Equipment for automatic and continuous rubbing tea-leaves

A kneading device and automatic technology, which is applied in tea processing before extraction, etc., can solve the problems of incompatibilities, etc., and achieve the effect of high reliability, mature technology and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

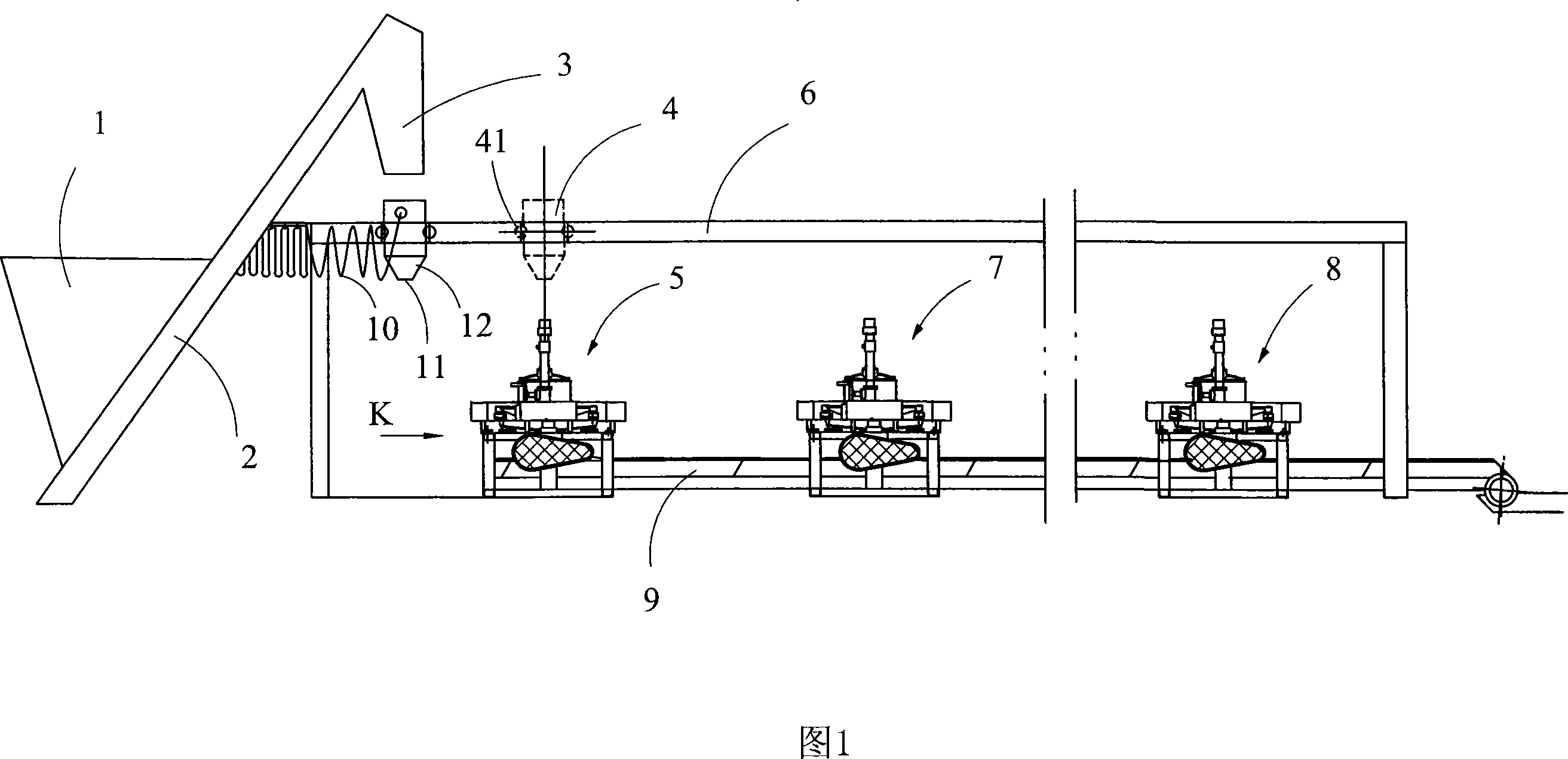

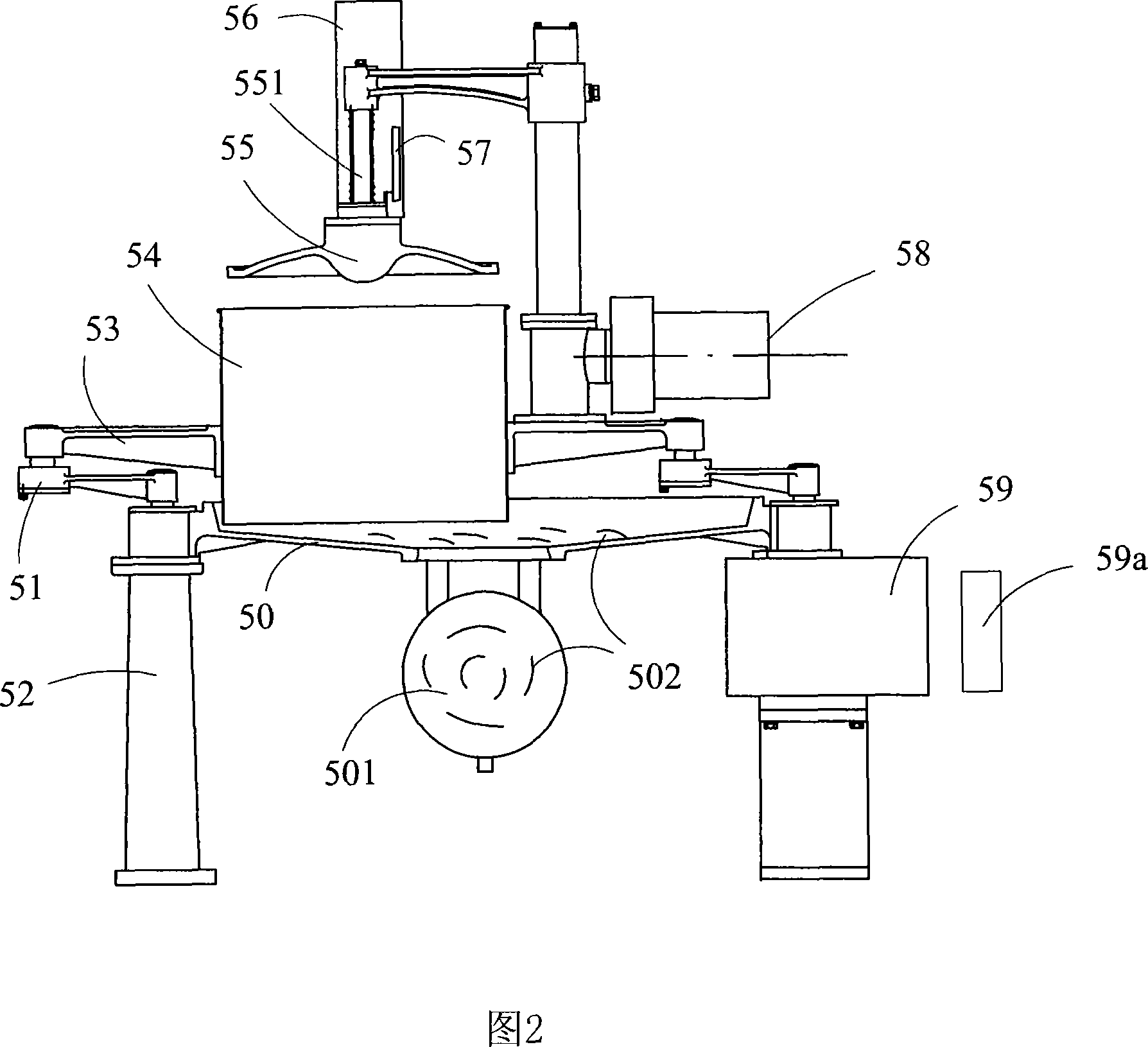

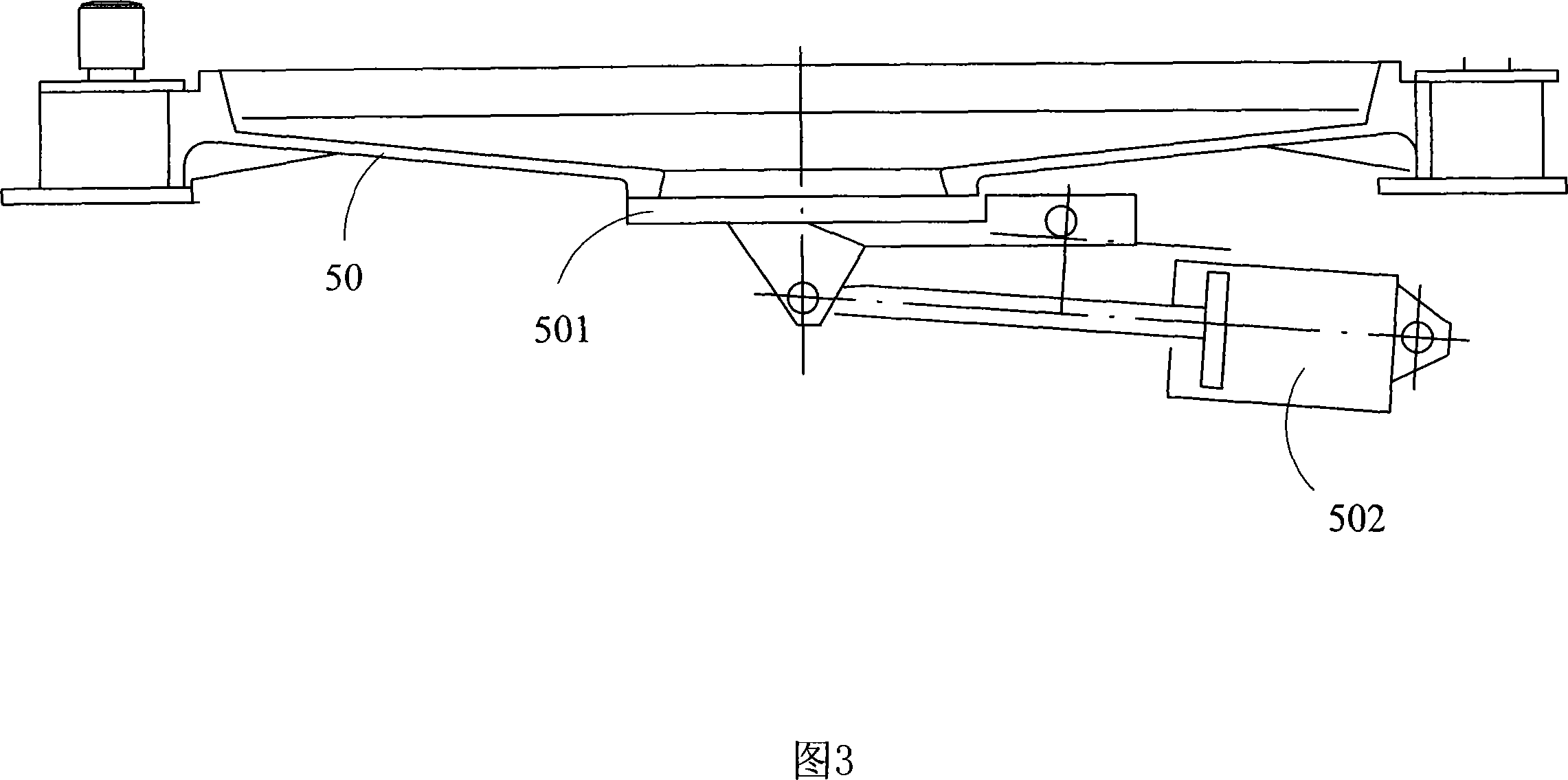

[0020] The serial numbers in the figure respectively represent: silo 1, elevator 2, feeding port 3, feeding hopper 4, the first set of kneading mechanism 5, guide rail 6, the second set of kneading mechanism 7, the third set of kneading mechanism 8, and the leaf conveyor belt 9, telescopic wire 10, feeding door 11, lower part 12, weighing frame 13; curved arm slewing mechanism 51, support 52, kneading bucket frame 53, kneading bucket 54, gland 55, guide post 551, outer cover 56, measuring Force device 57, motor 58, speed reducer 59, pulley cover 59a, kneading dish 50, tea door 501, rib 502, cylinder 503.

[0021] Referring to Fig. 1, this figure is mainly used to illustrate the inventor's design thinking. From the perspective of the whole machine, the tea leaves from the last process on the left side of the frame, such as finishing and cooling, are sent to the silo 1 by the conveyor belt, and the tea in the silo 1 is lifted to a certain height by the elevator 2, and then falls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com