Method for growing ZnO nano-wire array on flexible substrate

A nanowire array, flexible substrate technology, applied in crystal growth, single crystal growth, single crystal growth and other directions, can solve the problems of expensive equipment, harsh process conditions, unable to form large-scale production, etc., to achieve simple equipment, uniform thickness , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

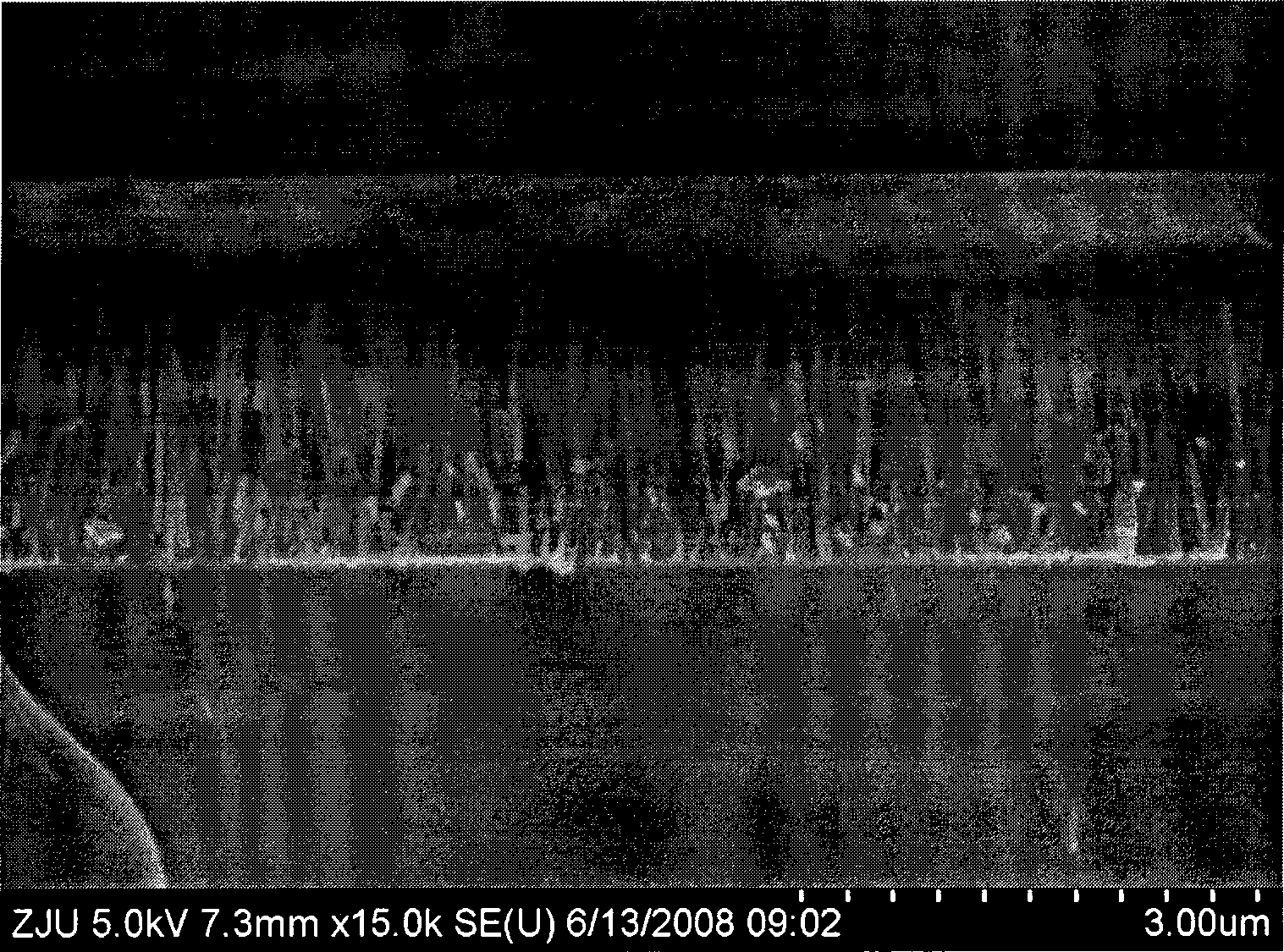

Image

Examples

Embodiment 1

[0019] 1) a zinc nitrate aqueous solution with a concentration of 0.05mol / L and a hexamethylenetetramine aqueous solution with a concentration of 0.05mol / L are respectively configured;

[0020] 2) Put the cleaned PET substrate into the growth chamber of the pulsed laser deposition device, use ZnO ceramics as the target material, keep the distance between the target material and the substrate at 4.5 cm, and pump the vacuum degree of the growth chamber to at least 10 -3 Pa, the growth chamber is fed with O 2 Gas, the control pressure is 0.03Pa, the laser power is 210mJ, the laser repetition frequency is 3Hz, and deposited on the PET substrate at room temperature for 2min to obtain the ZnO seed layer;

[0021] 3) Mix the zinc nitrate aqueous solution and the hexamethylenetetramine aqueous solution at a volume ratio of 1:1, then immerse the flexible substrate deposited with the ZnO seed layer in the mixed solution, react at 90°C for 6 hours, and take it out. Rinse and dry repeate...

Embodiment 2

[0024] 1) a zinc nitrate aqueous solution with a concentration of 0.01mol / L and a hexamethylenetetramine aqueous solution with a concentration of 0.01mol / L are respectively configured;

[0025] 2) Put the cleaned PET substrate into the growth chamber of the pulsed laser deposition device, use ZnO ceramics as the target material, keep the distance between the target material and the substrate at 6 cm, and pump the vacuum degree of the growth chamber to at least 10 -3 Pa, the growth chamber is fed with O 2 Gas, the control pressure is 0.02Pa, the laser power is 150mJ, the laser repetition frequency is 3Hz, and deposited on the PET substrate at room temperature for 5min to obtain the ZnO seed layer;

[0026] 3) Mix the zinc nitrate aqueous solution and the hexamethylenetetramine aqueous solution at a volume ratio of 1:1, then immerse the flexible substrate deposited with the ZnO seed layer in the mixed solution, react at 100°C for 1 hour, and then take it out. Repeatedly rinsing...

Embodiment 3

[0028] 1) a zinc nitrate aqueous solution with a concentration of 0.1mol / L and a hexamethylenetetramine aqueous solution with a concentration of 0.1mol / L are respectively configured;

[0029] 2) Put the cleaned PI substrate into the growth chamber of the pulsed laser deposition device, use ZnO ceramics as the target material, keep the distance between the target material and the substrate at 6 cm, and pump the vacuum degree of the growth chamber to at least 10 -3 Pa, the growth chamber is fed with O 2 Gas, the control pressure is 0.2Pa, the laser power is 300mJ, the laser repetition frequency is 3Hz, and deposited on the PI substrate at room temperature for 2min to obtain the ZnO seed layer;

[0030] 3) Mix the zinc nitrate aqueous solution and the hexamethylenetetramine aqueous solution at a volume ratio of 1:1, then immerse the PI substrate deposited with the ZnO seed layer in the mixed solution, react at 70°C for 12h, and then take it out , rinsed repeatedly with deionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com