Excavating and supporting integrating method and carrying type lifting and transporting support manipulator for heading machine

A technology for roadheaders and manipulators, which is applied to mine roof support, earthwork drilling, mining equipment, etc., and can solve problems such as unfavorable roof support, limited frame strength and connection strength, and insufficient distance from the roof to meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The integrated excavation method of excavation and support is based on the "crawler" hydraulic combined support (the applicant's "crawler" hydraulic combined support for temporary support and permanent support parallel operation excavation technology and equipment, application number 201310311586.9) or self-expanding roadway hydraulic pressure Supported lifting and moving support manipulator of the support and roadheader realizes the integration of excavation and support, that is, the driver of the roadheader completes the roadway excavation and the support of the temporary support area through the roadheader and the manipulator on the roadheader; The jack adopts electro-hydraulic control valve, coupled with visual monitoring and monitoring, to realize the integration of remote control and excavation.

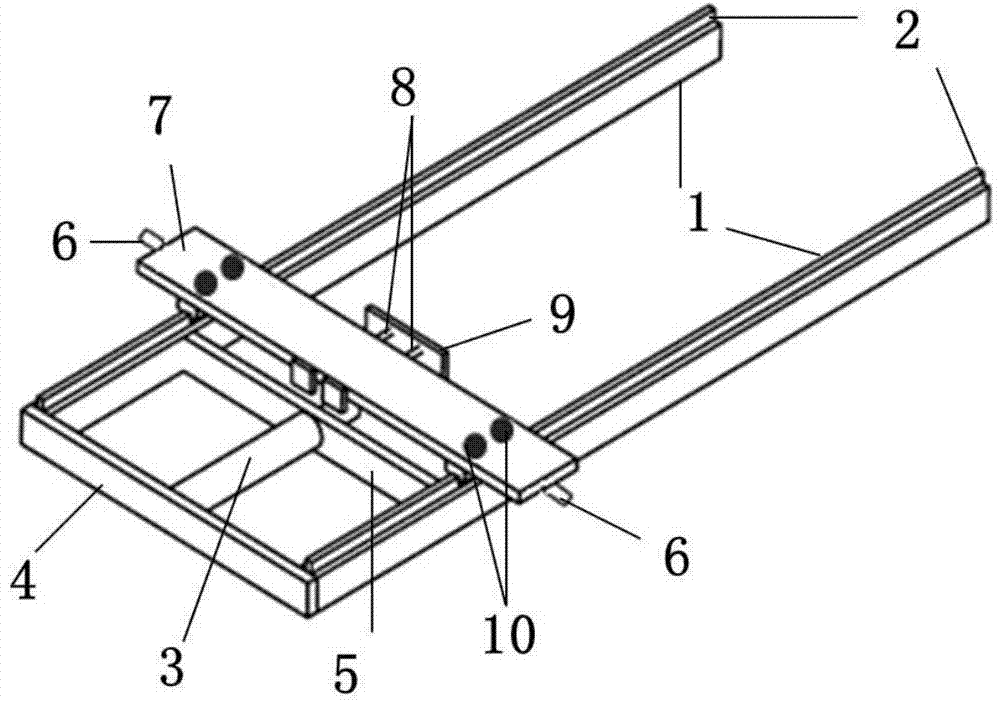

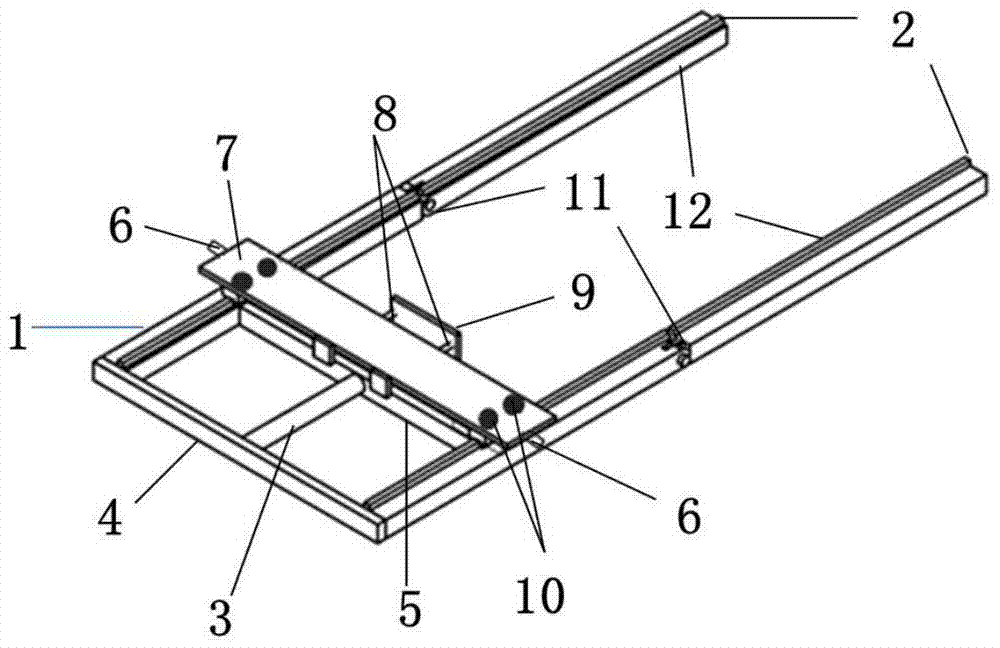

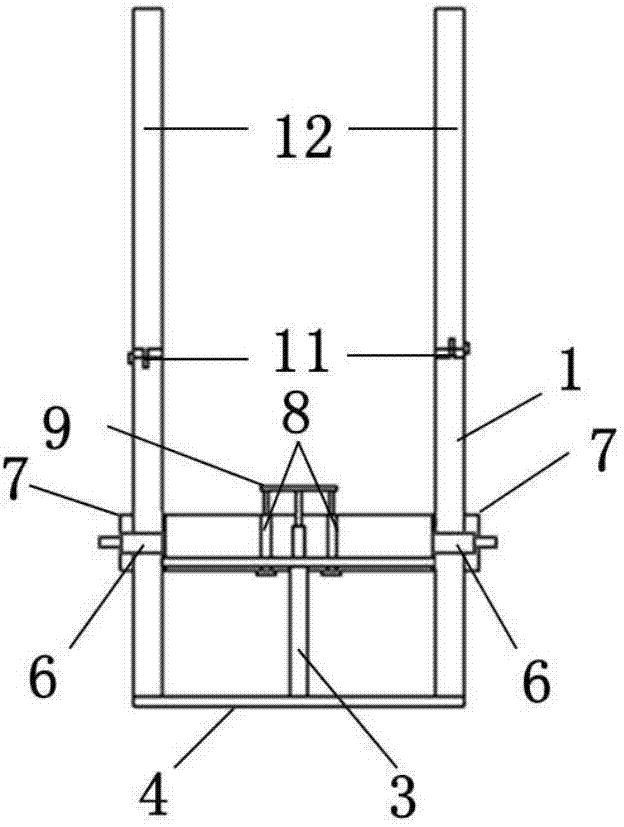

[0061] The supporting manipulator of the roadheader is composed of a supporting frame 1, a moving track 2, a carrier trolley 7, a supporting frame lifting jack V 14, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com