Patents

Literature

724 results about "Adsorption reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

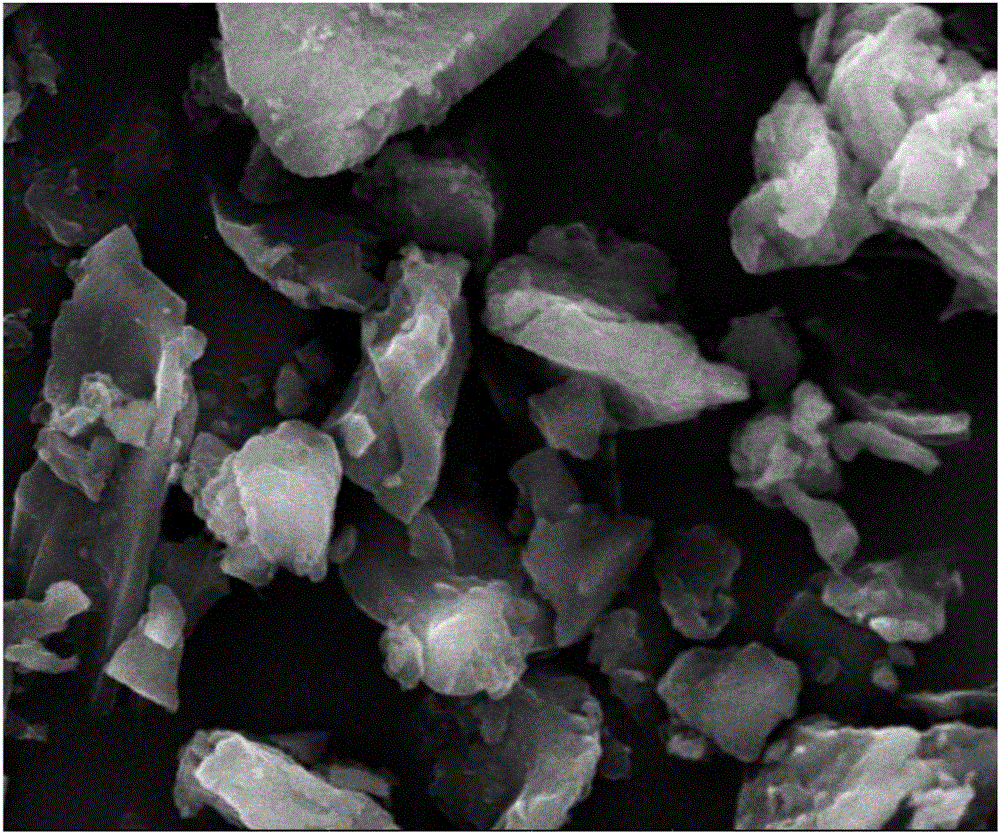

Nano-compound adsorbent for efficiently removing trace phosphorus, arsenic and antimony from water body

ActiveCN101804333ARealize deep purificationAchieving processing powerOther chemical processesWater/sewage treatment by sorptionDivinylbenzeneSorbent

The invention discloses a nano-compound adsorbent for efficiently removing trace phosphorus, arsenic and antimony from a water body, belonging to the technical field of environment functional materials. The organic framework of the nano-compound adsorbent of the invention is hypercrosslinked styrene-divinylbenzene ion exchange resin, a functional group for surface binding of the organic framework is a quaternary ammonium group or pyridyl, nano-inorganic functional particles are loaded, and the total volume of 1-20nm nano-pores accounts for greater than or equal to 90% of the total volume of all the pores of the organic framework. The nano-inorganic functional particles are nano-hydrated ferric oxide or nano-hydrated manganese oxide. The nano-compound adsorbent of the invention has more obvious nano effect, strong reaction activity, great adsorption capacity and high selectivity, well solves the defects of obvious swelling, weak adsorption reaction activity, small adsorption capacity, lower adsorption selectivity and the like of the existing nano-compound adsorbent, and is more suitable for advanced treatment of micro-pollution of water and waste water.

Owner:NANJING UNIV

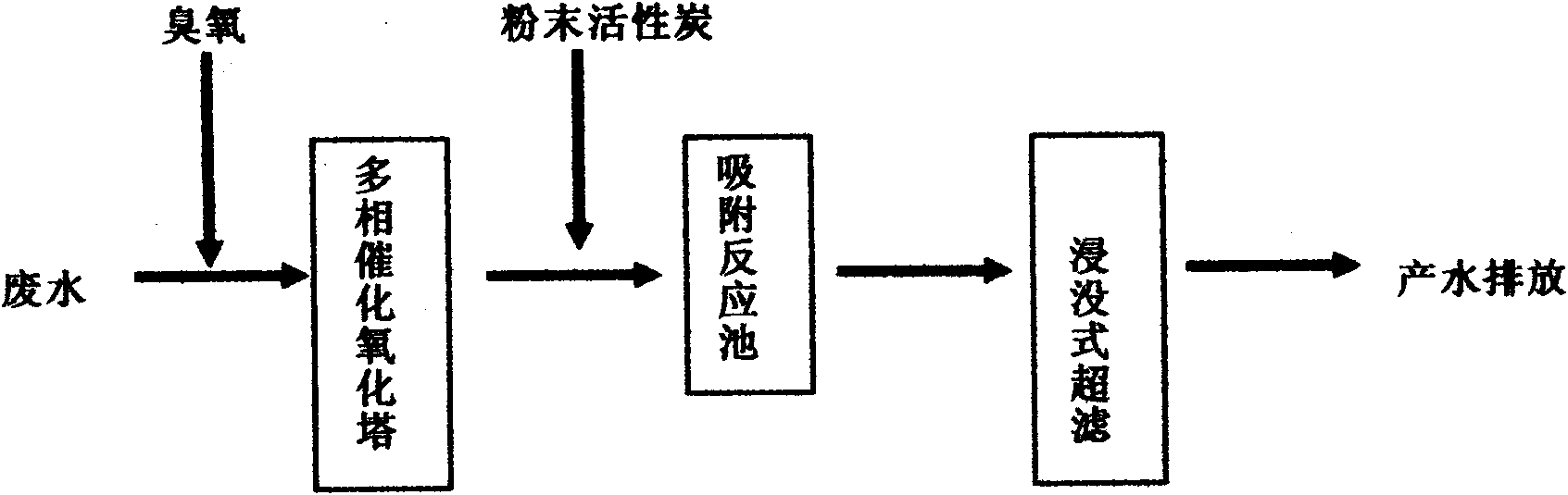

Reverse osmosis concentrated water treatment method

ActiveCN102372376AGuaranteed treatment effectShorten the oxidation reaction timeWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentUltrafiltrationCatalytic oxidation

A reverse osmosis concentrated water treatment method comprises the following steps: (1) adopting multi-phase catalytic oxidation technique to achieve deep oxidation and maximally remove organic pollutants in wastewater; (2) adding the effluent after catalytic oxidation into an adsorption reaction tank, in which a proper amount of powdered active carbon is added, and fully reacting for a period of time by aeration or stirring and the like to adsorb organic pollutants in the wastewater, wherein the adsorption effect depends on the addition amount of the powdered active carbon; and (3) filtering the effluent after the adsorption reaction by submerged ultrafiltration to further improve the quality of the effluent, which can be discharged directly. According to the reverse osmosis concentrated water treatment method, the oxidation reaction time can be reduced and the oxidation reaction effect can be enhanced at the same time, and not only can the wastewater treatment effect be ensured but also the treatment cost is greatly lowered when the method is in combination with the powdered active carbon adsorption process. In addition, the method has the advantages of simple process flow and high operability, and is worth popularizing.

Owner:CHINA PETROLEUM & CHEM CORP +1

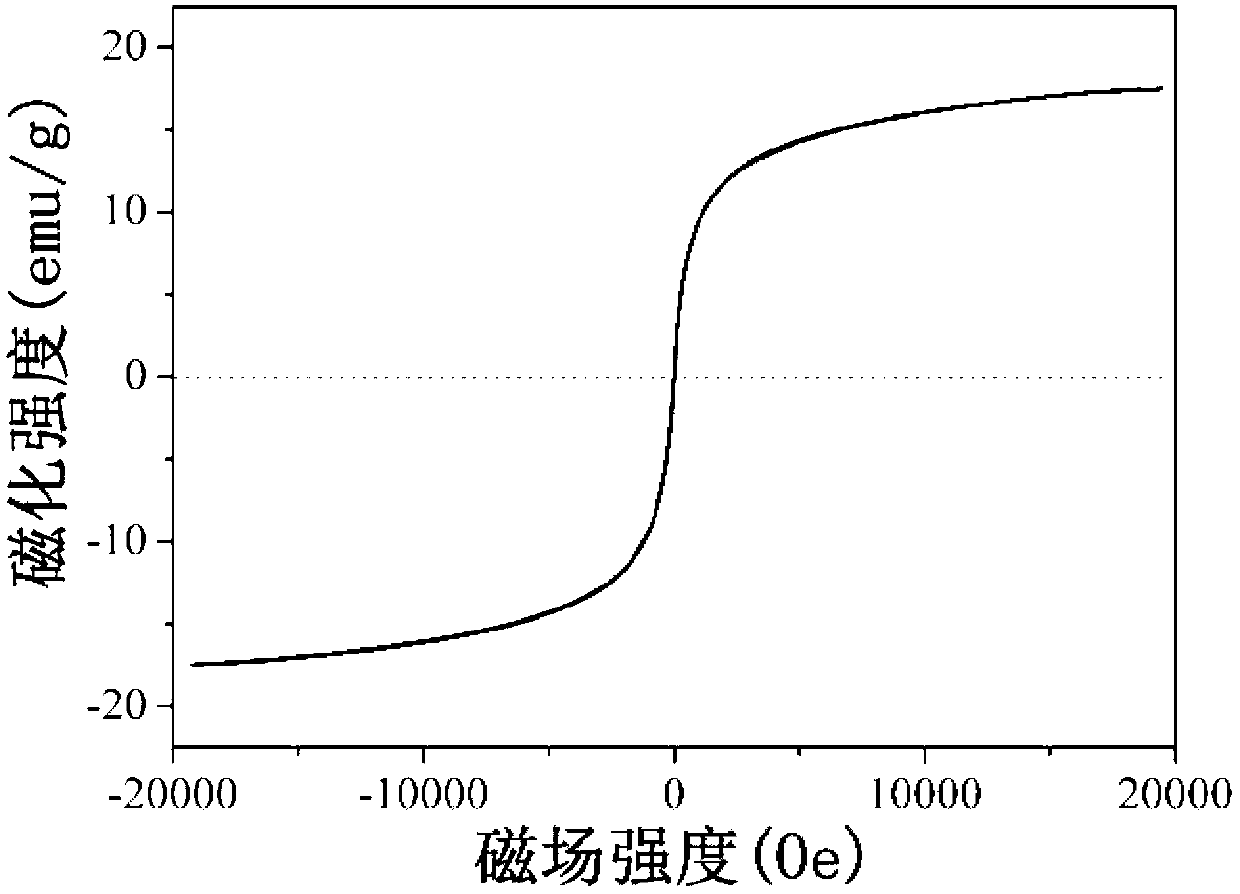

Beta cyclodextrin and magnetic oxidized graphene composite and preparation method and applications thereof

InactiveCN103341350AMagnetic easyLarge specific surface areaOther chemical processesWater/sewage treatment by magnetic/electric fieldsEthylenediamineWastewater

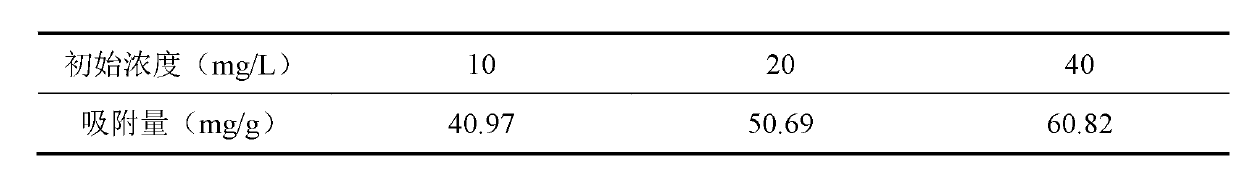

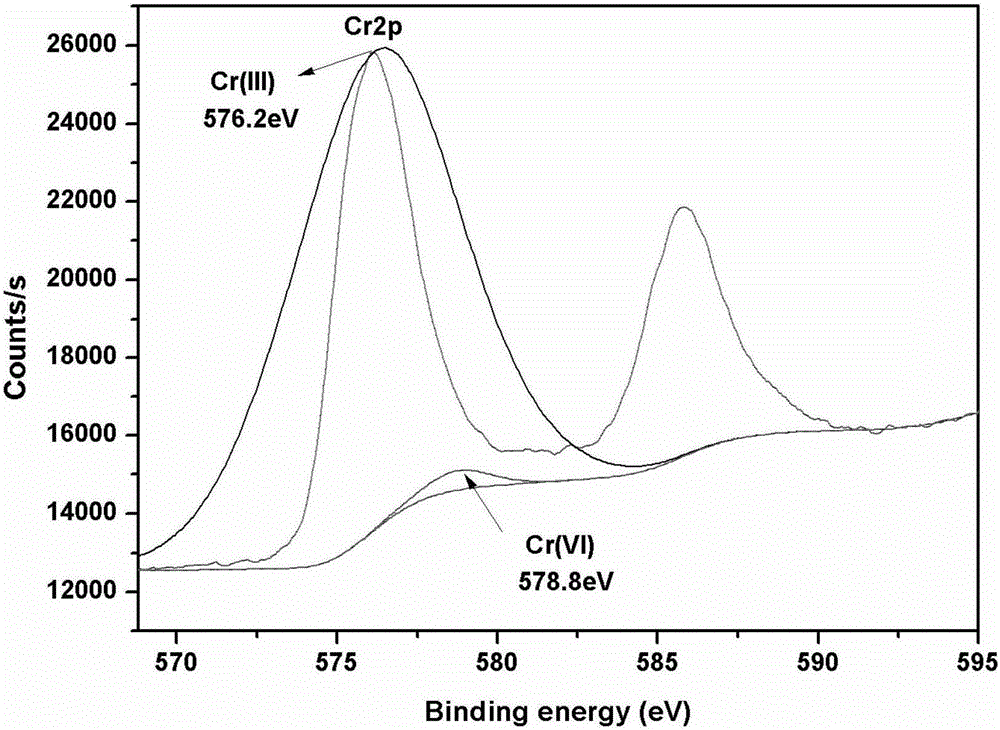

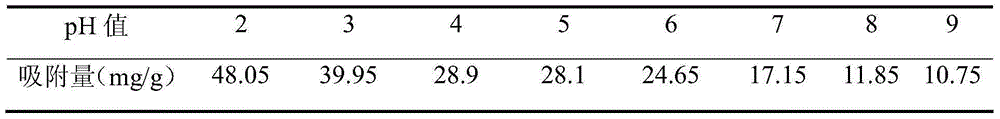

The invention discloses a method for removing the hexavalent chromium in waste water by using beta cyclodextrin and magnetic oxidized graphene composite. The method comprises the steps of: adding the composite into hexavalent chromium waste water with the concentration of 5-100g / L, wherein the usage amount of the composite is 0.1-1g / L; regulating the pH to be 3-8, conducting oscillation adsorption reaction for 1-49h at 10-50 DEG C, and then separating the composite from the waste water through a magnet. The beta cyclodextrin and magnetic oxidized graphene composite and the preparation method and applications thereof have the advantages of low cost, simple technique, high adsorptive property, easiness in separation, environmental protection and the like.

Owner:HUNAN UNIV

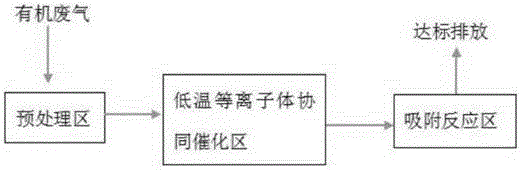

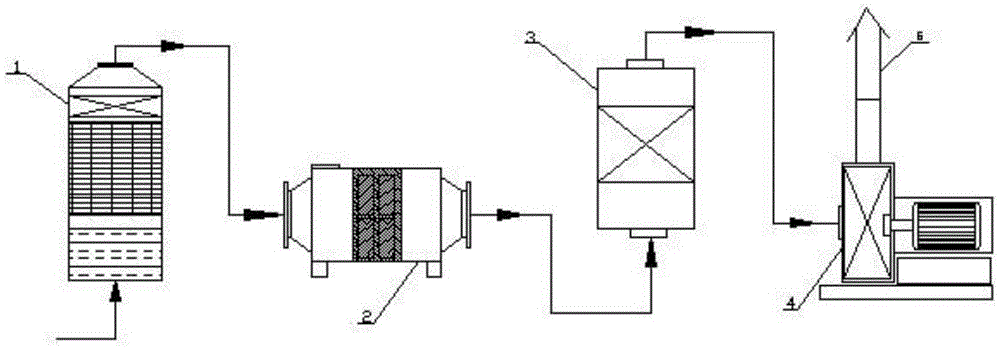

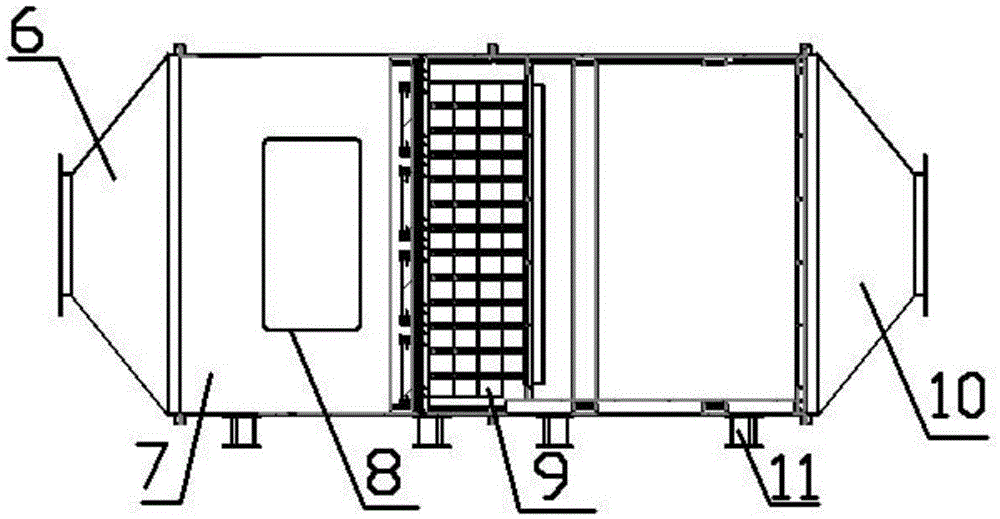

Method for treating organic waste gas through low-temperature plasma concerted catalysis

InactiveCN105521705AAvoid not enoughAvoid absorptionGas treatmentDispersed particle separationHigh energySorbent

The invention discloses a method for treating an organic waste gas through low-temperature plasma concerted catalysis. The treating steps are as follows: (1) pre-treating the organic waste gas to be treated, using manners of water cooling and filtering to perform cooling, dust removal and dehumidification on the organic waste gas; (2) sending the pre-treated organic waste gas into a low-temperature plasma concerted catalysis area, decomposing the organic waste gas by using low-temperature plasma concerted catalysis, and generating harmless micro-molecules; (3) sending the gas treated in the low-temperature plasma concerted catalysis area into an adsorption reaction area, and adsorbing organic molecules and high energy molecules which are not completely reacted by using an adsorbent, so as to further oxidize and decompose the organic molecules; (4) discharging the pollution-free gas after decomposing and oxidization through a discharge tower. The method has high purification efficiency on the organic waste gas, is good in effect, is less affected by various environments and external conditions, and especially has high purification efficiency on the organic waste gas with high flow, low concentration, and complex composition.

