Patents

Literature

647results about How to "Reduce coal consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

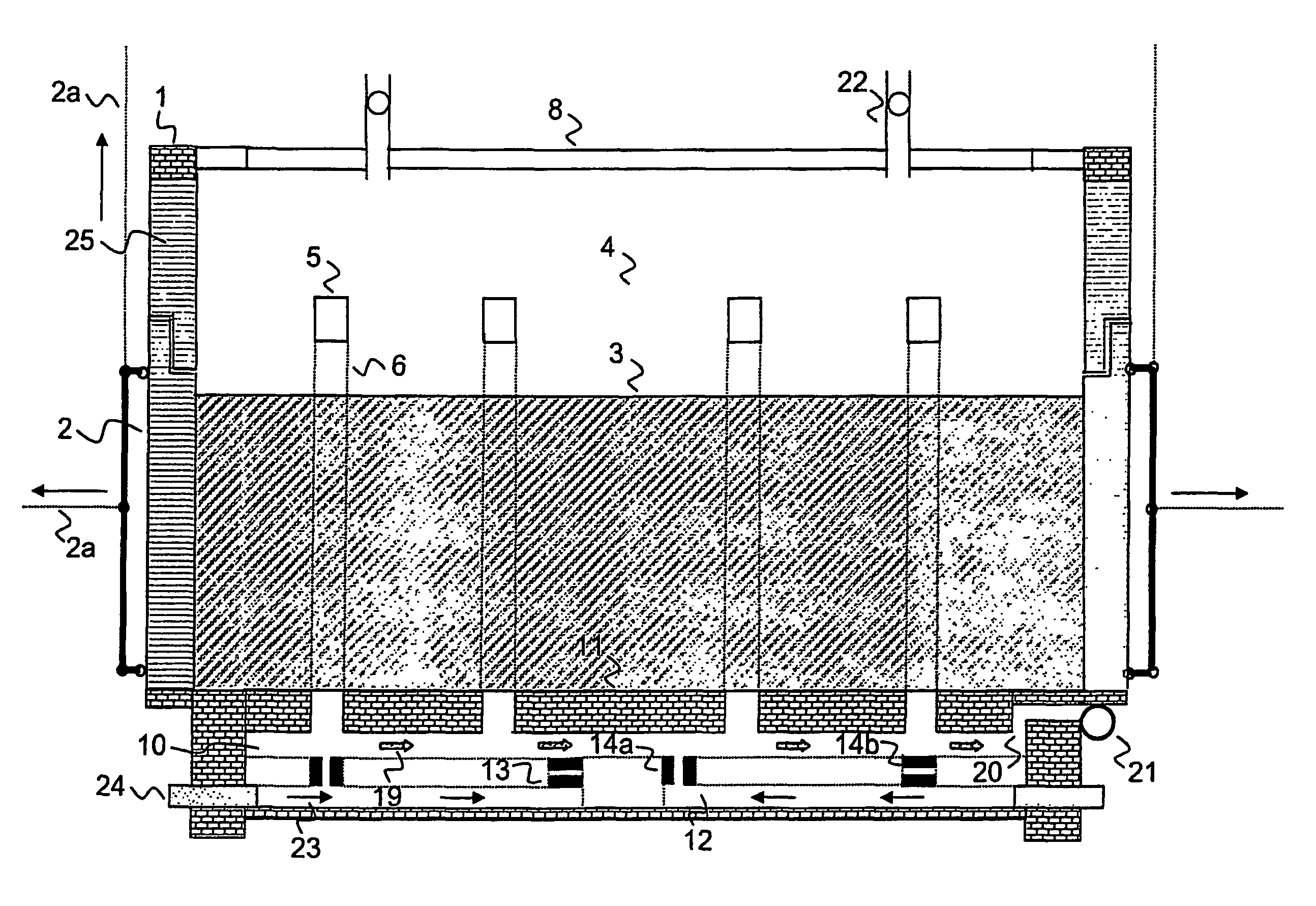

Controllable air ducts for feeding of additional combustion air into the area of flue gas channels of coke oven chambers

ActiveUS9039869B2Reduce carbonizationGood heat distributionCombustible gas coke oven heatingCoke oven safety devicesBrickCombustion

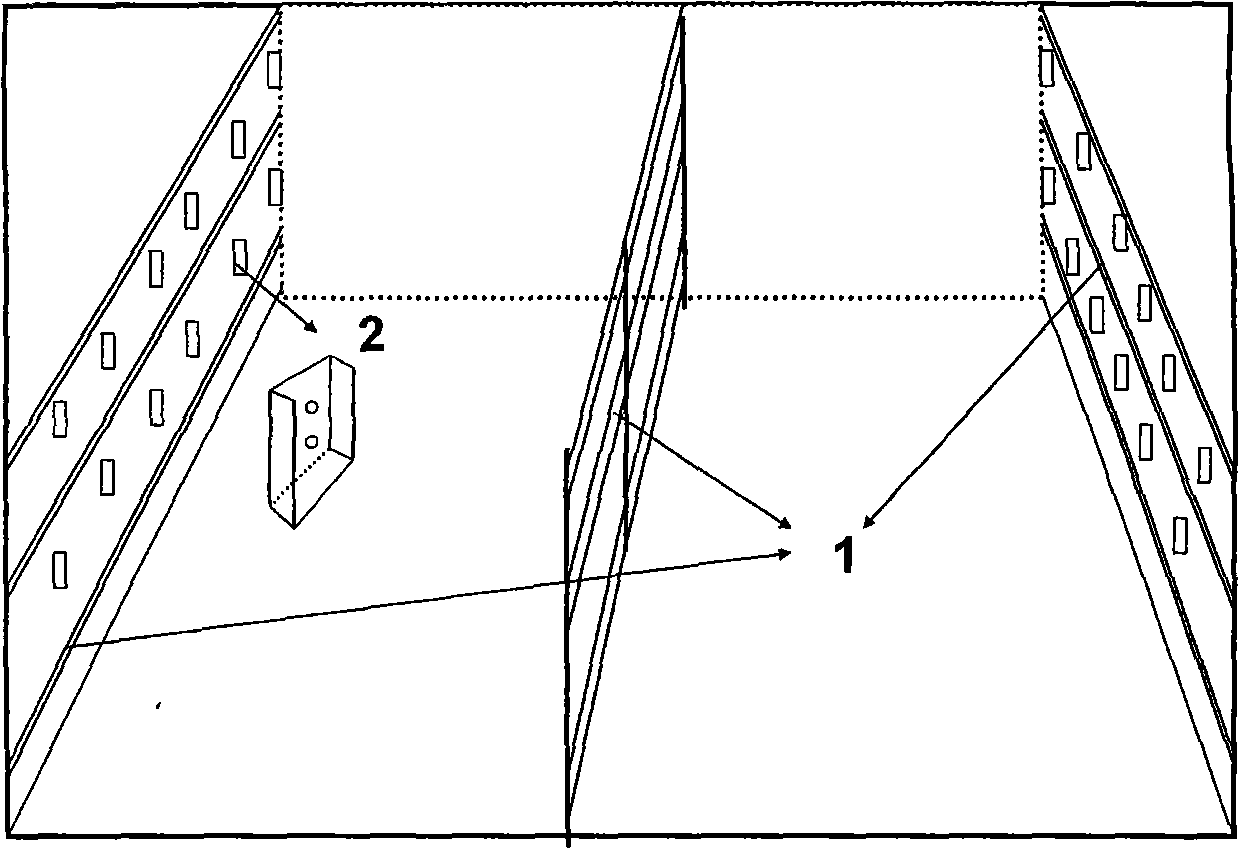

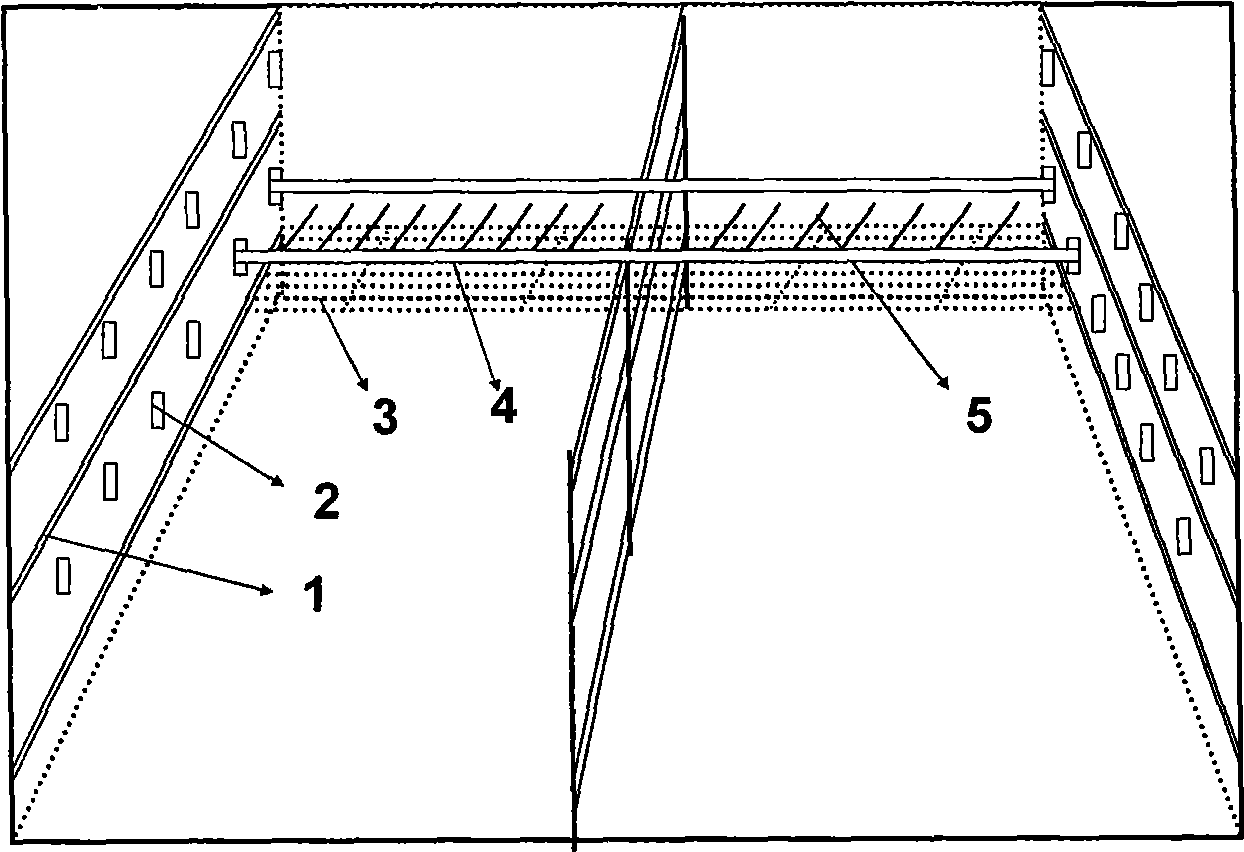

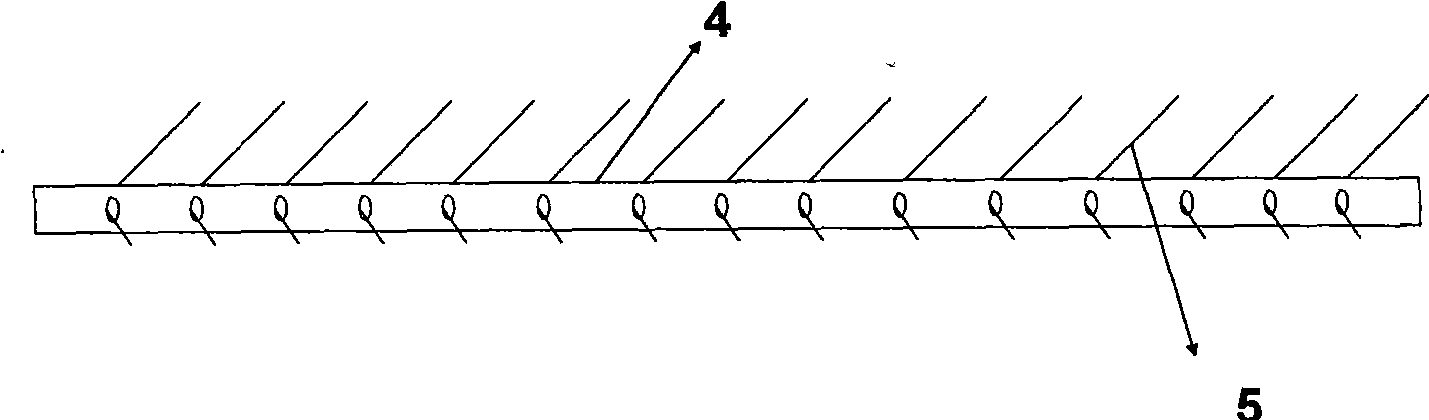

A device for feeding and controlling secondary air from secondary air ducts into flue gas channels of horizontal coke oven chambers is shown. The flue gas channels are located underneath the coke oven chamber floor on which coal carbonization is realized. The flue gas channels serve for combustion of partly burnt coking gases from the coke oven chamber. The partly burnt gases are burnt with secondary air, thus heating the coke cake also from below to ensure even coal carbonization. Secondary air comes from the secondary air ducts connected to atmospheric air and to the flue gas channels. Controlling elements are mounted in the connecting channels between the flue gas channels and secondary air ducts which can precisely control the air flow into the flue gas channels. Thereby, it is possible to achieve a much more regular heating and heat distribution in coke oven chambers. The actual controlling devices in the connecting channels can be formed by turnable pipe sections, wall bricks, or metal flaps. It is particularly advantageous to utilize a hump-like facility (tabouret) which sits in the secondary air ducts and which is comprised of a tabouret plate with a central opening that is slid under the corresponding embranchment to regulate the gas stream. The controlling mechanism can be actuated manually, electrically, or pneumatically. Thereby, the controlling device can also be automated.

Owner:UHDE GMBH

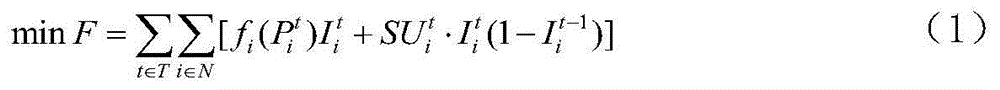

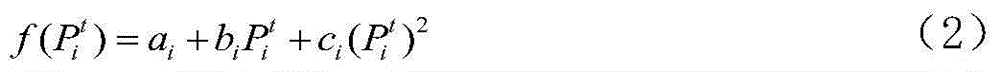

Optimized operation method of pumped-storage power station and wind power combined system

InactiveCN104795846ALow total operating variable costsBalancing wind power fluctuationsSingle network parallel feeding arrangementsWind energy generationOperation modelPower parameter

The invention relates to an optimized operation method of a pumped-storage power station and wind power combined system and belongs to the field of optimized operation of power systems. The method includes: building an optimized operation model of the pumped-storage power station and wind power combined system based on a unit combination, which uses lowest grid generation cost as a target function, constraint conditions of power balance constraint, spinning reserve constraint, climbing ability constraint, unit characteristic constraint and pumped-storage power station constraint, and boundary conditions of a daily load curve, grid loss and power parameters; solving the model to obtain an operation scheduling command to allow optimized operation of the combined system. Wind power intermittence, volatility and prediction inaccuracy are fully considered, and the spinning reverse constraint is corrected to optimize the operation of the combined system; by the use of the method, evident benefits are brought to the pumped-storage power station, in terms of hump modulation and trough stuffing, wind power fluctuation balancing, wind curtailment reduction and system coal consumption reduction.

Owner:TSINGHUA UNIV

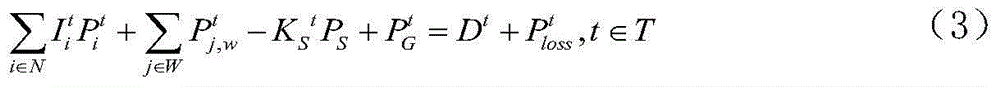

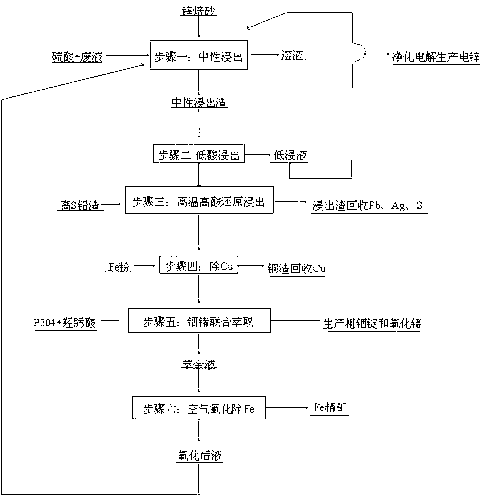

Coal gasification device for circulating fluidized bed and manufacturing method thereof

InactiveCN101054536AImprove gasification efficiencyReduce outputEnergy inputGranular/pulverulent flues gasificationCycloneHearth

A circulating fluidized bed coal gasification apparatus includes coal blending system, generator, cyclone dust collector, exhaust-heat boiler, water-cooling tower and Venturi scrubber, wherein the generator has up-and-down two rows of gasifying agent nozzles, helix dust collector and storage groove. The gas pipe which communicates to the cyclone dust collector is set on the top. A feed back pipe which communicates to the generator is set at the bottom of the cyclone dust collector. The cyclone dust collector communicates to the exhaust-heat boiler by gas pipe. The exhaust-heat boiler communicates to the water-cooling tower by gas pipe and communicates to the Venturi scrubber by gas pipe. The characteristics are: the feed back pipe facing to the generator hearth of the cyclone dust collector is a feed back machine with small-sized fluid bed; the cyclone dust collector is composed of at least two tandem dust collector; coal blending system has wind feeding and dust coal drier. The invention achieves the transition of the boiling bed to the circulating fluidized bed and increases the system gasification efficiency.

