Patents

Literature

113results about How to "Solve the loop problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

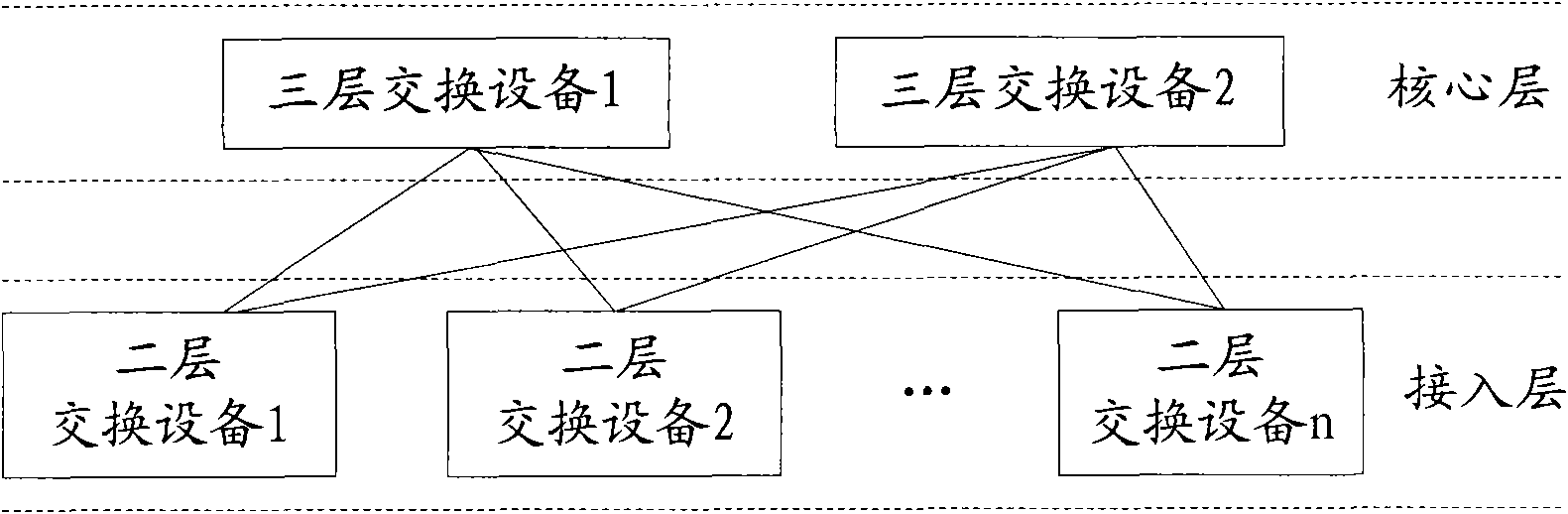

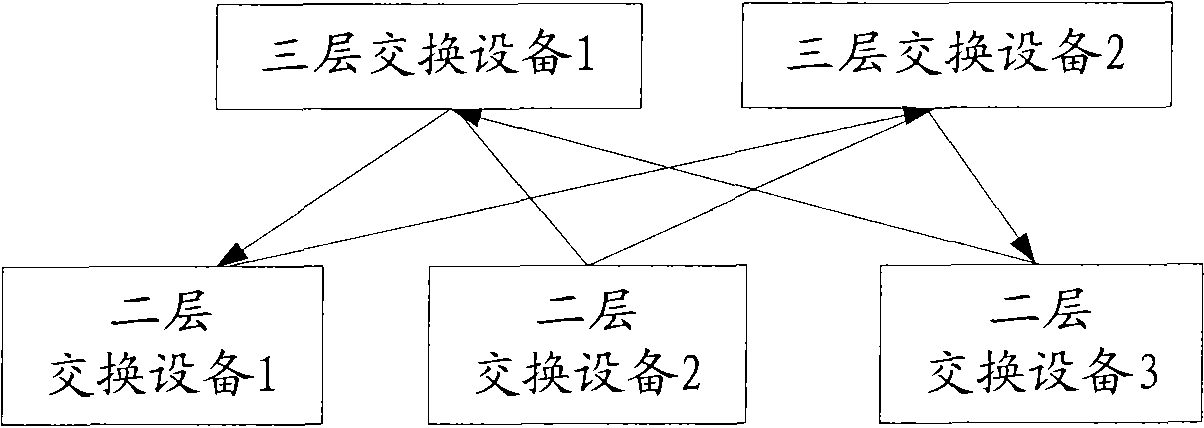

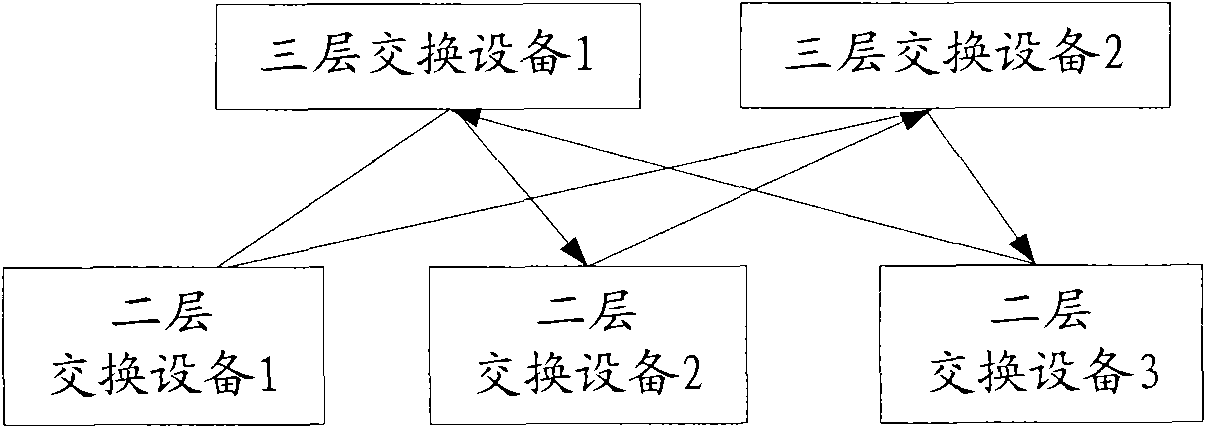

Detecting and protecting method of double-layer loop in VRRP topological network

InactiveCN101557343AEasy to detectAchieve protectionData switching networksState variationComputer science

The invention relates to a detecting and protecting method of a double-layer loop in a VRRP topological network. A core layer is accessed to two three-layer switching equipment which backup each other; one three-layer switching equipment is set as a sender state, one port is set as a main port, while the other three-layer switching equipment is set as a receiver state; when detecting the changes of a link state of the port thereof, the receiver initiatively sends a protocol message to notify the sender to conduct protection switching of the port state: if a mapping port exists at the port with the link state being connected state in the sender, the port is set as a blocked state, otherwise, the port is set as a forwarding state; the port with the link state being an off state in the sender is set as a closed state; the port with the link state being the connected state in the receiver is set as the forwarding state; and the port with the link state being the off state in the receiver is set as the closed state. The detecting and protecting method can effectively solve the problem of the loop in the existing VRRP topology, and simply and conveniently realize the detection and protection of the loop.

Owner:LENOVO TERECO NETWORKS SHENZHEN

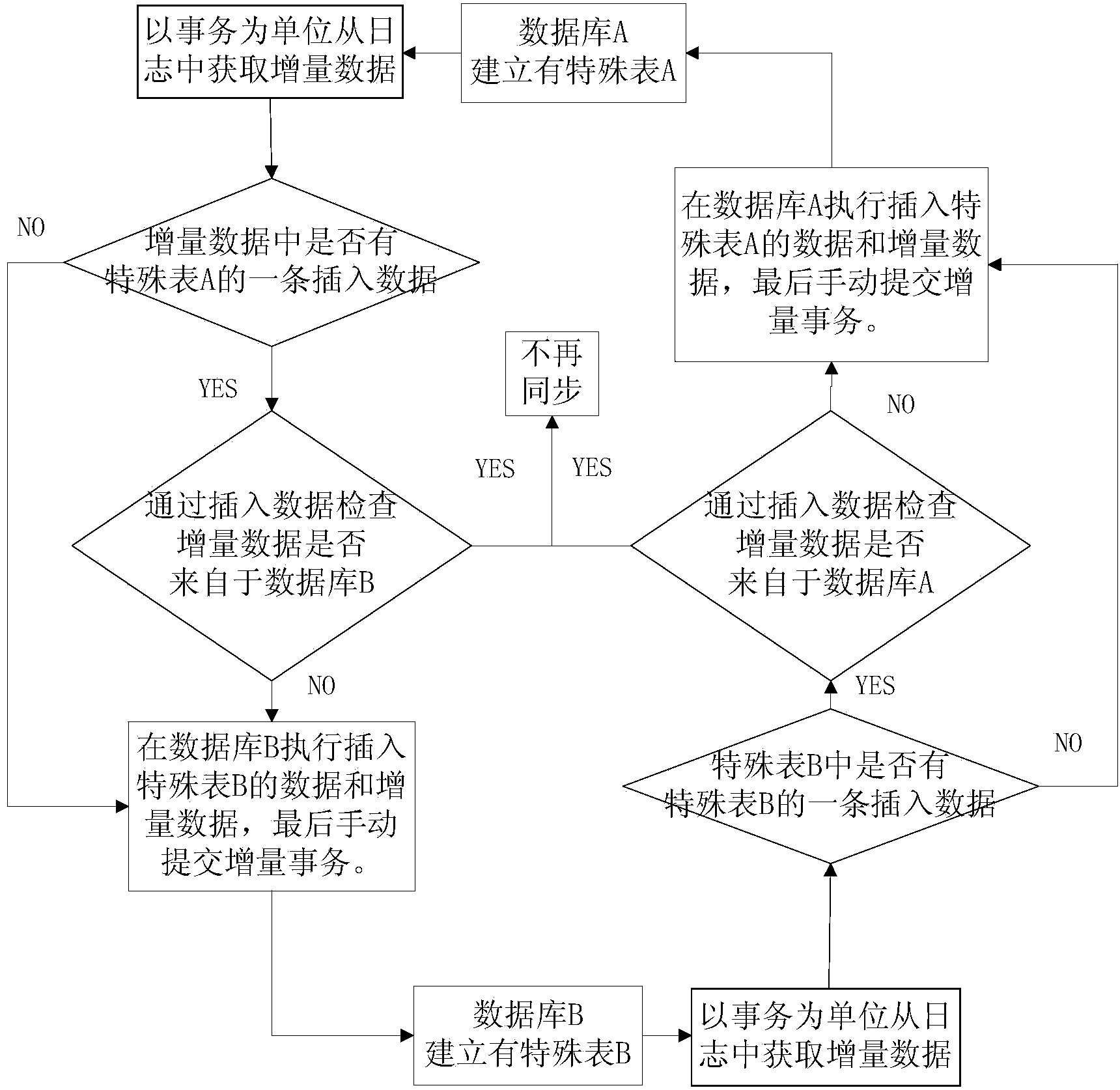

Method for achieving two-way synchronous data circulation in heterogeneous database synchronizing system based on logs

ActiveCN103970833APerformance is not affectedSolve the loop problemDatabase distribution/replicationSpecial data processing applicationsData synchronizationData bank

The invention discloses a method for achieving two-way synchronous data circulation in a heterogeneous database synchronization system based on logs. The method comprises the steps that special tables are established in databases for two-way synchronization respectively; when incremental data are transmitted to a destination database from a source database, a piece of special table data is inserted in the destination database firstly, all the incremental data are executed in the destination database secondly, and incremental data events are submitted manually in the destination database finally; in the incremental data synchronization process, incremental data are obtained from the logs with the events as units, whether the events contain a piece of inserted data of the special table B of the database B is checked, and the incremental data are no longer synchronized to the database A if the inserted data exist and the source of the inserted data is the database A; otherwise, the incremental data are synchronized to the database A. According to the method, the properties of the databases are not affected, the atomicity of the events is utilized, and data circulation is achieved simply and conveniently.

Owner:ZHEJIANG UNIV

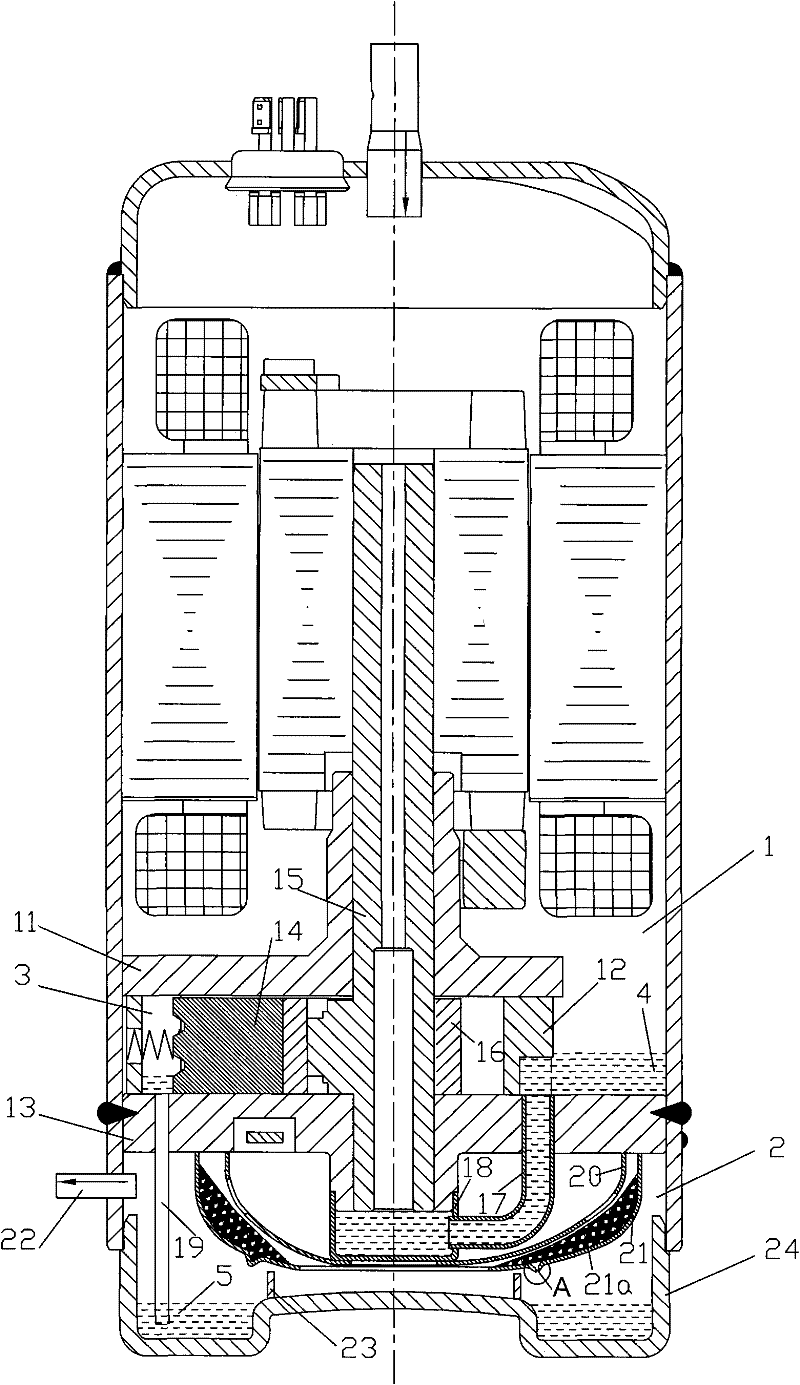

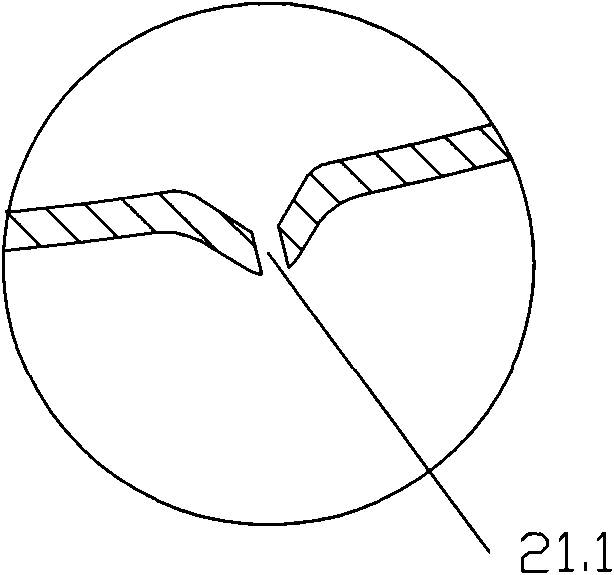

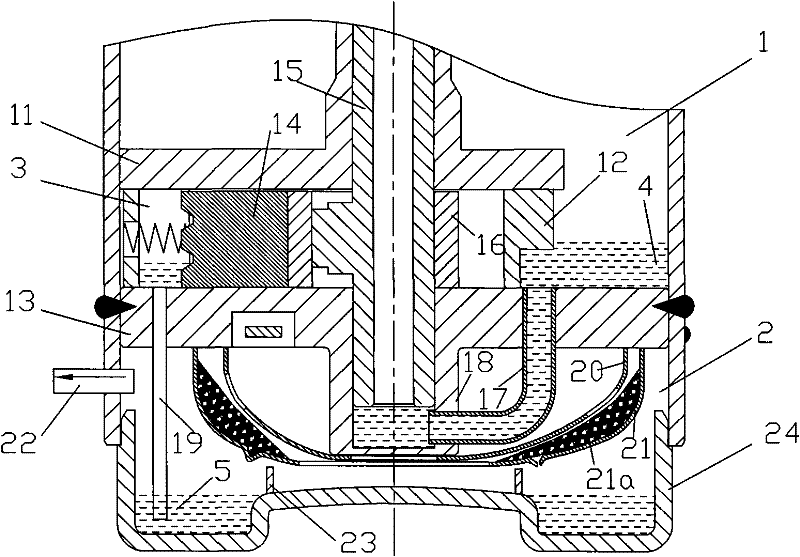

Rotary compressor

ActiveCN102192154AReduce noiseSmall pulsationRotary/oscillating piston pump componentsLiquid fuel engine componentsPistonLubrication

The invention provides a rotary compressor, comprising a compression component and a motor component which are arranged in a shell, wherein the compression component is arranged at the lower part of the shell; the motor component is arranged at the upper part of the shell; the compression component comprises an air cylinder, a piston arranged in the air cylinder and a slip sheet; a long bearing and a short bearing which are used for supporting an eccentric crankshaft are arranged on the air cylinder; the short bearing is used for dividing the inner space of shell into a low-pressure cavity atthe upper part and a high-pressure cavity at the lower part; the short bearing is provided with an upper oil pool, and an oil storage cavity is arranged at the lower end of the short bearing; the oilstorage cavity is communicated with the lubricant channel of the eccentric crankshaft; one end of an oil conduit is communicated with the upper oil pool and the other end of the oil conduit is communicated with the oil storage cavity; an oil conducting cover is arranged at the lower end of the short bearing; and the oil conducting cover, the lower end of the short bearing and the eccentric crankshaft form an oil storage chamber. The rotary compressor is simple and reasonable in structure, flexible in operation, good in lubrication performance, good in oil-gas separation effect, low in oil seal amount and high in safety degree.

Owner:GUANGDONG MEIZHI COMPRESSOR

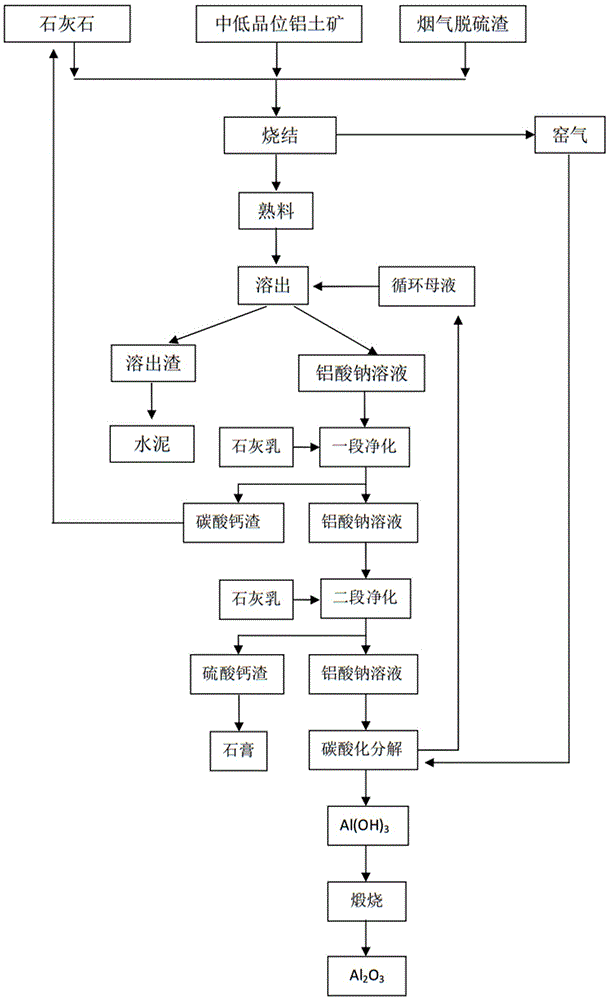

Method for producing aluminum oxide through sintering sulfur-containing monohydrallite and lime

ActiveCN105540628AAvoid the effect of dissolution rateAvoid corrosionAluminium oxides/hydroxidesSocial benefitsSlag

The invention relates to the technical field of aluminum oxide, and in particular relates to a method for producing aluminum oxide through sintering sulfur-containing monohydrallite and lime. According to the method, through properly adding a small amount of flue gas desulfurization slag and the lime into sulfur-containing monohydrallite for sintering, the aluminum oxide is produced, enabling aluminum element and sulphur element in a raw material to form a 4Cao.3Al2O3.SO3 phase, and by enabling silicon element to form a gamma-2CaO.SiO2 phase, and then adopting a low-temperature dissolution technology to perform aluminum oxide production, the deleterious effect of the sulphur element is reduced, the aluminum oxide dissolution performance of clinker is improved, and better market application value and social benefit are realized.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

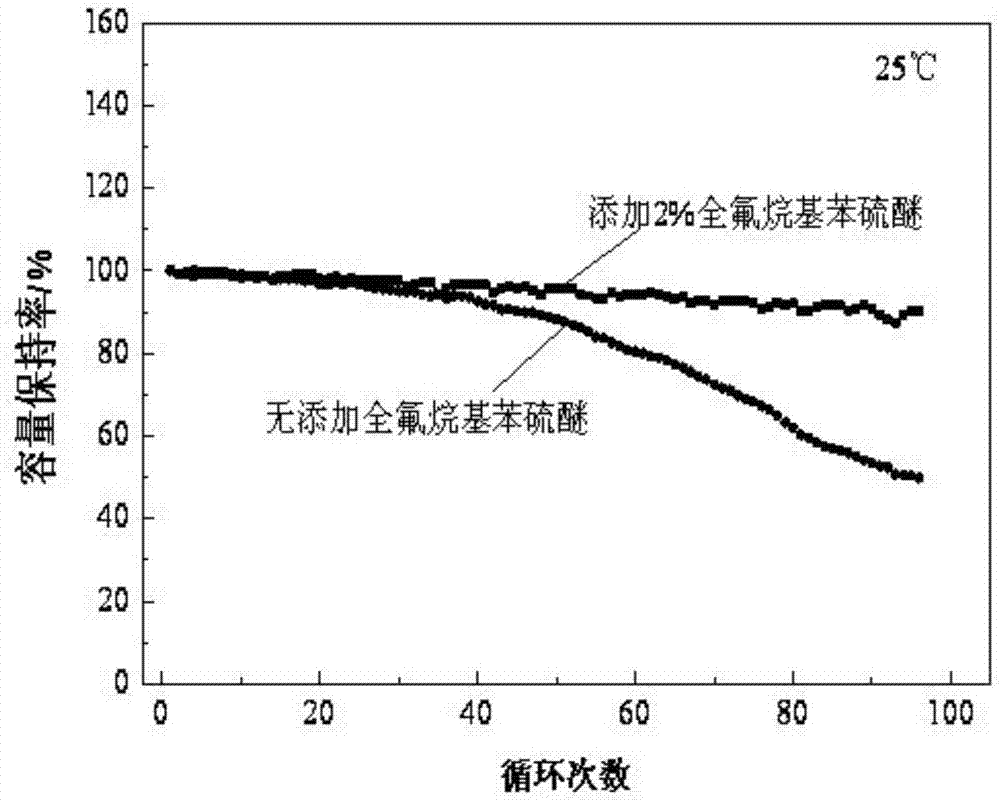

Lithium ion battery electrolyte and lithium ion battery

InactiveCN105449275AImprove securityImprove thermal stabilitySecondary cells servicing/maintenanceTriflic acidSulfonyl fluoride

The invention discloses a lithium ion battery electrolyte and a lithium ion battery. The lithium ion batter electrolyte comprises non-aqueous organic solvent, lithium salt, a functional additive, a flame-retardant additive and a negative electrode film-forming agent. According to the scheme of the lithium ion batter electrolyte, perfluoroalkyl diphenyl sulfide is used as the functional additive on the basis of reasonably optimizing the non-aqueous organic solvent, the lithium salt and the negative electrode film-forming agent; the problem that the novel lithium salt corrodes an aluminium current collector can be effectively solved, wherein the novel lithium salt comprises lithium trifluoromethanesulfonate (LiCF3SO3), perfluoroalkyl sulfonyl lithium methide (LiC (CF3SO2)3, bi(trifluoromethyl sulfonyl) lithium imide (LTFSI), bi(sulfonyl fluoride) lithium imide (LiFSI) and the like; the cycling performance of the lithium ion battery is improved; the LiPF6 can be well replaced by the lithium ion battery electrolyte, and the lithium ion battery electrolyte can be widely applied to the secondary lithium ion battery electrolyte, and particularly suitable for lithium ion power batteries for improving the thermal stability of the lithium ion power batteries.

