Method for producing phosphoric acid by utilizing middle grade phosphate ore

A technology of phosphate rock and phosphoric acid, applied in the direction of phosphoric acid, phosphorus oxyacid, etc., can solve the problems of ring formation and blockage of tail gas pipelines, achieve the effects of solving ring formation and blockage, reducing CO gas consumption, and reducing coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

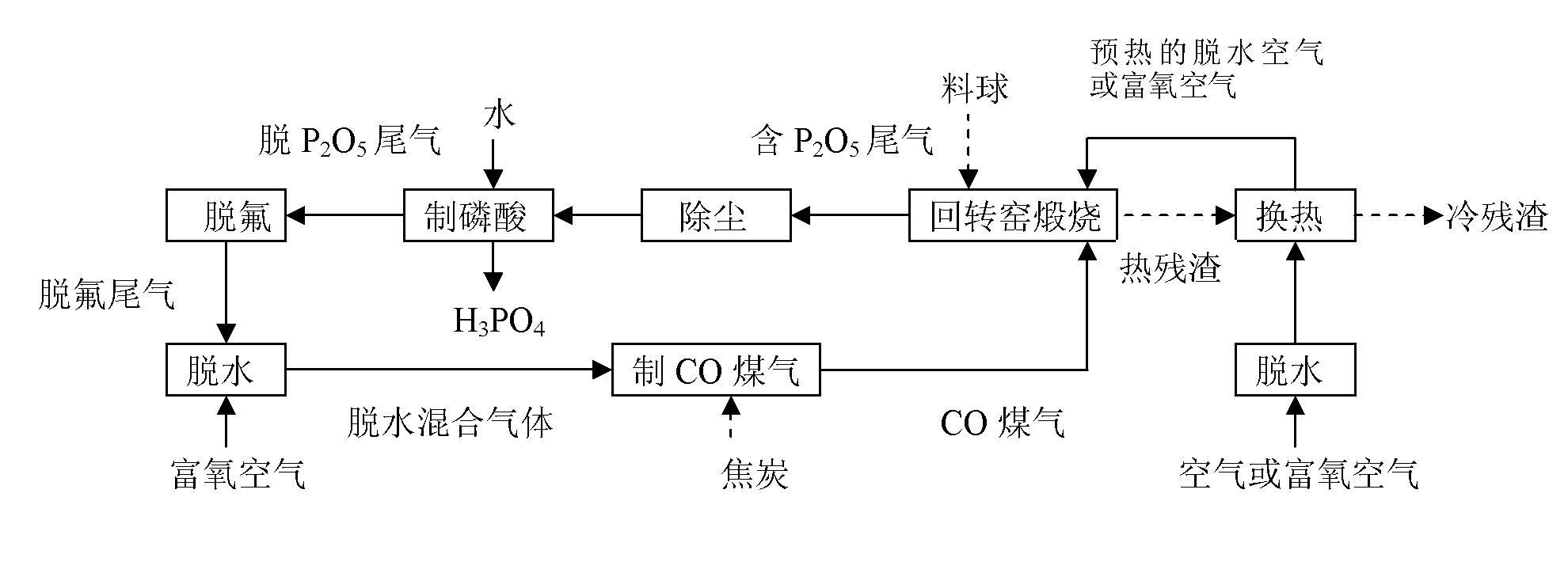

Method used

Image

Examples

Embodiment 1

[0023] In the present embodiment, the method for producing phosphoric acid is as follows:

[0024] (1) Preparation of pellets with a double-layer composite structure. The raw materials of the inner layer pellets include medium-grade phosphate rock powder, coal powder and silica powder, and the chemical composition (both percentages by weight) of the medium-grade phosphate rock powder is: P 2 o 5 20.6%, CaO 25.8%, SiO 2 46.9%; the chemical composition of coal dust (both percent by weight) is: fixed carbon 77.9%, ash 17.4% (wherein SiO 2 84.3%, Fe 2 o 3 8.3%, CaO 2.0%); SiO in silica powder 2 The content is 95.3% (percentage by weight). When batching, the pulverized coal is based on the P in the phosphate rock 2 o 5 Measure 1.5 times of the theoretical amount of fixed carbon required for reduction, and the silica powder is based on the SiO contained in the three raw materials of medium-grade phosphate rock powder, coal powder and silica powder. 2 / CaO=3 (molar ratio)...