Owner:CAS NEW WORLD HEFEI ENVIRONMENTAL PROTECTION TECH CO LTD

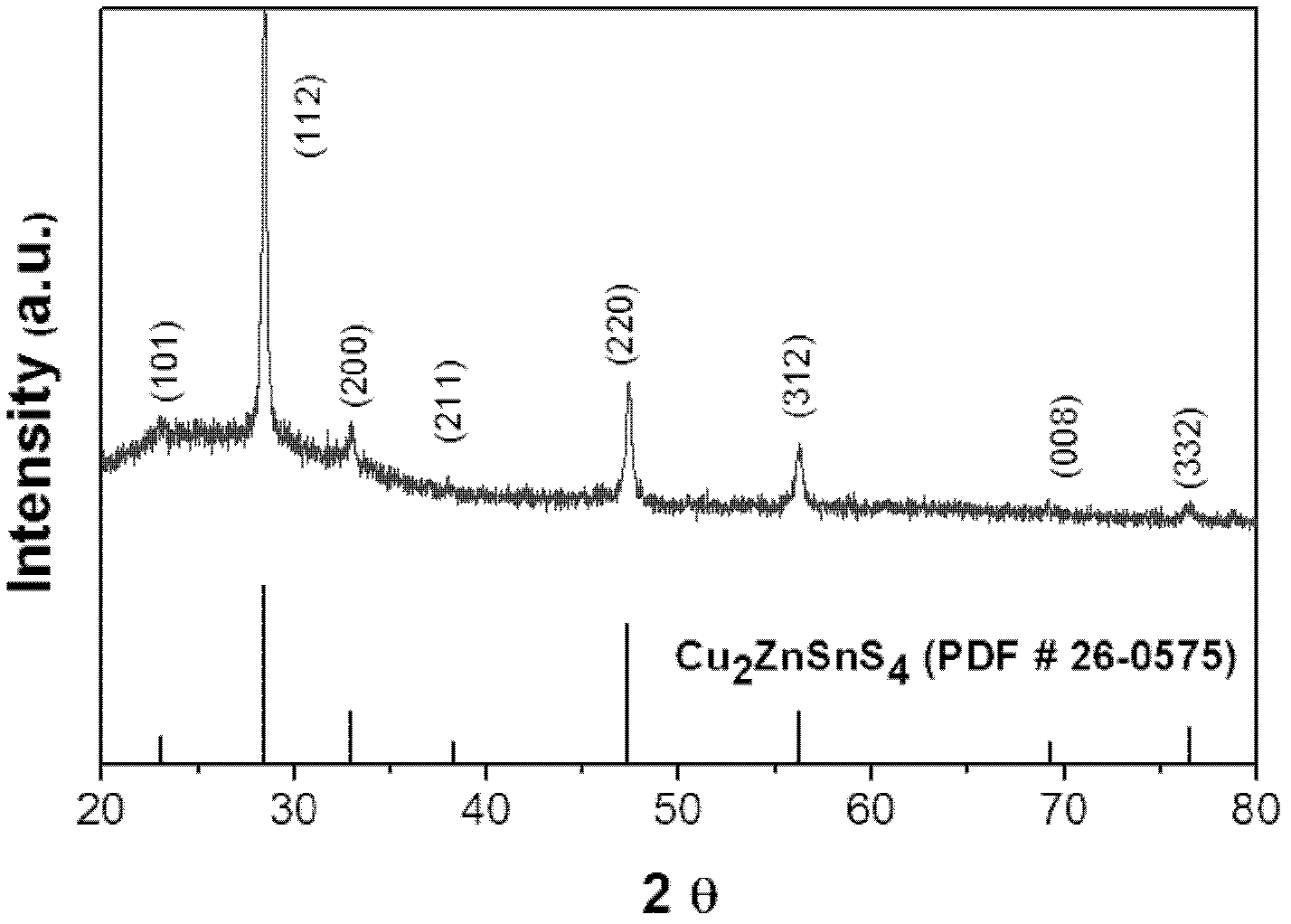

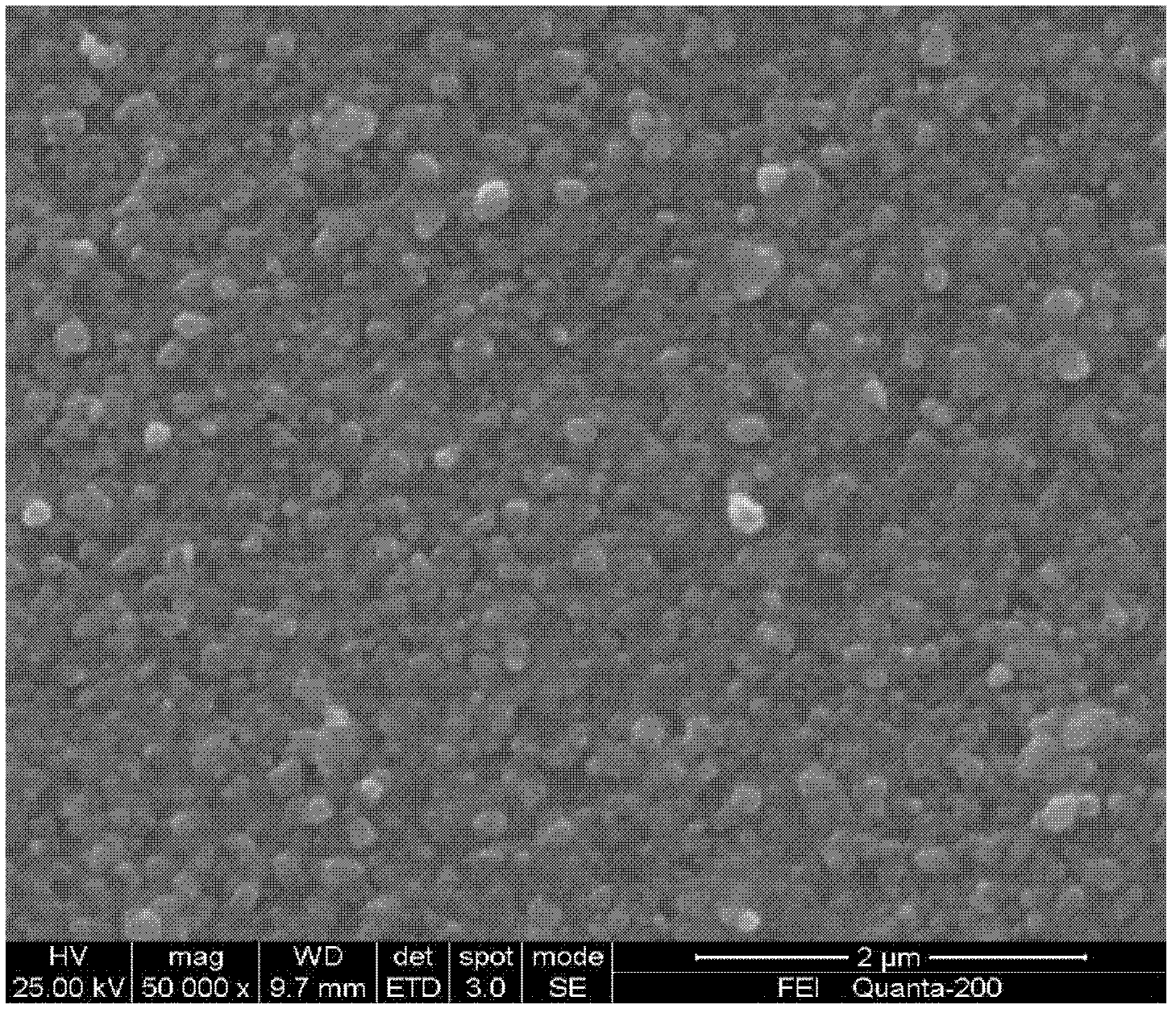

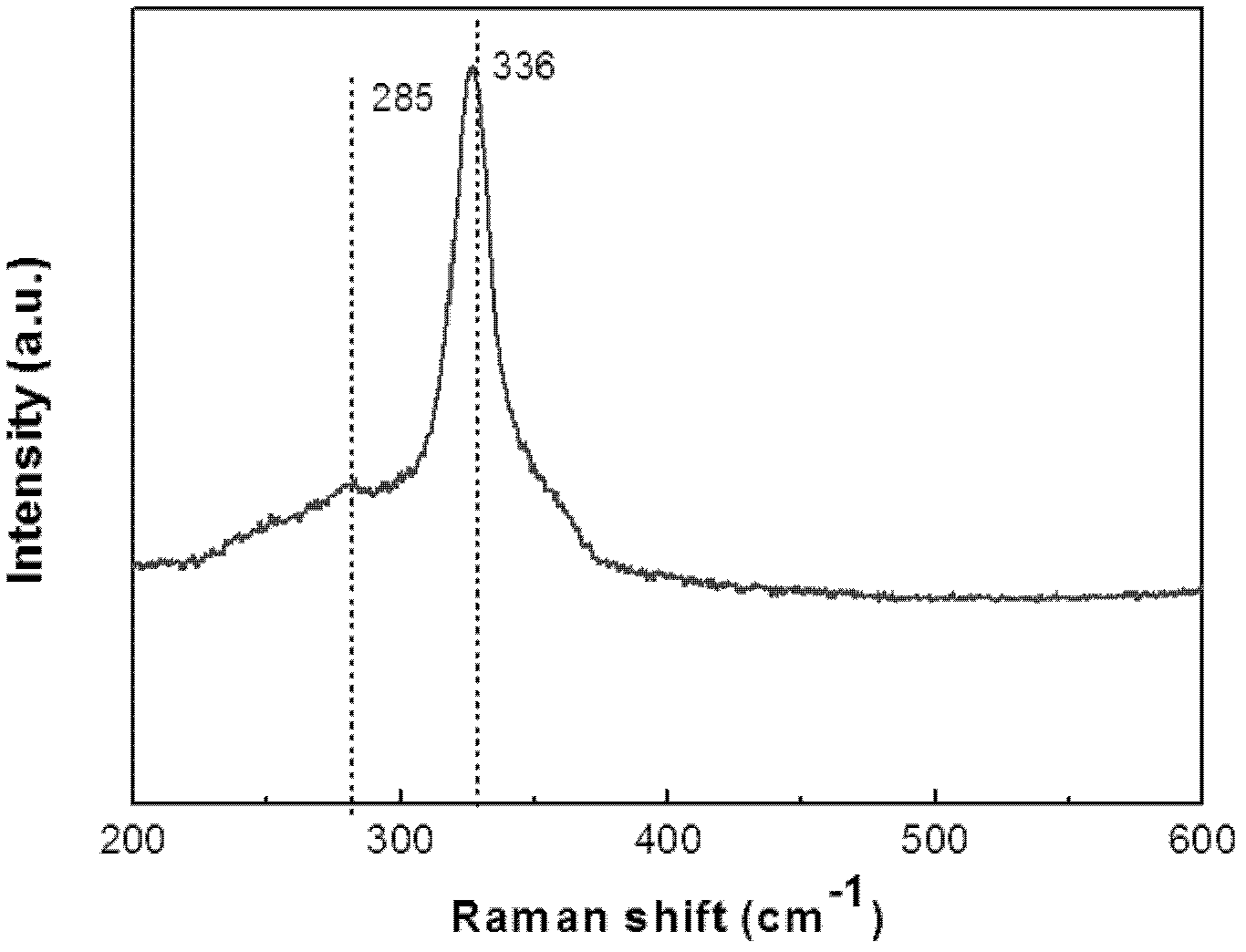

Preparation method of Cu-Zn-Sn-S thin film

InactiveCN102251235AReduce usageSolve unmanageable problemsFinal product manufactureSolid/suspension decomposition chemical coatingAmmonium sulphidePotassium sulfide

The invention discloses a preparation method of a Cu-Zn-Sn-S thin film, comprising the steps of: by adopting a successive ionic layer adsorption reaction method, sequentially or alternatively soaking one substrate in a cation precursor solution and an anion precursor solution to prepare a Cu2SnSx film and ZnS film laminated precast layer structure or a Cu2S film and ZnSnSx film laminated precast layer structure, and then performing heat treatment to obtain the Cu-Zn-Sn-S thin film; the cation precursor solution comprises at least one of copper ions, stannum ions and zinc ions, and the anion precursor solution is selected from at least one of a sodium sulfide solution, a potassium sulfide solution and an ammonium sulfide solution; the substrate is selected from one of glass, PI (polyimide), a stainless steel plate, a molybdenum plate and a titanium plate. The preparation method of Cu-Zn-Sn-S thin film not only solves the problem that the metal components are difficult to control, but also prevents the copper ions from moving to the surface of the film to form a sulfur copper phase. The preparation method is simple and applicable, low in cost and suitable for industrialization production.

Owner:CENT SOUTH UNIV

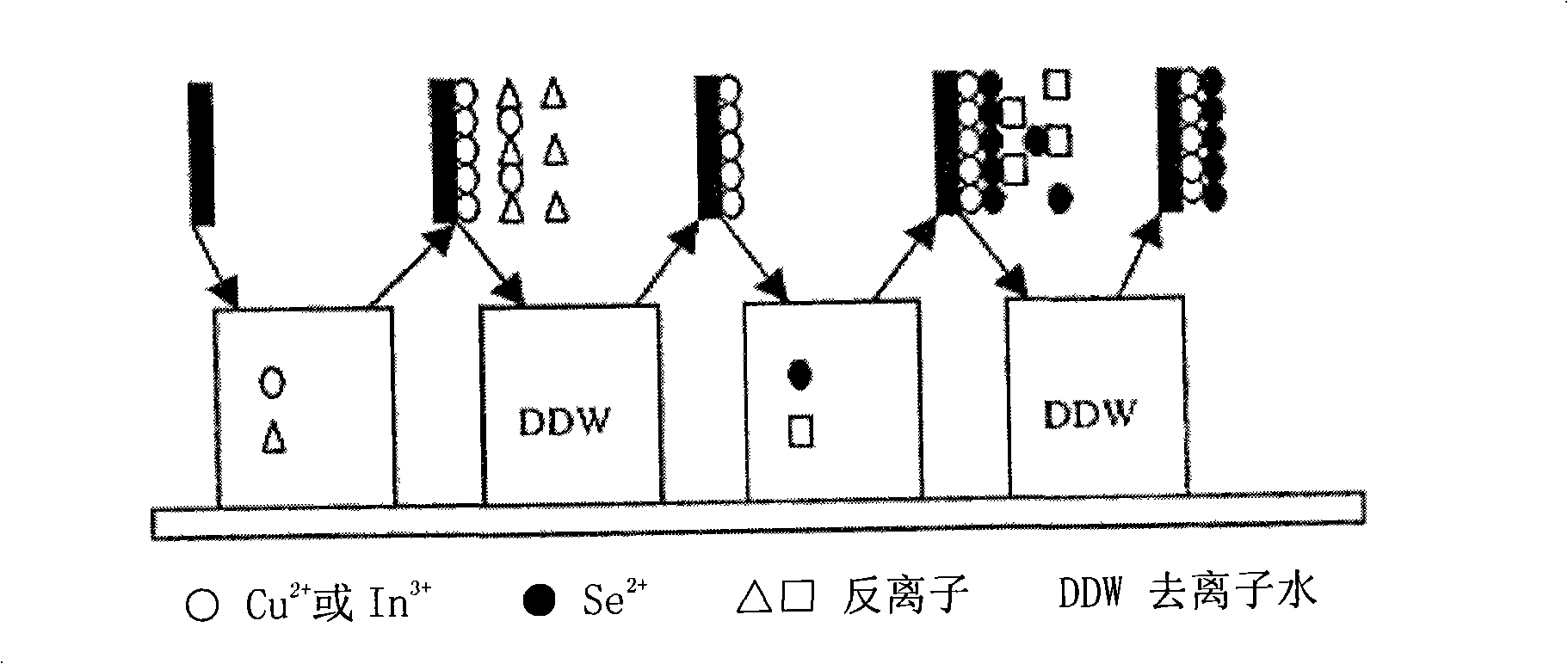

Method for preparing copper indium selenium compound thin film by continuous ion sheath adsorption reaction method

InactiveCN101312218AStoichiometric ratioGood lookingPolycrystalline material growthFinal product manufactureIndiumSolar cell

The invention discloses a process for preparing copper indium selenide compound films by a successive ionic layer adsorption and reaction method. The steps comprise (1) preparing Cu-In mixed cationic precursor solution, (2) preparing anionic precursor solution, (3) processing coating by using the successive ionic layer adsorption and reaction method, and (4) heat treating. The process for preparing copper indium selenide compound films firstly employs two different complexing agents, such as trolamine (TEA) and citric acid (C6H8O7), to respectively complex CuCl2 and InCl3, thereby obtaining near-neutral mixed cationic precursor solution with pH=8-8.5, enlarging the using range of a substrate when settling CuInSe2 by employing the SILAR method, and preparing a CIS photovoltaic film which meets stoichiometric proportion and has fine appearance. The copper indium selenide compound films of the invention can be applied to film photovoltaic cell and light absorption layers of other solar cells with novel structure.