Owner:OPTIMUM BATTERY CO LTD

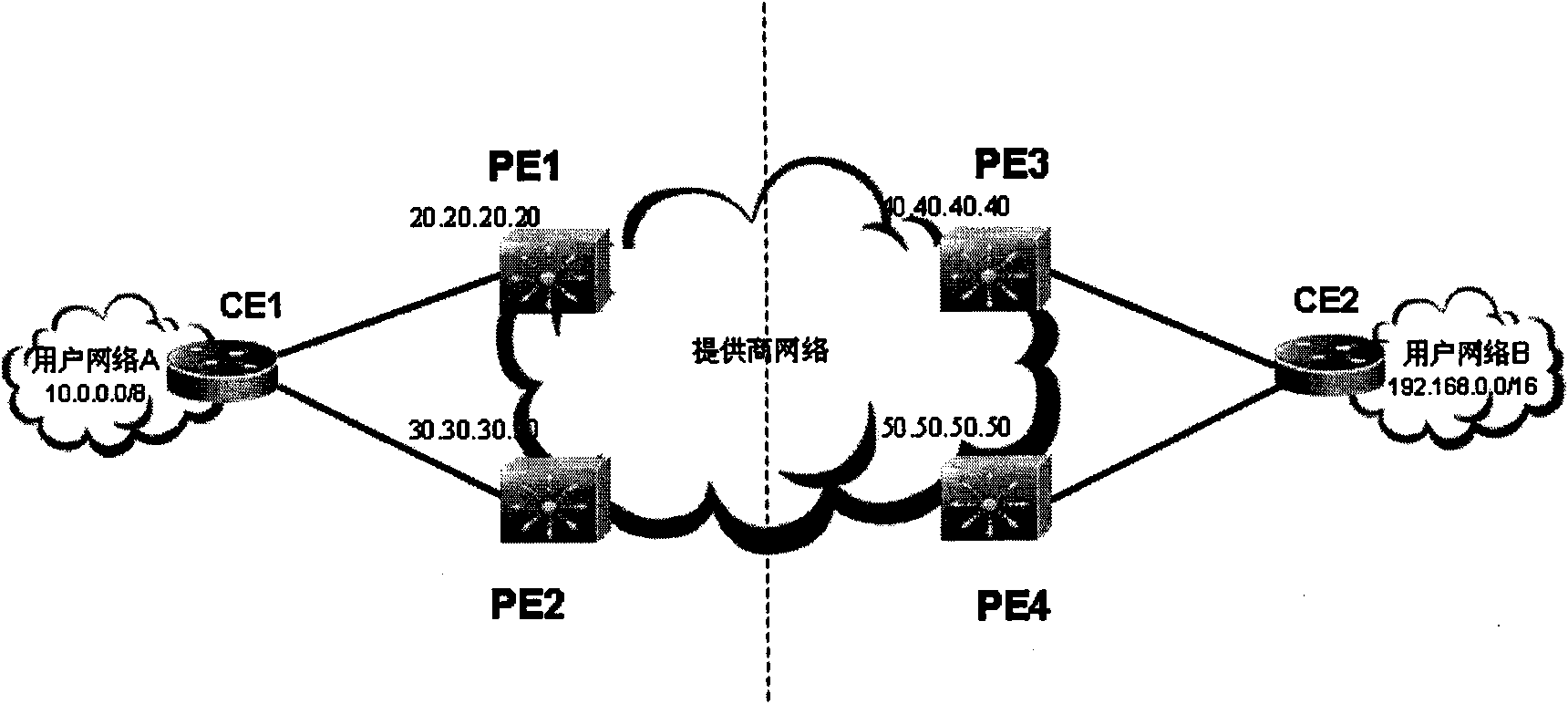

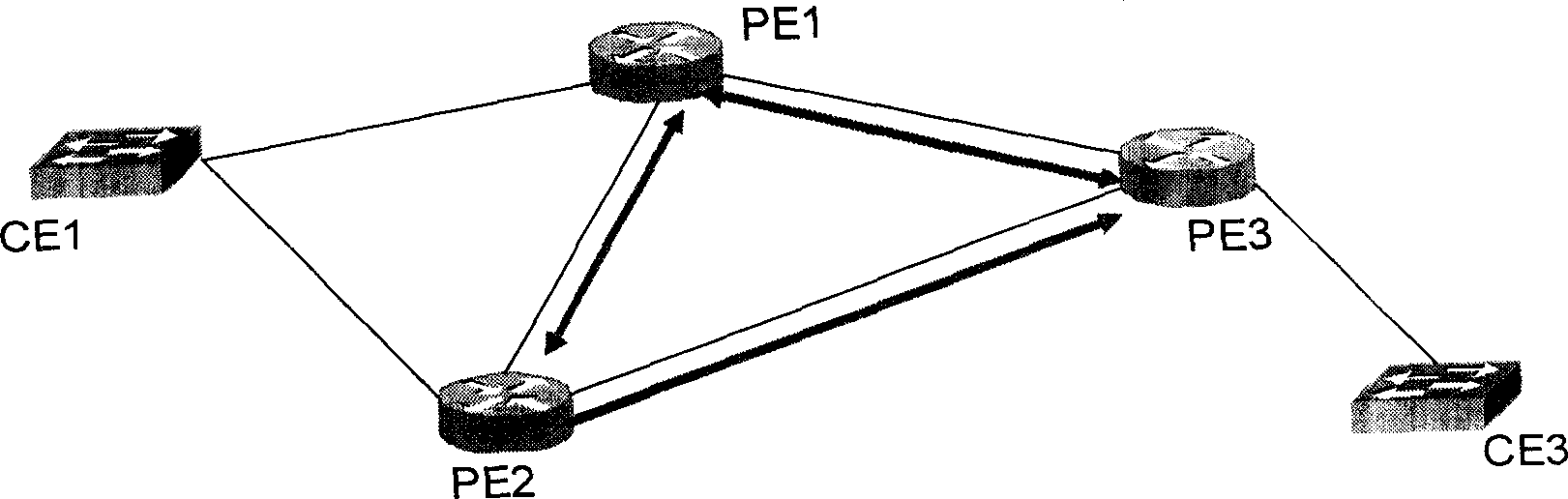

Method and device for realizing user access multi-homing network and network equipment

ActiveCN101616093AFlexible useSimplify functional requirementsNetworks interconnectionNetwork data managementAccess networkAdaptive routing

The invention discloses a method and a device for realizing a user access multi-homing network and network equipment, and solves the problem of dynamic routing loops generated when a user access network uses CE multi-homing networking. The method disclosed by the invention comprises that: a home location PE receives VPN routing information from other PE; if judging that the VPN routing information received from the other PE is required to be sent to homing CE, the home location PE reflects the VPN routing information to the other PE on the home location; and when receiving the VPN routing information from the homing CE, the home location PE judges whether the VPN routing information received from the homing CE is the same as the reflected VPN routing information, and if so, VPN routing entries are prohibited from being updated by the VPN routing information received from the homing CE. Because the home location PE filters routing which is received from the CE and possibly causes loops by utilizing the reflected VPN routing information, and the VPN routing information is not used to update the VPN routing entries, so the problem of the dynamic routing loops is solved.

Owner:BEIJING ZHIGU TECH SERVICE

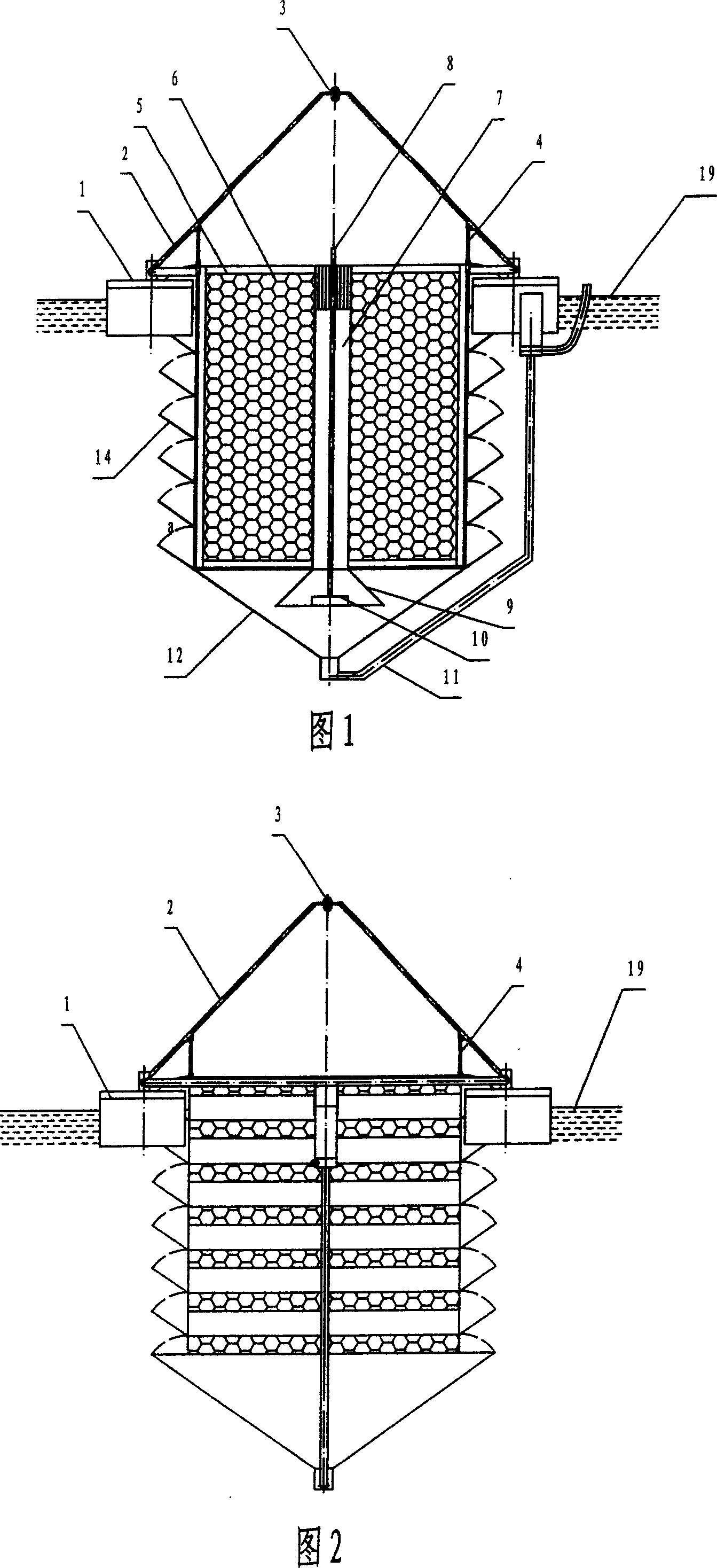

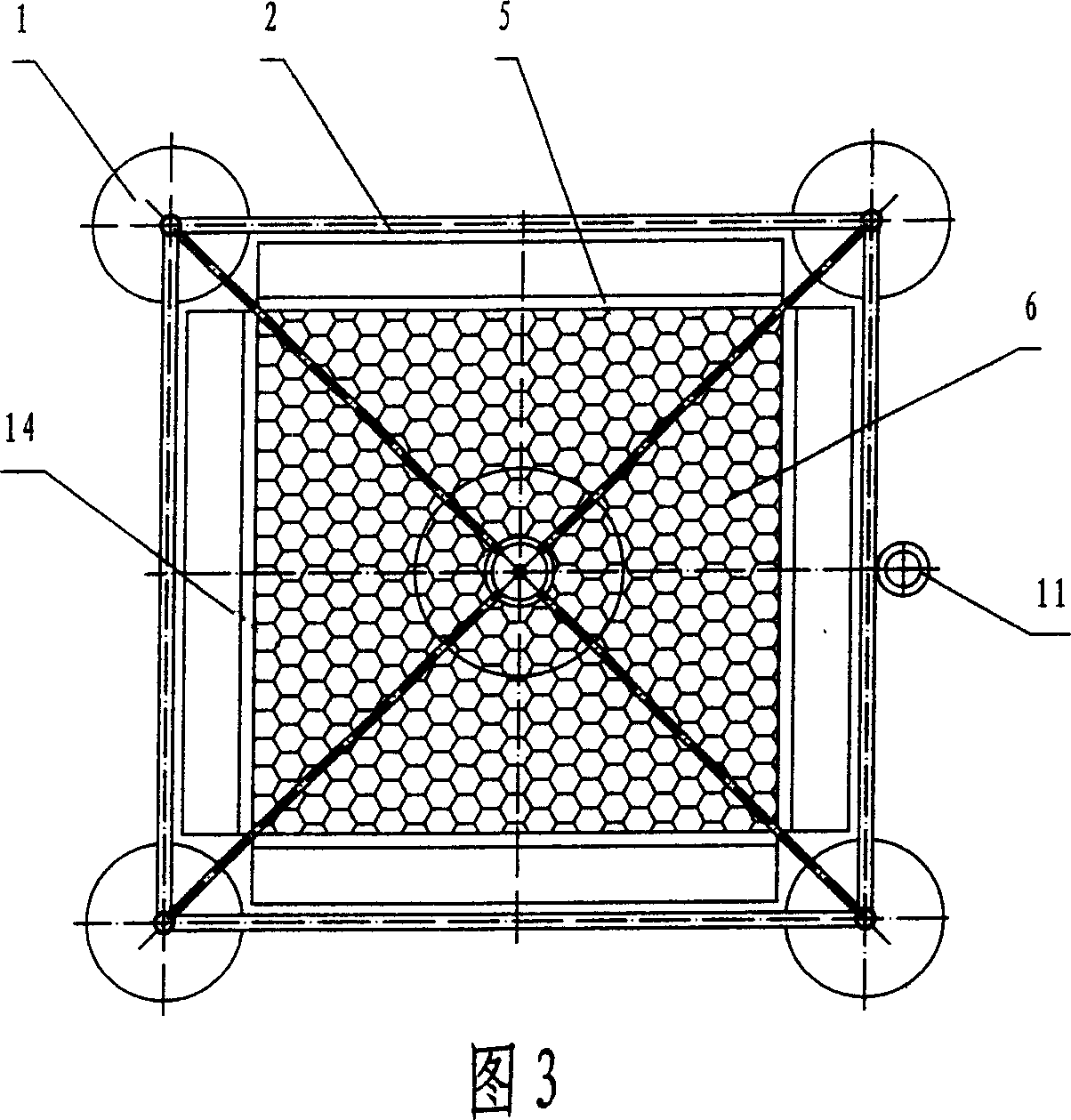

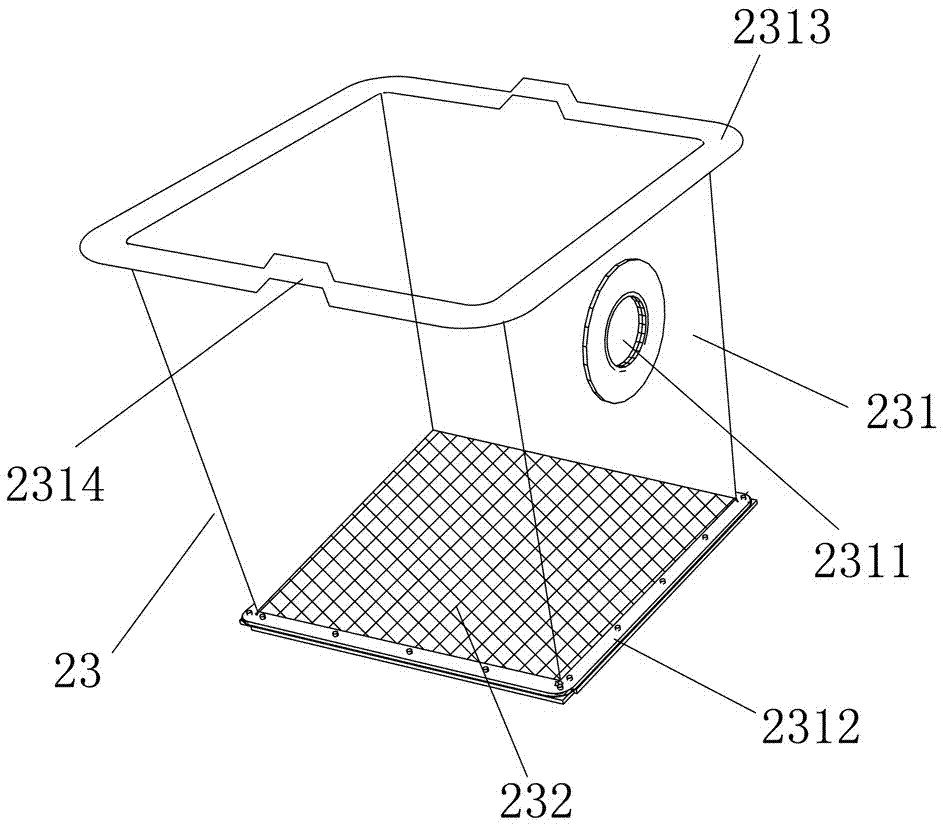

Controllable environment-friendly type fish culture box

InactiveCN101011043AIncrease breeding capacityImprove efficiencyClimate change adaptationPisciculture and aquariaEngineeringDrainage tubes

The invention relates to a controllable environment-friend fish box, which is formed by a floating support, a box, and a box bottom. The floating support comprises a floater, a support, a suspending ring, and a hook of fish box. The box comprises a frame, a mesh plate, a leaf side baffle plate, a suspending plate, a positioning plate, a lifting ear, a floating cylinder, a support of floating cylinder, a gas tube, a gas frame, and an aeration disc. The box bottom comprises a drainage groove, a hook of drainage groove, and a drainage tube. The frame of the fish box is arranged with outside leaf side baffle plate. The fish box mesh plate is arranged around the box and at the bottom. The floating cylinder, the gas frame, and the aeration disc are concentrically connected, via the support of floating cylinder to be fixed at the center of frame of fish box. The box bottom is arranged with the reverse-taper drainage groove, which is connected to the fixing hole of positioning plate via the hook of drainage groove. The floating support is partly arranged with a floater arranged on the support. The hook of fish box is connected with the lifting ear of positioning plate. The invention has simple structure.

Owner:天津市水产研究所

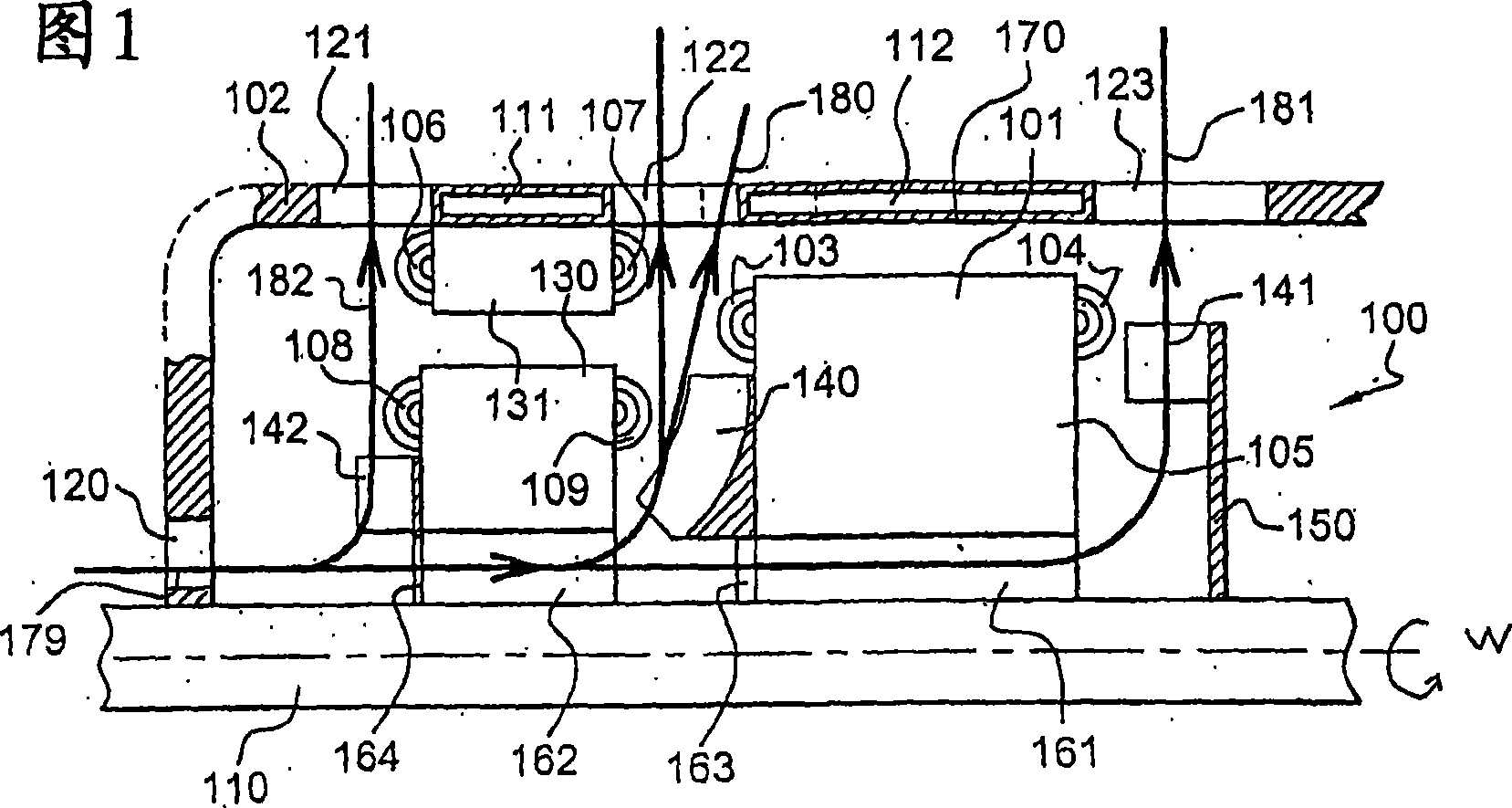

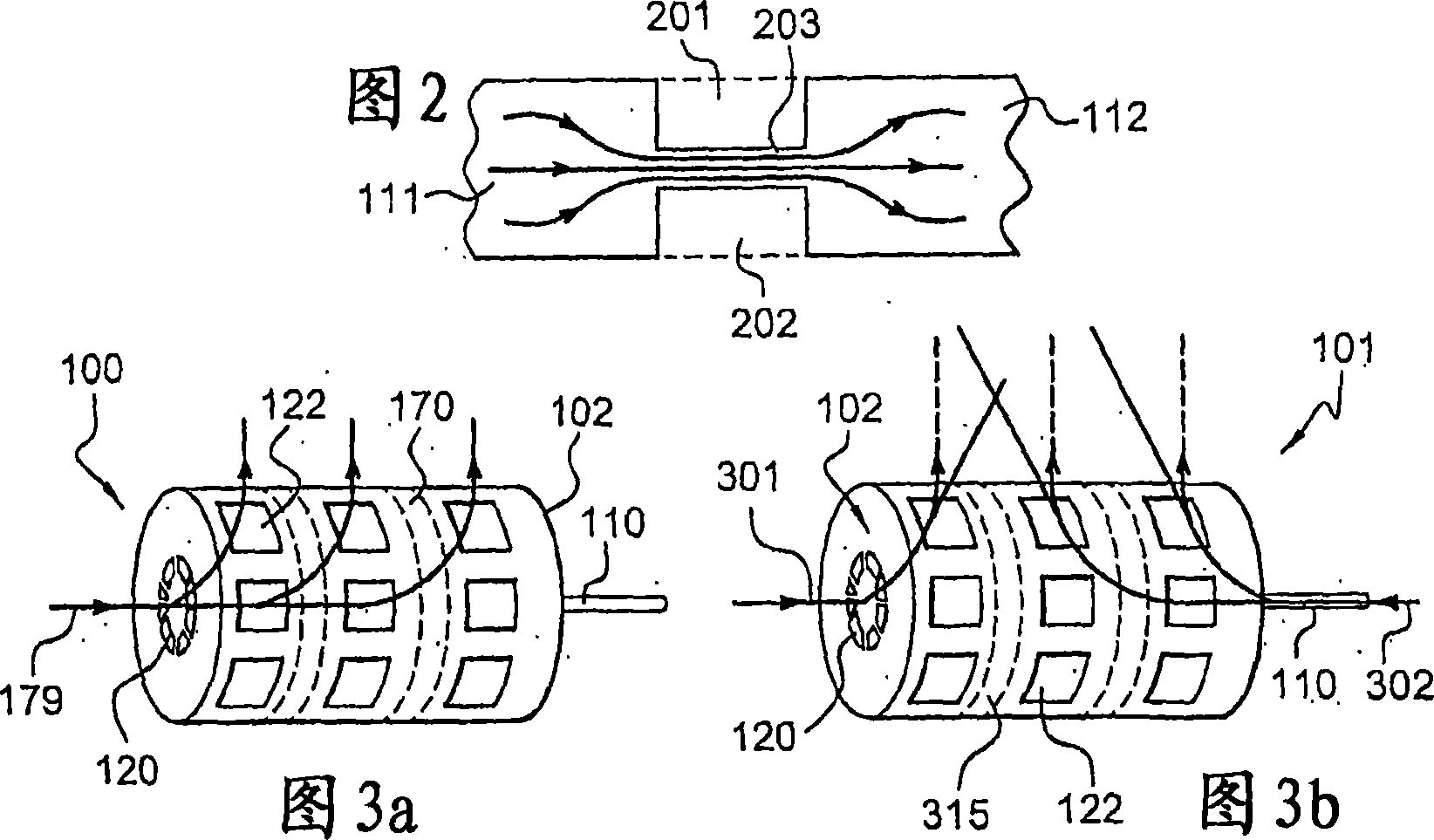

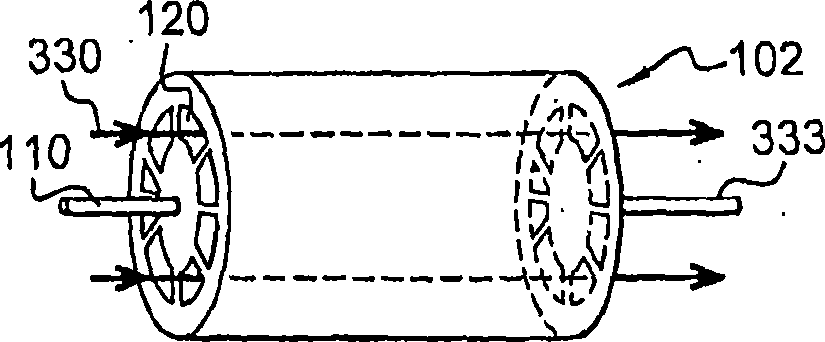

Electromagnetic retarder comprising means ensuring ventilation

InactiveCN1894841ASolve the loop problemSolution volumeMagnetic circuit rotating partsAsynchronous induction clutches/brakesCooling chamberEngineering

The invention essentially consists of a retarder(100) comprising a stator(170) and / or a housing(102) surrounding or encasing a rotor(101), means(140-142) for producing an air current and at least one inlet(120) enabling said air current to enter and at least one outlet(120) used to evacuate said air current. The outlet(121-123) is created between to cooling chambers(111-112) or through several cooling chambers which are borne by the housing and / or stator of the retarder.

