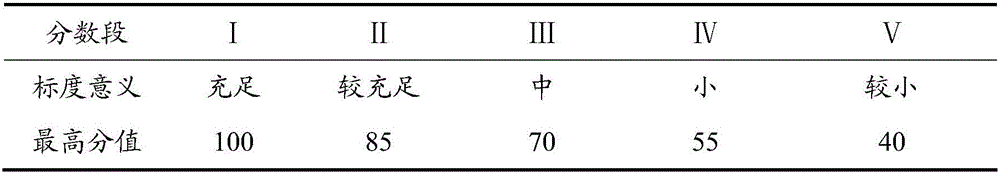

Patents

Literature

73results about How to "Large amount of smoke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

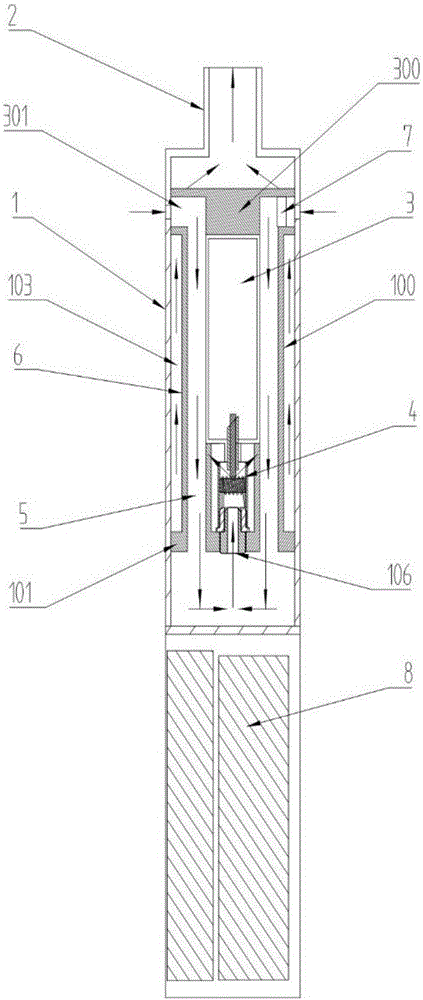

Electronic cigarette

ActiveCN105876869APrevent smoke oil leakageSimple stand-alone structureTobacco devicesSmokeElectrical and Electronics engineering

An electronic cigarette comprises a shell. A liquid storage part, an atomization head, an air inlet channel, a smoke outlet channel and a battery module are arranged in the shell. The liquid storage part comprises a liquid storage cavity, the atomization head is arranged outside the liquid storage part and communicated with the liquid storage cavity, the air inlet channel and the smoke outlet channel are formed outside the liquid storage part and communicated with the atomization head, the atomization head and the sensor are electrically connected with the battery module, an air inlet is formed in the shell and communicated with the air inlet channel, and the sensor is arranged outside the air inlet or arranged at the position, close to the air inlet, in the air inlet channel. According to the electronic cigarette, the automatic cigarette lighting function is achieved, and it is guaranteed that the liquid storage part is simple in structure as no component is arranged in the liquid storage part.

Owner:JOYETECH EURO HLDG

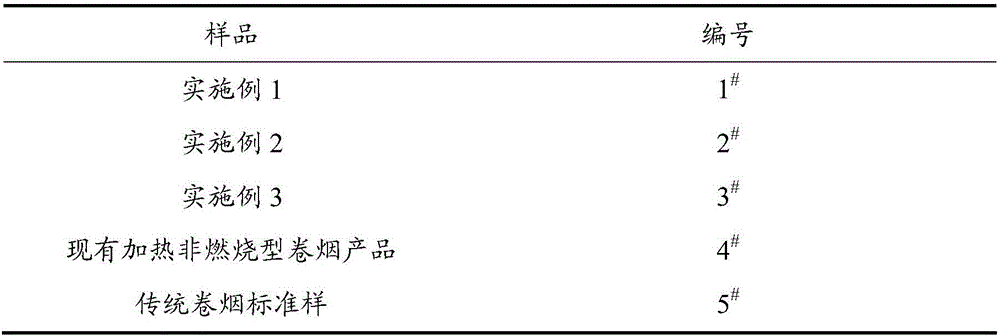

Reconstituted tobacco applicable to heating of non-combustion cigarettes

InactiveCN106235376AThe production process is simple and matureSimple production processTobacco preparationFlavorCombustion

The invention provides reconstituted tobacco applicable to heating of non-combustion cigarettes. The tobacco is prepared from, by mass, 65-80% of tobacco raw materials, 15-25% of a smoke agent, 0.5-5% of an adhesive and 0-5% of tobacco flavor. The reconstituted tobacco is made by adopting the thick slurry method production technology, and the thickness is 0.10-0.20 mm. The thick slurry method is adopted for producing the reconstituted tobacco, the production technology is mature, simple, high in controllability and stable in quality, and when the reconstituted tobacco manufactured through the method is used for heating the non-combustion cigarettes, and compared with similar products, the reconstituted tobacco has the obvious advantages of being sufficient in tobacco incense, proper in physiological satisfaction, large in smoke amount and adjustable in flavor style characteristic.

Owner:HUBEI CHINA TOBACCO IND

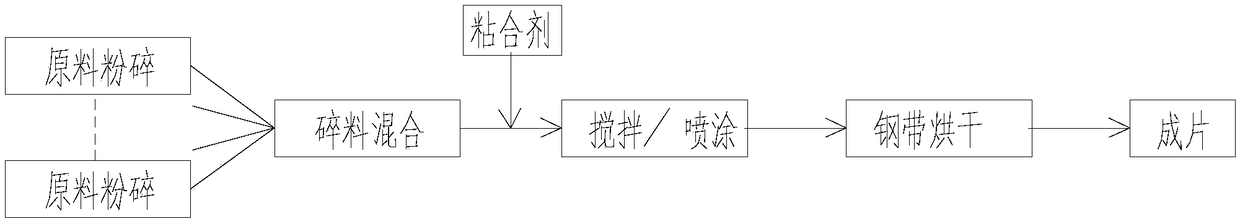

Ultra-micro powder plant slice and preparation method thereof

The invention relates to an ultra-micro powder plant slice and a preparation method thereof. The preparation method comprises the steps that ultra-micro plant powder, outer margin fibers, an adhesiveand other additives are homogenized to form adhesive colloidal fluid, the adhesive colloidal fluid is extruded to form a slice shape, and drying formation is conducted. The plant slice is suitable fora heat-not-burn flavor-producing section, the plant slice is large in smoke formation amount, rich in fragrance and high in physiological satisfiability, the smoke flavor is close to natural plant fragrance, the product density and the filling value are close to those of natural plant leaves, the machining performance is high, and the amount of water required during production is small; no wastewater is generated, the raw material utilization rate is high, the plant slice meets the requirements for energy conservation and environment protection, the production technology is simple, and the preparation method is suitable for industrial production.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD +1

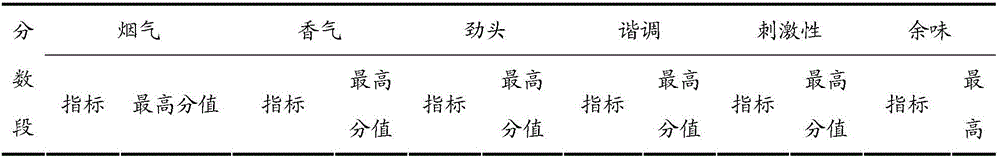

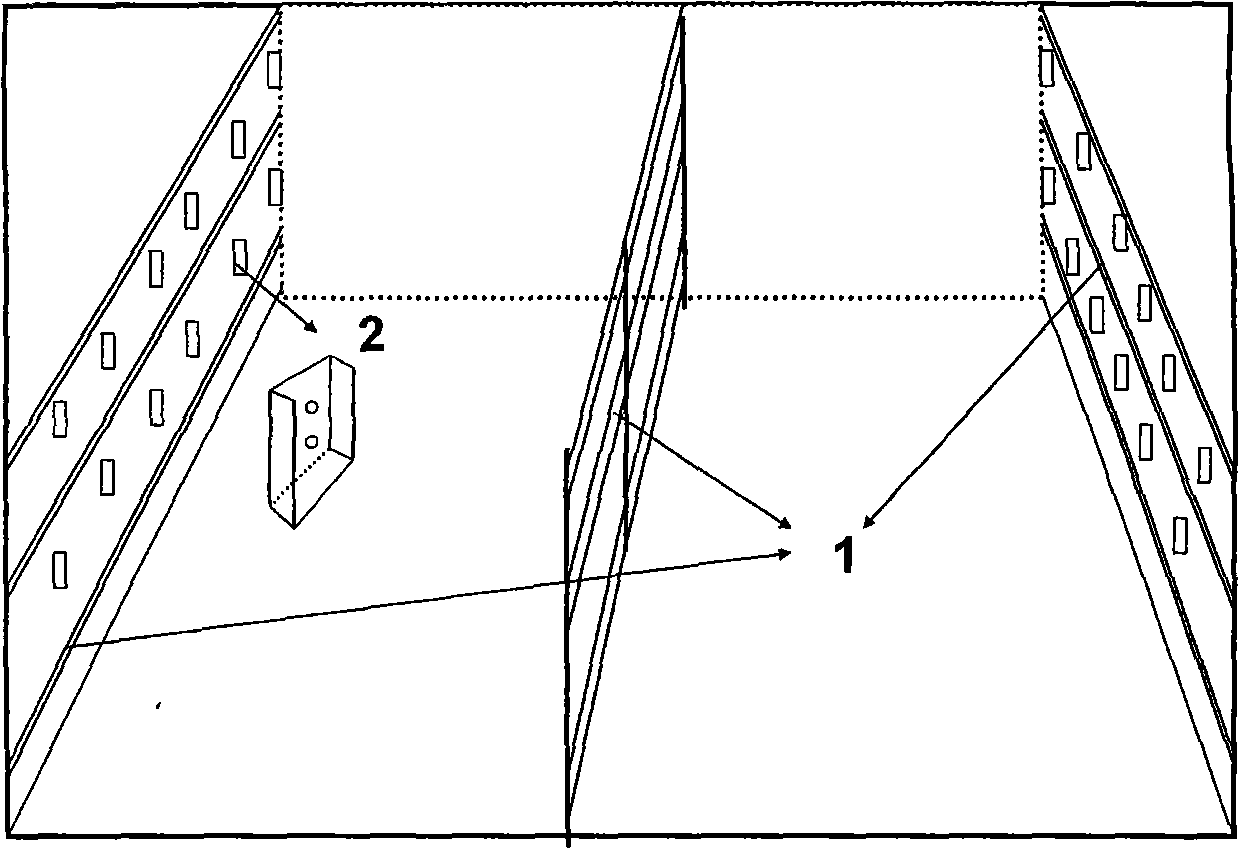

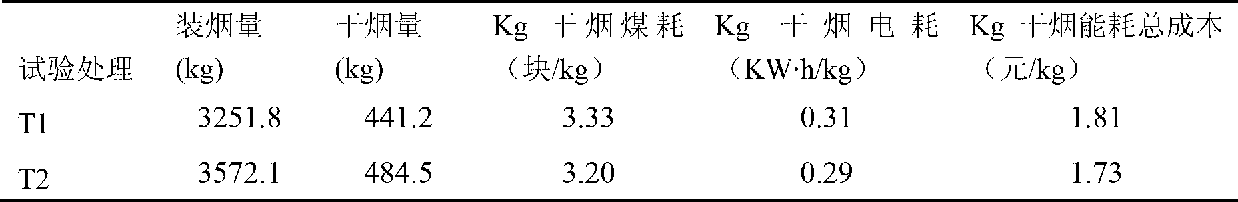

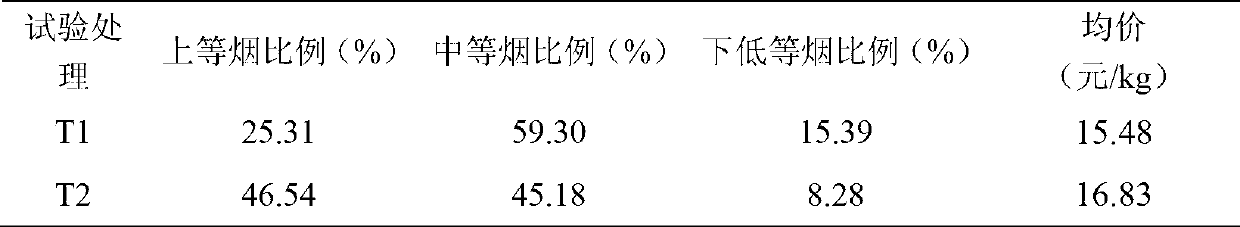

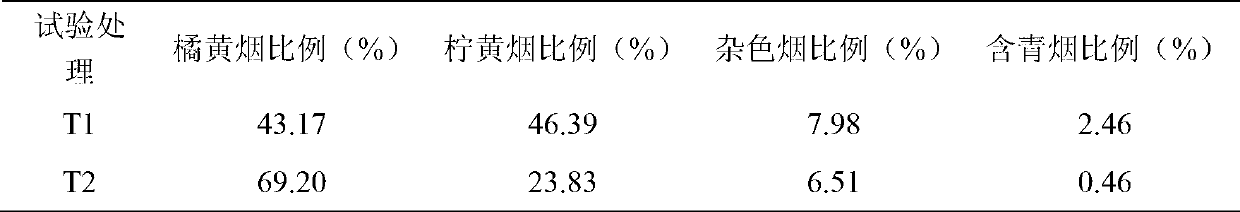

Close hothouse loose-tobacco loading method

The invention discloses a loose tobacco filling method for a bulk curing barn, which comprises the following steps: firstly, manufacturing fixed square bars, a loose tobacco air-distributing partition board and metal contact pins, arranging a tobacco filling bracket and a fixed groove in the bulk curing barn, horizontally placing the air-distributing partition board on the tobacco filling bracket in the curing barn, and inserting the fixed square bars into the fixed groove; and loosing bundled tobacco leaves before tobacco filling, stacking the loose tobacco leaves with leaf tips upward and leaf bases downward, filling the fresh tobacco leaves into two fixed square bars tidily, then inserting the contact pins into holes of the fixed square bars to fix the tobacco leaves, and curing the tobacco leaves after the curing barn is fully filled with the tobacco leaves. The method has the following advantages: (1) the tobacco filling amount is large and is increased by 30 percent compared with a rod hanging method and increased by 10 percent compared with a loose tobacco stacking method, and the utilization rate of the curing barn is high; (2) the method saves labor and energy, saves about 70 percent of labor, and reduces coal and electricity consumption by 20 percent; (3) the method fills the tobacco tidily and reserves even gaps for the tobacco leaf bases, so the method is favorable for discharging moisture and prevent the tobacco leaves form smoothening and not stretching, and the method is easy to control the curing operation; (4) the structure is simple, and the material cost is reduced by 60 percent; and (5) the bulk curing barn is convenient to load and unload.

Owner:GUIZHOU TOBACCO SCI INST

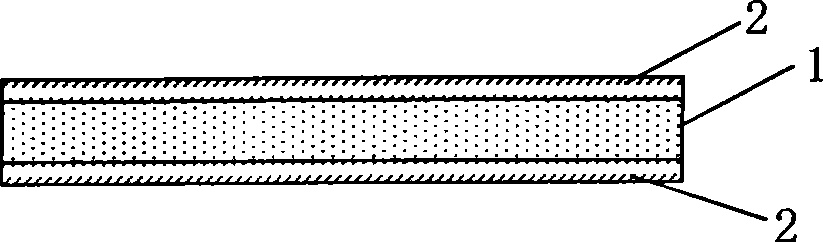

PIR energy-conserving thermal insulation board of polyurethane-modified hard polyisocyanurate foamed plastic

InactiveCN101509590ABreak through the limitations of the application fieldImpede burningThermal insulationLayered productsPolymer scienceThermal insulation

The invention relates to a polyurethane modified hard isocyanuric acid ester foamed-plastic PIR energy-saving heat preserving plate which features a PIR sandwich plate structure or a PIR plate structure. In the PIR sandwich plate structure, a middle sandwich layer is a polyurethane modified hard isocyanuric acid ester foamed-plastic PIR macromolecular structure monomer; an upper surface and a lower surface of the middle sandwich layer are metal or non-metal sheets; the PIR plate structure refers to the attachment-free polyurethane modified hard isocyanuric acid ester foamed-plastic PIR macromolecular structure monomer formed according to box type foaming. The polyurethane modified hard isocyanuric acid ester foamed plastic is a novel macromolecular structure obtained by embedding a polyurethane molecular chain into polymer isocyanuric acid ester molecular chain. The invention has the advantage that compared with polyurethane heat preserving material, the energy-saving heat preserving plate of the invention has good fireproof performance and better heat preserving property.

