Preparation method of composite nanowire array with one-dimensional ZnO(zinc oxide)-TiO2(titanium dioxide) core-shell structure

A nanowire array, titanium dioxide technology, applied in photosensitive equipment, electrolytic capacitors, photovoltaic power generation and other directions, can solve the problems of high temperature, high manufacturing cost, unfavorable promotion, etc., and achieve the effect of simple process, good repeatability and low environmental requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) First, dissolve monoethanolamine in 20 ml of ethylene glycol methyl ether, and then add 0.001 mole of zinc acetate dihydrate to make the ratio of monoethanolamine to zinc ions 1:1; then seal the mixture Place the zinc oxide sol in a 58°C water bath and stir evenly to obtain the zinc oxide sol. After the zinc oxide sol is taken out, it is allowed to stand for 15 hours at room temperature for later use. The spin coating process is used to apply the spin coating process at 3000 revolutions / min. The sol is deposited on clean conductive glass, and then it is immediately placed in an oven at 195°C for 10 minutes, and then the substrate is placed in a muffle furnace at 450°C for 1 hour to obtain a zinc oxide seed layer;

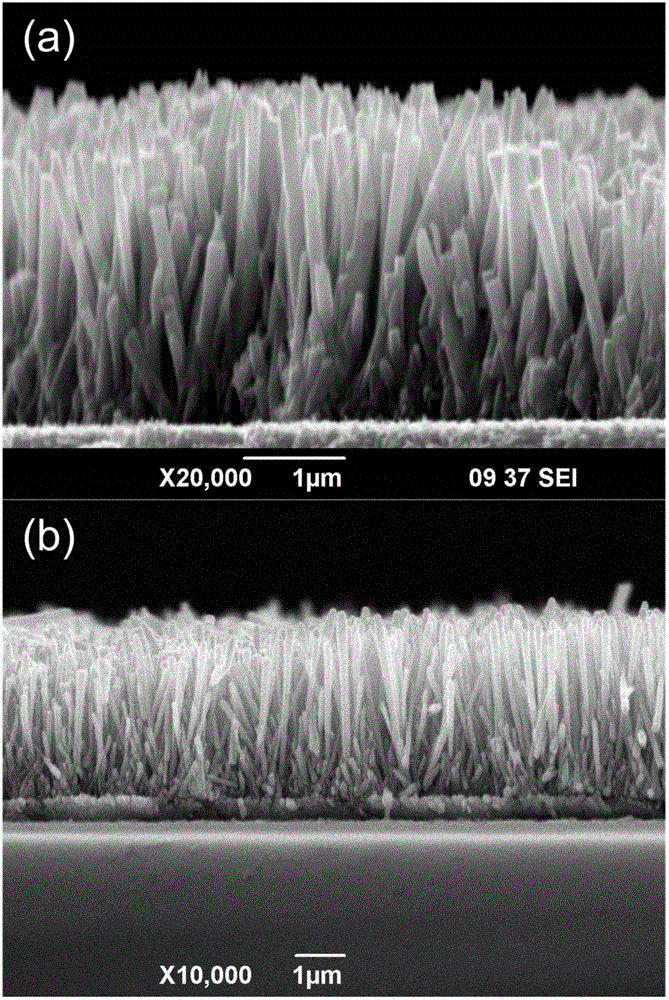

[0021] 2) Secondly, dissolve 2.5 millimoles of zinc nitrate hexahydrate and 2.5 millimoles of hexamethylenetetramine in 100 milliliters of deionized water, and mix them to obtain a growth solution. The prepared substrate covered with a seed layer The seed cry...

