Patents

Literature

398 results about "Zinc oxide nanowire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

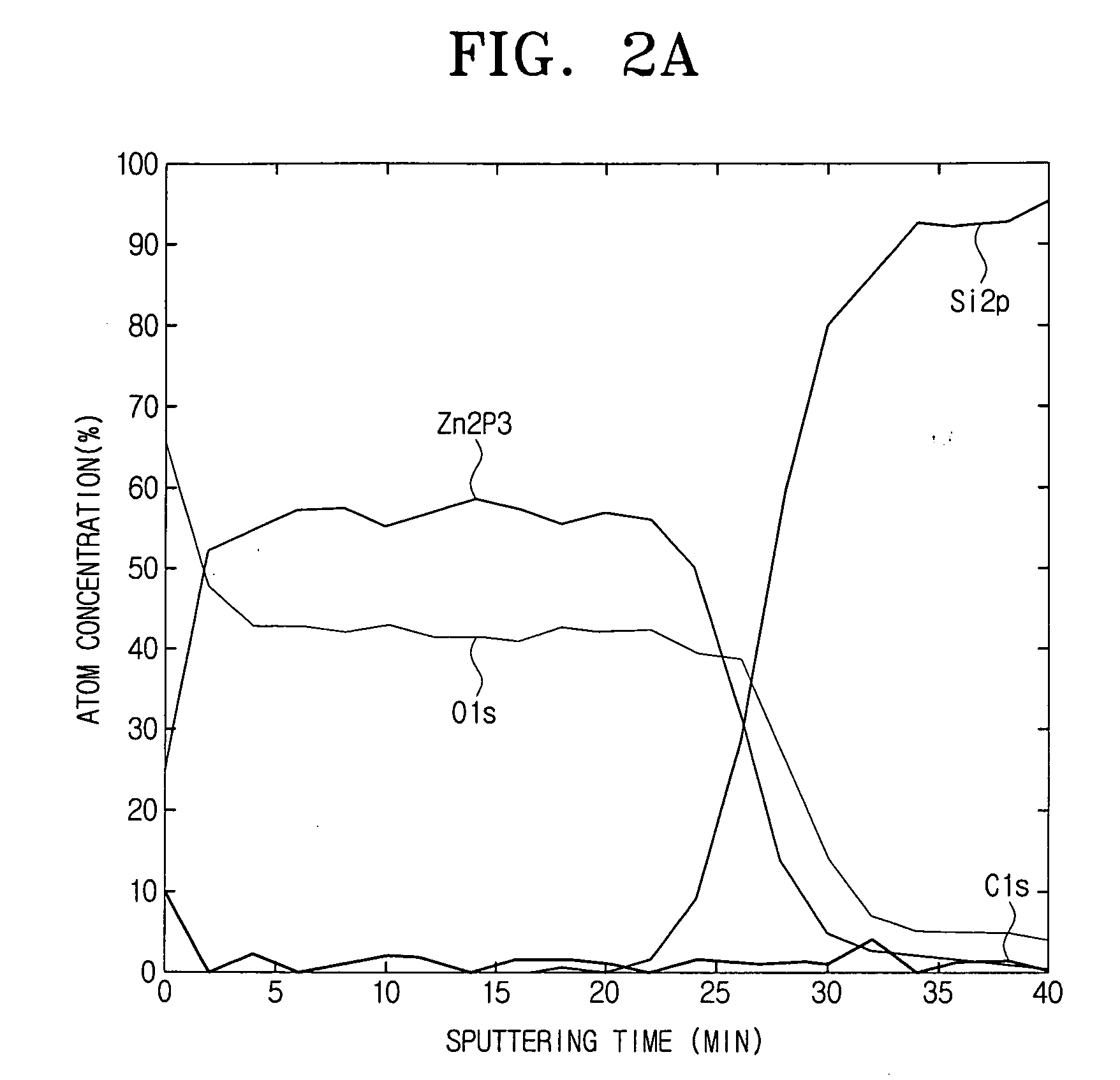

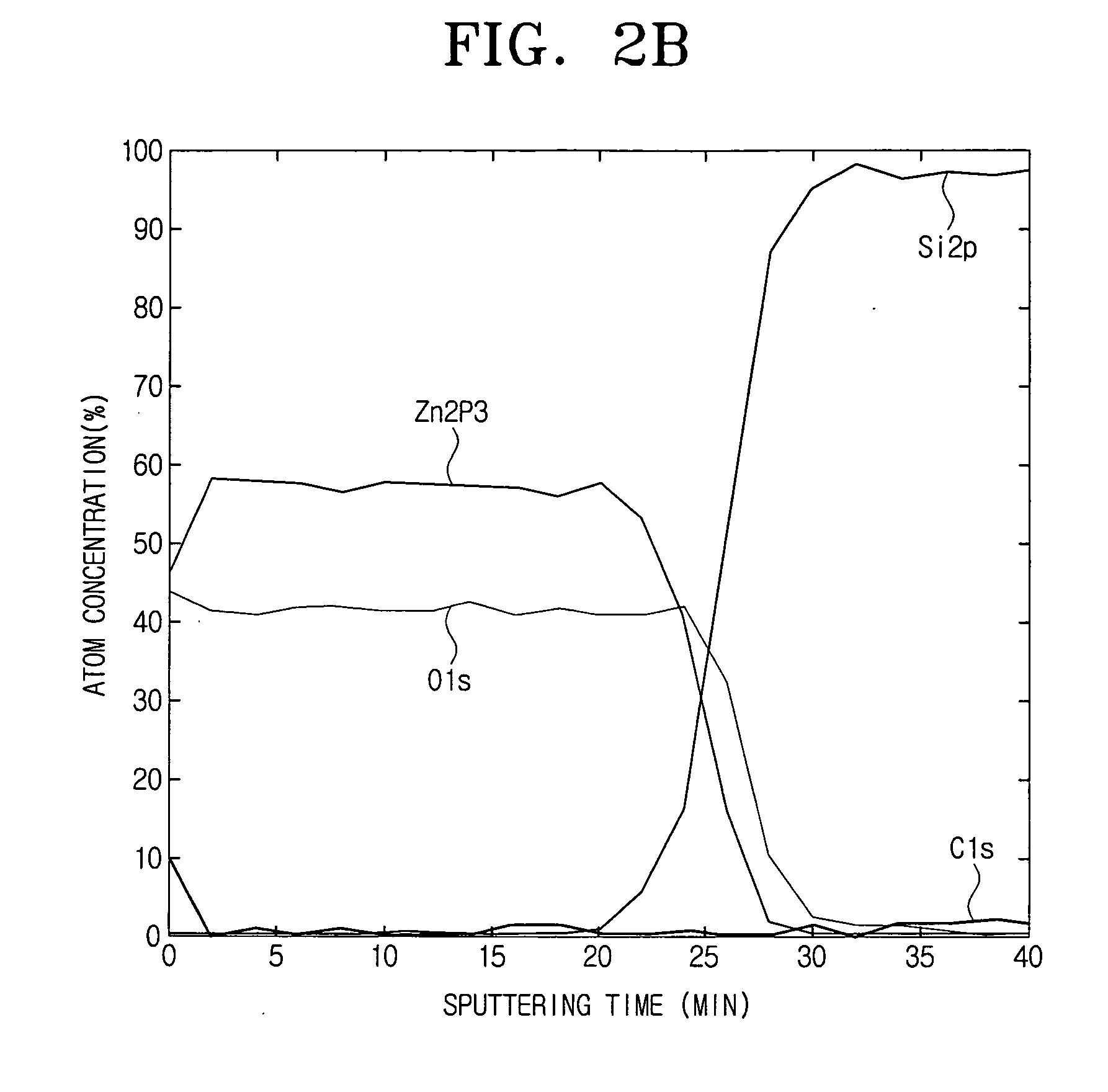

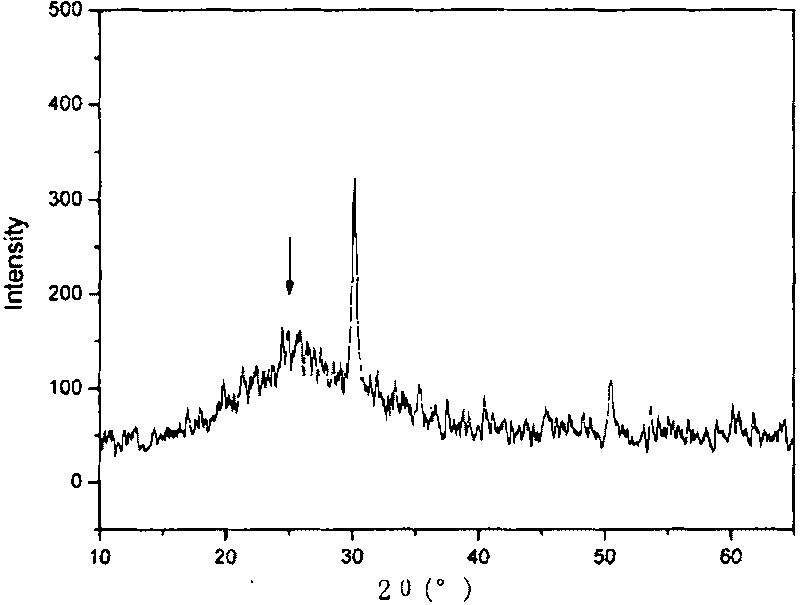

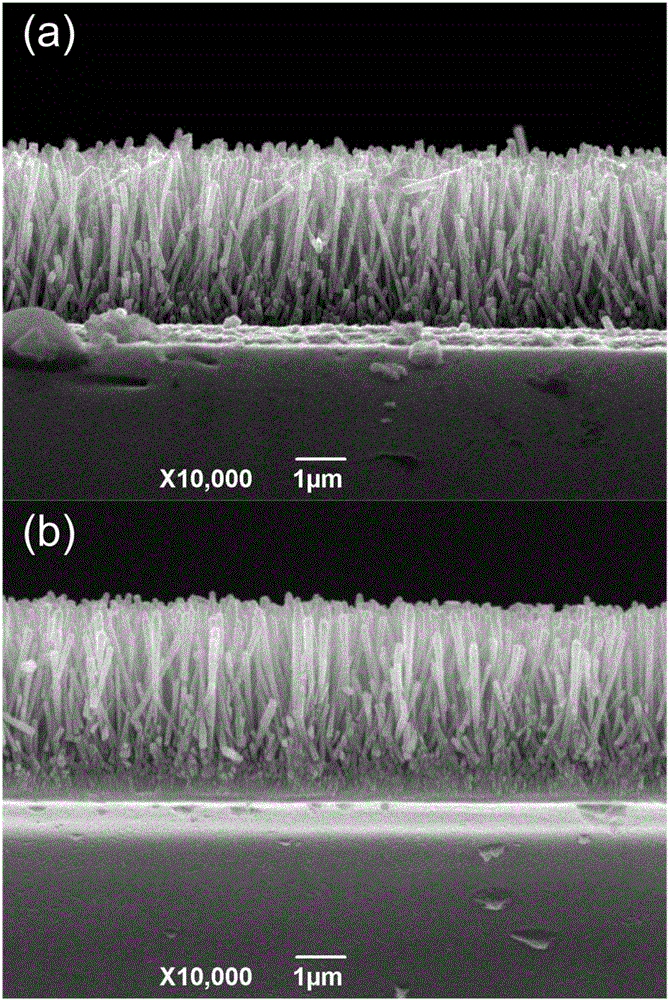

Semiconducting zinc oxide (ZnO) nanowire is doped (P-doped) silicon substrate (1.5–4.0 × 1016 cm−3 ) that is another one-dimensional nano-material that has been utilized in covered by a 40 nm SiO2 layer formed by thermal oxidization.