Owner:宋建元

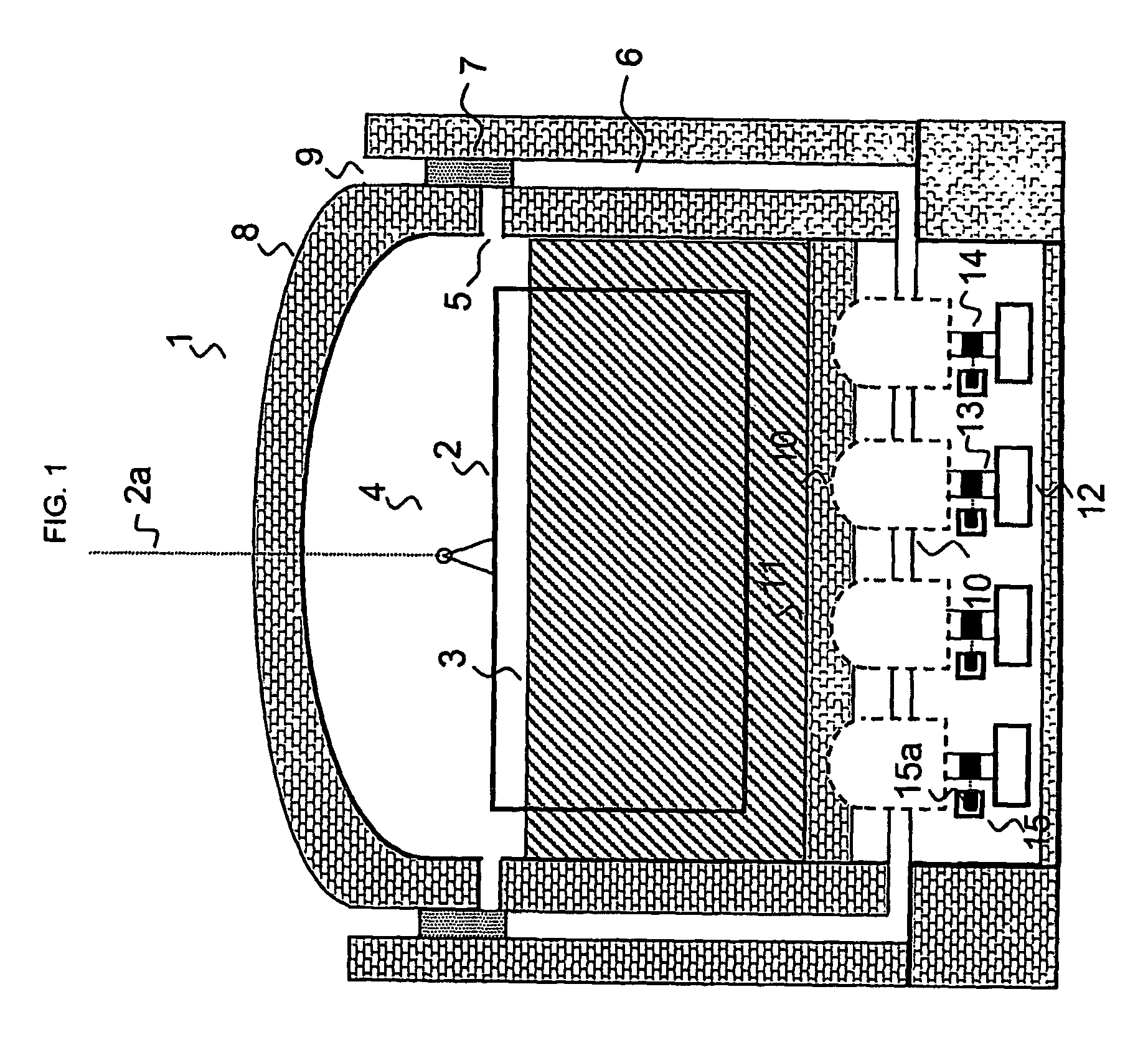

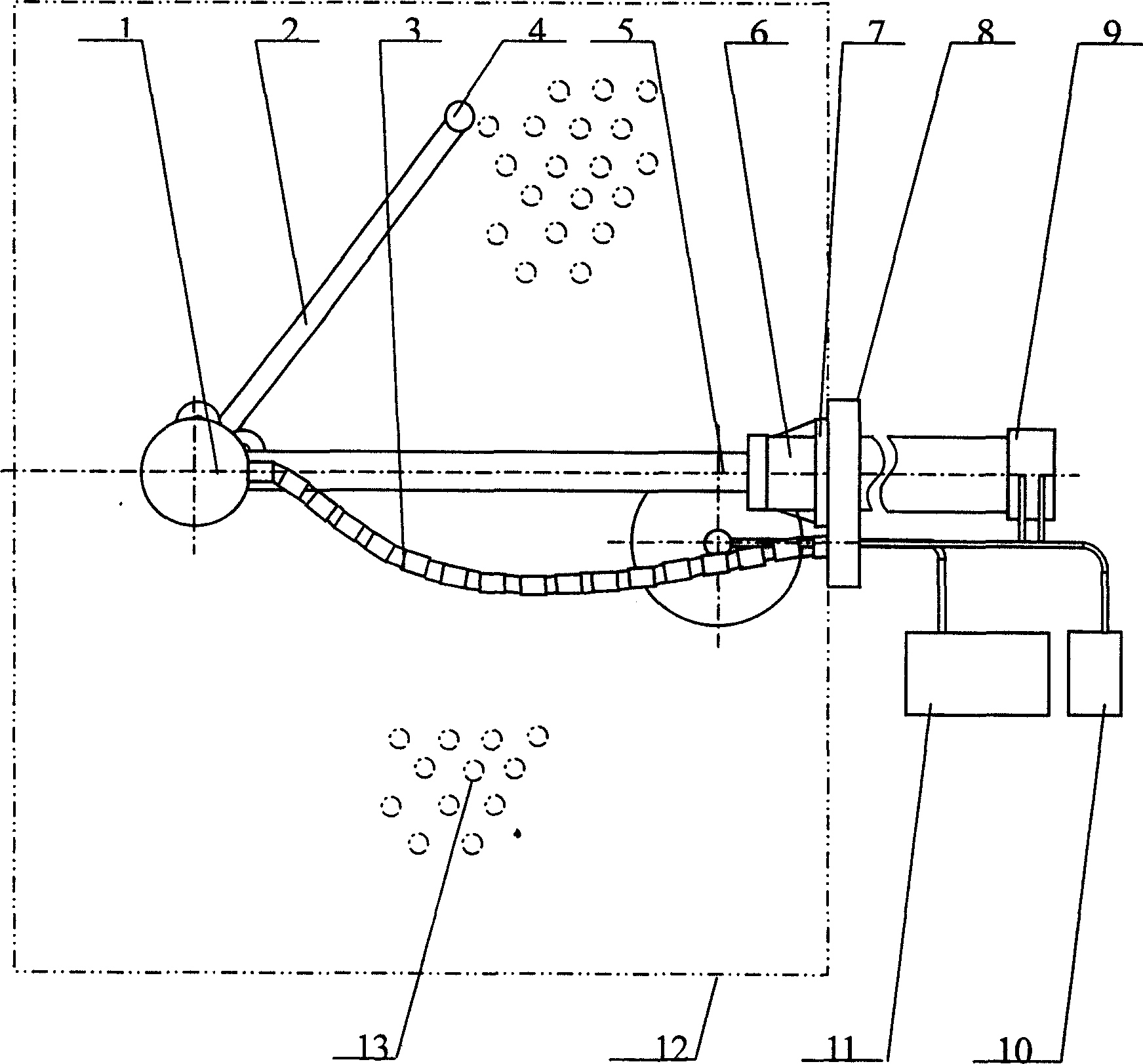

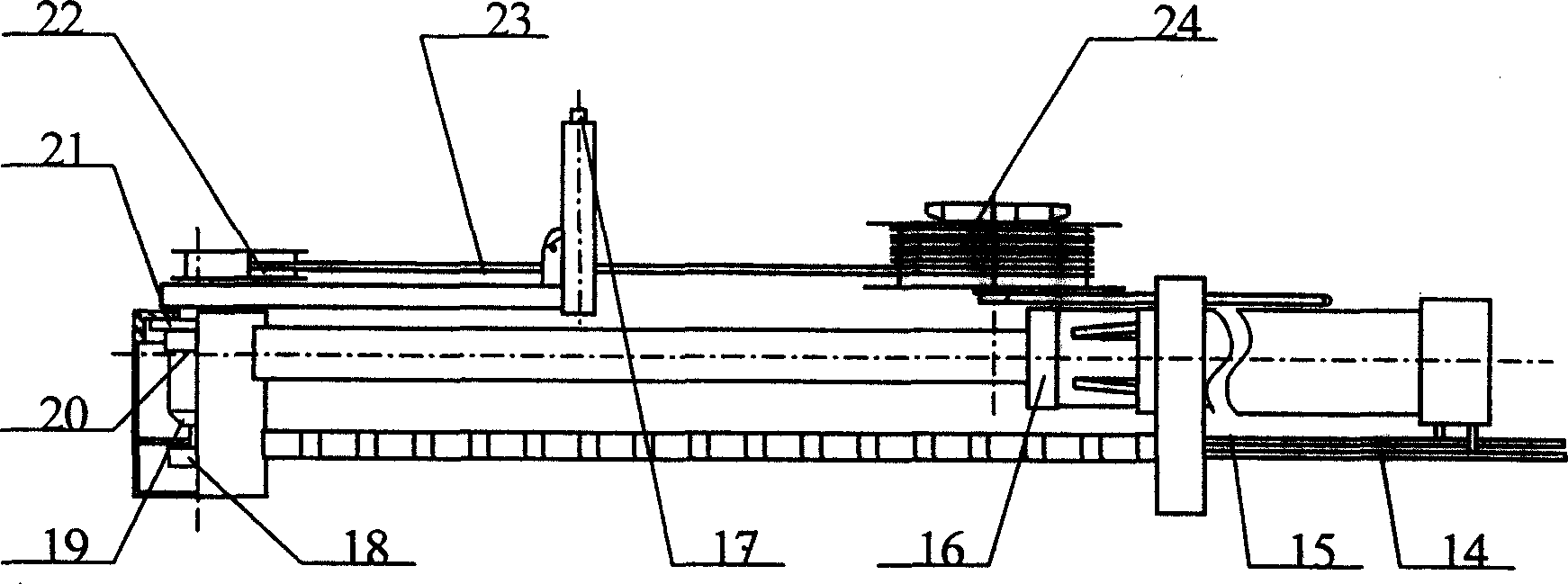

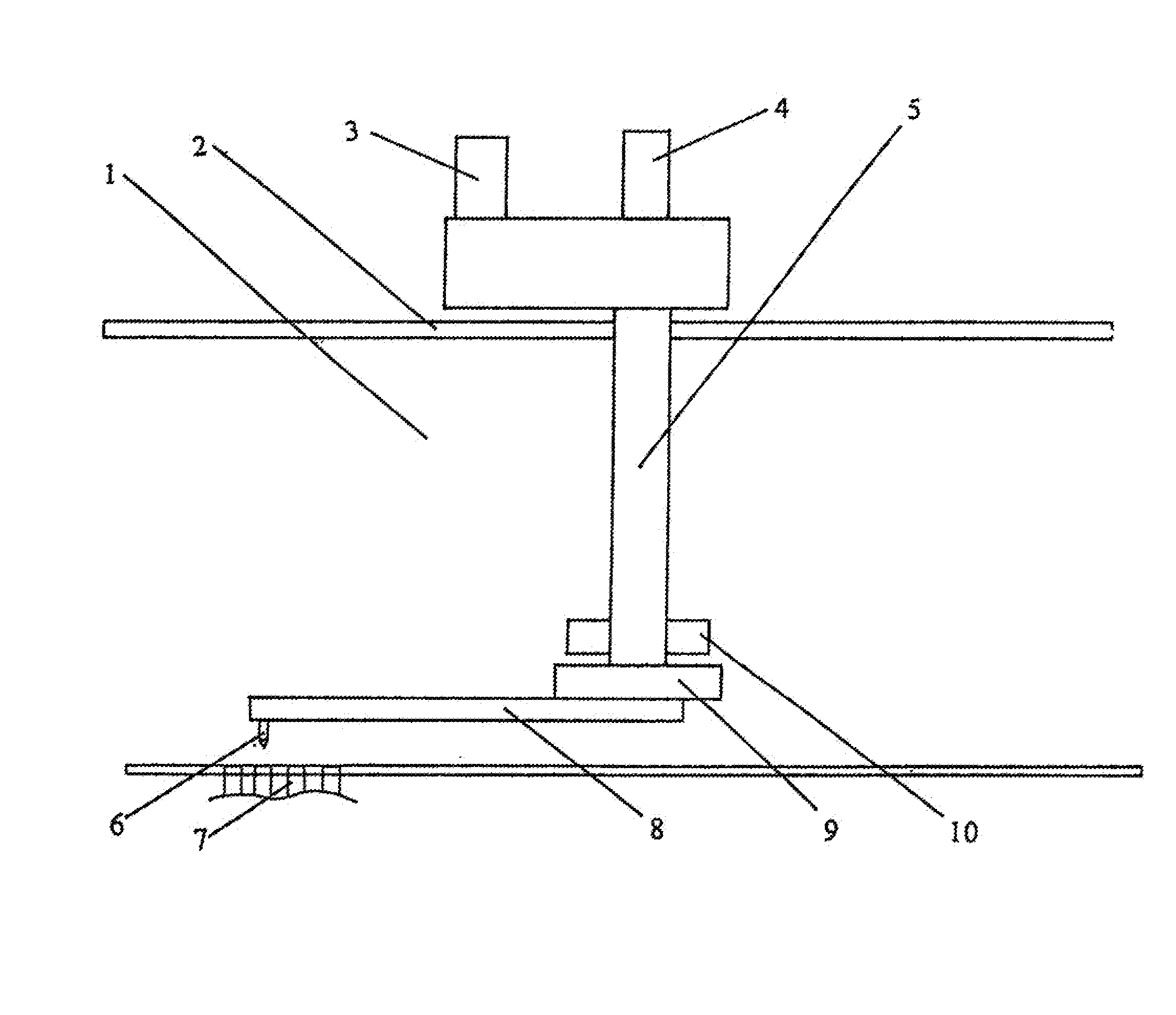

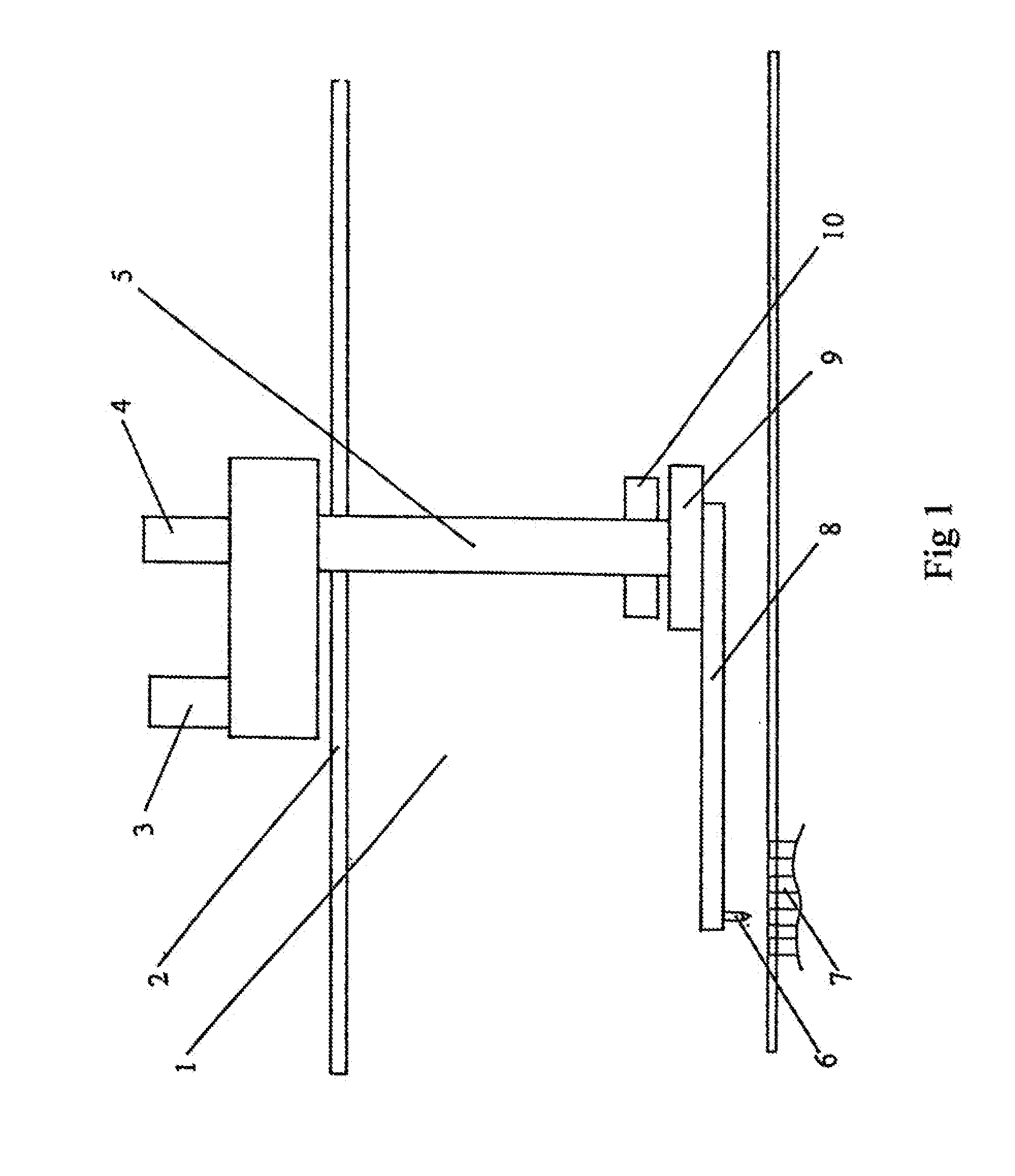

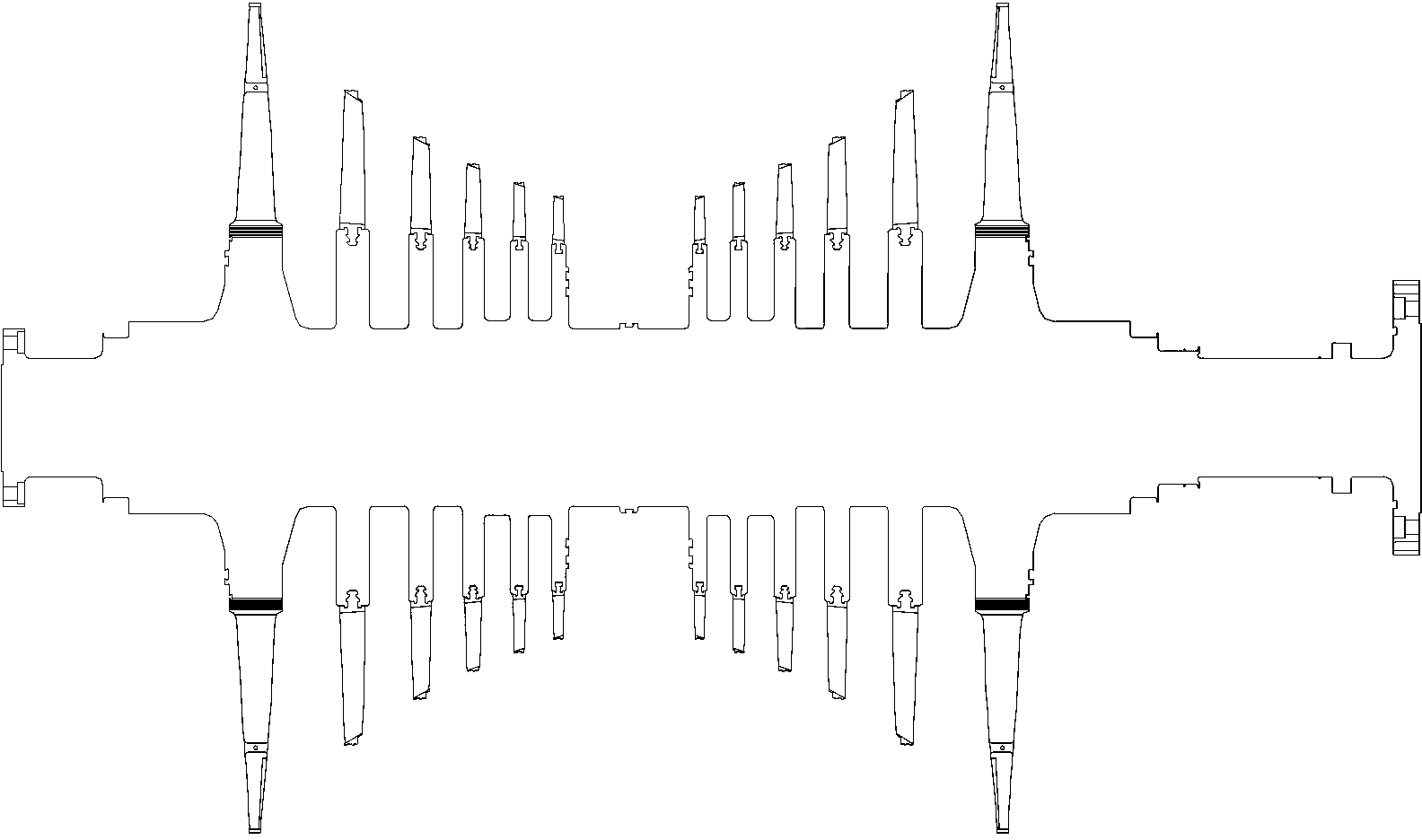

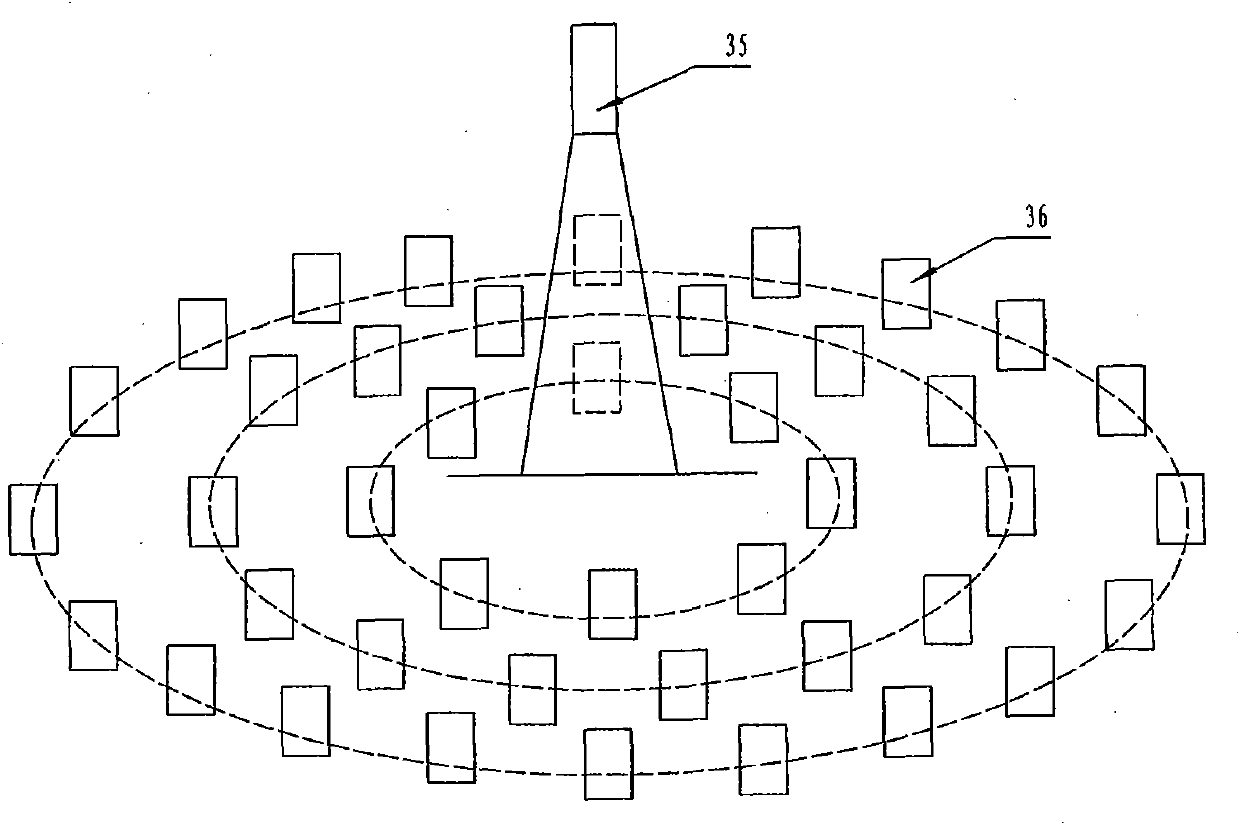

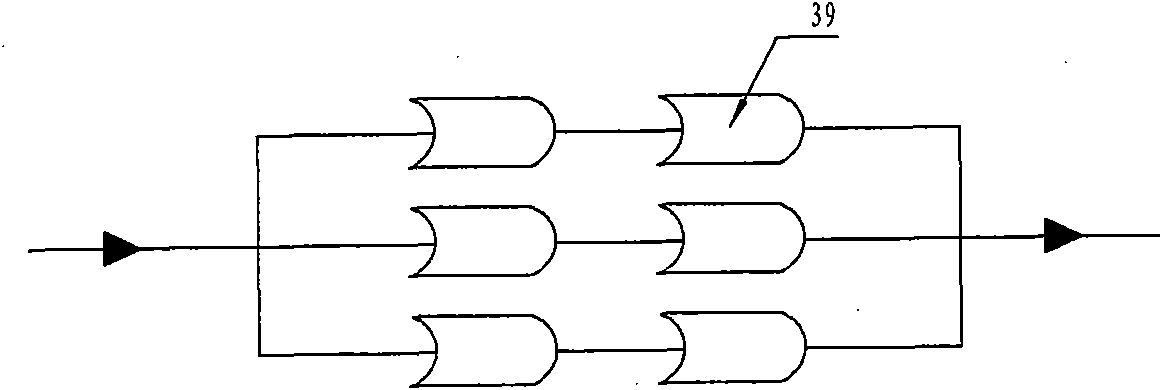

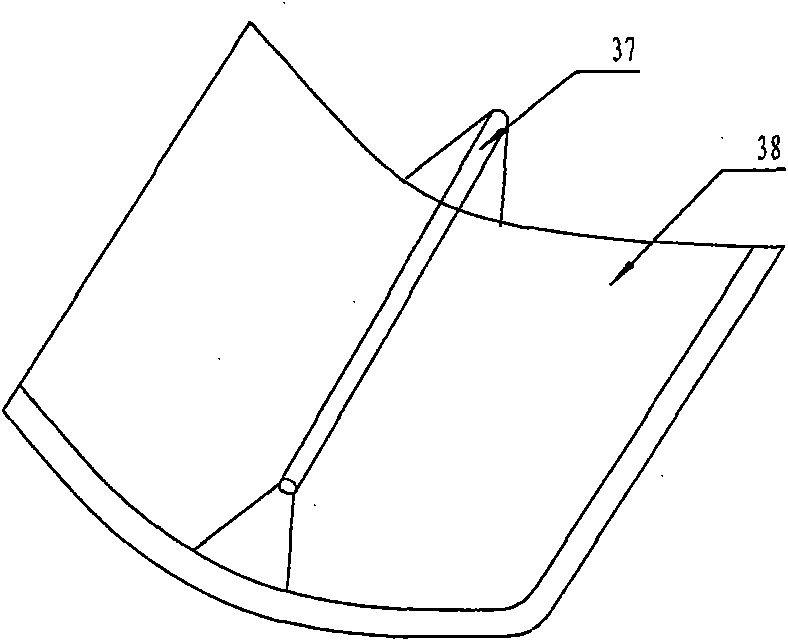

Robot technology of on-line cleaning power plant steam condenser using high pressure water jet

InactiveCN1664486AImprove operational efficiencyMaximize coverage areaRotary device cleaningNon-rotary device cleaningDevice formHigh pressure water

The invention relates to an electric power plant condenser high pressure water shooting flow online washing robot technology that cleans the electric power plant condenser by high pressure water shooting flow. Setting the mechanism arm locating device and high pressure soft tube into the condenser by using the combination method and install structure of locating mechanism arm orientation device formed by extending mechanism arm and rotating mechanism arm, high pressure soft tube manage device, and high pressure spray head control device, locates the spray head on the rotating mechanism arm by computer control system, sends to the inner of the condenser copper pipe, and cleans the dirt in the inner of the condenser copper pipe by high pressure water shooting flow. The generating set needs not stop while cleaning. The invention has advantage of simple structure, no pollution and high reliability.