Owner:TELMA

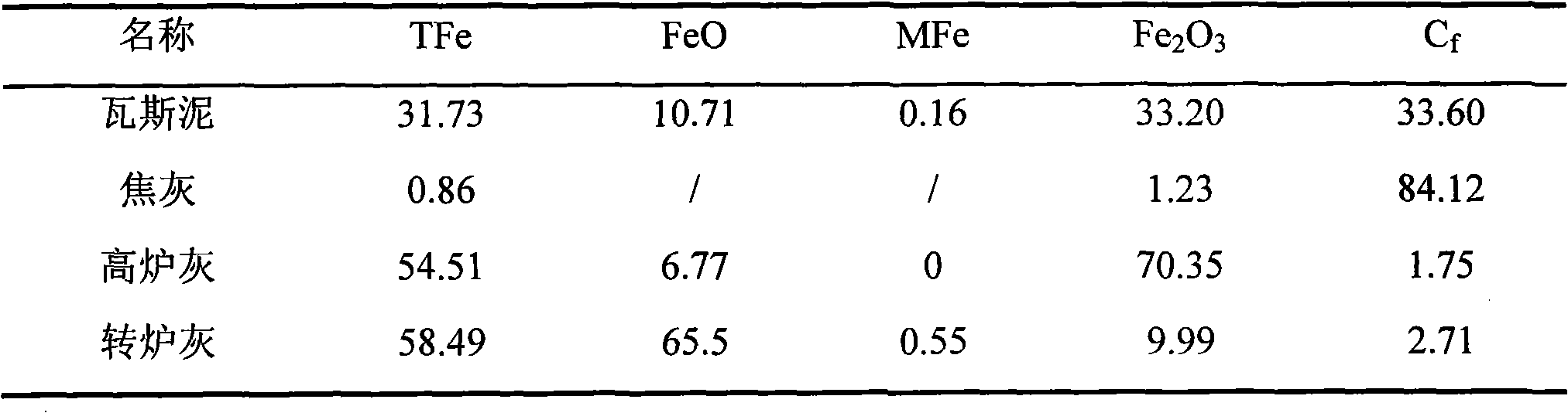

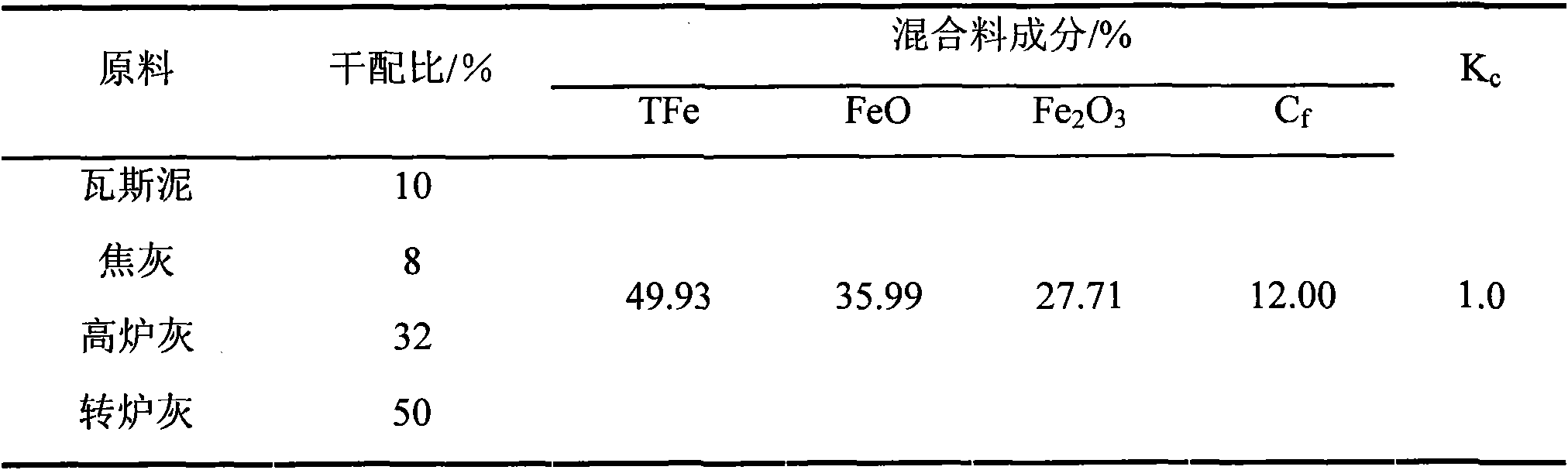

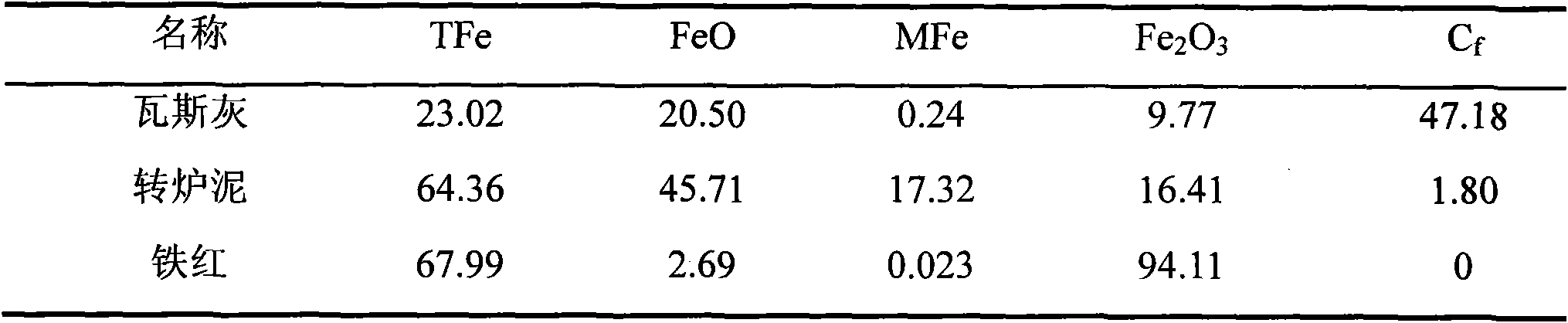

Method for comprehensively treating and utilizing dust sludge

ActiveCN102031361ALow melting pointSimplified processing facilitiesProcess efficiency improvementSteelmakingGranularity

The invention provides a method for comprehensively treating and utilizing dust sludge. The method comprises the following steps of: (1) dispensing: carrying out dispensing calculation according to main ingredients of various iron-containing dust sludge to ensure that the excess coefficient of the content of free carbon reaches 1.0-1.8; (2) mixing: uniformly mixing materials by using mixing equipment; (3) molding: pressing the mixed material into a dust sludge block mass with a granularity of 5-15mm by using molding equipment; (4) drying: drying the molded dust sludge block mass at a temperature below 300 DEG C; (5) charging: after steel-making molten iron in a molten iron pot is blended into a rotating furnace, putting the dust sludge block mass into the hollow molten iron pot through charging equipment according to a weight determined by calculation, preheating and partially reducing the dust sludge block mass by utilizing the molten iron pot and the heat of residual molten iron in the molten iron pot, and sufficiently reducing by utilizing the heat of a large quantity of molten iron and a scouring and stirring effect after the molten iron pot loses iron; and (6) desulfurizing: moving the steel-making molten iron pot which finishes receiving the molten iron and is filled with the dust sludge block mass to a desulfurizing position to desulfurize, wherein after desulfurizing, the molten iron pot can be normally used for steel-making. The method can be used for treating any dust sludge materials without separating the iron dust sludge, ensures that all the iron dust sludge is utilized, simplifies the dust sludge treatment facility, reduces the enterprise cost and has obvious economic benefit and environmental protection benefit.

Owner:ANGANG STEEL CO LTD

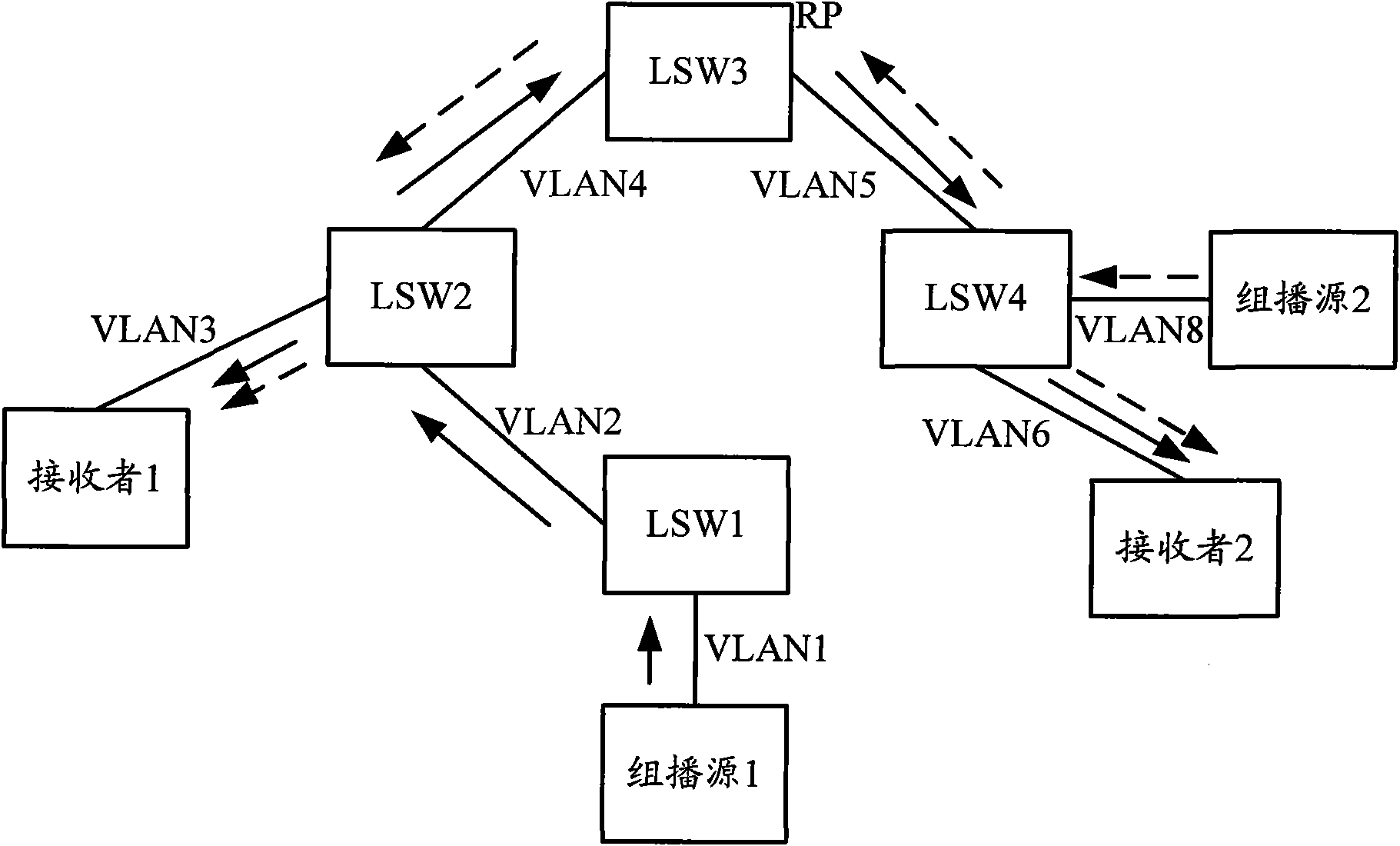

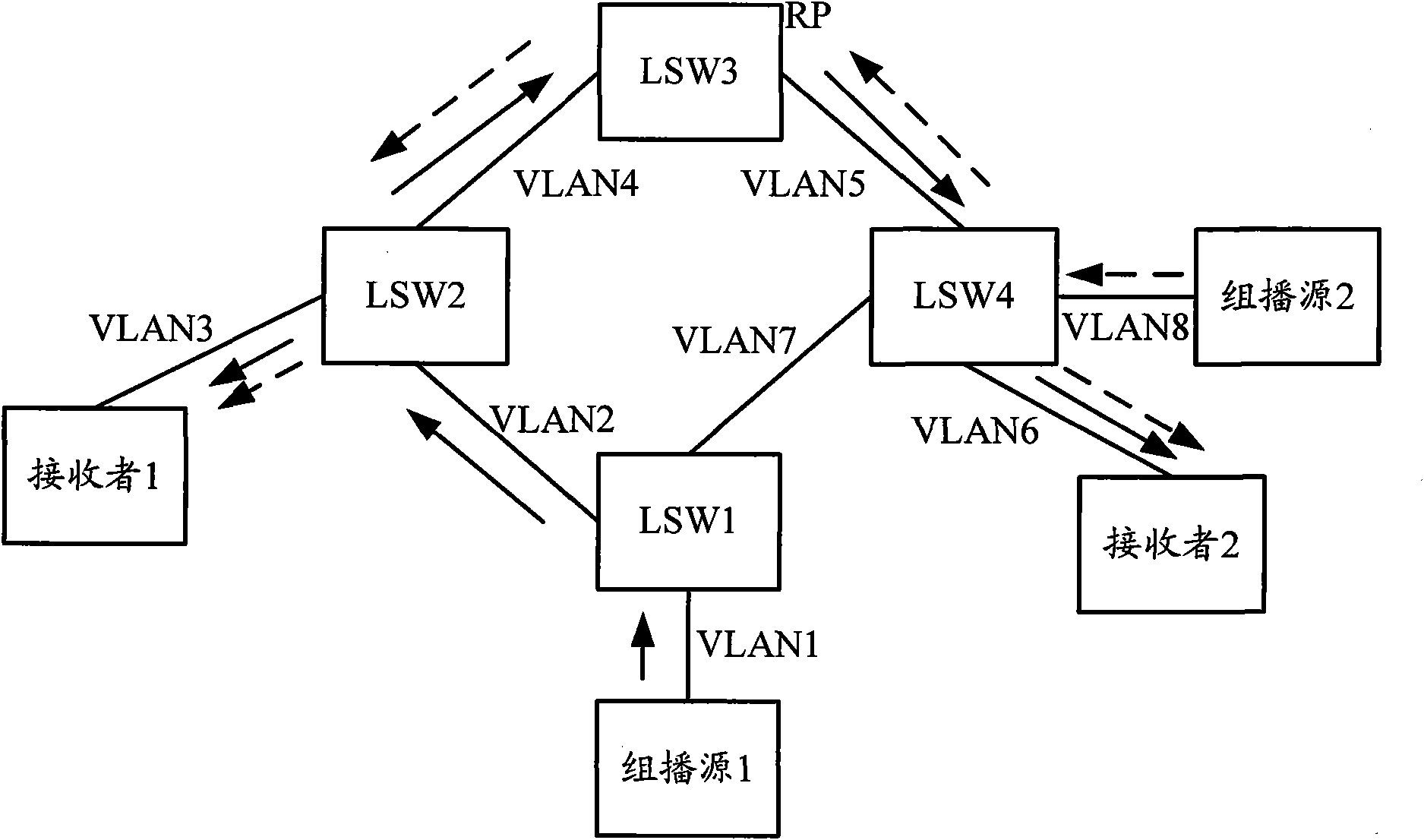

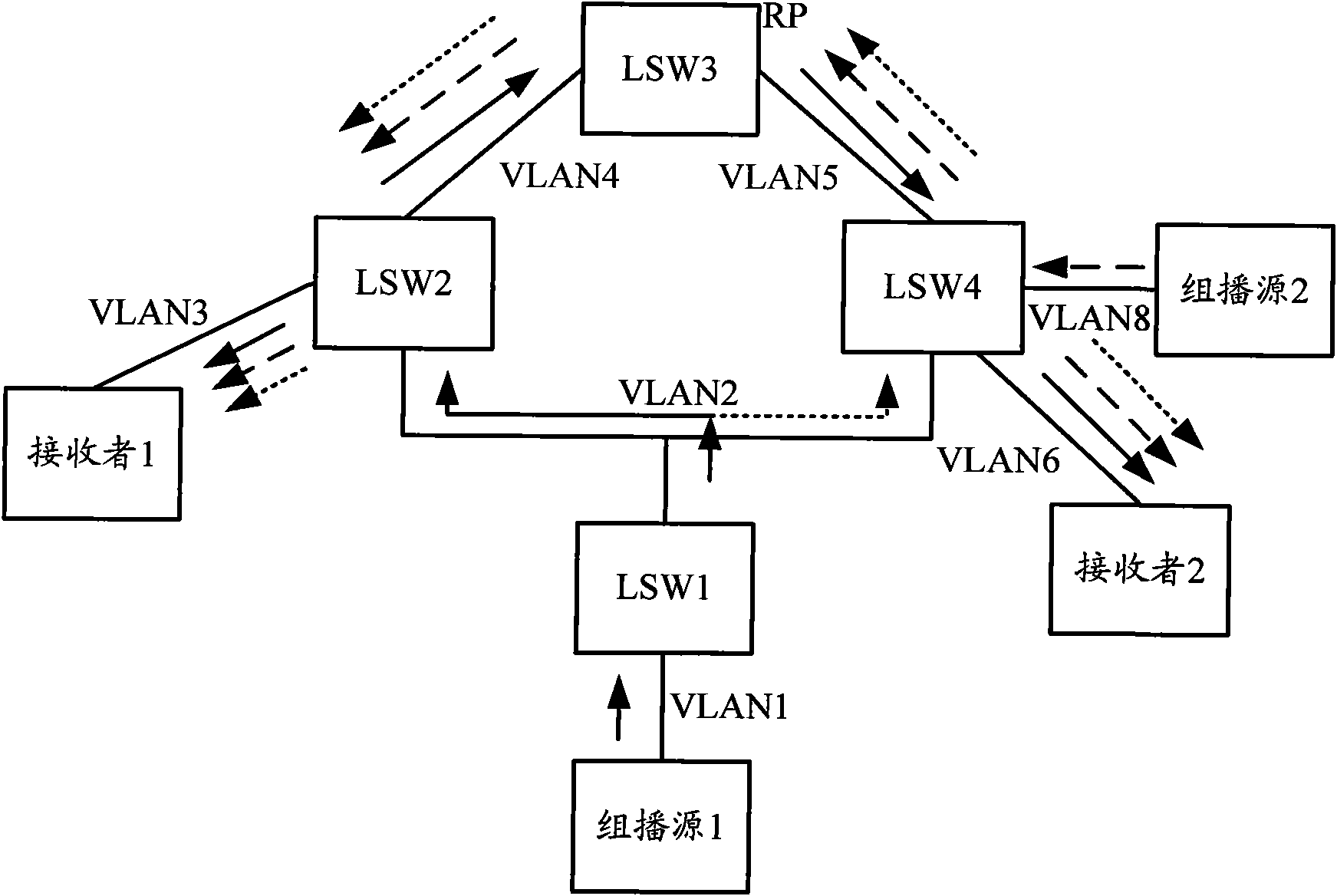

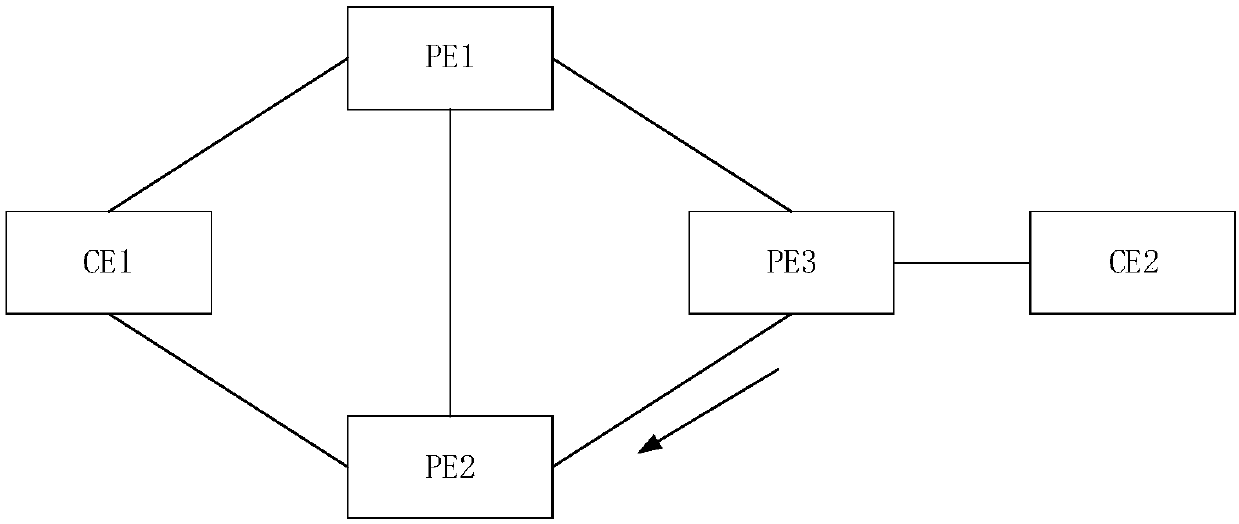

Multicast data transmission method and equipment

ActiveCN101986601AImplement DF check functionSolve the loop problemSpecial service provision for substationData transmissionProtocol Independent Multicast

The invention discloses a multicast data transmission method and multicast data transmission equipment. The method comprises that: network equipment determines the DF interfaces of the network equipment, and sets corresponding (*.G.V) table entries of the DF interfaces; and when receiving multicast data, and the network equipment forwards the multicast data through an outlet interface if a matched (*.G.V) table entry is found according to the inlet interface of the multicast data or discard the multicast data. In the invention, bidirectional protocol independent multicast (PIM) forwarding canbe realized, and the problem of loop of a multicast data stream is solved.

Owner:NEW H3C TECH CO LTD

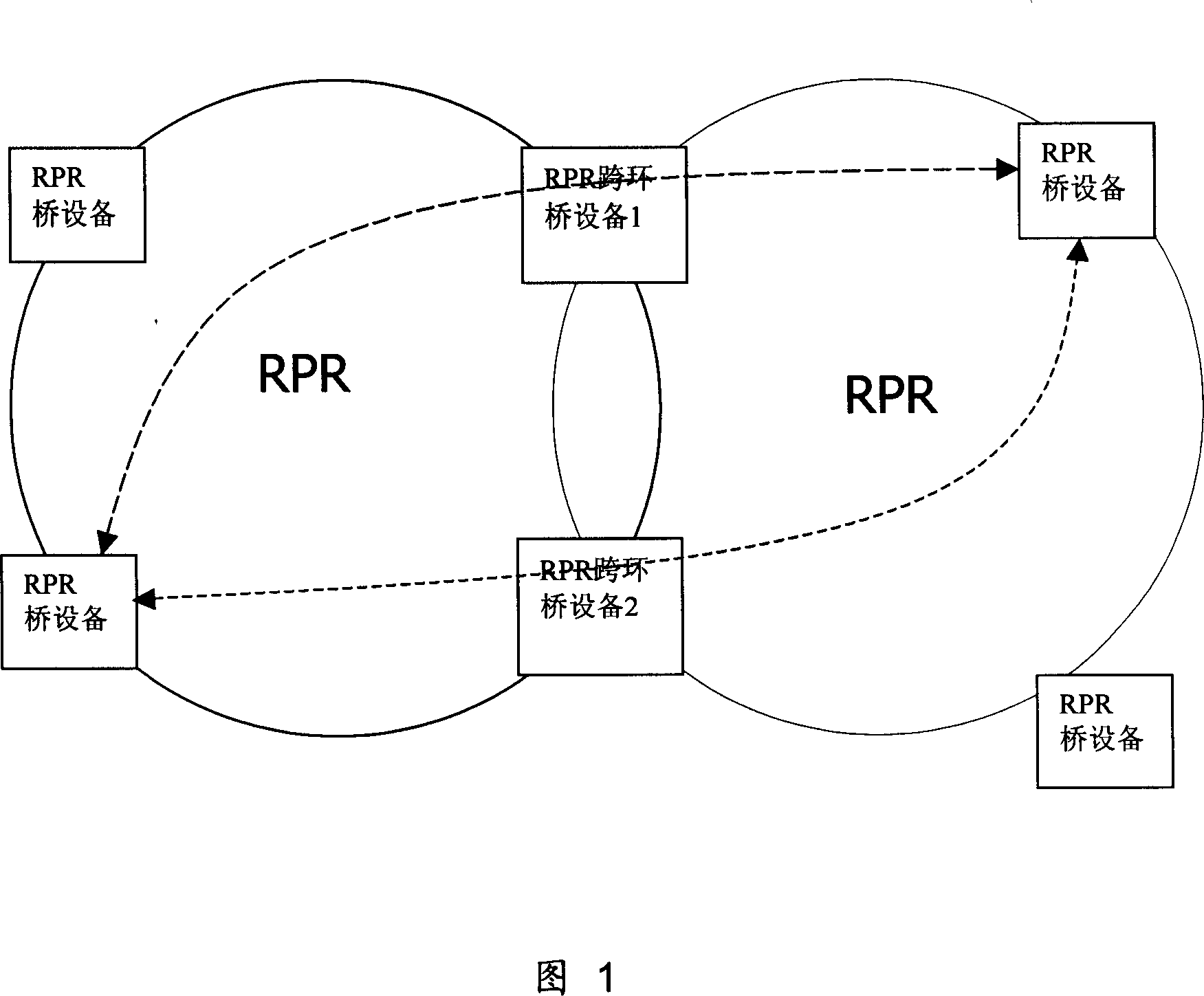

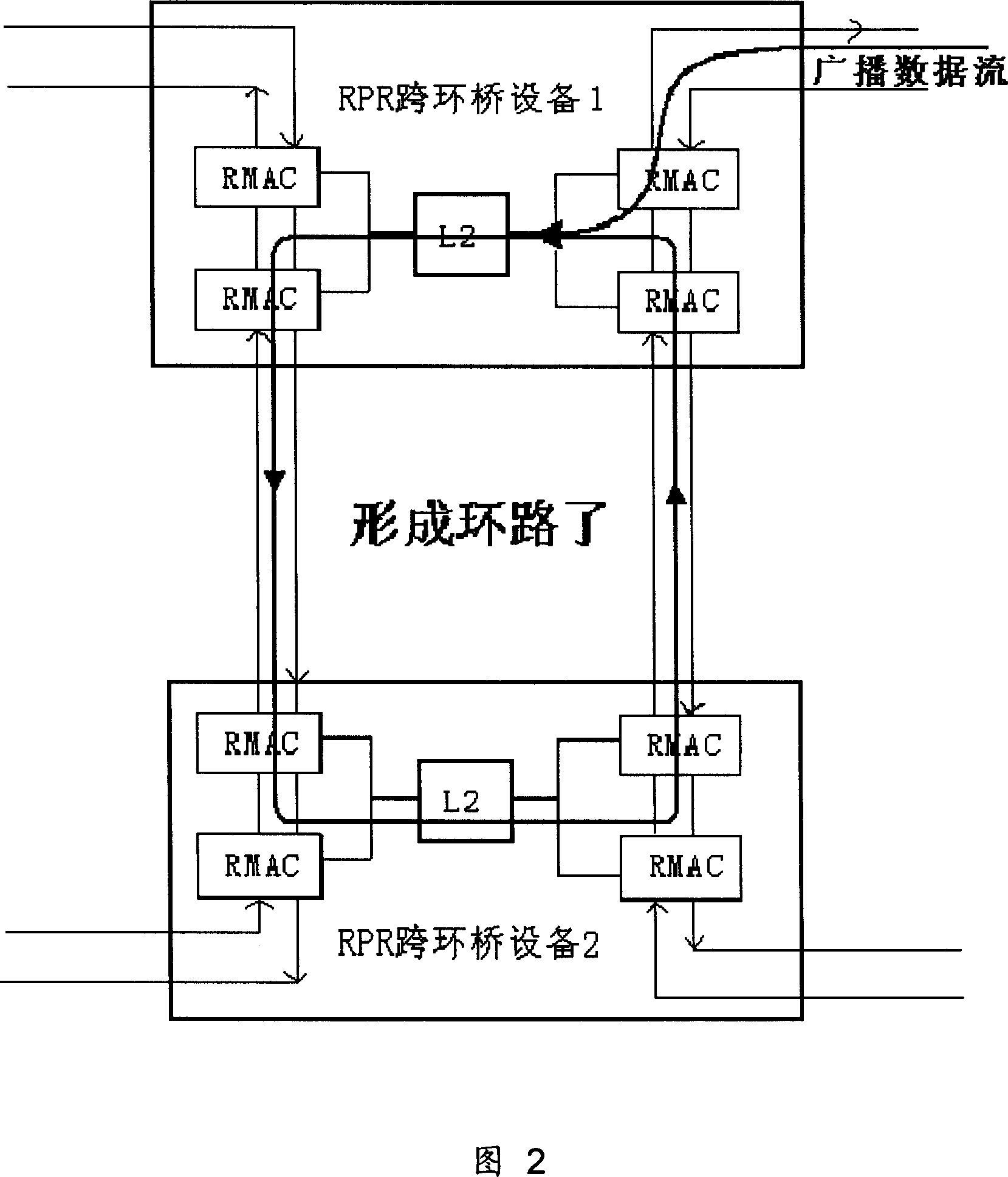

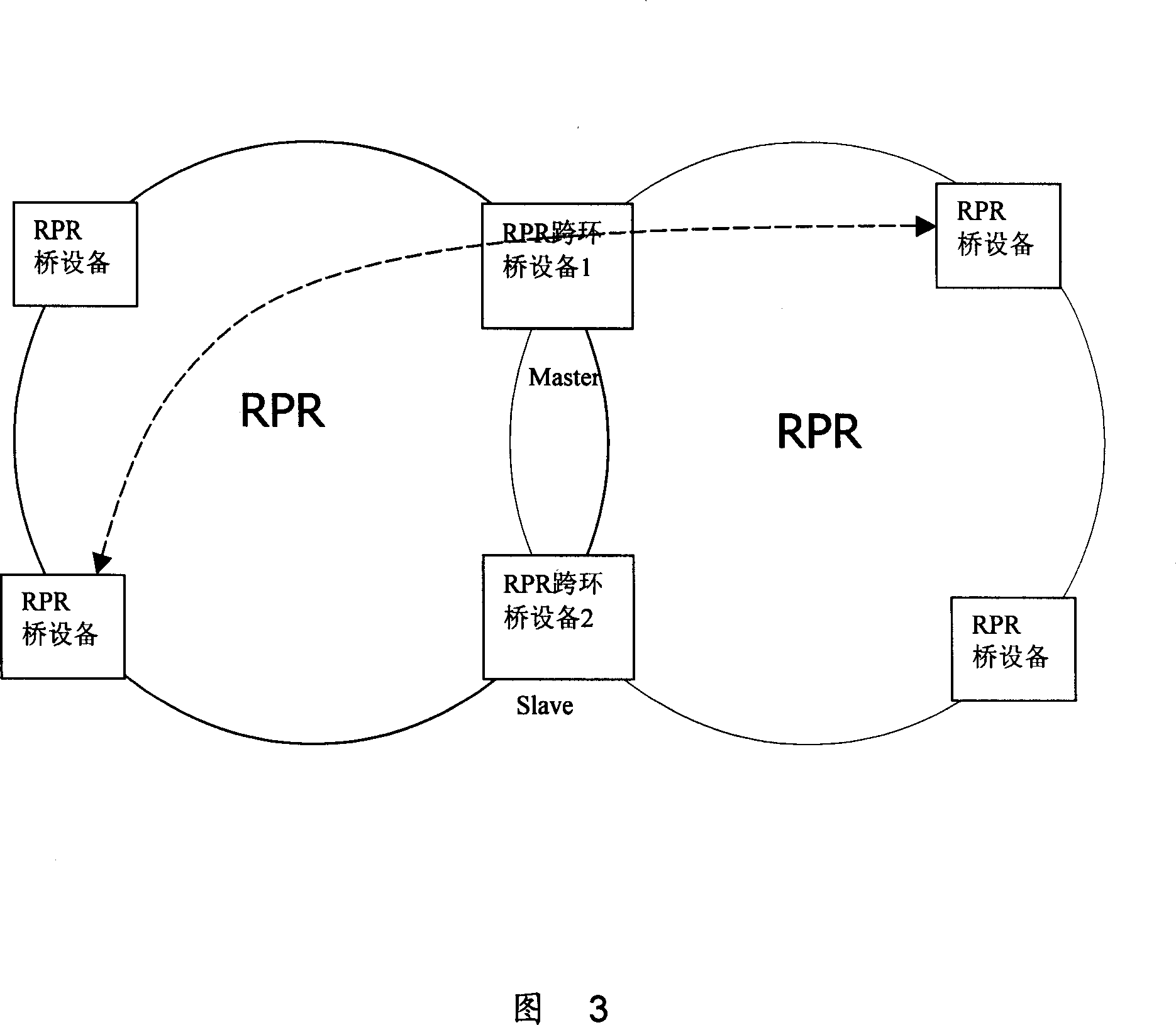

Method for protecting RPR bridge redundancy

InactiveCN1941730ASolve the loop problemAvoid broadcast stormsData switching networksResilient Packet RingReliability engineering

The method comprises: setting one of multi devices simultaneously located on the bridge between two RPRs (resilient packet ring) as an active device and other devices are set as standby devices; making interaction of device state control messages between active and standby devices to implement the redundancy protection of RPR bridge. By the invention, the switch speed from one failure cross-ring bridge device to other standby devices can be effectively improved.

