Desulphurization method for burned smoke of circulating fluidized bedboiler

A circulating fluidized bed and boiler combustion technology, which is applied to chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of poor desulfurization effect, high cost, and low desulfurization efficiency, so as to save cost and input, reduce The effect of low usage and treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for desulfurizing combustion flue gas of a circulating fluidized bed boiler, comprising the steps of:

[0031] 1) Limestone is crushed into limestone powder with a particle size of 345 meshes, and the limestone powder is introduced into the hearth of a circulating fluidized bed boiler; the circulating fluidized bed is a circulating fluidized bed with a processing capacity of 82t / h;

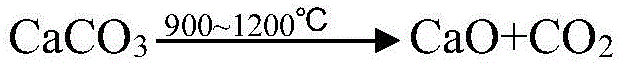

[0032] 2) Control the combustion temperature in the furnace to 900°C so that the limestone powder put into the furnace in step 1) is calcined into calcium oxide, and the calcined calcium oxide is in contact with the flue gas generated by the combustion of fuel in the furnace and with the sulfur and oxygen in the flue gas The compound reacts to generate calcium sulfate and calcium sulfite to complete the primary desulfurization of the combustion flue gas; the dosage of limestone powder is 5% of the fuel bituminous coal mass;

[0033] 3) Pass the combustion flue gas and the reaction ...

Embodiment 2

[0037] A method for desulfurizing combustion flue gas of a circulating fluidized bed boiler, comprising the steps of:

[0038] 1) Limestone is crushed into limestone powder with a particle size of 400 meshes, and the limestone powder is introduced into the hearth of a circulating fluidized bed boiler; the circulating fluidized bed is a circulating fluidized bed with a processing capacity of 82t / h;

[0039] 2) Control the combustion temperature in the furnace to 1100°C so that the limestone powder put into the furnace in step 1) is calcined into calcium oxide, and the calcined calcium oxide is in contact with the flue gas generated by fuel combustion in the furnace and with the sulfur and oxygen in the flue gas The compound reacts to generate calcium sulfate and calcium sulfite to complete the primary desulfurization of the combustion flue gas; the dosage of limestone powder is 10% of the fuel bituminous coal mass;

[0040] 3) Pass the combustion flue gas and the reaction produ...

Embodiment 3

[0045] A method for desulfurizing combustion flue gas of a circulating fluidized bed boiler, comprising the steps of:

[0046] 1) Limestone is crushed into limestone powder with a particle size of 500 mesh, and the limestone powder is blown into the furnace of a circulating fluidized bed boiler by pressurized air; the circulating fluidized bed is a circulating fluidized bed with a processing capacity of 82t / h ;

[0047] 2) Control the combustion temperature in the furnace to 1200°C so that the limestone powder put into the furnace in step 1) is calcined into calcium oxide, and the calcined calcium oxide is in contact with the flue gas generated by fuel combustion in the furnace and with the sulfur and oxygen in the flue gas The compound reacts to generate calcium sulfate and calcium sulfite to complete the primary desulfurization of the combustion flue gas; the dosage of limestone powder is 15% of the fuel bituminous coal mass;

[0048] 3) Pass the combustion flue gas and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com