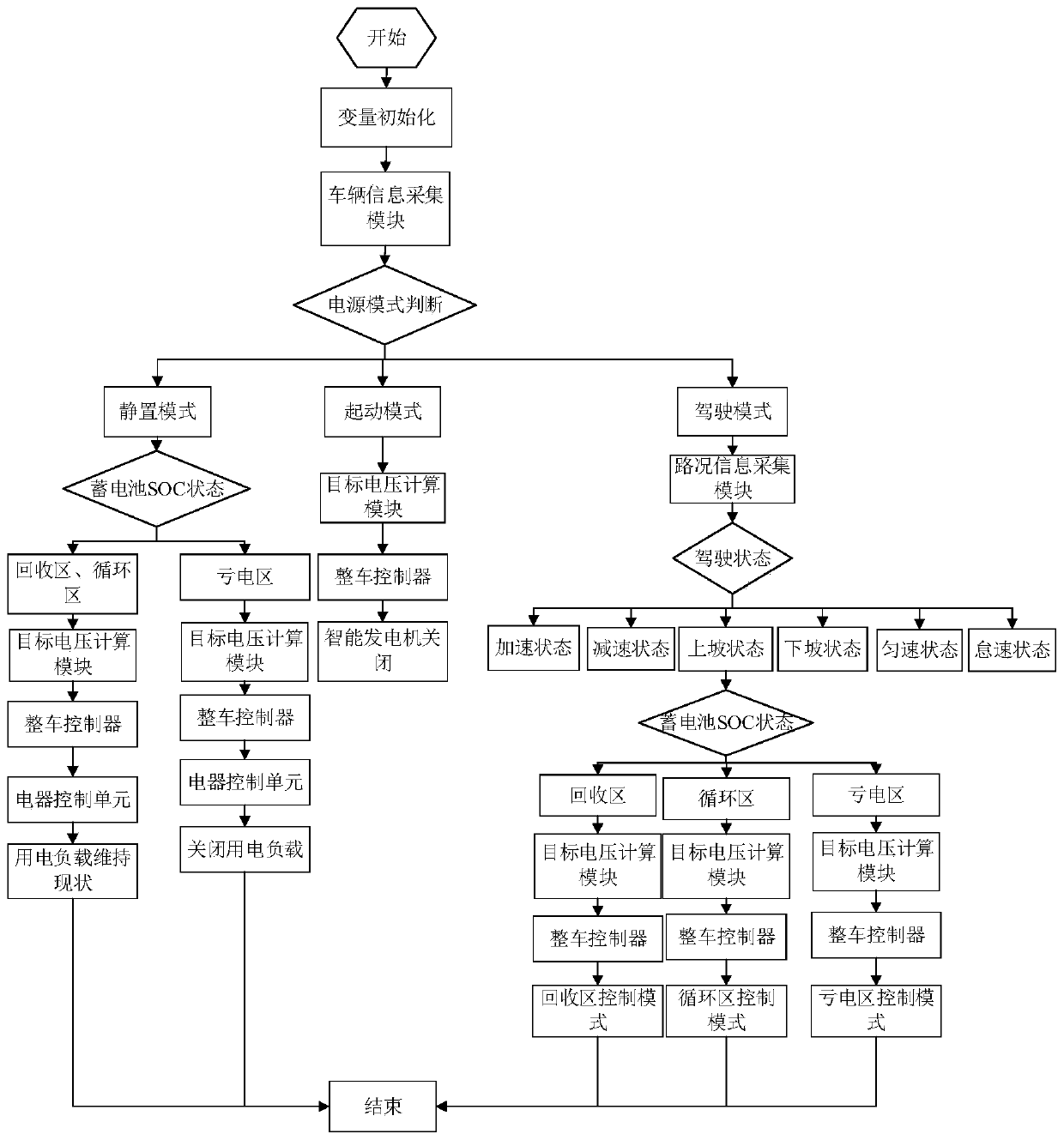

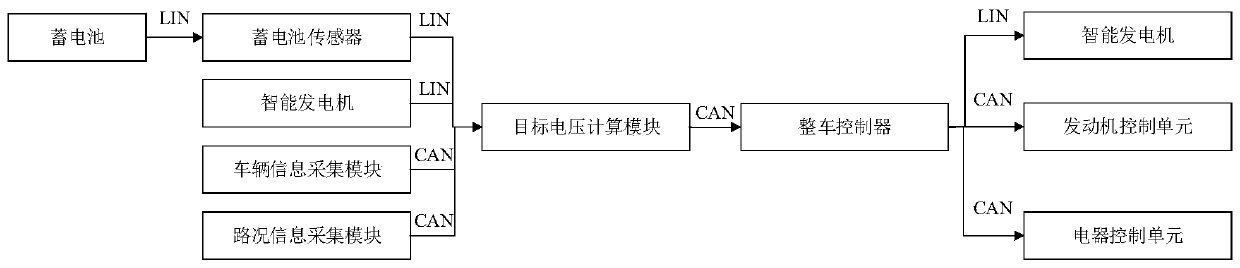

Vehicle generator control method and system

ActiveCN111409576ASolve frequent chargingSolve the discharge problemElectric/fluid circuitControl engineeringControl theory

The invention relates to a vehicle generator control method and system. The control method comprises the following steps of 1) judging the state of a vehicle, and judging road condition information infront of the vehicle when the vehicle is in a starting acceleration state, and 2) if the traffic jam occurs in the front road condition, controlling the generator to output the voltage value of the current storage battery end, so that the storage battery is not charged or discharged. The road condition is also considered in the generator control process, and the problem of frequent charging and discharging of the storage battery due to the fact that the road condition is not considered in the current control process is solved.

Owner:ZHENGZHOU YUTONG BUS CO LTD

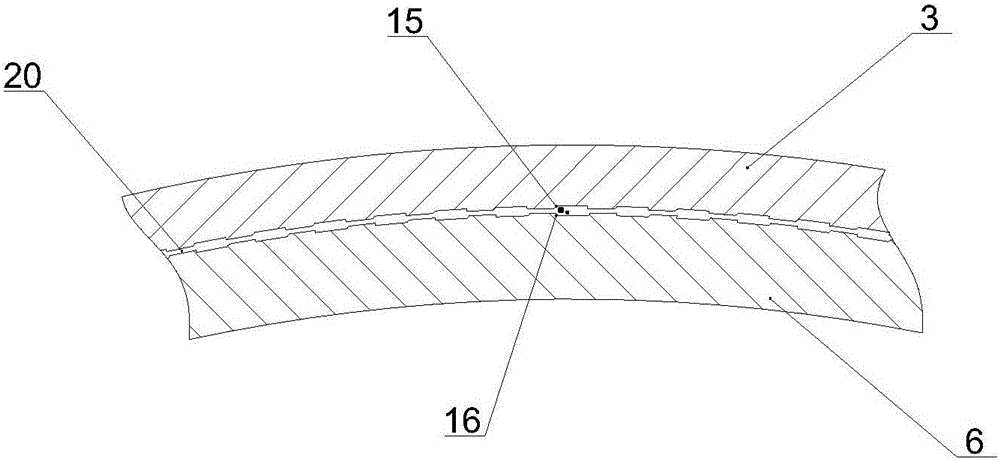

Rapid vulcanization die for building lamination shock insulation rubber bearing

InactiveCN103786282AAvoid heat transfer barriersAchieving direct heat conductionVulcanizationEngineering

The invention discloses a rapid vulcanization die for a building lamination shock insulation rubber bearing. The rapid vulcanization die comprises an inner heating die with a heat conduction strip, an outer heating die with a heat conduction strip, an excessive glue groove, heat conduction strips, an upper heating template, a lower heating template, a positioning shaft, a positioning hole and a positioning shaft mounting groove, wherein the lower heating template is mounted on a support, the outer heating die with the heat conduction strip is arranged on the upper surface of the lower heating template, the inner heating die with the heat conduction strip is arranged in the center of the outer heating die with the heat conduction strip, the height of the outer heating die with the heat conduction strip is equal to that of the inner heating die with the heat conduction strip, and the upper heating template is arranged at the tops of the outer heating die with the heat conduction strip and the inner heating die with the heat conduction strip. The rapid vulcanization die fully utilizes the structural principle of vulcanization equipment and a vulcanization target to realize rapid and uniform vulcanization and efficient mounting, is applicable to vulcanization processing of various rubber bearings, such as a standard rubber bearing, a pencil lead rubber bearing, a high damping rubber bearing and a stacked rubber bearing, and is high in vulcanization efficiency and rapid and convenient to mount and maintain.