Owner:TIANJIN UNIV

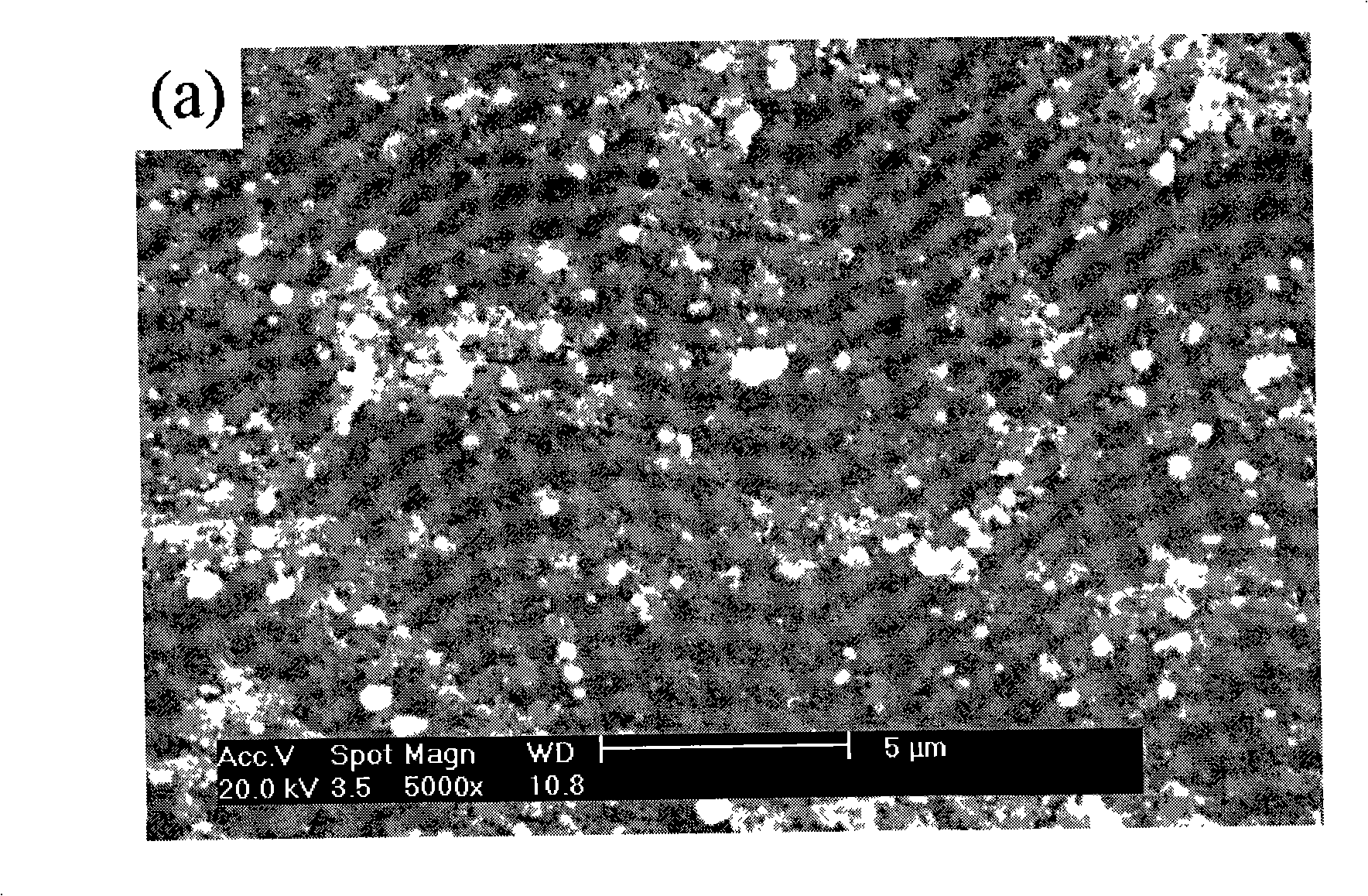

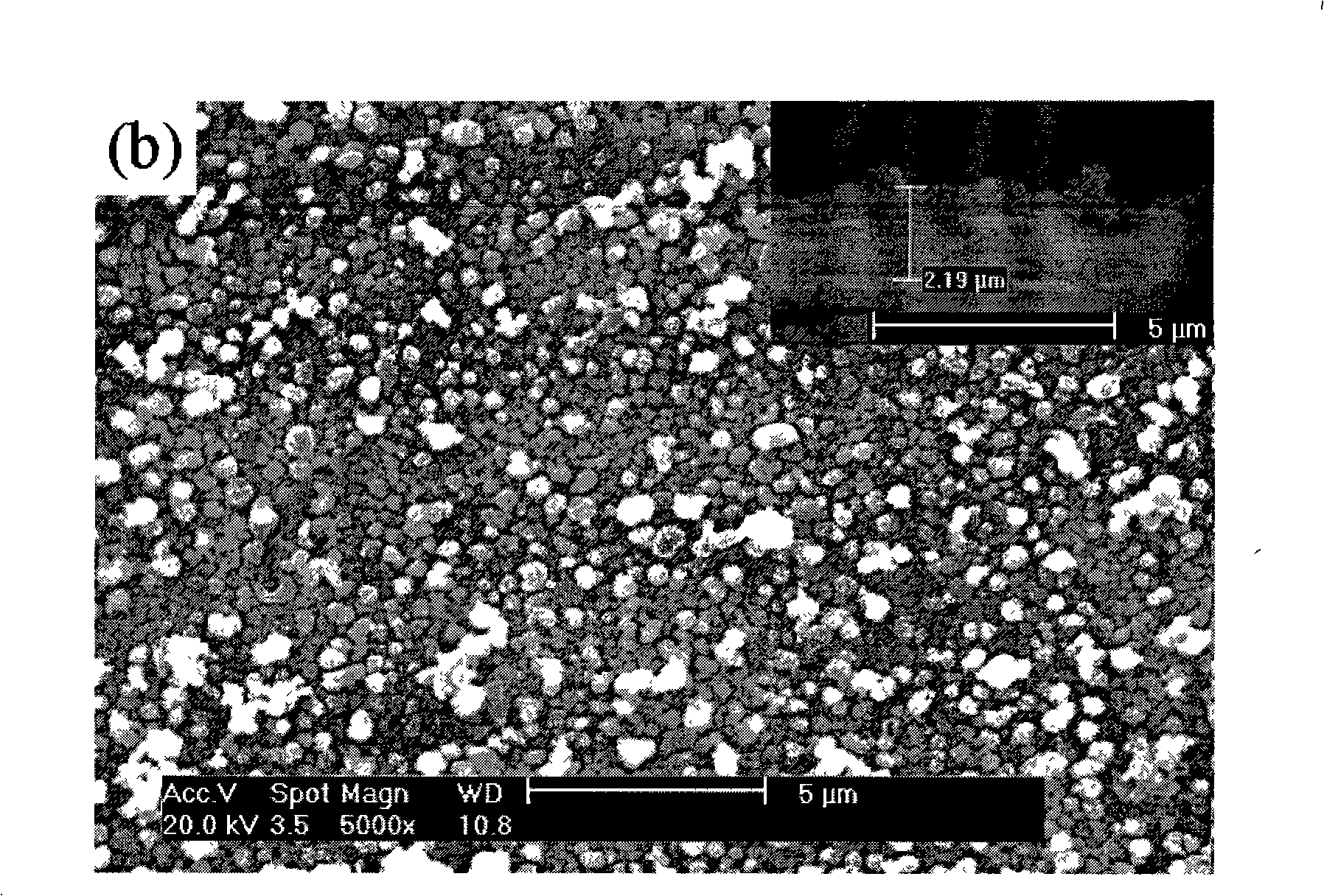

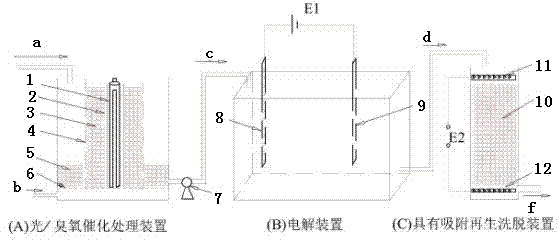

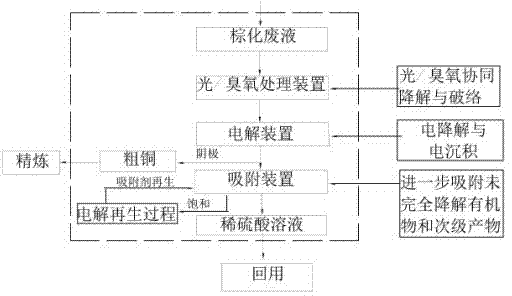

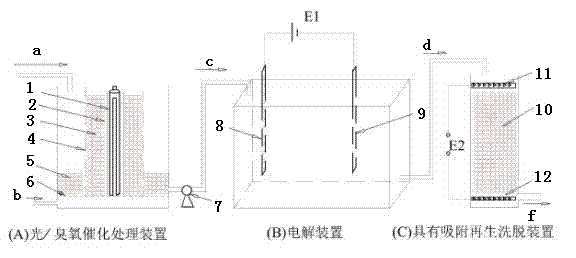

Light/ozone-electricity-adsorption reaction device and method for extracting copper by degrading browning waste liquor

ActiveCN102583840AInhibitory complexSimple designPhotography auxillary processesEnergy based wastewater treatmentEnvironmental resistanceElectrolysis

The invention relates to a light / ozone-electricity-adsorption reaction device and method for extracting copper by degrading browning waste liquor. The device comprises a light / ozone synergistic decomposing device, an electrolysis device for degrading and recovering metal copper and an adsorption elution device. In the device, a photocatalyst and an oxygen catalyst are loaded on a porous activated carbon carrier with high specific surface area; under the synergistic effect of ultraviolet light and ozone, photo-generated electron pairs are prevented from compounding, long-time catalytic treatment activity is kept, a free radical.OH with strong oxidation activity is generated, organic matters in the browning waste liquor can be oxidized and degraded, and the complexing bond of the complex in the browning waste liquor can be broken; insoluble reticular titanium base material serves as an anode, a copper sheet material serves as a cathode, organic matters in the browning liquor is continuously degraded by electrolysis to generate a second-grade degrading product which is easy to adsorb, and valuable metal copper is recovered on the cathode; and finally, common activated carbon is used for adsorbing to effectively treat the browning waste liquor, so as to realize green and environment-friendly treatment of the browning waste liquor.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD +1

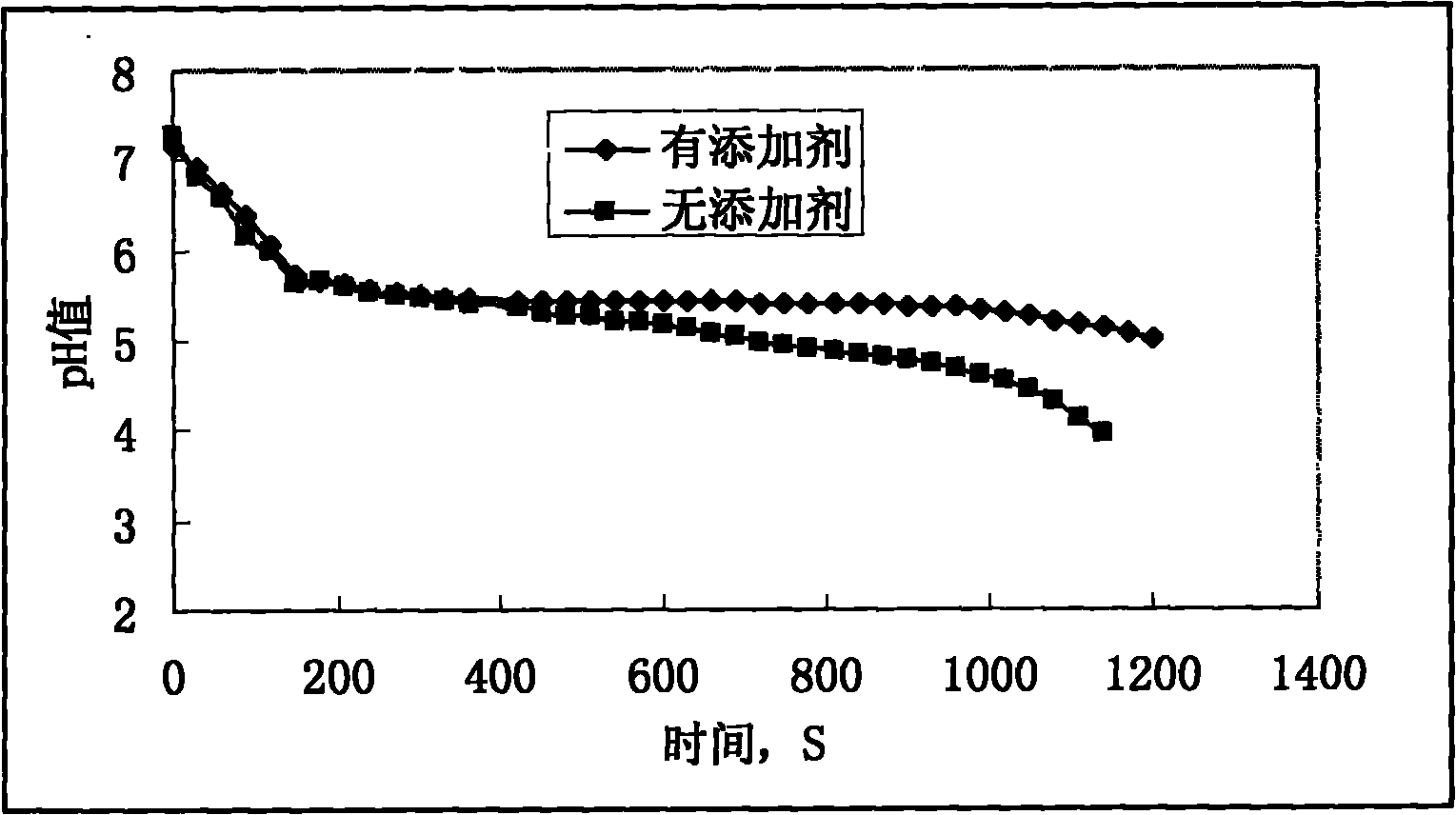

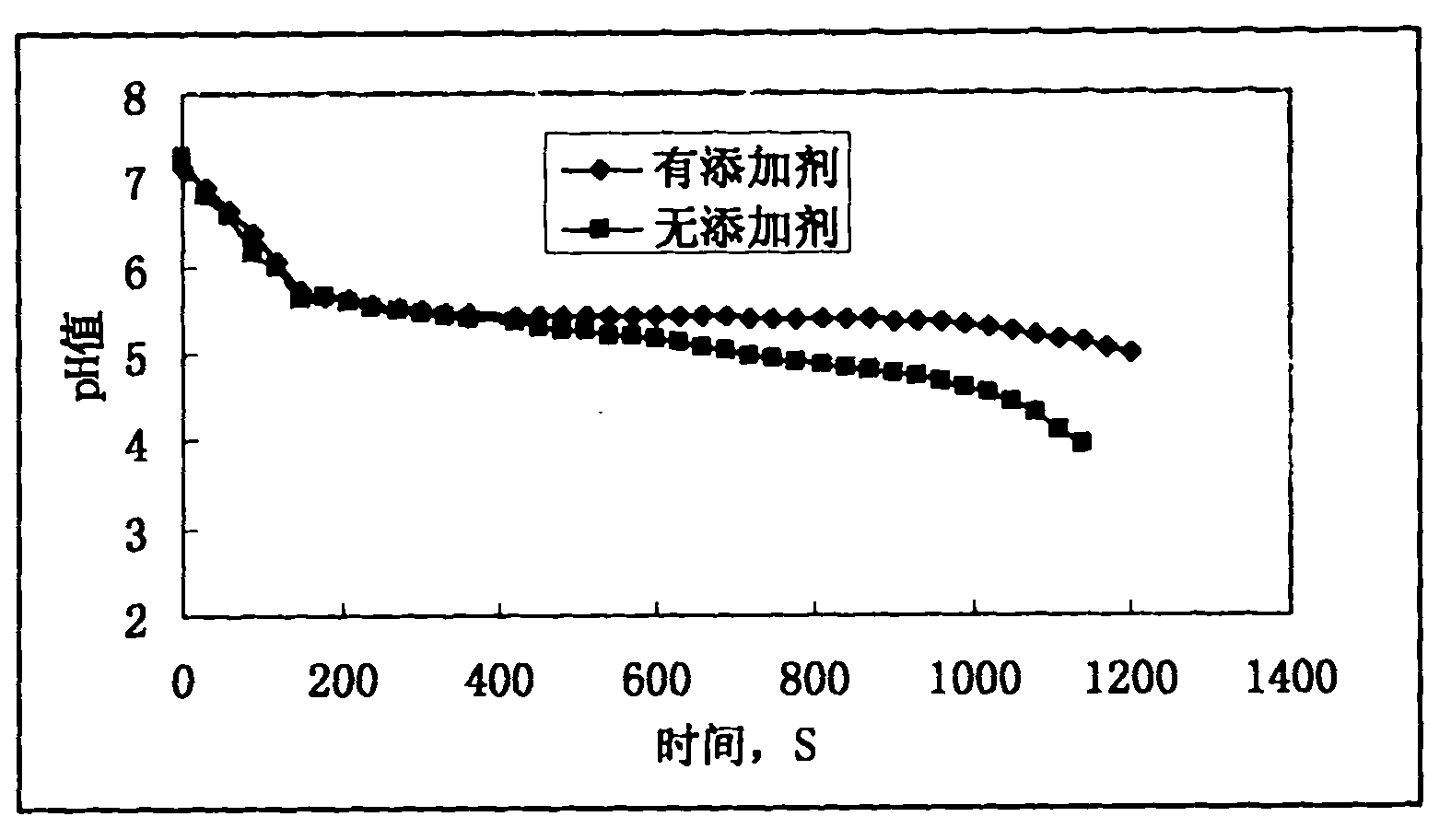

Multifunctional composite additive for wet-method flue gas desulfuration process and using method thereof

InactiveCN102019138AImprove solubilityFacilitate absorption reactionDispersed particle separationDissolutionSlurry

The invention belongs to the technical field of a limestone-gypsum wet-method flue gas desulfuration process and relates to a multifunctional composite additive for a wet-method flue gas desulfuration process and a using method thereof. The composite additive comprises the following components in percentage by mass: 31 to 45 percent of nylon acid, 31 to 45 percent of sodium humate, 6 to 9 percentof organic silicon defoaming agent, 2 to 5 percent of potassium formate, 2 to 5 percent of manganese sulfate and 2 to 5 percent of p-hydroxybenzoic acid. The composite additive can promote the dissolution of the limestone and reduce the using amount of the limestone, has an enhancement factor for improving an absorption reaction of sulfur dioxide (SO2), accelerates the migration speed of SO2 gas liquid, promotes the adsorption reaction of the SO2 in a liquid membrane, inhibits the soft scales of calcium sulfate (CaSO3) from generating, improves the pH value buffer capacity of limestone slurry, slows down the reducing speed of the pH value in the process of absorbing the SO2 by the desulfuration slurry continuously, and achieves the effect of avoiding bubbling and overflow of the desulfuration slurry.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for removing hexavalent chromium in wastewater by using beta-cyclodextrin chitosan and walnut shell biochar compounded adsorbent

InactiveCN105236507ALarge specific surface areaLarge pore volumeOther chemical processesWater contaminantsFiltrationSorbent

The present invention discloses a method for removing hexavalent chromium in wastewater by using a beta-cyclodextrin chitosan and walnut shell biochar compounded adsorbent, wherein beta-cyclodextrin and chitosan are compounded, and then the beta-cyclodextrin chitosan is grafted on a walnut shell biochar substrate so as to form the complex. The preparation method comprises: compounding beta-cyclodextrin and chitosan, carrying out high temperature calcination on walnut shell biomass powder formed through air-drying and grinding so as to prepare walnut shell biochar, and compounding the beta-cyclodextrin chitosan onto the biochar surface. The application steps comprise: adding the composite material to hexavalent chromium wastewater with a hexavalent chromium concentration of 20-800 mg / L, wherein the use amount of the composite material is 0.1-1 g / L; and carrying out an oscillation adsorption reaction for a certain time at a temperature of 20-50 DEG C under a pH value of 2-9, and collecting the adsorbent through filtration or precipitation separation so as to complete the removal of the hexavalent chromium ions in the wastewater. The method of the present invention has advantages of low cost, simple process, high adsorption performance, effective waste utilization, easy separation, environmental protection, and the like.