Owner:CHINA UNIV OF MINING & TECH

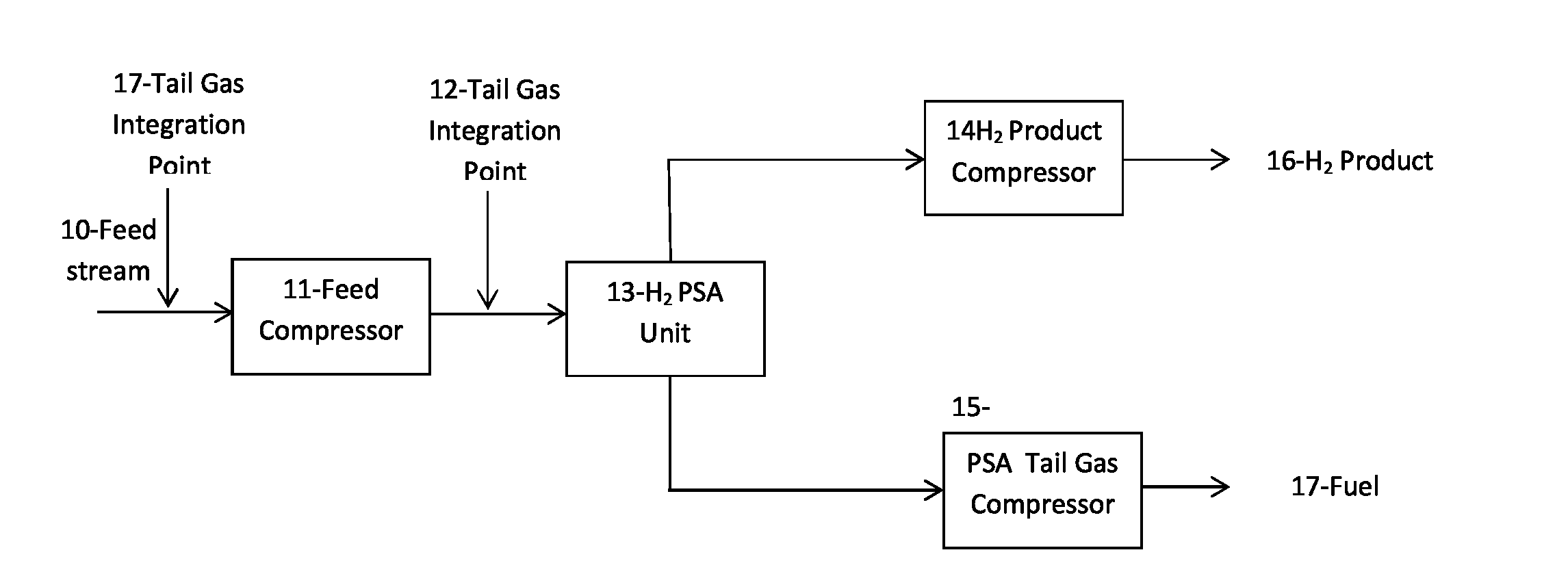

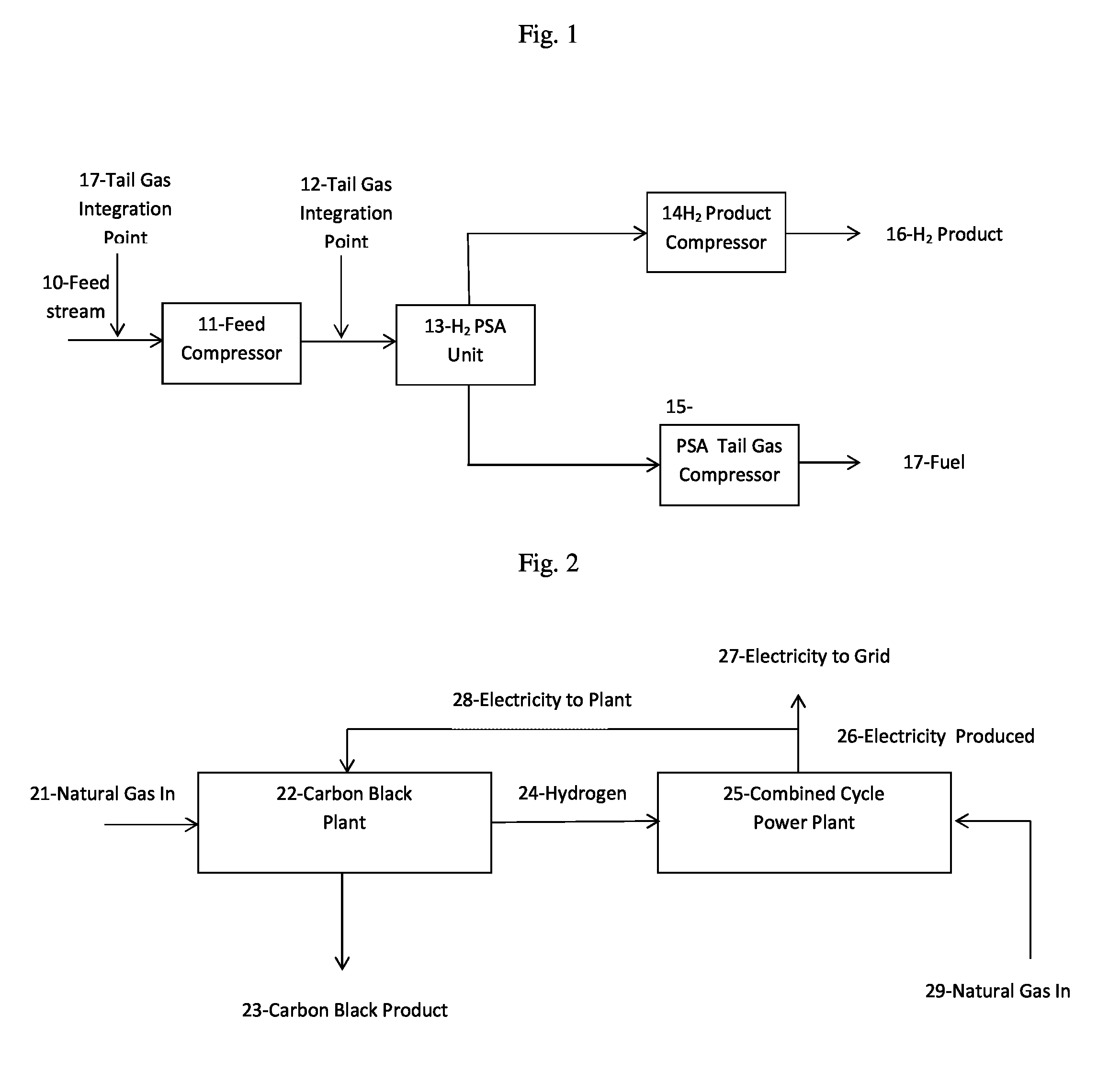

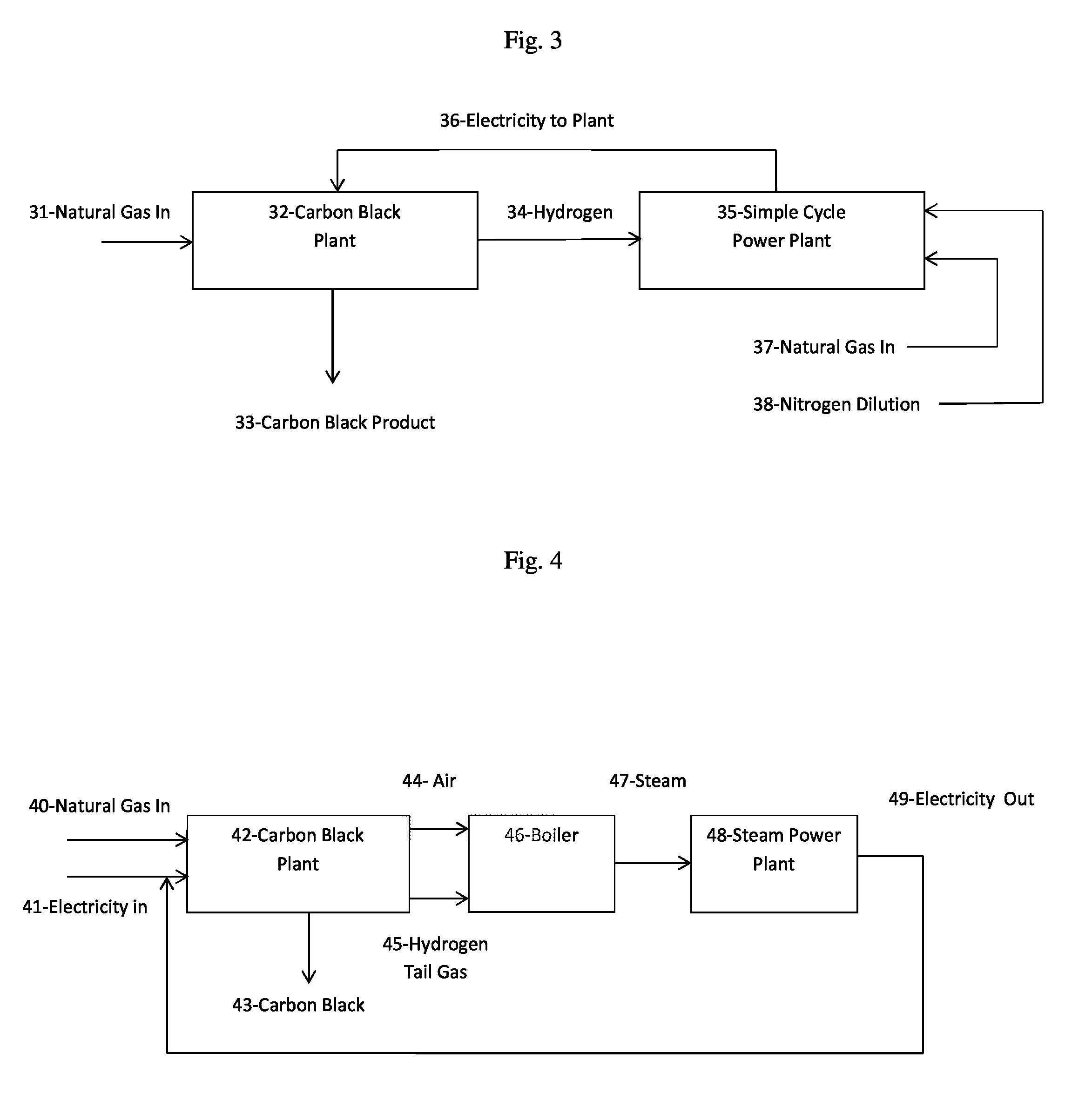

Integration of plasma and hydrogen process with combined cycle power plant, simple cycle power plant and steam reformers

InactiveUS20150211378A1Reducing net air emissionReduce coal consumptionPigmenting treatmentProductsSteam reformingElectric power

The integration of plasma processes with combined cycle power plant, simple cycle power plant, and steam reforming processes. A method of producing purified hydrogen gas and fuel is described including compressing a feed stream of hydrogen, adding tail gas from a plasma process to the feed stream, passing the tail gas modified feed stream into a pressure swing adsorption system generating a purified hydrogen product and a pressure swing adsorption tail gas, separating and compressing the purified hydrogen product, and separating and compressing the pressure swing adsorption tail gas for use as fuel. A method of generating and recapturing electricity from a single or combined cycle power plant is also described including flowing natural gas into a plasma process and hydrogen generating plant, flowing the hydrogen produced into the power plant, flowing natural gas into the power plant, resulting in the production of electricity. The electricity is flowed back into the plasma process plant, and in the case of the combined cycle power plant the electricity is partially flowed into a power grid as well. A method of generating and recapturing electricity from a steam power plant is also described, including inputting electricity and natural gas into a plasma process air and hydrogen generating plant, flowing the air and hydrogen produced into a steam generating boiler, flowing the steam generated into a steam power plant, resulting in the production of electricity which is flowed back into the plasma process plant.

Owner:MONOLITH MATERIALS

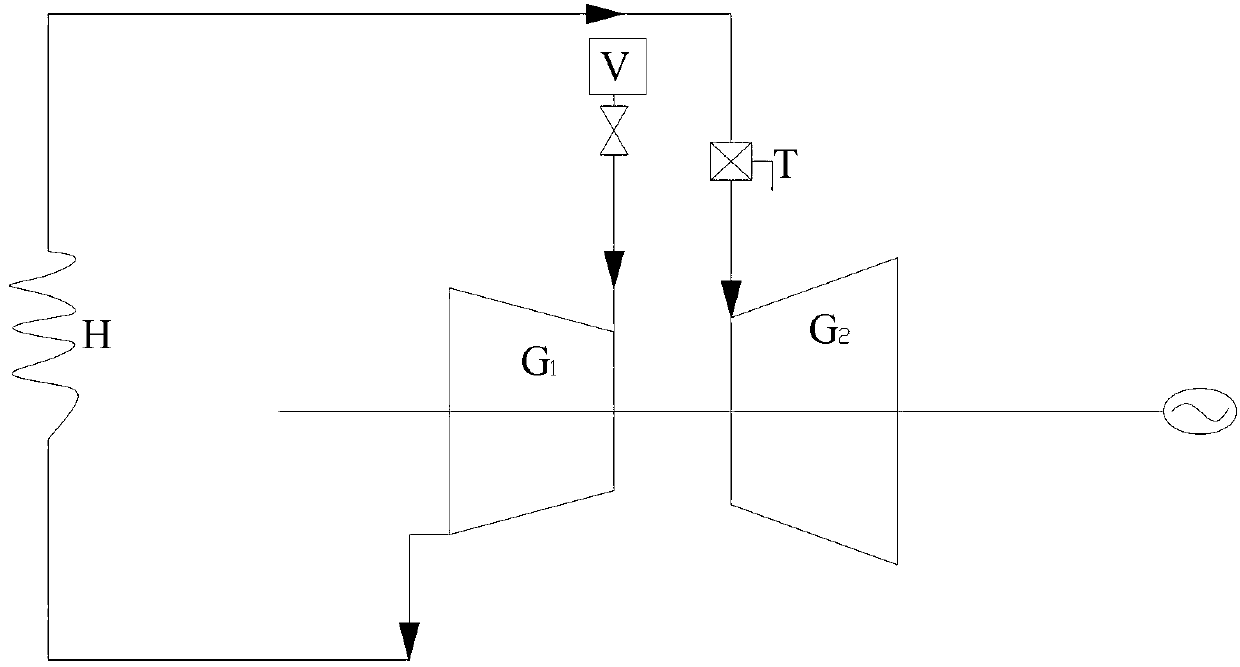

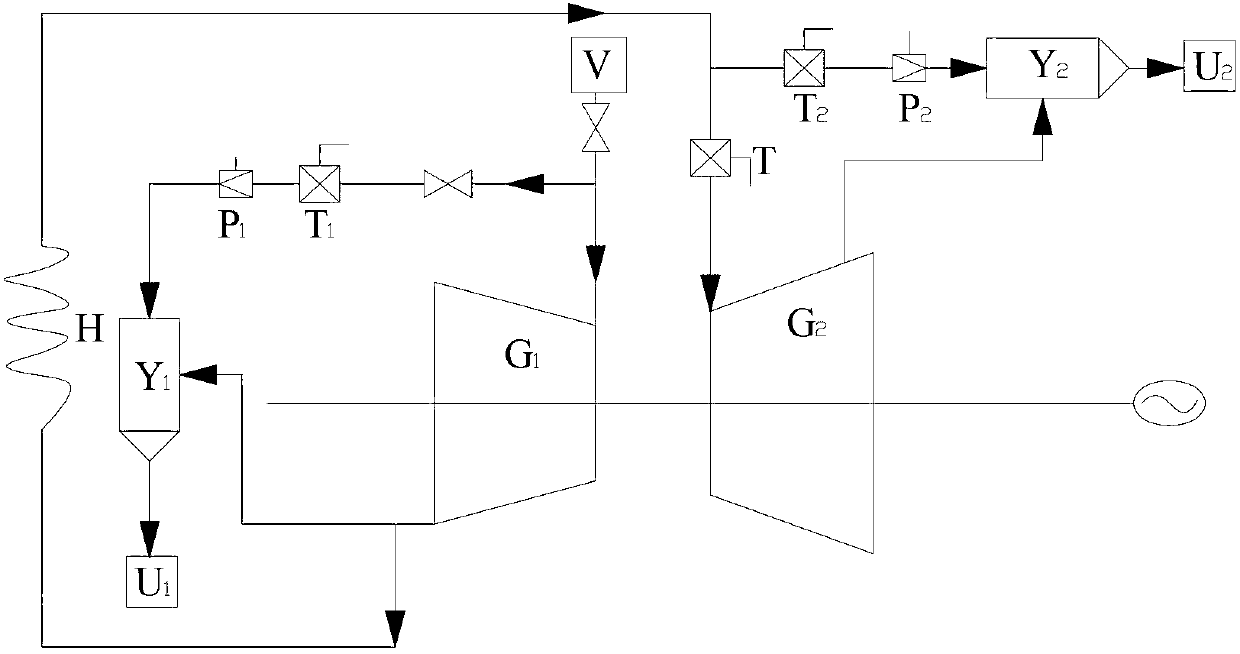

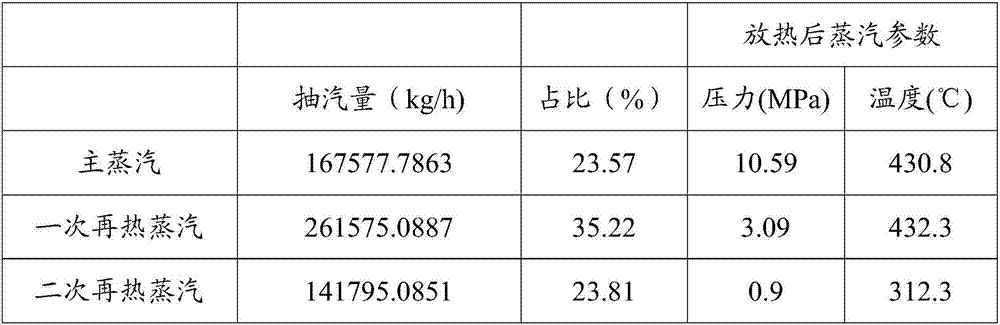

Double-extraction adjustable heating system of thermal power generating unit

ActiveCN102996191ARealize adjustable heatingAdjust supplySteam useCombined combustion mitigationHeating systemEngineering

The invention relates to the field of thermal power generating unit heating modification and discloses a double-extraction adjustable heating system of the thermal power generating unit. By modifying a turbine heating pipeline, a first by-pass pipeline and a second by-pass pipeline connected with a high-pressure cylinder and a medium-pressure cylinder in parallel are arranged on a steam supplying pipeline of the high-pressure cylinder and the medium-pressure cylinder respectively. Each by-pass pipeline is connected with an adjusting gate, a spray type desuperheater and a pressure matcher, and the pressure matcher of the first by-pass pipeline injects exhaust steam of the high-pressure cylinder to achieve high-pressure steam supplying. The second by-pass pipeline injects low-pressure extraction steam of the medium-pressure cylinder to achieve medium-pressure steam supplying. Simultaneously, the opening degree of a middle adjusting gate is adjustable, and the opening degree of the middle adjusting gate is adjusted according to exhaust steam pressure change of the high-pressure cylinder and reheating steam pressure change caused by load change. Therefore, a steam supplying pressure requirement towards the outside is met, qualified steam supplying pressure is guaranteed, a purpose of double-extraction, adjustability and heating of steam of the unit for high-pressure industries and medium-pressure industries is achieved, modification cost of a unit body is saved, and an effect of reducing energy and emission is achieved.

Owner:GUODIAN LONGYUAN ENERGY SAVING TECH

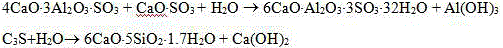

Processing method for recycling aluminum dross

ActiveCN101913634ANo pollutionReduce pollutionAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSocial benefitsPtru catalyst

The invention discloses a processing method for recycling aluminum dross, which comprises the following steps: adding crushed limestone and catalyst to aluminum dross, thoroughly homogenizing and mixing the three materials, carrying out catalyzed calcination on the thoroughly homogenized and mixed materials in a calcination reaction furnace, and directly grinding the calcined products or grinding the calcined products after cooling, thus obtaining the calcium aluminate powder product. The processing method has a simple operational process, and can not cause new environmental pollution, thereby according with the policy for industry development. The invention recycles the aluminum dross, simultaneously reduces environmental pollution caused by the aluminum dross, improves the environmental management on surrounding areas, and also provides a reasonable and effective way to recycle waste aluminum dross. Thus, the invention has obvious economic benefits and social benefits.

Owner:HENAN KETAI WATER PURIFYING MATERIALS

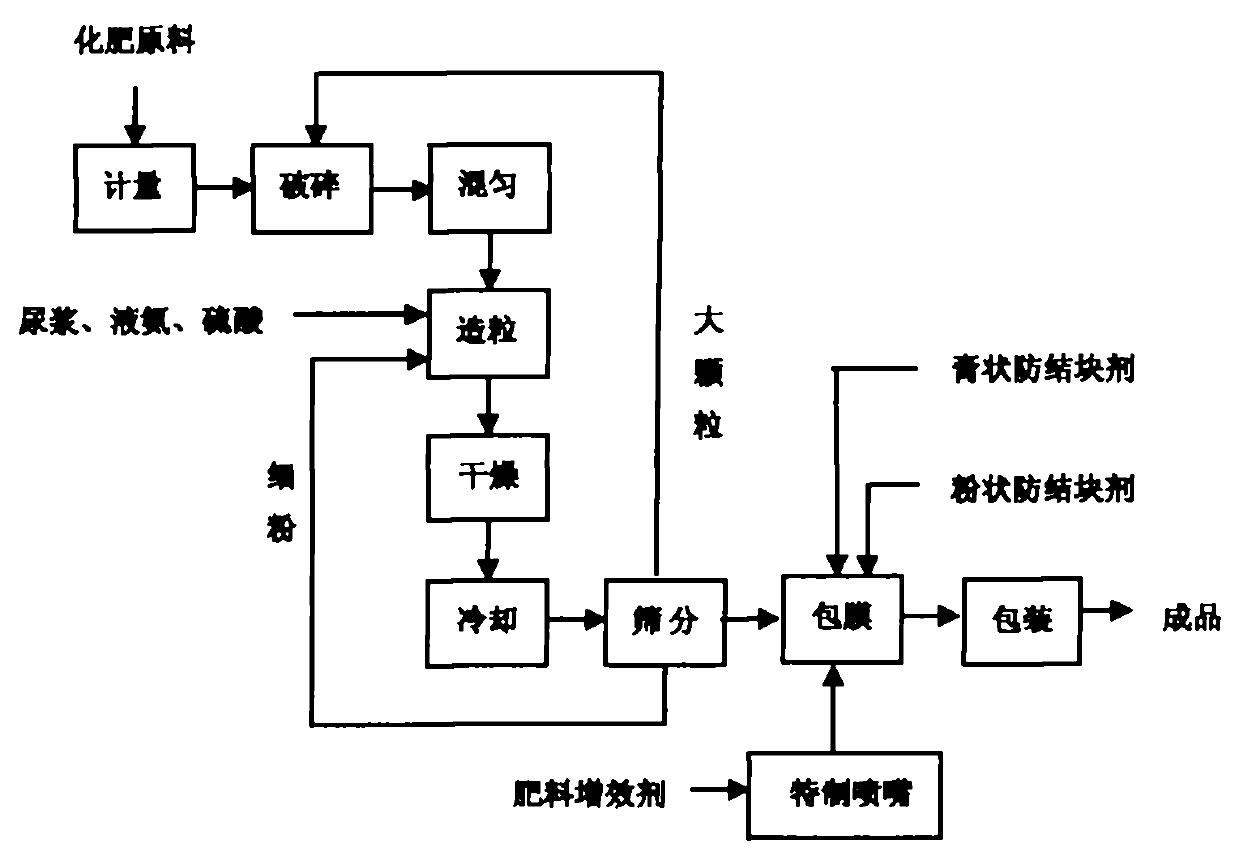

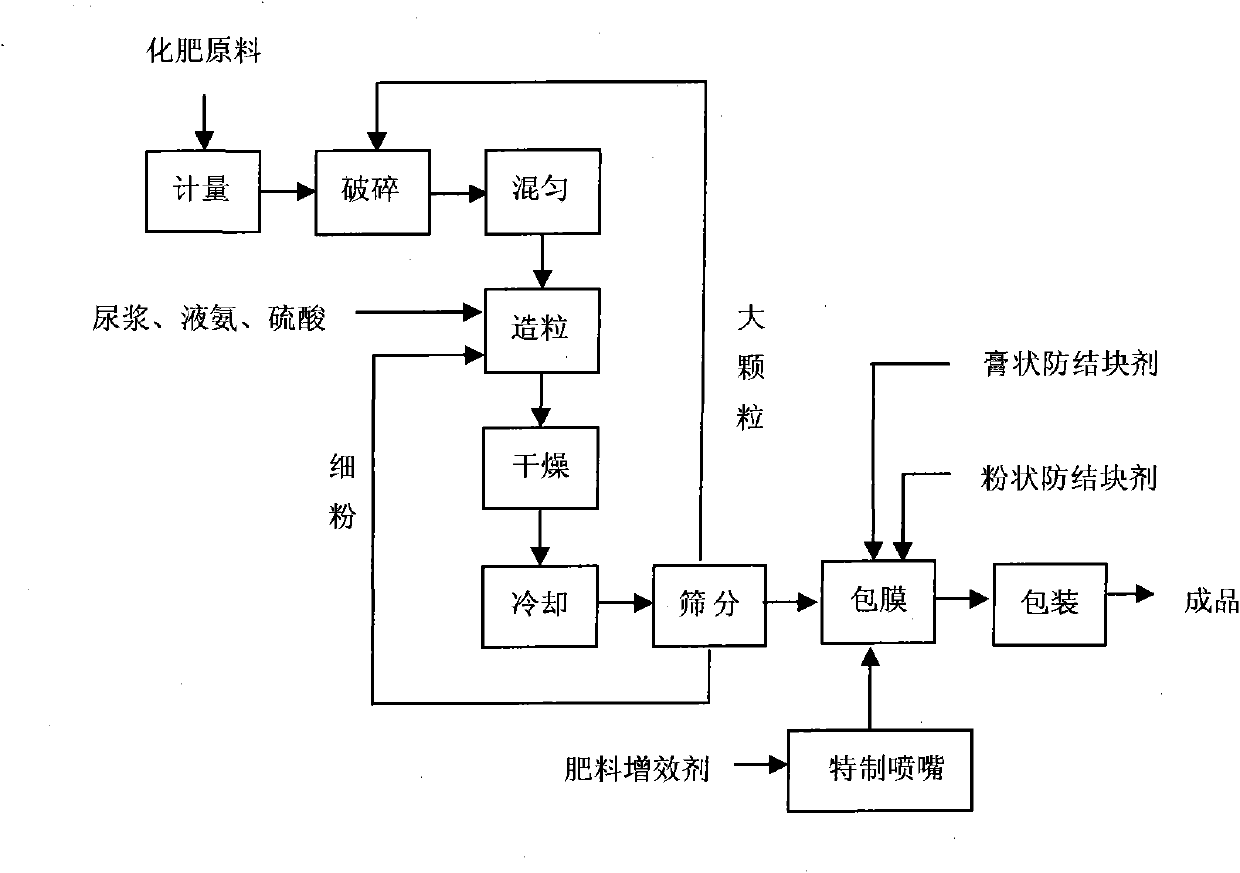

Filler-free synergistic compound fertilizer produced by urine syrup ammonia-acid method and production method thereof

The invention discloses a filler-free synergistic compound fertilizer produced by a urine syrup ammonia-acid method to pelletize and a production method thereof. The production method thereof comprises the following steps: selecting raw materials according to the product formulation, and metering, crushing and evenly mixing the raw materials; adopting the urine syrup ammonia-acid revolving drum pelleting process, carrying out first-segment drying, second-segment cooling and coarse and fine screening on the mixture, and then feeding the screened mixture into a coating machine; utilizing the front end of the coating machine to spray fertilizer synergist by a continuous pulverization coating method, utilizing the middle end of the coating machine to spray pasty anti-blocking agent, and utilizing the tail end of the coating machine to add powdery anti-blocking agent; and adequately stirring and packaging to obtain the finished product. The filler-free synergistic compound fertilizer produced by the pelleting process of the urine syrup ammonia-acid method has small investment, simple operation, low production cost, obvious energy conservation effect, beautiful product appearance, good dissolubility and improved nutrient utilization ratio; and after the filler-free synergistic compound fertilizer is applied to crops, production and income are increased.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

