Patents

Literature

83results about How to "Reduce liquid to gas ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

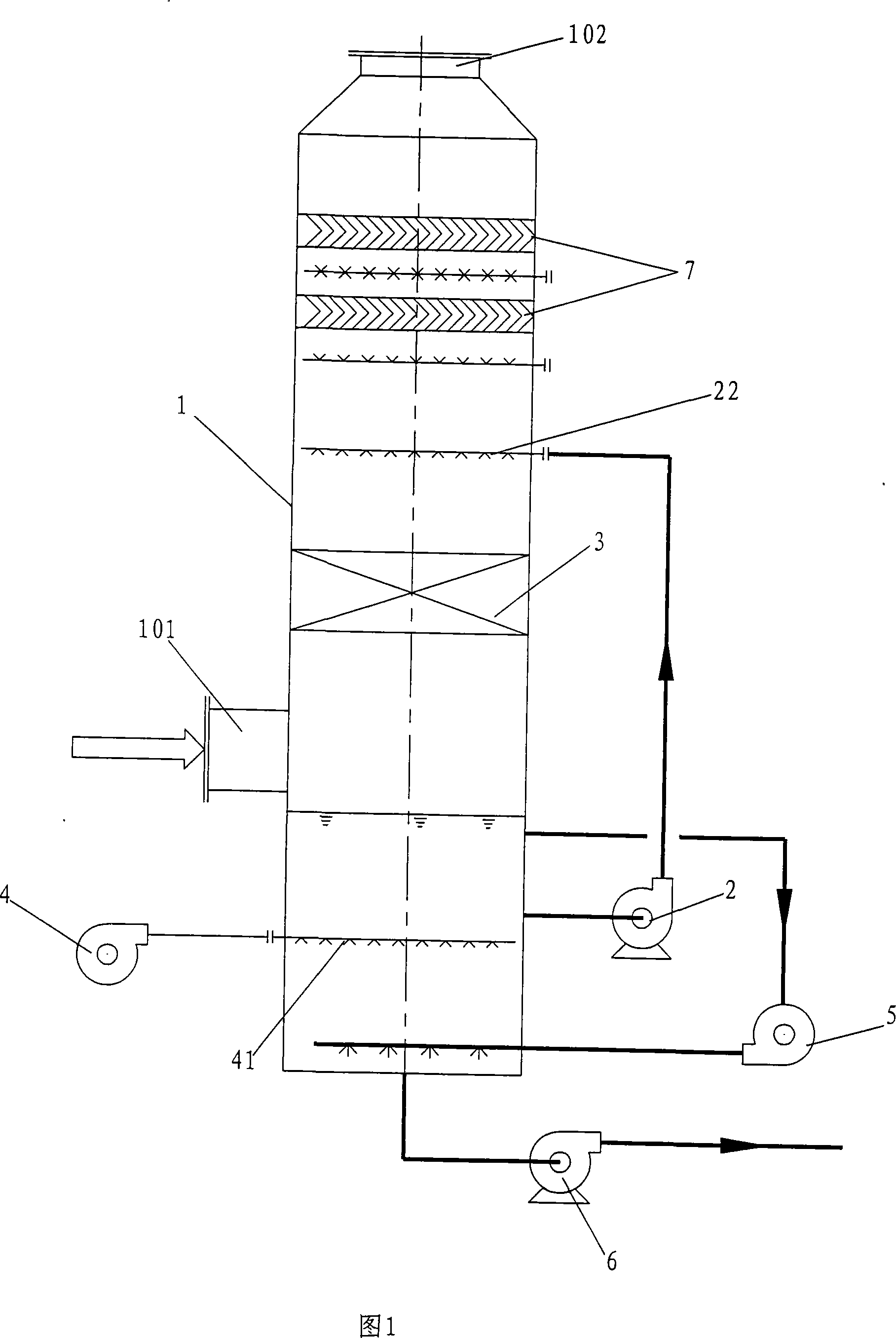

Novel barrier type air-actuated three-phase fluidization synthetized absorbing tower

InactiveCN101081348ANot easy to cause blockageTo achieve the purpose of purification and absorptionDispersed particle separationInlet channelGrating