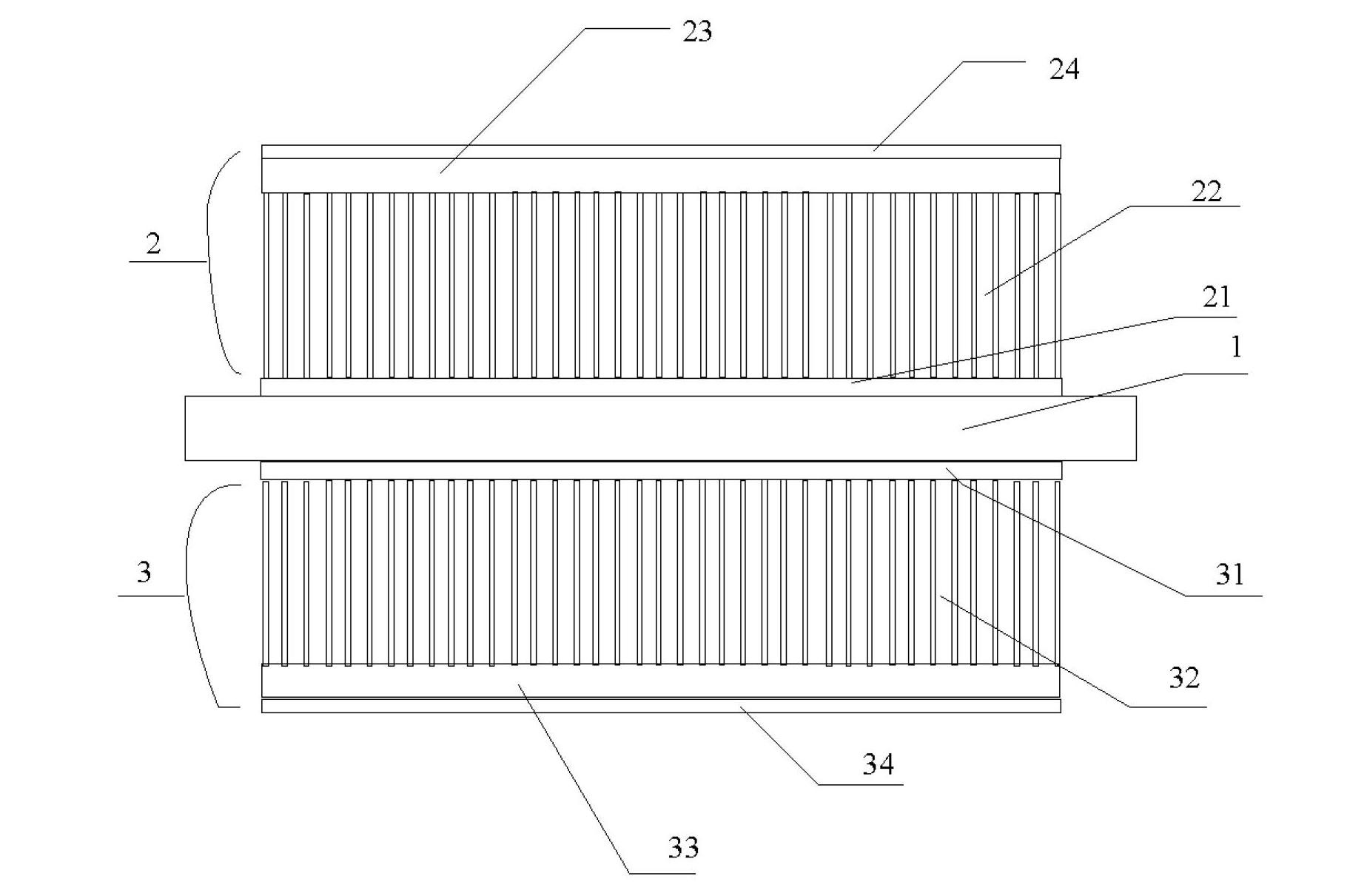

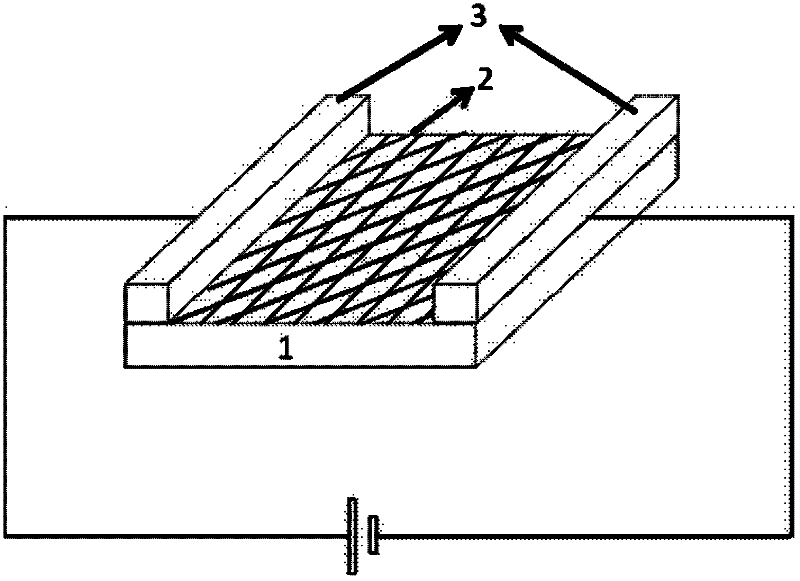

Nano generator, nano generator set and self-powered system comprising nano generator or nano generator set

InactiveCN102683573AImprove efficiencyImprove stabilityPiezoelectric/electrostriction/magnetostriction machinesNanotechnologyNanogeneratorPower flow

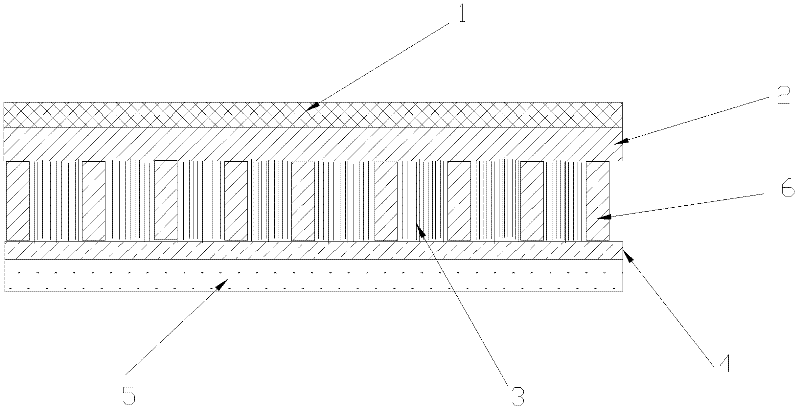

The invention provides a nano generator, a nano generator set and a self-powered system comprising the nano generator or the nano generator set. The nano generator comprises a supporting substrate, and upper and lower electrodes which are arranged at two sides of upper and lower surfaces of the supporting substrate by glue, wherein each electrode respectively comprises a zinc oxide nanowire array layer, a macromolecular insulating layer and a conductive thin film; the zinc oxide nanowire array layers vertically grow on the supporting substrate; the macromolecular insulating layers are coated on the zinc oxide nanowire array layers; the conductive thin films are arranged on the macromolecular insulating layers; and the conductive thin films form output electrodes of voltage and current of the nano generator. The self-powered system can obtain energy from very small force in an environment through utilizing the nano generator and can store most of the energy when a sensor is at a standby mode; the collected energy is used for triggering the sensor under an active mode to rapidly process and transmit data; and therefore, the self-powered system has huge potentials of application on the aspects of radio biological sensing, environment / infrastructure monitoring, sensor networks, individual electronic products, even national security.

Owner:NEWNAGY TANGSHAN

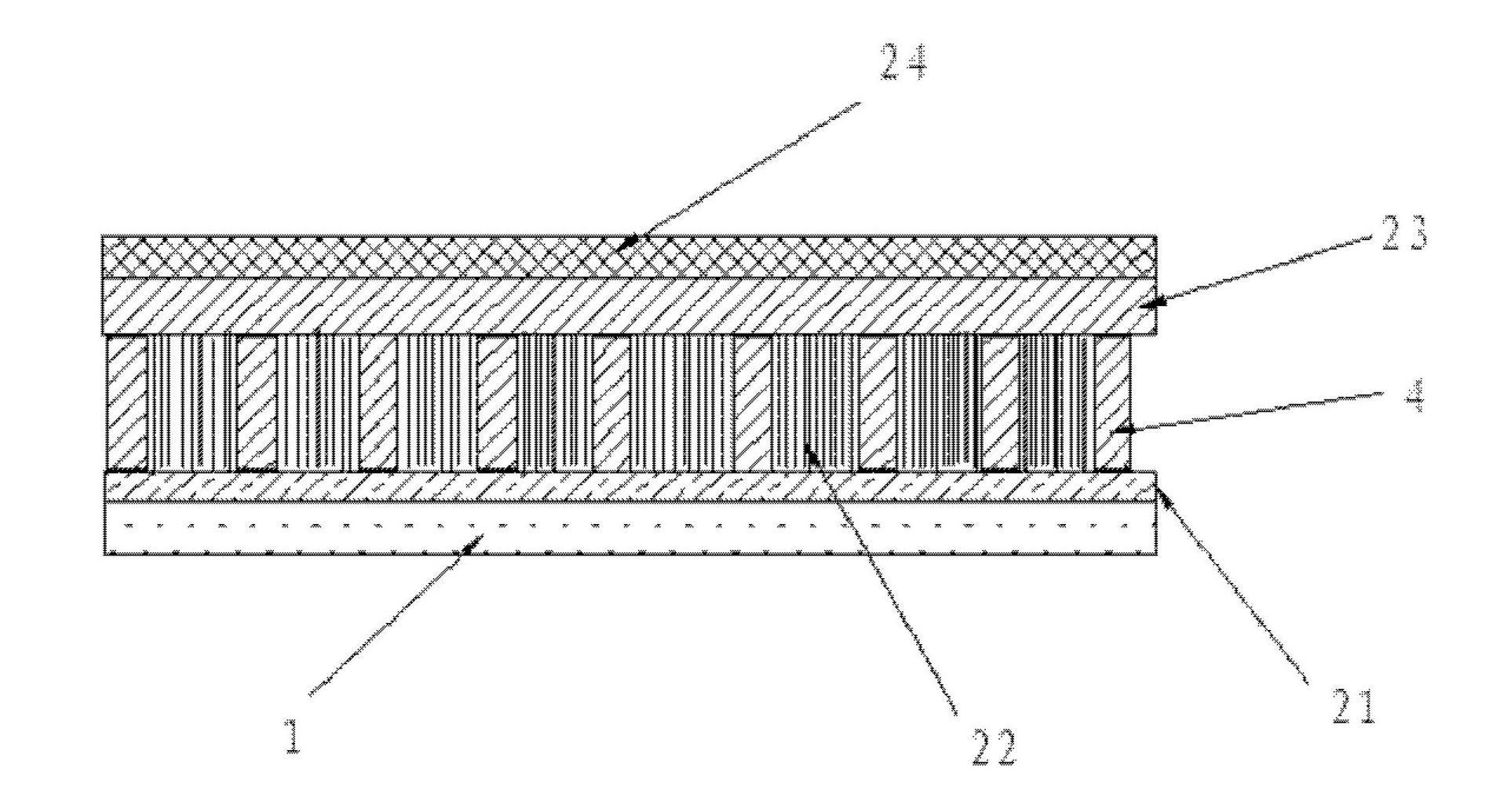

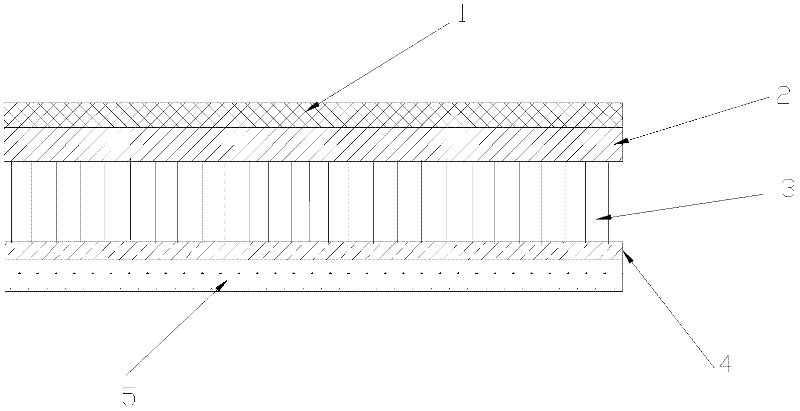

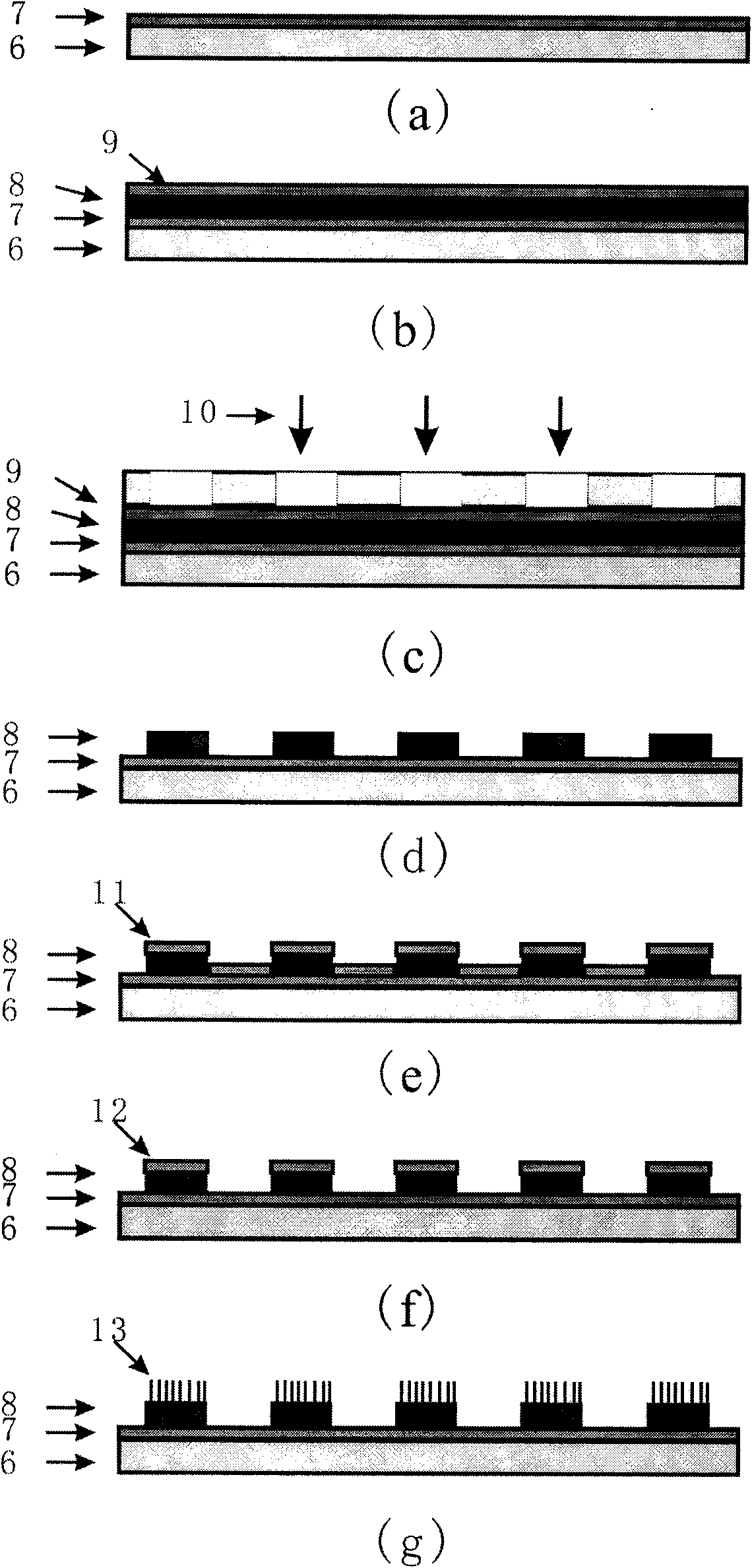

Nano generator and manufacturing method thereof

ActiveCN102646788AImprove efficiencyImprove stabilityPiezoelectric/electrostrictive device manufacture/assemblyNanotechnologyNanogeneratorPower flow

The invention provides a nano generator and a manufacturing method thereof. The nano generator comprises a base, a first electrode, a zinc oxide nano wire array, a macromolecule insulating layer and a second electrode, wherein the first electrode is arranged on the base; the zinc oxide nano wire array vertically grows on a first electrode layer; the macromolecule insulating layer is coated on a zinc oxide nano wire array layer; the zinc oxide nano wire array layer covers the zinc oxide nano wire array, and the second electrode is arranged on the macromolecule insulating layer; and the first electrode and the second electrode are used as a voltage output pole and a current output pole of the nano generator. The nano generator disclosed by the invention adopts a unique structure so that the electric performance output and the stability are effectively improved.

