Patents

Literature

386 results about "Zno nanowires" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

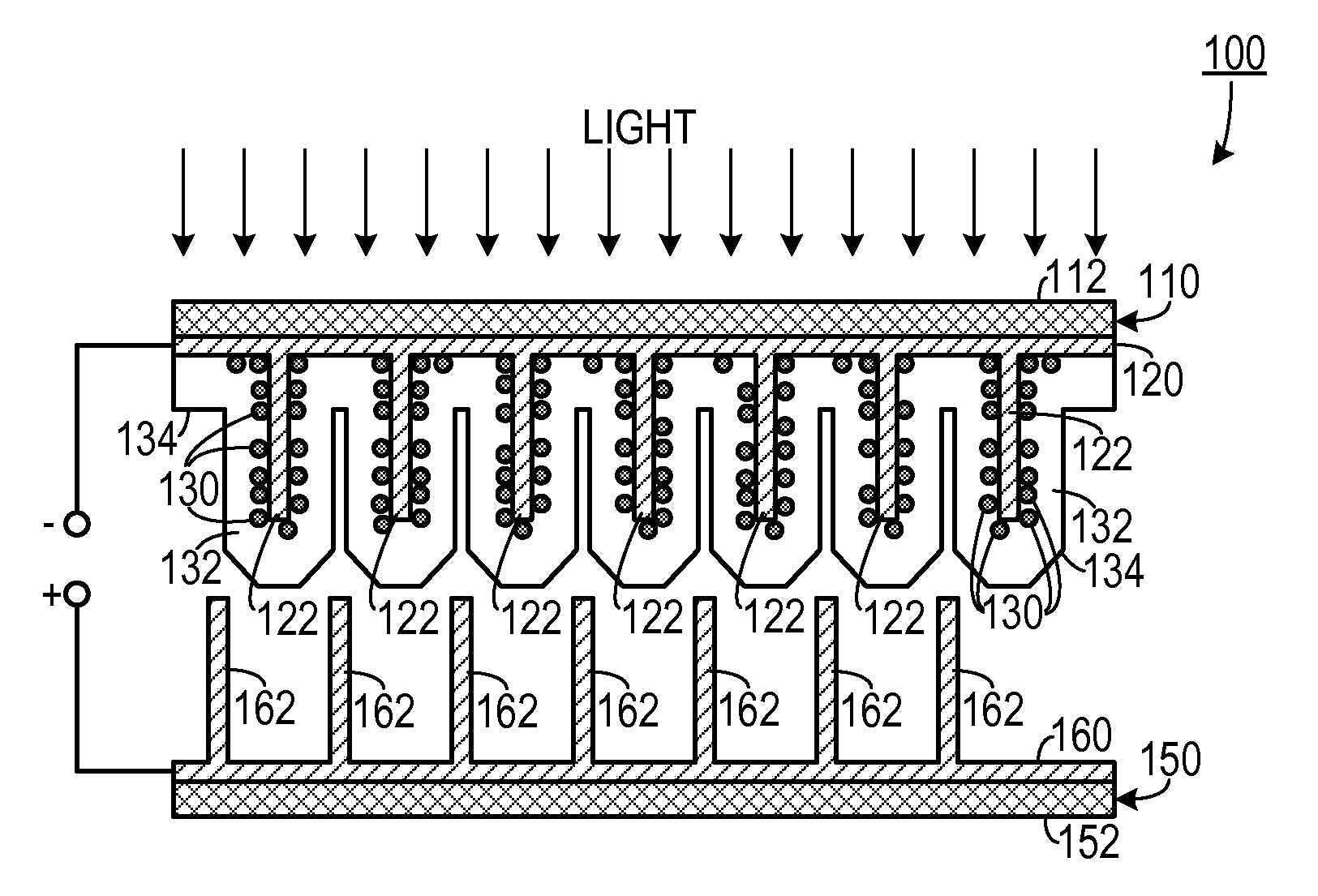

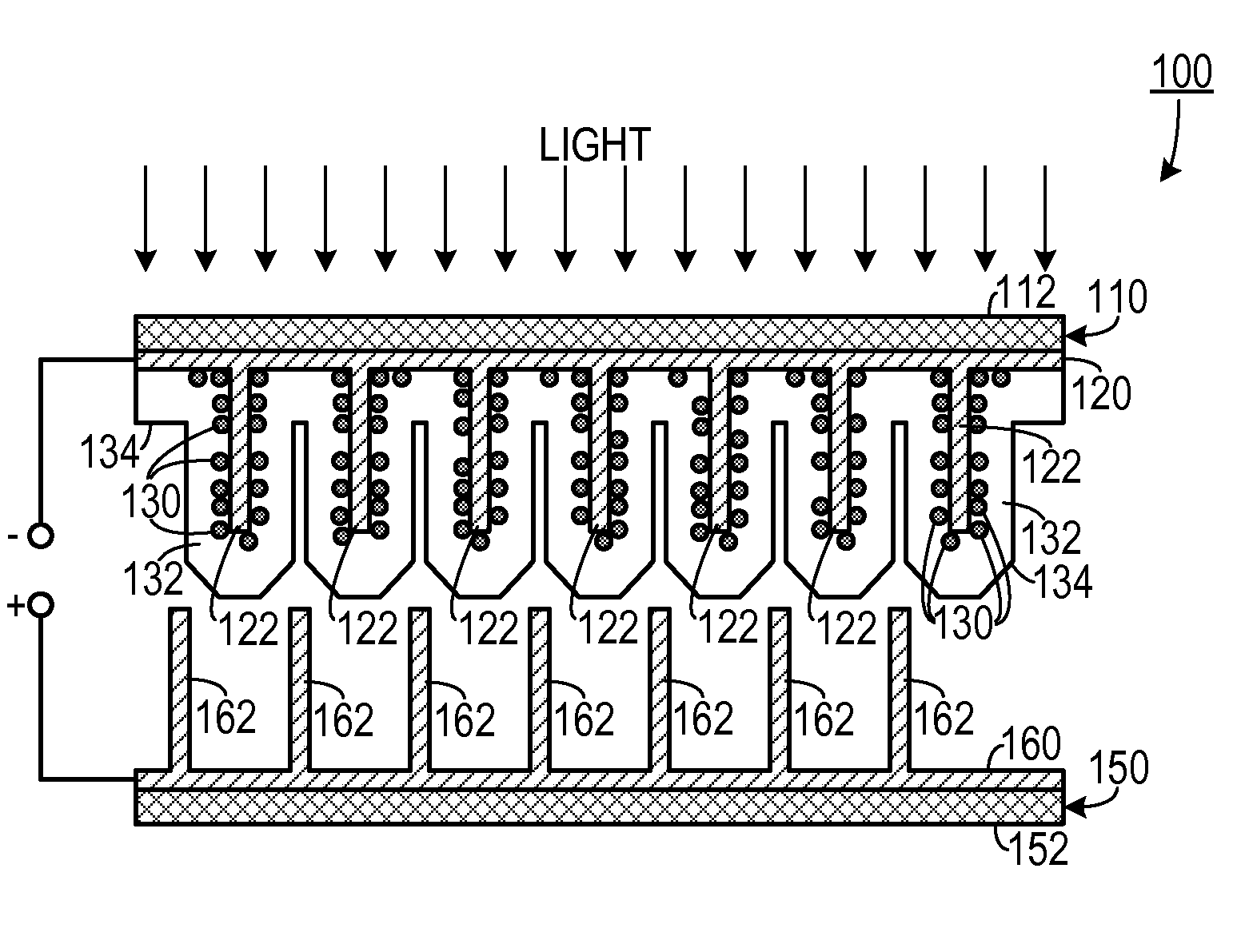

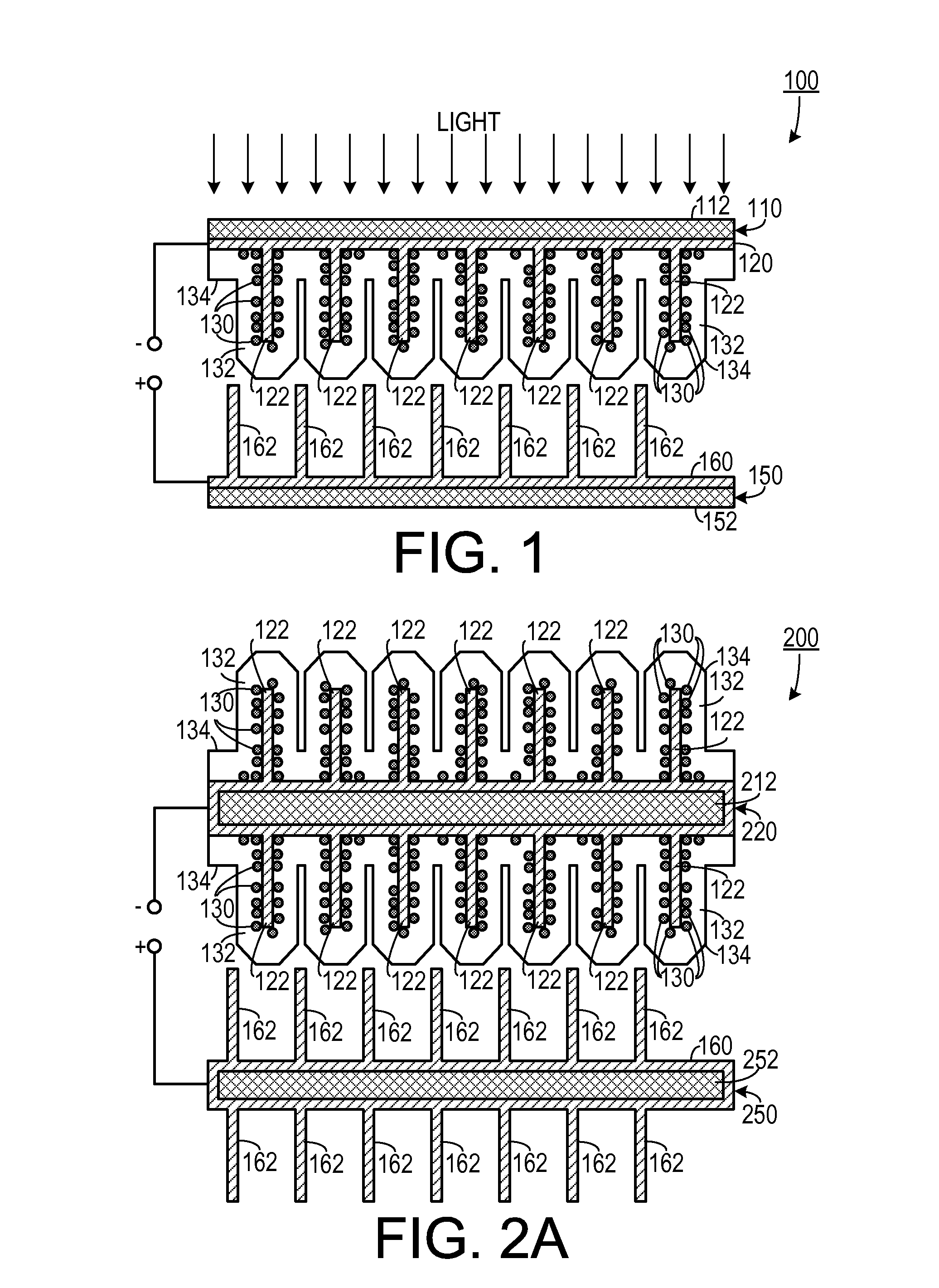

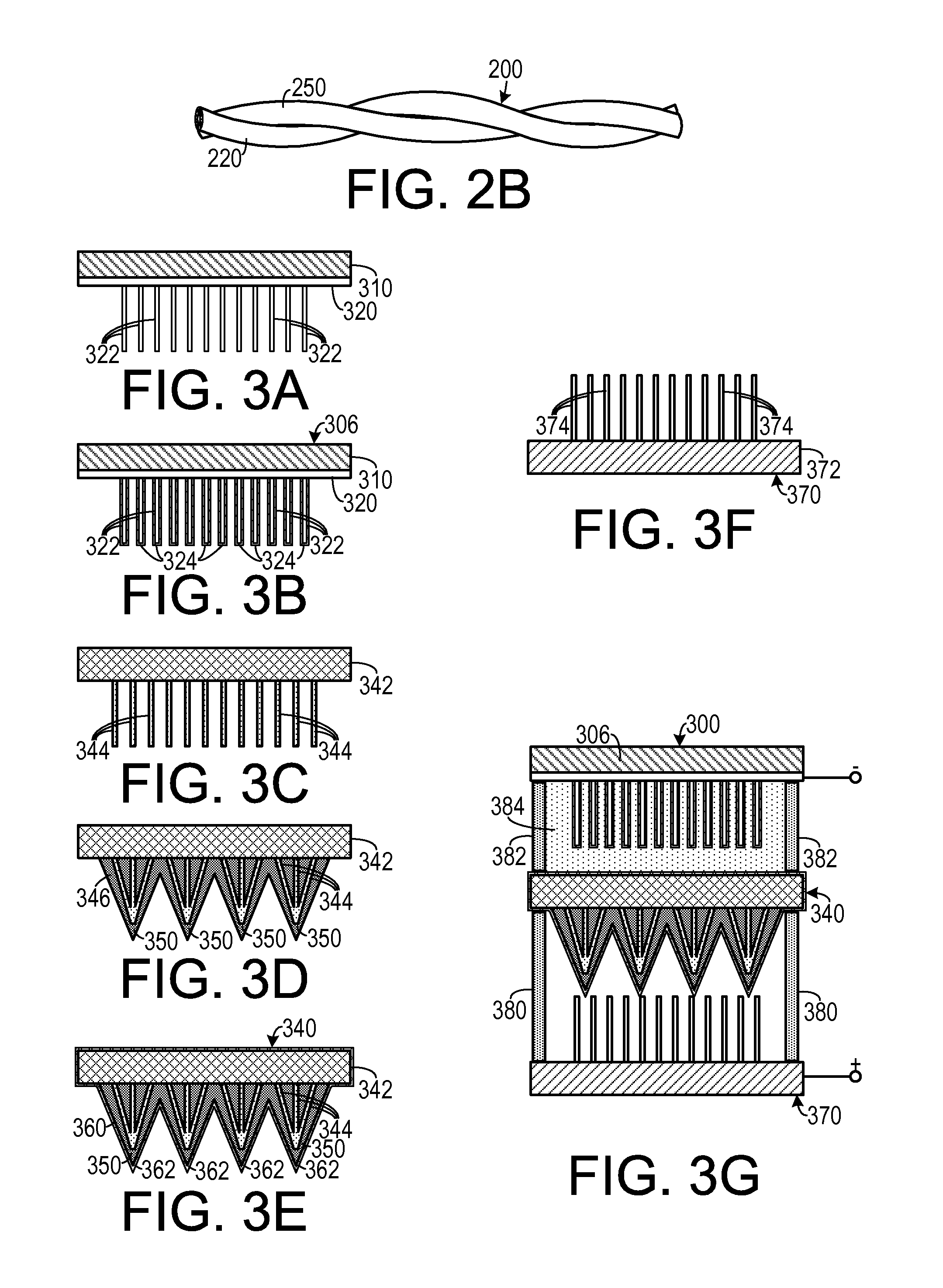

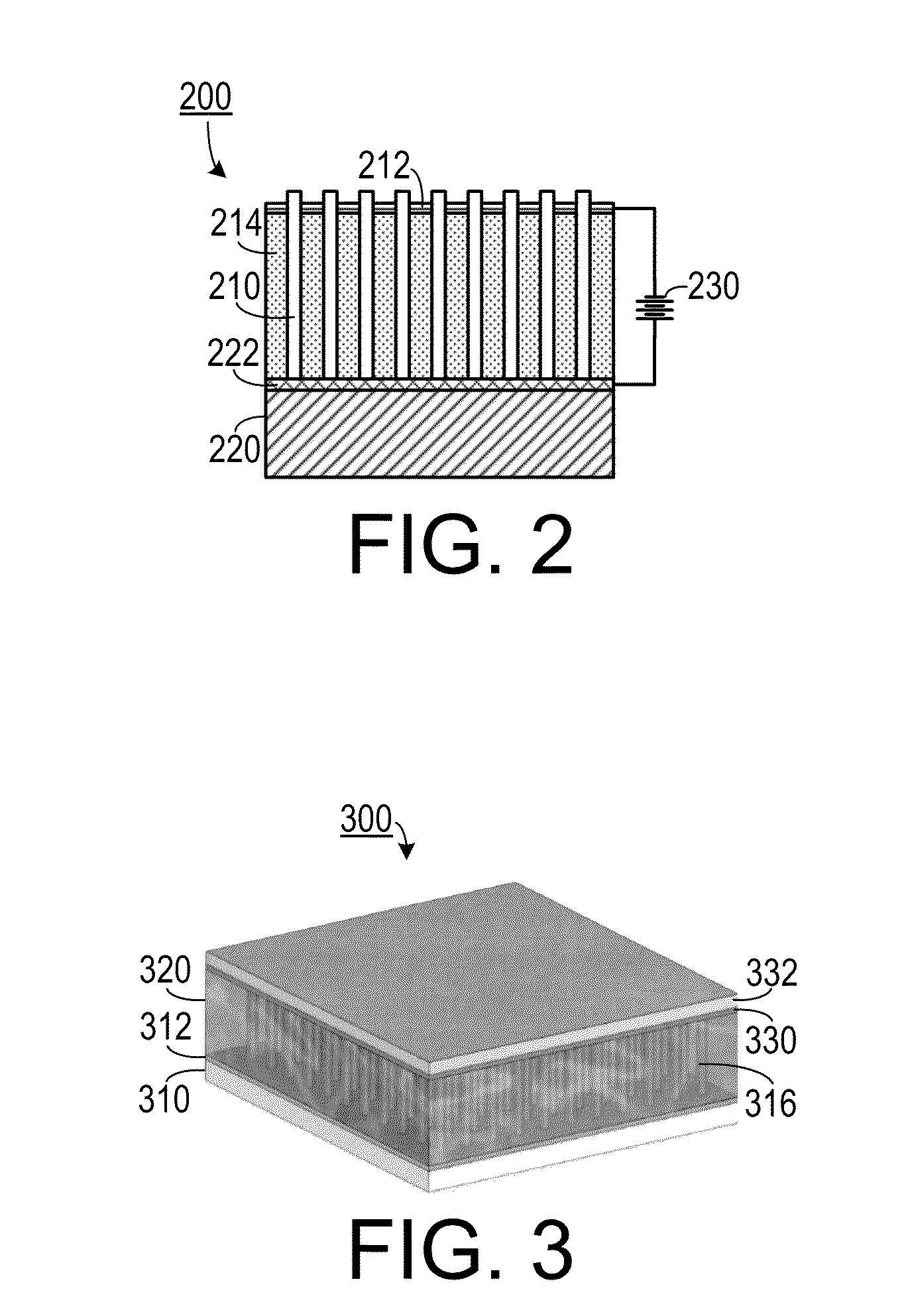

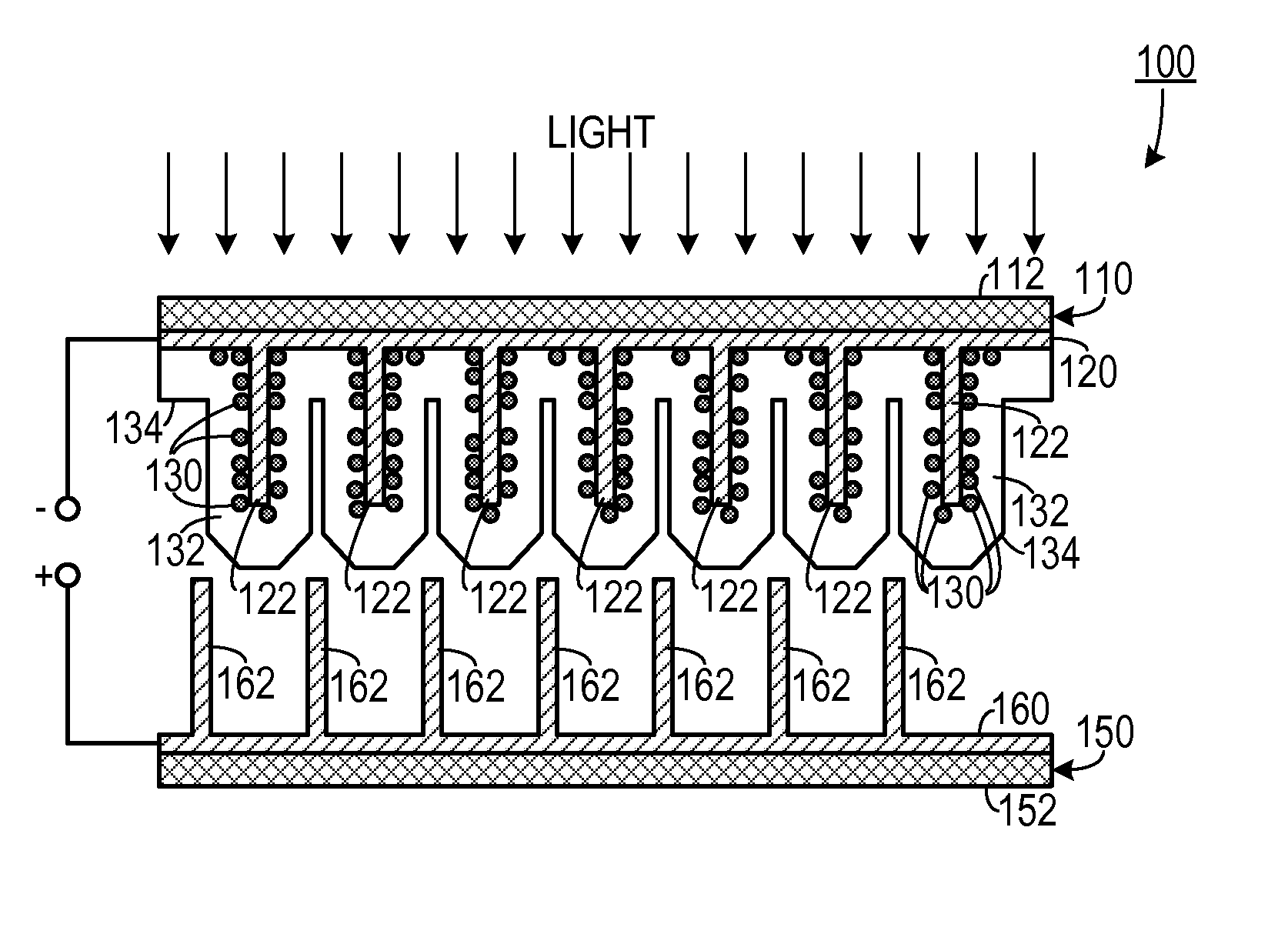

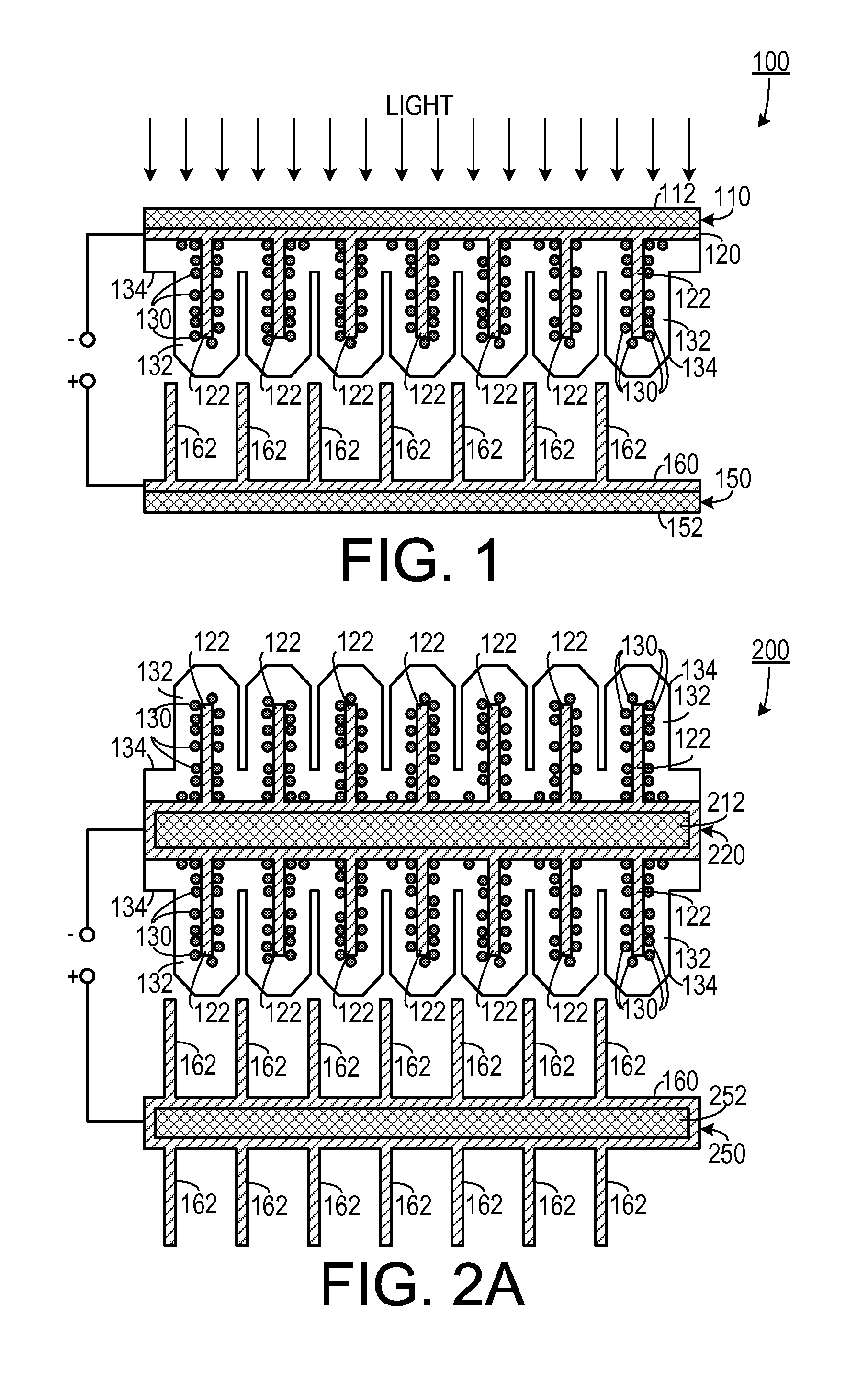

Hybrid solar nanogenerator cells

A dye-sensitized solar cell including ZnO nanowire arrays grown of a flat substrate for harvesting solar energy is integrated with a piezoelectric nanogenerator for harvesting ultrasonic wave energy. The two energy harvesting approaches work simultaneously or individually and can be integrated in parallel or serial for raising the output current, voltage or power, respectively. A solar cell employs an optical fiber and semiconductor nanowires grown around the fiber. A p-n junction based design, organic-inorganic heterojunction, or a dye-sensitized structure is built at the surfaces of the nanowires. Light entering the fiber from a tip propagates through the fiber until it enters a nanowire where it reaches a photovoltaic element. Light entering the fiber cannot escape until it interacts with a photovoltaic element, thereby increasing the solar conversion efficiency. The fiber can transmit light, while the nanowires around the fibers increase the surface area of light exposure.