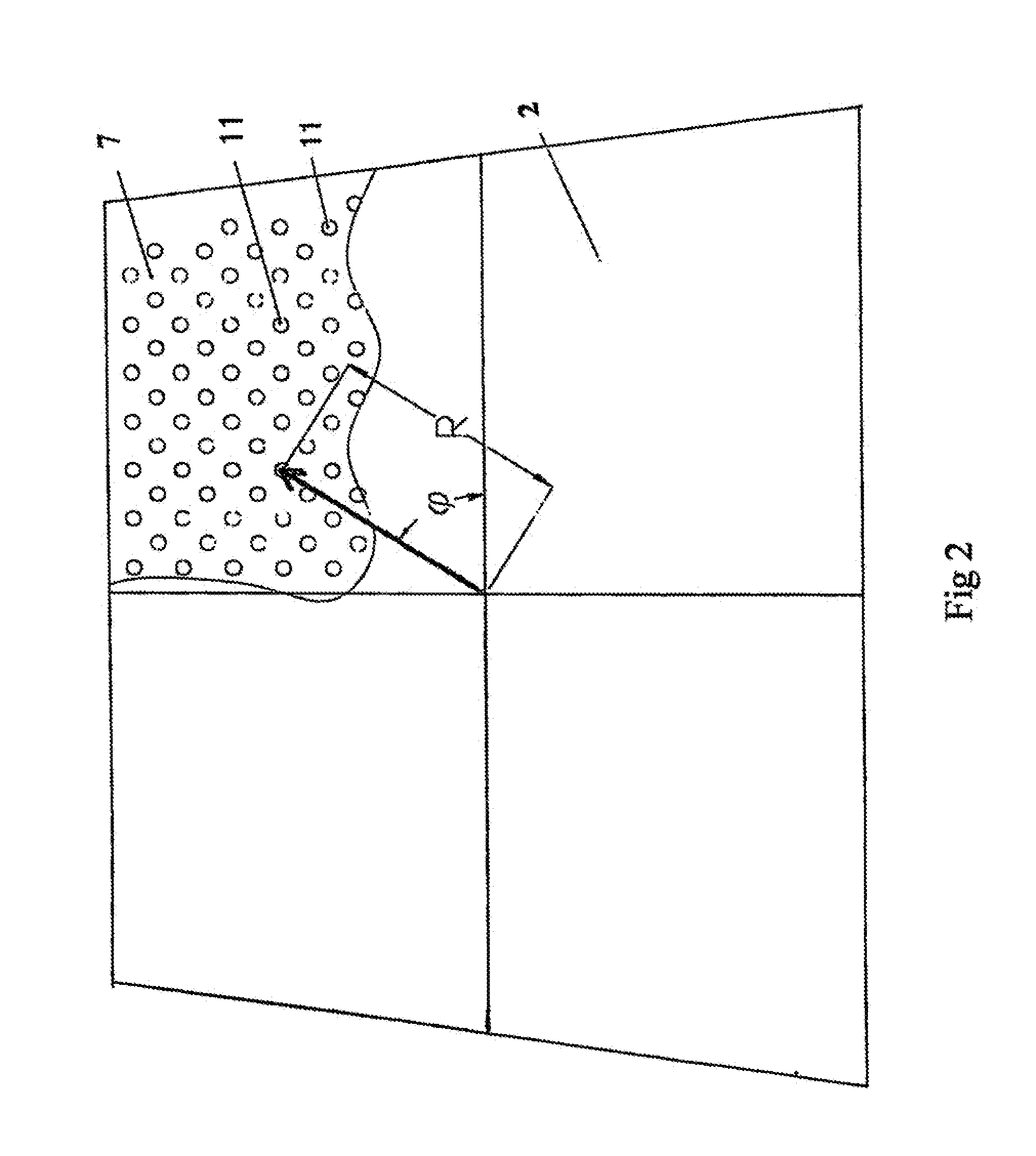

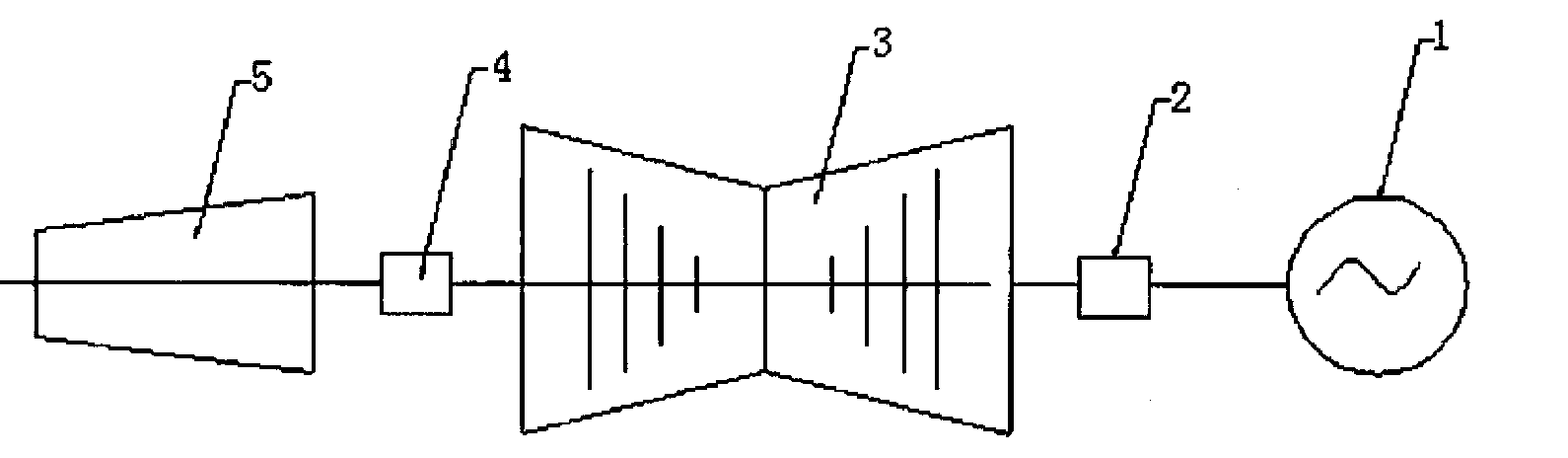

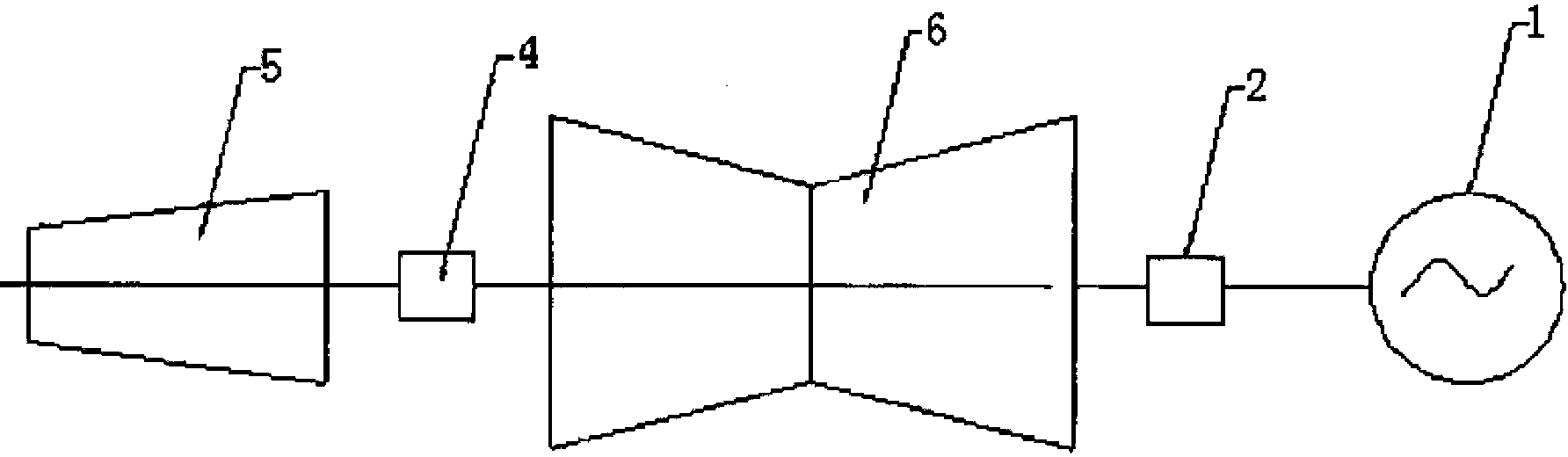

On-Line Automatic Cleaning Device For A Condenser In A Turbine Generator

InactiveUS20080185126A1Improve heat transfer efficiencyReduce coal consumptionHollow article cleaningBoiler cleaning apparatusEngineeringTitanium

A device and method to perform on-line automatic flushing and cleaning for a steam turbine generator condenser, related with technology for flushing and cleaning of equipment during steam turbine generator operation, the apparatus includes: a polar coordinate traveling mechanical system, including one computer program polar coordinate control unit, which will control the servo motors to position the high-pressure water jet on the opening for Copper tube (or Titanium tube); the benefit for the invention is that, the polar coordinate traveling mechanical system move the high-pressure water jet to flush and clean each Copper tube (or Titanium tube) on condenser tube plate, to realize high-pressure water cleaning for each pipe during operation of generator, therefore, the heat exchanging efficient can be increased, further to reduce the consumption of coal for steam turbine generator, and archive the aim to saving coal, and reduction in generating cost.

Owner:JIANG CONGQUAN

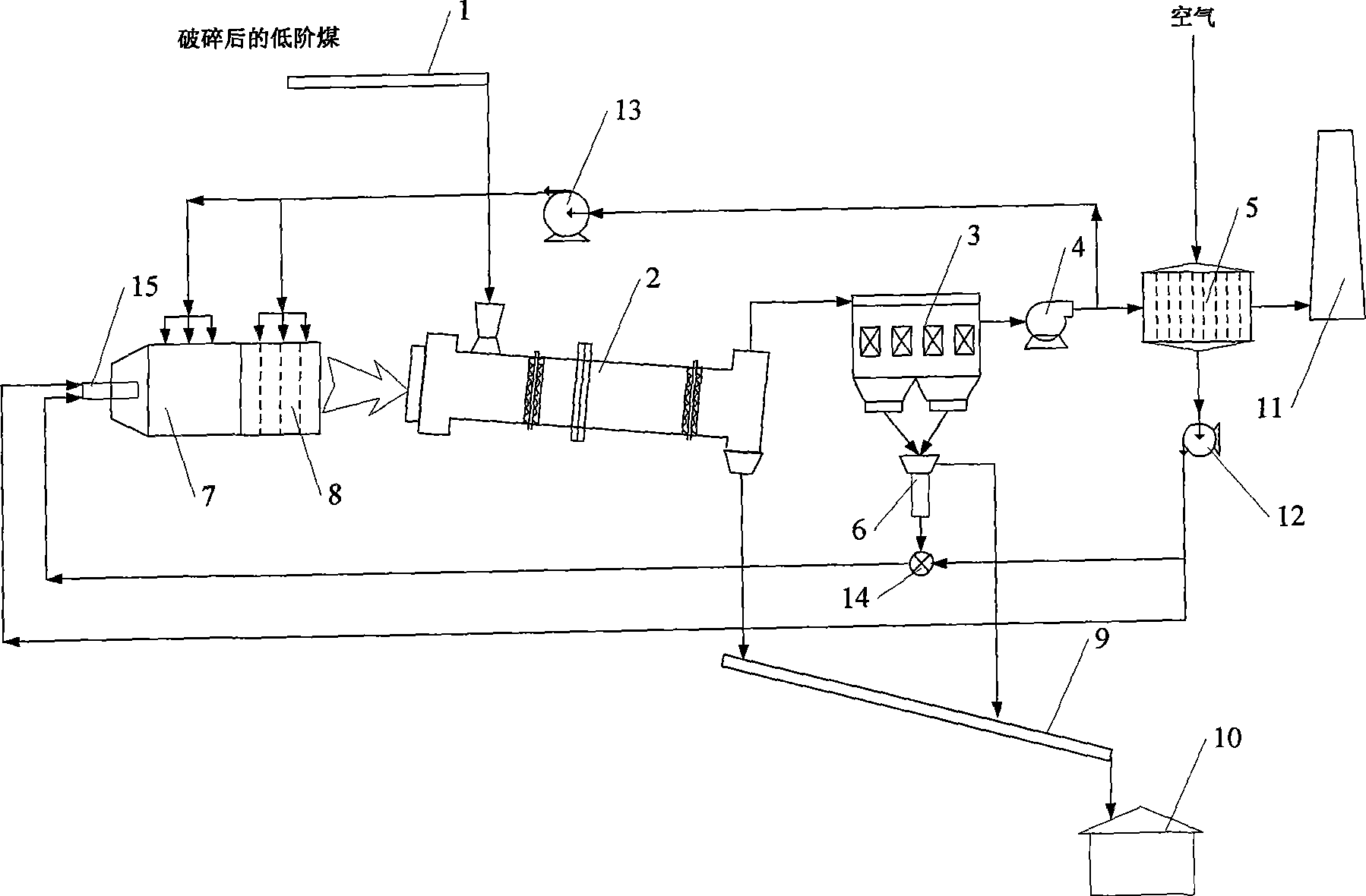

Low-rank coal drying method and system

InactiveCN101476814AReduce pollutionLow costDrying solid materials with heatDrying gas arrangementsComing outAir preheater

The invention discloses a method for drying low-rank coal, which comprises the following steps: (1) the low-rank coal is crushed, and the arrange of a grain diameter of the crushed low-rank coal is between 3 and 50mm; (2) the crushed low-rank coal is sent into a dryer and contacts hot flue gas which comes from a hot flue gas generation device; (3) the low-rank coal which comes out of the dryer is collected, and the hot flue gas discharged by the dryer as well as coal powder and water vapor which are carried by the hot flue gas are aerated into a coal powder treatment and acquisition system at the same time; (4) at least partial coal powder collected by the coal powder treatment and acquisition system is sent to the hot flue gas generation device to serve as a combustion material; (5) the hot flue gas which comes out of the coal powder treatment and acquisition system is divided into two parts, wherein the first part of flue gas circularly returns to the hot flue gas generation device, and the second part of the flue gas is discharged after heating combustion air through an air pre-heater; and (6) the heated combustion air is conveyed to the hot flue gas generation device to take part in the combustion. The invention also provides a low-rank coal drying system with self-supplied fuel, which has the advantages of high energy utilization rate and low production cost.

Owner:DATANG INT CHEM TECH RESINST +1

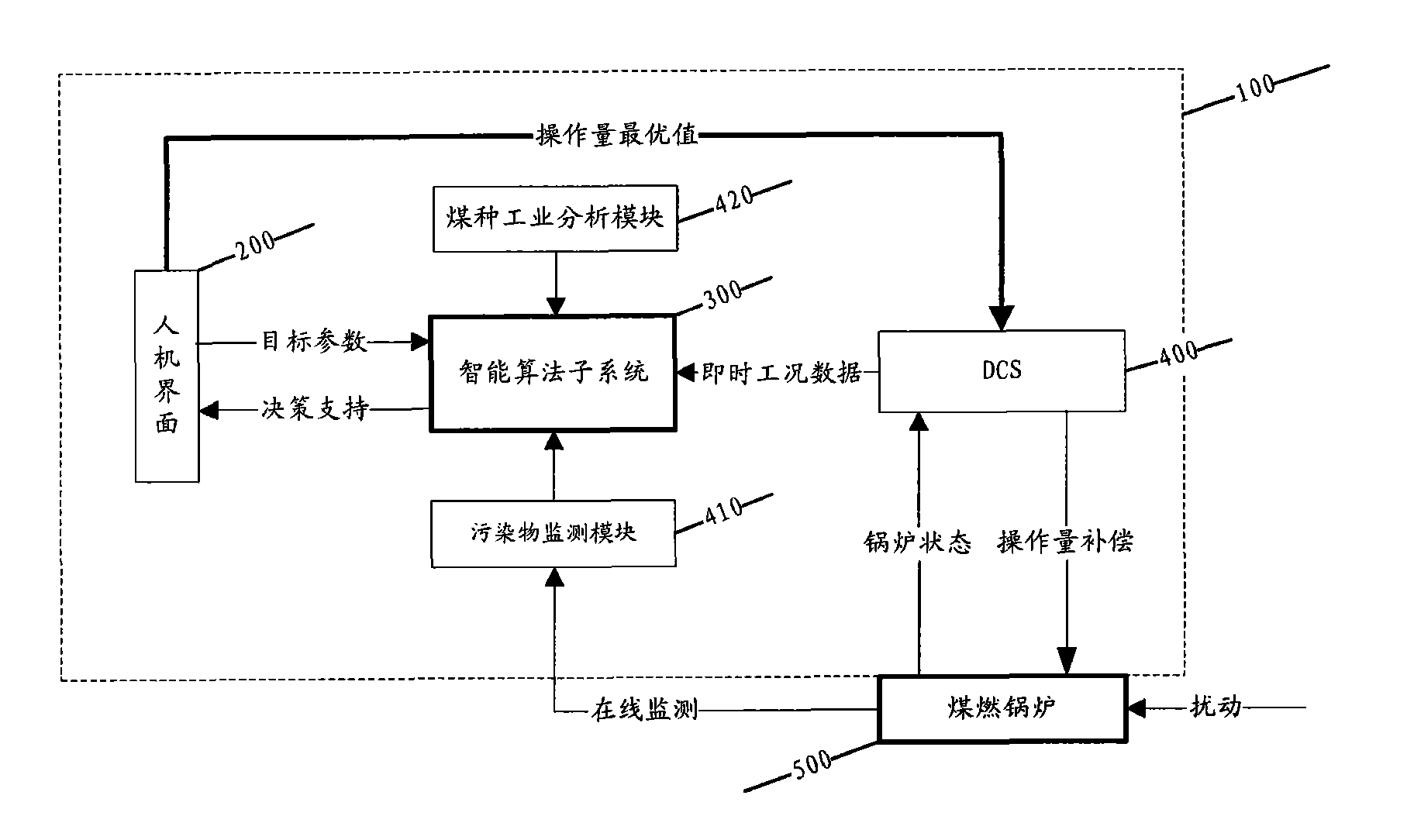

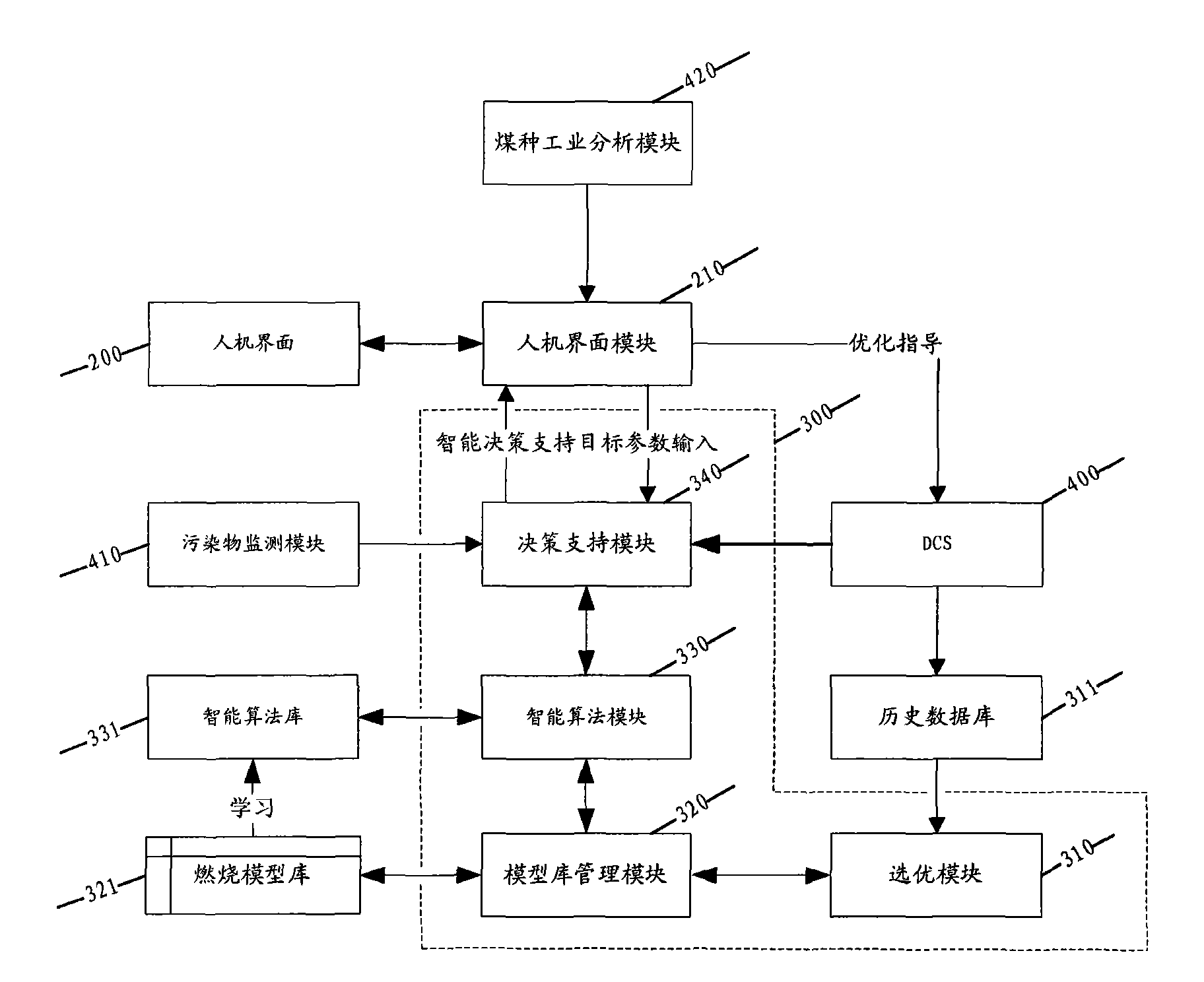

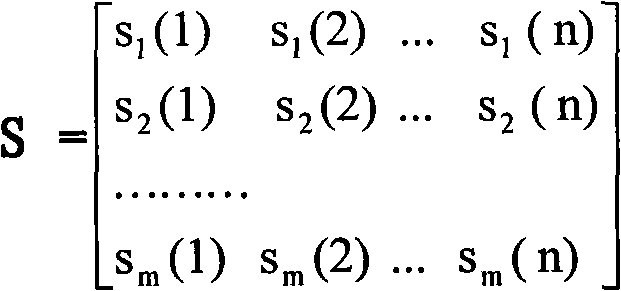

Thermal power generation boiler intelligent combustion optimizing system and realizing method thereof

InactiveCN101634459AEmission reductionReduce coal consumptionProgramme total factory controlCombustion regulationHuman–machine interfaceSystems analysis

The invention aims to provide a thermal power generation boiler intelligent combustion optimizing system and a realizing method thereof, belonging to the relevant technical fields of energy sources, environmental protection, software information, and the like. The system mainly comprises a human-computer interface module and an intelligent algorithm subsystem, wherein a boiler operator can configure relevant parameters of coal species, and the like by the human-computer interface module, and the human-computer interface module can provide an optimized target for the whole system and clearly display an optimized model predicted by the system; and the intelligent algorithm subsystem generates a combustion optimizing model under the guide of the human-computer interface module according to information provided by a distributed control system (DCS) and an environmental pollutant monitoring module. The invention can provide the boiler performance optimized real-time online analyzing function for a front-line staff of a power plant, analyze the optimized parameter and the optimized target of a boiler system by the system and provide a concrete performance optimizing measure and a technical guide.

