Patents

Literature

474 results about "Calcium sulfite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium sulfite, or calcium sulphite, is a chemical compound, the calcium salt of sulfite with the formula CaSO₃·x(H₂O). Two crystalline forms are known, the hemihydrate and the tetrahydrate, respectively CaSO₃·½(H₂O) and CaSO₃·4(H₂O). All forms are white solids. It is most notable as the product of flue-gas desulfurization.

Multifunctional composite absorbing material for purifying water and preparation method thereof

ActiveCN102350298AReduce wasteEfficient removalOther chemical processesWater/sewage treatment bu osmosis/dialysisAcrylic resinCerium

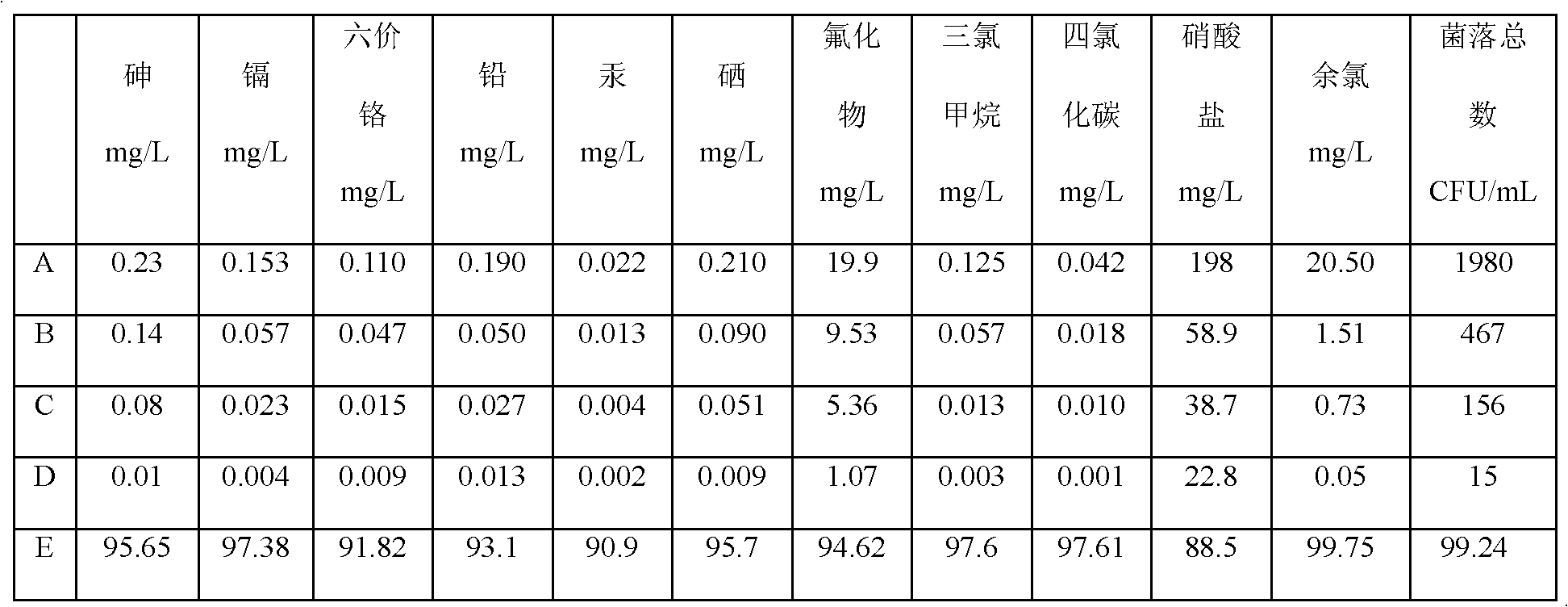

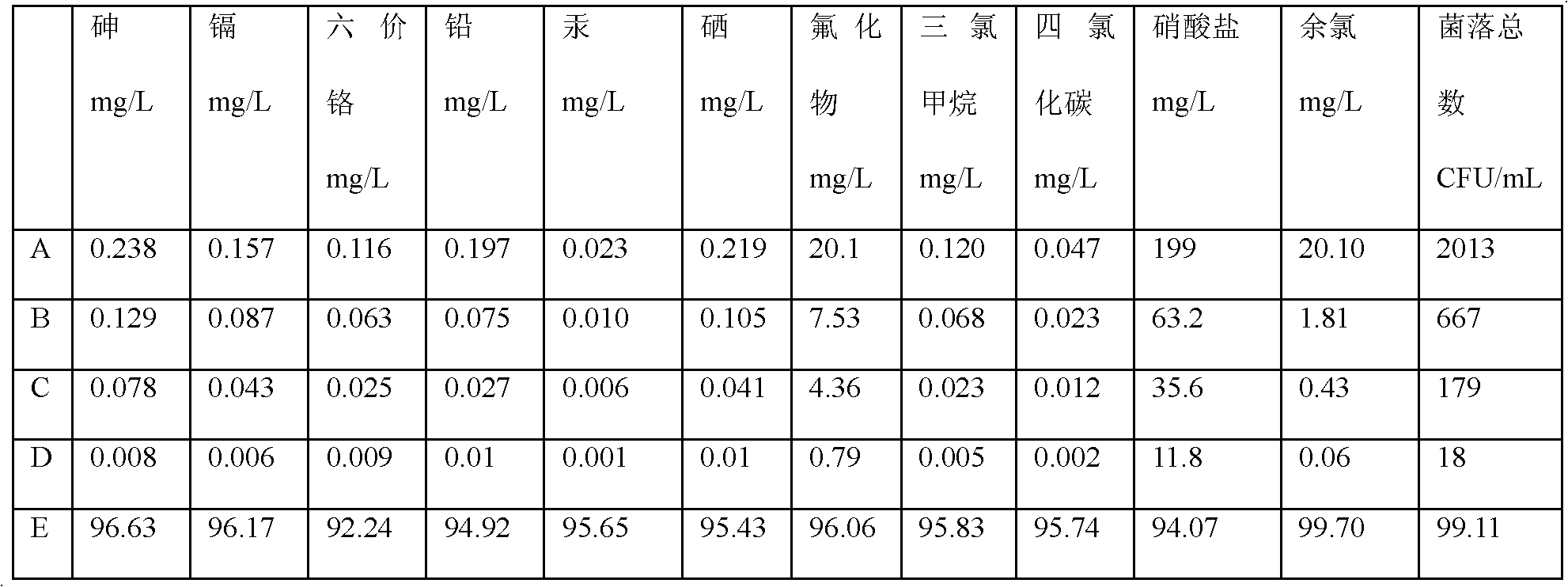

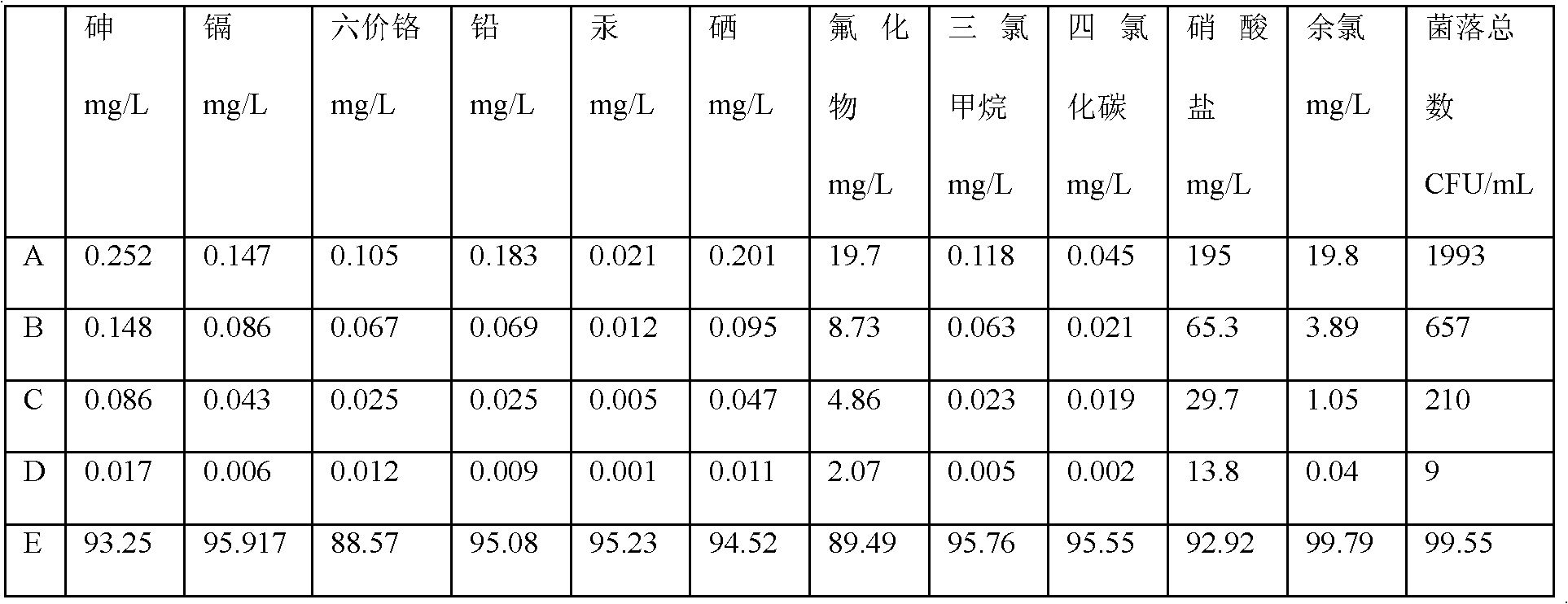

The invention provides a multifunctional composite absorbing material for purifying water and a preparation method thereof, relating to an absorbing material. The invention provides the multifunctional composite absorbing material for purifying water, which can be used for effectively removing a plurality of harmful substances in the water and has higher removal efficiency and lower production cost, and the preparation method thereof. The absorbing material is selected from at least one of absorbing materials A, B and C; the absorbing material A takes a mesoporous adsorption ceramic material as a carrier to load nano metals including nano silver, nano zinc, nano iron and nano cerium; the absorbing material B takes the mesoporous adsorption ceramic material as the carrier to load nano metal oxides including nano titanium dioxide, nano zinc oxide, nano ferric oxide and nano cerium dioxide; and the absorbing material C is prepared from the following raw materials according to the mass ratio: 100-200 parts of active carbon powder, 20-30 parts of polyethylene powder, 10-30 parts of calcium sulfite powder, 10-30 parts of natural zeolite powder, 20-40 parts of macroporous acrylic resin and 10-20 parts of attapulgite powder.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

Method for scavenging mercury

Owner:RGT UNIV OF CALIFORNIA

Sorbents for Removal of Mercury from Flue Gas

InactiveUS20070092418A1Enabling useLow costGas treatmentSolid waste managementParticulatesAlkaline earth metal

Metal sulfides having a micro-porous structure are disclosed for use as sorbents for removal of mercury from flue gas. Systems are disclosed for making and using micro-porous particulates at least partially composed of alkaline earth metal and transition metal sulfides as sorbents. Calcium sulfide micro-porous powders derived from the high temperature reduction of calcium sulfate and calcium sulfite are disclosed to be reactive substrates for a group of sorbents for adsorption of mercury from the myriad of coal combustion flue gases produced by the utilities industry, as well as from natural gas and gaseous and liquid hydrocarbons. Controlled addition of one or more of polyvalent metal ions, chloride ions, polysulfide ions, and sulfur to the micro-porous calcium sulfide substrate produces the sorbent. The sorbents are useful for cost-effectively adsorbing elemental mercury and oxidized mercury species such as mercuric chloride from flue gases, including those containing acid gases (e.g., SO.sub.2, NO and NO.sub.2, and HCI), over a wide range of temperatures.