Owner:NAZHIYUAN TECH TANGSHAN LLC

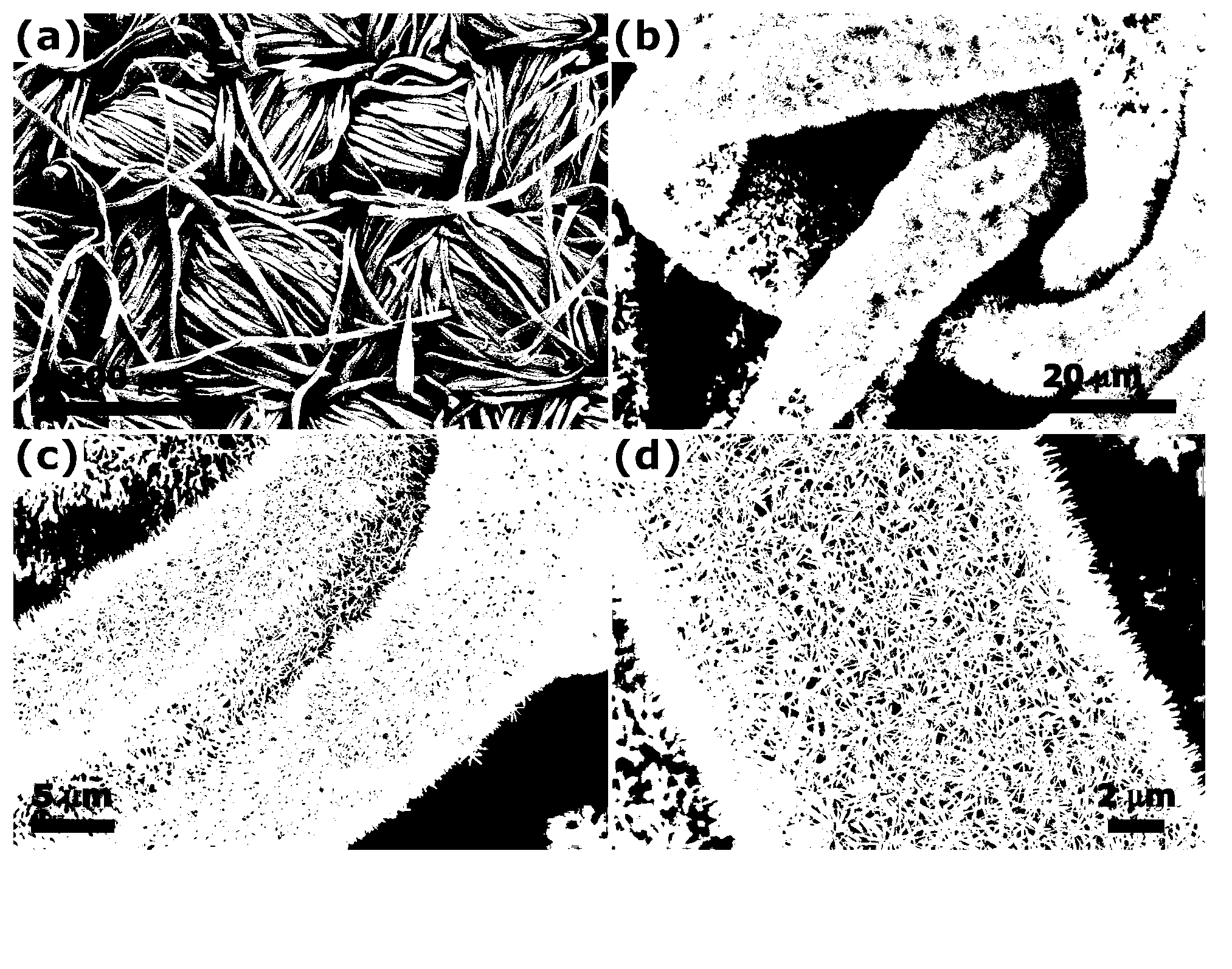

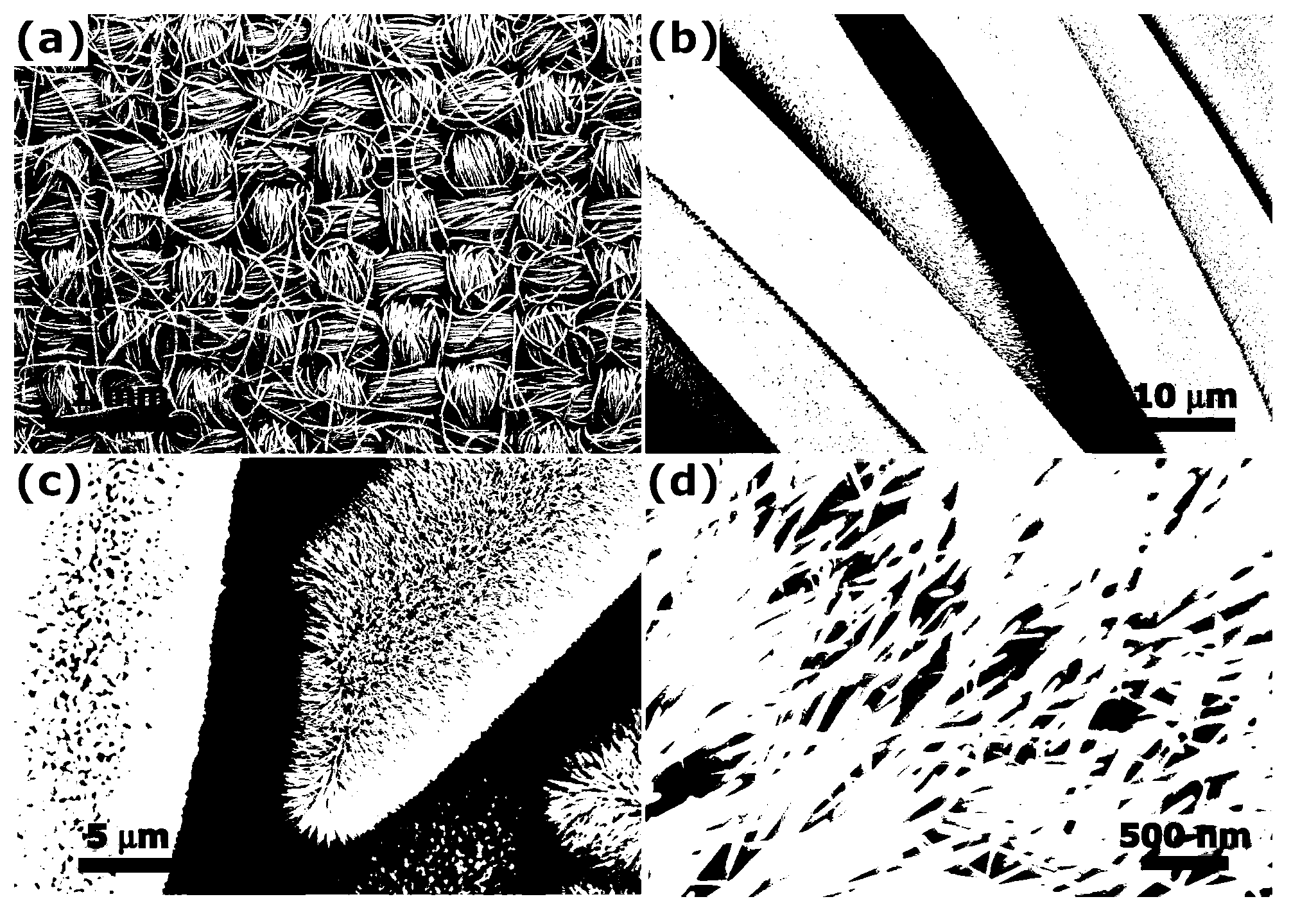

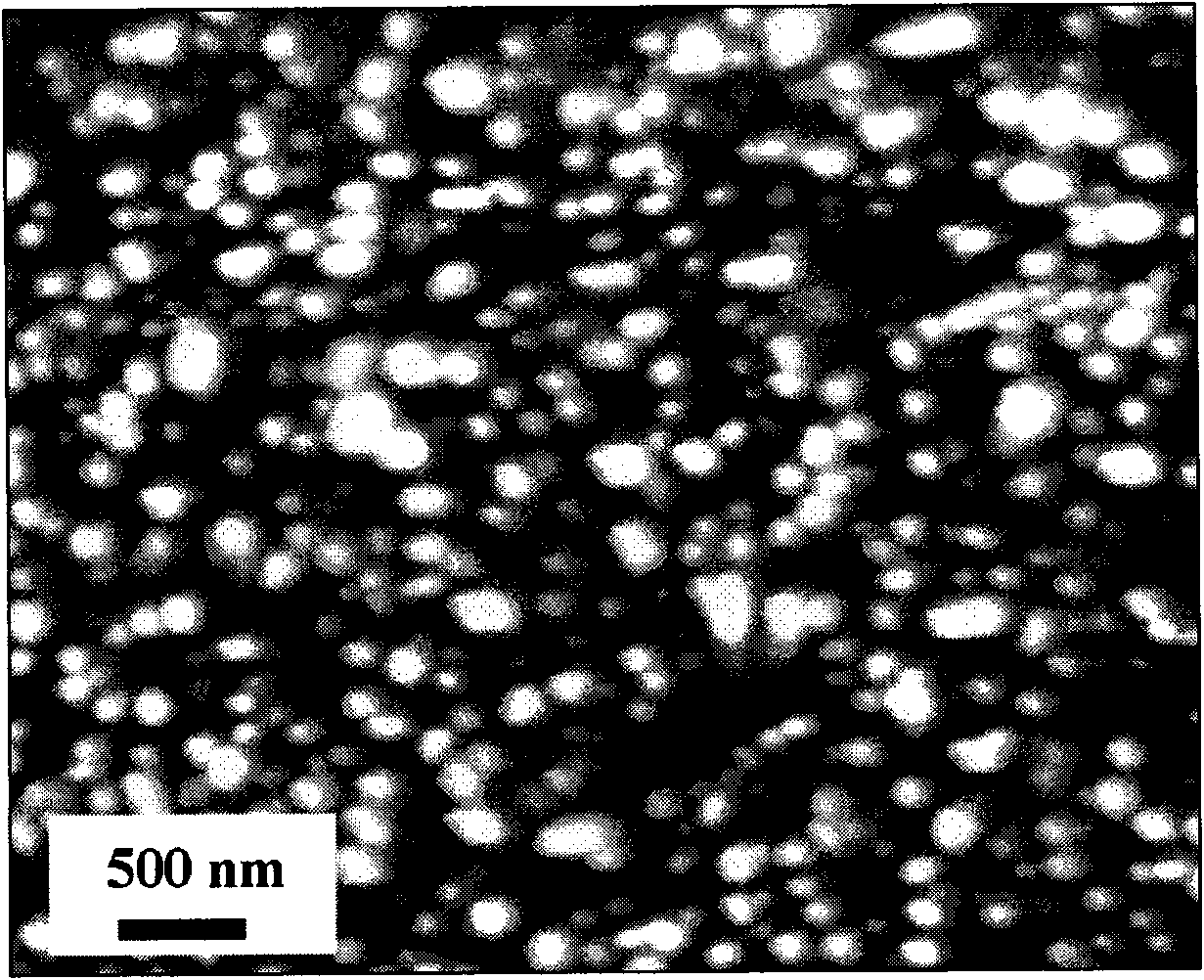

Nano-silver antibacterial fabric and preparation method thereof

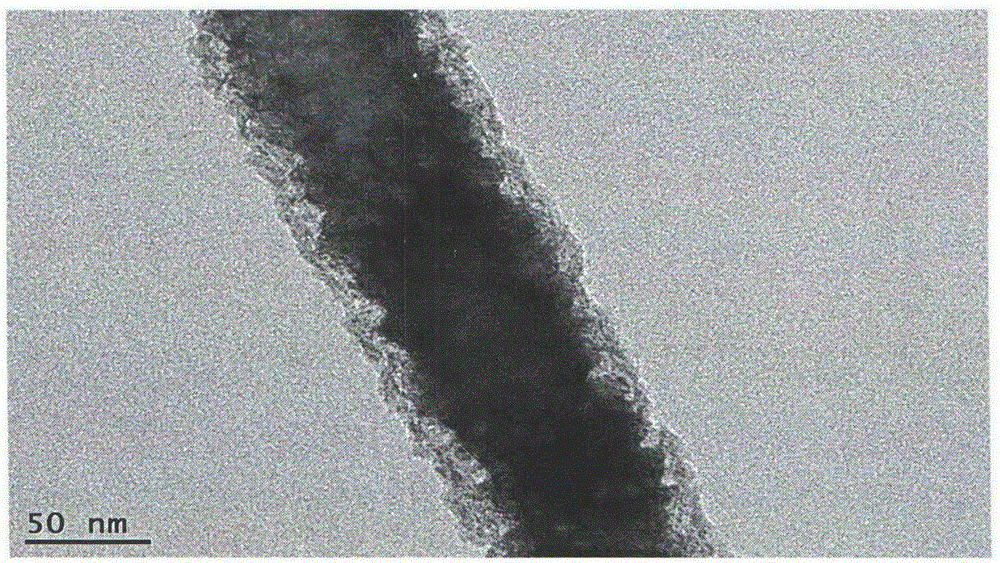

InactiveCN103015166ASmall sizeImprove release efficiencyPhysical treatmentSynthetic fibresAir filtrationBio aerosol

The invention provides a nano-silver antibacterial fabric and a preparation method thereof. The nano-silver antibacterial fabric has the characteristics that a zinc oxide nano line grows on the fabric; and silver nano particles are deposited on the zinc oxide nano line. The zinc oxide nano line is synthesized by a solution chemical method; and the silver nano particles are deposited on the zinc oxide nano line by a simple 'immersion-illumination' method. The nano-silver antibacterial fabric prepared by the method has extremely obvious long-time antibacterial performance; the silver nano particles are small in size and cannot be accumulated; a synthesis process is environment-friendly; and the nano-silver antibacterial fabric can be recycled and reused. The nano-silver antibacterial fabric can be used for single-point water treatment to reduce microorganism content in water and can be suitable for medical surgical dressing and medical fabrics; and the nano-silver antibacterial fabric can be used as an antibacterial air filtration device for preventing bio-aerosol from being gathered on a ventilating, heating and air conditioning system.

