System for wastewater oxidation treatment by using supercritical circulating water

A technology for oxidation treatment and circulating water, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effects of easy construction, high risk and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

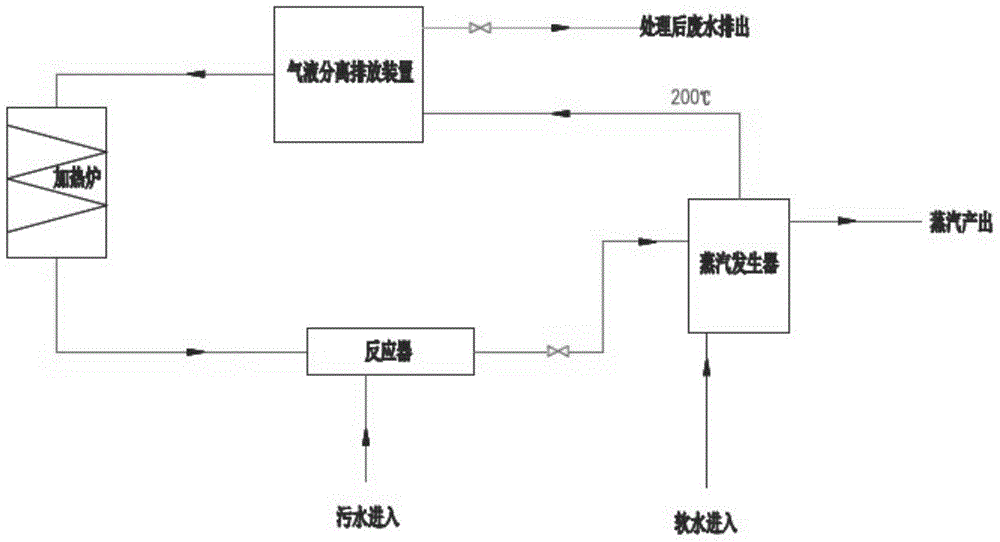

Image

Examples

Embodiment 2

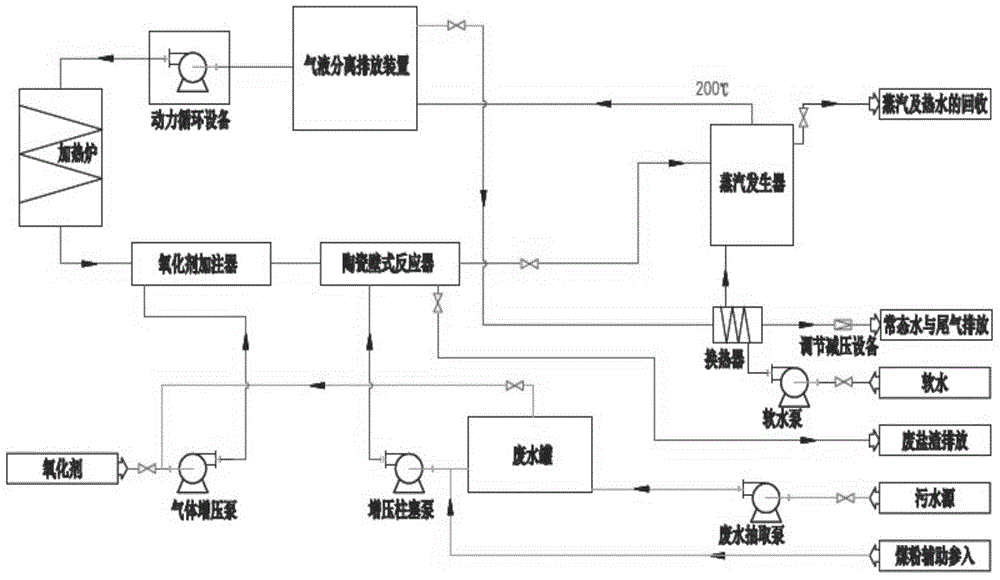

[0031] See attached figure 2 , a system for supercritical circulating water oxidation treatment of wastewater, including supercritical steam boiler, reactor, steam generator, gas-liquid separation device and power cycle equipment, supercritical steam boiler, reactor, steam generator, gas-liquid separation The device and the power cycle equipment are connected end to end through pipelines to form a circulation treatment system. The system is also equipped with a heat exchanger, an auxiliary pulverized coal injection device and an oxidant injector. The first input end of the heat exchanger is connected to the output end of the gas-liquid separation device, the first output end is connected to the normal water and the tail gas discharge device through the decompression equipment, the second input end of the heat exchanger is connected to the soft water input pump, and the second The output end is connected with the soft water input end of the steam generator. The pulverized coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com