Fiber Bragg Grating Temperature Sensor and Its Probe

A technology of temperature sensor and fiber grating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

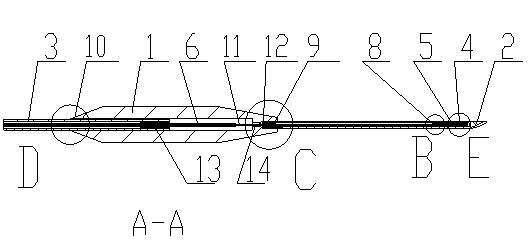

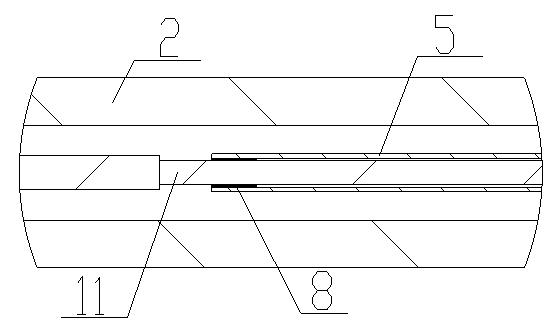

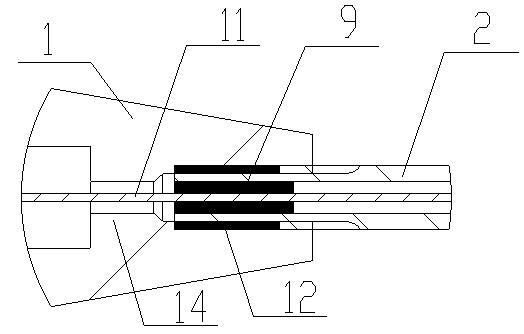

[0018] A fiber grating temperature sensor probe, which includes a needle 2 and a handle 1 connected together, the needle 2 is a round rod with a needle point, a blind hole is arranged in the center of the bottom surface of one end of the round rod, and the blind hole extends to nearly The other end of the round rod has a needle point; a fiber Bragg grating 4 is fixed through a quartz glass capillary 5 in the blind hole. Setting the fiber Bragg grating 4 in the blind hole refers to stripping the coating layer of the fiber Bragg grating 4 and its root 5mm tail fiber 11 and placing it in the fiber Bragg grating 4 root 5mm tail fiber at the rear part of the quartz glass capillary 5. After the surface of 11 is coated with glue, insert it into the quartz glass capillary 5 close to the front end, then insert the fiber Bragg grating 4 together with the quartz glass capillary 5 into the blind hole of the needle 2 and apply glue to the root of the needle 2, connect the needle 2 and the t...

Embodiment 2

[0022] The similarities between this embodiment and Embodiment 1 will not be repeated, the difference is that it is a fiber grating temperature sensor, which includes a probe and a demodulation system connected thereto. System block diagram as Figure 5 As shown, the narrowband light output by the laser enters the sensing fiber grating through the isolator and coupler, and the optical path of the narrowband laser is tuned through the signal generator, and the central wavelength of the output light is periodically changed to scan the reflection of the sensing fiber grating Spectrum. When the output spectrum of the laser changes, the change of the received light intensity of the detector reflects the matching condition of the output spectrum of the laser and the reflection spectrum of the sensing fiber grating. Theoretically, when the central wavelength of the laser and the sensing FBG is completely matched, the optical power received by the detector reaches the maximum value. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com