Owner:彭勃

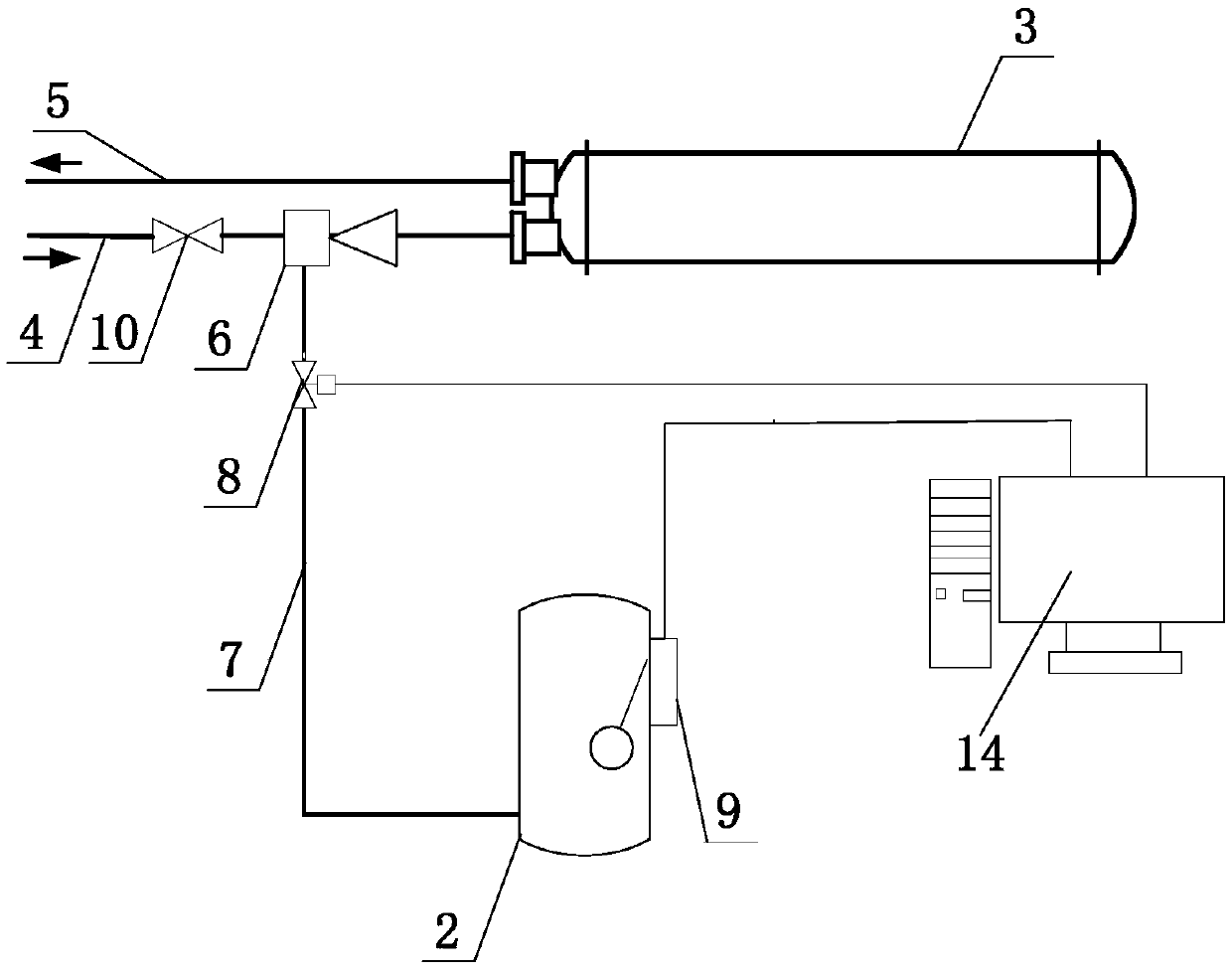

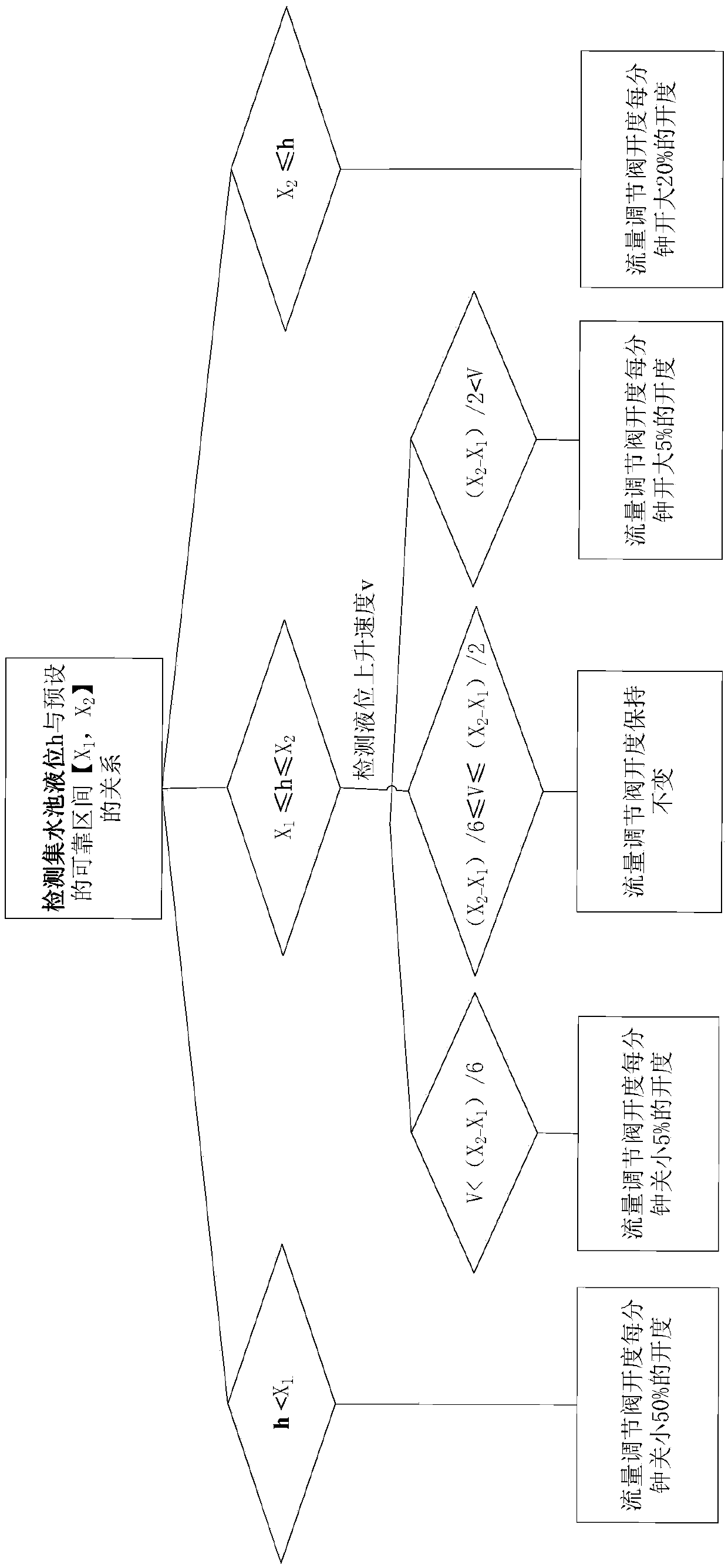

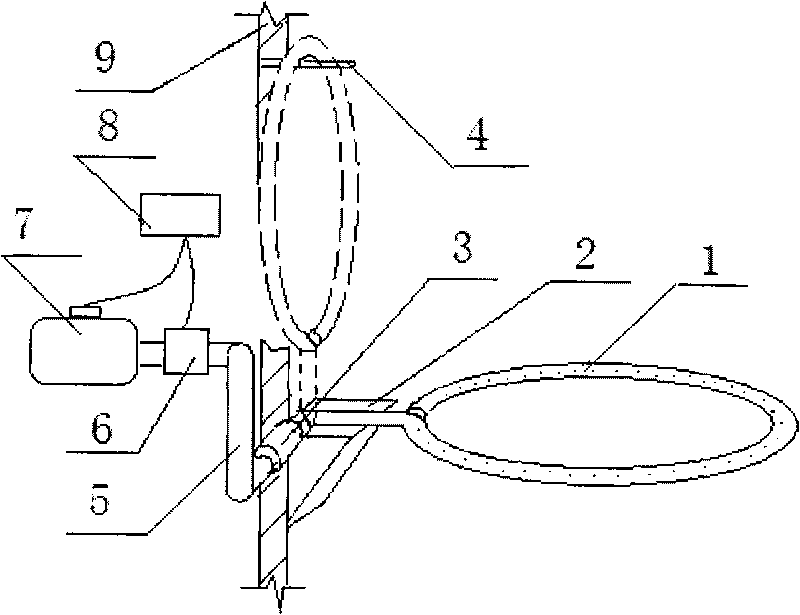

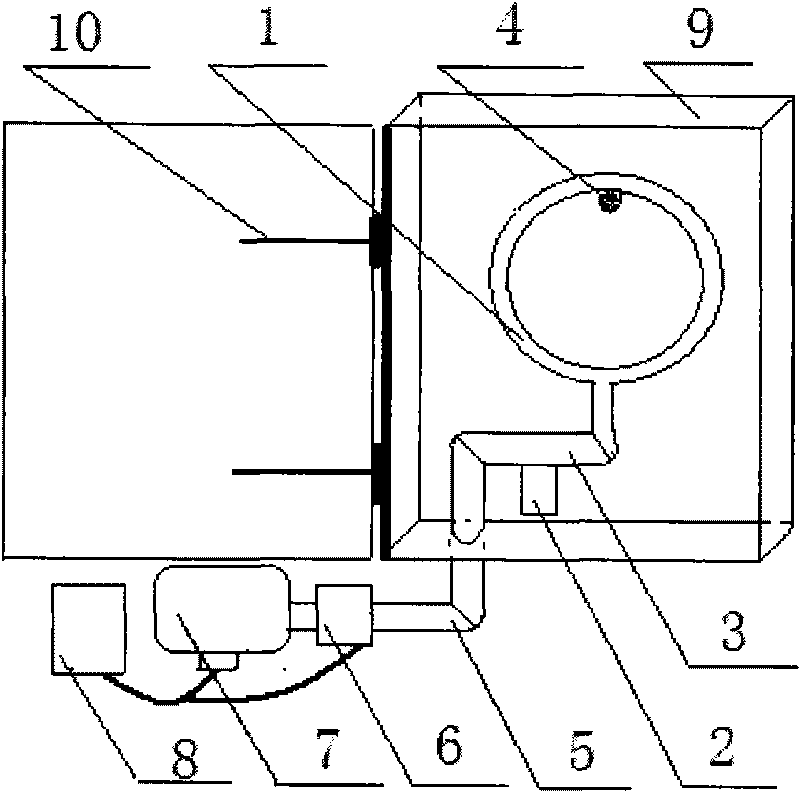

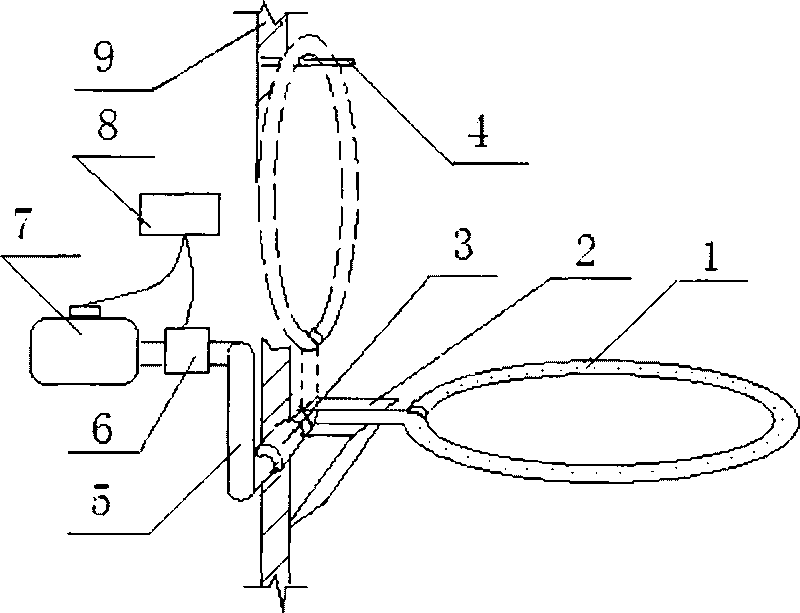

Water-cooling conditioner and condensate water control method thereof

ActiveCN105509256AImprove energy efficiencySolve the problem of loss and need to replenish waterMechanical apparatusCondensate preventionEnvironmental engineeringControl valves

The invention discloses a water-cooling conditioner and a condensate water control method. The water-cooling conditioner comprises a bottom drain pan (1), a condenser (3), a cooling water inlet pipe (4), a cooling water outlet pipe (5), a water pumping device (6), a condensate water inlet pipe (7) and a first control valve (8), wherein a water collection tank (2) is arranged at the bottom of the bottom drain pan (1); the cooling water inlet pipe (4) is connected to a water inlet of the condenser (3); the cooling water outlet pipe (5) is connected to a water outlet of the condenser (3); the water pumping device (6) is arranged on the cooling water inlet pipe (4); the condensate water inlet pipe (7) is communicated with a part between the cooling water inlet pipe (4) at the inlet end of the water pumping device (6) and the water collection tank (2); the first control valve (8) is arranged on the condensate water inlet pipe (7). According to the water-cooling conditioner disclosed by the invention, the problems in the prior art that the air quality in a room is seriously influenced since condensate water is accumulated in a unit and exposed to the outside to generate a great deal of bacteria can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

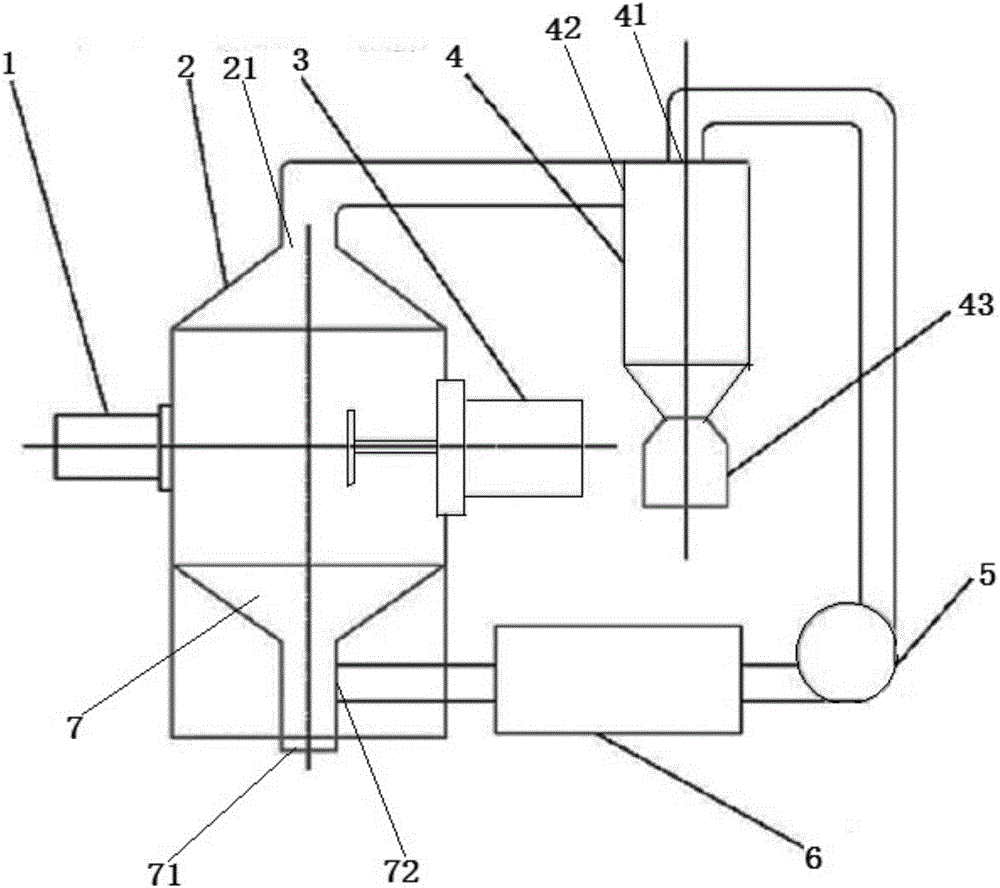

Preparation equipment for metallic nano powder and use method of preparation equipment

ActiveCN106392091ACool evenlySolve pollutionTransportation and packagingMetal-working apparatusCold airEngineering

Preparation equipment for metallic nano powder comprises a feeding mechanism, a reactor, a high-pressure generator, a cyclone collector, a high-pressure fan and a cooler; the reactor is a vertical reactor; a first air outlet is formed in the top of the reactor; a funnel-shaped collecting device is arranged at the bottom of the reactor and comprises a first air inlet and a discharging port; the feeding mechanism and the high-pressure generator are located at the upper part of the collecting device; the cyclone collector comprises a second air outlet formed in the top, a second air inlet formed in the side and a collector arranged at the bottom; the cyclone collector communicates with the reactor through an air pipe connecting the first air outlet with the second air inlet; the high-pressure fan communicates with the cyclone collector through an air pipe and is connected with a condenser through an air pipe; and the condenser communicates with the collecting device via the first air inlet through an air pipe and supplies cold air to the reactor through the collecting device. With the equipment, metal wire residues and large-particle metallic nano powder can be effectively separated from metallic nano powder with the target particle size.