Owner:CHEM PROD CORP

Method for scavenging mercury

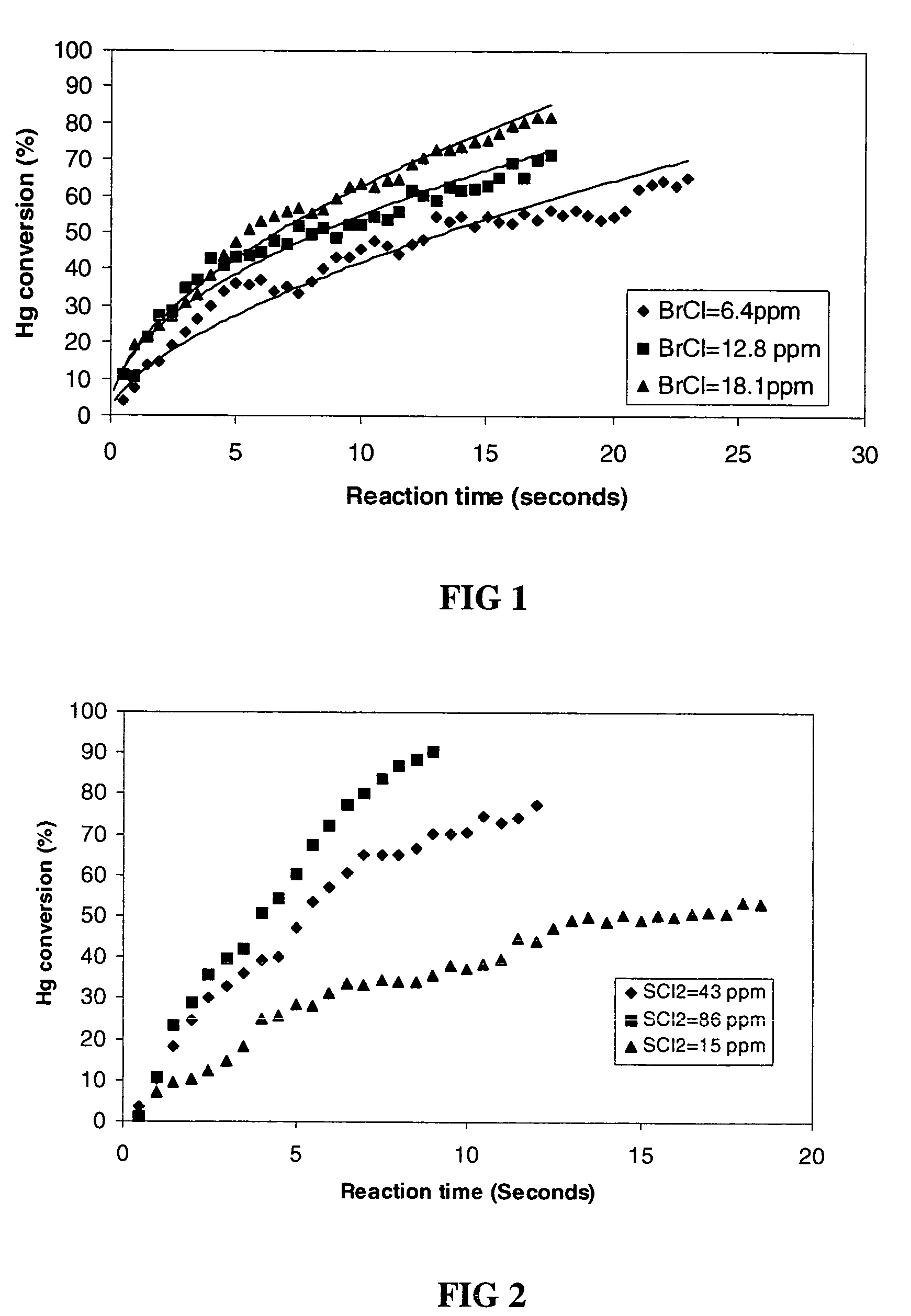

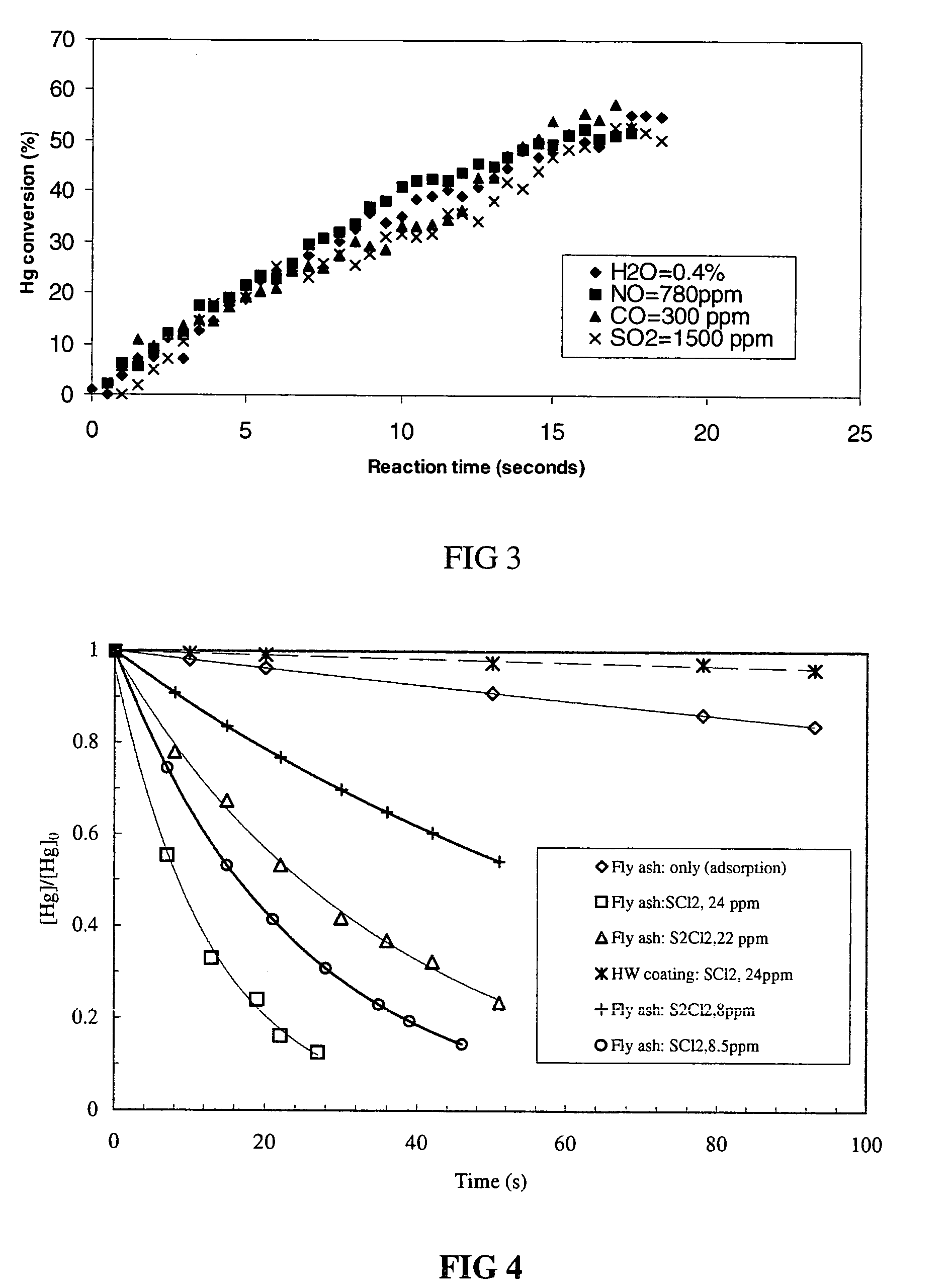

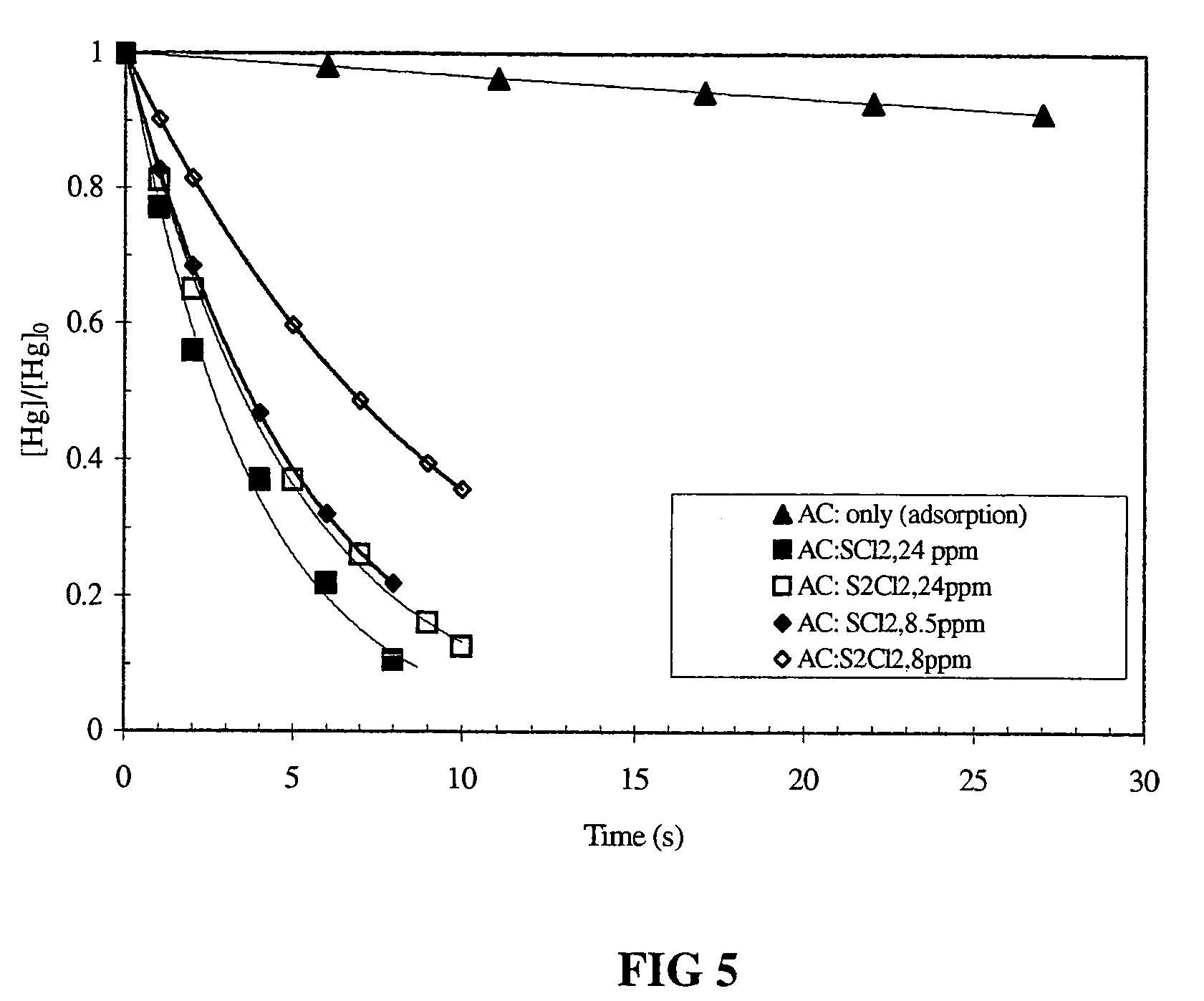

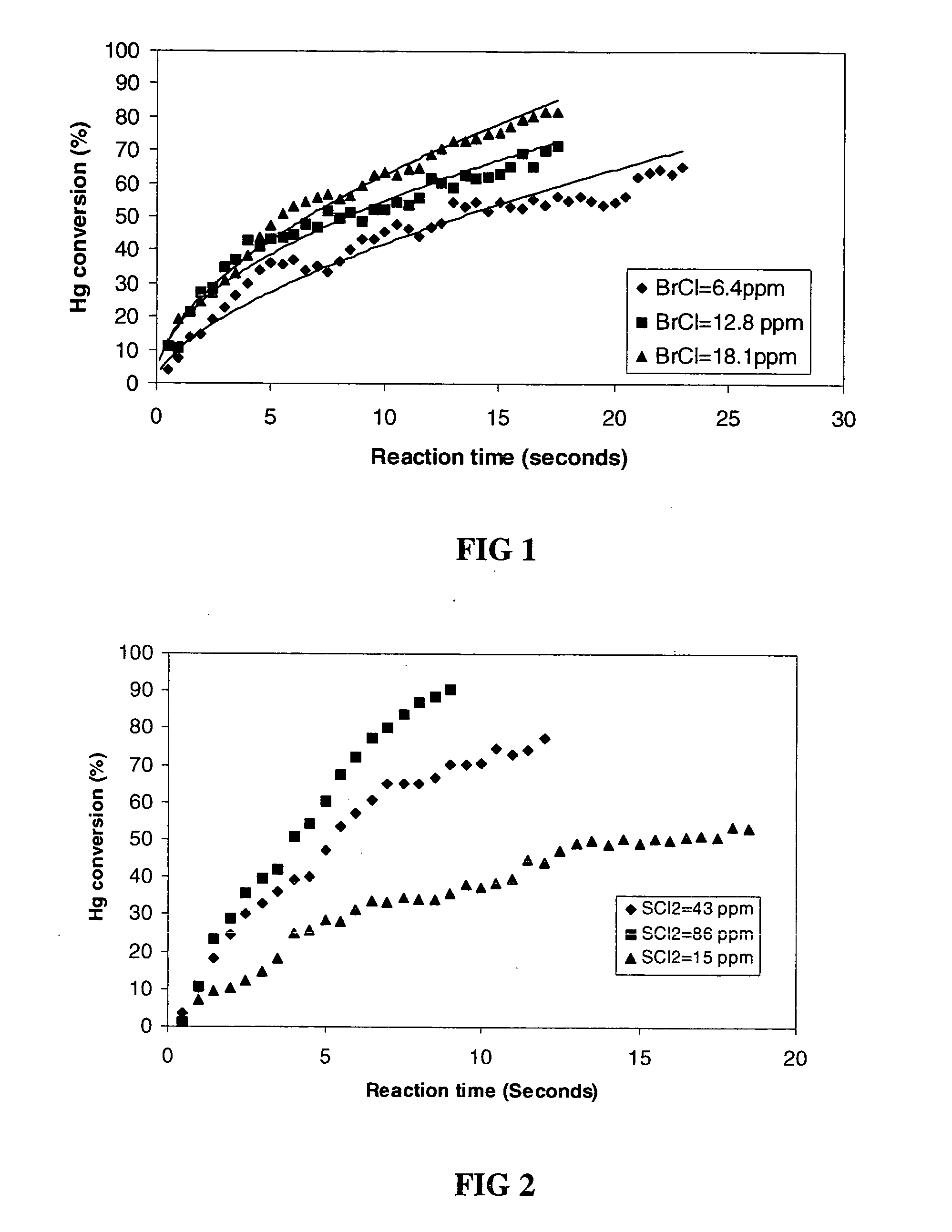

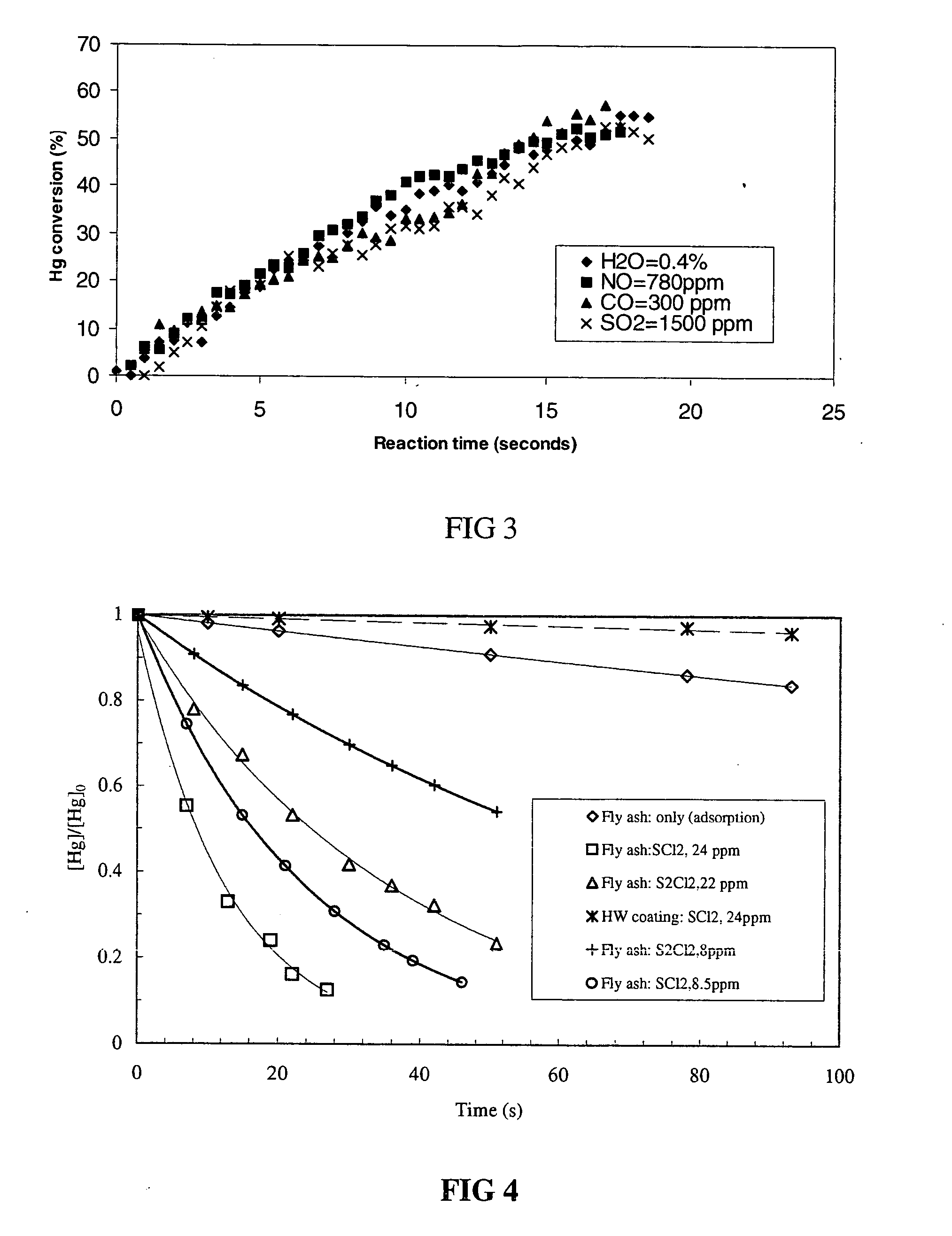

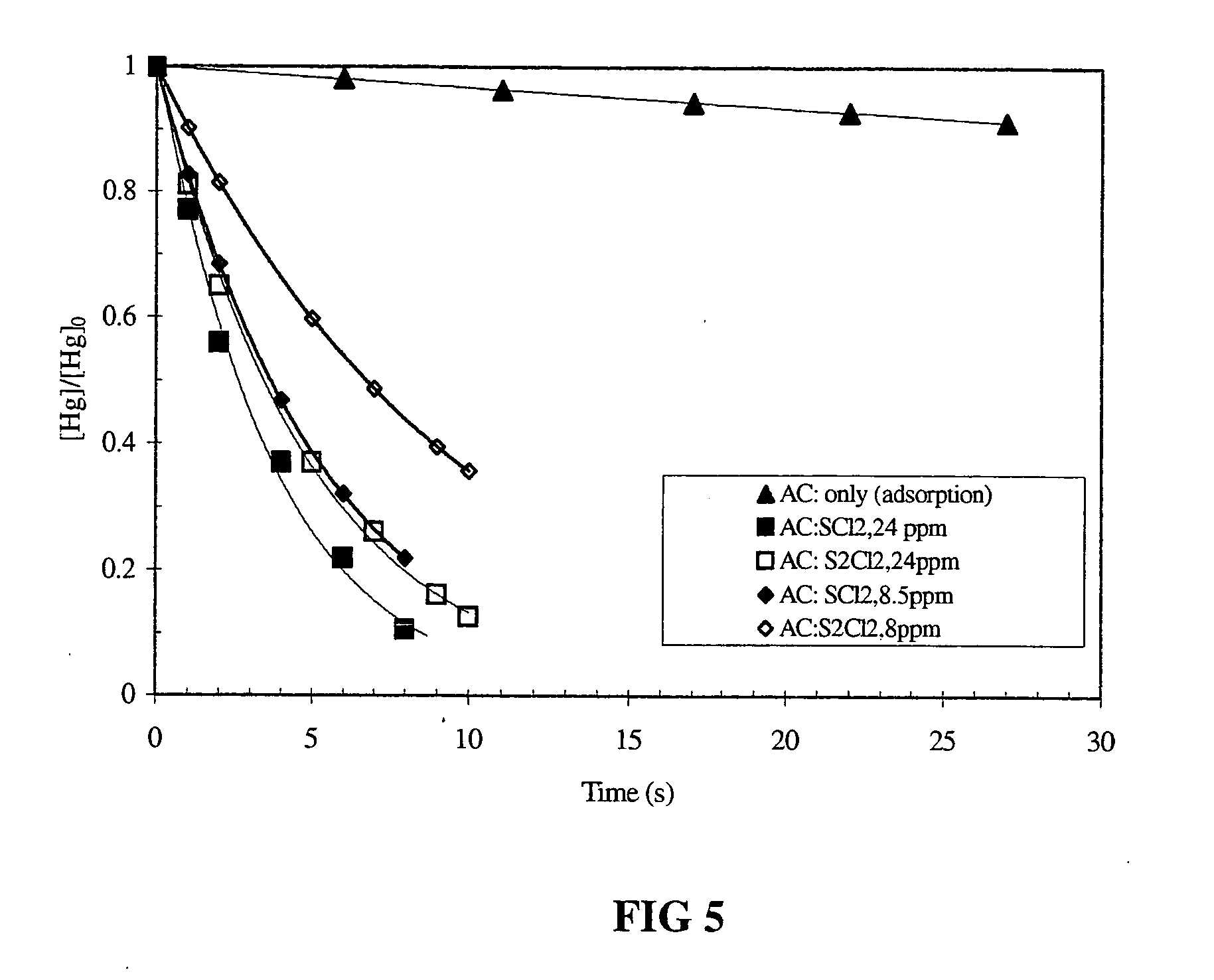

Disclosed herein is a method for removing mercury from a gas stream comprising contacting the gas stream with a getter composition comprising bromine, bromochloride, sulphur bromide, sulphur dichloride or sulphur monochloride and mixtures thereof. In one preferred embodiment the getter composition is adsorbed onto a sorbent. The sorbent may be selected from the group consisting of flyash, limestone, lime, calcium sulphate, calcium sulfite, activated carbon, charcoal, silicate, alumina and mixtures thereof. Preferred is flyash, activated carbon and silica.