Owner:GEORGIA TECH RES CORP

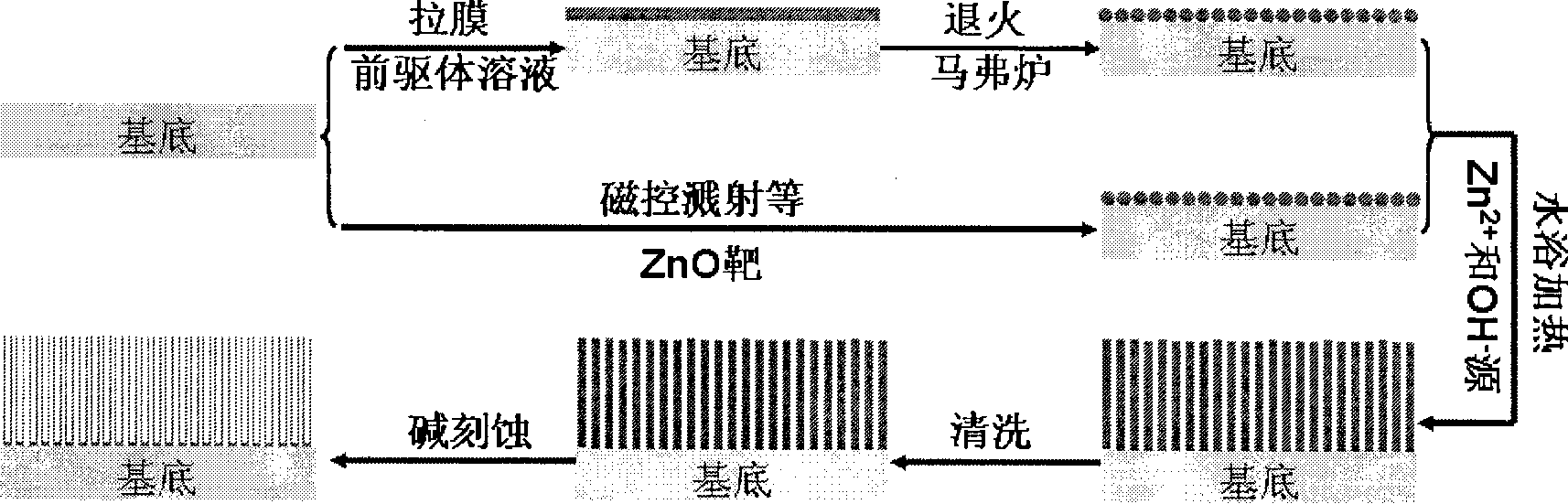

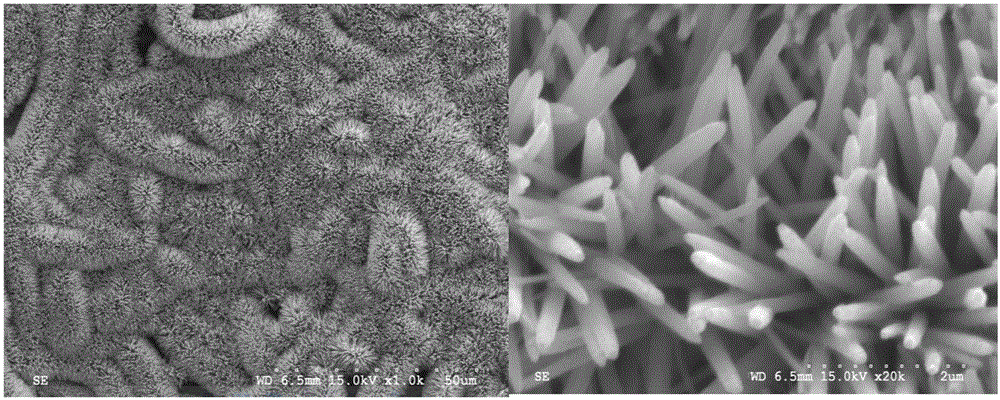

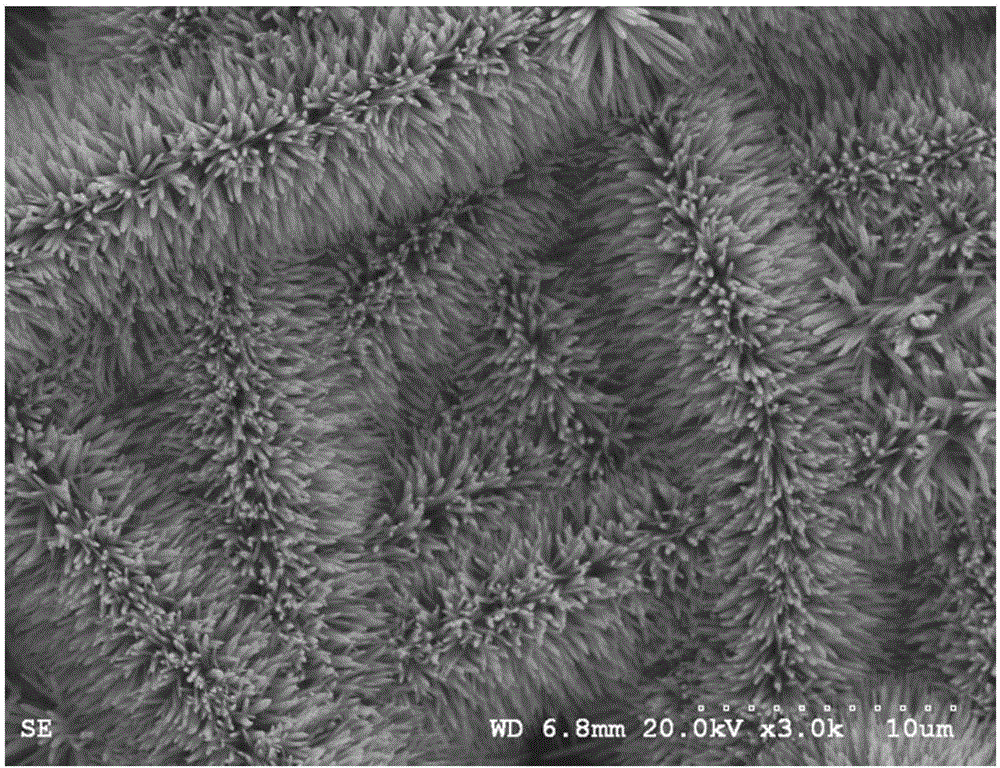

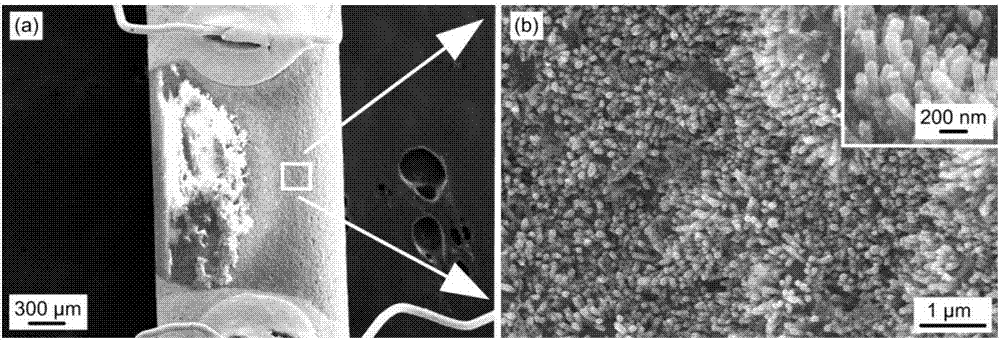

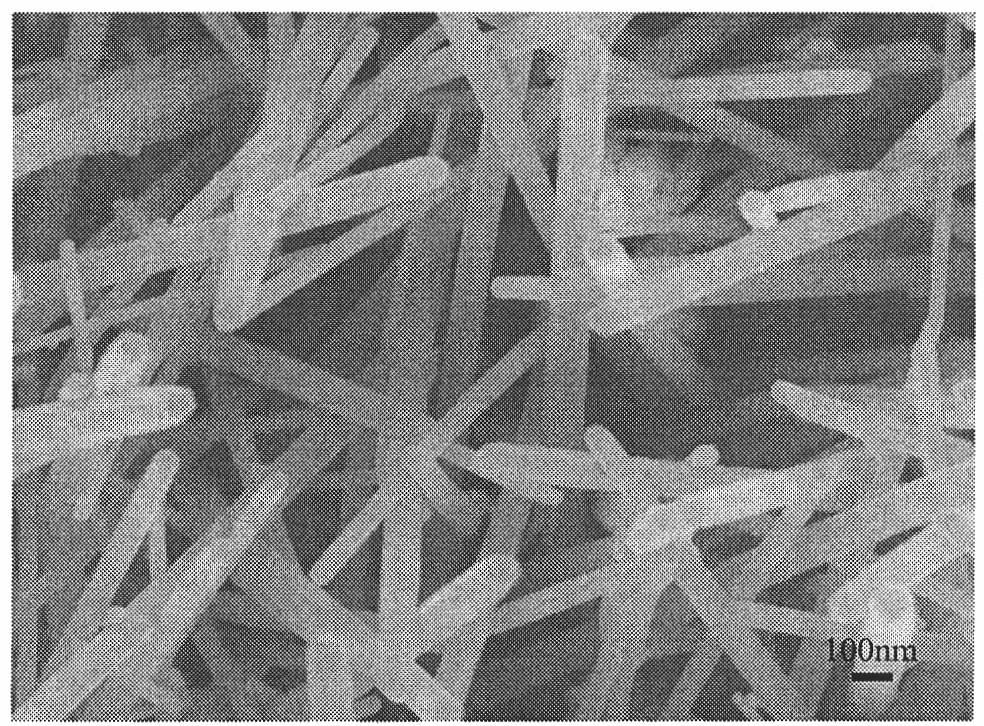

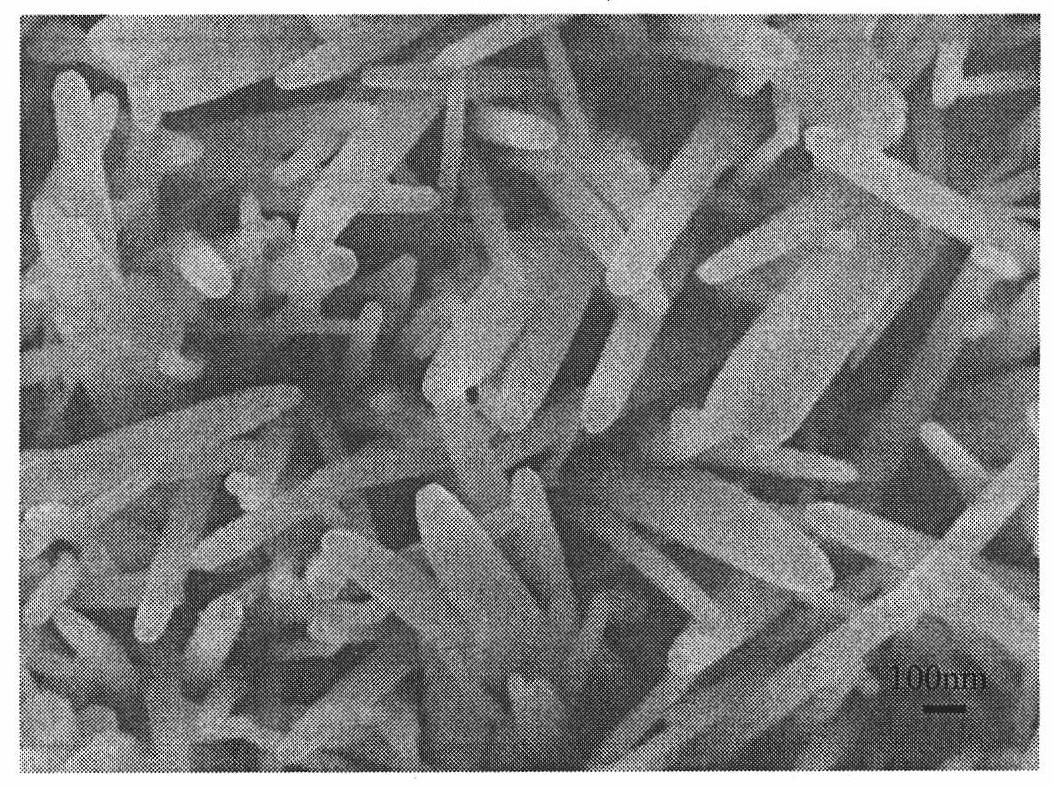

Method for synthesizing zinc oxide nano tube array by low-temperature hydrothermal method

InactiveCN101456579ALow costLow reaction temperatureZinc oxides/hydroxidesEtchingReaction temperature

The invention discloses a method for synthesizing a zinc oxide nano-tube array by a low-temperature hydrothermal method, which comprises: firstly, preparation of ZnO crystal seed layers; secondly, low-temperature hydrothermal growth of ZnO nano wires; and thirdly, chemical etching of the ZnO nano wires into ZnO nano-tubes. The method adopts the low-temperature hydrothermal method and utilizes pure chemical etching technology to synthesize the ZnO nano-tube array, does not need electrochemical assistance and a template, can prepare the ZnO nano-tubes with controllable pipe diameters on different types of substrates by controlling the concentration of a reactant, the hydrothermal growth time and the etching time of an alkali liquor, has low cost, low reaction temperature, short production cycle and high investment-return rate, can be directly performed in an aqueous solution, and does not generate toxic and harmful waste.

Owner:TIANJIN UNIV

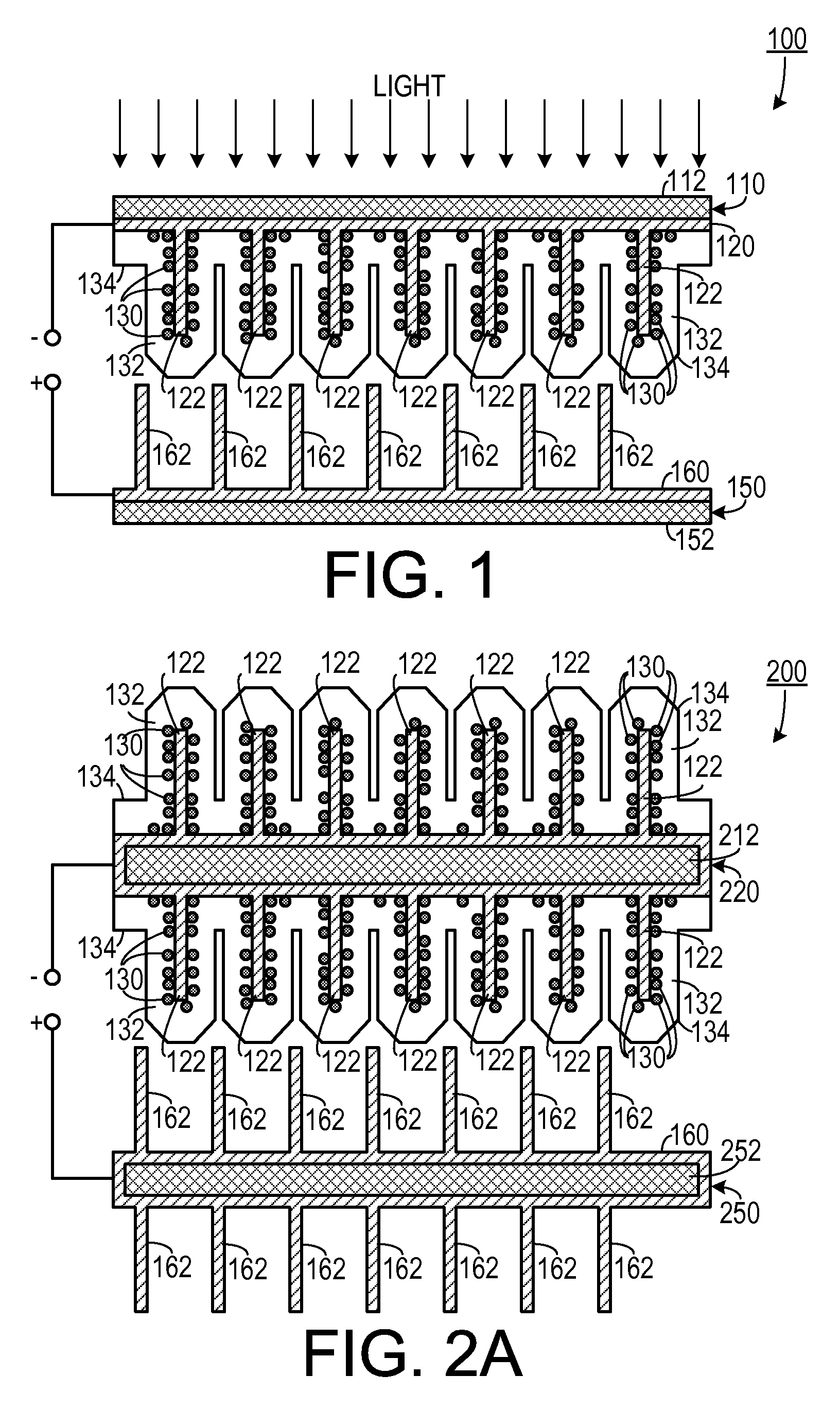

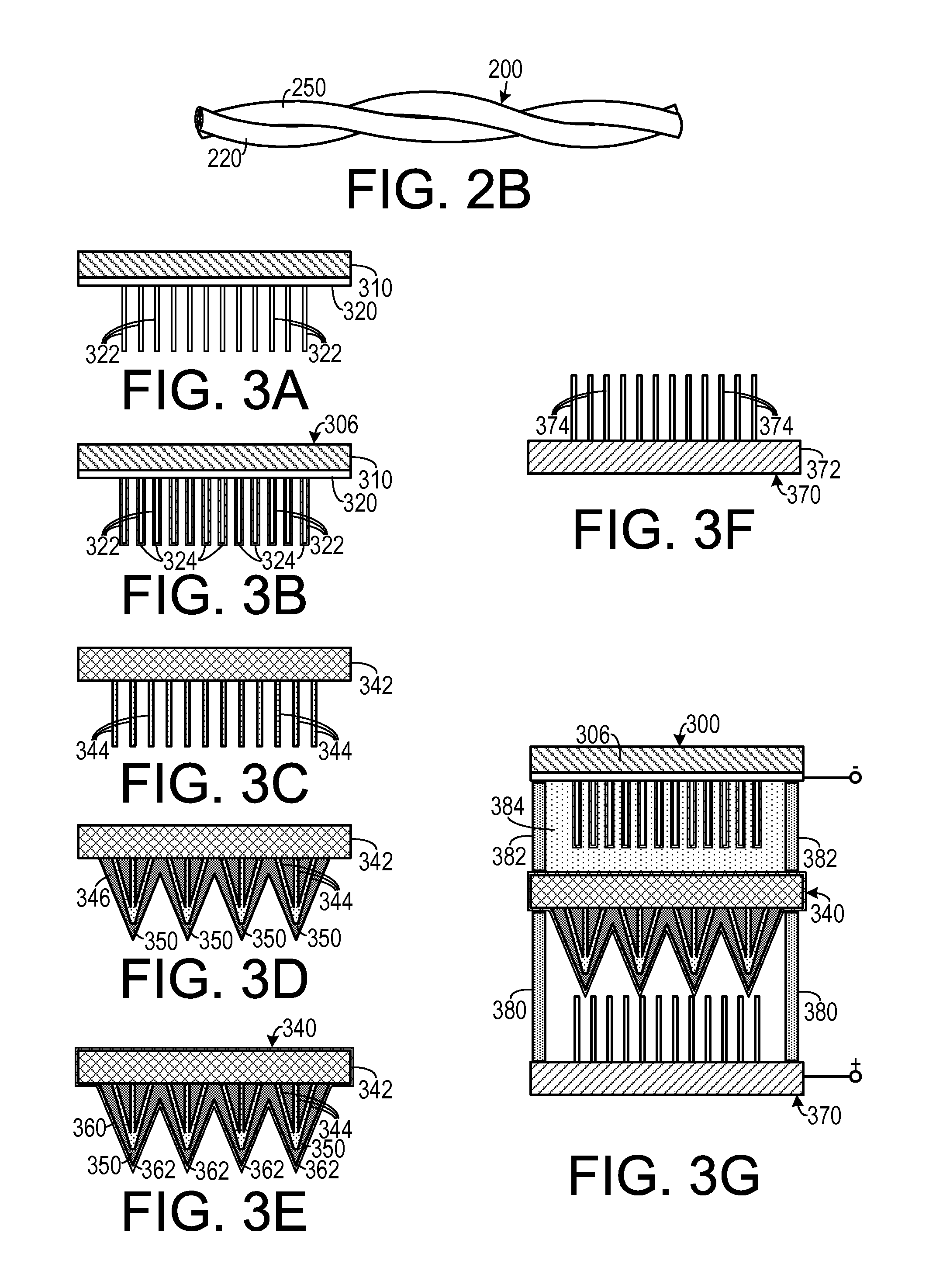

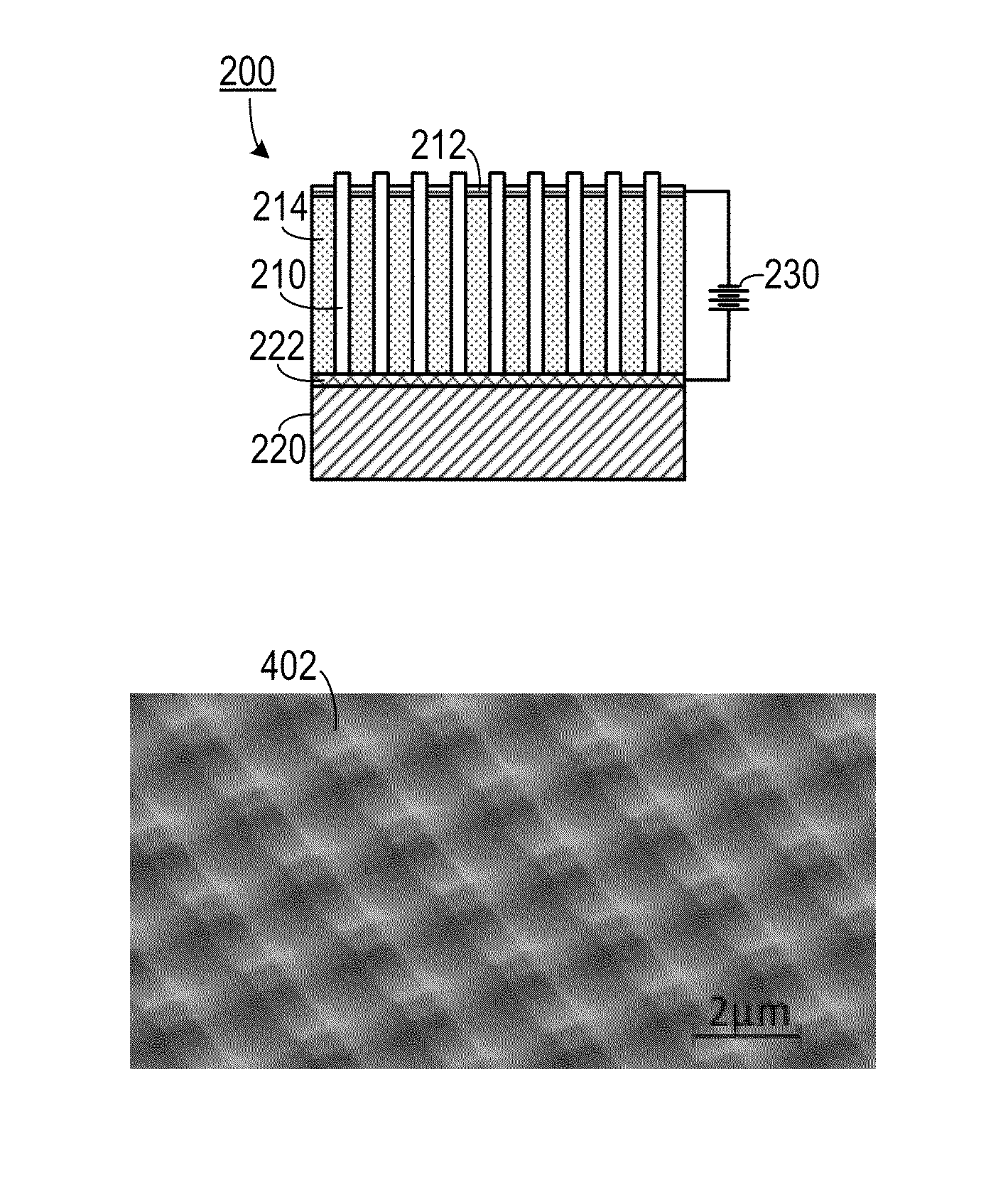

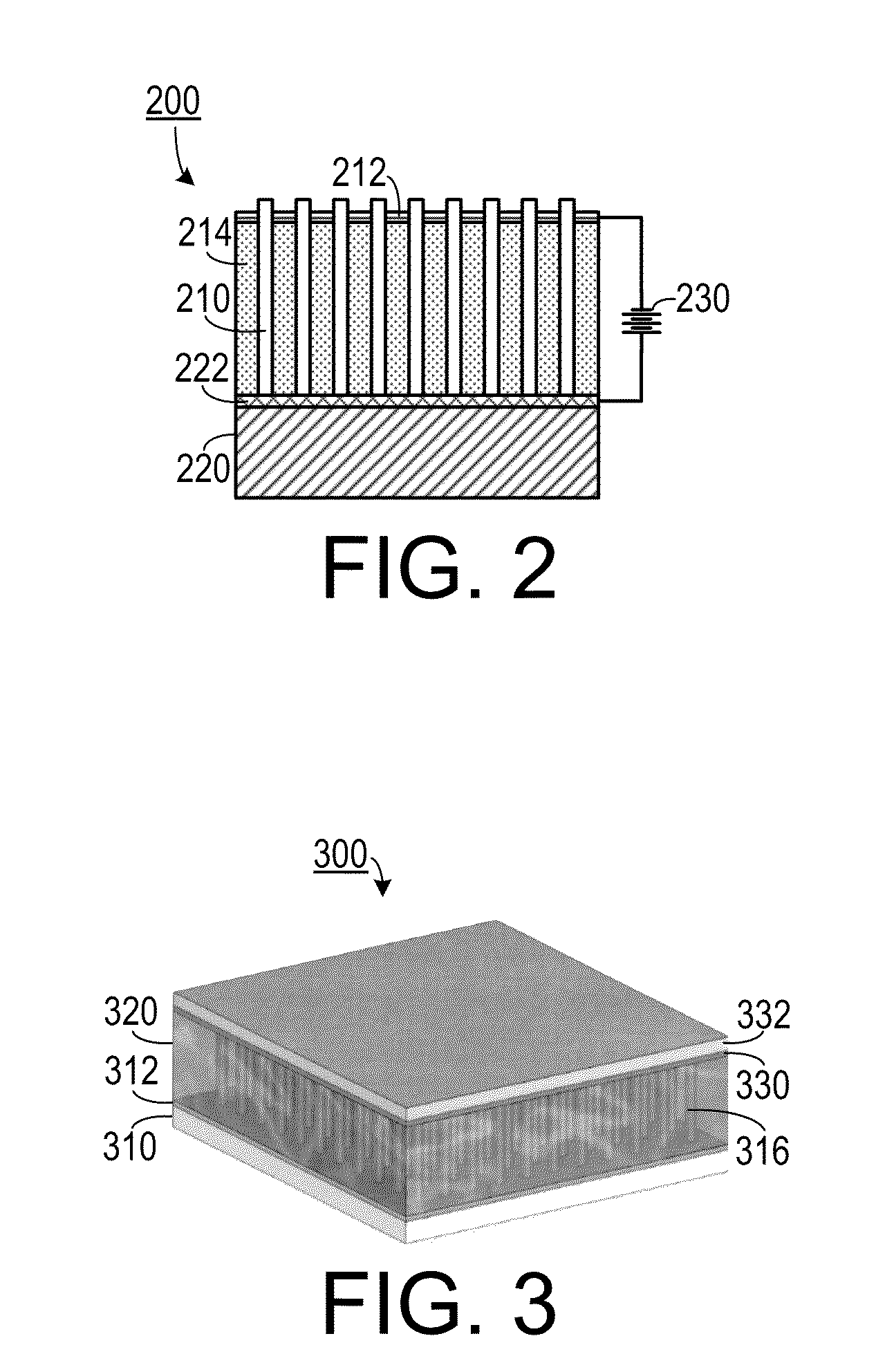

Hybrid Solar Nanogenerator Cells

ActiveUS20090295257A1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesHeterojunctionFiber

A dye-sensitized solar cell including ZnO nanowire arrays grown of a flat substrate for harvesting solar energy is integrated with a piezoelectric nanogenerator for harvesting ultrasonic wave energy. The two energy harvesting approaches work simultaneously or individually and can be integrated in parallel or serial for raising the output current, voltage or power, respectively. A solar cell employs an optical fiber and semiconductor nanowires grown around the fiber. A p-n junction based design, organic-inorganic heterojunction, or a dye-sensitized structure is built at the surfaces of the nanowires. Light entering the fiber from a tip propagates through the fiber until it enters a nanowire where it reaches a photovoltaic element. Light entering the fiber cannot escape until it interacts with a photovoltaic element, thereby increasing the solar conversion efficiency. The fiber can transmit light, while the nanowires around the fibers increase the surface area of light exposure.