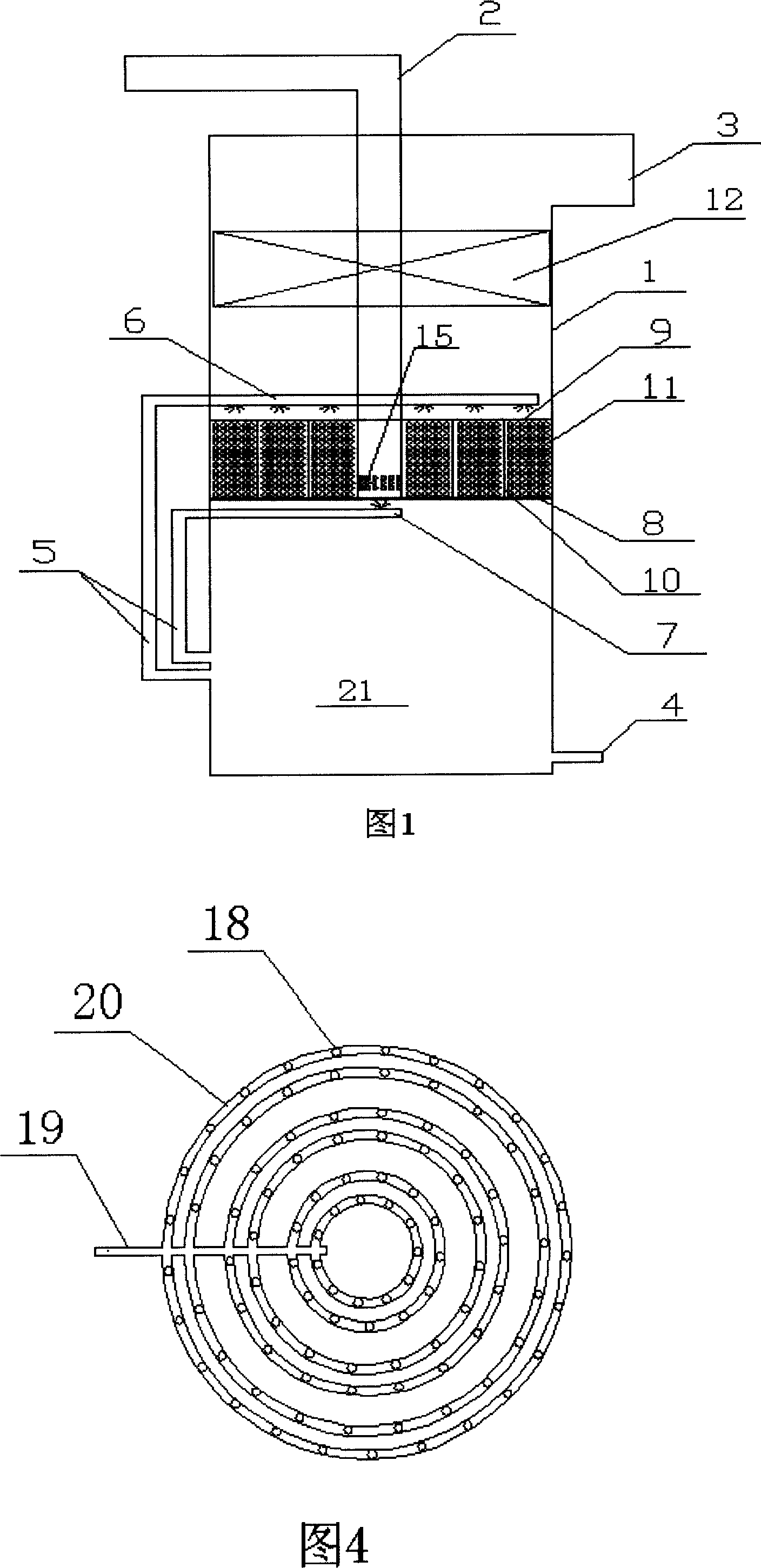

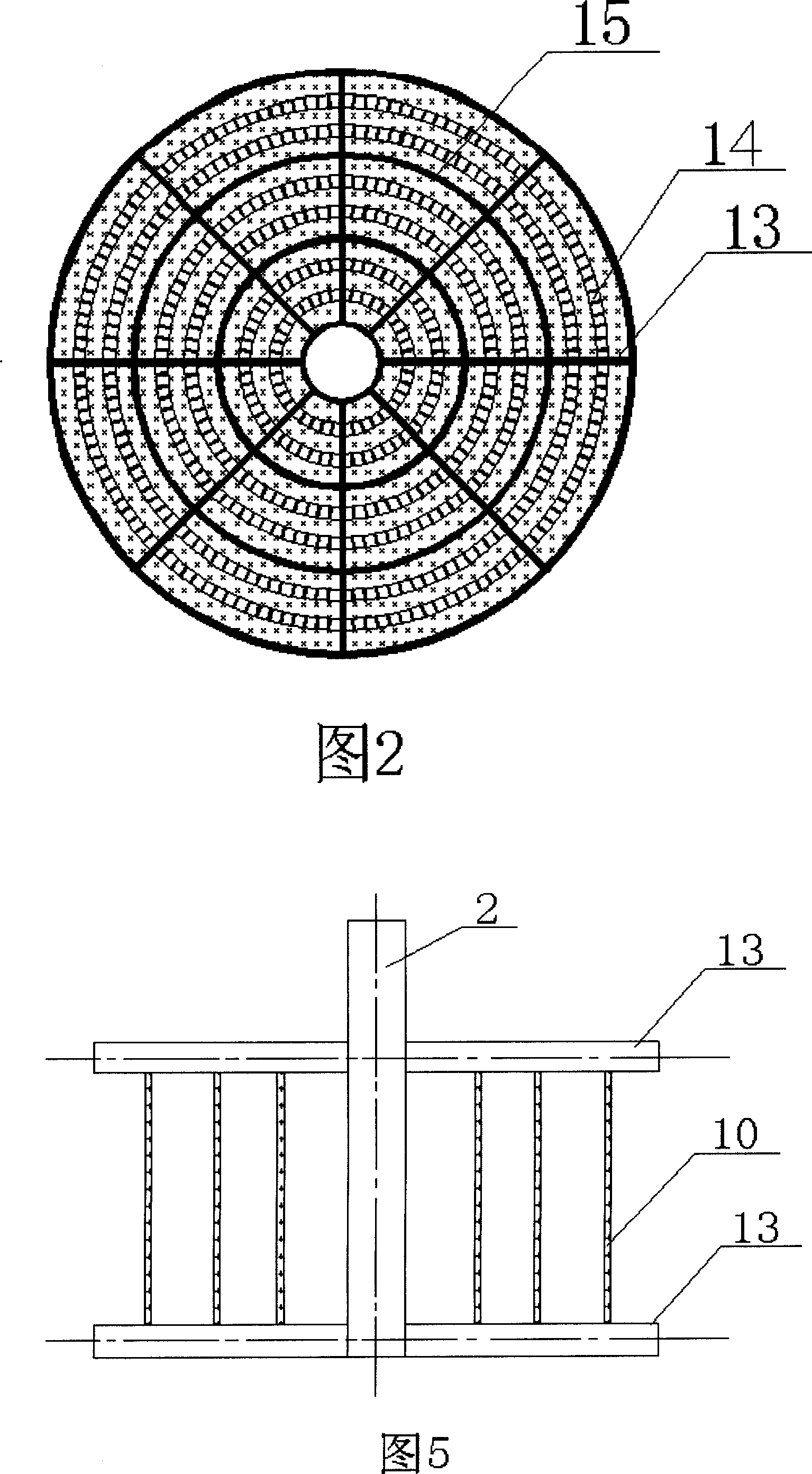

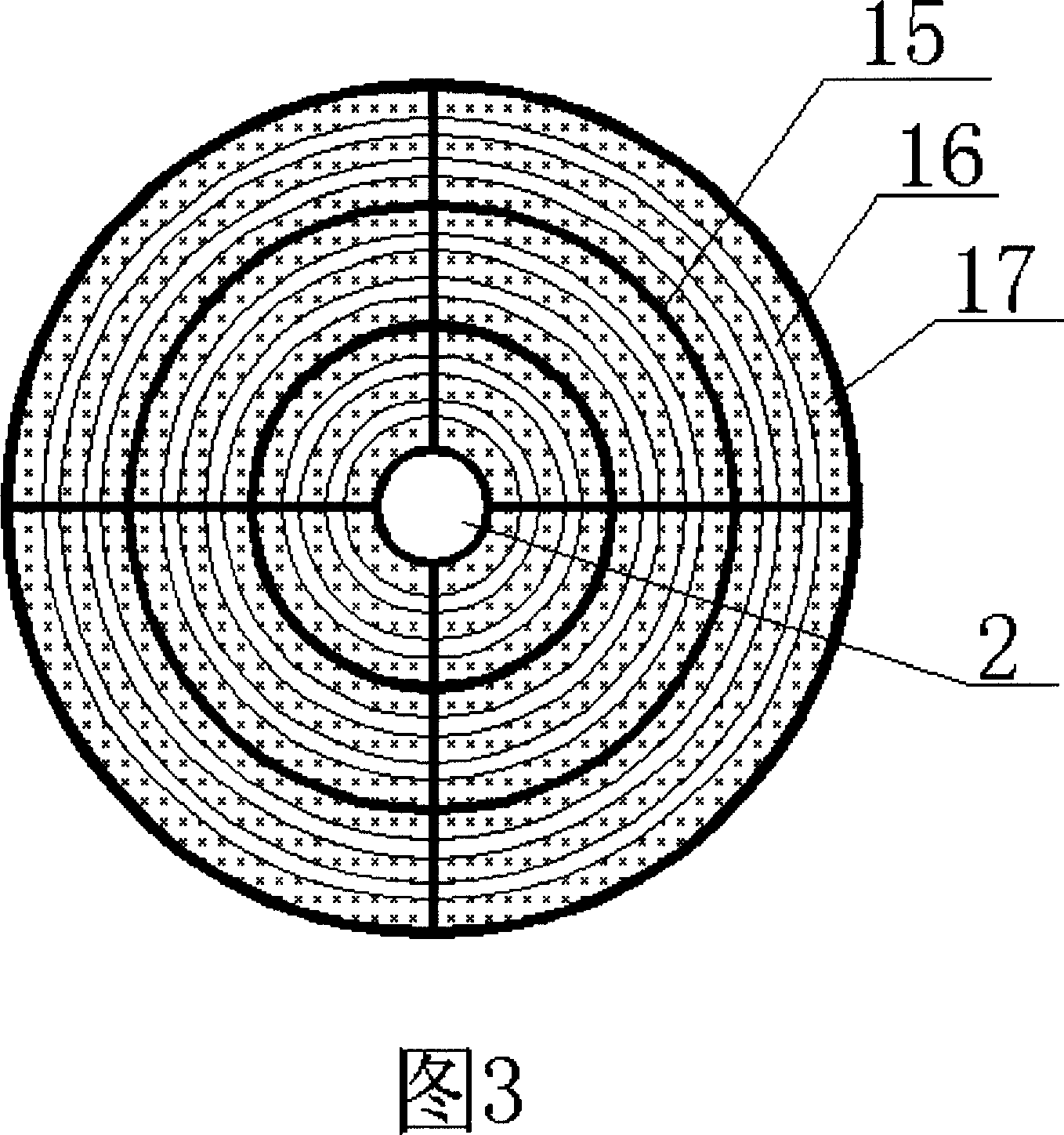

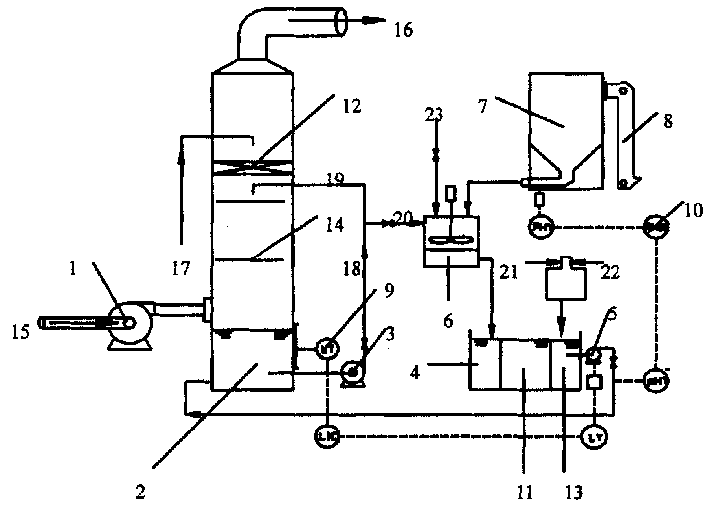

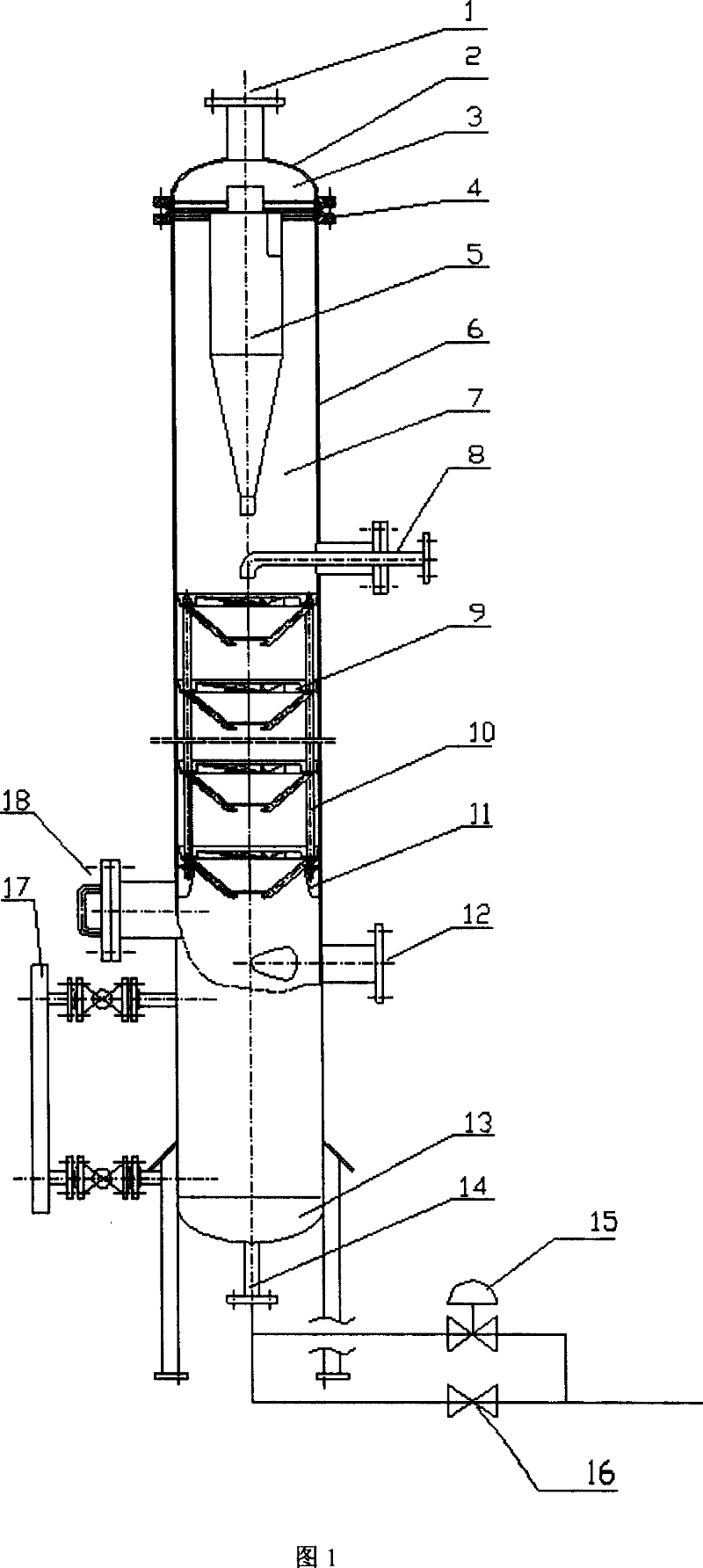

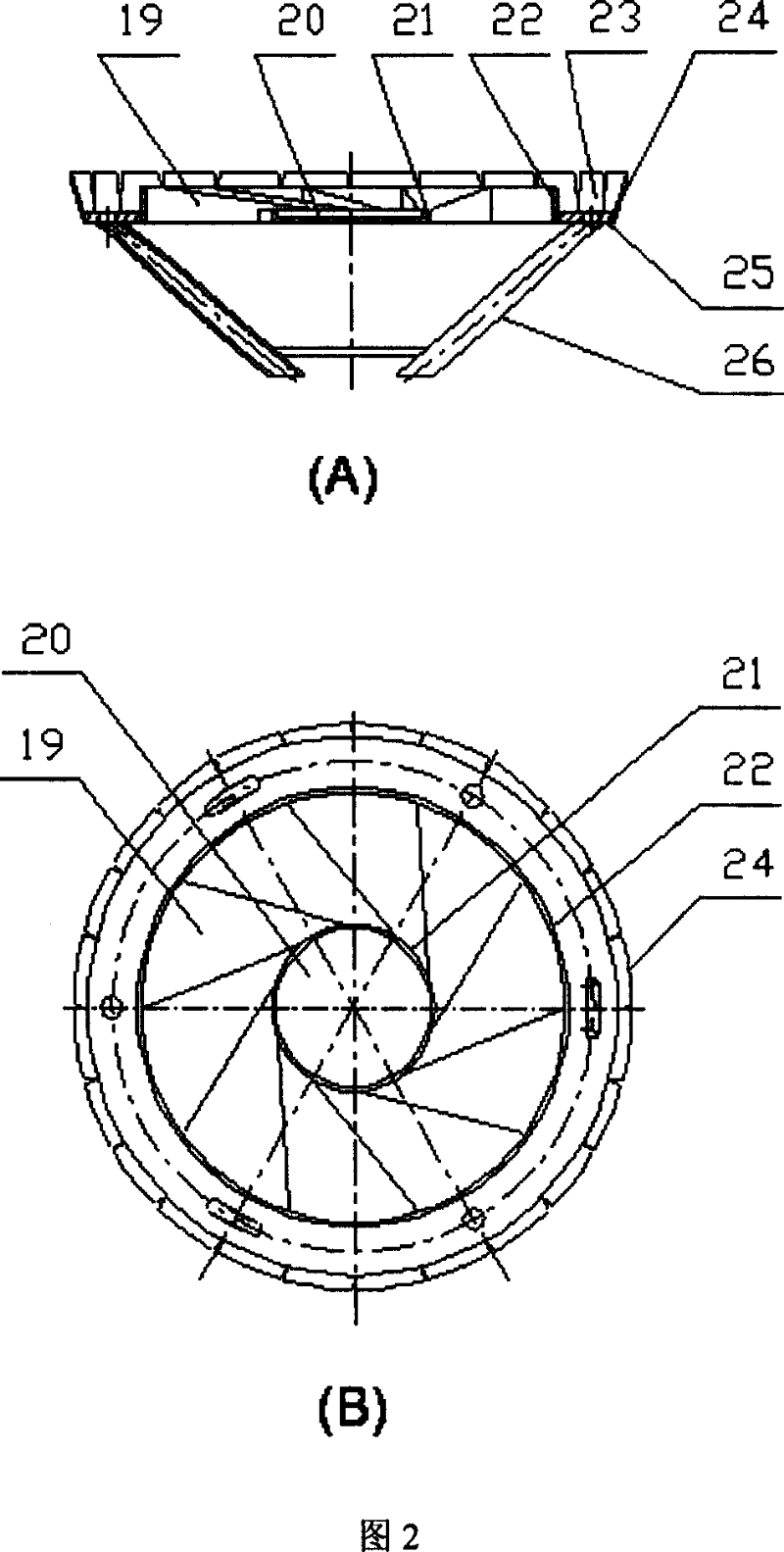

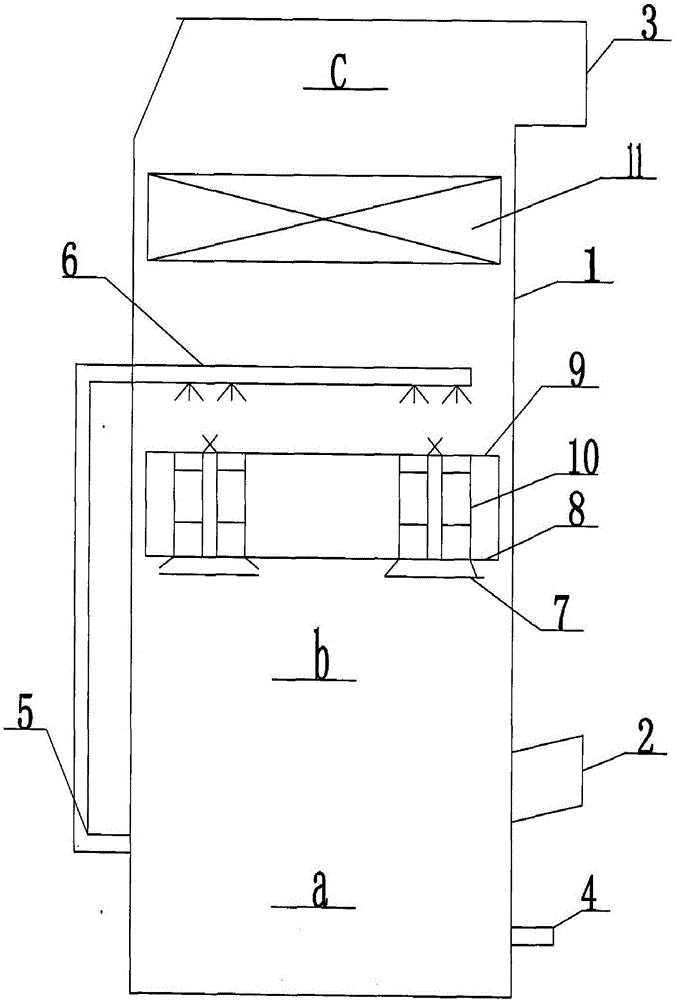

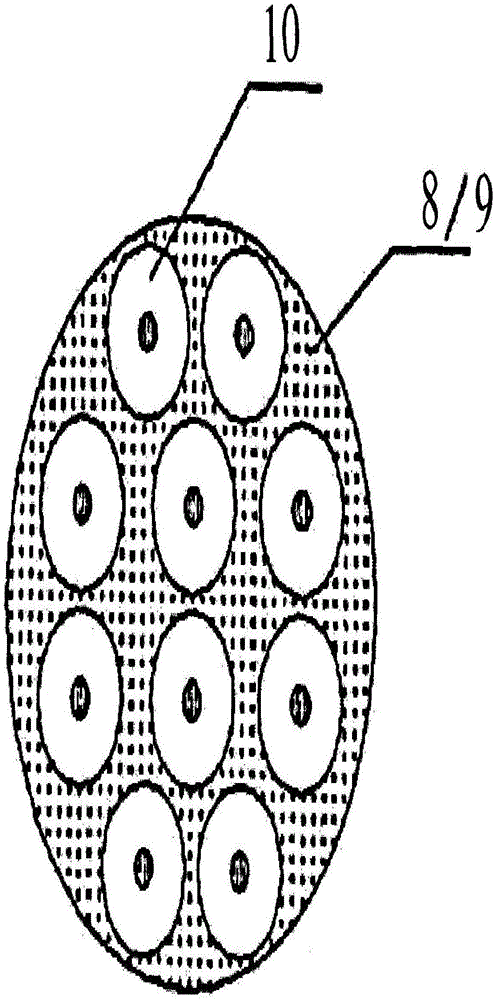

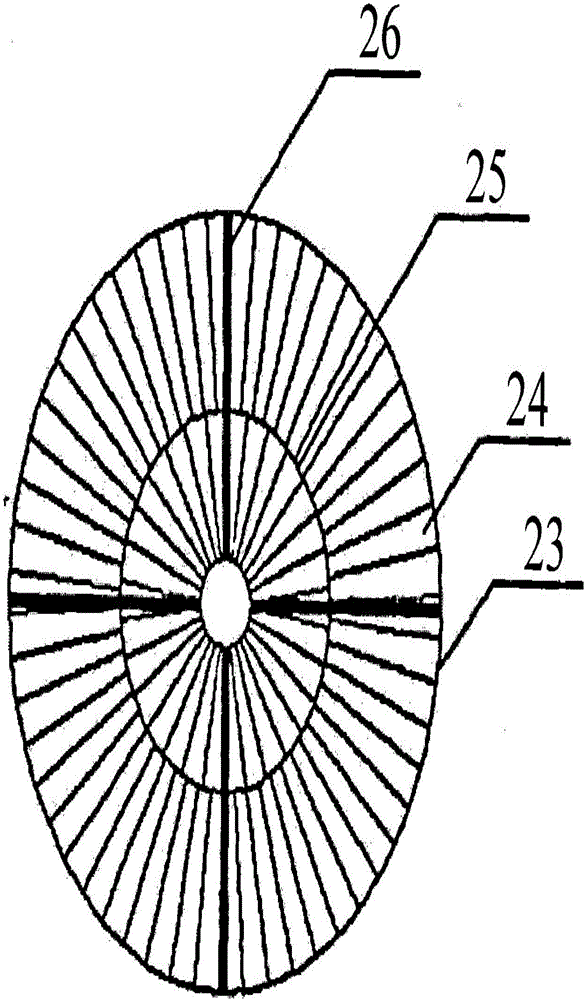

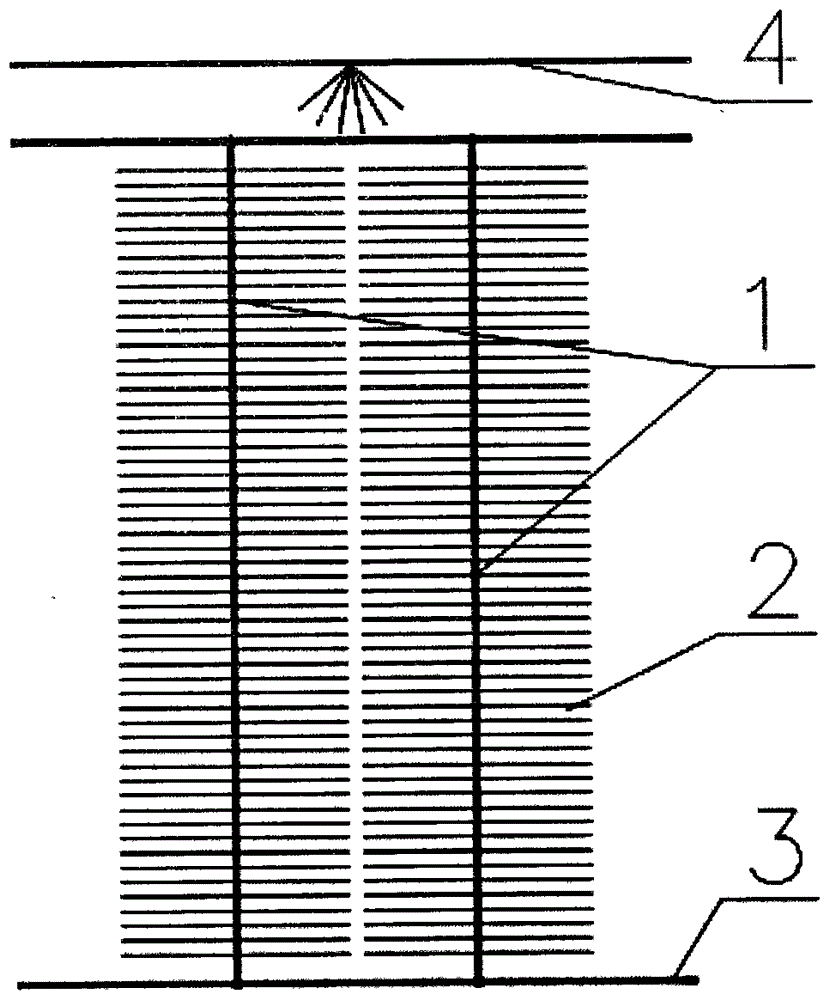

The grating type pneumatic triphase fluidizing comprehensive absorption tower includes one housing, one gas inlet channel and gas outlet channel in the top of the tower, one rotary defogging and dewatering unit, one stuffing assembly comprising support boards, hold-down boards and stuffing, one coaxial tubular grating member, one liquid distributor with ring sprinkler pipe, one large caliber reverse sprayer inside the gas inlet channel, and one absorbing slurry pond in the bottom of the tower. It features the special grating structure, the regularly arranged stuffing for cyclic fluidizing, the combined foam absorption and stuffing absorption, etc, and has high absorption efficiency, great gas treating amount and other advantages.

Owner:BEIJING HUAYU RONGTONG POWER TECH DEV

Concentrated alkali double alkali method stack gas desulfurizing technology

InactiveCN1475298AReduce areaImprove desulfurization efficiencyDispersed particle separationSulfateCalcium sulfite

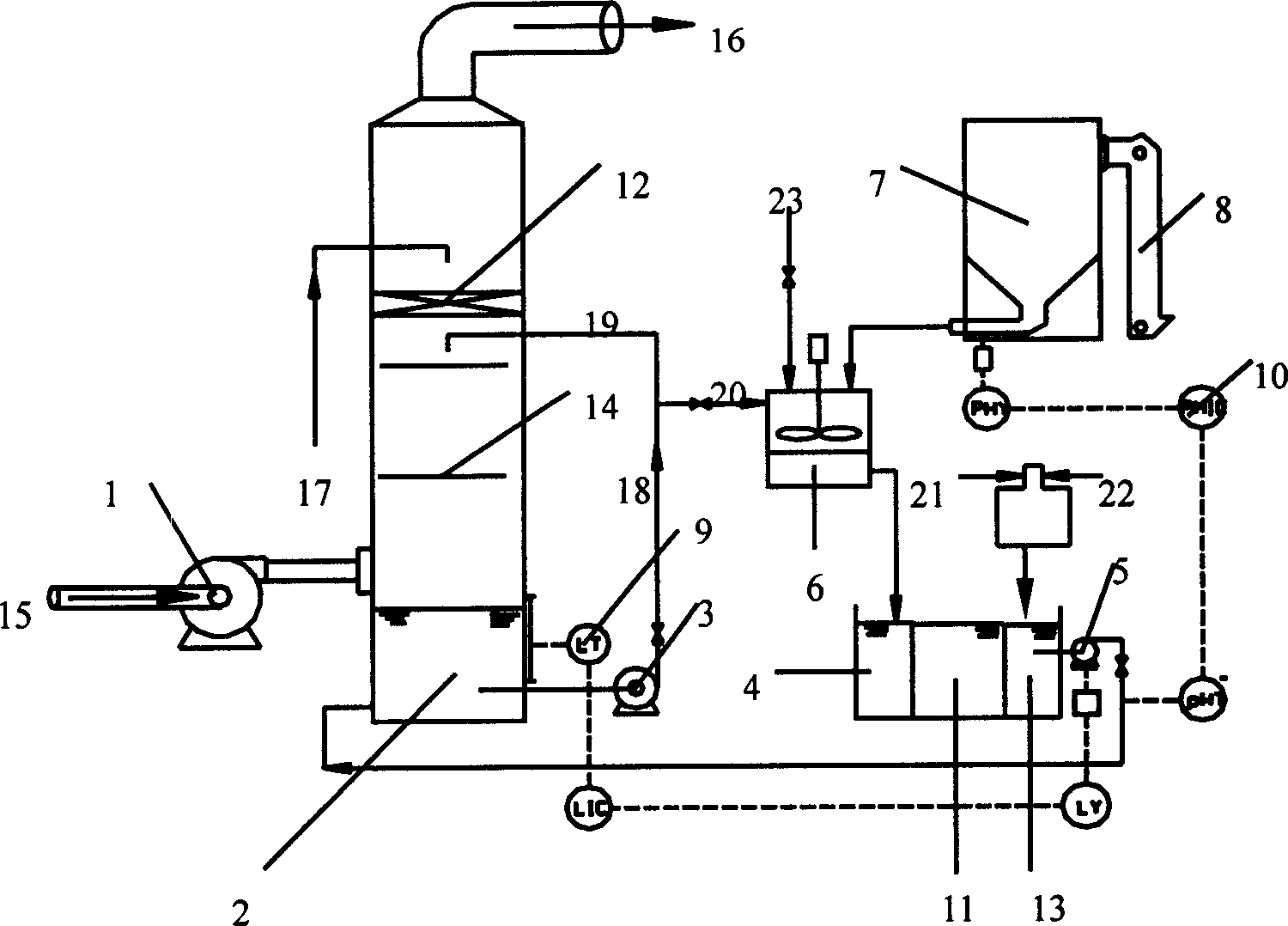

A process for desulfurizing fume by concentrated alkali dual-alkali method features that the SO2 is absorbed by absorbing liquid in absorption tower, the most of absorbing liquid is circulated for absorbing SO2 cyclically, a small part of it is regenerated in regenerating pool for reusing it while generating calcium sulfite and calcium sulfate to be treated further. Its advantages are less possesses ground area and high desulfurizing efficiency up to 95% or more.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

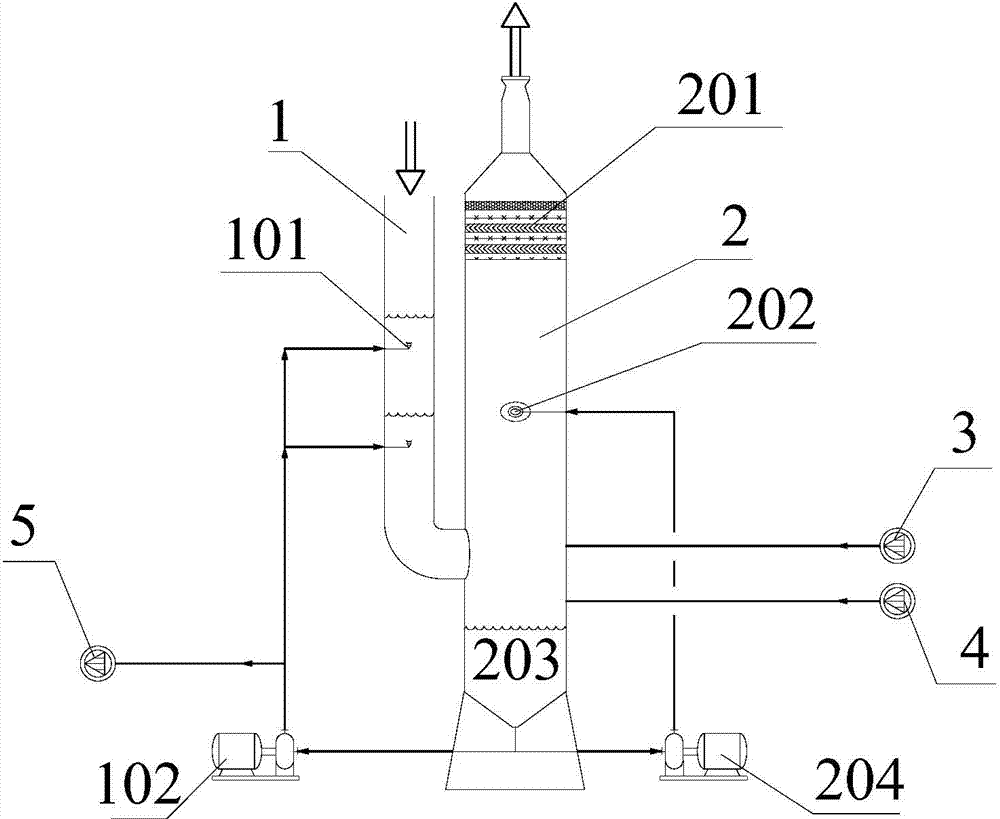

Desulfurization process of flue gas or waste gas by using external regenerative cycle magnesium sulfate method

ActiveCN101607173AReduce power consumptionGood environmental benefitsDispersed particle separationExhaust fumesRegenerative cycle

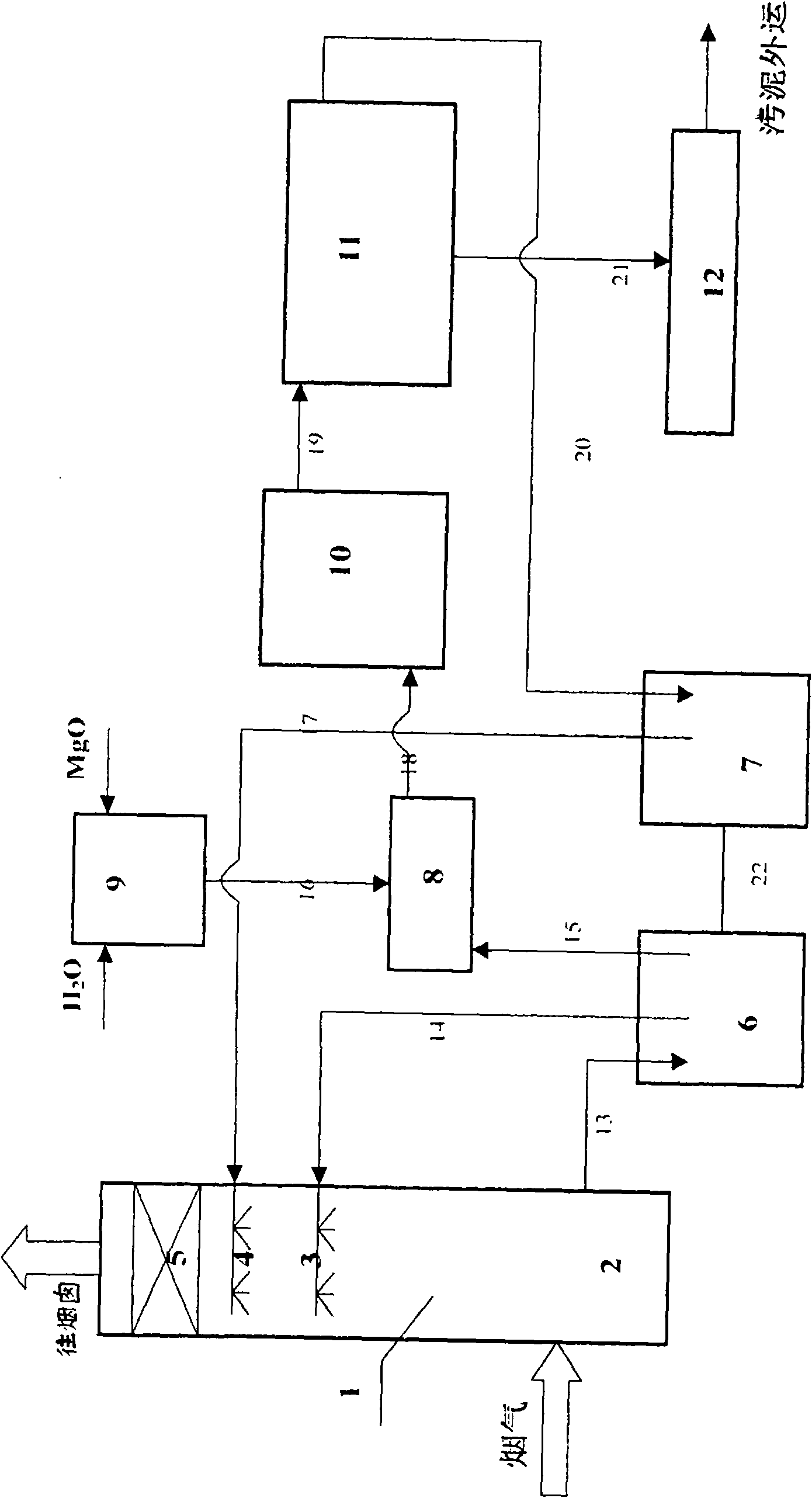

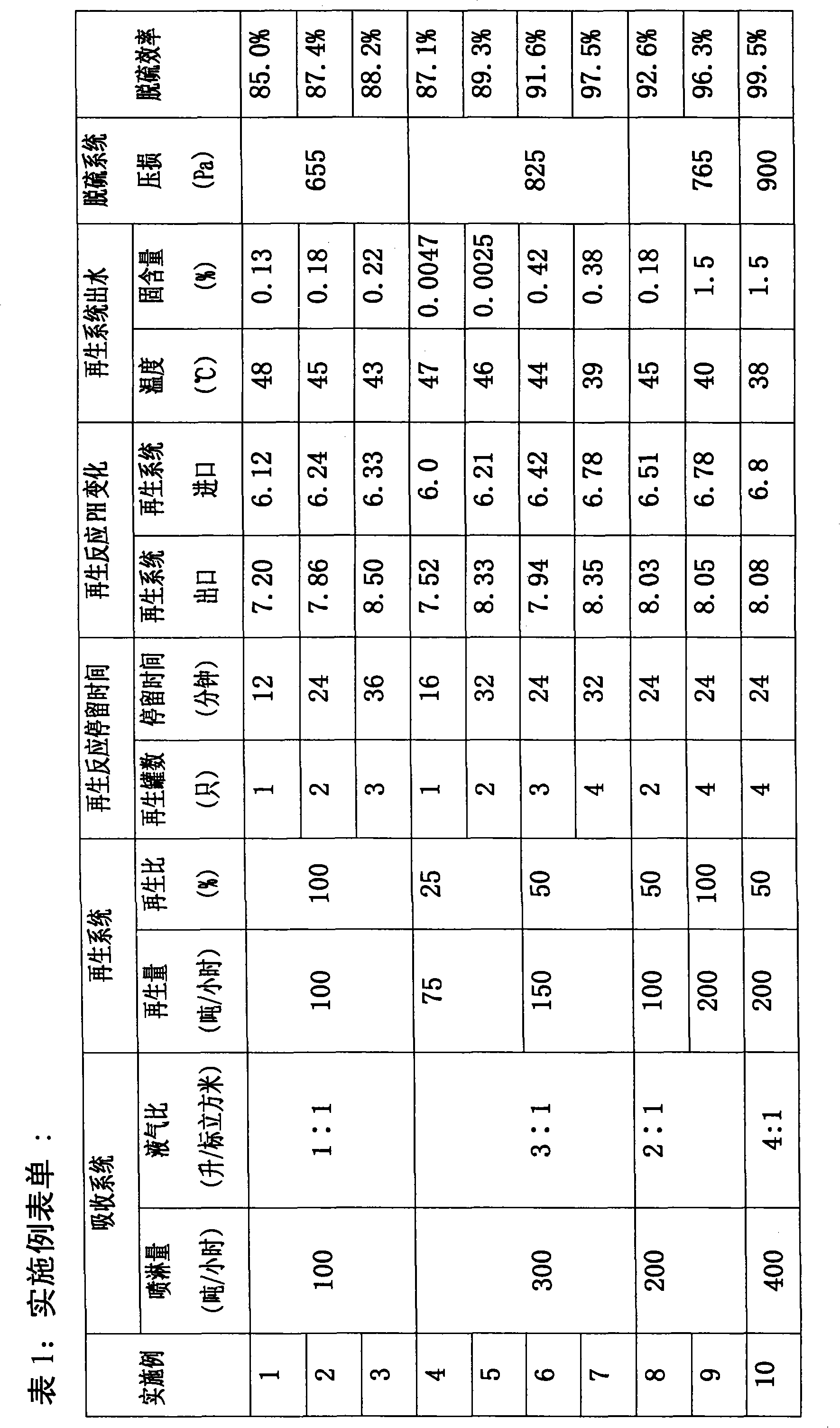

The invention relates to a desulfurization process of flue gas or waste gas by using an external regenerative cycle magnesium sulfate method. The flue gas or the waste gas containing sulfur dioxide is continuously introduced into an absorbing tower, the sulfur dioxide in the flue gas or the waste gas is absorbed by circularly spraying magnesium sulfite absorbing liquid, the magnesium sulfite in the absorbing liquid is transformed into magnesium bisulfite, the sulfur dioxide in the flue gas or the waste gas is removed, the absorbing liquid at the bottom of the absorbing tower is partially or fully shunted to enter in a regeneration system outside the tower and reacts with magnesium oxide slurry for regeneration, the obtained regenerative liquid is filtered, the magnesium sulfite solid is recovered, the filtrate is returned backed to the absorbing tower for cycle absorption and the sulfur dioxide in the flue gas or the waste gas is continuously removed. Due to the adoption of the regeneration process of the absorbing liquid, the pH value of the regeneration reaction end point and the transformation ratio of the agent are increased, the temperature of the absorbing liquid is reduced, the absorbing liquid has the characteristics of high pH value (7.2-8.5), low temperature (38-48 DEG C) and high absorbing capacity and the absorbent activity of the absorbing liquid is effectively improved.