Owner:佛山市金纳新材料科技有限公司

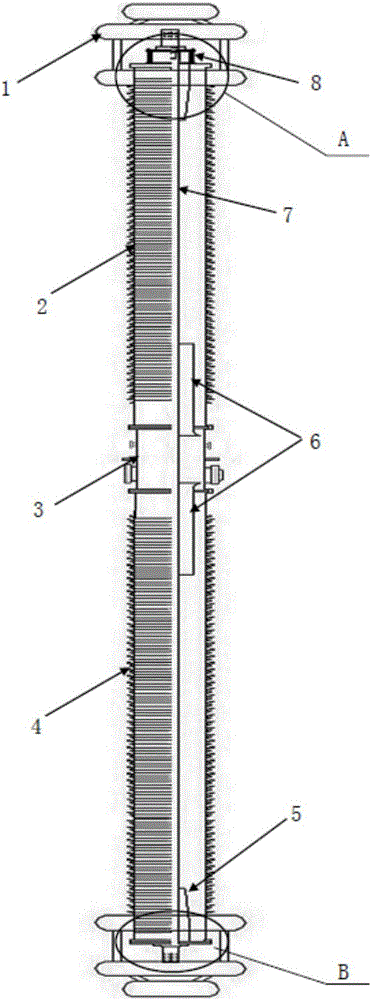

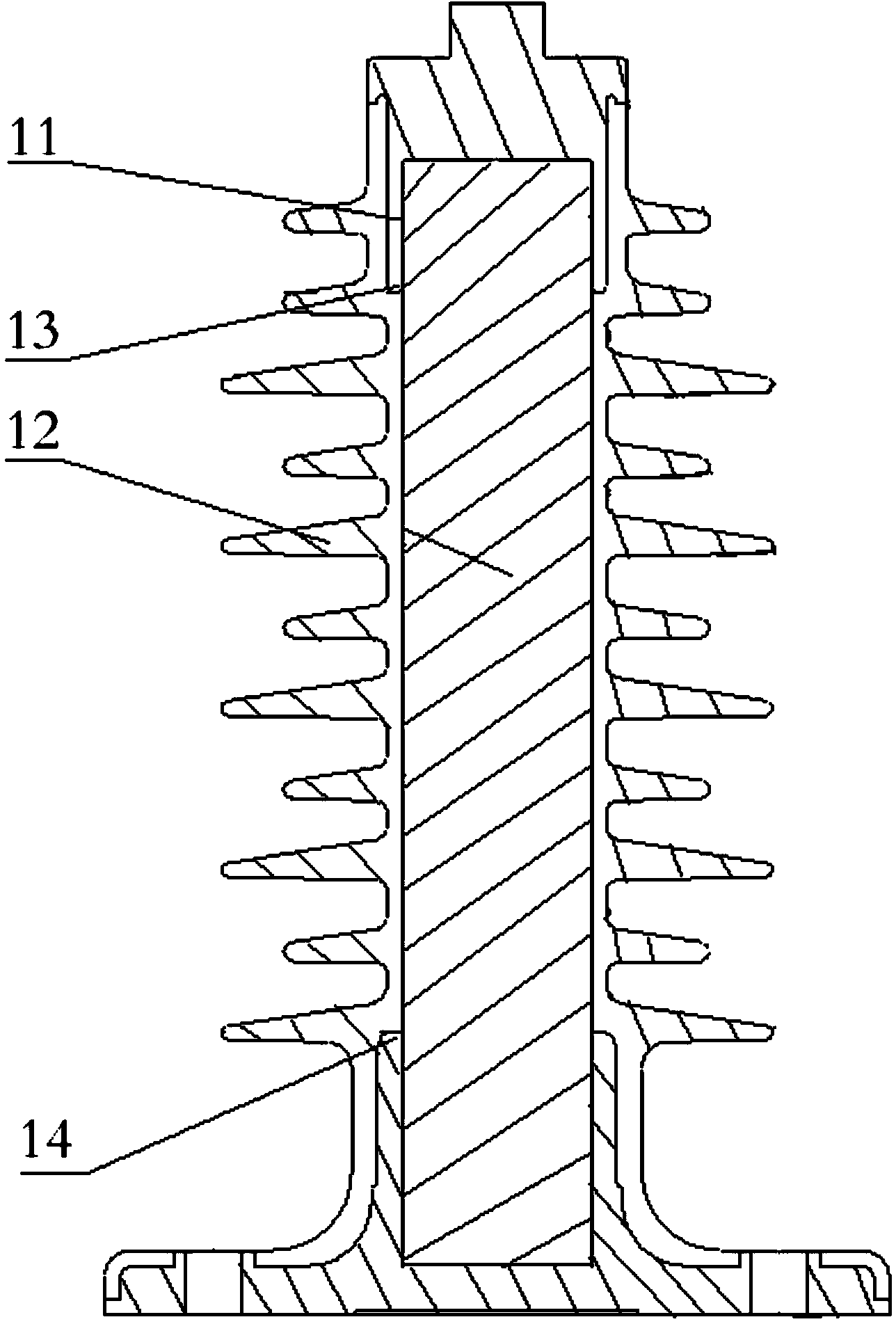

Motor train roof composite insulator with interface breakdown prevention function

InactiveCN103971861ANot easy to penetrateBreakdown will notElectric locomotivesSupporting insulatorsComposite insulatorsEngineering

The invention relates to the field of motor trains, in particular to a motor train roof composite insulator with the interface breakdown prevention function. The motor train roof composite insulator with the interface breakdown prevention function comprises a supporting body. At least five sets of umbrella skirts are arranged side by side in the axial direction by surrounding the side wall of the supporting body. According to the at least five sets of umbrella skirts, the at least four umbrella skirts located at the upper end respectively comprise a large umbrella and a small umbrella, and the at least one set of umbrella skirts at the bottommost end respectively comprise two small umbrellas. Due to the improved umbrella skirt structure, surge voltage withstanding is facilitated, an interface is not easily broken down, even, the intensity of an electric field of the improved interface is not larger than 3 kV / mm, and interface breakdown does not occur even if gas exists in the interface.

Owner:BEIJING RAILWAY INST OF MECHANICAL & ELECTRICAL ENG

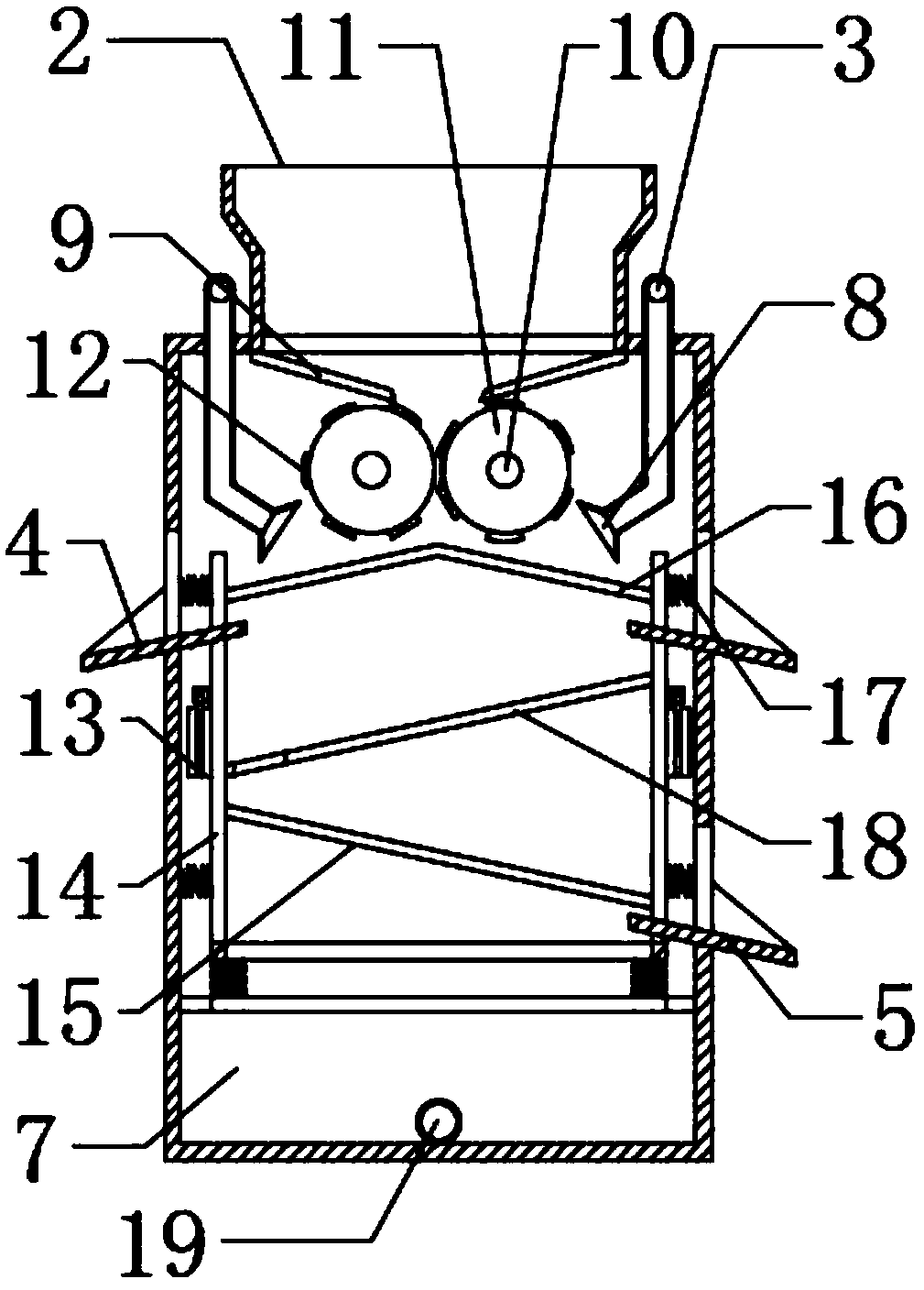

River sludge treatment device for environmental control

InactiveCN109081534ASolve the discharge problemIncrease moisture contentSludge treatmentGrain treatmentsMotor driveSludge

The invention discloses a river sludge treatment device for environmental control. The device comprises a device body, the top of the device body is provided with a feeding port and a branch water pipe in a penetrating manner, the feeding port is positioned in the middle of the top of the device body, and the river way sludge treatment device for environmental control is provided with a baffle plate, two grinding rollers and projection. After sludge to be treated is added from the feeding port, the sludge flows between the two grinding rollers along the an oblique plane under the guide actionof the baffle plate, a motor drives two rotating shafts to reversely rotate through two engaged gears and drives the two grinding rollers to rotate, the sludge falling between the grinding rollers isextruded by the grinding rollers, blocks in the sludge are rolled and crushed, the crushed sludge falls to the top of a first filter screen to be filtered, fine sludge penetrates holes of the first filter screen, the device solves the problem that block-shaped sludge serves as an impurity to be discharged, and filtering effects are improved.