Owner:HUNAN UNIV

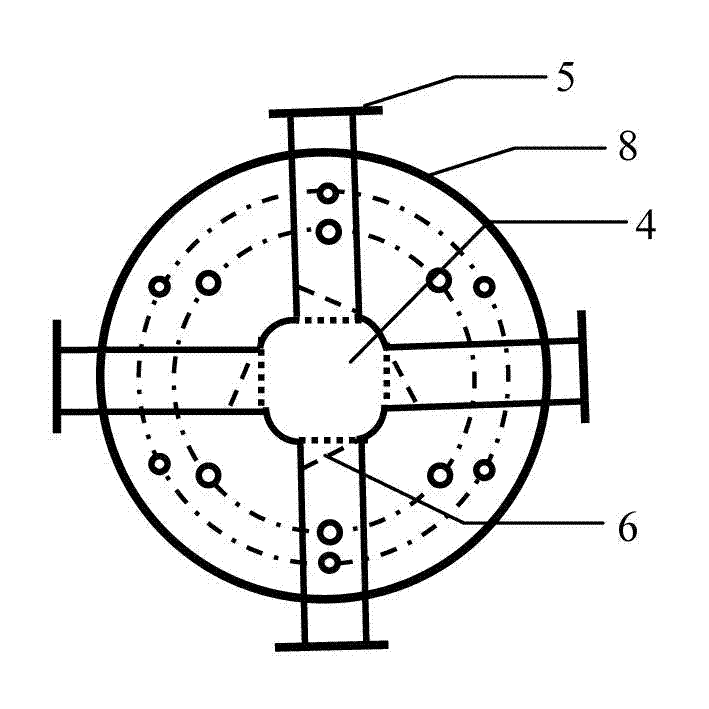

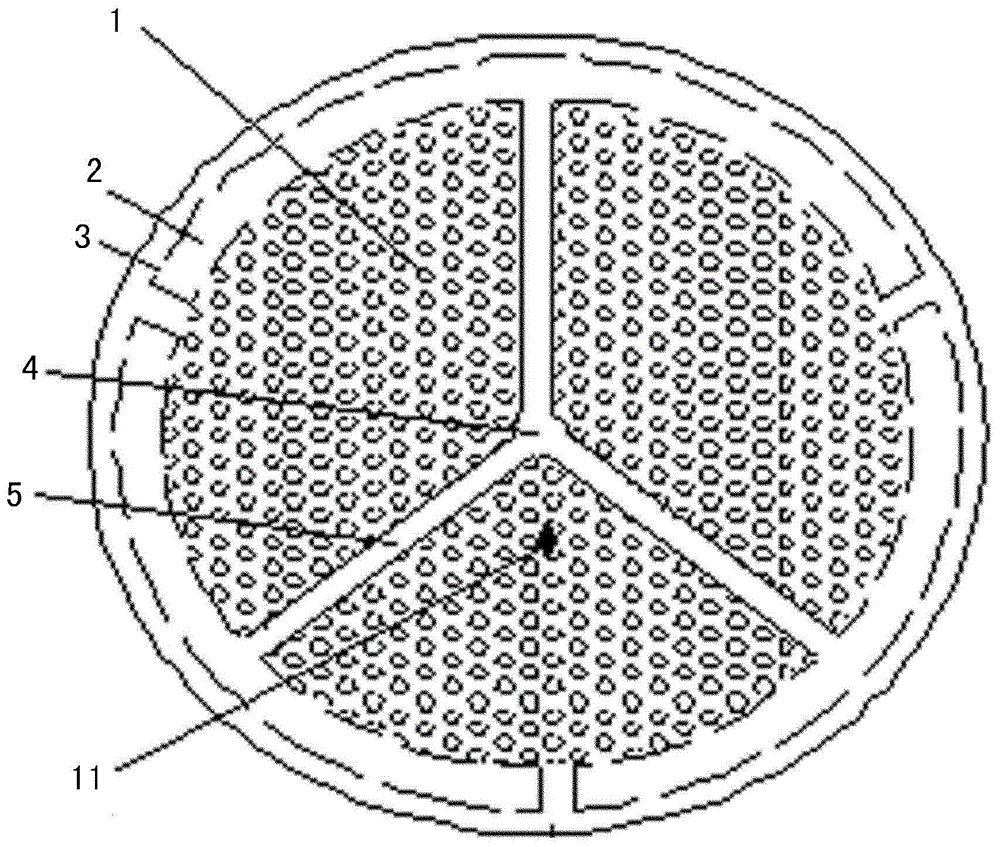

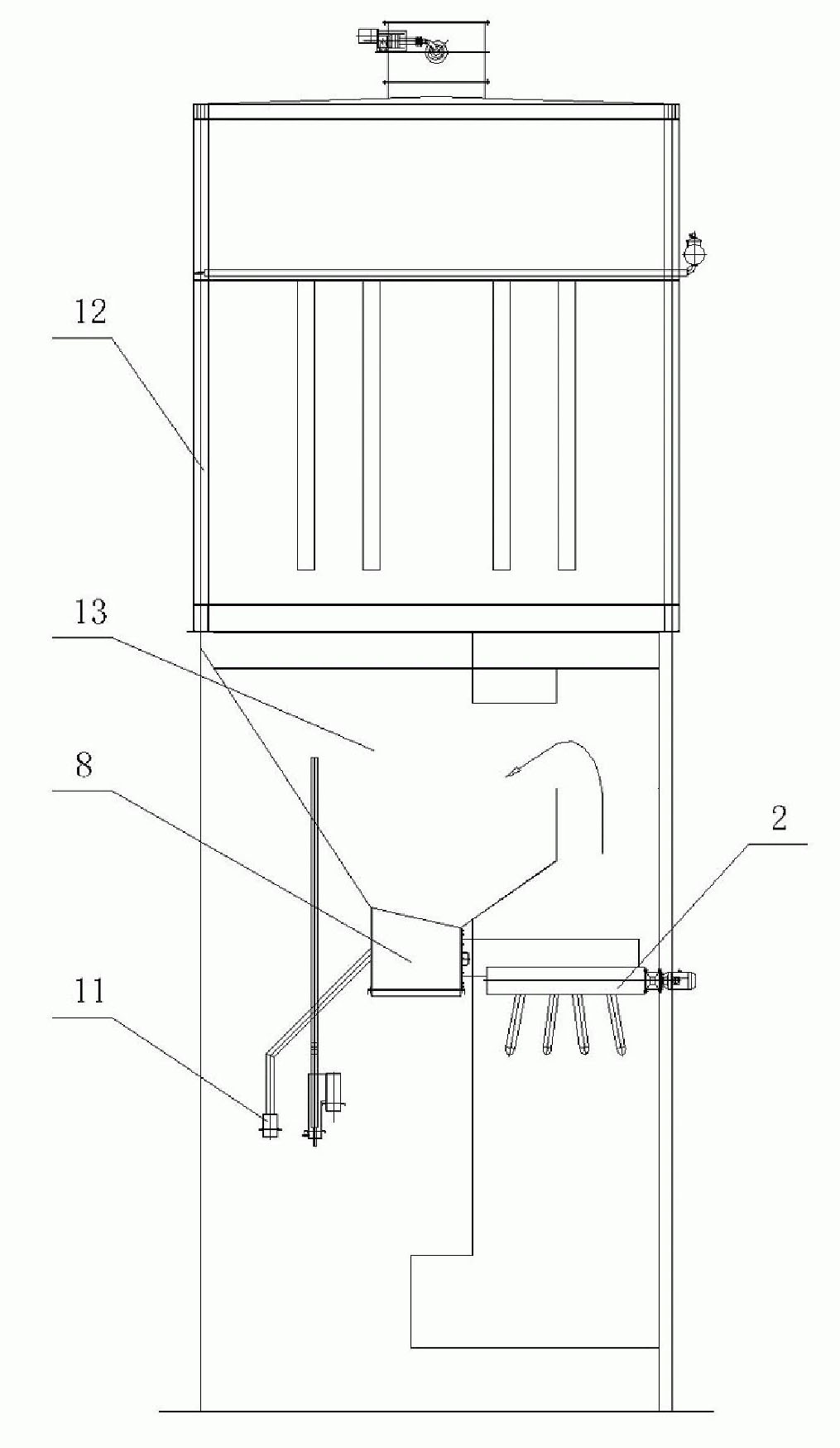

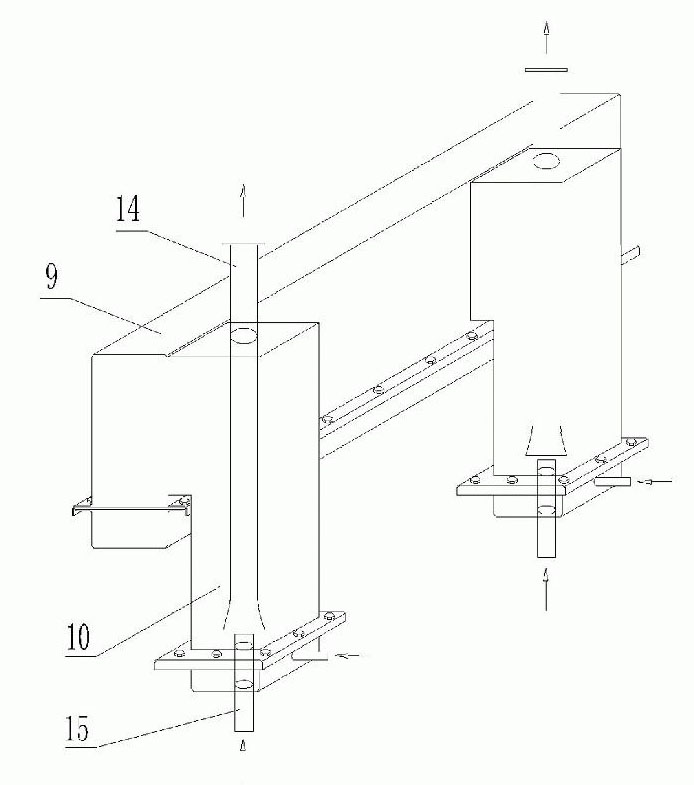

Axial and radial cross flow moving bed reactor and activated coke flue gas desulfurization and denitration technology thereof

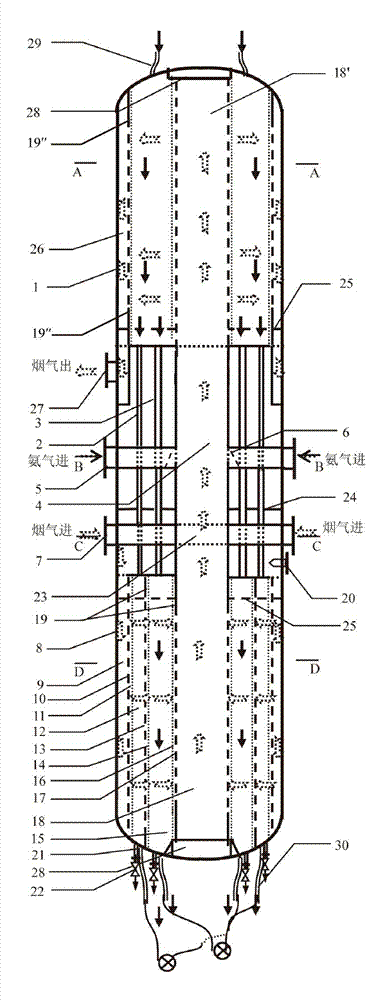

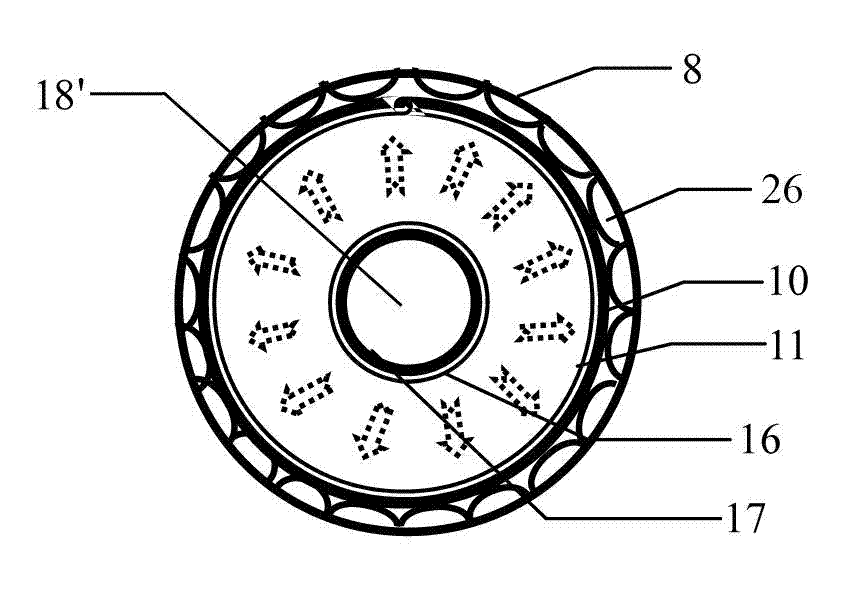

ActiveCN102824846ACombined removalAchieve efficient utilizationDispersed particle separationAir quality improvementThermodynamicsFlue gas

An axial and radial cross flow moving bed adsorption reactor and an activated coke flue gas desulfurization and denitration technology thereof are used for realizing the purposes that SO2, NOx, mercury, dioxin and other pollutants in flue gas are unitedly removed and integrally purified in an adsorption reactor, and belong to the technical field of comprehensive waste flue gas treatment. The adsorption reactor is a combined type double-section double-inverse U-type axial and radial cross flow moving bed, awherein desulfurization area is arranged at a lower section of the axial and radial cross flow moving bed, an annular internal activated coke particle layer and an annular external activated coke particle layer are arranged, and the desulfurization area is divided into a coarse desulfurization area and a fine desulfurization area; a denitration area is arranged at an upper section of the axial and radial cross flow moving bed, and an activated coke particle layer is arranged; an ammonia spray pipe is arranged between the upper section and the lower section; and flue gas is filled along a double-port counter annular gas flow channel structure, the flue gas of the lower section centripetally flows to be desulfurized, and the flue gas of the upper section centrifugally flows to be denitrated. According to the reactor and the technology, desulfurization and denitration are realized in one adsorption reactor, so the adsorption reactor has the advantages of efficient utilization of activated coke, uniform flue gas mixing, sufficient gas-solid contact, stability and reliability in operation, operation cost saving and the like.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

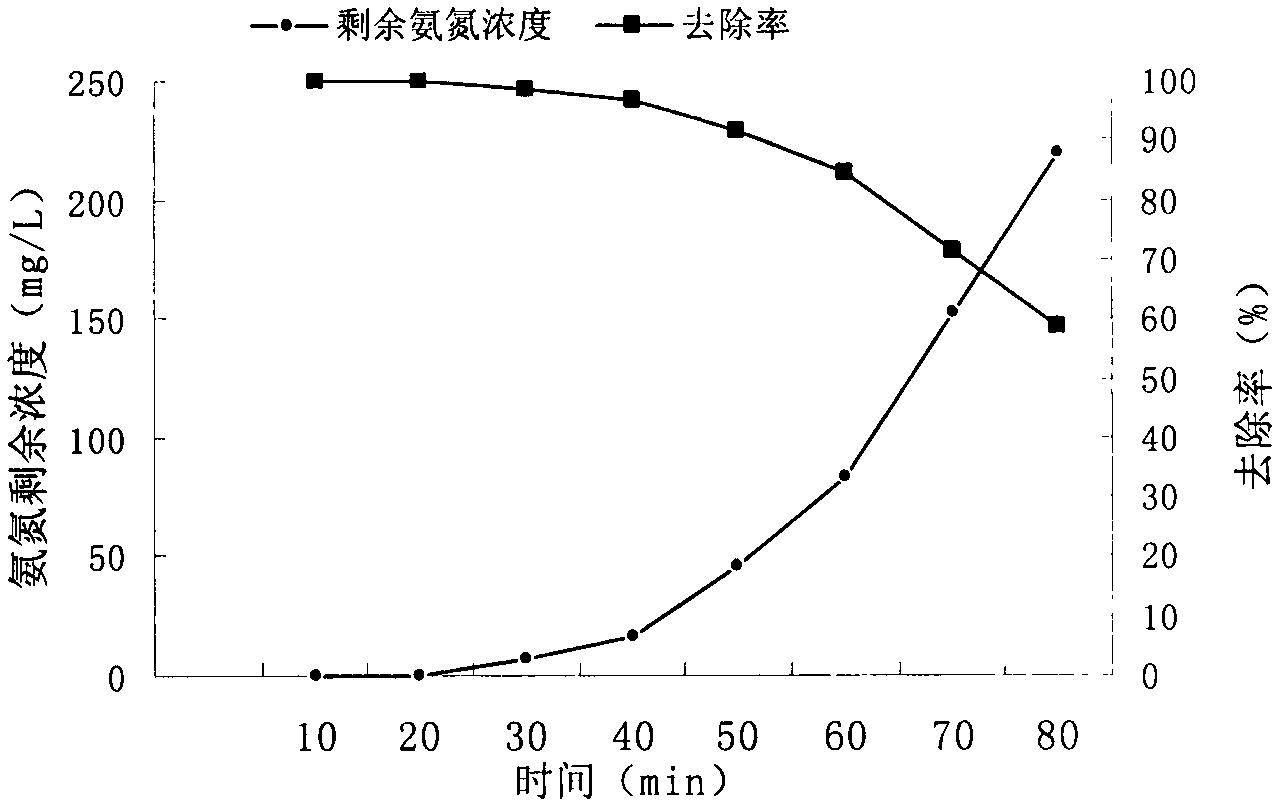

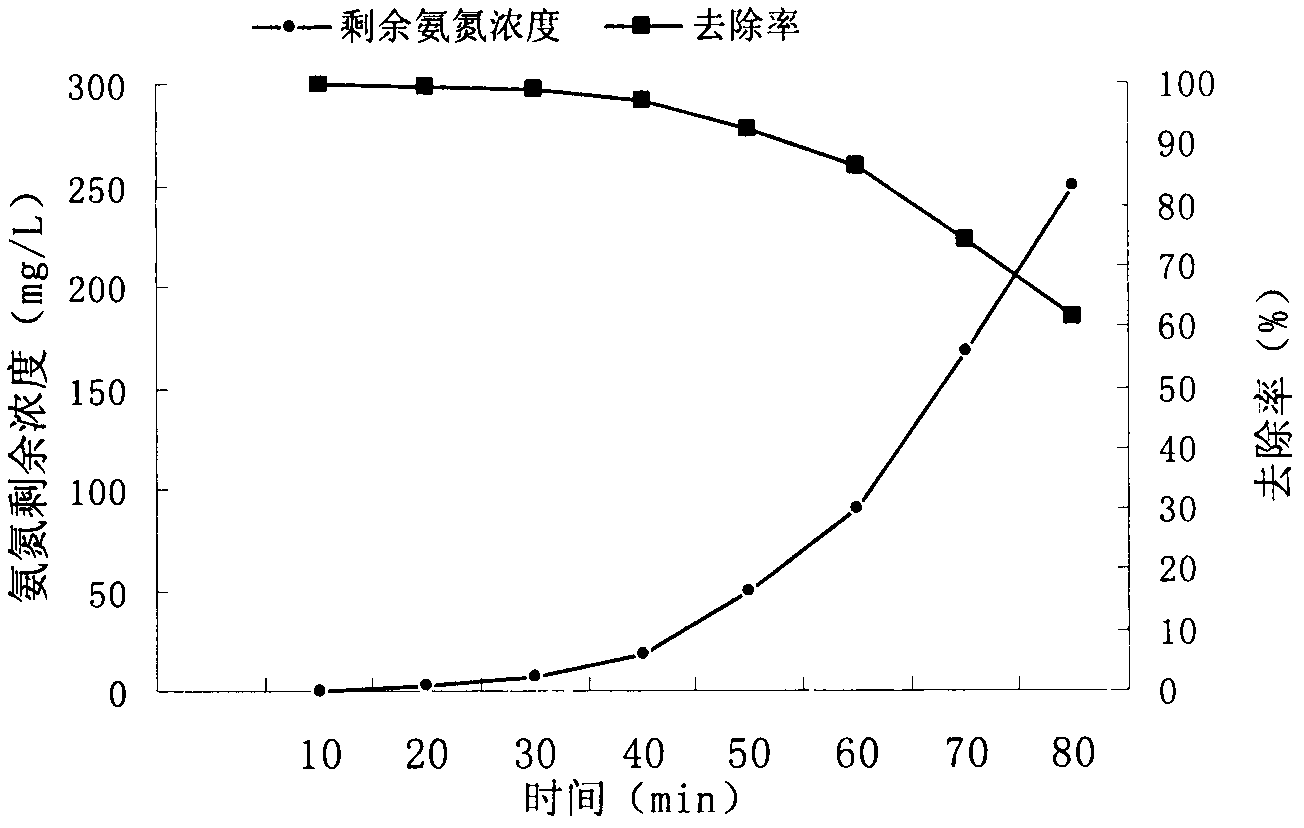

Method for treating ammonia nitrogen wastewater

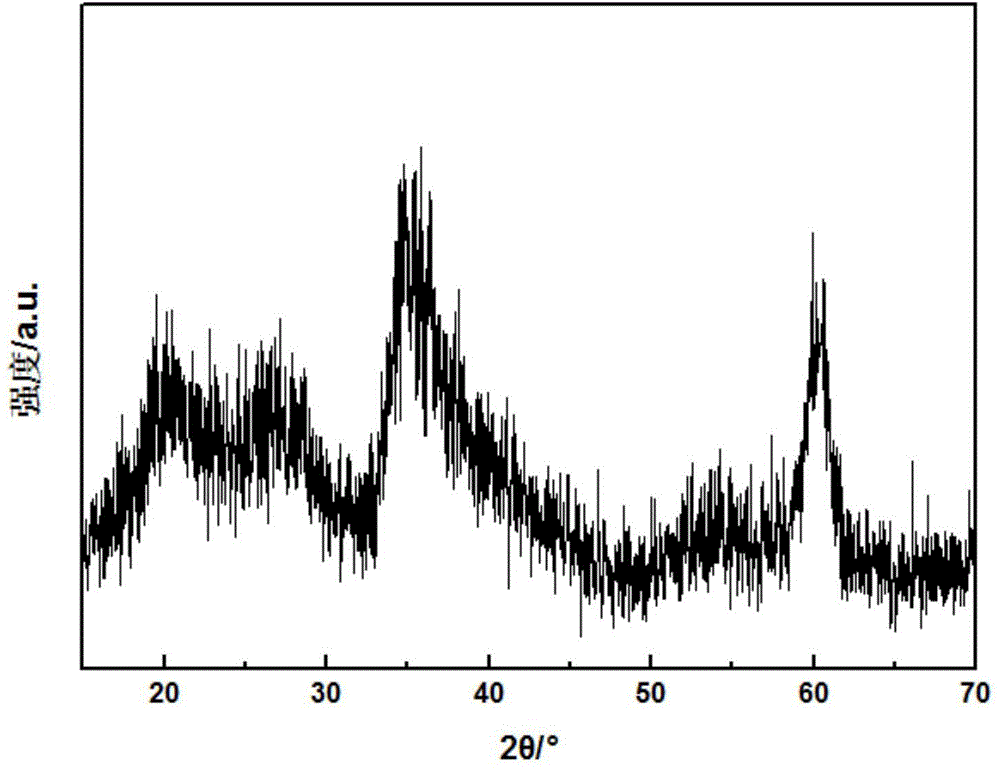

ActiveCN101559988AEasy to desorbLow costOther chemical processesCombustible gas purificationPyrolusiteSorbent

The invention provides a method for treating ammonia nitrogen wastewater, which relates to a method for treating the ammonia nitrogen wastewater by using an adsorption method. The method is characterized in that in the treating process, a natural manganese mineral is used as an adsorbent to perform adsorption reaction with the ammonia nitrogen wastewater so as to remove the ammonia nitrogen in thewastewater. The natural manganese mineral is crushed into a manganese mineral adsorbent of 0-2 millimeters, the pH value of the wastewater containing the ammonia nitrogen is adjusted to be between 2and 12 by using acid or alkali, then the manganese mineral adsorbent contacts and is mixed with the ammonia nitrogen wastewater to perform adsorption, and the adsorption can be performed by adopting afixed bed adsorption column or in a stirring and mixing mode. When the fixed bed adsorption column is adopted for adsorption, the manganese mineral after being crushed is classified to remove fine particles for the best so as to improve the permeability of the adsorption column; and in the same way, when the stirring and mixing mode is adopted, the manganese mineral after being crushed is classified to remove coarse particles for the best so as to reduce the abrasion to equipment. The natural manganese mineral applicable to the method comprises a terrestrial manganese oxide mineral, an oceanpolymetallic nodule, an ocean cobalt-rich incrustation and a terrestrial manganese nodule, the natural manganese minerals usually contain manganese minerals of cryptomelane, todorokite, birnessite, vernadite, rancieite, pyrolusite and the like, have good pore structure and large specific surface area so as to have good adsorption property, and can be used as the adsorbent for treating the ammonianitrogen wastewater after being crushed into certain particle size, and the manganese minerals have the advantages of simple process, easy reproduction and stable performance.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

