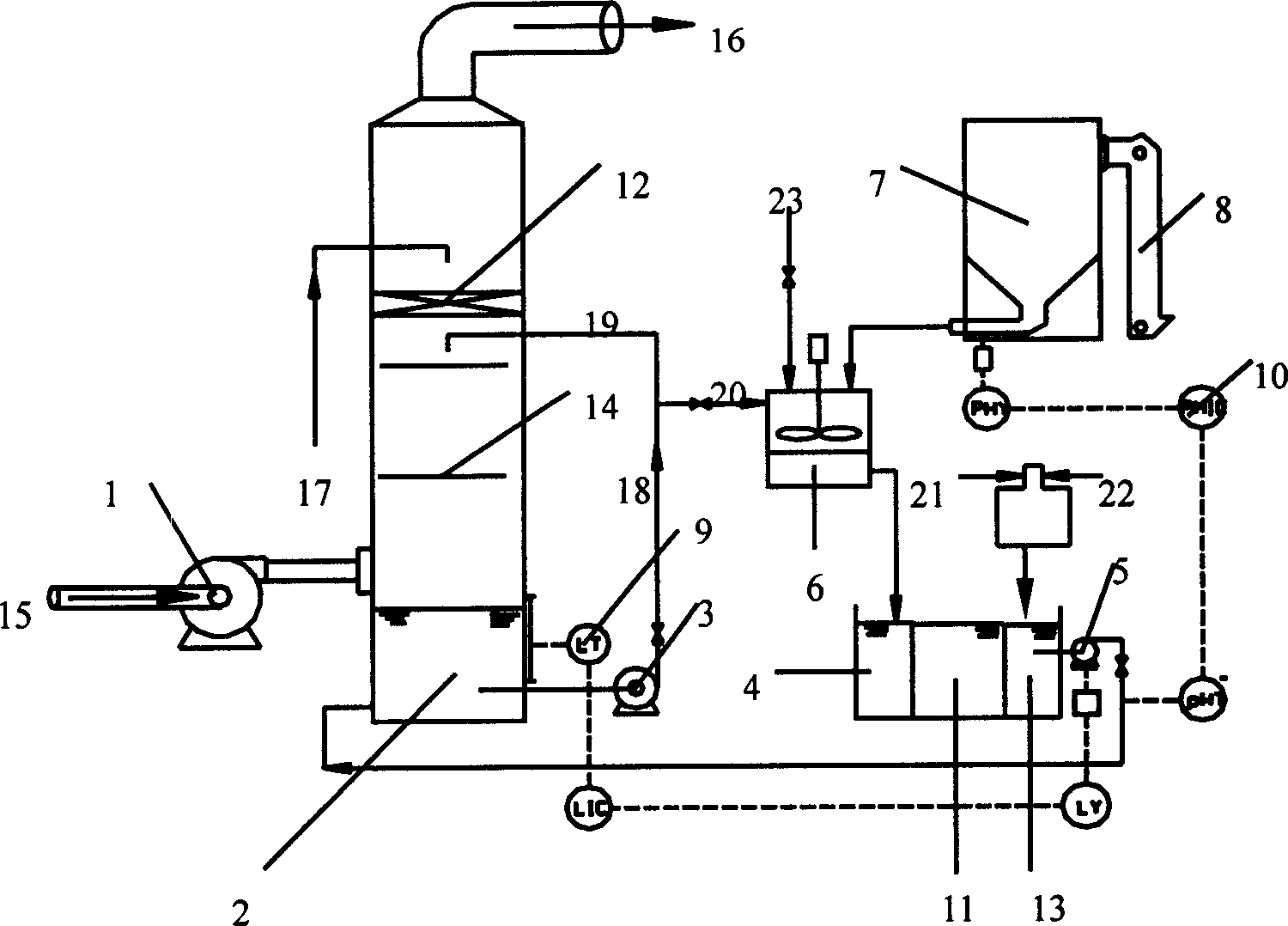

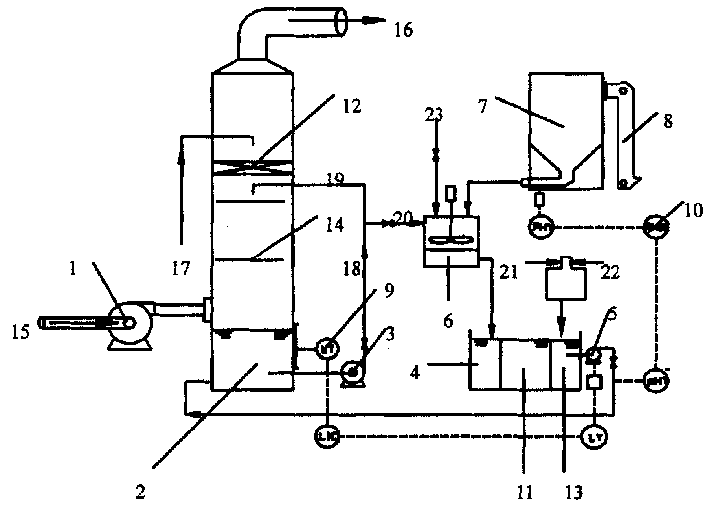

Concentrated alkali double alkali method stack gas desulfurizing technology

A desulfurization process and double-alkali technology, which is applied in the environmental field, can solve the problems of large area occupied by regeneration tanks and clarification tanks, and achieve the effects of reducing liquid-gas ratio, high desulfurization efficiency, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] At a flue gas temperature of 130°C, the inlet flue gas SO 2 The concentration is 1500mg / m 3 , the sodium ion concentration of the absorption liquid is 0.3mol / L, pH=7.0, L / G=3.0L / m 3 , the reflux ratio is 10%, the pH value in the regeneration tank is controlled at 9, the calcium ion concentration of the clarified liquid is 50mg / L, and the clarified liquid is mixed with the absorption liquid at the bottom of the absorption tower 2 when it is refluxed. After the whole system is running, the flue gas desulfurization efficiency up to 90%.

Embodiment 2

[0036] At a flue gas temperature of 130°C, the inlet flue gas SO 2 The concentration is 1000mg / m 3 , the sodium ion concentration of the absorption solution is 2mol / L, pH=9.0, L / G=8.0L / m 3, the reflux ratio is 25%, the pH value in the regeneration tank is controlled at 13, the calcium ion concentration of the clarified liquid is 100mg / L, the clarified liquid is sent back to the absorption tower 2, and directly enters the circulation. After the whole system is running, the flue gas desulfurization efficiency is 98%.

Embodiment 3

[0038] At a flue gas temperature of 130°C, the inlet flue gas SO 2 The concentration is 3000mg / m 3 , the sodium ion concentration of the absorption solution is 0.3mol / L, pH=6.0, L / G=1.0L / m 3 , the reflux ratio is 5%, the pH value in the regeneration tank is controlled at 11, the calcium ion concentration of the clarified liquid is 500 mg / L, and the clarified liquid is mixed with the absorption liquid at the bottom of the absorption tower 2 when the clarified liquid is refluxed. After the operation of the whole system, the flue gas desulfurization efficiency 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com