Owner:HUAWEI TECH CO LTD

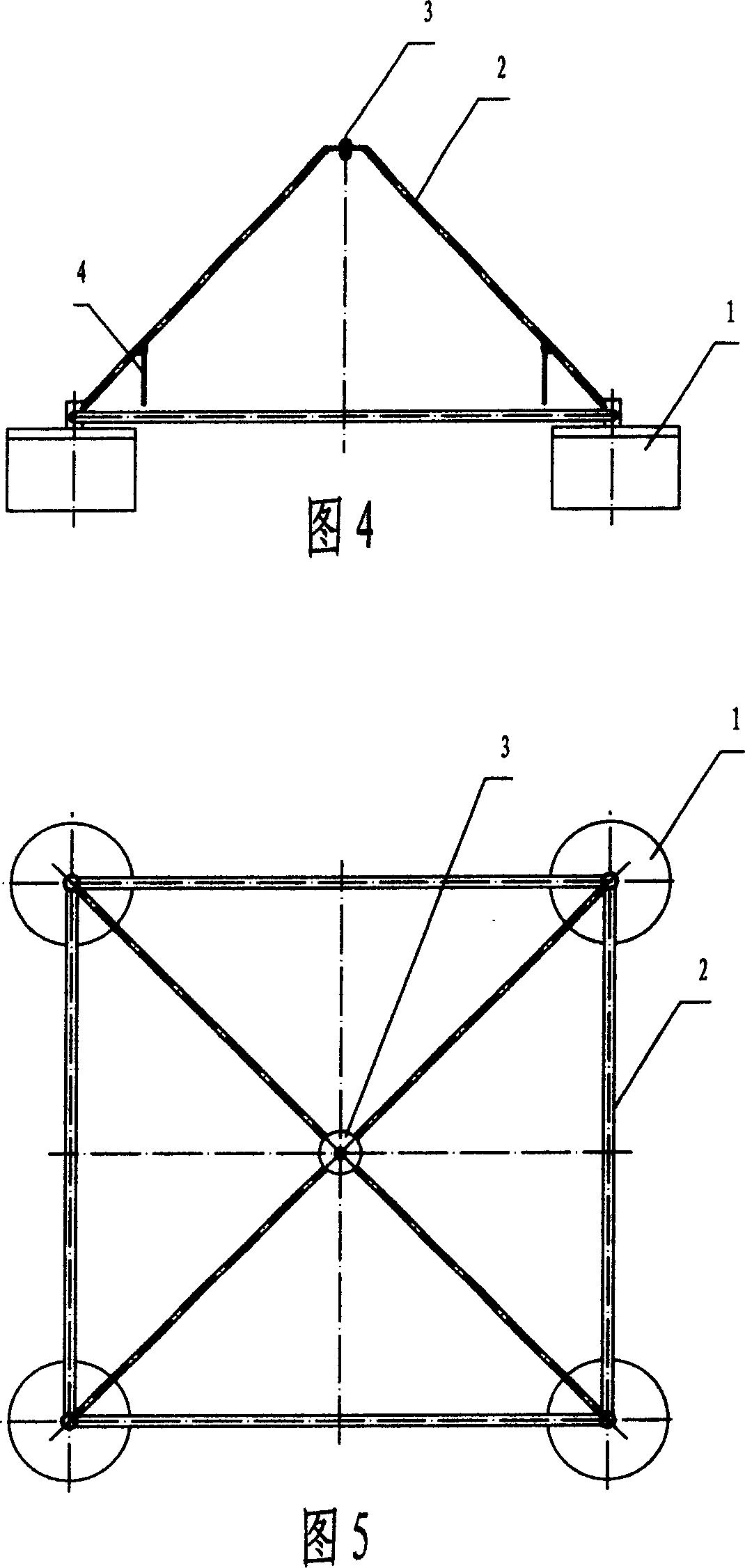

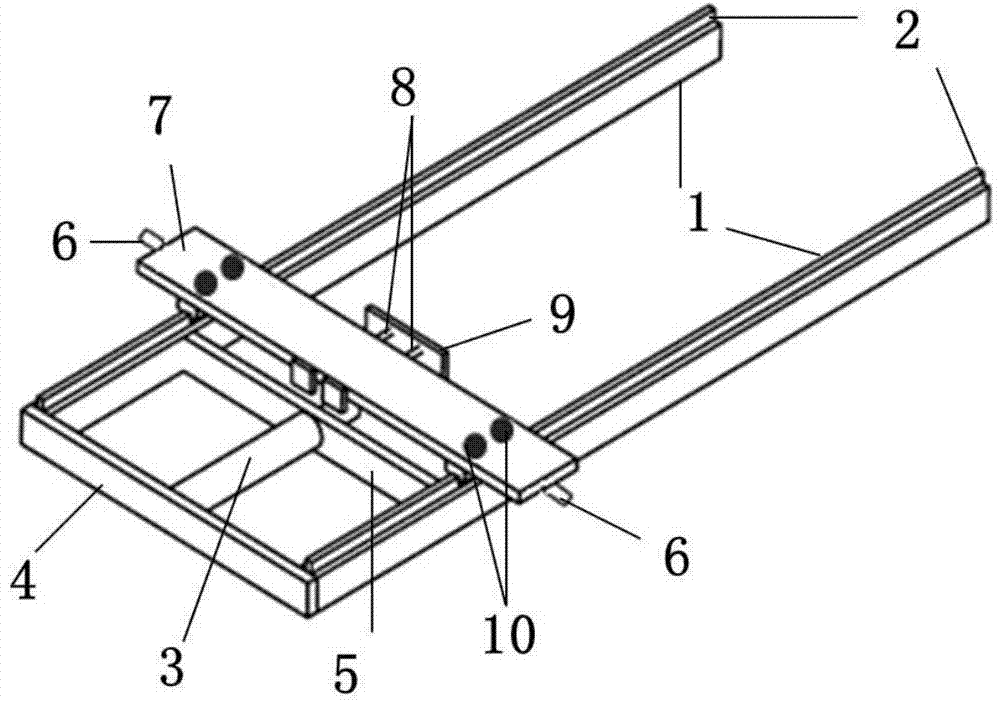

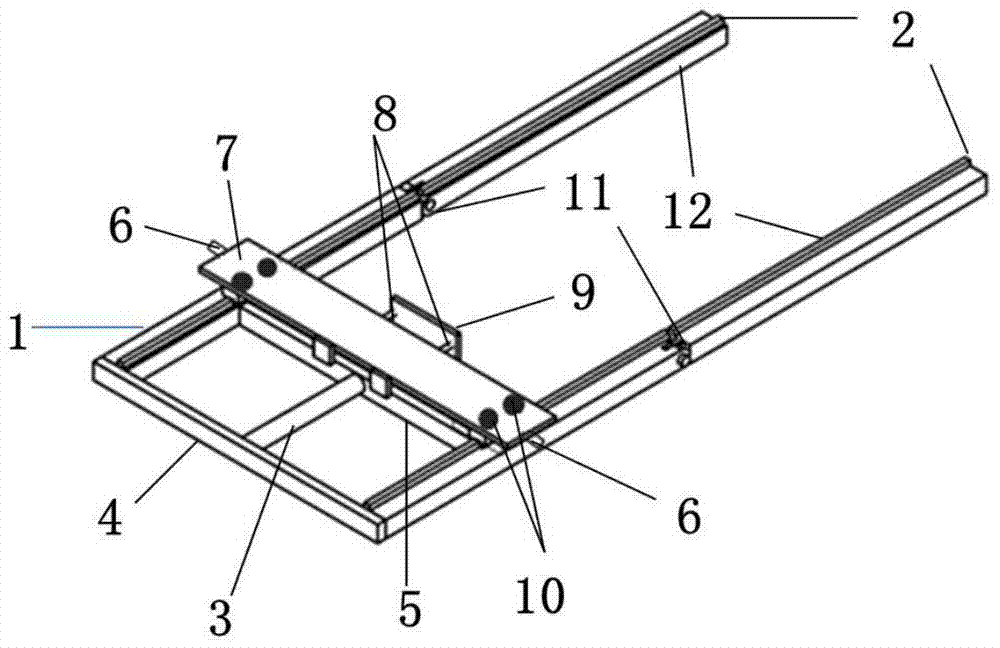

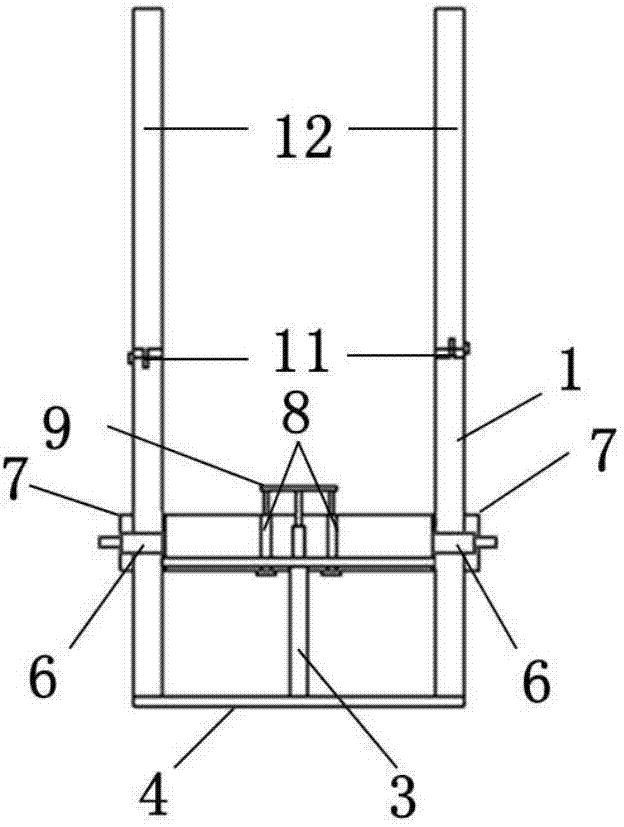

Excavating and supporting integrating method and carrying type lifting and transporting support manipulator for heading machine

ActiveCN103670425ASolve the loop problemSolve the problem of cutting parallel operationsMine roof supportsTunnelsRemote controlElectro hydraulic

The invention specifically discloses an excavating and supporting integrating method and a carrying type lifting and transporting support manipulator for a heading machine. The manipulator structurally comprises a supporting frame which is provided with a guide rail; a support carrying trolley is arranged on the guide rail, can slide along the guide rail back and forth and can move back and forth forwards and backwards under the action of a drive device; a mobile beam is arranged at the front of the support carrying trolley and is driven by the drive device to move forwards and backwards. In this way, remote-control excavating and supporting integration can be achieved if the automatic heading machine is adopted, electro-hydraulic control valves are arranged on jacks on the device, and visualized monitoring is added.

Owner:郑东风 +1

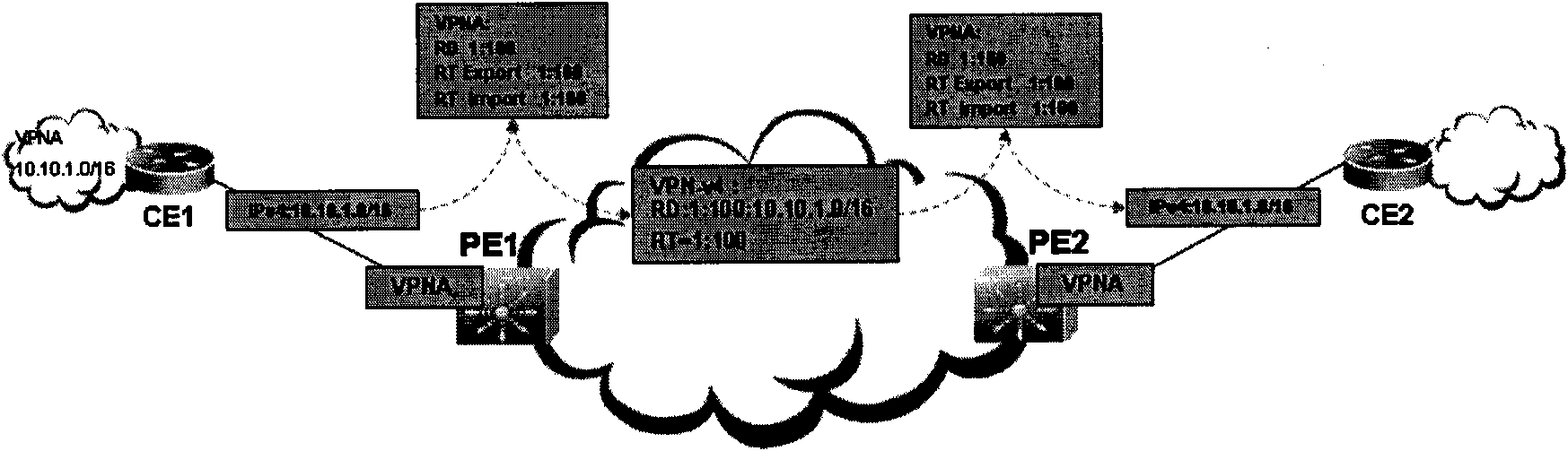

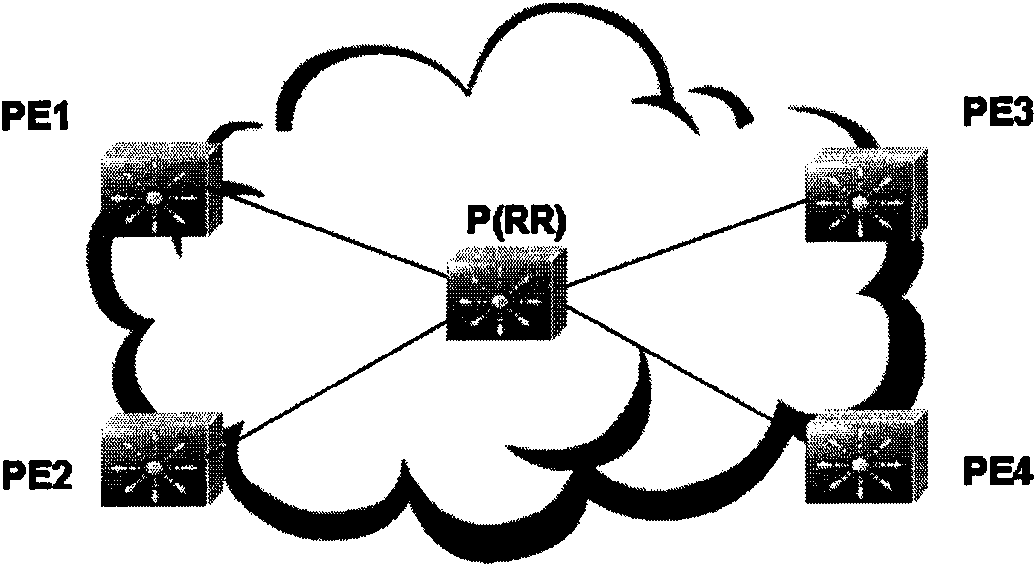

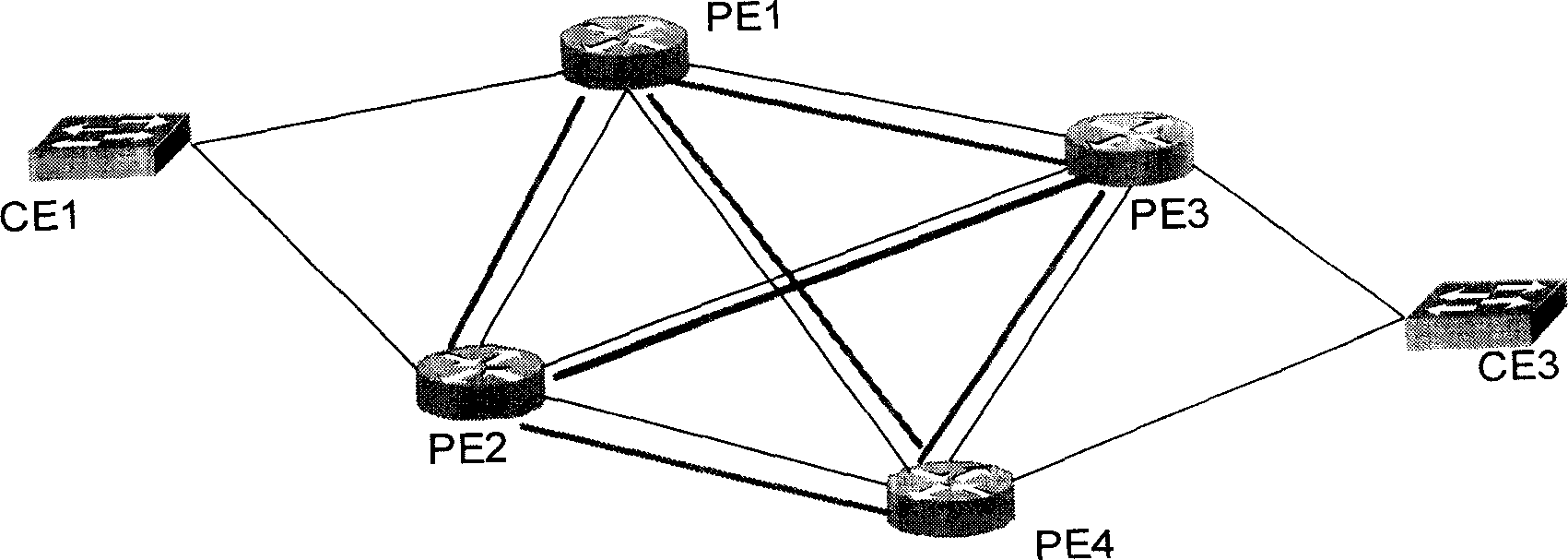

Double-attach/multi-attach logical packet network method and supplier equipment

InactiveCN1870634AAvoid learning mistakesSolve the loop problemData switching by path configurationBorder Gateway ProtocolGroup method

This invention provides a double / single attribute logic grouping method based on the BGP and a device of providers including: setting different CE attribute priorities for the PE belonging to the CE in a VPN, each PE gets the CE attribute priority of the far end PE equivalent to it, when the PE decides that the CE attribute priority of the far end PE equivalent to it is not lower than that of the local, it cancels the virtual connection PW with other PE, which effectively avoids the possibility for generating loops and avoid the error study of MAC address and solves the problem of loops in double-attribute and multi-attribute network grouping.

Owner:HUAWEI TECH CO LTD

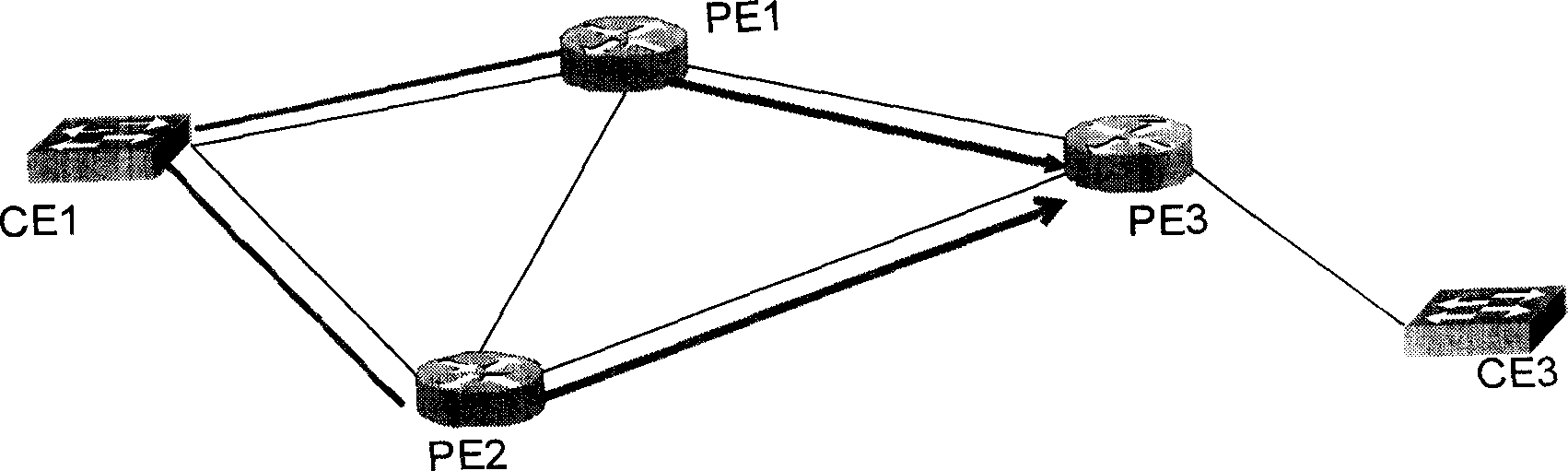

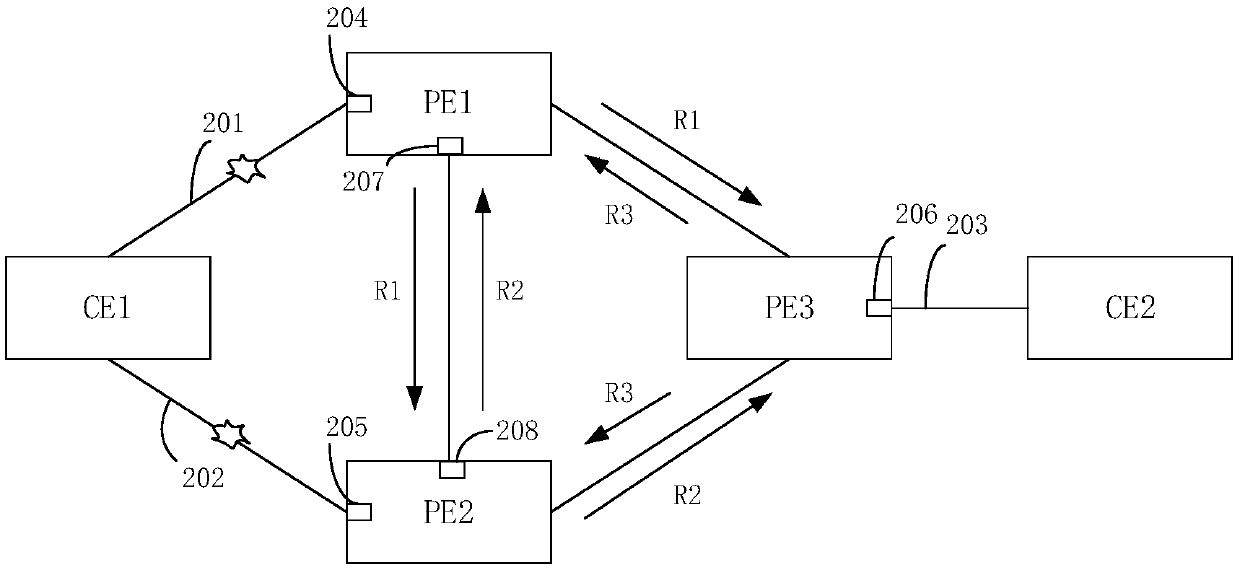

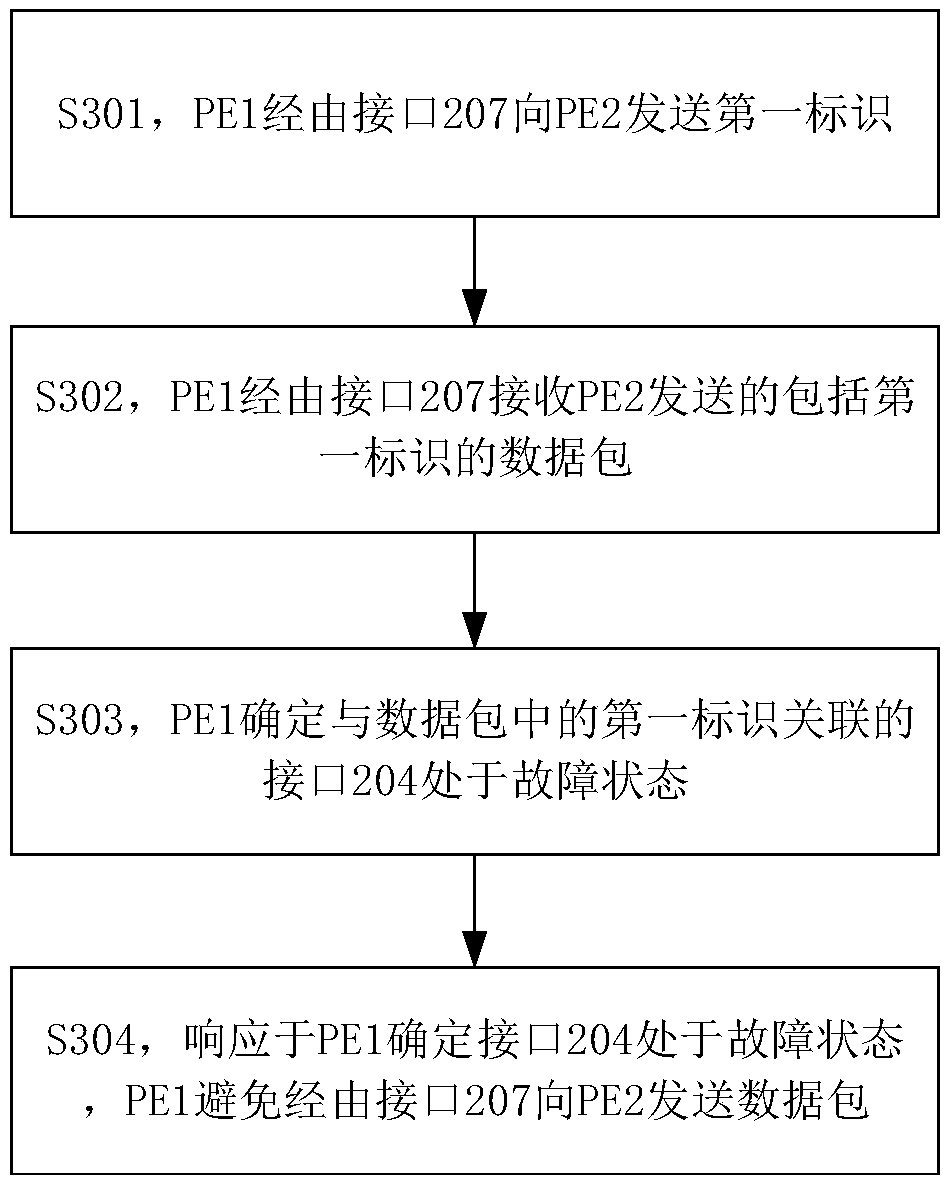

Communication method, device and system for avoiding loop

ActiveCN110661701AAvoid loopsAvoid transmission loop problemsNetworks interconnectionData packEmbedded system

The invention provides a communication method, device and system for avoiding a loop. The invention discloses a communication method. The first PE device sends a first identifier to the second PE device through the first interface, then, the first PE equipment receives a data packet which is sent by the second PE equipment and comprises a first identifier through the first interface; and then thefirst PE device determines that a second interface associated with the first identifier is in a fault state, and in response to determining that the second interface is in the fault state, the first PE device avoids sending a data packet to the second PE device via the first interface, and the second interface is an interface of the first PE device for connecting the CE device. Through the schemeprovided by the invention, a loop can be avoided.