Owner:江苏联慧资源环境科技有限公司

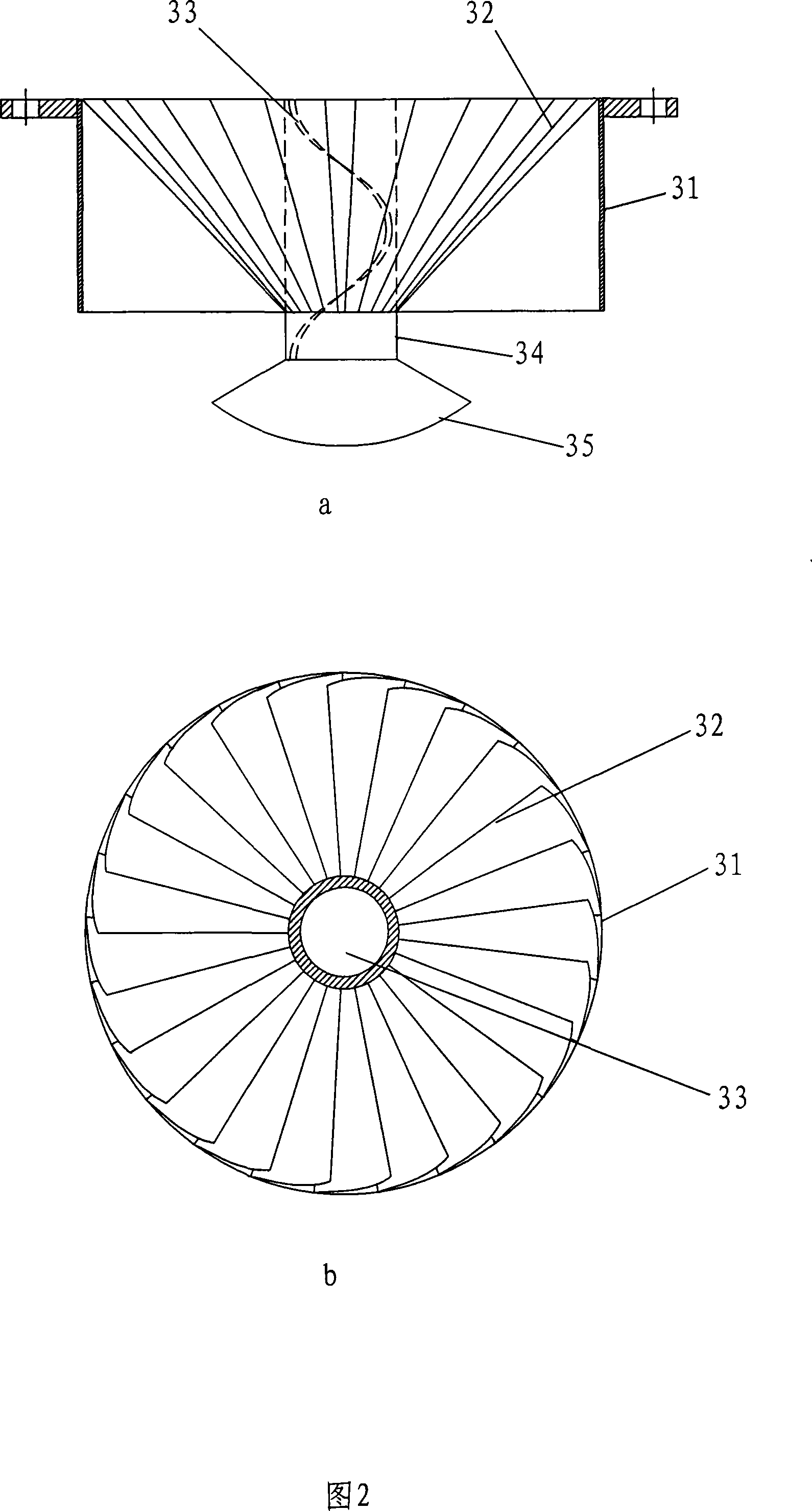

Gas absorption purifier

InactiveCN101036848AFully contactedHigh speedUsing liquid separation agentAbsorption effectProduct gas

The invention relates to a gas purifying device, which is a vertical drum-type equipment, on the top thereof are arrange a gas collection chamber and a gas outlet, and a liquid collection chamber and a liquid outlet are arranged on the bottom of the gas purifying device, a main chamber is provided between the gas collection chamber and the liquid collection chamber, on the upper part of the main chamber is arranged a mist eliminator, a gas tangential inlet is arranged on the lower part of the main chamber near to the liquid chamber, and an absorption liquid inlet is provided below the mist eliminator. In the main chamber, a group of fluid directors are coaxially arranged in a certain space. The leakage between the fluid directors and the tower inner wall can be reduced maximally via the outer rings on the fluid directors. After the gas to be treated enters the tower via the gas inlet, it rotates and runs up simultaneously. The absorption liquid injected via the liquid inlet has a contact with the rising rotary gas flow, and the absorption liquid can form liquid film, liquid silk, and liquid drop to under turbulent shearing action of swirling flow field, which makes gas and liquid have a sufficient contact; and because of the fast gas-liquid relative velocity and great turbulent degree, the invention is provided with high gas-liquid mass transfer rate and good absorption effect.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

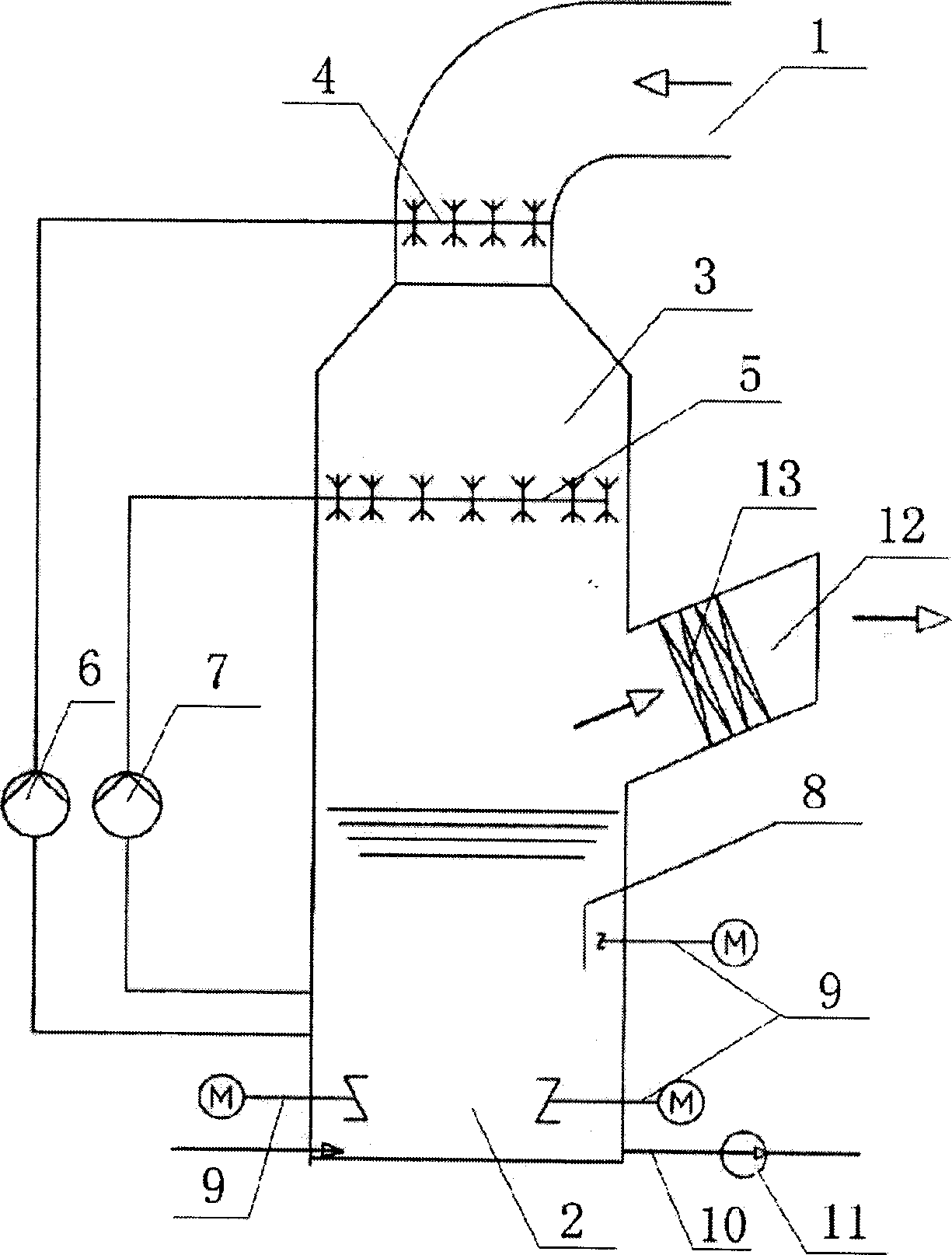

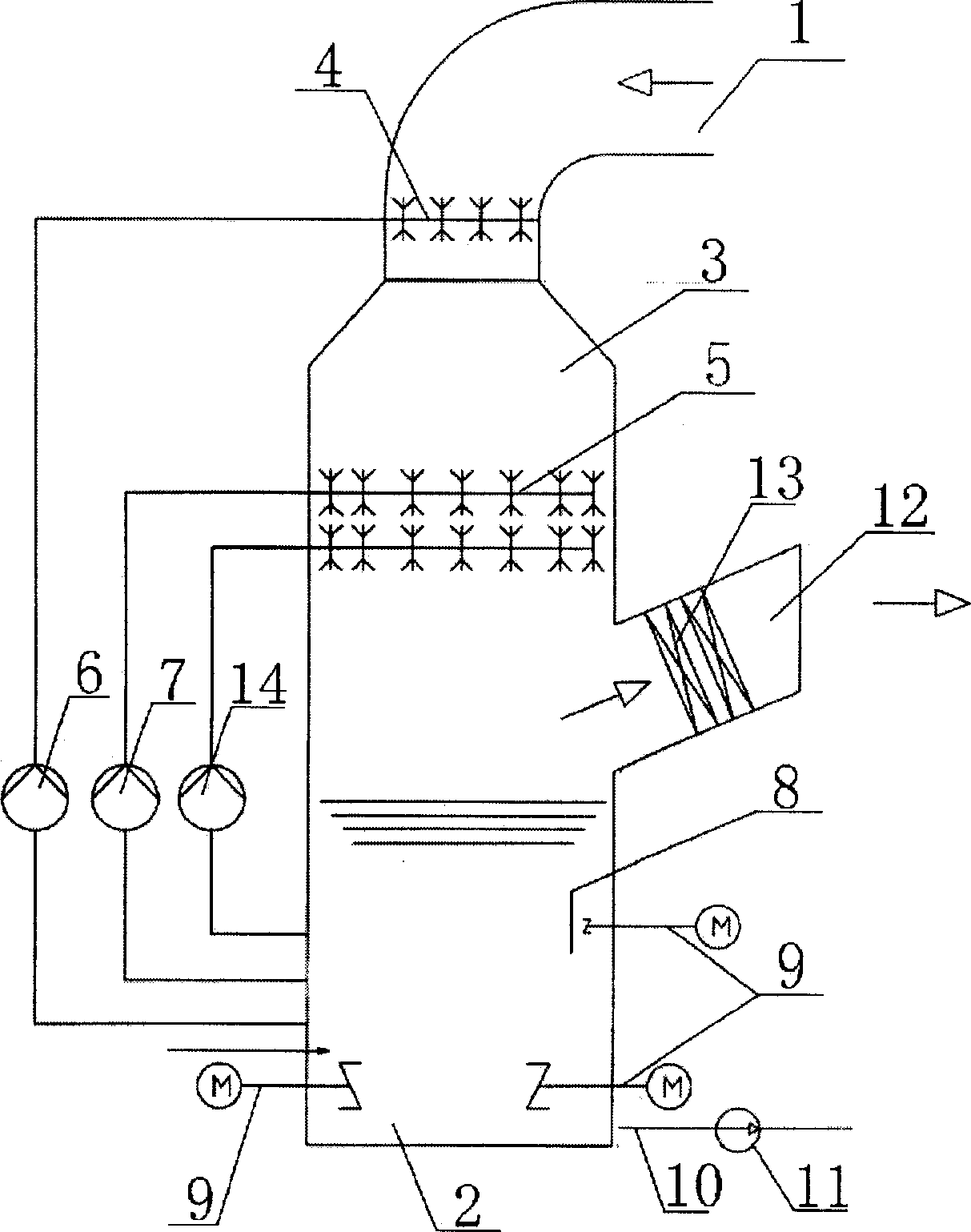

Device and method for depriving sulfur dioxide in flue gas by using ammonia water

InactiveCN101898082AQuality improvementImprove desulfurization efficiencyDispersed particle separationAmmonium sulfatesEngineeringLine filter

The invention relates to a device and a method for depriving sulfur dioxide in flue gas by using ammonia water. The device comprises an absorption tower, wherein the absorption tower comprises a tower bottom pulp chest, spraying layers, packing layers and defrosters from bottom to top; the middle part of the absorption tower is arranged below the spraying layer, a flue gas inlet is arranged above the of the tower bottom pulp chest, and the top of the absorption tower is provided with a flue gas outlet; the tower bottom pulp chest of the absorption tower is internally provided with an aeration pipe; the absorption tower is externally provided with circulating pumps, the number of the circulating pumps accords with the number of layers for the spraying layers, an outlet of each circulating pump is respectively connected with spray throwers in the spraying layer in one layer, the defrosters are arranged in the upper part of the absorption tower and an inlet of each circulating is connected with the tower bottom pulp chest of the absorption tower; and the tower is externally provided with an in-line filter, and filtered unsaturated ammonium sulfate solution is taken as absorption liquids of the packing layers to thoroughly eliminate the possibility of filler scaling block. The method of the invention has the advantages of high deprivation efficiency, low liquid-air ratio, difficult scaling block, low content of ammonium sulfate particles and liquid drops contained in the flue gas from the outlets, good quality of secondary products and the like.