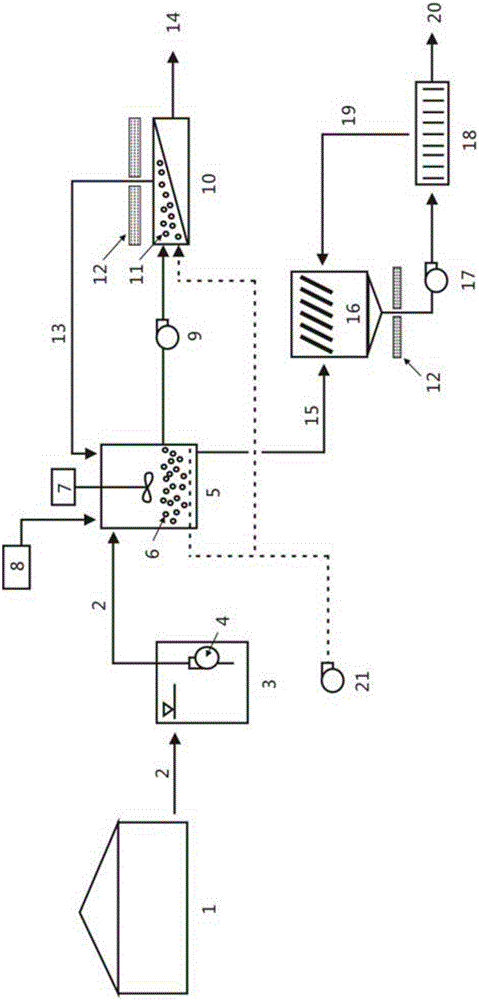

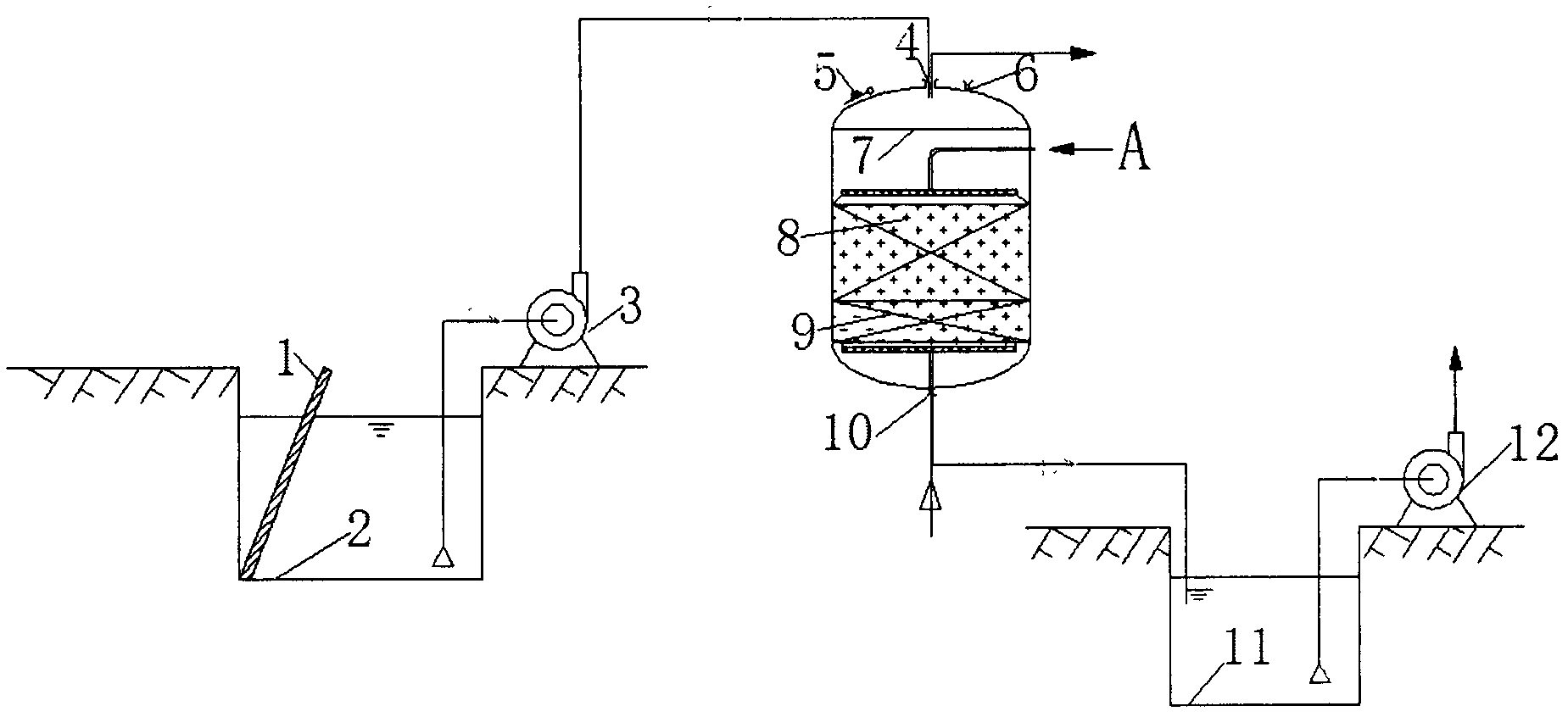

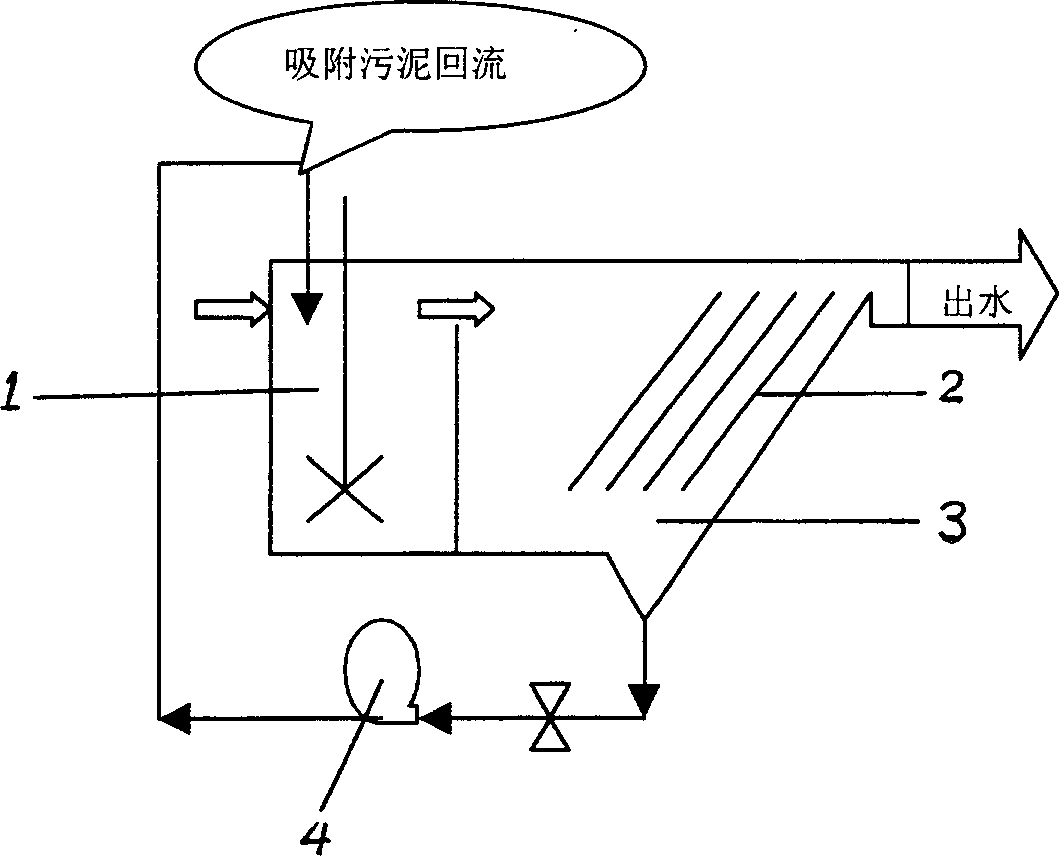

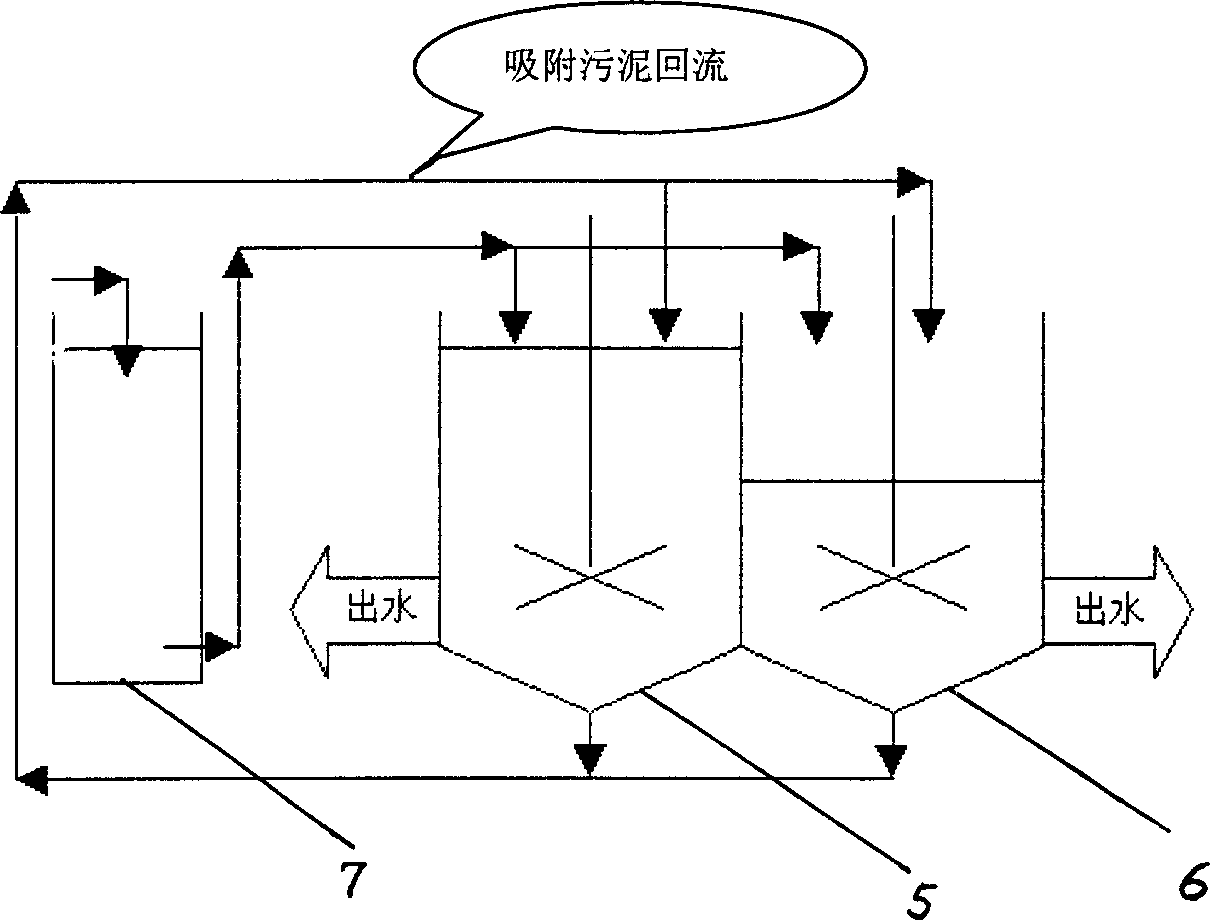

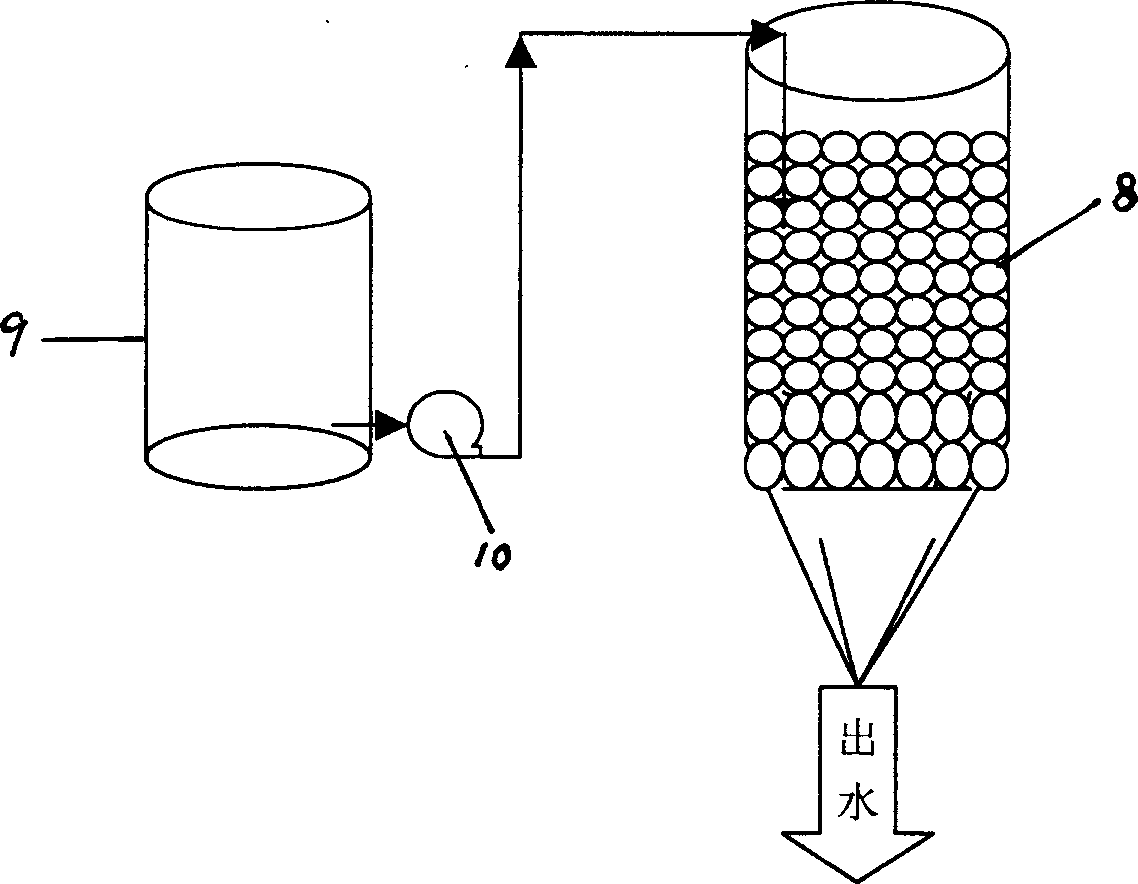

Nano quantum dot adsorption and film separating system for removing heavy metal in water

ActiveCN105130087AAvoid secondary pollutionShort hydraulic retention timeMultistage water/sewage treatmentSludgeWater storage tank

The invention relates to a nano quantum dot adsorption and film separating system for removing heavy metal in water, which comprises a waste water storage tank (3); the waste water storage tank (3) is connected with an adsorption reaction tank (5) internally provided with a fine aeration system (6) and a stirring apparatus (7); a magnetic organic carbon carrier (8) is cast into the adsorption reaction tank (5) connected with a gas wiping cross flow film system (10) by a circulation pump (9); the gas wiping cross flow film system (10) is connected to the adsorption reaction tank (5) of which the bottom is connected with an oblique pipe deposition tank (16); the outlet of the oblique pipe deposition tank (16) is connected with a press filter (18) by a sludge pump (17) and the press filter (18) is connected to the oblique pipe deposition tank (16). The nano quantum dot adsorption and film separating system can realize continuous operation, is large in adsorption capacity, small in occupation space without the need of adding chemical agents and generation of sludge, and is small in film system cross flow rate, high in film separation precision and low in system operation energy consumption.