Owner:上海万国科技发展有限公司

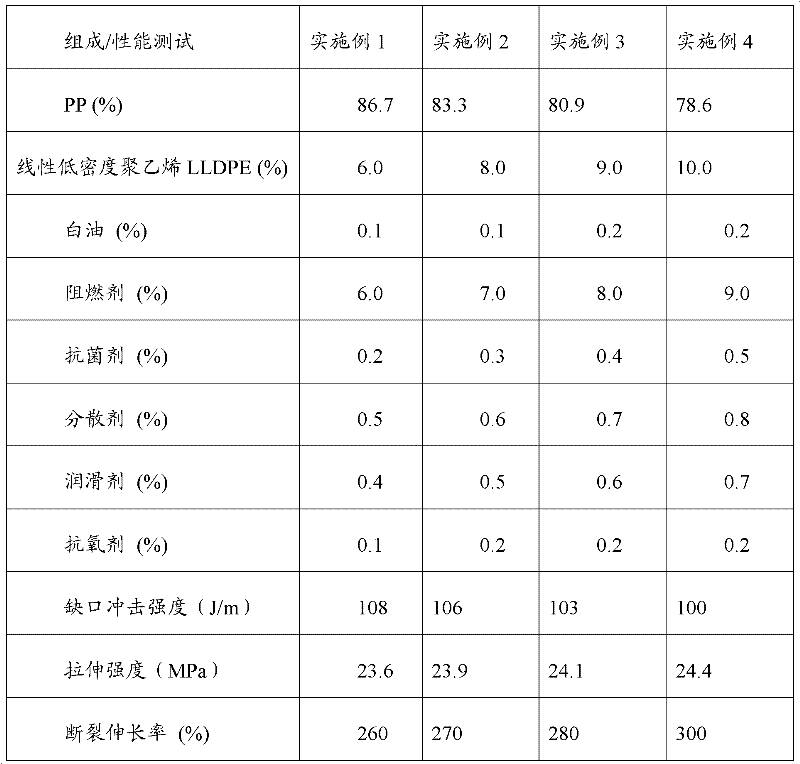

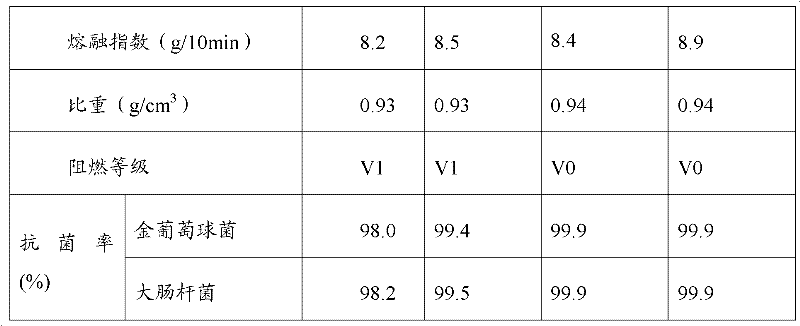

Flame-retardant anti-bacteria polypropylene composite material and preparation method thereof

The invention discloses a flame-retardant anti-bacteria polypropylene composite material and a preparation method thereof. The flame-retardant anti-bacteria polypropylene composite material is prepared by the following raw materials according to the weight percentage: 78.6% to 86.7% of polypropylene, 6.0% to 10.0% of linear low-density polyethylene, 0.1% to 0.2% of white oil, 6.0% to 9.0% of fire retardant, 0.2% to 0.5% of anti-bacterial agent, 0.5% to 0.8% of dispersant, 0.4% to 0.7% of lubricant, and 0.1% to 0.2% of oxidation inhibitor. The raw materials are weighed according to the above weight percentages so as to be mixed uniformly, melted and extruded by a double-screw extruder and pelleted. The preparation method is simple in technology, low in cost and high in cost performance, and has fire retardant property and anti-bacterial performance, and the prepared material is excellent in combination property.

Owner:SHENZHEN KEJU NEW MATERIAL

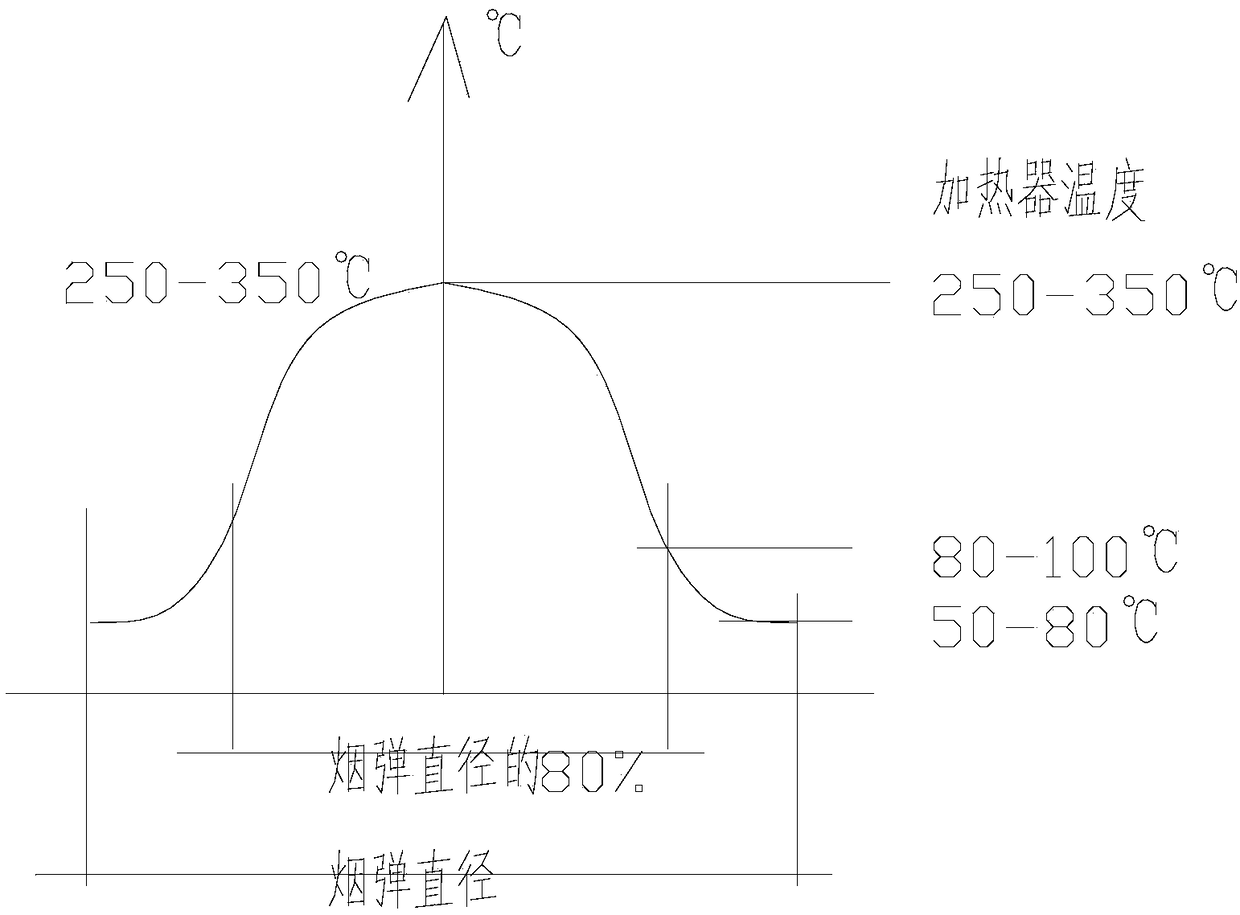

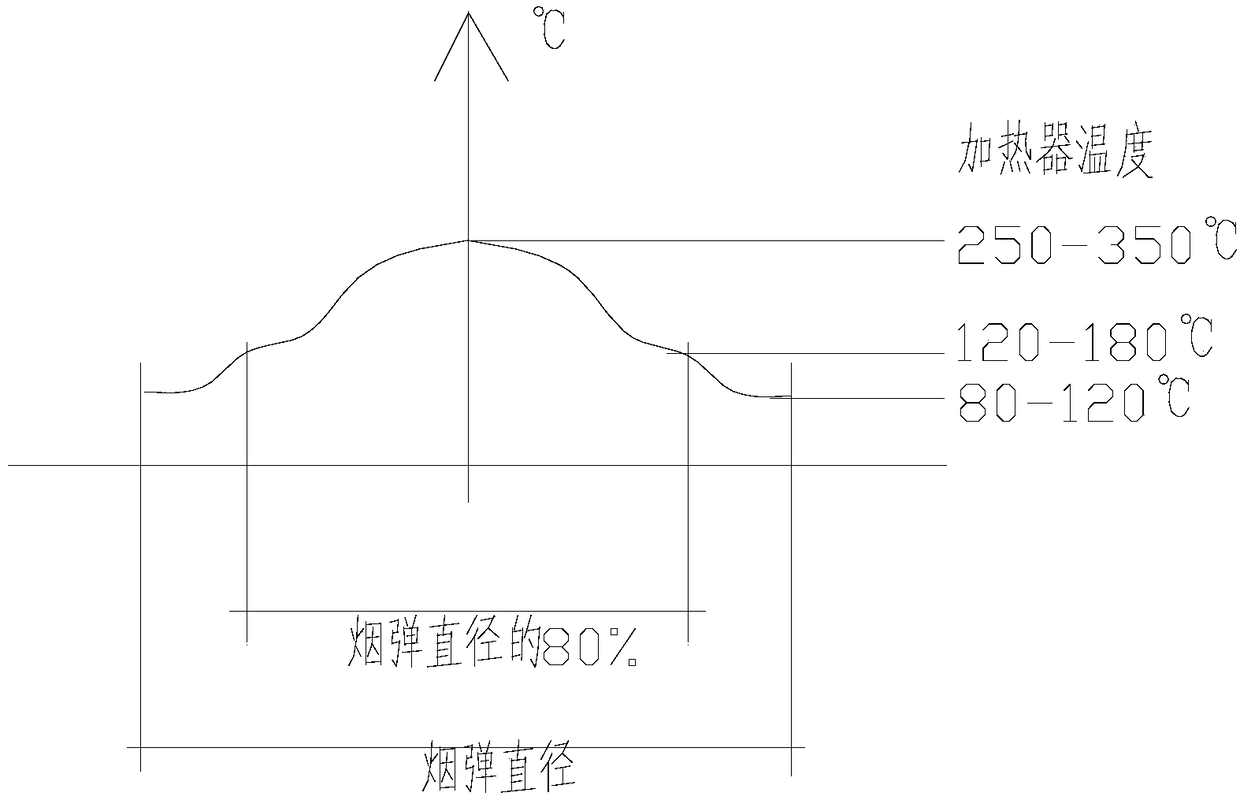

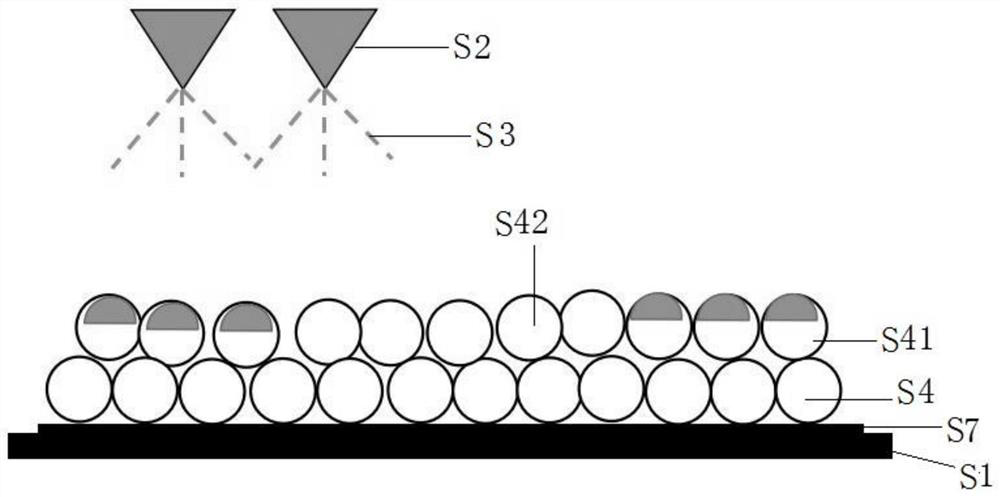

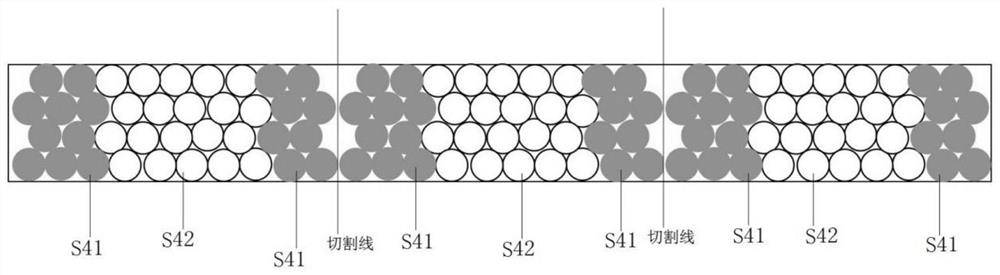

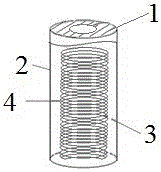

A substrate capable of raising heating temperature and increasing smoke emission amount and a preparation method thereof

The invention relates to a substrate capable of raising heating temperature and increasing smoke emission amount, which is prepared by pulverizing tobacco raw material and pulping plant fibers throughthick pulp method or other similar papermaking method. A metal product and an adhesive are added to that tobacco substrate during the preparation process, and the substrate is finally formed into a smoky rod by cutting or slicing through roll, and is a filler material for heating a smoky bomb, wherein a smoky substance (propylene glycol, for example) contained therein is heated and evaporated toform smoke.

Owner:江苏瑞驰机电科技有限公司

Tobacco leaf prewilting baking process for bulk curing barn

InactiveCN102987540ALarge amount of smokePromote post-ripening and physiological and biochemical reaction processTobacco preparationCuring of tobaccoLeaf blade

The invention provides a tobacco leaf prewilting baking process for a bulk curing barn. The tobacco leaf prewilting baking process for the bulk curing barn provided by the invention comprises the concrete steps of clamping the collected fresh tobacco leaves with a weaving pole or a tobacco clamp, prewilting on a shady tobacco hanging frame, so that the tobacco leaves meet prewilting requirement, then transferring the tobacco leaves into the bulk curing barn, and warming for twice to meet the yellowing requirement, wherein 2-3cm of apex of the tobacco leaves from a bottom shed to a middle shed is in an almost dry state; then warming for twice and baking until the tobacco leaves are dried into large winding drums and leaf blades are absolutely dry; and then warming at the speed of 0.5 DEG C per hour until the temperature is increased to 68 DEG C, controlling wet bulb temperature to be 42-43 DEG C, and maintaining rotating speed of a fan to be 720 revolutions until stems of the tobacco leaves are completely dry. By adopting the tobacco leaf prewilting baking process provided by the invention, tobacco leaf stacking capacity of the bulk curing barn is greatly increased, baking energy consumption is reduced, and the problem that starch content of the tobacco leaves after being baked and mixed colour tobacco proportion are high is solved, so that economic character of the tobacco leaves after being baked is improved.