Owner:RGT UNIV OF CALIFORNIA

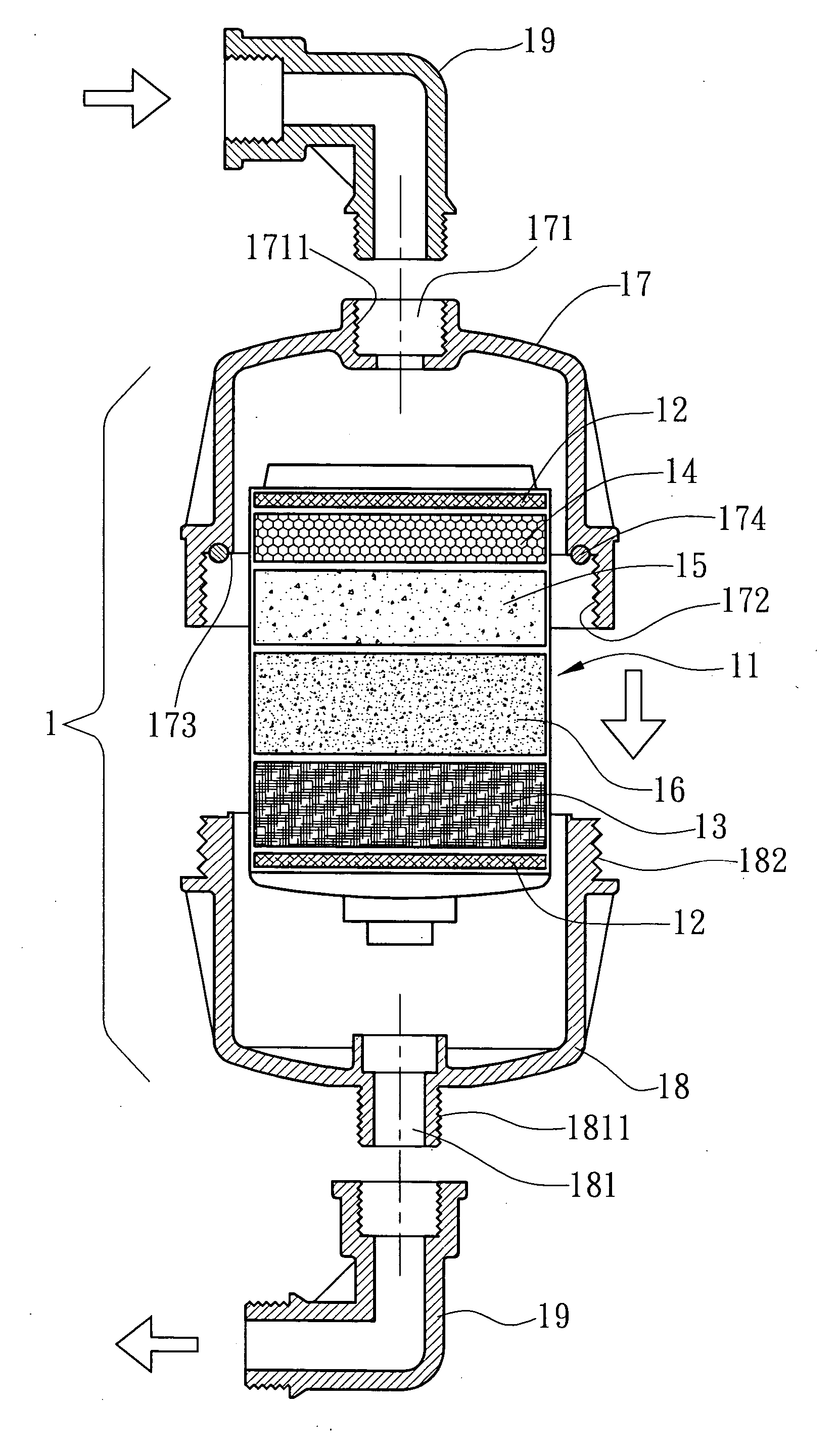

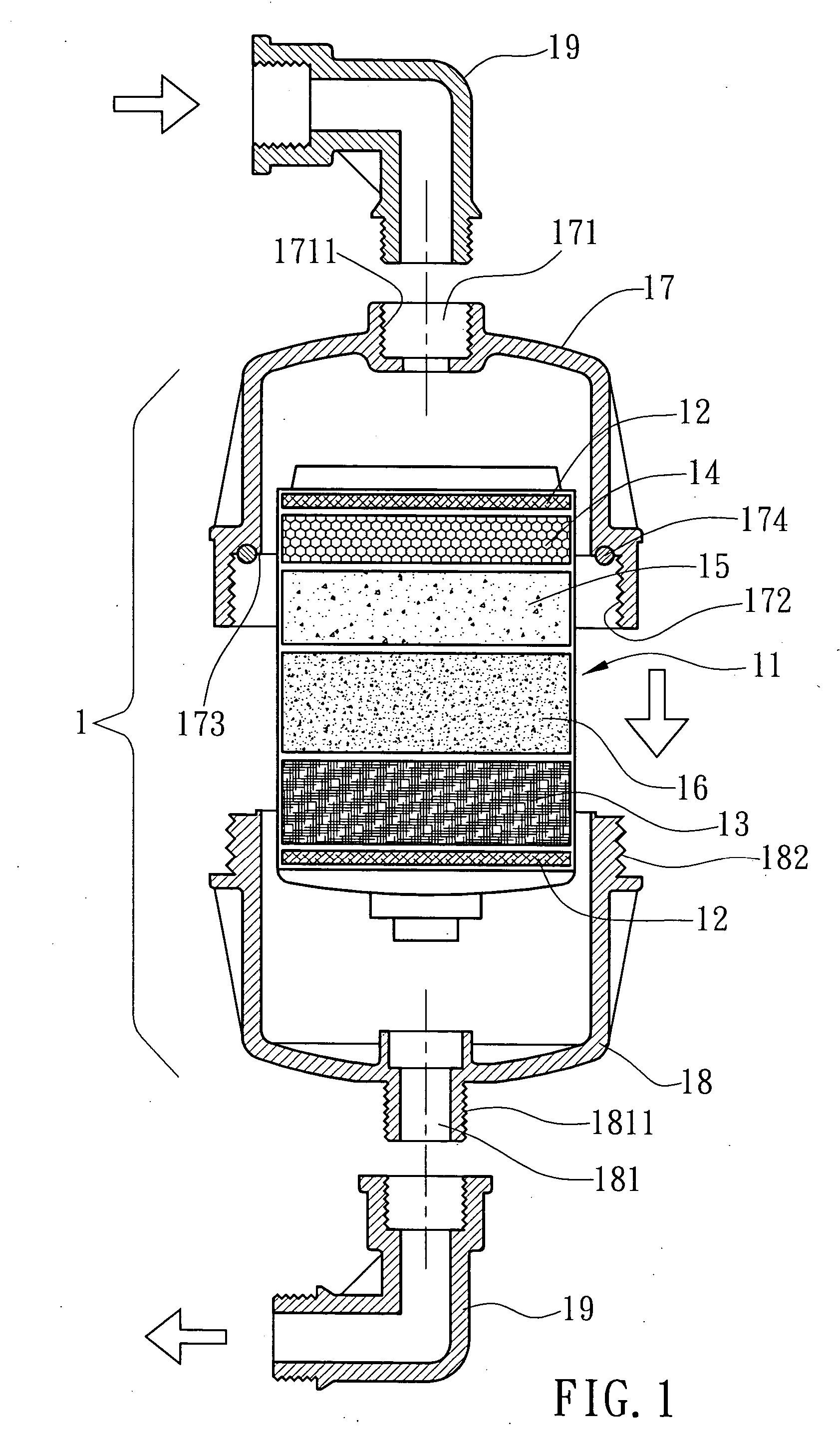

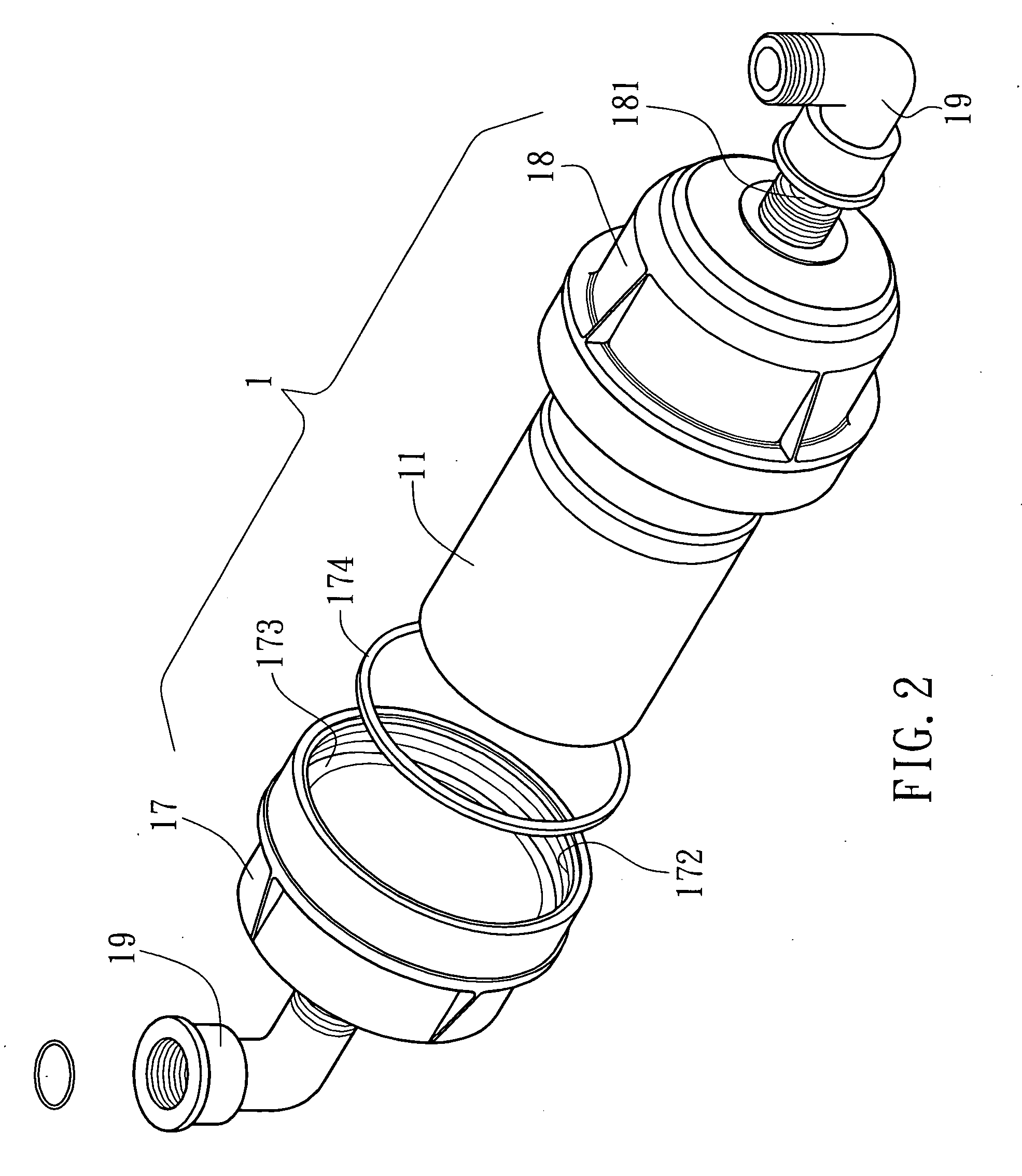

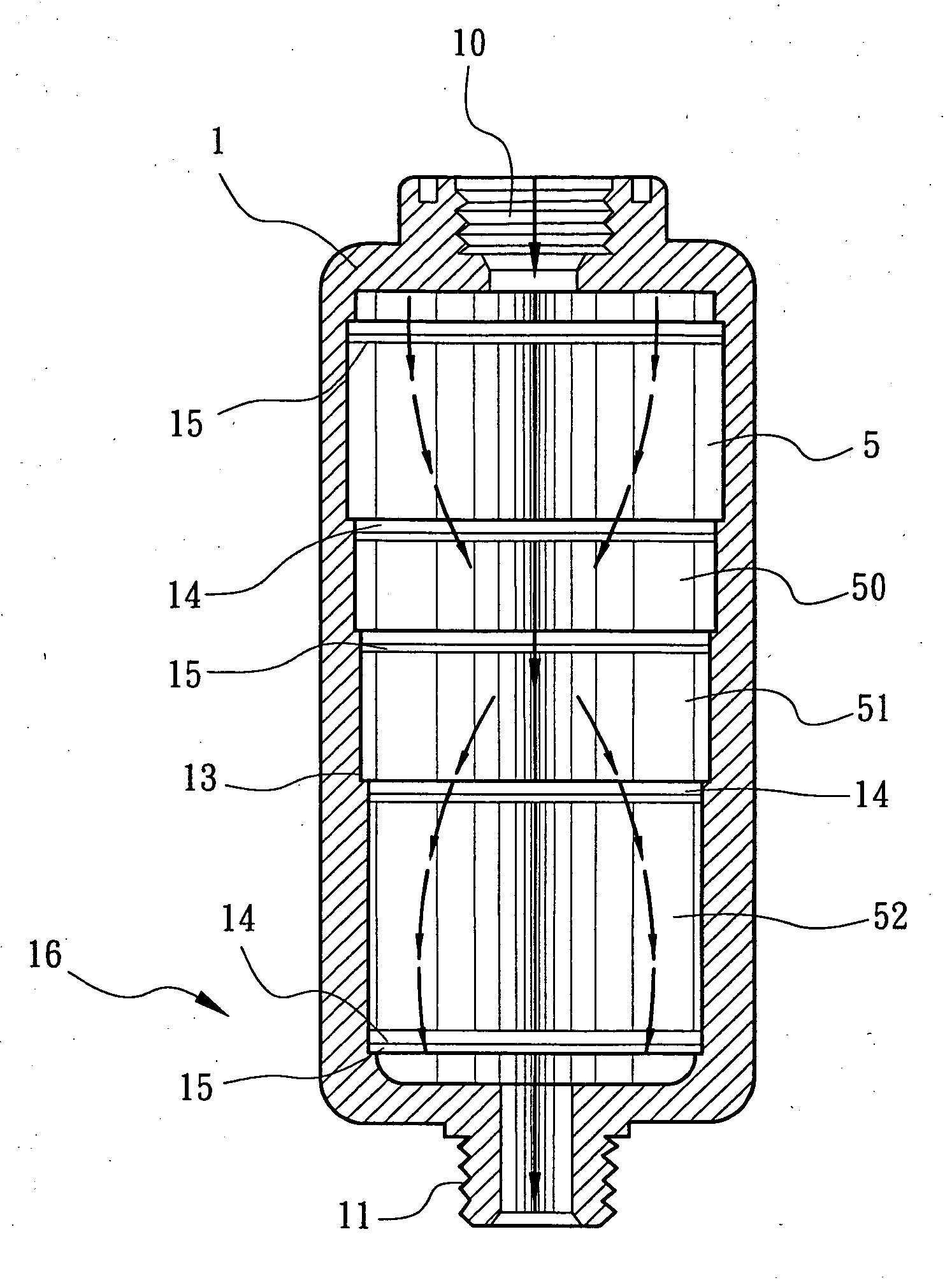

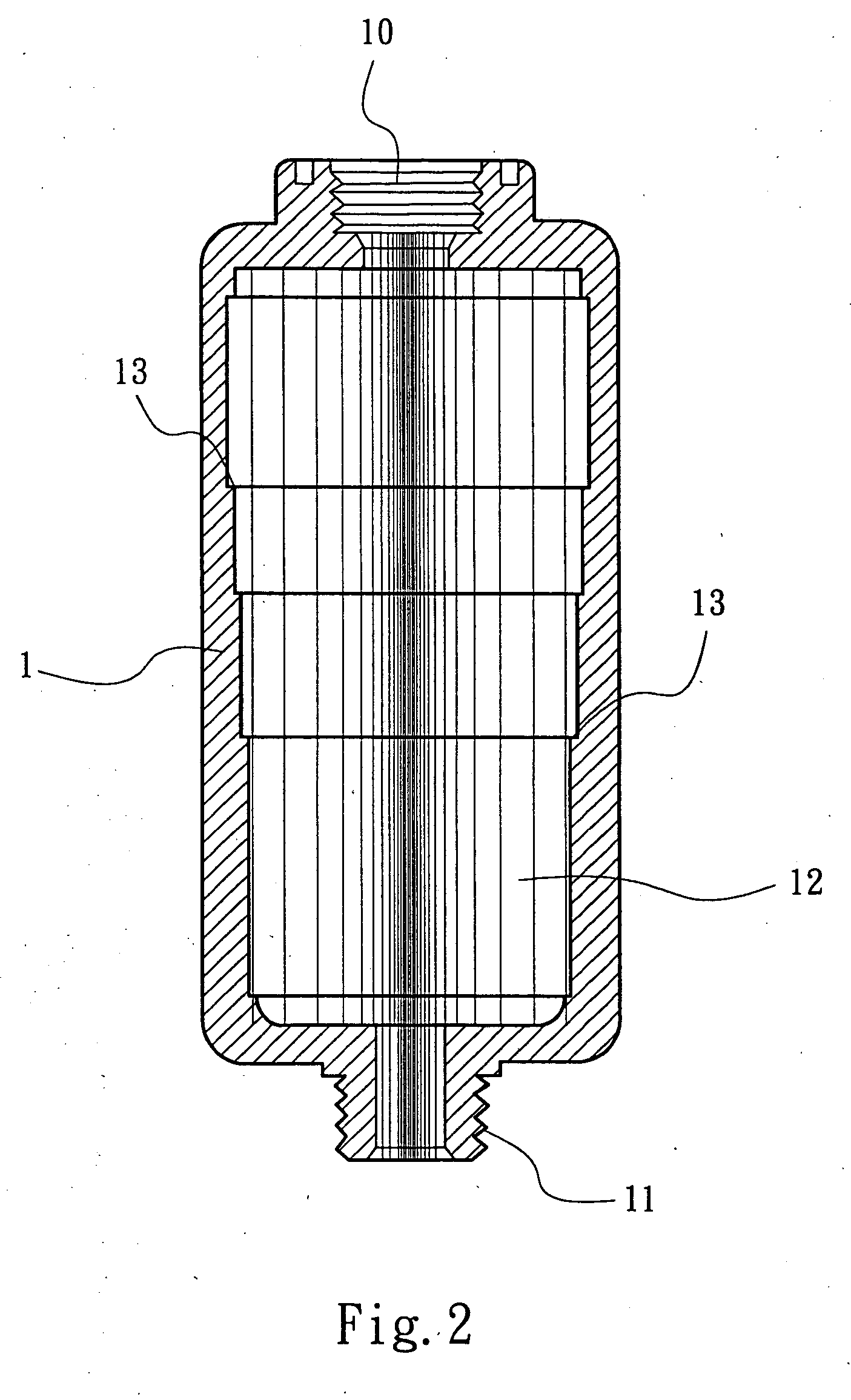

Water filter

InactiveUS20070235381A1Efficient removalHarmful substanceTreatment involving filtrationWater treatment locationFiberWater filter

A water filter is disclosed to include a housing formed of a top cover shell and a bottom cover shell, and a filter element mounted in the housing for filtrating water passing through the housing, the filter element containing nanosilver fabrics, nanocarbon fibers, calcium sulfite, KDF-55, and coconut shell active carbon.

Owner:TSAI JACKIE

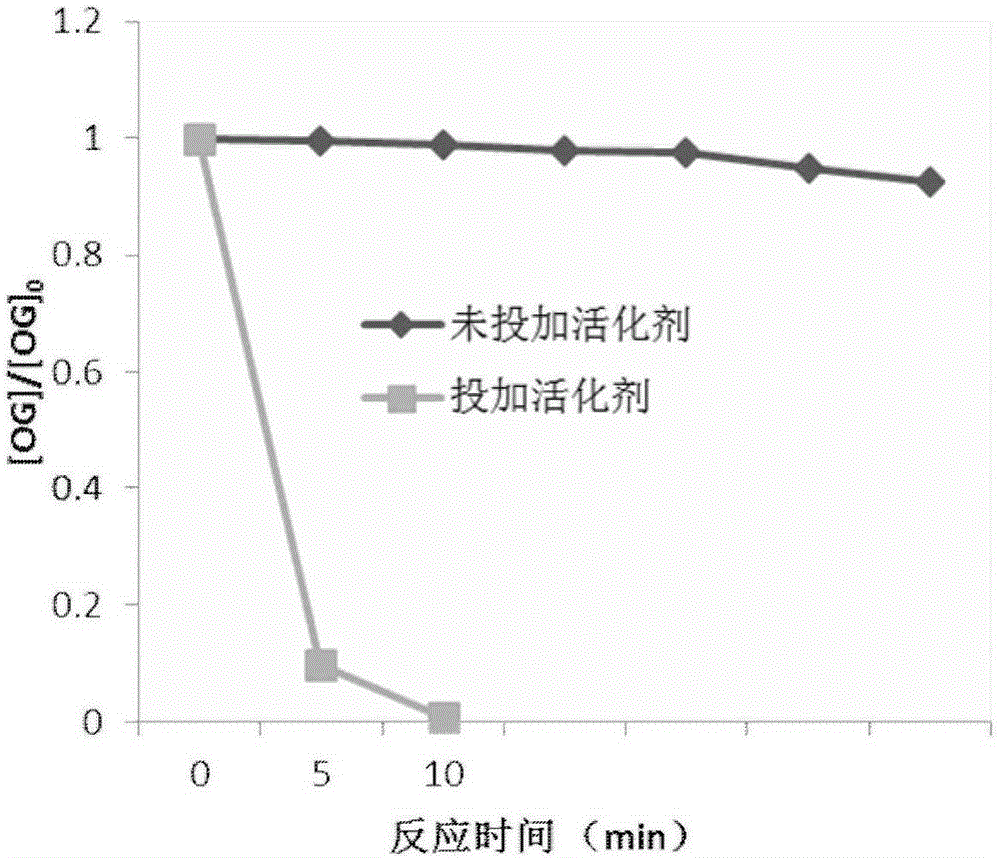

Fenton and Fenton-like system fortifier and using method thereof

ActiveCN101792205AReduce dosageEasy to useWater treatment parameter controlWater treatment compoundsSulfite saltHydrazine compound

The invention provides a Fenton and Fenton-like system fortifier and a using method thereof, which relate to a water treating fortifier and a using method thereof and overcomes the defects that the pH value of the Fenton and Fenton-like system reaction water body is limited, the adding amount of Fe<2+> is overhigh in the Fenton reaction, and the reaction speed is low in Fenton-like reaction. The fortifier is selected from ascorbic acid, sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine, hydroxyl-ammonium perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, carbohydrazide, ethanolamine, a hydroxylamine solution or N,N,N',N'-tetra substituted phenylenediamines. The using method has the following steps of: adding the Fenton and Fenton-like system fortifier, fortificated chemicals and peroxide into the treated water body; and then, uniformly stirring to react. The fortifier can accelerate the reaction of water treatment and decrease the using amount of the fortificated chemicals.

Owner:HARBIN INST OF TECH

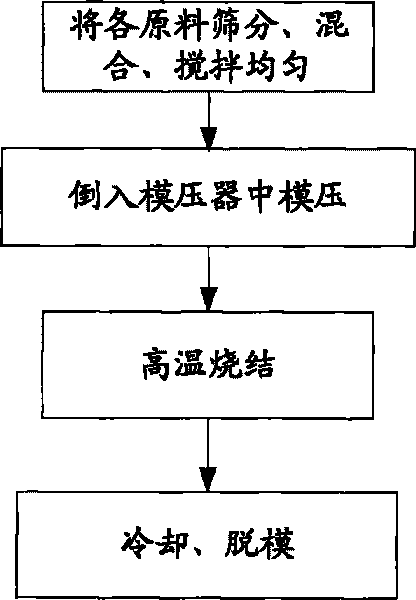

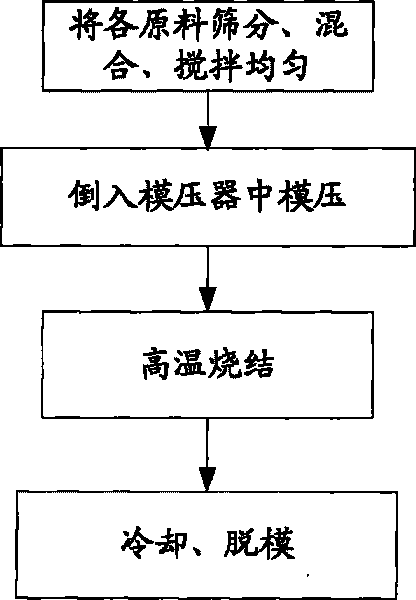

Micro electrolytic energy water treatment element and its preparation method

ActiveCN1868900APromote excretionImprove solubilityWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by substance additionCalcium sulfiteTitanium oxide

A water activating chemical with micro electrolytic energy for cleaning water is prepared from tourmalinite, ferromagnetic powder, Ca ion, charcoal, Zn powder, Cu powder, Mg powder, titanium oxide, RE oxide and one or more of Chinese medical stone, mica, sepiolite and calcium sulfite through respectively breaking and ball grinding, proportional mixing and shaping.