Owner:上海一途膜分离技术有限公司

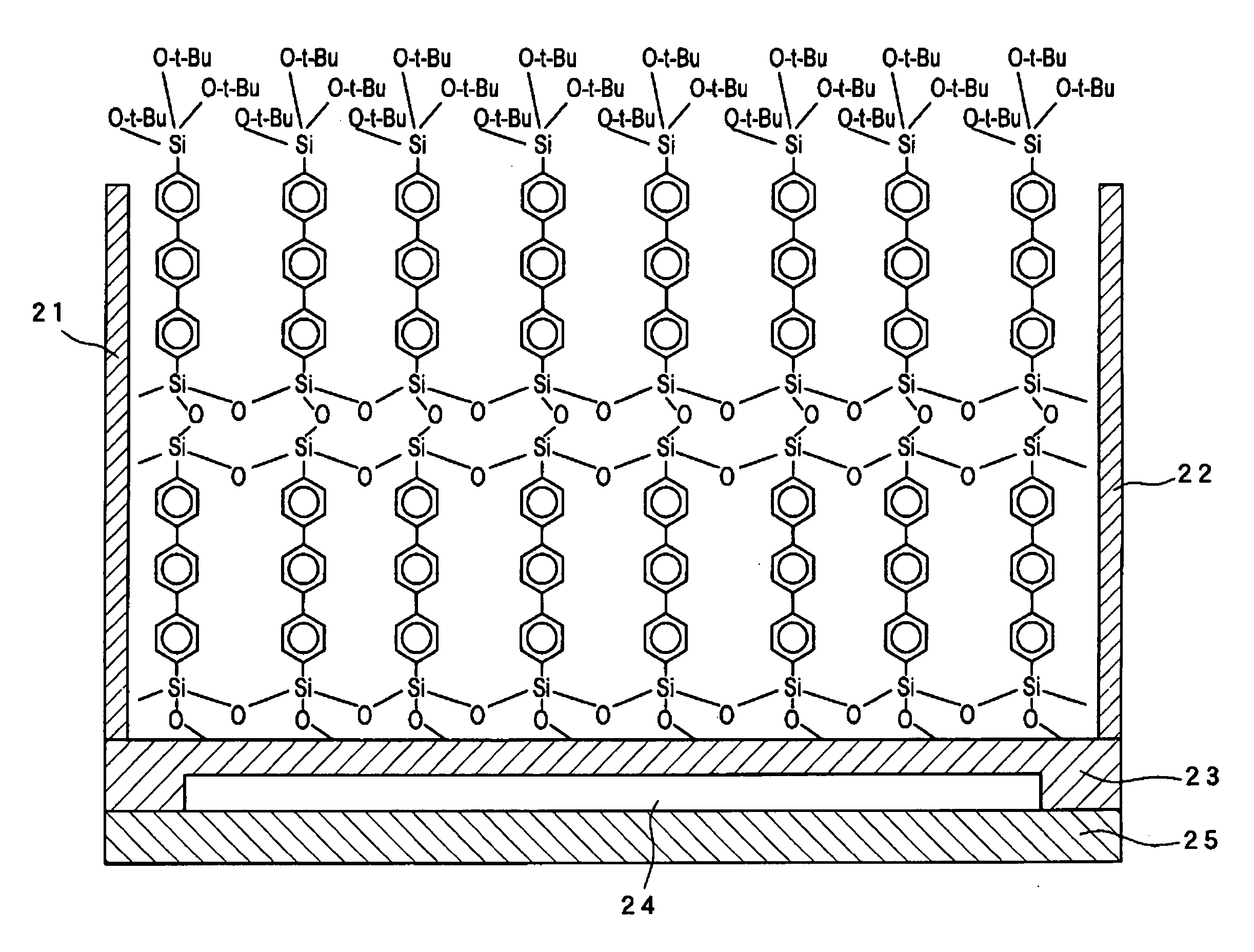

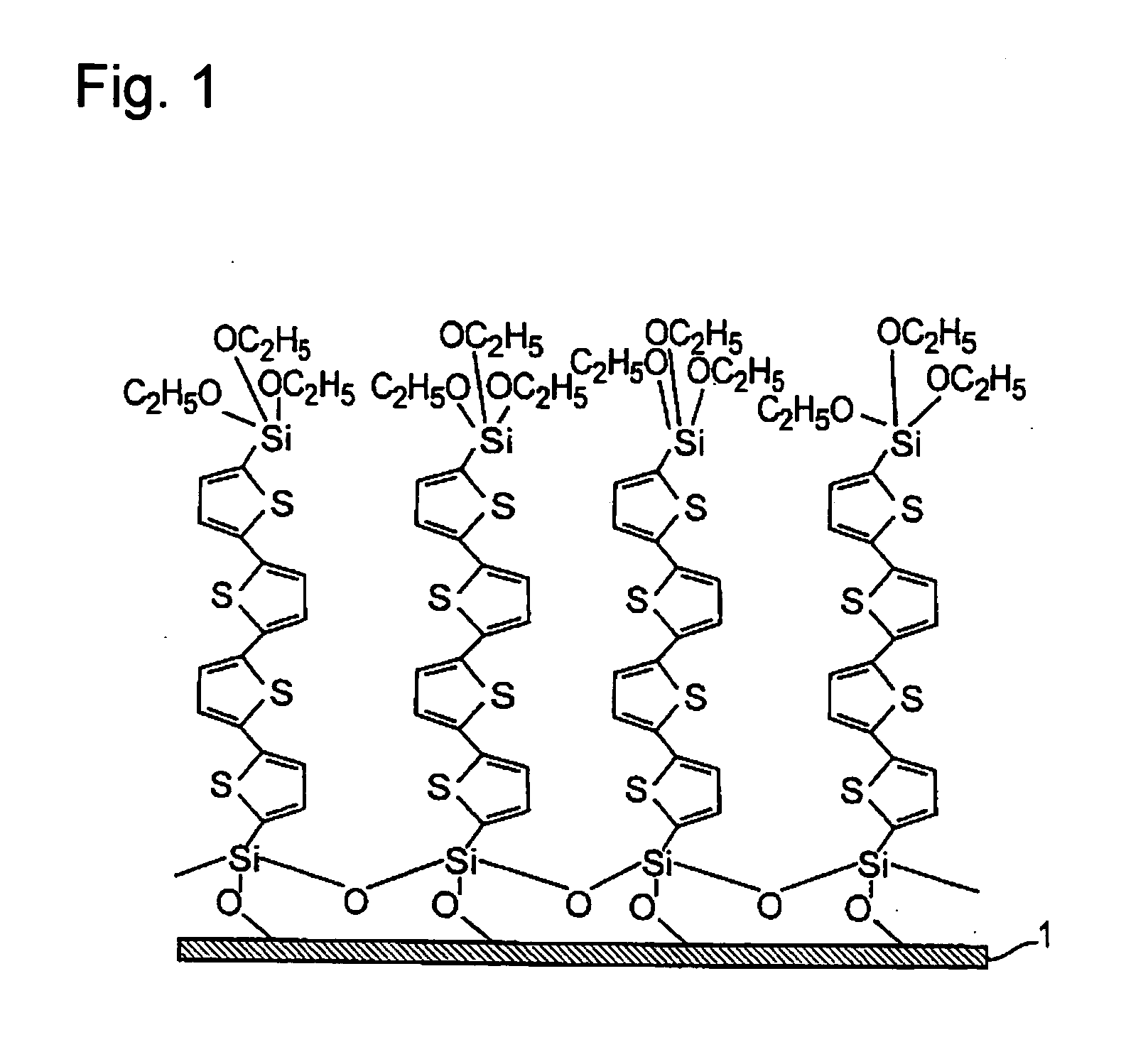

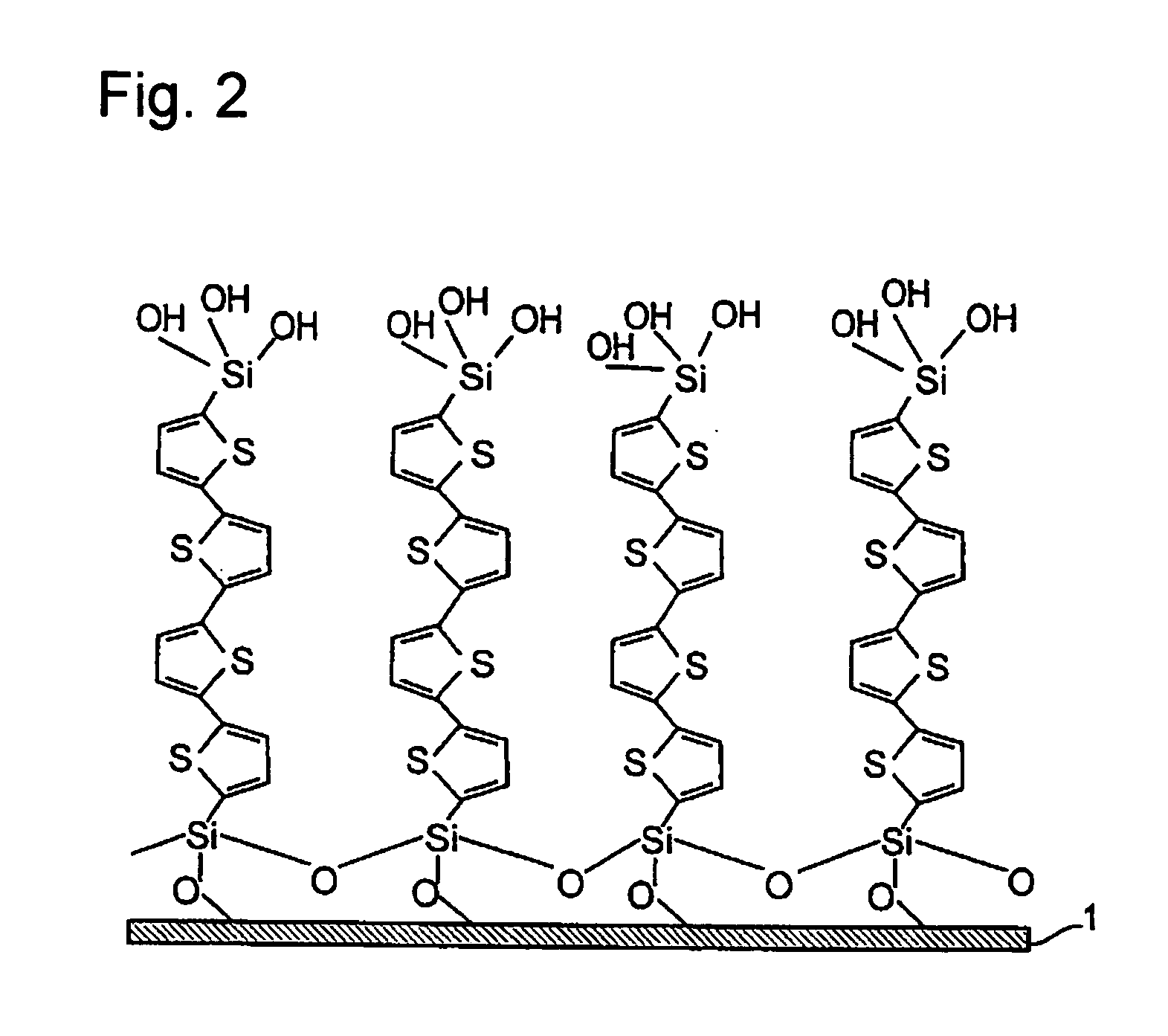

Organic compound having functional groups different in elimination reactivity at both terminals, organic thin film, organic device and method of producing the same

InactiveUS20070195576A1Prevents physical exfoliationImprove stabilityTransistorSilicon organic compoundsSilyleneHalogen

Provided are a single monomolecular film uniform in film thickness and highly ordered in molecule alignment and its multilayer film, an organic compound allowing production of such films at high reproducibility, an organic device superior in electroconductive properties and a method of producing the same. An organic compound represented by Formula:Si(A1)(A2)(A3)-B—Si(A4)(A5)(A6)(A1 to A6 each represent a hydrogen atom, a halogen atom, an alkoxy group or an alkyl group and satisfy the relationship in elimination reactivity of: A1 to A3>A4 to A6; and B represents a bivalent organic group), an organic thin film using the compound, and an organic device having the thin film; A method of producing an organic thin film and organic device, comprising a step of forming a single monomolecular film by allowing the silyl group having A1 to A3 in the organic compound to react with the substrate surface; a step of removing unreacted organic compounds by using a non-aqueous solvent; and a step of forming an additional monomolecular film of the organic compound by using the unreacted silyl groups present on the film surface side of the monomolecular film obtained as the sites for adsorption reaction.

Owner:SHARP KK

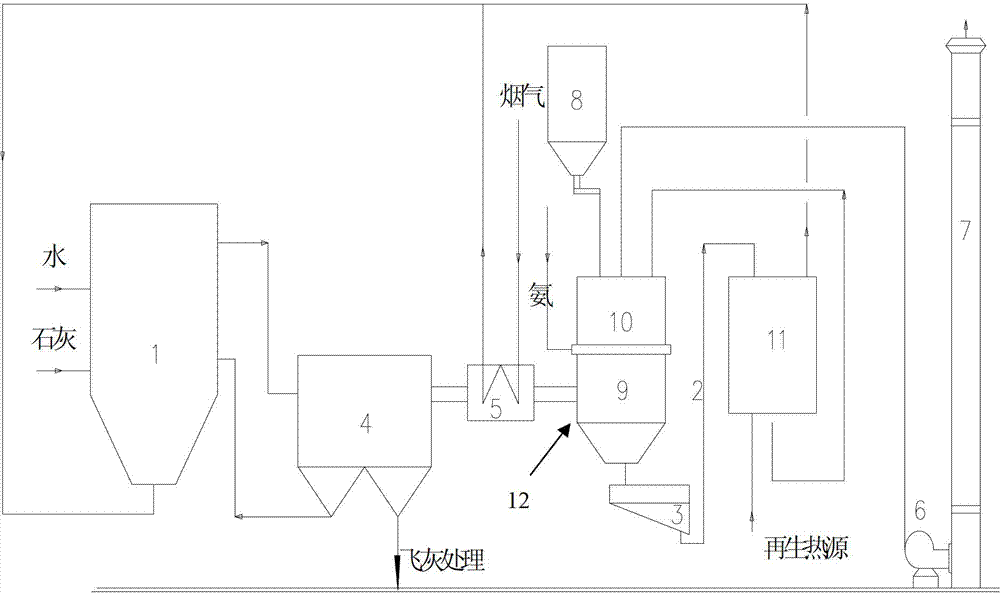

Comprehensive waste incineration flue gas purification system and purification method thereof

ActiveCN102895857ADispersed particle separationAir quality improvementPurification methodsHazardous substance

The invention relates to waste incineration flue gas purification equipment, which comprises a semi-dry deacidification device (1), a dust removing system (4), a heat exchanger (5), a carbon base adsorption reaction system, an induced draft fan (6) and a chimney (7), wherein the carbon base adsorption reaction system comprises a carbon base adsorbent bin (8), a carbon base adsorption tower (12), a carbon base adsorbent regeneration tower (11), a conveyor belt (2) and a sifter (3). According to the purification process, acidic gases HCl, HF, SO2 and the like can be pre-removed from an incineration flue gas to prepare for a carbon base adsorption process, the pre-treated flue gas is heated to more than 85 DEG C by the heat exchanger, fed into at least one layer of carbon base adsorption reactor, and reacted with sprayed NH3 and the like to remove NOx from the incineration flue gas. Tail gases generated by waste incineration can be fully purified, and harmful substances such as acidic substances, nitrogen oxides and heavy metal can be removed from the gases.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

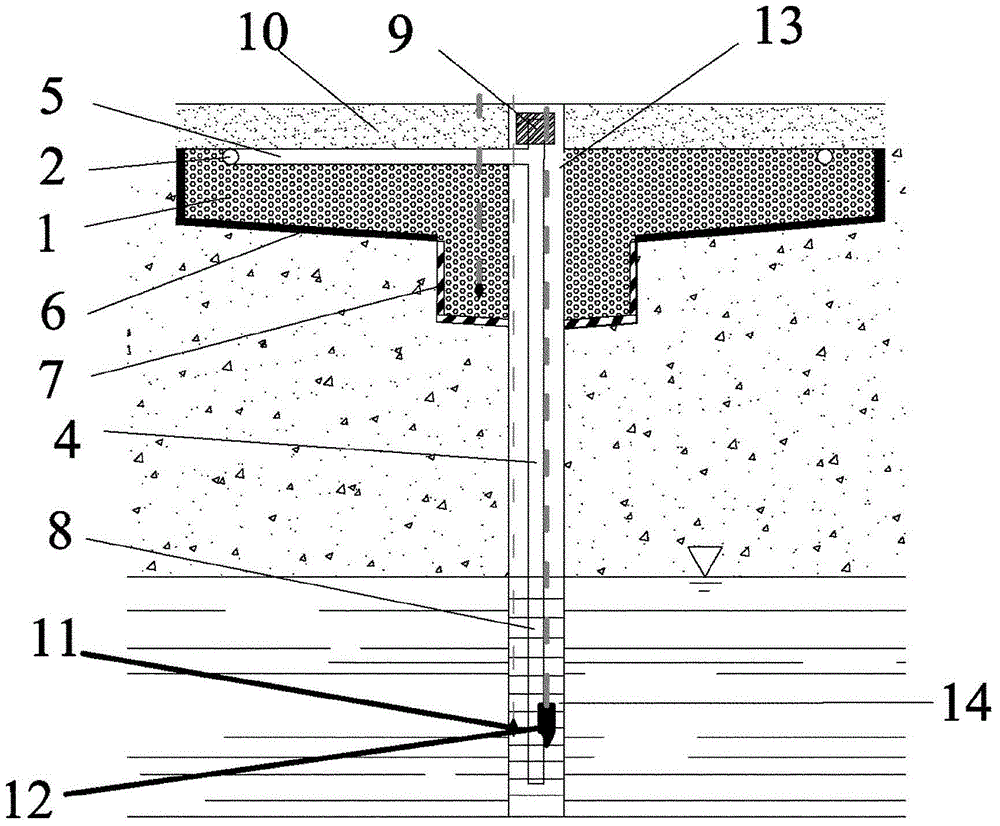

Underground water heavy metal pollution remediation device

ActiveCN104692531AImprove repair effectGood removal effectWater contaminantsSustainable biological treatmentHyperaccumulatorChemical adsorption

An underground water heavy metal pollution remediation device mainly includes a pumping system, a water distribution system, an adsorption reaction zone, a phytoremediation zone, a rapid seepage zone and a monitoring system. The adsorption reaction zone is filled with a medium for the adsorption of heavy metals in order to remove the heavy metals in the underground water. The phytoremediation zone is planted with hyperaccumulator with absorption and enrichment effects on heavy metals, so as to enhance the removal effect of heavy metals. The technique organically combines physical adsorption, chemical adsorption and phytoremediation, and can remediate heavy metals pollution of As, Zn, Cd, Mn, Cu, Cr and Pb and reach good removal effect; replacement of the adsorption reaction medium filler is simple; and the device has low operation cost, and is applicable to groundwater pollution sites in different water depths.

Owner:北京德瑞科森环保科技有限公司

Modified zeolite ammonia nitrogen adsorbent and application and regeneration method thereof

ActiveCN102423684ALarge adsorption capacityImprove adsorption capacityAluminium silicatesWater contaminantsPeristaltic pumpSorbent

The invention discloses a modified zeolite ammonia nitrogen adsorbent and an application and regeneration method thereof; the preparation process of the adsorbent comprises the following steps: crushing and grinding natural zeolites, soaking the zeolites in acids, mixing the zeolites with an aqueous solution of CuSO4.5H2O, performing a high temperature reaction, cooling, cleaning, and drying to obtain the finished product. The application and regeneration method of the adsorbent comprises the following steps: selecting organic glass as an adsorption column, adding the adsorbent into the column, adjusting the PH of nitrogen-containing waste water to be weak alkaline, injecting the waste water into the adsorption column through a peristaltic pump for an adsorption reaction; backwashing the adsorption column after adsorption for a while, when the adsorption is completed, cleaning the adsorbent by hydrochloric acid or sulfuric acid, recovering the cleaning solution, performing evaporation and crystallization to obtain ammonium chloride or ammonium sulfate crystals. The cleaned adsorbent can be reused. The modified zeolite ammonia nitrogen adsorbent of the invention has a large adsorption capacity, and good adsorption effect, and is simple and convenient for regeneration; when the adsorbent is used for the treatment of nitrogen-containing waste water, the process is simple and the effluent is stable.

Owner:HUNAN HUAYI MUNICIPAL ENG DESIGN

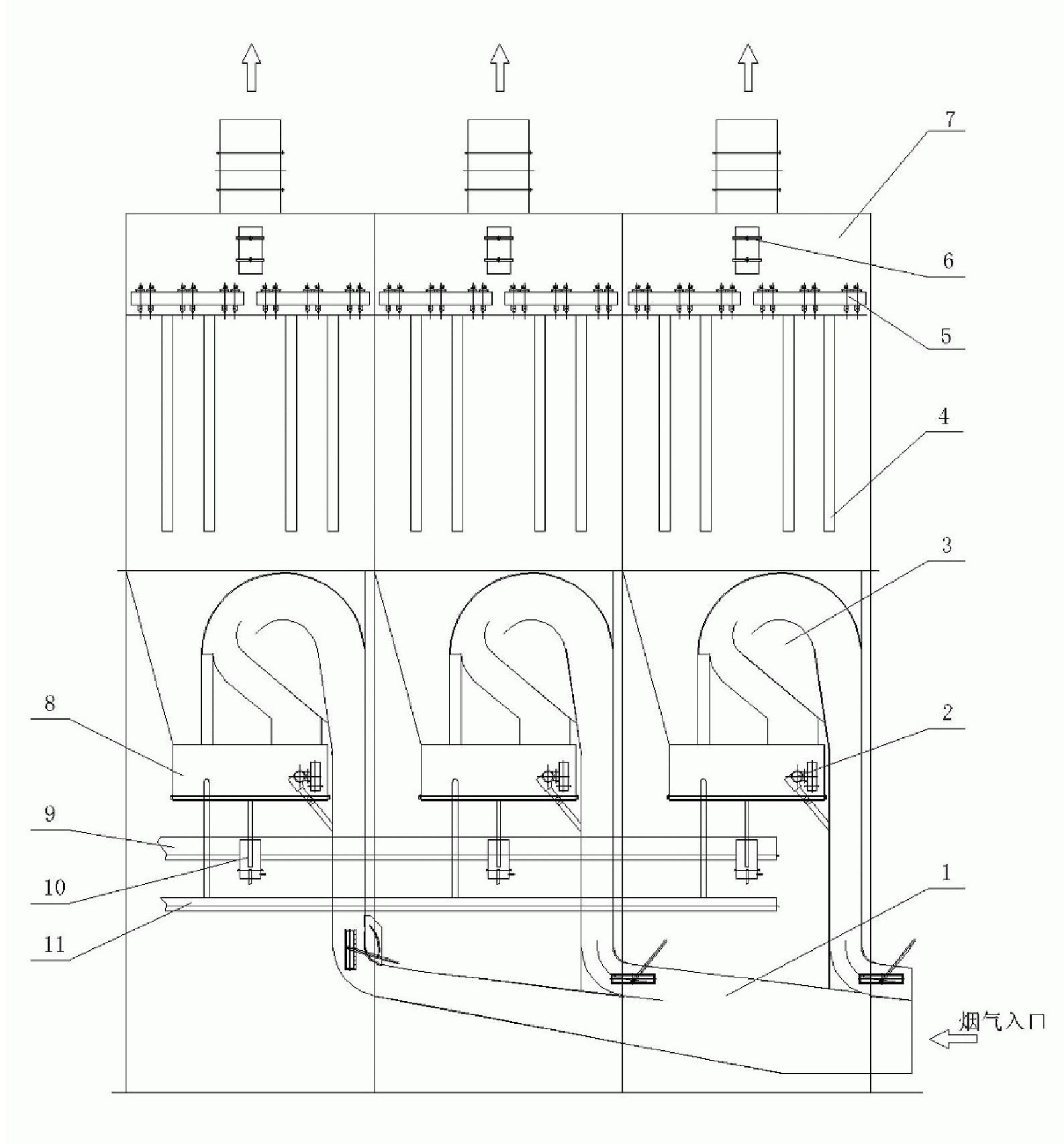

Method and device for purifying electrolytic aluminum smoke

ActiveCN101775625AImprove adsorption efficiencyImprove recycling ratesDispersed particle separationFrequency conversionBaghouse

The invention relates to a technology for purifying electrolytic aluminum smoke, in particular to a method and a device for purifying electrolytic aluminum smoke. The smoke generated in an electrolytic tank is sucked into an inlet pipeline by the sucking force of a draught fan and distributed into an R-shaped flue by a guide plate and an adjusting door; an outlet of the R-shaped flue is connected with a dust hopper, fresh aluminum oxide enters a delivery chute and is sprayed into the dust hopper under a filter bag by a pneumatic hoister to carry out adsorption reaction with the smoke; the gas and solid separation is carried out by the filter bag of a bag dust remover; fluorine-containing aluminum oxide in a dust hopper boiling bed enters a frequency conversion feeder by the chute, and the aluminum oxide is sprayed into a pipeline at the lower part of the R-shaped flue by a spray hole discharge opening through frequency conversion feeder to carry out adsorption reaction again; the gas and solid separation is carried out by the filter bag of the bag dust remover after the adsorption reaction, the aluminum oxide containing fluoride is filtered and delivered in a fluorine-containing aluminum oxide bin by a fluorine-containing aluminum oxide chute, and the purified smoke is emptied by the fan. The invention improves the adsorbing efficiency on the fluoride by utilizing the R-shaped flue at the lower part of a smoke inlet, simultaneously improves the recycling rate of raw materials, reduces the consumption of the raw materials and has the advantages of good purifying effect and high working efficiency.