Owner:HUAWEI TECH CO LTD

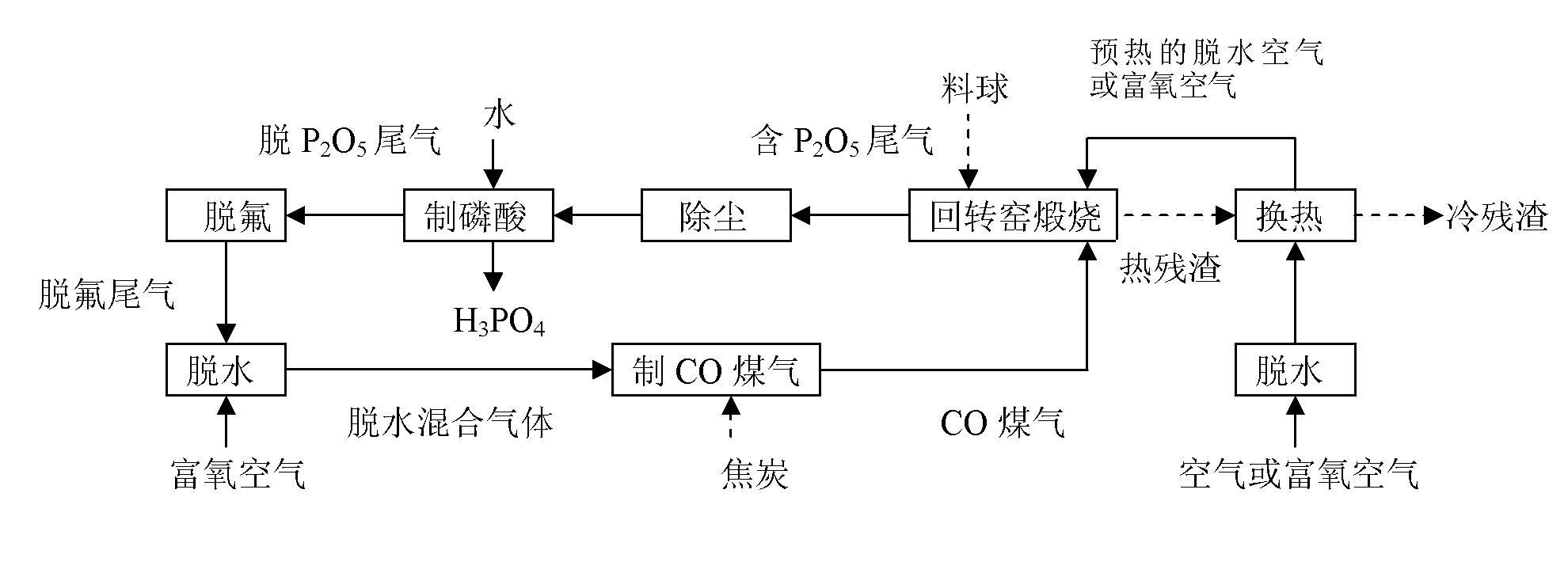

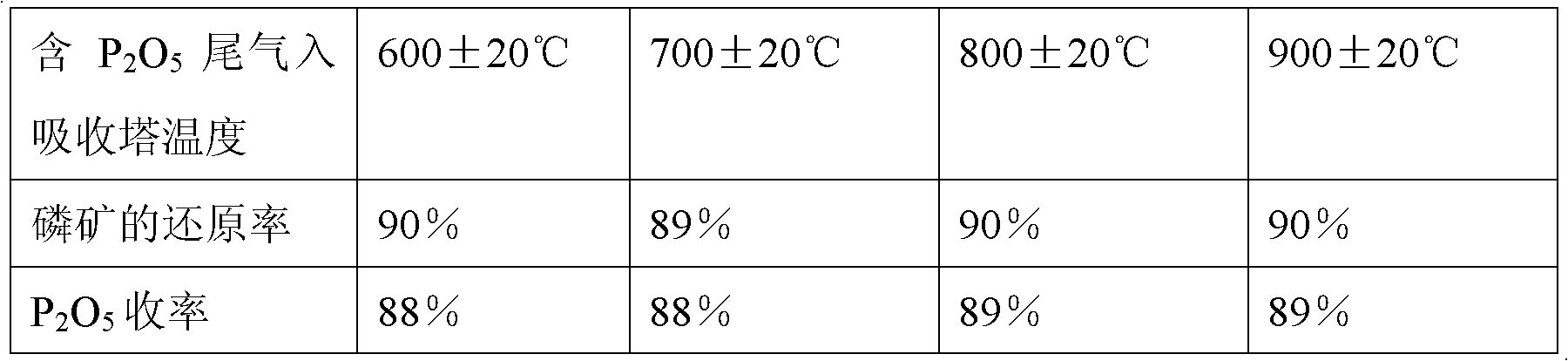

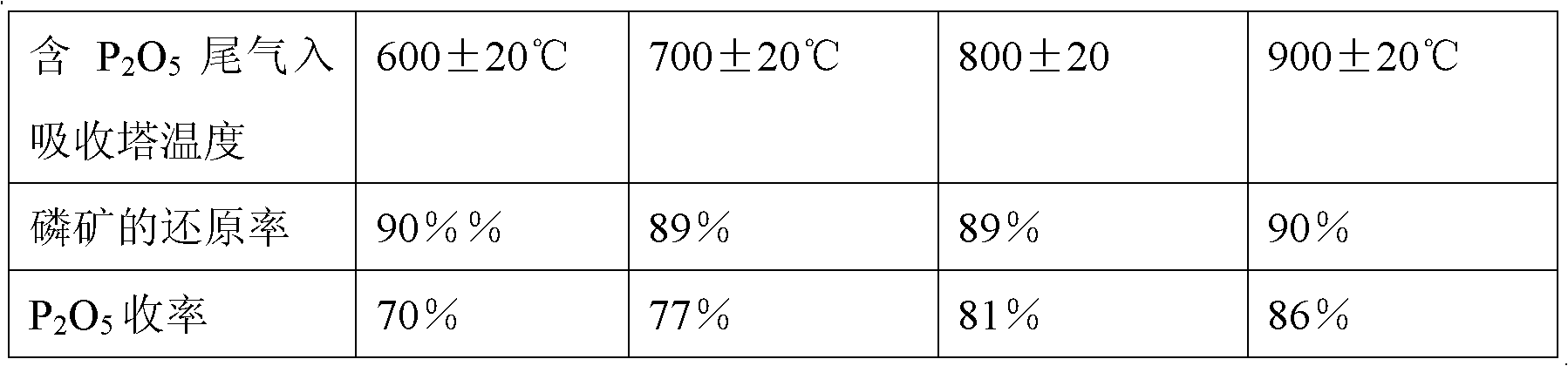

Method for producing phosphoric acid by utilizing middle grade phosphate ore

InactiveCN102126712ASolve the loop problemSolve the blockagePhosphoric acidPhosphoric acidReaction temperature

The invention discloses a method for producing phosphoric acid by utilizing middle grade phosphate ore, comprising the following steps: (1) preparing a double-layer composite structure pellet containing the middle grade phosphate ore, wherein, the water content of the pellet is less than or equal to 0.5wt%; (2) sending the pellet into a rotary kiln from the tail part of the rotary kiln; delivering the carbon monoxide (CO) coal gas, dehydration air or dehydration oxygen-enriched air into the rotary kiln from the head part of the rotary kiln; carrying out heat exchanging on the high-temperaturegas generated in burning of the CO coal gas and the pellet in reversed operation in the rotary kiln; heating the pellet to the reaction temperature of 1250-1400 DEG C; carrying out heat exchanging onthe tail gas containing P2O5 generated in reaction and the pellet entering into the rotary kiln; cooling to the temperature of 600-650 DEG C, and leading out from the tail part of the rotary kiln; and (3) dedusting the tail gas containing the P2O5 led out from the rotary kiln; and absorbing P2O5 by utilizing recycle acid to prepare the phosphoric acid.

Owner:SICHUAN UNIV

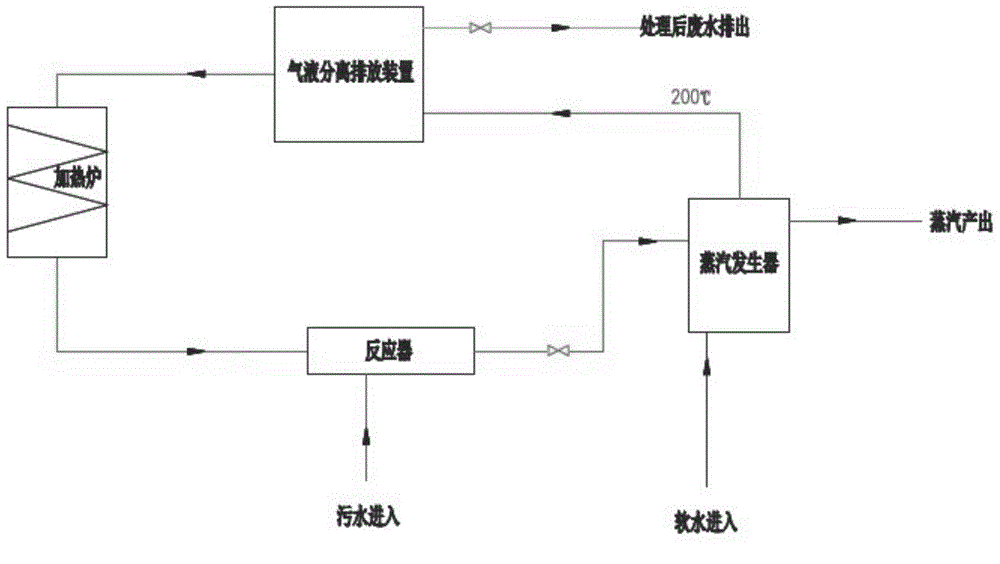

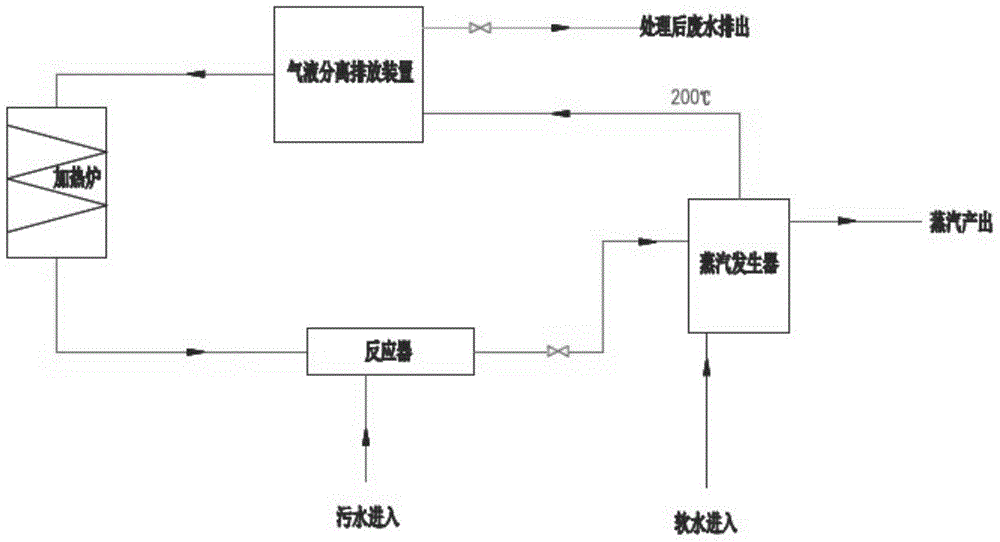

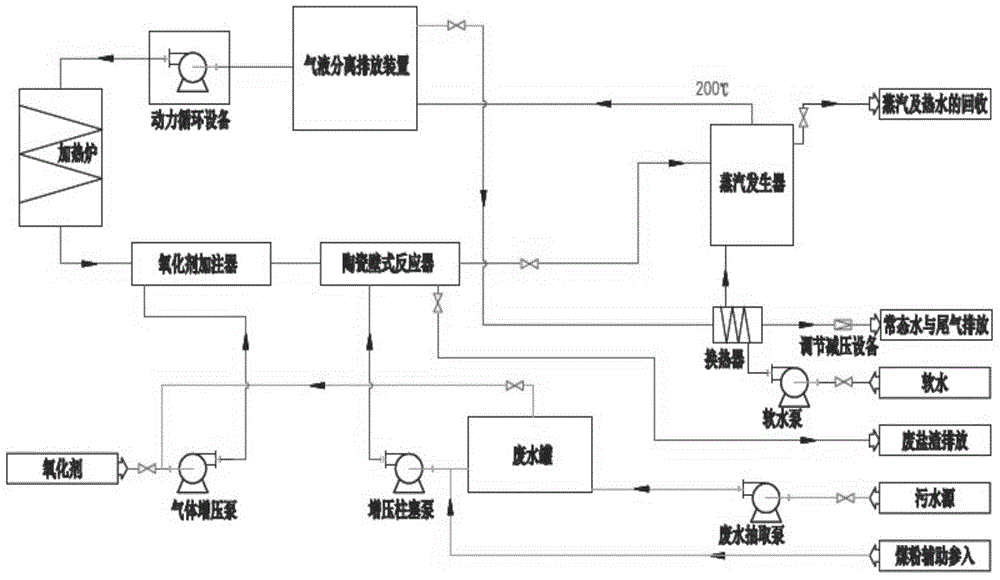

Process for waste oxidation treatment and steam co-production by using supercritical circulating water

ActiveCN103553202AReduce excess spaceShorten the timeSteam generation using hot heat carriersWater/sewage treatment by oxidationInorganic saltsChemical oxygen demand

The invention provides a process for waste oxidation treatment and steam co-production by using supercritical circulating water. A treatment system is a circulating treatment system. The process comprises the steps of filling circulating water into a supercritical circulating water oxidation treatment system, heating the circulating water in a heating device, driving the circulating water to circularly operate in the system, and controlling the temperature to be raised to 395-450 DEG C and the pressure to be higher than 22.1Mpa; inputting sewage and an oxidizing agent to a reactor, and enabling the sewage and the oxidizing agent to react in a supercritical state; enabling the water after reacting to enter a steam generator for heat recovery, and outputting steam; carrying out gas-liquid separation on the water subjected to heat exchange through the steam generator, and discharging inorganic salt gas and a part of water; inputting the other part of water after gas-liquid separation as the circulating water to the heating device. In the process, the sewage is up to the supercritical state through being mixed with the circulating water, a sewage preheating device in traditional sewage treatment is omitted, and the sewage with a high-concentration COD (Chemical Oxygen Demand) value can be directly treated.

Owner:NANJING TECH UNIV

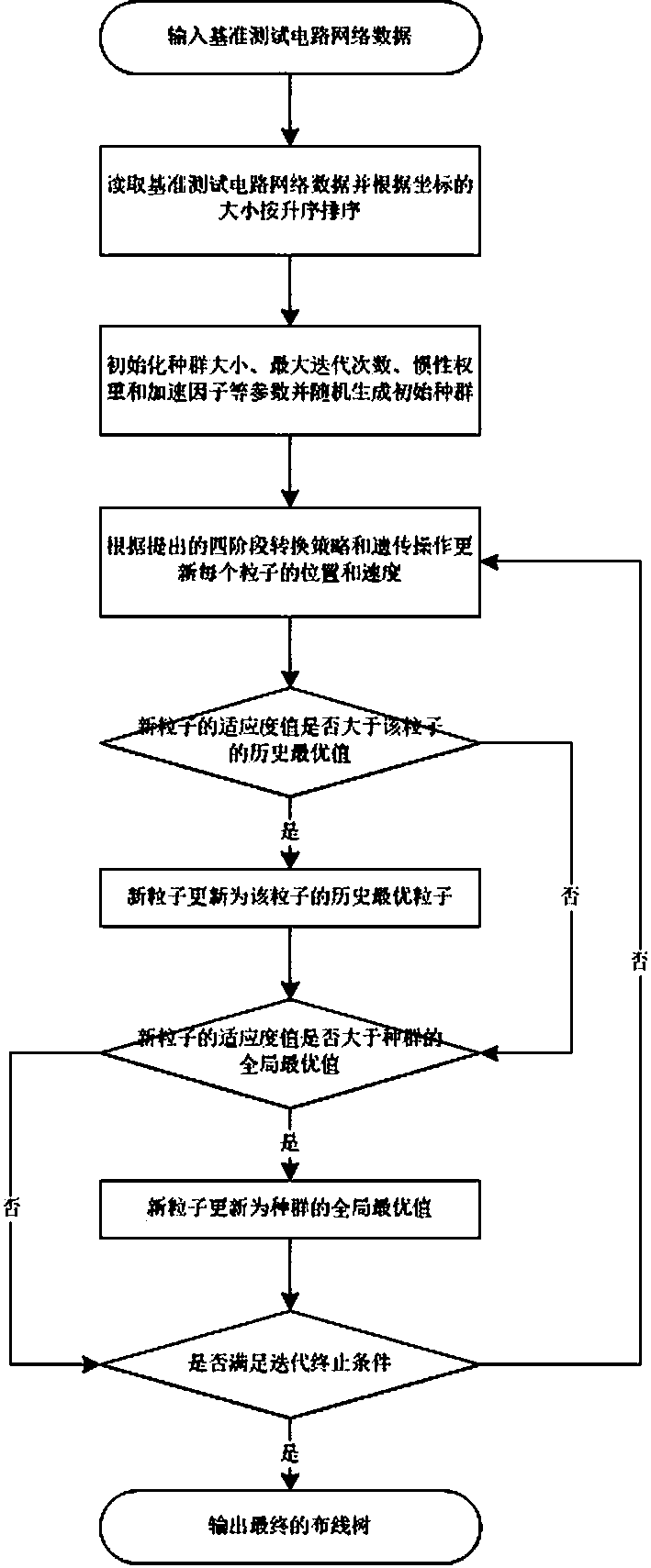

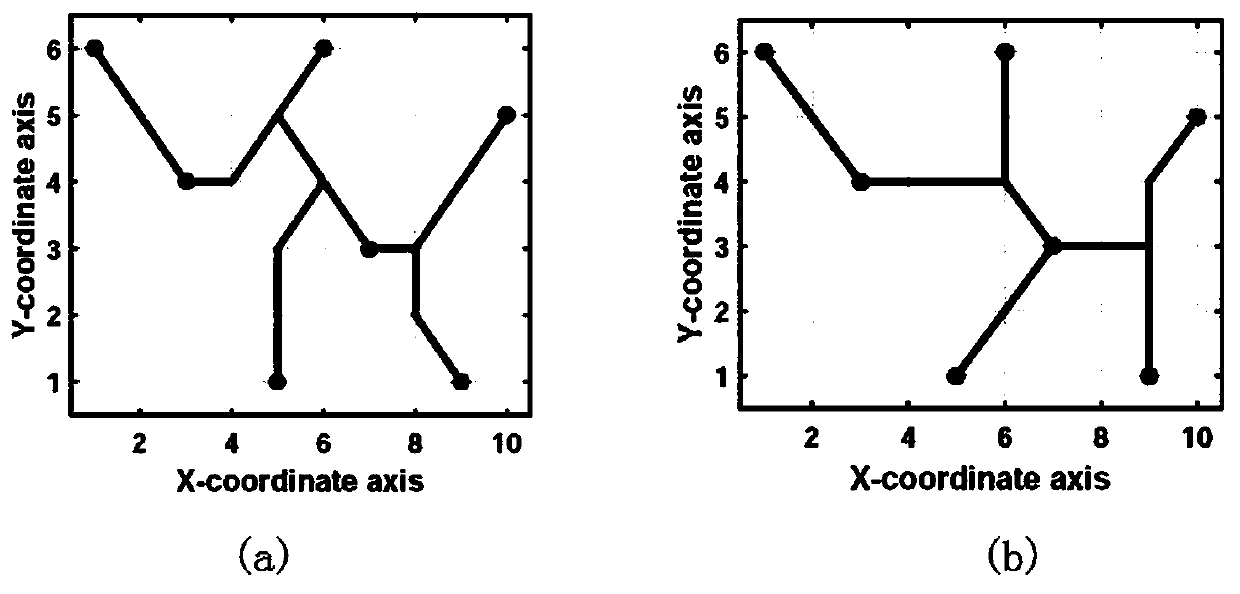

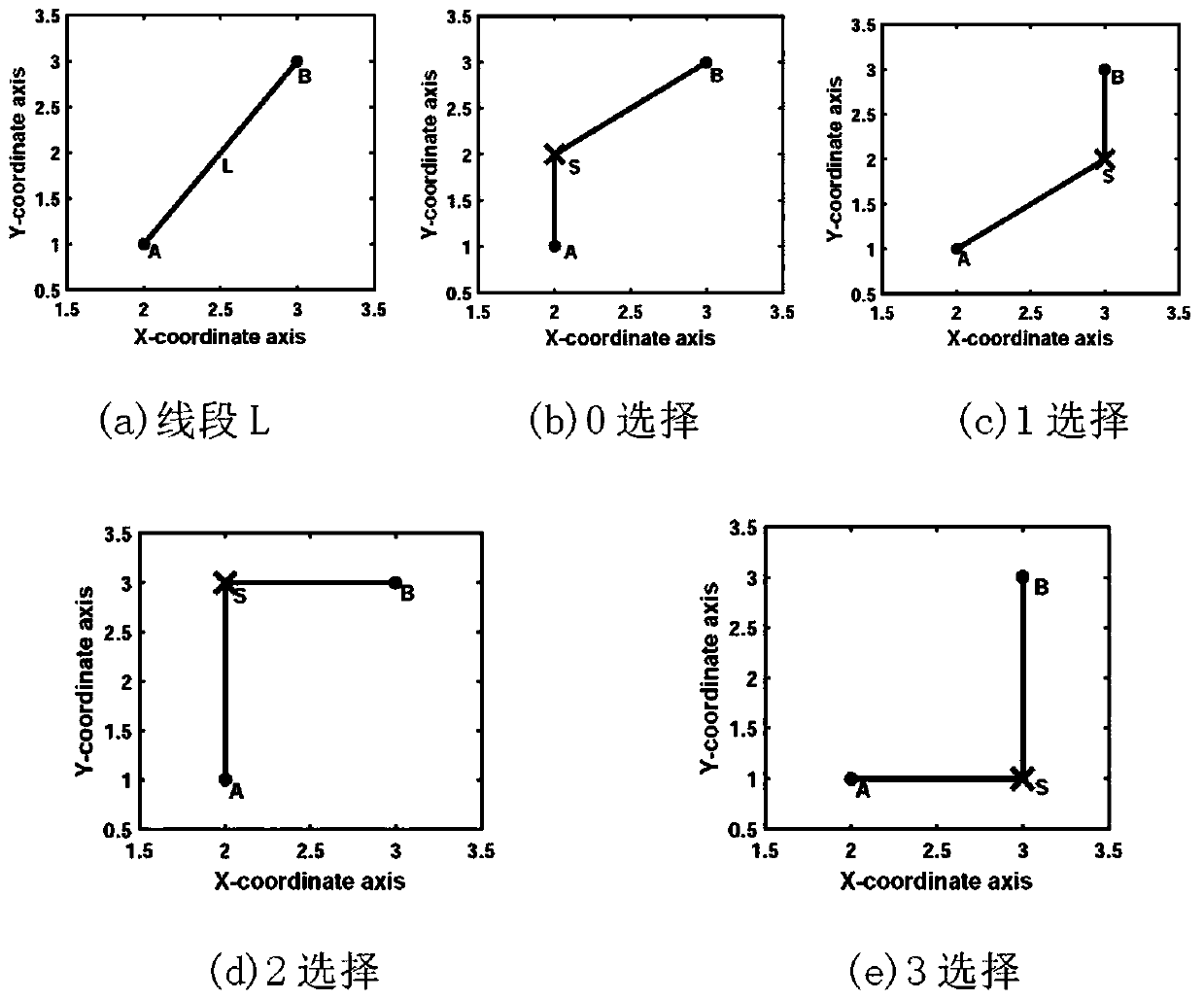

A particle swarm optimization Steiner minimum tree construction method based on multi-stage transformation and genetic manipulation under an X structure

ActiveCN109583133AUpdate locationUpdate SpeedSpecial data processing applicationsGenetic algorithmsPhacusPhases of clinical research

The invention relates to a particle swarm optimization Steiner minimum tree construction method based on multi-stage transformation and genetic operation under an X structure, and provides an effective edge-edge-genetic operation method in order to solve two SMT problems at the same time. Point coding strategy. The invention provides a multi-stage conversion strategy which not only can enlarge thesearch space of an algorithm, but also can ensure effective convergence. By testing three schemes from two stages to four stages and different combinations of the schemes, an optimal combination is given. At the same time, the present invention constructs a discrete particle update operation for discrete VLSI wiring using a genetic operation in combination with union-lookup set segmentation. In addition, in order to introduce uncertainty and diversity, the invention provides a variation operation for improving an edge conversion strategy. According to the method, a wiring scheme with the bestquality can be obtained from a global angle.

Owner:FUZHOU UNIV

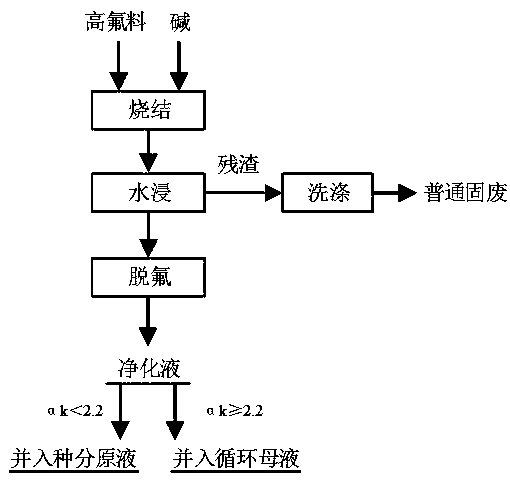

Method for achieving defluorination and recycling of secondary aluminum ash with series-parallel method

ActiveCN109365473ASolve the loop problemReduce corrosionSolid waste disposalCorrosion reactionPregnant leach solution

The invention discloses a method for achieving defluorination and recycling of secondary aluminum ash with a series-parallel method. The method specifically includes the following steps that (1), theraw material secondary aluminum ash comprises high-fluorine secondary aluminum ash and low-fluorine secondary aluminum ash, and the low-fluorine secondary aluminum ash is treated with a Bayer process;(2), the high-fluorine secondary aluminum ash is treated with an alkali sintering method, volatile silicon fluoride gas is absorbed with alkali liquor, and sintered clinker is obtained; (3), the sintered clinker is immersed in water, a defluorination agent is added into leachate, the materials are stirred, the materials are filtered, purified liquor is obtained, and after leached residues are washed, common solid waste is obtained; and (4), a defluorinated solution is merged into the Bayer process flow for treating the low-fluorine secondary aluminum ash according to the causticity ratio. Thelow-fluorine secondary aluminum ash and the high-fluorine secondary aluminum ash are treated with the series-parallel method, on one hand, the aqueous leachate of the sintered clinker supplements losses of liquid alkali of the Bayer process flow, on the other hand, most of the harmful element fluorine in the raw material can be removed, and it is avoided that soluble fluorine enters a high-temperature high-pressure alkali dissolution system, so that reaction equipment is corroded.