Owner:北京宜生伟业科技发展有限公司

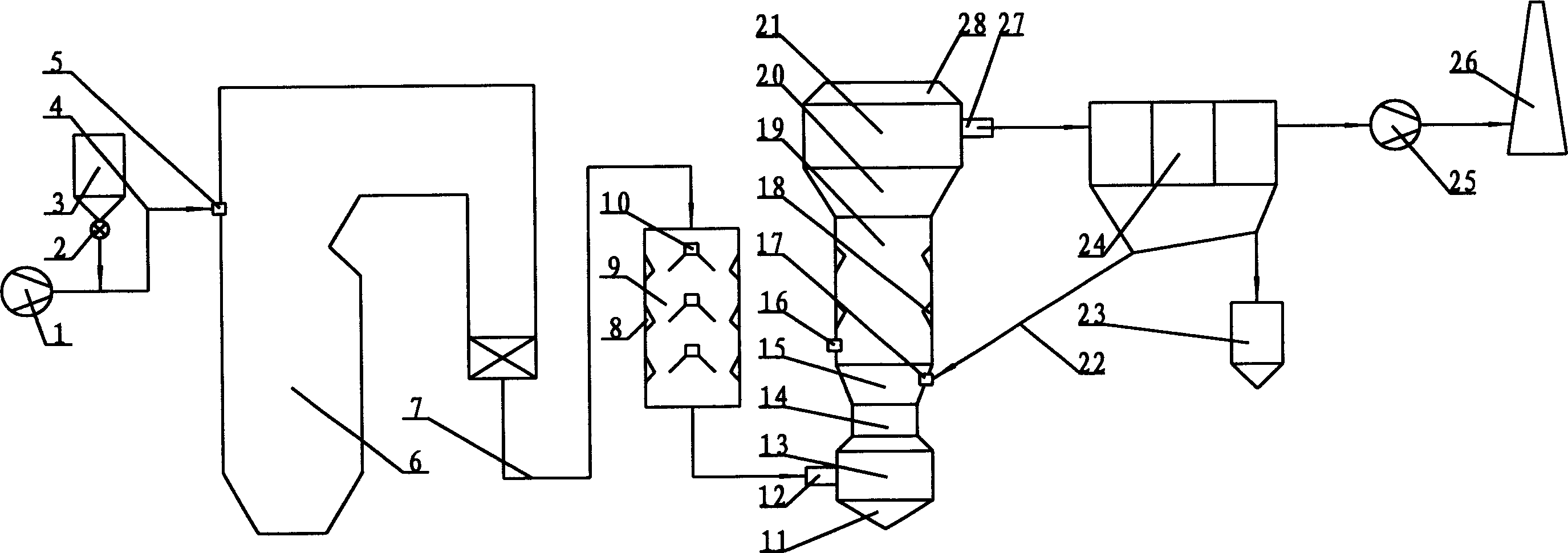

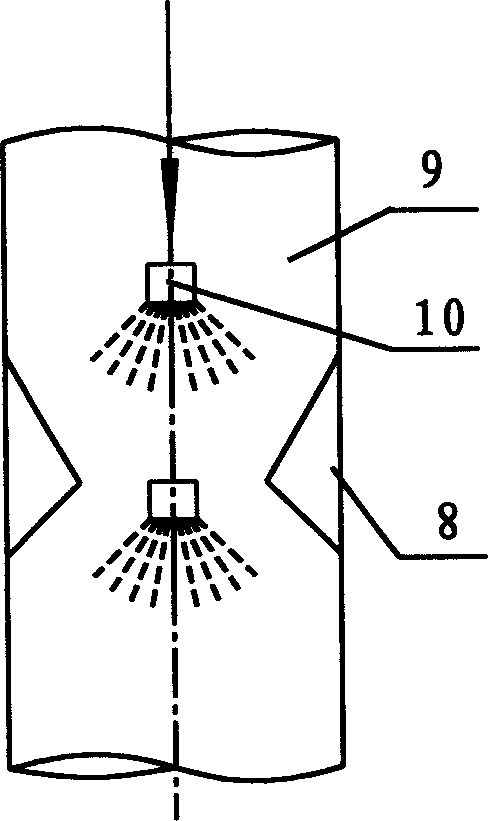

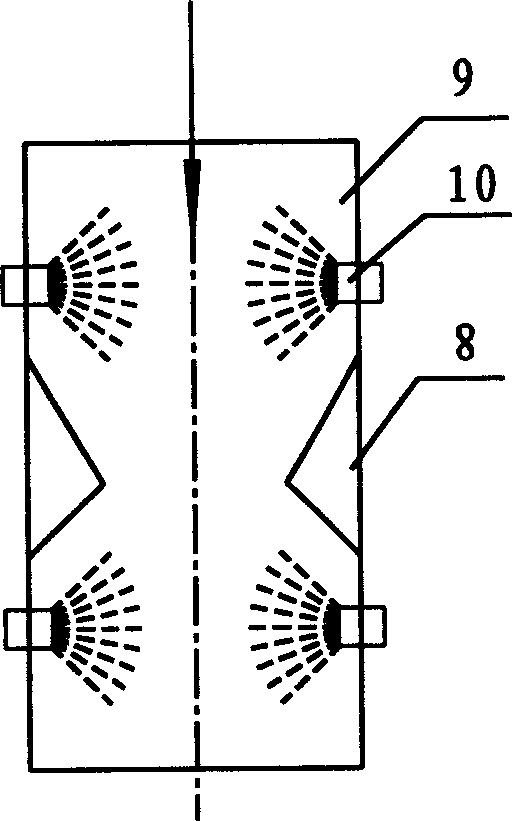

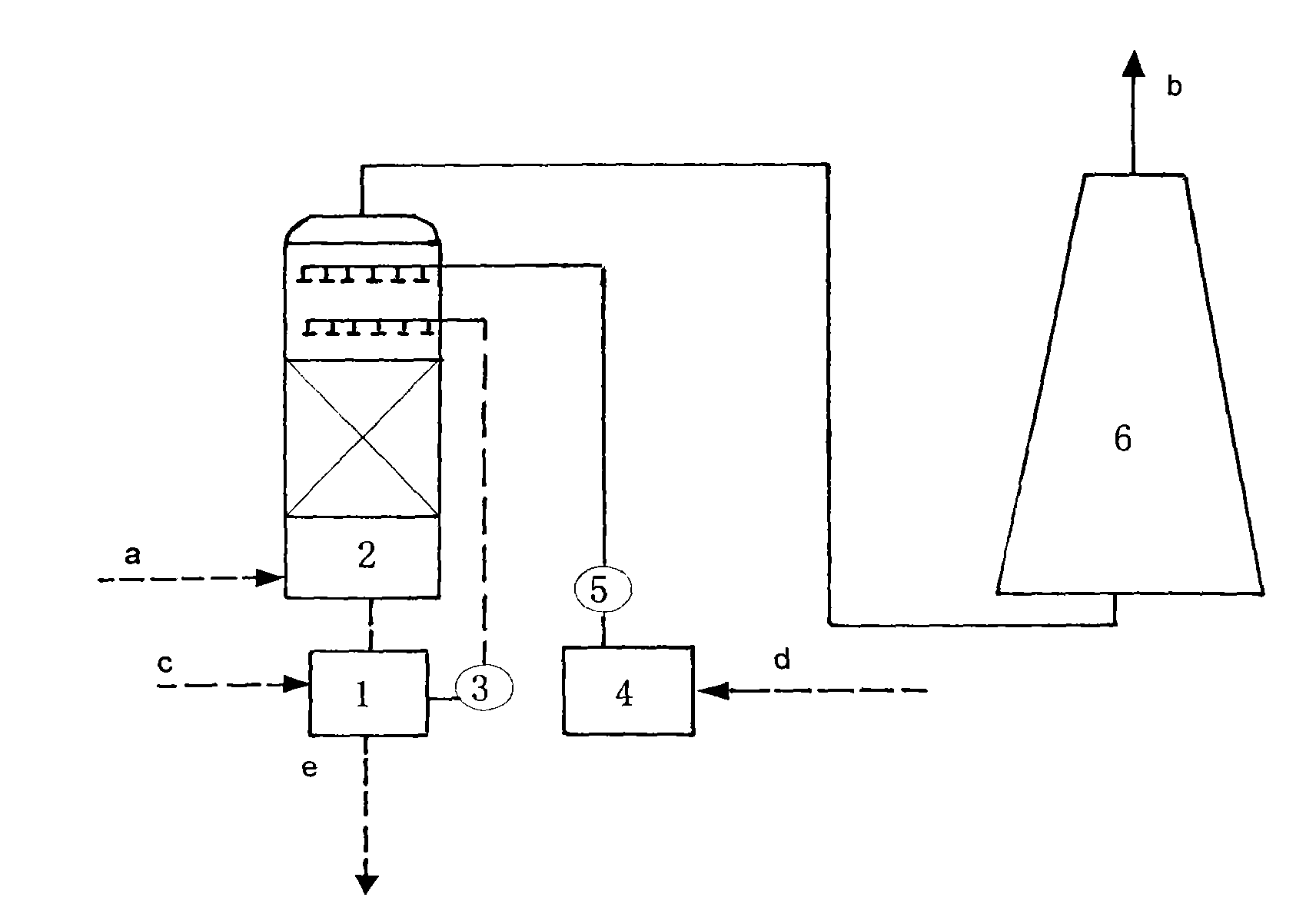

Multiple reaction integrated process for desulfuizing from fume by dry method and its system

ActiveCN1537668AImprove surface activityReduce desulfurization costDispersed particle separationPartial oxidationCalcium sulfite

A multiple reactions integrated process for desulfurizing from the fume by dry method includes such steps as spraying limestone powder in high-temp combustion box from its top to decompose calcium carbonate into calcium oxide and CO2, absorbing SO2 from fume by partial calcium oxide to generate calcium sulfate, spraying water to activate calcium oxide to transform partial calcium oxide to calcium hydroxide and absorb SO2 from fume to generate calcium sulfite, and using the residual calcium hydroxide and calcium oxide to desulfurize the fume in desulfurizing tower. Its system is composed of limestone powder sprayer, moistening flue, desulfurizing tower, external electric duster, draught blower and chimney.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

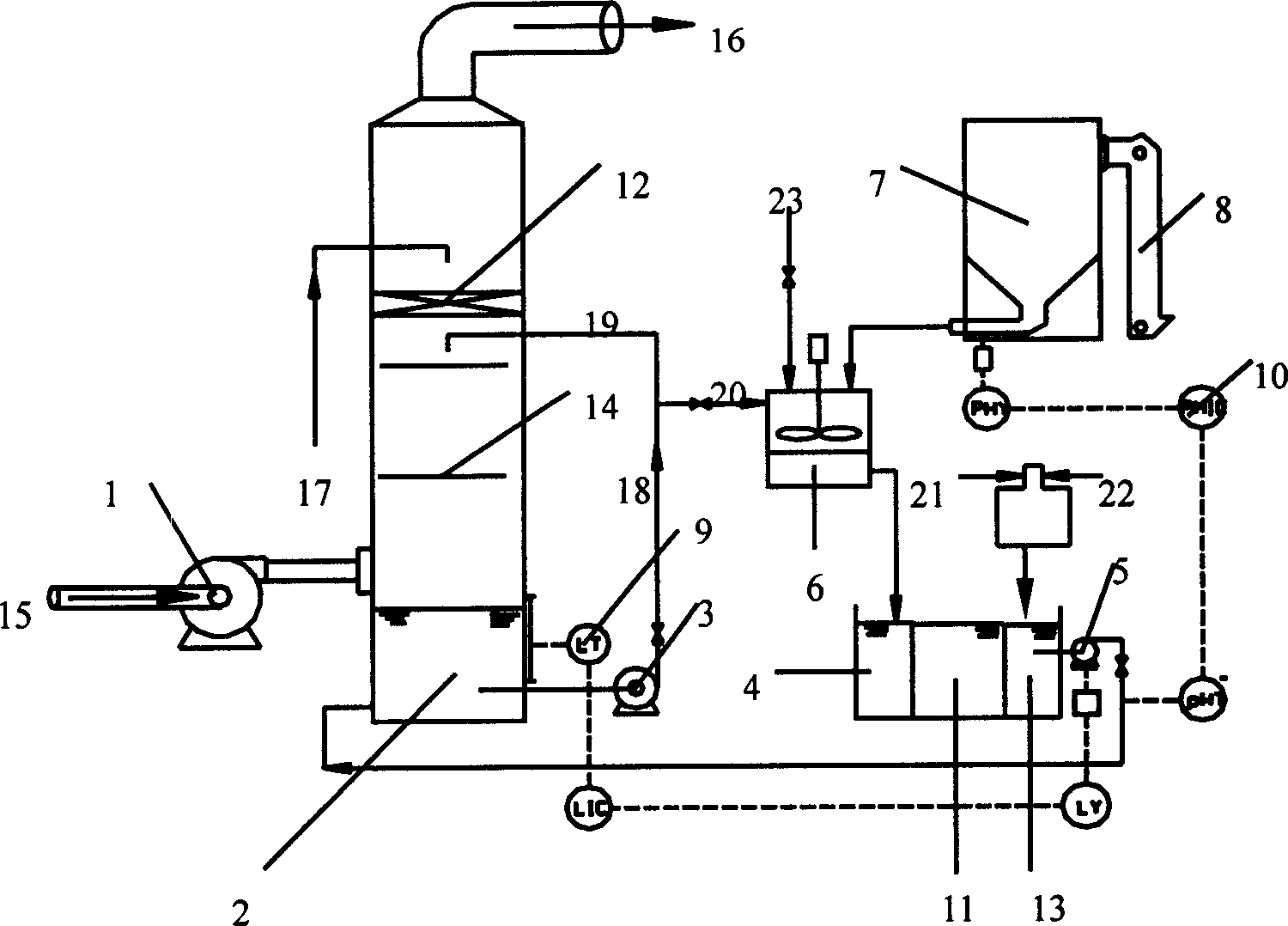

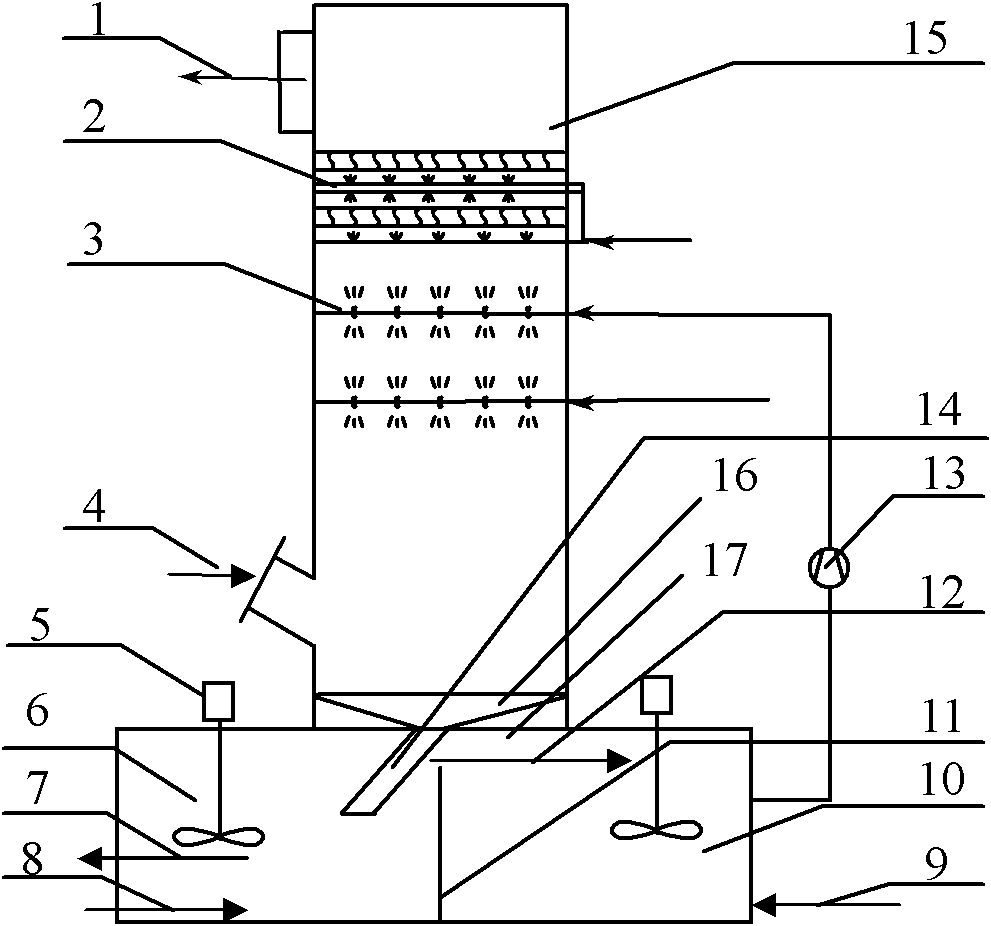

Dual-alkali flue gas desulfurization device and desulfurization method

InactiveCN101879406ASmall footprintImprove sedimentation efficiencyDispersed particle separationEngineeringCalcium sulfite

The invention relates to a dual-alkali flue gas desulfurization device and a desulfurization method. The dual-alkali flue gas desulfurization device comprises an absorption tower, a liquid alkali storage tank and a quick lime powder cabin, wherein the quick lime powder cabin is communicated with a lime slurry tank, an oxidation recovery tank, a primary sedimentation tank, a secondary sedimentation tank and a circulating tank in turn; the bottom of the absorption tower is provided with pipes leading to the oxidation recovery tank, the secondary sedimentation tank and the circulating tank; and an absorption tower circulating pump leading to the upper part of the absorption tower is arranged in the circulating tank. The desulfurization process comprises the following steps of: pumping NaOH solution into the absorption tower by using a pump to fully contact a flue gas so as to ensure that sulfur dioxide reacts with NaOH to produce NaHSO3 solution; discharging the NaHSO3 solution into the oxidation recovery tank from the absorption tower; simultaneously, adding Ca(OH)2 slurry into the oxidation recovery tank to produce the calcium sulfite precipitate; and producing a CaSO4 sediment through an oxidation effect of the air provided by an oxidation blower. The device and the method have the advantages of completely eliminating the possibility of fouling and blocking in the tower, having high desulfurization efficiency and low operating cost and preventing huge waste of a desulfurizing agent.

Owner:COAL IND JINAN DESIGN & RES

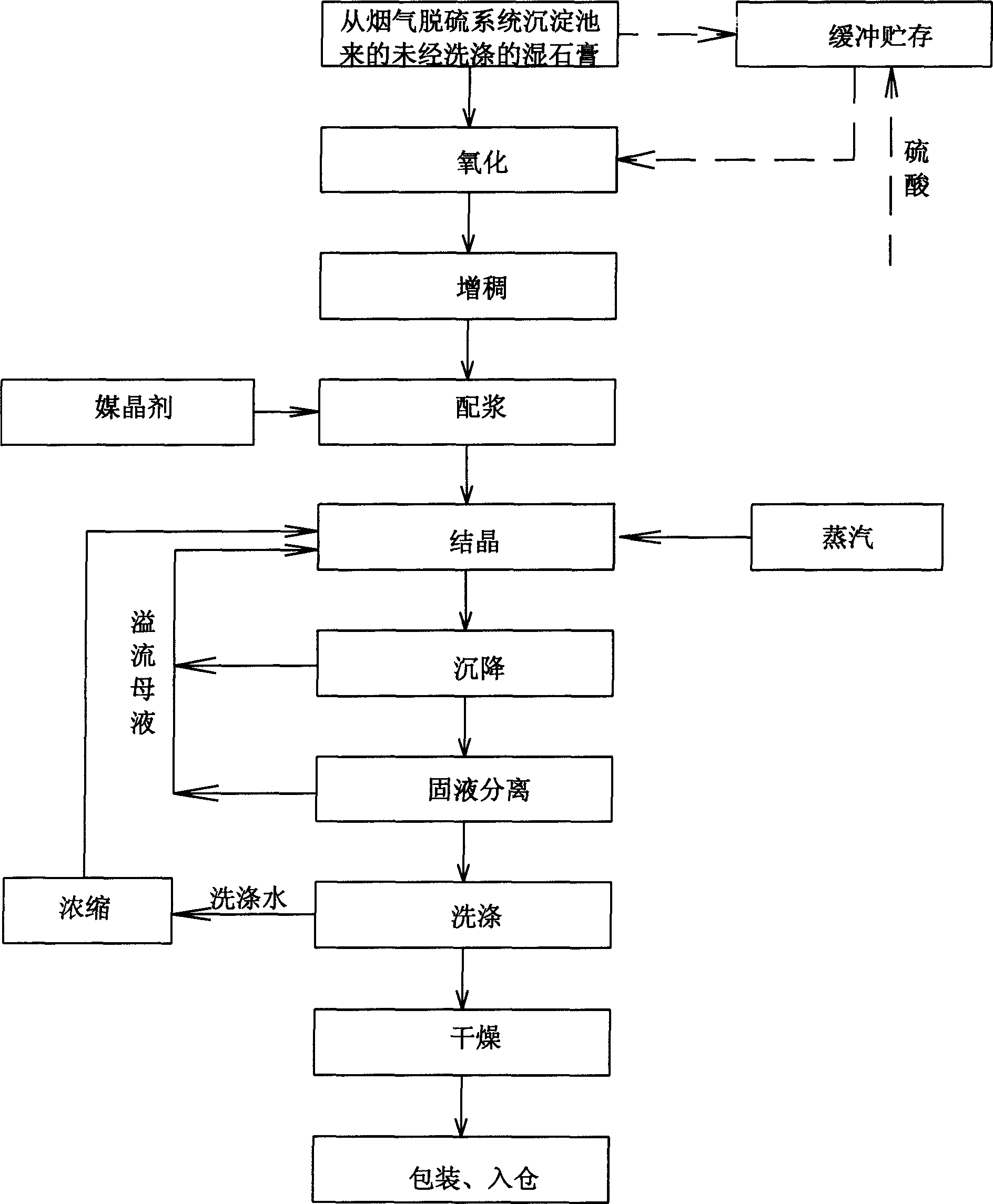

Techlogogy for making alpha semi-water desulfur gypsum using normal pressure salt solution method

InactiveCN1513766AEasy to operate continuouslyEasy to controlCalcium/strontium/barium sulfatesDispersed particle separationCalcium sulfiteSalt solution

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

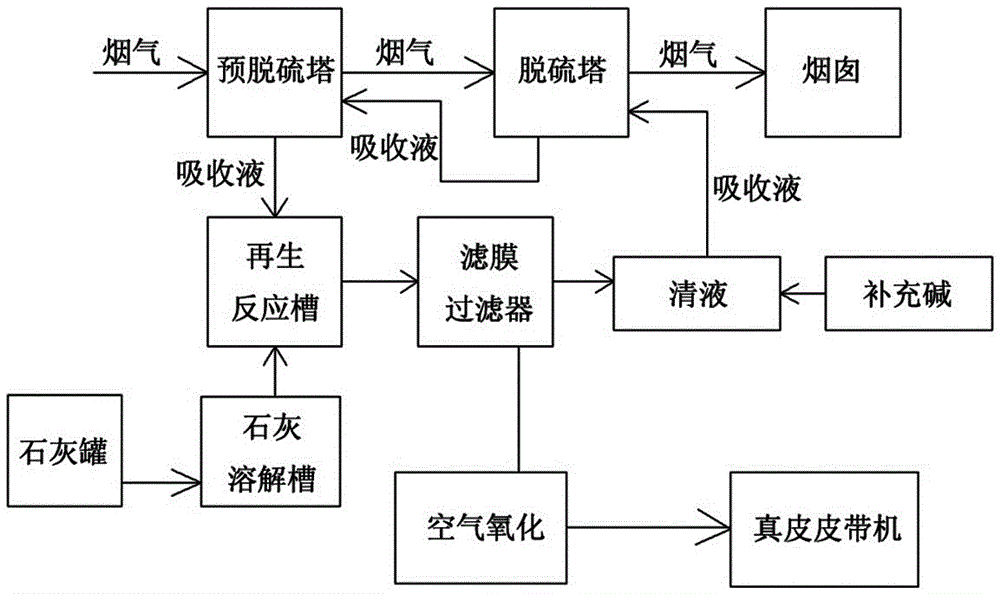

Concentrated alkali double alkali method stack gas desulfurizing technology

InactiveCN1475298AReduce areaImprove desulfurization efficiencyDispersed particle separationSulfateCalcium sulfite

A process for desulfurizing fume by concentrated alkali dual-alkali method features that the SO2 is absorbed by absorbing liquid in absorption tower, the most of absorbing liquid is circulated for absorbing SO2 cyclically, a small part of it is regenerated in regenerating pool for reusing it while generating calcium sulfite and calcium sulfate to be treated further. Its advantages are less possesses ground area and high desulfurizing efficiency up to 95% or more.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Sorbents for Removal of Mercury From Flue Gas Cross Reference To Related Applications

Systems are disclosed for making and using micro-porous particulates at least partially composed of metal sulfides, particularly alkaline earth metal and transition metal sulfides, as sorbents for removal of mercury from flue gas. Calcium sulfide micro-porous powders derived from the high temperature reduction of calcium sulfate and calcium sulfite are disclosed to be reactive substrates for a group of sorbents for adsorption of mercury from coal combustion flue gases produced by the utilities industry, as well as from natural gas and gaseous and liquid hydrocarbons. The sorbents are useful for cost-effectively adsorbing elemental mercury and oxidized mercury species such as mercuric chloride from flue gases, including those containing acid gases (e.g., SO.sub.2, NO and NO.sub.2, and HCl), over a wide range of temperatures.

Owner:CHEM PROD CORP

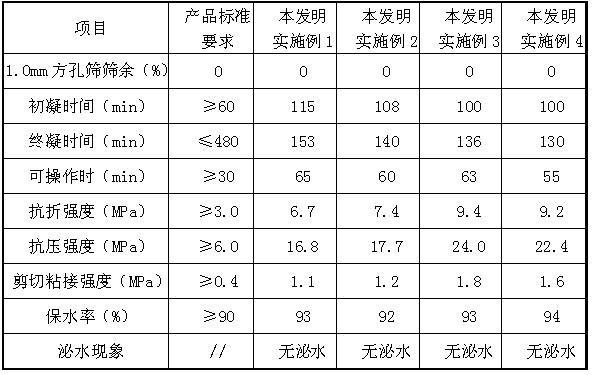

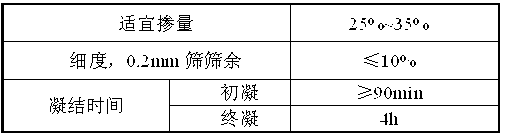

Method for using calcium sulfite type desulfurization gypsum to produce high-strength environmental-friendly type plastering gypsum

ActiveCN102701618AImprove flexural strengthHigh compressive strengthFluidized bedEnvironmental engineering

The invention relates to a method for using calcium sulfite type desulfurization gypsum to produce high-strength environmental-friendly type plastering gypsum. The method comprises the following steps: (1) placing calcium sulfite type desulfurization gypsum into a fluidized bed roaster, continuously blowing air through an air blasting port of the fluidized bed roaster to enable the interior of the fluidized bed roaster to be in the oxidizing atmosphere, and to enable the calcium sulfite type desulfurization gypsum to be boiled, frying at the temperature of 480 to 500 DEG C, and oxidizing the main component, that is, calcium sulfite, of the calcium sulfite type desulfurization gypsum to be made into II-type anhydrous gypsum after frying for 20 to 40 minus; and (2) sequentially mixing 25 to 35 percent of II-type anhydrous gypsum exciting agent and 0.2 to 0.4 percent of water-retaining agent in the II-type anhydrous gypsum according to mass ratio, and packing according to 40 kg per bag after uniformly mixing. The method has a simple process, and the produced high-strength environmental-friendly type plastering gypsum is nontoxic, tasteless, harmless to the human body, free from environmental pollution, and suitable for indoor plastering.

