Near-field photocatalyst containing zinc bloom nanometer line

A photocatalyst and near-field light technology, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, nanotechnology, etc., can solve problems such as increased production costs, complex devices and processes, and achieve The effect of simplifying production steps and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

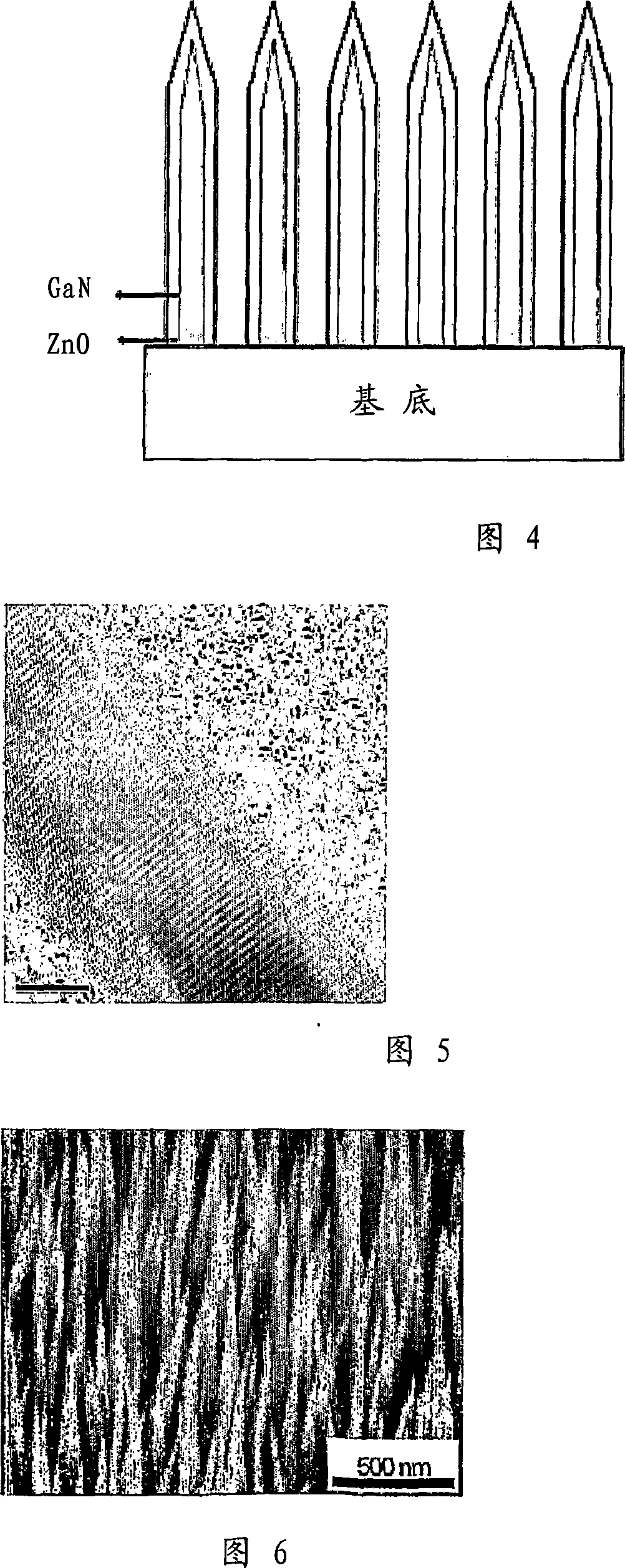

[0054] Example 1: Fabrication of photocatalysts containing ZnO nanoneedles (MOCVD)

[0055] The glass substrate was placed in a metal organic chemical vapor deposition (MOCVD) reactor, dimethyl zinc (Zn(CH 3 ) 2 ) and O 2 The gas was fed into the reactor through the respective lines at rates of 0.1-10 sccm and 10-100 sccm, respectively. Along with the above gases, there is also argon (Ar) used as a carrier gas.

[0056] Dimethyl zinc and oxygen were chemically reacted on the glass substrate while maintaining a pressure of 0.2 Torr and a temperature of 500°C in the reactor for one hour to grow and deposit ZnO nanoneedles thereon.