Owner:武汉兴能环保技术有限公司

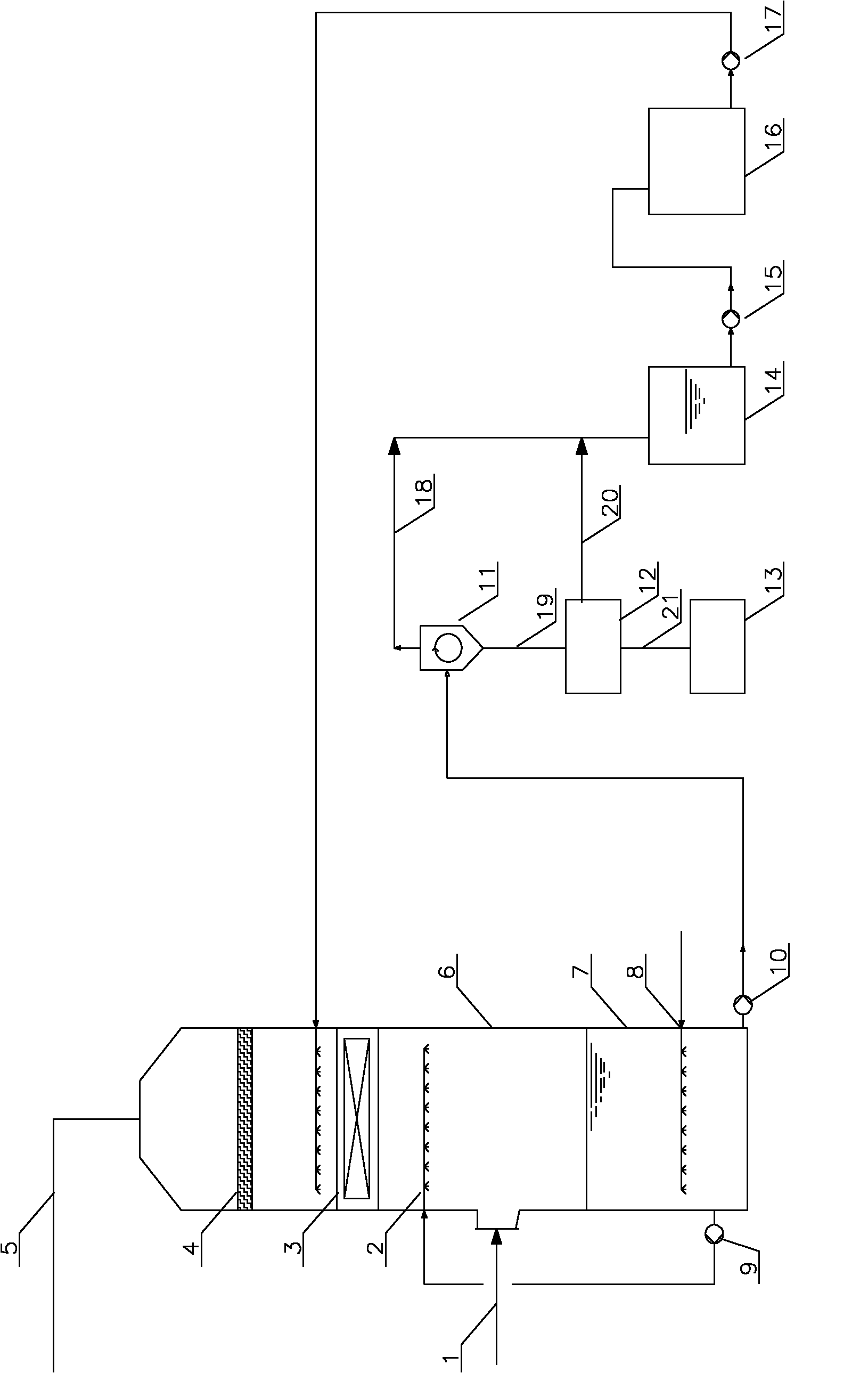

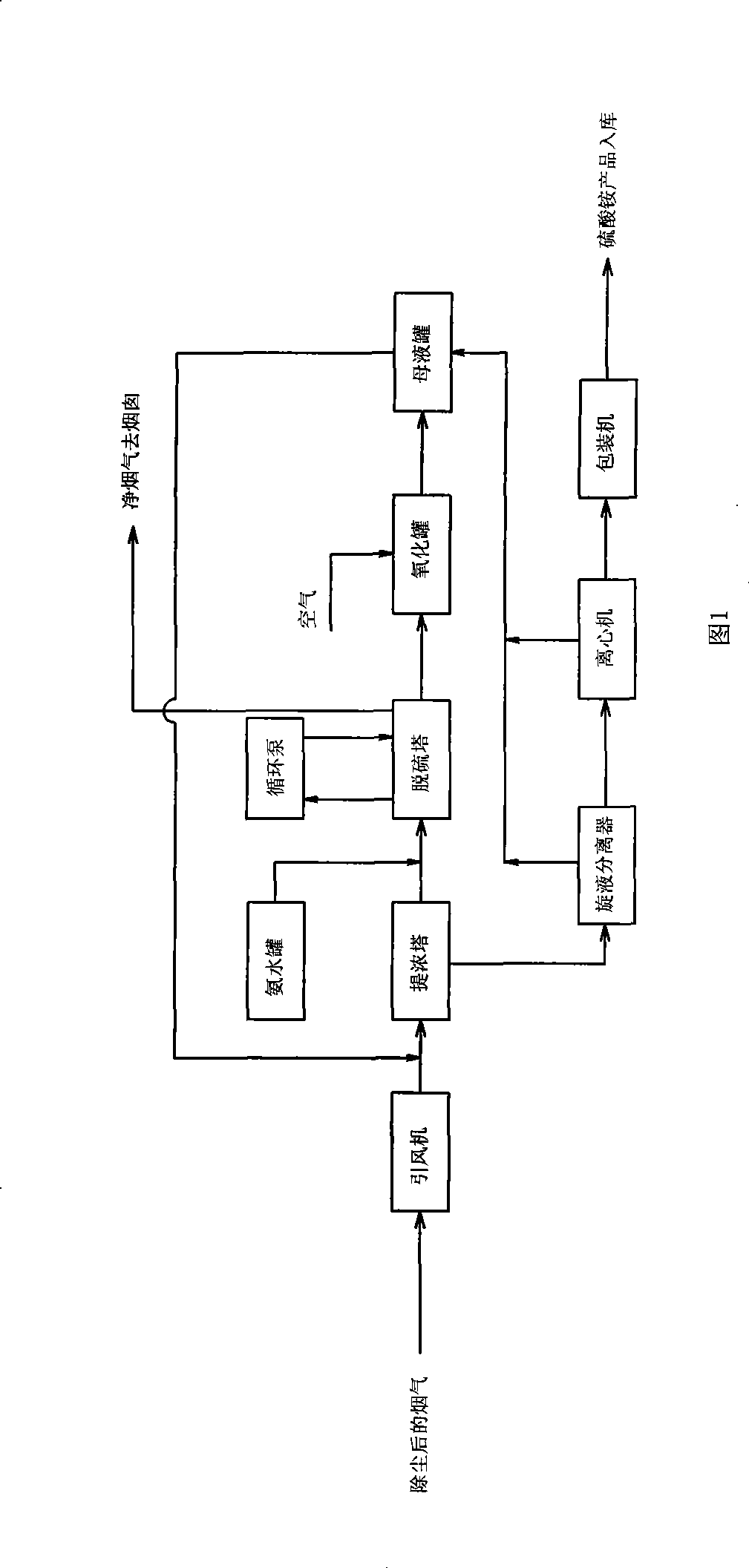

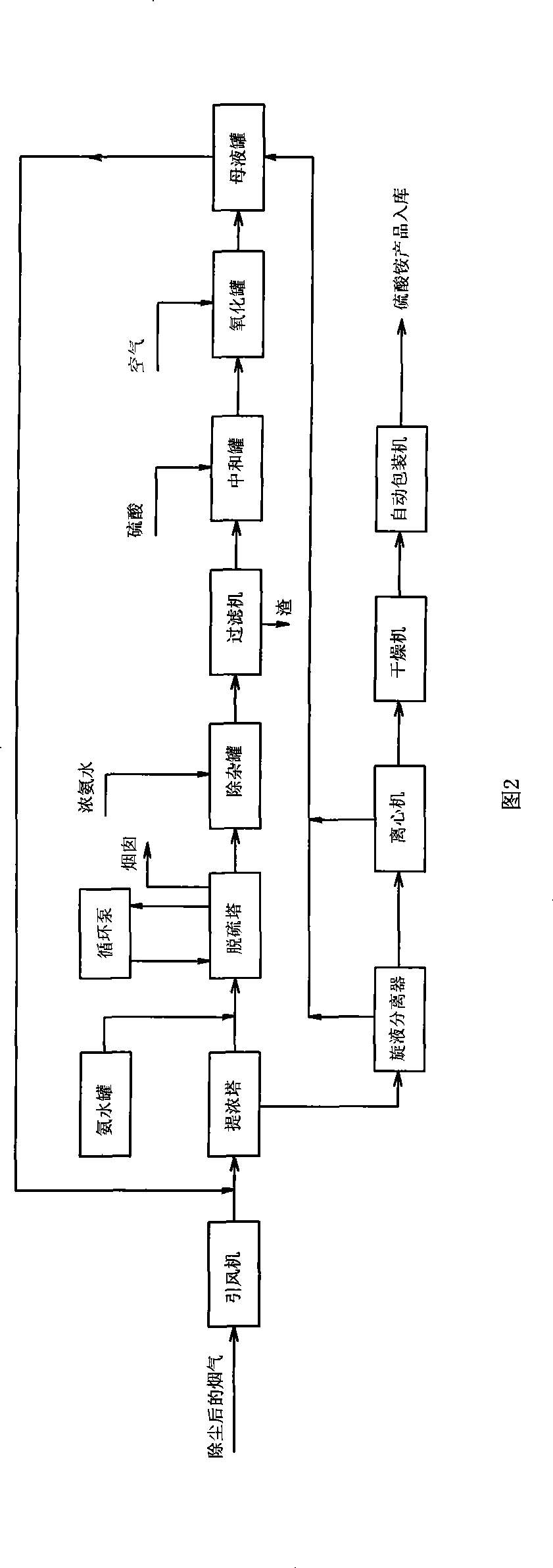

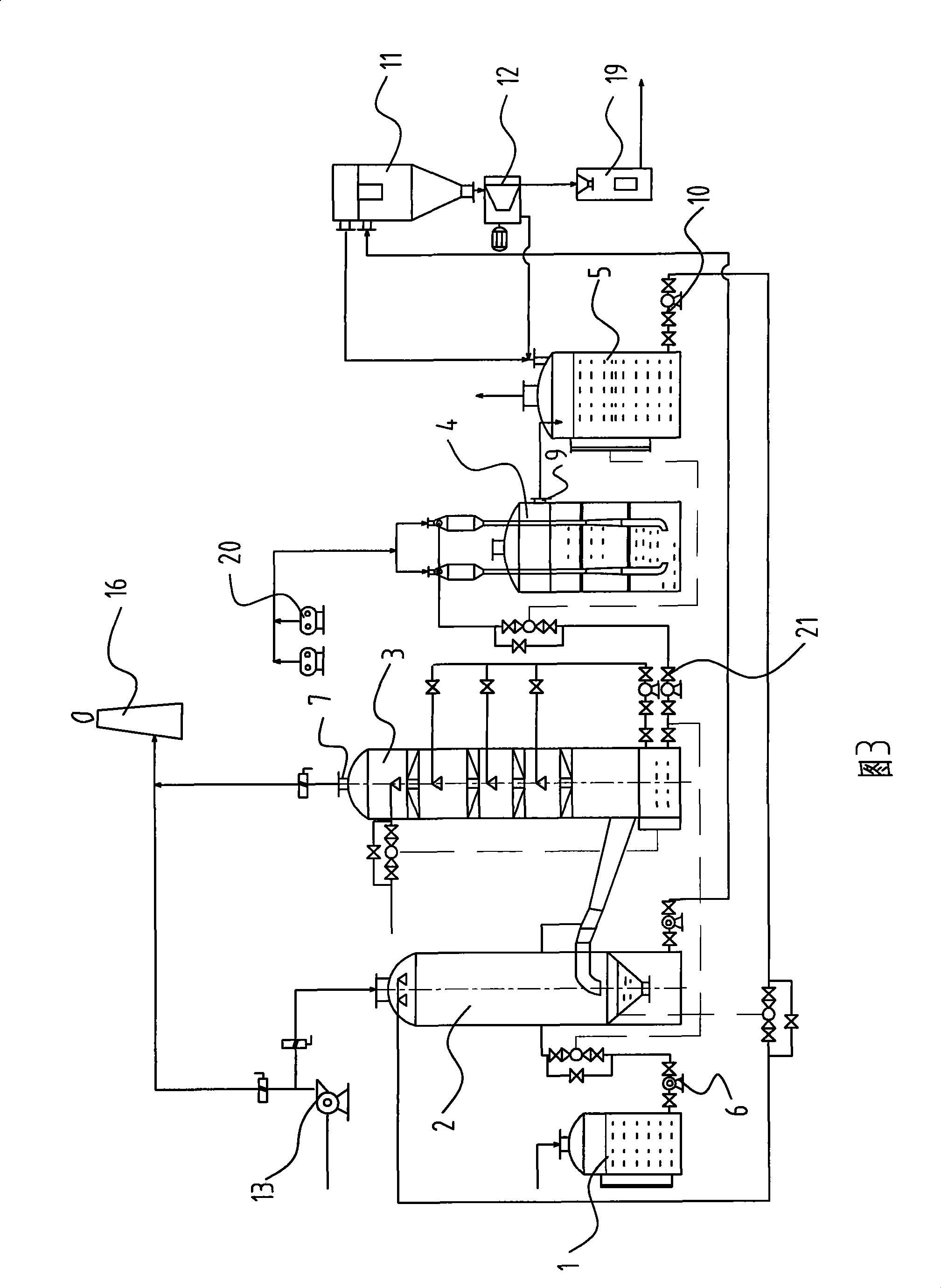

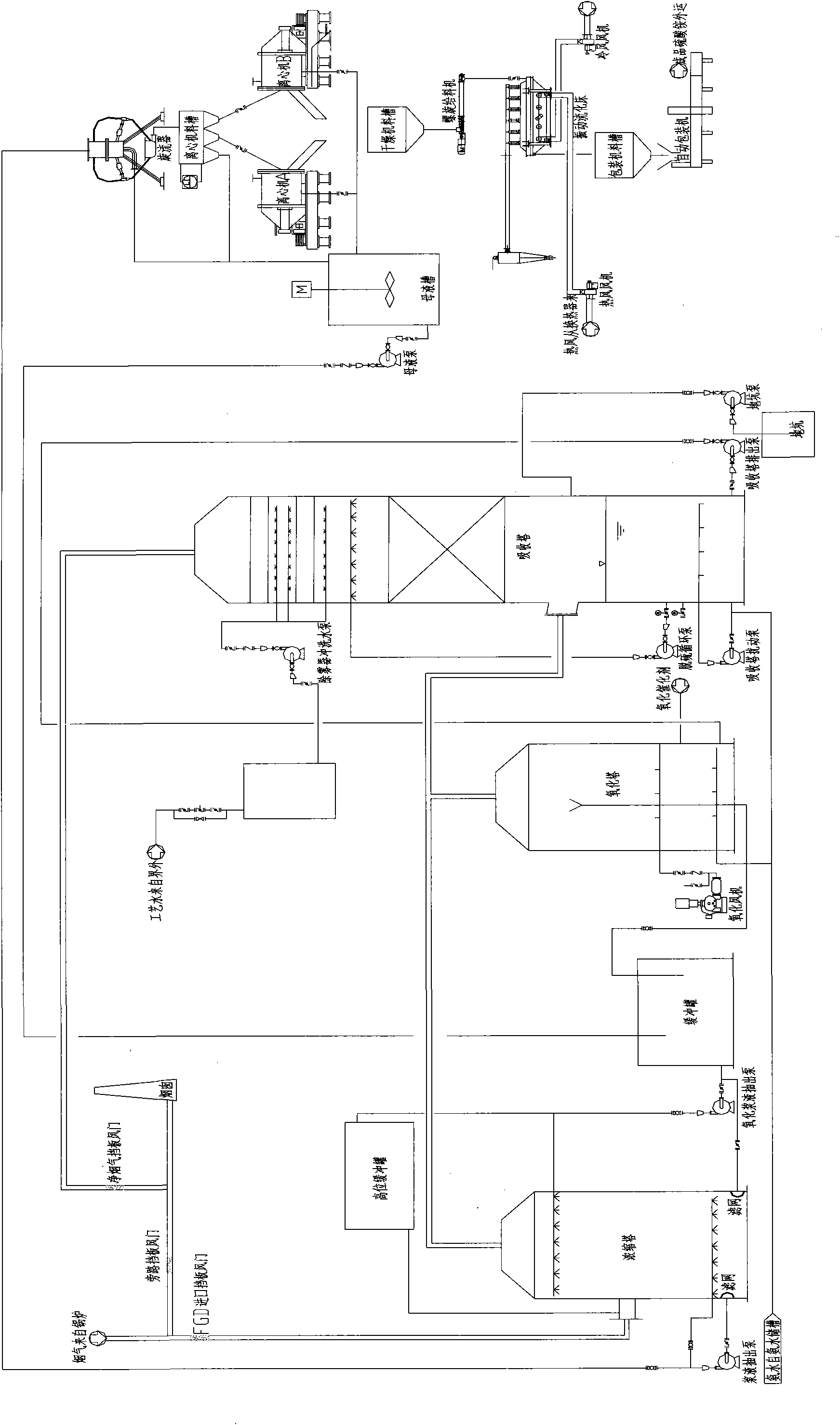

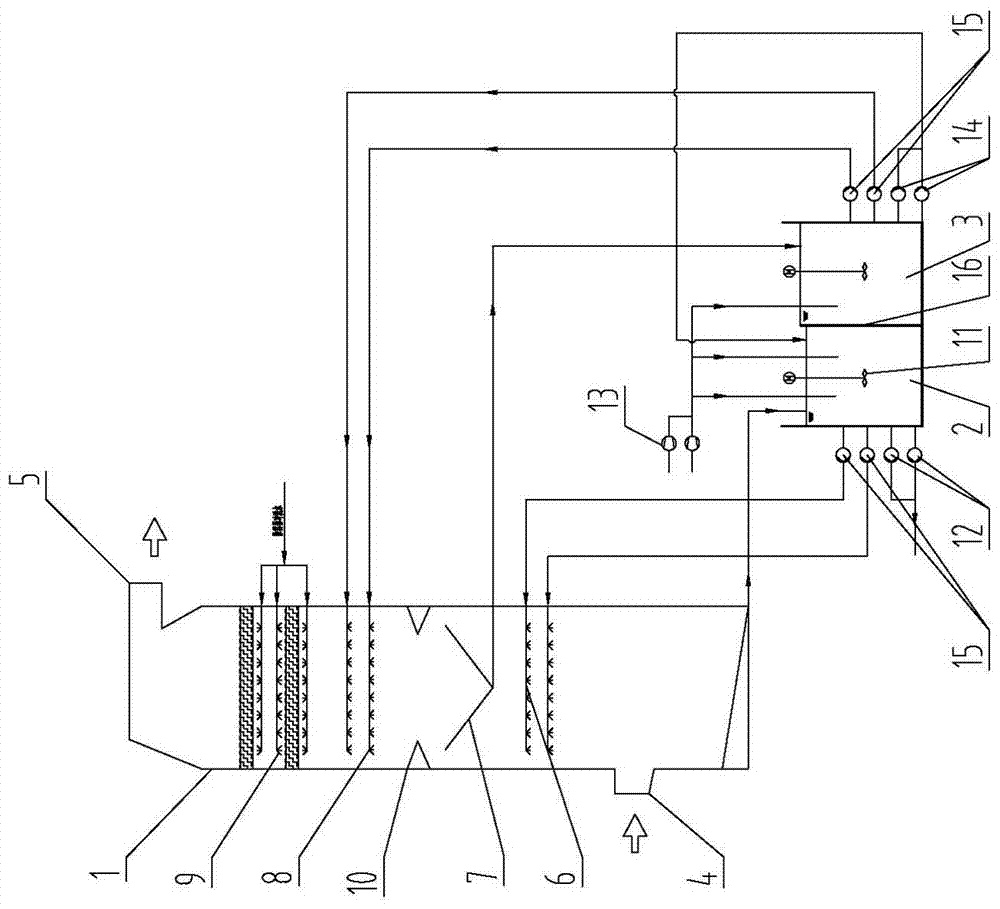

High-efficient wet-type ammonia recovering method desulfuration method with oxidation and concentration processes outside tower and device thereof

InactiveCN101433798AReduce the chance of being corrodedHigh gas velocityDispersed particle separationCycloneRecovery method

The invention discloses a high efficiency wet-type desulfurization method through ammonia recovery method for oxidation and concentration outside a tower, and a device thereof. The method comprises the following steps: (1) feeding flue gas into the top part of a concentrating tower after dust removal, cooling down and humidifying the flue gas, then feeding the flue gas into a first level venturi section of a desulfurization absorption system to contact atomized ammonia water so as to have the first level absorption reaction, performing the second level and the third level desulfurizations, and discharging the flue gas after the purification; (2) oxidizing the ammonium sulfite solution generated in a desulfurizing tower and then overflowing the ammonium sulfite solution into a mother liquor tank from the top part of an oxidation tank; and (3) pumping the ammonium sulfate solution in the mother liquor tank to the top part of the concentrating tower through a mother liquor pump to perform heat exchange with the high temperature flue gas after atomization so as to form a supersaturated solution containing 3 to 5 percent of crystal, wherein the supersaturated solution flows out of the bottom of the concentrating tower and is pumped into a hydraulic cyclone through a slurry pump to perform the first level solid-liquid separation, and then the clear solution automatically flows into the mother liquor tank; the crystal-liquid mixed solution flowing out of the bottom of the concentrating tower automatically flows into a centrifugal machine to perform the second level solid-liquid separation, and then the clear solution automatically flows into the mother liquor tank; and solid ammonia sulfate is fed into an automatic packaging machine to be packaged and put into storage. The method has simple processes, greatly reduces investment, and can reclaim agricultural level ammonia sulfate and industrial level ammonia sulfate.

Owner:HENAN XUHUI ENVIRONMENT PROTECTION ENG

Turbine type pressure charging acceleration fuel gas desulfurization gas wash tower

ActiveCN101185840AIncrease contact timeIncrease contact spaceDispersed particle separationEngineeringLiquid gas

The invention relates to a turbine typed turbocharged accelerating flue gas desulfurization dust abatement tower, belonging to the field of gas purification technique, which includes a spray pump tower body, a slurry pump that is arranged on the tower from bottom to top and is connected with a slurry outlet at the bottom of the tower, a roots blower that is connected with a fall trachea and is arranged in a liquid storage district at the bottom in the tower, a spray pump pipe arranged over the liquid storage district, a circulating pump that is connected with and arranged in a circulating pipeline communicated with the spray pump pipe, and a demister arranged on the spray pump pipe; a flue gas inlet, a flue gas outlet and a slurry outlet are arranged on the lateral wall, on the top and at the bottom of the lower part of the spray pump tower body; a disturbance pump and a turbine typed turbocharged accelerating flue gas desulfurization dust abatement system are also included, wherein, the disturbance pump is connected with and arranged in the circulating pipeline communicated with the liquid storage district at the bottom of the tower, and the desulfurization dust abatement apparatus is arranged under the spray pump pipe in the tower and over the flue gas inlet. The invention has the advantages that sufficient connection of gas and liquid can be realized and high speed mass transfer can be carried out within the shortest time, in the smallest space and with the minimum liquid-gas ratio, thus improving high dust abatement and desulfurization efficiency with minimum energy consumption.

Owner:北京紫光威肯环保工程技术有限公司

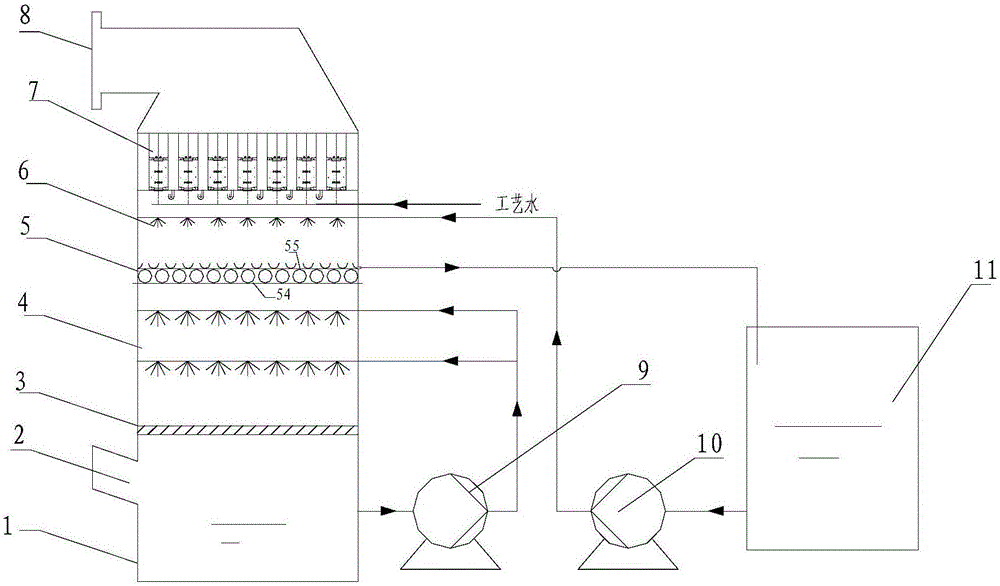

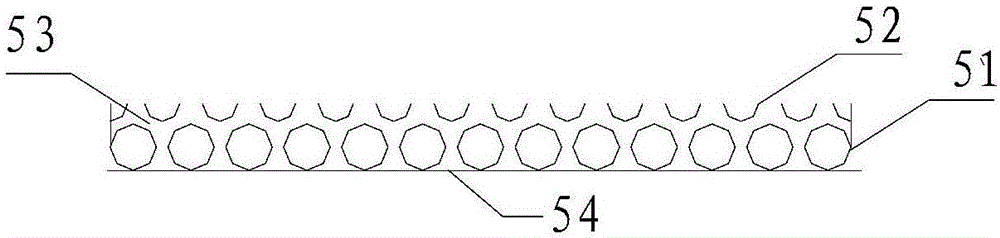

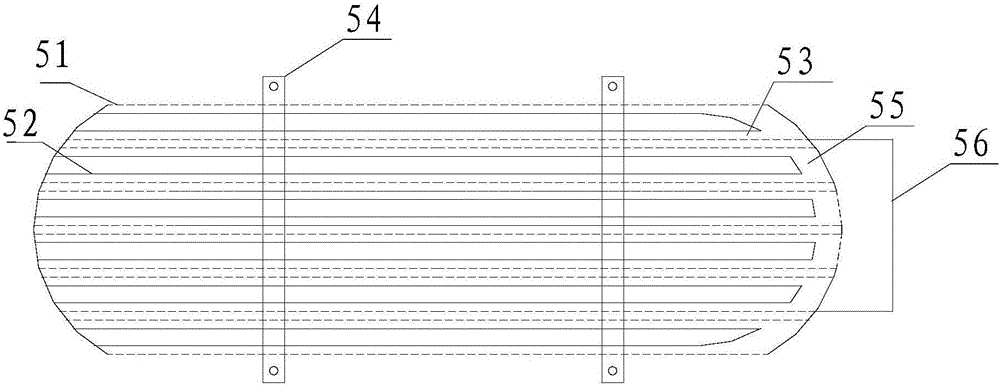

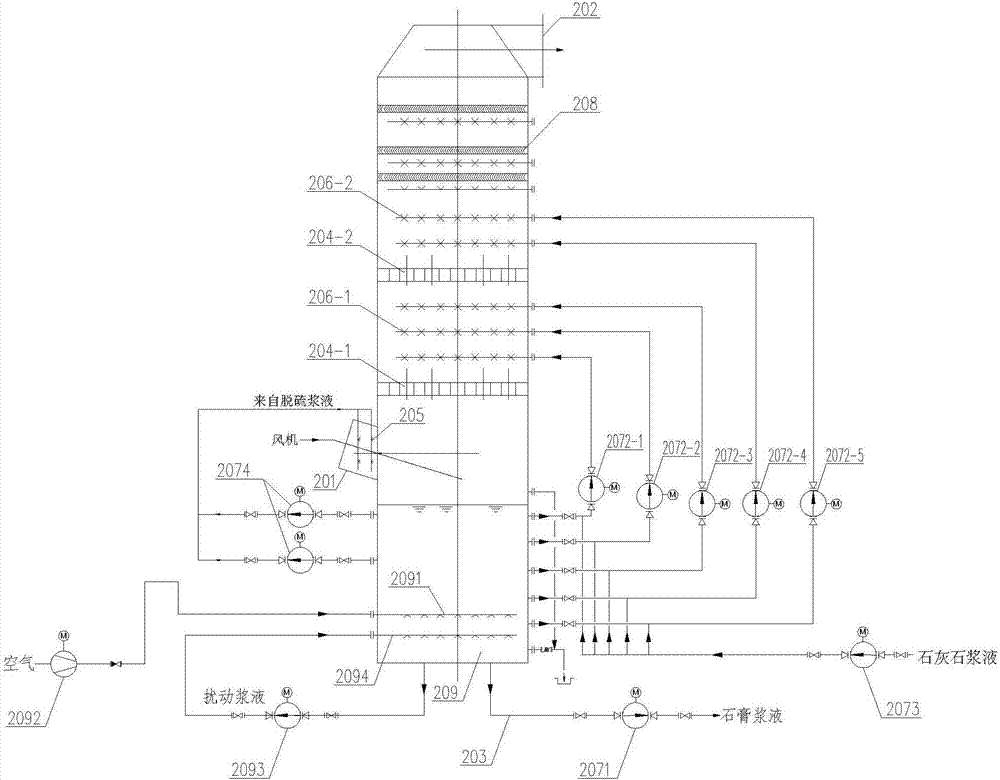

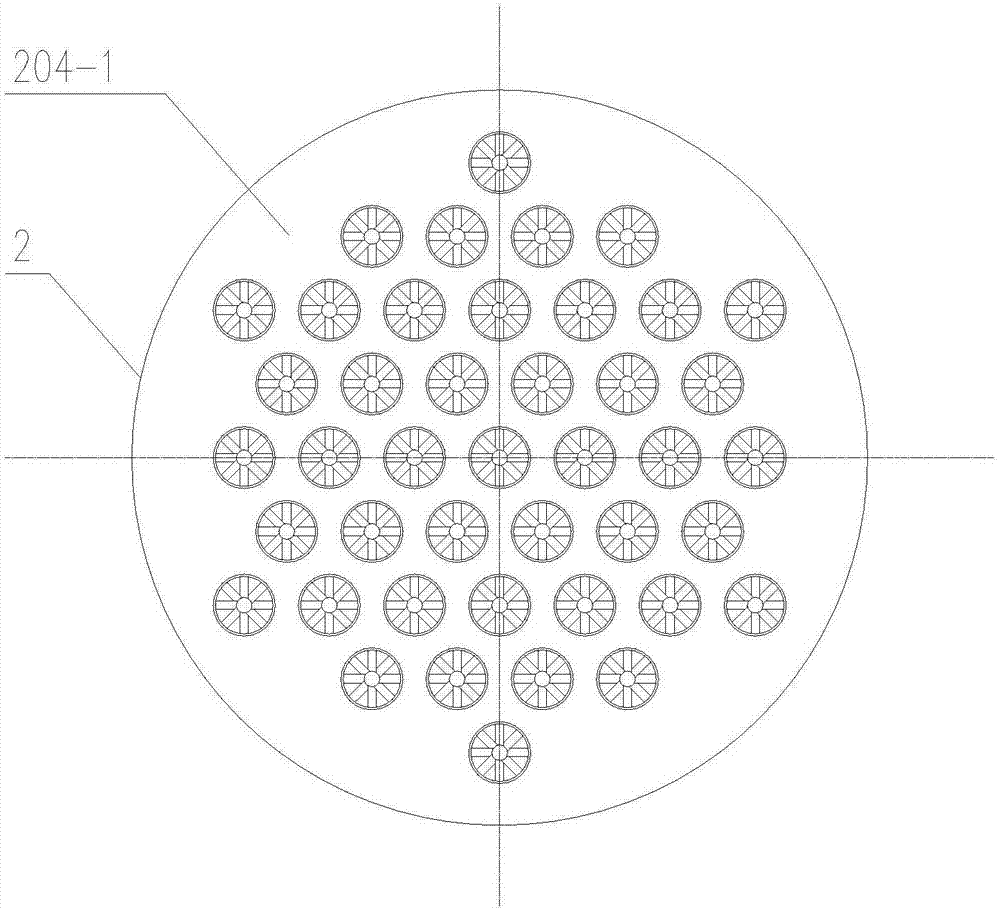

Single-tower and double-circulation desulfurization and dust removal device and technology