Owner:GANSU BUILDING MATERIALS DESIGN & RES INST CO LTD

Method for selectively removing calcium ions from concentrated water byproduct of sea water desalination process and other high-calcium-magnesium-content concentrated brines

InactiveCN102936067AHigh removal rateQuick responseGeneral water supply conservationMultistage water/sewage treatmentLoss rateWater desalination

The invention relates to a method for selectively removing calcium ions from a concentrated water byproduct of a sea water desalination process and other high-calcium-magnesium-content concentrated brines, which comprises the following steps: regulating the pH value of the concentrated water to 7.0-8.5, and then heating to a certain temperature; introducing the concentrated water into a heat-insulating apparatus capable of realizing sealed stirring, adding a sodium sulfite or sodium carbonate solution having a certain concentration while stirring, reacting for 1-40 minutes while sufficiently stirring, standing for 5-10 minutes, and then filtering to remove calcium sulfite or calcium carbonate precipitate; and adding hydrochloric acid into the filtrate to regulate the pH value back to 6. According to the invention, the problems of low calcium removal rate, high magnesium loss rate, long stirring time and the like during the concentrated water treatment based on the traditional normal-temperature sodium carbonate precipitation method are overcome, the operation is convenient, the investment is low, and the operation cost is low; and the concentrated water liquid subjected to decalcification treatment can be further deeply concentrated through a membrane method or hot method, thereby improving the fresh water recovery rate and realizing the reutilization and zero discharge of the resources. The method provided by the invention is suitable for selectively removing calcium ions from sea water, sea water or brackish water subjected to other treatment processes such as reverse osmosis or multiple-effect evaporation and concentration, underground salt brines and concentrated water of industrial waste water subjected to reverse osmosis treatment.

Owner:天津凯铂能膜工程技术有限公司

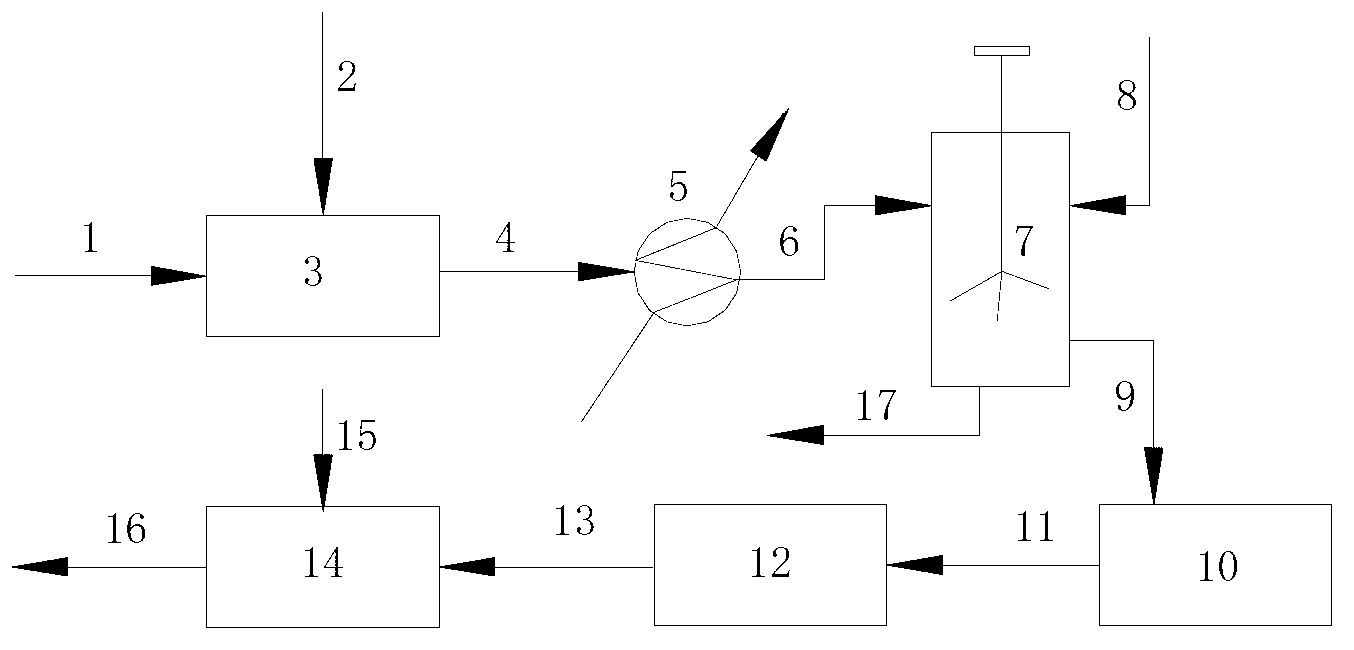

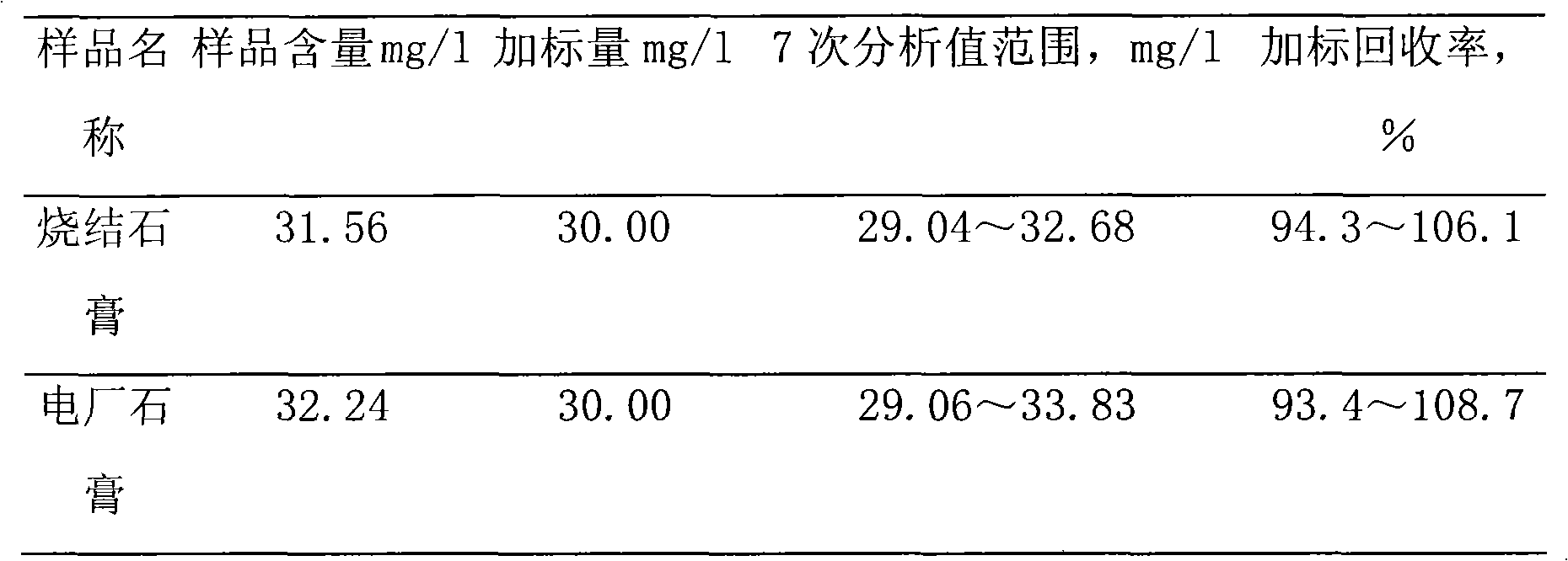

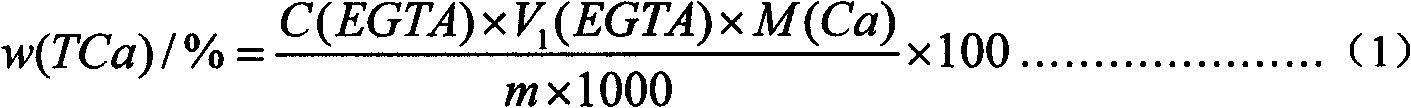

Method for measuring calcium sulfate in desulfuration gypsum

ActiveCN101852736ASimple methodHigh precisionPreparing sample for investigationAnalysis by thermal excitationSulfateCalcium sulfite

The invention discloses a method for measuring calcium sulfate in desulfuration gypsum, which is characterized by comprising the following steps of: 1, preparing a lime slurry sample; 2, measuring the total calcium content and the total sulfur content of the sample by using an ICP method; 3, measuring the calcium sulfite content of the sample by using a volumetric method; and 4, obtaining the content of calcium sulfate, namely subtracting the calcium sulfite content measured in the third step from the total sulfur content measured in the second step to obtain the content of the calcium sulfate. The method for measuring the calcium sulfate in the desulfuration gypsum has the advantages of simple operation, short analysis time, high analysis precision and capability of meeting field processrequirements.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

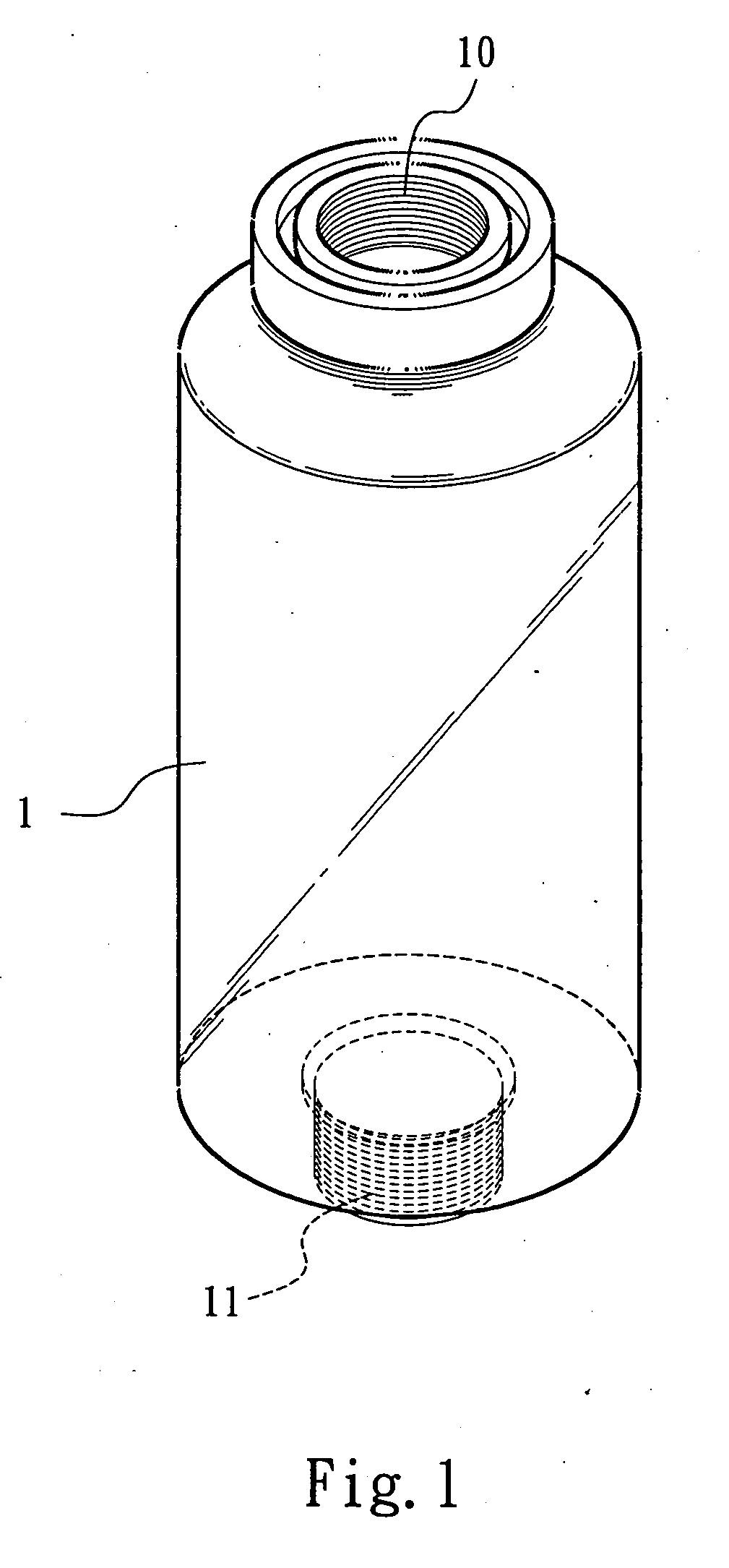

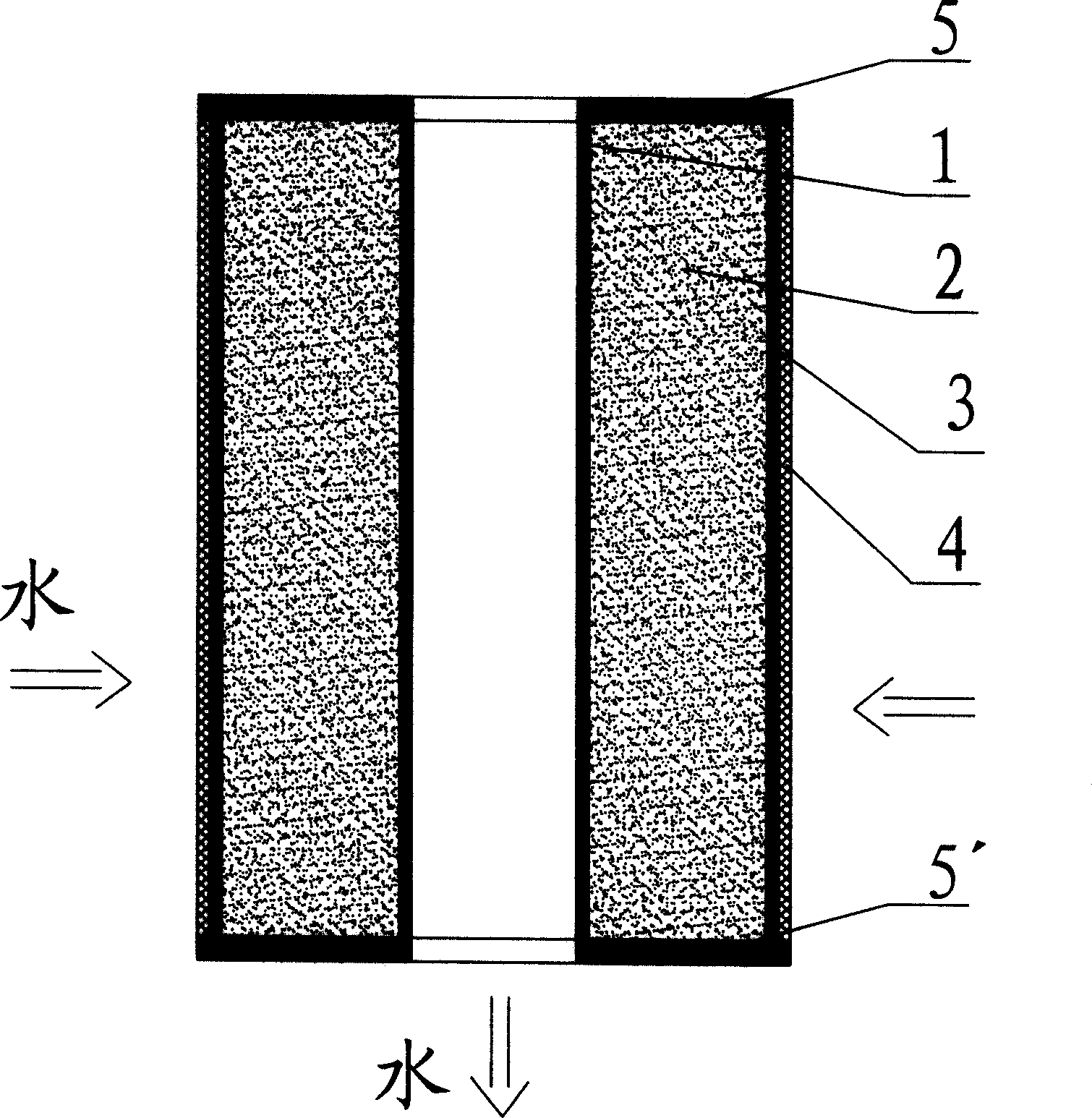

Intersecting water conducting filter

InactiveUS20060266691A1Provide effectWater/sewage treatment by irradiationTreatment involving filtrationActivated carbonWater flow

An intersecting water conducting filter including a filter main body. An oblique tapered assembly chamber is formed in the filter main body. A sidewall of the assembly chamber is formed with multiple insertion grooves in each of which awater conducting layer is inlaid. Each water conducting layer is composed of a partitioning board and a filtering cotton. The partitioning board of each water conducting layer is formed with several conducting holes at different intervals. When water flows through the conducting holes, an intersecting conducting effect is provided for the water flow so that the water can fully flow through the Far-infrared precision ceramic / porcelain particle layer, KDF copper / zinc filtering layer, calcium sulfite layer and coconut shell activated carbon layer installed between the water conducting layers. The filter main body has a first end formed with inner thread for connecting with a shower sprinkler, an intake controller or a water inlet end. A second end of the filter main body is formed with outer thread for connecting with an outlet conduit.

Owner:CHENG SHIH

Semi-dry process flue gas desulfurized ash modification treatment method

ActiveCN105819480AColor does not changeEasy to reuseCalcium/strontium/barium sulfatesCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideSulfate

The invention discloses a semi-dry process flue gas desulfurized ash modification treatment method. Flue gas desulfurized ash, which is obtained after a CFB desulfurization technology, is modified by MnO2, water, and an oxidant; during the modification process, flue gas desulfurized ash is continuously oxidized, calcium oxide in flue gas desulfurized ash is converted into calcium hydroxide, calcium sulfite is converted into calcium sulfate, and modified desulfurized ash is obtained. Specifically, the modification treatment comprises the following steps: spraying atomized water, which contains a MnO2 catalyst, on desulfurized ash, stirring for 5 to 10 minutes to uniformly mix desulfurized ash and water; then spraying an oxidant on the desulfurized ash, stirring for 25 to 40 minutes, and evenly mixing so as to fully modify desulfurized ash. According to the modification treatment method, atomized water containing MnO2 and an oxidant are combined to modify desulfurized ash in an enclosed environment; after modification, the water content of desulfurized ash is 15 to 17%, desulfurized ash can be directly entrucked without dehydration or drying, and the energy and time are saved.

Owner:株洲醴陵旗滨玻璃有限公司 +1

Material and apparatus for filtering tap water, and method for mfg. said apparatus

InactiveCN1751772AExtend the life cycleEasy to useStationary filtering element filtersMolecular sieveActivated carbon

A filtering material for removing the harmful substance from running water is proportionally prepared from activated carbon, KDFT, calcium sulfite, zeolite molecular sieve, and Ag carried phosphate. Its filter apparatus is a multi-layer hollow structure composed of internal non-woven fabric layer, activated carbon mixed core layer, external non-woven fabric layer and plastic mesh layer. Its manufacture method features that its both ends are blocked by polyethene covers and its core layer is prepared from multiple substances through mixing and screw extruding out to become a hollow cylinder.