Owner:BEIHANG UNIV

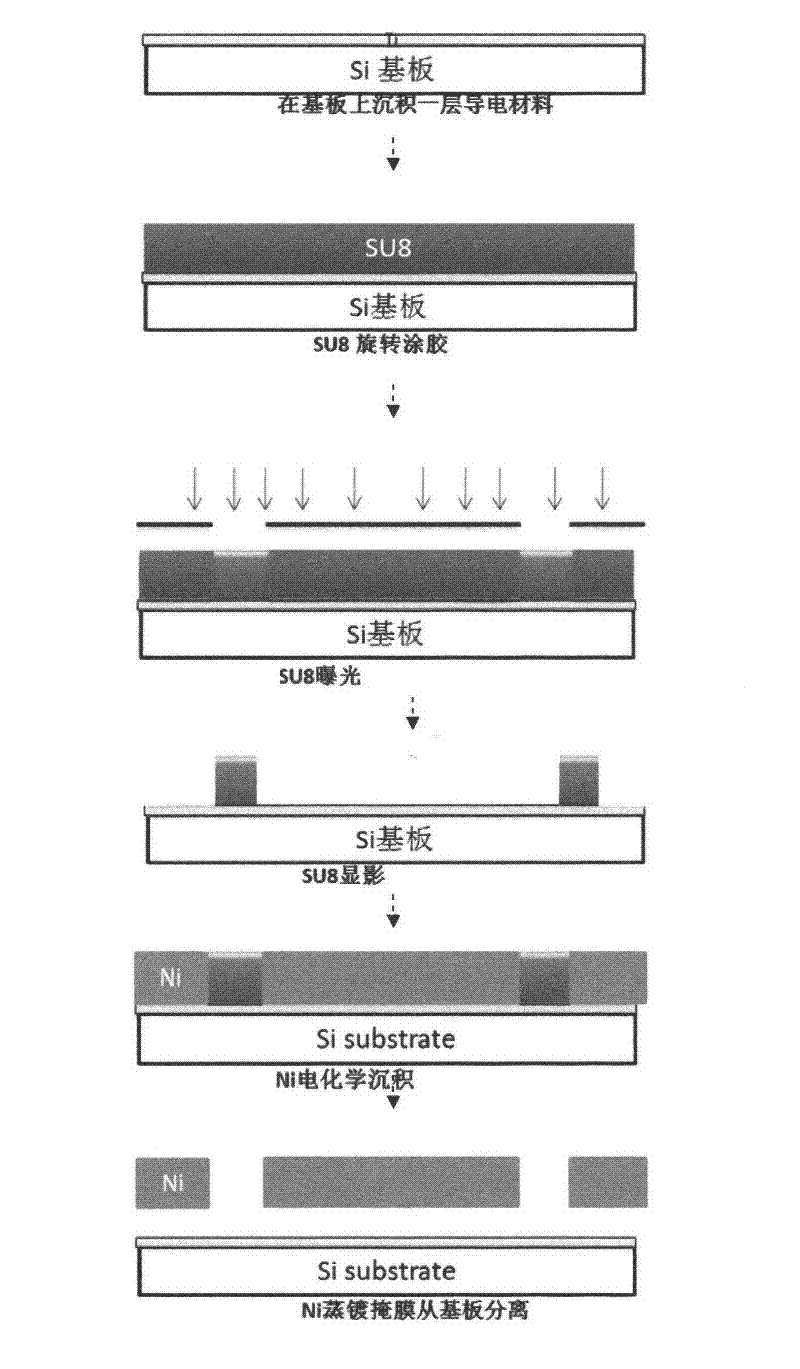

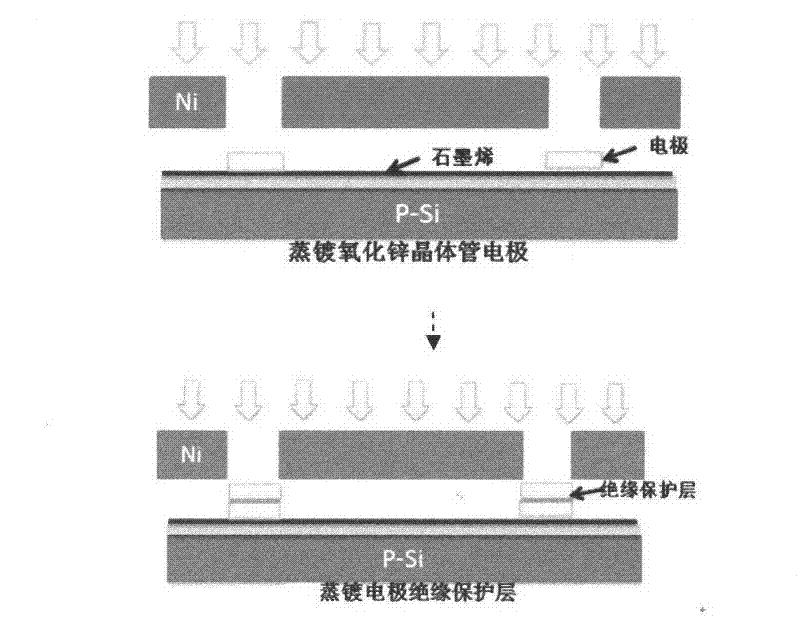

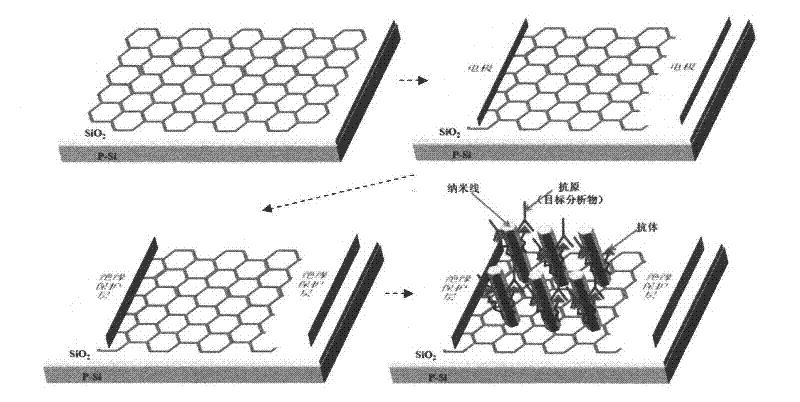

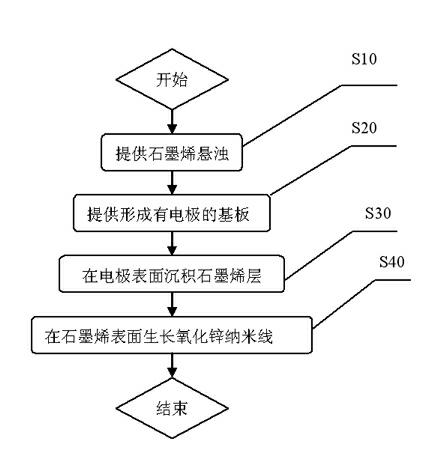

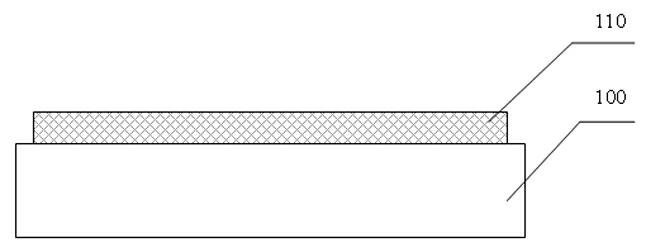

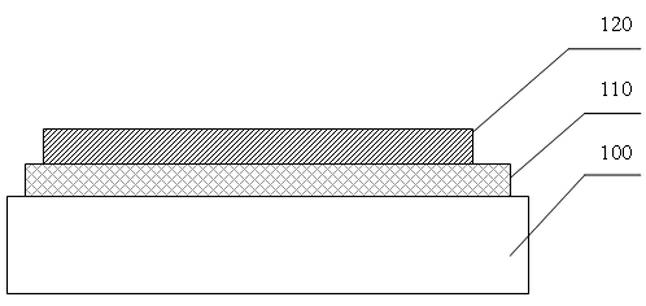

Manufacture and application method for graphene transistor and biosensor of graphene transistor

InactiveCN102590309ANotable featuresRemarkable effectMaterial analysis by electric/magnetic meansElectronTransistor

The invention discloses a manufacture and application method for a graphene transistor and a biosensor of the graphene transistor, which is low in price, avoids chemical pollution of the surface of the graphene transistor, and is suitable for integrated manufacture and mass production of the graphene transistor and the existing electronic devices. A method used for growing zinc oxide nanowires or metal nano-particles on the surface of the graphene transistor and based on the manufacture method for the biosensor of the graphene transistor is further provided. Nanometer materials on the surface of the transistor are favorable for absorbing biological active substances (such as enzyme, deoxyribonucleic acid (DNA), ribonucleic acid (RNA), aptamer, antigen or antibody) with special identification capacity. Therefore, a graphene transistor channel has capacity of absorbing target analyte selectively, and sensitivity and selectivity of a sensor based on the graphene transistor channel are improved.