Owner:GEORGIA TECH RES CORP

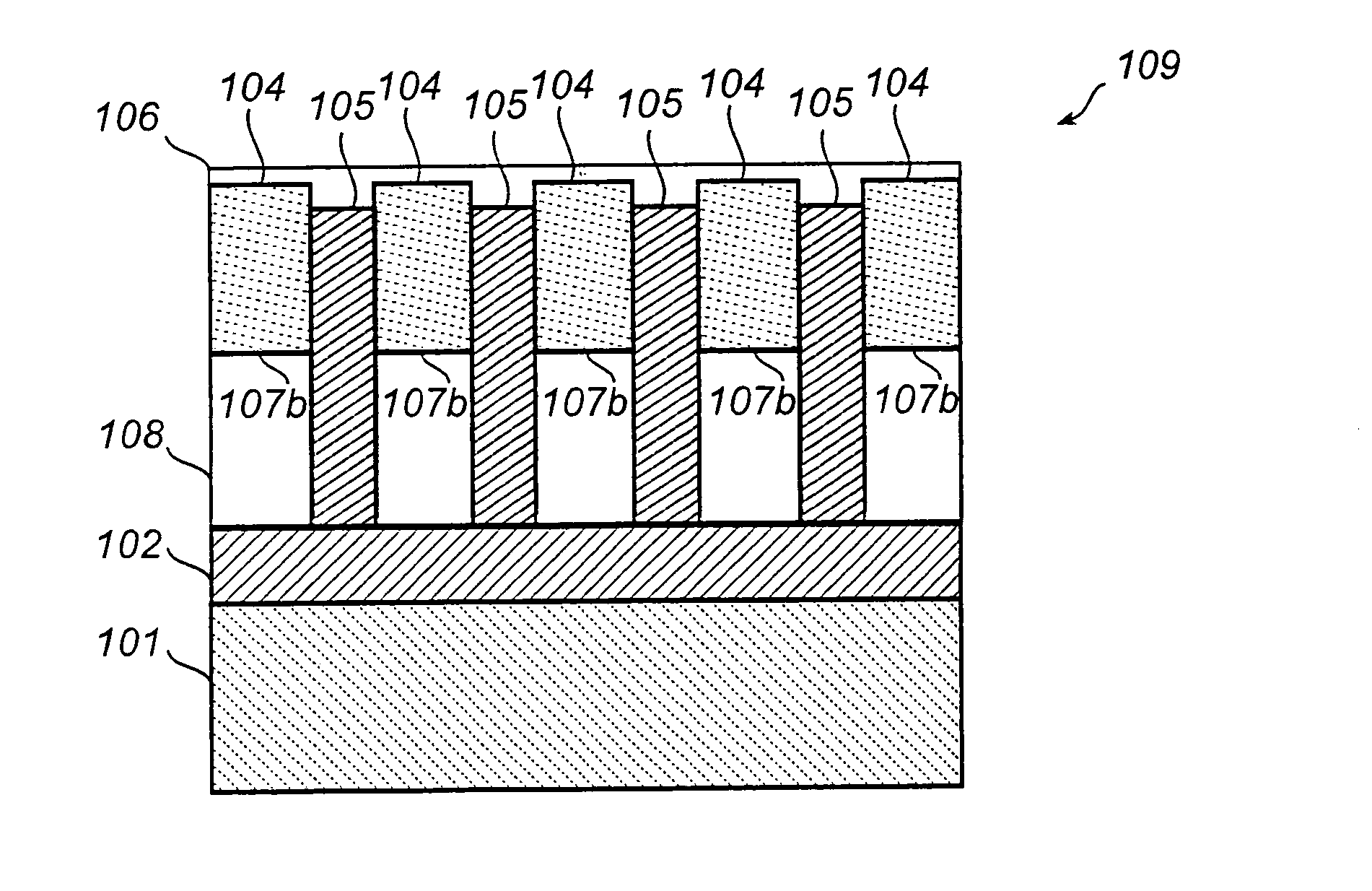

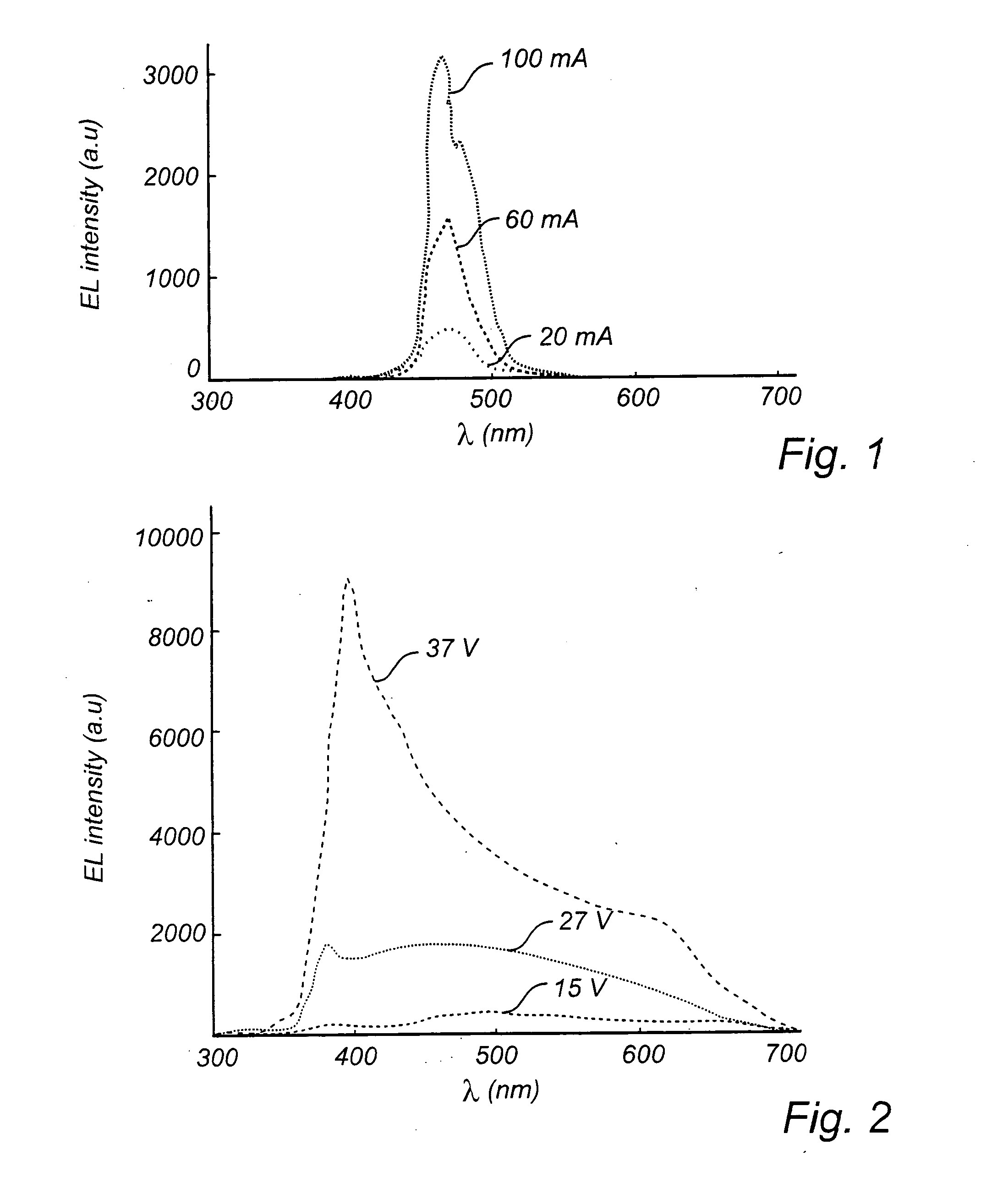

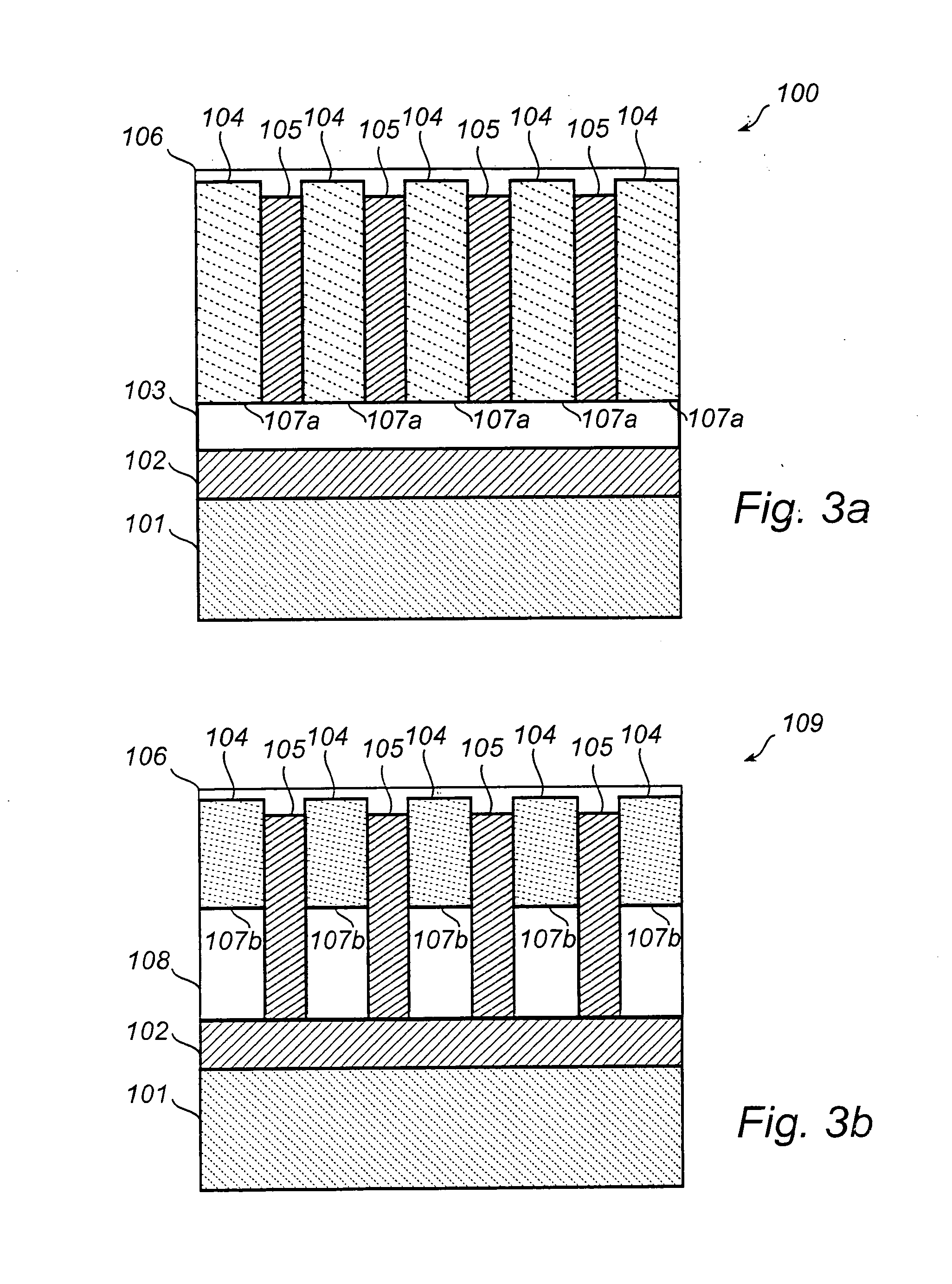

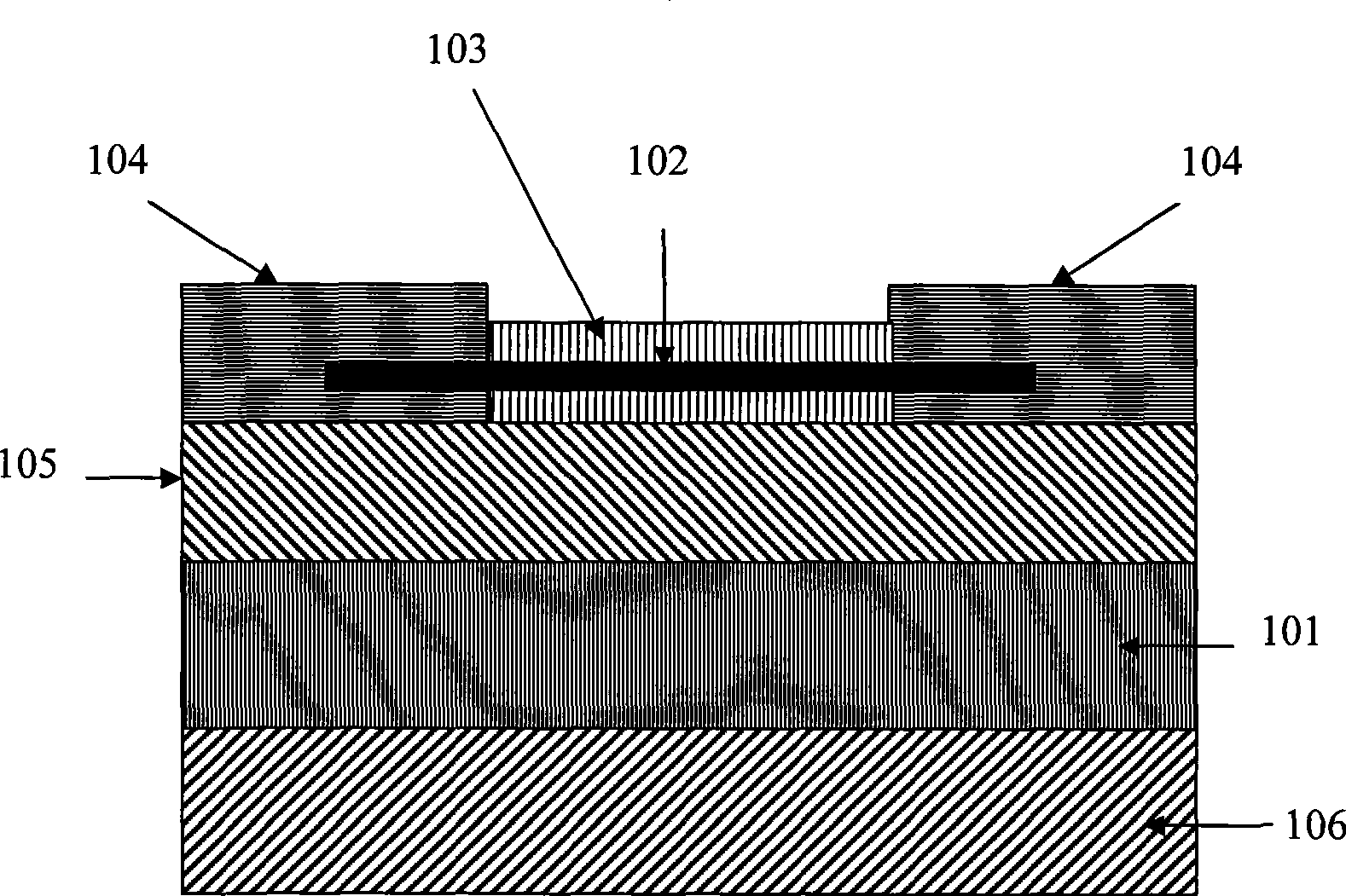

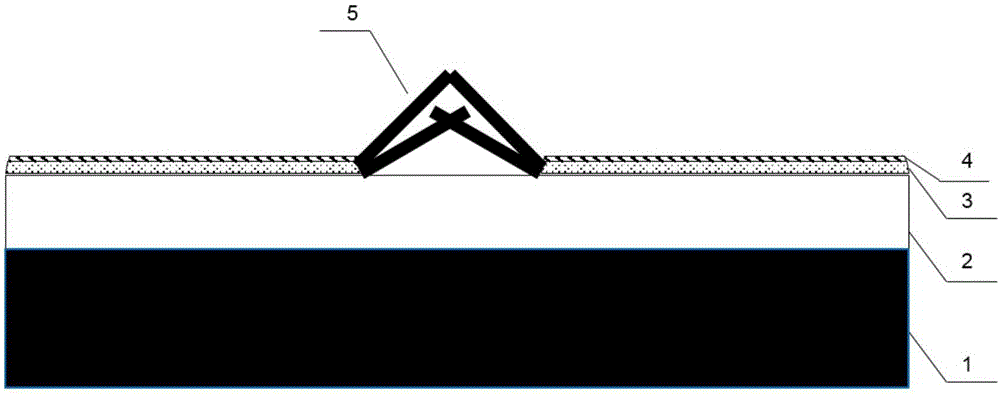

Light Emitting Diode and Method for Manufacturing the Same

InactiveUS20100025673A1Improve stabilityLong lastingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringP–n junction

The present invention relates to a light emitting diode (100, 109), comprising at least one p-doped structure, a plurality of n-doped zinc-oxide (ZnO) nanowires (104) arranged on the at least one p-doped structure, thereby forming a plurality of p-n junctions (107a, 107b), an insulating structure (105) arranged among the plurality of ZnO-nanowires (104), to electrically separate the plurality of p-n junctions (107a, 107b), and a transparent conductive layer (106), arranged on the at least one insulating structure (105) and in electrical contact with the plurality of ZnO-nanowires (104), to enable application of a voltage over the plurality of p-n junctions (107a, 107b), thereby enabling emission of light. An advantage with the above light emitting diode (100, 109) is its improved broadband spectral distribution. Furthermore, as ZnO-nanowires (104) are used, it is possible to achieve a high brightness.

Owner:ECO SPARK

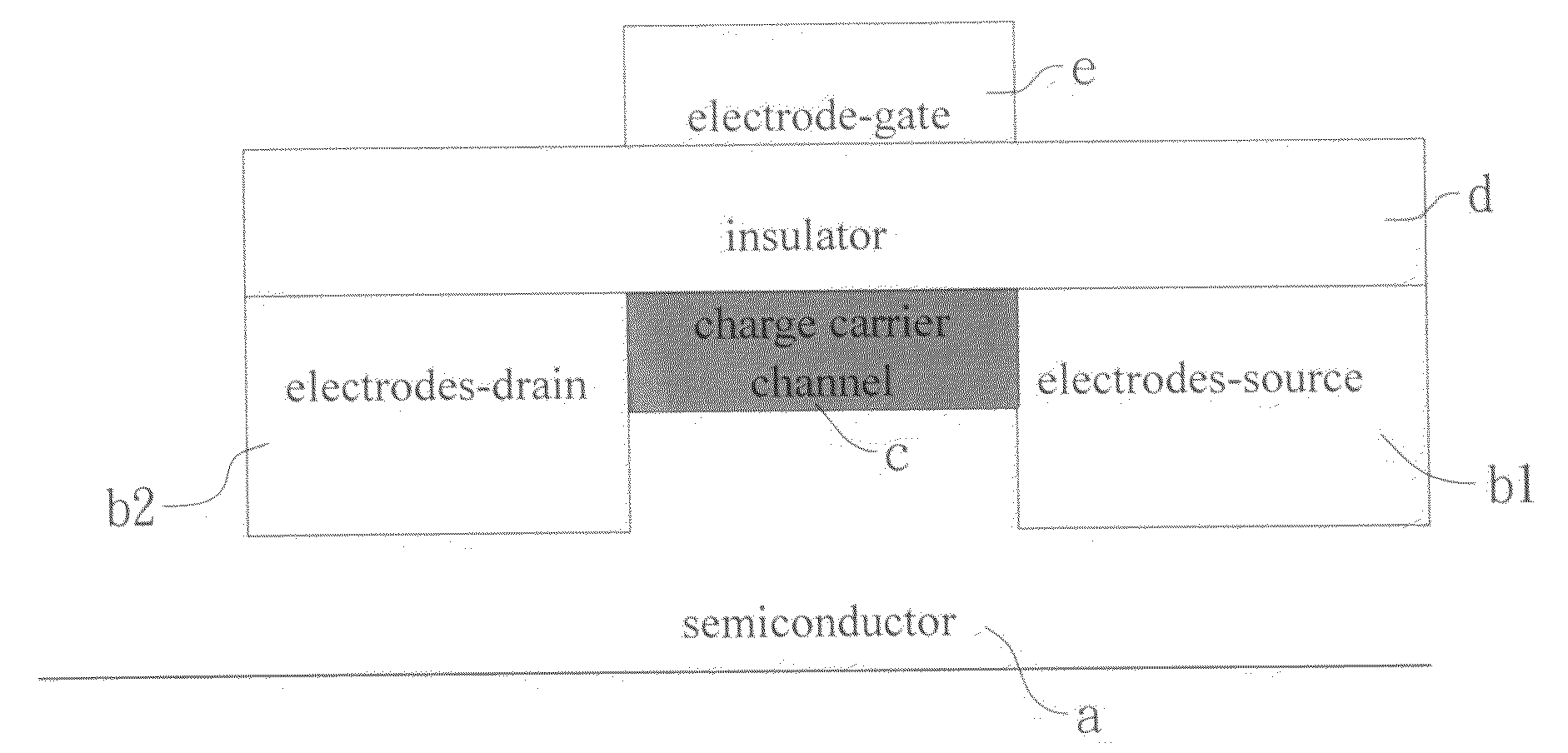

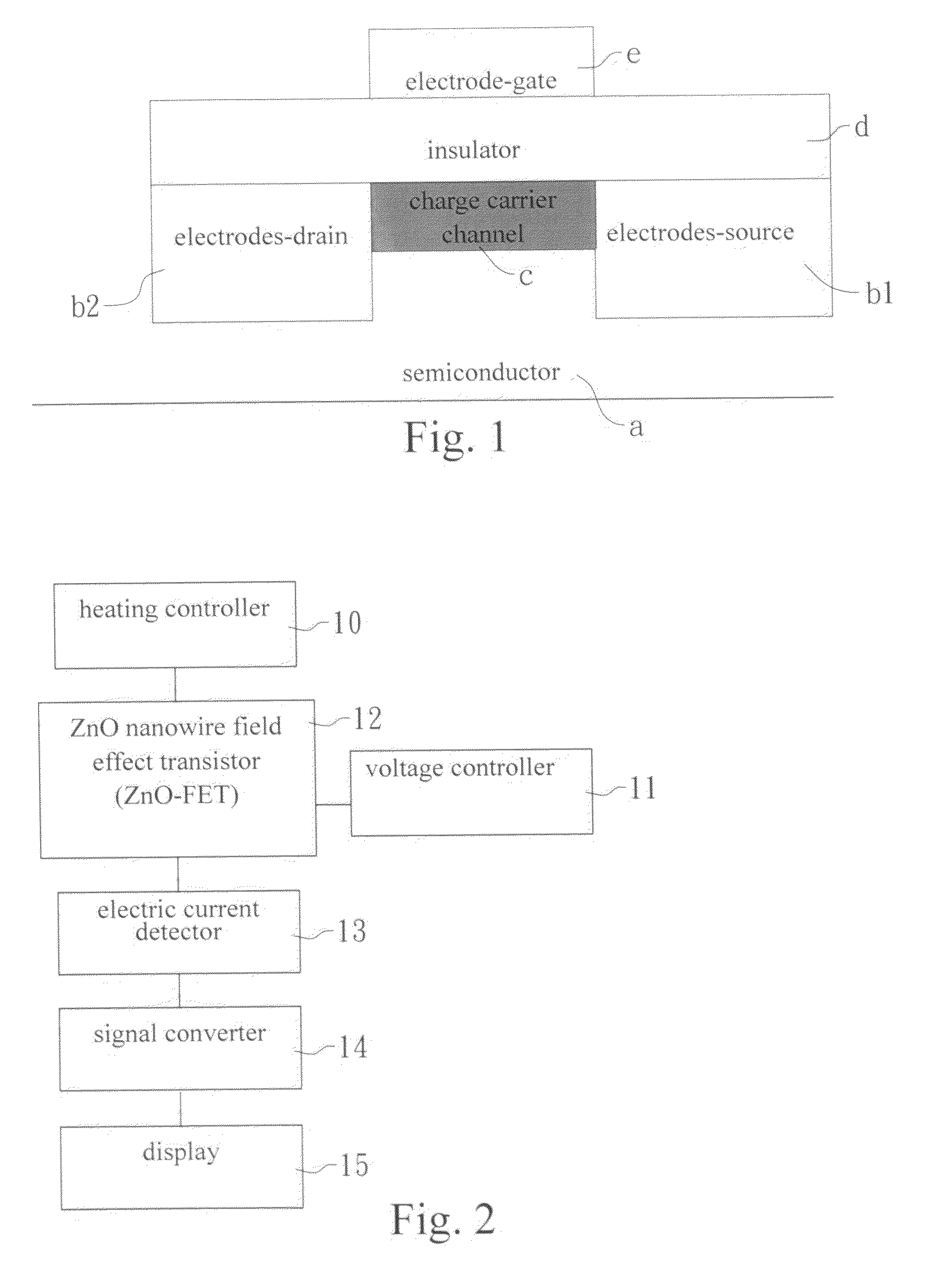

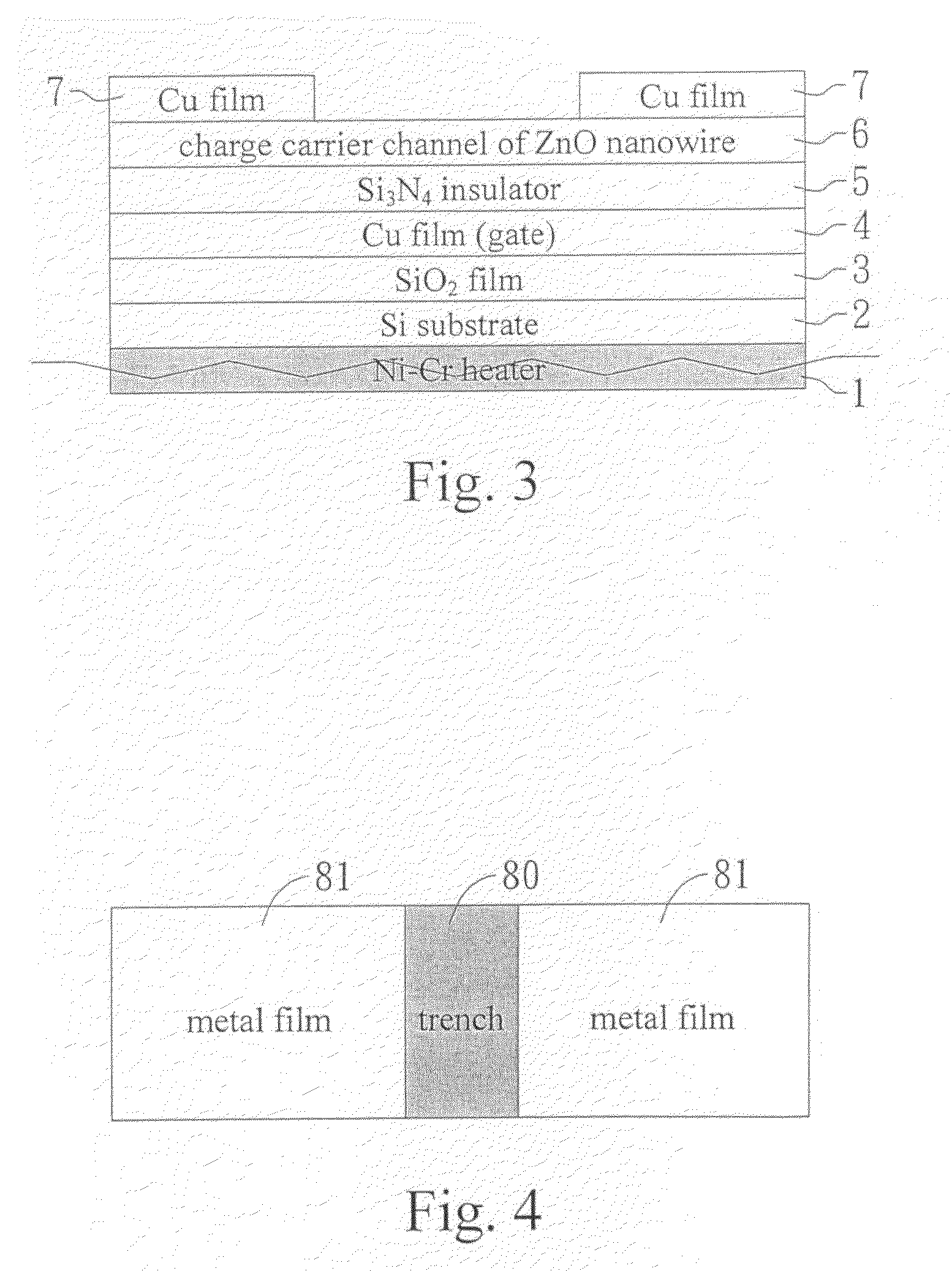

Gas sensor made of field effect transistor based on ZnO nanowires

InactiveUS20100050745A1Small sizeLight weightMaterial analysis by electric/magnetic meansSpecific gravity measurementMOSFETOrganic field-effect transistor

The present invention discloses a gas sensor made of field effect transistor based on ZnO nanowires (ZnO-FET) which operates according to the principle of metal-oxide-semiconductor field effect transistor (MOSFET) and has a charge carrier channel made of ZnO nanowires between source and drain. The gas sensor device disclosed in the present invention has three electrodes-gate, source and drain, so that it is different from the known gas sensor device which has only two electrodes-cathode and anode. The ZnO nanowires as charge channel in the gas sensor device of the present invention is an n-type semiconductor with high specific surface area, and its electric resistance can be controlled by the gate bias, so that the capability of the present device for sensing gas can be largely promoted.

Owner:NAT FORMOSA UNIV

Method for manufacturing zinc oxide nanowires and device having the same

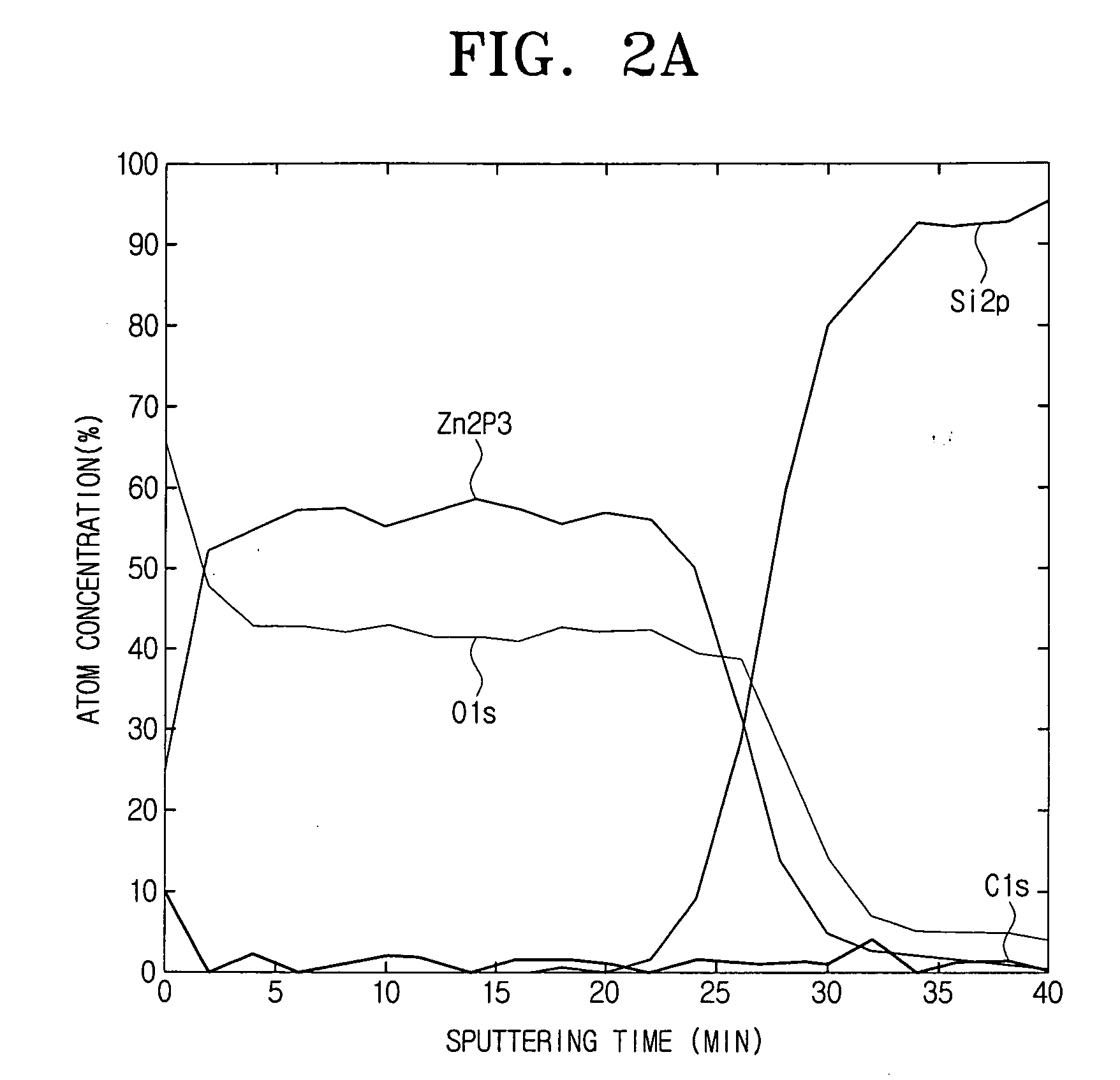

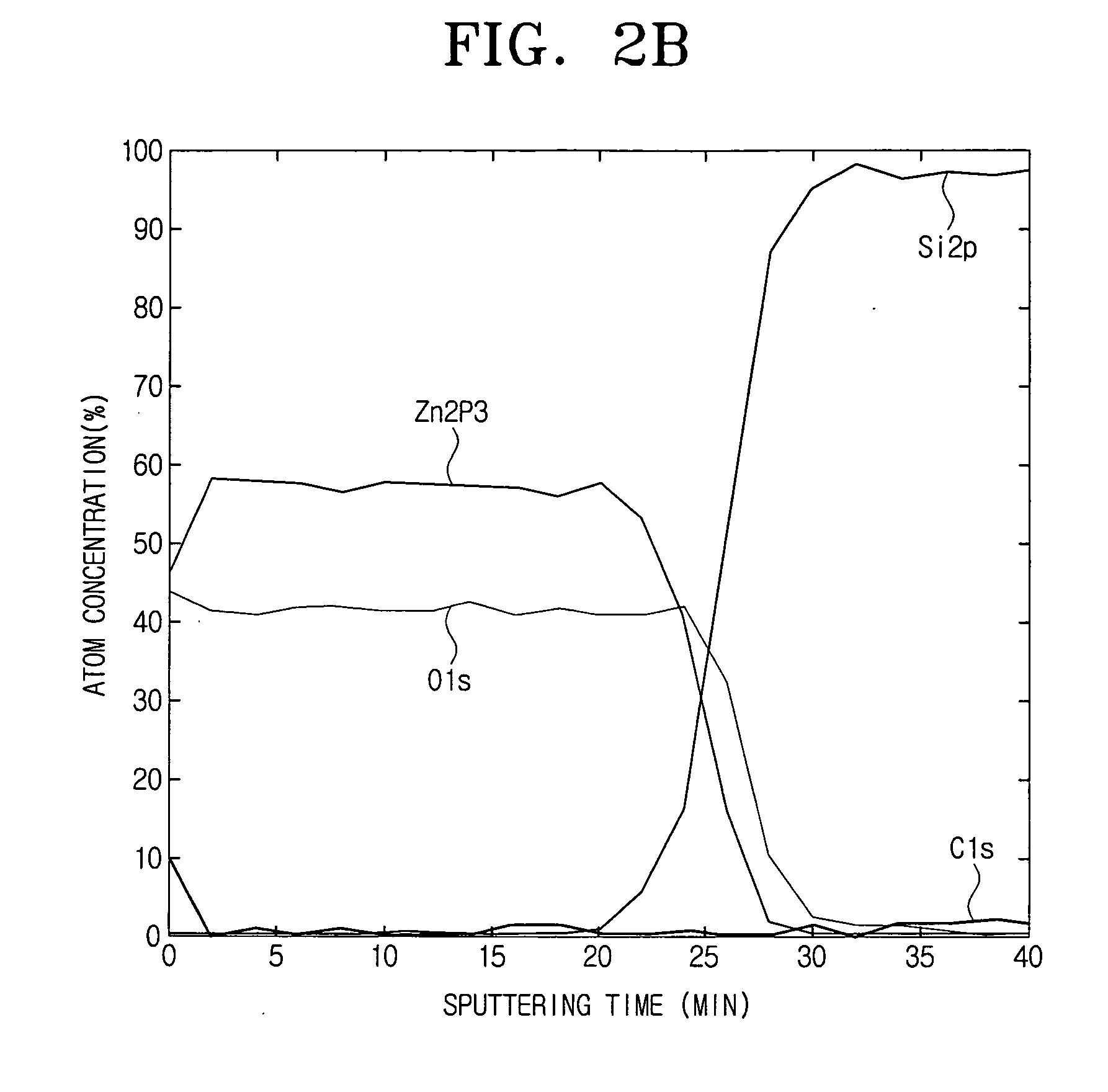

ActiveUS20070154385A1Material nanotechnologyPolycrystalline material growthAdemetionineZinc oxide nanowire

A method for manufacturing ZnO nanowires with a small diameter and increased length and a device comprising the same. The manufacturing method includes: forming a ZnO seed layer containing a hydroxyl group on a substrate; and growing ZnO nanowires on the ZnO seed layer containing the hydroxyl group. Preferably, the ZnO seed layer is a thin ZnO seed layer containing more than 50% of the hydroxyl group.