Owner:VITOP BIOENERGY SCI & TECH

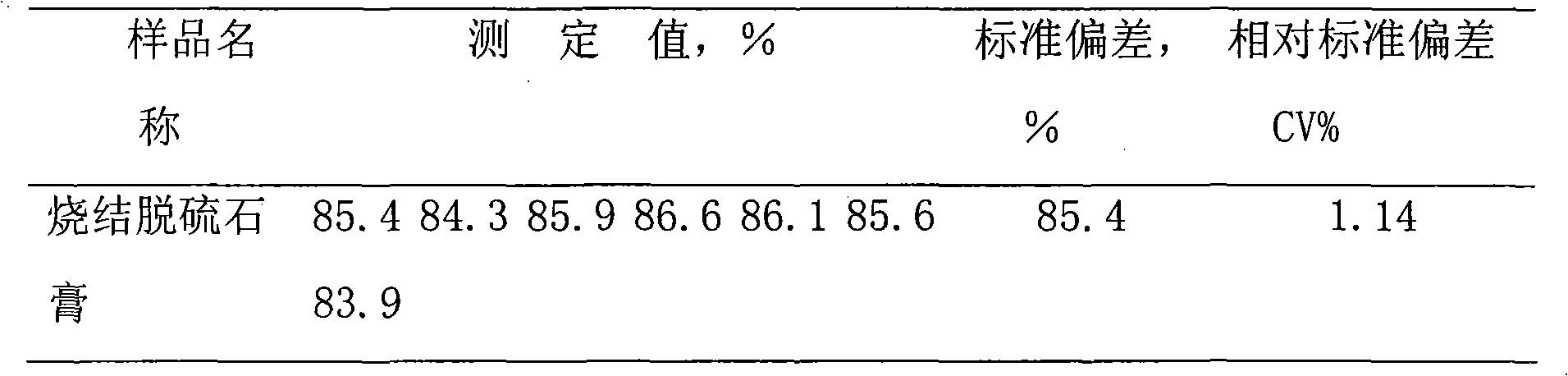

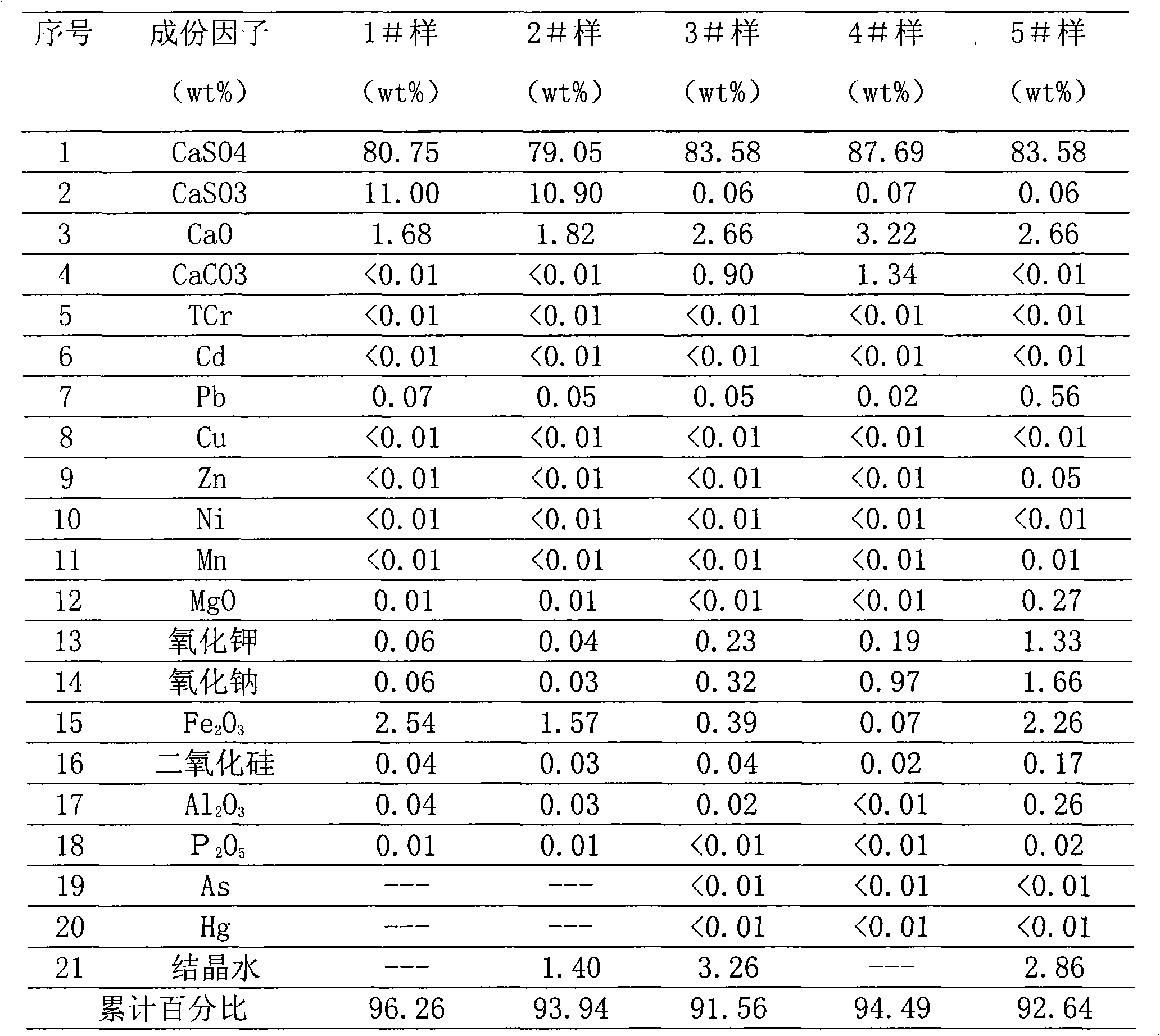

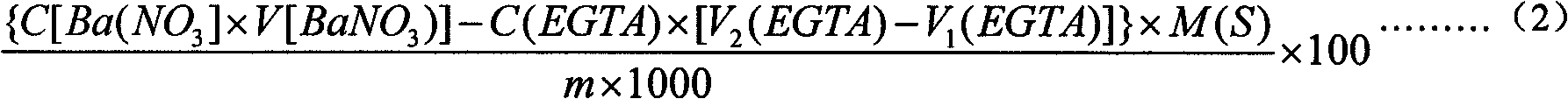

Method for simultaneously determining total calcium, sulfate calcium and calcium sulfite in desulfurized fly ash

InactiveCN103033550ARealize joint determinationEliminate distractionsMaterial electrochemical variablesSulfate radicalsCalcium sulfite

The invention discloses a method for simultaneously determining total calcium, sulfate calcium and calcium sulfite in desulfurized fly ash. The method comprises the following steps: decomposing the calcium sulfite to lead calcium sulfite radical to be volatilized out in sulfur dioxide by acid; precipitating barium sulfate; determining the calcium sulfate by an indirect titration method; oxidizing the calcium sulfite into the calcium sulfate; precipitating the total sulfate radical; and realizing the calcium sulfite determination by difference reduction of the total sulfate radical and the sulfate radical. With the adoption of the method, the interference of substances such as calcium hydroxide and calcium chloride is eliminated; the barium sulfate is precipitated and needs not to be filtered; after the acidity is adjusted, the direct titration can be carried out; the method is simple and rapid to operate; titration is carried out by a potential titrimeter; and the simultaneous determination of the total calcium, the sulfate calcium and the calcium sulfite is realized. With the adoption of the method, the defect that an iodine method is not suitable for determining the calcium sulfite in the desulfurized fly ash is greatly overcome, and meanwhile, the content of the total calcium can be determined, so that the condition that the total calcium, the sulfate calcium and the calcium sulfite in the desulfurized fly ash at each stage in a metallurgy sintering smoke gas dry method and semi drying method desulfurizing process can be accurately determined is realized; and the simultaneous determination method is shortened for 3-5 times compared with the method for determining three components respectively.

Owner:ANGANG STEEL CO LTD

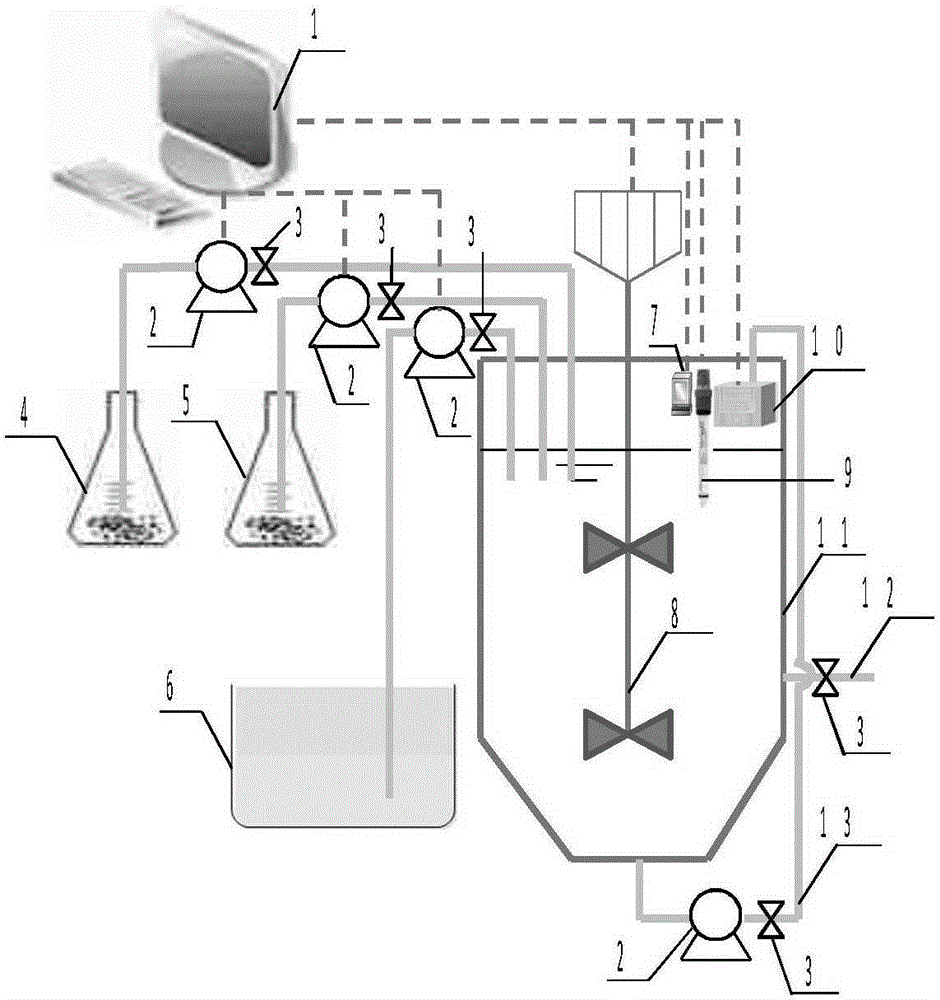

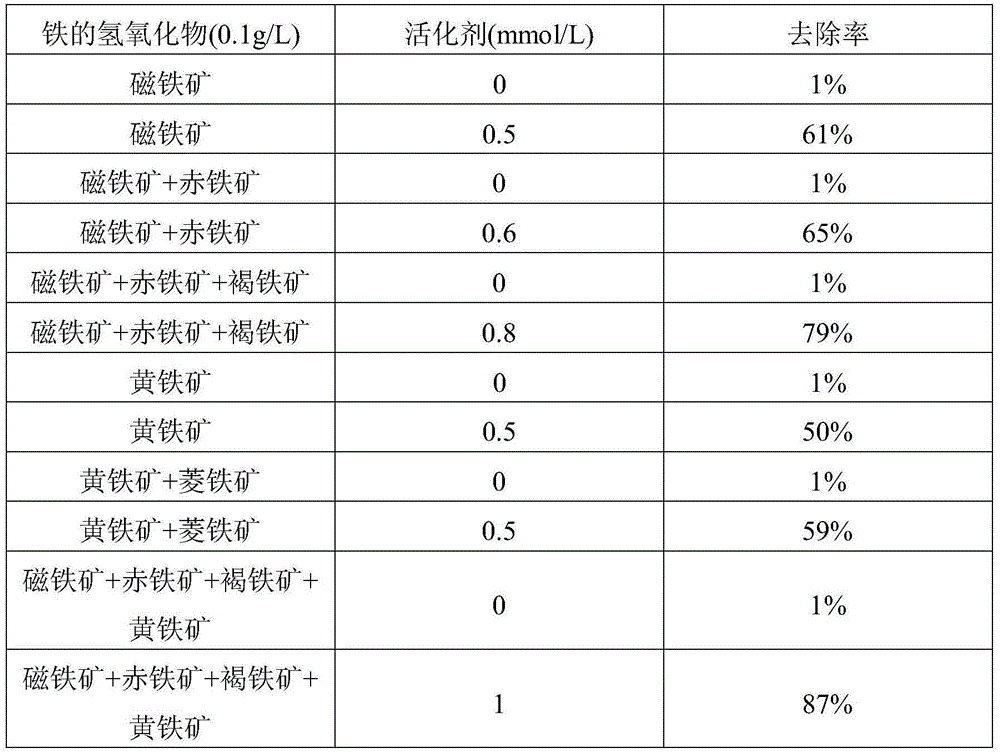

Method for recycling iron waste for fenton technology and water treating device of method

InactiveCN105174413AIncrease reaction rateRealize resource utilizationWater/sewage treatment by oxidationPotassium borohydrideSulfite salt

The invention discloses a method for recycling iron waste for the fenton technology. The method comprises the following steps that hydrogen peroxide, the iron waste and an activating agent are added to waste water to be treated, stirring is conducted so that the iron waste can be dispersed in a reaction system, a reaction is conducted, and then solid and liquid separation is conducted, wherein the activating agent is any one or a mixture of sodium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, sodium thiosulfate, potassium thiosulfate, calcium thiosulfate, magnesium thiosulfate, sodium borohydride, potassium borohydride, hydroxylamine hydrochloride and ascorbic acid. By means of the method, various kinds of iron waste are recycled, meanwhile, zero iron mud emission is achieved, and thus pollution to the environment is effectively reduced. The invention further provides a water treating device capable of achieving the method. By means of the method and the water treating device, the reaction speed of the iron waste in the fenton system is greatly increased, the effective pH range of the fenton system is expanded, meanwhile zero iron mud emission is achieved, and thus pollution to the environment can be easily reduced.

Owner:HOHAI UNIV

Molecular sieve filter element and preparation method thereof

InactiveCN101732926AImprove filtering effectOther chemical processesDomestic articlesWater qualityCalcium sulfite

The invention discloses a molecular sieve filter element, which is prepared by the following raw materials in parts by weight: 10-30 parts of activated carbon powder, 15-60 parts of functional material, 15-55 parts of polyethylene and 2-12 parts of gas generation agent, wherein the functional material is selected from one of calcium sulfite, nano metal, medical stone, activated aluminum oxide and alkaline Tourmaline. The molecular sieve filter element provided by the invention takes activated carbon as base stock matched with the gas generation agent, then is prepared by adding the functional material selected from any one of the calcium sulfite, nano metal, medical stone, activated aluminum oxide and alkaline Tourmaline, and has the functions of residual chlorine removal heavy metal removal, water quality mineralization, and fluorine and arsenic removal to alkalinize the water, thus being capable of filtering water better. The invention also discloses a preparation method for the molecular sieve filter element.

Owner:潘峰

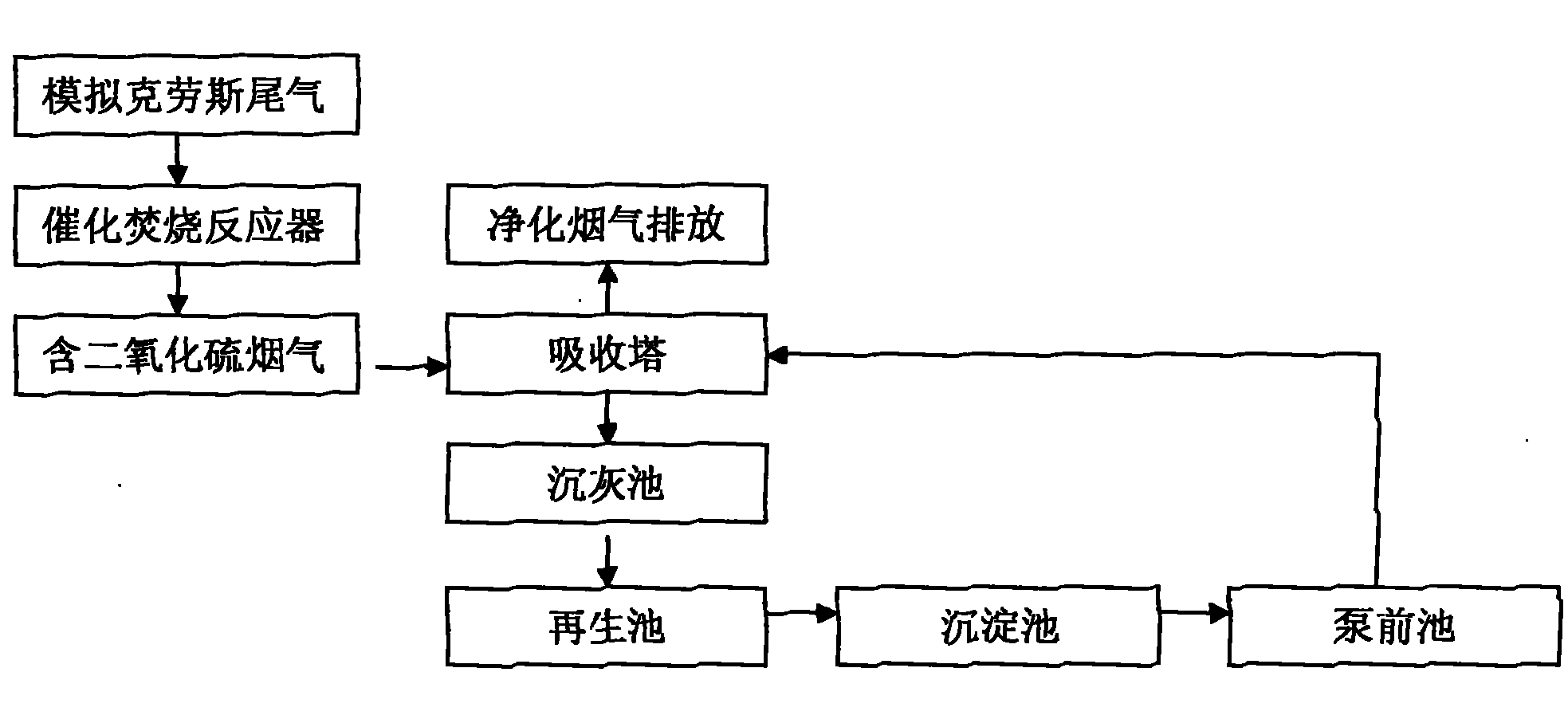

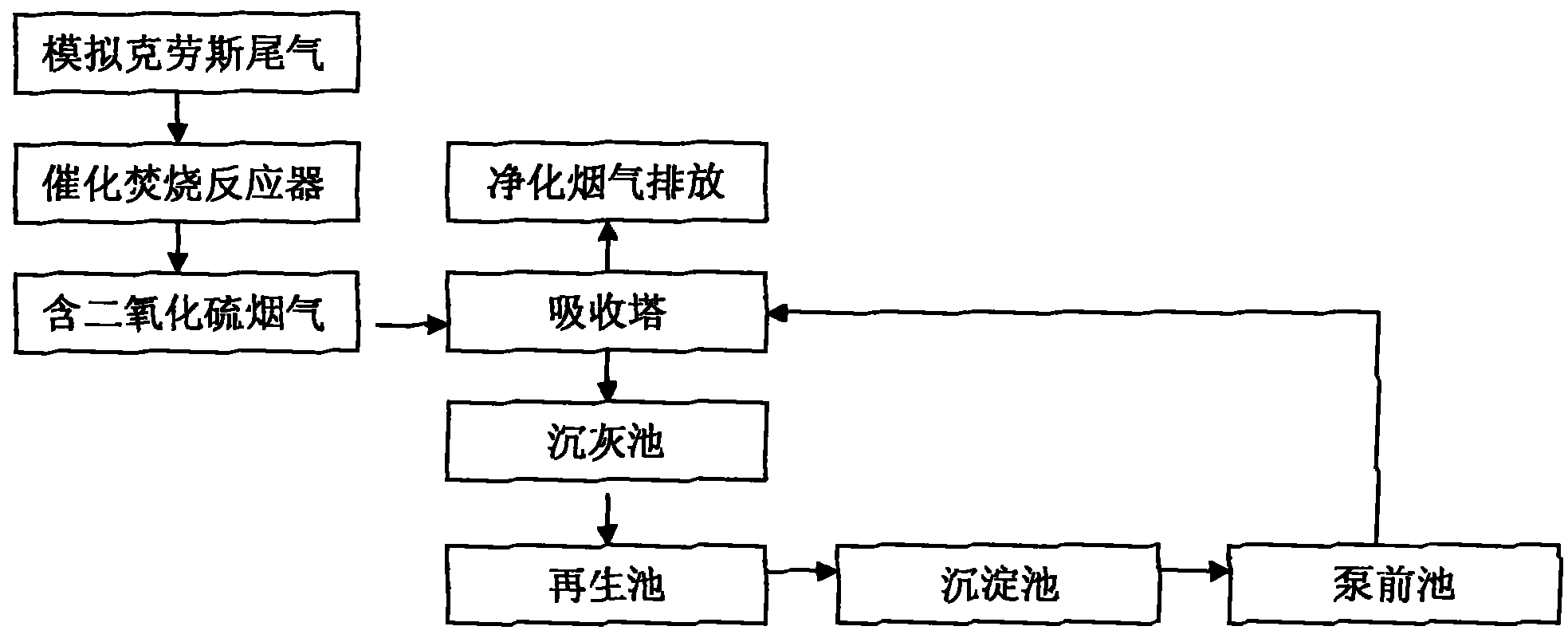

Combined treatment method for waste gas containing sulfur compounds

The invention discloses a combined treatment method for waste gas containing sulfur compounds. The method comprises the following steps of: mixing the waste gas containing the sulfur compounds and air, delivering the preheated gas to a catalytic incineration reactor, and performing catalytic incineration operation at the temperature of between 150 and 450 DEG C under the conditions that the space velocity is 1,000 to 35,000h<-1> and the peroxide coefficient is 0.5 to 8.0; delivering the flue gas formed after catalytic incineration to an absorption tower after heat exchange and cooling, discharging the desulfurized and washed purified flue gas, delivering the desulfurized and washed slurry to a regeneration tank provided with a stirring device, performing regeneration reaction on the slurry and regeneration alkali, delivering the reaction product to a sedimentation tank, overflowing the clarified liquid in the sedimentation tank to a pre-pumping tank, recycling the alkali supplemented clarified liquid to a desulfurization tower, and regularly clearing the settled calcium sulfite, calcium sulfate and calcium carbonate. By the method, hydrogen sulfide and organic sulfides in the waste gas containing the sulfur compounds can be efficiently converted into sulfur dioxide, and the sulfur dioxide is recycled.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for inhibiting fouling of double-alkali flue gas desulfurization process

InactiveCN102284237ASolve the problem of easy fouling in the delivery pipelinePrevent scalingDispersed particle separationCarboxylic acidCalcium sulfite

The invention relates to a method for inhibiting scaling of a double-alkali flue gas desulfurization process, comprising adding a scale inhibitor to the desulfurization regeneration liquid to prevent calcium sulfite and calcium sulfate from scaling, wherein the scale inhibitor consists of at least one organic phosphine acid and at least one organic carboxylic acid polymer. After the scale inhibitor of the present invention is added to the desulfurization regeneration liquid, the Ca2+ deposition rate is greatly reduced, which can effectively inhibit the formation of calcium scale in the double-alkali flue gas desulfurization process. On the one hand, the present invention can solve the problem that the lye of saturated calcium sulfite and calcium sulfate after regeneration is easy to scale in the conveying pipeline; In addition, the pH value of the absorption liquid is neutral, so that calcium sulfite and calcium sulfate are supersaturated and precipitated, resulting in fouling of the absorption tower and affecting long-term operation.