Owner:厦门思明银河整形外科门诊部有限公司

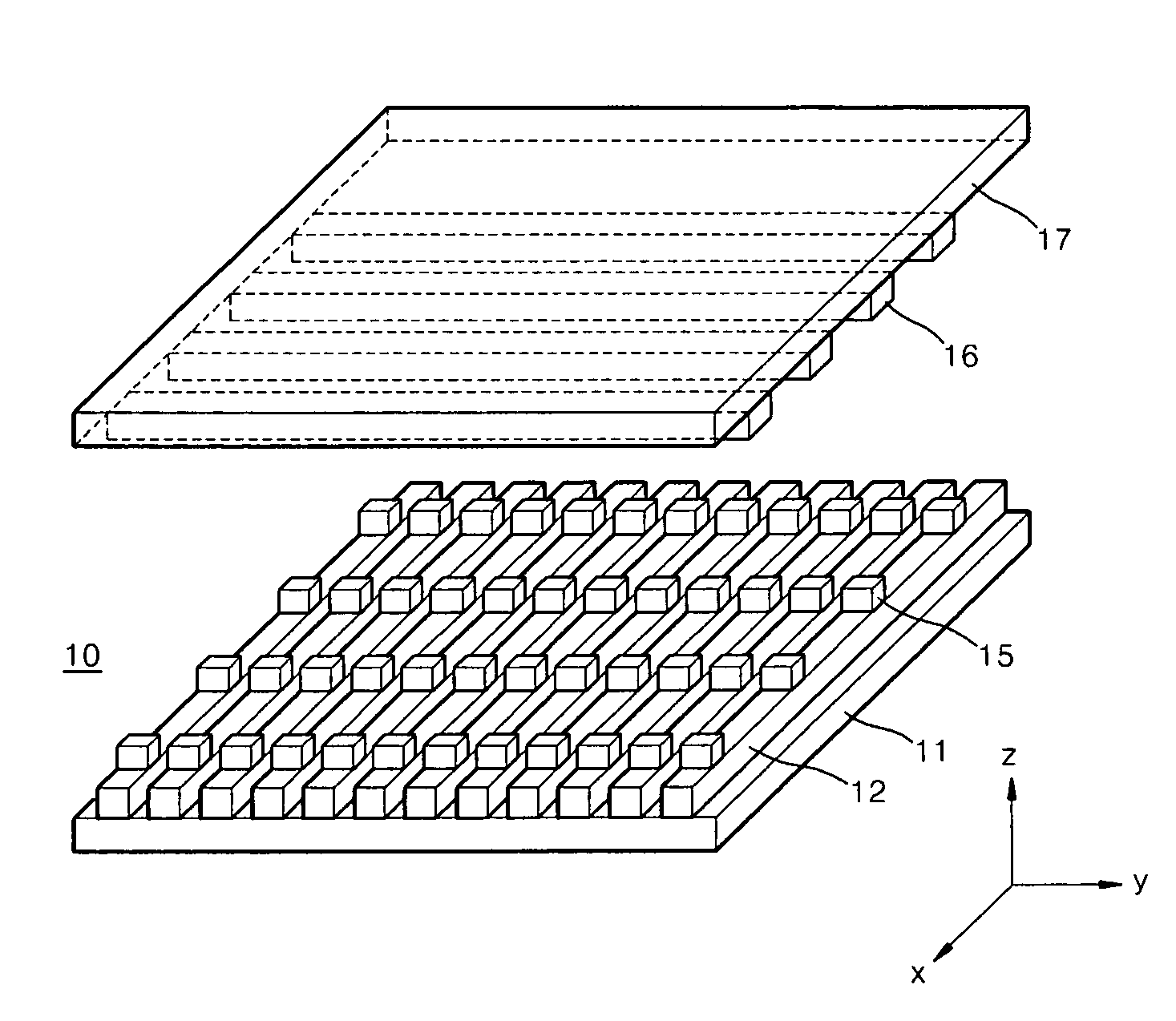

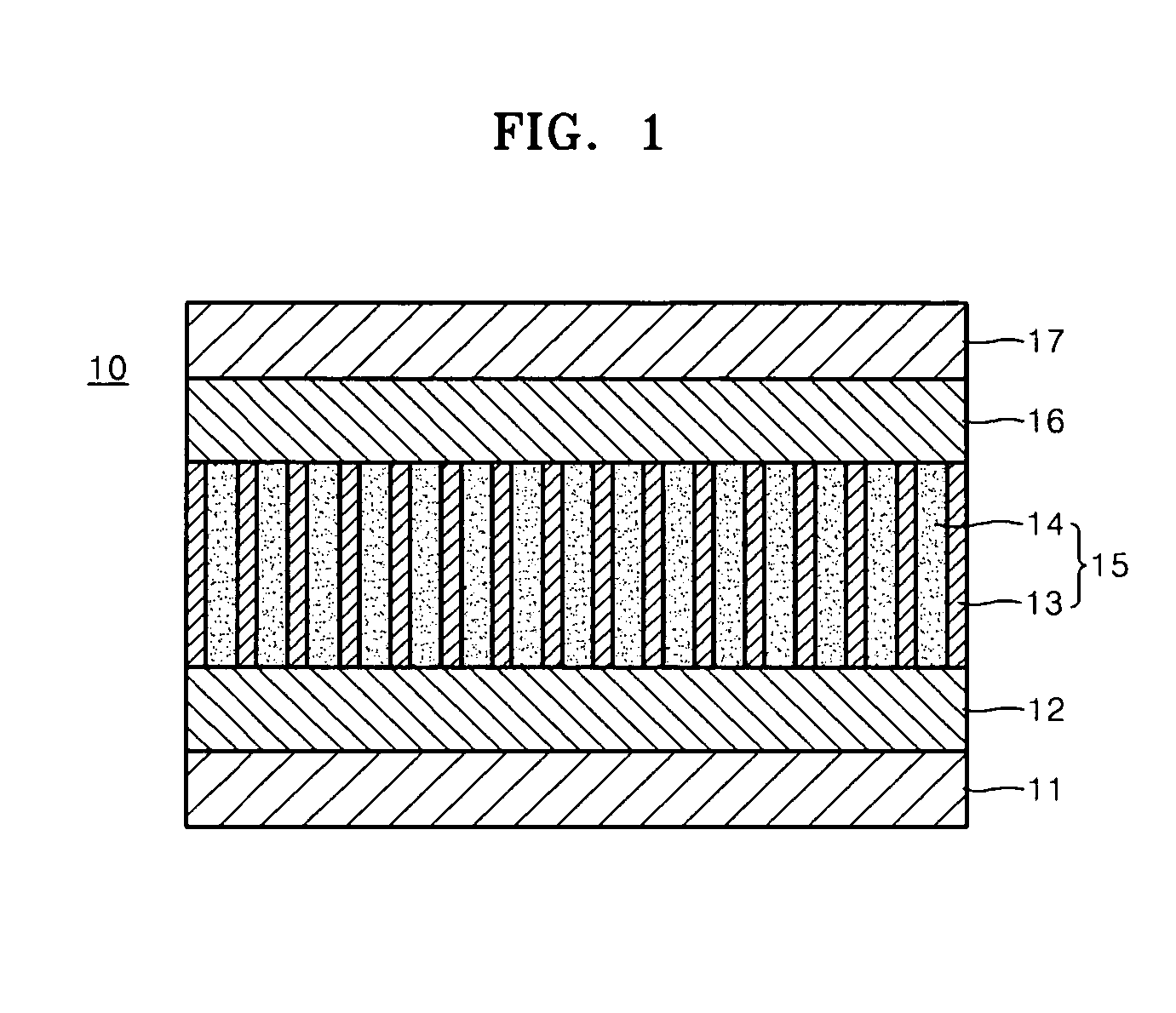

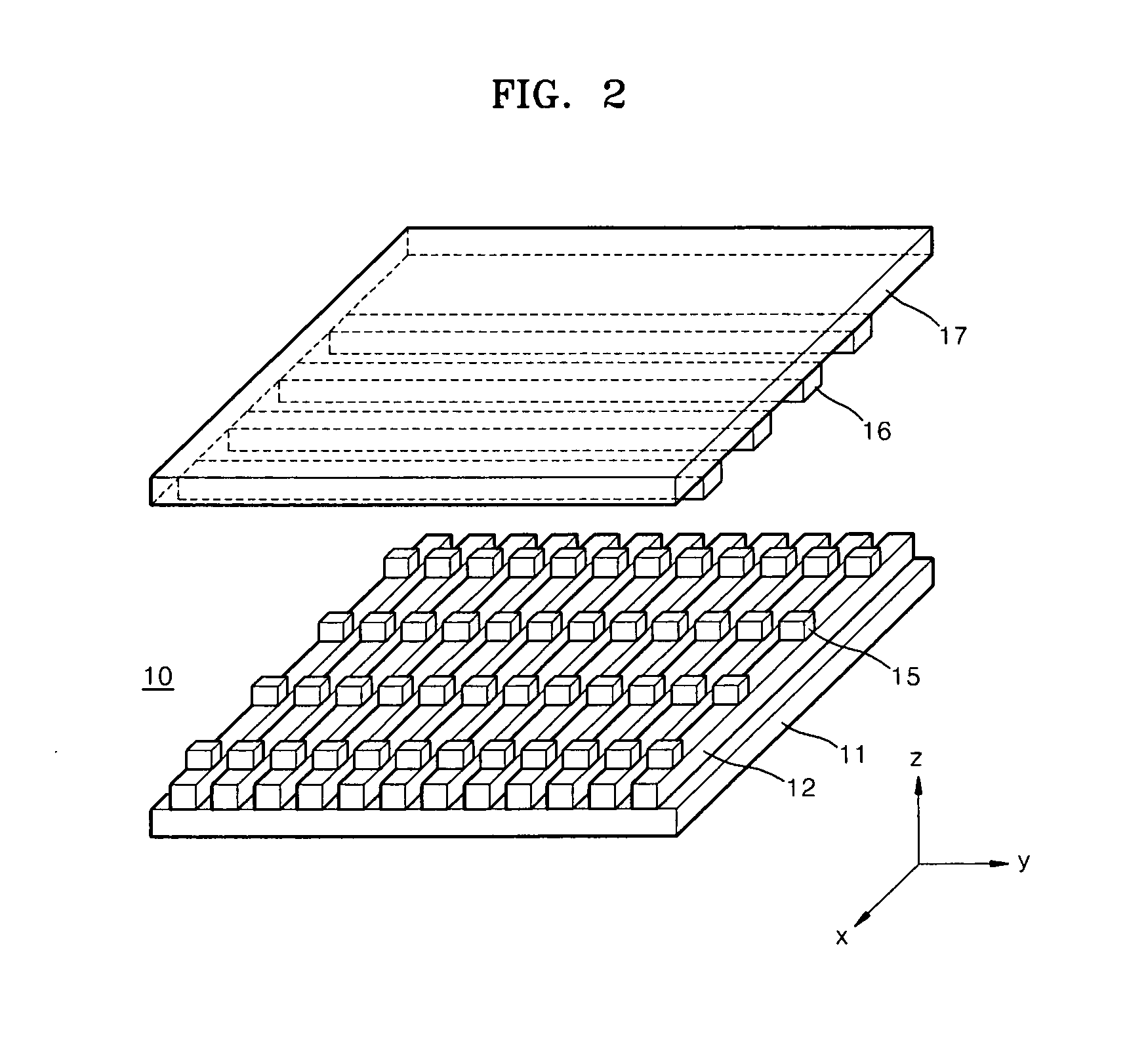

Touch panel using nano-wire

ActiveUS20090309843A1Improve performanceHigh light transmittanceConductive layers on insulating-supportsInput/output processes for data processingZinc oxide nanowireNanometre

Provided is a touch panel using a zinc oxide (ZnO) nano wire. The touch panel may include a first transparent substrate, a first transparent electrode layer on the first transparent substrate, a light transmissive nano wire layer including a plurality of piezoelectric nano wires that may be arranged on the first transparent electrode layer so as to be perpendicular to the first transparent electrode layer, a second transparent electrode layer on the nano wire layer, and a second transparent substrate on the second transparent electrode layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Flexible semi-clarity strain sensor and preparation method thereof

InactiveCN102353324AIncreased durabilityIncreased sensitivityDecorative surface effectsElectrical/magnetic solid deformation measurementPolystyreneEngineering

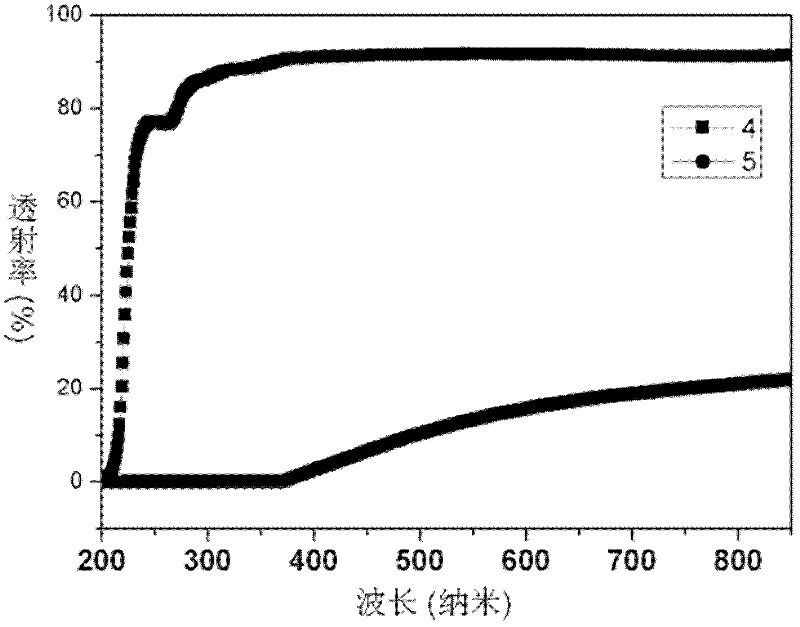

The invention discloses a flexible semi-clarity strain sensor and a preparation method thereof. The sensor is characterized in that: a functional layer is provided on a flexible polymer substrate, the functional layer is a latticed structure which is formed by ZnO and nanofiber, and two sides of the functional layer are titanium and silver electrodes. The invention provides a method for preparinga super-high strain resistance semi-clarity stretching type mechanics sensor based on a zinc oxide nano wire / polystyrene nanofiber hybrid structure on a polydimethylsiloxane substrate. Transmissivities of the sensor before and after zinc oxide growth are represented. The sensor can detect force as high as 50% and has high endurance, rapid response and high sensitivity. A device can be applied to a human body rapid motion test simultaneously. In addition, through driving of a solar energy cell, the device becomes potential application of an outdoor self driven sensor system. The method in the invention has the characteristics of simplicity and a low price, and the sensor has the characteristics of semi-clarity, high strain resistance, high sensitivity, rapid response and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

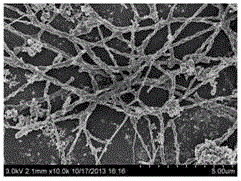

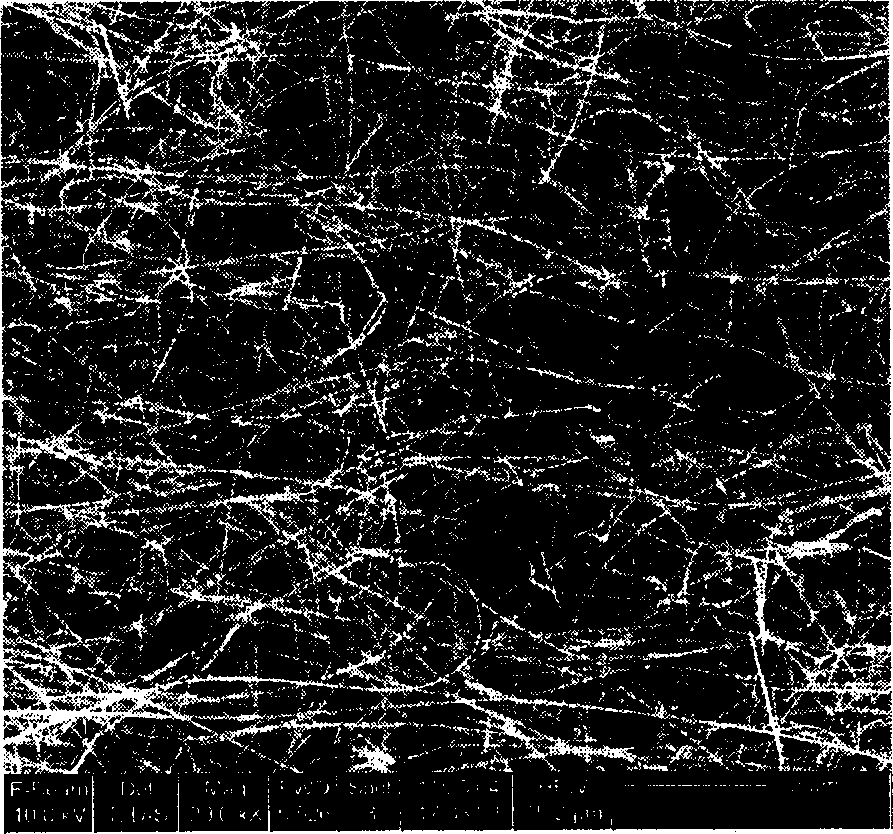

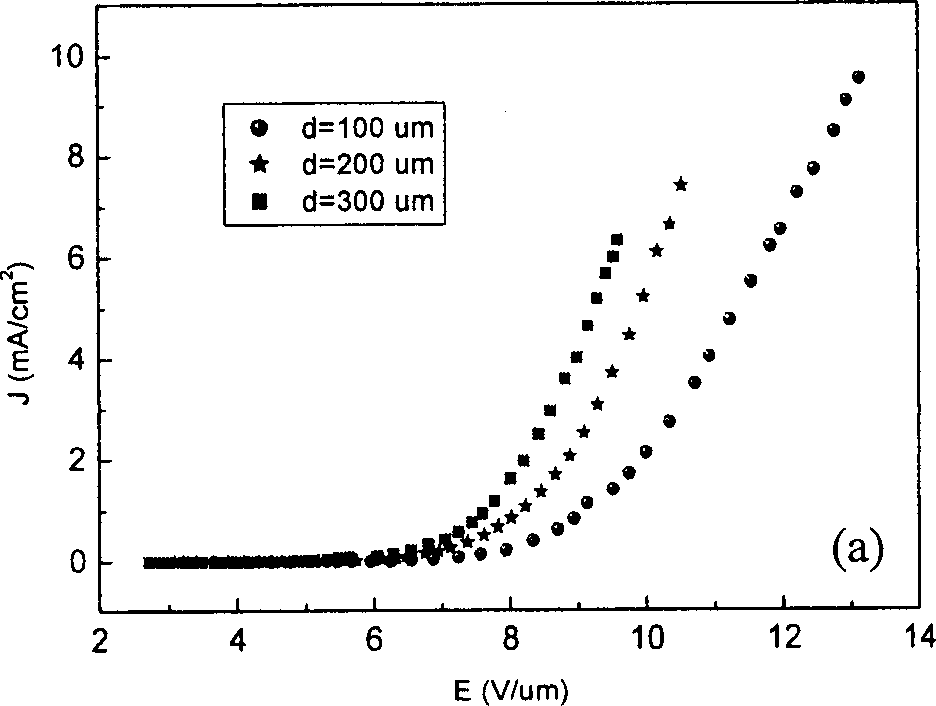

Emitting cathode based on composite material of graphene/zinc oxide nanowire and preparation of same