Owner:HEFEI YAOSHI TONGHUI TECH CO LTD

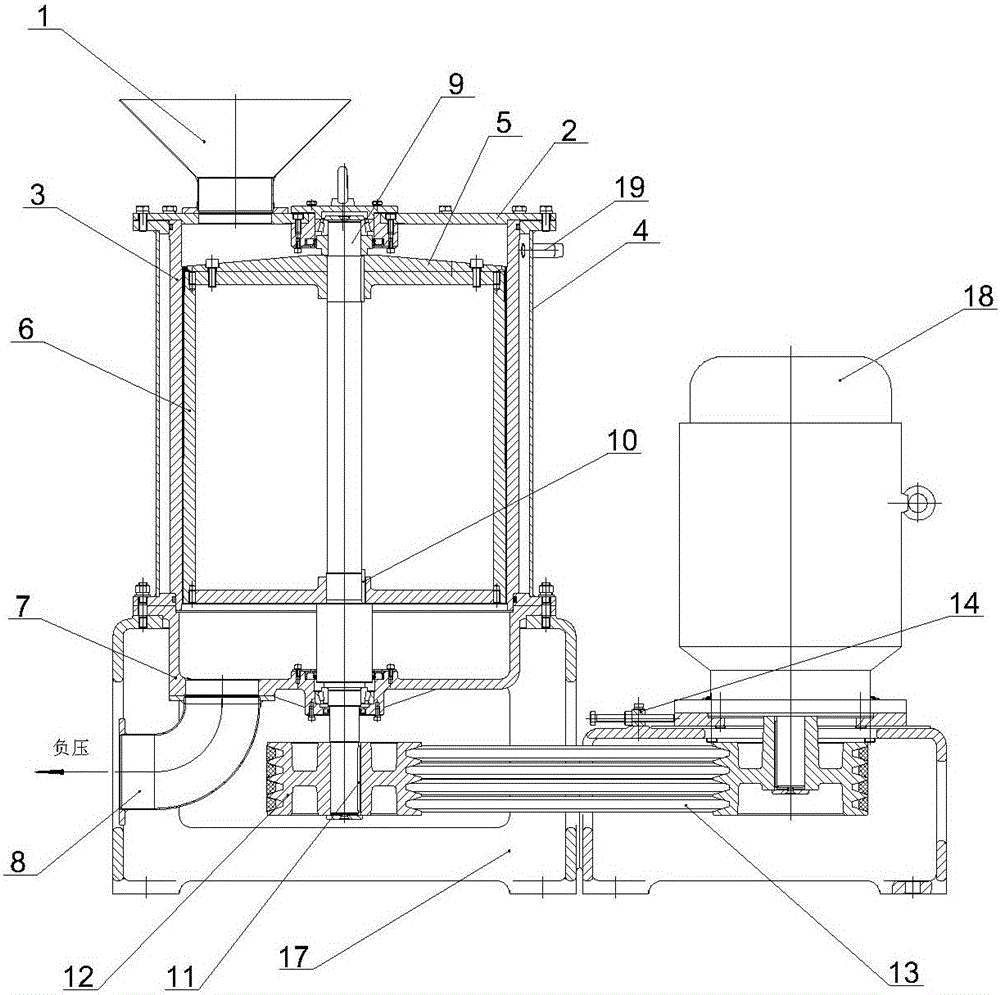

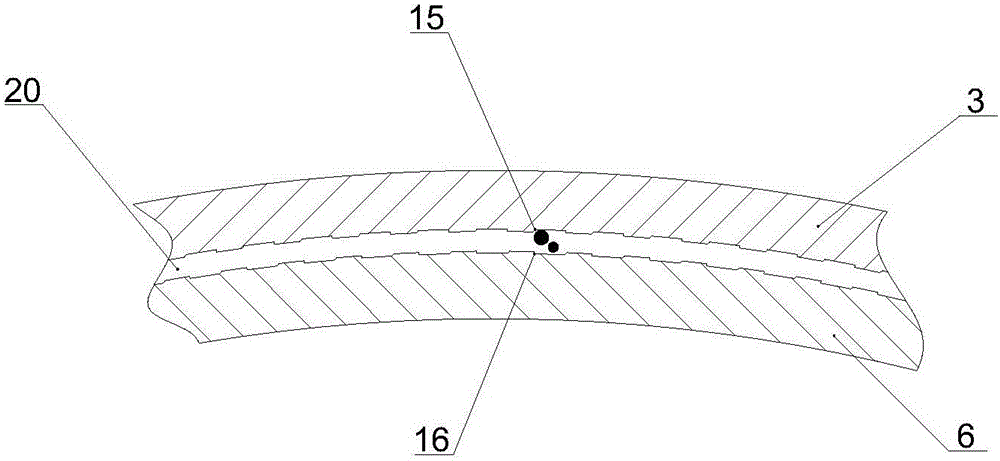

Ultrafine maize straw grinding device

The invention relates to an ultrafine maize straw grinding device. The ultrafine maize straw grinding device comprises a machine frame. The machine frame is provided with a grinding assembly and a motor assembly. The grinding assembly comprises a rotating shaft, a movable grinding sleeve and a fixed grinding sleeve. The movable grinding sleeve and the fixed grinding sleeve are columnar and installed with the rotating shaft as the axis. The movable grinding sleeve is fixed to the rotating shaft through a first key. The fixed grinding sleeve is fixed to the machine frame. An upper cover is fixed to the upper end of the fixed grinding sleeve. A hopper is fixed to the upper cover. A discharging bin is fixed to the lower end of the fixed grinding sleeve. A discharging pipe is fixed to the lower end of the discharging bin. The ultrafine maize straw grinding device further comprises a transmission assembly. The grinding assembly is connected with the motor assembly through the transmission assembly. The ultrafine maize straw grinding device can effectively cut and grind fiber straw materials to needed fineness, and the problem that after the straw achieves certain fineness, discharging is difficult is solved. The ultrafine maize straw grinding device can achieve ultrafine grinding of maize straw in a large-flux, high-efficiency and low-energy-consumption manner.