Owner:WEIHAI ZHENGDA ENVIRONMENTAL PROTECTION EQUIP LTD BY SHARE LTD

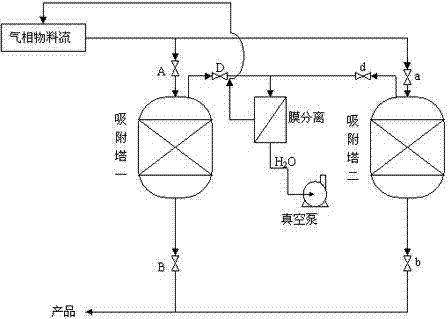

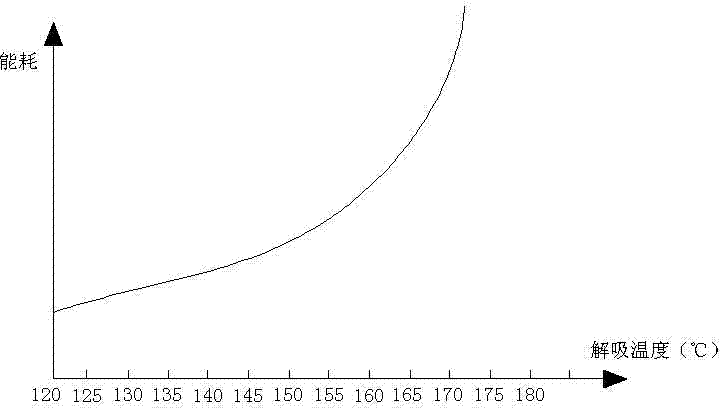

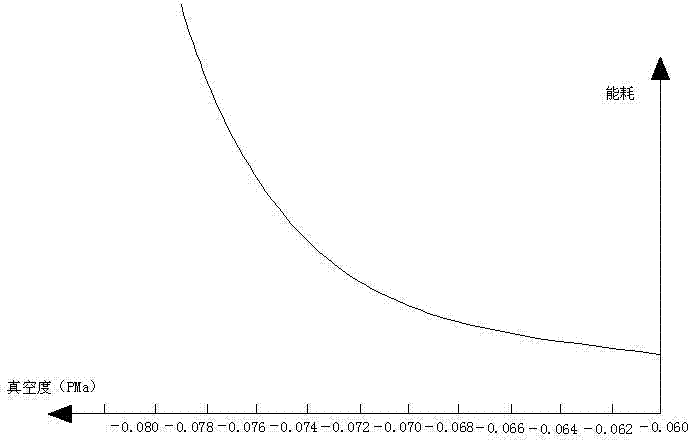

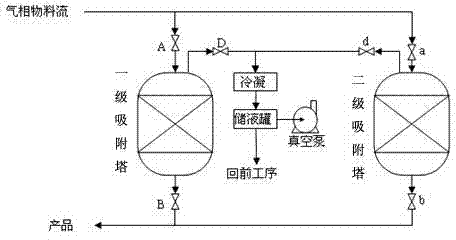

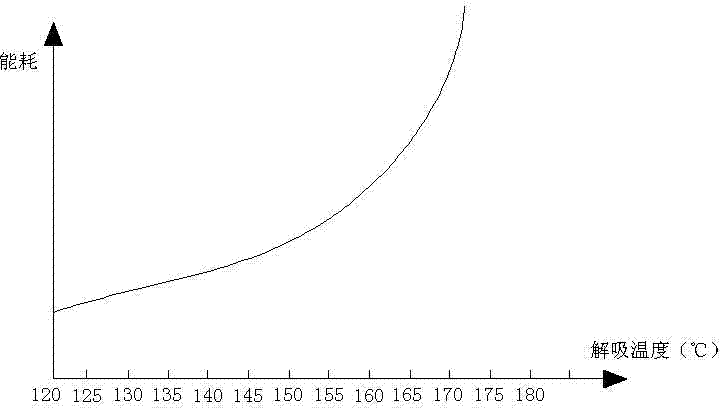

Method for adsorption, membrane separation and dehydration of polyoxymethylene dimethyl ether

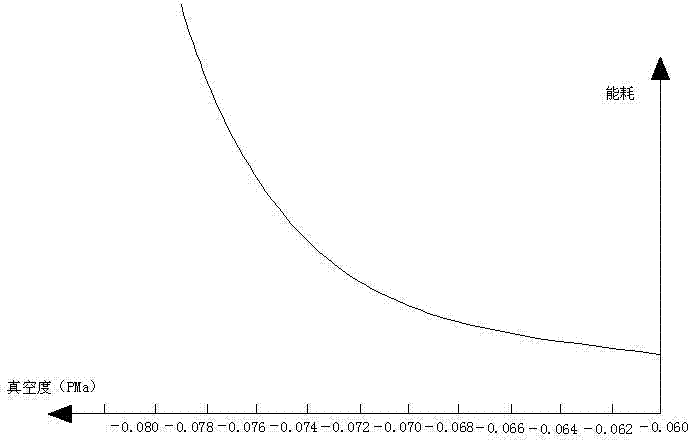

ActiveCN104725201AReduce energy consumptionReduce processing timeOrganic chemistryOrganic compound preparationMolecular sieveGas phase

Owner:ZHEJIANG TIANCAIYUNJI TECH CO LTD

Method for removing anion pollutants from water

InactiveCN102502913AReduce manufacturing costImprove adsorption efficiencyWater/sewage treatment by sorptionSorbentAdsorption reaction

The invention belongs to the technical field of purification treatment, and relates to a method for removing anion pollutants from water. The method comprises the following steps of: (1) adding an adsorbent into a water body polluted by anion pollutants and undergoing an adsorption reaction at a certain temperature; and (2) after adsorption is completed, intercepting, separating and treating the adsorbent in water. The anion pollutants in drinking water are adsorbed by using the structure recovery function of a stratified bimetal hydroxide. The adsorbent has the advantages of mild preparation conditions, readily-available raw materials, low production cost, high adsorption efficiency, recyclability, removing rate of over 80 percent on common anion pollutants and good application prospect.

Owner:TONGJI UNIV

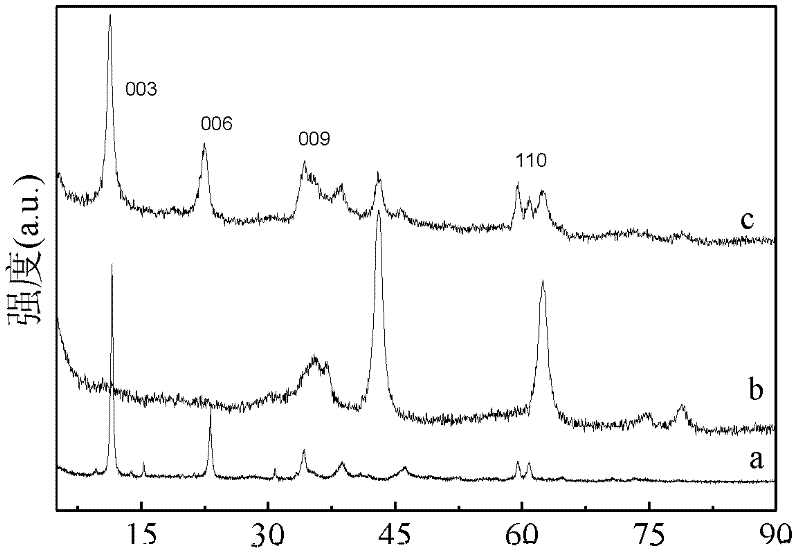

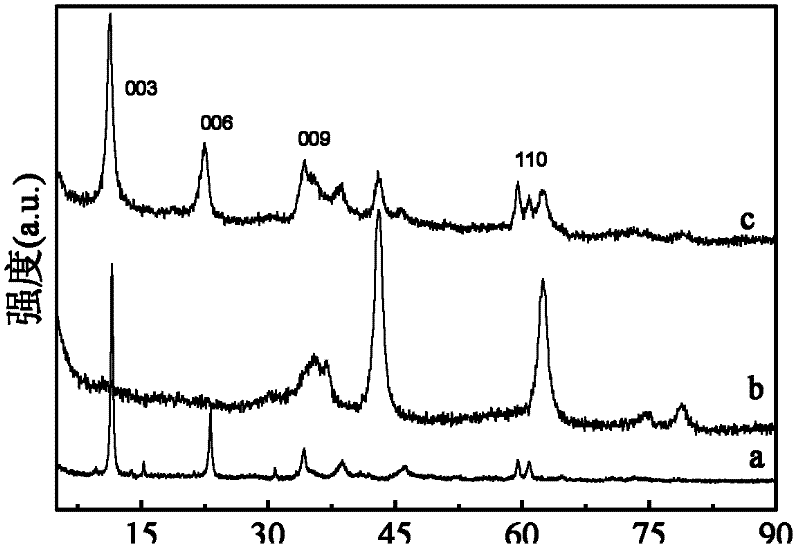

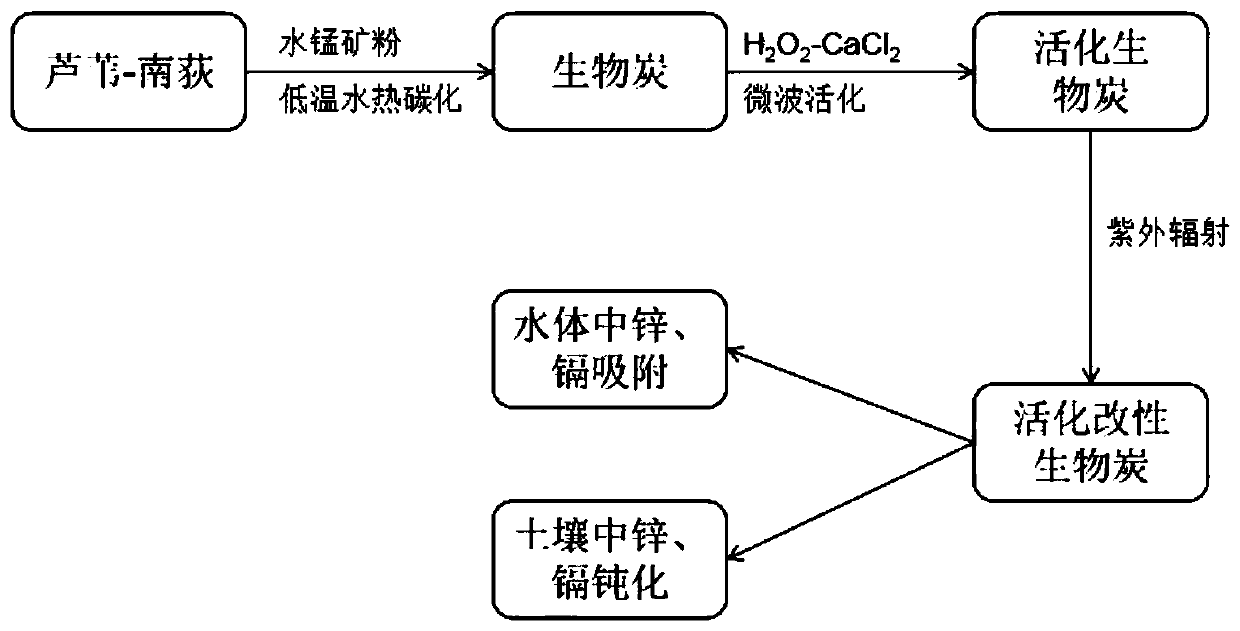

Preparation method and application of multi-site activated and modified reed-lutarioriparius biochar

ActiveCN110327882AImprove stabilityHigh pHOther chemical processesWater contaminantsMulti siteSoil heavy metals

The invention relates to the field of treatment to heavy metal pollution in water and soil, in particular to a preparation method of multi-site activated and modified reed-lutarioriparius biochar andapplication thereof to removal of heavy metals zinc and cadmium. The preparation method comprises the following steps: firstly washing, drying and crushing reed-lutarioriparius biomass, ultrasonicallystirring in an aqueous manganese ore powder solution thoroughly, then performing low-temperature hydrothermal carbonization to produce unactivated and unmodified biochar, then soaking the biochar ina calcium chloride-hydrogen peroxide mixed solution, activating a biochar-calcium chloride-hydrogen peroxide mixed solution by using microwave, and then modifying the dried biochar through ultravioletradiation to obtain activated and modified biochar, wherein the obtained biochar is applied to the removal of the heavy metals zinc and cadmium in the water and the soil. An application method comprises the following steps: adding the activated and modified biochar into heavy metal zinc and cadmium wastewater for an adsorption reaction; or directly adding into heavy metal zinc and cadmium contaminated soil, thoroughly mixing uniformly, and aging for a period of time to complete bioremediation of heavy metal zinc and cadmium pollution in the soil.

Owner:JIANGXI ACADEMY OF SCI

Composite material and preparation method thereof

ActiveCN108079934ALarge specific surface areaIncrease loadOther chemical processesAluminium silicatesCarbon filmMicrosphere

The invention relates to a composite material and a preparation method thereof, and can be widely applied to the fields of batteries, environmental protection, adsorptive dehumidification, air conditioning, refrigeration, heat pumps, pressure-variable separation purification, hydrogen storage production and the like. The composite material comprises a supporting framework material, carbon microspheres and / or a carbon film and a loading material, the loading material comprises salt, an electrode material and a physical adsorbent, the carbon microspheres and / or the carbon film are / is firmly attached to the wall surfaces of pores in the supporting framework material, and the loading material is uniformly distributed inside the carbon microspheres and / or the carbon film, so that direct embedment of the loading material between carbon atoms is achieved, the anti-agglomeration inactivation capacity is obviously enhanced, and the service life is effectively prolonged; the composite material breaks through a limitation of the specific surface area of the original skeleton material, so that the specific surface area of the composite material can be effectively increased under the premise ofincreasing the loading capacity, and the adsorption, reaction or electron migration rate can be increased; the composite material conveniently achieves close contact between the adsorbent and a heat-exchanging wall surface by an extruding, bonding or brazing method, so that the contact heat resistance between the two is effectively reduced.

Owner:SHANDONG UNIV

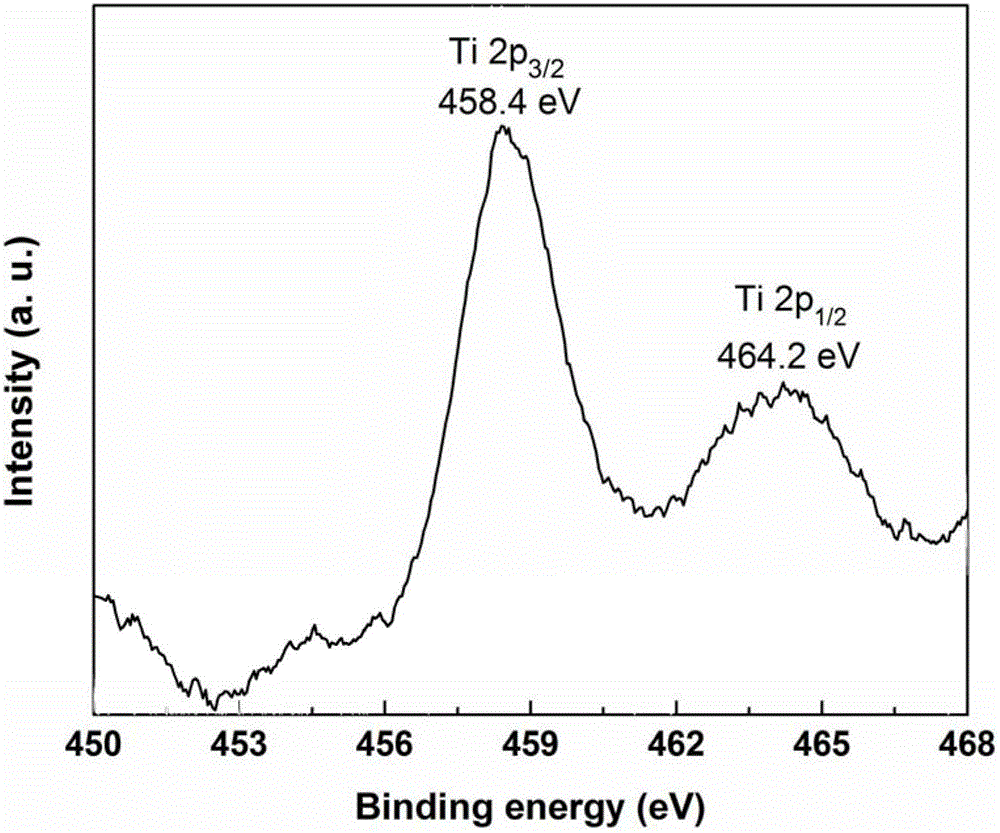

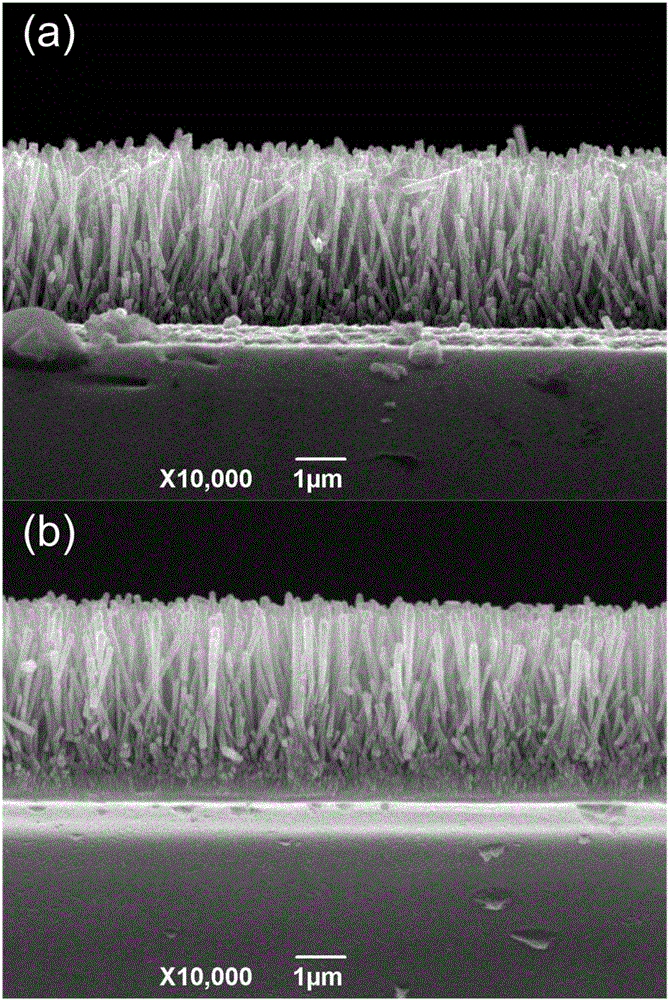

Preparation method of composite nanowire array with one-dimensional ZnO(zinc oxide)-TiO2(titanium dioxide) core-shell structure

InactiveCN102723208AImprove efficiencyLow environmental requirementsLight-sensitive devicesPhotovoltaic energy generationAtomic layer depositionZno nanowires

A preparation method of a composite nanowire array with a one-dimensional ZnO(zinc oxide)-TiO2(titanium dioxide) core-shell structure. In the whole preparation process, a wet chemistry method is adopted. The preparation method comprises the following steps: at first, a ZnO seed layer is prepared on conductive glass in a sol-gel method, then a ZnO nanowire array is grown on the seed layer in a liquid-phase deposition method, and next a TiO2 shell layer is prepared on a ZnO nanowire array in a circulating adsorption reaction method, so as to obtain the composite nanowire array with the one-dimensional ZnO-TiO2 core-shell structure. The preparation method has the advantages that (1) compared with the other methods (such as a chemical meteorology deposition method, an atom layer deposition method and a magnetron sputtering method), the preparation method has a simple process, does not require complex equipment and severe environments, and is low in cost; (2) the preparation method can control the diameter and the length of the ZnO nanowire and the thickness of the TiO2 shell layer conveniently; and (3) the preparation method can be combined with a photoanode preparation method of a quantum dot dye-sensitized solar cell conveniently to facilitate the research of the cell performance.

Owner:XI AN JIAOTONG UNIV

Method for preparing, using and regenerating Fe-Mn-Al composite oxide/zeolite antimony removal adsorbent

InactiveCN102553520AExcellent adsorption performanceEasy to prepareOther chemical processesCombustible gas purificationChemistryComposite oxide

The invention disclosed a method for preparing, using and regenerating novel antimony removing adsorbent-Fe-Mn-Al composite oxide / zeolite antimony removal adsorbent, belonging to the technical field of water treatment application. The Fe-Mn-Al composite oxide / zeolite antimony removal adsorbent also has oxidation and adsorption properties and has a moderate pore structure and rich active adsorption sites, therefore, excellent adsorption efficiency is provided to trivalent antimony and pentavalent antimony in a broad-spectrum pH range. The material can be used for removing antimony after being filled into an adsorption reactor and can be regenerated through a simple method after adsorption is saturated, and the operation is simple and practical.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

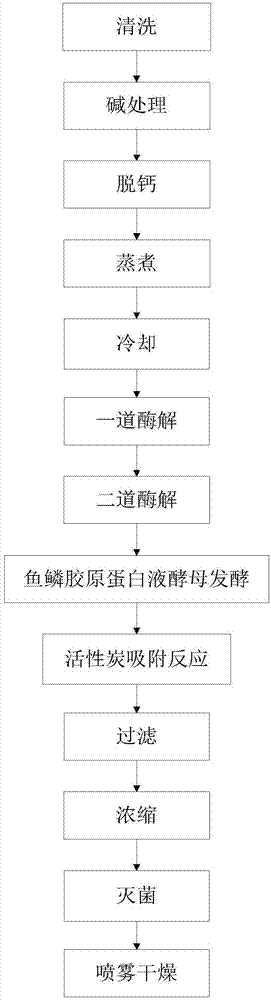

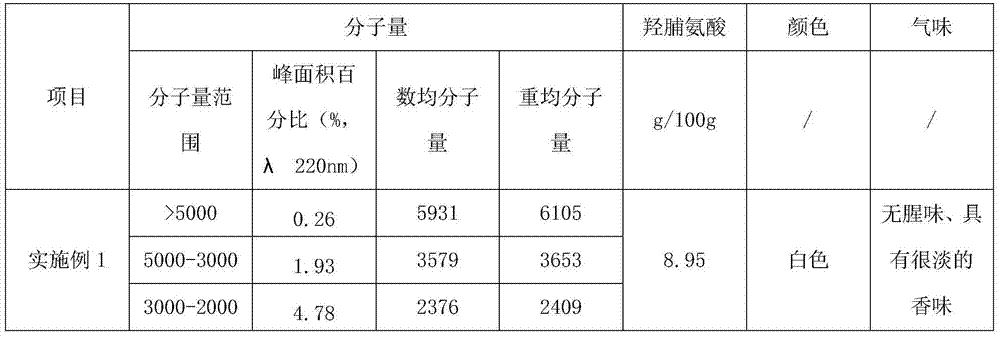

Preparation technology for producing collagen through enzymolysis of fish scales

The invention relates to a preparation technology for producing collagen and in particular relates to a preparation technology for producing collagen through enzymolysis of fish scales, belonging to the technical field of collagen extraction. The preparation technology comprises the following steps of (1) washing, (2) alkali treatment, (3) decalcification, (4) cooking, (5) cooling, (6) primary enzymolysis, (7) secondary enzymolysis, (8) yeast fermentation of a fish scale collagen solution, (9) activated carbon adsorption reaction, (10) filtration, (11) concentration, (12) sterilization and (13) spray drying. The method provided by the invention not only can achieve the effect of obtaining collagen peptides with high contents and low molecular components from the fish scales but also can achieve the effects of removing pigment substances affecting the appearances of collagen products and reducing the peculiar fishy smell of collagen, thus improving the values of fish collagen products.