Owner:CHINA PETROLEUM & CHEM CORP

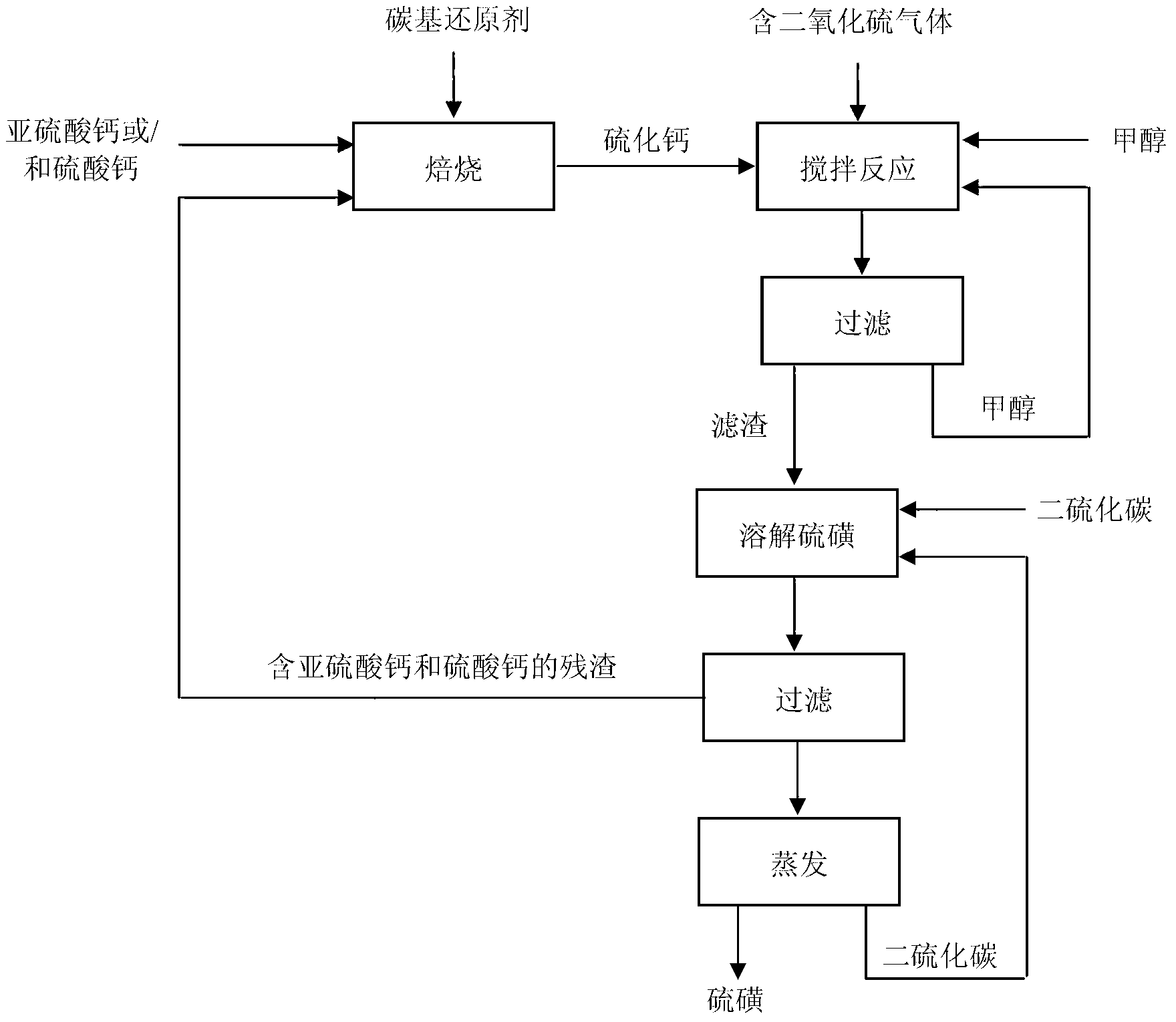

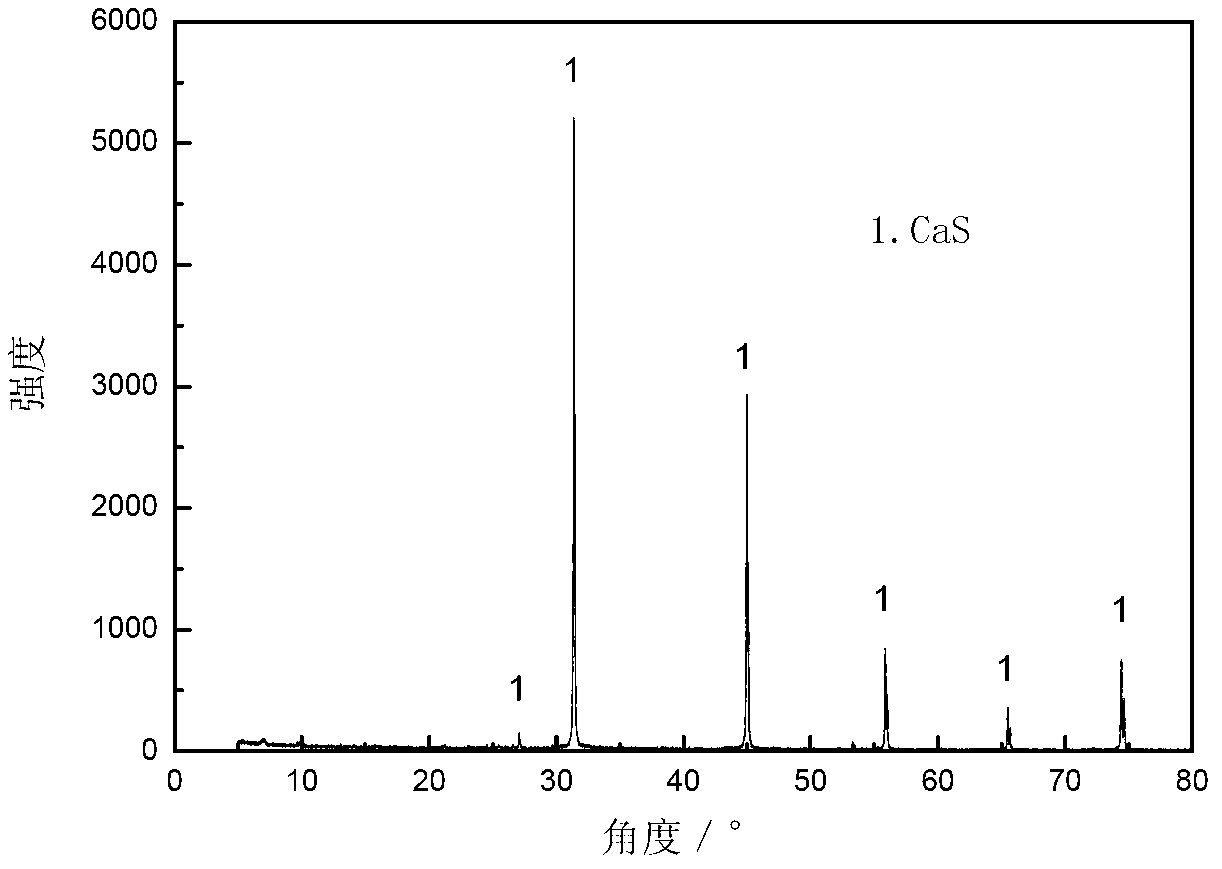

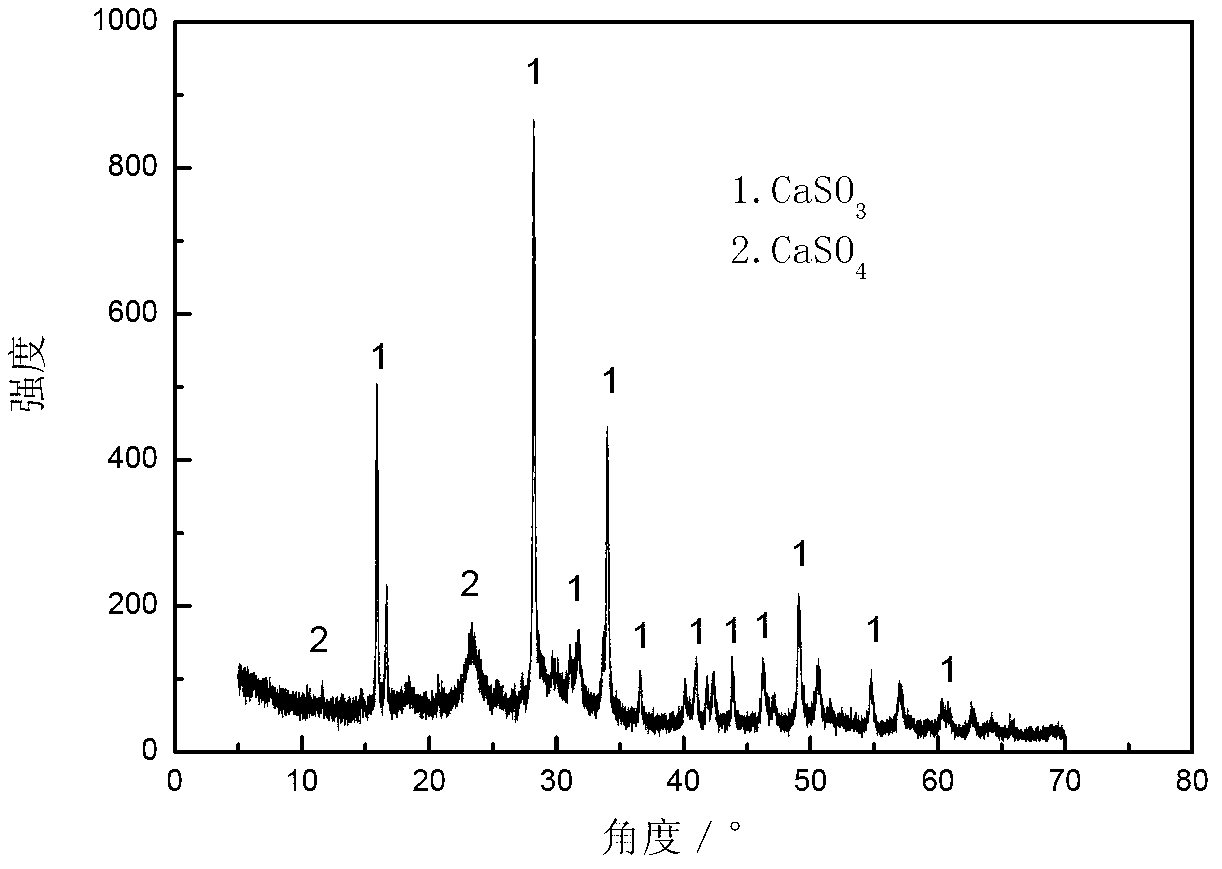

Method for absorbing sulfur dioxide and co-producing sulphur

ActiveCN103316578ASubstantiveEffective absorptionDispersed particle separationSulfur preparation/purificationCalcium sulfideSulfate

The invention provides a method for absorbing sulfur dioxide and co-producing sulphur. The method comprises the following basic steps of: mixing calcium sulfite or / and calcium sulfate with a carbon-based reducing agent; roasting for 1.5 to 2 hours at 800 to 1,000 DEG C to obtain calcium sulphide; adding calcium sulphide, methanol or / and ethanol to a reactor; adjusting the liquid-solid mass ratio to 3 to 10:1; charging sulfur dioxide containing gas along with stirring; stirring for reacting sulfur dioxide with calcium sulphide under room temperature of 0 to 40 DEG C; separating after the reaction is done to obtain sulphur and a mixture containing calcium sulfite and calcium sulfate. By adopting the method, the sulfur dioxide in the gas can be absorbed, and the sulfur can be recovered; the method has the advantages of being economic, efficient and free of waste residues.

Owner:CENT SOUTH UNIV

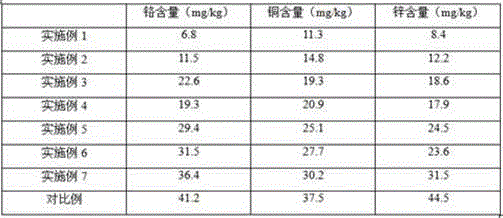

Soil restoration agent capable of reducing chromium, zinc and copper pollution and preparation method thereof

InactiveCN104449752AEasy to fixShort repair timeOrganic fertilisersSoil conditioning compositionsCelluloseSodium Bentonite

The invention belongs to the field of soil restoration, and discloses a soil restoration agent capable of reducing chromium, zinc and copper pollution. The soil restoration agent is characterized by comprising the following components in parts by weight: 6-19 parts of diammonium hydrogen phosphate, 12-25 parts of cellulose, 2-9 parts of calcium sulfite, 4-15 parts of bentonite, 3-10 parts of montmorillonite and 5-13 parts of ammonium phosphate. A preparation method comprises the following steps of: respectively taking diammonium hydrogen phosphate, cellulose, calcium sulfite, bentonite, montmorillonite and ammonium phosphate, and crushing the components into powder; (2) taking the components in parts by weight: 6-19 parts of diammonium hydrogen phosphate, 12-25 parts of cellulose, 2-9 parts of calcium sulfite, 4-15 parts of bentonite, 3-10 parts of montmorillonite and 5-13 parts of ammonium phosphate, and uniformly mixing the powder of the components to prepare the soil restoration agent. The prepared soil restoration agent has good effects when being used for restoring soil with the chromium, zinc and copper pollution.

Owner:JIANGSU GAIYA ENVIRONMENTAL SCI & TECH CO LTD

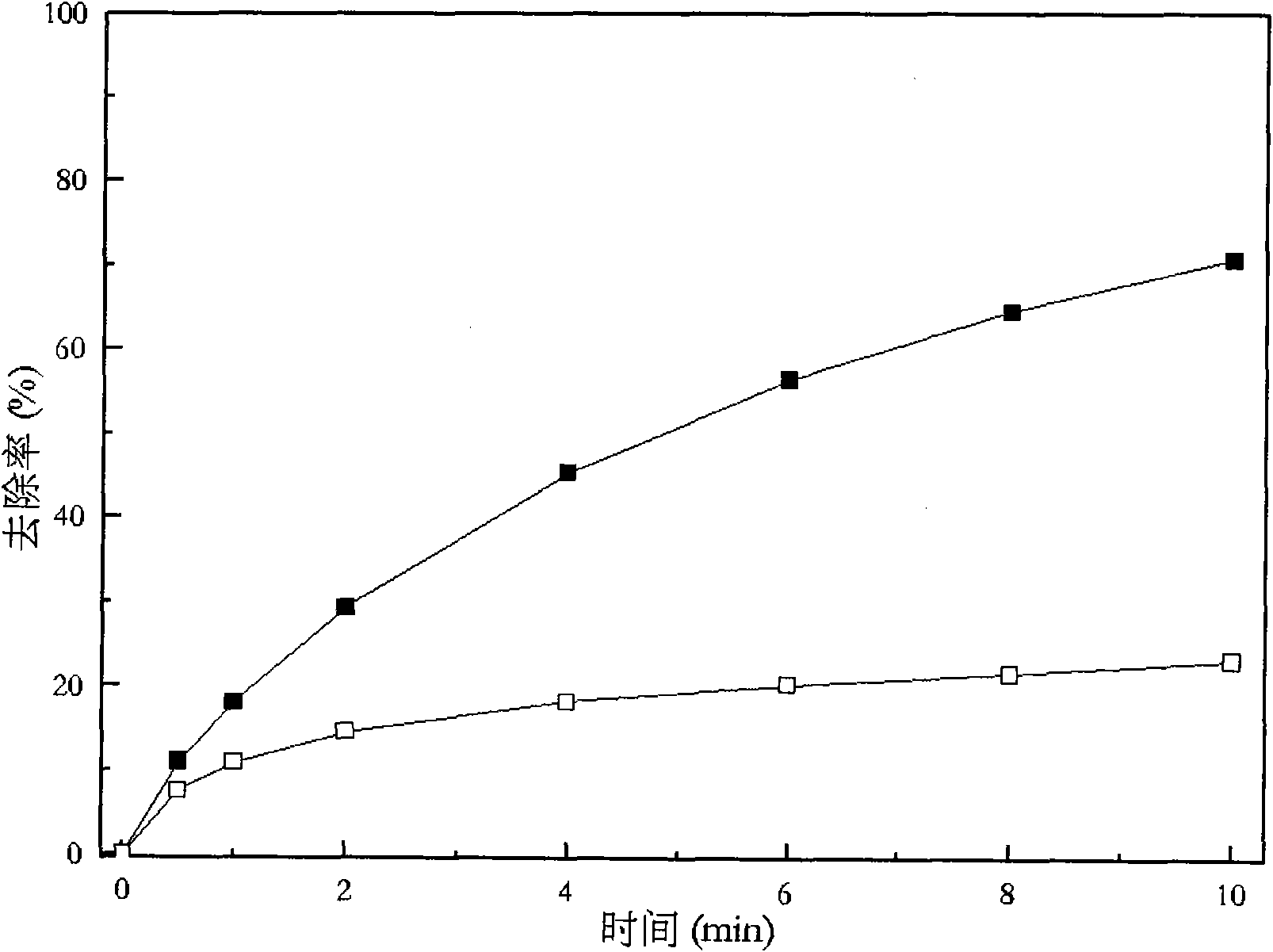

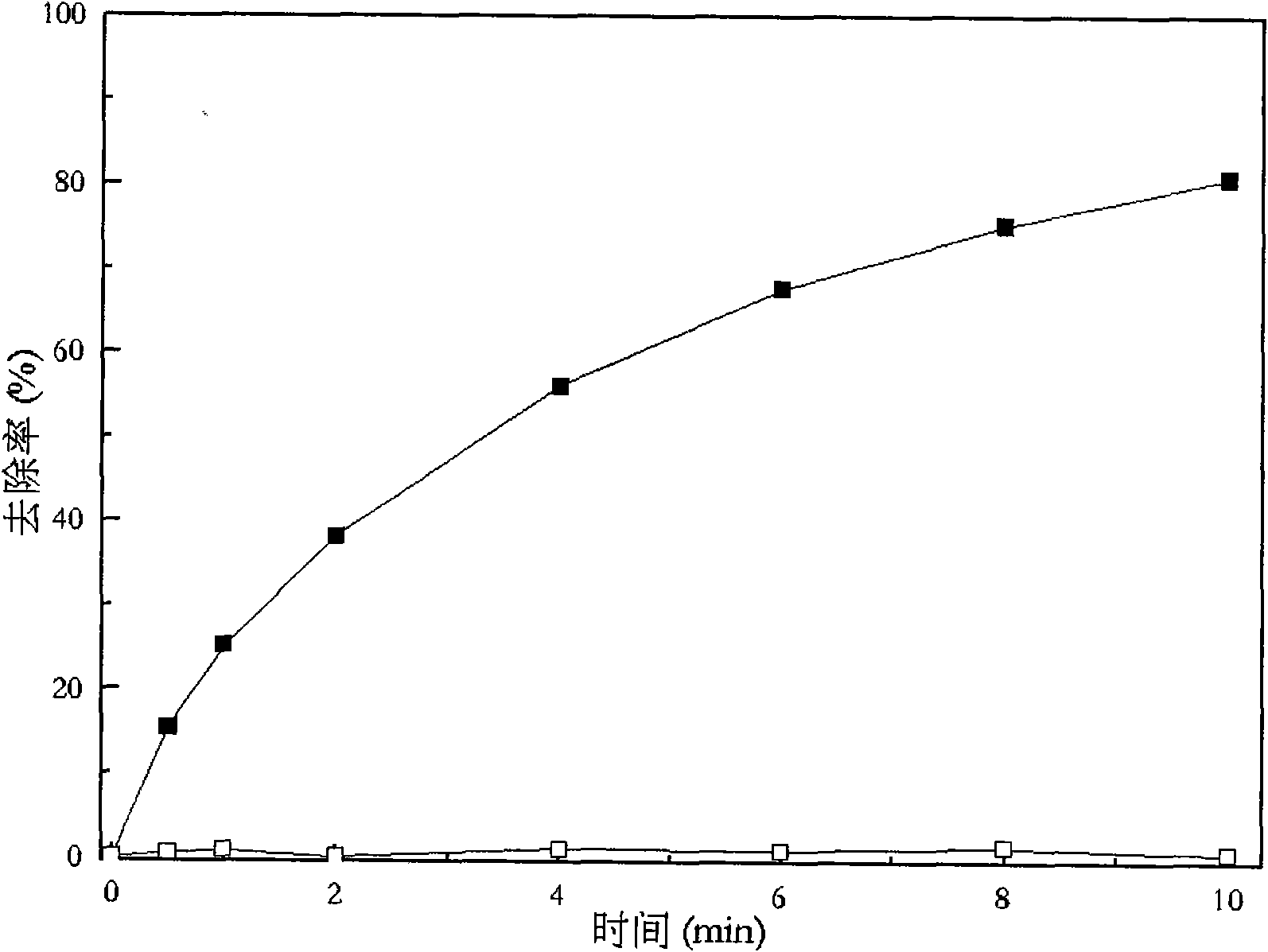

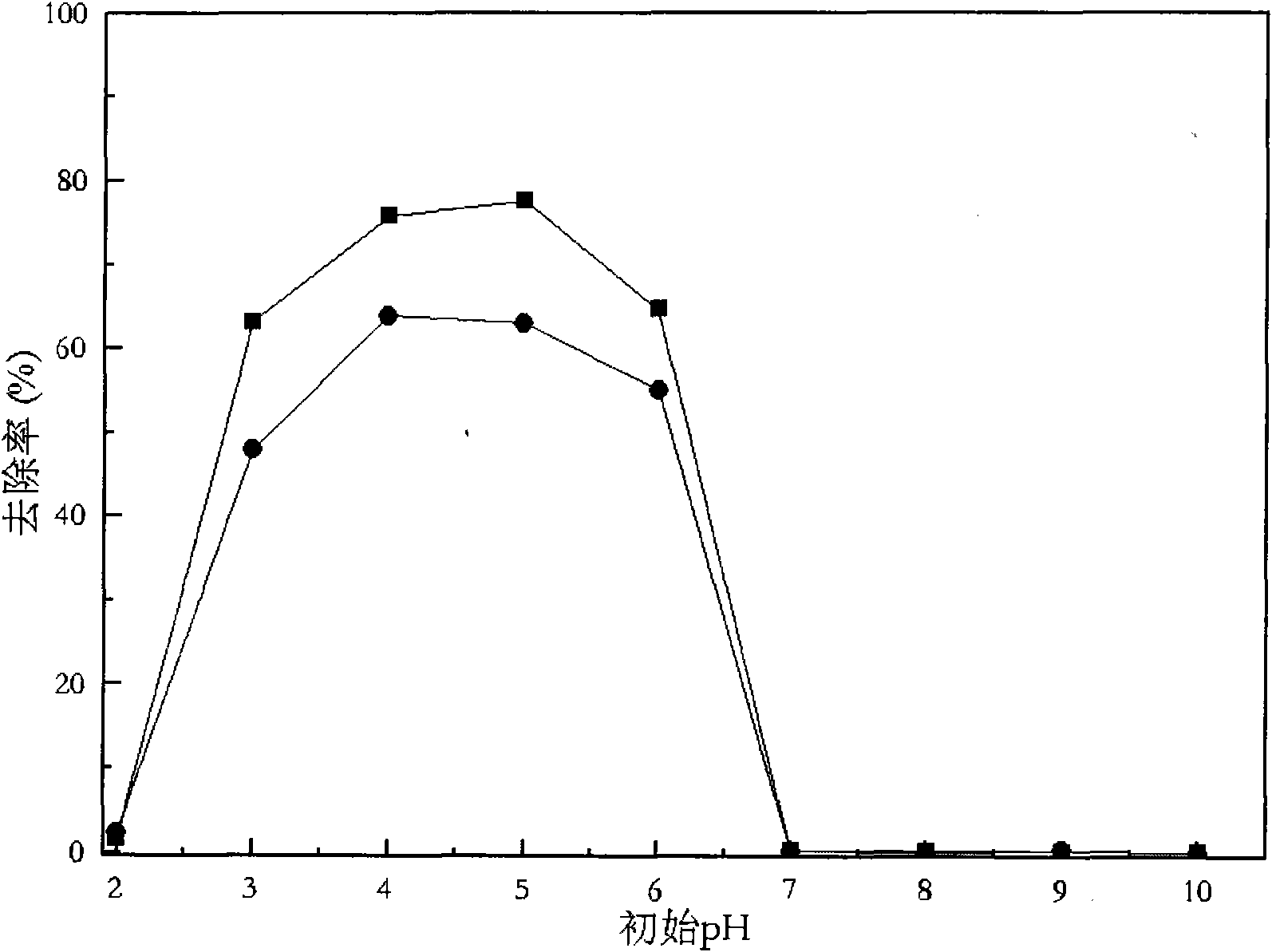

Mercury removal process based on lime-gypsum method desulphurization system and mercury removal absorption liquid