Owner:JIANGNAN UNIV

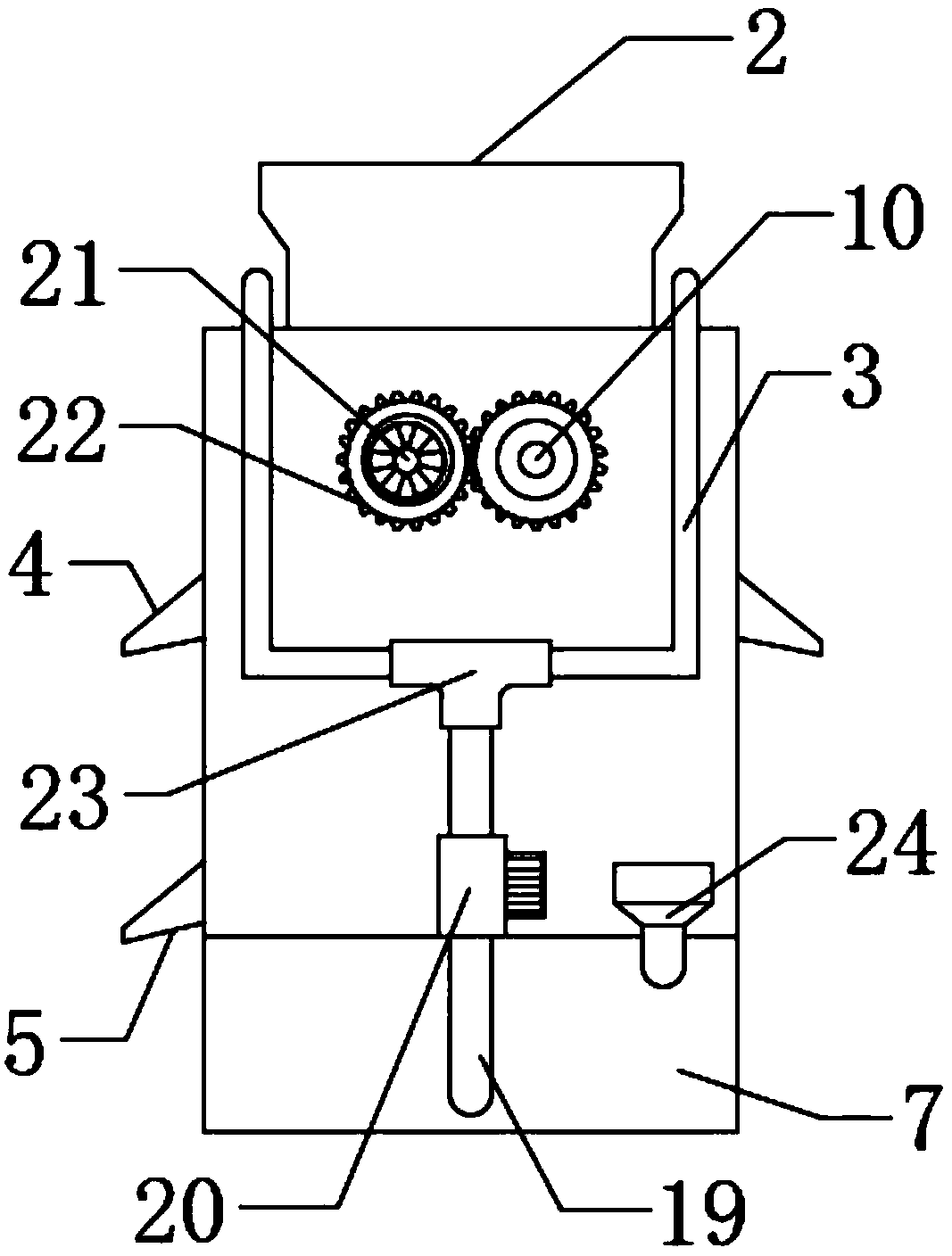

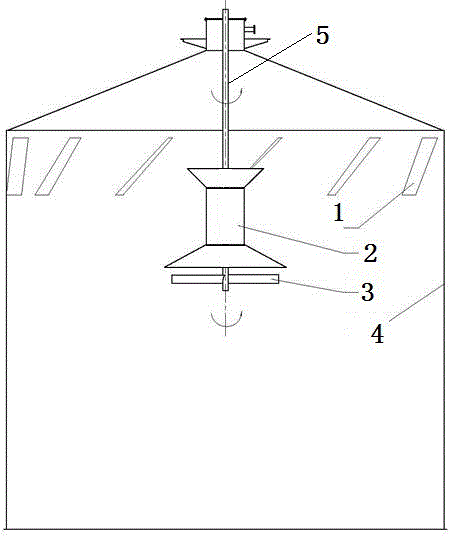

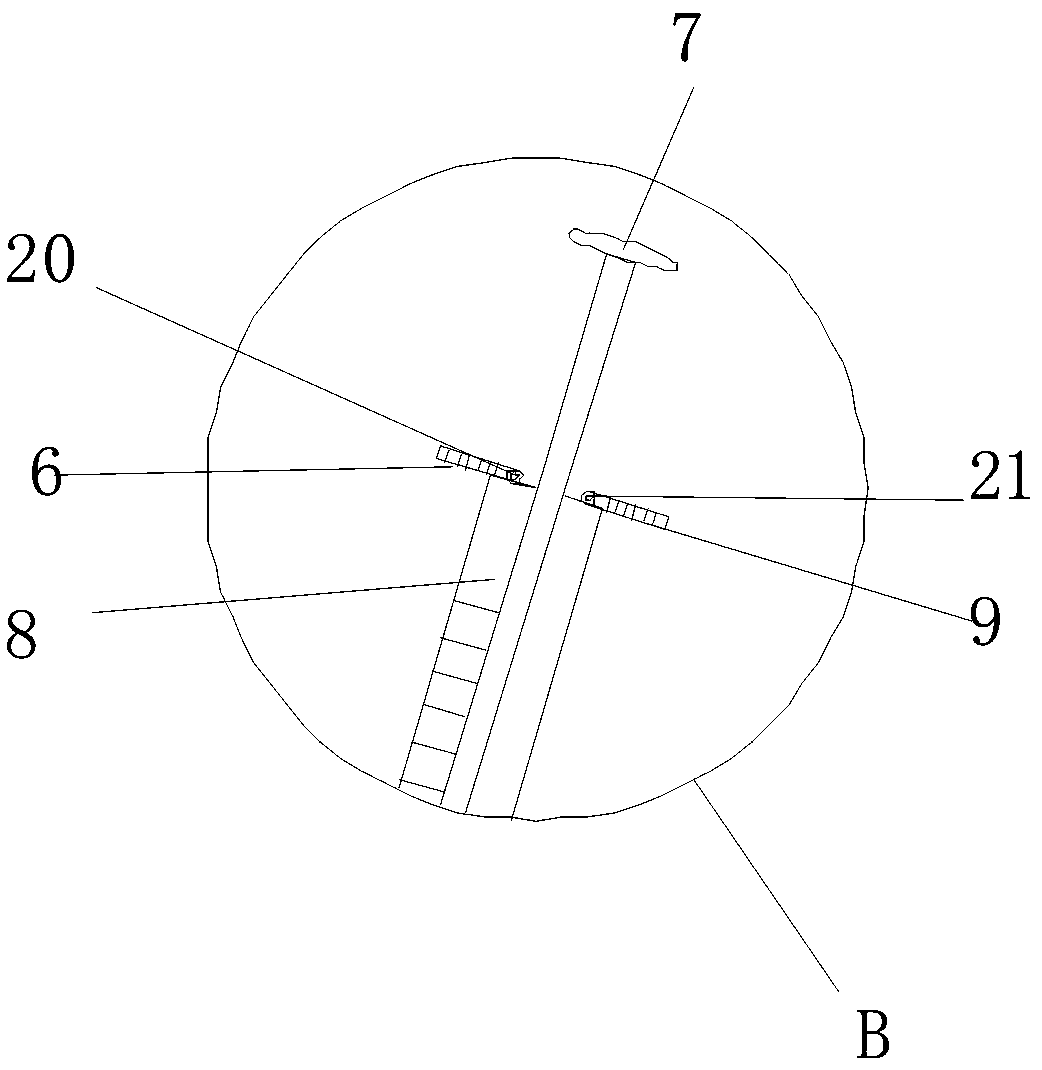

Biogas fermentation tank top scum shell breaking device and shell breaking method

InactiveCN106834094ASolve the crustSolve the discharge problemBioreactor/fermenter combinationsBiological substance pretreatmentsReduction drivePulp and paper industry

The invention discloses a biogas fermentation tank top scum shell breaking device and a shell breaking method. The shell breaking device comprises a guide cylinder and a stirrer. The guide cylinder is arranged in a biogas fermentation tank. The upper and lower ends of the guide cylinder are in a shape of a horn mouth. The middle of the guide cylinder is cylindrical. The top surface of the horn mouth at the upper end of the guide cylinder is lower than the liquid surface in the biogas fermentation tank. The stirrer comprises a motor, a reducer, a stirring shaft and stirring blades. The motor is arranged on the top of the biogas fermentation tank. The stirring blades are located below the horn mouth at the lower end of the guide cylinder. One end of the stirring shaft is connected to the motor through the reducer and the other end passes through the inner cavity of the guide cylinder and is connected to the stirring blades. The device can effectively solve the problem of caking of scum top in a biogas fermentation process, improves a raw material use rate in biogas fermentation and solves the problem of discharge of easily caked raw materials in biogas fermentation.

Owner:BIOGAS SCI RES INST MIN OF AGRI

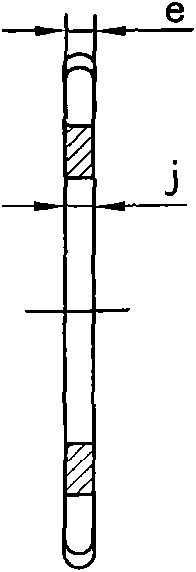

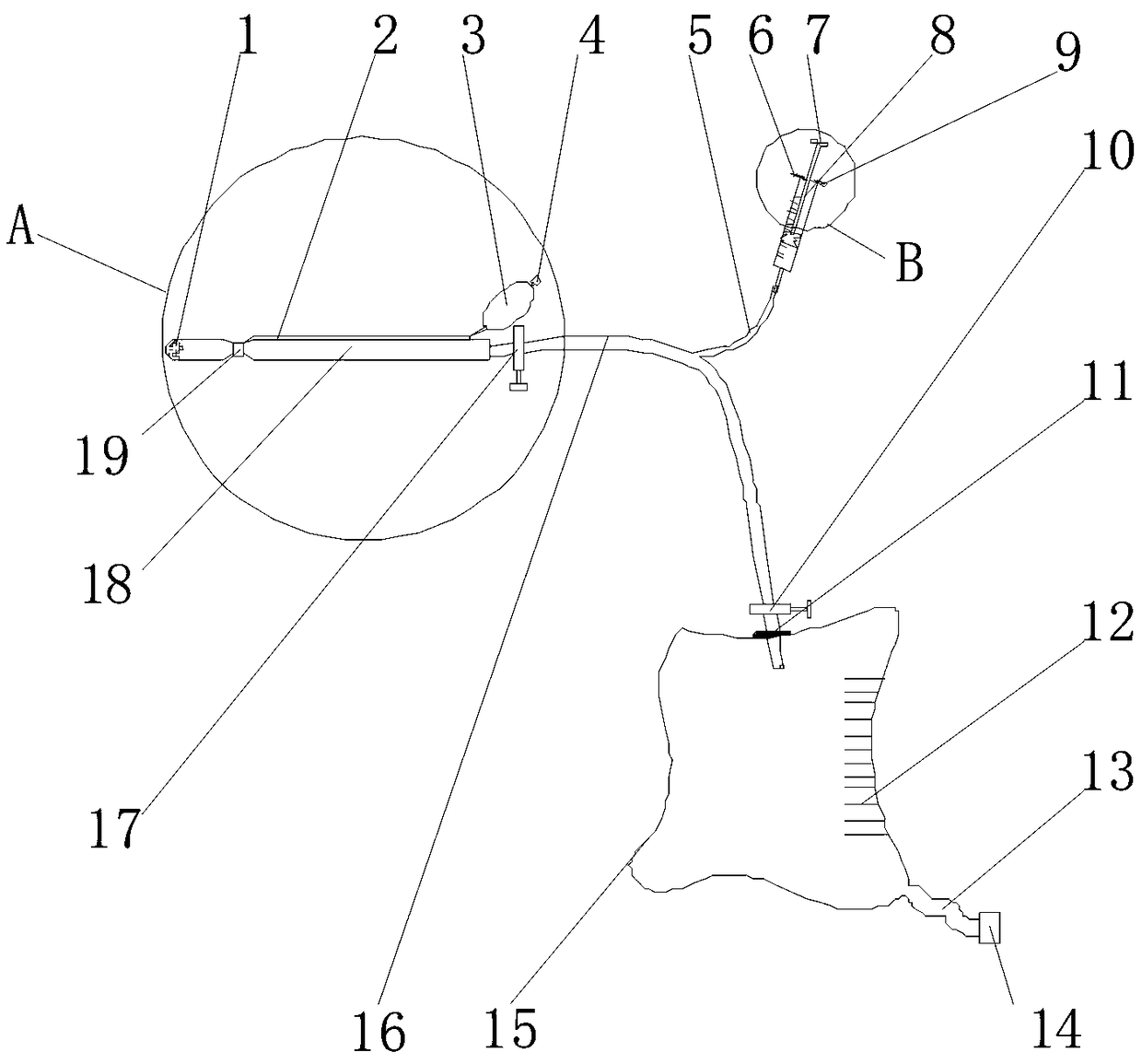

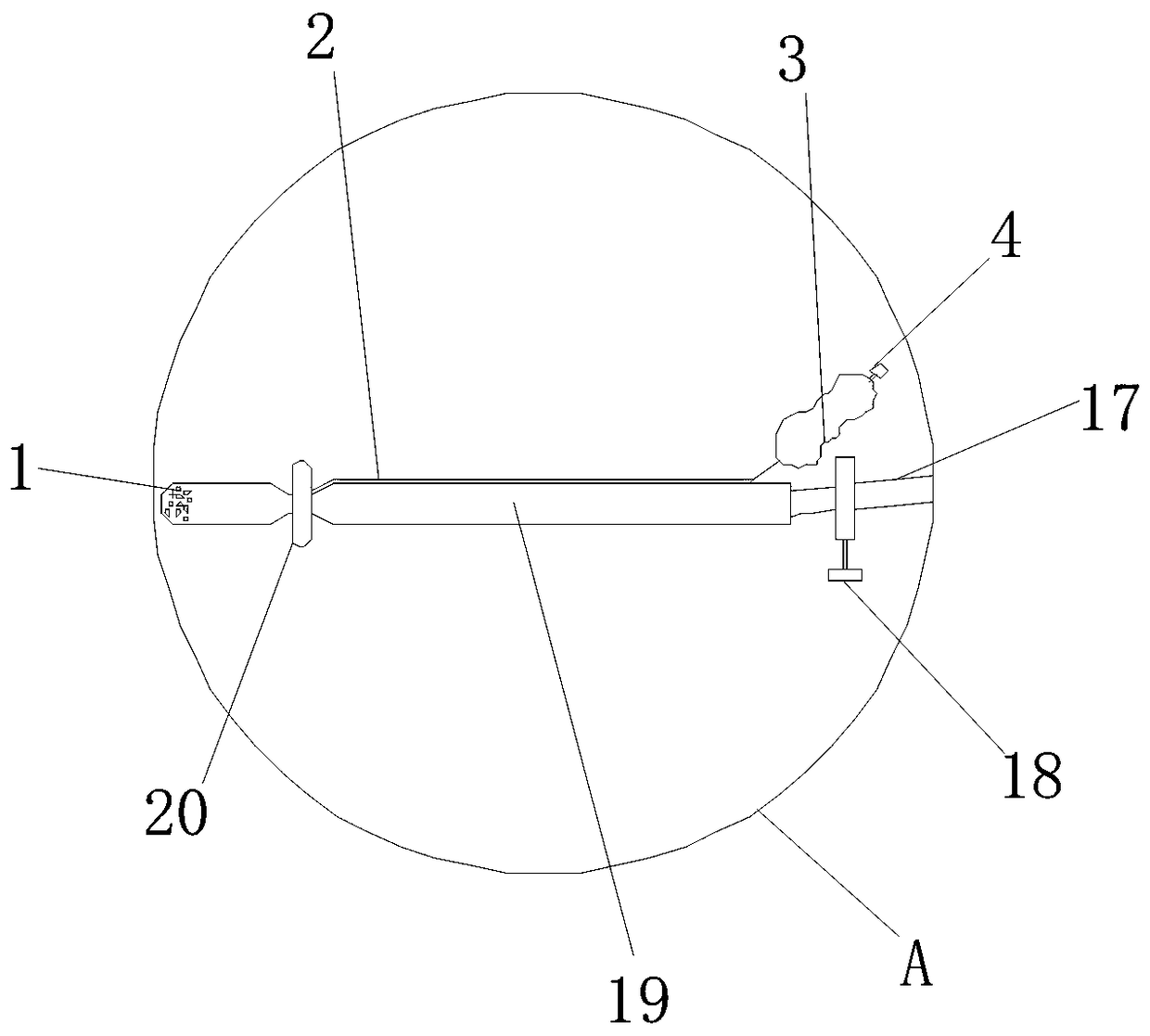

A urological catheter

A urological catheter includes a composite glass catheter. A lead end of that composite glass catheter body is provided with a catheter hole, the composite glass urethral catheter is provided with anair bag at a groove of the composite glass urethral catheter, the tail end of the composite glass catheter is fixedly connected with a voiding tube, A second valve is arranged on one end of the urination tube close to the composite glass urination tube, and a first valve is fixedly connected on the other end of the urination tube close to the urination bag, the urination bag is marked with a graduation, a drainage tube is arranged on the right lower end of the urination bag, and a drainage plug is arranged on the other end of the drainage tube. A manual inflator, an air bag, a syringe, a firstvalve and a second valve are arrange to solve that problems of liquid leakage and urine leakage, inconvenience for medical personnel to check the condition and inconvenience for patient to remove blood clots and necrotic tissues existing in urine and urine through a catheter.