Owner:TOBACCO RES INST OF HUBEI PROVINCE

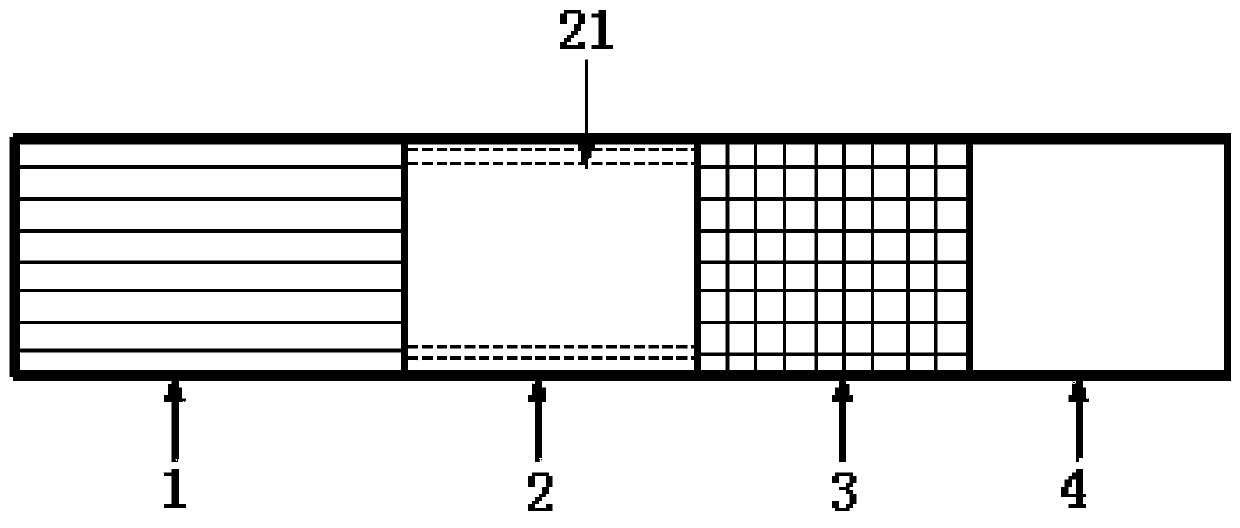

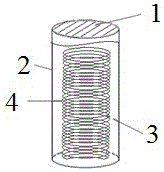

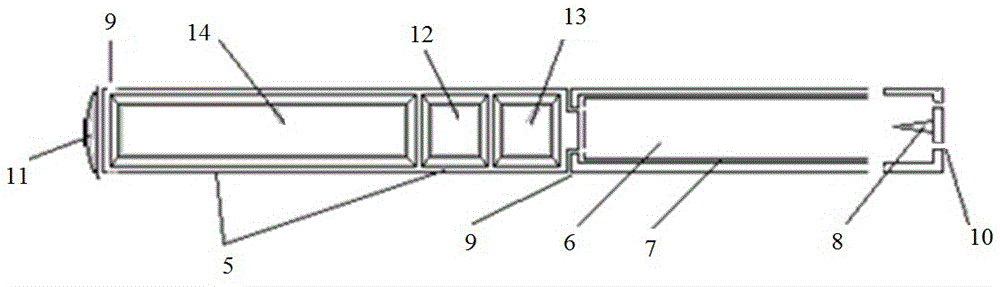

Cigarette used for heating non-combustion cigarette

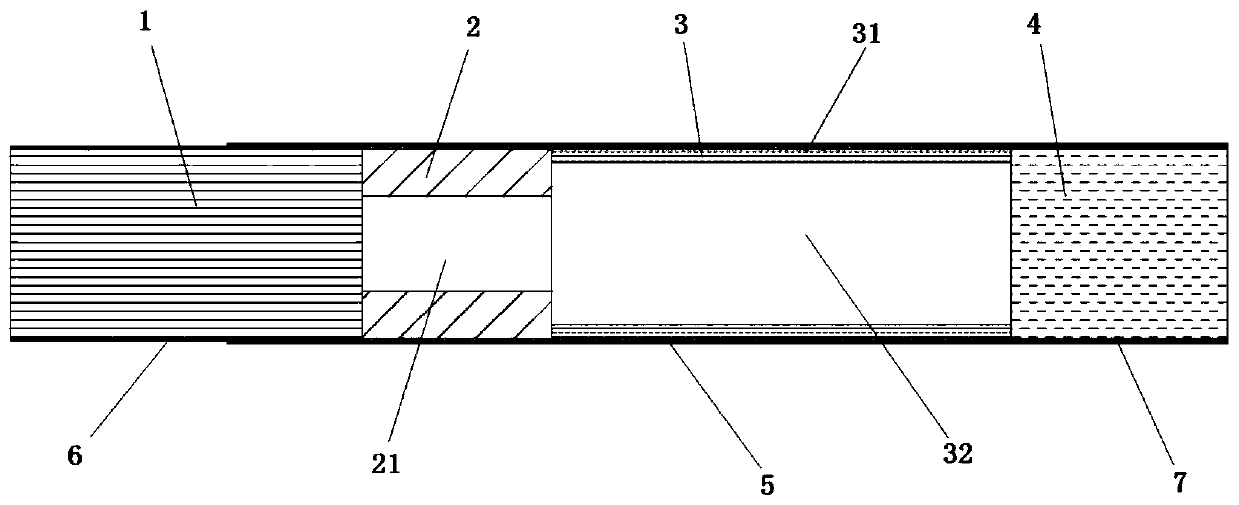

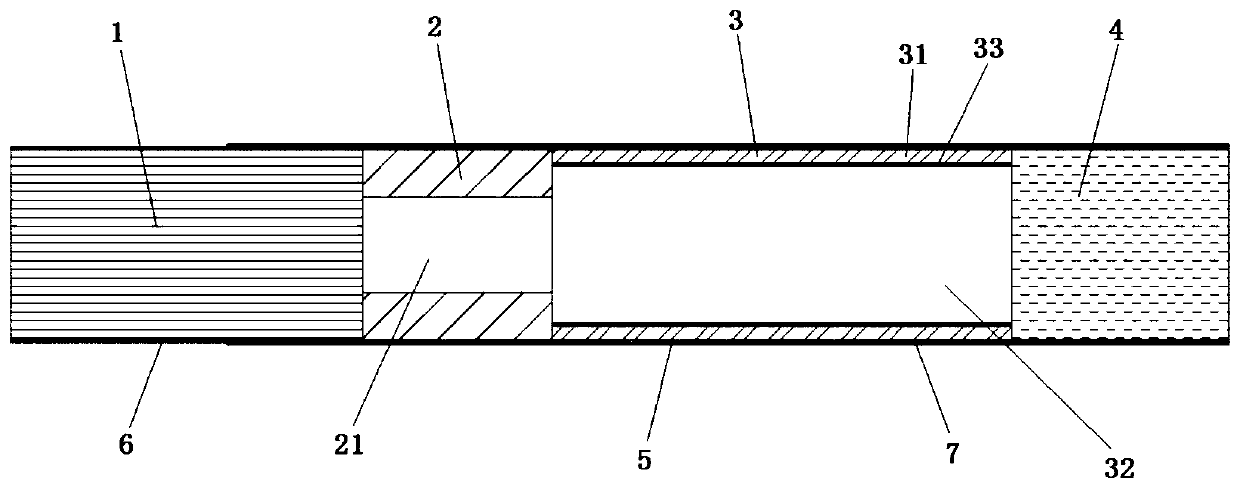

PendingCN109998158AReduce retentionImprove throughputCigar manufactureTobacco devicesCombustionCigarette use

The invention discloses a cigarette used for a heating non-combustion cigarette. The cigarette sequentially comprises a cigarette core section (1), a support section (2), a cooling section (3) and a filter tip section (4), wherein the support section (2) is provided with an axial cavity (21); the cooling section (3) is a hollow pipe with a pipe wall (31) and a pipe cavity (32), and the inner wallof the pipe wall (31) is a non-woven fabric layer adopting a high polymer material; and the support section (2), the cooling section (3) and the filter tip section (4) are wrapped by forming paper (5)to form a ternary compound tip rod, the cigarette core section (1) is wrapped by cigarette paper (6) to form a tobacco section, and the ternary compound tip rod and the tobacco section are connectedand mounted through tipping paper (7). For the cooling section of the cigarette, while the cooling effect is guaranteed, the interception for smoke is reduced, then the passing amount of the smoke isincreased, meanwhile, the cooling section seldom collapses, and therefore, the support performance of the cooling section for the cigarette is improved.