[0057] The ZnO nanoneedles oriented perpendicular to the shape of the substrate on the resulting glass substrate are shown in Figure 6. Each nanoneedle has a diameter of 60 nm, a length of 1D, and a density of 1010 / cm 2 .

example 2

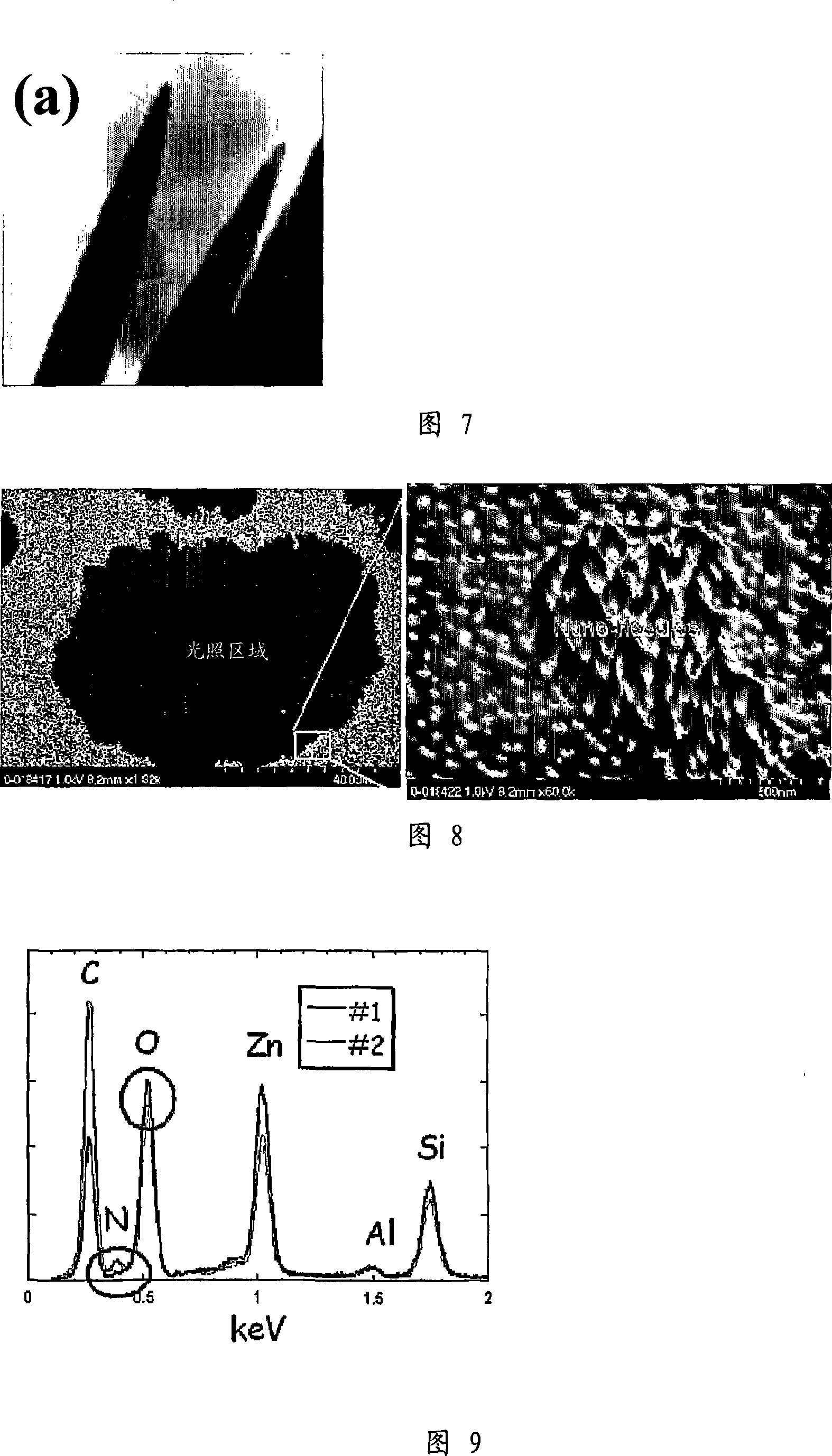

[0058] Example 2: Fabrication of photocatalysts containing ZnO nanoneedles (MOVPE)

[0059] After placing the substrate in the reactor, dimethylzinc (Zn(CH 3 ) 2 ) and O 2 The gas sources are fed through the respective routes at rates of 0.1-10 sccm and 10-100 sccm, respectively, while the substrate temperature is maintained at 400-500°C. In connection with this, argon (Ar) is used as a carrier gas.

[0060] Dimethyl zinc and oxygen were chemically reacted on the glass substrate while maintaining a pressure of 0.2 Torr and a temperature of 500°C in the reactor for one hour to grow and deposit ZnO nanoneedles thereon. As shown in FIG. 7 , nanoneedles with sharp ends perpendicular to the substrate were formed on the substrate.

[0061] Evaluation Example 1

[0062] The ZnO nanoneedles generated in Example 1 and Example 2 were immersed in ultrapure distilled water, and then exposed to He-Cd laser light with a wavelength of 325 nm for 30 seconds. Thereby obtaining superhydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com