Owner:陶晓鹏 +1

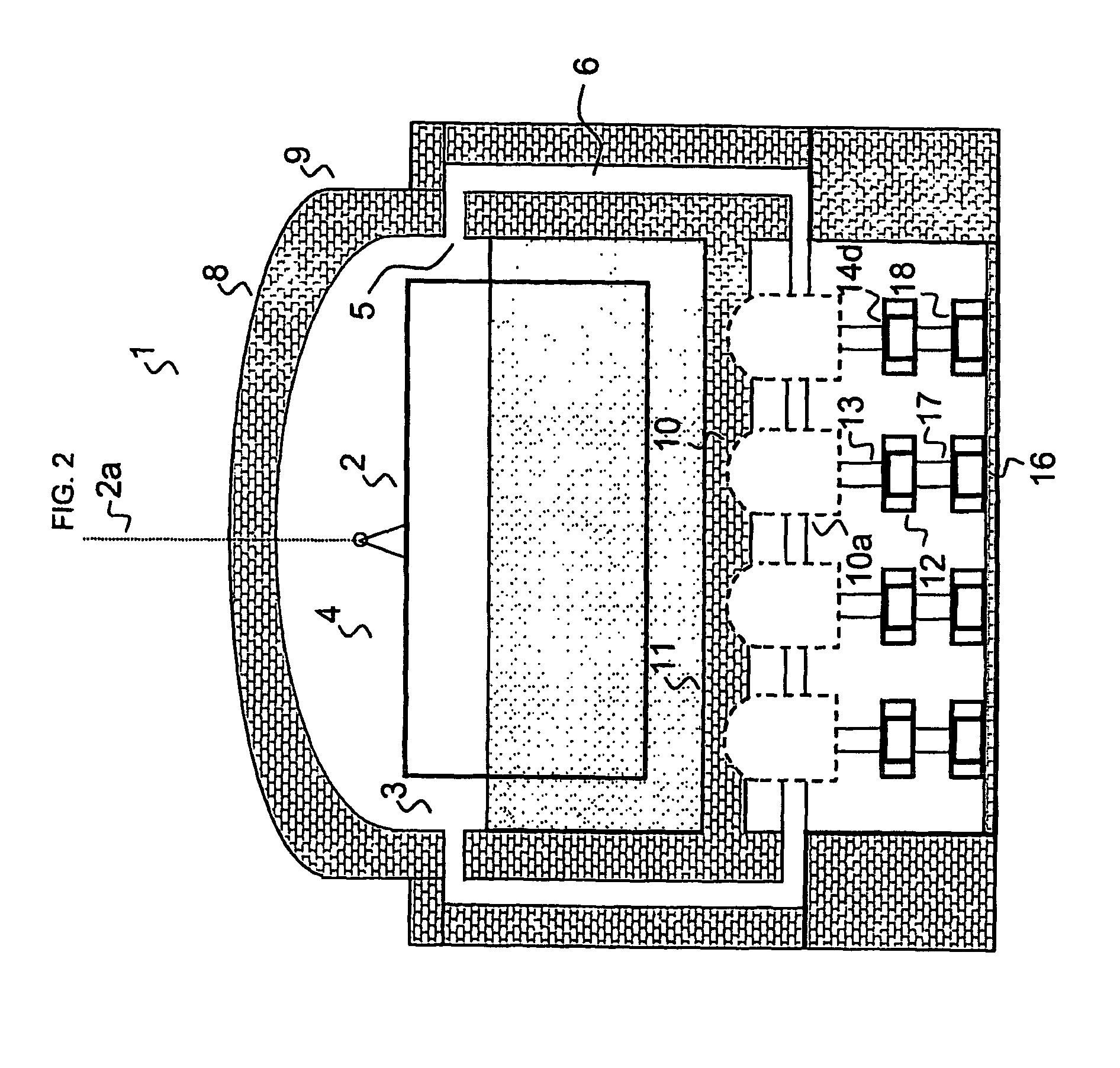

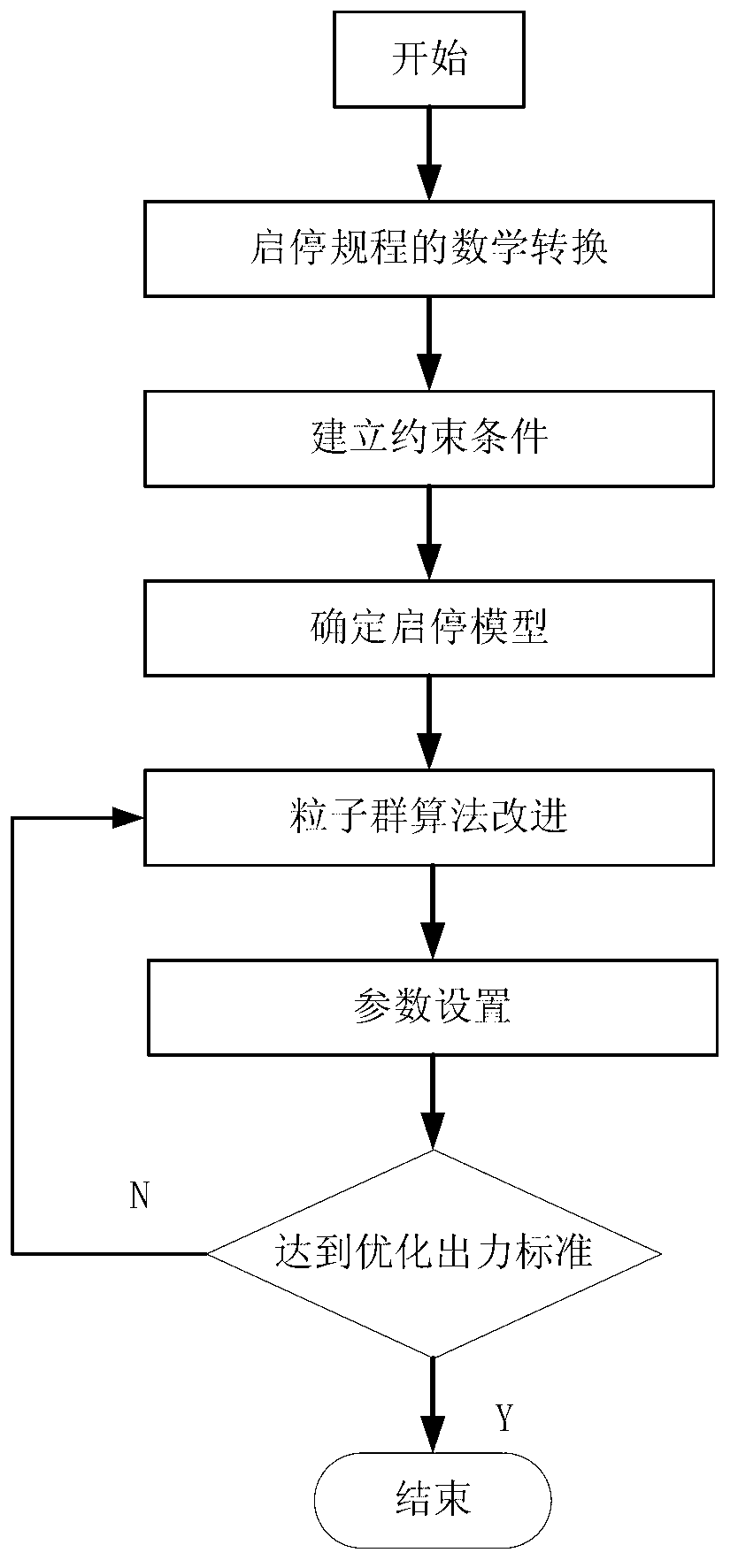

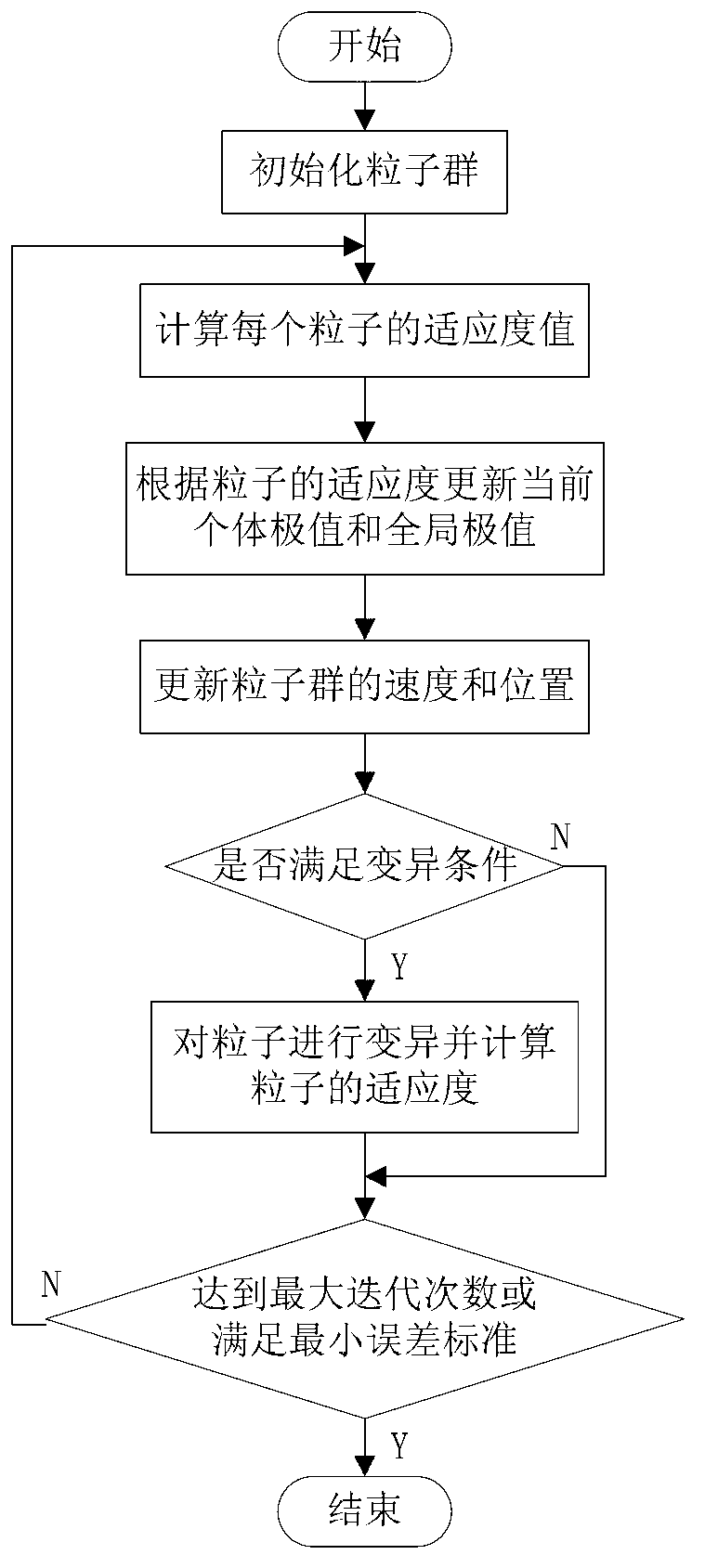

Energy-saving optimization method for output of coal pulverizer in power station

ActiveCN103056016AMeet the output requirementsReduce running timeGrain treatmentsLocal optimumPower station

The invention provides an energy-saving optimization method for the output of a coal pulverizer in a power station. The method comprises the following steps: S1, mathematic conversion of start-up and shut-down rules; S2, establishment of constraint conditions; S3, determination of a start-up and shut-down model; S4, improvement of particle swarm algorithm, wherein aimed at the problem of improvement, a mutation operator is introduced at a later search stage of a PSO algorithm, a PSO algorithm with the mutation operator is brought forward, which enables restraints by a locally optimal solution in the later search stage of the PSO algorithm to be overcome, and the PSO algorithm with the mutation operator retains the characteristic of a fast search speed at an early stage of the PSO algorithm; S5, setting of parameters; and S6, optimization, wherein the set parameters are input into the start-up and shut-down model, and computational results are obtained. According to the invention, optimized operation of the coal pulverizer and complex on-site working conditions are fully considered, so the start-up and shut-down optimization model of the coal pulverizer is more accurate and practical; an optimized start-up and shut-down combined mode of the coal pulverizer can basically satisfy requirements for output of the coal pulverizer during operation of a unit, operation time under the condition of low output of the coal pulverizer is shortened, coal-grinding efficiency of the coal pulverizer is improved, and thus, coal consumption of the unit is reduced.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Close hothouse loose-tobacco loading method

The invention discloses a loose tobacco filling method for a bulk curing barn, which comprises the following steps: firstly, manufacturing fixed square bars, a loose tobacco air-distributing partition board and metal contact pins, arranging a tobacco filling bracket and a fixed groove in the bulk curing barn, horizontally placing the air-distributing partition board on the tobacco filling bracket in the curing barn, and inserting the fixed square bars into the fixed groove; and loosing bundled tobacco leaves before tobacco filling, stacking the loose tobacco leaves with leaf tips upward and leaf bases downward, filling the fresh tobacco leaves into two fixed square bars tidily, then inserting the contact pins into holes of the fixed square bars to fix the tobacco leaves, and curing the tobacco leaves after the curing barn is fully filled with the tobacco leaves. The method has the following advantages: (1) the tobacco filling amount is large and is increased by 30 percent compared with a rod hanging method and increased by 10 percent compared with a loose tobacco stacking method, and the utilization rate of the curing barn is high; (2) the method saves labor and energy, saves about 70 percent of labor, and reduces coal and electricity consumption by 20 percent; (3) the method fills the tobacco tidily and reserves even gaps for the tobacco leaf bases, so the method is favorable for discharging moisture and prevent the tobacco leaves form smoothening and not stretching, and the method is easy to control the curing operation; (4) the structure is simple, and the material cost is reduced by 60 percent; and (5) the bulk curing barn is convenient to load and unload.

Owner:GUIZHOU TOBACCO SCI INST

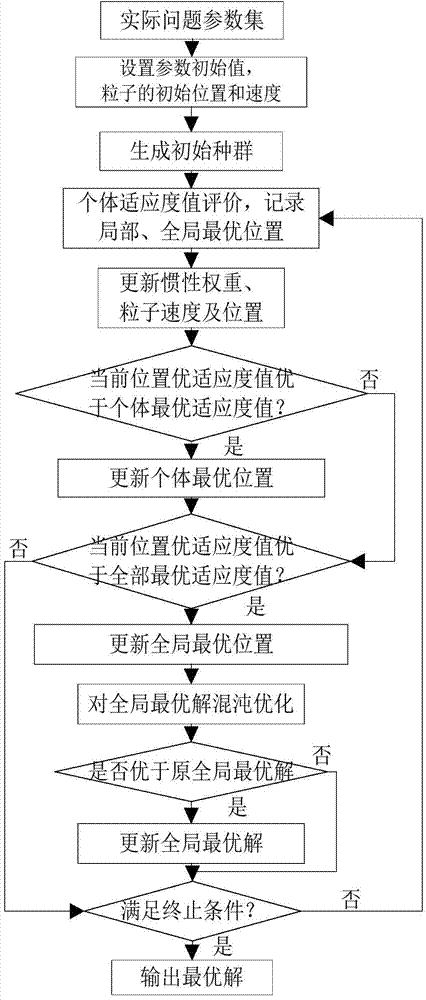

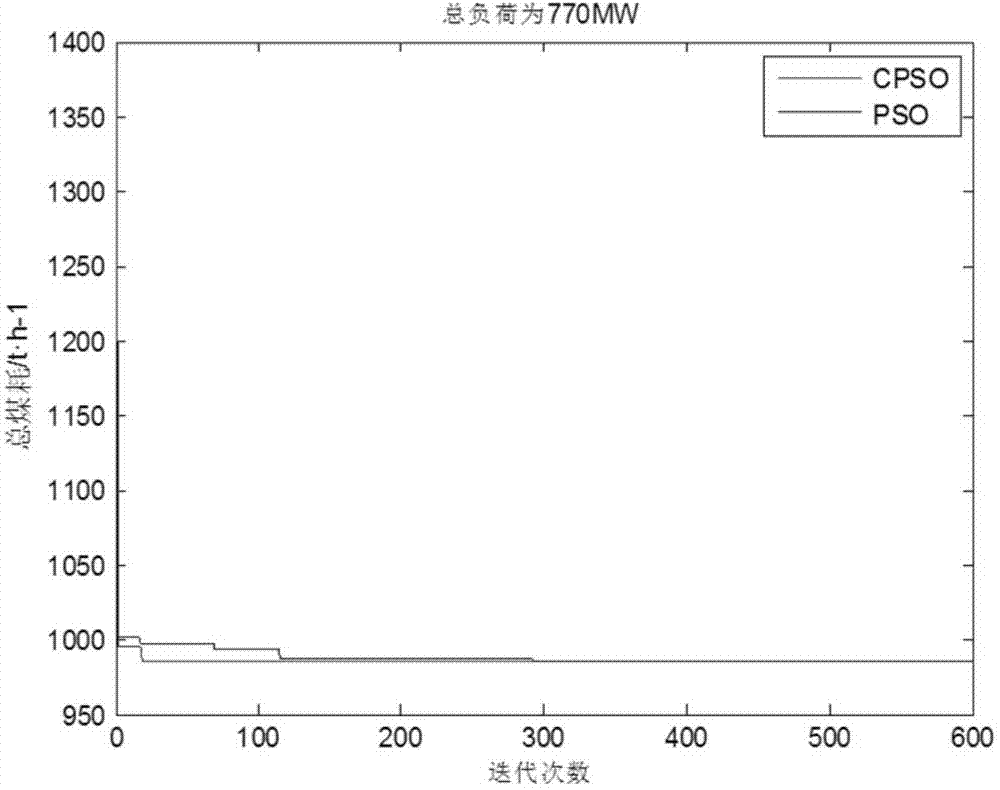

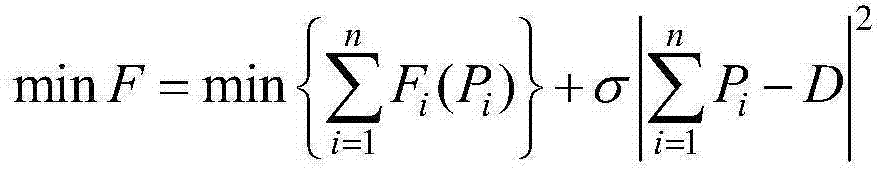

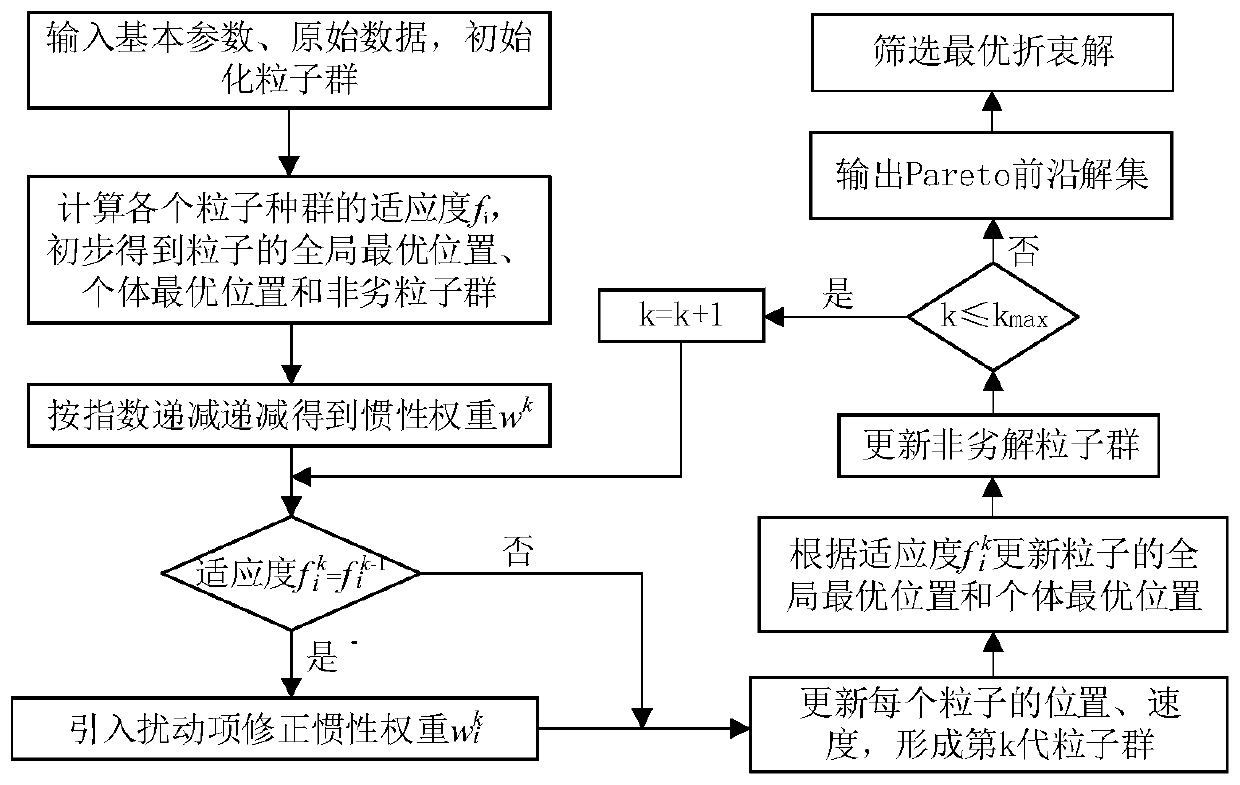

Chaos particle swarm based thermal power unit load optimal distribution method

ActiveCN104850908AReduce coal consumptionReduce coal consumption for power supplyForecastingSystems intergating technologiesGenerating unitParticle swarm algorithm

The invention relates to a chaos particle swarm based thermal power unit load optimal distribution method, which comprises the steps of fitting a coal consumption characteristic curve according to coal consumption characteristic parameters of a power generating unit, establishing a load optimal distribution model, converting the load optimal distribution model into a non-restraint problem through a penalty function method, distributing the total generation power to each unit by being combined with a chaos particle swarm algorithm, and finally acquiring an optimal load distribution result of each unit. Compared with the prior art, the method provided by the invention can distribute the optimal output point of each power generating unit scientifically and reasonably under the given total generation power, thereby enabling power supply coal consumption of the unit after optimization to be obviously reduced.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for comprehensively recovering iron and germanium from zinc calcine containing high iron and high indium

InactiveCN102703695AShort processSimple methodPhotography auxillary processesProcess efficiency improvementIndiumSlag

The invention discloses a method for comprehensively recovering iron and germanium from zinc calcine containing high iron and high indium. The method comprises the following steps of: leaching the zinc calcine containing the indium, the germanium and zinc by using a sulfuric acid, sending a solution to electrolyze the zinc, leaching a leaching residue by using a low acid, merging with a high-lead residue together to leach by using a high-temperature high acid, adding a hydroximic acid and P204 kerosene to synergistically extract the indium and the germanium to respectively acquire an indium ingot and a germanium concentrate, and recycling extracting liquid after the iron is recovered. By using the method, the germanium and the indium can be extracted from slag with a lower grade; a procedure is simple; the operation is easy; and fewer pollutants are discharged.

