Cross double pull comprehensive test platform and method suitable for high temperature conditions

A cross double pull and comprehensive testing technology, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, instruments, etc., can solve problems such as providing data basis, affecting test accuracy, and inability to form plates to achieve test content Comprehensive, diverse test environments, and convenient test operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

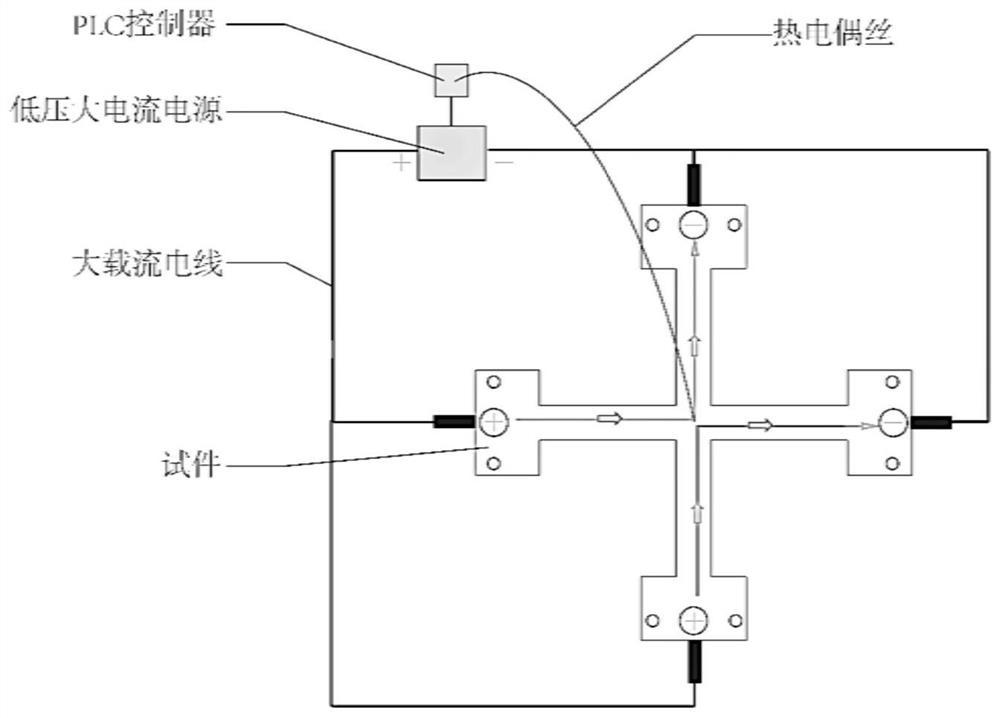

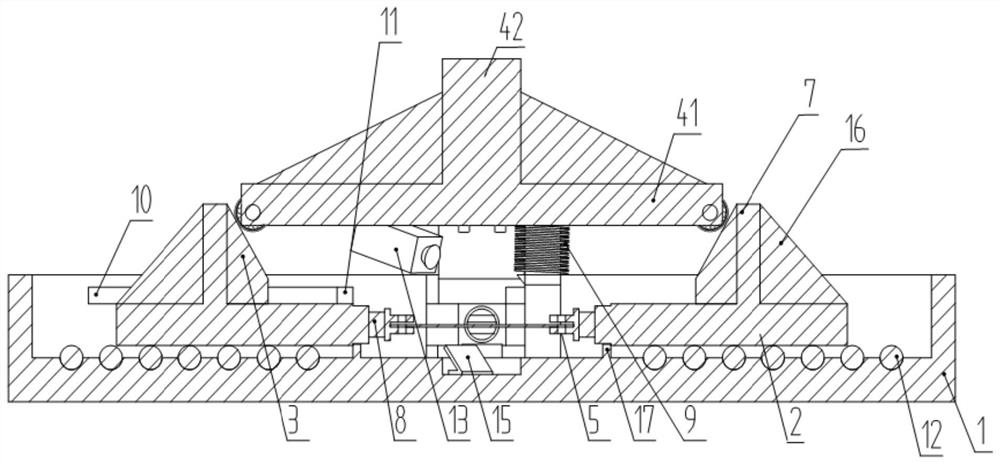

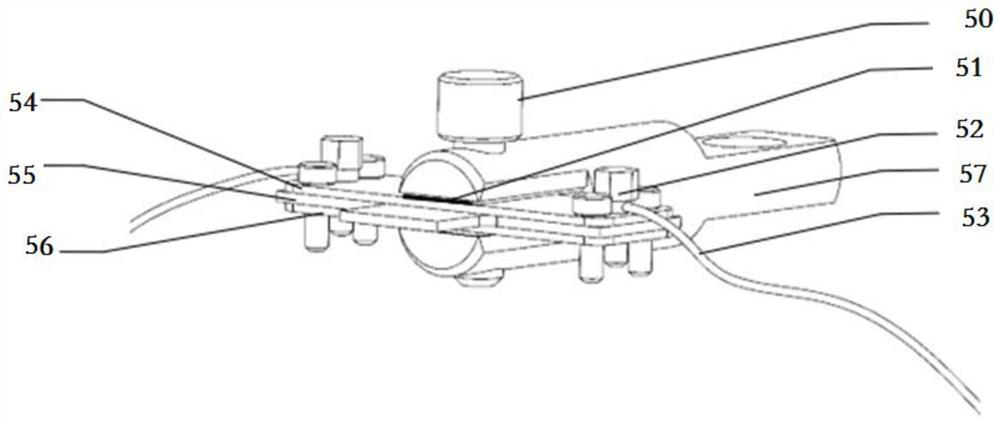

[0042] Such as Figure 1-4 As shown, a test platform is provided, including an electric heating temperature control system, a tensile control system and a strain measurement system. The tensile control system includes a testing machine, a bidirectional cross tensile device, a scale grating and a force sensor. The cross stretching device is connected to apply pressure to it. The two-way cross stretching device is used to clamp and stretch the test piece, and the scale grating and the force sensor are used to read the tensile force of the test piece. length and force value;

[0043] The electric heating temperature control system includes a controller, a temperature sensor and an adjustable DC power supply. The adjustable DC power supply is connected to the test piece, which can cause the test piece to generate Joule heat and increase the temperature of the test piece. The temperature sensor collects the The temperature of the test piece is fed back to the controller, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com