Owner:SAMSUNG ELECTRONICS CO LTD

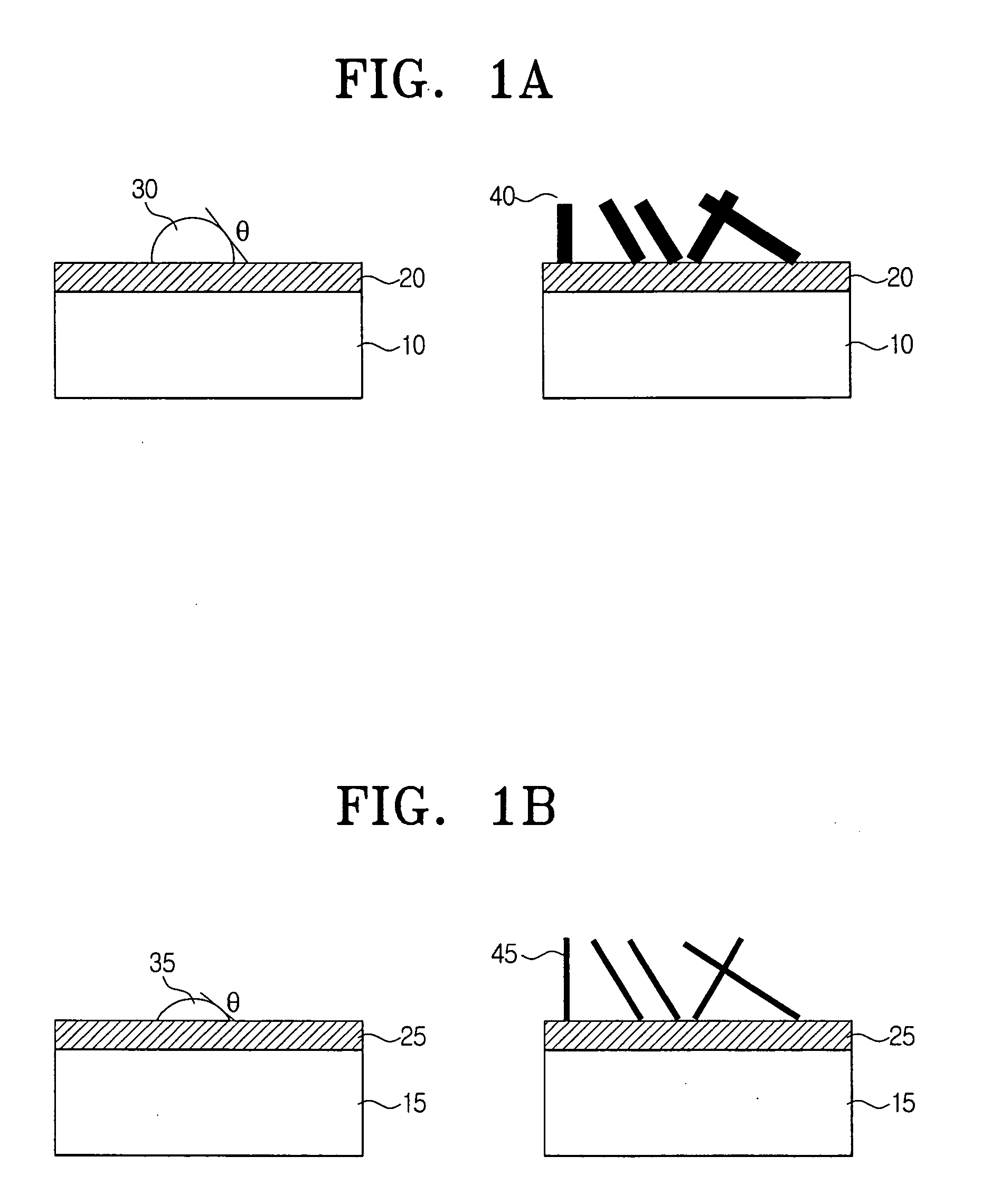

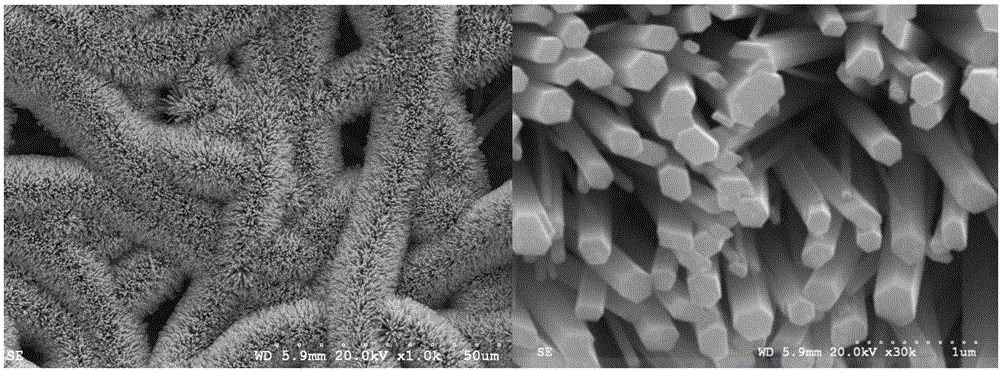

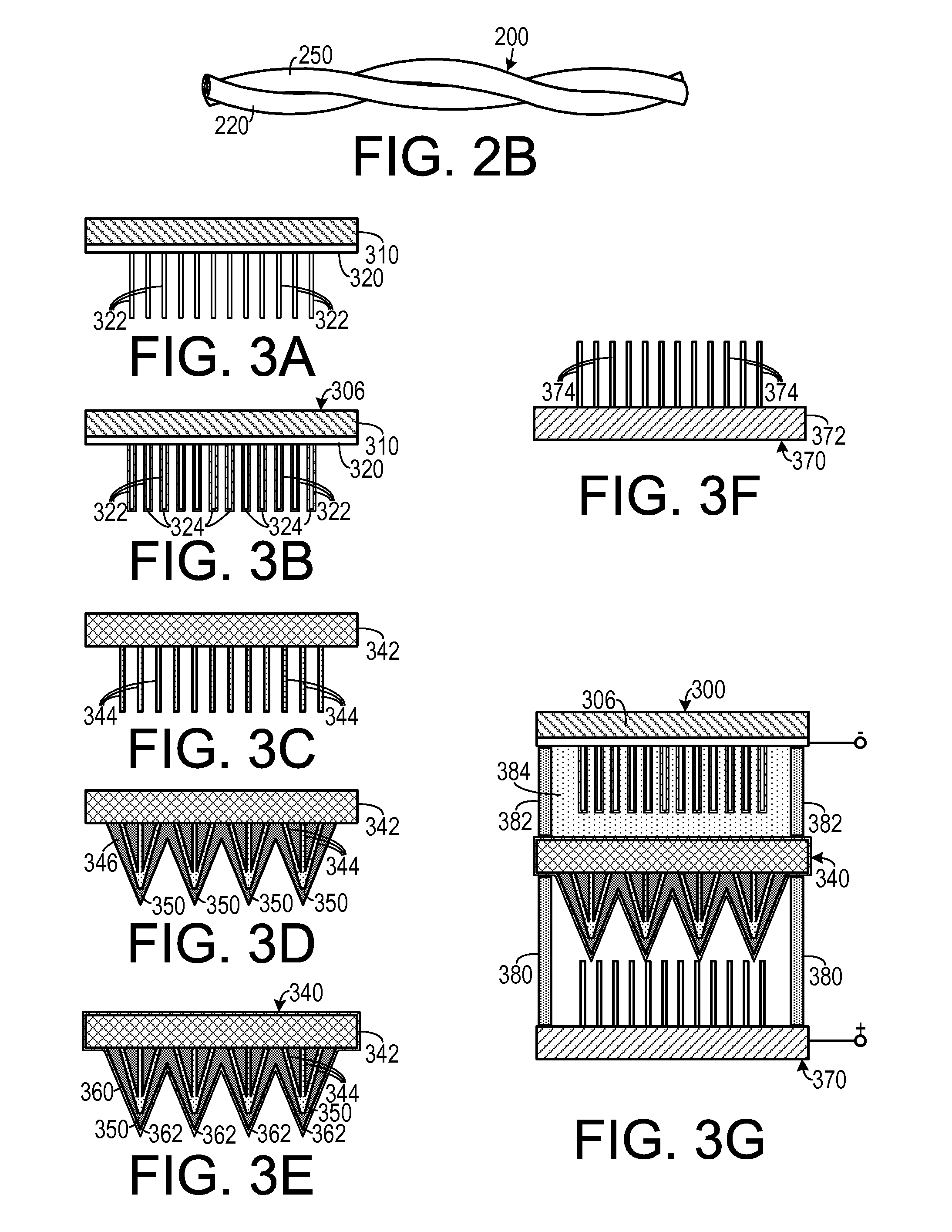

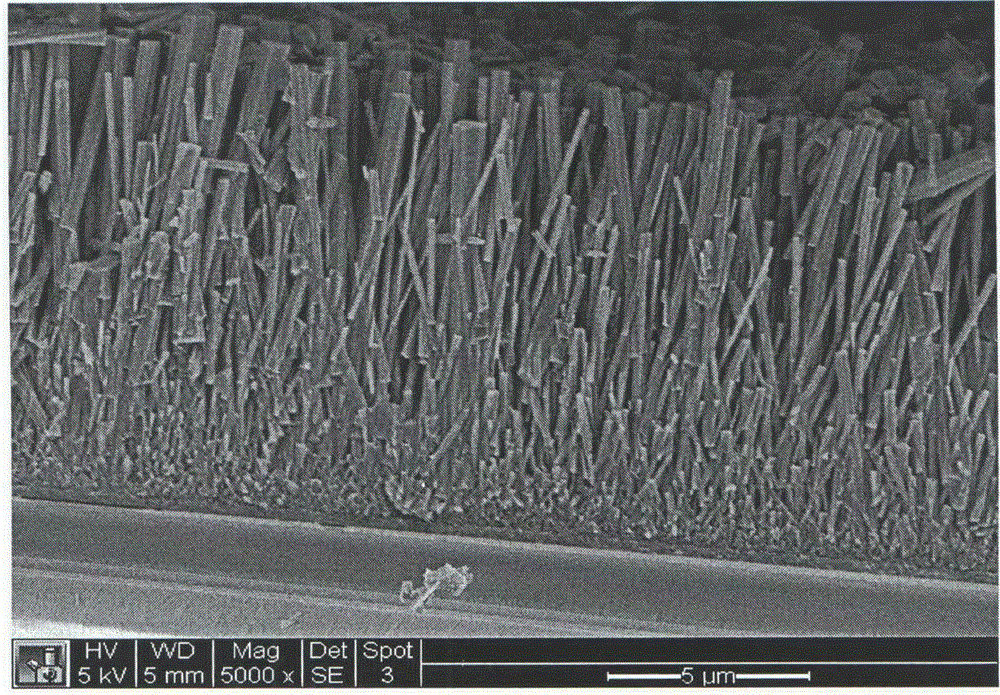

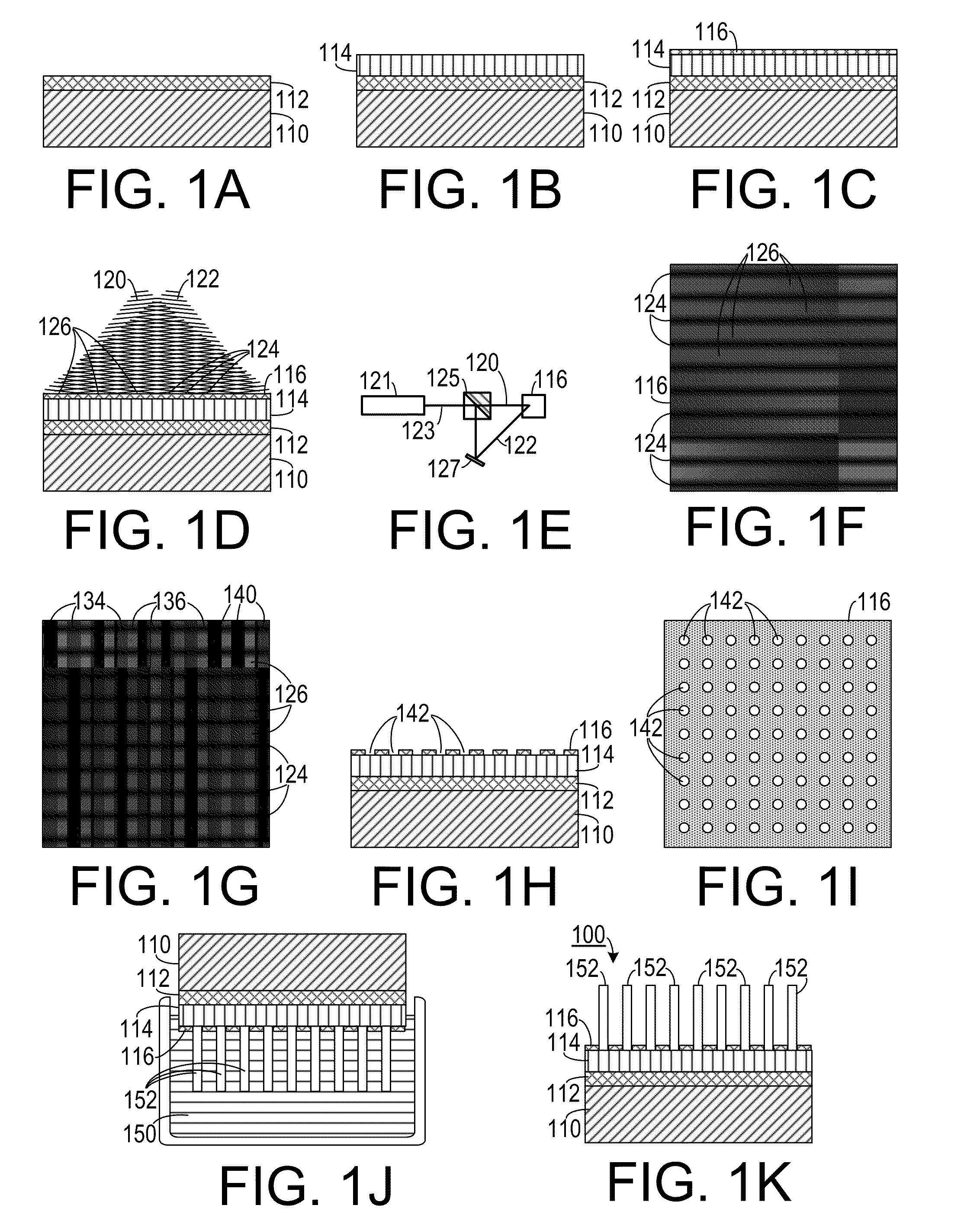

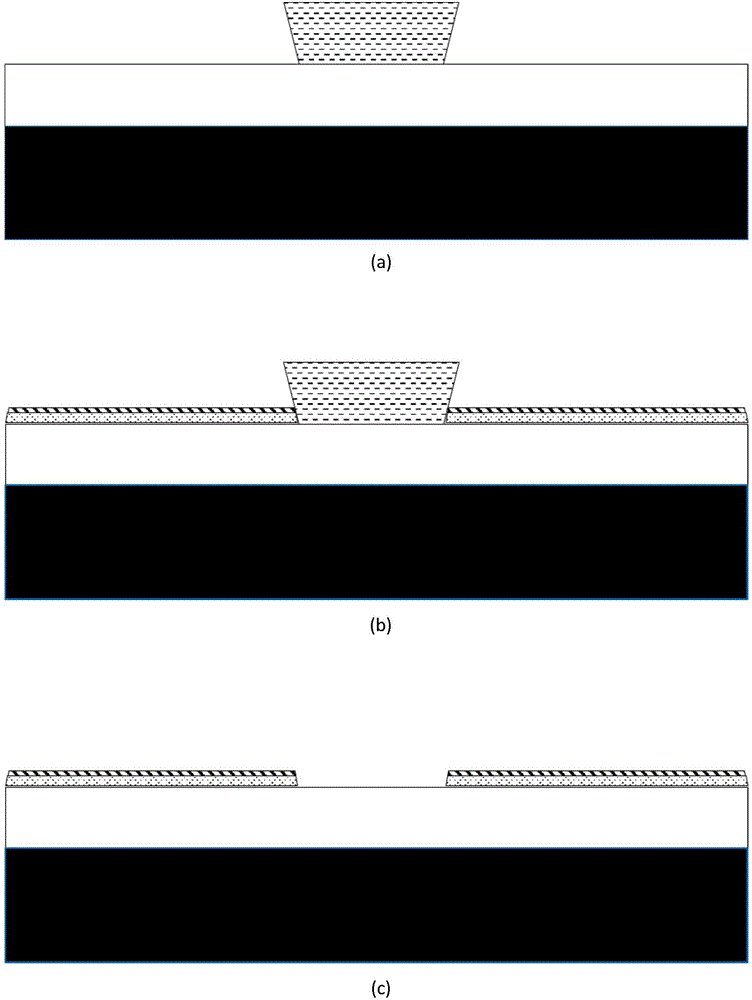

Large-scale Fabrication of Vertically Aligned ZnO Nanowire Arrays

InactiveUS20110309354A1NanoinformaticsSemiconductor/solid-state device manufacturingNanowire arrayNanometre

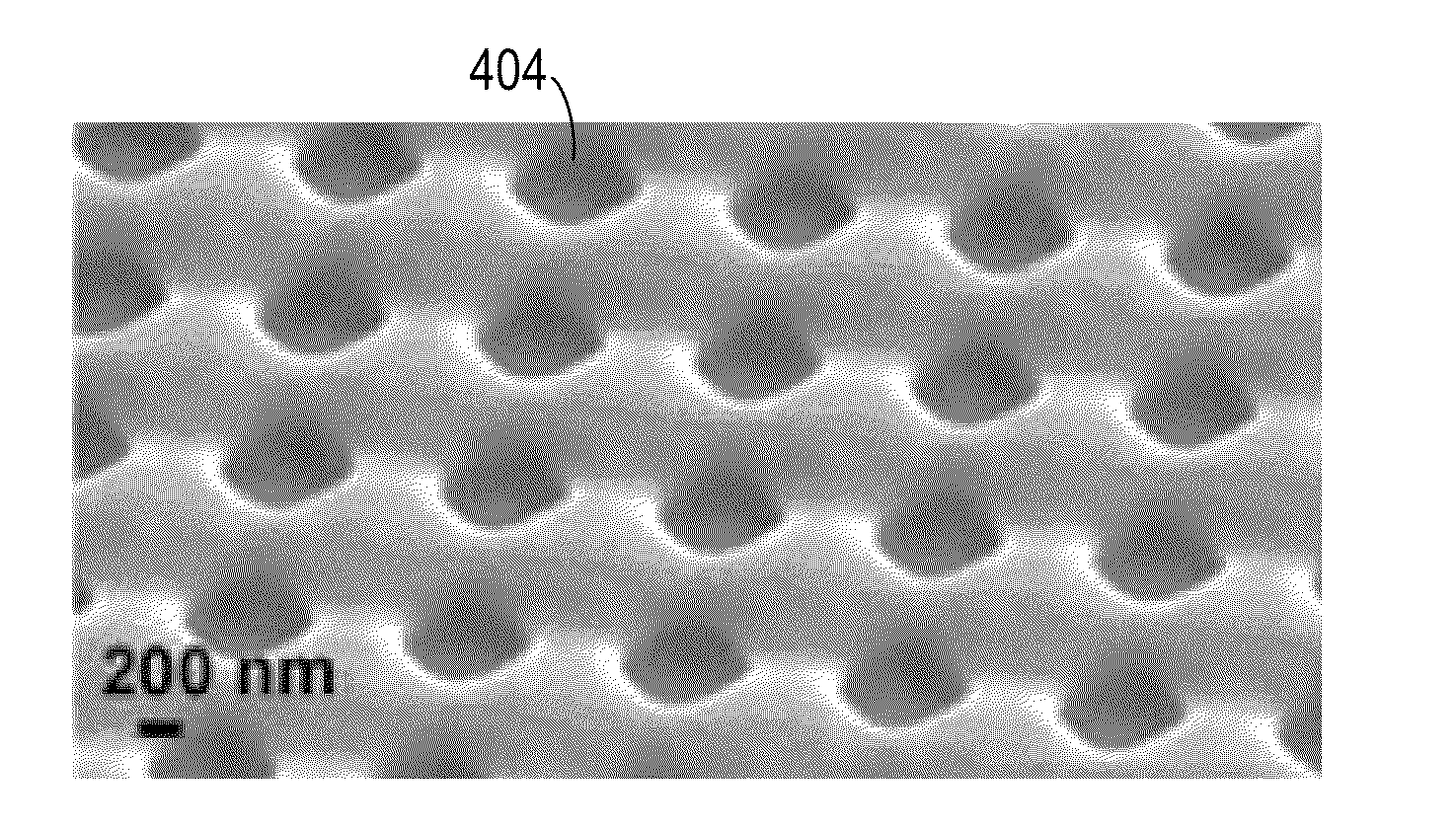

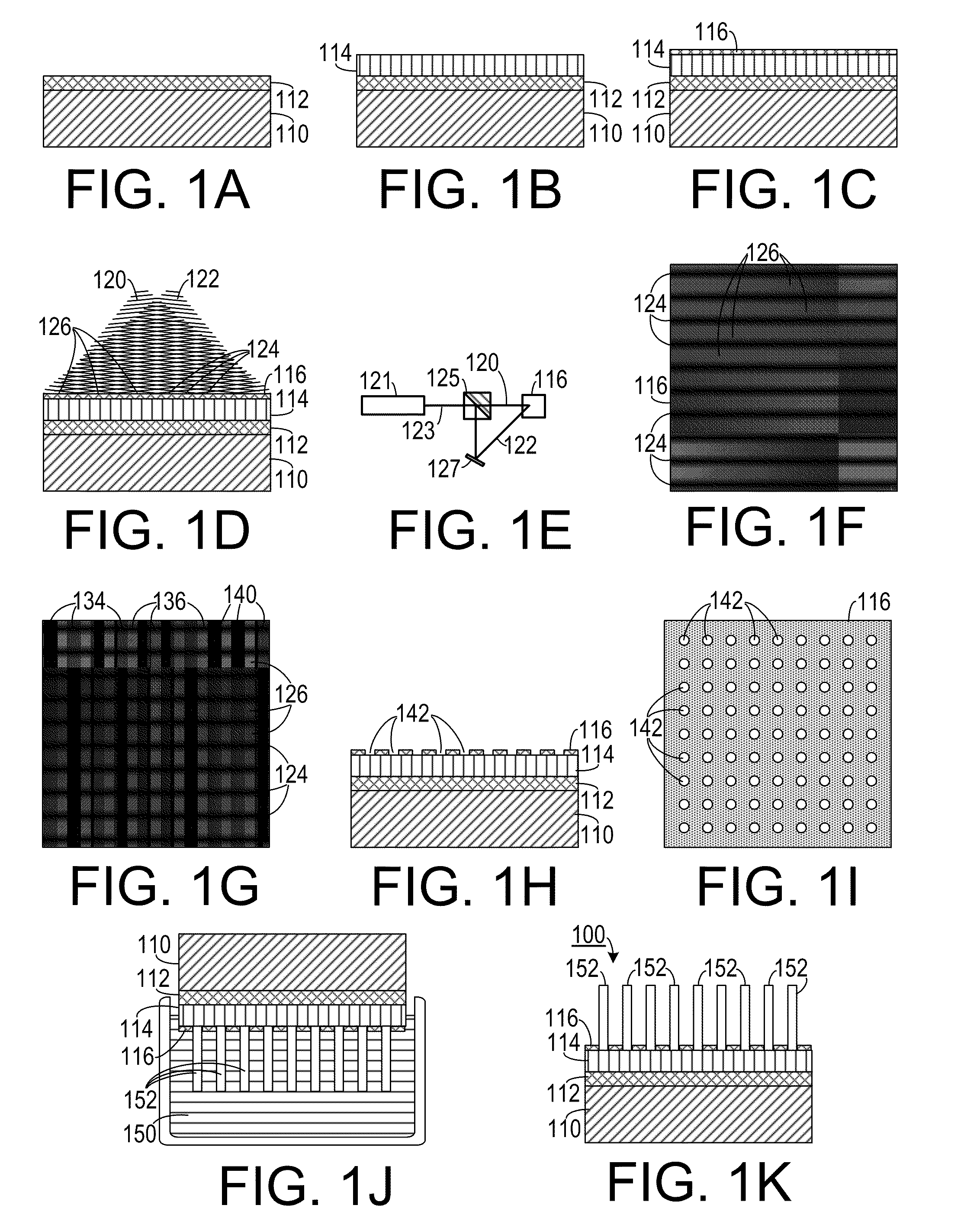

In a method for growing a nanowire array, a photoresist layer is placed onto a nanowire growth layer configured for growing nanowires therefrom. The photoresist layer is exposed to a coherent light interference pattern that includes periodically alternately spaced dark bands and light bands along a first orientation. The photoresist layer exposed to the coherent light interference pattern along a second orientation, transverse to the first orientation. The photoresist layer developed so as to remove photoresist from areas corresponding to areas of intersection of the dark bands of the interference pattern along the first orientation and the dark bands of the interference pattern along the second orientation, thereby leaving an ordered array of holes passing through the photoresist layer. The photoresist layer and the nanowire growth layer are placed into a nanowire growth environment, thereby growing nanowires from the nanowire growth layer through the array of holes.

Owner:GEORGIA TECH RES CORP

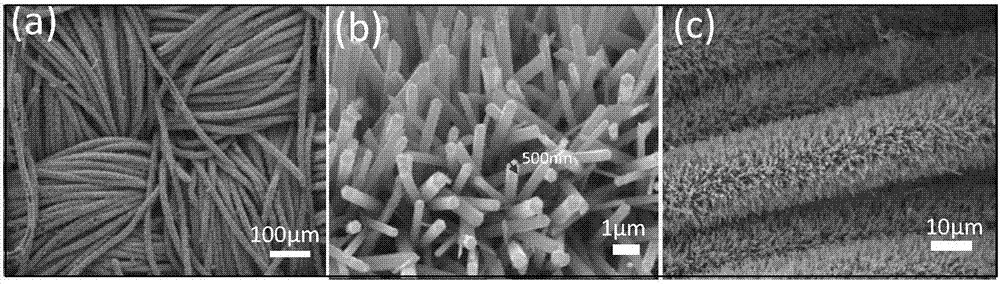

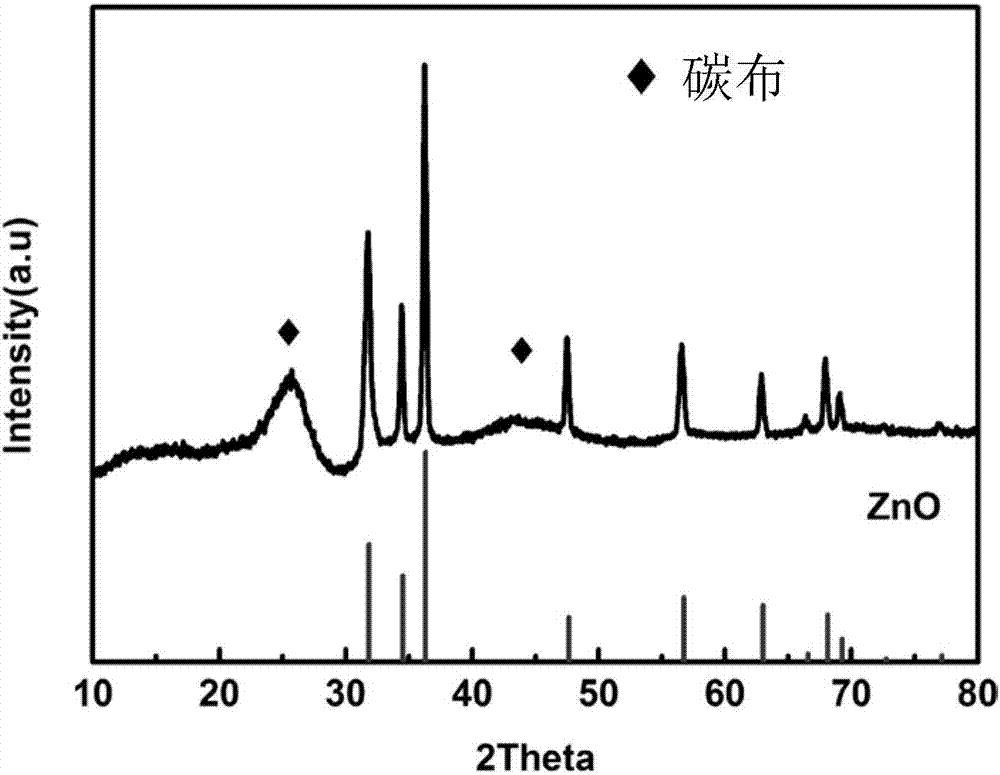

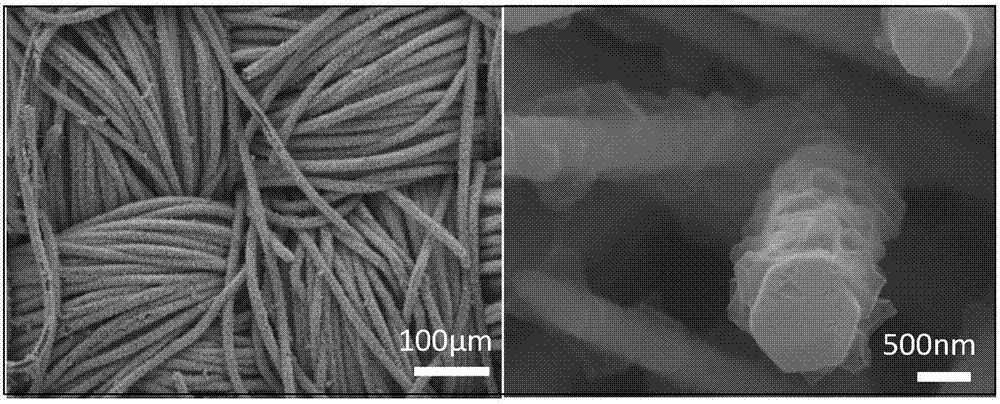

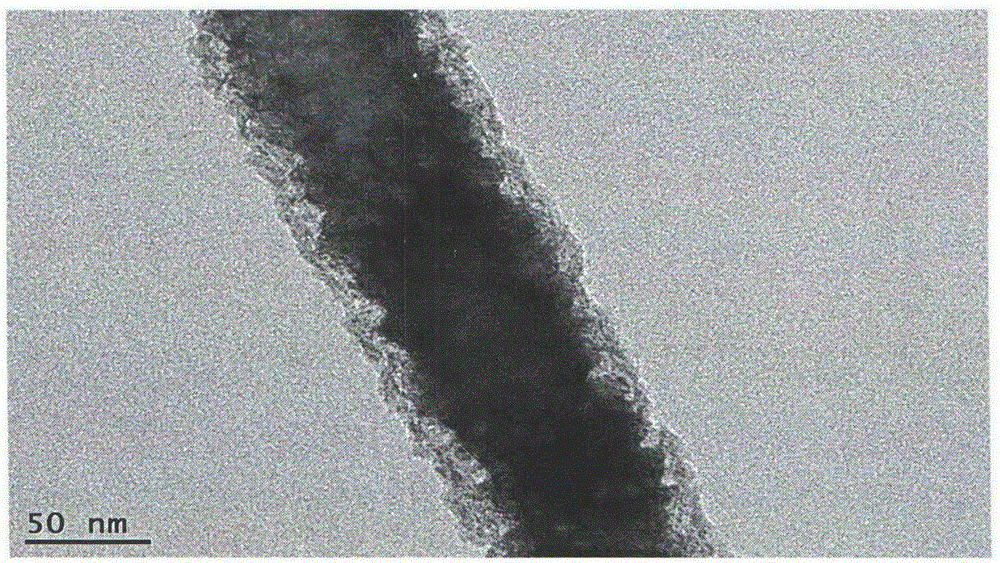

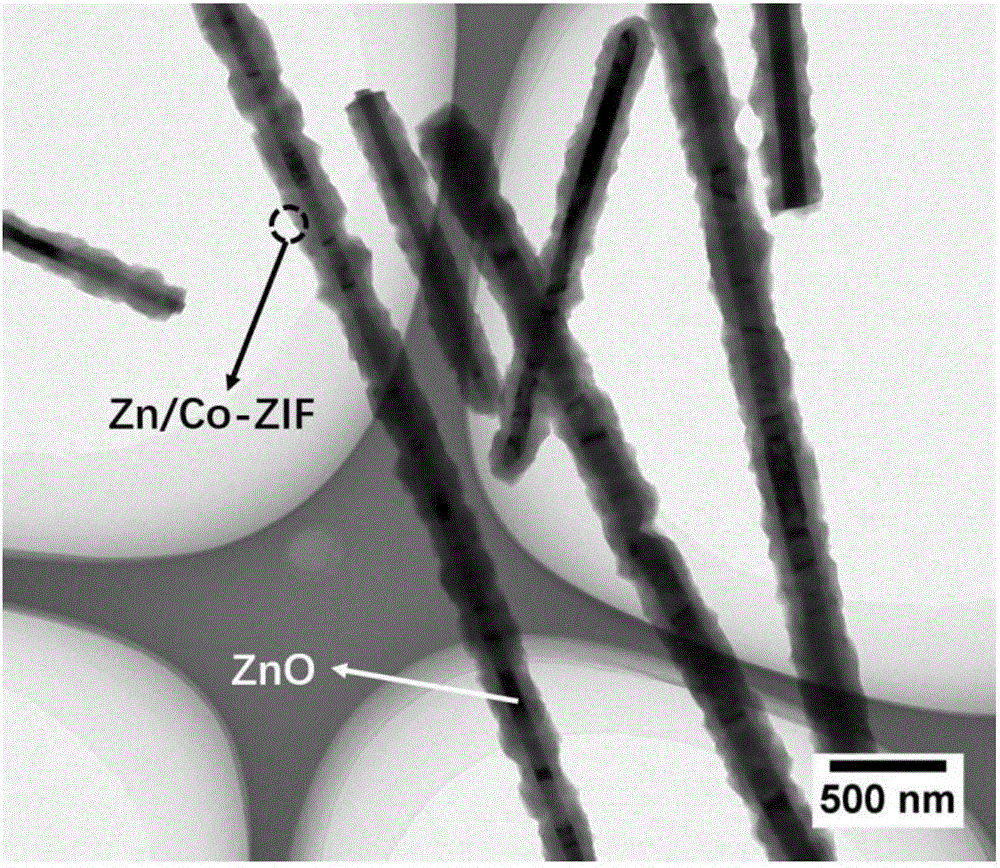

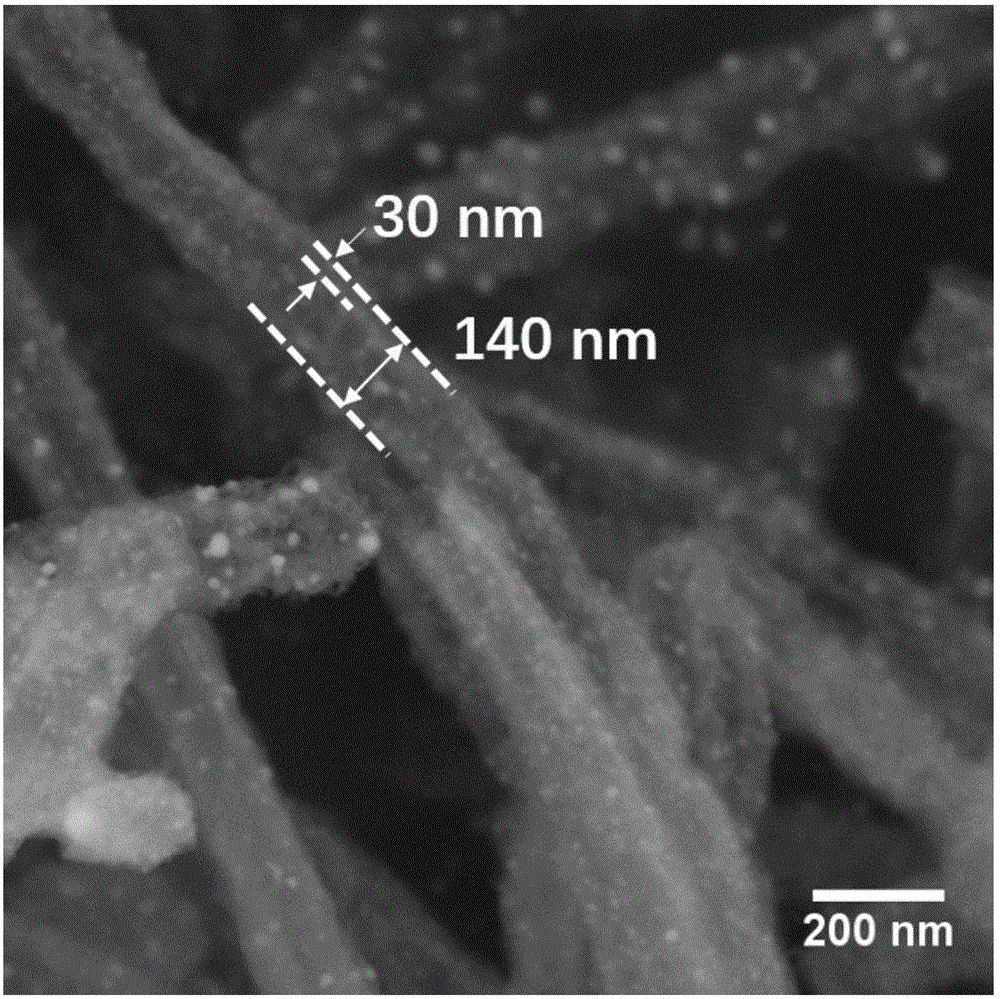

Carbon coated ZnO nanowire, and preparation method and application thereof

ActiveCN107887592AImprove mechanical propertiesGood flexibilityMaterial nanotechnologyNegative electrodesGas phasePorous carbon

The invention belongs to the field of nanomaterials and electrochemical energy storage, and particularly relates to a carbon coated ZnO nanowire and a preparation method thereof. The ZnO nanowire canbe used as a negative electrode material of a Zn-Co battery, the ZnO nanowire has a carbon particle coated ZnO nanowire structure which has a degree of graphitization and is formed by high temperaturepyrolysis of a metal organic frame structure (ZIF-8) and the ZnO nanowire after being compounded on carbon cloth, the diameter of the ZnO nanowire is 300-500nm, the length of the ZnO nanowire is 8-10micrometers, and the carbon particle coating thickness is 10-30nm. A hydrothermal method is combined with a low pressure gas phase deposition method to synthesize an electrode with good mechanical properties and flexibility, porous carbon carbon-coated ZnO is formed by the pyrolysis of ZIF-8 to inhibit the dissolution and deformation of the negative electrode so as to improve the cycle performance, and excellent cycle performance of the Zn-Co battery is achieved at last.