Owner:郑州中科新兴产业技术研究院 +1

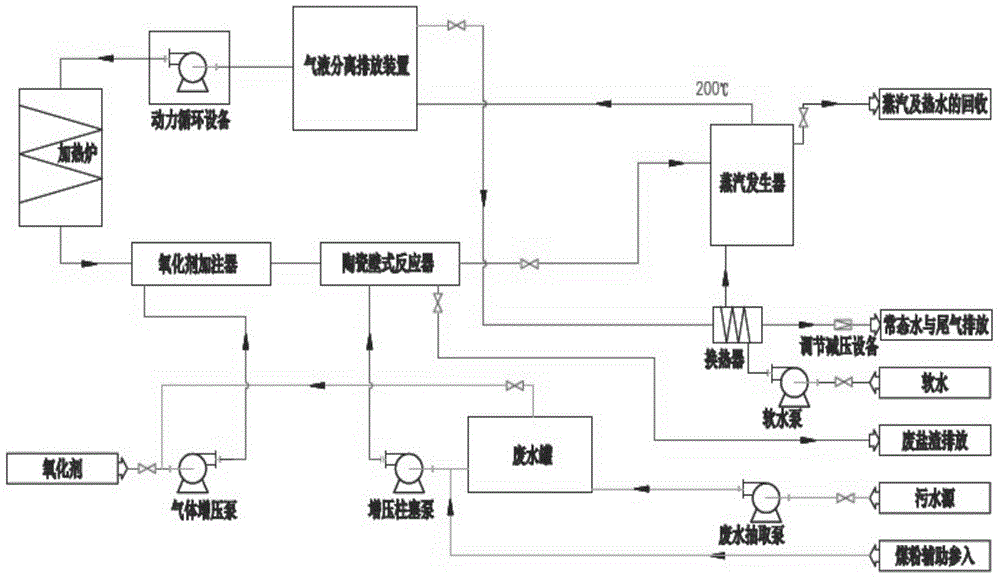

System for wastewater oxidation treatment by using supercritical circulating water

InactiveCN103553254AReduce excess spaceShorten the timeMultistage water/sewage treatmentChemical oxygen demandSewage

The invention provides a system for wastewater oxidation treatment by using supercritical circulating water. The system comprises a heating device, a reactor, a steam generator and a gas-liquid separation device which are sequentially connected end to end through pipelines to form a circulating treatment system, wherein the heating device is used for heating circulating water. In the system, the heating device is used for heating the circulating water to promote the whole treatment process to operate, sewage is up to a supercritical state through being mixed with the circulating water, a sewage preheating device in traditional sewage treatment is omitted, and the sewage with a high-concentration COD (Chemical Oxygen Demand) value can be directly treated.

Owner:NANJING TECH UNIV

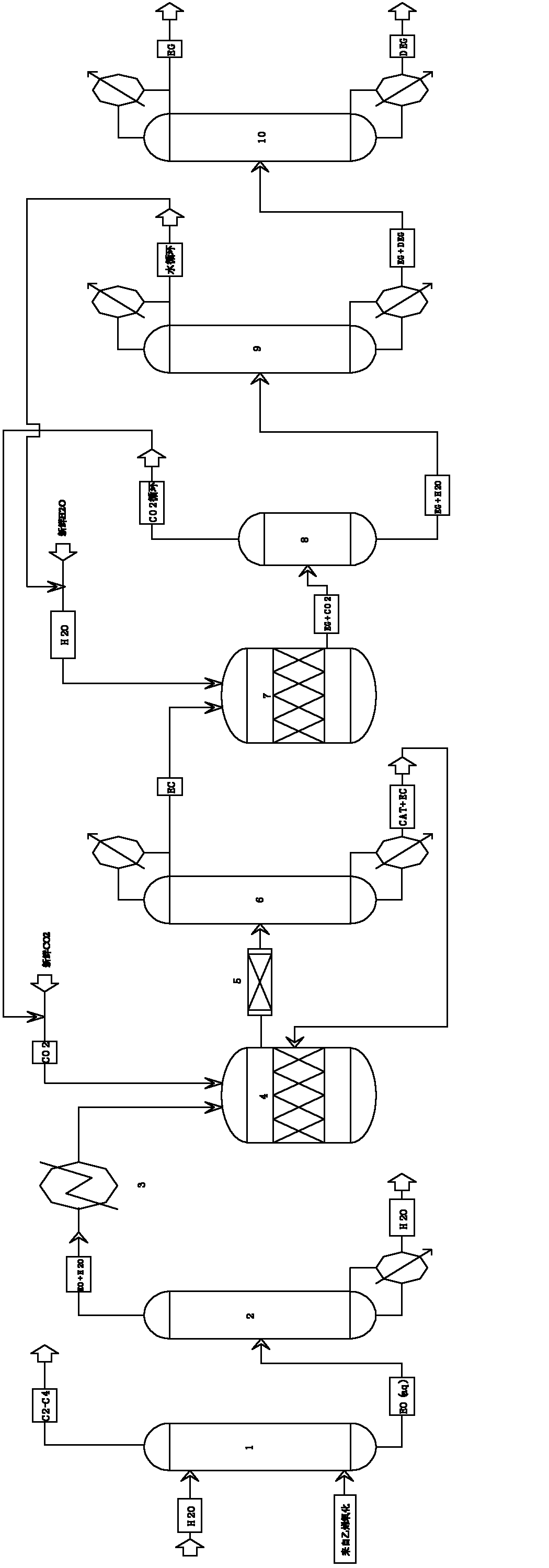

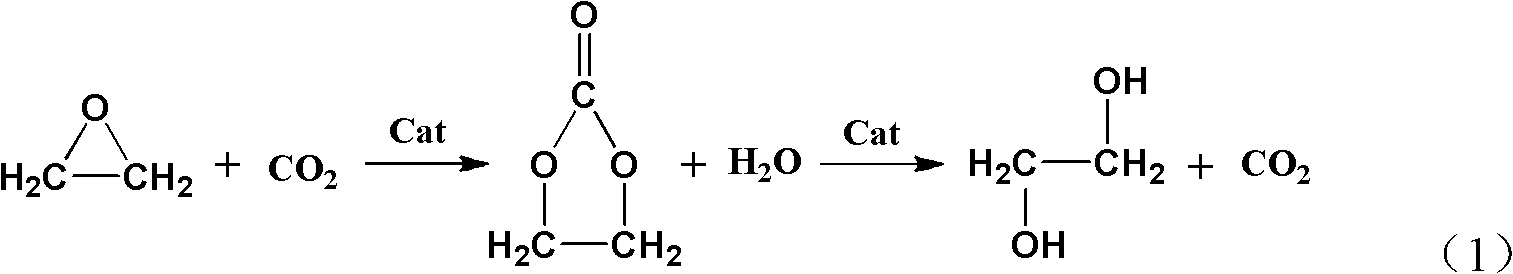

Method for preparing ethylene glycol by ethylene carbonate method

InactiveCN102603477AReduce energy consumptionReduce water ratioChemical recyclingBulk chemical productionChemistryEthyl cellulose

The invention discloses a method for preparing ethylene glycol by an ethylene carbonate method. By using the method, the EO (ethylene oxide) conversion rate and the EC (ethyl cellulose) selectivity are greatly improved. The method mainly comprises the following steps of: removing the vast majority of non-condensable impurity gas contained in the mixed gas obtained by ethylene epoxidation in a washing tower, and introducing washing liquor into a desorber for desorbing, to obtain crude EO raw material gas; cooling and refining the crude EO raw material gas in a packed tower to obtain a high-concentration EO raw material; carrying out esterification on the high-concentration EO raw material liquid and CO2 to generate EC; and recovering a thick catalyst solution obtained by a tower kettle to an esterification work section to be recycled; carrying out a heterogeneous hydrolysis reaction on the EC product obtained by means of esterification and vacuum rectification and water which is approximate to a stoichiometric ratio in a hydrolysis reactor to obtain a target product EG (ethylene glycol), and separating out the byproduct CO2 and then circulating the byproduct CO2 to an esterification reactor to be reused; and refining the EG generated by the hydrolysis reaction in a refining tower to obtain the high-purity EG target product.

Owner:NANJING UNIV OF TECH

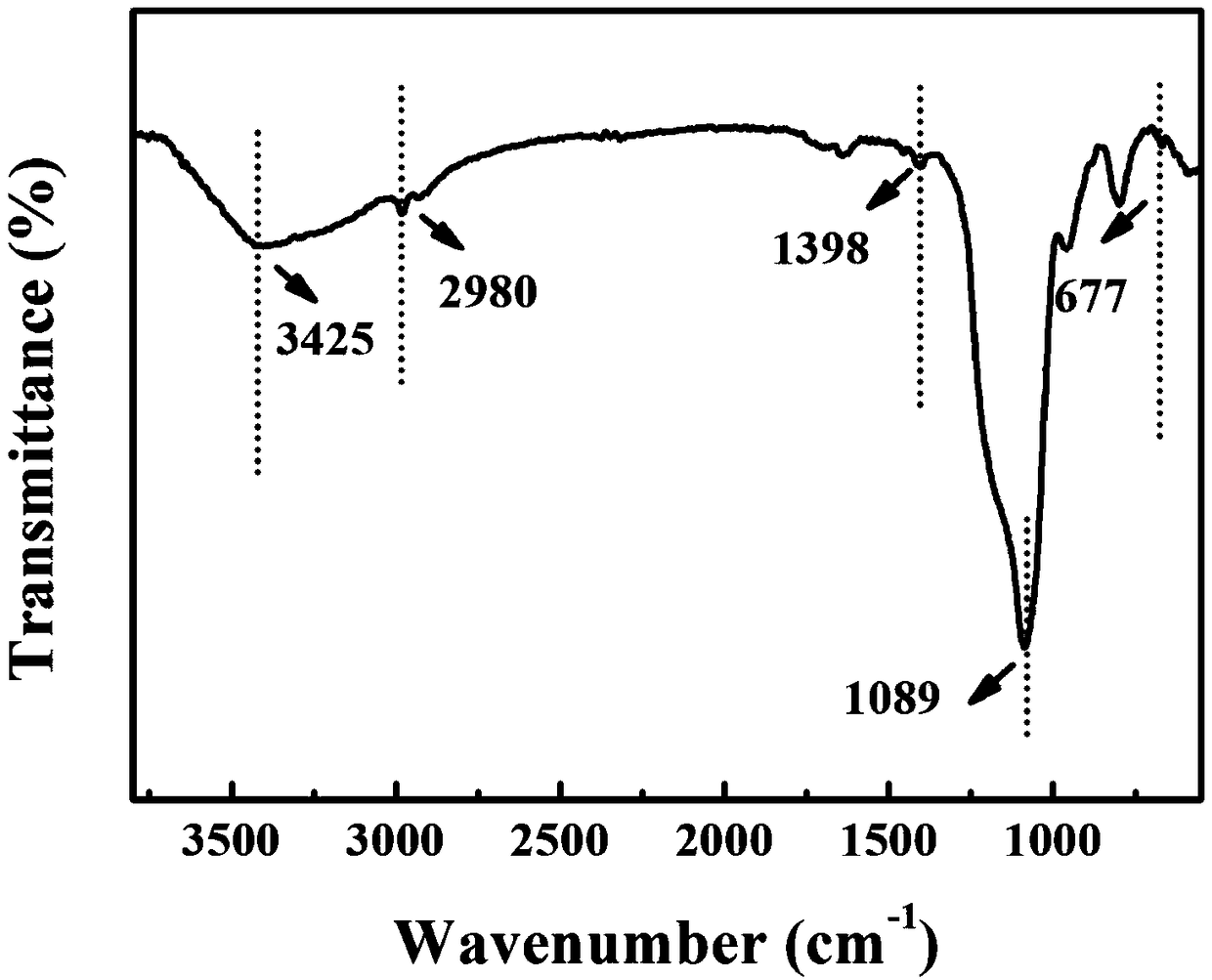

Oxidized graphene doped mesoporous silicon film, preparation method thereof and application of film

InactiveCN108325507AEasy to operate continuouslyEasy to recycleOther chemical processesProcess efficiency improvementPhysical chemistrySilicon membrane

The invention belongs to the technical field of material preparation and separation, and relates to a preparation method of an oxidized graphene doped ordered mesoporous silicon film with high lanthanum adsorption capacity and high selectivity. The one-step direct synthesis preparation method is used for adsorption and recovery of lanthanum serving as a rare earth element. Biomass nano-crystallinecellulose (NCCs) serves as a template, diethyl phosphinylidyne ethyltriethoxysilane (PETES), tetraethl silicate (TEOS) and graphene oxide (GO) are synthesized into film materials, the adsorption performance of adsorbents is greatly improved, continuous operation of the film materials is facilitated, and the film materials are easily recovered and superior to powder materials and have great advantages among various adsorption materials.

Owner:JIANGSU UNIV

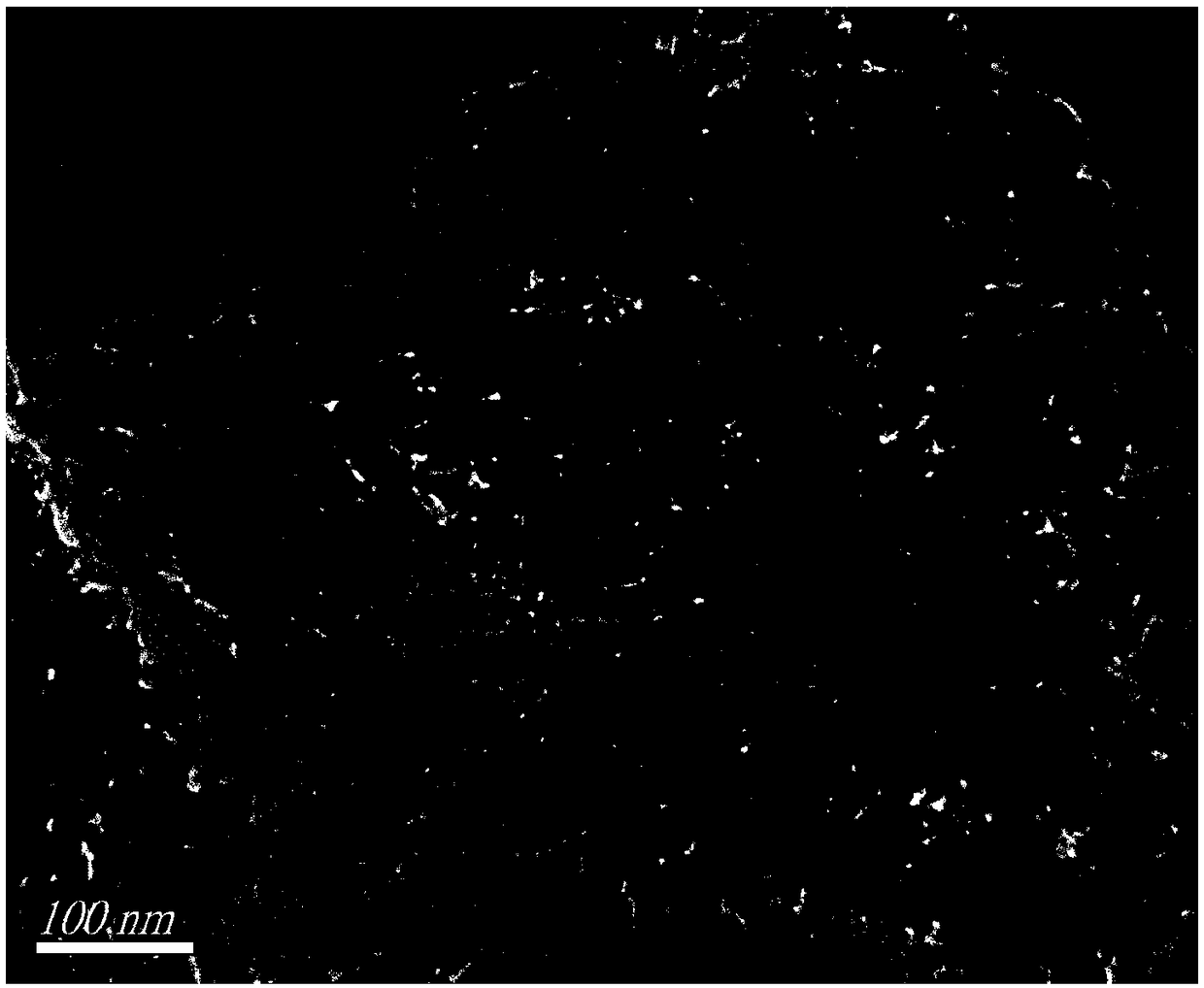

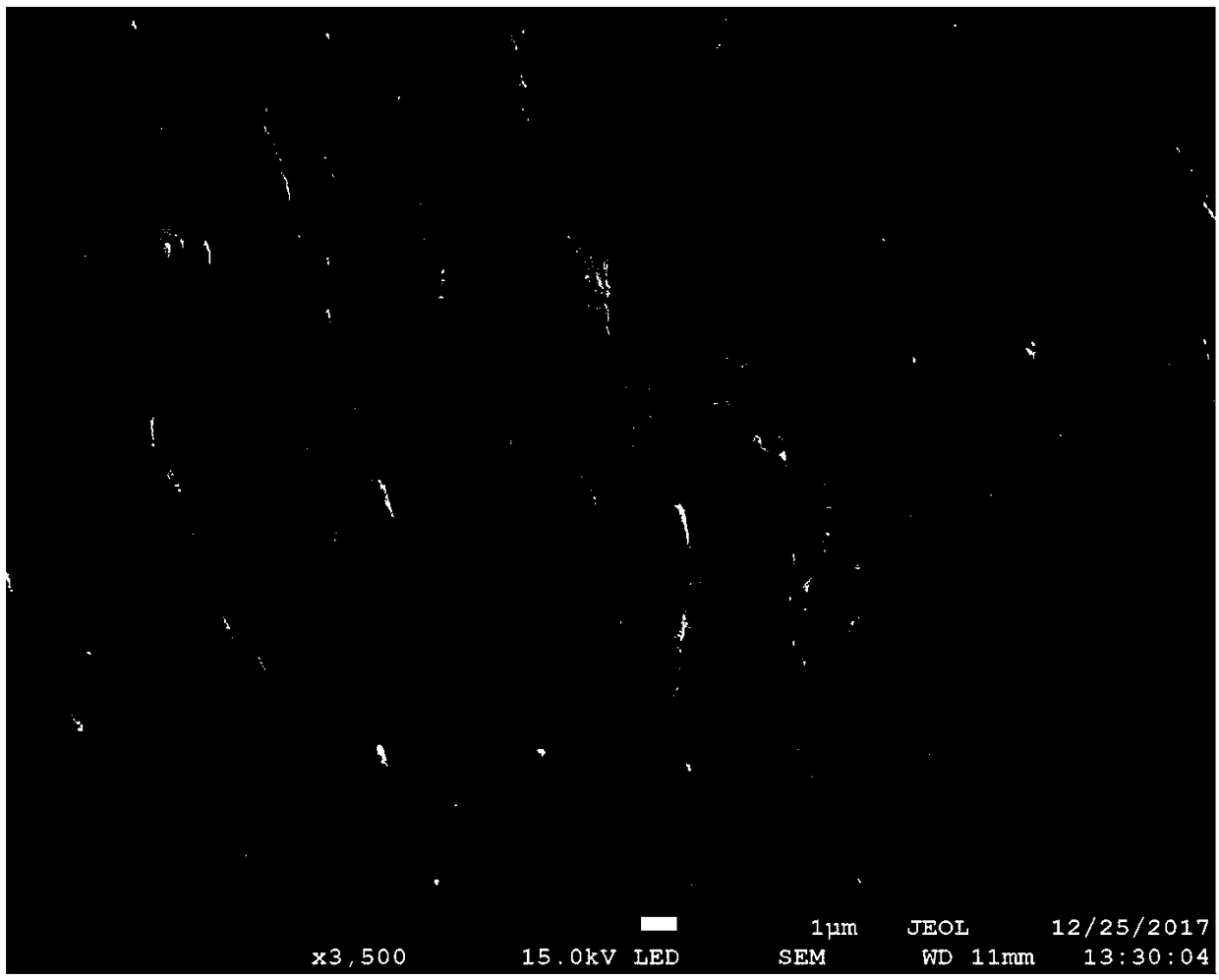

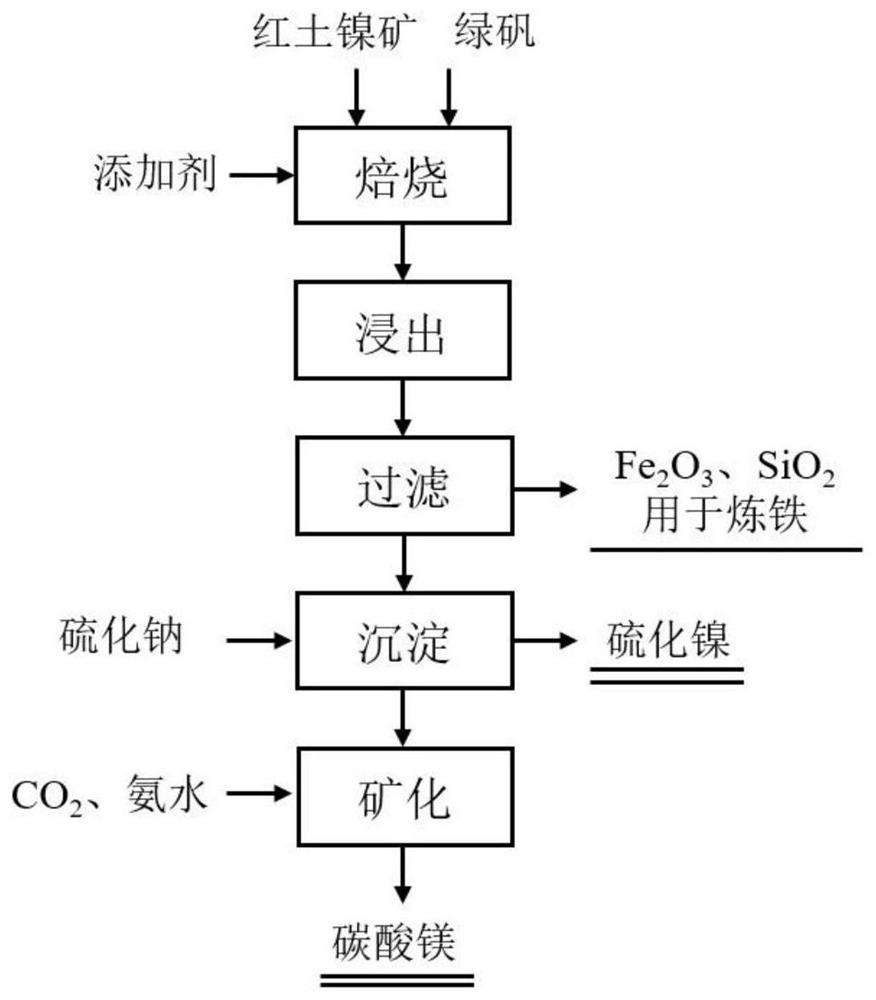

Method for extracting nickel from laterite-nickel ore and mineralizing CO2 simultaneously

ActiveCN113025832AReduce pollutionNo emissionsMagnesium carbonatesNickel sulfatesPregnant leach solutionMining engineering

The invention discloses a method for extracting nickel from laterite-nickel ore and mineralizing CO2 simultaneously. The method comprises the following steps that (1) the crushed laterite-nickel ore is mixed with copperas and an additive at a certain temperature to be roasted, so that nickel and magnesium elements in the laterite-nickel ore are converted into corresponding sulfate; (2) the roasted product obtained in the first step is leached out with water to obtain a sulfate leaching solution and leaching residues rich in SiO2 and Fe2O3; (3) sodium sulfide is added into the leaching solution to obtain a nickel sulfide product and a precipitation mother solution; and (4) ammonia water is added into the mother solution obtained in the third step, and CO2 is further connected in to generate magnesium carbonate so as to realize CO2 mineralization.

Owner:CHONGQING UNIV

Upward flow circulating water culture system for hirudo

ActiveCN107094676AIncrease oxygen contentPass smoothlyClimate change adaptationPisciculture and aquariaWater flowEngineering

The invention belongs to the field of hirudo culture, and particularly relates to an upward flow circulating water culture system for hirudo. The upward flow circulating water culture system comprises a water platform and a culture zone. The water platform comprises a support, a buoyancy tank and pedals, the support is formed in a longitudinal and transverse crossing manner, the buoyancy tank is arranged at the bottom of the support, and the pedals are fixed to the upper surface of the support; the culture zone comprises a drainage channel, a flow pushing pump and a plurality of culture tanks, the culture tanks are arranged on the support, and the drainage channel is arranged among the culture tanks. The upward flow circulating water culture system is characterized in that an inflation hole is formed in the buoyancy tank, and an air release valve is arranged on the buoyancy tank; the culture tanks comprise tank side walls and metal netted tank bottoms; first through holes are formed in the upper portions of the tank side walls; second through holes which correspond to the first through holes are formed in the side walls of the drainage channel, and the first through holes are fixedly connected with the second through holes by water outlet pipes; a drainage pipe is arranged on the lower portion of a side wall of the drainage channel and is connected with the flow pushing pump by a tee joint. The upward flow circulating water culture system has the advantages that water flow in the culture tanks can be effectively circulated and can be in flow states constantly, and accordingly the oxygen content of water can be increased.