Owner:GUANGXI JINSHAN INDIUM & GERMANIUM METALLURGICAL CHEM

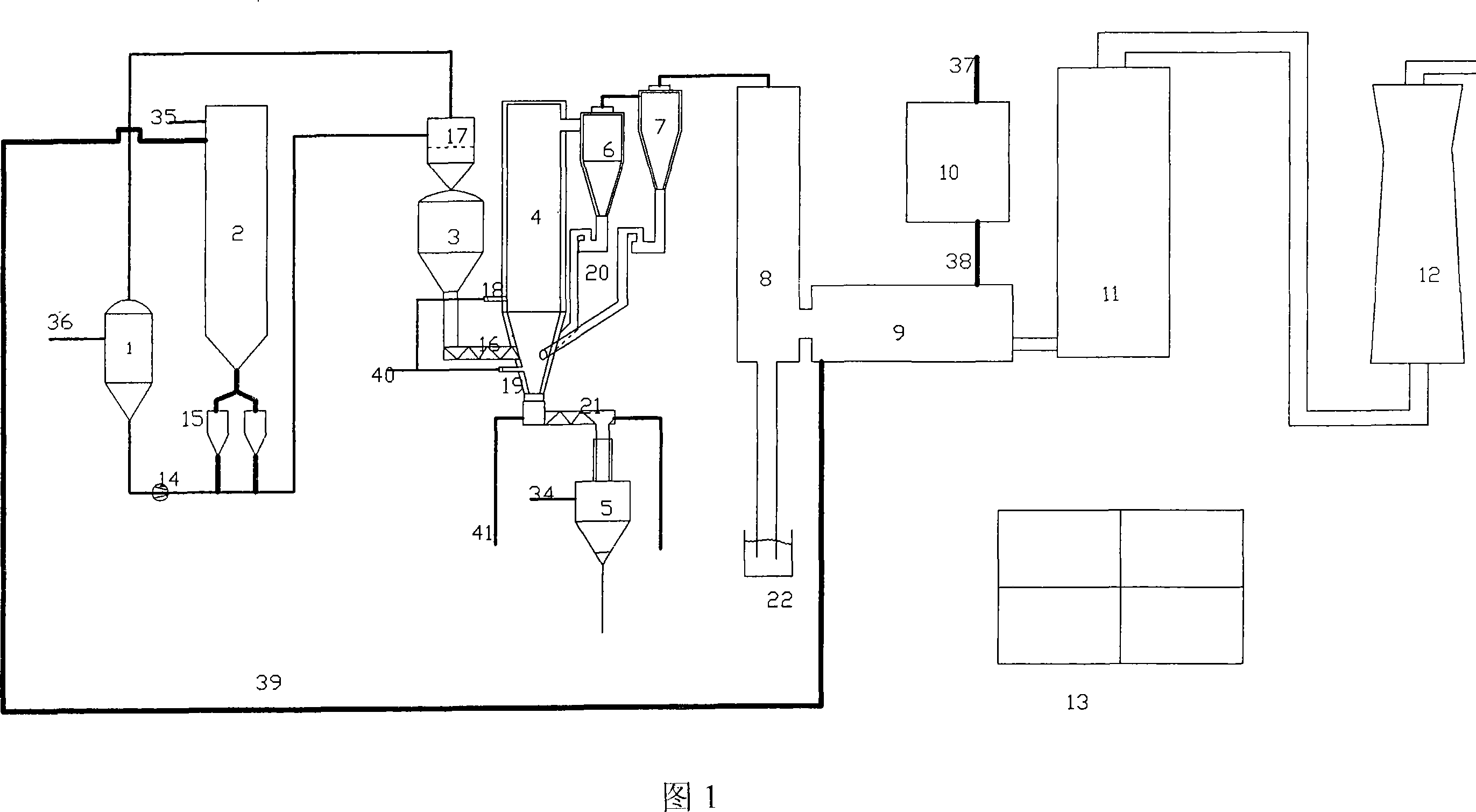

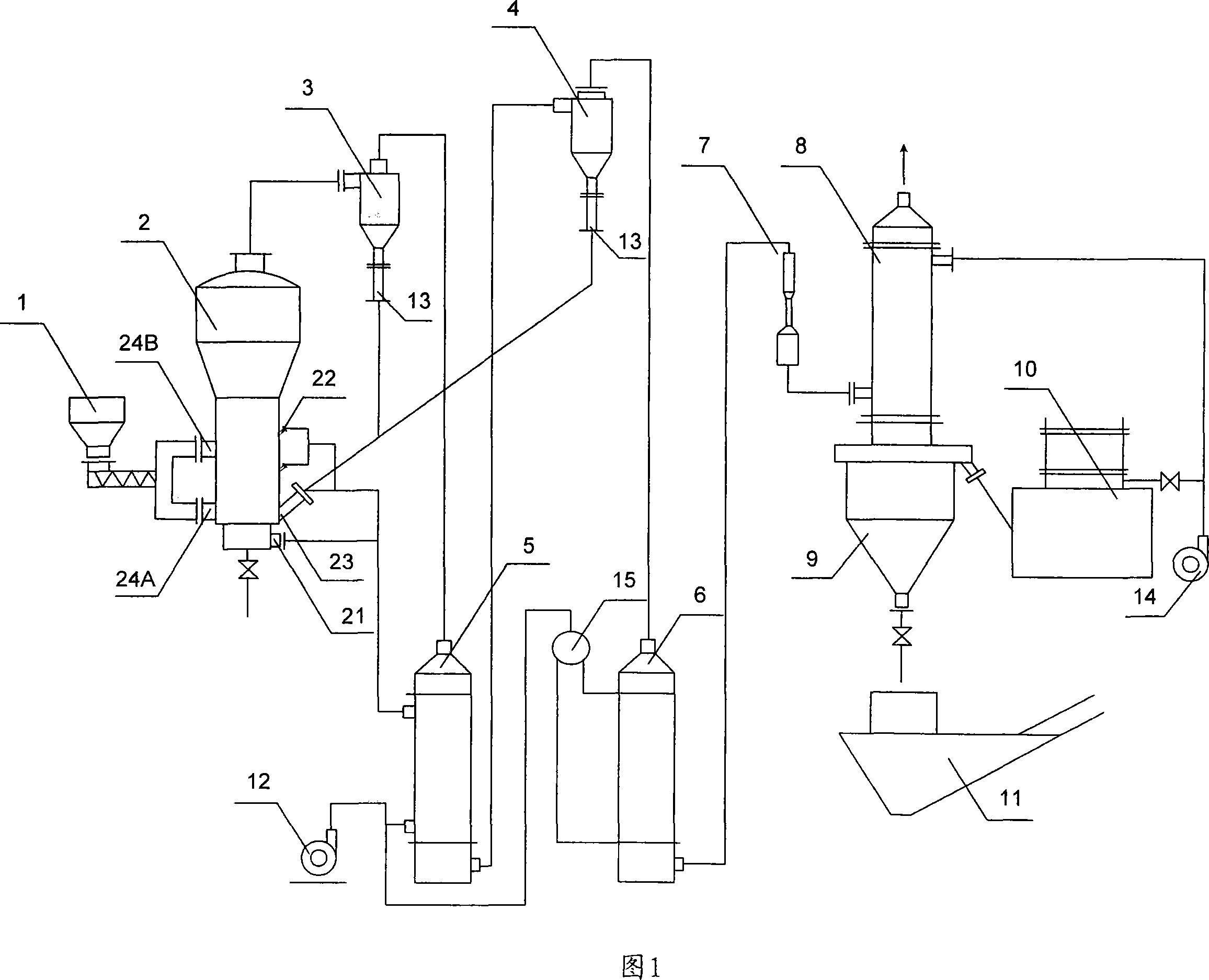

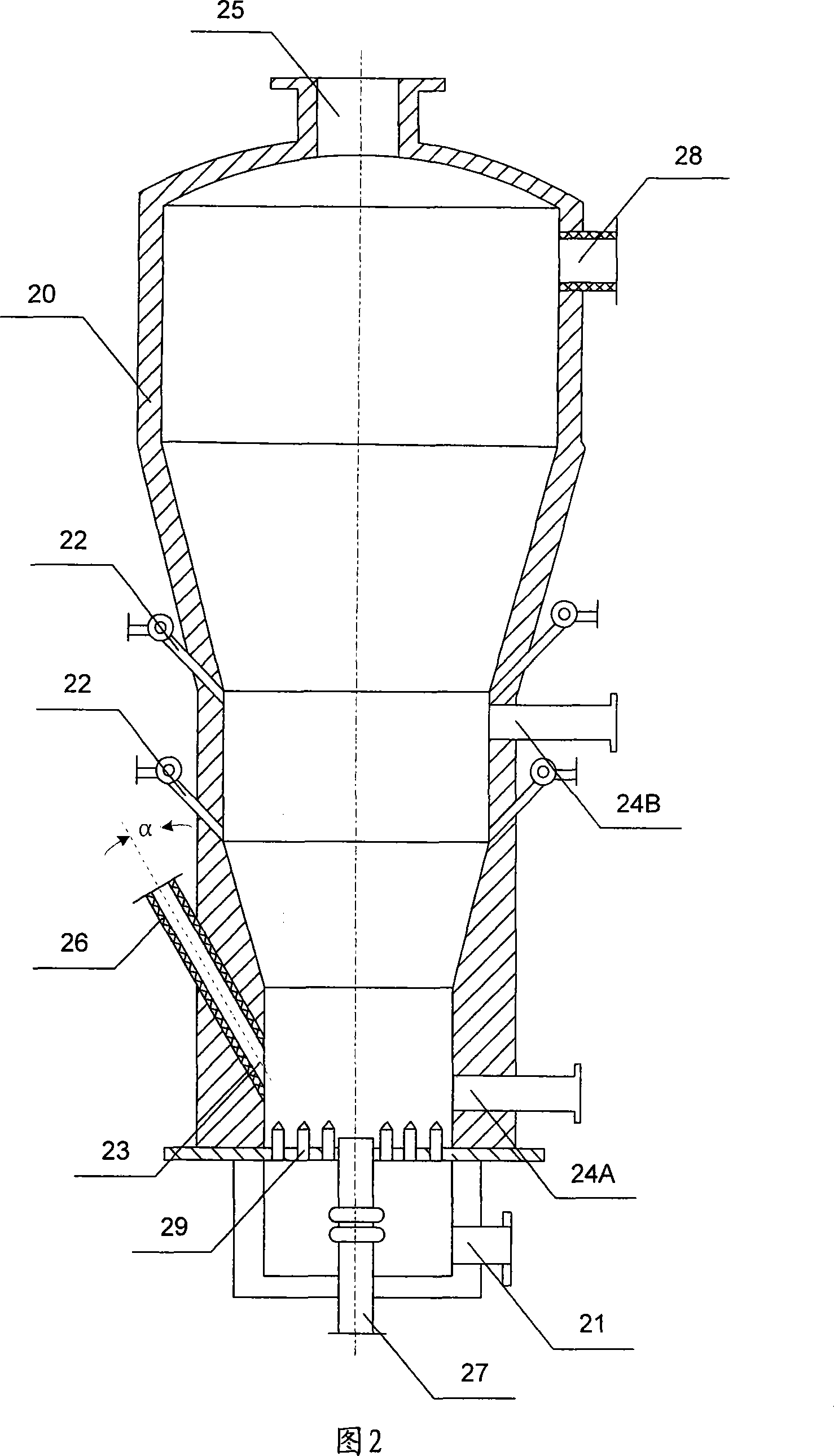

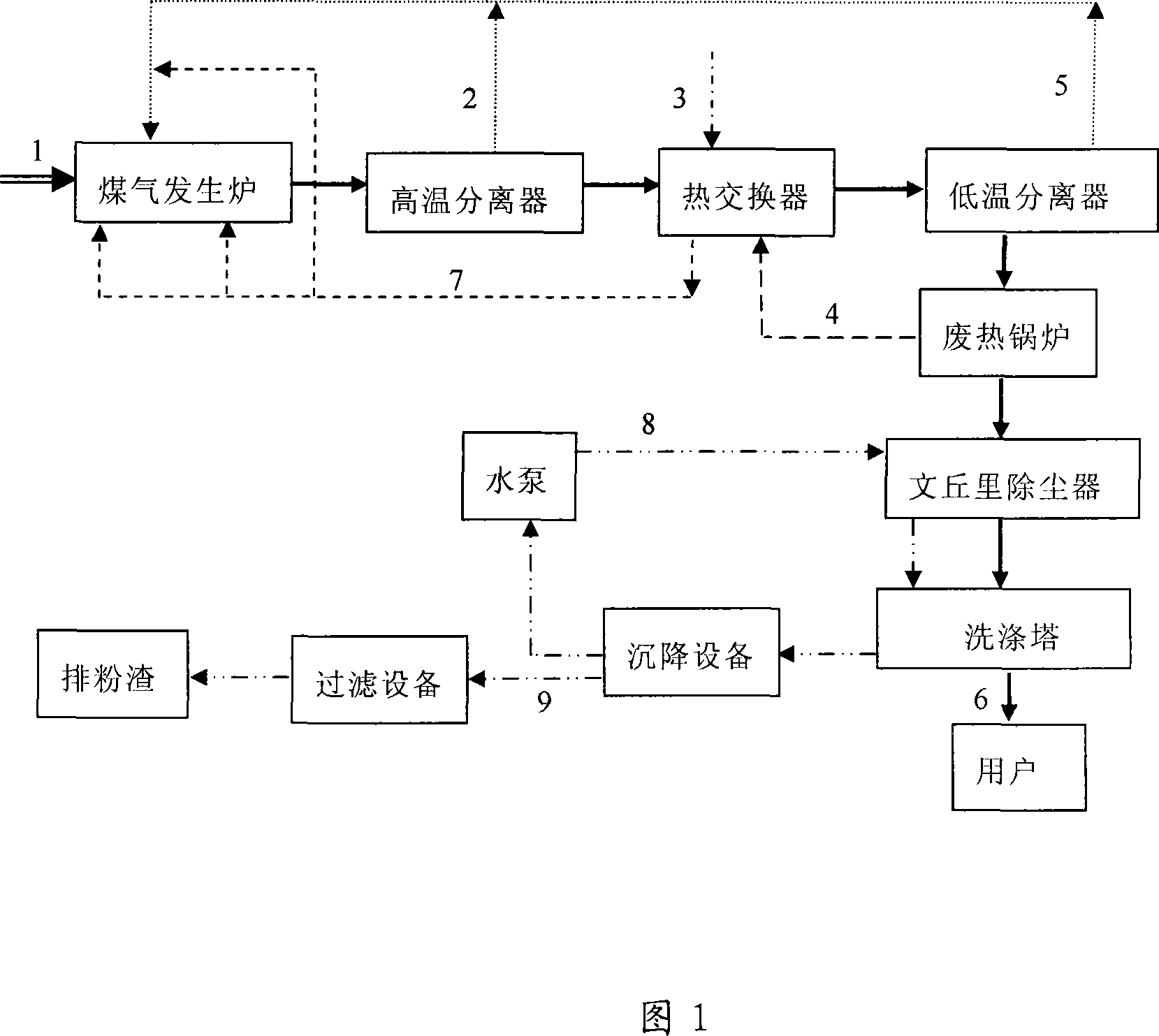

Circulating fluidized bed gas generator system

ActiveCN101063053AEfficient recyclingReduce heat of reactionEnergy inputGranular/pulverulent flues gasificationFluidized bedEngineering

The invention discloses a circulating coal fluidized bed coal gas producer system, which is characterized by the following: comprising coal-gas producer, high temperature segregator, heat exchanger, low temperature segregator and exhaust heat boiler; arranging primary air port entered high temperature gasifying agents into the burner and at least a overfire air port on coal-gas producer; equipping circling coal inlet to enter circling coal into burner; connecting the primary air port and overfire air port with heat exchanger; connecting circulating coal inlet with high temperature segregator, low temperature segregator and heat exchange; proceeding twice air intake, twice coal intake and twice separation. This invention possesses low coal consumption, high heat value, high productive efficiency and low cost, which can make the temperature of gasifying agents reach 750-850 deg. c.

Owner:KEDA INDUSTRIAL GROUP CO LTD +1

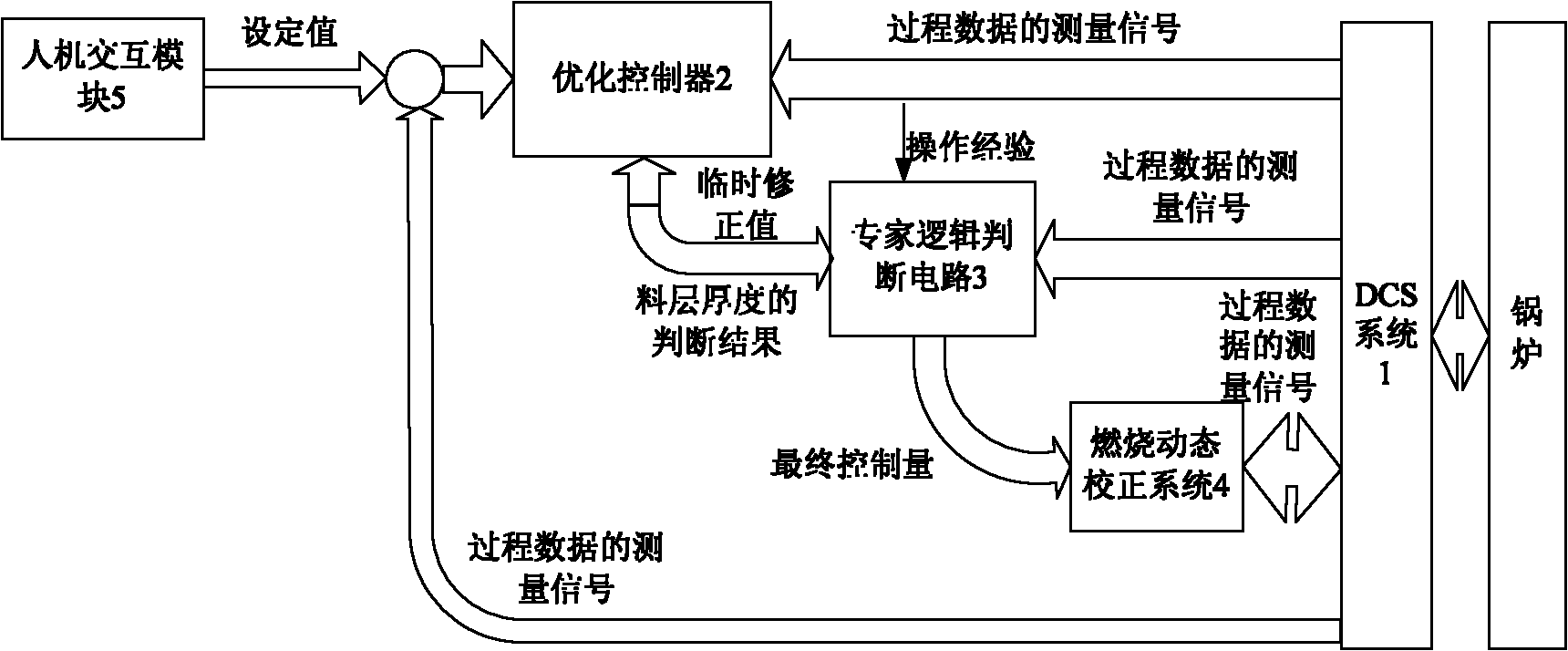

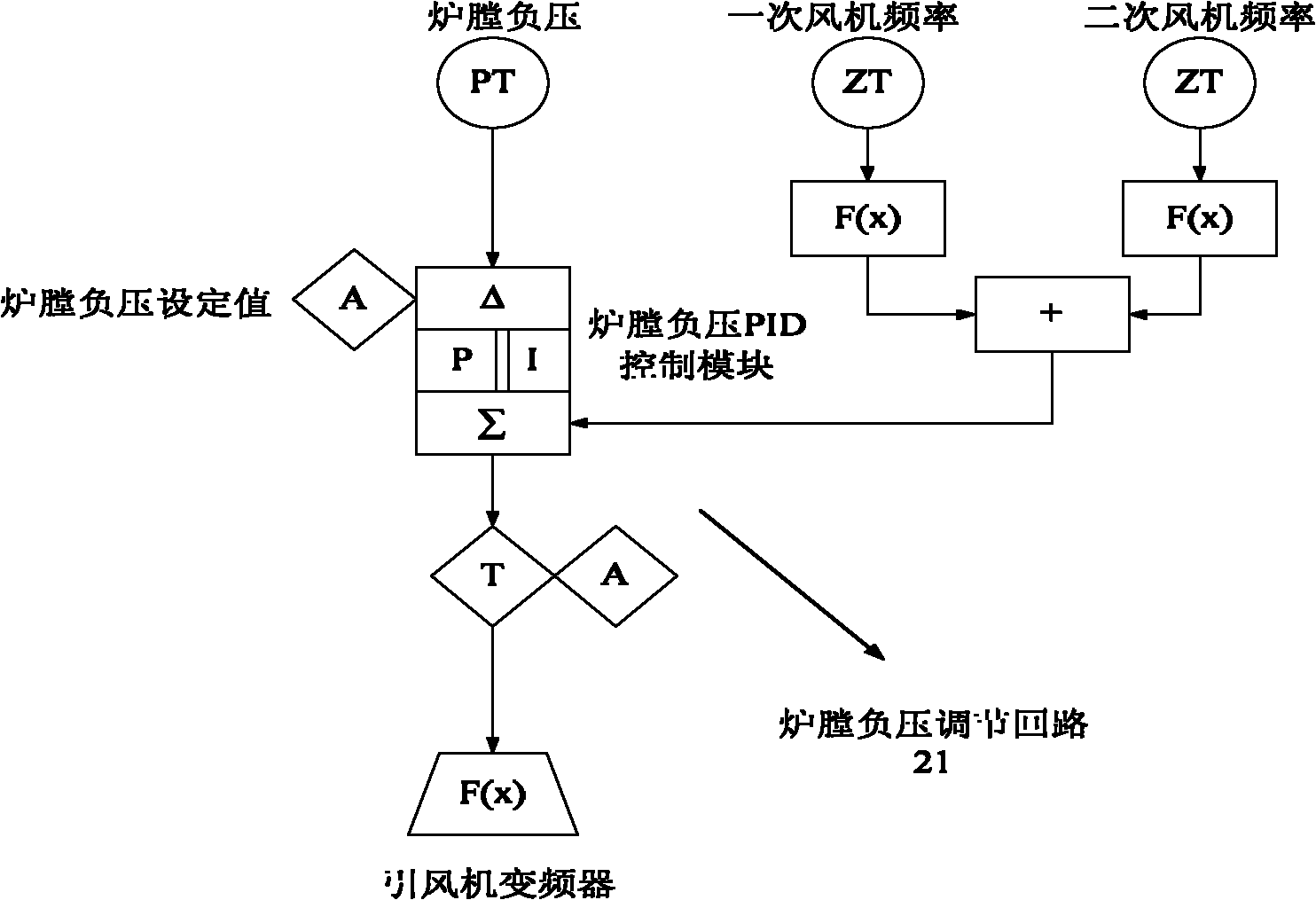

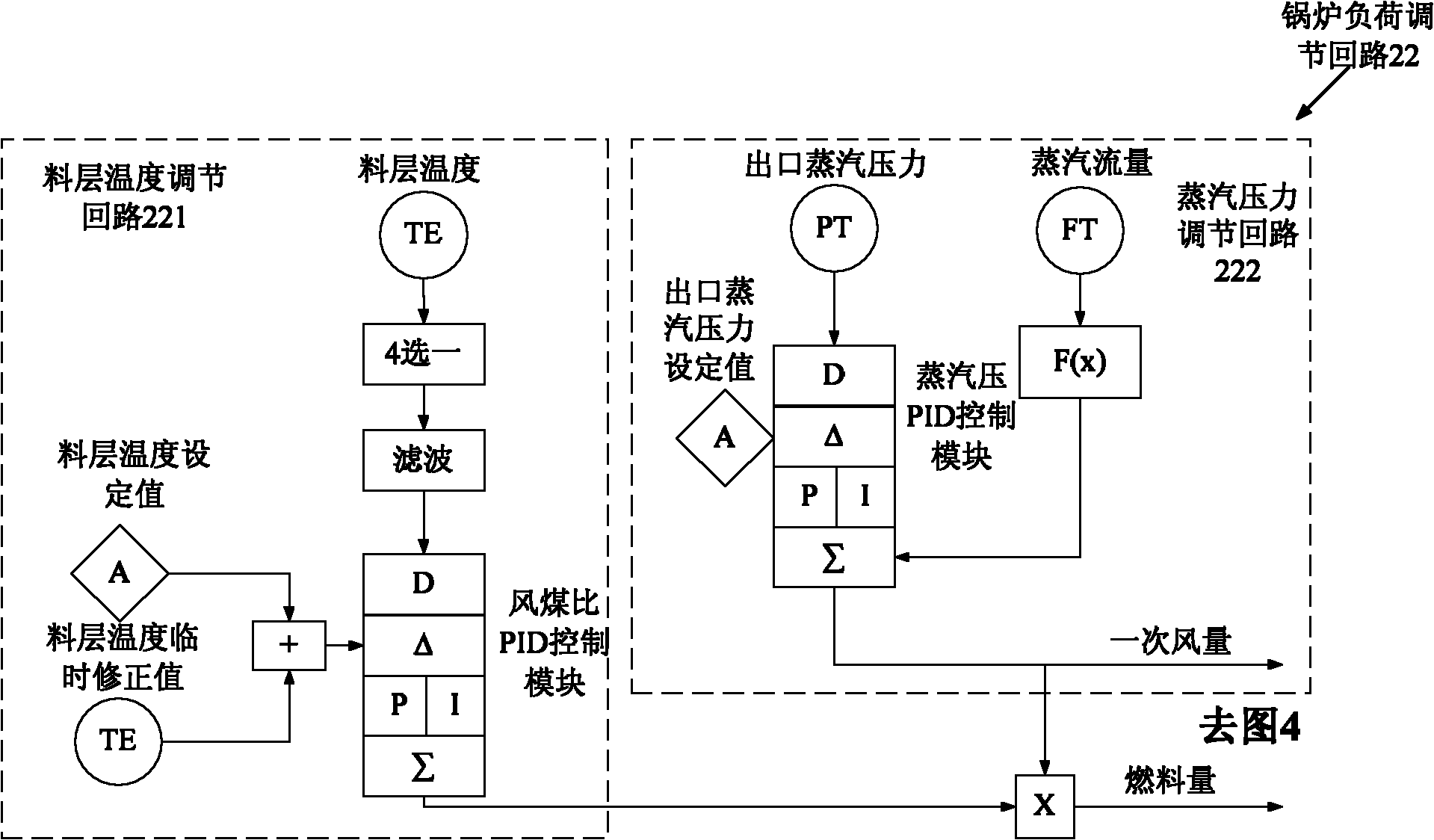

Combustion optimizing control system of circulating fluidized bed boiler in wide-range change of load

InactiveCN102183015APure Latency LargeKeep the pressureFluidized bed combustionBoiler controlCirculating fluidized bed boilerCoal

The invention relates to a combustion optimizing control system of a circulating fluidized bed boiler in wide-range change of load. An optimizing controller comprises a boiler load adjusting loop and an in-boiler material distribution estimator, wherein the boiler load adjusting loop outputs a primary air quantity calculated value, a secondary air quantity calculated value and a fuel quantity calculated value to the in-boiler material distribution estimator; the in-boiler material distribution estimator outputs a material layer thickness judging result to an expert logic judging circuit; and the expert logic judging circuit outputs a final controlled quantity to a distributed control system (DCS) according to the input material layer thickness judging result and the measuring signal of process data, and inputs a temporary bed temperature modified value and a temporary secondary air modified value to the boiler load adjusting loop. In the invention, according to the characteristics of multiple variables, close coupling, large pure delay, time varying and the like of the combustion system of the circulating fluidized bed boiler, an in-boiler kinetic model is arranged in the in-boiler material distribution estimator, and the in-boiler kinetic model and the expert logic judging circuit are combined to estimate the quantity of material and carbon concentration of all parts so as to correct the air-coal ratio dynamically.

Owner:北京三博中自科技有限公司

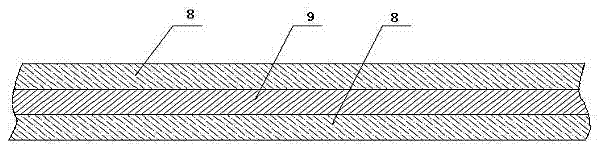

Exhaust gas dedusting, denitration and desulfuration method for thermal power plant

InactiveCN102393023AHigh strengthImprove flame retardant performanceDispersed particle filtrationCombustion processAir preheaterWhole body

The invention relates to an exhaust gas dedusting, denitration and desulfuration method for a thermal power plant. According to the invention, after being dedusted firstly by a bag-type dust collector, high-temperature raw exhaust gas is introduced in an SCR (selective catalytic reduction) reactor for performing SCR for realizing denitration, and then, the exhaust gas subjected to denitration passes through an air preheater and a heat exchanger in sequence to be cooled to 90-100 DEG C, and then is subjected to wet desulfuration in a desulfurizer; and the exhaust gas subjected to desulfuration and discharged from the desulfurizer is heated to 100-105 DEG C by the heat exchanger and then enters a chimney to be discharged. In the bag-type dust collector, filter cloth in a filter bag has base cloth which is PBO (Poly-p-phenylenebenzobisthiazole) fiber woven cloth and has two surface layers referring to composite fibrofelts formed by cross-laying of PBO fiber nets and basalt fiber nets, the base cloth is sandwiched between the two surface layers and sewed up into a whole body, the whole body is subjected to hot rolling, singeing and heat shaping, Teflon dipping and drying to finally form high-temperature resistant filter cloth. By the adoption of the high-temperature resistant filter bag, the raw exhaust gas can be dedusted firstly at a high temperature and then is subjected to denitration, therefore, ash fouling of subsequent equipment and damages to a catalyst can be reduced, and the effects of low catalyst consumption and high denitration efficiency can be achieved; and since the catalytic reaction does not need additional heat, the effects of energy saving and emission reduction are achieved.