Owner:CHINA TOBACCO YUNNAN IND

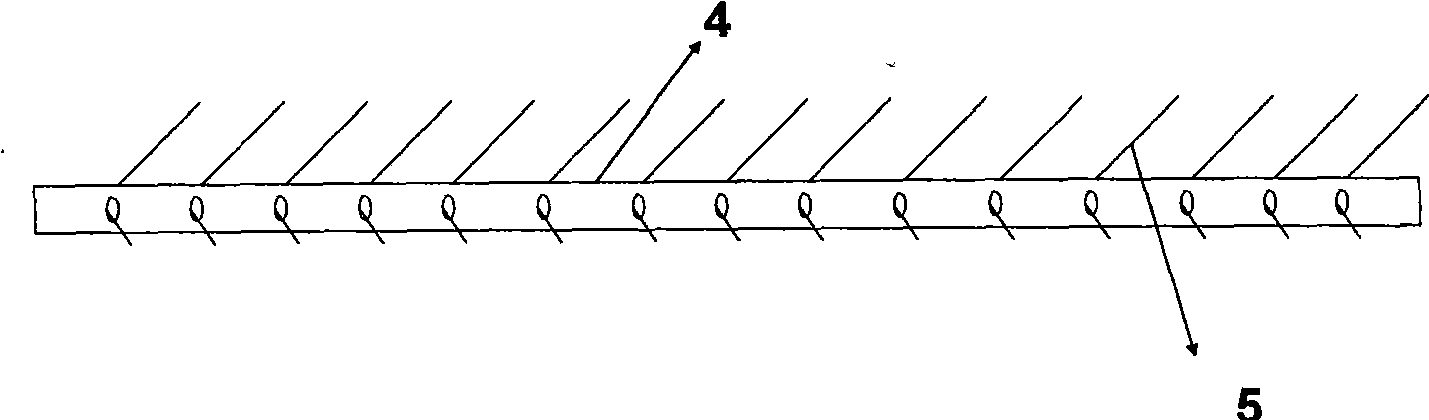

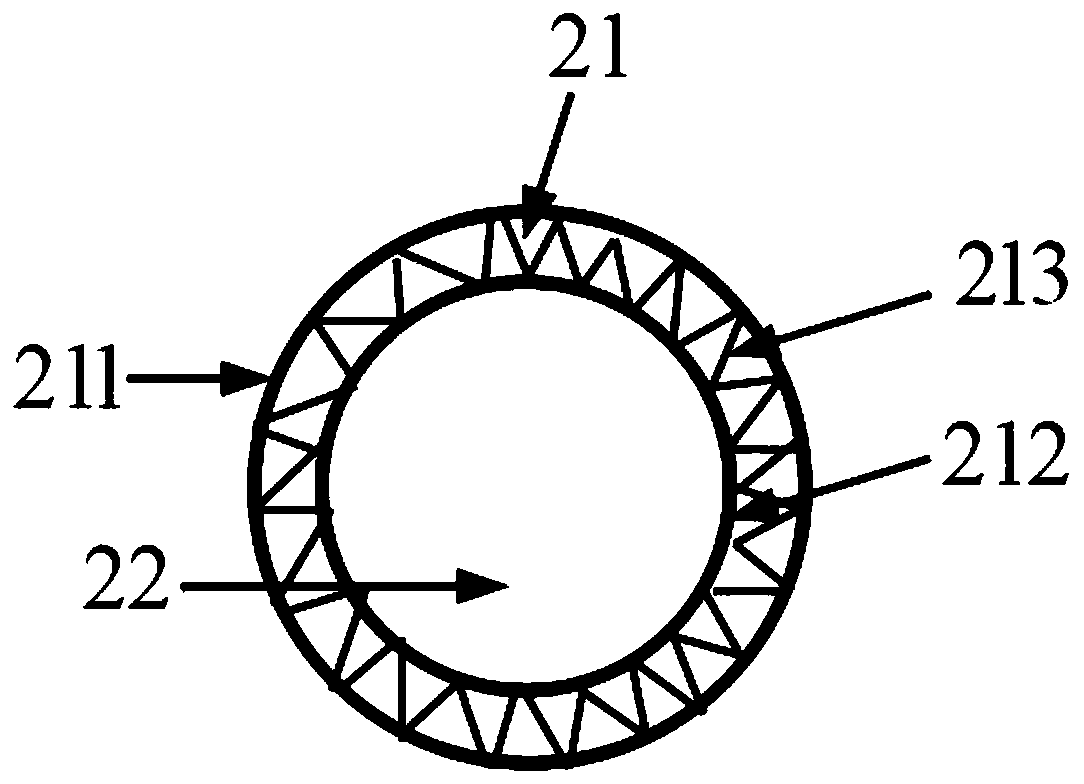

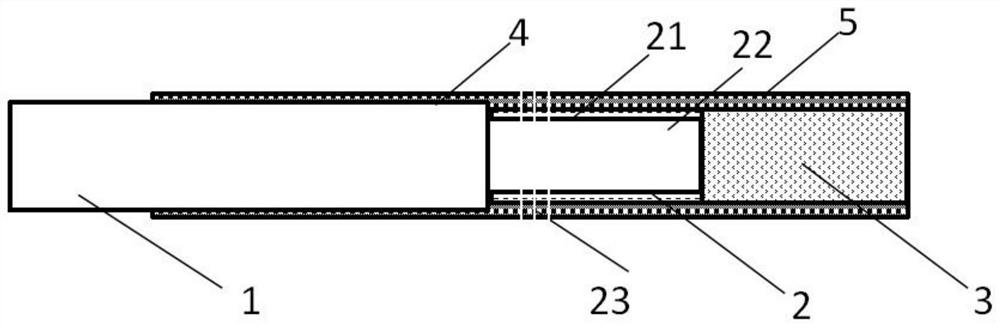

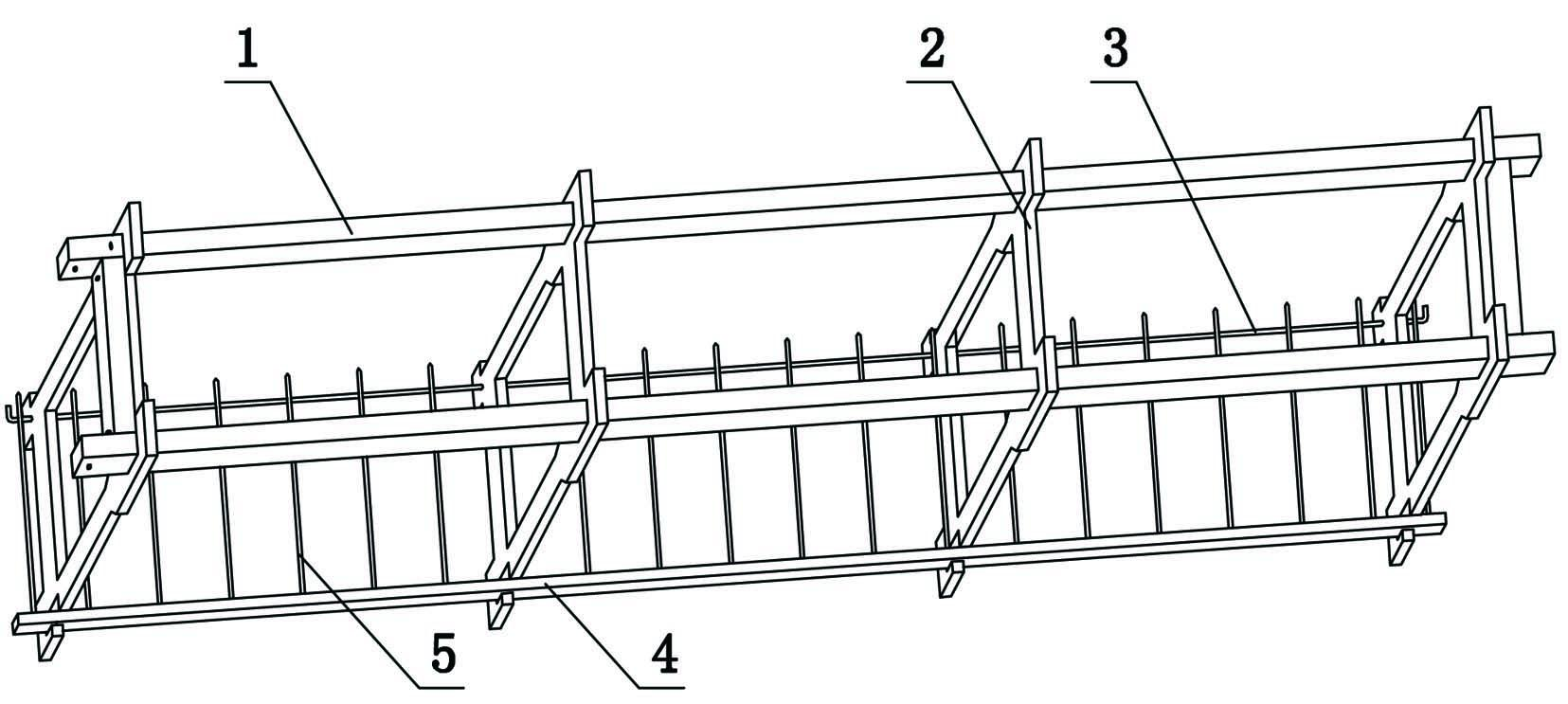

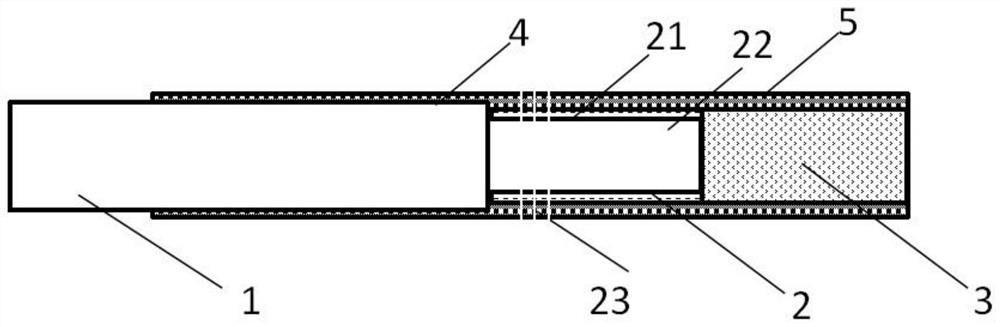

Cigarette support for heating non-burning cigarettes

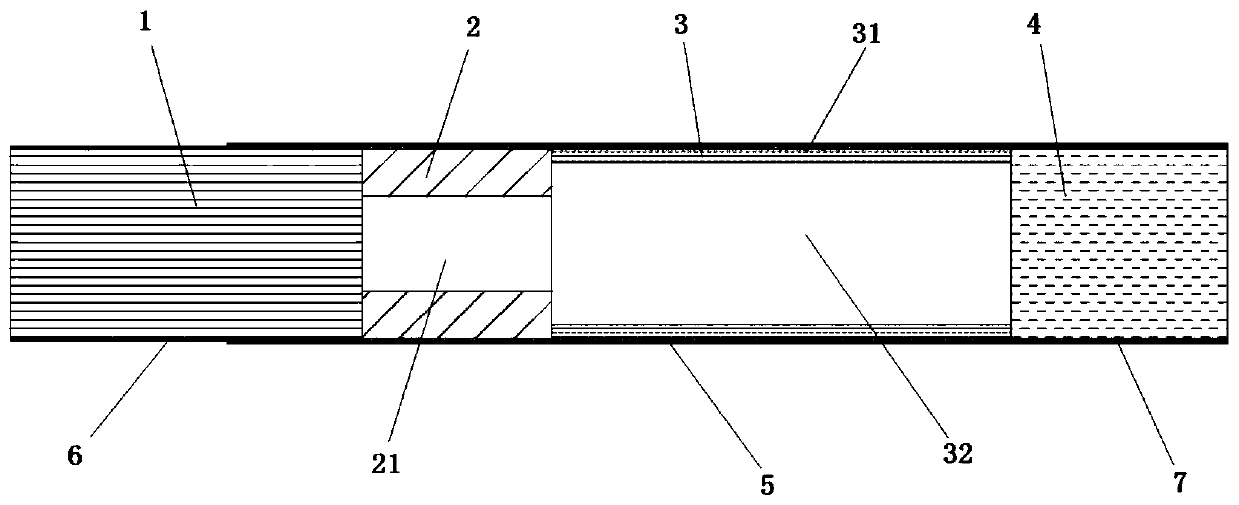

PendingCN110037338AReduce retentionImprove throughputCigar manufactureTobacco devicesCooling effectComposite filter

The invention discloses a cigarette support for heating non-burning cigarettes. The cigarette support comprises a cigarette core section (1), a cooling section (2) and a filter tip section (3) in sequence; the cooling section (2) is a hollow pipe with a pipe wall (21) and a pipe cavity (22), and the inner wall of the pipe wall (21) is a polymer material non-woven fabric layer (23); the cooling section (2) and the filter tip section (3) are wrapped in forming paper (4) to form a binary composite filter tip rod; the tobacco core section (1) is wrapped in cigarette paper (5) to form a tobacco section, and the binary composite filter tip rod and the tobacco section are spliced with each other through splicing paper (6). According to the cigarette support, the cooling section of the cigarette support ensures the cooling effect; at the same time, the interception of smoke is reduced, and the passing flow of the smoke is increased. Meanwhile, the cigarette filter tip rod is the binary composite filter tip rod, so that the cigarette filter tip rod is simpler to produce and low in cost.

Owner:CHINA TOBACCO YUNNAN IND

Aerosol disinfectant for edible fungus and preparation method thereof

InactiveCN101411336ALarge amount of smokeImprove disinfection and sterilization efficiencyBiocideFungicidesHigh concentrationDisinfectant

The invention discloses an edible fungus smoke disinfectant and a preparation method thereof, which are used to solve the disinfection and sterilization problems during the production of edible fungi. The technical proposal of the invention comprises that the edible fungus smoke disinfectant is prepared by the following raw materials in weight unit: 100 portions of sodium dichloro isocyanurate powder, 4 to 13 portions of potassium permanganate, 4 to 11 portions of starch, and 8 to 16 portions of stearate. The invention also provides the preparation method for the disinfectant. After the edible fungus smoke disinfectant is ignited, the edible fungus smoke disinfectant has quick smoke formation, fine smoke particles, and large smoke formation amount, and forms high-concentration aerosol, thereby ensuring that effective constituents are quickly dispersed and perpetually floated to achieve the aims of high-efficiency disinfection and sterilization.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

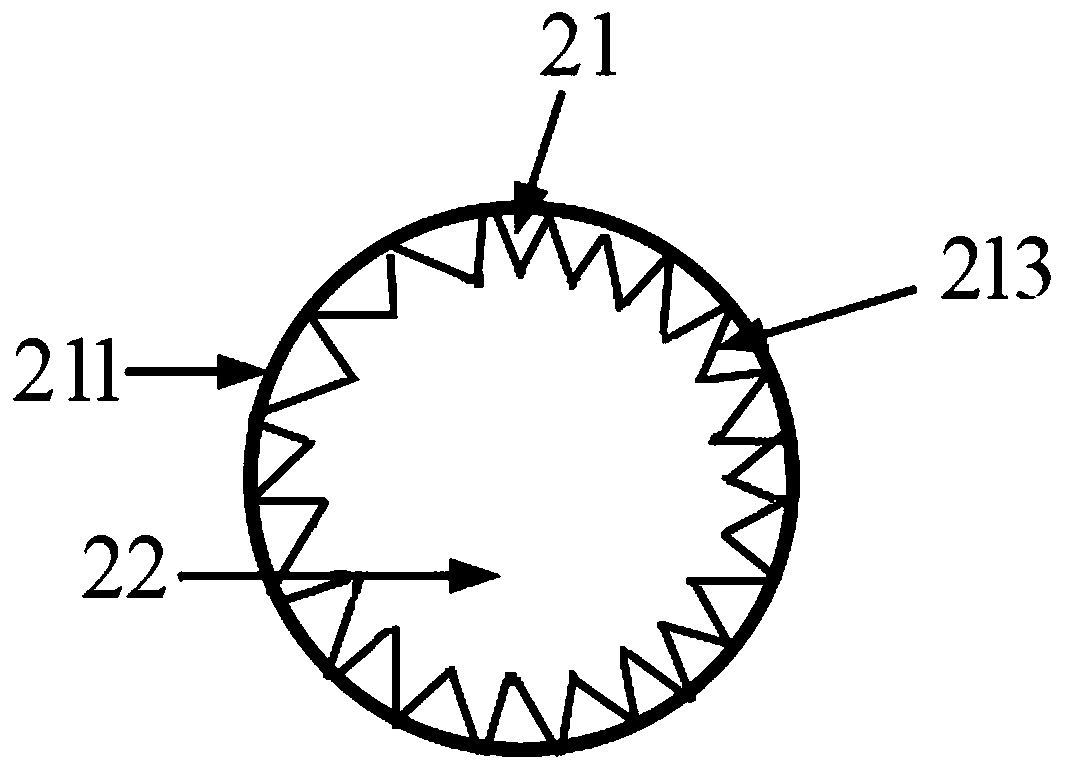

Heating non-combustion cigarette

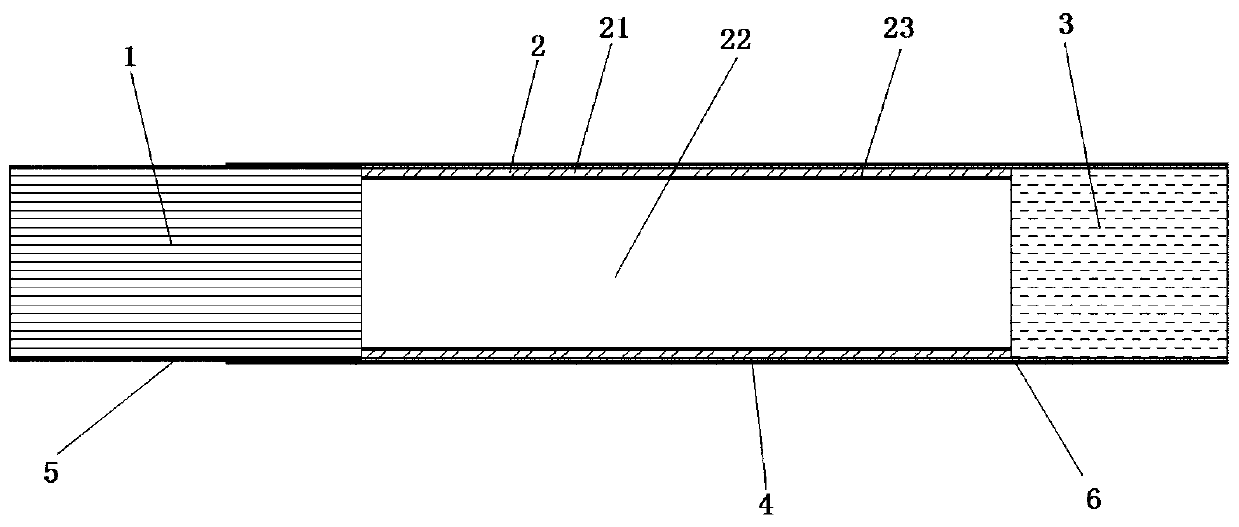

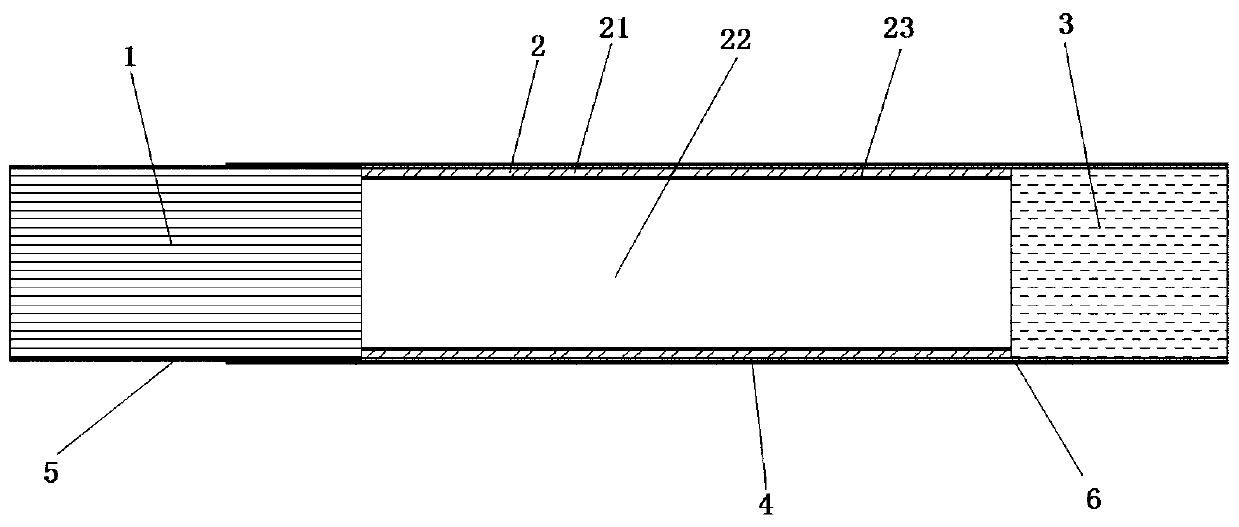

PendingCN109998160AImprove machine adaptabilityIncrease elasticityCigar manufactureTobacco devicesCombustionBiomedical engineering

The invention discloses a heating non-combustion cigarette. The heating non-combustion cigarette sequentially comprises an aerosol generating section (1), a support element (2), a cooling section (3)and a filter tip section (4), wherein the support element (2) is a hollow tube with a tube wall (21) and a tube cavity (22), the tube wall (21) comprises an outer wrapping layer (211) and a groove corrugated layer (213), and the groove corrugated layer (213) is close to the tube cavity (22). After the tube wall (21) of the support element (2) is subjected to a cutter, the deformed part can rebound, the on-machine adaptation of the support element (2) is good, so that the production efficiency and the product quality of the cigarette are improved, meanwhile, the support element (2) seldom collapses, and the supporting property of the support element (2) for the cigarette is high.