Owner:WUHAN UNIV OF TECH

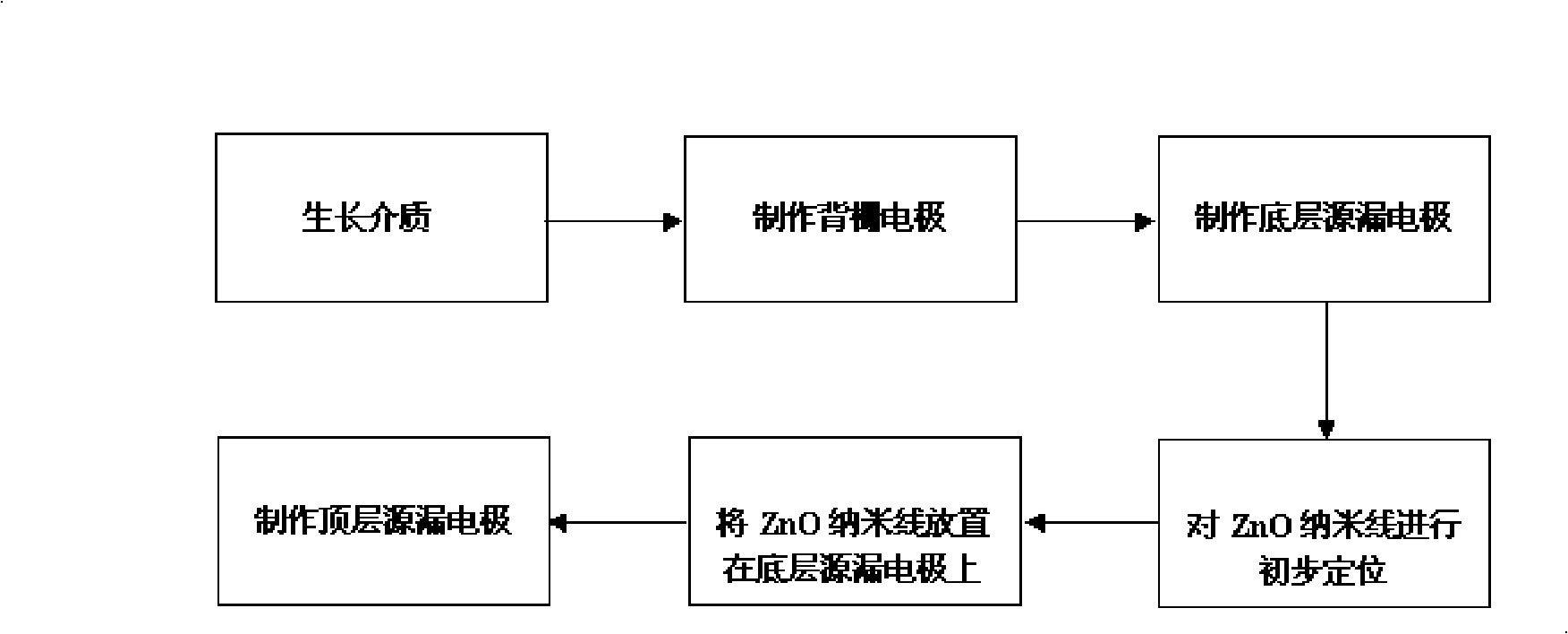

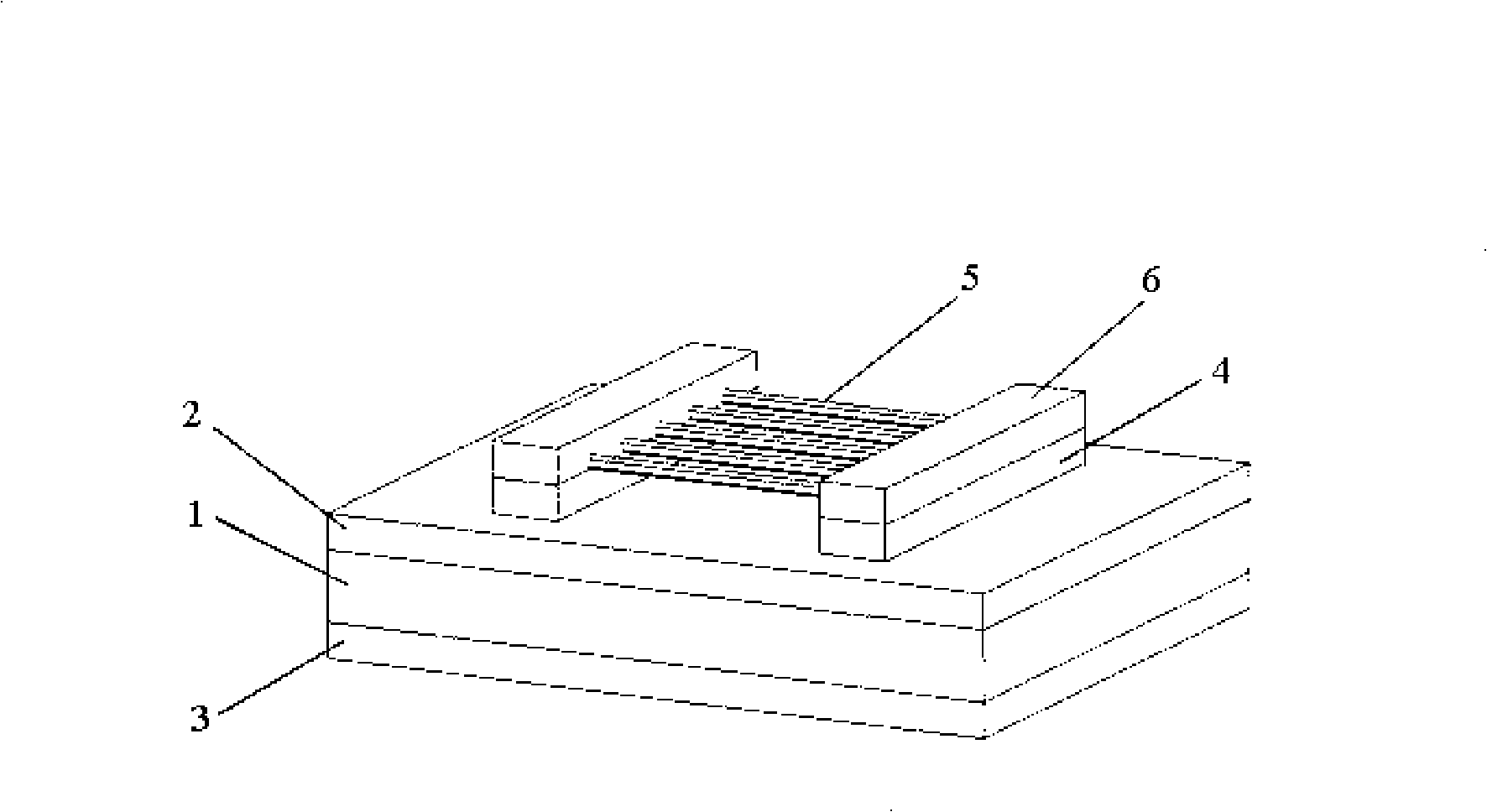

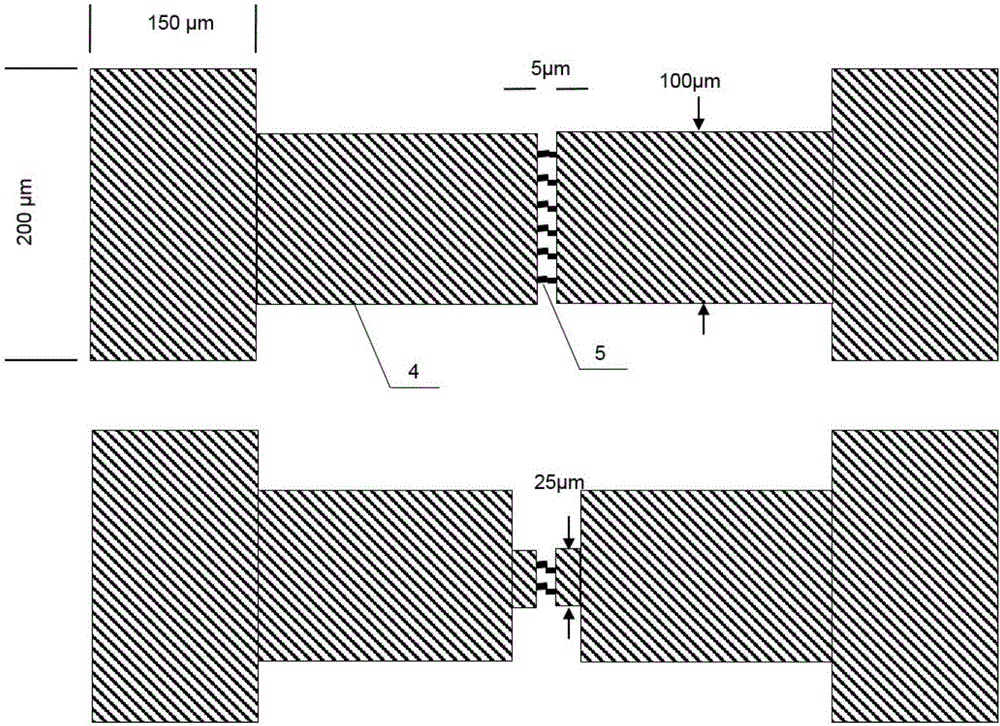

Method for preparing slot field-effect transistor with back-gate ZnO multi-nano wire

InactiveCN101540287AIncrease currentImprove performanceNanostructure manufactureSemiconductor/solid-state device manufacturingSemiconductor materialsUltraviolet

The invention discloses a method for preparing a slot field-effect transistor with a back-gate ZnO multi-nano wire, which belongs to the technical field of compound semiconductor materials and devices. The invention provides a method for preparing a slot field-effect transistor with back-gate ZnO multi-nano wire so as to solve the problem that the existing field effect transistor with back-gate ZnO nano wire has small working current which has large gap with practical applications; the method comprises the following steps of: growing medium, preparing a back-gate electrode, preparing a bottom source-drain electrode, fixing the ZnO nano wire primarily by using alternating current bi-directional dielectrophoresis technology, controlling the ZnO nano wire accurately by using nano controlling technology based on AFM, and preparing a top source-drain electrode. A plurality of ZnO nano wires are taken as parallel slots and suspended in the air, which can greatly improve the performance of current, transconductance, and cut-off frequency and the like of devices, and improve the performance of ultraviolet, gas and chemical sensing.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

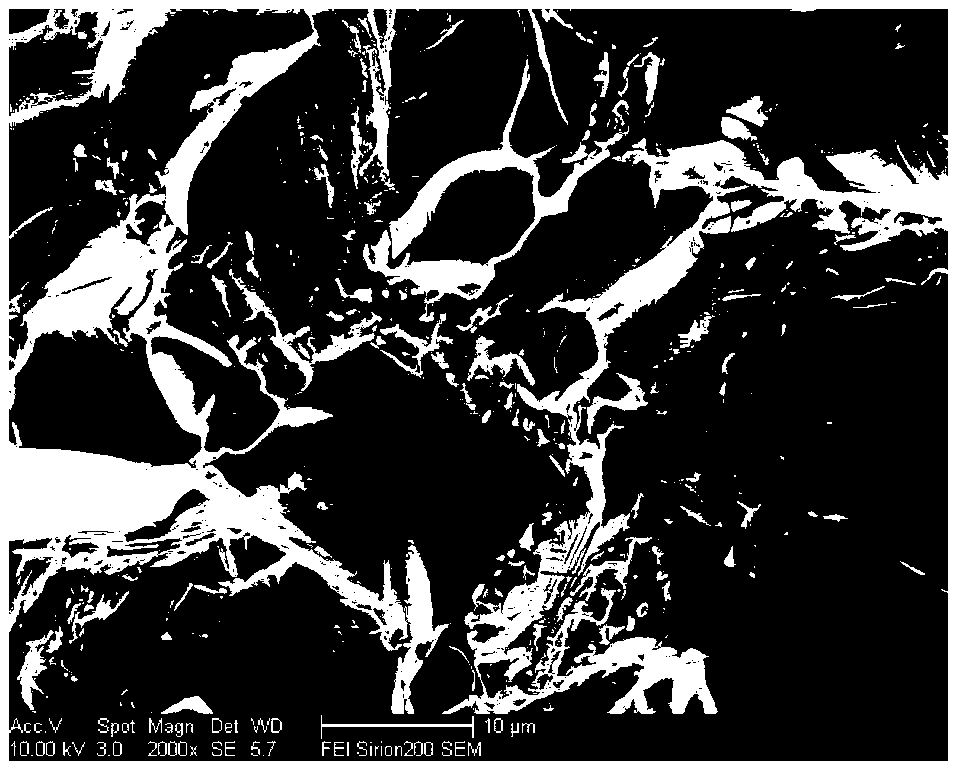

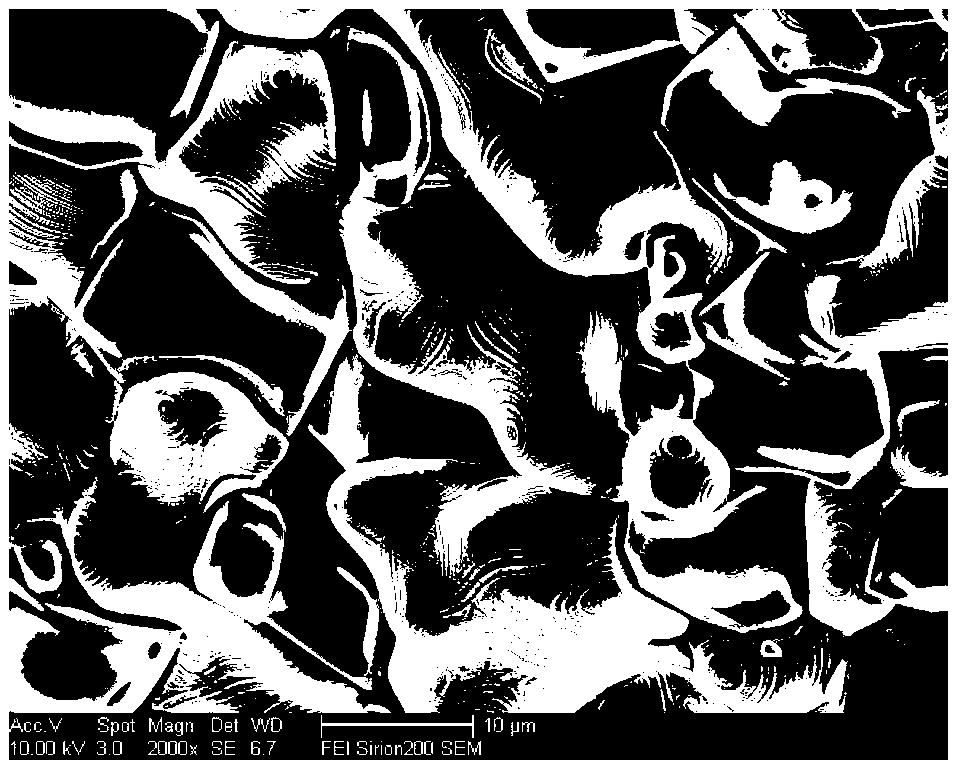

Preparation method of polymer fiber-based ZnO nanowire fiber

ActiveCN106521678AAvoid ingredientsAvoid the effects of natureMonocomponent halogenated hydrocarbon artificial filamentSynthetic polymer filament chemical after-treatmentFiberElectrospinning

The invention relates to the technical field of fiber manufacturing, and in particular relates to a preparation method of polymer fiber-based ZnO nanowire fiber. The preparation method comprises the following steps: (1) carrying out electrostatic spinning on a polymer solution and a ZnO precursor to obtain nano-fiber containing a polymer and the ZnO precursor; (2) carrying out low-temperature heat treatment on the nano-fiber to obtain the nano-fiber containing uniformly-distributed Zn nanoparticles inside; (3) by combining a hydrothermal method, putting the nano-fiber into a growth solution and growing for a period of time, so that the Zn nano-particles on surfaces of the nano-fiber and inside the nano-fiber are self-assembled and grow into ZnO nanowires, thereby forming the polymer fiber-based ZnO nanowire fiber. The polymer fiber-based ZnO nanowire fiber prepared by the preparation method has a good mechanical property and contains high-ratio nano zinc oxide.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION +2

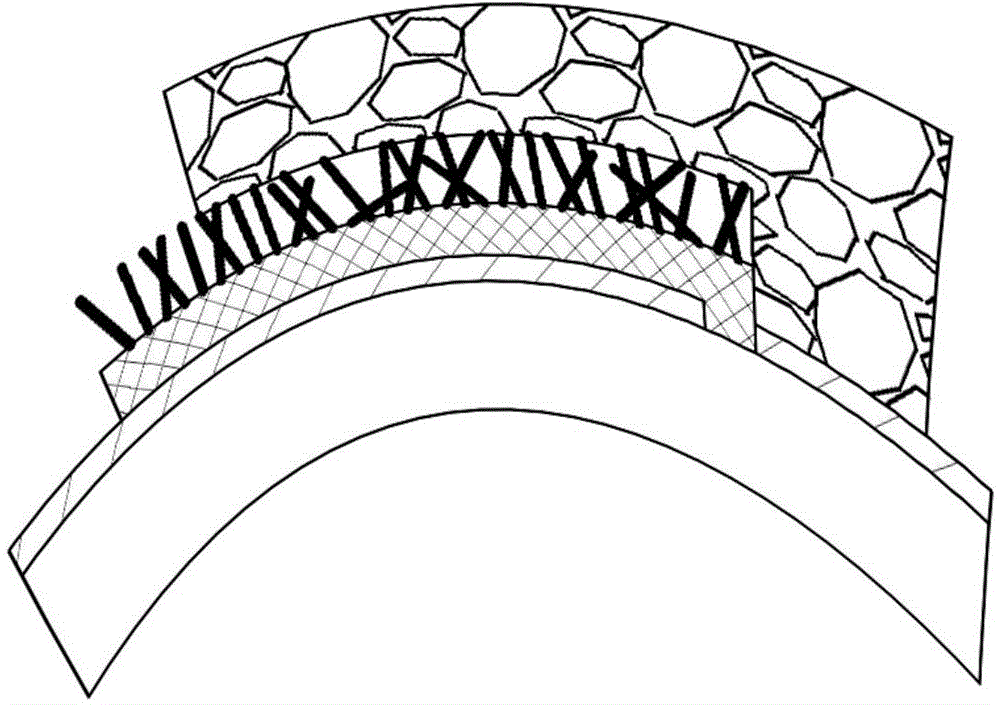

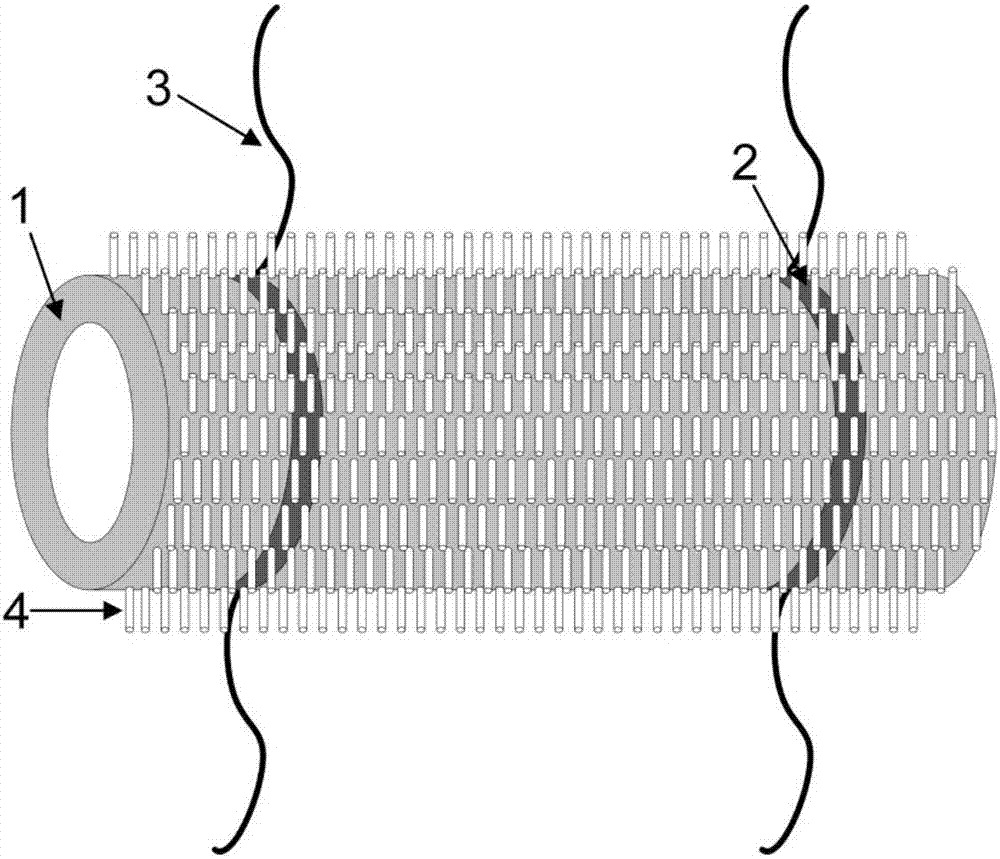

Fiber Optic Solar Nanogenerator Cells

A dye-sensitized solar cell including ZnO nanowire arrays grown of a flat substrate for harvesting solar energy is integrated with a piezoelectric nanogenerator for harvesting ultrasonic wave energy. The two energy harvesting approaches work simultaneously or individually and can be integrated in parallel or serial for raising the output current, voltage or power, respectively. A solar cell employs an optical fiber and semiconductor nanowires grown around the fiber. A p-n junction based design, organic-inorganic heterojunction, or a dye-sensitized structure is built at the surfaces of the nanowires. Light entering the fiber from a tip propagates through the fiber until it enters a nanowire where it reaches a photovoltaic element. Light entering the fiber cannot escape until it interacts with a photovoltaic element, thereby increasing the solar conversion efficiency. The fiber can transmit light, while the nanowires around the fibers increase the surface area of light exposure.

Owner:GEORGIA TECH RES CORP

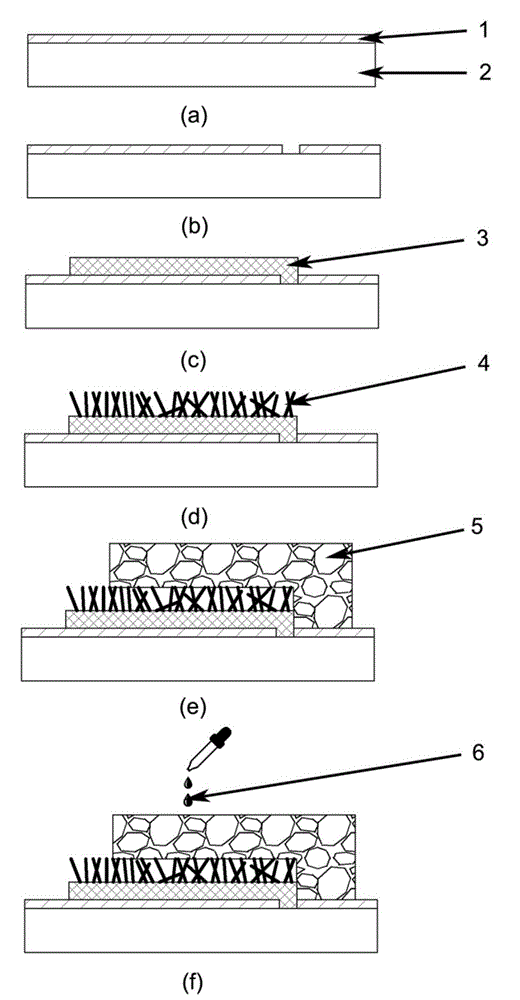

Flexible perovskite solar cell production technology

InactiveCN104795498AReduce manufacturing costEasy to dryFinal product manufactureSolid-state devicesOptoelectronicsElectrode Contact

The invention discloses a flexible perovskite solar cell production technology. The flexible perovskite solar cell production technology includes the steps of 1), etching; 2), producing a photo-anode; 3), performing film formation by printing to obtain a carbon counter electrode, namely, performing film formation on a flexible conductive substrate by using conductive carbon paste with the drying temperature below 150 DEG C according to a silk-screen printing method so as to obtain the carbon counter electrode of a solar cell, wherein one end of the carbon counter electrode contacts with an ITO (indium tin oxide) conductive layer, a gap is formed between the other end of the carbon counter electrode and the ITO conductive layer, and a grown ZnO nanowire is arranged in the gap; 4), adding perovskite. The flexible perovskite solar cell production technology has the advantages that the photo-anode of the cell is produced on the flexible conductive substrate through a low-temperature production technology; then, the carbon counter electrode of the cell is produced from the low-temperature conductive carbon paste with the organic solvent drying temperature below 150 DEG C, and a film is produced by means of silk-screen printing, so that production cost of the counter electrode of the cell is reduced greatly; the flexible perovskite solar cell production technology is rapid in drying and good in conductivity, and heating temperature does not exceed borne temperature limit of the flexible conductive substrate.

Owner:HUAZHONG UNIV OF SCI & TECH

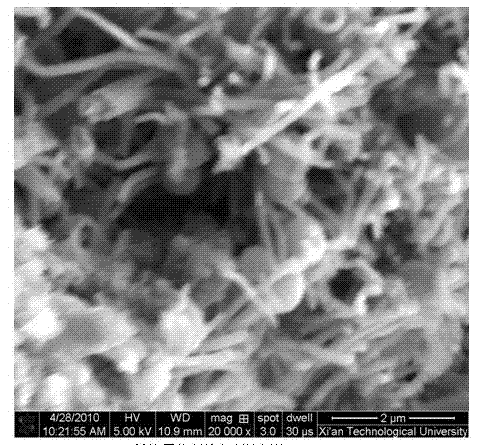

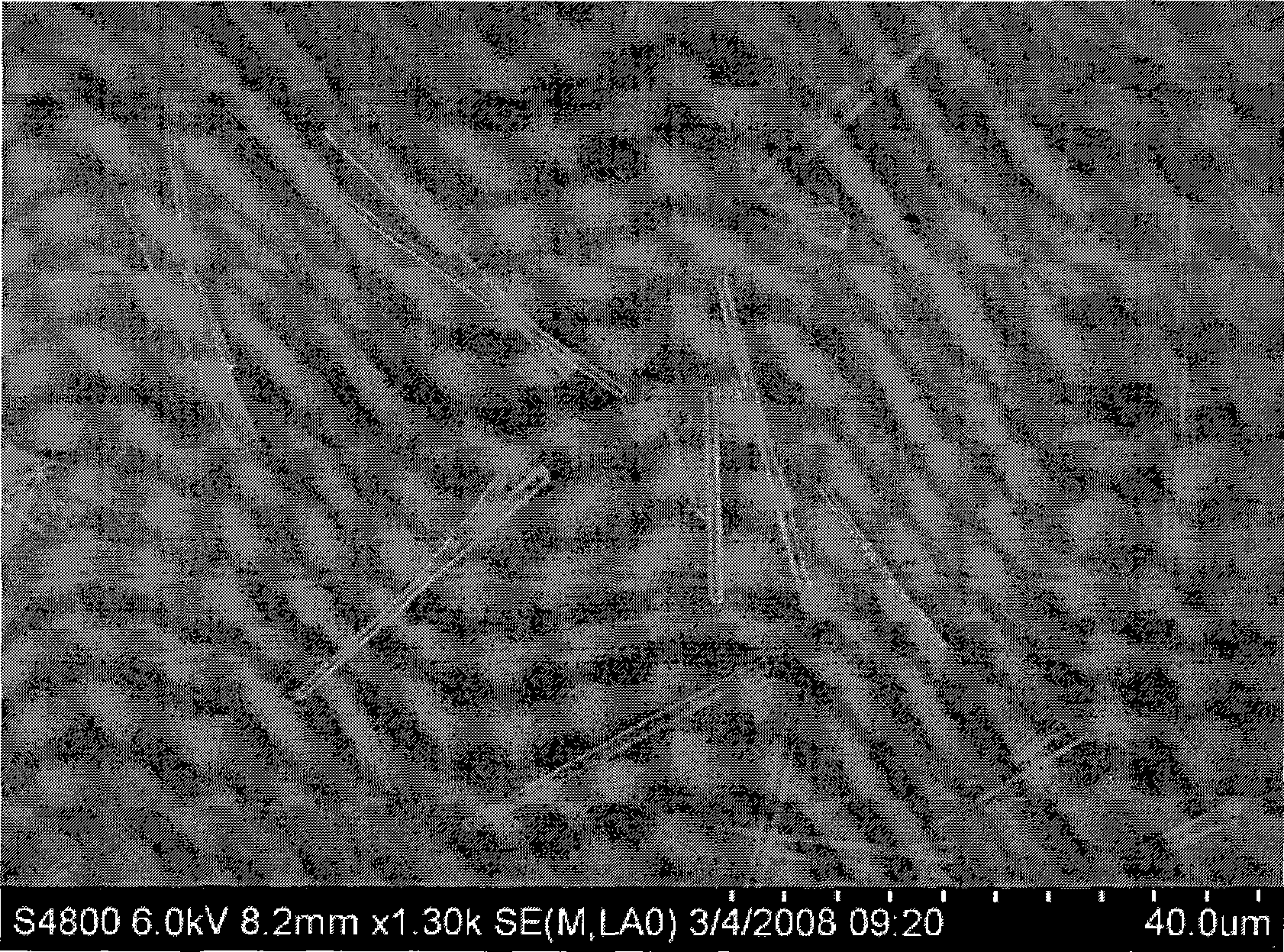

Composite resistance NH3 gas-sensitive gas sensor and preparation method thereof

The invention relates to the technical field of gas-sensitive materials, in particular to a composite resistance NH3 gas-sensitive gas sensor and a preparation method thereof. In the technical scheme, the preparation method for the composite resistance NH3 gas-sensitive gas sensor is characterized by comprising the following steps of: preparing materials, namely preparing large-scale ZnO nanowires without any catalysts by a physical thermal evaporation method, and preparing HCl-doped polyaniline nanotubes by a chemical oxidation method; weighing 10 mass parts of HCl-doped polyaniline nanotubes and 1 to 5 mass parts of ZnO nanowires, grinding powder of polyaniline and zinc oxide in a mortar for half an hour, adding N-methyl pyrrolidone for wet grinding for half an hour, and blending to obtain slurry; coating the slurry on a ceramic tube of which both ends are coated with a gold electrode and a platinum heating wire to obtain a thick film; and drying the thick film in the air for half an hour, and performing heat treatment in a vacuum drying oven at the temperature of 60 DEG C to obtain the gas-sensitive gas sensor.