Owner:WEISHAN NANSIHU FISHERY CO LTD +1

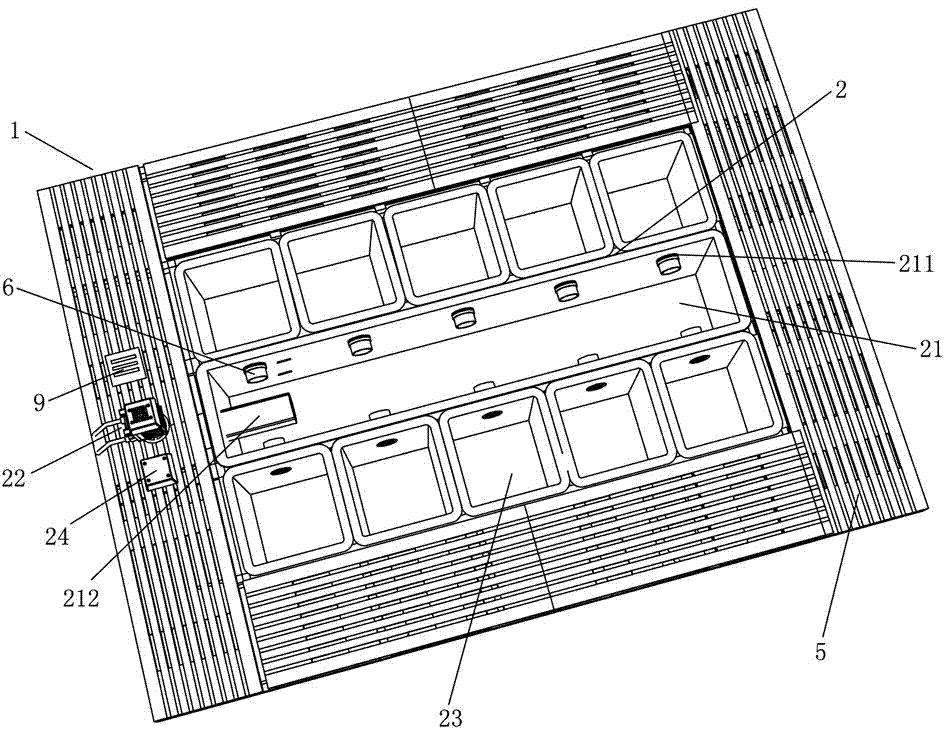

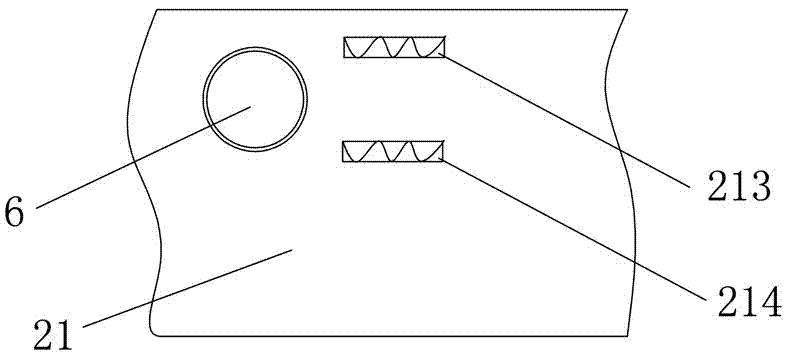

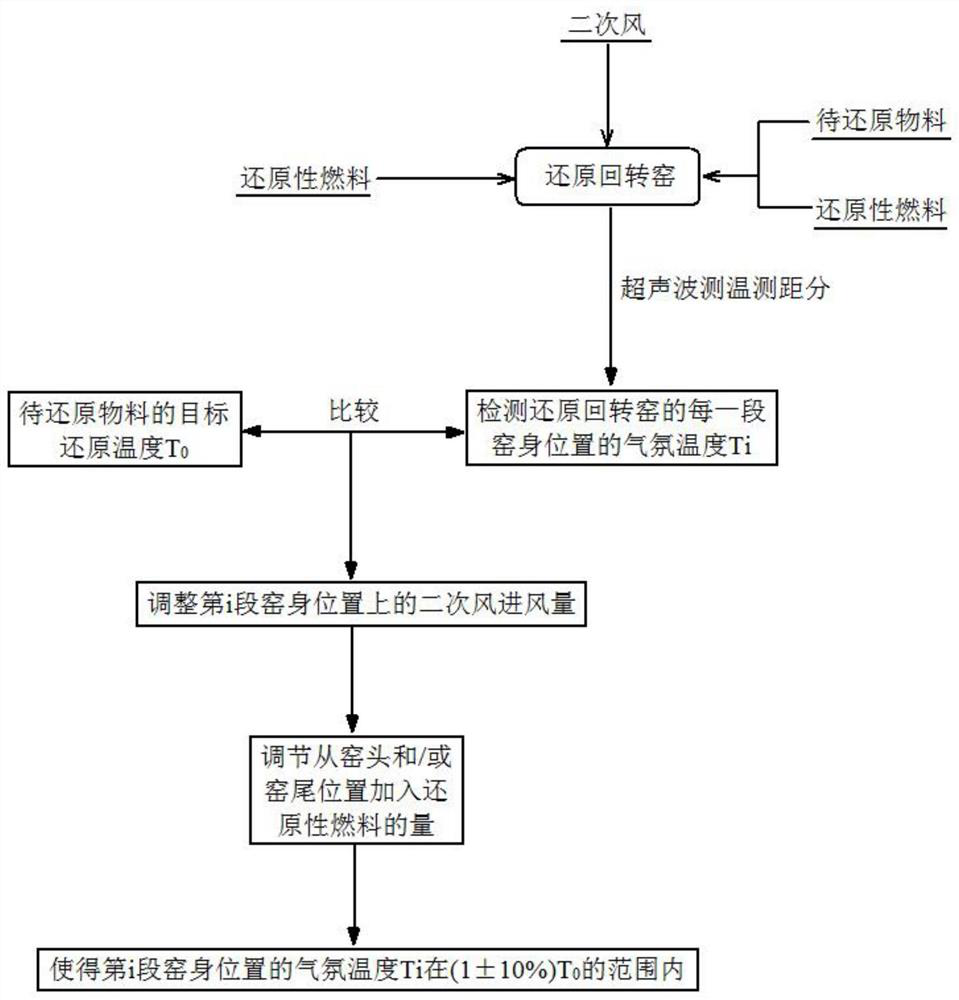

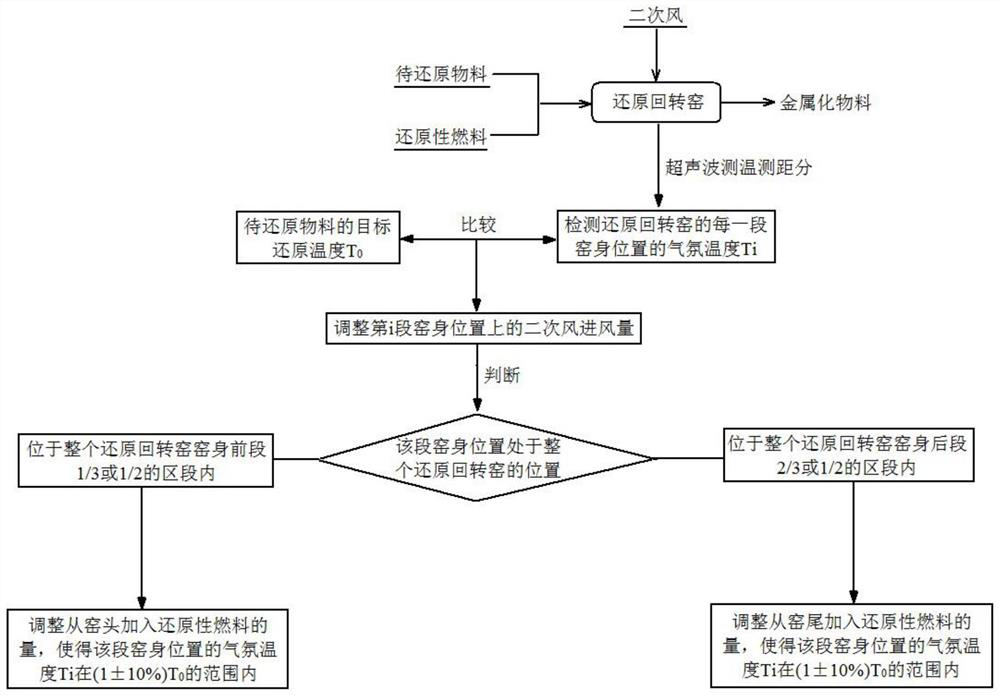

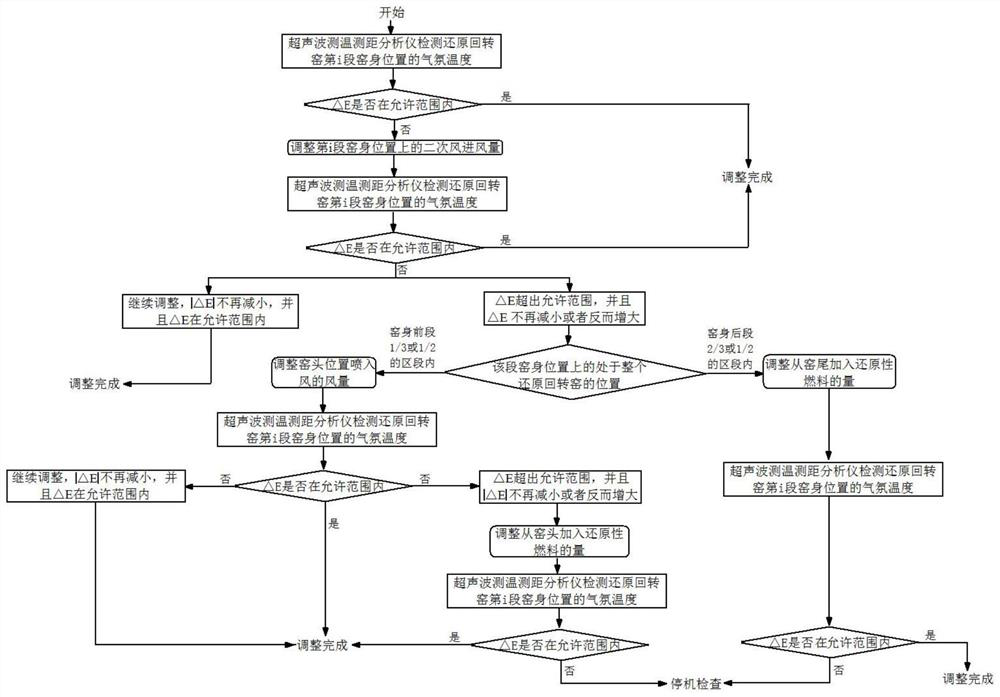

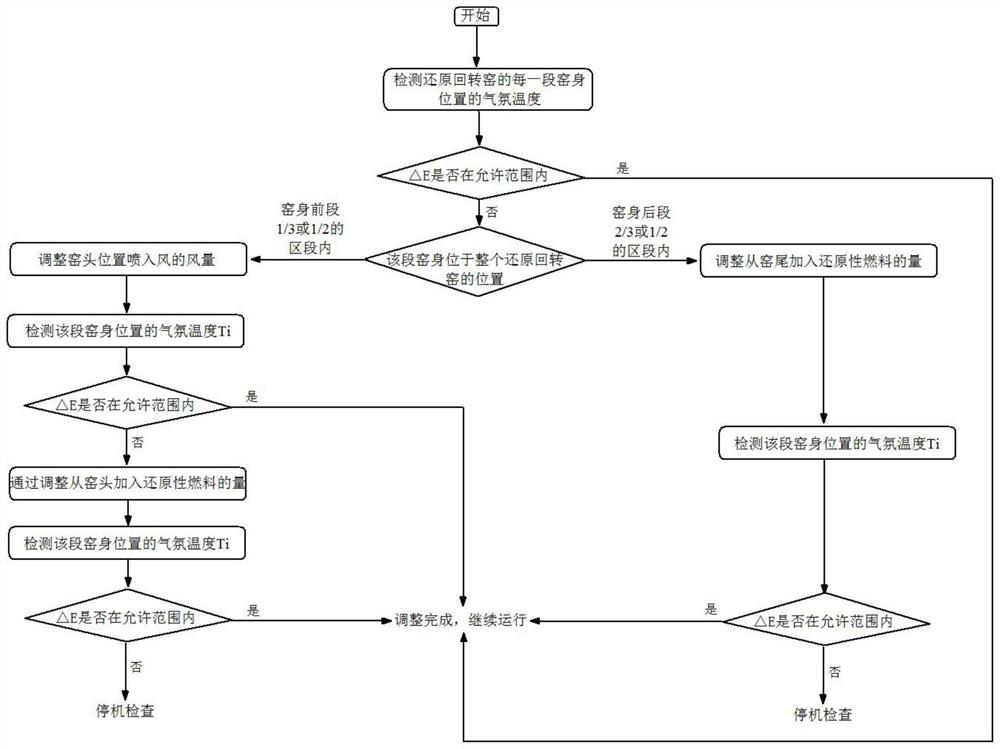

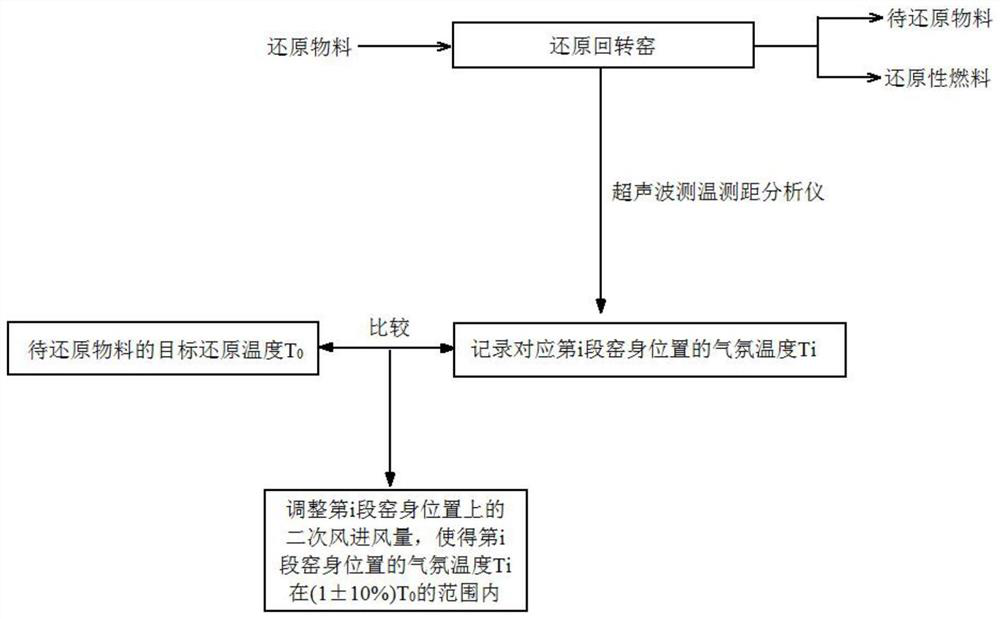

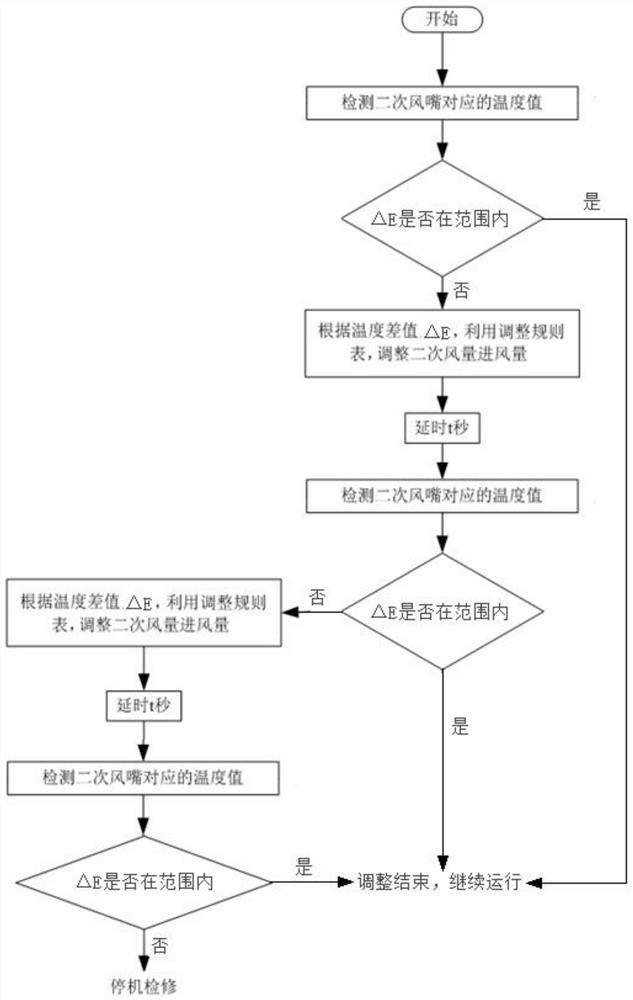

Method for controlling temperature of reduction rotary kiln by optimizing and adjusting fuel amount and air volume

ActiveCN112050626AAccurate temperature measurementExtended high temperature sectionRotary drum furnacesControl devices for furnacesAir volumeProcess engineering

The invention discloses a method for controlling the temperature of a reduction rotary kiln by optimizing and adjusting the fuel amount and the air volume. An ultrasonic temperature and distance measurement analyzer is additionally arranged on a kiln head cover of a rotary kiln in order to monitor the temperature in the kiln length direction online in real time. a series of secondary air nozzles are installed on a kiln body in the kiln length direction, and the air volume of the secondary air nozzle at a corresponding point is changed according to the difference between the temperature of a measured point and a target temperature, or the amount of reductive fuel added from the kiln head and / or the kiln tail of the reduction rotary kiln is adjusted. The uniformity of a temperature field inthe kiln in the kiln length direction is ensured. The local temperature is prevented from being too high or too low, ring formation in the rotary kiln is avoided, a longer high-temperature zone is provided for reduced materials, and the product quality index is remarkably improved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

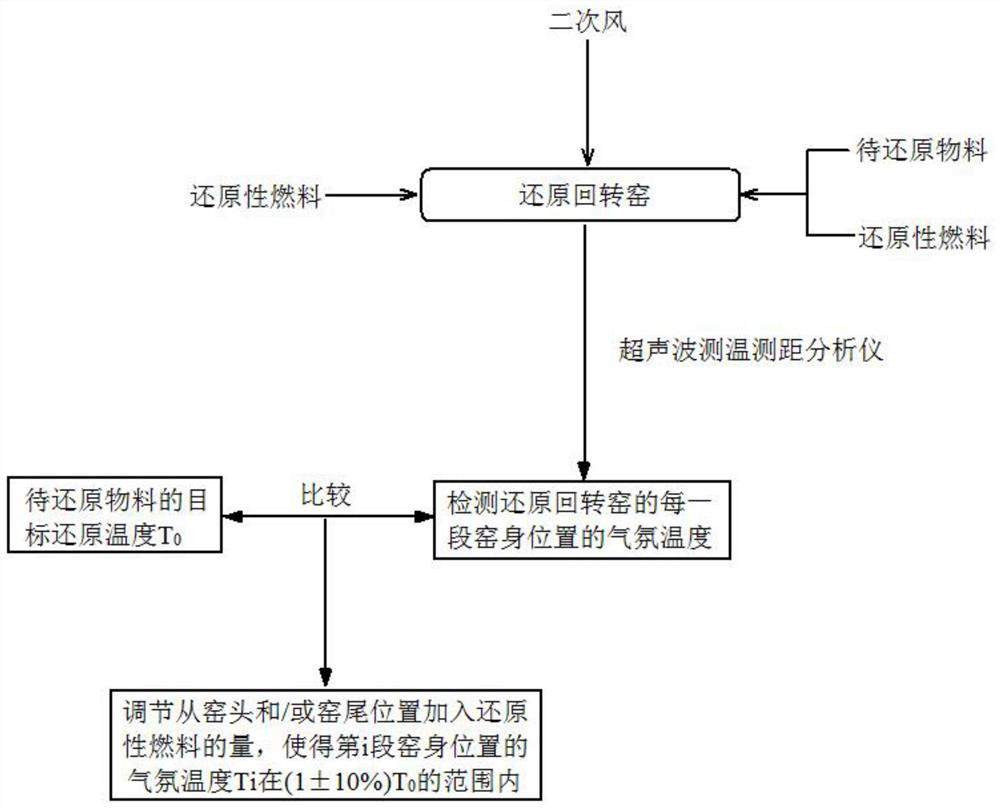

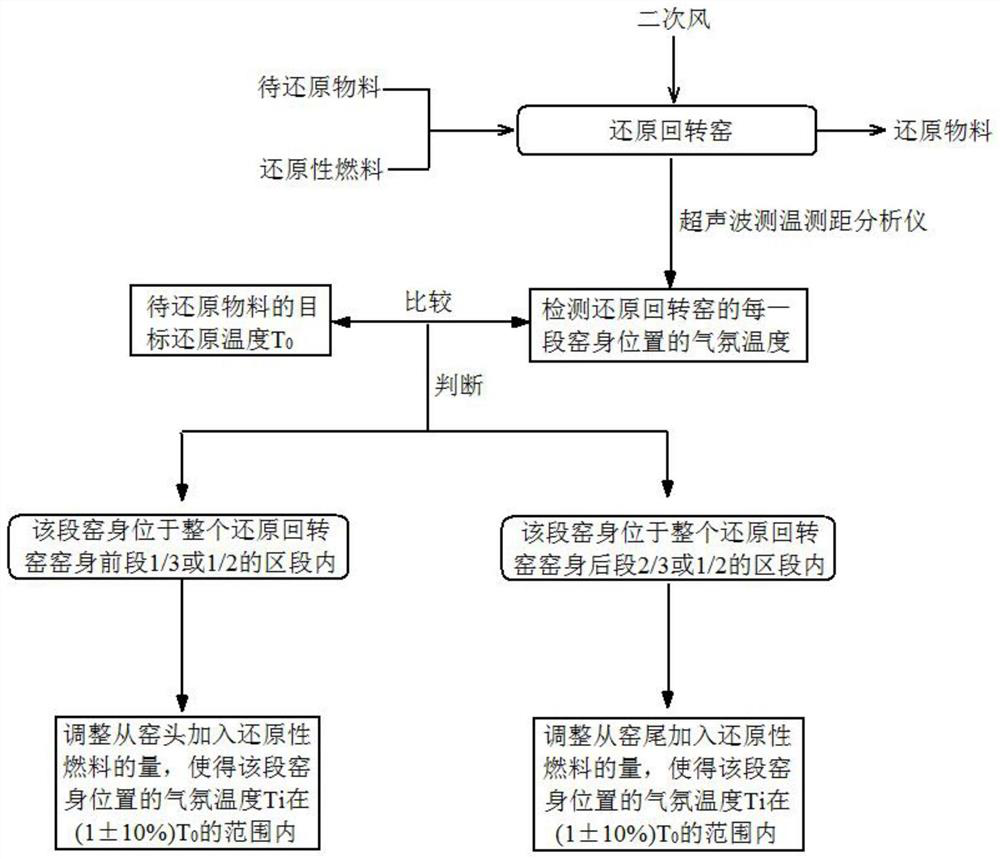

Method for controlling temperature of reduction rotary kiln by optimization and adjustment of fuel amount

ActiveCN112048587AAccurate temperature measurementImprove product qualityRotary drum furnacesProcess efficiency improvementProcess engineeringRotary kiln

The invention discloses a method for controlling the temperature of a reduction rotary kiln by optimization and adjustment of the fuel amount. The method includes the following steps of: additionallyinstalling an ultrasonic temperature and distance measurement analyzer on a kiln head cover of the rotary kiln; simultaneously adding a reductive fuel through the kiln head and the kiln tail of the reduction rotary kiln; monitoring the temperature along a kiln length direction line on line in real time; adjusting the amount of added reductive fuel at the kiln head and / or the kiln tail of the reduction rotary kiln according to the difference between the temperature of a measured point and the target temperature to ensure that the uniformity of a temperature field in the kiln and in the kiln length direction is guaranteed, the local temperature is prevented from being too high or too low, and ring formation in the rotary kiln is avoided; a longer high-temperature zone is provided for reduction materials; and the product quality index is remarkably improved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