Owner:NINGDE XIAWEI FOOD

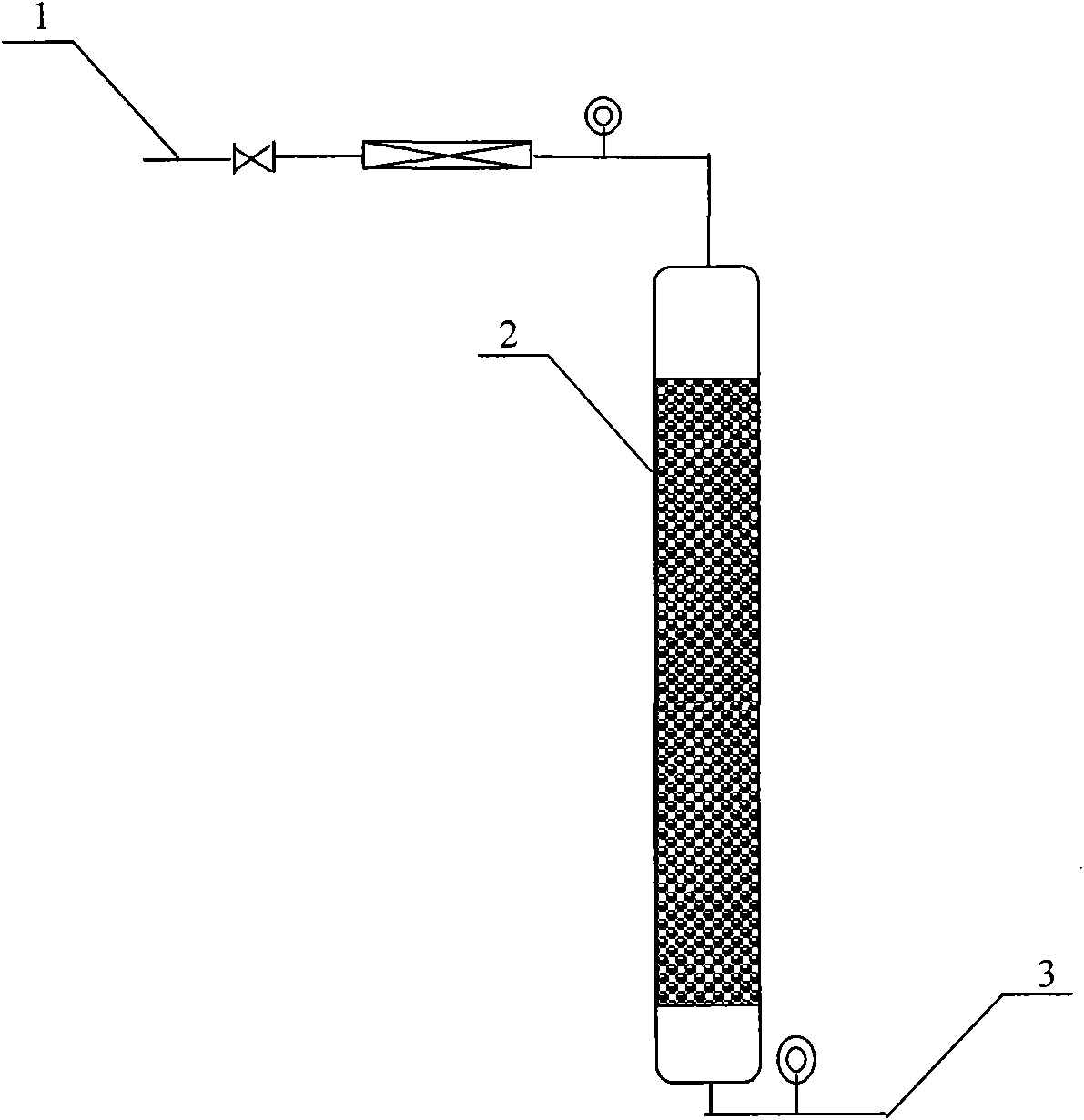

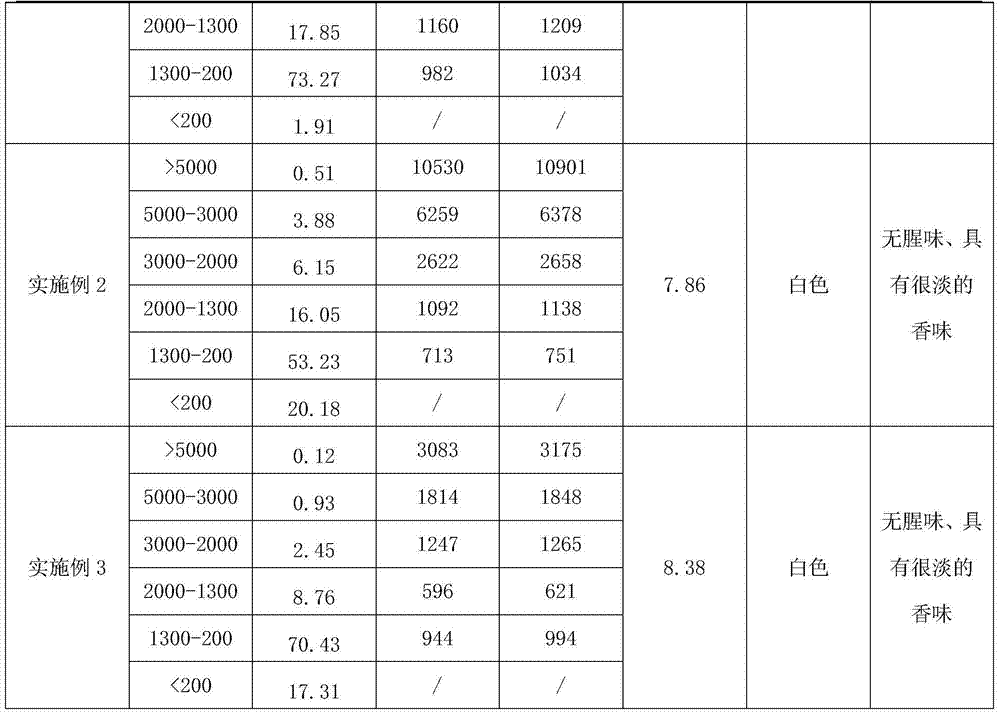

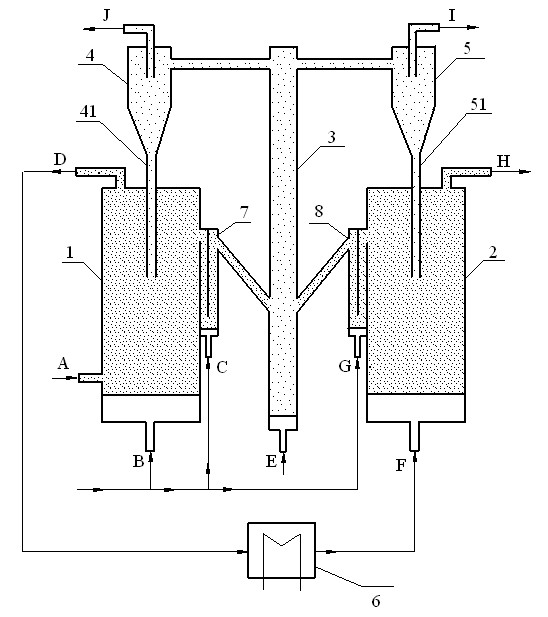

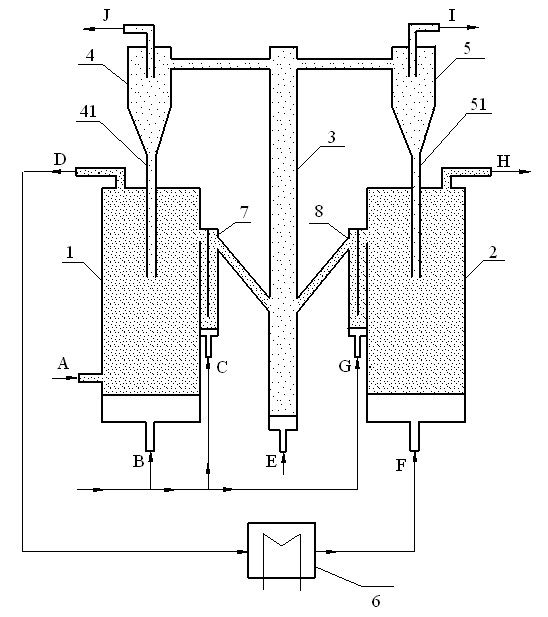

Device and method for producing hydrogen through coal gasification

InactiveCN102585911AReduce qualityEfficient captureGas purification with selectively adsorptive solidsGranular/pulverulent flues gasificationSorbentCarbonatation

The invention discloses a device and a method for producing hydrogen through coal gasification. The device comprises a gasification reactor (1), an adsorption reactor (2) arranged opposite to the gasification reactor (1), a calcination reactor (3) arranged between the gasification reactor (1) and the adsorption reactor (2), a gasification cyclone separator (4), an adsorption cyclone separator (5), an external heat exchanger (6), a gasification isolator (7) and an adsorption isolator (8). A high temperature synthetic gas inlet of the external heat exchanger (6) is connected with a high temperature synthetic gas outlet (D) of the gasification reactor (1). The method for producing the hydrogen through coal gasification comprises the following steps of: performing pyrolysis gasification reaction of coal particles; performing carbonation reaction on calcium-based adsorber particles; and performing calcinations reaction on calcium carbonate particles. By the device and the method, the coal particles are gasified to form high-quality hydrogen rich gas, and carbon dioxide is effectively captured.

Owner:SOUTHEAST UNIV

Method of treating heavy metal industrial effluent with turf as adsorbent

InactiveCN1772635AImprove adsorption capacityHigh saturated adsorption capacityEnergy based wastewater treatmentWater/sewage treatment by flocculation/precipitationIndustrial effluentSorbent

The present invention relates to the treatment of heavy metal waste water, and is especially method of treating heavy metal industrial effluent with turf as adsorbent. Dried and crushed turf is used as adsorbent, and industrial effluent is injected into reaction pond with excessive turf adsorbent to produce adsorption reaction eliminating heavy metal ions. The treating process may be a continuous one, intermittent one or column adsorption one. In the continuous and intermittent adsorption process to treat great amount of low concentration heavy metal industrial effluent, the turf adsorbent is circularly utilized until reaching the adsorption capacity. The present invention uses turf adsorbent with low cost, wide source, simple preparing process and stable technological process, and may be used in treating various kinds of heavy metal industrial effluent.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Thallium-containing waste water purification method, thallium element enriching and recovering method and application of purification method

ActiveCN107381926ALow costEasy to operateWater contaminantsMultistage water/sewage treatmentHigh concentrationHydrogen

The invention discloses a thallium-containing waste water purification method which is used for removing a thallium element in waste water. The purification method includes the steps: 1) adding alkali liquor into the waste water, and adjusting pH (potential of hydrogen) to be alkaline; 2) adding magnet powder into the waste water adjusted to be alkaline, performing adsorption reaction on mixture; 3) sucking the magnet powder after reaction by the aid of a magnet block, and performing solid and liquid separation to obtain liquid supernatant, namely, purified water removing the thallium element. The invention further provides a thallium element enriching and recovering method. According to the method, the magnet powder after adsorption reaction in the thallium-containing waste water purification method is desorbed, and the thallium element adsorbed by the magnet powder is enriched into desorption liquid. The method is low in cost and simple and convenient to operate, adsorption materials can be repeatedly used, the thallium element in the waste water can be efficiently removed, and the method is applicable to purifying, enriching and recovering of the thallium element in the thallium-containing waste water with low, medium and high-concentration.

Owner:GUANGZHOU UNIVERSITY

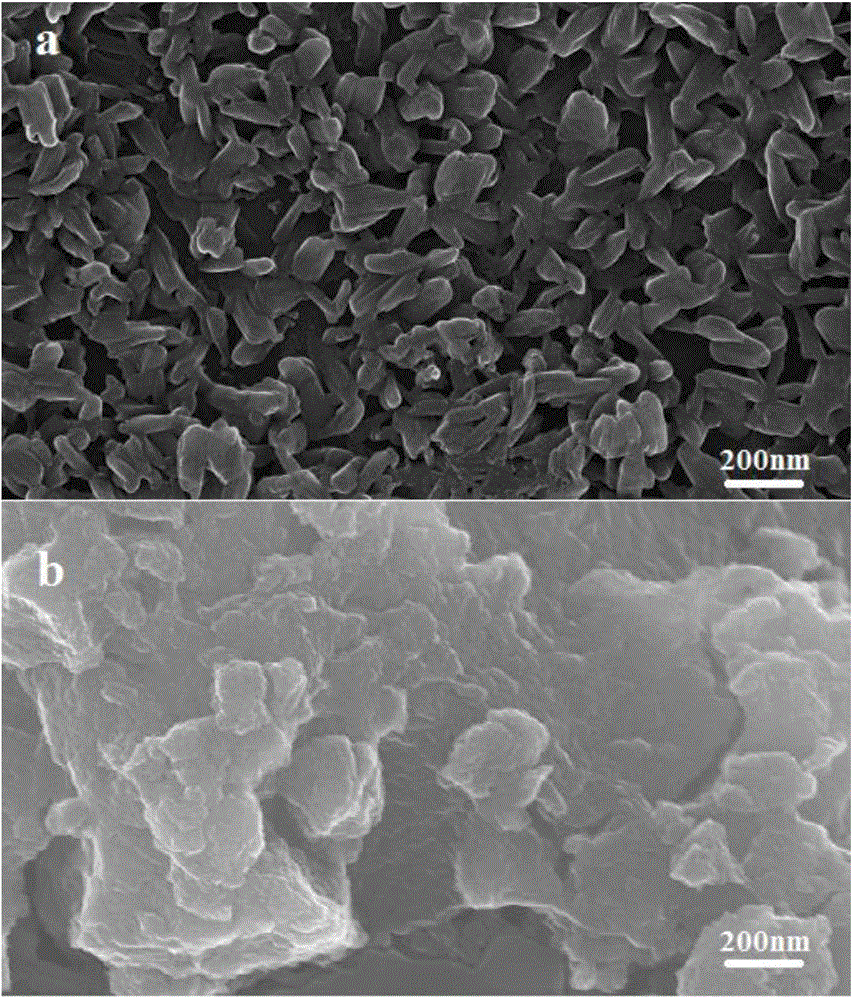

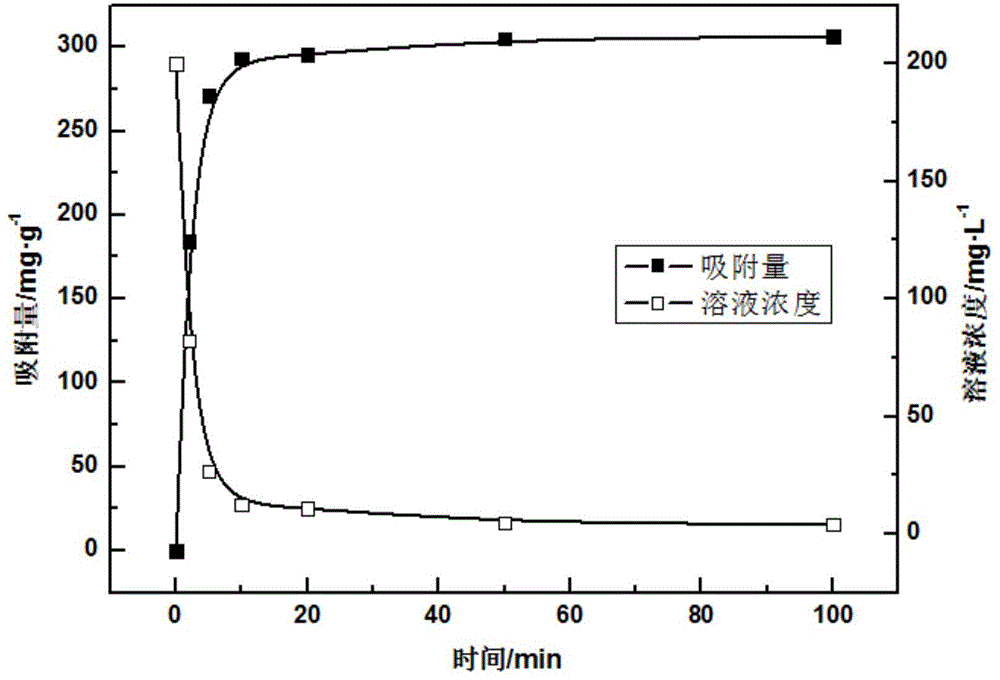

Nanometer magnesium silicate adsorbing material and preparation method therefor

ActiveCN104971691AImprove adsorption capacityOvercome the disadvantages of inconvenient mass productionOther chemical processesSilicon compoundsOrganic dyeHigh surface

The invention provides a method for preparing an efficient nanometer magnesium silicate adsorbing material by using common raw materials through simple steps. A magnesium silicate colloid is synthesized by a liquid film reactor and a nucleation-crystallizing isolating method, and nanometer magnesium silicate particles are obtained through low temperature drying. The rotating liquid film reactor is used, and reaction conditions are regulated, so that the agglomeration of products is effectively improved, and the particle diameter of the products is decreased. Tests prove that the prepared magnesium silicate adsorbing material is the particles of 100nm-2 <mu>m, the specific surface area is 140-200m2 / g, and the magnesium silicate adsorbing material has excellent characteristics of rich hole structures, large specific surface area, high surface charge and the like. The capacity of the magnesium silicate adsorbing material for removing organic dye namely methylene blue is excellent, after about 10 minutes, an adsorption reaction is close to balance, and under the premise that the removing rate is ensured to be more than 90%, the largest adsorption quantity achieves 280-365mg / g. The preparation method provided by the invention has high maneuverability, the used raw materials are cheap, the industrial production is facilitated, and the preparation method has wide application prospects in the field of wastewater treatment.

Owner:BEIJING UNIV OF CHEM TECH

Double-layer permeable reactive barrier system for repairing chromium-polluted underground water

ActiveCN103880107APromote reductionIncrease surface areaWater contaminantsWater/sewage treatment by sorptionElectron donorSorbent

The invention relates to a double-layer permeable reactive barrier system for repairing chromium-polluted underground water. The double-layer permeable reactive barrier system comprises a reduction reaction barrier and an adsorption reaction barrier behind the reduction reaction barrier, wherein the space between the reduction reaction barrier and the adsorption reaction barrier is 2.5-5m, the bottom ends of the reduction reaction barrier and the adsorption reaction barrier stretch into an impervious bed by at least 0.60-0.8m, and the tops of the reduction reaction barrier and the adsorption reaction barrier are 0.4-0.5m higher than the maximum water level of the underground water. When the double-layer permeable reactive barrier system is used, the polluted stream sequentially flows through the reduction reaction barrier and the reduction reaction barrier; when flowing through the system, the chromium-polluted underground water firstly flows through the reduction reaction barrier to generate a reduction reaction with zero-valent iron powder to convert hexavalent chromium into trivalent chromium, and organic matters in straw can be taken as electron donors to accelerate the reduction of the hexavalent chromium; a biomass adsorbent has a huge surface area, the residual pollutants can be strongly adsorbed by the adsorption reaction barrier, so that the problems that a reductant is washed away, reduction products are diluted and washed away, the reduction of the hexavalent chromium cannot be realized when the utilization of the reductant is saturated, and the like are solved, and the chromium pollution in the underground water is economically and efficiently removed.

Owner:ZHONGKE DINGSHI ENVIRONMENTAL ENG CO LTD +1

Method for dehydrating gas-phase material flow in production process of polymethoxyl dimethyl ether

InactiveCN104725198AReduce energy consumptionReduce processing timeOrganic chemistryOrganic compound preparationSorbentGas phase

The invention discloses a method for dehydrating a gas-phase material flow in the production process of polymethoxyl dimethyl ether. The method comprises the following steps: feeding feed gas of the gas-phase material flow through the top of a first-stage adsorption tower, and carrying out adsorption reaction in the first-stage adsorption tower; entering a regeneration stage after completing adsorption through a molecular sieve in the first-stage adsorption tower, and feeding the feed gas of the gas-phase material flow in a second-stage adsorption tower to carry out adsorption reaction; entering an adsorption state again after completing regeneration through the first-stage adsorption tower; entering the regeneration state after completing adsorption through the second-stage adsorption tower; and circulating the above steps till the moisture content in the feed gas of the gas-phase material flow meets requirements. By adopting the above process, the moisture content of a polymethoxyl dimethyl ether rectifying gas-phase material flow is controlled below 0.05%; simultaneously, on the premise of ensuring the adsorption quality, the energy consumption can also be effectively reduced; the utilization rate of an adsorbent is increased; a stripping liquid returns to previous production workshop sections; no pollutant is discharged; and the continuity of the whole workshop section production is ensured.

Owner:SICHUAN TECHAIRS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com