Owner:XIAN TECHNOLOGICAL UNIV

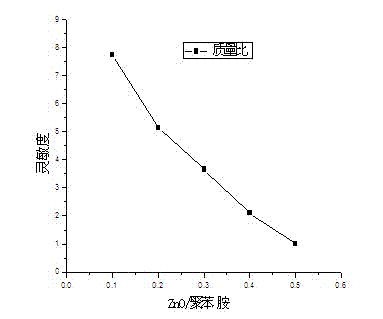

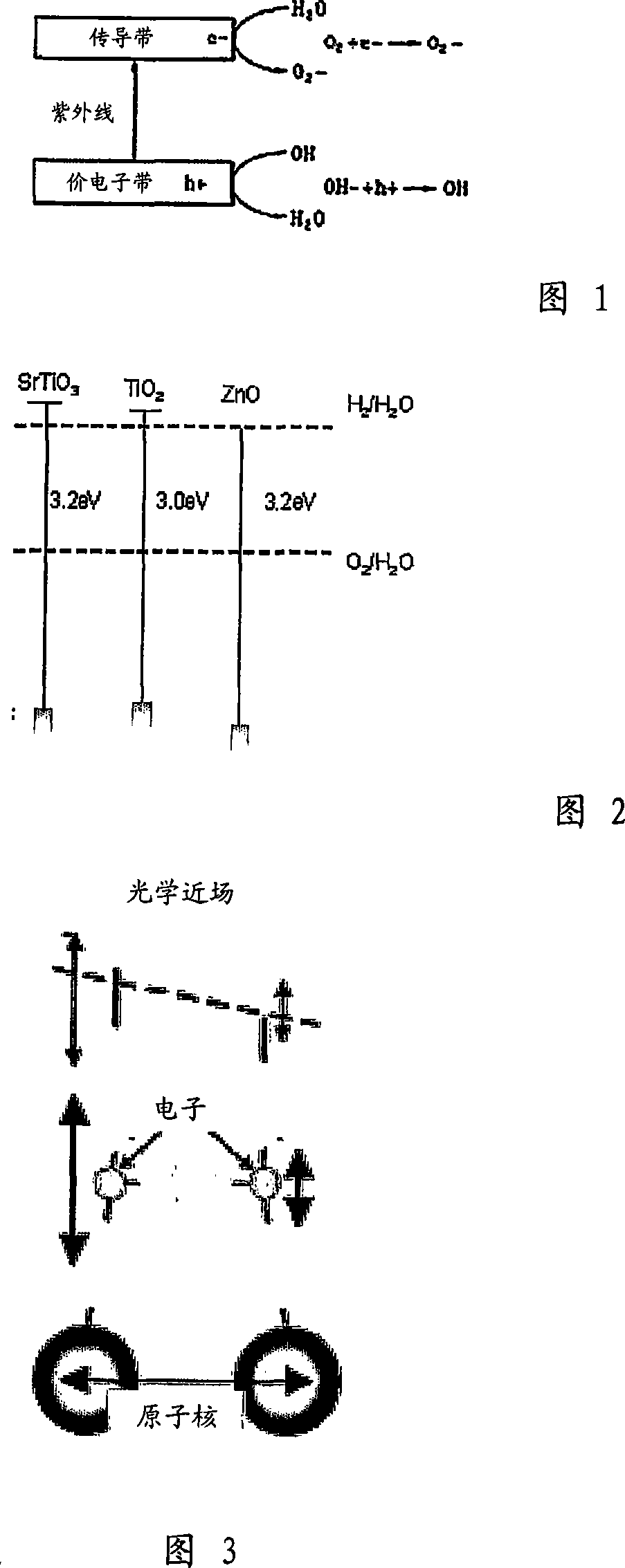

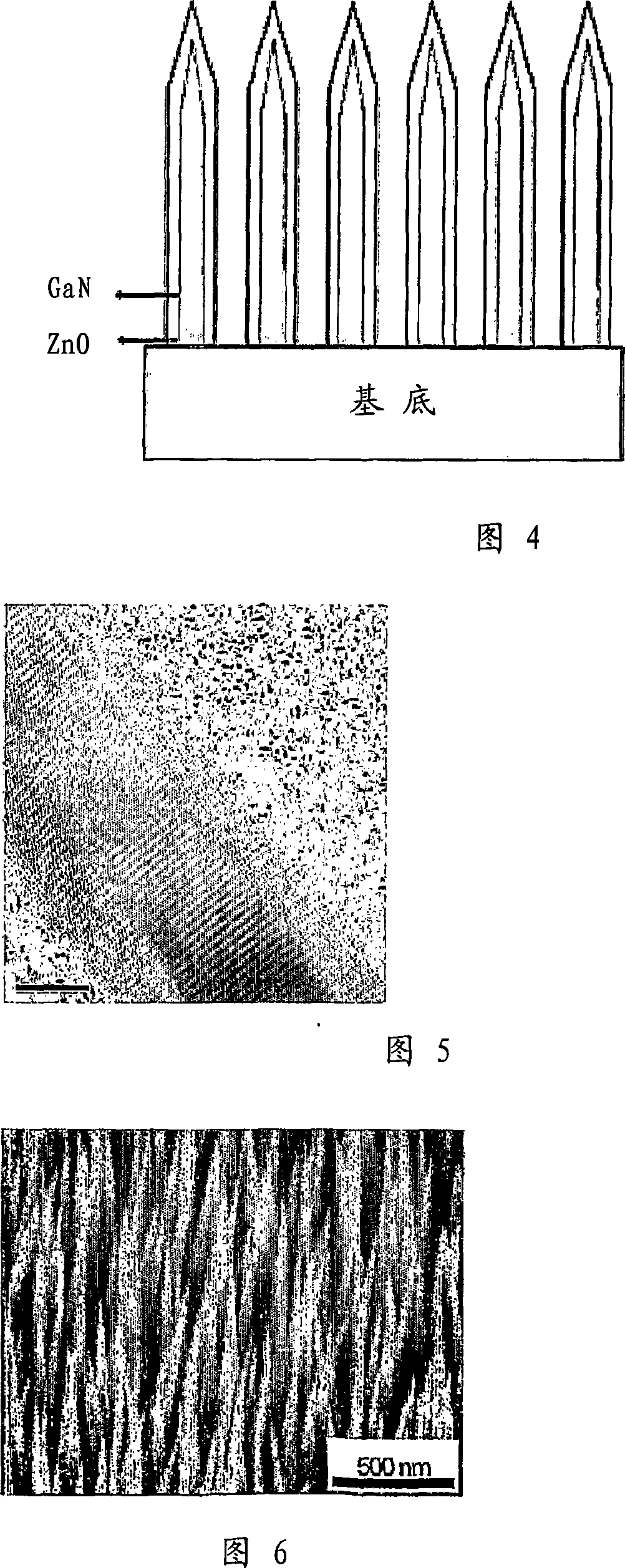

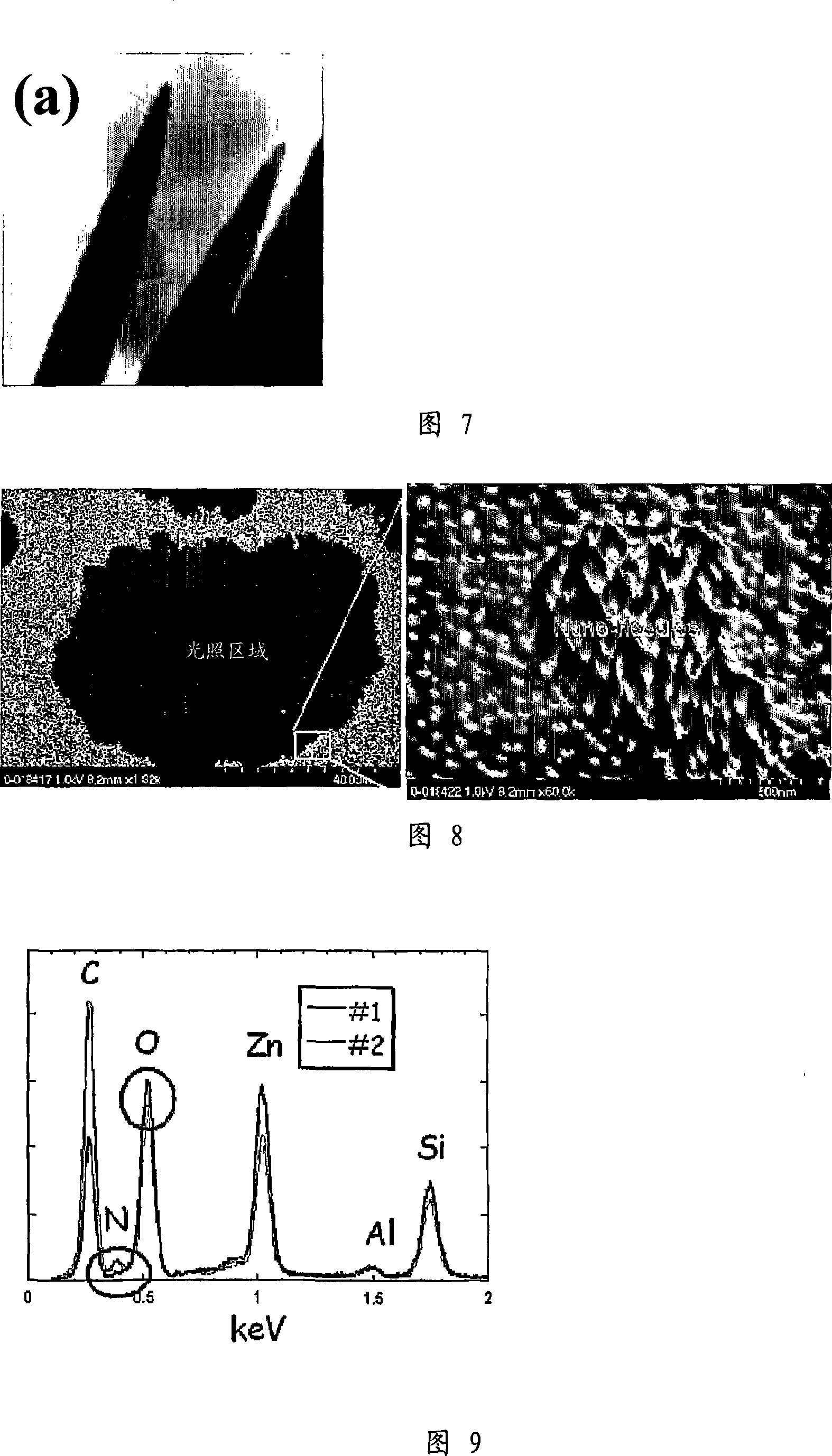

Near-field photocatalyst containing zinc bloom nanometer line

InactiveCN101252988ALow costSimplify production stepsNanostructure manufactureMetal/metal-oxides/metal-hydroxide catalystsOvervoltagePlatinum

Disclosed is a near-field photocatalyst using a ZnO (ZnO) nanowire. The photocatalyst is advantageous in that low-priced zinc is used instead of titanium, conventionally used as a photocatalyst to reduce expenses, and that it is possible to obtain overvoltage which is sufficient to generate hydrogen using an optical near field formed around an end of a ZnO nanowire without the application of additional extenal voltage, thus the use of a costly electrode, such as platinum, is avoided and a process is simplified.

Owner:POHANG UNIV OF SCI & TECH +1

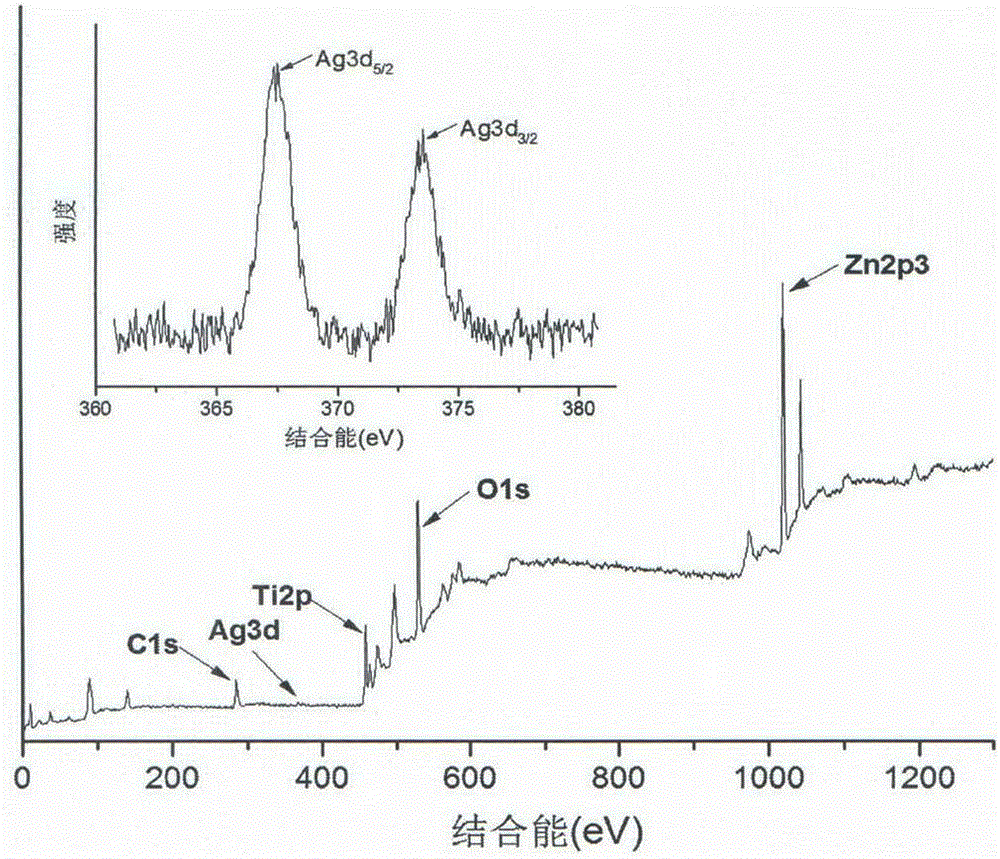

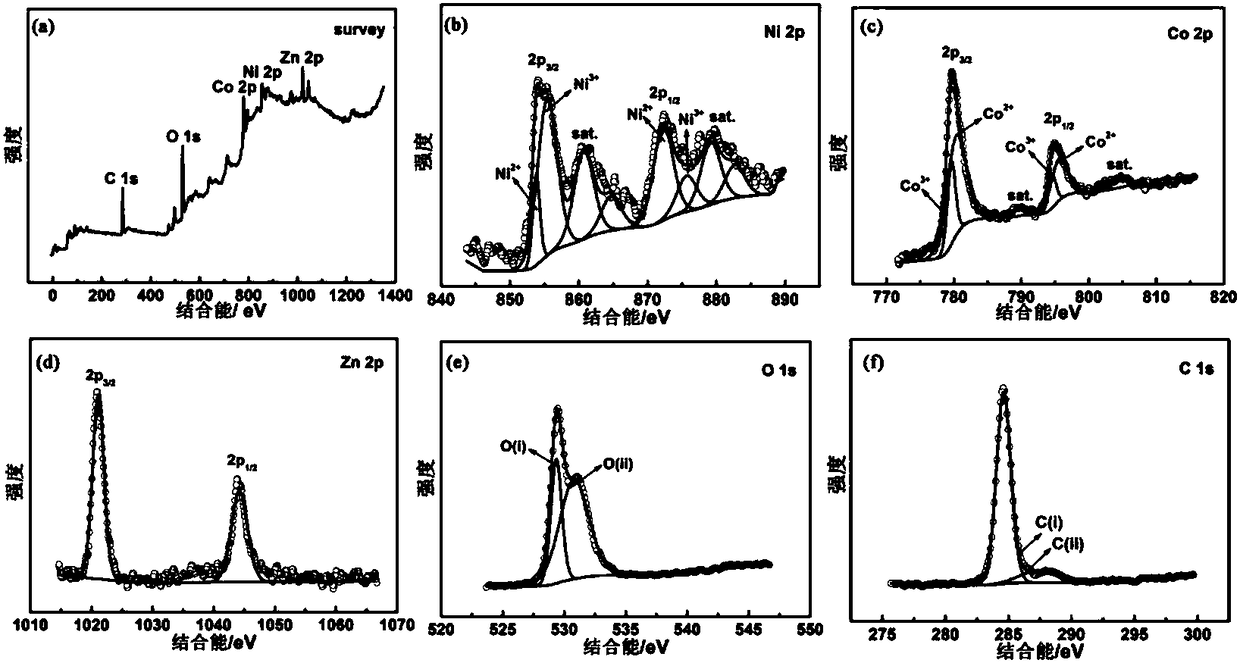

ZnO nano-wire array synergistically modified by nano-Ag and TiO2 and preparation method of zinc oxide nano-wire array

InactiveCN105336501ALarge specific surface areaImprove adsorption capacityLight-sensitive devicesPhotovoltaic energy generationElectronic transmissionSolar cell

The invention relates to a ZnO nano-wire array synergistically modified by nano-Ag and TiO2 and a preparation method of the zinc oxide nano-wire array. The structure of the array is as follows: a ZnO nano-wire is taken as an inner core, nano-Ag is loaded on the surface of the ZnO nano-wire, a TiO2 film is modified at the outermost part of the nano-Ag, wherein the length of the ZnO nano-wire array is 10mum, the thickness of the TiO2 film is 5-10nm. The preparation method comprises the following steps: the ZnO nano-wire array is prepared by a hydro-thermal method, AgNO3 solution is taken as a precursor, nano-Ag is loaded on the surface of the ZnO nano-wire array by an illumination reduction method, then the ZnO nano-wire array is put into mixed solution of Ammonium hexafluorotitanate and boric acid, and the TiO2 film is formed on the surface of the array by an immersion method. The structure has the main purpose that the ZnO nano-wire modified by Ag inside a nanocable can be taken as an expressway for electronic transmission, and the light absorption is enhanced by utilizing the Ag surface plasmon resonance effect. The preparation method has the advantages that the cost is low, the process is controllable, and the repeatability is good, therefore, the preparation method can be applied to photo anode materials of a solar cell and can be also utilized in the photocatalysis field.

Owner:SHIHEZI UNIVERSITY

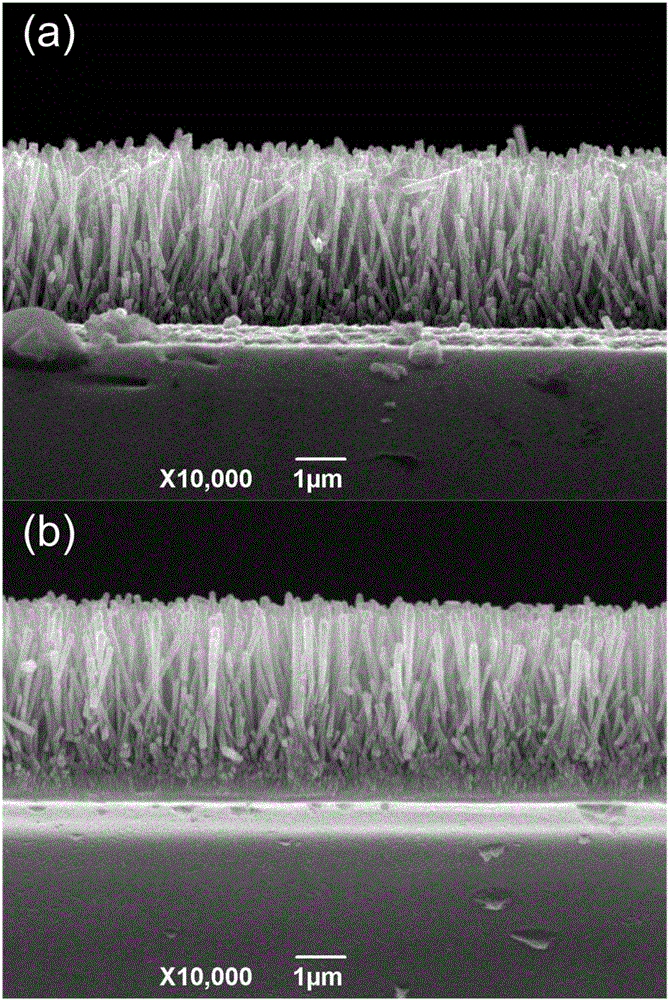

Preparation method of composite nanowire array with one-dimensional ZnO(zinc oxide)-TiO2(titanium dioxide) core-shell structure

InactiveCN102723208AImprove efficiencyLow environmental requirementsLight-sensitive devicesPhotovoltaic energy generationAtomic layer depositionZno nanowires

A preparation method of a composite nanowire array with a one-dimensional ZnO(zinc oxide)-TiO2(titanium dioxide) core-shell structure. In the whole preparation process, a wet chemistry method is adopted. The preparation method comprises the following steps: at first, a ZnO seed layer is prepared on conductive glass in a sol-gel method, then a ZnO nanowire array is grown on the seed layer in a liquid-phase deposition method, and next a TiO2 shell layer is prepared on a ZnO nanowire array in a circulating adsorption reaction method, so as to obtain the composite nanowire array with the one-dimensional ZnO-TiO2 core-shell structure. The preparation method has the advantages that (1) compared with the other methods (such as a chemical meteorology deposition method, an atom layer deposition method and a magnetron sputtering method), the preparation method has a simple process, does not require complex equipment and severe environments, and is low in cost; (2) the preparation method can control the diameter and the length of the ZnO nanowire and the thickness of the TiO2 shell layer conveniently; and (3) the preparation method can be combined with a photoanode preparation method of a quantum dot dye-sensitized solar cell conveniently to facilitate the research of the cell performance.

Owner:XI AN JIAOTONG UNIV

Large-scale fabrication of vertically aligned ZnO nanowire arrays

InactiveUS8367462B2NanoinformaticsSemiconductor/solid-state device manufacturingNanowire arrayPhotoresist

In a method for growing a nanowire array, a photoresist layer is placed onto a nanowire growth layer configured for growing nanowires therefrom. The photoresist layer is exposed to a coherent light interference pattern that includes periodically alternately spaced dark bands and light bands along a first orientation. The photoresist layer exposed to the coherent light interference pattern along a second orientation, transverse to the first orientation. The photoresist layer developed so as to remove photoresist from areas corresponding to areas of intersection of the dark bands of the interference pattern along the first orientation and the dark bands of the interference pattern along the second orientation, thereby leaving an ordered array of holes passing through the photoresist layer. The photoresist layer and the nanowire growth layer are placed into a nanowire growth environment, thereby growing nanowires from the nanowire growth layer through the array of holes.

Owner:GEORGIA TECH RES CORP

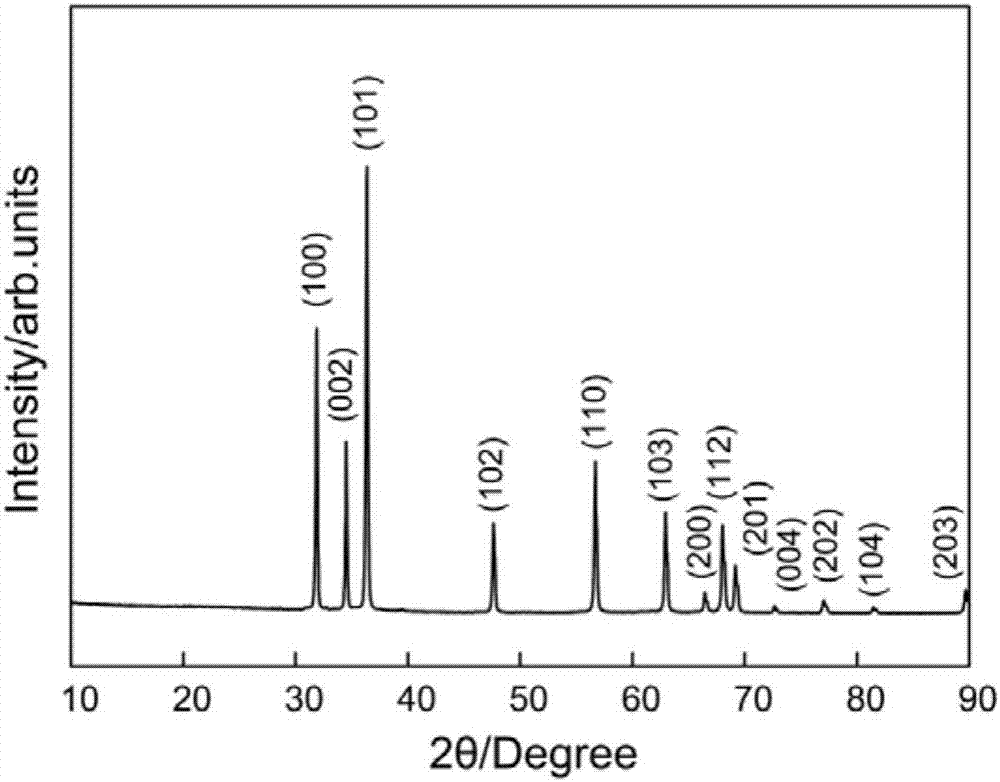

Electrode surface in-situ growth nano ZnO based NO2 sensor

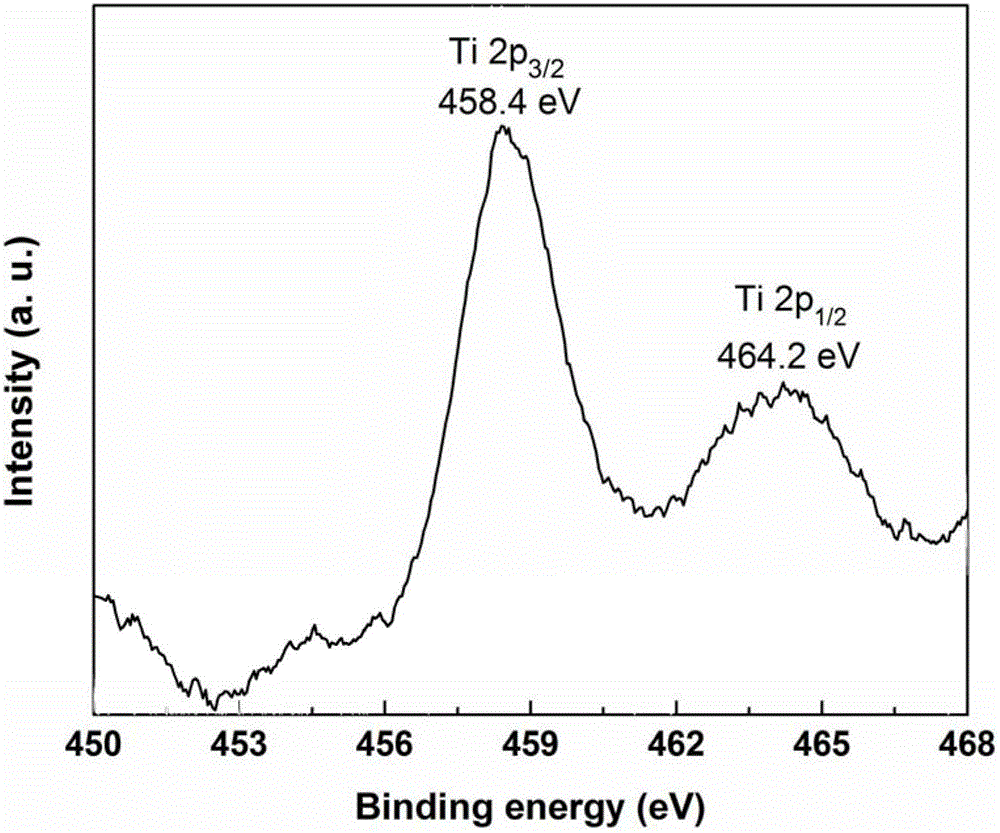

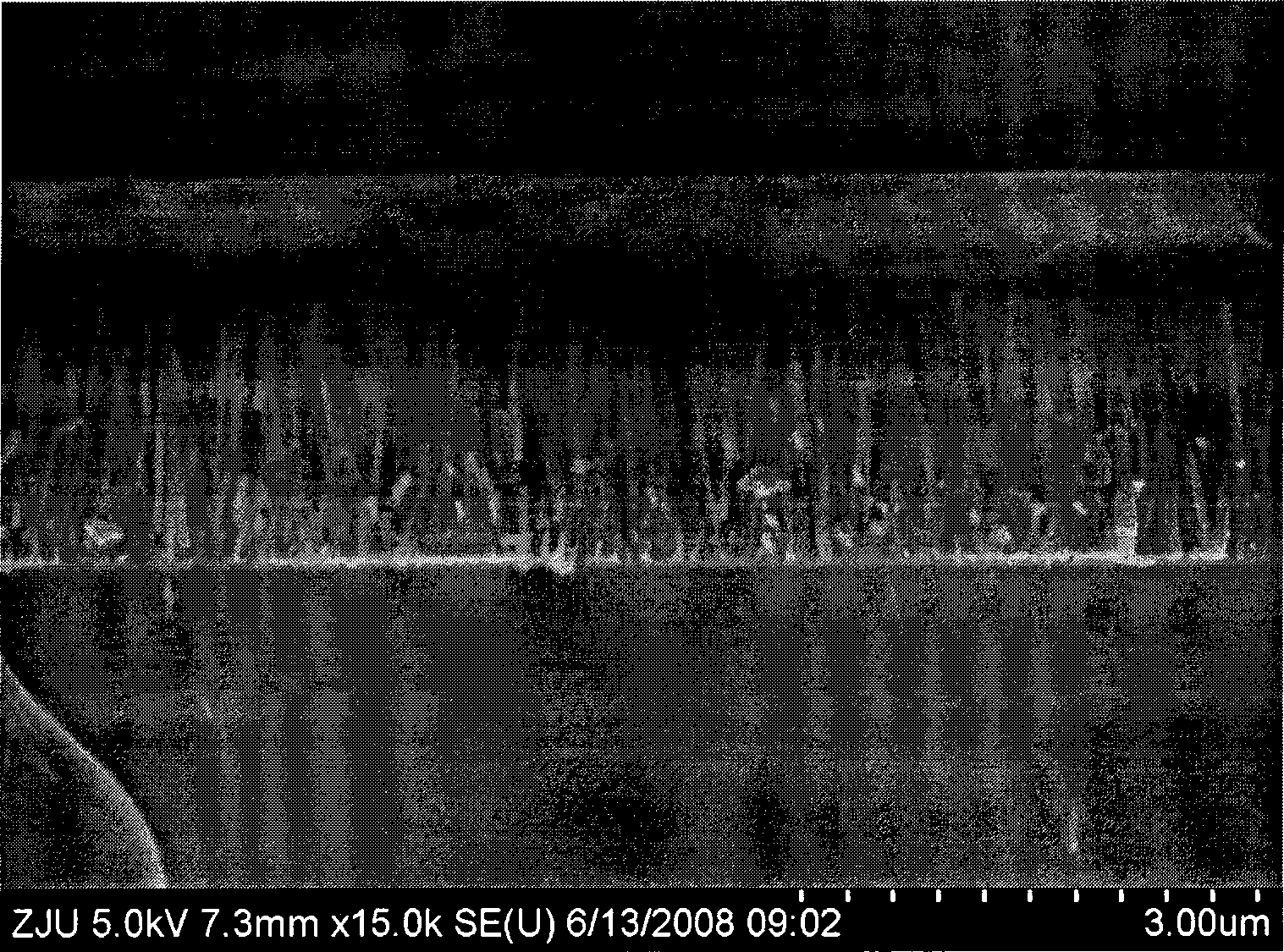

ActiveCN106970117APromote crystallizationHigh aspect ratioMaterial resistanceCrystal structureWurtzite crystal structure

The invention relates to an electrode surface in-situ growth nano ZnO based NO2 sensor and belongs to the technical field of gas sensors of one-dimensional semiconductor metal oxide materials. The electrode surface in-situ growth nano ZnO based NO2 sensor is characterized by being obtained through in-situ growth ZnO nanowire arrays on the electrode elements, a ZnO nanowires are 80-100nm in diameter and 600nm-1umm in length, and the crystal structure of the ZnO nanowires is of the hexagonal-phase wurtzite crystal structure. The gas sensor acquiring maximum sensitivity on NO2 gas in the working temperature of 250DEG C is short in response and recovery time, good in reversibility and selectivity and good in development prospect.