Embodiment 2

[0025] 1) First, dissolve monoethanolamine in 20 ml of ethylene glycol methyl ether, and then add 0.005 mole of zinc acetate dihydrate so that the ratio of the amount of monoethanolamine to zinc ion is 1:1; then the mixture is sealed Place it in a 60℃ water bath and stir it evenly to obtain zinc oxide sol. After removing the zinc oxide sol, let it stand for 12 hours at room temperature for later use. The spin coating process is used to apply the spin coating process at 3000 revolutions / min. The sol is deposited on clean conductive glass, and then it is immediately placed in an oven at 198°C for 8 minutes, and then the substrate is placed in a muffle furnace at 470°C for 1 hour to obtain a zinc oxide seed layer;

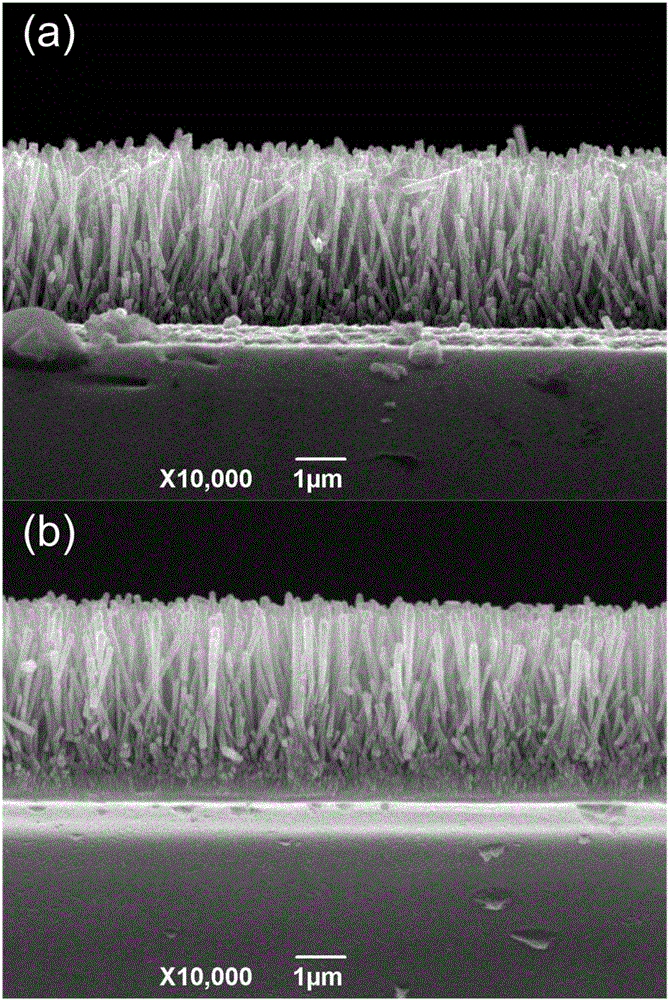

[0026] 2) Secondly, dissolve 5 millimoles of zinc nitrate hexahydrate, 5 millimoles of hexamethylenetetramine and 0.5 millimoles of polyethyleneimine with a molecular weight of 1800 in 100 milliliters of deionized water and mix well to obtain a growth solution , The prep...

Embodiment 3

[0030] 1) First, dissolve monoethanolamine in 20 ml of ethylene glycol methyl ether, and then add 0.01 mole of zinc acetate dihydrate to make the ratio of monoethanolamine to zinc ion 1:1; then seal the mixture Place the zinc oxide sol in a 62°C water bath and stir evenly to obtain the zinc oxide sol. After the zinc oxide sol is taken out, it is allowed to stand for 18 hours at room temperature for later use. The spin coating process is used to apply the spin coating process at 3000 revolutions / min. The sol is deposited on clean conductive glass, and then it is immediately placed in an oven at 202°C for 6 minutes, and then the substrate is placed in a muffle furnace at 485°C for 0.5 hours to obtain a zinc oxide seed layer;

[0031] 2) Secondly, dissolve 3 millimoles of zinc nitrate hexahydrate, 3 millimoles of hexamethylenetetramine and 0.3 millimoles of polyethyleneimine with a molecular weight of 1800 in 100 milliliters of deionized water and mix well to obtain a growth solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com