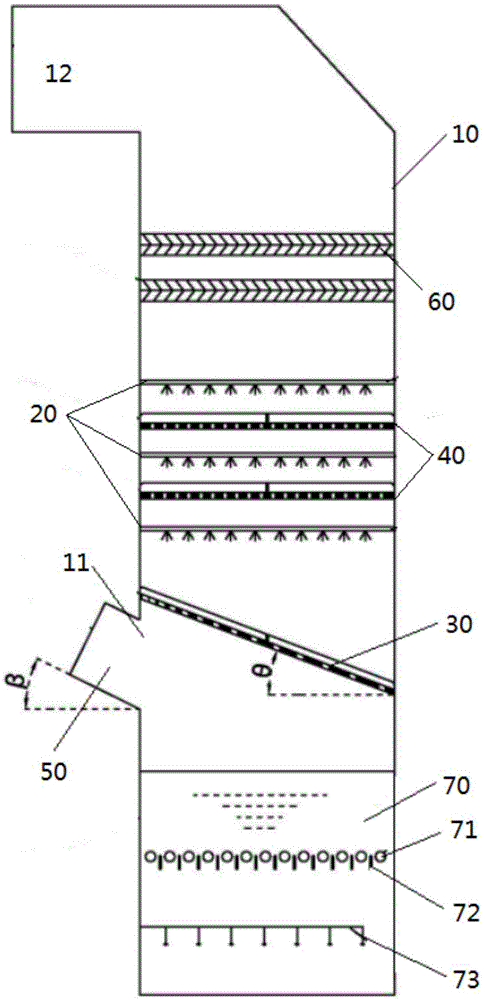

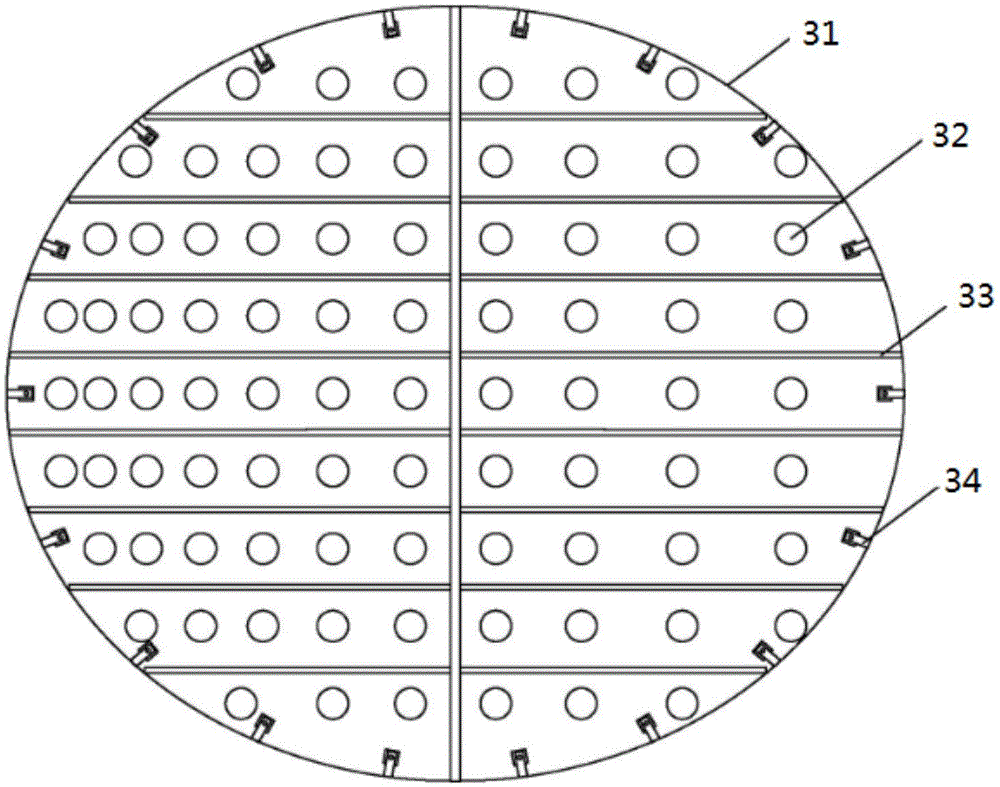

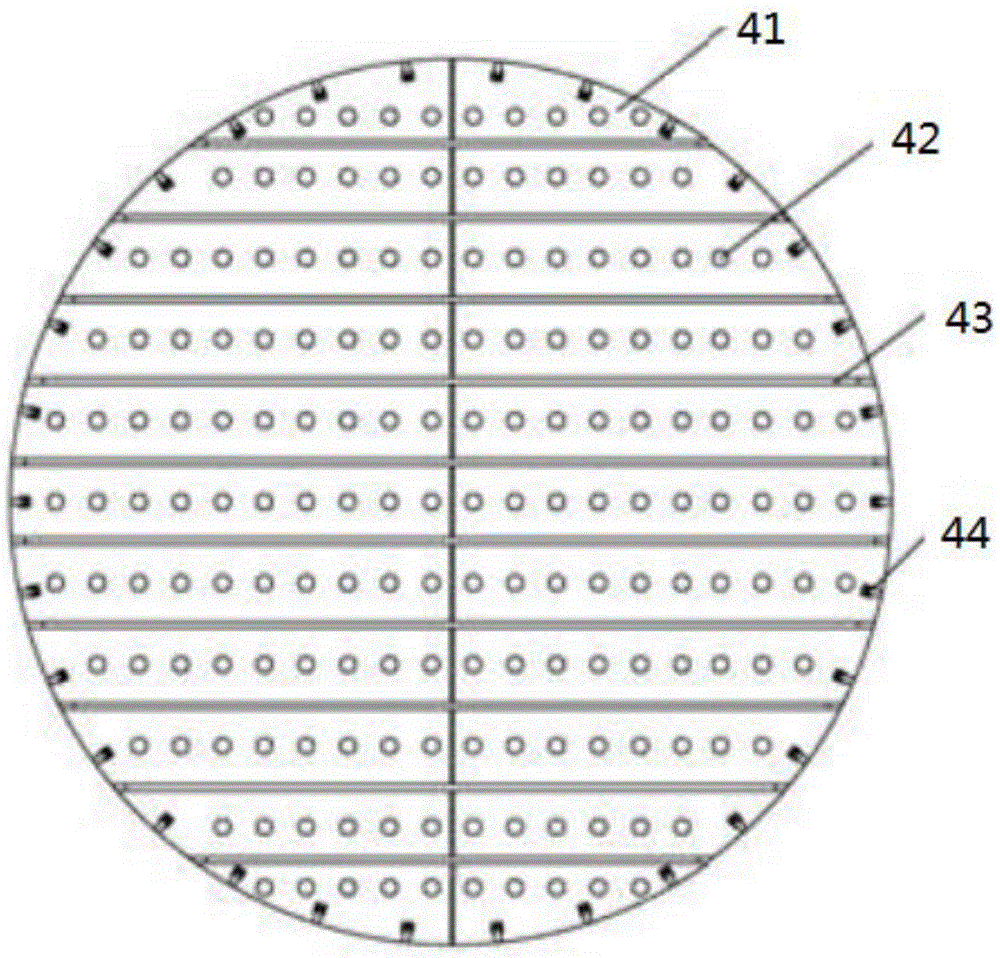

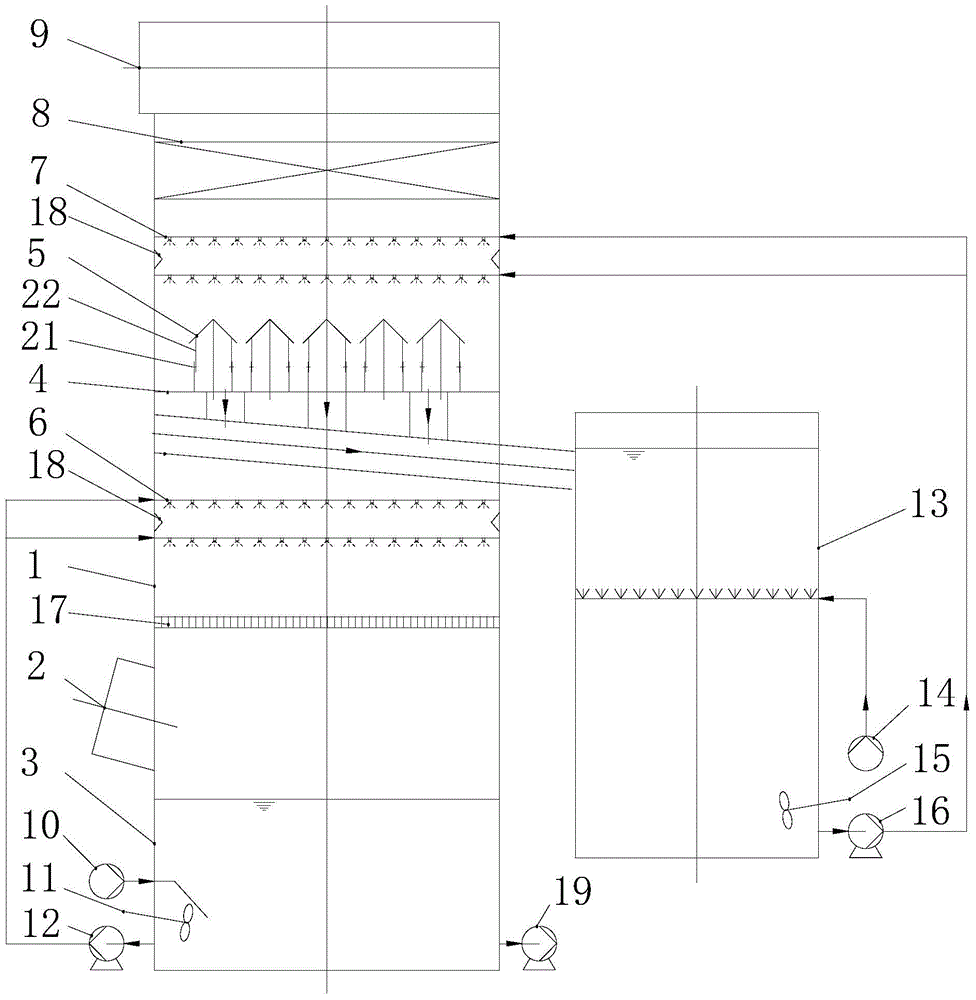

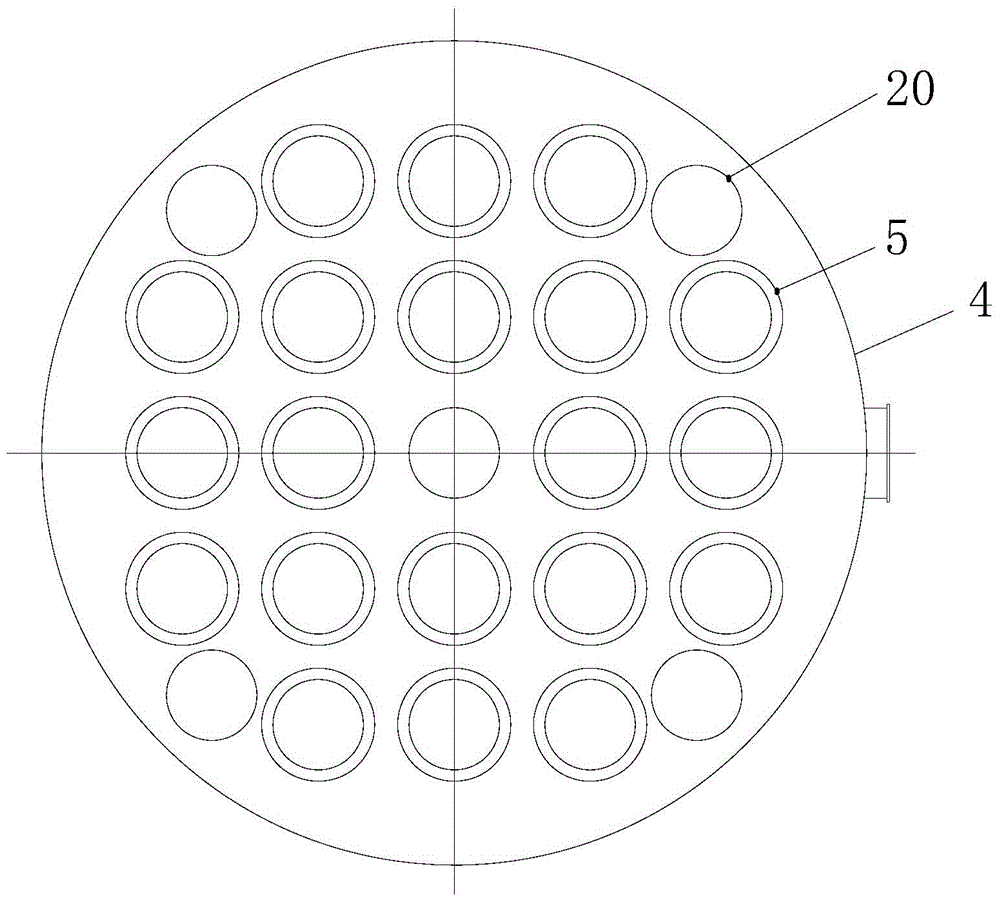

ActiveCN106693657AAdjustable widthAdjustable resistanceCombination devicesGas treatmentVena contracta diameterSprayer

The invention discloses a single-tower and double-circulation desulfurization and dust removal device and technology. The device comprises an absorption tower, wherein a tray orifice plate, coarse desulfurization sprayers, a gas redistribution and liquid collection layer, fine desulfurization sprayers and a cyclone demister are arranged in the adsorption tower and located above a flue gas inlet from bottom to top in sequence, the coarse desulfurization sprayers are communicated with a column bottom through a circulating pump, and the fine desulfurization sprayers are externally connected with a slurry feed pump; the gas redistribution and liquid collection layer comprises a liquid collection part and a gas redistribution part, the liquid collection part is fixed on the wall of the adsorption tower and covers a cross section of the adsorption tower completely, the gas redistribution part is located below the liquid collection part, the mounting height of the gas redistribution part is adjustable, the liquid collection part is communicated with an external pipeline, the gas redistribution part comprises a plurality of round pipes which are parallel to each other and are arranged horizontally, and a gas channel is formed by a gap between every two adjacent round pipes. The technology comprises a coarse desulfurization and dust removal stage and a fine desulfurization and dust removal stage, wherein by means of a Venturi bar layer at the fine desulfurization and dust removal stage, liquid-gas contact area can be increased and gas-liquid mass transfer rate is increased.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Desulfurization and dedusting absorption tower with porous current equalizer

ActiveCN105617852AHigh desulfurization and dust removal efficiencyEvenly distributedGas treatmentUsing liquid separation agentFlue gasContact time

The invention discloses a desulfurization and dedusting absorption tower with a porous current equalizer. The desulfurization and dedusting absorption tower comprises a tower body, at least one sprayer and at least one porous current equalizer, wherein the tower body is provided with a flue gas inlet and a flue gas outlet; the sprayer is arranged in the tower body, is positioned between the flue gas inlet and the flue gas outlet and is used for spraying slurry; the porous current equalizer comprises a porous current equalizing plate, is arranged in the tower body and is positioned above the flue gas inlet and above the sprayer, and a plurality of airflow holes for flue gas as well as the slurry to pass through are formed in the porous current equalizing plate; when the desulfurization and dedusting absorption tower is in use, the upper surface of the porous current equalizing plate receives the slurry sprayed by the sprayer and forms a slurry holding layer; when the flue gas passes through the slurry holding layer, a bubbling phenomena occurs, so that the contact area and the contact time between the flue gas and the slurry in the slurry holding layer are effectively increased, the slurry can fully absorb sulfides in the flue gas as well as dust, and further, the desulfurization and dedusting efficiency of the desulfurization and dedusting absorption tower is effectively improved.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

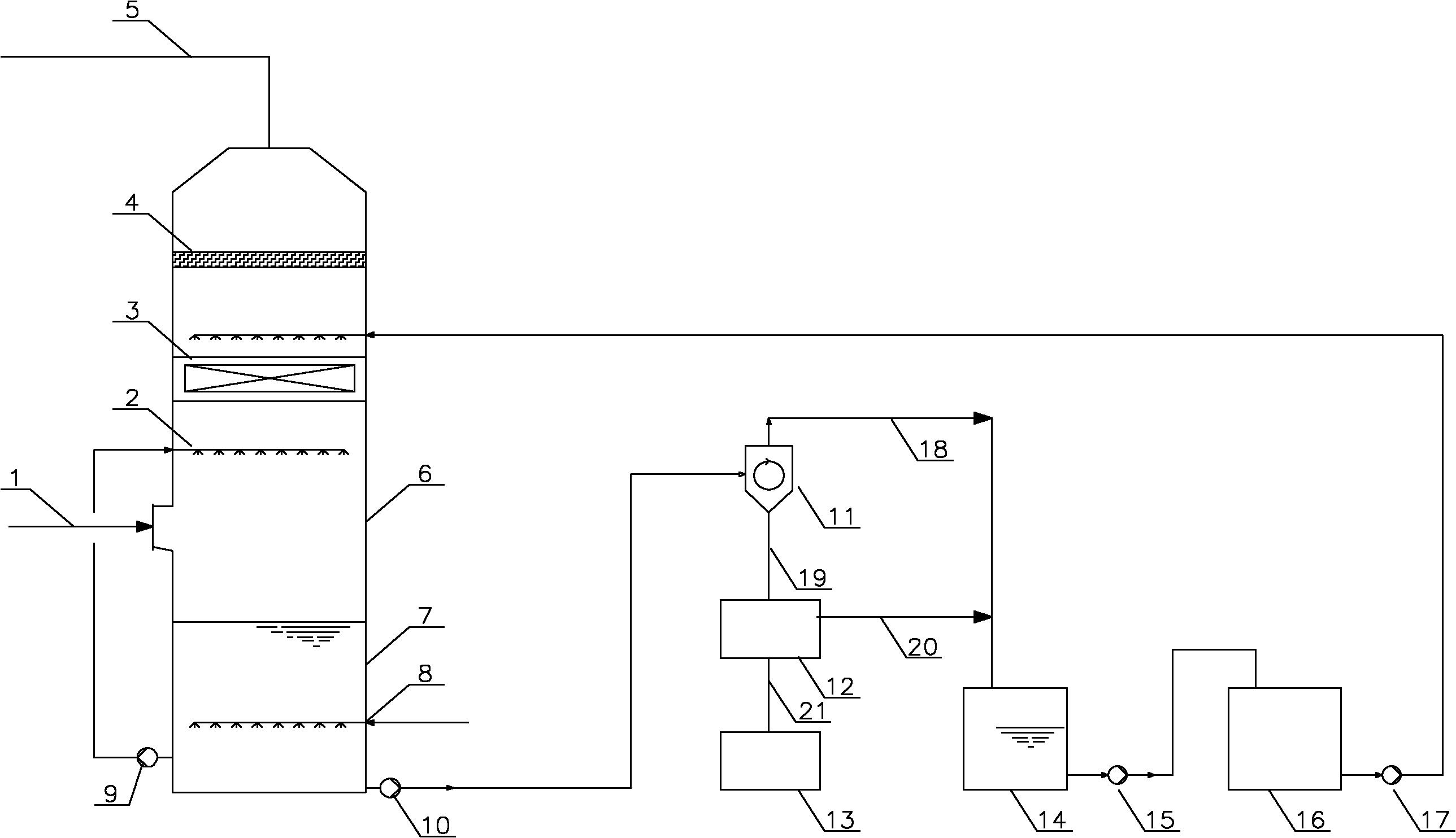

Separation tower type boiler flue gas desulfurization process

InactiveCN101862582AHigh desulfurization rateLow running costDispersed particle separationEvaporationHeat energy

The invention discloses a process technology for removing sulfur dioxide from boiler flue gas to produce an ammonium sulfate fertilizer. High-temperature flue gas is firstly cooled by a concentrating tower and then enters a desulfurizing tower (absorption tower), and the flue gas is desulfurized together with an ammonium sulfite solution in the desulfurizing tower and is exhausted. Desulfurized ammonium sulfite solution is sent to an oxidizing tower so that ammonium sulfite is thoroughly converted into ammonium sulfate, the ammonium sulfate enters the concentrating tower to perform countercurrent heat exchange with the flue heat, so that water in the ammonium sulfite solution is evaporated. After the concentration reaches supersaturation, ammonium sulfate crystals are separated out, and a suspension containing the ammonium sulfate crystals is spirally flowed, centrifuged and dried into the finished product. The invention effectively utilizes the low-grade heat energy of the flue gas, and the ammonium sulfate evaporation system is saved; oxidation is adopted outside the desulfurizing tower, so that the oxidation is more thorough; the desulfurizing tower is a packed tower, the specific surface area is increased, the liquid-air ratio is low, the circulating volume of the absorbing liquid is reduced, and the equipment saves more energy; and the absorbing liquid controls not to crystallize at low concentration, and the phenomena of bias current and packing collapse caused by packing crystallization are avoided.

Owner:北京九州美电环保工程有限公司 +2

Porous partition spray equipped desulfurization tower

InactiveCN104959017AGuaranteed fluencyImprove solubilityCombination devicesUsing liquid separation agentSulfurFlue gas

The invention discloses a porous partition spray equipped desulfurization tower. The lower part in the tower body is a first order absorption zone, the upper part in the tower body is a second order absorption zone, and a porous air flow distribution plate is disposed between the first order absorption zone and the second order absorption zone. The porous air flow distribution plate includes a plate body, the plate body is provided with liquid leakage holes, the plate body is also provided with upward ventilation columns, each ventilation column is equipped with an air cap, the tower body is externally provided with a tower outside slurry pool of the second order absorption zone, and the tower outside slurry pool is connected to the liquid leakage holes through a seal pipeline. According to the porous partition spray equipped desulfurization tower provided by the invention, the first order spray operates at a low Ph value, the second order spray operates at a high Ph value, the energy consumption of a circulating pump is greatly reduced, the porous air flow distribution plate is used for separating the two order absorption systems, the rising flue gas and falling slurry can pass separately, thus ensuring smooth flue gas rising and uniform flue gas distribution. The desulfurization tower is especially suitable for high sulfur coal flue gas desulfurization, can lower the investment and operation cost, and is applicable to current ultra-clean emission reconstruction of power plants.

Owner:浙江菲达环保科技股份有限公司

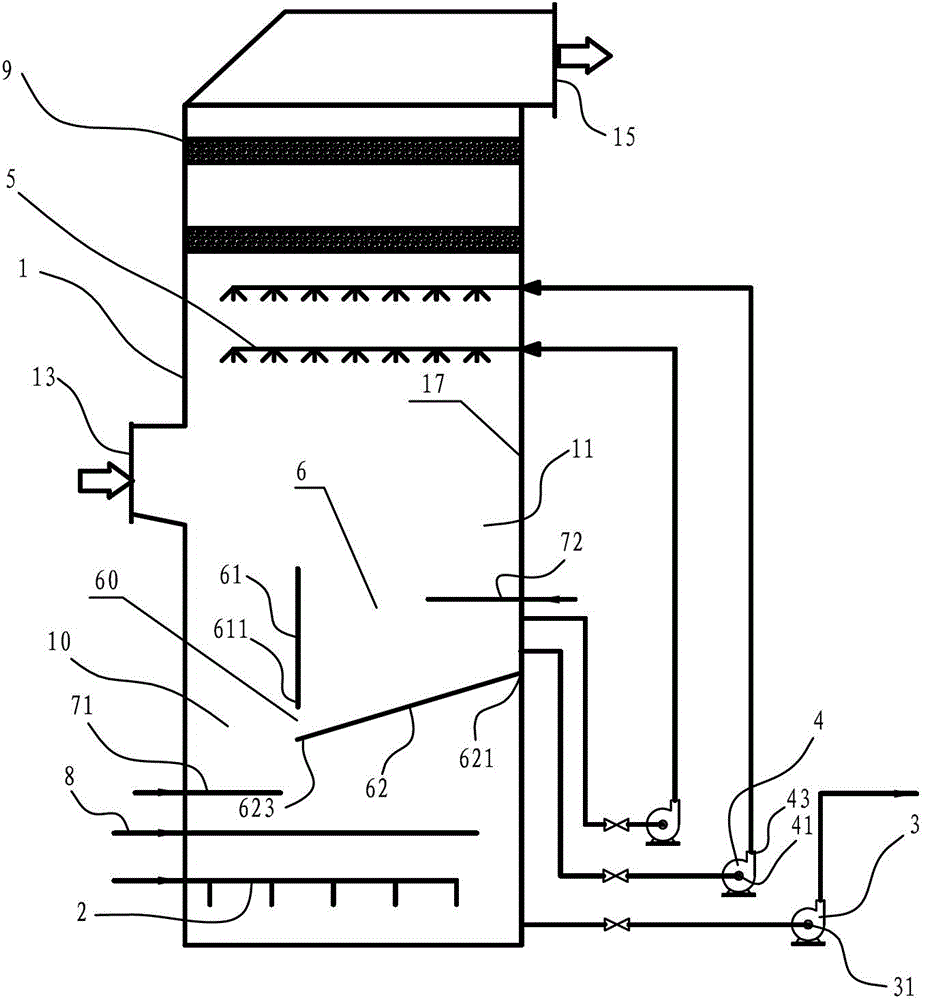

Synergistic treatment device for dust removing and desulphurization

InactiveCN104941432AReduce energy consumptionImprove desulfurization efficiencyUsing liquid separation agentSpray towerCo-processing

The invention discloses a synergistic treatment device for dust removing and desulphurization. The synergistic treatment device adopts the structure that a primary smoke dust removing and desulphurization area, a secondary smoke dust removing and desulphurization area and a defogging device are sequentially arranged in a tower body in the smoke flowing direction; a porous distribution plate of the primary smoke dust removing and desulphurization area is arranged in the tower body above a smoke inlet; primary spraying layers are arranged in the tower body above the porous distribution plate; a synergistic ring I is arranged between two adjacent primary spraying layers; a liquid collection disc of the secondary smoke dust removing and desulphurization area is positioned in the center of the tower body above the primary spraying layer; a ring-shaped plate is arranged in the tower body above the liquid collection disc; the inner diameter of the ring-shaped plate is smaller than the outer diameter of the liquid collection disc; secondary spraying layers are fixed above the ring-shaped plate in the tower body; a synergistic ring II is arranged between two adjacent secondary spraying layers. The synergistic treatment device has the advantages that dust removing and desulphurization are subjected to hierarchical and synergistic treatment, and a desulphurization spraying tower can be used for achieving efficient dust removing and desulphurization simultaneously, so that the investment and the operation cost can be reduced.

