Temperature control method for reduction rotary kiln

A temperature control method and rotary kiln technology, applied in the field of rotary kiln, can solve problems such as incongruity, volatile matter and CO escape, easy ring formation, etc., and achieve the effect of quality assurance and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

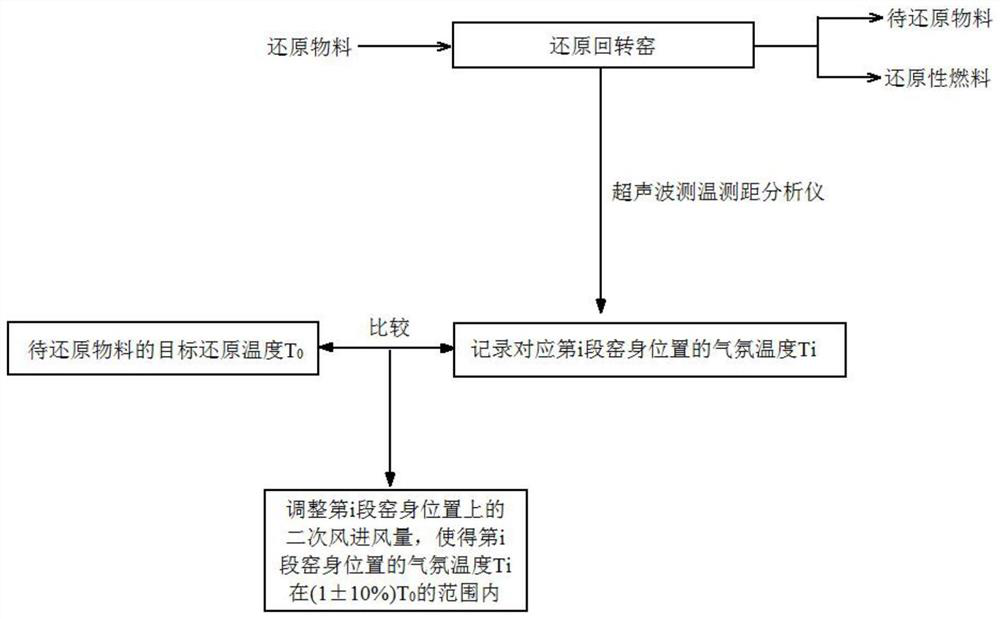

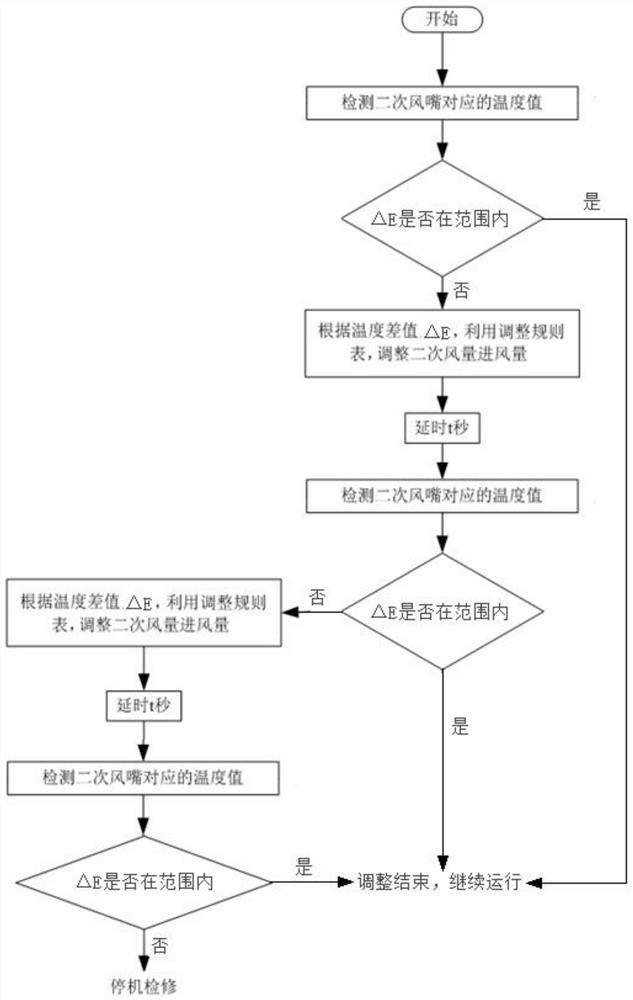

[0086] Such as figure 1 As shown, a reduction rotary kiln temperature control method, the reduction rotary kiln 1 is equipped with an ultrasonic temperature measurement distance analyzer 2, the kiln body of the reduction rotary kiln 1 is divided into n sections, and each section of the kiln body is provided with a secondary air nozzle 3 , and each secondary air nozzle 3 is connected to the blower fan 4 . The method includes the following steps:

[0087] 1) Put the material to be reduced into the reducing rotary kiln 1, and add reducing fuel at the kiln head 101 and the kiln tail 102 of the reducing rotary kiln 1;

[0088] 2) A burner 103 is provided at the position of the kiln head 101 of the reduction rotary kiln 1, and the reduction material is obtained in the reduction rotary kiln 1 through combustion and reduction of a reducing fuel;

[0089] 3) Ultrasonic temperature measurement and distance measuring analyzer 2 detects the atmospheric temperature of each kiln body pos...

Embodiment 2

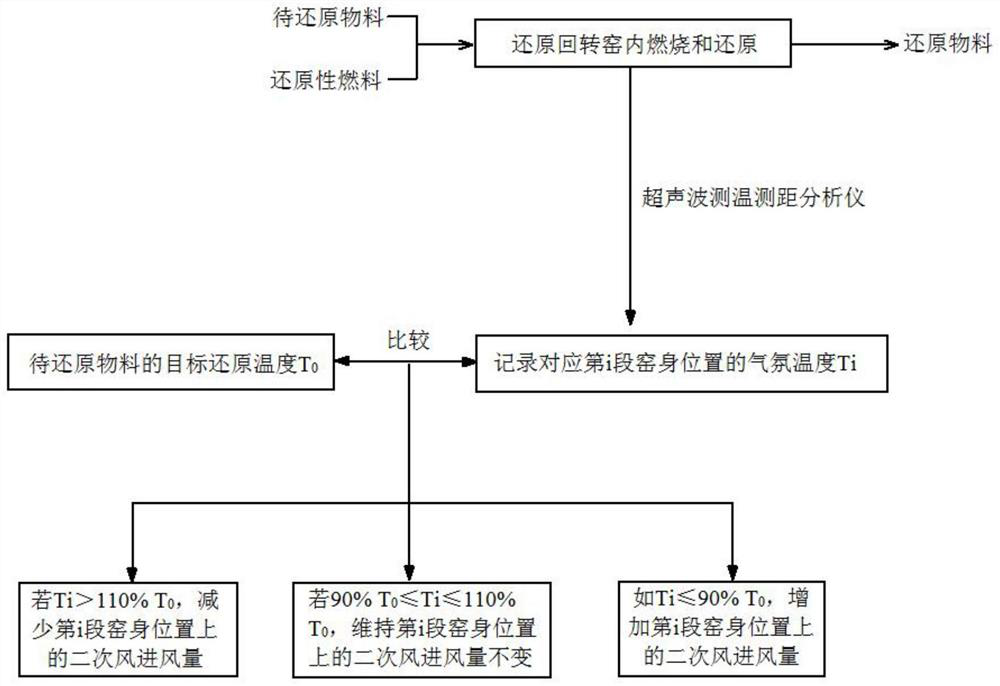

[0092] Such as figure 2 As shown, a reduction rotary kiln temperature control method, the reduction rotary kiln 1 is equipped with an ultrasonic temperature measurement distance analyzer 2, the kiln body of the reduction rotary kiln 1 is divided into n sections, and each section of the kiln body is provided with a secondary air nozzle 3 , and each secondary air nozzle 3 is connected to the blower fan 4 . The method includes the following steps:

[0093] 1) Put the material to be reduced into the reducing rotary kiln 1, and add reducing fuel at the kiln head 101 and the kiln tail 102 of the reducing rotary kiln 1;

[0094] 2) A burner 103 is provided at the position of the kiln head 101 of the reduction rotary kiln 1, and the reduction material is obtained in the reduction rotary kiln 1 through combustion and reduction of a reducing fuel;

[0095] 3) Ultrasonic temperature measurement and distance measuring analyzer 2 detects the atmospheric temperature of each kiln body pos...

Embodiment 3

[0099] Repeat embodiment 2, just adjust the secondary air intake volume on the i-th section kiln body position to be specifically:

[0100] If Ti>110%T 0 , to reduce the secondary air intake volume at the location of the i-th kiln body;

[0101] If 90% T 0 ≤Ti≤110%T 0 , keep the secondary air intake volume at the position of the kiln body in the i section unchanged;

[0102] Such as Ti≤90%T 0 , increase the secondary air intake volume at the position of the kiln body in the i section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com