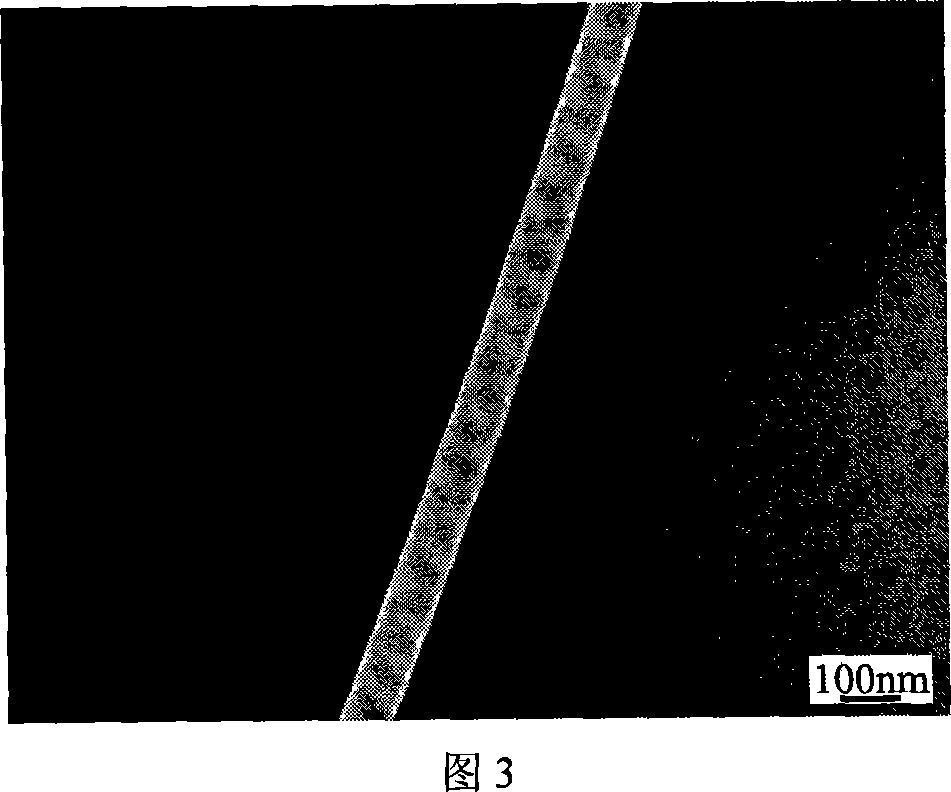

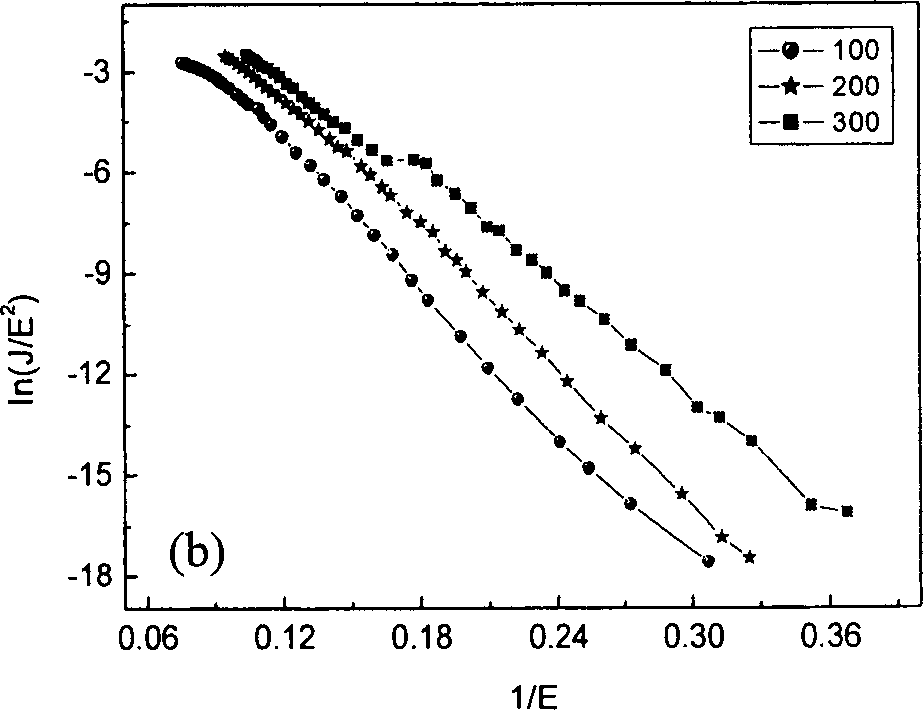

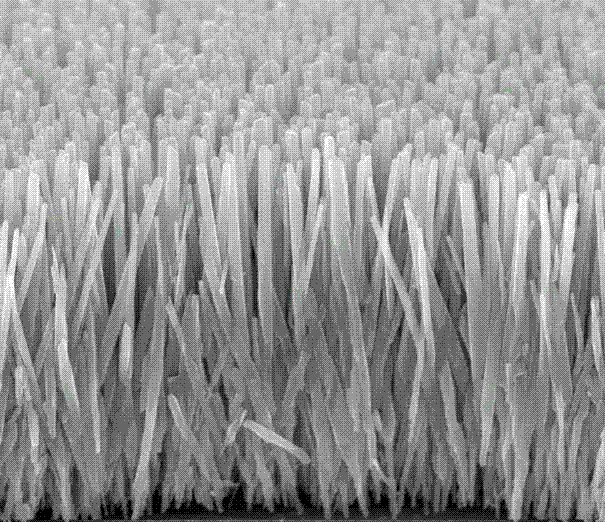

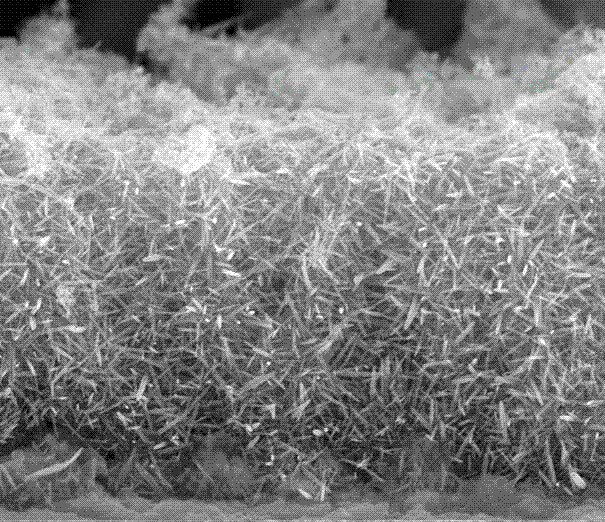

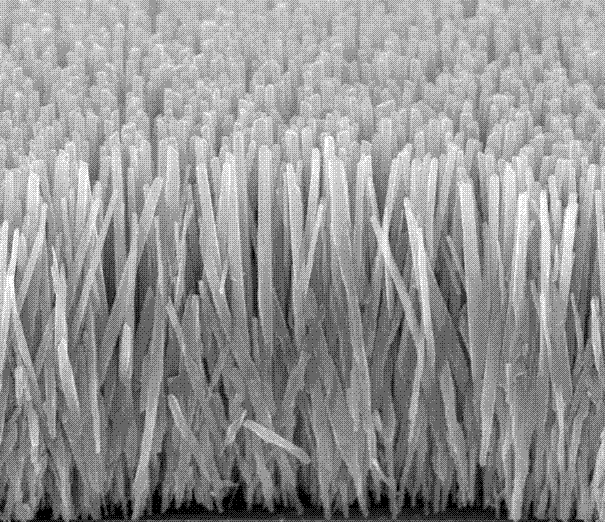

ActiveCN102157315AReduce the turn-on electric fieldIncreased emission current densityDischarge tube/lamp detailsCold cathode manufacturePower flowElectron source

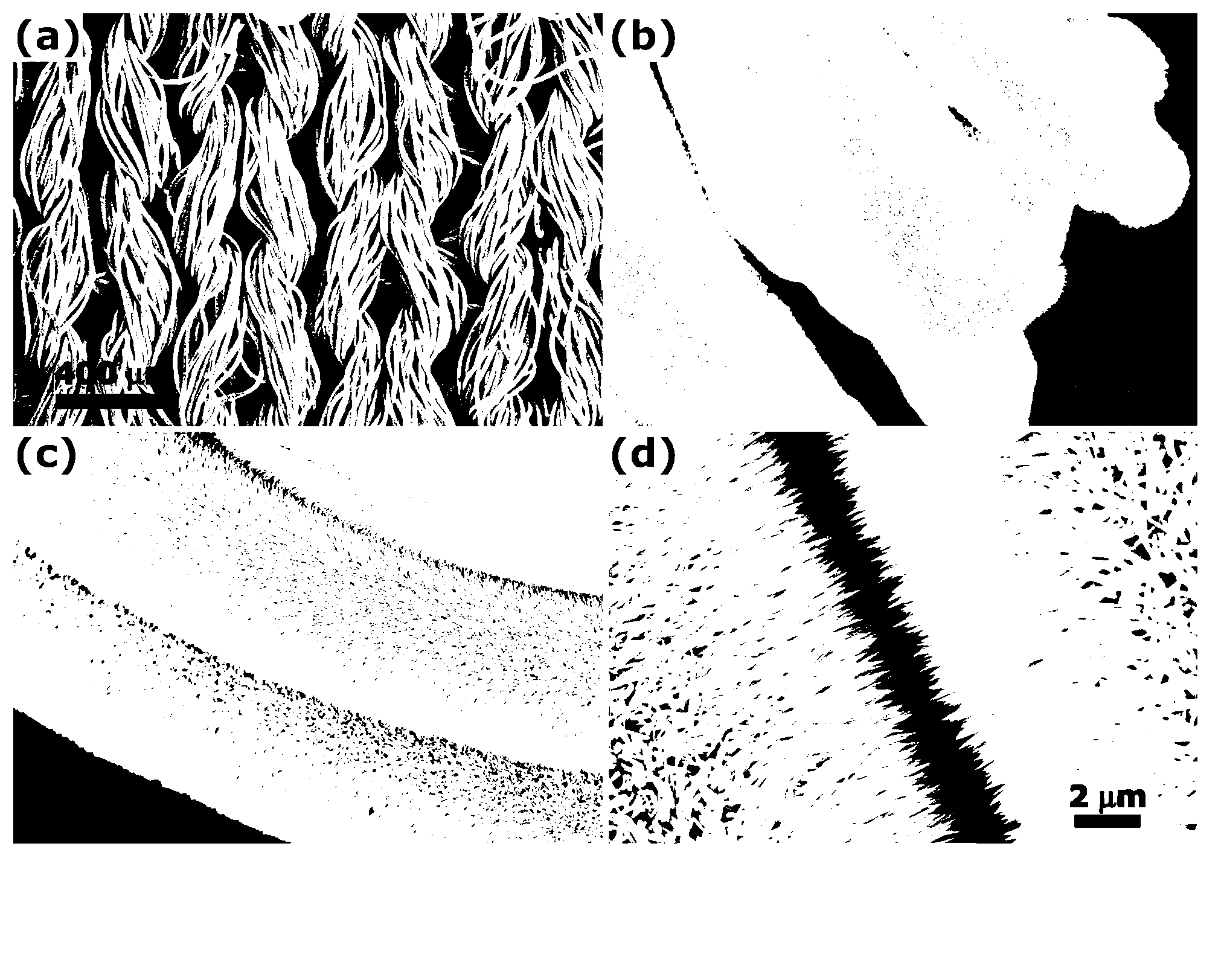

The invention relates to a field electron emitting cathode based on the composite material of graphene / zinc oxide nanowire, comprising a conductive electrode and the composite material of graphene / zinc oxide nanowire, wherein the composite material of graphene / zinc oxide nanowire is positioned on the surface of the electrode, and consists of the graphene with the size ranging from 2 to 10 micronsand the zinc oxide nanowire with the length ranging from 1 to 2 microns and the diameter being 100 nanometers; and the turn-on field is lower than or equal to 1.7 volt / microns, and the threshold field is lower than or equal to 4 volt / microns. The filed emission electron source has the advantages of lower turn-on field, low threshold field, high emission current density, stable emission, easy preparation method and easy realization of industrialized volume production.

Owner:FUZHOU UNIV

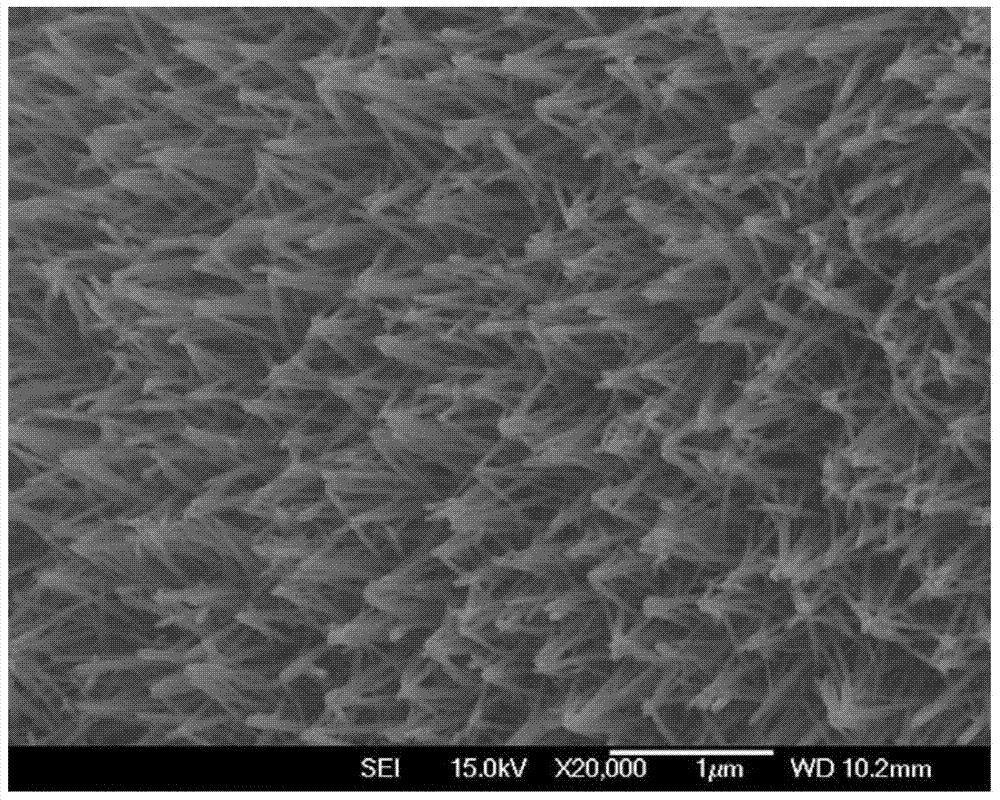

Method for manufacturing zinc oxide nanowires and device having the same

ActiveUS20070154385A1Material nanotechnologyPolycrystalline material growthAdemetionineZinc oxide nanowire