Owner:NANJING LONGYUAN ENVIRONMENTAL CO LTD

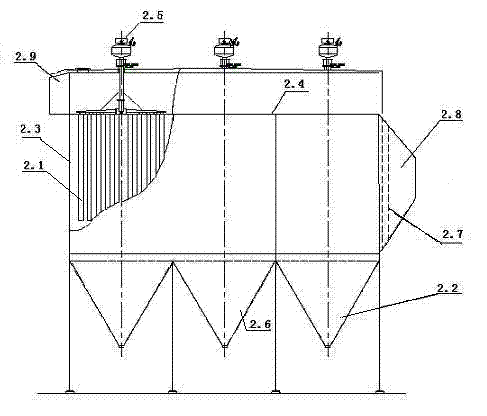

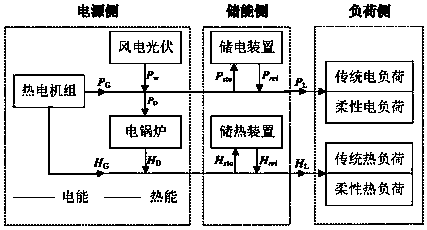

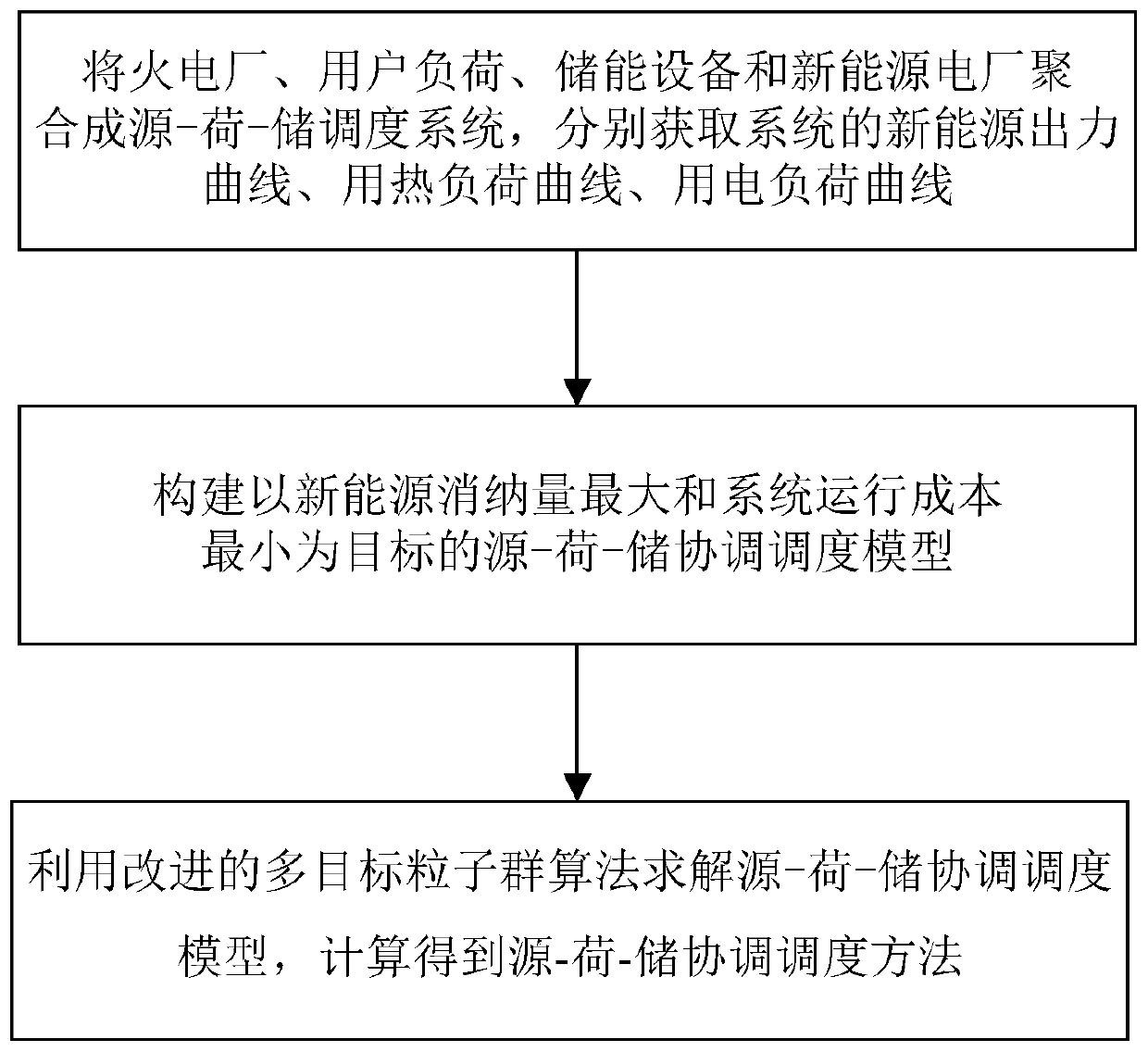

Source-load-storage coordinated scheduling method for improving new energy consumption

ActiveCN109742812AExpand the consumption spaceImprove consumption rateSingle network parallel feeding arrangementsAc network load balancingNew energyPower equipment

The invention discloses a source-load-storage coordinated scheduling method for improving new energy consumption. The method comprises the steps of S1, aggregating a thermal power plant, a new energypower plant, user loads and energy storage equipment into a source-load-storage scheduling system, and obtaining a new energy output curve, a heat utilization load curve and a power utilization load curve of the system; S2, establishing a source-load-storage coordinated scheduling model with the objective of maximizing new energy consumption quantity and minimizing the system operation cost; and S3, solving the source-load-storage coordinated scheduling model through utilization of improved multi-objective particle swarm optimization, and carrying out computing to obtain the source-load-storage coordinated scheduling method. The method has the advantages of simple realization method and flexible application. Schedulable resources such as power equipment, the user loads and the energy storage equipment in the system can be utilized rationally. The new energy consumption is facilitated, and moreover, operation cost of the system is reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Power station machine furnace integrated cold end comprehensive optimization system

The invention discloses a power station machine furnace integrated cold end comprehensive optimization system which belongs to the field of power station energy saving. The system mainly comprises a steam turbine, a main economizer, a main flue, a bypass flue, a convergence flue, a main air pre-heater, smoke-water heat exchangers, a high pressure heater, a low pressure heater, a deaerator, a smoke-air heater and steam extraction condensed air pre-heaters. Multi-stages of the steam extraction condensed air pre-heaters are serially arranged, sequentially extract a part of exhaust steam of the steam turbine and corresponding low-pressure-stage extraction steam and preheat cold air stage by stage; and the first, second and third stage smoke-water heat exchangers are used for heating feeding water and condensed water, and high-pressure extraction steam of the steam turbine is replaced. According to the machine furnace integrated cold end comprehensive optimization system, by means of efficient waste-heat utilization, low-pressure extraction steam is used for heating air, and the high-pressure extraction steam for backheating is saved so that unit output power is obviously increased, deep energy saving and consumption reduction of the coal-fired power generation unit are achieved, the problem of low-temperature corrosion on a heated surface during waste-heat utilization is solved, and economical benefits are remarkable.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

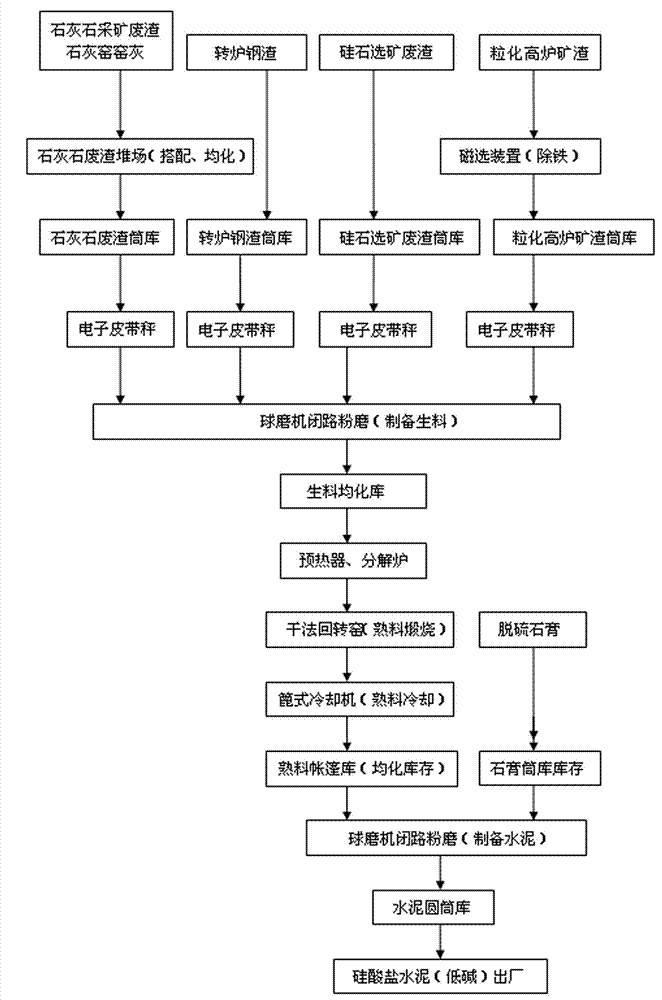

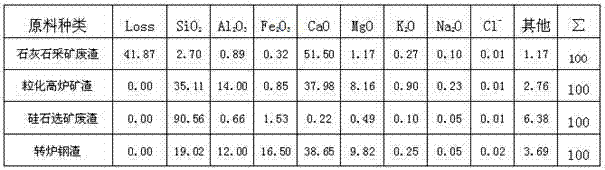

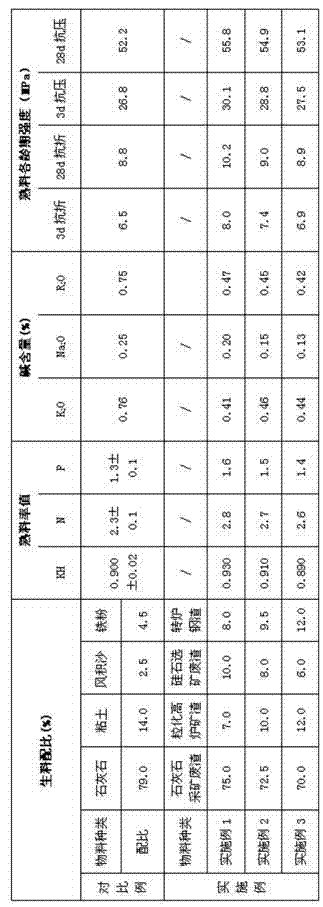

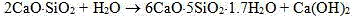

Method for producing low-alkali Portland cement by using industrial solid waste

The invention discloses a method for producing low-alkali Portland cement by using industrial solid waste and aims to overcome the problem that alkali content in cement produced by using traditional methods is high. The method comprises the following steps: A, preparation of the raw materials of 70 to 75% of mining debris of limestone, 7.0 to 12.0% of granulated blast-furnace slag, 6.0 to 10.0% of rejects of silica and 8.0 to 12.0% of converter steel slag; B, clinker calcination; and C, cement grinding. The method provided in the invention has the following characteristics: rejects of silica are used as a silico-regulating material, and not only the characteristic of low alkali content of the rejects of silica is made use of, but also the silica modulus N of the clinker can be adjusted by adjusting the proportion of the rejects of silica so as to inhibit the probability of skinning of a preheater and ring formation in a rotary kiln caused by excessively good burnability of materials. Lime kiln ash, the granulated blast-furnace slag and the converter steel slag are subjected to high temperature calcination, so alkali in the above-mentioned materials greatly volatilizes; therefore, alkali content in the raw materials is decreased, thereby meeting compounding requirements and creating conditions for production of low alkali cement.

Owner:嘉峪关祁连山水泥有限公司

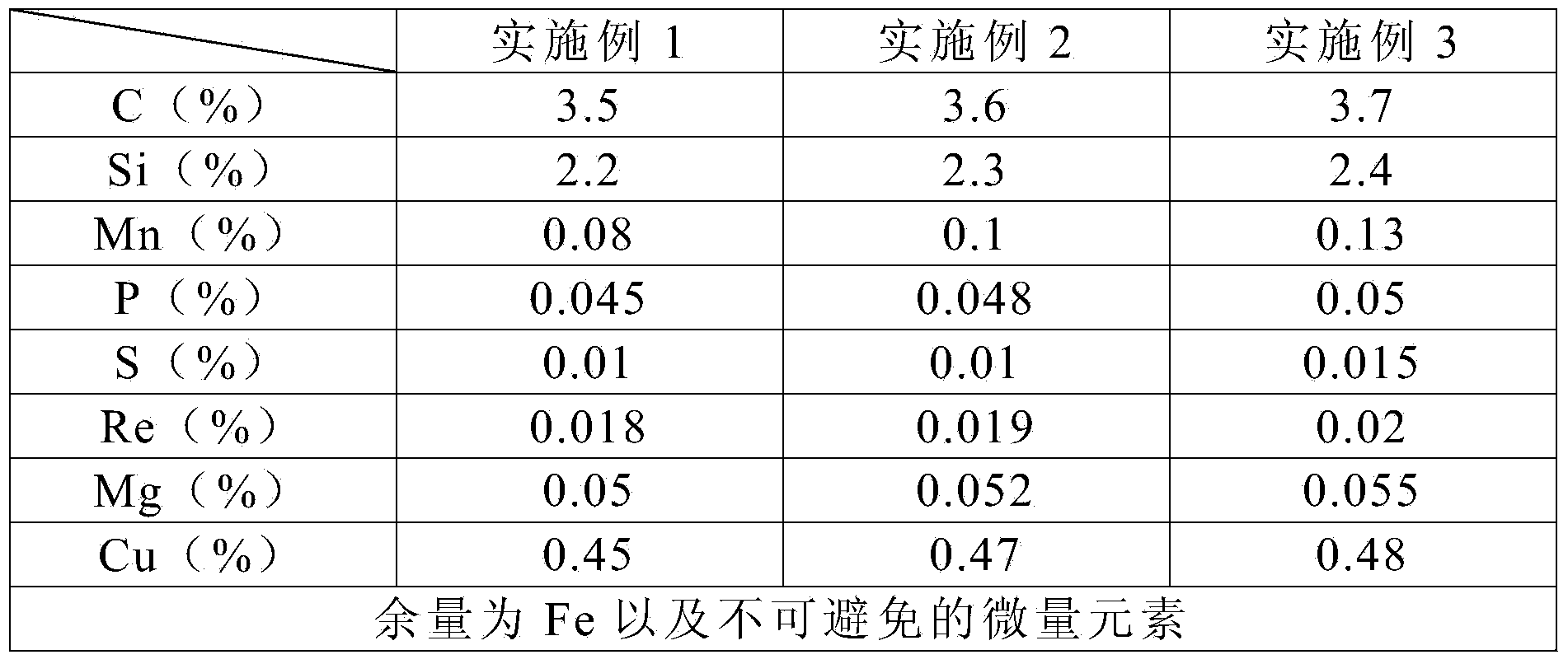

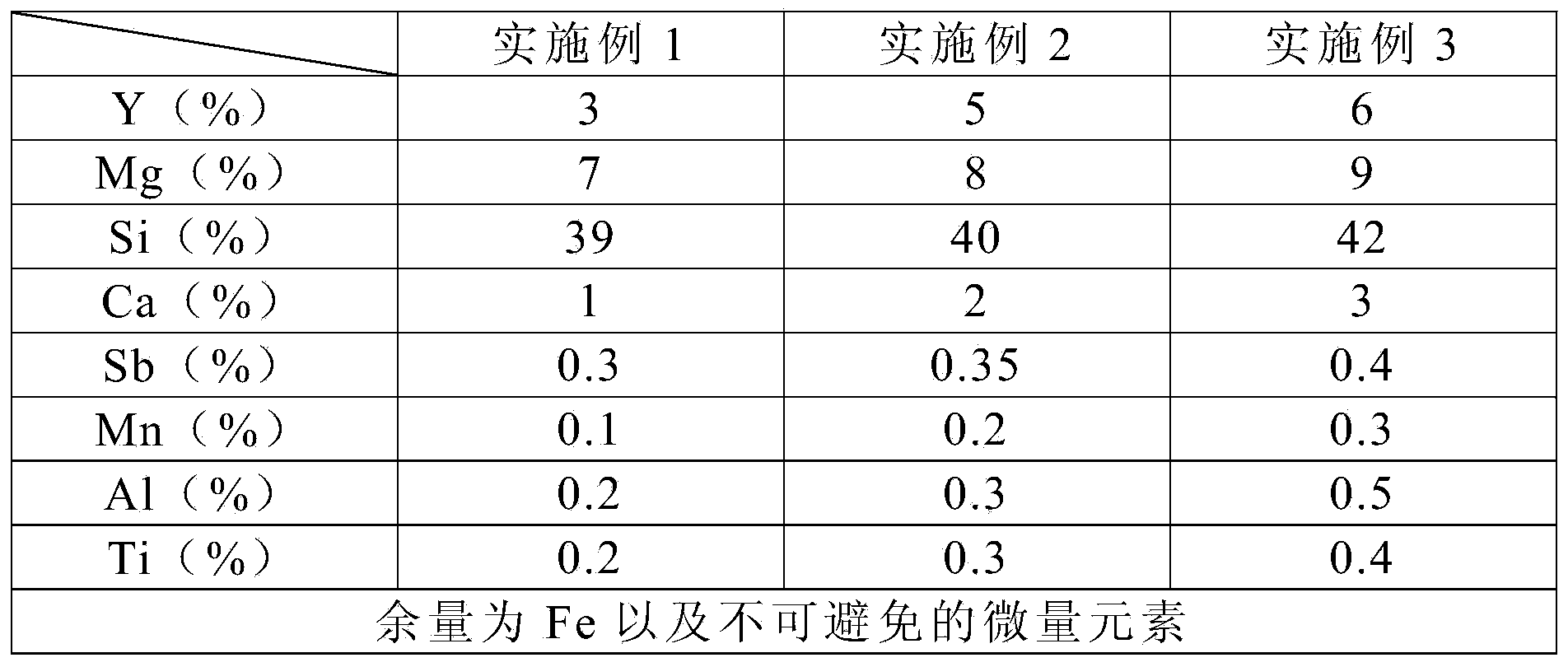

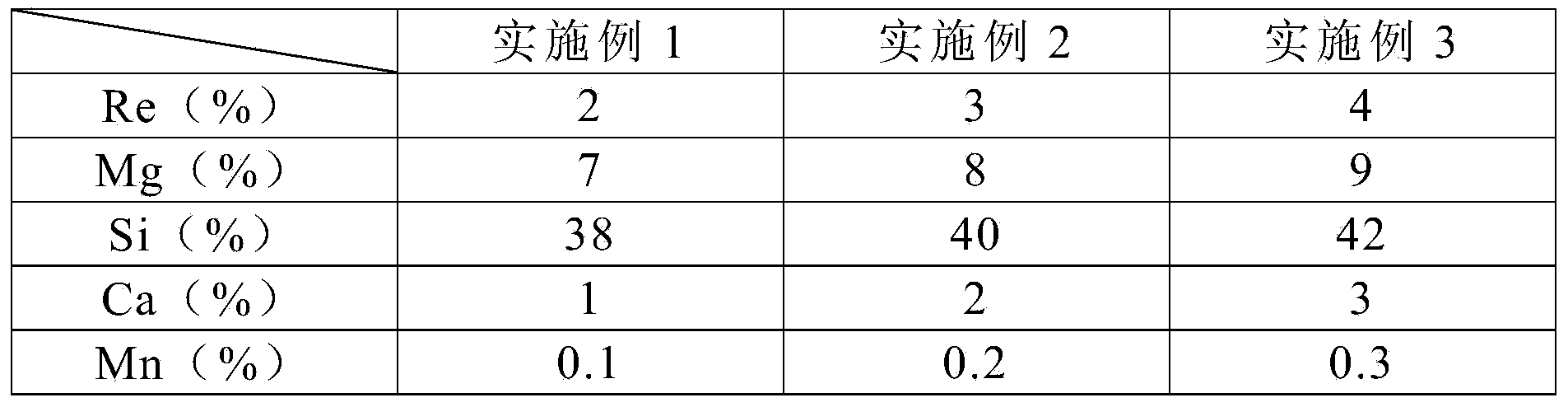

Novel as-cast 500-7 nodular cast iron

InactiveCN103484753AShorten the production cycleReduce coal consumptionTrace element compositionDuctile iron

The invention relates to a novel as-cast 500-7 nodular cast iron which comprises the following components in percentage by mass: 3.5-3.7% of C, 2.2-2.4% of Si, 0.1-0.2% of Mn, 0.045-0.05% of P, 0.01-0.015% of S, 0.018-0.02% of Re, 0.05-0.055% of Mg, 0.45-0.48% of Cu, and the balance of Fe and inevitable microelements. The elements come from coke, limestone, new pig iron, returning iron, electrolytic copper, steel scrap and iron alloy. The preparation method comprises the following steps: weighing the raw materials according to the percentage by mass of the novel as-cast 500-7 nodular cast iron, smelting, spheroidizing and inoculating three times to obtain the novel as-cast 500-7 nodular cast iron. The novel as-cast 500-7 nodular cast iron has the advantages of short production cycle, low pollution, low cost and high strength, and can obtain a ferrite / pearlite mixed matrix under as-cast conditions.