Owner:CHINA TOBACCO YUNNAN IND

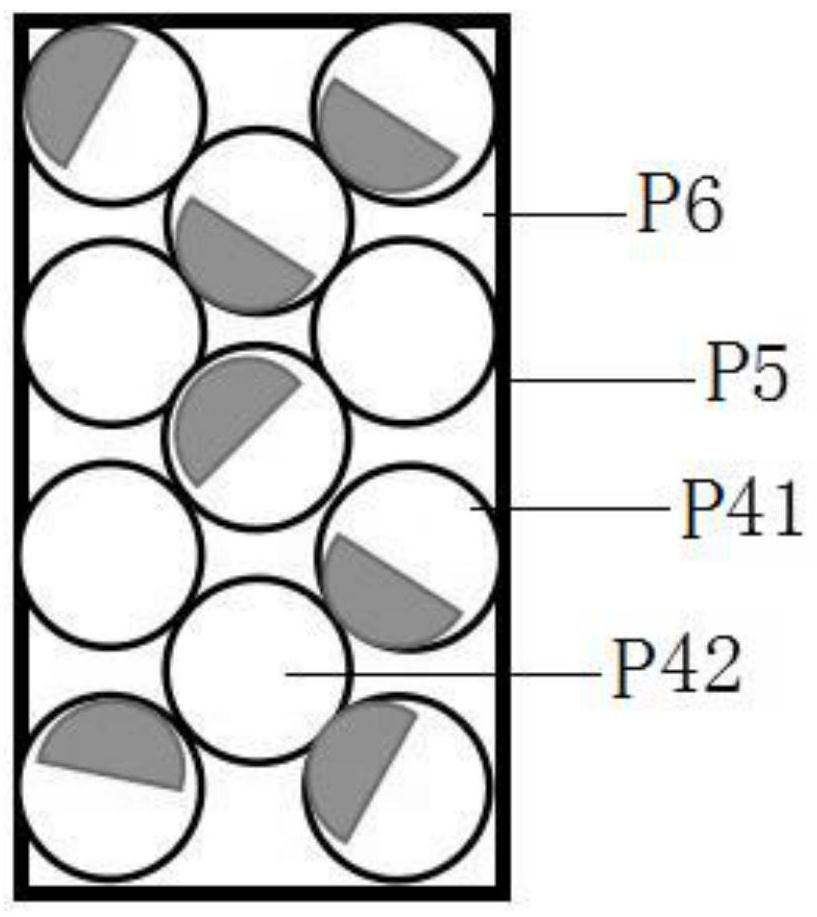

Aerosol generating product with sectional aerosol generating substrate rod

PendingCN113925196AGuaranteed releaseGuaranteed ventilationCigar manufactureTobacco smoke filtersThermodynamicsAdhesive

The invention discloses an aerosol generating product with a sectional aerosol generating substrate rod, which is characterized by comprising a smoke generating core material section (1), a breathable hollow section (2) and a filter section (3), the smoke generating core material section (1) comprises a sectional type aerosol generating matrix rod and anti-seepage / heat-conducting cigarette paper wrapping the sectional type aerosol generating matrix rod, the two ends of the sectional type aerosol generating matrix rod are short rod sections (11) formed by bonding sizing tobacco particles, and the middle of the sectional type aerosol generating matrix rod is a scattered particle section (12) formed by non-sizing tobacco particles; the breathable hollow section (2) and the filter section (3) are wrapped by the forming paper (5) to form a filter rod, and the smoke generating core material section (1) and the filter rod are connected through the tipping paper (4). The short rod sections (11) at the two ends can ensure that tobacco particles which are not bonded in the middle do not fall off and scatter, no adhesive exists on the surfaces and in gaps of the tobacco particles which are not bonded in the middle, and the axial ventilation capacity, porosity and smoke release amount of the aerosol generation matrix rod are ensured. The cigarette core with high porosity not only can increase the smoke amount, but also can simplify the structure of an aerosol generating product.

Owner:CHINA TOBACCO YUNNAN IND

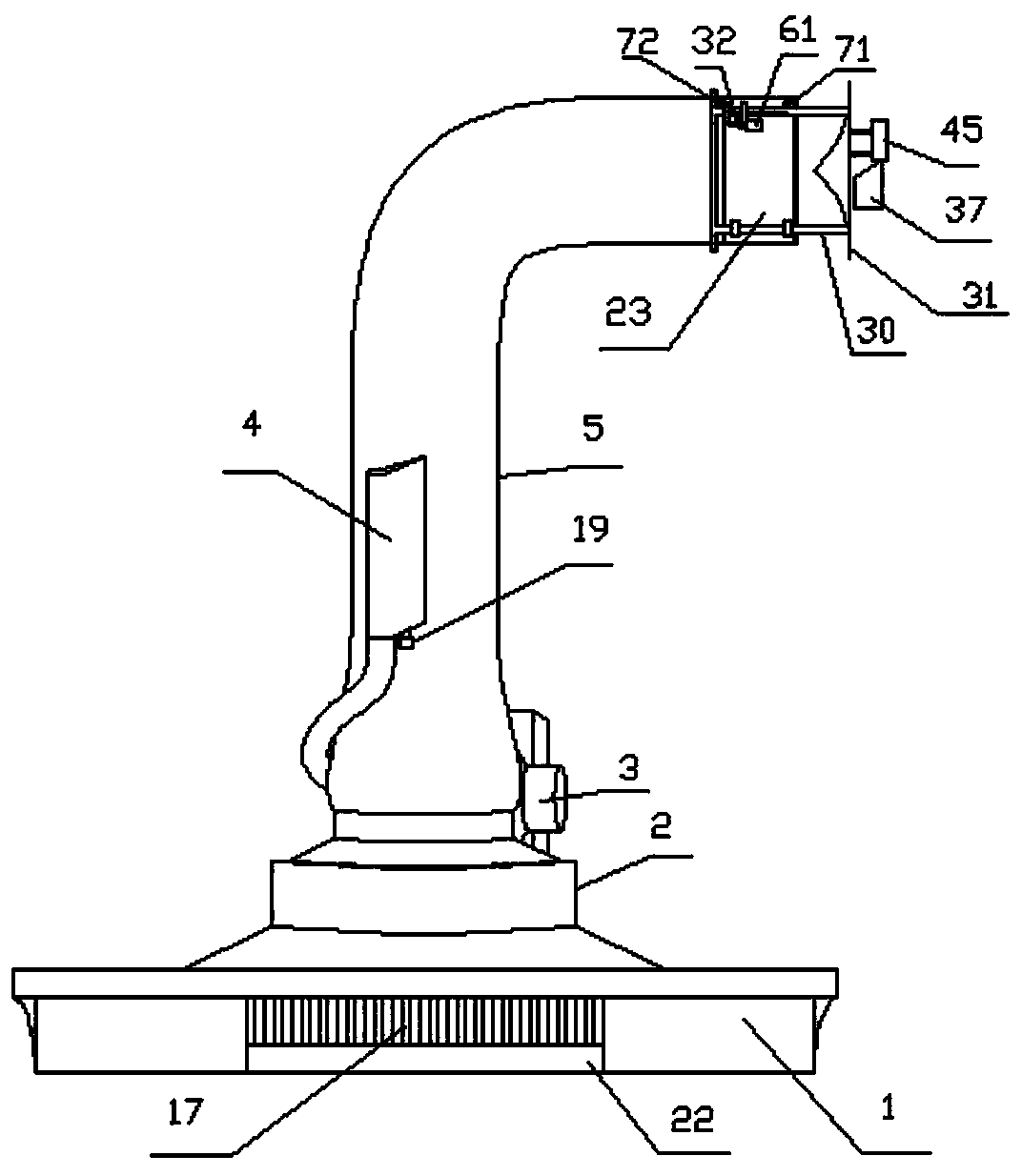

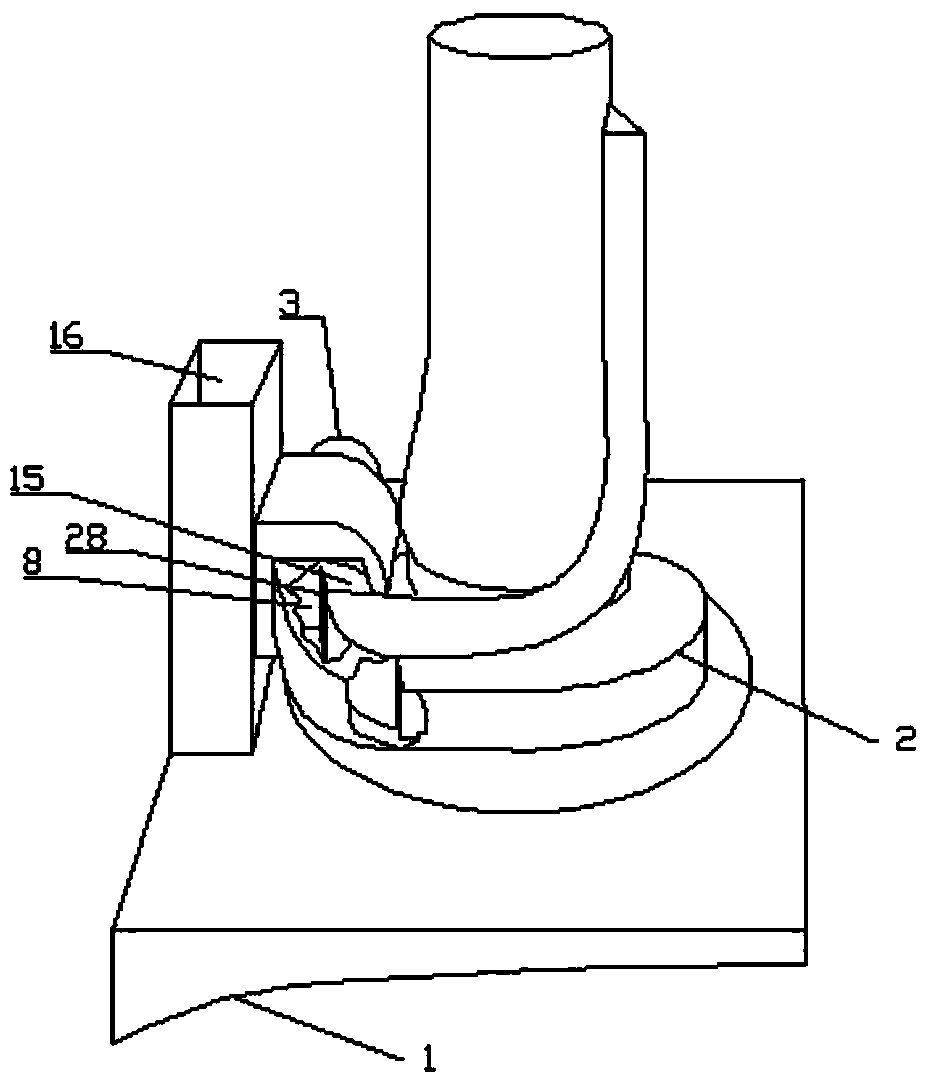

Cooking fume extraction method and smoke exhaust ventilator manufactured by utilizing cooking fume extraction method

ActiveCN104061612AReduce energy consumptionLarge amount of smokeDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke

Owner:江苏择善精密机械有限公司

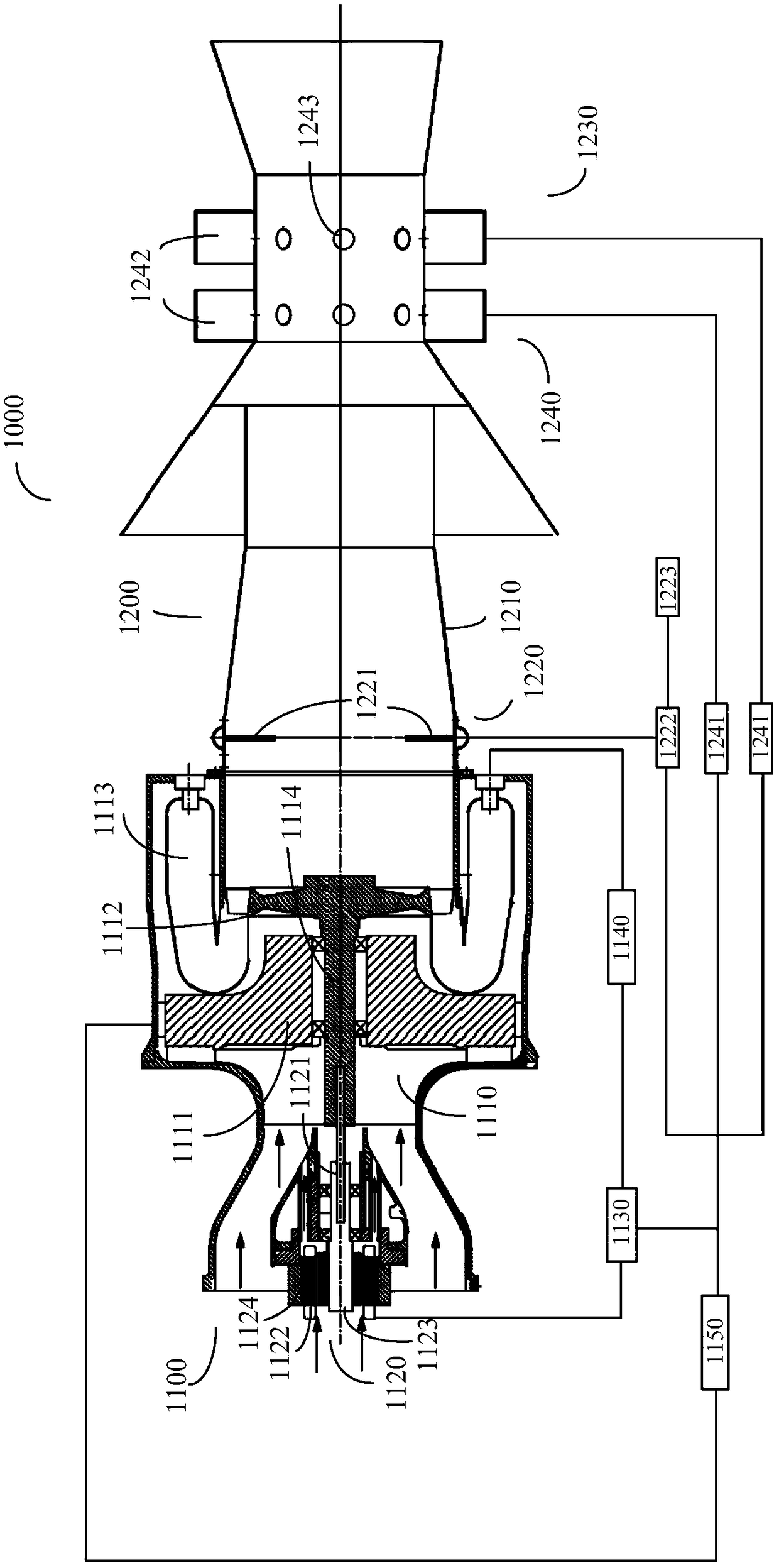

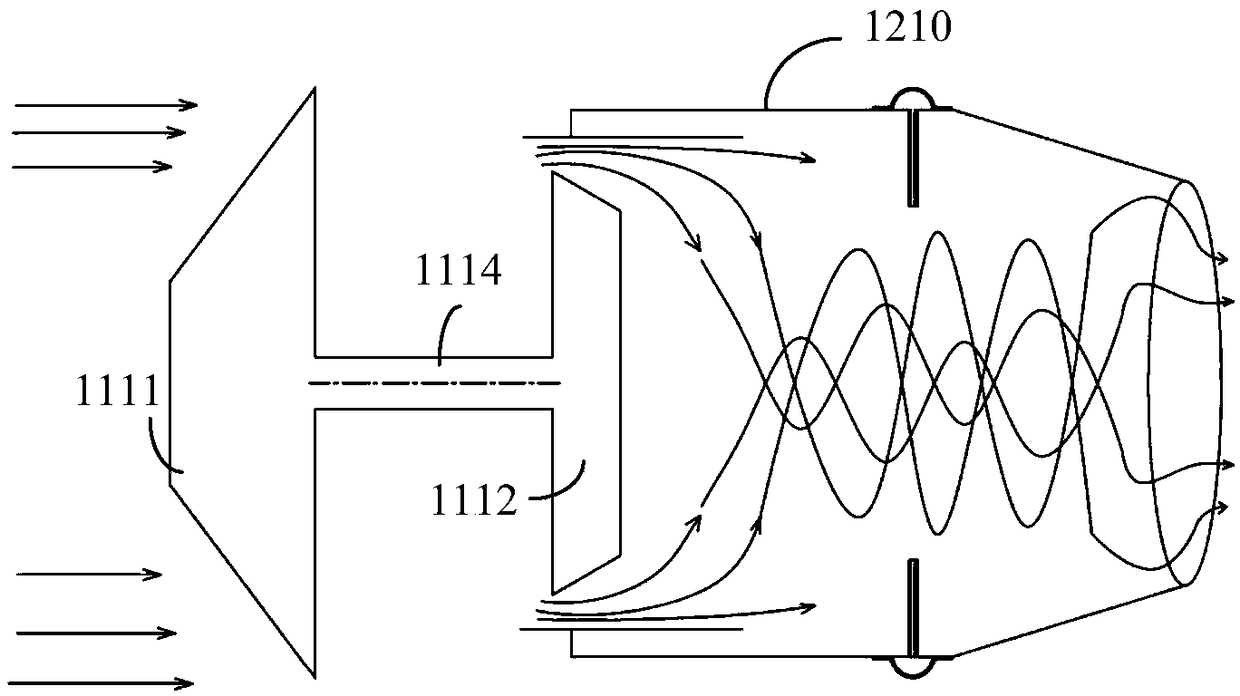

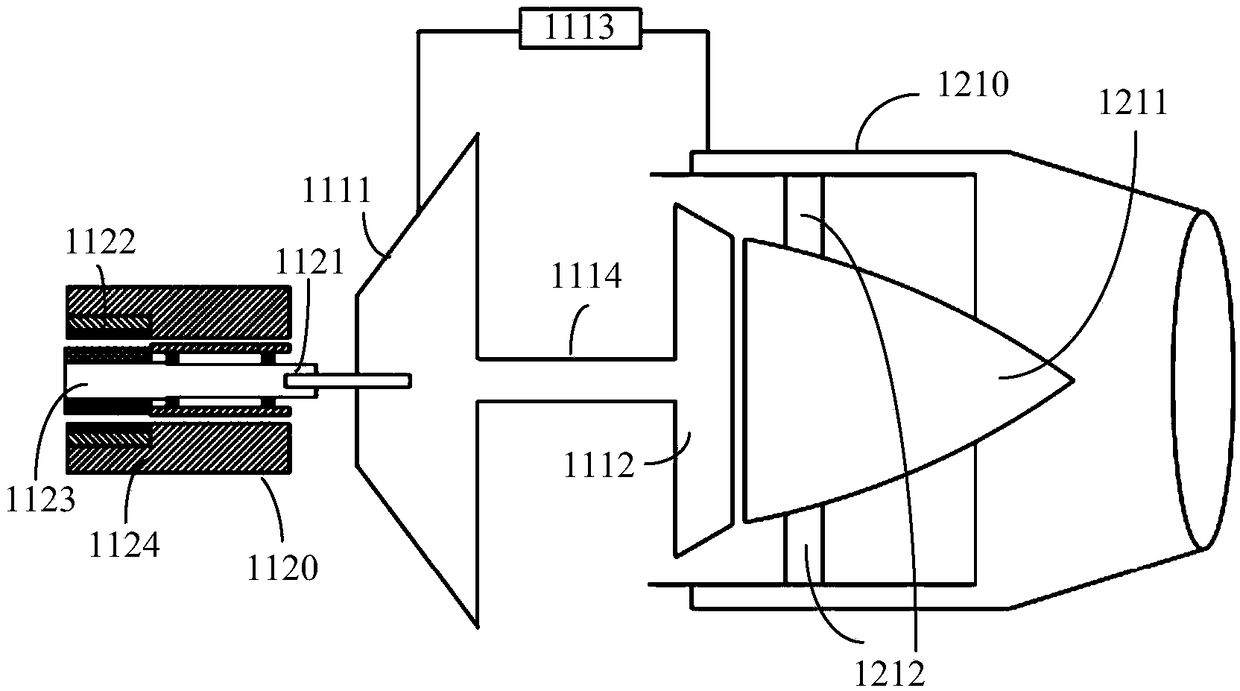

Smoke generator and operation method of smoke generator

ActiveCN109141126AImprove environmental adaptabilityRich choiceGas turbine plantsFog generating apparatusCombustionGas turbines

The invention provides a smoke generator. The smoke generator comprises a gas turbine and a smoke generating system, wherein the gas turbine comprises a gas turbine main machine, and the gas turbine main machine provides combustion-gas flow with required temperature and flow rate for the smoke generating system. The smoke generating system comprises a first exhaust nozzle and a mist oil input system, wherein the first exhaust nozzle communicates with the gas turbine main machine in a fluid mode, and the first exhaust nozzle is provided with a first exhaust nozzle inlet arranged close to the gas turbine main machine and a first exhaust nozzle outlet arranged away from the gas turbine main machine. The mist oil input system is used for conveying mist oil into the first exhaust nozzle, so that the mist oil forms smog under the action of the combustion-gas flow provided by the gas turbine main machine, and the smog is ejected outwards through the first exhaust nozzle outlet. The inventionfurther provides an operation method of the smoke generator. The smoke generator and the operation method of the smoke generator have the advantages of high smoke generating efficiency, high exhaust gas stability, large smoke generating amount, compact structure, good working stability, flexible maneuvering and the like.

Owner:潍坊云深机械科技有限公司

Smoke disinfectant for hygiene sterilization and preparation method thereof

The invention discloses a smoke disinfectant for hygiene sterilization and preparation method thereof, used for the smoke hygiene sterilization on the surfaces of hospital wards, epidemic focus, contaminator walls and grounds, warehouses, silkworm rearing rooms, poultry rooms and the like and in the production process of edible mushrooms, and belonging to the technical field of smoke hygiene sterilization sterilization. The technical solution for solving the technical problem is as follows: the smoke disinfectant for hygiene sterilization is made of 1000.0 parts of sodium dichloroisocyanurate by weight, 4.0-5.9 parts of adipic acid by weight, 3.5-3.9 parts of potassium permanganate by weight, and 28.0-36.0 parts of bamboo powder by weight, and has large smoke after combustion, long lasting time, high sterilization efficiency, wide application range, simple preparation method, easy raw material resource, low cost and good quality.

Owner:汪文华

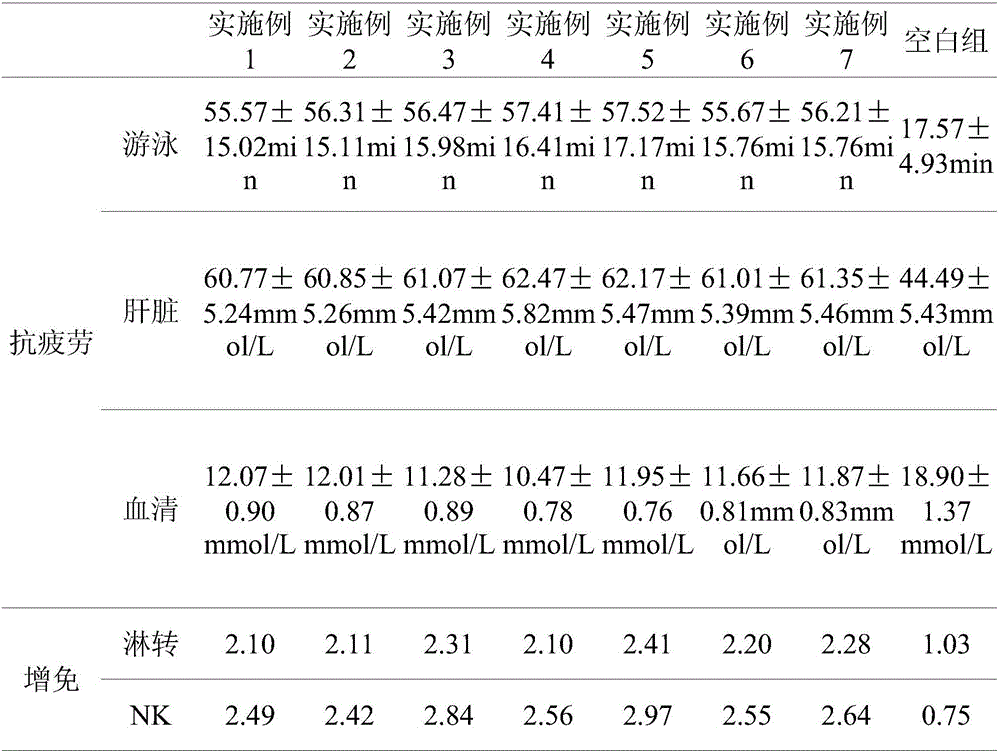

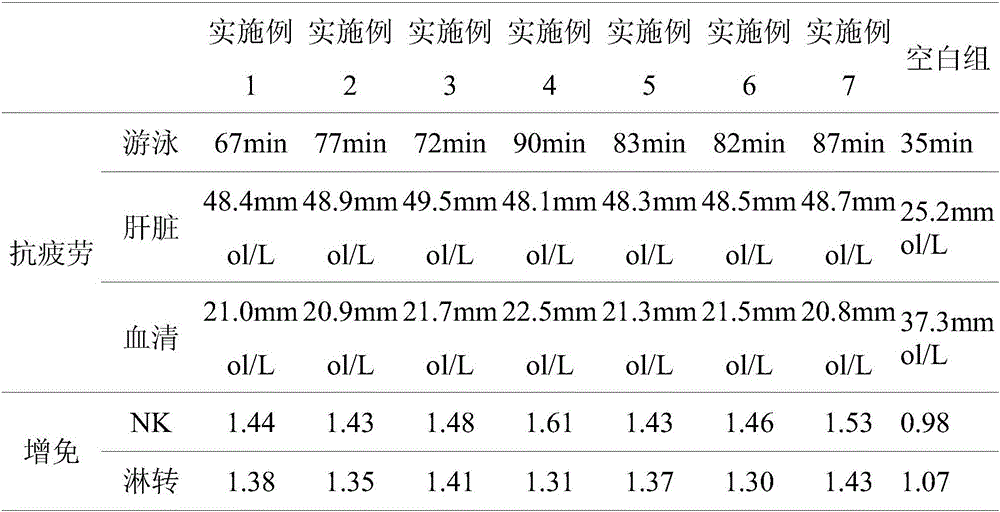

Clove-leaf non-tobacco cigarette and preparation method thereof

The invention discloses a clove-leaf non-tobacco cigarette and a preparation method thereof and belongs to the technical field of cigarettes. The problems of clove-leaf resource waste, poor taste and flavor of medical cigarettes, body harm, poor mildew resistance, unstable product aroma and taste, unstable guarantee period and the like in the prior art are solved. The preparation method of the cigarette comprises the steps that clove leaves are firstly soaked in hydrogen-rich normal saline with the hydrogen concentration of 0.3-0.8 mmol / L, then the soaked clove leaves are sequentially heated at the temperature of 40 DEG C for 5 minutes, heating is performed at the temperature of 40-50 DEG C for 5-15 minutes, heating is performed at the temperature of 50-55 DEG C for 3-8 minutes, then cooling is performed to reach room temperature, microwave drying is performed, moisture regaining is performed to reach the moisture content of 13-15%, the clove leaves are cut into cut tobaccos, a mildew preventive is added for even mixing, the cigarette is formed, and the clove-leaf non-tobacco cigarette is obtained. Resource waste is reduced, the aroma, taste and mildew resistance are good, the health of smokers is not influenced, and the cigarette also has the functions of fatigue resistance and immunity enhancement.

Owner:白山市禄程农林科技有限公司

Halogen-free flame retardant thermoplastic elastomer and preparation method thereof

The invention relates to the technical field of thermoplastic elastomers, in particular to a halogen-free flame retardant thermoplastic elastomer and a preparation method thereof. The halogen-free flame retardant thermoplastic elastomer comprises, by weight, 75-110 parts of polyurethane elastomers, 12-30 parts of phosphorus based flame retardant, 5-35 parts of phosphorus-nitrogen containing flame retardant, 1-3 parts of inorganic salt flame retardant, 5-12 parts of plasticizer and 1.3-3 parts of lubricant. The halogen-free flame retardant thermoplastic elastomer solves the problem that an existing elastomer containing halogen flame retardant can generate toxic and corrosive gas, and the smoke formation quantity can be greatly controlled in the open fire burning process of the elastomer. According to the halogen-free flame retardant thermoplastic elastomer, the above raw materials are adopted, the weight ratio of all the raw materials is strictly controlled, the flame retardant effect is good, the flame retardant can reach the UL94-V0 level, fireproofing is good, and the smoke formation quantity is small; precipitation is low, dripping can be prevented, high electrical performance can be achieved, and the heat resistance is good. Moreover, the abrasion resistance is excellent, ozone resistance is extremely good, hardness is large, strength is high, elasticity is good, and comprehensive performance is excellent.

Owner:浙江凯阳新材料股份有限公司

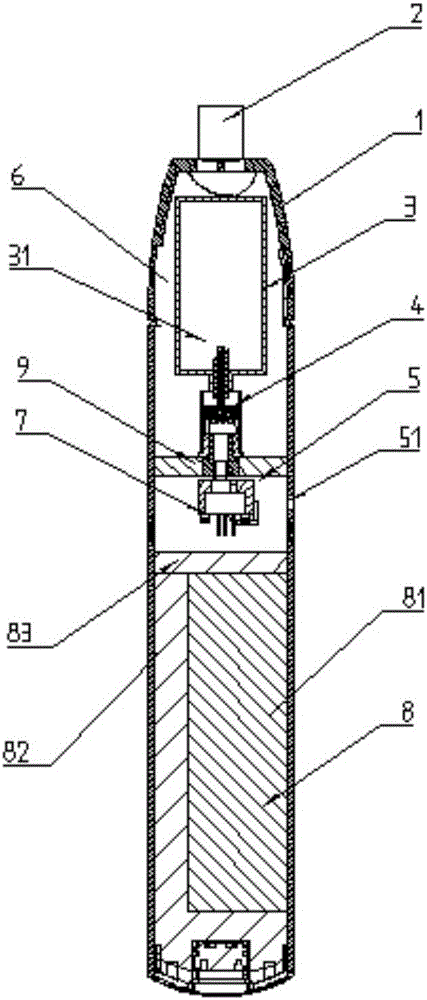

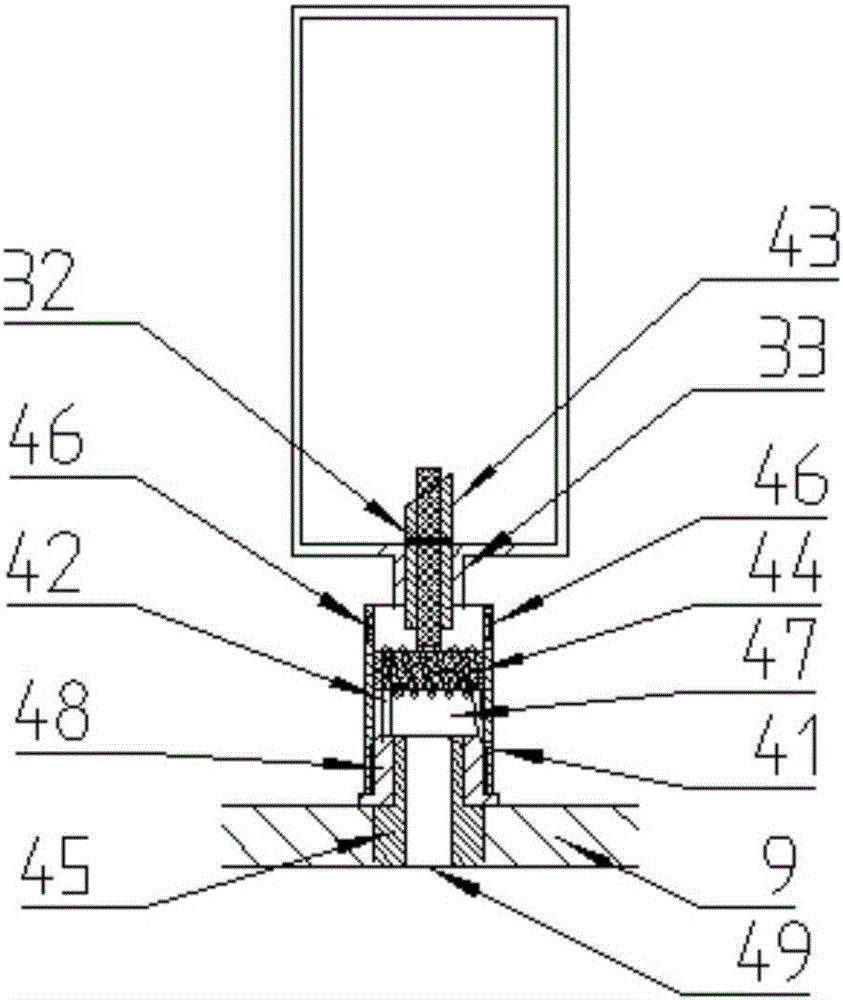

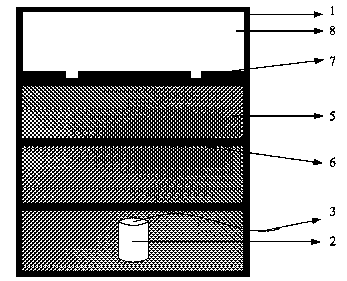

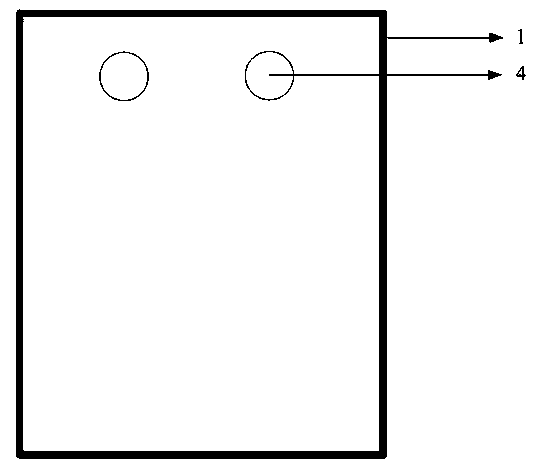

Disposable smoke cartridge and heating non-combustion cigarette comprising same

The invention discloses a disposable smoke cartridge and a heating non-combustion cigarette comprising the same. The smoke cartridge comprises a smoke cartridge outer wall, a seal membrane and a cavity, wherein the cavity consists of a the smoke cartridge outer wall and athe seal membrane and is capable of accommodating solid smoke formation substances; the cavity is internally provided with a metal component capable of generating eddy-current heating. The invention also discloses a heating non-combustion cigarette comprising the disposable smoke cartridge. The heating non-combustion cigarette comprises a shell, wherein the shell is internally provided with a power source and an accommodating cavity; the accommodating cavity is internally provided with the disposable smoke cartridge; an electromagnetic induction coil is wound on the disposable smoke cartridge. By virtue of combined use of the disposable smoke cartridge and the heating non-combustion cigarette, coking can be avoided, and sucking feeling of the heating non-combustion cigarette is improved.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Heating non-burning cigarette with temperature regulating filter stick structure