Owner:浙江菲达环保科技股份有限公司

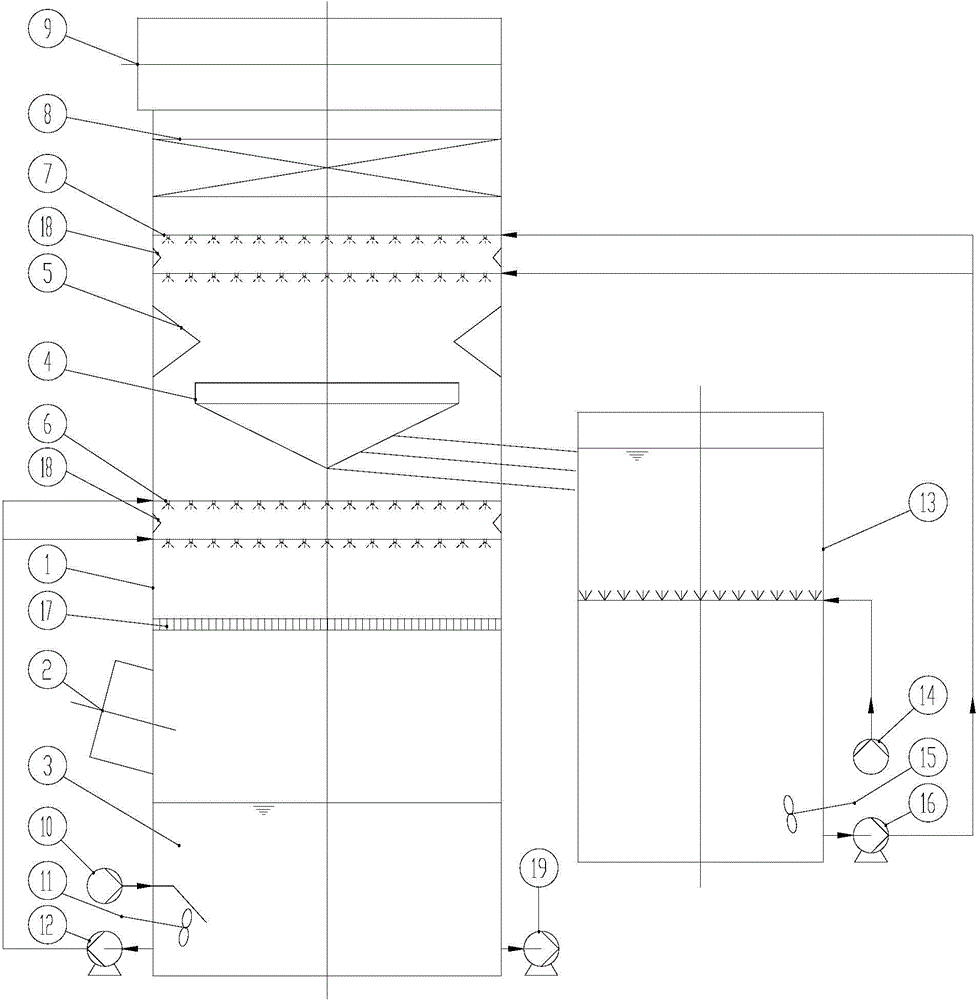

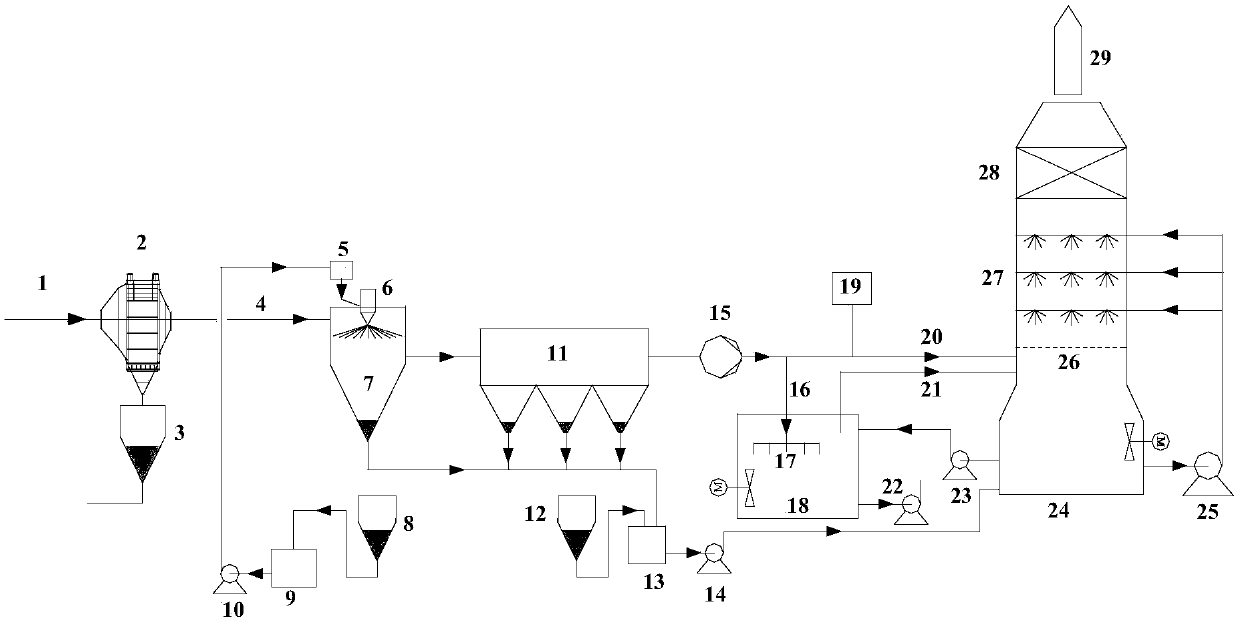

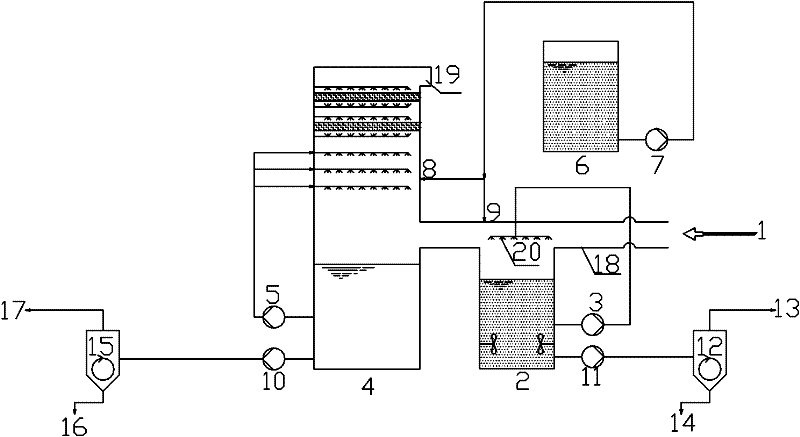

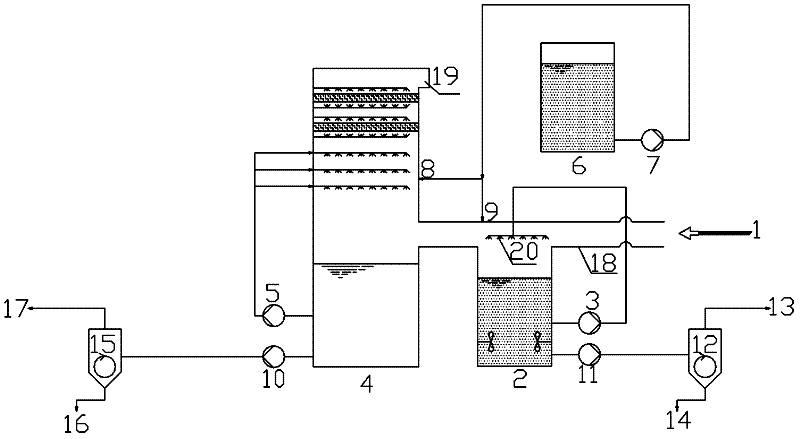

Semi-dry method-wet method series SO2 flue gas desulfurization process and device

InactiveCN109647173AImprove desulfurization efficiencyIncrease oxidation rateCombination devicesElectrostatic precipitatorFlue-gas desulfurization

The invention discloses a semi-dry method-wet method series SO2 flue gas desulfurization process and device. The process includes the following steps: low-dust flue gas from a electrostatic precipitator enters a semi-dry desulfurization tower, SO2 flue gas is purified by a bag filter after first-stage desulfurization by a semi-dry desulfurization tower, the flue gas from the bag filter is pressurized by a booster fan and then sent into a wet spray desulfurization tower, the flue gas is rectified by a distributor in the tower and in countercurrent contact with spray slurry for secondary desulfurization, and the purified flue gas is discharged from a chimney after defogging; and desulfurization ash collected at the bottom of the semi-dry desulfurization tower and the bag filter is used as araw material of a desulfurization agent of the wet desulfurization tower. The series process of semi-dry and wet desulfurization towers has the advantages of being low in liquid-gas ratio, low in water consumption and energy saving, a desulfurization by-product gypsum product has high purity, and the discharge of solid waste is reduced.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

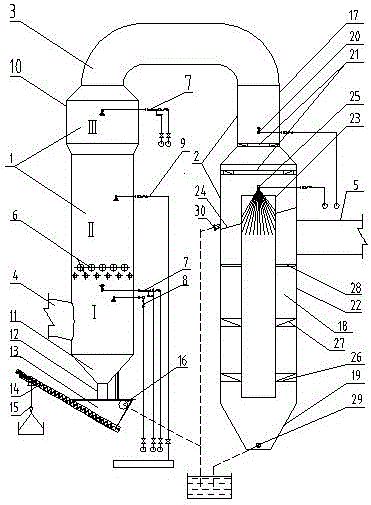

Combined flue gas cleaning system and flue gas cleaning method thereof

The invention provides a combined flue gas cleaning system. The combined flue gas cleaning system comprises a spraying washing tower, and an upstream injection pipe arranged vertically, wherein an inlet of the upstream injection pipe is communicated with a waste flue gas discharge hole, while an outlet of the upstream injection pipe is communicated with the spraying washing tower, and the position at which the outlet of the upstream injection pipe is communicated with the spraying washing tower is located between an upper spraying layer and a lower spraying liquid tank of the spraying washing tower, wherein an upstream spraying layer is arranged inside the upstream injection pipe and the spraying direction of the upstream spraying layer is opposite to the flowing direction of the flue gas. The invention also provides a flue gas cleaning method. Due to the adopted combined flue gas cleaning system, the operation pressure drop, the sewage discharge quantity and the equipment investment can be reduced.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

Intra-tower crystallized ammonia-process desulfurization tower

ActiveCN102974205AIncrease ammonium sulfite contentExtend your lifeDispersed particle separationSolution crystallizationOxidation zonePulp and paper industry

The invention provides an intra-tower crystallized ammonia-process desulfurization tower. The intra-tower crystallized ammonia-process desulfurization tower comprises a tower body, an oxidized air pipe, an ammonia water replenishing pipe, a circulating absorption pump, a discharge pump, and a segmenting structure, wherein a tower pool is formed in the internal space of the tower body; the oxidized air pipe is communicated with the internal space of the tower body and can be used for providing air; the ammonia water replenishing pipe provides ammonia water for the tower pool of the tower body; the circulating absorption pump is communicated with the tower pool, pumps out absorption liquid in the tower pool, circularly leads the pumped absorption liquid into the internal space of the tower body, and absorbs sulfur dioxide contained in smoke; the discharge pump is communicated with the bottom of the tower pool; the segmenting structure is positioned in the tower pool and is used for segmenting the tower pool into an oxidization zone and an non-oxidization zone, and the absorption liquid with absorbed sulfur dioxide contained in the smoke flows in the oxidization zone and the non-oxidization zone; and the ammonia water replenishing pipe consists of a first ammonia water replenishing pipe communicated with the oxidization zone, and a second ammonia water replenishing pipe communicated with the non-oxidization zone; the air provided by the oxidized air pipe is led to the oxidization zone; an inlet of the discharge pump is communicated with the oxidization zone; and an inlet of the circulating absorption pump is communicated with the non-oxidization zone. The intra-tower crystallized ammonia-process desulfurization tower can improve the capability of absorbing the sulfur dioxide.

Owner:GUODIAN LONGYUAN POWER TECH ENG

Single-circulation double-turbulence double-spray ultra-clean desulphurization dedusting tower

PendingCN107261808ASimple structureGuaranteed uptimeUsing liquid separation agentDust controlEngineering

The invention provides a single-circulation double-turbulence double-spray ultra-clean desulphurization dedusting tower, and belongs to the technical field of boiler flue gas purifying. The lower side wall, the top part, and the bottom part of a tower body of the single-circulation double-turbulence double-spray ultra-clean desulphurization dedusting tower are provided with a flue gas inlet, a flue gas outlet, and a thick liquid outlet; the tower bottom is provided with a thick liquid discharge pump connected with the thick liquid outlet; a liquid storage zone is arranged at the internal bottom part of the tower body; an aeration oxygen-increasing device and a disturbance tube are arranged in the liquid storage zone; the disturbance tube is communicated with the liquid storage zone via a thick liquid disturbance pump so as to form a circulation loop; a flue gas inlet gas flue is provided with jet device which is connected with the liquid storage zone via a pipeline provided with a jet pump; a first rotational flow device, a first spray zone, a second rotational flow device, a second spray zone, and a multi-layer demister are arranged in the tower body above the flue gas inlet gas flue from bottom to top; spray pipes of different layers in the first spray zone and the second spray zone are connected with corresponding circulating pumps respectively; and the circulating pumps are communicated with the liquid storage zone respectively. The single-circulation double-turbulence double-spray ultra-clean desulphurization dedusting tower is small in occupied land area, is capable of reducing cost, and is high in efficiency.

Owner:北京威肯泛联能源科技有限公司

Dedusting and deep purification apparatus with high efficiency and low energy consumption for flue gas in metallurgical slag treatment process

InactiveCN106731403AHigh efficiency of dust removal and purificationAchieve Energy Efficiency UpgradesCombination devicesGas treatmentEnvironmental resistanceMetallurgical slag

The invention relates to a dedusting and deep purification apparatus with high efficiency and low energy consumption for flue gas in a metallurgical slag treatment process. The apparatus comprises a tower for spraying, sprinkling and washing and a downstream type gas-liquid tower for deep purification, dehydration and demisting with foam suspension and pneumatic swirling flow; an outlet at the upper end of the tower for spraying, sprinkling and washing and an inlet at the upper end of the downstream type gas-liquid tower for deep purification, dehydration and demisting with foam suspension and pneumatic swirling flow are connected by a connection flue; a sidewall at the lower end of the tower for spraying, sprinkling and washing is provided with a flue gas inlet pipeline; a sidewall of the downstream type gas-liquid tower for deep purification, dehydration and demisting with foam suspension and pneumatic swirling flow is provided with a flue gas outlet pipeline; the tower for spraying, sprinkling and washing employs a wet type multilayer gas-liquid countercurrent contact mode, and the downstream type gas-liquid tower for deep purification, dehydration and demisting with foam suspension and pneumatic swirling flow employs a gas-liquid current contact mode. The dedusting and deep purification apparatus with high efficiency and low energy consumption for flue gas in the metallurgical slag treatment process is adapted to characteristics of high temperature, high moisture and high viscosity flue gas, and realizes ultra-low flue dust emission concentration in a low energy consumption condition, in order to satisfy more strict environmental protection emission requirements of pollution treatment.

Owner:SHANGHAI BAOSTEEL ENERGY TECH +1

Limestone-gypsum wet flue gas desulfurization synergist and preparation method thereof

InactiveCN105251335AIncrease profitGood pH buffering capacityDispersed particle separationOrganic acidFood additive

The present invention discloses a limestone-gypsum wet flue gas desulfurization synergist, which comprises, by weight, 70-90 parts of an organic acid salt, 5-20 parts of an organic anhydride, and 5-15 parts of a surfactant. According to the present invention, the type of the component of the desulfurization synergist is simplified while the obtained synergetic desulfurization effect is good; due to the excellent and stable desulfurization effect, under the same conditions, the used raw materials are less, the production cost of the enterprise is low, and the performance price ratio is high; and the sodium diacetate accounting for the absolute proportion in the desulfurization synergist components is the internationally-recognized efficient, safe and inexpensive food additive, and has characteristics of good safety and good environmental protection during the production process, the storage and transportation process, the use process and other processes.

Owner:麦适(上海)化工有限公司

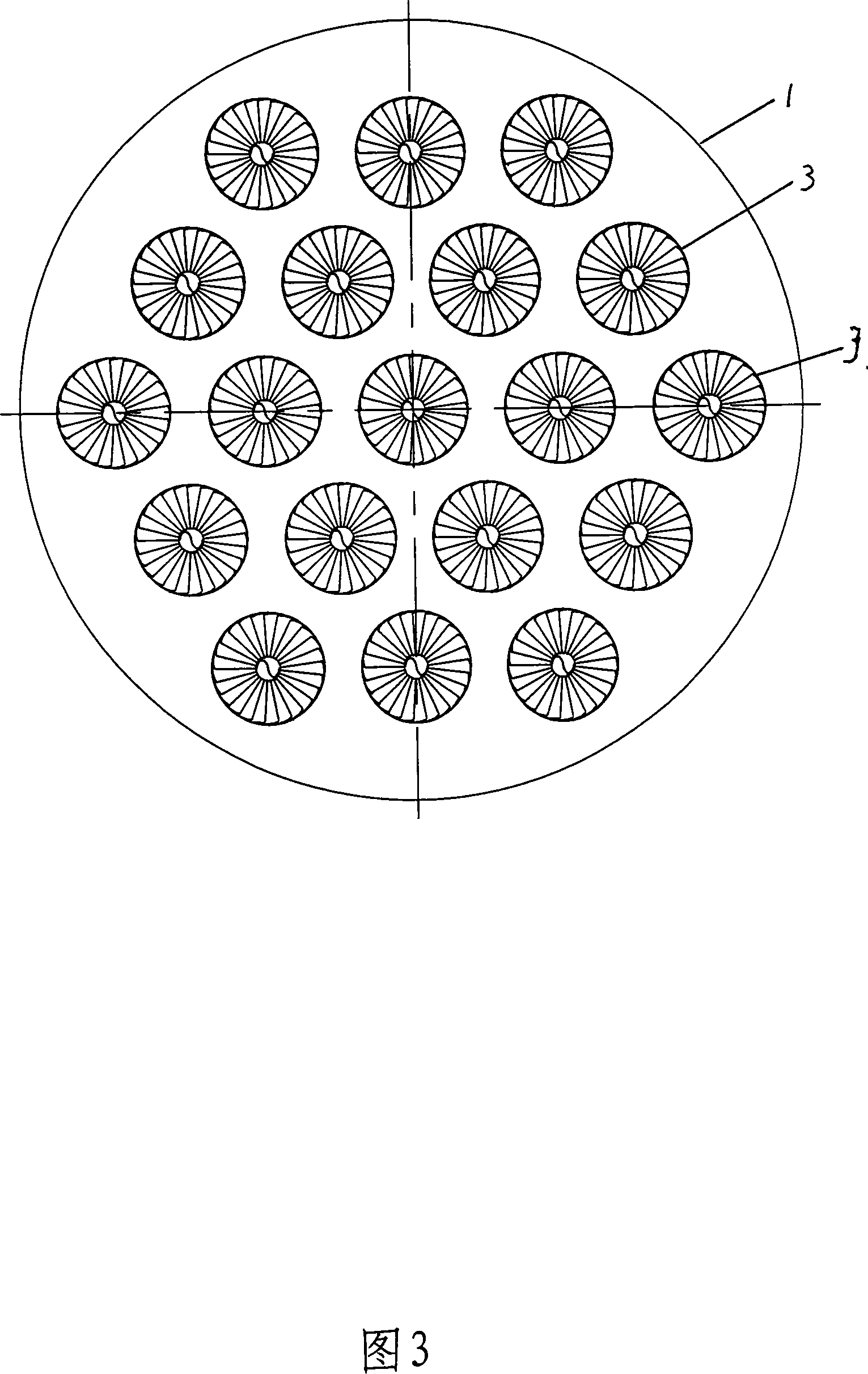

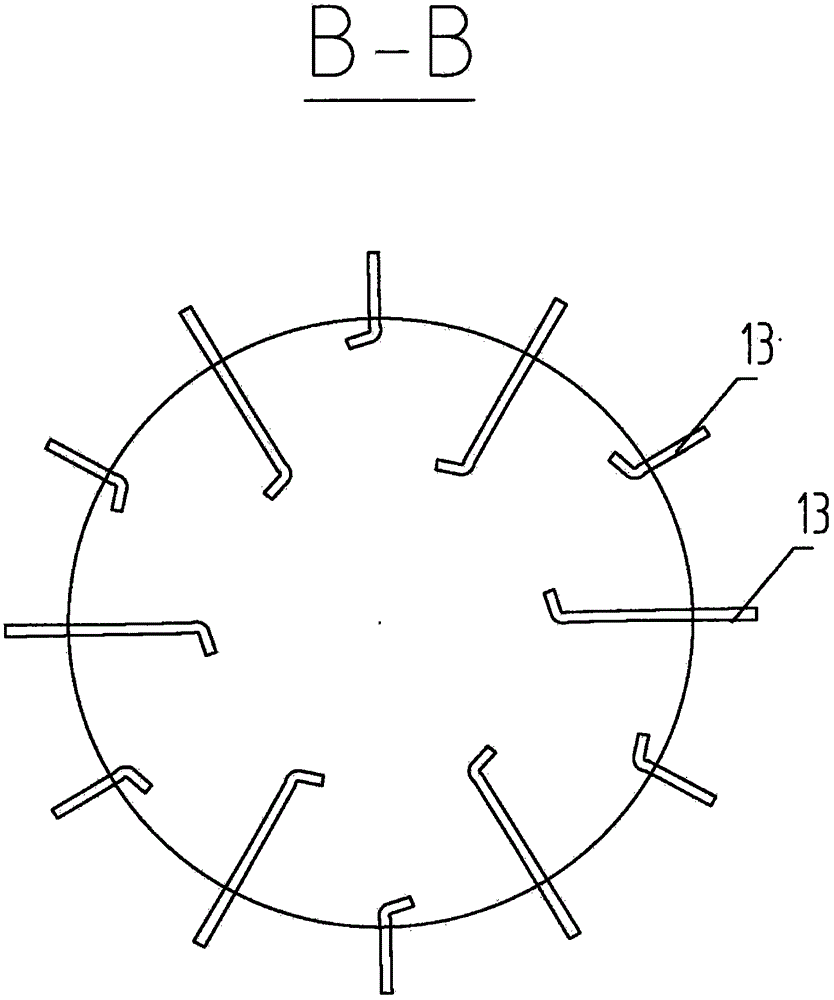

Pneumatic packed rotating tower realizing self-distribution parallel flow

InactiveCN106178768AUniform self-distributing airflowConfiguration parameter reductionUsing liquid separation agentFlue gasEngineering

The invention provides a pneumatic packed rotating tower realizing self-distribution parallel flow. The pneumatic packing rotating tower comprises a desulphurization and dust removal absorption tower body, a rotary demister arranged at the internal upper part of the tower, a self-distribution parallel flow separating plate arranged in the tower, a liquid distributing device arranged on an upper separating plate, annular pneumatic rotational flow devices arranged in holes in the upper separating plate and a lower separating plate, annular packing supporting plates arranged in holes located in the upper separating plate and the lower separating plate, packing press plates and packing, wherein concentric inner and outer cylinders arranged in the holes in the upper separating plate and the lower separating plate are welded with the upper separating plate and the lower separating plate, each inner cylinder adopts a hollow structure with sealed end and is equipped with a gas flow adjusting plate located on the upper separating plate and on the periphery of an outer cylinder of the corresponding hole. By means of the pneumatic packing rotating tower, self-distribution parallel flow of gas in the tower can be realized, the amplification effect of a packed tower is solved, and scaling and blockage in a packing region are avoided due to the internal circulation flow of the packing. The invention aims to provide a packing absorption device with simple structure, high mass transfer efficiency, low investment, low operation and maintenance cost and wide flue gas load application range.

Owner:天津深蓝宇节能减排技术有限公司

Out tower double circulation desulfurization system and desulfurization process thereof

PendingCN107213776AAvoid easy problemsLow failure rateGas treatmentCalcium/strontium/barium sulfatesProcess engineeringSlurry

The invention relates to a limestone-gypsum wet desulphurization of coal-fired boiler flue gas, and in particular relates to an out tower double circulation desulfurization system and a desulfurization process thereof; the out tower double circulation desulfurization system comprises a tower body, an out tower low pH value slurry pool and an out tower high pH value slurry pool; the bottom of the tower body is provided with a flue gas inlet, the top of the tower body is provided with a flue gas outlet, and a low pH value spray zone, a conical liquid collecting bucket, a high pH value spray zone and a demister are arranged fixedly in turn from bottom to top at the position between the flue gas inlet and the flue gas outlet in the tower body. The out tower low pH value slurry pool and the out tower high pH value slurry pool are arranged outside the tower body, so that operation effect is visual, the problems such as bubbling, overflowing, agitator seal position slurry leakage and the like of a traditional desulfurization system with a slurry pond arranged in an absorption tower can be effectively avoided, the failure rate of the desulfurization system is reduced, the desulfurization equipment availability can be improved, the normal unit operation can be ensured, full oxidation and efficient desulfurization can be ensured, and high-quality gypsum can be produced.

Owner:姜顺民

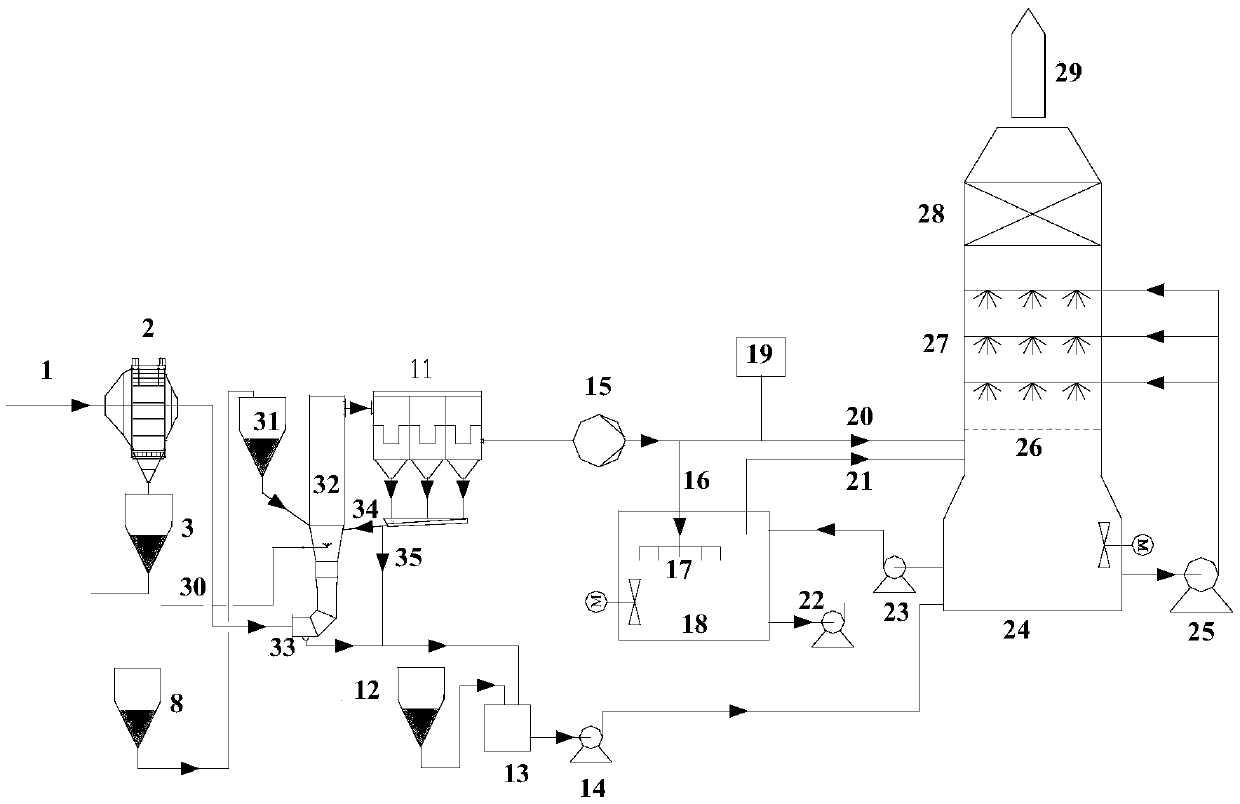

Sintering machine flue gas desulfurization process and device thereof

InactiveCN102527223ALow investment costLow costUsing liquid separation agentCalcium/strontium/barium sulfatesFlue gasSlurry

The invention discloses a sintering machine flue gas desulfurization process and a device thereof, and belongs to the technical field of air pollution control. The device comprises a slurry tank, an absorption tower, an inlet flue channel and an outlet flue channel. A flue gas washing tank is arranged below the inlet flue channel, wherein the flue gas washing tank is communicated with the inlet flue channel. A spraying device is arranged inside the inlet flue channel above the flue gas washing tank, and is communicated with the bottom of the flue gas washing tank through a circulating pump. The process comprises that: before the sintering machine flue gas enters the absorption tower, more than 95% of dust and all acid gases in the sintering machine flue gas are removed through a washing liquid when the sintering machine flue gas flows through the inlet flue channel above the flue gas washing tank, and then the treated sintering machine flue gas enters an absorption tower to carry out desulfurization. The device and the process of the present invention are used for pretreatment of the sintering machine flue gas before the desulfurization to remove the dust and the acid gas in the flue gas so as to improve the desulfurization efficiency and the oxidation rate of the flue gas in the absorption tower, reduce the investment cost and the operation cost of the sintering machine flue gas desulfurization, improve the purity of the desulphurization byproduct gypsum, and achieve the economic benefits of the flue gas desulfurization.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Oxidative acid dust-separation desulfurate denitration technology

InactiveCN1413759ASimplify the purification processSmall footprintDispersed particle separationSulfurNitrogen

An acidic oxidizing process for removing dust, sulfur and nitrogen from the fume of coal-burning furnace features that the fume is cooled and dusted by showering water and the SO2 and NO are dissolved in water, the oxygen is aerated in the water to increase its acidity, and in acidic condition, the metallic oxides in fume are dissolved in water and decomposed into ions to adsorb, dissolve and complex the SO2 and NO in fume, so removing dust, sulfur and nitrogen.

