Nanometer magnesium silicate adsorbing material and preparation method therefor

An adsorption material, magnesium silicate technology, applied in chemical instruments and methods, adsorption water/sewage treatment, silicon compounds, etc. Overcome the effects of large-scale production, good adsorption capacity, and broad practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step A: take by weighing 10.256g (40mmol) Mg (NO 3 ) 2 ·6H 2 O and 11.369g (40mmol) Na 2 SiO 3 9H 2 Dissolve O in 200mL deionized water, stir well to dissolve.

[0027] Step B: Pour the two solutions of step A into the liquid film reactor at a flow rate of 1000mL / min in equal volume, adjust the rotor speed to 4000rpm, and the rotor-stator distance to 0.1mm, and mix quickly for 2min.

[0028] Step C: Transfer the above slurry to a hydrothermal reaction kettle with stirring, the heating rate is 1°C / min, the temperature is slowly raised to 170°C, the temperature is kept constant for 12 hours, and the stirring rate is 100r / min.

[0029] Step D: After the reaction, the slurry was naturally cooled to room temperature, centrifuged, washed with 100 mL of deionized water for 3 times, and dried in an oven at 60°C for 24 hours to obtain the nano-magnesium silicate adsorption material.

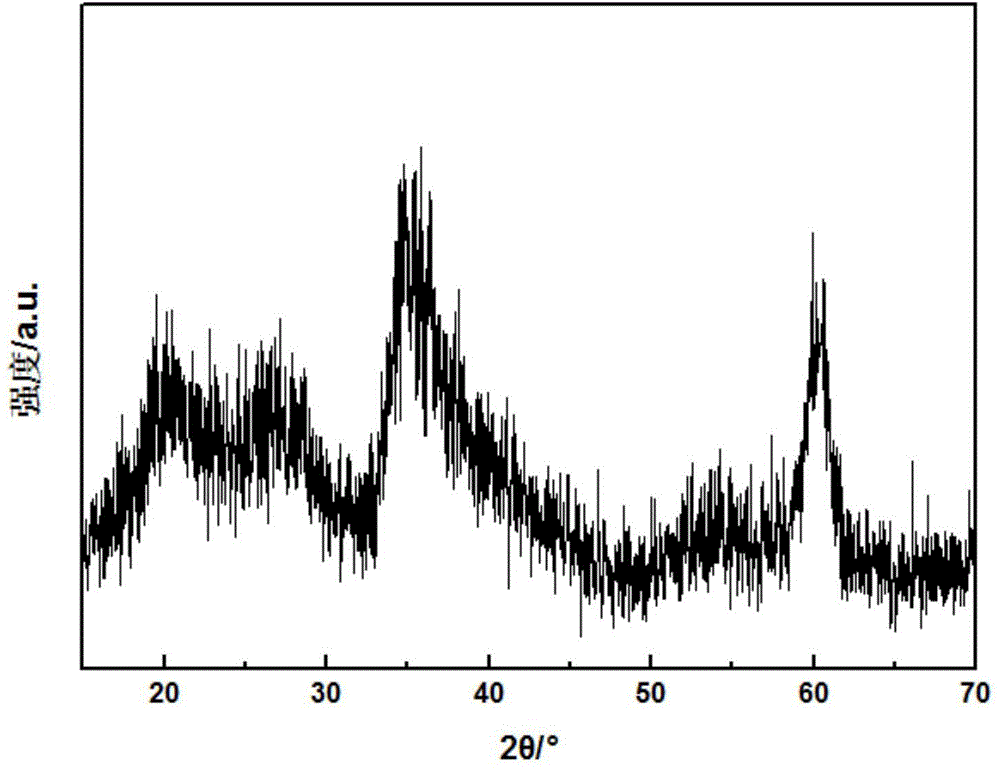

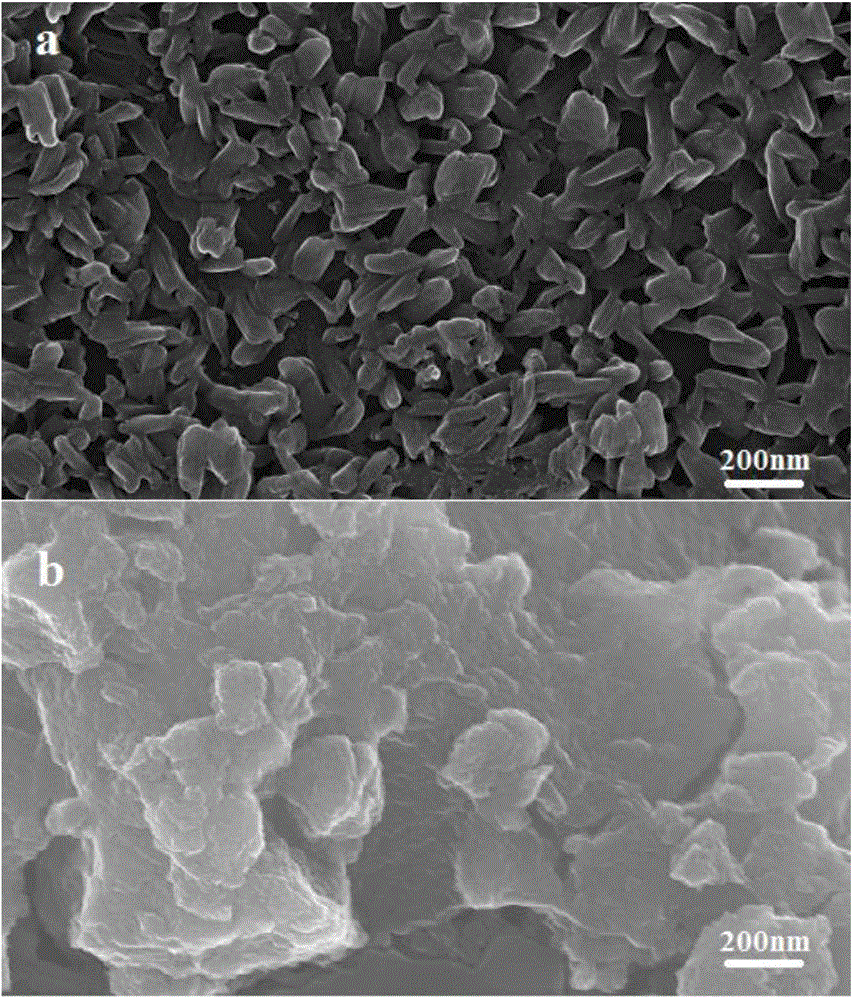

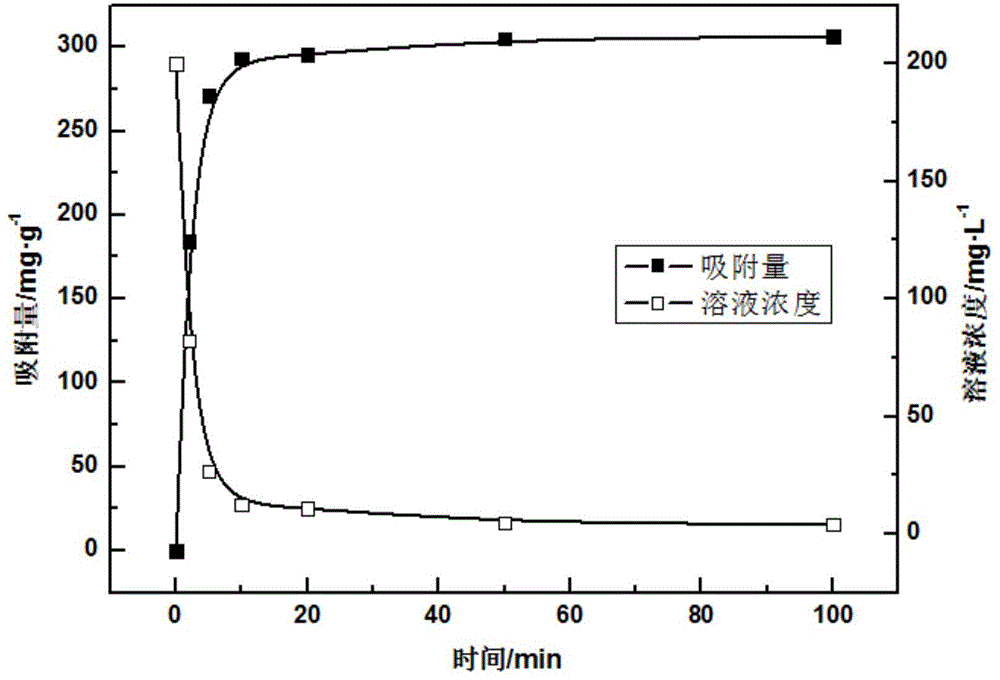

[0030] figure 1 It is the XRD analysis result of the prepared nano-magnesium silicate, w...

Embodiment 2

[0032] Step A: Weigh 8.132g (40mmol) MgCl 2 ·6H 2 O and 11.369g (40mmol) Na 2 SiO 3 9H 2Dissolve O in 200mL deionized water, stir well to dissolve.

[0033] Step B: Pour the two solutions of step A into the liquid film reactor at a flow rate of 1000mL / min in equal volume, adjust the rotor speed to 4000r / min, the rotor-stator distance to 0.1mm, and quickly nucleate for 2min.