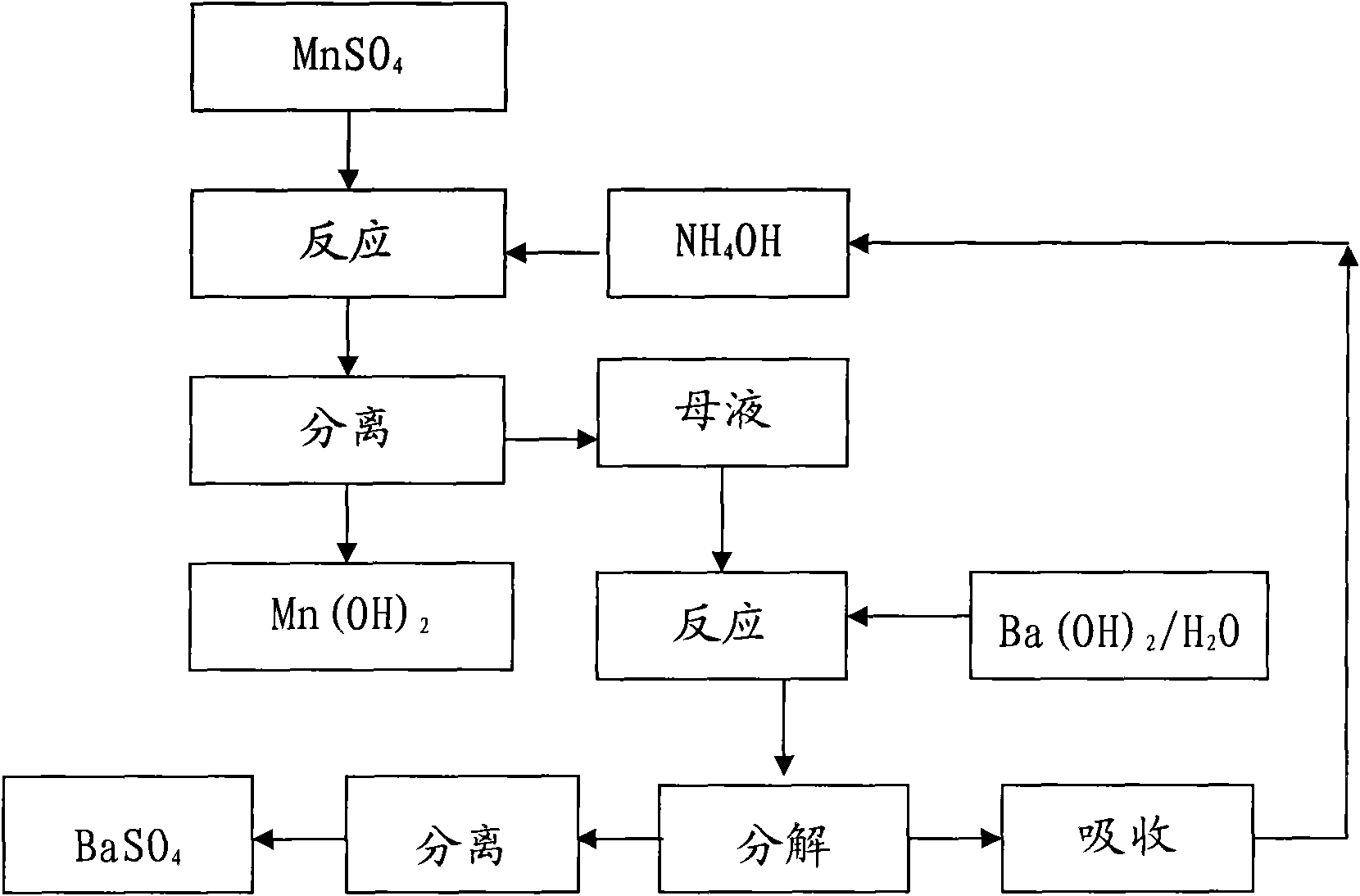

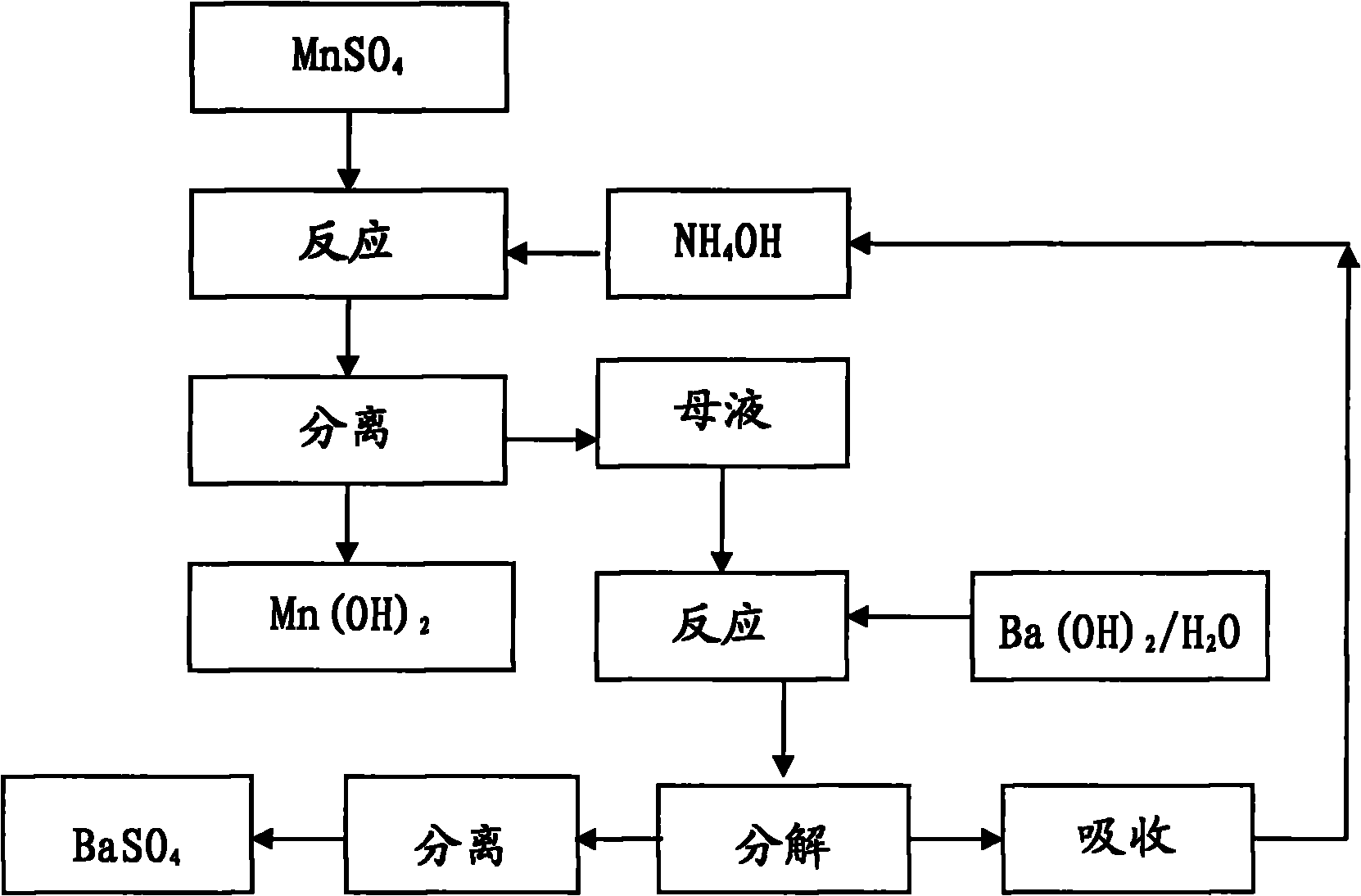

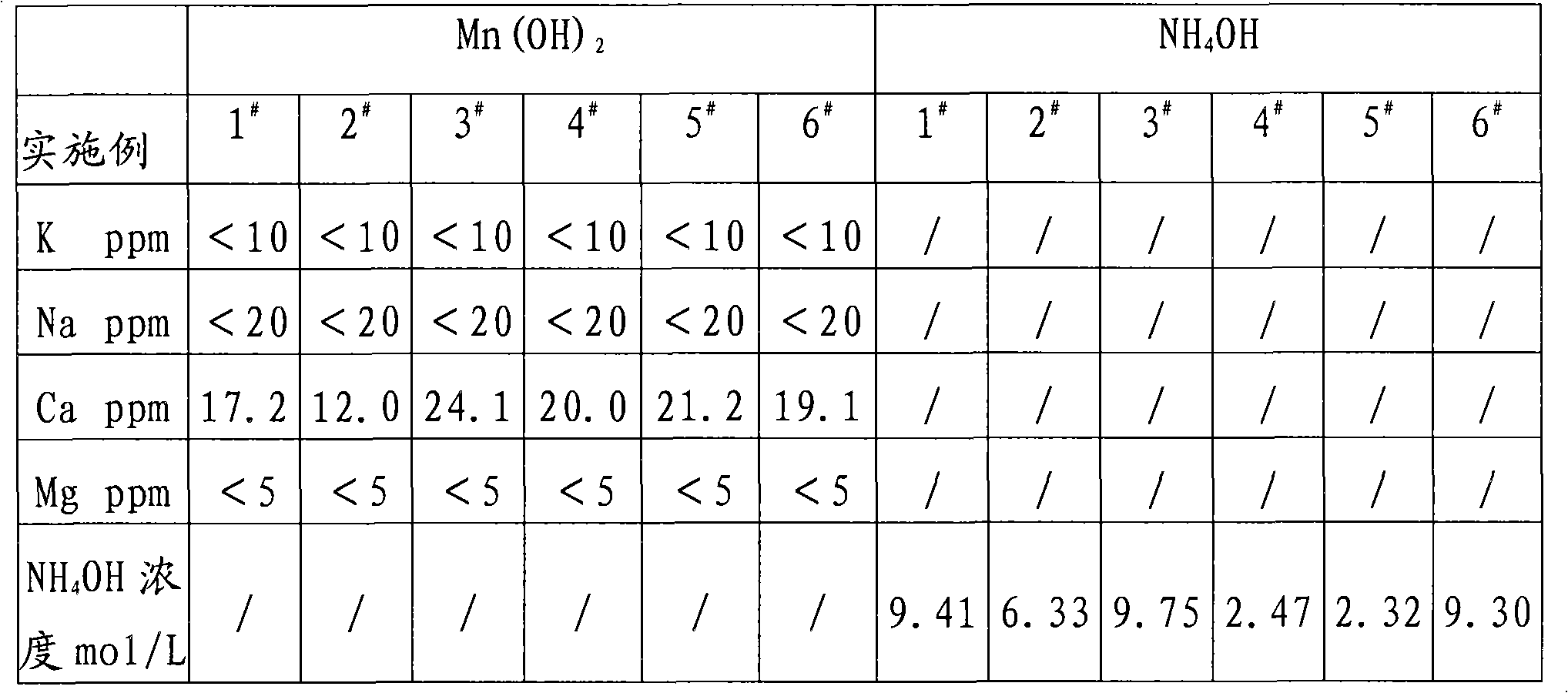

Method for preparing Mn(OH)2 by circularly using ammonia water

InactiveCN101774644ASolve protection problemsSolve the separation problemManganese oxides/hydroxidesChemistryFiltration

The invention relates to a method for preparing Mn(OH)2 by circularly using ammonia water, which comprises the following steps: making MnSO4 into a solution with the concentration of 100-450g / L, precisely filtering the solution, putting in a reaction vessel, adding ammonia water which is quantitatively prepared and has the concentration of 2-10mol / L while stirring at normal temperature, carrying out reaction, controlling pH of end point of the reaction to be 7-8, continuously stirring for 15-30 minutes, carrying out pressure filtration and separation to obtain a filtrate and Mn(OH)2 solid; reacting the filtrate in the step A with a Ba(OH)2 solution with the concentration of 0.5-3mol / L at the same molar weight in a closed container, turning on a heating device after the end point of the reaction is reached, raising temperature, stirring so that the solution is decomposed into ammonia gas, and finally absorbing by using deionized water to prepare the ammonia water.

Owner:GUIZHOU REDSTAR DEVING +1

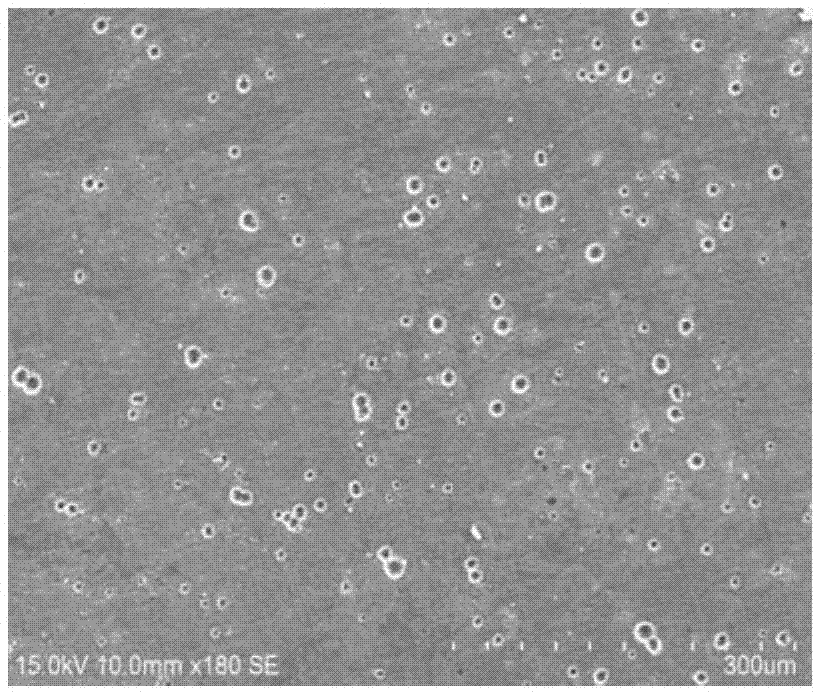

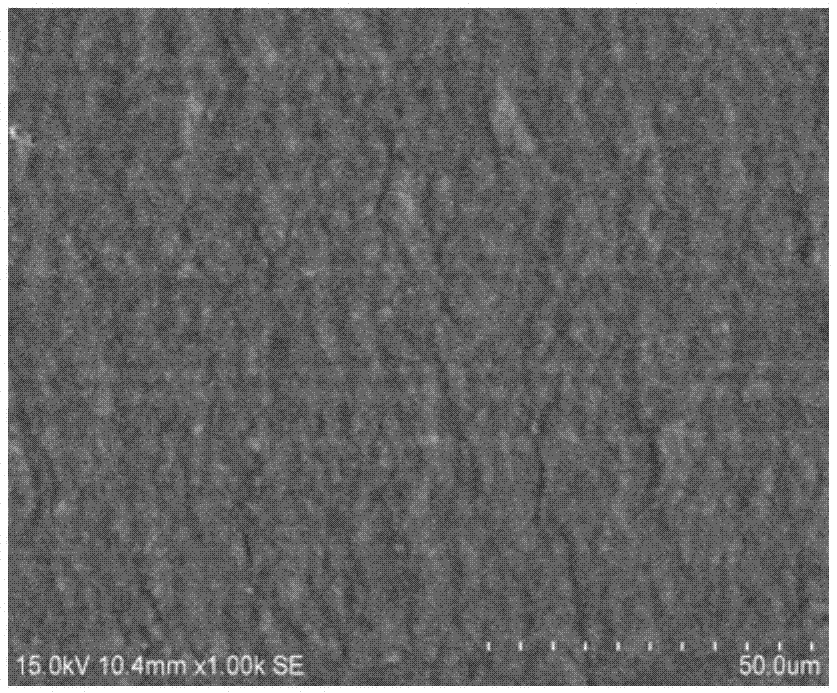

Multi-component silicon carbon material and preparation method thereof

ActiveCN109786696ASolve the bloat problemSolve the loop problemCell electrodesSecondary cellsSolventCore shell

The invention provides a preparation method of a multi-component silicon carbon material for a lithium ion battery. The preparation method comprises the following steps: uniformly dispersing nanometersilicon, carbonaceous conductive agent and amorphous carbon precursor in solvent, and removing solvent, and powdering to obtain a core material; and manufacturing the silicon carbon material of a core-shell structure with a double-deck shell through two-step cladding treatment. The silicon carbon material prepared through the invention is used as the lithium ion battery negative material, the reversible capacity is 1300-1600mAh / g, the first effect is 80-85%, and the capacity retention ratio after circulating for 1300 cycles at the 1C / 1C system is greater than and equal to 80%.

Owner:HUNAN SHINZOOM TECH

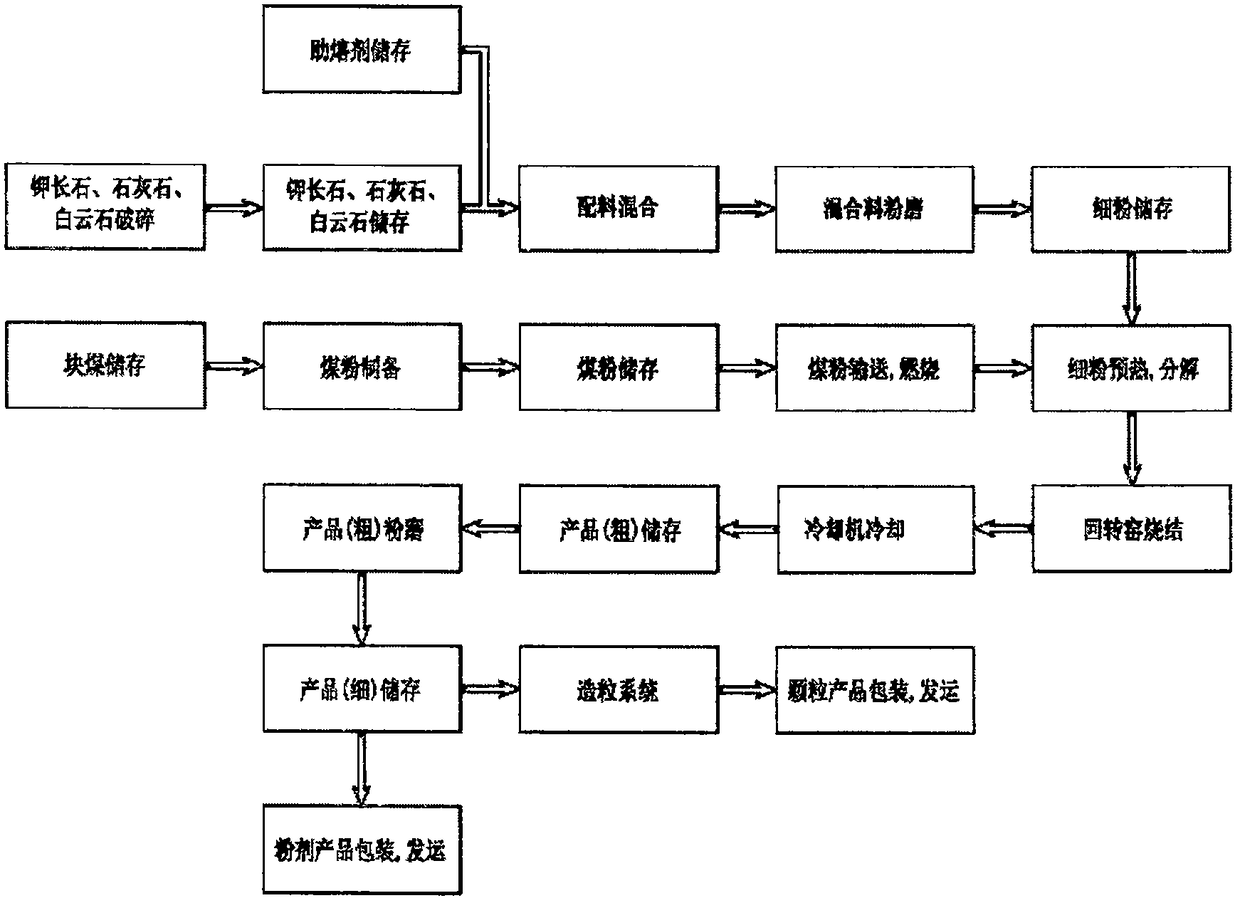

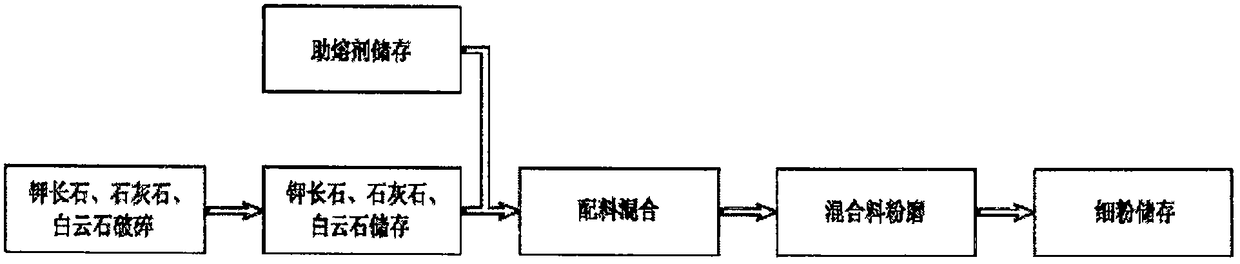

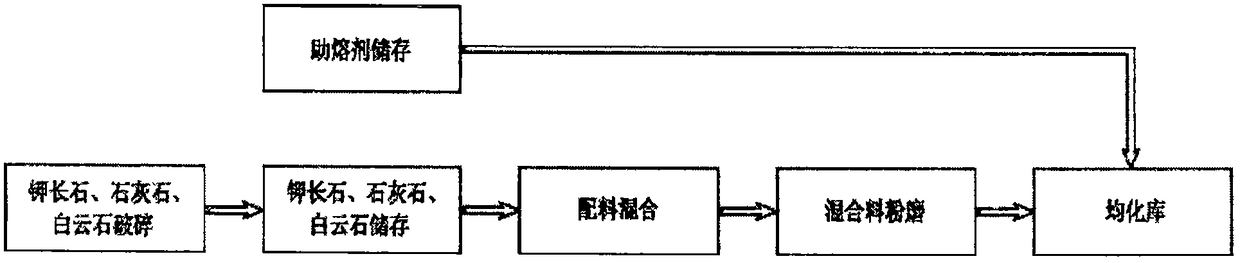

Preparation method for producing potassium calcium silicon magnesium fertilizer calcining fluxing agent

PendingCN108558506AEnergy-saving and synergisticSolve the loop problemCalcareous fertilisersEnergy inputInstabilitySolvent

The invention discloses a preparation method for producing a potassium calcium silicon magnesium fertilizer calcining fluxing agent. The fluxing agent comprises, by weight percentage, 40-60% of potashfeldspar, 20-40% of limestone and 10-20% of dolomite. The preparation method has the advantages that the production temperature of the method is 100-300 DEG C lower than that of a traditional production process, and sintering time is shortened from original 40-60 minutes to 30 minutes; the ring forming problem in a kiln is solved fundamentally, heat utilization rate is increased greatly, power consumption is lowered, and operating rate is increased greatly; the use amount of the fluxing agent is low, the fluxing agent is mixed with the raw materials during grinding, operation convenience is achieved, and product cost is not increased by using the fluxing agent; by using the fluxing agent, the conversion rate of effective components is increased, the minimum content of the potash feldsparis changed from the original 10% to 8.5%, and mineral utilization rate is increased greatly; raw material preparing tolerance is increased, sintering's requirements on magnesium and iron are lowered,and problems such as material preparing difficulty and quality instability caused by production enterprise raw material component instability are solved.

Owner:中材鼎原生态肥业有限公司

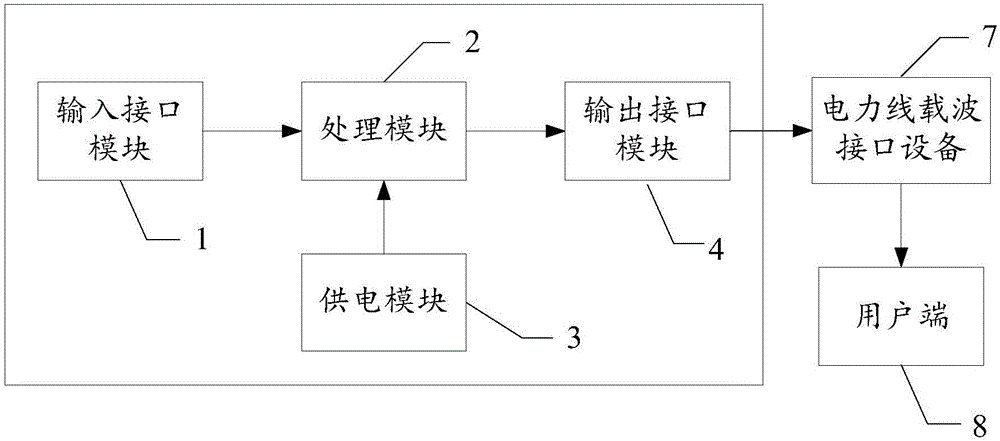

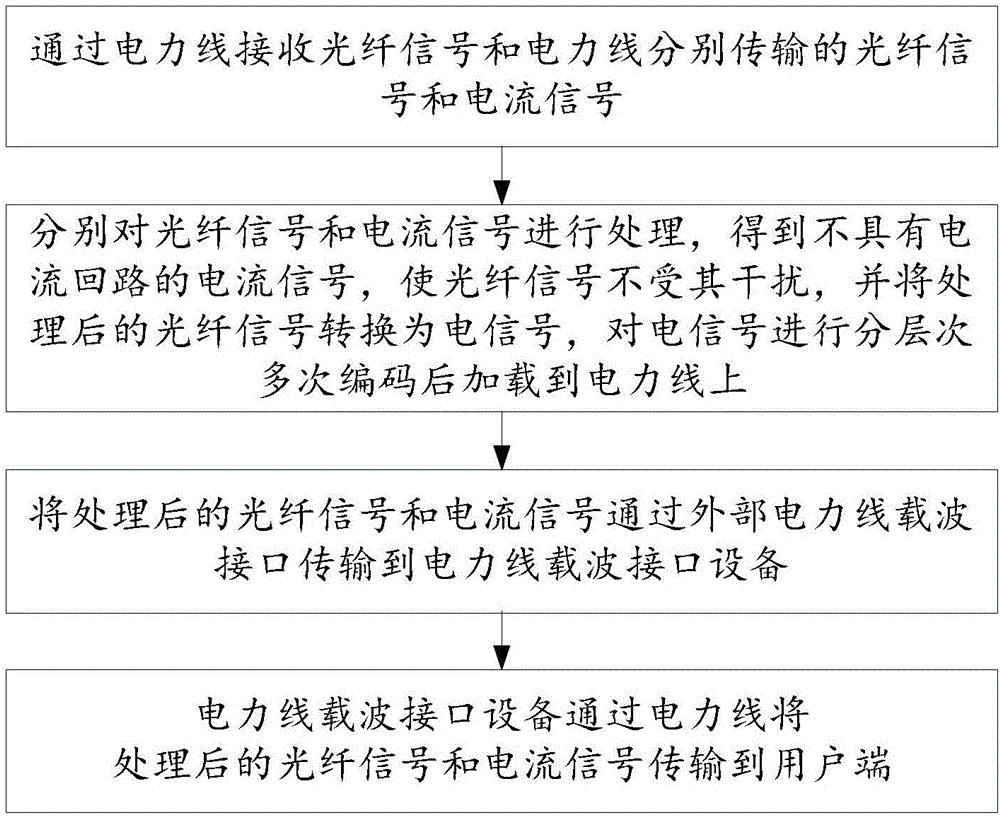

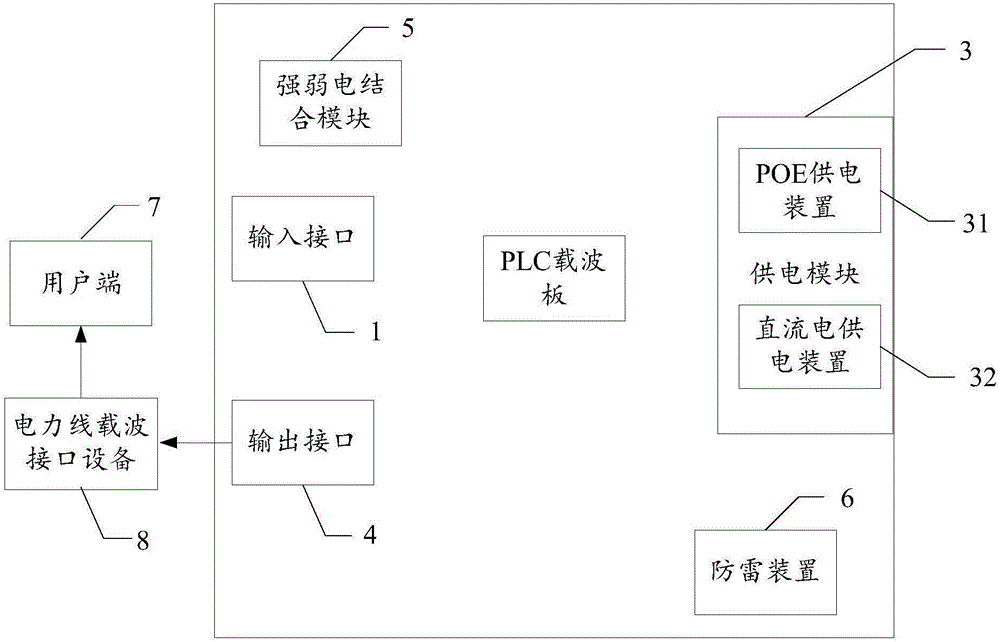

Communication coding system and method based on optical fibers and power lines

InactiveCN106685481ASolve the Internet does not interfere with each otherSolve management problemsPower distribution line transmissionBroadcast radiationCarrier signal

The invention relates to a communication coding system and method based on optical fibers and power lines. The communication coding system includes an input interface module, a processing module, a power supply module, an output interface module, power line carrier interface equipment and a user terminal; the input interface module is used for receiving optical fiber signals and current signals transmitted by the optical fibers and the power lines respectively and sending the optical fiber signals and the current signals to the processing module; the processing module is used for processing the optical fiber signals and the current signals respectively, converting the processed optical fiber signals into electric signals, conducting hierarchical multiple coding on the electric signals and then loading the result electric signals to the power lines; the output interface module is used for transmitting the processed optical fiber signals and the electric signals to the power line carrier interface equipment through an external power line carrier equipment interface; the power line carrier interface equipment is used for transmitting the processed optical fiber signals and the current signals to the user terminal. A hierarchical multiple coding networking technology is adopted, a broadcasting storm is solved, and the situation that users do not interfere with one another on the Internet under the high-speed broadband is achieved.

Owner:重庆金燕巢科技有限公司

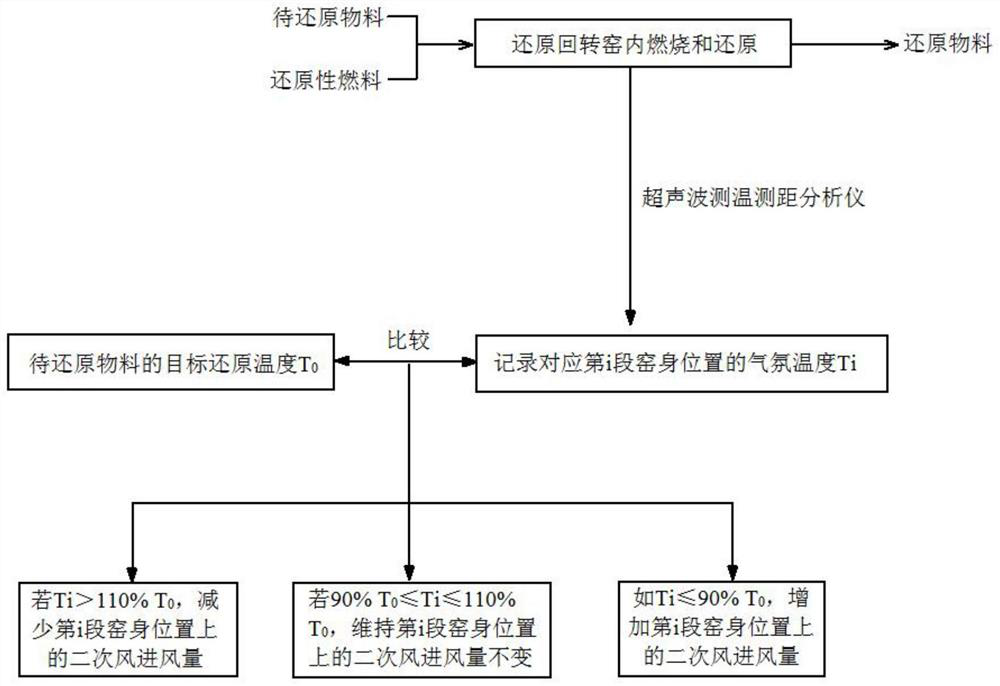

Temperature control method for reduction rotary kiln

InactiveCN112050627AAccurate temperature measurementExtended high temperature sectionRotary drum furnacesTemperature control using electric meansTemperature controlCombustion chamber

The invention provides a temperature control method for a reduction rotary kiln. The temperature control method includes the following steps of: additionally arranging an ultrasonic temperature and distance measurement analyzer on a kiln head cover of the rotary kiln; monitoring the temperature along a kiln length direction line on line in real time; simultaneously installing a series of secondaryair nozzles on a kiln body in the kiln length direction; and changing the air volume of the secondary air nozzle at the corresponding point according to the difference between the temperature of a measured point and a target temperature to ensure that the uniformity of a temperature field in the kiln and along the length direction of the kiln is guaranteed, the local temperature is prevented frombeing too high or too low, ring formation in the rotary kiln is avoided, a longer high-temperature zone is provided for reduction materials, and the product quality index is remarkably improved; besides, volatile components, CO and the like volatilized from material layers are fully combusted with secondary air, so that the reduction materials in the rotary kiln are provided with a temperature, the content of volatile components and CO entering a re-combustion chamber is greatly reduced as well, the fuel utilization efficiency is high, and high-temperature ring formation and water explosion of the re-combustion chamber are avoided.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com