Owner:宁波康发铸造有限公司

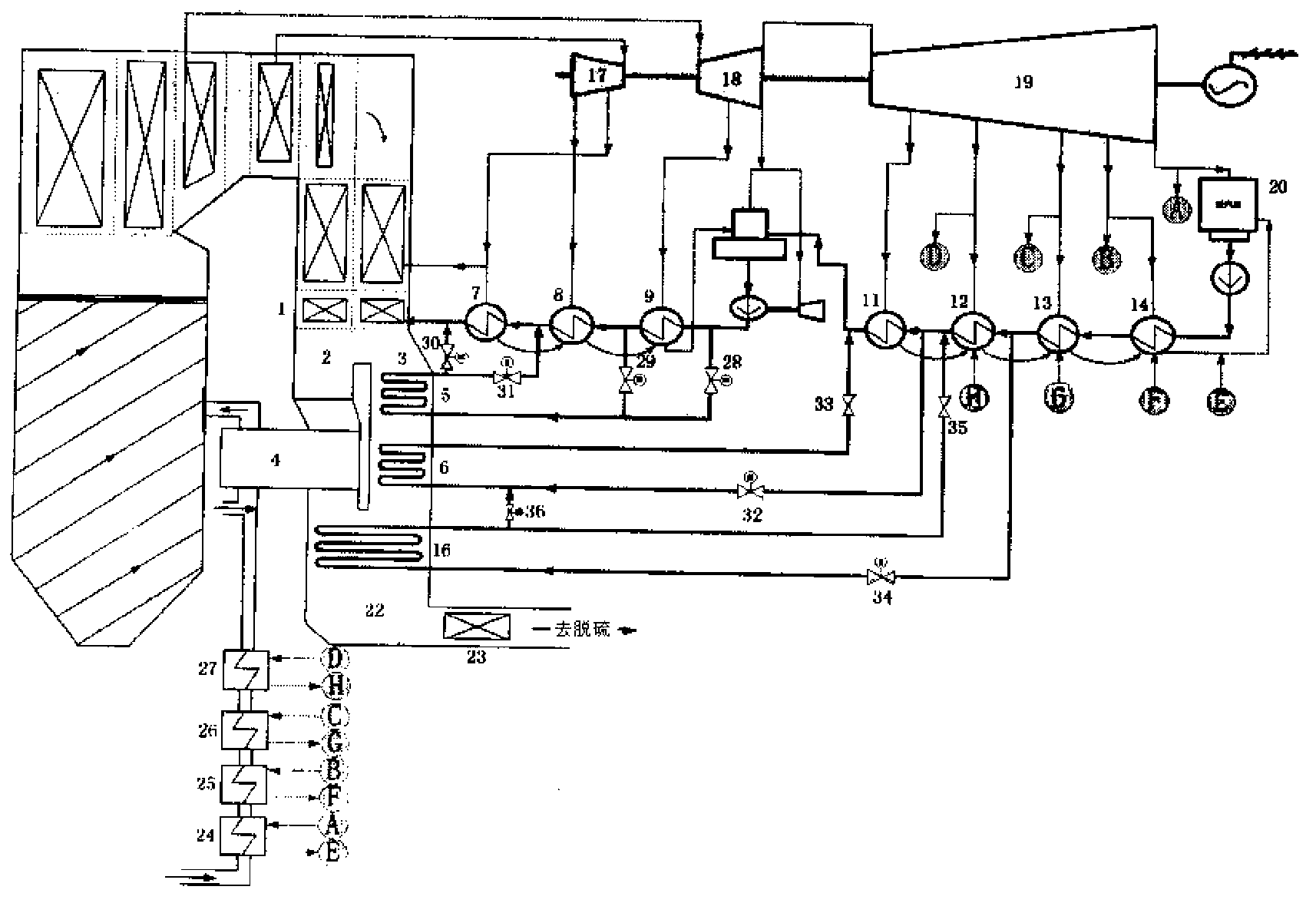

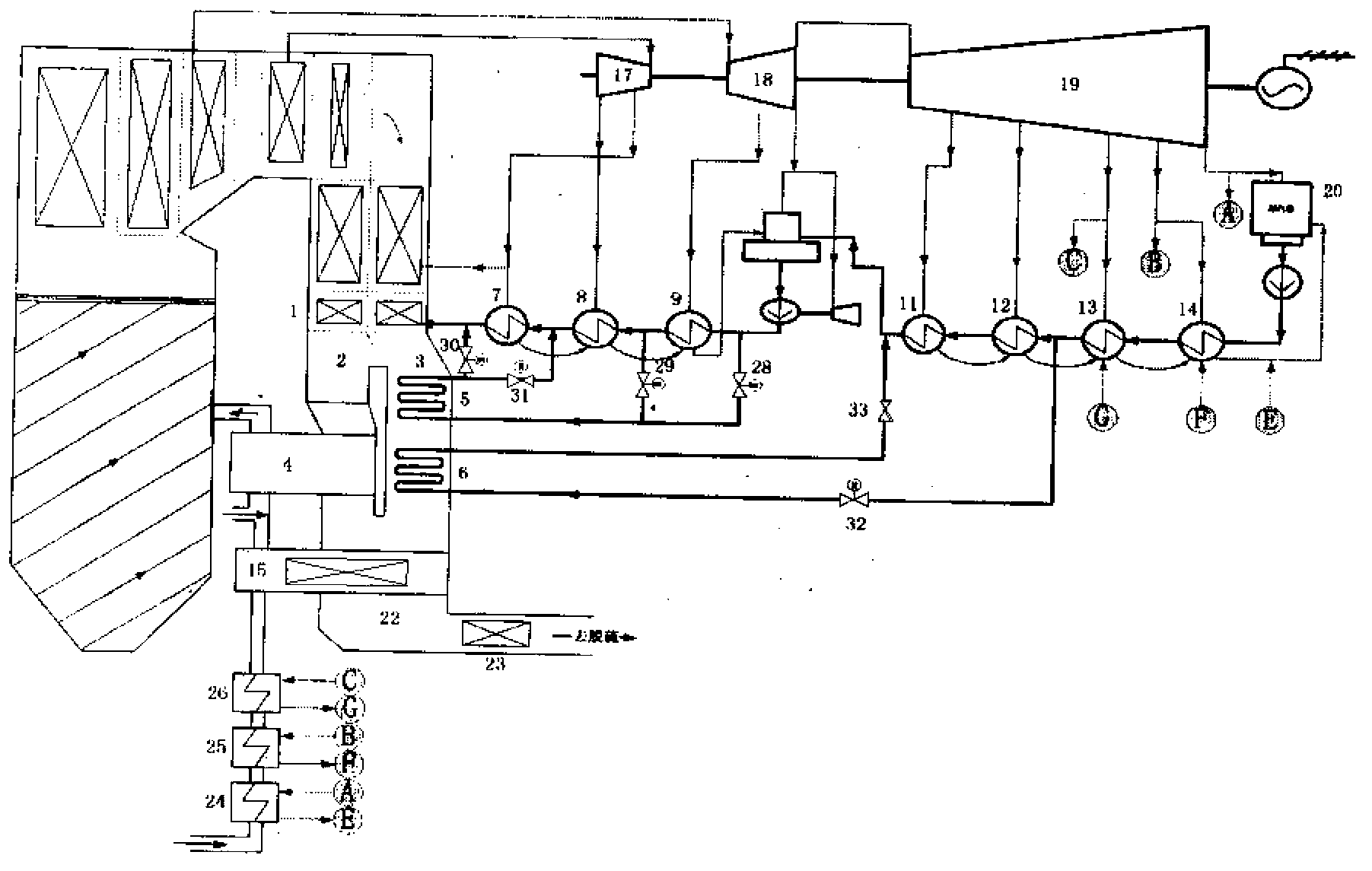

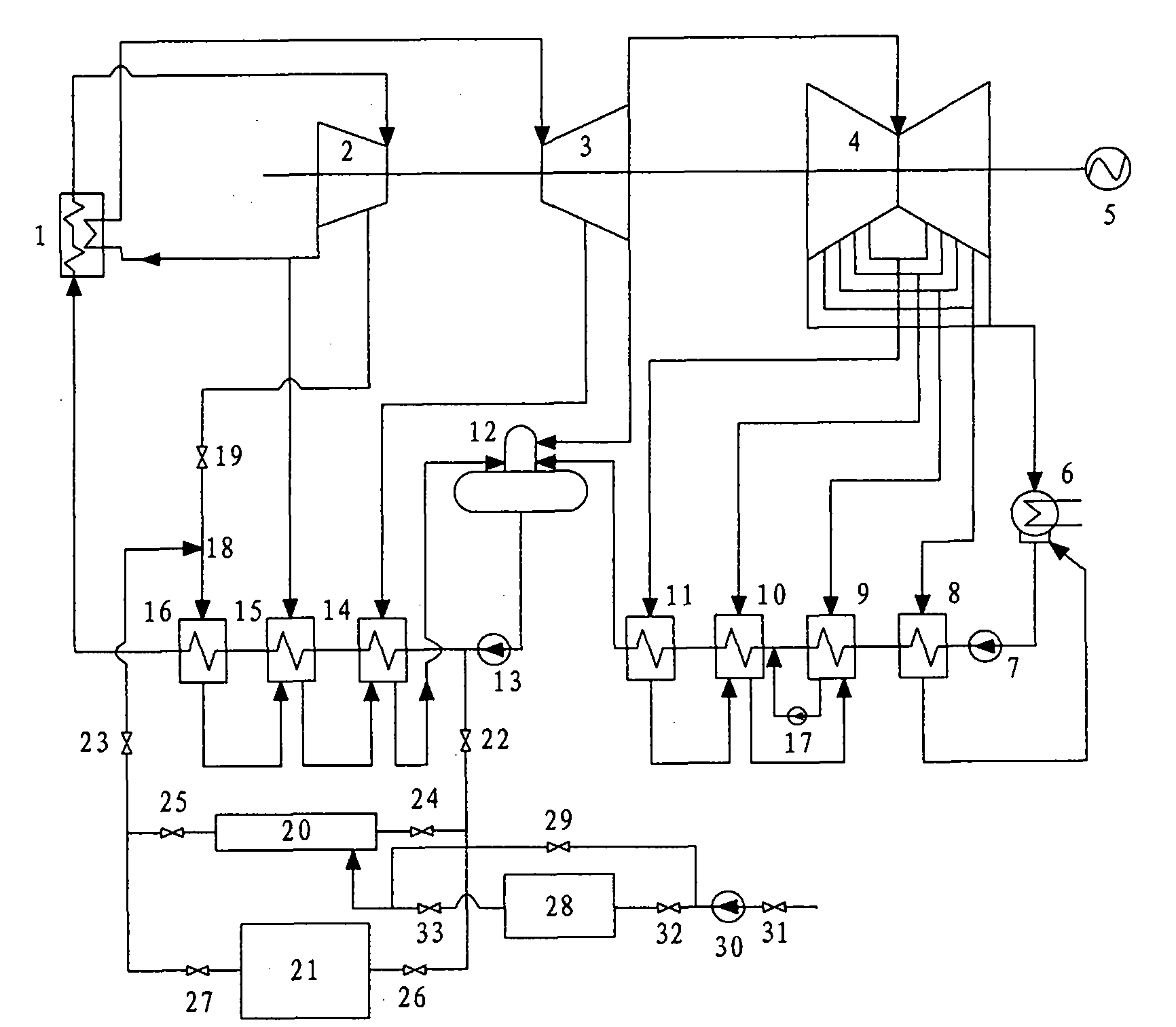

Steam turbine generating heating system with double running modes

InactiveCN103291391ALoss reduced to zeroZero lossSteam useCombined combustion mitigationCouplingEngineering

The invention provides a steam turbine generating heating system with double running modes. The steam turbine electric heating system comprises a generator, a first coupler, a low-pressure rotor, a second coupler, a high- and medium-pressure rotor, a condenser and a low-pressure cylinder flow portion. The low-pressure rotor comprises a pure coagulating rotor and a backpressure heating rotor. The high- and medium-pressure rotor of a steam turbine is connected with one end of the low-pressure rotor through the second coupler, and the other end thereof is connected with the generator through the second coupler to perform generating heating. In an off-heating season, the pure coagulating rotor serves as the low-pressure rotor, and a system is operated in a coagulating mode; in a heating season, the pure coagulating rotor is replaced by the back pressure heating rotor, and the system is operated in a backpressure mode. The steam turbine generating heating system with the double running modes is characterized in that flow grade of the pure coagulating rotor is of 2X6, while flow grade of the back pressure heating rotor which is a one-piece-forged centerless rotor is of 2X4.

Owner:HUADIAN POWER INTERNATIONAL CORPORATION LTD

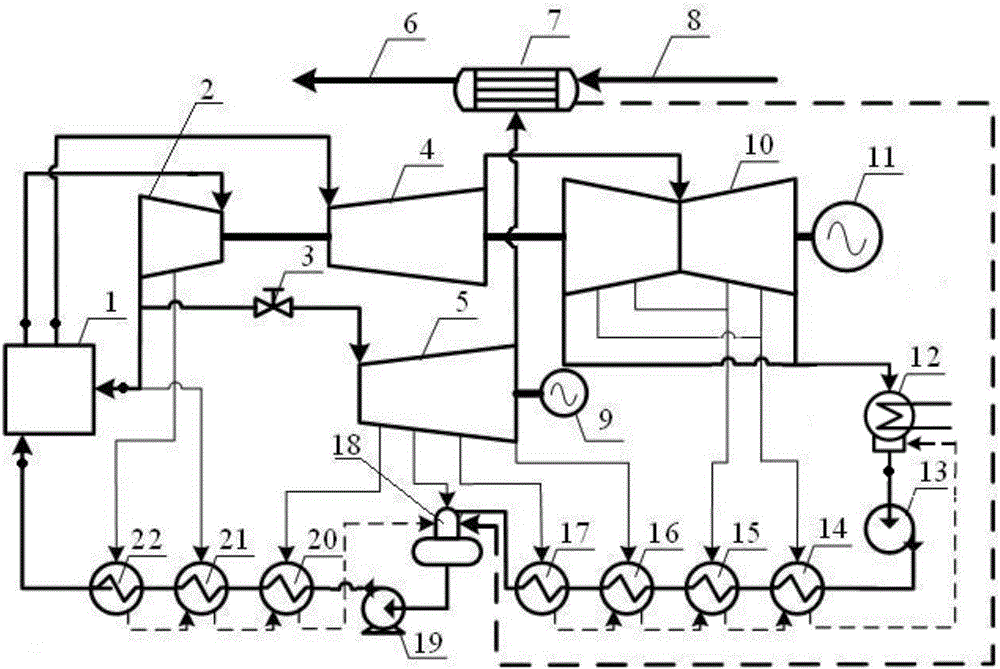

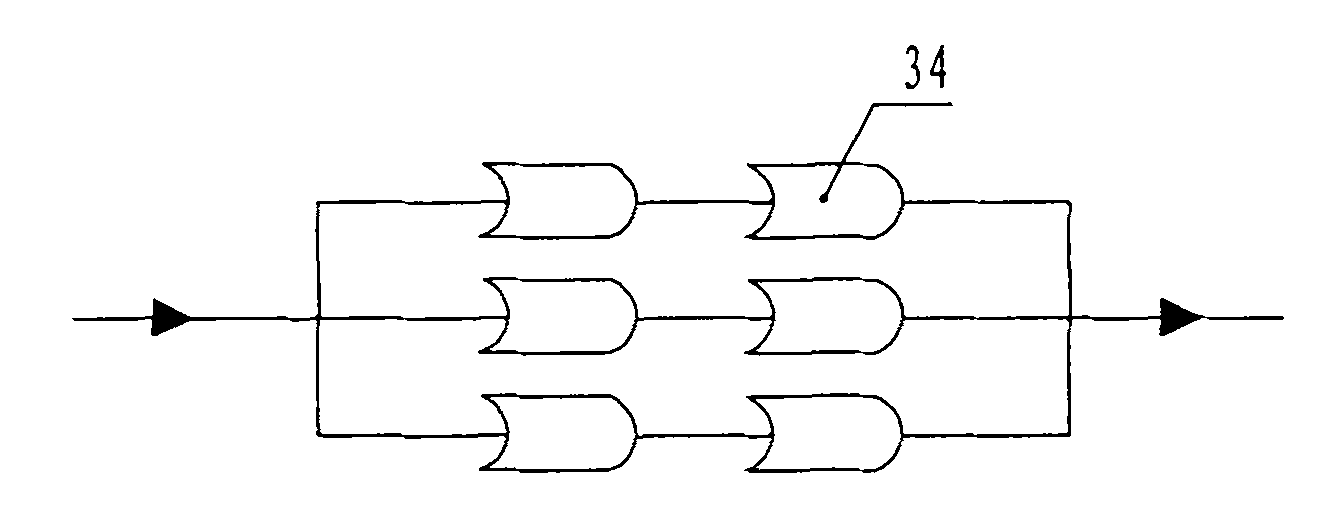

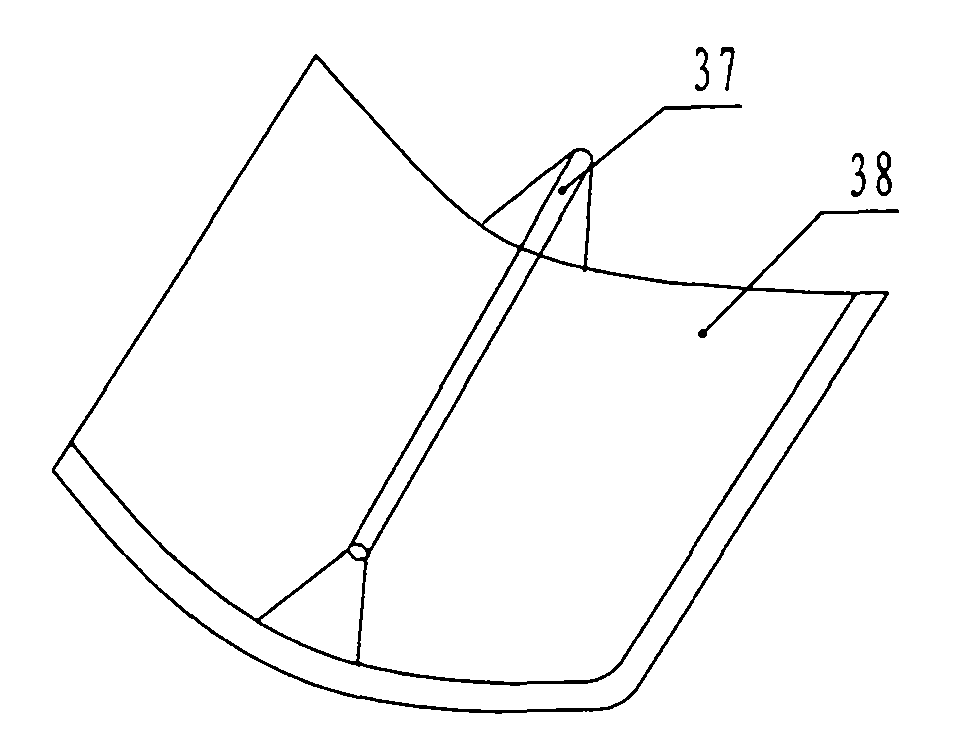

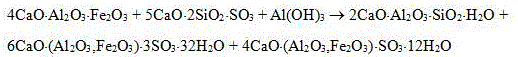

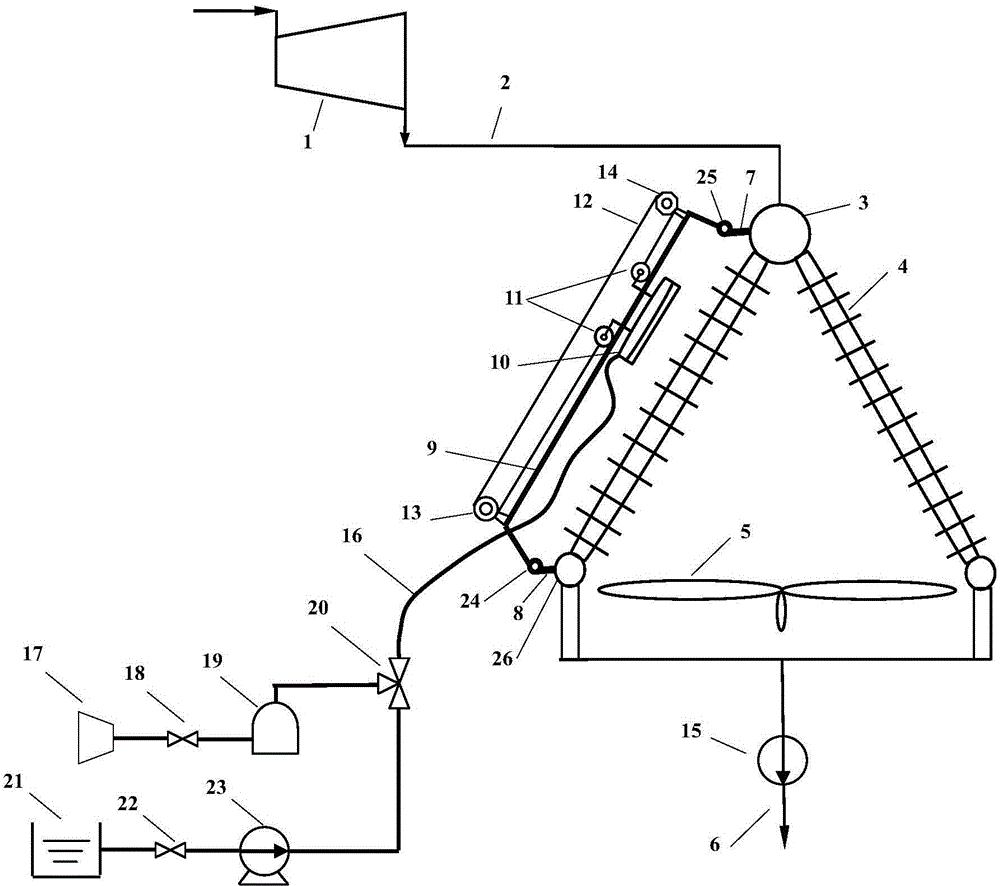

Cogeneration system by firing coil assisted by biomass and solar energy

InactiveCN101906996ADoes not affect normal operationReduce coal consumptionSolar heating energySolar heat devicesLow voltageCogeneration

The invention relates to a cogeneration system by firing coil assisted by biomass and solar energy, which comprises a coal-fired boiler generation system and a series assistance system, wherein the coal-fired boiler generation system comprises a generator and a condenser, a condensate pump, a multi-stage low-voltage heaters, a deaerator, a feed water pump, a multi-stage high-voltage heaters, a coal-fired boiler and a steam turbine orderly connected in series, wherein a steam inlet of the condenser is connected with exhaust steam of the steam turbine, and the multi-stage low-voltage heaters, the deaerator and the multi-stage high-voltage heaters are all connected with extracted steam of the steam turbine, and the steam turbine drives the generator; and the series assistance system comprises a biomass gasification device and a paraboloid channel type solar energy heat collector array, and the biomass gasification device and the paraboloid channel type solar energy heat collector array are connected in series and then connected between an outlet of the feed water pump and an extracted steam inlet of one of the multi-stage high-voltage heaters. The invention reduces the coal consumption, optimizes the energy utilization structures, solves the problem of high pollution of the traditional generation system by firing coal to a great extent and is beneficial to ecological protection.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Extraction condensing heat supply system additionally provided with non-reheat medium-pressure steam turbine

InactiveCN105697075AReduce superheatImprove the flow structureLiquid degasificationSteam useEngineeringHeat losses

The invention belongs to the technical field of thermoelectricity, and relates to an extraction condensing heat supply system additionally provided with a non-reheat medium-pressure steam turbine. A part of steam is separated from a steam exhaust port of a high-pressure cylinder of a main steam turbine to enter the added non-reheat medium-pressure steam turbine, and the rest of steam enters a reheater of a boiler and a No.II high-pressure heater; the steam entering the medium-pressure steam turbine does not need to be reheated, an independent generator II is driven, four-stage extraction steam of the medium-pressure steam turbine serves as a heat source for a No.III high-pressure heater, a No.V low-pressure heater, a No.VI low-pressure heater and a deaerator to replace a part of regenerative extraction steam of the main steam turbine, and the extraction steam of the medium-pressure steam turbine is discharged into a heater for heating network to heat heating network water. An effect of additionally installing the medium-pressure steam turbine in the extraction condensing heat supply system disclosed by the invention is to reduce heat exchange exergy loss by reducing heat exchange temperature difference of a part of regenerative heaters and the deaerator; work capability of heat supply steam flow is increased, and therefore heat loss of a high-capacity heat supply unit is caused by a high extraction steam parameter is reduced; and the extraction condensing heat supply system disclosed by the invention is suitable for heat supply and energy conservation transformation on 300 MW (megawatt), 600 MW and above steam turbine units.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

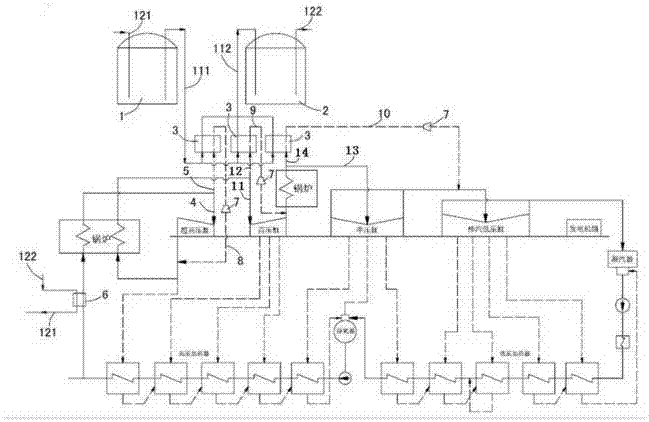

Renewable energy resource assistant coal hybrid power generation system

InactiveCN101892877AReduce coal consumptionReduce steam extractionSteam engine plantsDeaeratorEngineering

The invention discloses a renewable energy resource assistant coal hybrid power generation system. The hybrid power generation system comprises a coal-fired boiler power generation system and a parallel-connection assistant system, wherein the coal-fired boiler power generation system comprises a generator, and a condenser, a condensation water pump, multi-level low pressure heaters, a deaerator, a feed pump, multi-level high pressure heaters, a coal-fired boiler and a steam turbine sequentially connected in series, wherein a steam inlet of the condenser is connected with the steam turbine to exhaust the steam; the multi-level low pressure heaters, the deaerator and the multi-level high pressure heaters are all connected with the steam turbine for steam extraction; the steam turbine drives the generator; and the parallel-connection assistant system consists of a biomass gasifying device and a paraboloid trough type solar heat collector field which are parallelly connected and then connected between an outlet of the feed pump and a steam extraction inlet of one of the multi-level high pressure heaters. The hybrid power generation system reduces coal consumption of the conventional coal-fired power plant, optimizes energy utilization structure, solves a problem of high pollution of the conventional coal-fired power generation system to a great degree and is favorable for ecological protection.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Liquid state energy storage system applicable to depth peak load regulation of heat power generating unit

PendingCN106885232AMeet the needs of low-load Internet accessRaise the inlet temperatureSteam engine plantsFeed-water heatersSteam pressureMolten salt

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

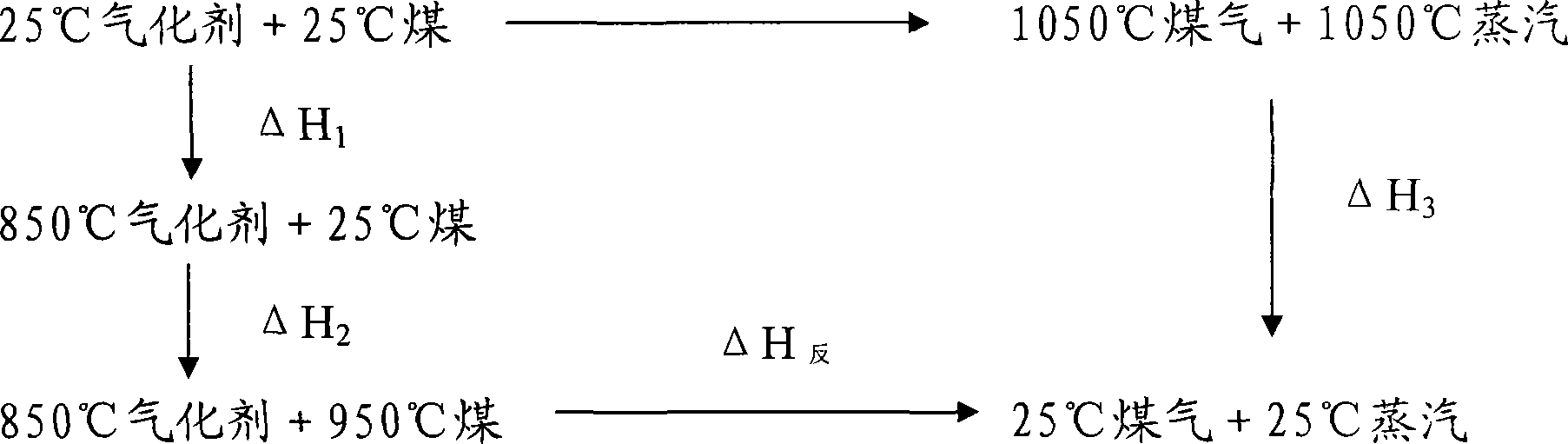

Coal gas production method

ActiveCN101063050AFast responseReduce coal consumptionEnergy inputCombustible gas productionTemperature treatmentProcess engineering

The invention discloses a preparing method of coal-gas, which comprises the following steps: which comprises the following steps: adding raw material ash coal and high temperature gasifying agent into coal-gas producer; proceeding heat change with exiting furnace coal gas and gasifying agents; generating high temperature gasifying agents; proceeding heat change with coal gas and water after heat change with gasifying agent; generating steam; setting the steam as component of gasifying agent; further-dedusting and desulfurizing the coal gas; exporting; proceeding dry type high temperature treatment before heat-changing with gasifying agent and after generating coal gas; separating dust coal; coming back to coal-gas producer; proceeding dry type low temperature treatment before heat-changing with coal gas and water and after generating high temperature gasifying agent; separating dust coal; coming back to coal-gas producer; setting the temperature of high temperature gasifying agent at 750-850 deg. c; entering through three position of the coal-gas producer. This method possesses low coal consumption and small device depletion.

Owner:KEDA INDUSTRIAL GROUP CO LTD +1

Preparation method and application method of low-carbon cement clinker

InactiveCN106220008ALower sintering temperatureIncrease the blending ratioCement productionSiliconGypsum

The invention relates to a preparation method and an application method of low-carbon cement clinker. The low-carbon cement clinker is prepared by the steps: uniformly mixing raw materials of silicon-aluminum containing material, limestone and gypsum according to a certain ratio; grinding the mixture to form a raw material, wherein the grain size of the ground raw material requires that residue on a 0.08-mm square hole sieve is less than 10%; calcining the ground raw material for 20 to 40 minutes at the calcining temperature of 1200 to 1300 DEG C; cooling to obtain the low-carbon cement clinker. The low-carbon cement clinker provided by the invention comprises 10 to 25 percent of beta-dicalcium silicate, 5 to 15 percent of calcium sulphosilicate, 15 to 45 percent of tricalcium silicate and 15 to 45 percent of calcium sulphoaluminate. 0.01 to 15 percent of gypsum and 0.01 to 15 percent of limestone are added into the low-carbon cement clinker and then are ground to obtain a cement finished product. The preparation method and the application method of the low-carbon cement clinker have the advantages of low calcining temperature, short coagulation time, high hardening speed, high early strength and continuously enhanced later strength.

Owner:郑州市王楼水泥工业有限公司

Dry-wet parallel air-cooling condenser washing system and washing cycle determining method thereof

ActiveCN104976919ASimple mechanical structureIncrease purge pressureFlush cleaningHigh pressure waterDrive motor

Disclosed are a dry-wet parallel air-cooling condenser washing system and a washing cycle determining method thereof. The dry-wet parallel air-cooling condenser washing system is characterized in that an air compressor is communicated with a high-pressure air storage cabinet; the high-pressure air storage cabinet is communicated with a first tee reversing valve; a desalting water tank is communicated with a high-pressure water pump through a second stop valve; the high-pressure water pump is communicated with a mobile washer through the first tee reversing valve; the mobile washer is arranged on a transversely-moving frame through a vertical track pulley; the lower end of the transversely-moving frame is arranged on a lower transverse track through a first transverse track pulley, and the upper end of the transversely-moving frame is arranged on an upper transverse track through a second transverse track pulley; the vertical track pulley is connected with a drive motor and a fixed pulley; a low-pressure cylinder of a turbine is communicated with an air-cooling condenser pipe bundle and a condensation tank through a steam exhaust distribution pipe; the condensation tank is communicated with a boiler water supply. The washing cycle determining method of the dry-wet parallel air-cooling condenser washing system is scientific and reasonable, so that the sum of the ash scale loss cost and compressed air blowing loss cost of an air-cooling condenser is minimum, and the service life of the air-cooling condenser is prolonged.

Owner:NORTHEAST DIANLI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com