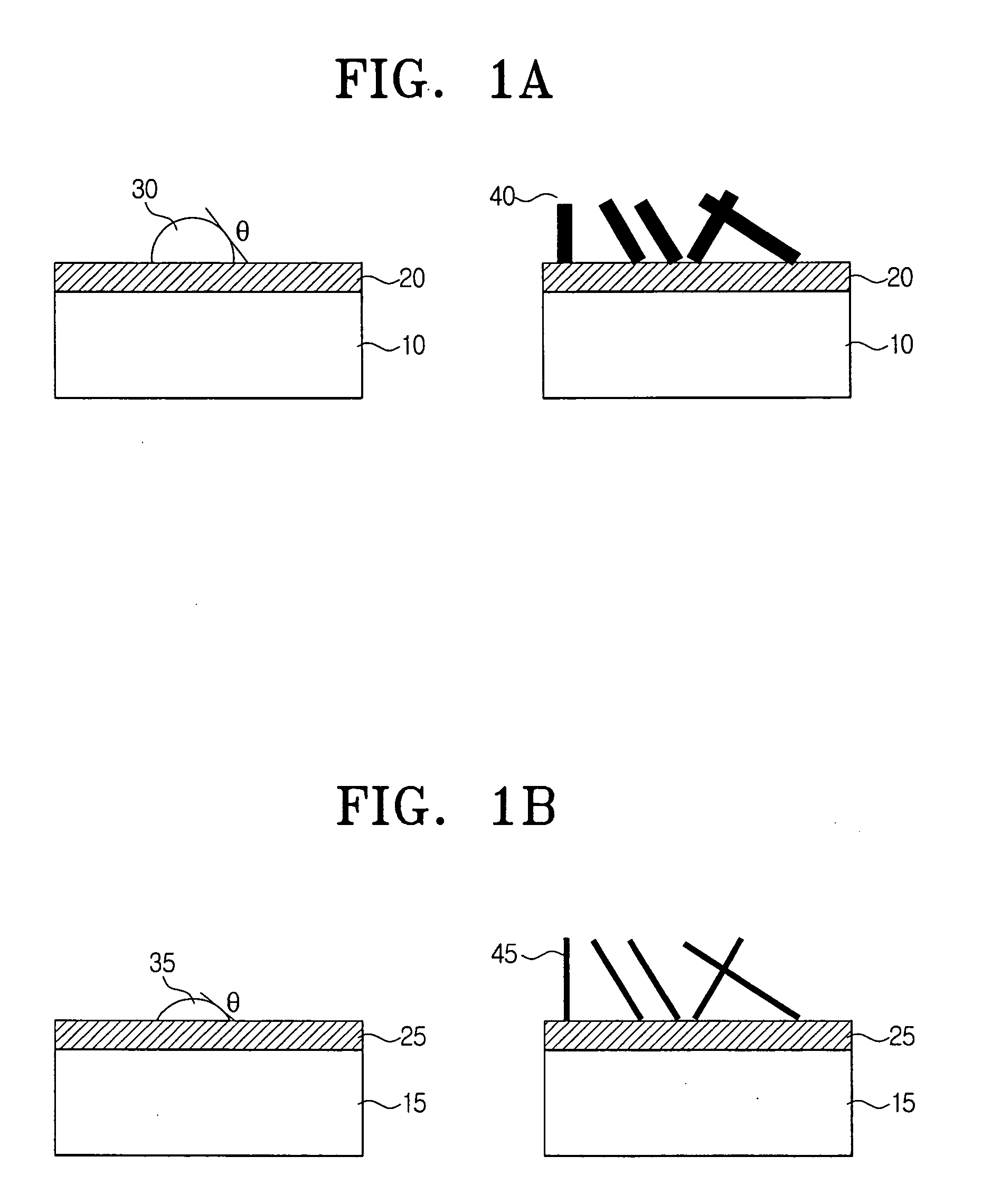

A method for manufacturing ZnO nanowires with a small diameter and increased length and a device comprising the same. The manufacturing method includes: forming a ZnO seed layer containing a hydroxyl group on a substrate; and growing ZnO nanowires on the ZnO seed layer containing the hydroxyl group. Preferably, the ZnO seed layer is a thin ZnO seed layer containing more than 50% of the hydroxyl group.

Owner:SAMSUNG ELECTRONICS CO LTD

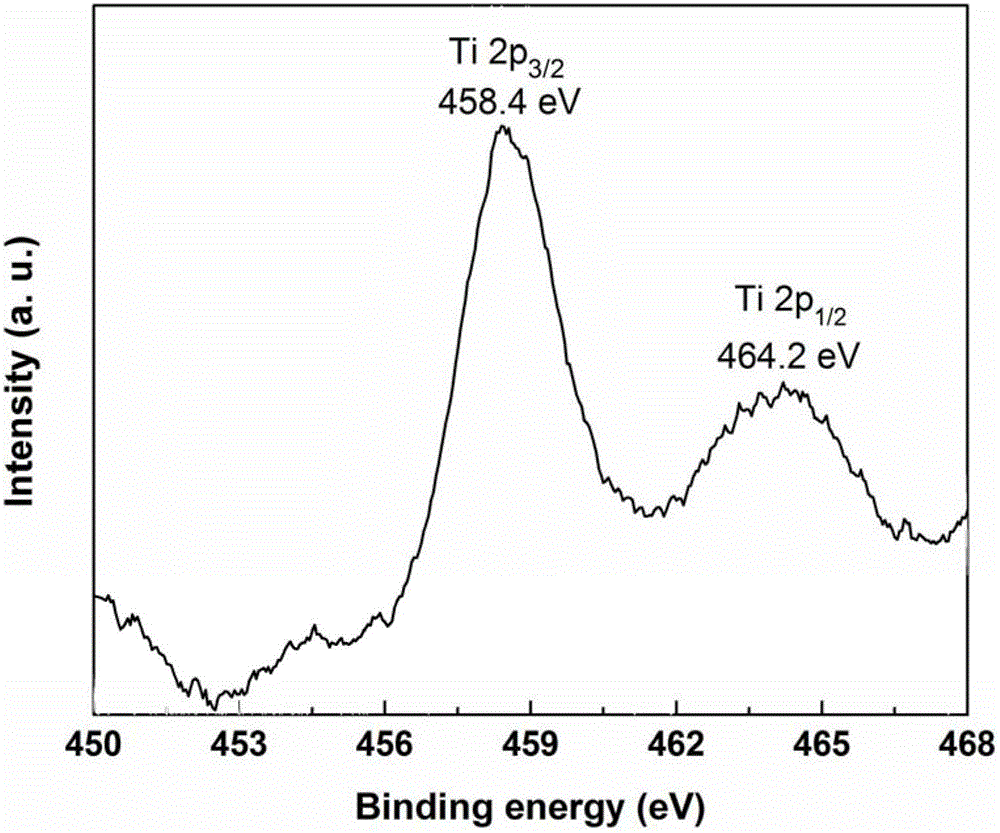

Direct vertical deposition method of zinc oxide nanometer rod array on titanium dioxide film

InactiveCN101760739AAchieve vertical growthAvoid pre-deposition processLiquid surface applicatorsLiquid/solution decomposition chemical coatingReaction temperatureZinc oxide nanorod

The invention discloses a direct vertical deposition method of a zinc oxide nanometer rod array on a titanium dioxide film, wherein the zinc oxide is an important inorganic semiconductor function material and arouses wide public concern due to the unique performances of catalysis, electricity, optics and photochemistry, and the like. Persons are interested in the control synthesis of one-dimensional zinc oxide due to the remarkable laser behavior of the one-dimensional zinc oxide. The method comprises the steps of: preparing titanium dioxide sol under room temperature; preprocessing; adhering with one layer of titanium dioxide sol on a preprocessed glass or an electric glass ITO by means of dipping and pulling; preprocessing titanium dioxide grains before drying and spinning; fixing a layer of titanium dioxide grains prepared by means of a sol-hydrothermal method on the substrate by means of spinning; drying; roasting to obtain the nanometer zinc oxide film; putting the zinc oxide film into a sealed water solution system of zinc salt and organic amine; reacting for 12-72 h under the reaction temperature of 45-90 DEG C; taking out; washing with secondary water; and drying. The invention relates to a nanometer material.

Owner:HEILONGJIANG UNIV

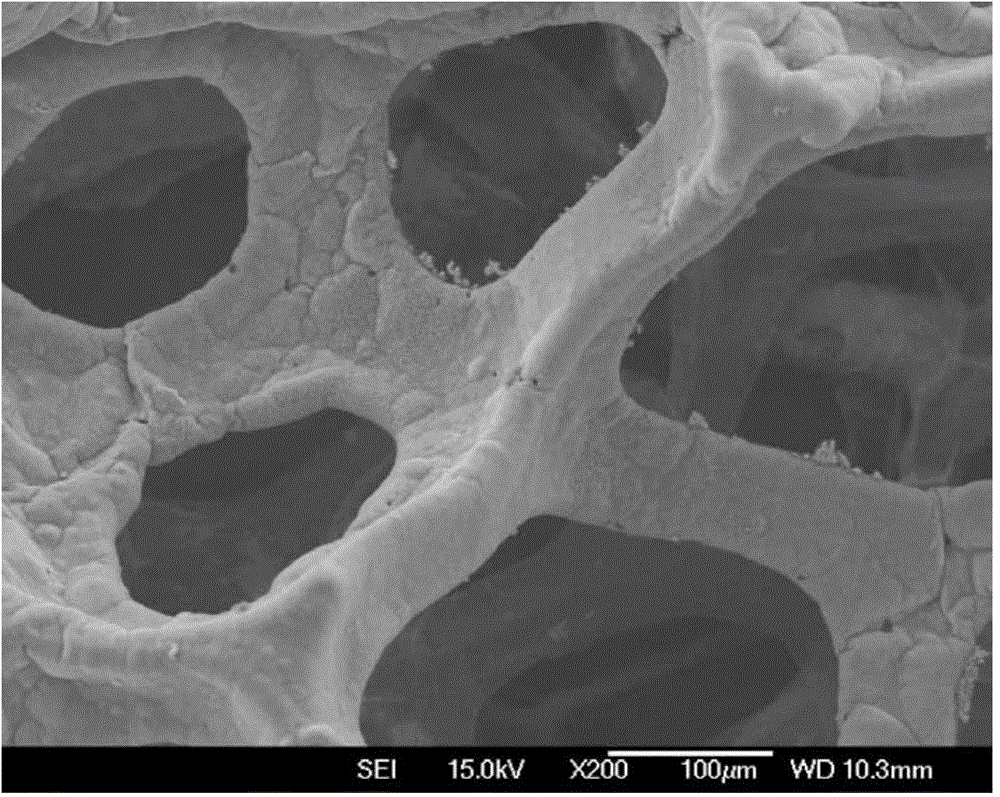

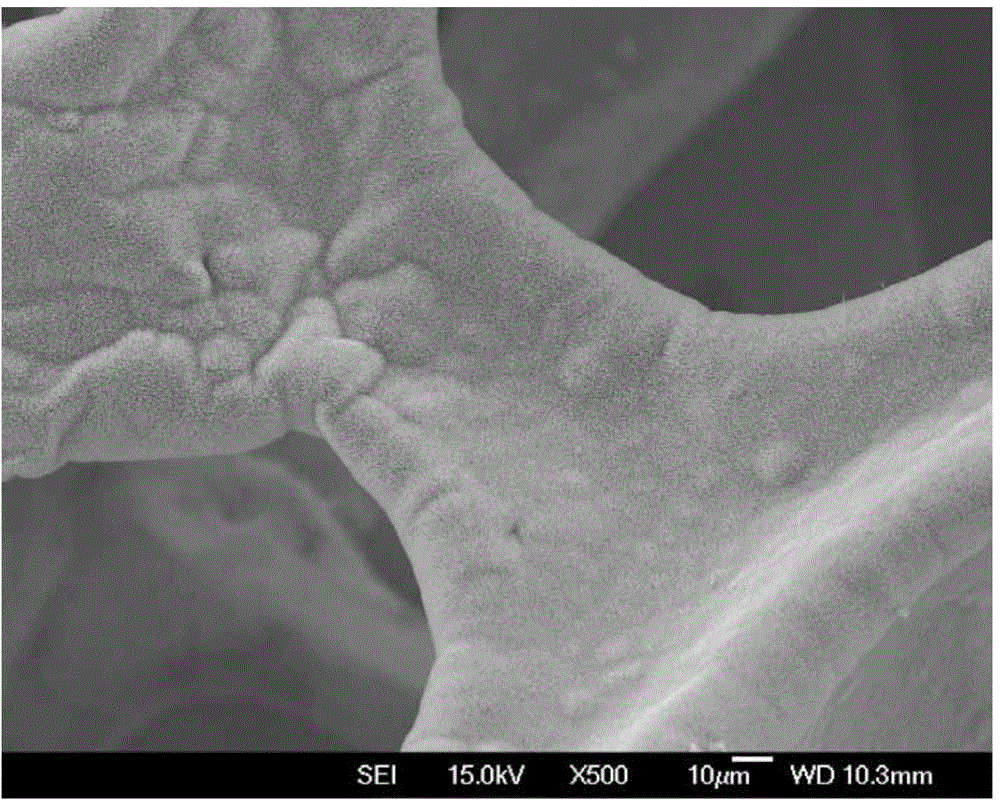

Synthesis method of zinc oxide nano wire harness array/foam graphene composite material and application thereof

InactiveCN103482683AImprove bindingHigh sensitivityMaterial nanotechnologyZinc oxides/hydroxidesSynthesis methodsHydrothermal synthesis

The invention discloses a synthesis method of a zinc oxide nano wire harness array / foam graphene composite material and an application thereof, relating to a synthesis method of a composite material and an application thereof. The invention aims at solving the technical problems of low sensitivity and relatively high detection limit by applying the existing zinc oxide nano wire / foam graphene composite material to dopamine detection. The synthesis method comprises a chemical vapor deposition method and a hydrothermal synthesis method. The zinc oxide nano wire harness array / foam graphene composite material can be used as an electrode material to detect dopamine. The synthesis method disclosed by the invention is mainly used for synthesizing a zinc oxide nano wire harness array / foam graphene composite material.

