Close hothouse loose-tobacco loading method

A technology of tobacco loading and curing room, which is applied in the field of flue-cured tobacco, which can solve the problems of slow moisture regain, difficulty in curing, and non-retraction of tobacco leaves, and achieve the effects of large amount of tobacco loading, easy curing operation, and reduced material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Take a loose-leaf intensive barn of 8m x 2.7m and 3 layers of tobacco as an example. The capacity of fresh tobacco leaves is 5000-6000kg, and the amount of dry smoke per kang is 600-700kg, which can be used for growing tobacco. Tobacco leaves with an area of 30 mu are used for baking. Choose a wooden square with a specification of 400mm wide x 250mm thick x 3000mm long to make fixed square bars. A barn needs to fix 60 square bars.

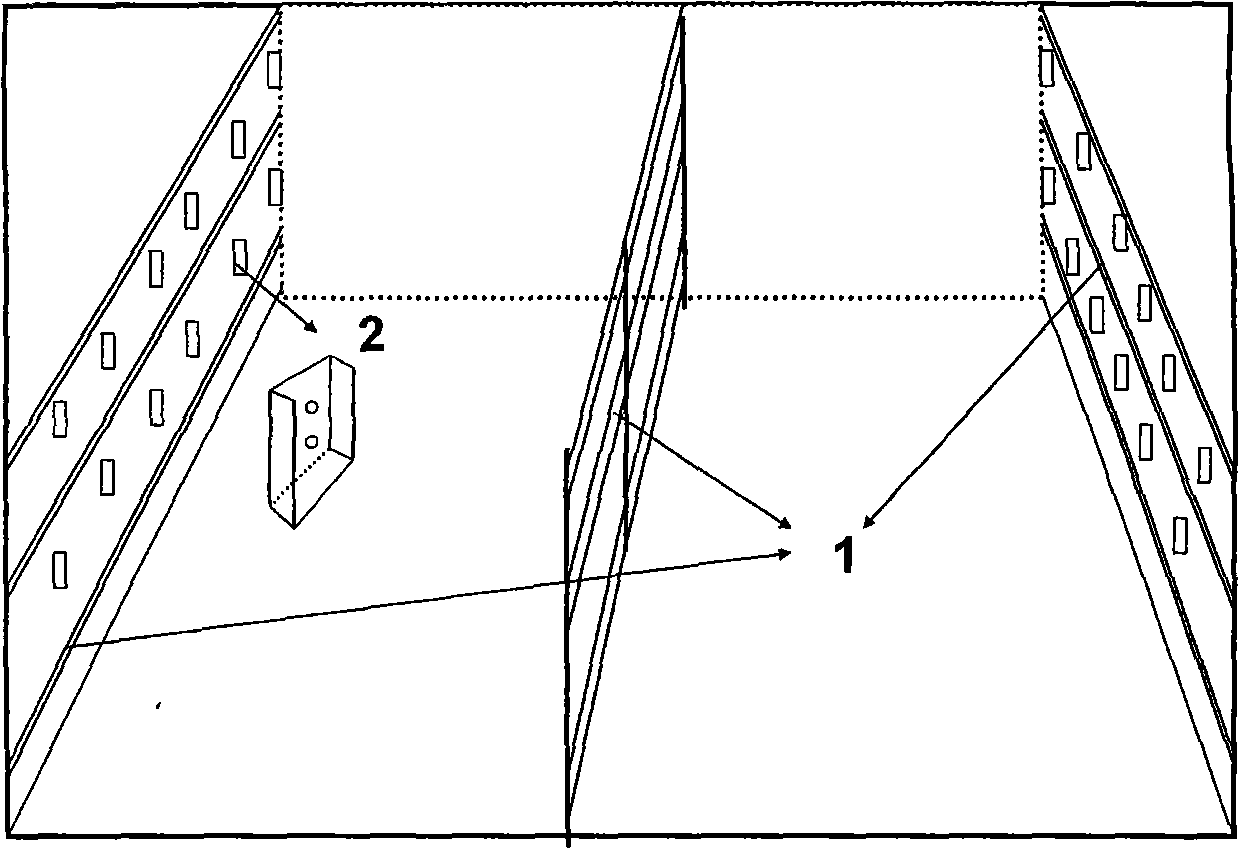

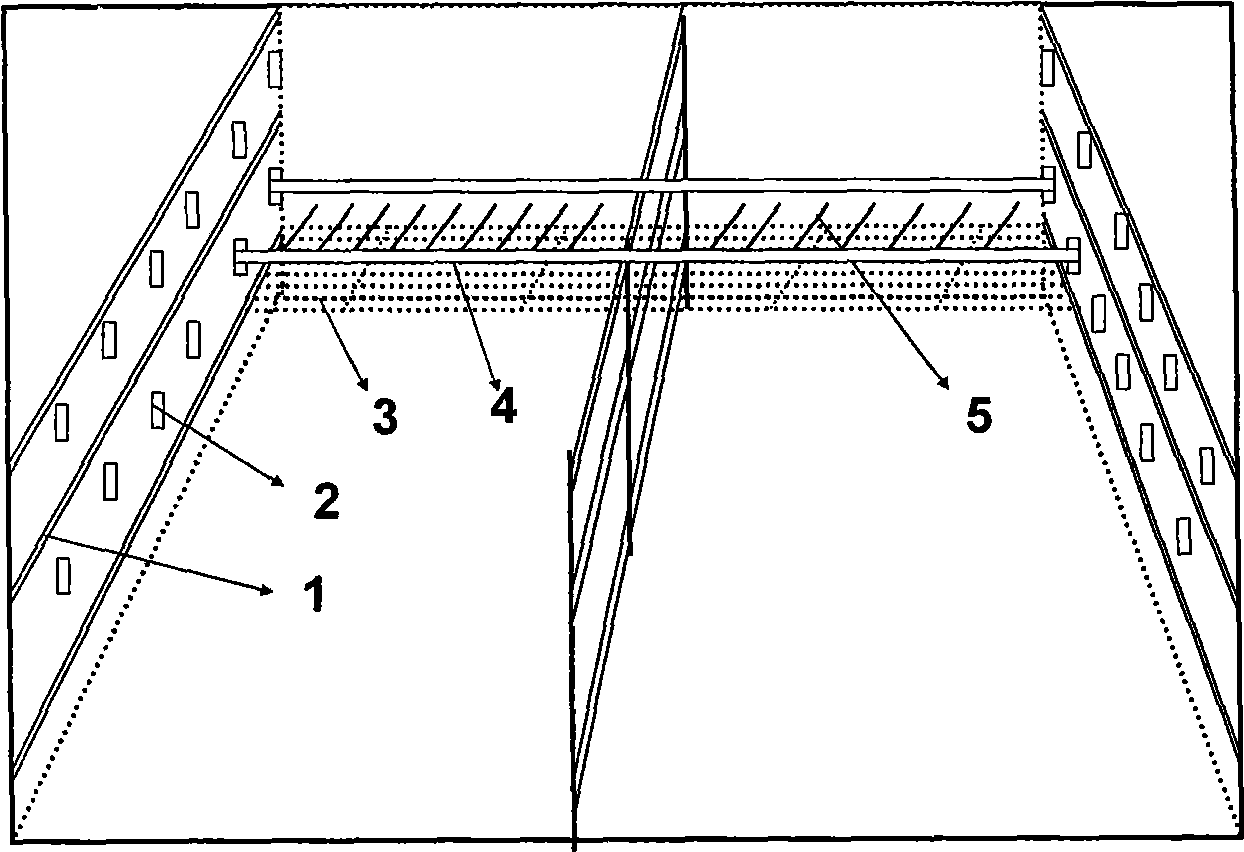

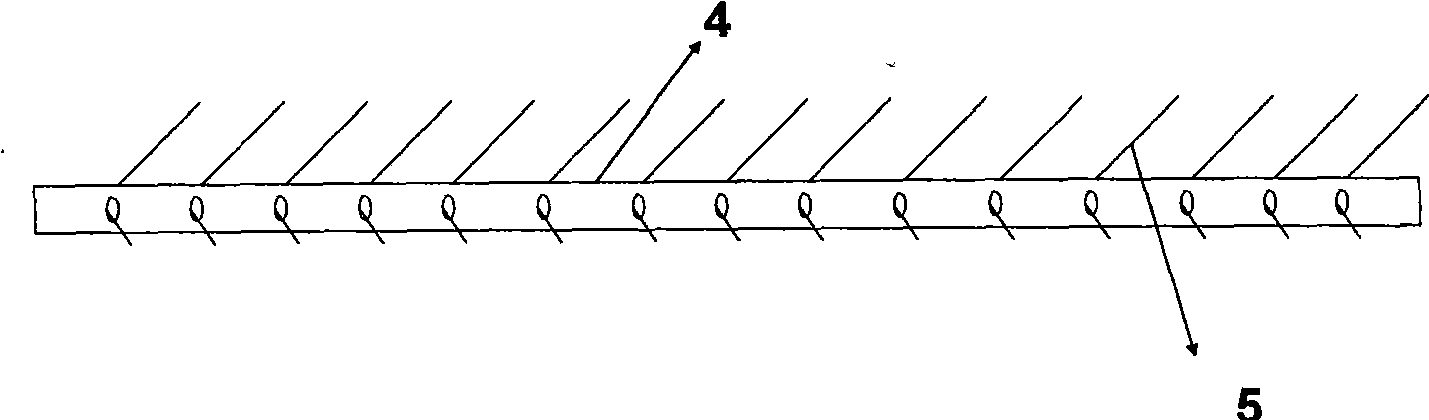

[0019] Such as figure 1 with figure 2 As shown, install the smoke mounting bracket (1) on the two side walls and the center of the barn, and install the fixing groove (2) on the top of the smoke bar on both sides of the wall; make the air divider according to the inner space specification of the barn (3), fixed square bar (4) and pin (5); image 3 As shown, place the smoke-loading partition (3) on the smoke-loading bracket (1) in turn, put the fixed square rod (4) into the fixing groove (2) above the smoke-loading bracket (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com