Owner:樊金鑫

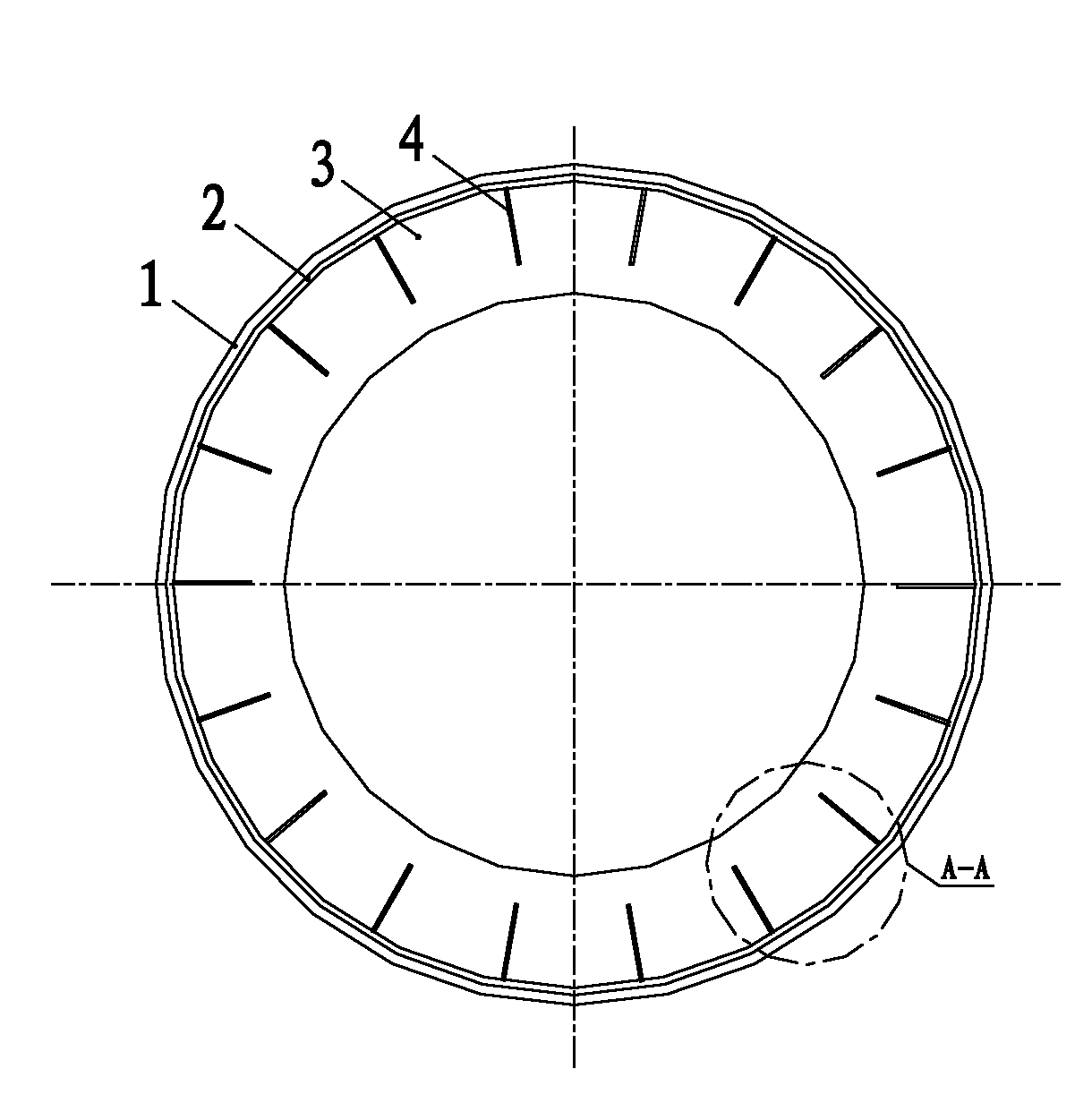

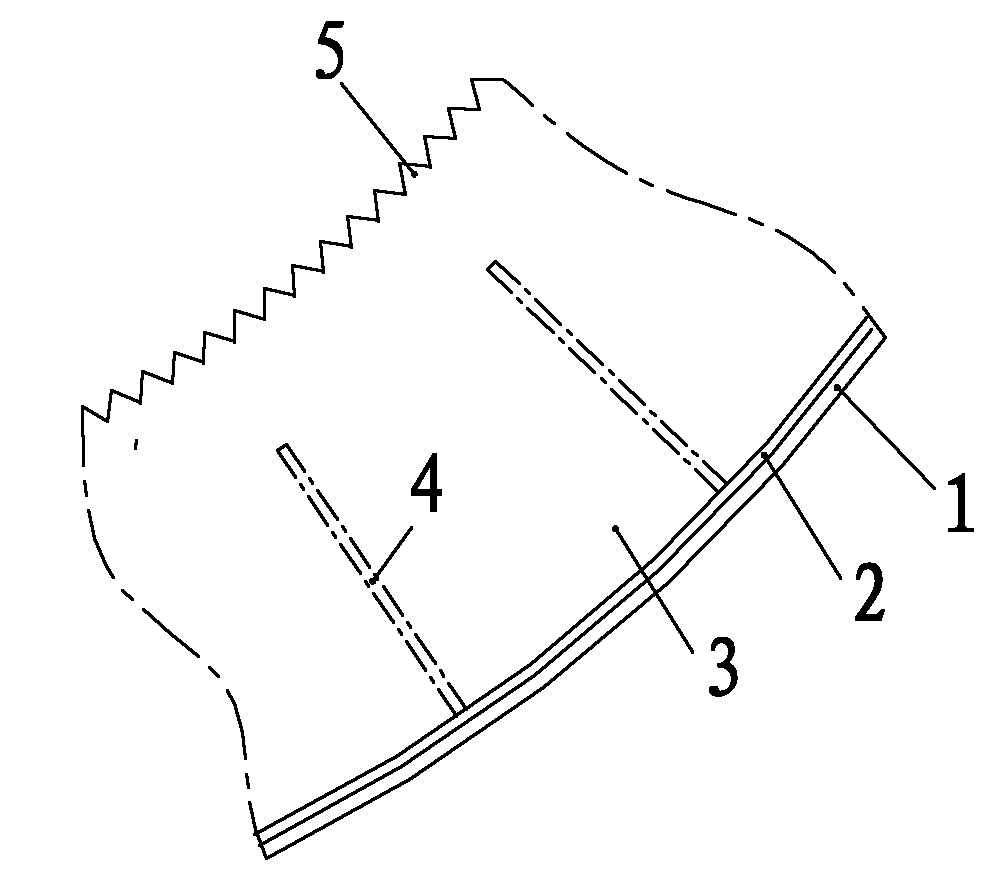

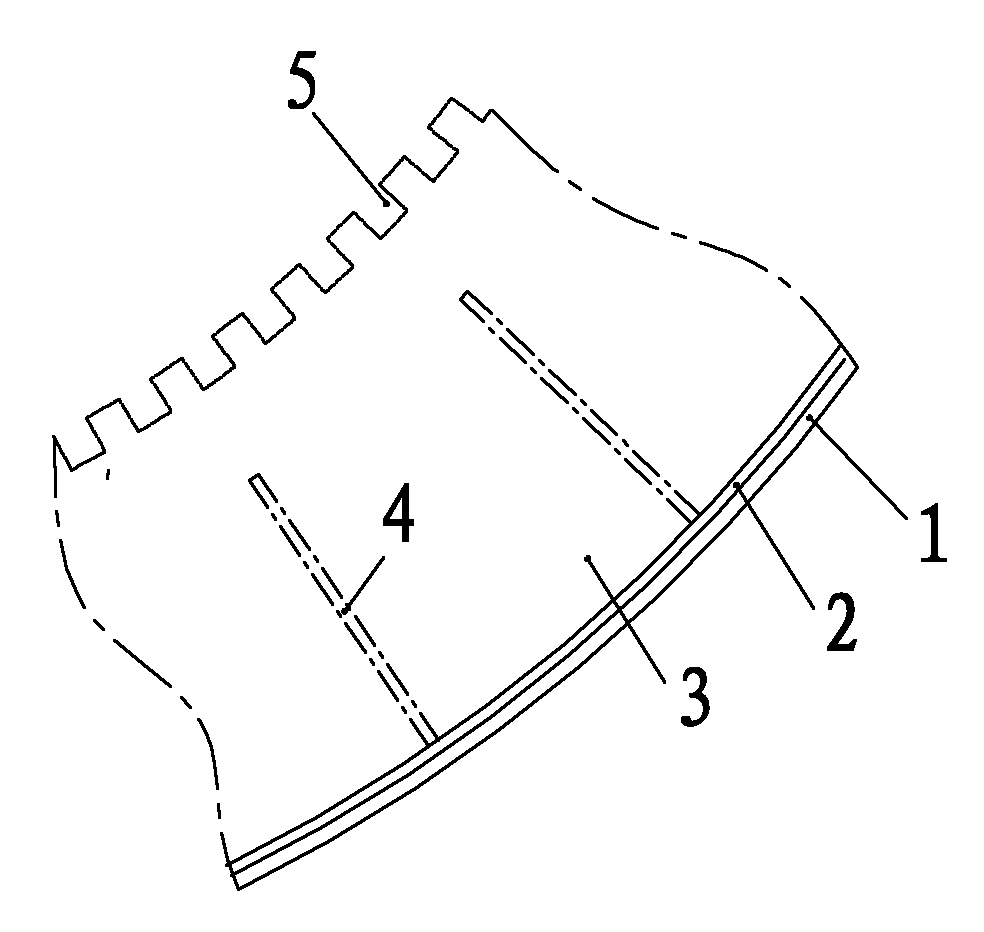

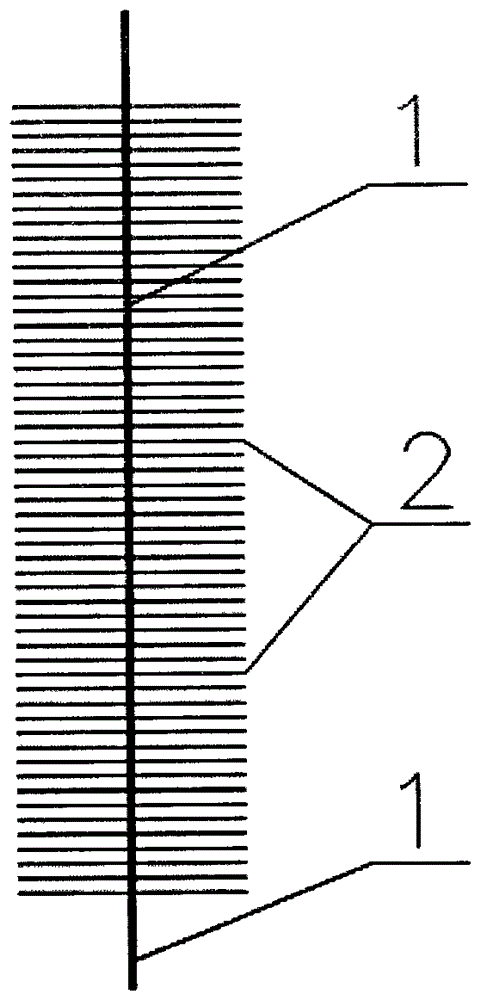

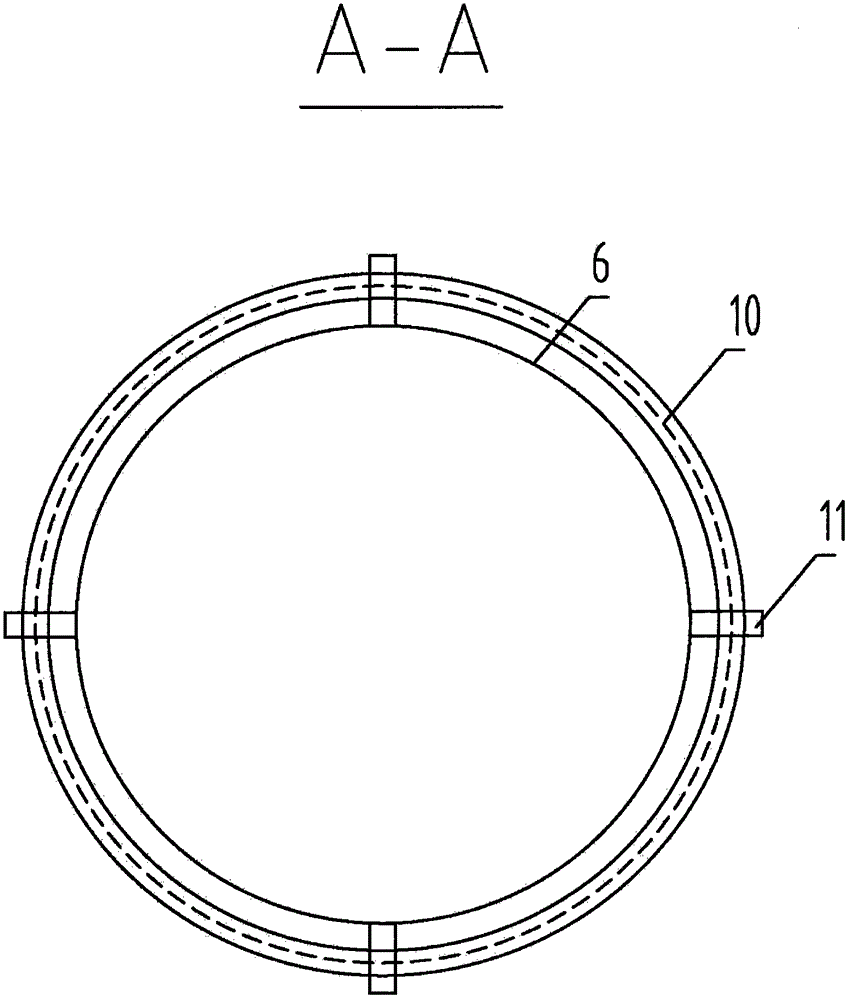

Liquid phase redistributor for spray towers

The invention relates to a liquid phase redistributor for spray towers. The liquid phase redistributor comprises a distribution plate 3 and a support 4 for supporting the distribution plate 3, wherein the distribution plate 3 is annular, and is annularly arranged along the tower wall 1 of a spray tower; the tower wall 1 is provided with a reinforcing plate 2; an annular outer ring of the distribution plate 3 is welded on the tower wall 1 through the reinforcing plate 2; an annular inner ring of the distribution plate 3 is inclined two the lower part of the tower wall 1; and the lower part of the distribution plate 3 is provided with the support 4 which is fixedly connected with the reinforcing plate 2. The liquid phase redistributor can improve the distribution condition that sprayed slurry is dense in the middle and thin at the periphery in the tower, improves the gas absorption efficiency near the tower wall, improves the slurry utilization rate, reduces operating cost of equipment such as a circulating pump, has the advantages of simple manufacturing process, no blockage and entrainment, convenience of installation and simple operation and maintenance, and can be widely applied to various spray towers.

Owner:中钢集团天澄环保科技股份有限公司

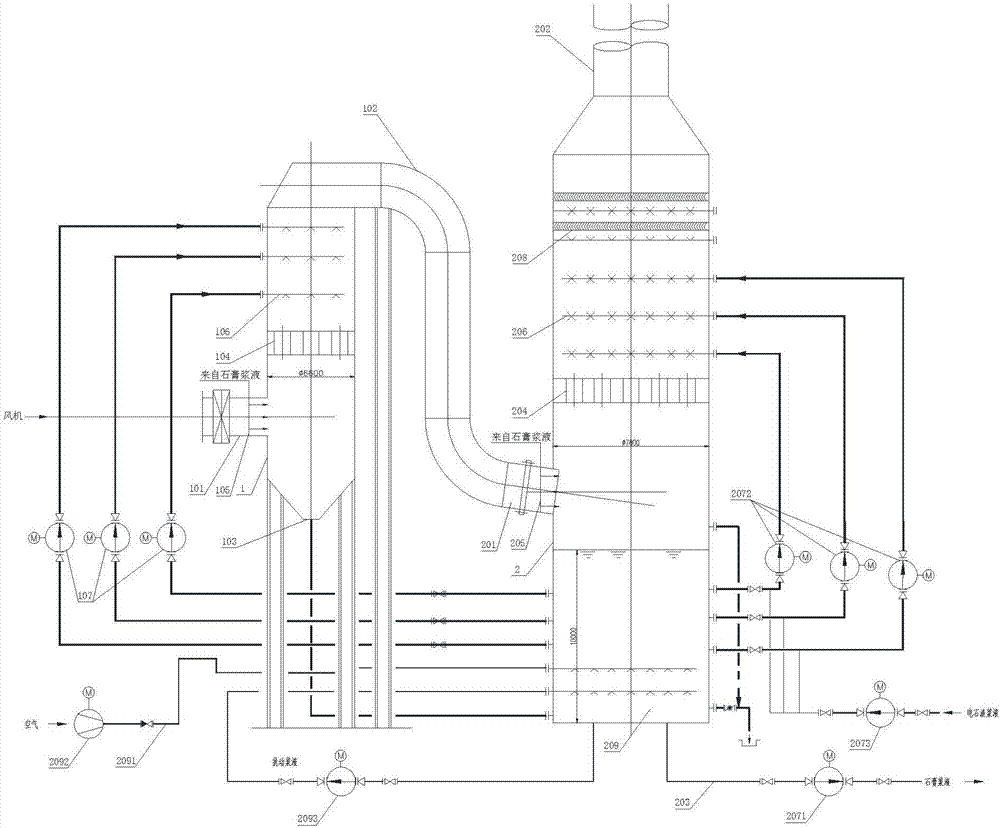

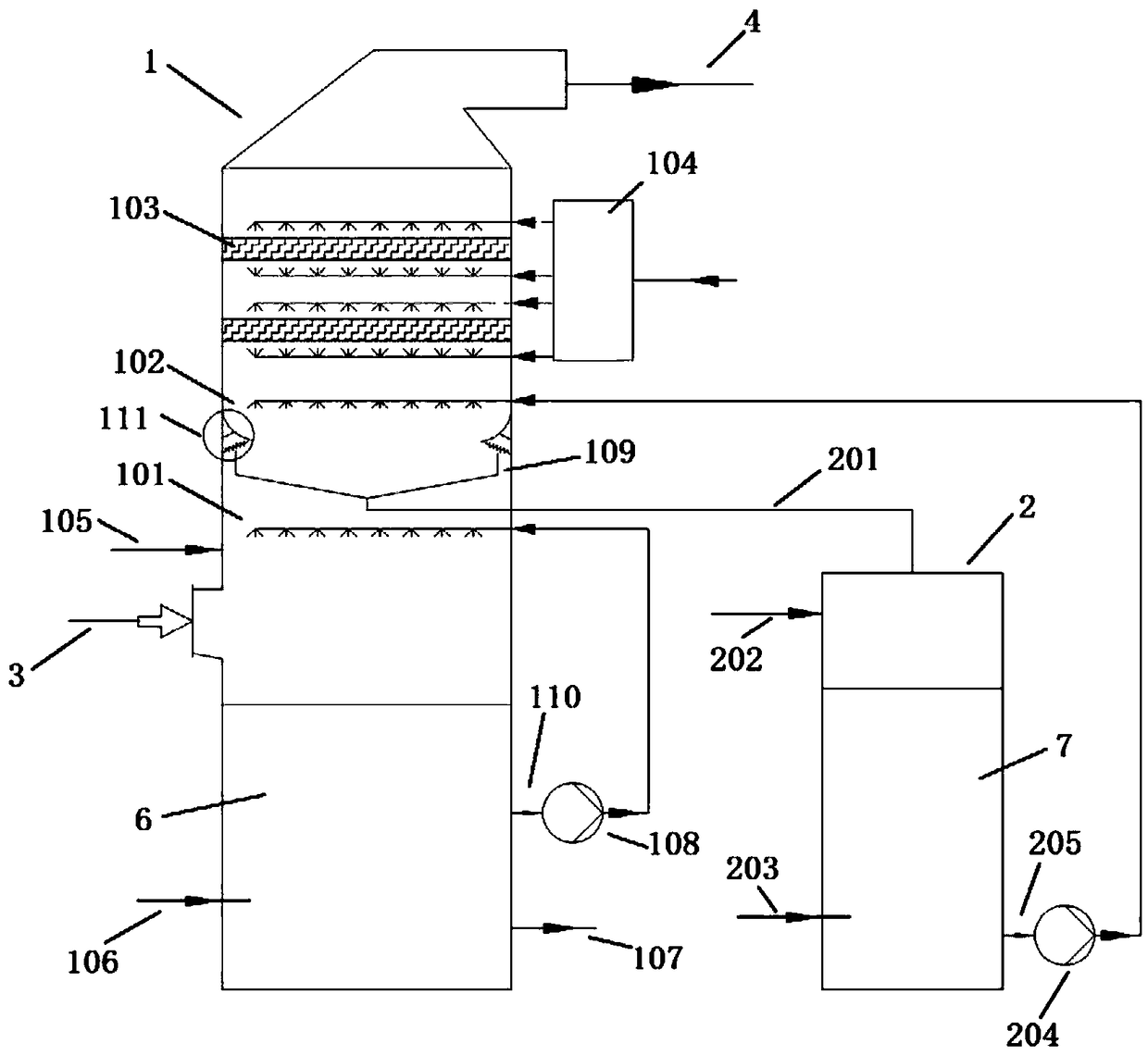

Single-tower and dual-cycle desulfurizing system and desulfurizing technology

InactiveCN109107357AAchieve series effectImprove solubilityGas treatmentCalcium/strontium/barium sulfatesFlue gasSlurry

The invention relates to a single-tower and dual-cycle desulfurizing system which comprises a desulfurizing tower and an oxidizing tower, wherein the tower body of the desulfurizing tower is providedwith a flue gas inlet, a flue gas outlet, a first limestone slurry inlet, a first oxidized air inlet, a gypsum slurry discharge port and a first limestone slurry outlet; a first-level spray layer, a tray, a second-level spray layer and a demister are arranged in the desulfurizing tower from bottom to top; the first limestone slurry outlet is connected with the first-level spray layer through a pipeline and a first limestone slurry circulating pump; the demister is provided with a demister flushing water system; the tray is connected with the oxidizing tower through a pipeline; the oxidizing tower is also provided with a second limestone slurry inlet, a second oxidized air inlet and a second limestone slurry outlet; the second limestone slurry outlet is connected with the second-level spraylayer through a pipeline and a second limestone slurry circulating pump. The desulfurizing system provided by the invention realizes a higher desulfurizing efficiency and also can obtain gypsum withperfect quality.