Embodiment 2

[0036] (1) prepare the material ball of double-layer composite structure, raw material and its proportioning and operation are with embodiment 1;

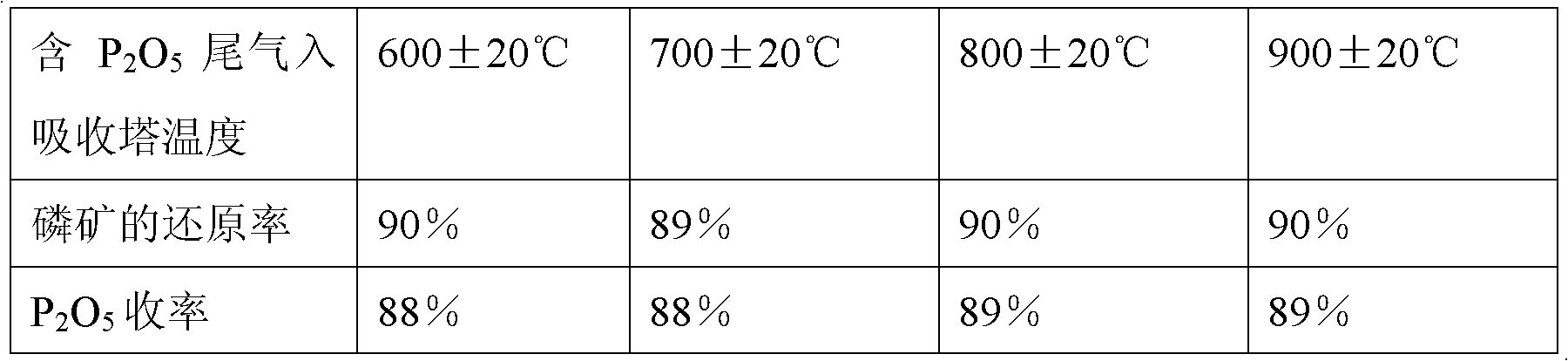

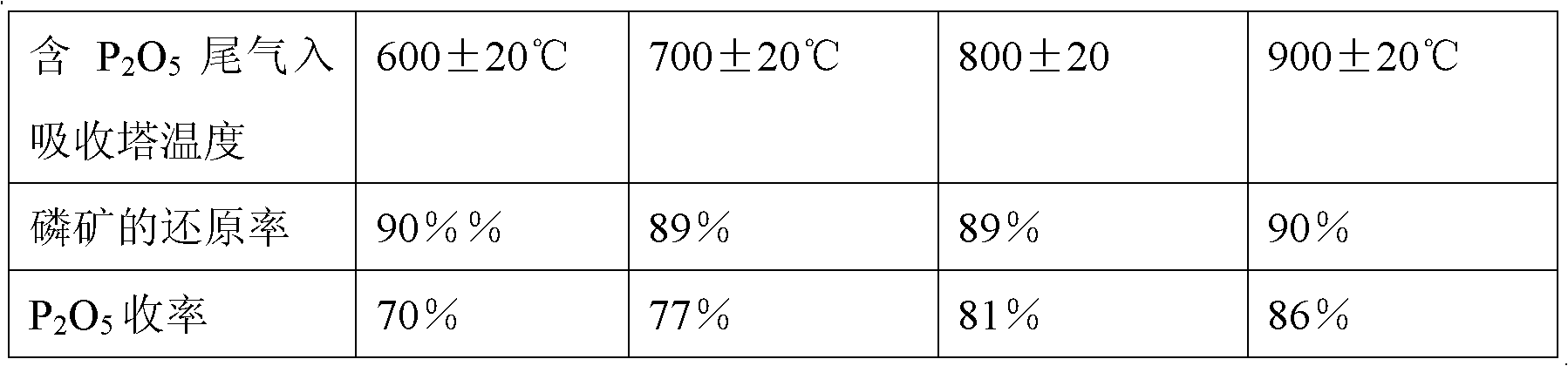

[0037] (2) Feed the material balls into the rotary kiln continuously from the tail of the rotary kiln at a speed of 220kg / h, and continuously feed CO gas into the rotary kiln from the head of the rotary kiln, and its speed varies with the oxygen concentration in the oxygen-enriched air , the dehydrated oxygen-enriched air is preheated to 550°C and then continuously input to the rotary kiln from the head of the rotary kiln. The theoretical oxygen required for complete combustion is calculated by 10% excess. In the rotary kiln, the high-temperature gas generated by the combustion of CO gas and the balls run in reverse to exchange heat. The balls are heated to a reaction temperature of 1300°C to 1350°C in the main reaction section, and the residence time of the balls in the main reaction section is at least 40 minutes. P 2 o 5 Exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com