[0034] Step C: Transfer the above slurry to a hydrothermal reaction kettle with stirring. The heating rate is about 1°C / min, and the temperature is slowly raised to 170°C. The temperature is kept constant for 12h at a stirring rate of 100r / min.

[0035] Step D: After the reaction, the slurry was naturally cooled to room temperature, centrifuged, washed 5 times with 100 mL of deionized water, and no visible precipitation of chloride ions was detected with silver nitrate solution, and then dried in an oven at 60°C for 24 hours to obtain nano Magnesium silicate adsorption material.

[0036] XRD analysi...

Embodiment 3

[0038] Step A: Weigh 4.815g MgSO 4 (40mmol) and 11.369g Na 2 SiO 3 9H 2 O (40mmol) was dissolved in 200mL deionized water respectively, and stirred thoroughly to dissolve it.

[0039] Step B: Pour the two solutions of step A into the liquid film reactor at a flow rate of 1000mL / min in equal volume, adjust the rotor speed to 4000r / min, the rotor-stator distance to 0.1mm, and quickly nucleate for 2min.

[0040] Step C: Transfer the above slurry to a hydrothermal reaction kettle with stirring, the heating rate is 1°C / min, the temperature is slowly raised to 170°C, the temperature is kept constant for 12 hours, and the stirring rate is 100r / min.

[0041] Step D: naturally cool the reacted slurry to room temperature, centrifuge, wash 5 times with 100 mL of deionized water, use barium nitrate solution to detect no visible precipitation of sulfate ions, and then dry it in an oven at 60°C for 24 hours to obtain Nano magnesium silicate adsorption material.

[0042] XRD analysis sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com