Owner:徐州百芈商贸有限公司

Auxiliary air curtain device for kitchen range hood

InactiveCN101726026AImprove the air environmentImprove the efficiency of removing oily fumes and miscellaneous odors in the kitchenDomestic stoves or rangesLighting and heating apparatusSocial benefitsLife quality

The invention relates to an auxiliary air curtain device for a kitchen range hood, comprising an air curtain ring, an air pipe, a blower and a control switch device; the air curtain ring is communicated with the blower by the air pipe, and the air curtain ring is connected with the blower by a control line; the auxiliary air curtain device for the kitchen range hood is adopted, oil smoke diffusion can be effectively prevented, the efficiency of the range hood on removing oil smoke foreign flavor in the kitchen is improved and the life quality of people is improved; in addition, the energy is saved and the consumption is reduced, the effect is good, the structure is simple and reliable, and the device can be suitable for structural characteristics and spatial position of the kitchen range hood and the cookware, the usage is rapid and convenient, the device is easy to popularize, and the working performance is stable and reliable, thereby bringing great convenience to daily life of people; the application range is wide, thereby having obvious reality benefit and long-term social benefit.

Owner:张佩刚

Acid- and alkali-resistant stirring drier

ActiveCN105352295AImprove heat transfer efficiencyReduce heat lossDrying solid materials without heatDrying chambers/containersMechanical engineeringInsulation layer

The invention discloses an acid- and alkali-resistant stirring drier. The acid- and alkali-resistant stirring drier comprises a barrel cover which is arranged at the upper end of a barrel cylinder, a feeding port which is formed in one upper side of the barrel cover, an air exhausting device which is arranged at the other upper side of the barrel cover, and a stirring device which is arranged in the upper middle of the barrel cover, wherein a slipping-aiding wear-resisting layer is arranged on the inner wall of the barrel cylinder; a plurality of U-shaped grooves are excavated in the outer wall of the barrel cylinder; a barrel body is arranged at the outer part of the barrel cylinder, and a discharging port is formed in the lower end of the barrel cylinder; a heat insulation layer is also arranged between the barrel body and the barrel cylinder, and a vertical slot is formed in the surface of the heat insulation layer. With the adoption of the acid- and alkali-resistant stirring drier, the problem of low efficiency of the drier in the heat exchanging process can be solved, and the damage caused by that the inside of the drier is affected with damp can be removed; meanwhile, a material for the barrel cylinder is also provided, thus various comprehensive performances of the barrel cylinder are improved, and the service life is prolonged.

Owner:四川知格科技有限公司

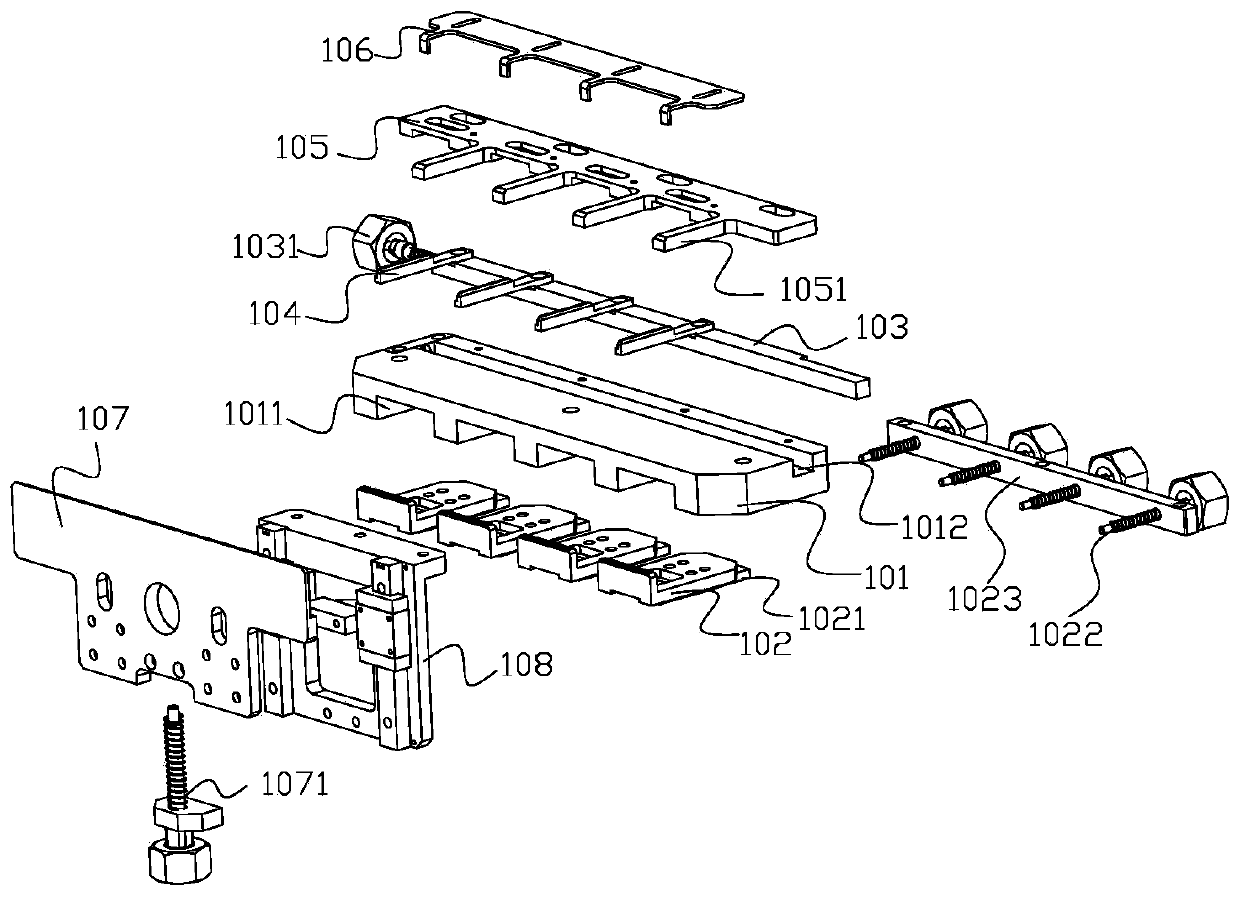

Fine sand screening device capable of automatically discharging coarse sand

InactiveCN107837998ASolve the problem that the remaining coarse sand after fine sand screening cannot be automatically dischargedSolve the discharge problemSievingScreeningEngineeringSand filter

The present invention relates to a screening device, in particular to a fine sand screening device capable of automatically discharging coarse sand, comprising a sand feeding cylinder assembly, a rotating disk assembly, a sand screening assembly, a coarse sand collection assembly, a sand screening drive assembly and The installation frame assembly, the sand inlet barrel assembly includes the sand inlet barrel body, the sand falling pipe, the sand rotating anti-blocking device, the upper supporting plate, the fixing column and the lower supporting plate; the lower end of the sand inlet barrel body is welded and connected to the falling Sand pipe; the lower end of the sand rotating anti-blocking device is connected to the inside of the sand inlet barrel body in rotation, and the upper end of the sand rotating anti-blocking device is connected to the upper supporting plate in a rotating fit, and the lower end of the upper supporting plate is fixed by The column is connected to the lower supporting plate; the sand falling pipe is connected to the lower supporting plate through threads. The invention can effectively solve the problem that the sand screening device in the prior art cannot automatically discharge the remaining coarse sand after fine sand screening; the invention can automatically discharge the coarse sand without manual cleaning, and its sand screening efficiency is high, and Sand works better.