The invention provides a heating non-burning cigarette with a temperature regulating filter stick structure. The heating non-burning cigarette with the temperature regulating filter stick structure comprises a scent-producing section, a temperature regulating section and a filtering section which have the same circumference length. The heating non-burning cigarette is suitable for central heatingor annular heating non-burning heating devices which are available in the market at present. The ternary composite heating non-burning cigarette has a simple structure and the functions of adjusting heat conduction and cooling and is suitable for industrial production. The temperature regulating section performs temperature heat distribution and cooling before the cigarette enters a mouth cavity;smoke has low temperature after the cigarette enters the mouth cavity; and the heating non-burning cigarette with the temperature regulating filter stick structure has the advantages of diversified taste, capability of absorbing certain harmful substances and the like.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

Aerosolized smoke-generating material for use in heat-not-burn article

PendingCN112273707AReduce generationSatisfy the sensesTobacco treatmentCigar manufactureAerosolizeTobacco product

The invention relates to an atomized smoke-generating material for a heat-not-burn product. The atomized smoke-generating material is prepared from arecoline, herbaceous plant powder, starch, an adhesive, an acid-base regulator, a smoke-generating auxiliary agent and edible spices. A heat-not-burn product prepared from the atomized smoke-generating material can provide physiological satisfaction and functional effects similar to those of tobacco, so existing tobacco products are replaced to a certain extent. Compared with the effective component nicotine content of the existing tobacco product, the effective component are coline content of the heat-not-burn product can be reduced by 10-20 times, so the heat-not-burn product has obvious advantages in product safety and manufacturing cost.

Owner:云南纯旭生物科技有限公司

Ginseng/pseudo-ginseng leaves non-tobacco cigarette and preparing method thereof

InactiveCN106666814AImprove stabilityAvoid damageTobacco preparationTobacco treatmentNicotiana tabacumHydrogen

The invention discloses a ginseng / pseudo-ginseng leaves non-tobacco cigarette and a preparing method thereof, and belongs to the technical field of cigarettes. The problems in the prior art that resources of ginseng and pseudo-ginseng leaves are wasted, drug cigarettes are bad in taste, poor in mouthfeel, harmful to human body, poor in mildew resistance, and unstable in product smell mouthfeel and expiration date and the like are solved. The preparing method of the ginseng / pseudo-ginseng leaves non-tobacco cigarette comprises the steps of firstly soaking ginseng leaves and pseudo-ginseng leaves in a hydrogen-enriched normal saline solution with the concentration being 0.3-0.8 mmol / L respectively, then conducting stepwise heating on the soaked ginseng leaves and pseudo-ginseng leaves respectively, then cooling the temperature to the room temperature, conducting microwave drying, finally conducting resurgence on the dried ginseng leaves and pseudo-ginseng leaves respectively, and cutting the leaves into tobacco shreds; weighing the ginseng leaf tobacco shreds and the pseudo-ginseng leaf tobacco shreds according to the mass ratio of 1:1, adding a mildew preventive into the tobacco shreds, mixing the mixture uniformly, conducting cigarette molding to obtain the ginseng / pseudo-ginseng leaves non-tobacco cigarette. According to the ginseng / pseudo-ginseng leaves non-tobacco cigarette and the preparing method thereof, the waste of resources is reduced; meanwhile, the ginseng / pseudo-ginseng leaves non-tobacco cigarette is good in smell, mouthfeel and mildew resistance, has no influences on the health of a smoker, and has the functions of resisting fatigue and enhancing immunity.

Owner:白山市禄程农林科技有限公司

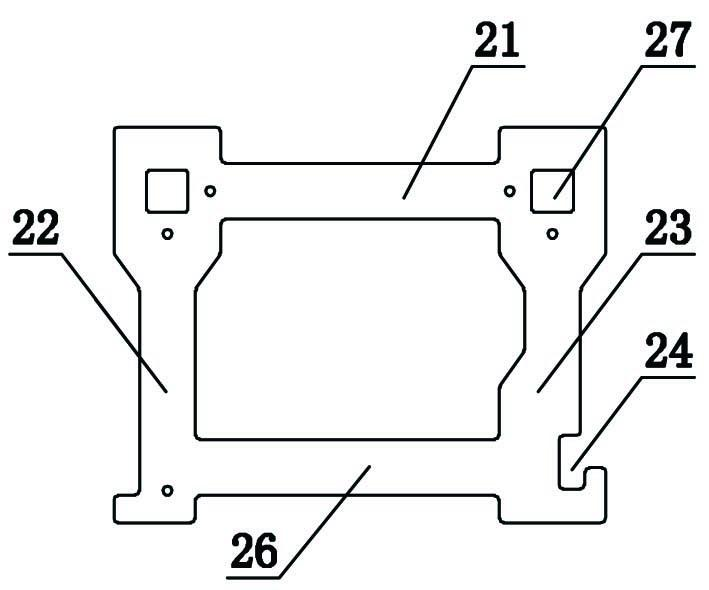

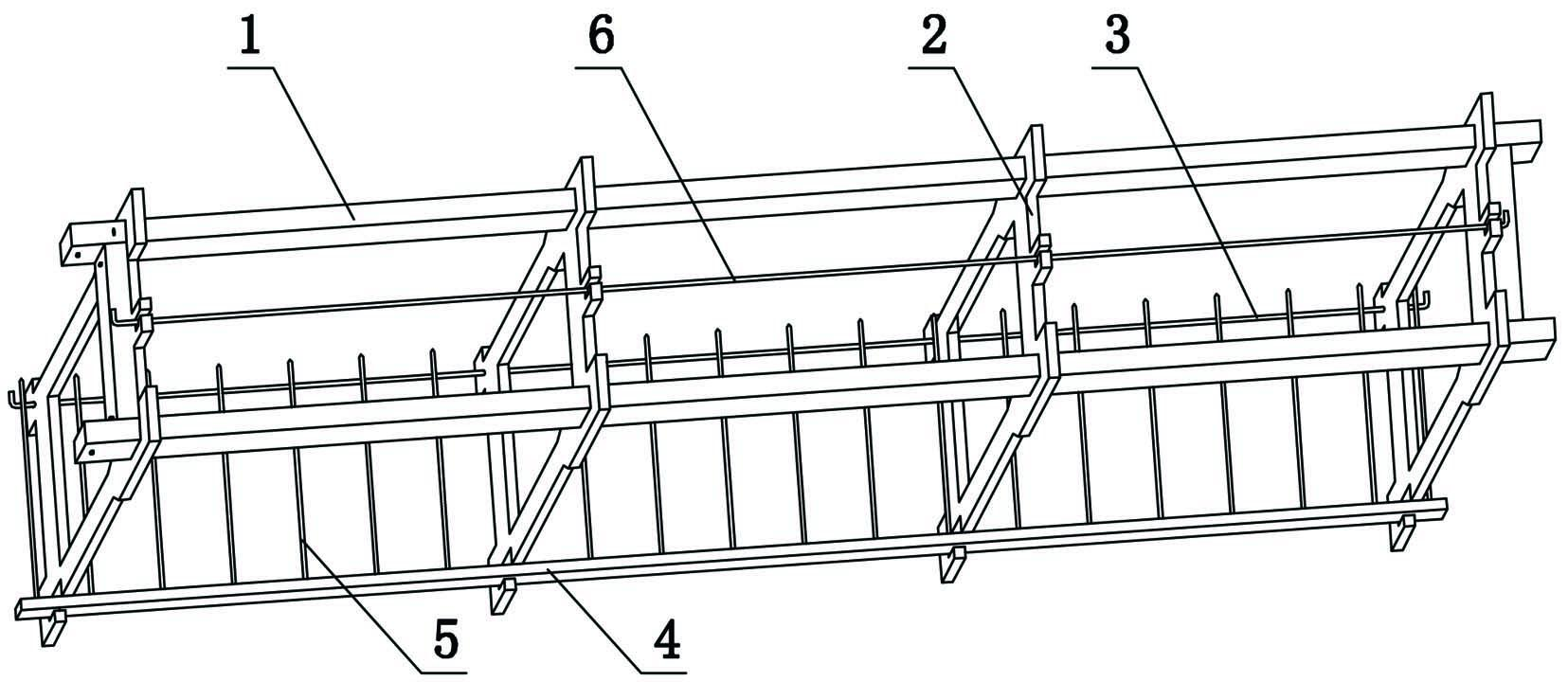

Novel combined cigarette clamp

InactiveCN102613683ASimple structurePrevent lodgingTobacco preparationStructural engineeringMechanical engineering

Owner:江苏科地现代农业有限公司

Orchard frost-prevention smoke bomb and manufacture

The invention relates to an orchard frost-prevention smoke bomb and manufacture. The burning material filling layers of the orchard frost-prevention smoke bomb are designed in a multiple layered manner, each layer is sequentially composed of a mixture layer of saw dust and potassium nitrate and a coal powder layer, a layer of porous partition is covered on the top, and manufacturing procedures of the orchard frost-prevention smoke bomb are standardized. The orchard frost-prevention smoke bomb has the advantages of low cost as a traditional smoke method, environment-friendly materials are selected, smoke generating material ratio and smoke bomb processing and manufacturing are optimized, energy produced by burning is increased, released heat and smoke are increased, smoke is almost professional smoke agent, burning time is long, and toxic gas emission of sulfur dioxide and the like is reduced. By inventor implementing, operation is convenient and practical, the temperature of an orchard can be increased to 0.5 to 1.5 DEG C, and loss due to mild to moderate frost disasters of the orchard can be prevented and reduced effectively.