ActiveCN101590369APromote absorptionHigh removal rateDispersed particle separationAir quality improvementCALCIUM HYDROXIDE SOLUTIONNitric oxide

The invention discloses mercury removal absorption liquid based on a lime-gypsum method desulphurization system. Main components of the mercury removal absorption liquid comprise desulphurization slurry and oxidant; the desulphurization slurry is at least one of calcium hydroxide solution and calcium sulfite solution, and the mass concentration of the desulphurization slurry is 1 to 30 percent; and the oxidant is soluble salt or mixture of soluble salt of which positive ions contain ammonium radical and negative ions contain peroxosulfuric acid radical or peroxosulfuric acid hydrogen radical. Moreover, a soluble transition metal salt as an oxidation catalyst can be added into the mercury removal absorption liquid to increase the removal efficiency of mercury. The invention also discloses a specific mercury removal process using the mercury removal absorption liquid; and the process has the characteristics of high mercury removal effect, little byproduct and low transformation cost, does not introduce other corrosive ions, does not influence the quality of gypsum, and can promote the system to absorb sulfur dioxide and nitric oxide to a certain extent.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

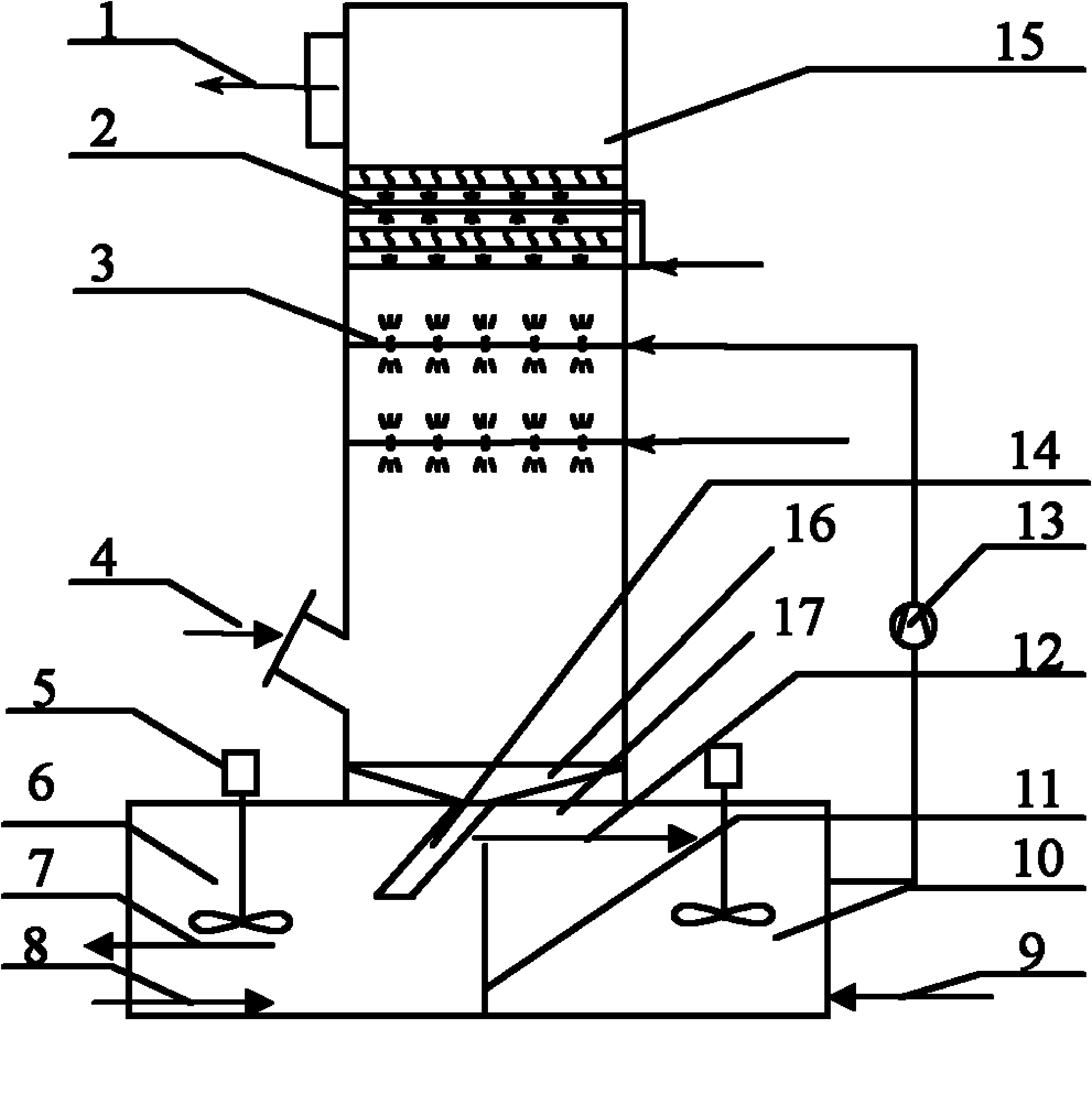

Double-groove wet-process flue gas desulfuration device and method operating on basis of two pH values

InactiveCN102091519AAvoid badSolve the problem of operation safety and stabilityDispersed particle separationSulfurCalcium sulfite

The invention discloses a double-groove wet-process flue gas desulfuration device and a double-groove wet-process flue gas desulfuration method operating on the basis of two pH values, which relate to a flue gas desulfuration device and a flue gas desulfuration method. The aim of the invention is to remove SO2 from the flue gas under a high pH value condition by using desulfurating spray slurry and to dissolve limestone and oxidize calcium sulfite under a low pH value condition so as to improve desulfuration efficiency and quality of gypsum and reduce limestone consumption, investment and operation cost. In the invention, a circulating oxidization tank at the bottom of an absorption tower is divided into two parts, an oxidation pond receives desulfurizating slurry flowing out from a desulfurization tower, the oxidation pond operates in a pH range from 4.0 to 5.5, and in the oxidation pond, sulfite ions are oxidized, and byproduct of desulfuration is led out from the oxidation pond; and fresh limestone slurry is added into a circulating pond, the circulating pond operates in a pH range from 6 to 6.5, and slurry is led from the circulating pound into the absorption tower to be sprayed for deselfuration. The device and the method contribute to improving quality of gypsum, desulfuration efficiency, reducing limestone consumption and lowering investment and operation cost, and are suitable for flue gas desulfuration when sulfur coal is burnt or different kinds of fire coal are burnt.

Owner:HARBIN INST OF TECH

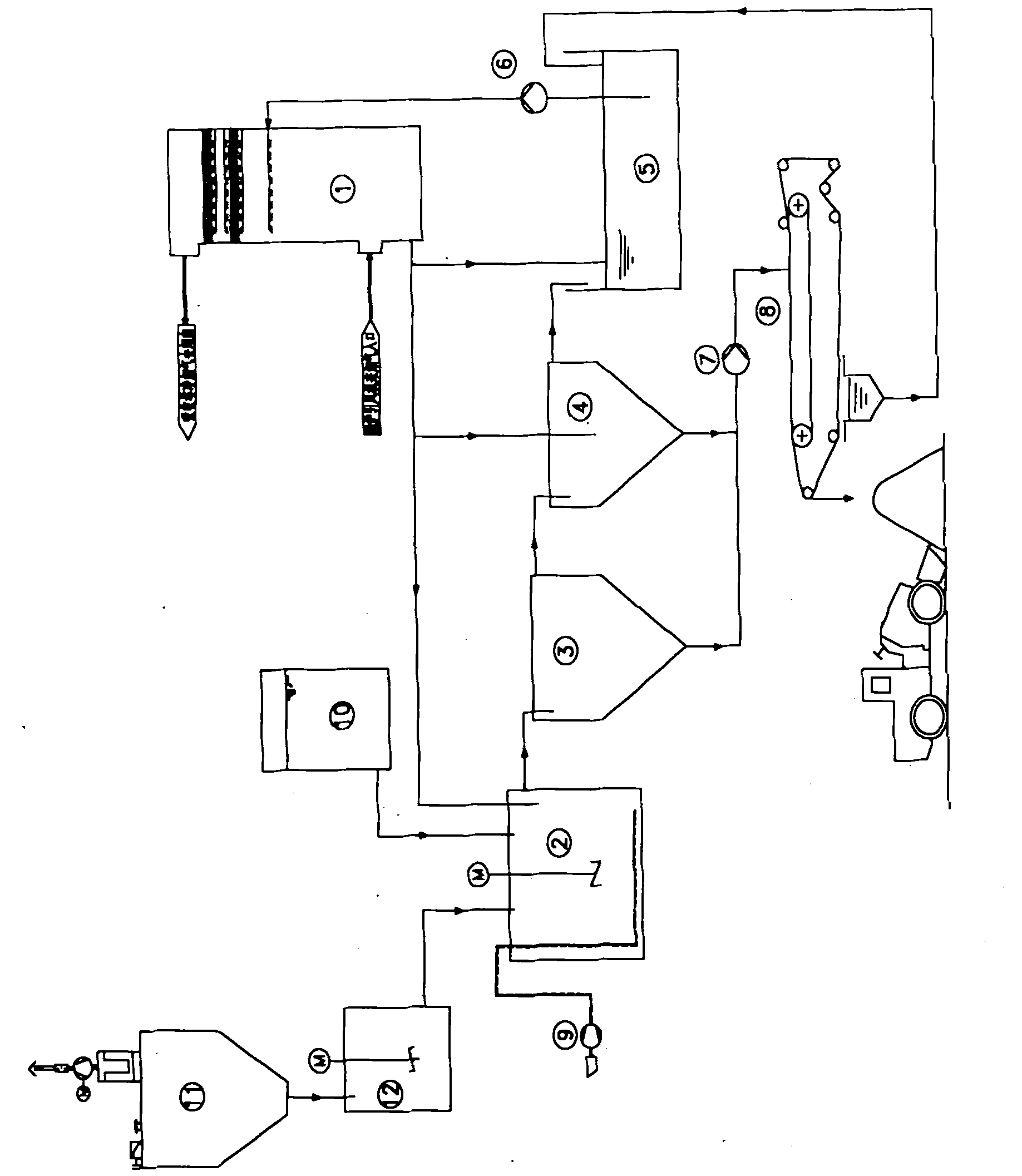

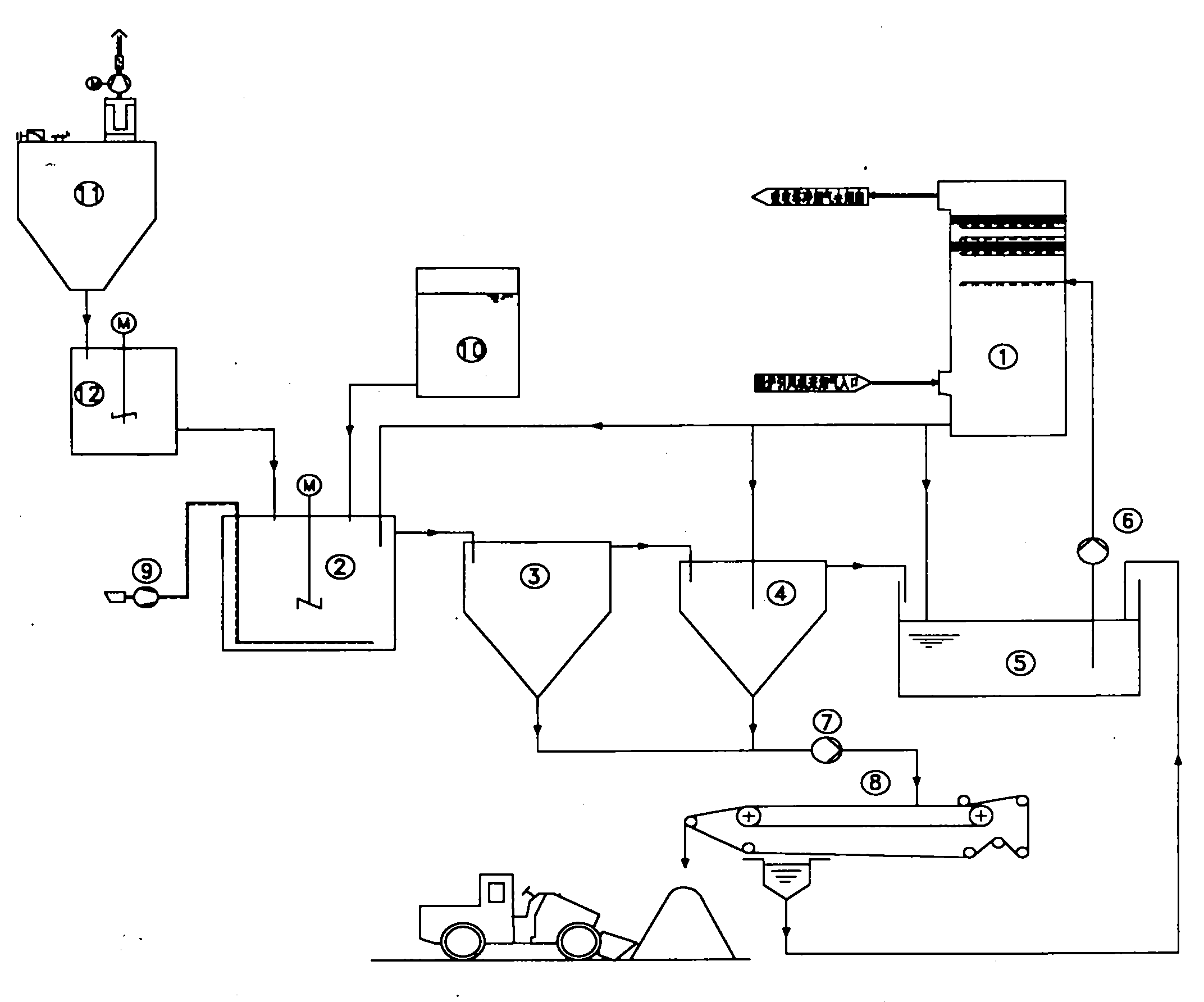

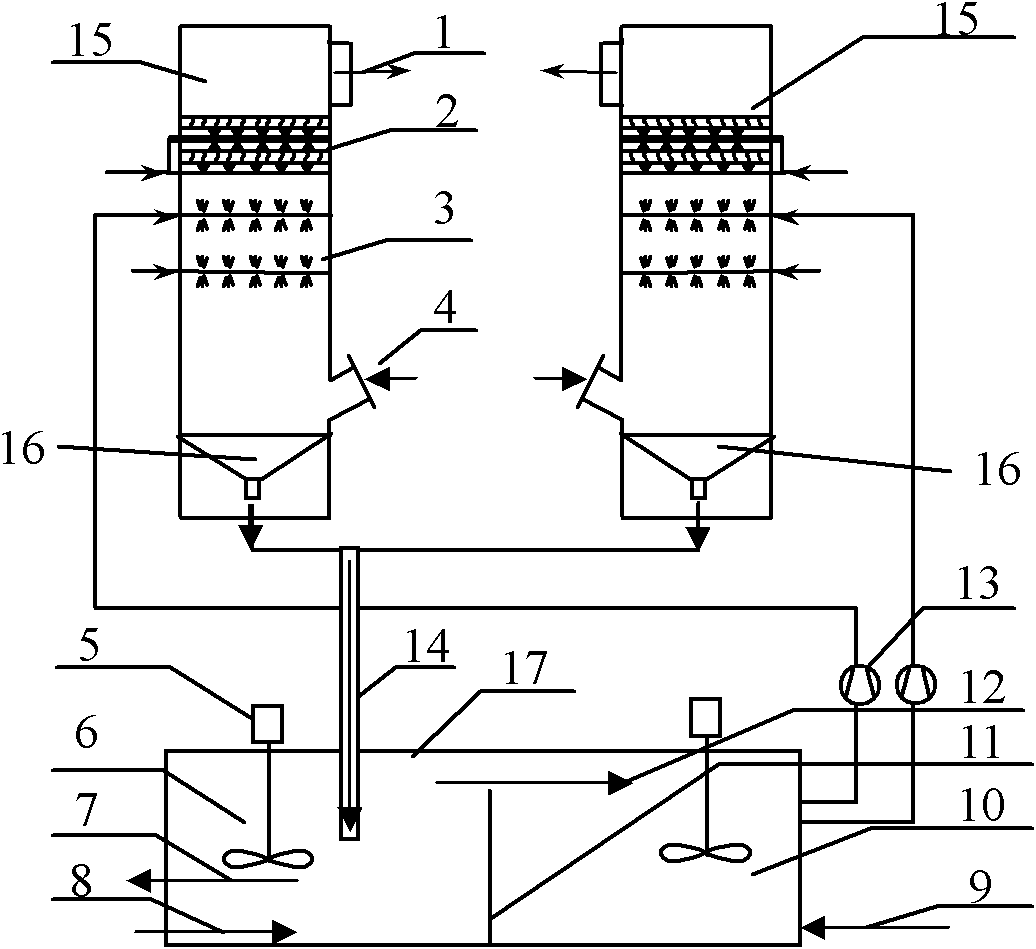

Sodium-calcium dual-alkali flue gas desulfurization method and system

InactiveCN105457477AImprove qualityQuality improvementGas treatmentDispersed particle separationCalcium hydroxideCalcium sulfite

The invention provides a sodium-calcium dual-alkali flue gas desulfurization method and system. The method comprises the steps of flue gas desulfurization and sodium-based desulfurizer regeneration; in the flue gas desulfurization step, a sodium hydroxide solution is adopted as a desulfurization starting agent, the prepared sodium hydroxide solution is directly put into a desulfurization tower to wash flue gas to remove sulfur dioxide in the flue gas; in the sodium-based desulfurizer regeneration step, liquid obtained through a desulfurization reaction is reduced into a sodium-based desulfurizer through calcium hydroxide contained in a regeneration reaction tank, in the sodium-based desulfurizer regeneration process, the regeneration reaction tank is mechanically stirred, semi-aqueous calcium sulfite is filtered out from the regenerated sodium-based desulfurizer through a filter membrane filter and then oxidized into gypsum through air, and after the pH value of a clear solution obtained through filtering of the filter membrane filter is regulated by supplementing alkali, the clear solution is returned into the desulfurization tower to be used repeatedly as an absorption solution. According to the method and system, the gypsum quality can be improved, the alkali amount consumed in the regeneration process can be decreased, a spray system can be prevented from being blocked due to scaling, and the better sulfur dioxide absorption effect is achieved.

Owner:SHANGHAI MINGTAI ENVIRONMENTAL PROTECTION ENG CO LTD

Additive for limestone-gypsum wet flue gas desulfurization and denitration process

InactiveCN102847418ARealize desulfurization and denitrificationImprove desulfurization efficiencyDispersed particle separationAir quality improvementTreatment fieldCarboxylic acid

The invention provides an additive for limestone-gypsum wet flue gas desulfurization and denitration process, which belongs to the flue gas treatment field. The additive comprises amines 40-60 wt.%, organic acids 30-45 wt.%, and polymeric organic carboxylate 10-30 wt.%. The amines can directly react with sulfur dioxide acidic gas to form ammonium sulfite, thus realizing desulfurization. The amines can react with nitrogen oxides to form nitrogen gas, thus realizing denitration. The organic acids and polymeric organic carboxylate can promote the dissolution of limestone for reducing the usage amount of limestone, promote pH buffering capability of limestone slurry, prevent rapid pH decrease during the absorption of sulfur dioxide, inhibit formation of calcium sulfite soft scale, and prevent plugging of demister. Compared with the existing limestone method, this invention has increased desulfurization efficiency (by 5-10%) and increased denitration efficiency (by above 50%) under the same liquid-gas ratio condition.

Owner:SNTO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com