Owner:张萤

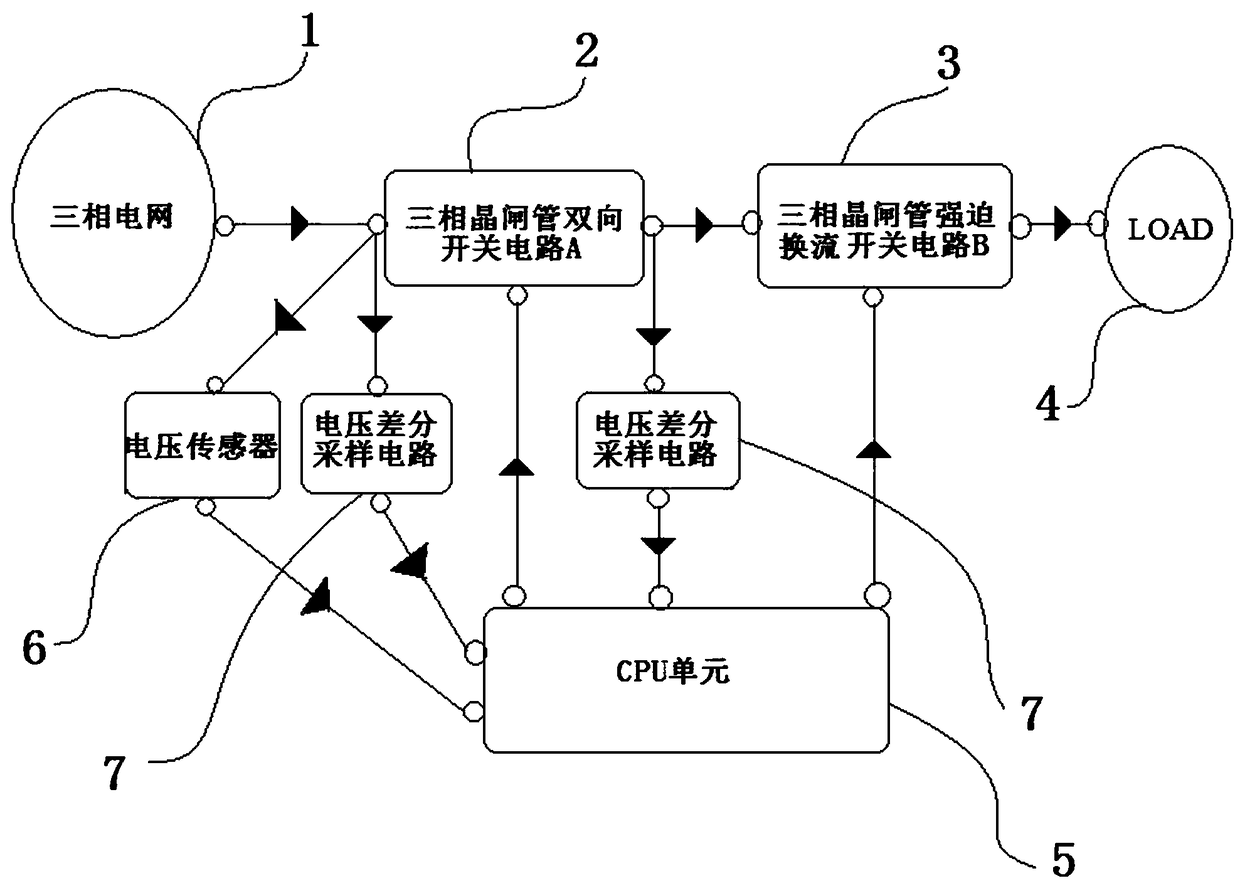

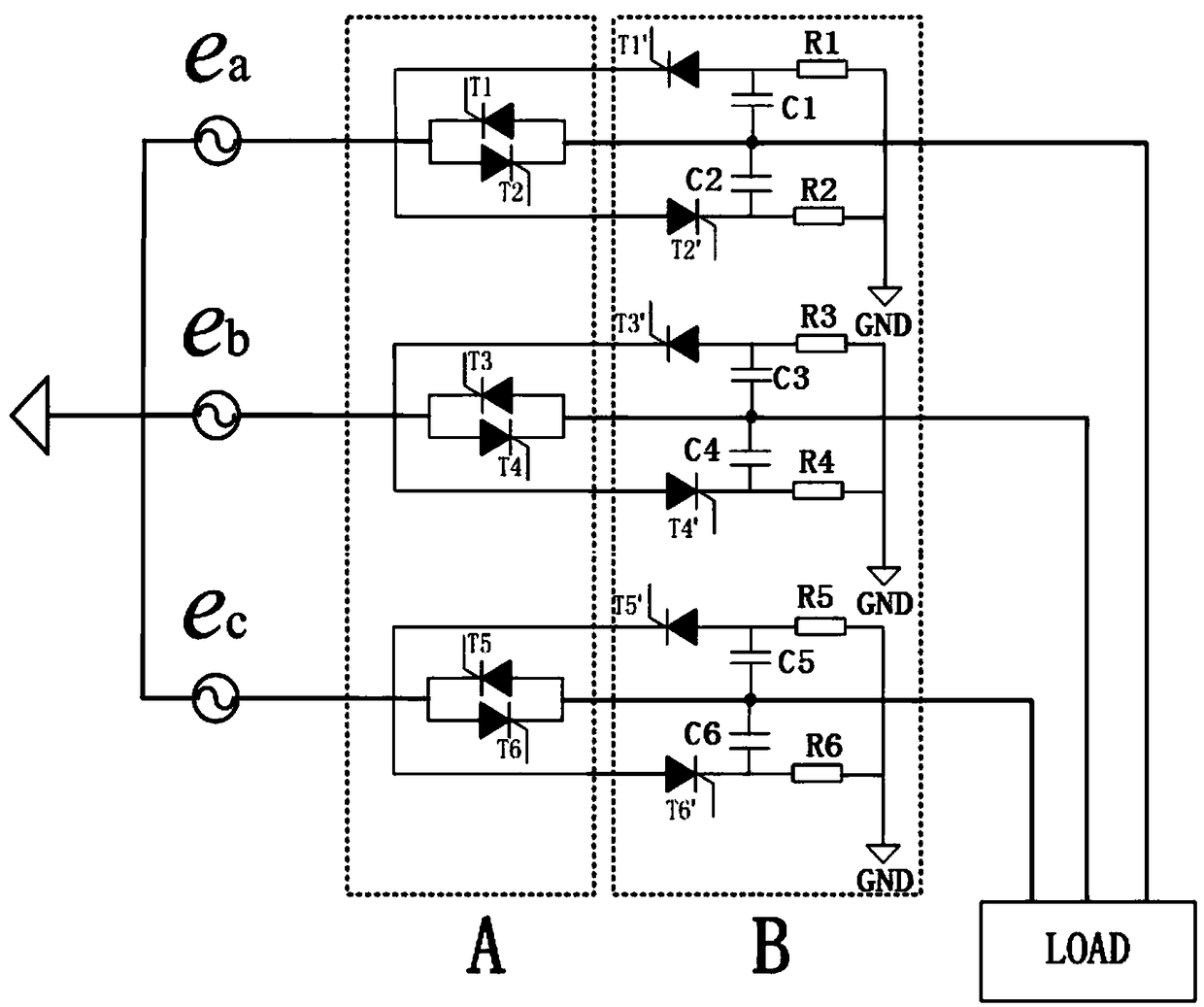

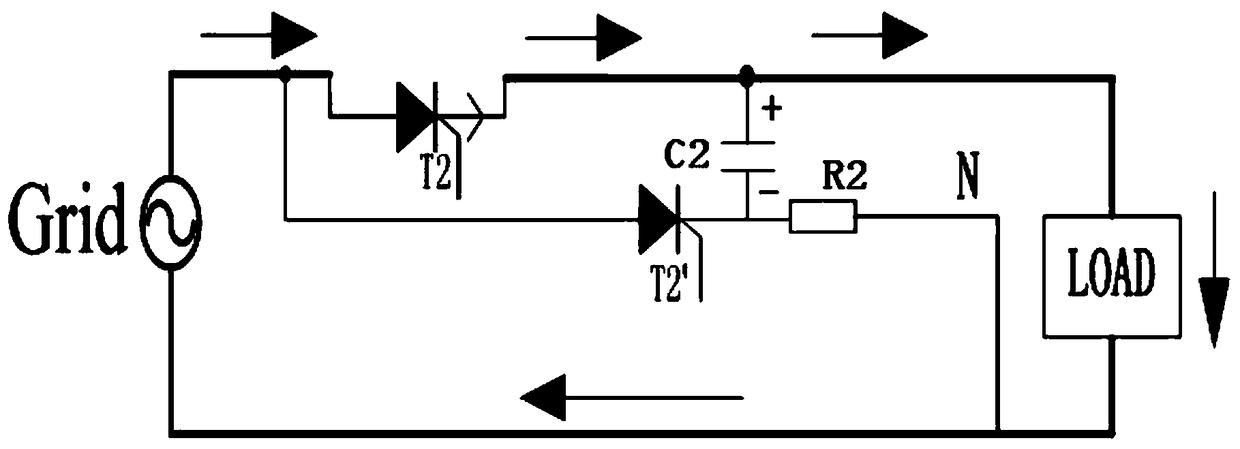

Micro-grid three-phase thyristor fast switch and control method

ActiveCN108879672AShort action timeWith forced shutdown functionAc network circuit arrangementsCapacitancePower grid

The invention discloses a micro-grid three-phase thyristor fast switch and a control method. The fast switch comprises a three-phase grid and a LOAD, and further comprises a three-phase thyristor bidirectional switch circuit A, a three-phase thyristor forced commutation switch circuit B and a CPU. The three-phase grid is connected to an input end of the three-phase thyristor bidirectional switch circuit A; an output end of the three-phase thyristor bidirectional switch circuit A is connected to the LOAD through the three-phase thyristor forced commutation switch circuit B; the CPU is separately connected to a control end of the three-phase thyristor bidirectional switch circuit A and a control end of the three-phase thyristor forced commutation switch circuit B. According to the micro-gridthree-phase thyristor fast switch and the control method, a forced turn-off function is realized; the requirements of fast and off-grid switching of a micro-grid system is met; and a conduction failure problem that may be caused by a voltage zero-crossing is taken into account, so that the turn-off function of the thyristor switch is realized, and a problem that a capacitor is discharged to the micro-grid caused by the conduction failure is effectively solved.

Owner:NANJING GUODIAN NANZI POWER GRID AUTOMATION CO LTD

Full-automatic tin cream printing machine capable of achieving repeated cleaning

The present invention provides a fully automatic solder paste printing machine with multiple cleanings, which cleans the circuit board that is about to enter the processing program, so as to improve the yield rate of the circuit board during and after printing. Platform correction system, guide rail transportation system, stencil frame clamping system, scraper printing system and subsequent cleaning system, which also includes a pre-cleaning system, the pre-cleaning system includes splint rails for clamping and moving circuit boards, The first water outlet for spraying water to the circuit board, the water collection bottom tank for collecting the water flowing through the circuit board, the drying part for drying the circuit board, and a water recovery device, the water recovery device includes a connection The water suction pump of the water collection bottom tank is used to guide water from the water suction pump to the water diversion pipe above the circuit board. There are flushing ports at the outlet of the water diversion pipe, and the flushing ports are arranged at intervals in the vertical direction A long rectangular opening extending horizontally.

Owner:连江捷恒工业设计有限公司

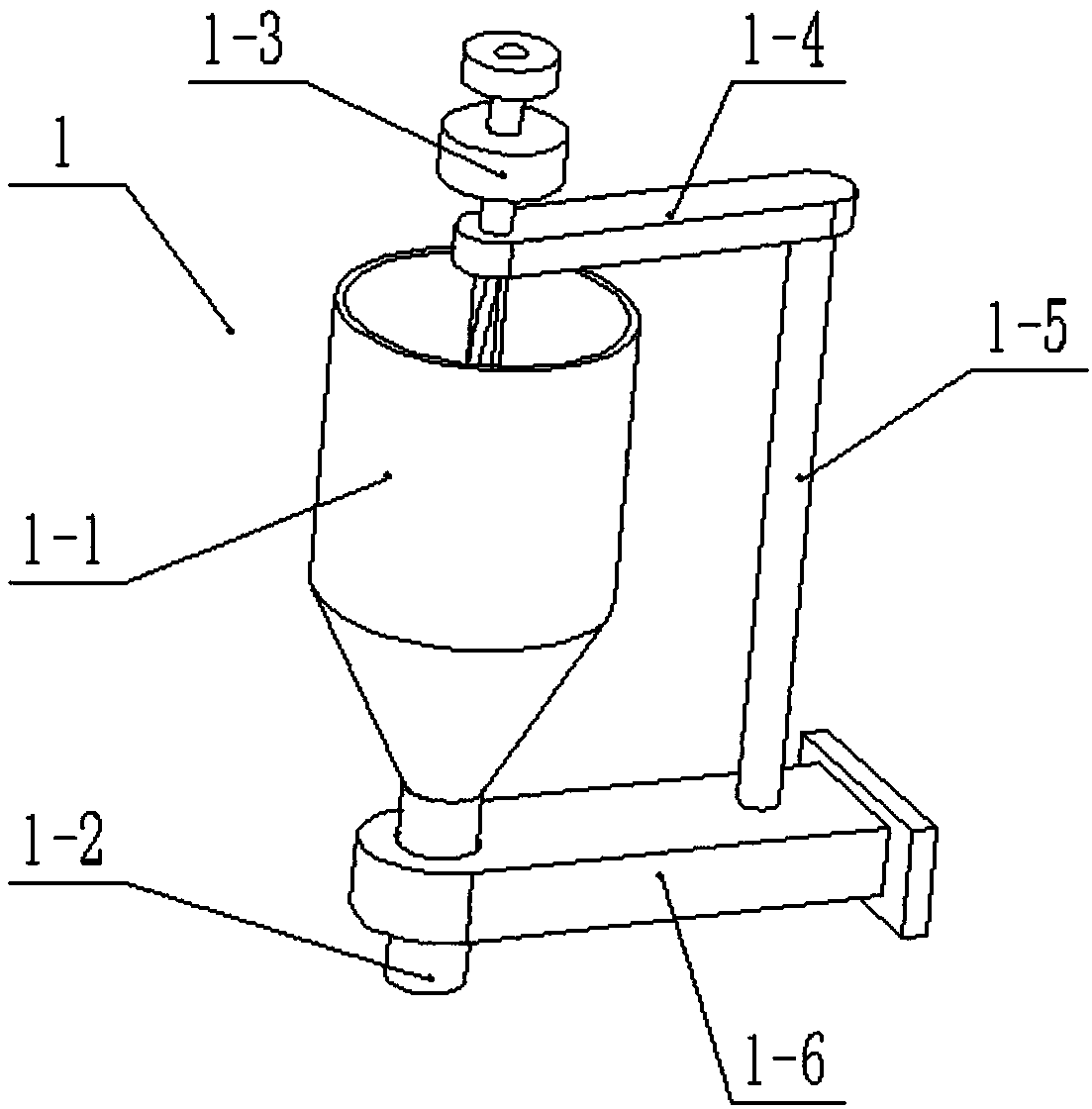

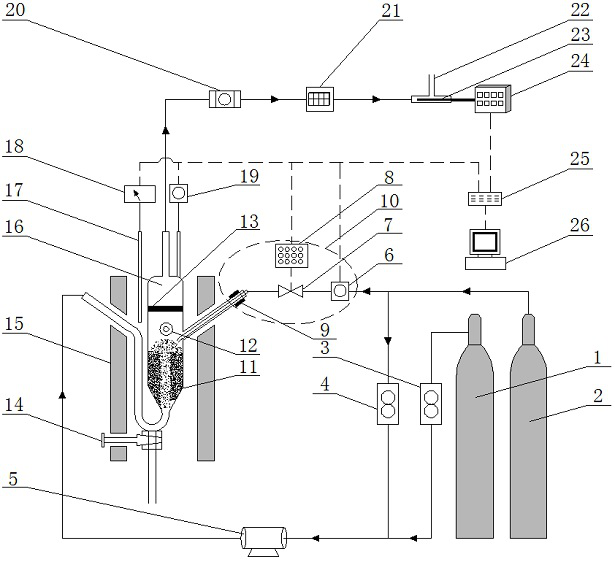

Micro spouted bed gas-solid reaction kinetic analysis device and analysis method

PendingCN112255257AHigh simulationReal dataMaterial analysis by electric/magnetic meansMaterial thermal analysisGas analysisGas solid

The invention discloses a micro spouted bed gas-solid reaction kinetic analysis device and analysis method, which belong to the field of gas-solid reaction test methods and instruments. The analysis device comprises a pulse sample feeding device, an isothermal reaction generation device, a gas path device and an online gas analysis test device. A solid sample is instantaneously fed into the microspouted bed reactor through the pulse sample feeding device, reactions such as combustion, pyrolysis, gasification or decomposition are rapidly carried out under the isothermal condition of the microspouted bed reactor, a reaction mechanism is speculated by measuring a gas component generation sequence and concentration change characteristics in the reaction through the rapid online process massspectrometry, and then reaction kinetic parameters are solved. The micro spouted bed is used as a reactor, so that the online instantaneous feeding of reaction materials can be ensured, the reaction under an approximate isothermal condition is realized, the reaction condition is closer to the reaction condition in practical application, and the measured reaction kinetic parameters are closer to the intrinsic reaction kinetic parameters.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