Owner:NINGXIA HUI AUTONOMOUS REGION METEOROLOGICAL SCI INST

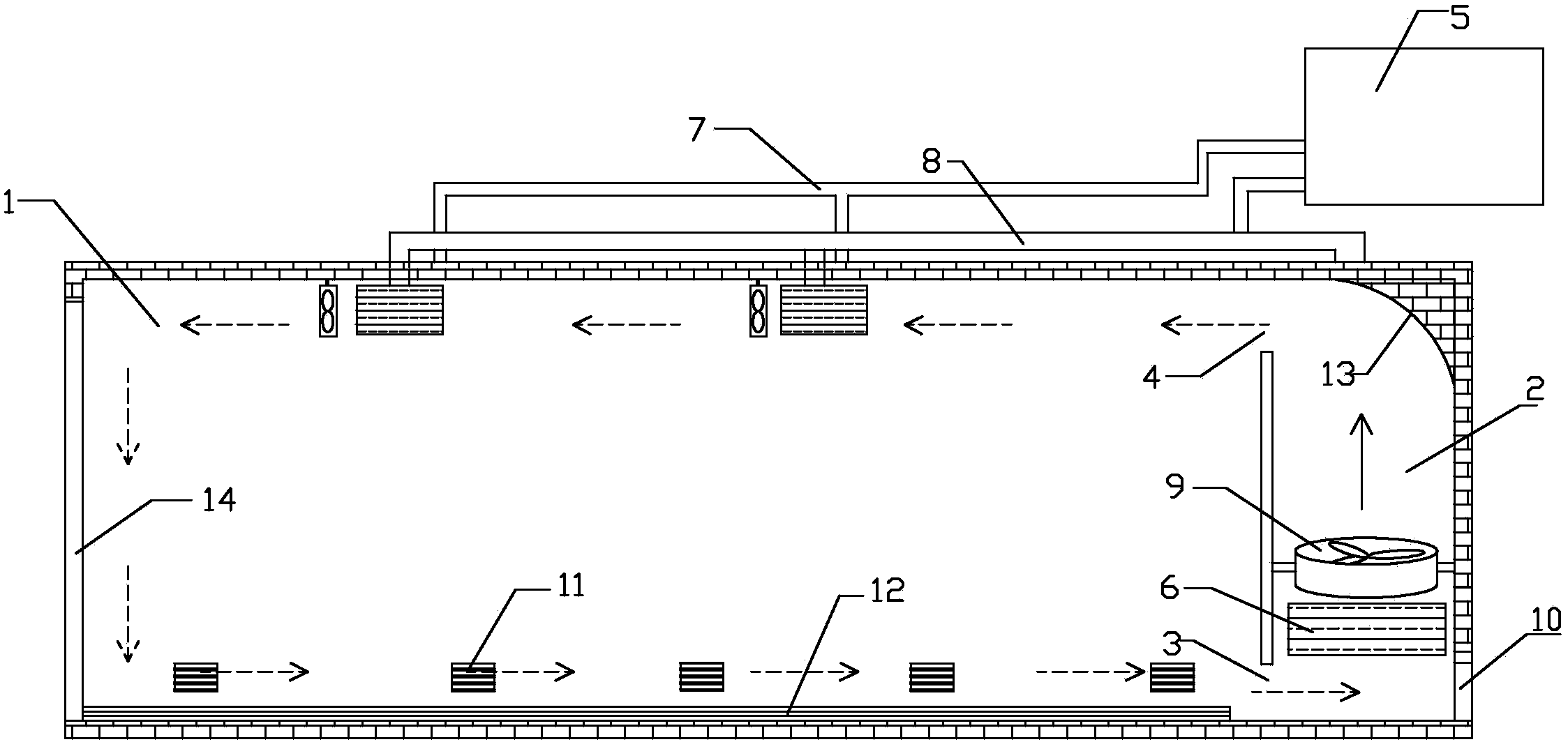

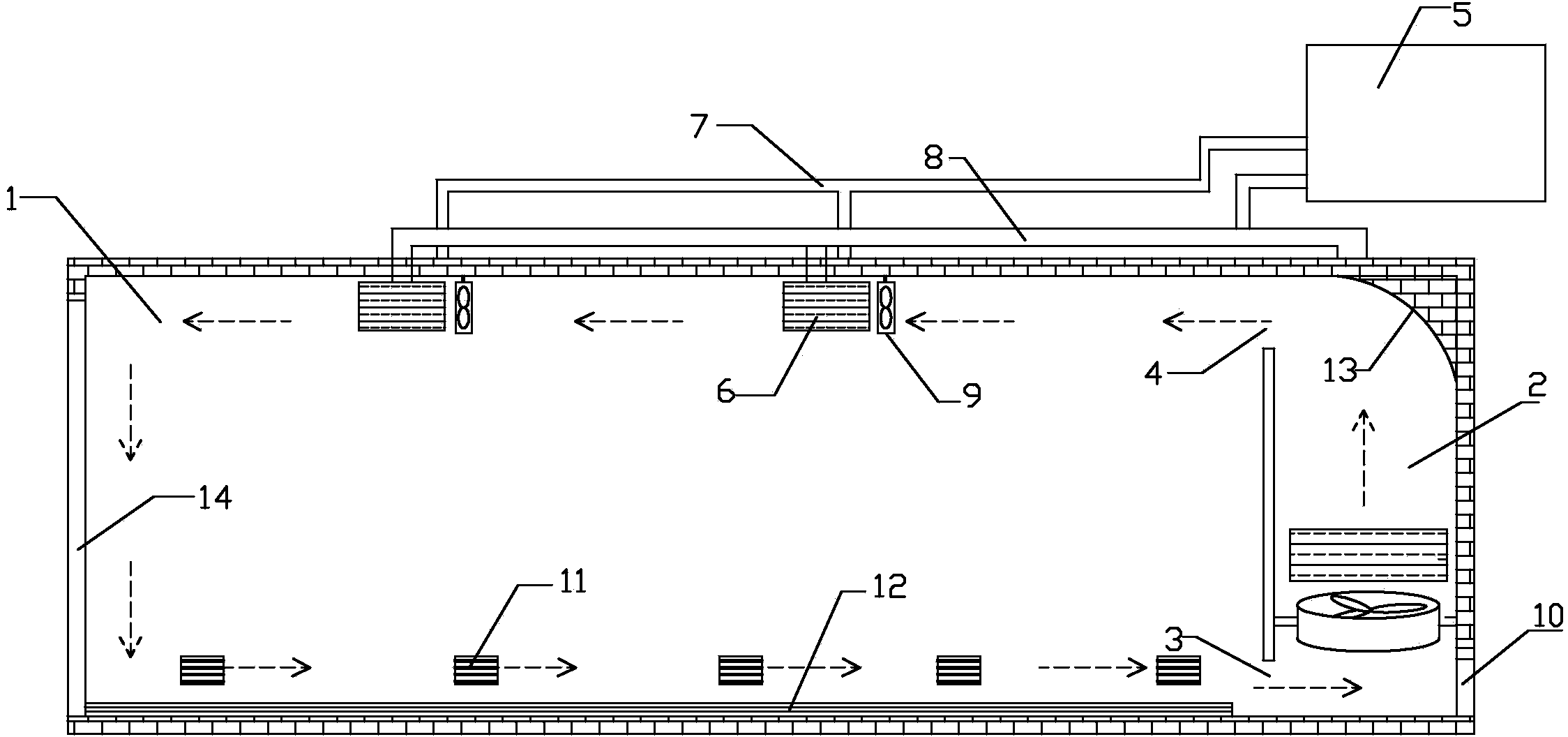

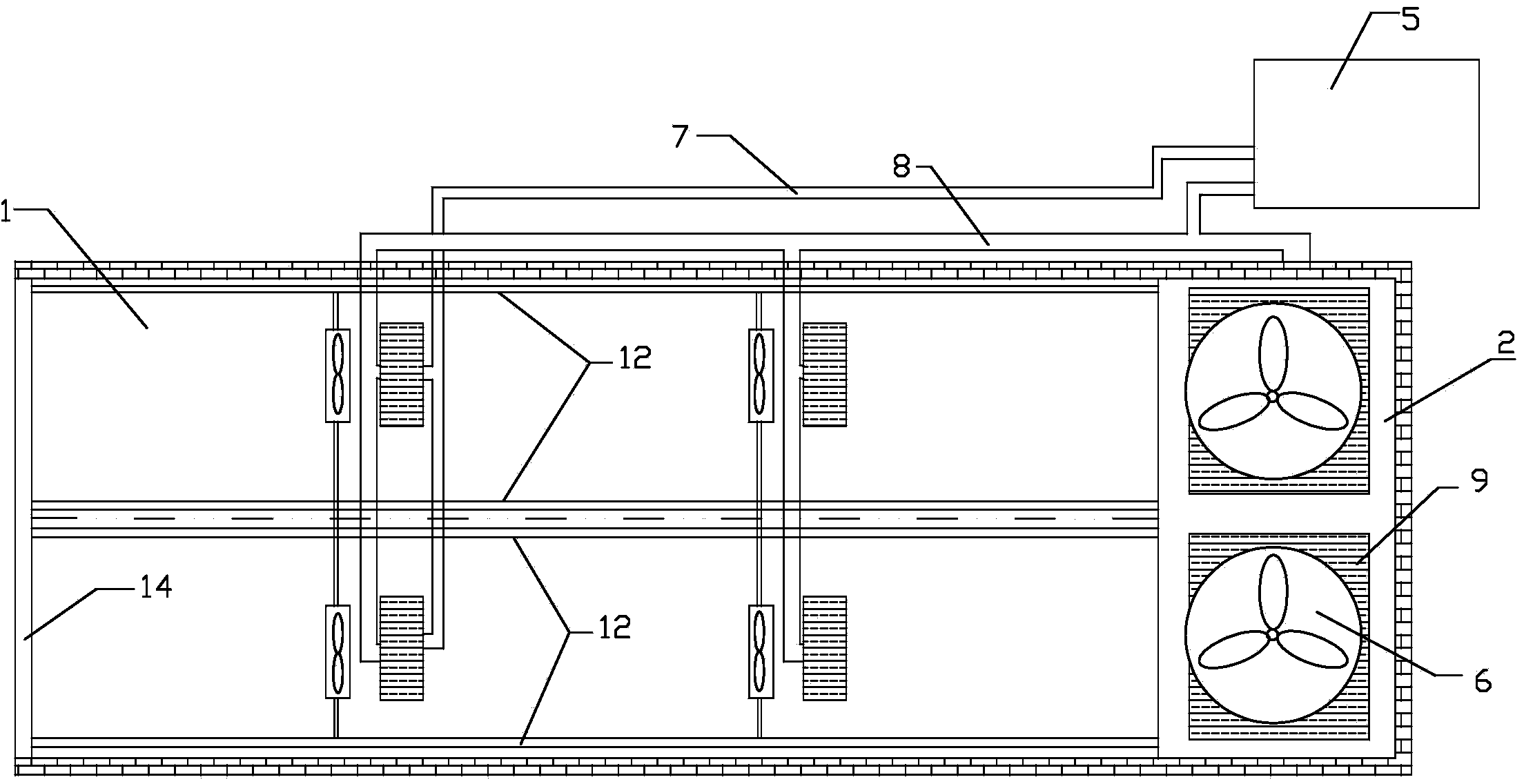

Large-capacity energy-saving environment-friendly bulk curing barn

The invention provides a large-capacity energy-saving environment-friendly bulk curing barn which comprises a curing chamber and a heating chamber. The curing chamber is provided moisture discharge openings, and a heating device is arranged in the heating chamber. The large-capacity energy-saving environment-friendly bulk curing barn is characterized in that the heating device is composed of a steam boiler and a plurality of steam heat radiators, the steam boiler is arranged outside the curing barn, the steam heat radiators are arranged in the heating chamber and the curing chamber in a disperse mode, the steam inlet ends of the steam heat radiators are respectively communicated with a steam outlet of the steam boiler through steam pipelines, water return openings of the heat radiators are respectively communicated with a water inlet of the steam boiler through water return pipes, and a fan is arranged on a heat radiating opening of each steam heat radiator. Tobacco inlet rails are arranged on the ground of the curing chamber. The moisture discharge openings are formed in the positions, as high as a cold air door, of the lower portions of the two side walls of the curing chamber respectively. According to the large-capacity energy-saving environment-friendly bulk curing barn, the construction cost of the curing barn is greatly lowered, meanwhile, the cost of a coal stove, the fans and other curing equipment is saved, labor force for curing is reduced, and the labor intensity of tobacco curing is lowered.

Owner:HUBEI TOBACCO SCI RES INST

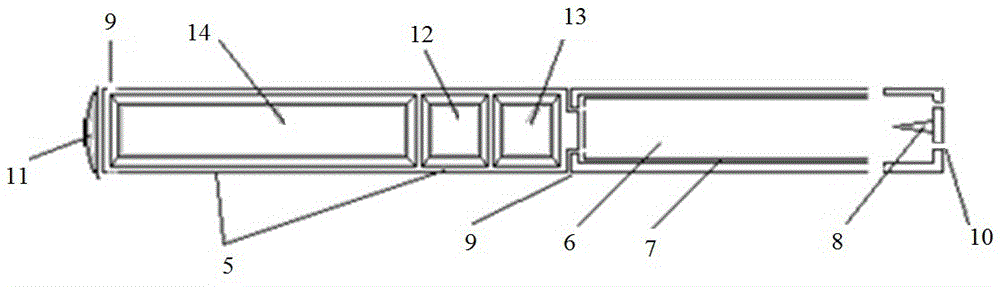

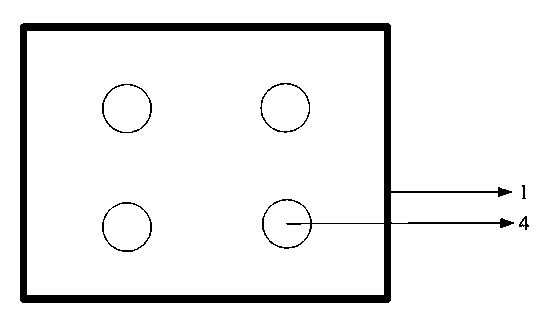

Disposable cigarette cartridge and heating non-combustion cigarette utilizing multiple disposable cigarette cartridges

InactiveCN105852218AIncrease contact areaLarge amount of smokeTobacco devicesElectromagnetic inductionEngineering

The invention discloses a disposable cigarette cartridge and a heating non-combustion cigarette utilizing multiple disposable cigarette cartridges. The disposable cigarette cartridge comprises a cigarette cartridge outer wall, a sealing film and a cavity which is formed by the cigarette cartridge outer wall and the sealing film and can contain solid smoke formation matters, wherein a metal element which can generate eddy-current heating is arranged in the cavity. The invention also discloses the heating non-combustion cigarette utilizing multiple disposable cigarette cartridges. The heating non-combustion cigarette comprises a shell, wherein a power supply and a containing cavity are arranged in the shell; the containing cavity is internally provided with a fixing bar which is matched with an inner hole of the disposable cigarette cartridge; the fixing bar is provided with the disposable cigarette cartridge; an electromagnetic induction coil is arranged in the shell in a winding way. The disposable cigarette cartridge and the heating non-combustion cigarette which are disclosed by the invention are matched for use, so that coking can be avoided, and the smoking taste of the heating non-combustion cigarette is improved.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Preparation method of tobacco material applied to heating non-burning tobacco products

The invention discloses a preparation method of a tobacco material applied to heating non-burning tobacco products. The preparation method comprises the following steps: (1) preparing tobacco powder;(2) preparing tobacco extract; (3) preparing a dispersing auxiliary solution; (4) dispersing a heat conduction material; (5) adding a flame retardant into the tobacco extract obtained in the step (2)according to a mass ratio of 1:1 to 1:4; (6) preparing a mixed system; (7) feeding the mixed system obtained in the step (6) into a single screw extruder to be continuously mixed, and injecting a foaming agent CO2 to perform foam extrusion molding, enabling the extrudate to present a porous structure, drying the extrudate, and cutting the extrudate into a filamentous tobacco material by a cutter after drying, thereby obtaining the tobacco material applied to heating non-burning tobacco products. The preparation method disclosed by the invention solves the problems that the tobacco quality is low, the smoke release property is poor and the flame retardant property of the tobacco is poor, is simple in preparation process and low in cost, and has excellent industrialization prospects.

Owner:HUNAN POLYTECHNIC OF ENVIRONMENT & BIOLOGY

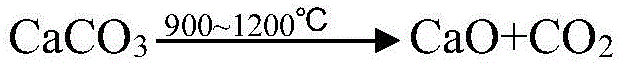

Desulphurization method for burned smoke of circulating fluidized bedboiler

InactiveCN106215683AEvenly distributedImprove contact effectDispersed particle separationSulfurEmission standard

The invention provides a desulphurization method for the burned smoke of a circulating fluidized bedboiler. The method provided by the invention comprises the following steps: limestone is added into smoke produced by the burning of a fuel inside the circulating fluidized bedboiler, so that an oxygen-sulfur compound in the smoke and the limestone are in calcinating reaction to accomplish primary desulfuration, after dedusting is performed on the smoke after primary desulfuration, a sodium hydroxide solution is sprayed onto the smoke treated through dedusting, so that unreacted sulphur oxides in the smoke and sodium hydroxide react to achieve secondary desulfuration. By adopting the method provided by the invention for desulfuration to the smoke of a boiler, the desulphurization efficiency can reach more than 85 percent each time, the desulphurization efficiency is improved by more than 20 to 30 percent, the content of sulfur dioxide in the smoke treated through desulfuration is equal to or smaller than 200mg / Nm3, the emission standard can be met strictly, and unexpected technical effects can be obtained.

Owner:重庆合川盐化工业有限公司

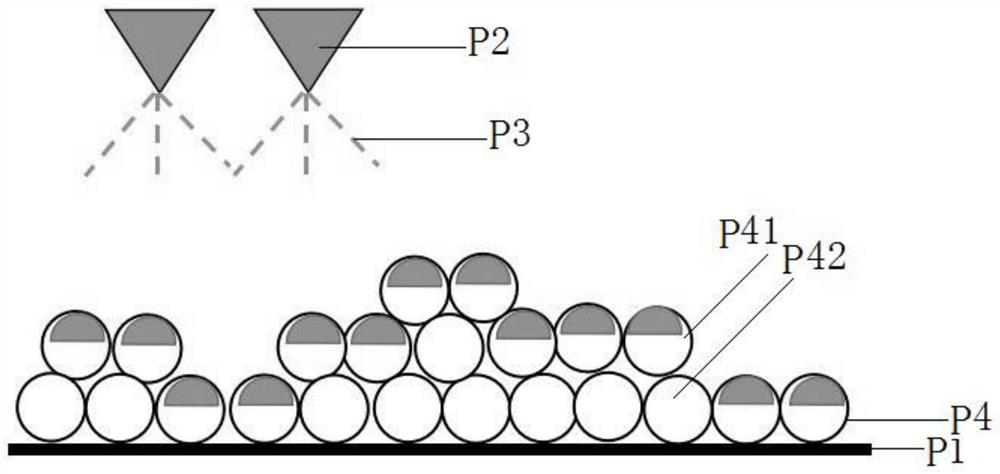

Aerosol generating product having granular aerosol-generating matrix rod with high porosity

PendingCN113925197AGuaranteed ventilationGuaranteed porosityCigar manufactureTobacco smoke filtersThermodynamicsEngineering

The invention discloses an aerosol generating product having a granular aerosol generating matrix rod with high porosity. The aerosol generating product comprises a smoke generating core material section (1), a breathable hollow section (2) and a filtering section (3), the smoke generating core material section (1) comprises an aerosol generating matrix rod and anti-seepage / heat-conducting cigarette paper wrapping the aerosol generating matrix rod, the aerosol generating matrix rod is formed by binding scattered tobacco particles through a binding agent, and the binding agent is arranged on part of the surfaces of only part of the tobacco particles in the aerosol generating matrix rod; the internal porosity of the smoke generating core material section (1) is 40-80%; the breathable hollow section (2) and the filter section (3) are wrapped by the forming paper (5) to form a filter rod, and the smoke generating core material section (1) and the filter rod are connected through the tipping paper (4). Before the scattered tobacco particles are bonded, the surfaces of all the tobacco particles are not provided with the binder, and the binder does not cover all the surfaces of the tobacco particles, so that the problem that gaps formed between the tobacco particles are blocked after the binder is cooled does not exist in the gaps formed between the tobacco particles after the tobacco particles are bonded; therefore, the axial ventilation capacity and porosity of the aerosol generation matrix rod are ensured.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com