Owner:NORTHEASTERN UNIV

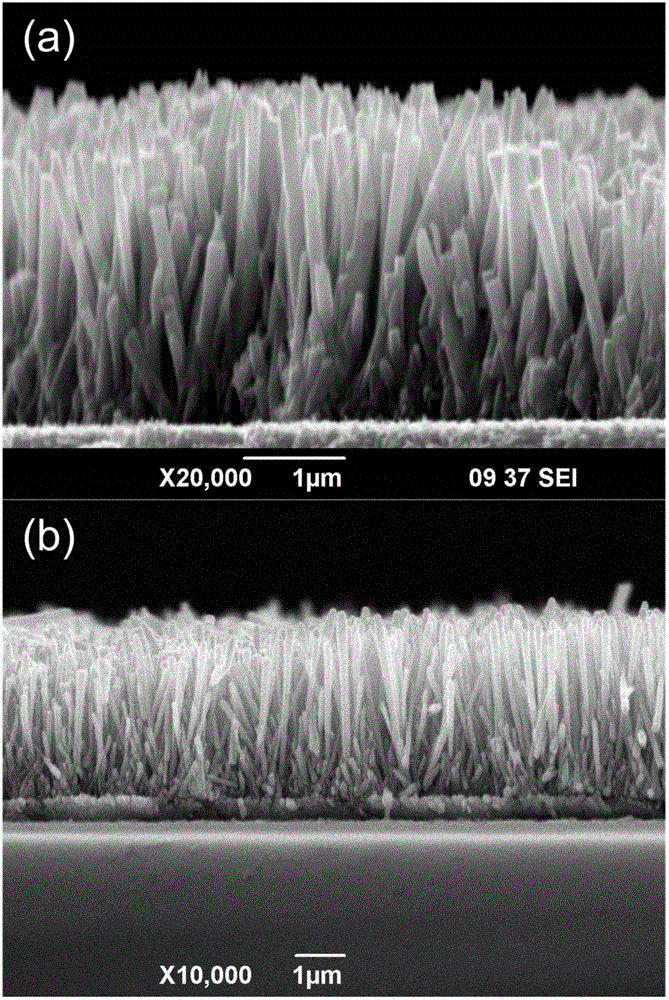

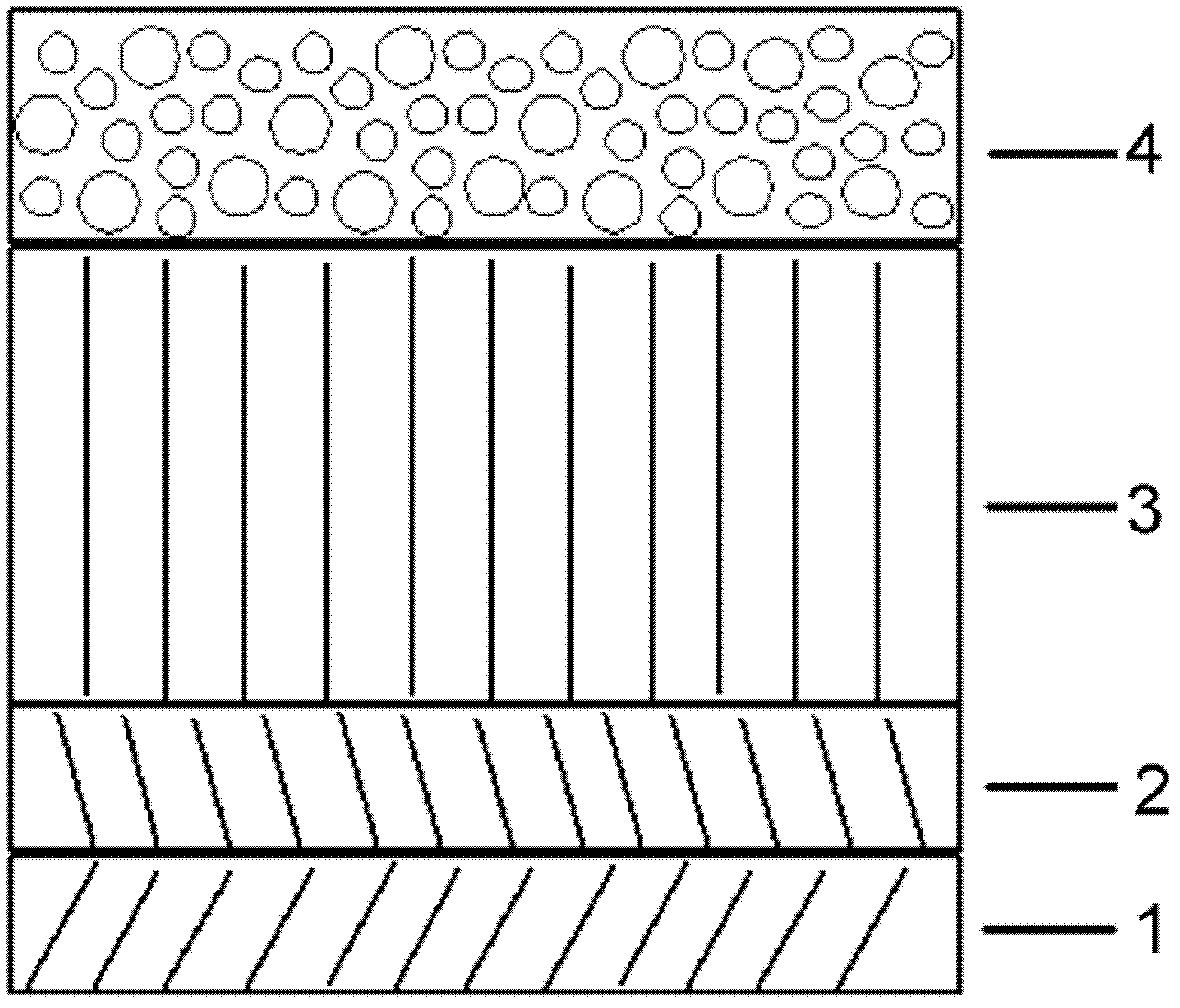

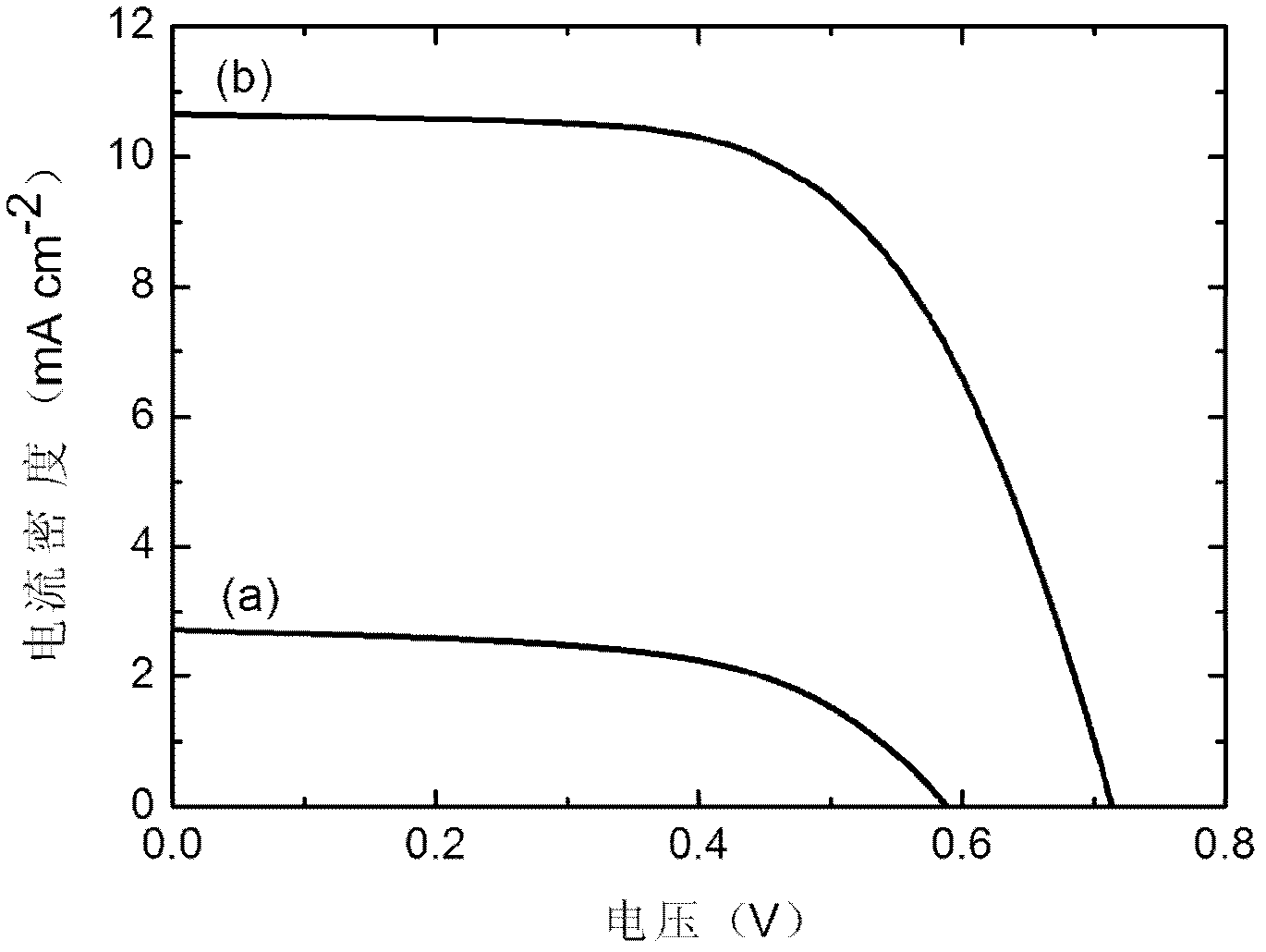

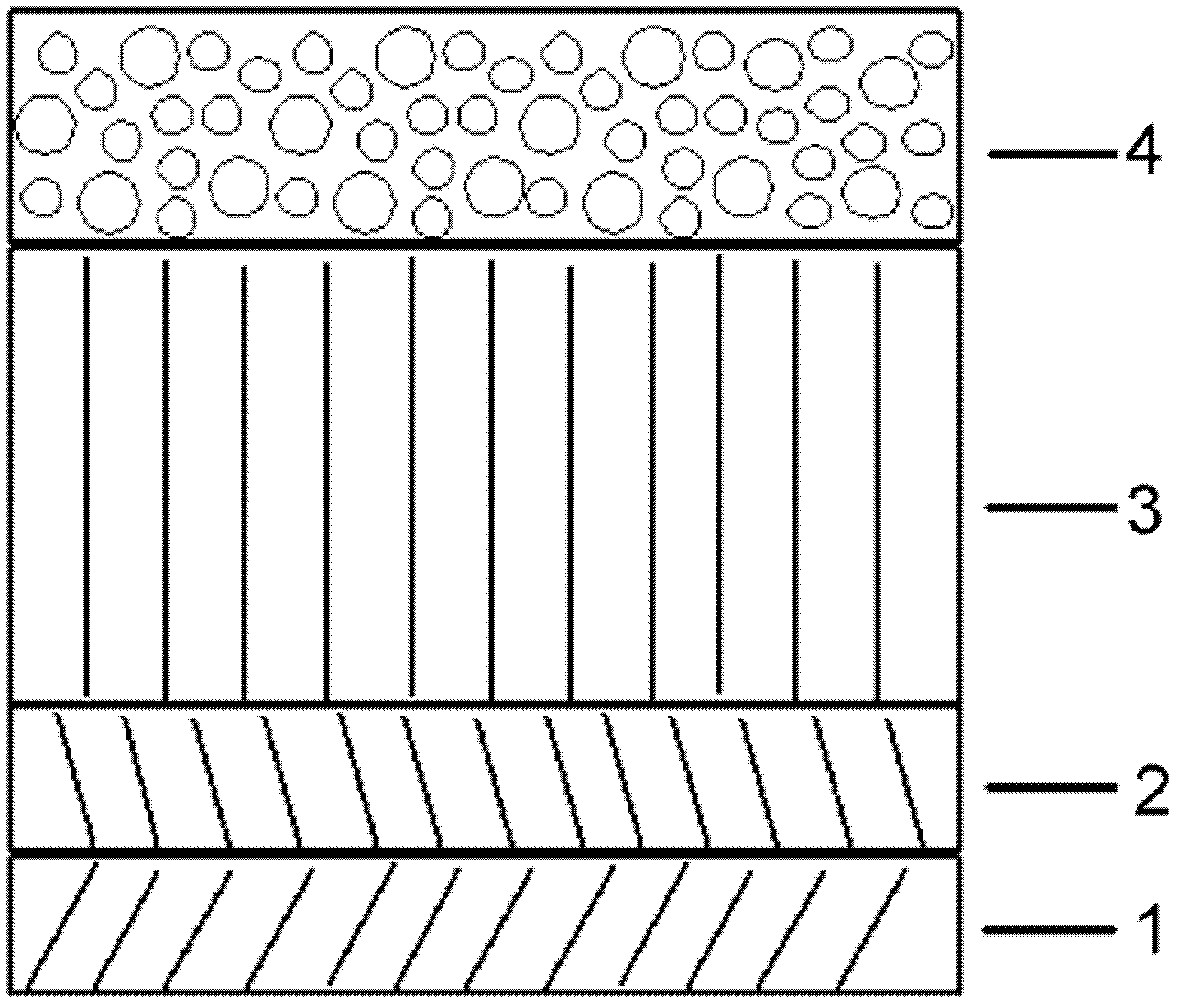

A preparation method of high-efficiency composite photoanode for dye-sensitized solar cells

InactiveCN102290248AImprove microstructureFacilitate transmissionLight-sensitive devicesSolid-state devicesDye absorptionChemical reaction

The invention relates to the field of development and utilization research of new energy resources, and in particular relates to a method for preparing an efficient compound light anode of a dye sensitized solar cell. The method comprises the following steps: firstly depositing a ZnO thin film doped with In on a transparent substrate by utilizing a magnetic control sputtering technology; then growing a ZnO nanowire array on the ZnO thin film doped with In by adopting a hydrothermal chemistry reaction method; and finally coating a layer of TiO2 nano particle dispersion solution on the surface of the ZnO nanowire array through a silk screen printing technology, and heating the dispersion solution to enable an organic solvent in the dispersion solution to volatilize, thus obtaining a hole-shaped TiO2 nano crystalline porous membrane / ZnO nanowire array compound light anode structure. Each TiO2 nano particle mainly comprises small particles with the diameter about 10 nanometers, and simultaneously a small quantity of large particles with the diameter about 200 nanometers are dispersed; and the compound light anode can be used for not only improving the photosensitive dye absorption capacity and the light capture efficiency, but also improving the transport capability of photoproduction electrons, and improving the photoelectric conversion efficiency of the dye sensitized solar cell.

Owner:东晶电子金华有限公司

Preparation of ZnO back gate nano line field effect tube

InactiveCN101383291AAchieve depositionAchieve positioningSemiconductor/solid-state device manufacturingMicrowaveEngineering

The invention relates to the technical field of a compound semiconductor device, in particular to a method for preparing a back gate ZnO nano wire field effect pipe. The method adopts a ZnO nano wire as a channel of a field effect transistor, the deposition and the position from the nano wire to a device substrate are realized by adopting a groove method and a cross method, the ohm contact is formed by adopting Ti / Au and a ZnO channel, Al2O3 gate oxygen is formed by a traditional Liff-off method in a spattering mode, and a P<++> type Si substrate is used as a back gate of the field effect pipe. The invention has the advantages of obvious effect, simple technology, easy operation, economy, applicability and high reliability, and is easy to adopt and popularize in the preparation of microwave and millimeter wave compound semiconductor devices and sensors.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

ZnO nanowire biosensor and preparation method thereof

InactiveCN101776639AGood orientationHigh detection sensitivityZinc oxides/hydroxidesMaterial analysis by electric/magnetic meansSemiconductor materialsEnzyme electrode

The invention relates to a ZnO nanowire biosensor and a preparation method thereof, belonging to the technical field of nano semiconductor materials. In the prior art, the mixed solution of ZnO nano particles and enzyme are spun on an electrochemical electrode so that an enzyme electrode is made; the ZnO nano particles are fully wrapped by the non-conducting enzyme, and besides, an enzyme film formed on the surface of the electrochemical electrode is uneven, thereby affecting the direct electronic transfer between the active center of the enzyme and the electrode; and therefore, the sensitivity of the electrochemical electrode as a biosensor is reduced. The ZnO nanowire biosensor comprises a substrate, ZnO and the enzyme, wherein a conducting layer is arranged on the substrate, a ZnO nanowire is grown on the conducting layer, and an enzyme-wrapped layer is attached to the surface of the nanowire. The method of the invention comprises the following steps of: firstly making the conducting layer on the substrate, then growing the ZnO nanowire on the conducting layer, and thirdly generating the enzyme-wrapped layer on the surface of the nanowire. The biosensor as a working electrode is used for electrochemical working stations as chemical test devices to realize accurate tests.

Owner:CHANGCHUN UNIV OF SCI & TECH

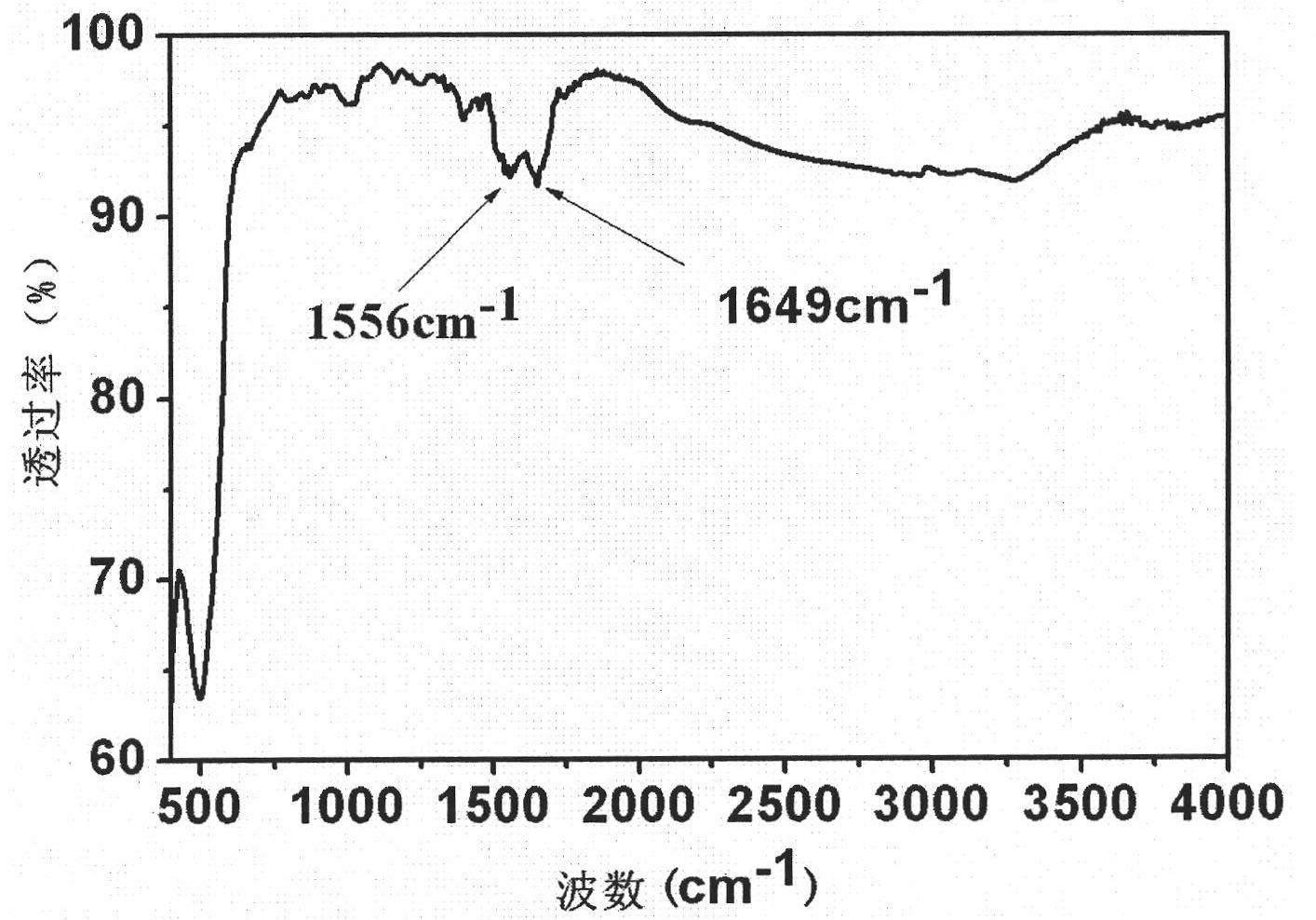

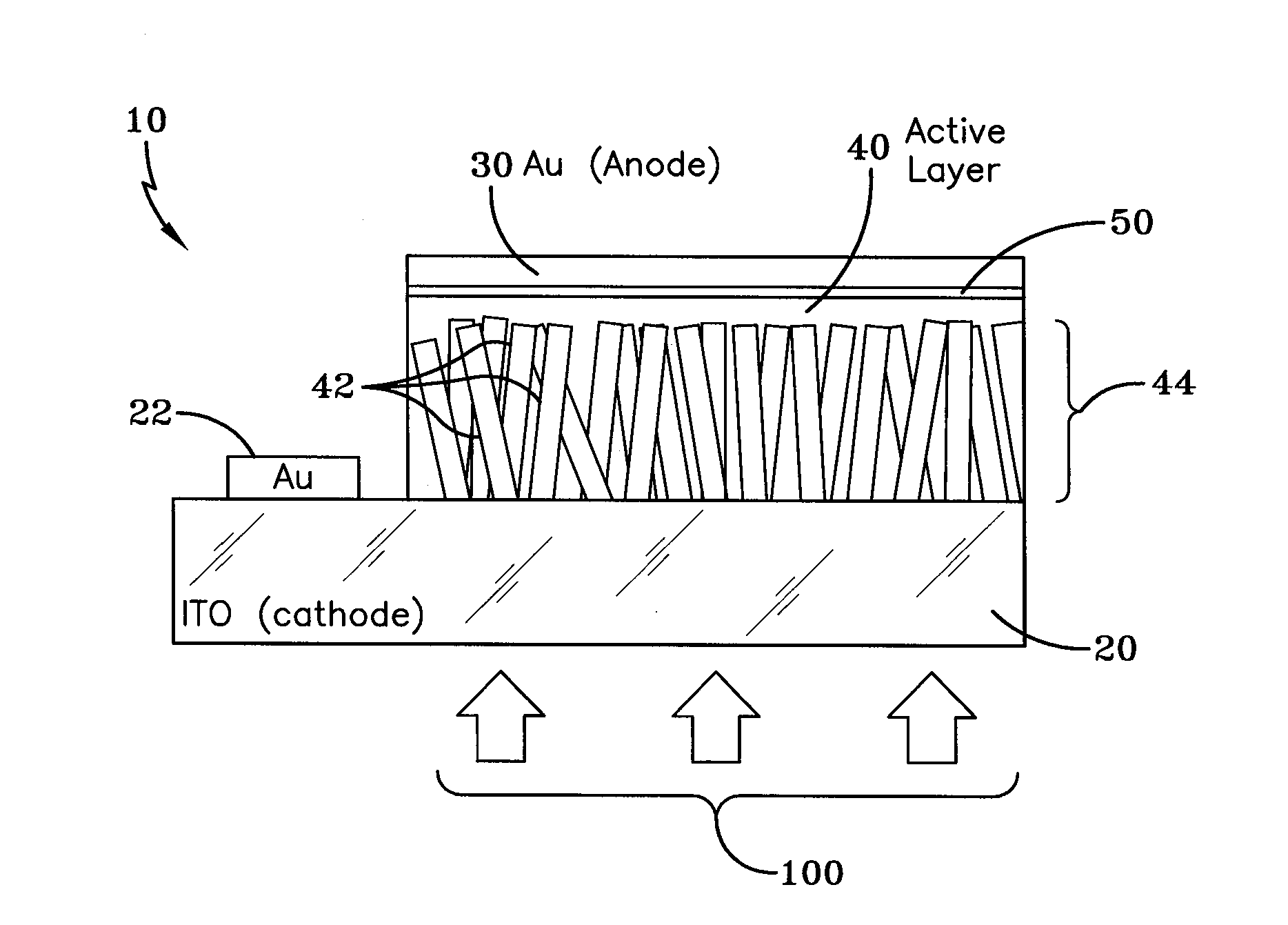

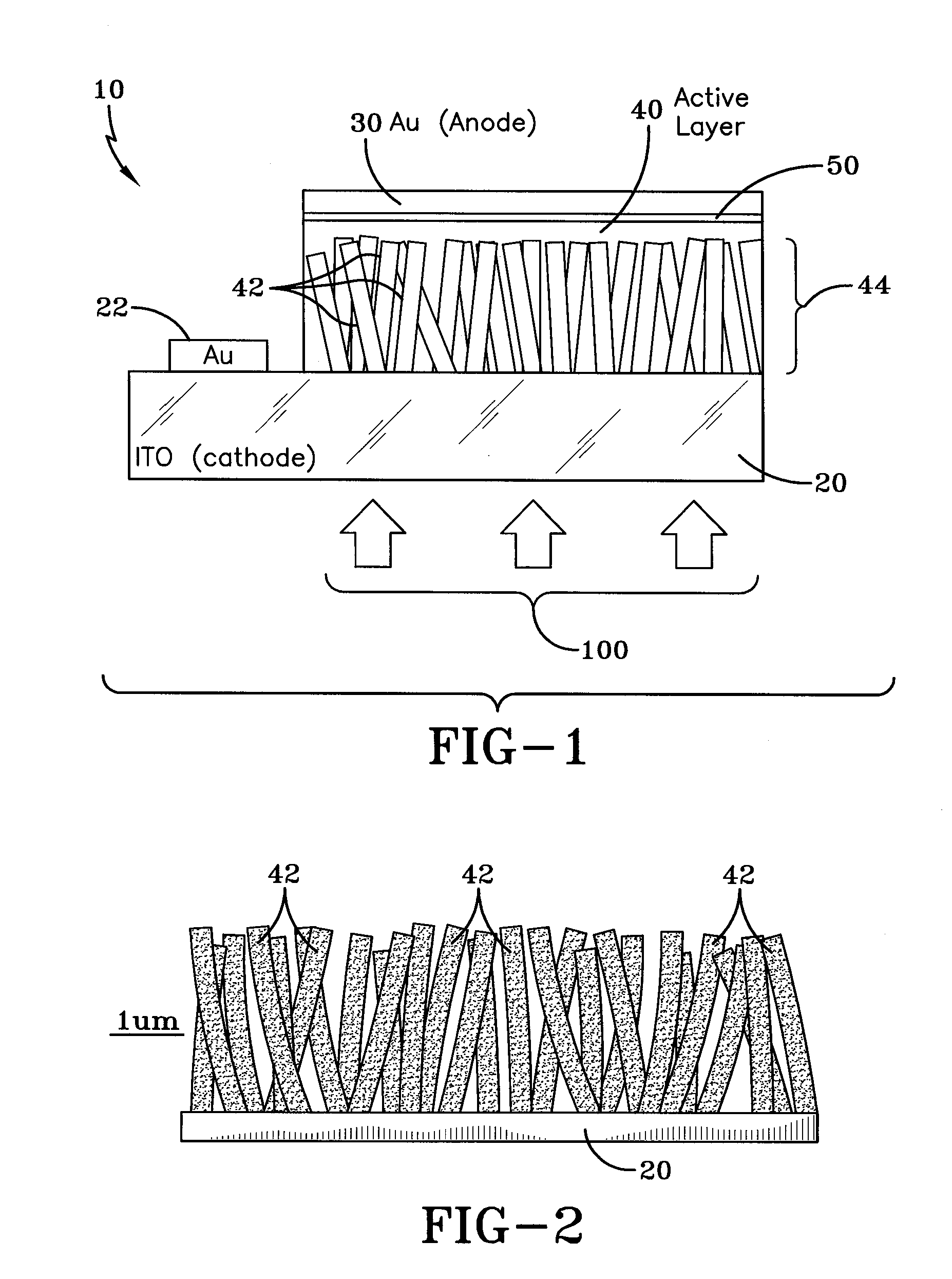

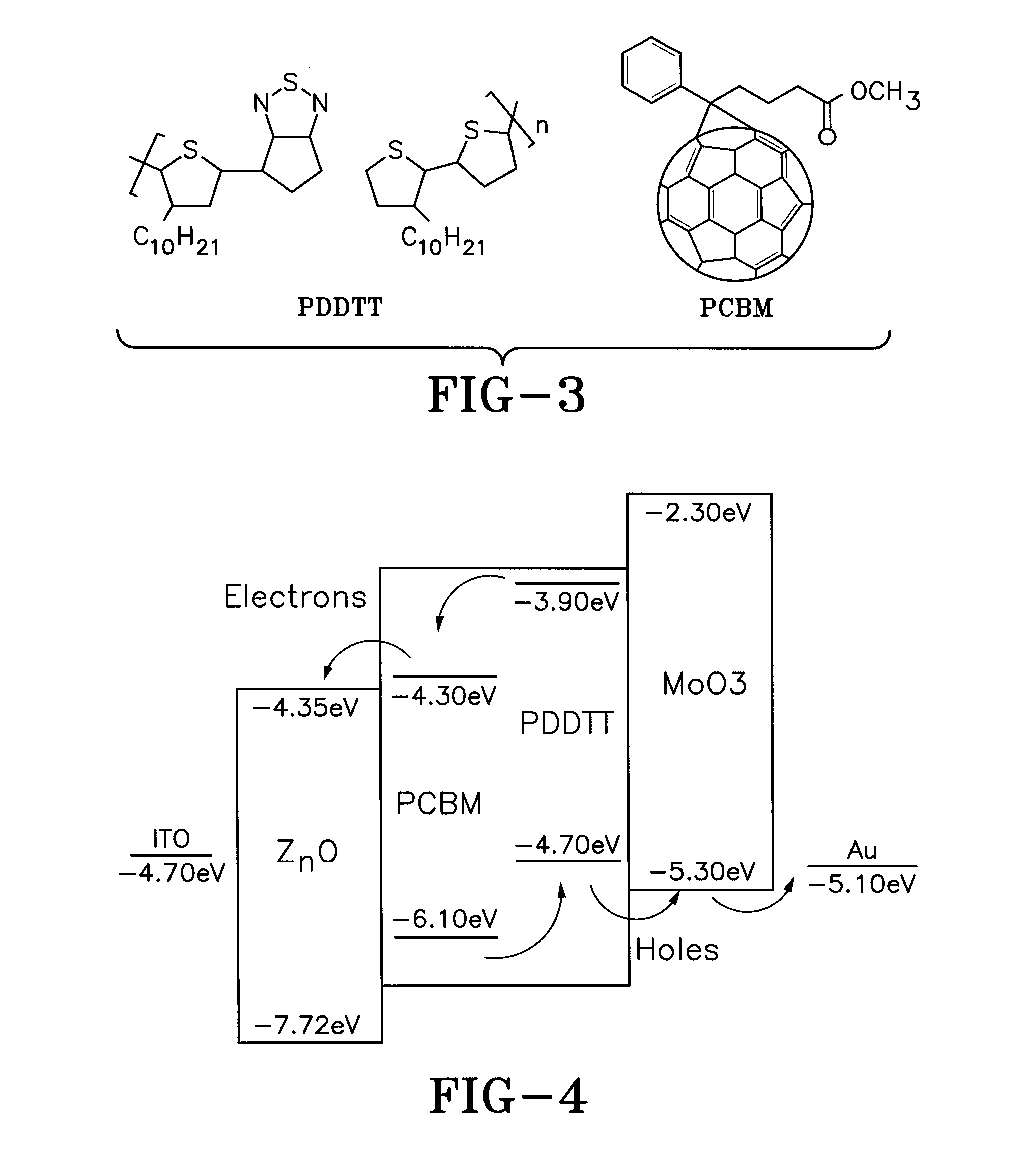

Broadband Polymer Photodetectors Using Zinc Oxide Nanowire as an Electron-Transporting Layer

InactiveUS20130248822A1Increase surface areaEfficient extractionSolid-state devicesSemiconductor/solid-state device manufacturingSpectral responsePhotodetector

A polymer photodetector has an inverted device structure that includes an indium-tin-oxide (ITO) cathode that is separated from an anode by an active layer. The active layer is formed as a composite of conjugated polymers, such as PDDTT and PCBM. IN addition, a cathode buffer layer formed as an matrix of ZnO nanowires is disposed upon the ITO cathode, while a MoO3 anode buffer layer is disposed between a high work-function metal anode and the active layer. During operation of the photodetector, the ZnO nanowires allows the effective extraction of electrons and the effective blocking of holes from the active layer to the cathode. Thus, allowing the polymer photodetector to achieve a spectral response and detectivity that is similar to that of inorganic photodetectors.

Owner:THE UNIVERSITY OF AKRON

Method for growing ZnO nano-wire array on flexible substrate

InactiveCN101413141AEasy to operateLow costPolycrystalline material growthFrom normal temperature solutionsHexamethylenetetramineRoom temperature

The invention discloses a method for growing a ZnO nanometer wire array on a flexible substrate, which comprises the following steps: putting the washed flexible substrate into a growth chamber of a pulse laser deposition device, using ZnO ceramic as a target material, introducing O2 into the growth chamber, controlling the pressure to between 0.01 and 2 Pa, and depositing a ZnO seed crystal layer through pulse laser on the flexible substrate at room temperature; and respectively preparing a zinc nitrate aqueous solution the concentration of which is between 0.01 and 0.1 mol per liter and a hexamethylenetetramine aqueous solution, mixing the two aqueous solutions according the volume ratio of 1 to 1, then immerging the flexible substrate deposited with the ZnO seed crystal layer into the mixed solution, taking out the flexible substrate after reacting for 1 to 12 hours at a temperature of between 70 and 100 DEG C, rinsing the flexible substrate by using deionized water, and drying the flexible substrate. Devices used in the method is simple and is easy to operate, the prepared ZnO nanometer wire is good in array, has even thickness and low cost, and is suitable for mass production.