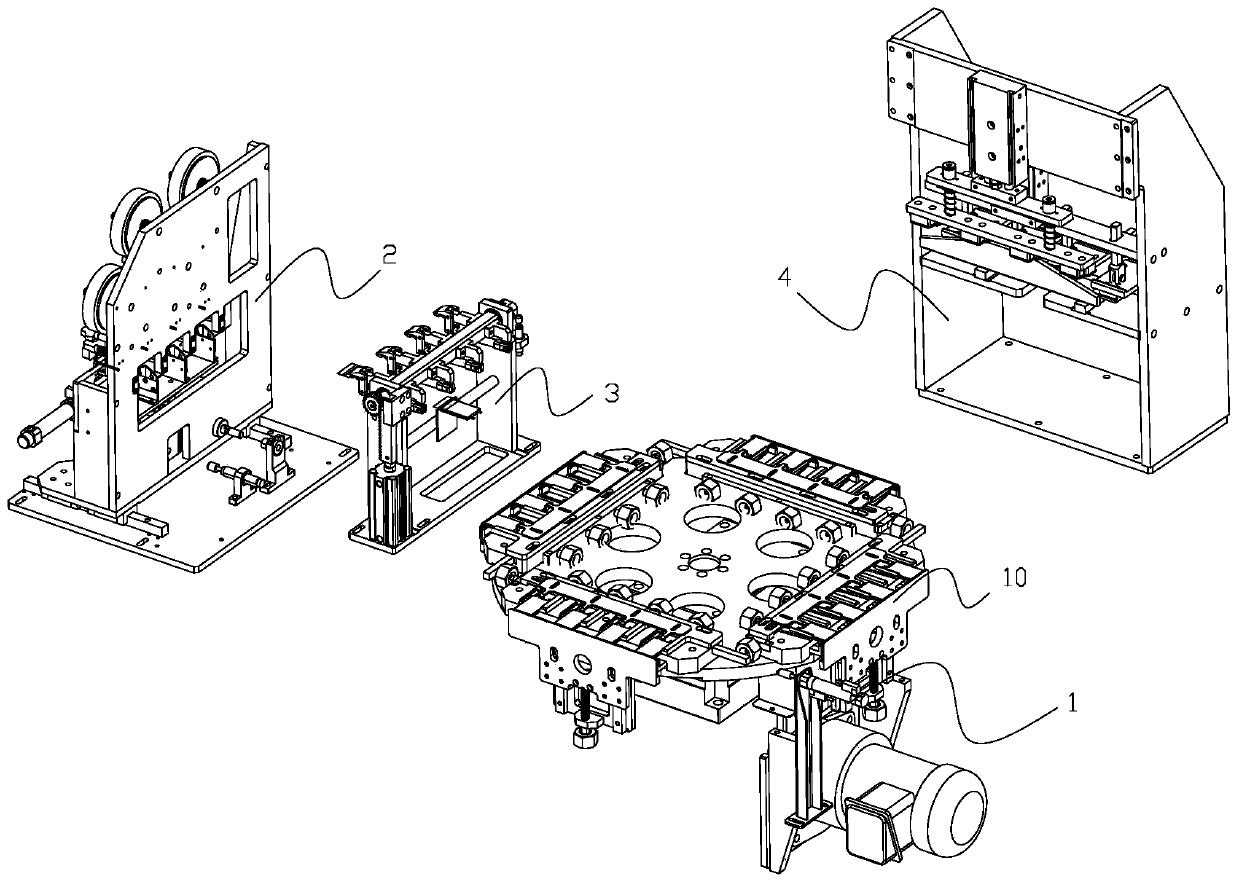

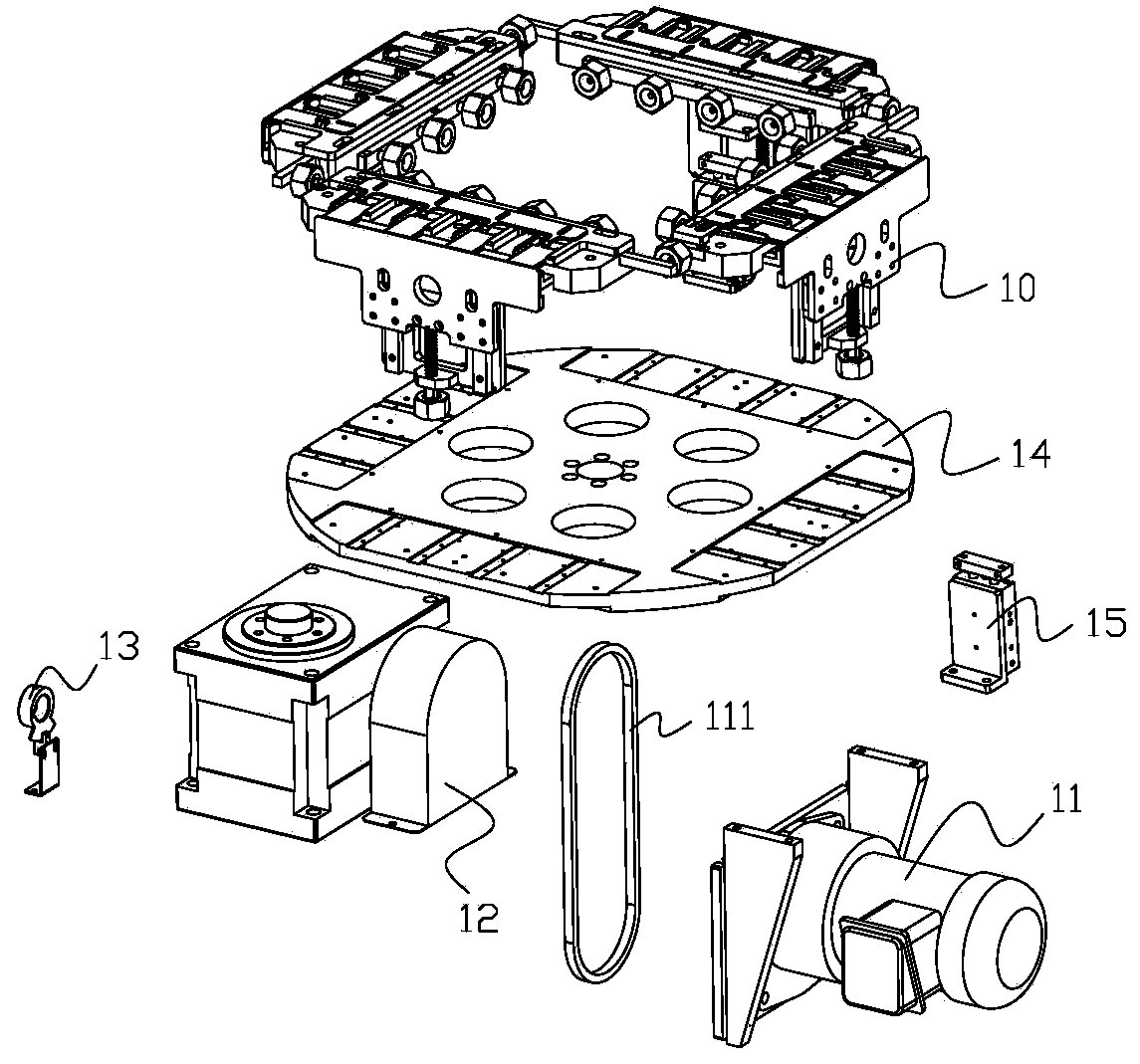

Automatic rubberizing method and equipment for lithium battery

InactiveCN110911758ASolve the loop problemImprove orderNon-aqueous electrolyte cellsFinal product manufactureAdhesive beltEngineering

The invention relates to the field of battery production mechanical automation, in particular to lithium battery automatic adhesive tape sticking equipment which comprises a conveying device, an adhesive tape preparation device, an adhesive tape sticking device and an adhesive tape pressing and wrapping device. The conveying device is of a rotary disc structure, jigs are arranged on the conveyingdevice, and the conveying device conveys a battery to be machined into the glue preparing device, the glue pasting device and the glue pressing and wrapping device through the jigs to be machined formachining. The adhesive tape preparation device is arranged in an adhesive tape pasting area of the conveying device and is used for feeding and cutting an adhesive tape; the adhesive tape sticking device is connected to the adhesive tape preparation device and is used for sticking the cut adhesive tape to the battery in the adhesive tape sticking area; the adhesive pressing and coating device isarranged in the adhesive pressing and coating area, and is used for pressing the front surface of the adhesive tape and coating the redundant adhesive tape on the back surface of the battery; and after the glue pressing and the glue coating are completed, the conveying device discharges the processed batteries. The battery gluing device has the technical effects that the battery is limited throughthe jig, so that the gluing accuracy is ensured; and the back surface of the battery is coated with rubber through the rubber folding mechanism and the rubber coating mechanism, so that equipment functions are enriched.

Owner:张俊

Upper punching structure for continuous deep drawing or molding die

InactiveCN103350140AGuaranteed StrengthGuaranteed stabilityPerforating toolsStripping-off devicesPunchingEngineering

The invention discloses an upper punching structure for a continuous deep drawing or molding die. The upper punching structure comprises a drawing molding upper die and a drawing molding lower die, wherein the drawing molding lower die is provided with a punching male die, the drawing molding upper die is provided with a punching female die corresponding to the punching male de, when in die assembly, a punching material removing block is pressed down by the punching female die so that the punching male die stretches out to cooperate with the punch female die so as to complete upper punching operation after drawing molding. Under the premise of not changing the original drawing or molding direction, the punching direction is changed so as to guarantee the strength of the punching female die to guarantee the die to be produced stably, the problem of waste discharge is solved through a blowing manner, and the upper punching structure has the advantages of reasonable structure, stability in product machining, and the like.

Owner:厦门锐腾电子科技有限公司

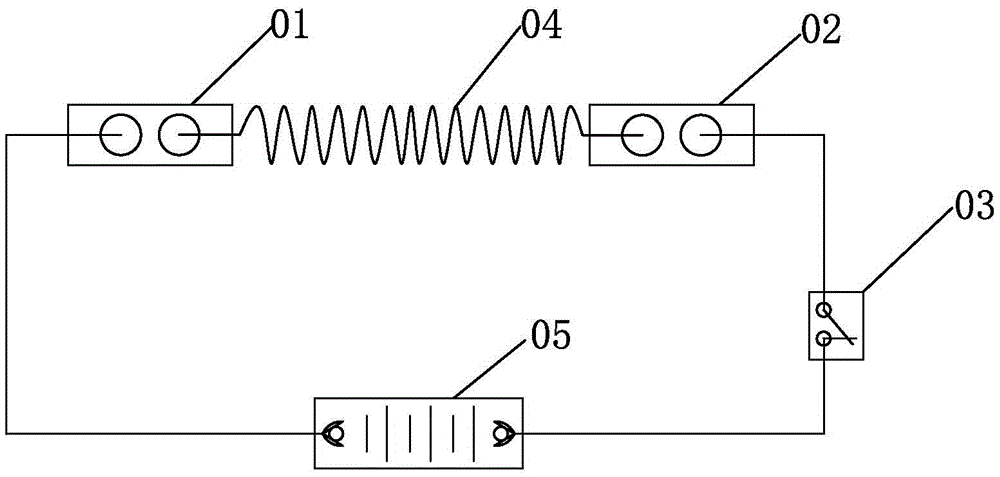

Economical and practical portable automobile rechargeable battery discharging device

ActiveCN105552461ASolve the discharge problemImprove cooling effectSecondary cells charging/dischargingBatteriesEngineeringDischarge problems

The invention discloses an economical and practical portable automobile rechargeable battery discharging device. The device comprises an insulation base, a first terminal fixing plate and a second terminal fixing plate; the first terminal fixing plate and the second terminal fixing plate are vertically fixed on the insulation base and are parallel; first wiring terminals are fixed at the top end of the first terminal fixing plate; second wiring terminals are fixed at the top end of the second terminal fixing plate; monopole circuit breakers are fixed on the insulation base at the outer side of the second terminal fixing plate; the first wiring terminals are arranged at intervals; the second wiring terminals are arranged at intervals; and the monopole circuit breakers are arranged at intervals. The discharging problem of the automobile storage battery is effectively solved; the discharging device is convenient and economical; the concentrated discharging heat energy can form airflow stack effect; and meanwhile heat radiation is accelerated by fans.

Owner:深圳安博检测股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com