Owner:吉林省京能水处理技术有限公司

Wet method flue gas-desulfurizing absorption tower with dual speed sprinkling and desulfurizing absorption method thereof

ActiveCN1843582AAvoid depositionReduce operating power consumptionDispersed particle separationFlue gasSlurry

The invention relates to a dual-speed spray smoke wet desulfuration adsorption tower and relative desulfuration adsorption method. Wherein, the middle of tower is connected to the purified smoke outlet tube; the outlet of said tube is mounted with a defroster; the top of tower is connected to the former smoke inlet tube; the bottom of tower is a slurry tank; the middle of tower is a desulfuration reaction section; the inlet of the connection between the former smoke inlet tube and the top part of tower is mounted with the first-stage spray device; the purified smoke outlet tube at the middle of tower is mounted with the second-stage spray device; said two spray devices are individually through to the limestone slurry cycle pump outside the adsorption tower and the slurry tank at the bottom of adsorption; the slurry tank is inserted with forced oxygenation air tube and the mixing oar; the bottom of tower is connected to the gesso outlet pump via the gesso outlet tube. The invention can effectively utilize the space at the inlet of adsorption tower; increase the area of first-stage adsorption reaction section to react the smoke with the slurry in two different flow speed; therefore, the smoke can react with the slurry concurrent or reversed to strengthen the reaction effect, with saved energy and improved desulfuration efficiency.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

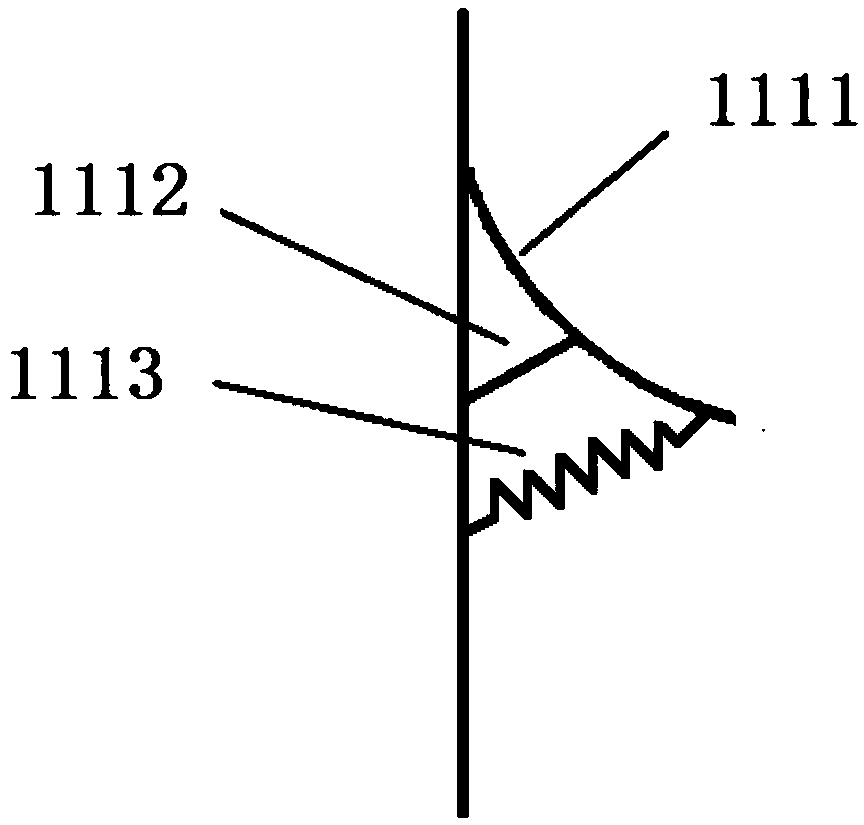

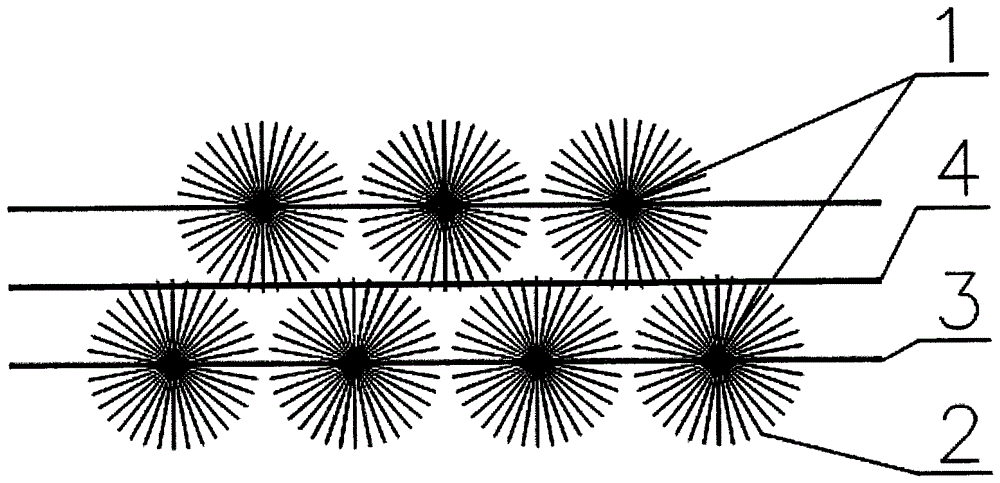

Elastic needle wire packing and composed air purification forest thereof

InactiveCN105749852ASolve the purification problemReduce operating energy consumptionUsing liquid separation agentChemical/physical/physico-chemical processesParticulatesEnvironmental resistance

The invention discloses an elastic needle wire packing for air purification and an engineering use method thereof, and relates to mass transfer purification products and technologies in the field of environment friendliness. A plastic elastic wire is alternately stranded on a central rope, elastic needle wire packing monomers in uniform radiation is prepared, and one end or two ends of the packing monomer center rope are fixedly hung on towers, structures or hanging rods in a frame, so that elastic wires are stereoscopically and uniformly spread and filled in an effective area like a forest, the packing is wetted or a water flow is formed by virtue of spray of a spraying device, air blows to the packing forest from any direction, air and liquid can intensively collide and cut on the packing and fully contact to realize high-efficiency mass transfer, particulate matters are washed, soluble matters are absorbed by the liquid, biodegradable organics are dissolved in the absorbing liquid and form biological films on the packing to be degraded, and air is purified. The invention provides widened application of elastic space packing for wastewater treatment, which is just like that a medicine sildenafil for treating cardiovascular diseases is invented by accident to be used for treating male erectil dysfunction.

Owner:路林茫

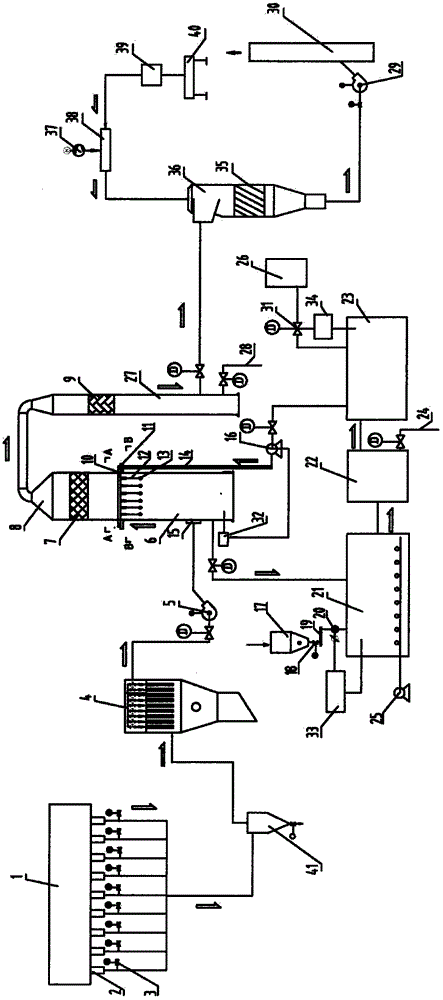

Flue gas desulfurization and denitrification equipment of sintering machine

InactiveCN106152799AFull desulfurization reactionHigh desulfurization rateWaste heat treatmentEngineeringSmall footprint

The invention discloses flue gas desulfurization and denitrification equipment of a sintering machine. The flue gas desulfurization and denitrification equipment comprises the sintering machine, an air box, a cyclone dust collector, a bag-type dust collector, a booster fan, a desulfurizing tower, a dehumidification purifying tower, an SCR reactor, a draught fan and a chimney and is characterized in that the sintering machine is sequentially connected with the air box, the cyclone dust collector, the bag-type dust collector, the booster fan, the desulfurizing tower, the dehumidification purifying tower, the SCR reactor, the draught fan and the chimney; an electric control valve is connected between the air box and the cyclone dust collector; an outlet of the draught fan is connected with an air inlet of the desulfurizing tower; a pH detection controller is arranged on the side wall of the lower part of the air inlet of the desulfurizing tower and is connected with a desulfurizing pump through a control cable; the lower part of the air inlet of the desulfurizing tower is connected with an aeration replacement reaction tank through a pipeline; the aeration replacement reaction tank is connected with a sedimentation tank; and a Roots blower is arranged on one side of the aeration replacement reaction tank. The flue gas desulfurization and denitrification equipment has the following advantages that the desulfurization efficiency is high, the investment operating cost is low, the maintenance is easy, the occupied area is small, and the service life of the equipment is long.

Owner:WUXI SHENGJIE ENVIRONMENTAL PROTECTION TECHCO LTD

Integrated desulfuration and dust removal method for medium and small boiler flue gas

InactiveCN102085450AAvoid enteringSuitable for desulfurization transformationCombination devicesFlue gasEngineering

The invention discloses an integrated desulfuration and dust removal method for medium and small boiler flue gas, which comprises that: after the boiler flue gas is subjected to dust removal through an electric dust remover, the boiler flue gas is tangentially fed into a desulfuration tower under the traction of a draft fan to perform desulfuration reaction, the desulfurized and water mist removed flue gas can be directly fed into a flue and discharged by a chimney; and a mode of circular absorption in the tower is adopted for the desulfuration solution, kettle solution of the desulfuration tower flows into a circulation tank through a pipeline, the solution is first added into a crystallization tank, crystal seeds are added to induce the crystallization of gypsum, the crystallized circulation solution is fed into a regeneration tank for regeneration, the regenerated desulfuration solution is added into a sedimentation tank for sedimentation, and the supernate and the desulfuration solution fed into the crystallization tank are pumped into the desulfuration tower in a certain ratio through a circulating pump and serve as desulfuration solution for the desulfuration reaction.

Owner:秦皇岛双轮环保科技股份有限公司

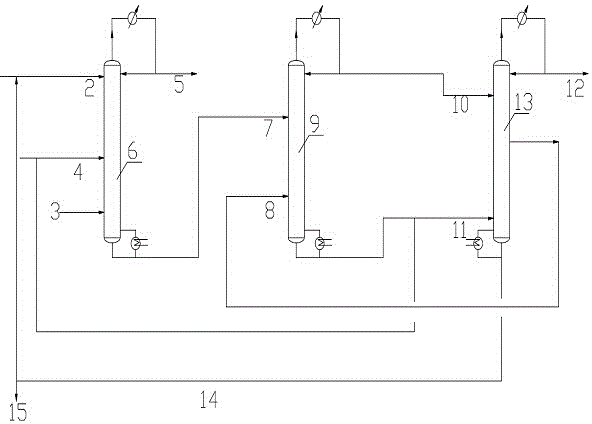

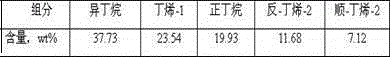

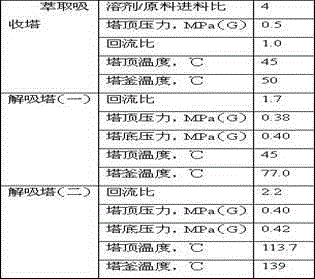

Novel technology for concentrating post-MTBE C4

ActiveCN105712820APromote absorptionReduce liquid to gas ratioDistillation purification/separationAbsorption purification/separationTowerMechanical engineering

The invention discloses a novel technology for concentrating post-MTBE C4. The technology comprises that a C4 raw material is introduced into an extraction absorbing tower through the lower part of the extraction absorbing tower, absorbents are introduced into the extraction absorbing tower through the upper part and the middle part of the extraction absorbing tower and are respectively used as an absorbent 1 and an absorbent 2, the material at the top of the extraction absorbing tower is butane, the material at the bottom of the extraction absorbing tower enters the upper part of an desorption tower 1, the material at the top of the desorption tower 1 enters the upper part of an desorption tower 2, a part of the material at the tower bottom is used as the absorbent 2 for recycle, a part of the material at the tower bottom enters the lower part of the desorption tower 2, the material at the top of the desorption tower 2 is a butene product, the material collected from the middle of the desorption tower 2 is circulated to the lower part of the desorption tower 1 and the material at the desorption tower 2 bottom as the absorbent 1 is recycled. The technology can produce a high-purity butane product and a butylene product under conditions of a low tower bottom temperature and a low liquid-gas ratio and has a butylene recovery rate of 99% or more and an n-butene concentration greater than or equal to 99.9%.

Owner:CHINA PETROLEUM & CHEM CORP +1

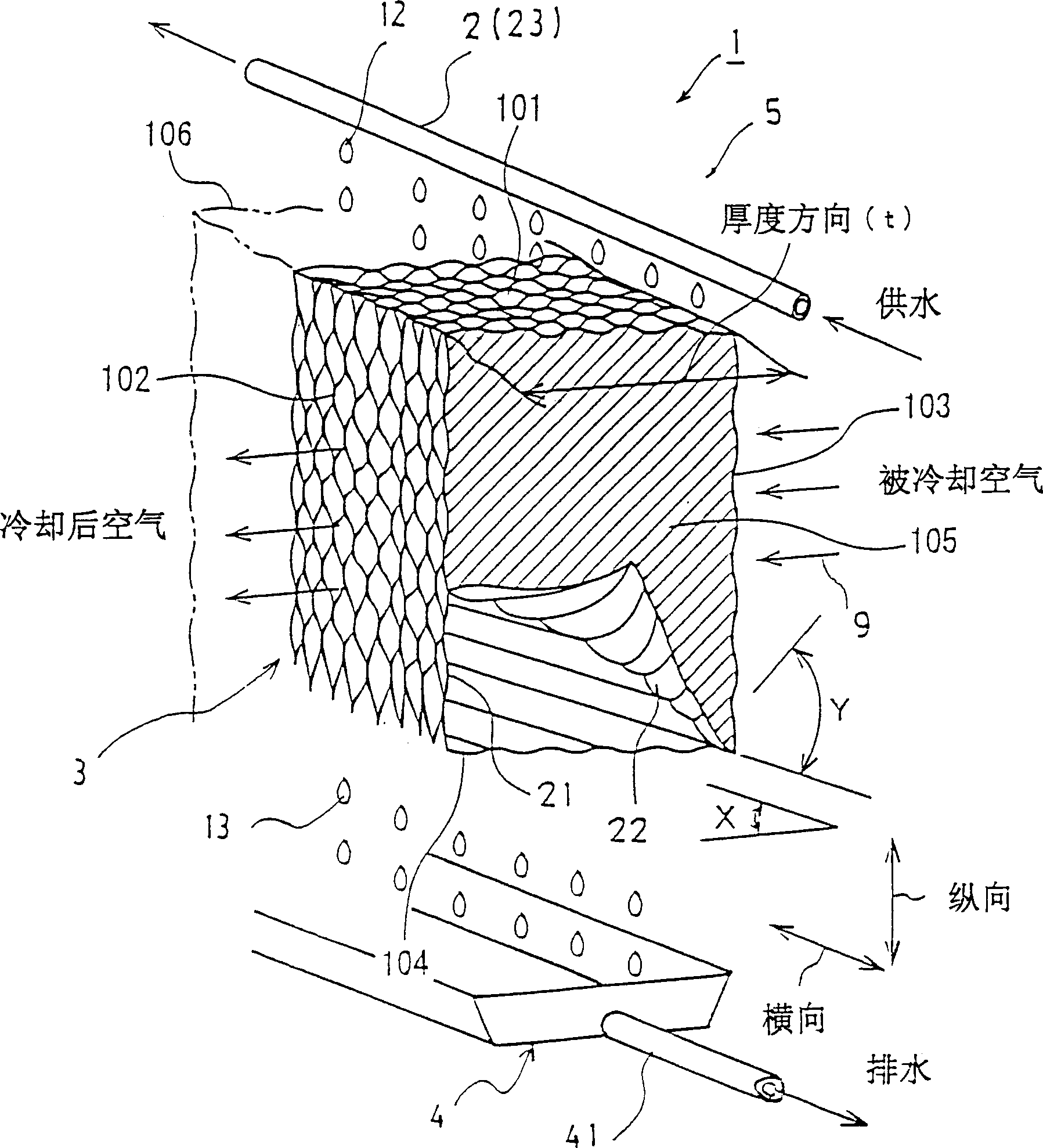

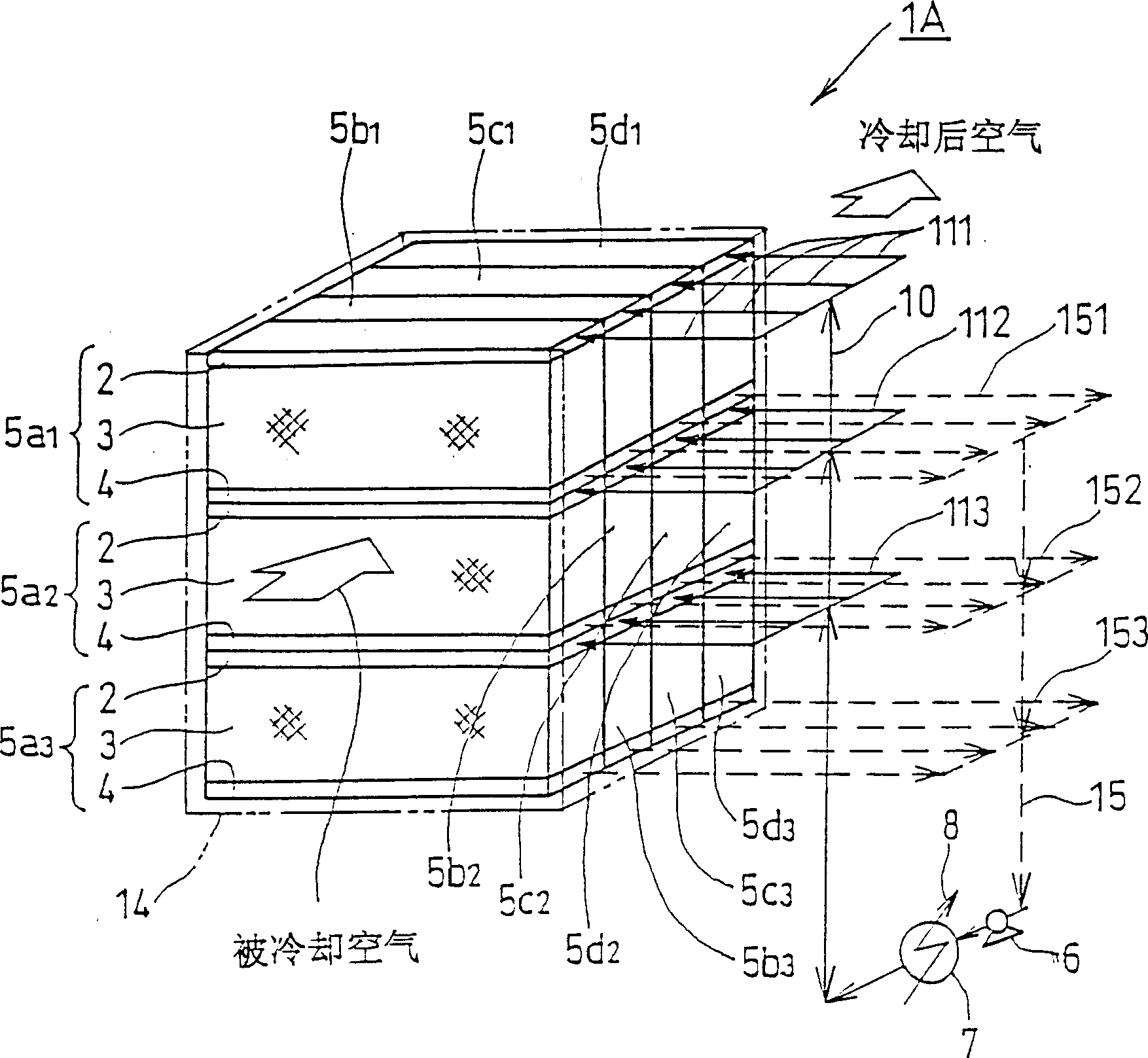

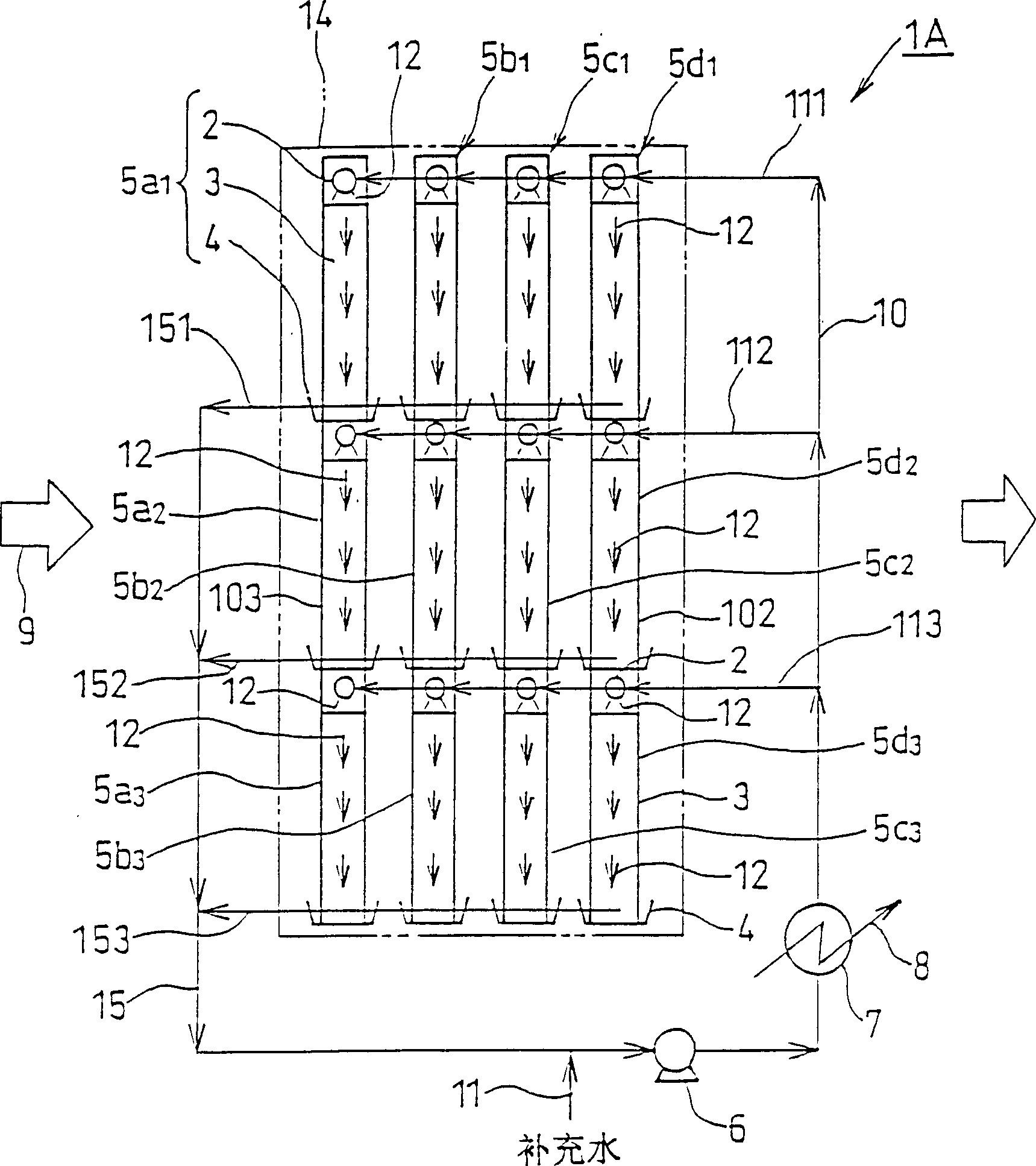

Air cooling apparatus and air cooling method

InactiveCN1434253ALow costHigh thermal efficiencyDomestic cooling apparatusFree-cooling systemsHoneycombEngineering

An air cooling device includes at least one cooling unit which includes an oblique honeycomb having front, rear, upper, and lower openings and disposed so that air to be cooled is introduced into the front opening and cooled air is discharged from the rear opening, a cooling water supply means which supplies cooling water to the upper opening of the oblique honeycomb, and a water receiving section which receives discharge water discharged from the lower opening of the oblique honeycomb, and a blower means which introduces air to be cooled into the front opening of the oblique honeycomb and allows cooled air to be discharged from the rear opening of the oblique honeycomb, wherein the height of one oblique honeycomb in the cooling unit is 200 to 800 mm. The air cooling device has high thermal efficiency, a small liquid-gas ratio, and a small pressure drop, and is capable of saving space and energy.

Owner:大见忠弘 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com