Owner:ZHEJIANG UNIV

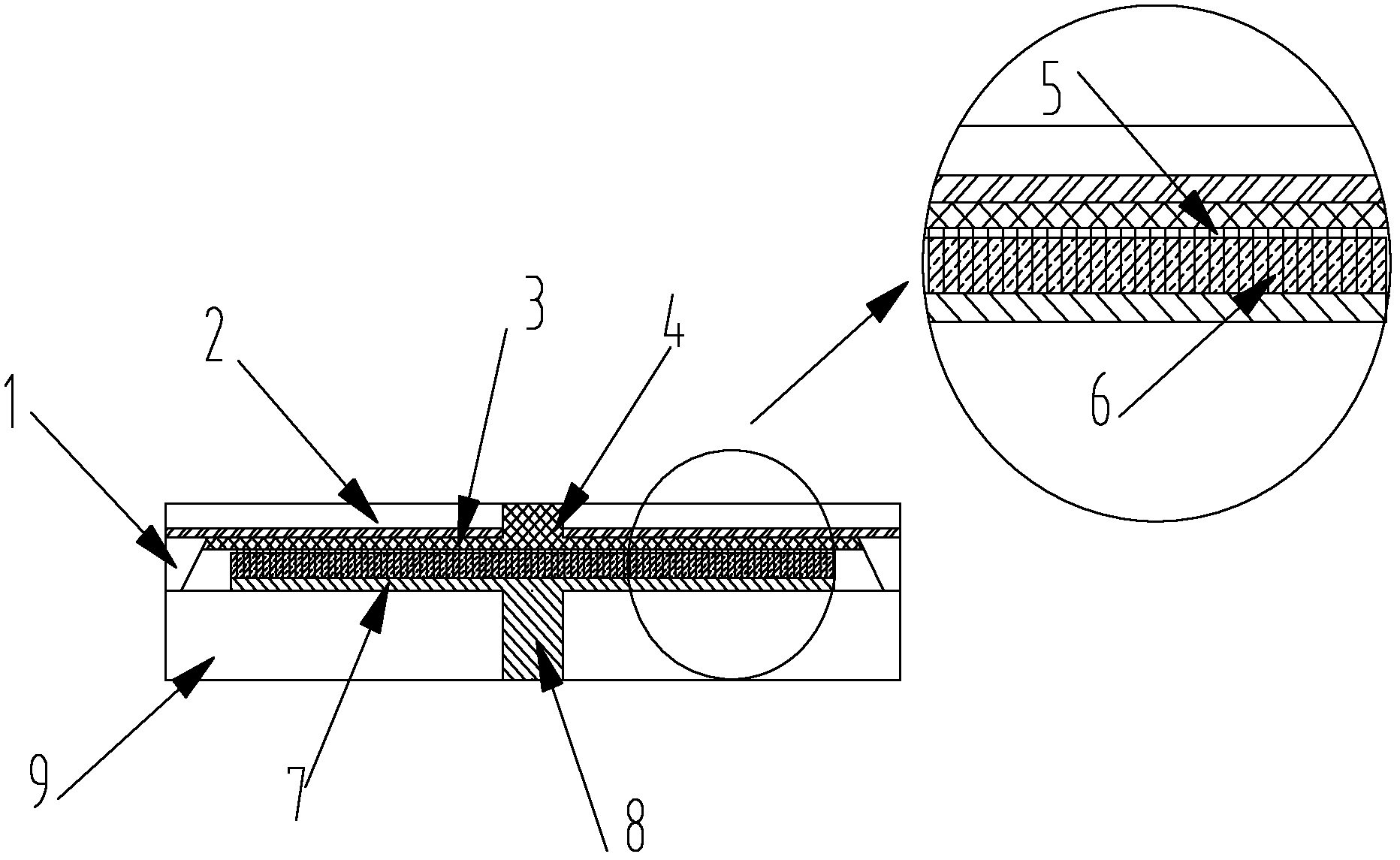

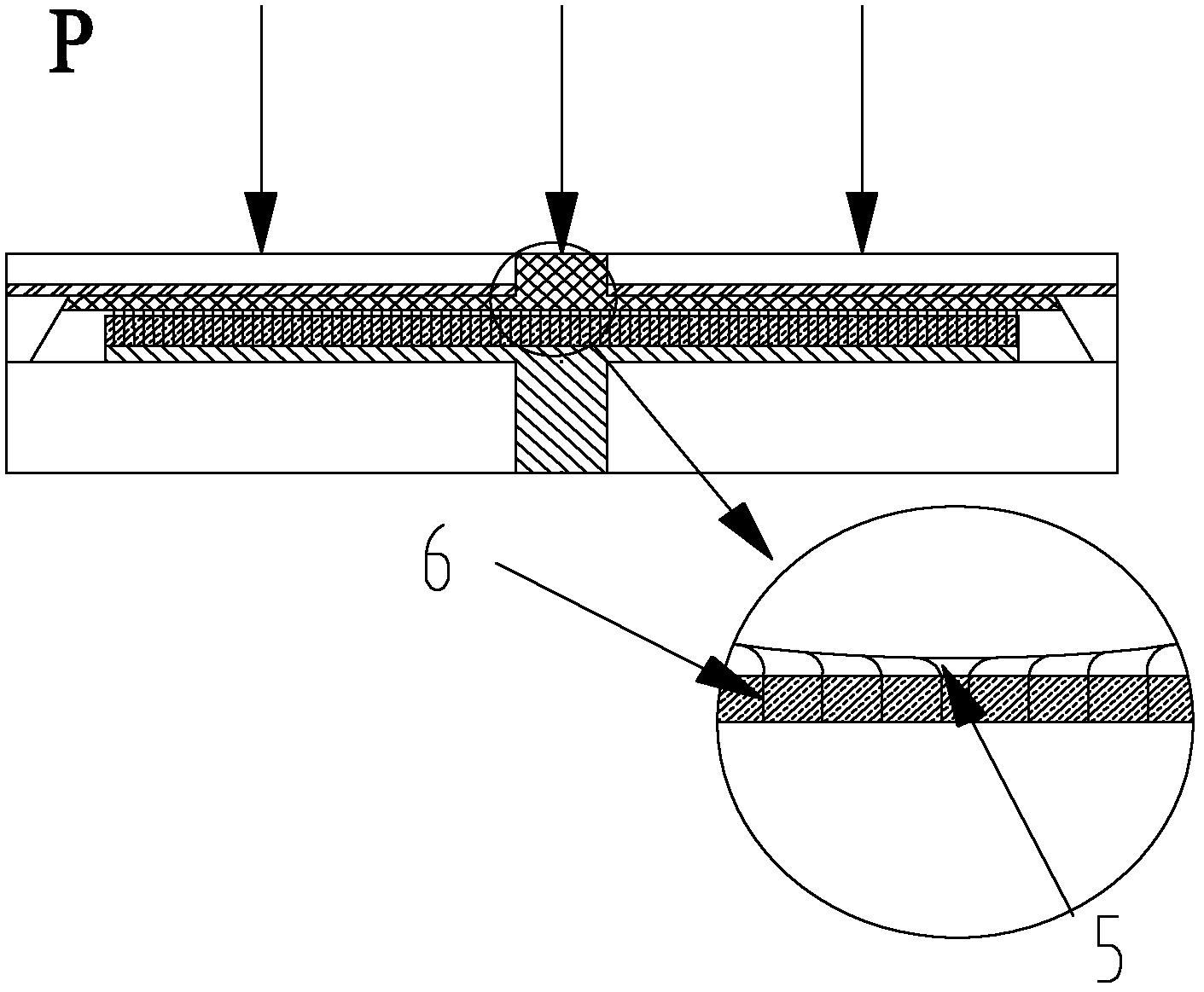

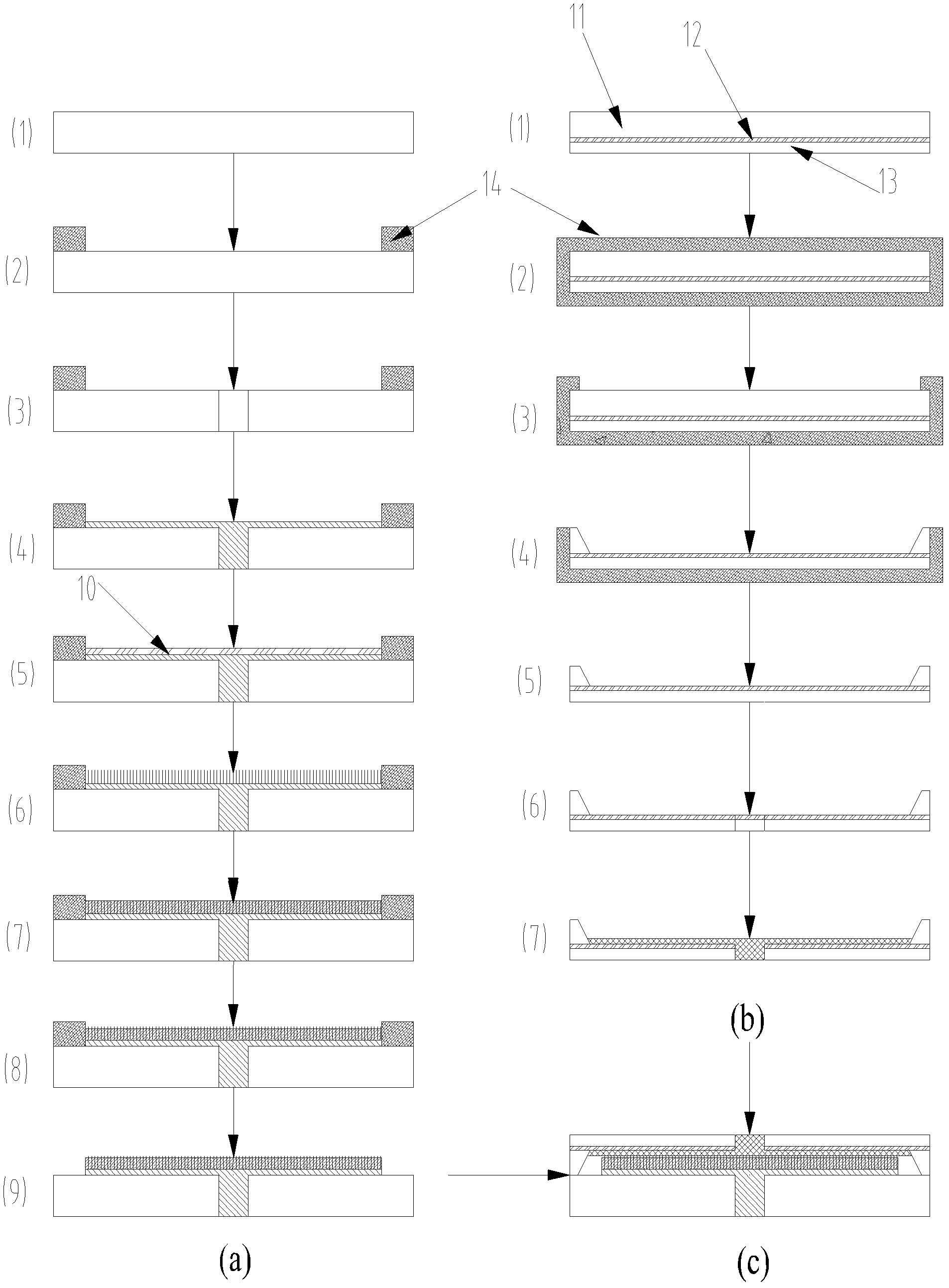

Pressure sensor chip based on ZnO nanoline array, and manufacturing method of pressure sensor chip

InactiveCN102645294AEasy to synthesizeSimple chemical compositionPrecision positioning equipmentFluid pressure measurement using ohmic-resistance variationScale structureMechanical energy

The invention provides a pressure sensor chip based on a ZnO nanoline array and a manufacturing method of the pressure sensor chip. The ZnO nanoline is adopted as a piezoelectric element of a pressure sensor for the chip; the mechanical energy is converted into electric signals by using the piezoelectric effect of the ZnO so as to achieve the purpose of pressure detection; as the ZnO nanoline is used as the piezoelectric element, compared with ordinary piezoelectric elements, the process from accumulation to release can be realized by using the piezoelectric effect of the ZnO nanoline and the Schottky contact of semiconductors and metals, so that high impedance output amplifying circuits desired by the ordinary piezoelectric elements are unnecessary; in addition, the piezoelectric pressure sensor can be further minimized by synchronizing a nano-scale structure of high quality.

Owner:XI AN JIAOTONG UNIV

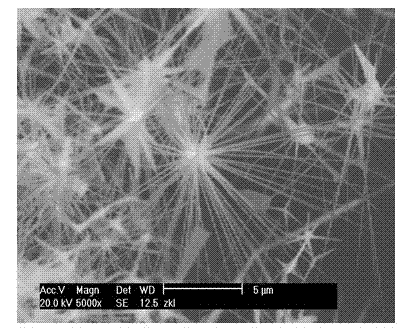

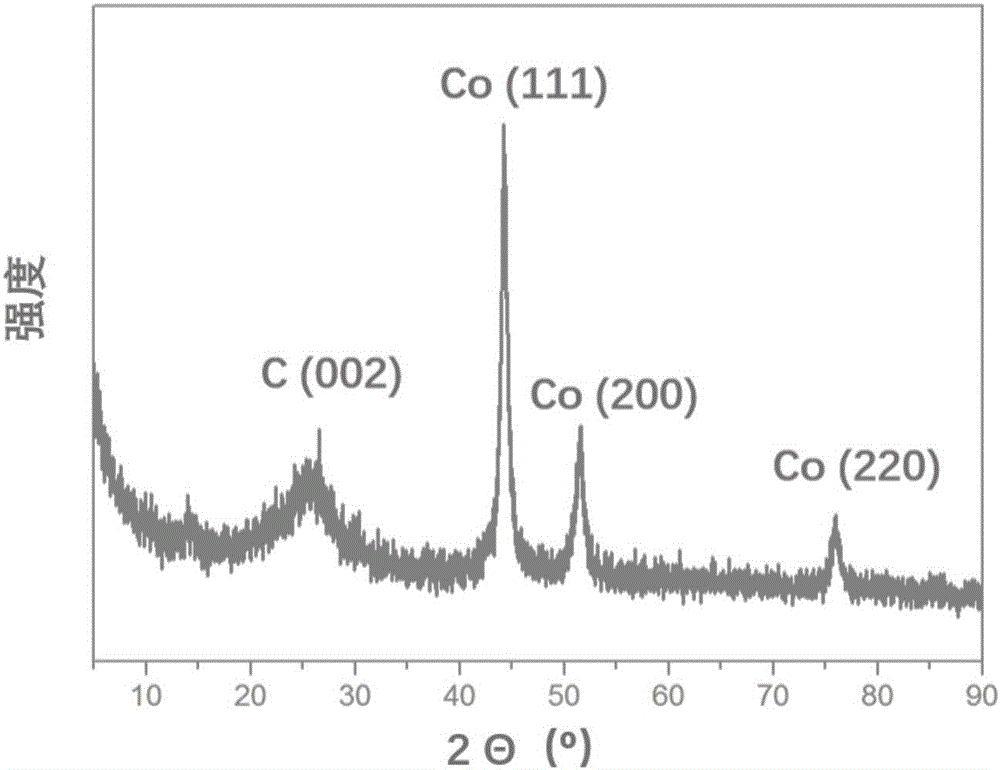

Preparation method of one-dimensional porous carbon nanotube

InactiveCN106829924AUniform co-dopingGood monodispersityCarbon nanotubesPorous carbonThermal energy storage

The invention relates to a preparation method of a one-dimensional porous carbon nanotube. The one-dimensional porous carbon nanotube is of a nitrogen-doped one-dimensional porous carbon nanotube or a nitrogen and cobalt doped one-dimensional porous carbon nanotube; a ZnO@ZIF-8 and ZnO@Zn / Co-ZIF precursors are prepared by taking a ZnO nanowire as a nuclear and a monometallic zeolite-imidazate skeleton compound ZIF-8 or a bimetallic hybridization zeolite-imidazate skeleton compound Zn / Co-ZIF as a shell; ZnO@ZIF-8 or ZnO@Zn / Co-ZIF is subjected to high-temperature calcination in inert atmosphere to obtain the one-dimensional porous carbon nanotube. The preparation method is simple in synthesis, a nuclear layer template can be removed without acid pickling, and the preparation process which is environment friendly can be realized; the prepared carbon nanotube is high in specific surface area and rich in catalyst activity sites and has great application potential in fields of electrochemical energy storage, catalytic and metallic air batteries and the like.

Owner:JIANGSU UNIV OF TECH

Customizable high-gain ZnO nanowire array UV detector and preparation method thereof

ActiveCN106409975AImprove uniformitySolve the problem of controllability of growth directionFinal product manufactureSemiconductor devicesUv detectionUv detector

A customizable high-gain ZnO nanowire array UV detector and a preparation method thereof relate to the fields of microelectronic technologies, nanometer technologies and UV detection. On the basis of a synergic theory, nanowires compete for a reaction solute when fluctuation is instable, an in such a competition mechanism, the thinner a seed layer is, the fewer solute resources are needed, and growth time is decided by the growth speed. Based on such a growing principle, the thickness of the seed layer, the solution concentration and growth time are adjusted to obtain nanowires of higher quality, and UV detection devices of different gains are obtained. The method is simple and effective, and the customized devices of different gains can be suitable for UV detection in different environments.

Owner:BEIJING UNIV OF TECH

Preparation method of modified carbon fiber-reinforced composite ceramic

The invention provides a preparation method of modified carbon fiber-reinforced composite ceramic. The preparation method comprises the following steps: (1) placing carbon fiber into concentrated nitric acid, soaking and then washing with deionized water; (2) heating an ethanol solution of zinc acetate and the ethanol solution of NaOH to 65 DEG C, then mixing in equal molar ratio to prepare a ZnO sol; (3) dipping and lifting the carbon fiber in the ZnO sol for 2-3 times and pre-placing a ZnO crystal seed; (4) mixing a zinc salt solution and a hexamethylene tetramine solution in equal molar ratio to prepare a growth solution, placing the carbon fiber provided with the ZnO crystal seed into the growth solution, firstly performing heat preservation at the temperature of 80-90 DEG C, then washing, and drying to get a ZnO nano-wire array thin film growing on the carbon fiber in the fixed direction; (5) placing NiO and Fe2O3 on a planet mill for wet milling so as to form slurry, drying the slurry, and then pre-burning to get NiFe2O4-based ceramic powder; and (6) taking the NiFe2O4-based ceramic powder, additionally adding the short-cut carbon fiber after modification, performing dry pressing and forming, then placing into a multifunctional sintering furnace, and sintering under the protection of nitrogen to get the modified carbon fiber-reinforced composite ceramic.

Owner:SHANDONG UNIV OF TECH

Process for growth of ZnO nano-wire array on flexible substrate by using solution method

InactiveCN102492987ALower technical barriersLow costFrom gel statePolycrystalline material growthOrganic solventDip-coating

The invention discloses a process for growth of a ZnO nano-wire array on a flexible substrate by using a solution method. According to the invention, after acid-alkali treatment, a polyimide (PI) film is coated with ZnO sol by using a dip-coating method, and the ZnO sol is prepared from the raw materials of a zinc salt, an amine substance and an organic solvent; then postheat treatment is carried out at a high temperature so as to prepare a seed layer used for growth of ZnO nano-wires, and the ZnO nano-wire array is prepared on the PI film through a low temperature hydro-thermal reaction. The process provided in the invention uses simple equipment without using any special equipment, is easy to operate, enables the prepared ZnO nano-wire array to be uniformly thick and to have a good array form, costs little and is suitable for large scale production.

Owner:NANJING UNIV OF TECH

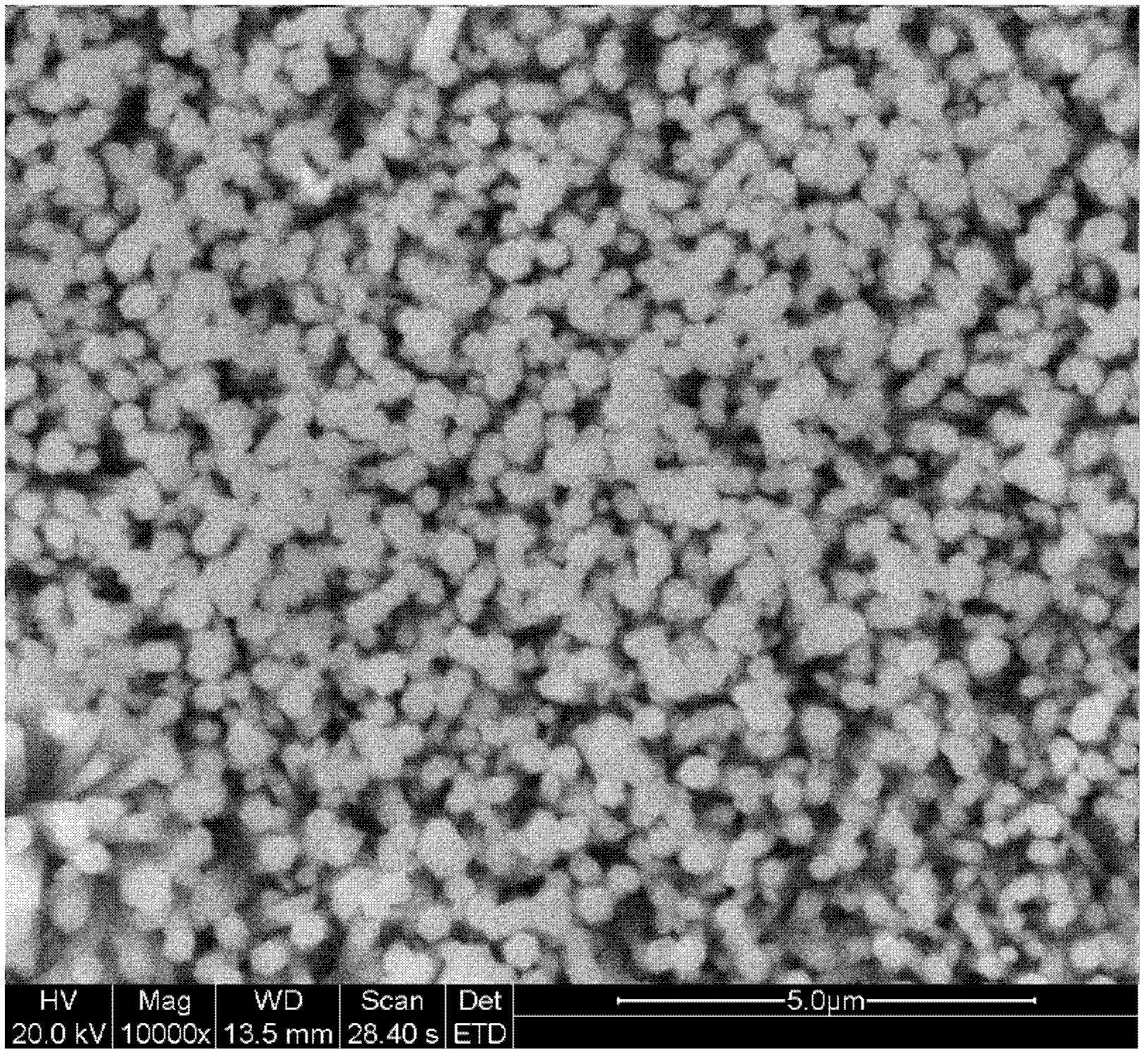

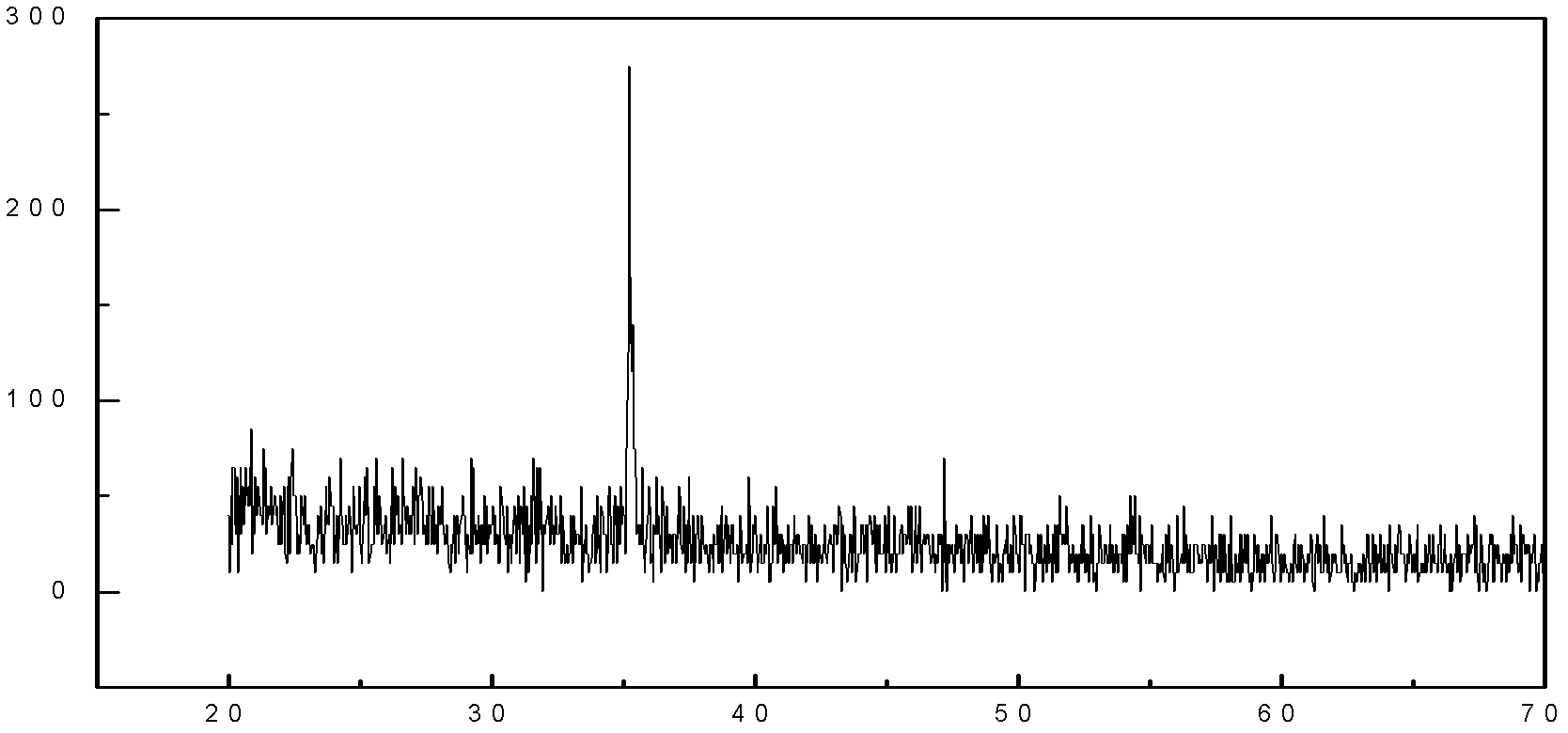

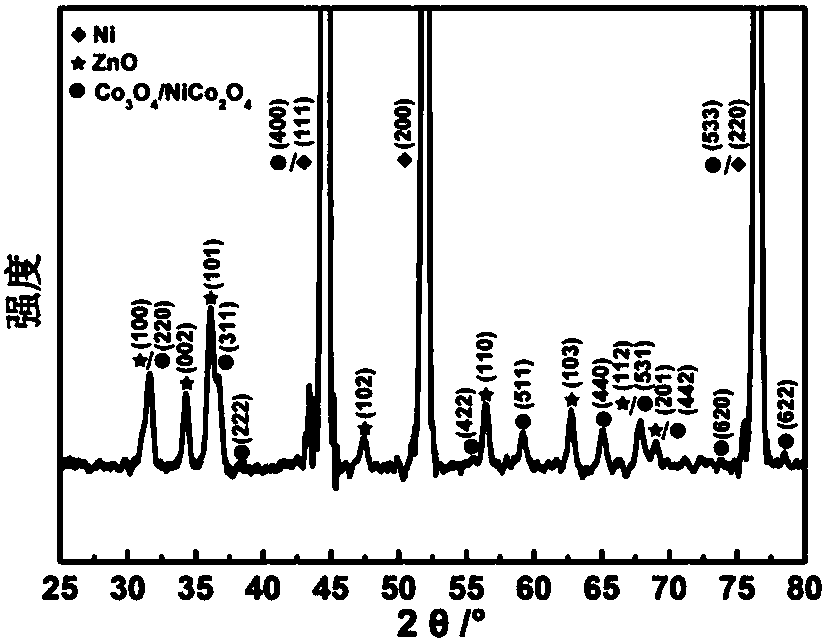

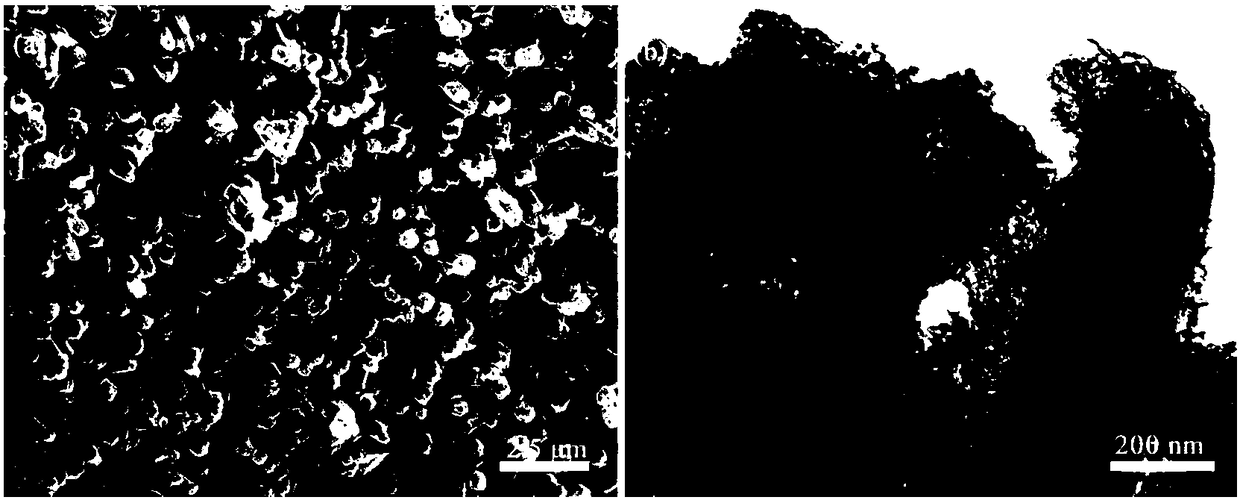

Preparation method of foam nickel-loaded composite nano metal oxide electrode material

ActiveCN108144620AHigh porosityAvoid technical issues that could lead to reunionsHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPorosityNanoparticle

The invention discloses a preparation method of a foam nickel-loaded composite nano metal oxide electrode material, and aims to solve the technical problem that the existing preparation method of an existing electrode material has poor practicability. The preparation method disclosed by the invention is characterized in that In the technical scheme, foam nickel is adopted as a substrate, and ZnO nanowire and ZIFs -derived Co3O4 / NiCo2O4 doubel-shell nano cage structure nano particle material are loaded; ZnO / Co3O4 / NiCo2O4 / foam nickel is prepared in combination with the large specific surface area and quick electron transmission performance of ZnO as well as the high porosity and excellent catalytic performance of the ZIFs -derived Co3O4 / NiCo2O4 double-shell nano cage., ZnO / Co3O4 / NiCo2O4 / foamnickelwhich has the advantages of goodhigh electrocatalytic activity on H2O2, high sensitivity, low detection limit, wide detection range, goodhigh stability and the like, and avoids the technical problem of frequent agglomeration caused byof a powder modified electrode.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

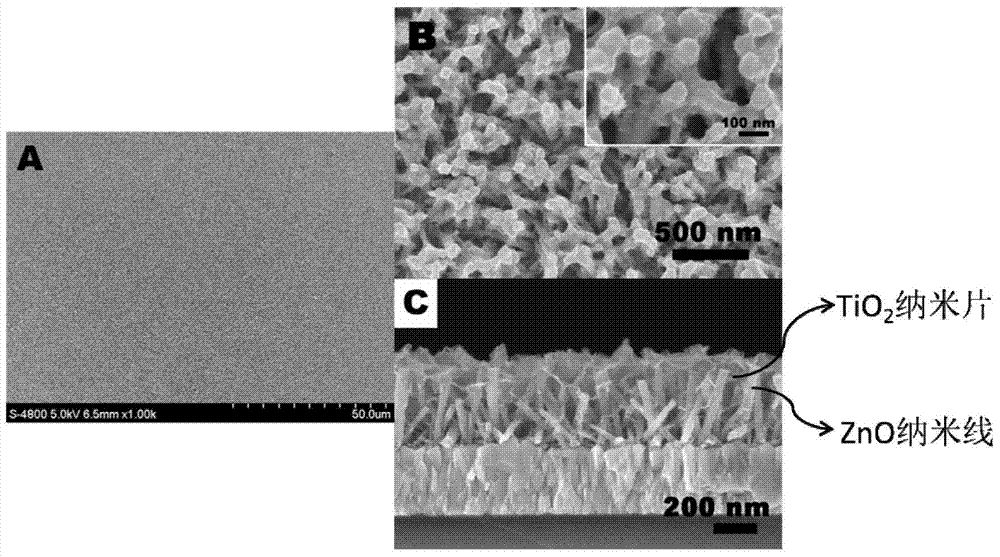

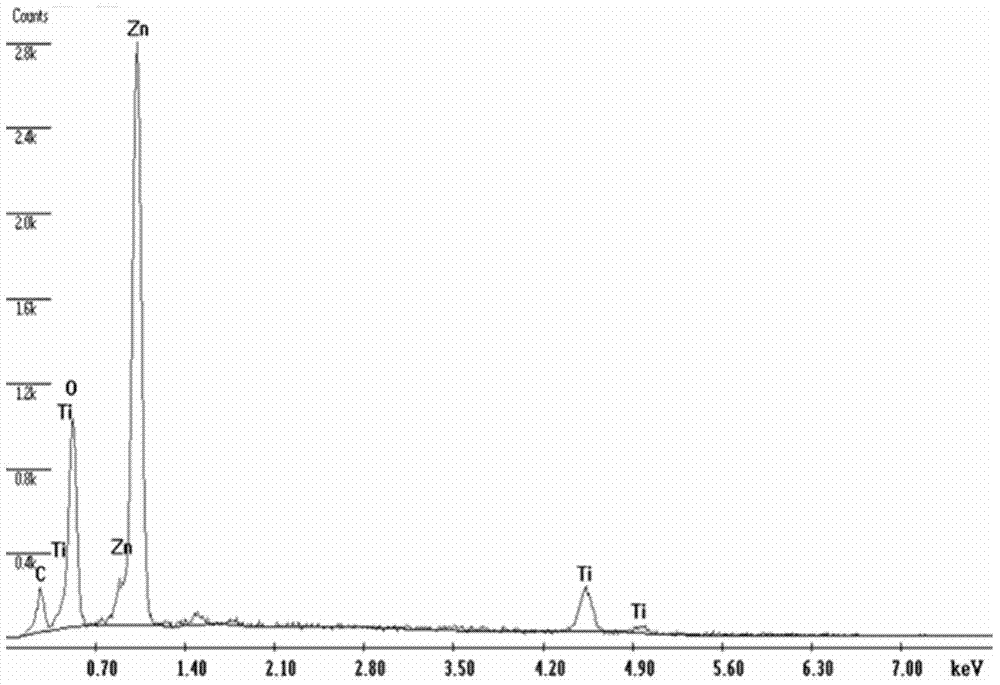

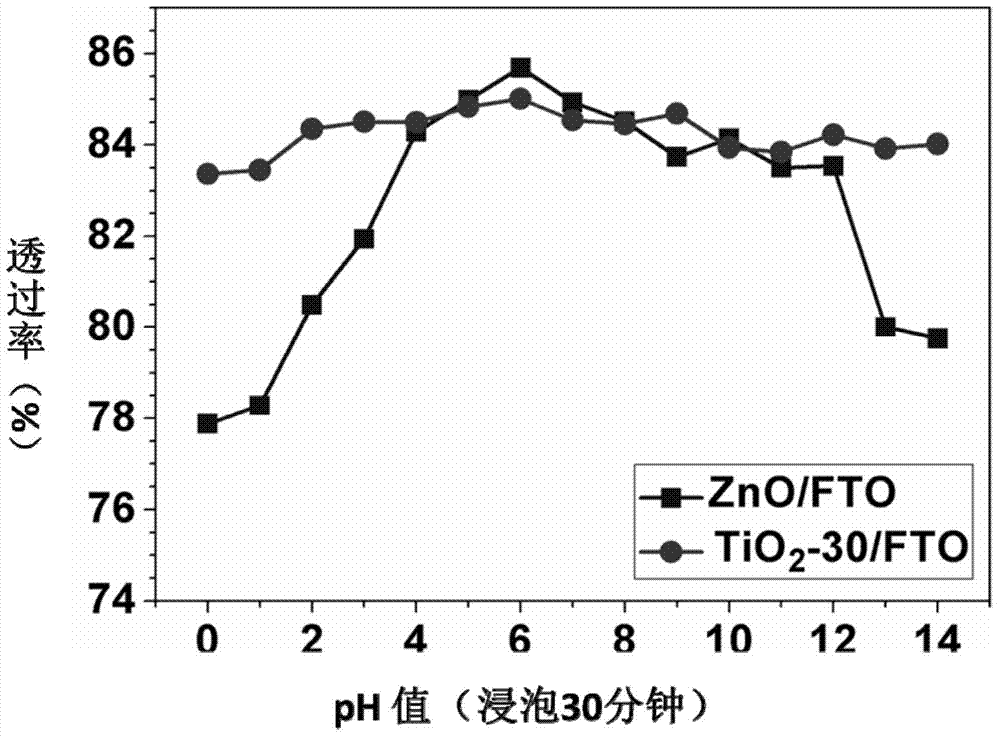

Antireflection type super-hydrophilic zinc oxide/titanium dioxide composite nanometer structure self-cleaning coating and preparation method thereof

The present invention relates to an antireflection type super-hydrophilic zinc oxide / titanium dioxide composite nanometer structure self-cleaning coating and a preparation method thereof. According to the present invention, a hydrothermal method is adopted to grow a layer of 300-800 nm ZnO nano-wire array structure film on the surface of a substrate, a layer of a TiO2 nanometer thin sheet grows on the surface of the ZnO, and a lot of gaps exist between the nano-wire lattices, such that the film has a certain antireflection characteristic, wherein the transmittance is increased to more than 85% of the substrate transmittance from 80% of the substrate transmittance, the contact angle of the ZnO nano-wire array is reduced to about 10 DEG from the original 60 DEG with introduction of the TiO2 layer, and more importantly the TiO2 layer can be provided for effectively degrading the organic pollutants attached on the surface under sunlight so as to achieve the self-cleaning effect; and the preparation method has characteristics of simple process, easily available materials and low cost, and the coating is suitable for automotive, aircraft windshields, lenses, building curtain walls and glasses, and other occasions.

Owner:JIANGSU SHIKEXINCAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com