Owner:HARBIN UNIV OF SCI & TECH

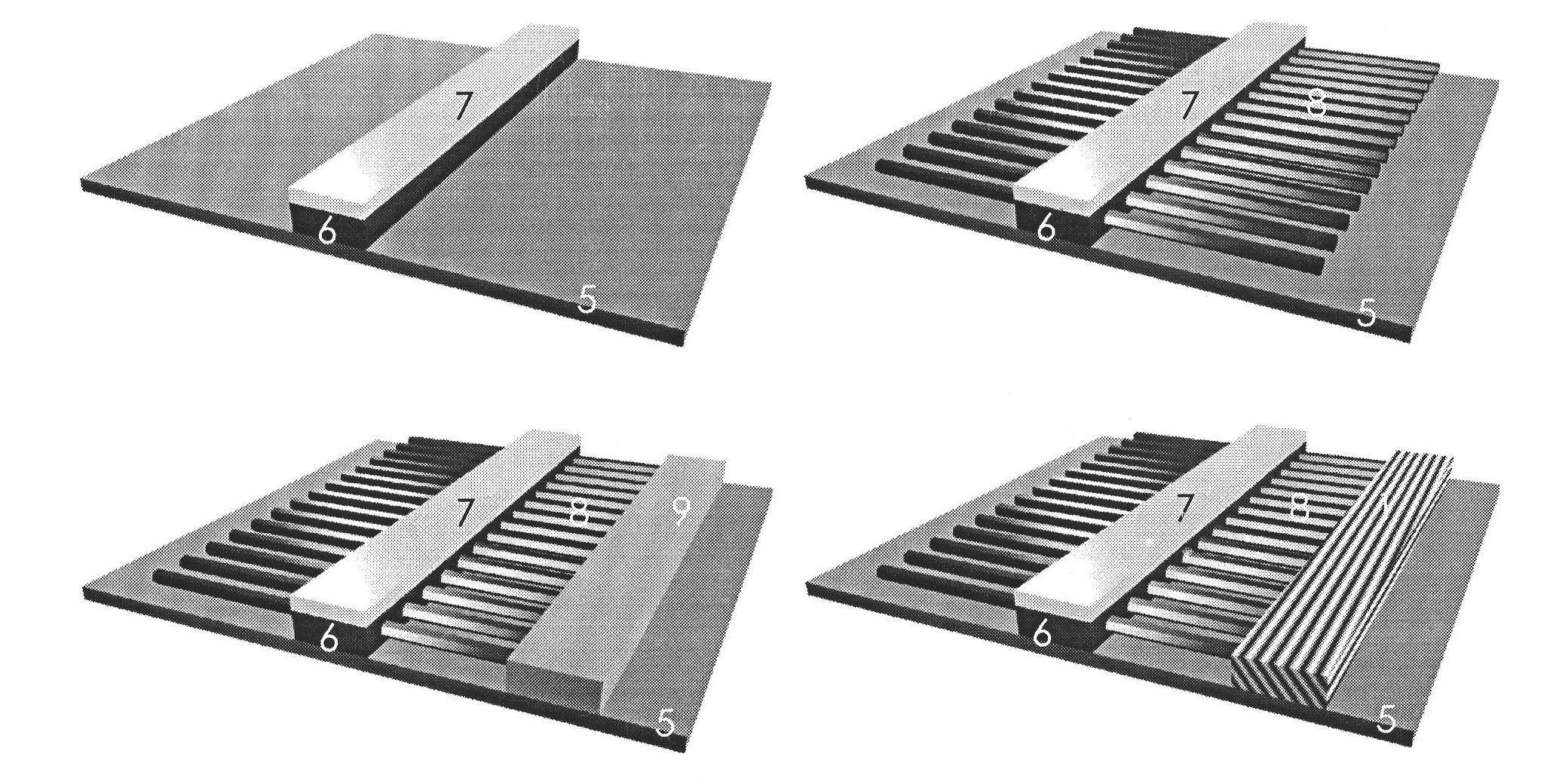

Semiconductor ultraviolet detection sensor and preparation method thereof

InactiveCN102110735AAvoid influenceService life of directorFinal product manufacturePhotometry using electric radiation detectorsUltravioletSemiconductor sensor

The invention discloses a semiconductor sensor for ultraviolet detection and a preparation method of the sensor. The semiconductor ultraviolet detection sensor comprises a baseplate, electrodes loaded on the baseplate and zinc oxide nanowires which are positioned between the electrodes, connected in parallel and integrated, wherein the electrodes are two comb tooth-shaped electrodes which are arranged oppositely, one comb tooth of one electrode is inserted between two comb teeth of the other electrode so as to form the tooth insertion shape, and the zinc oxide nanowires are respectively connected in parallel and integrated on the adjacent two comb teeth. The light response current of the semiconductor ultraviolet detection sensor can achieve the milliamp magnitude, thereby significantly reducing the ultraviolet detection difficulty and the characterization difficulty of the strength thereof.

Owner:LANZHOU UNIVERSITY

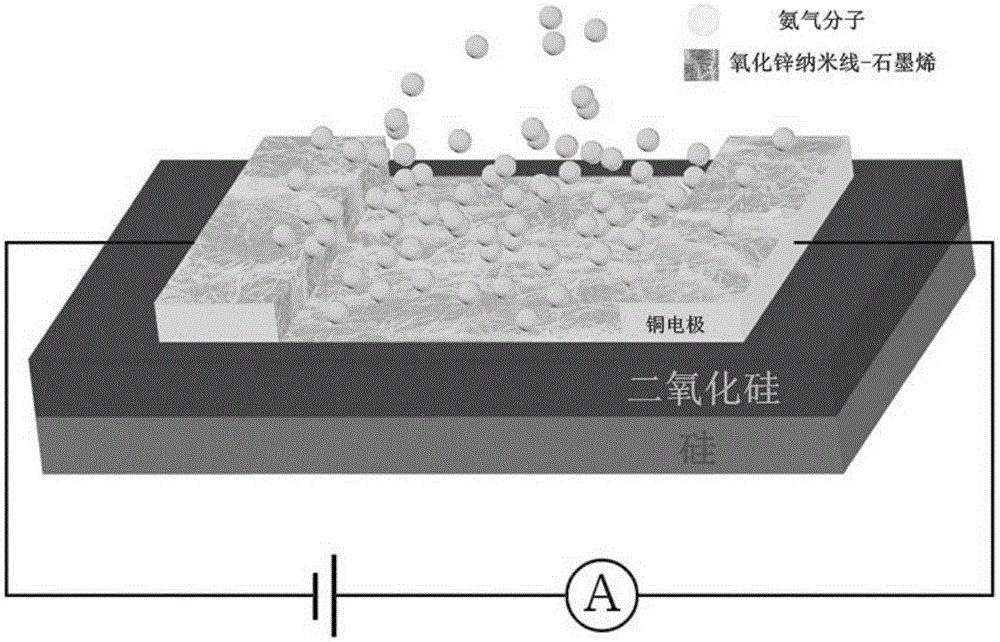

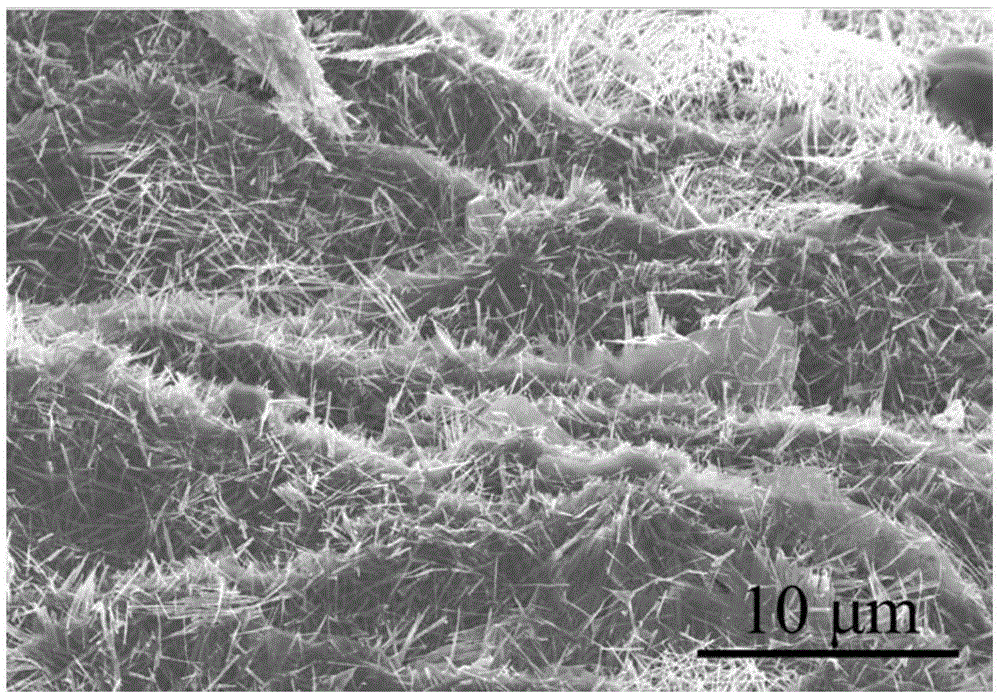

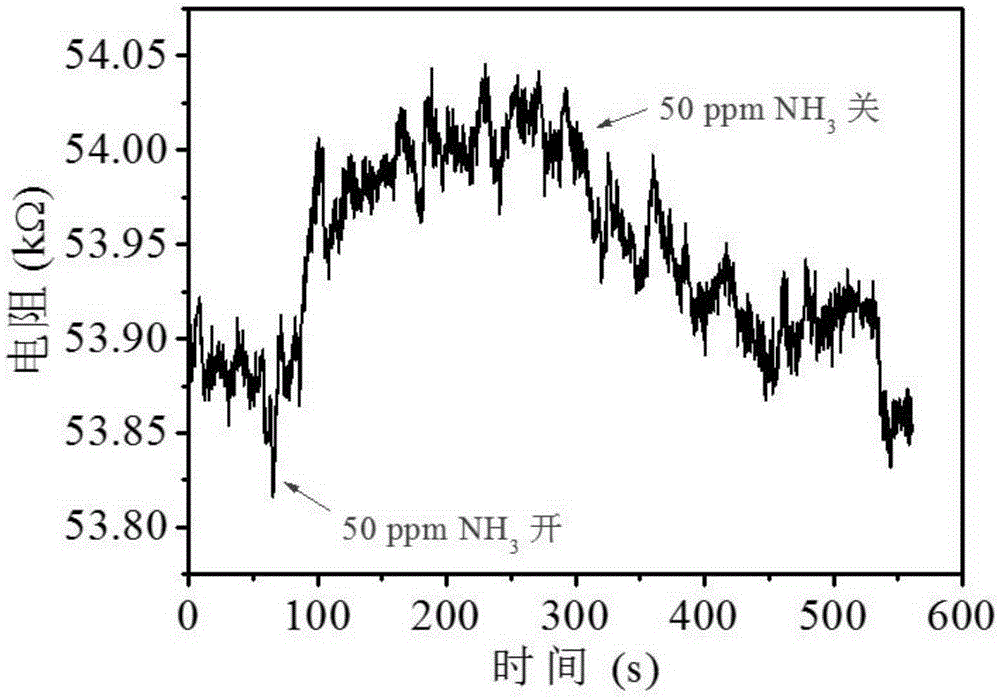

Zinc oxide nanowire-graphene gas sensor and preparation method thereof

The invention discloses a zinc oxide nanowire-graphene gas sensor and a preparation method thereof, and belongs to the technical field of gas detection. The gas sensor consists of a substrate, an interdigital electrode and a gas sensitive coating, wherein the gas sensitive coating is made of a zinc oxide nanowire-graphene composite material. The preparation process of the sensor comprises the following steps: (1) preparing the zinc oxide nanowire-graphene nano-composite material; (2) machining and preparing the interdigital electrode on the substrate by a micromachining method and covering the surface of the interdigital electrode with a layer of nano-composite material serving as the gas sensitive coating to form a sensing device. The lower detection limit of the gas sensor to ammonia gas under room temperature reaches 50 ppb; meanwhile, the gas senor is shorter in response time, higher in repeat stability and higher in gas selectivity. The gas sensor is suitable for performing high-sensitivity detection on the ammonia gas under the room temperature.

Owner:SHANGHAI JIAO TONG UNIV

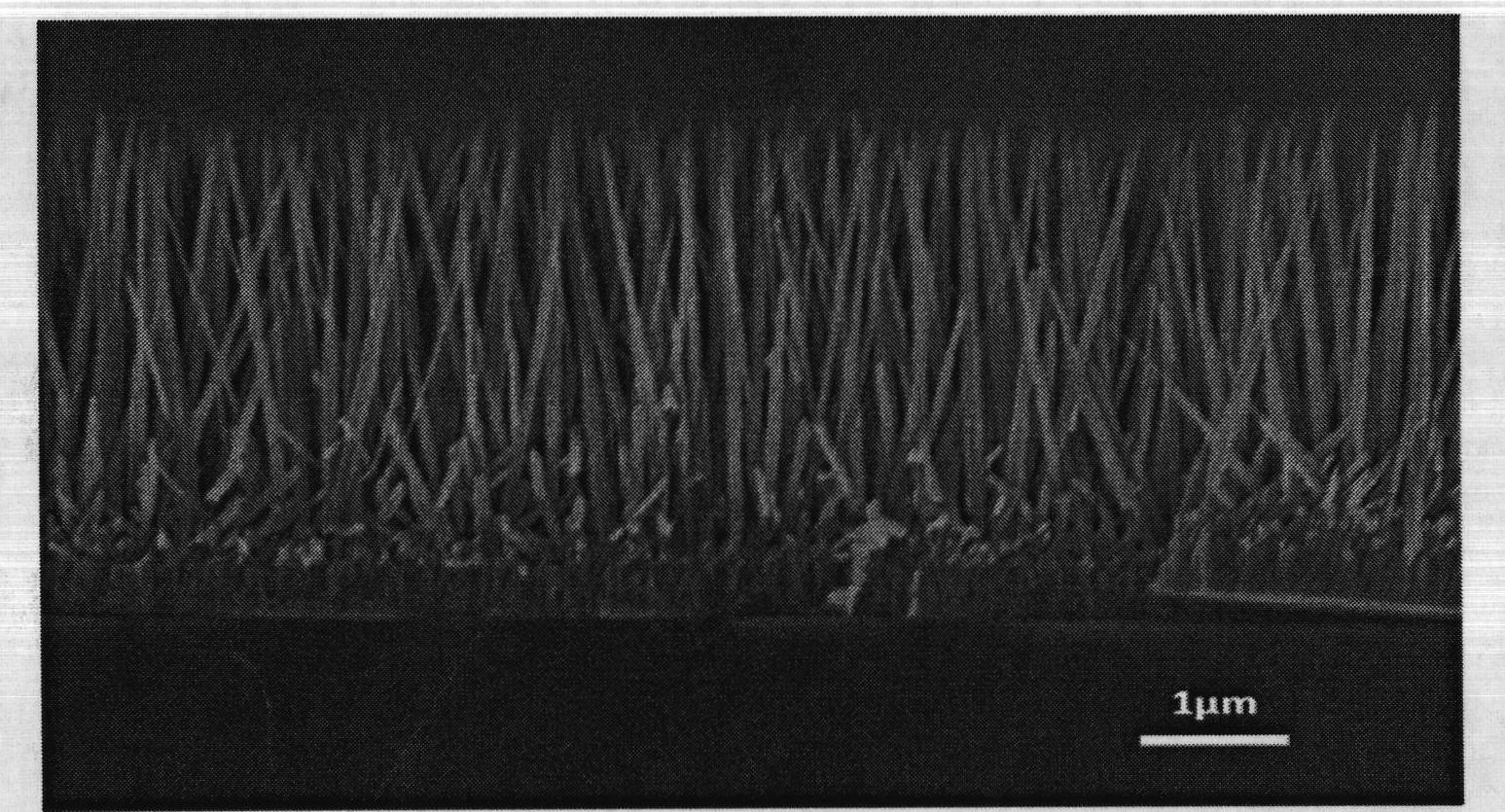

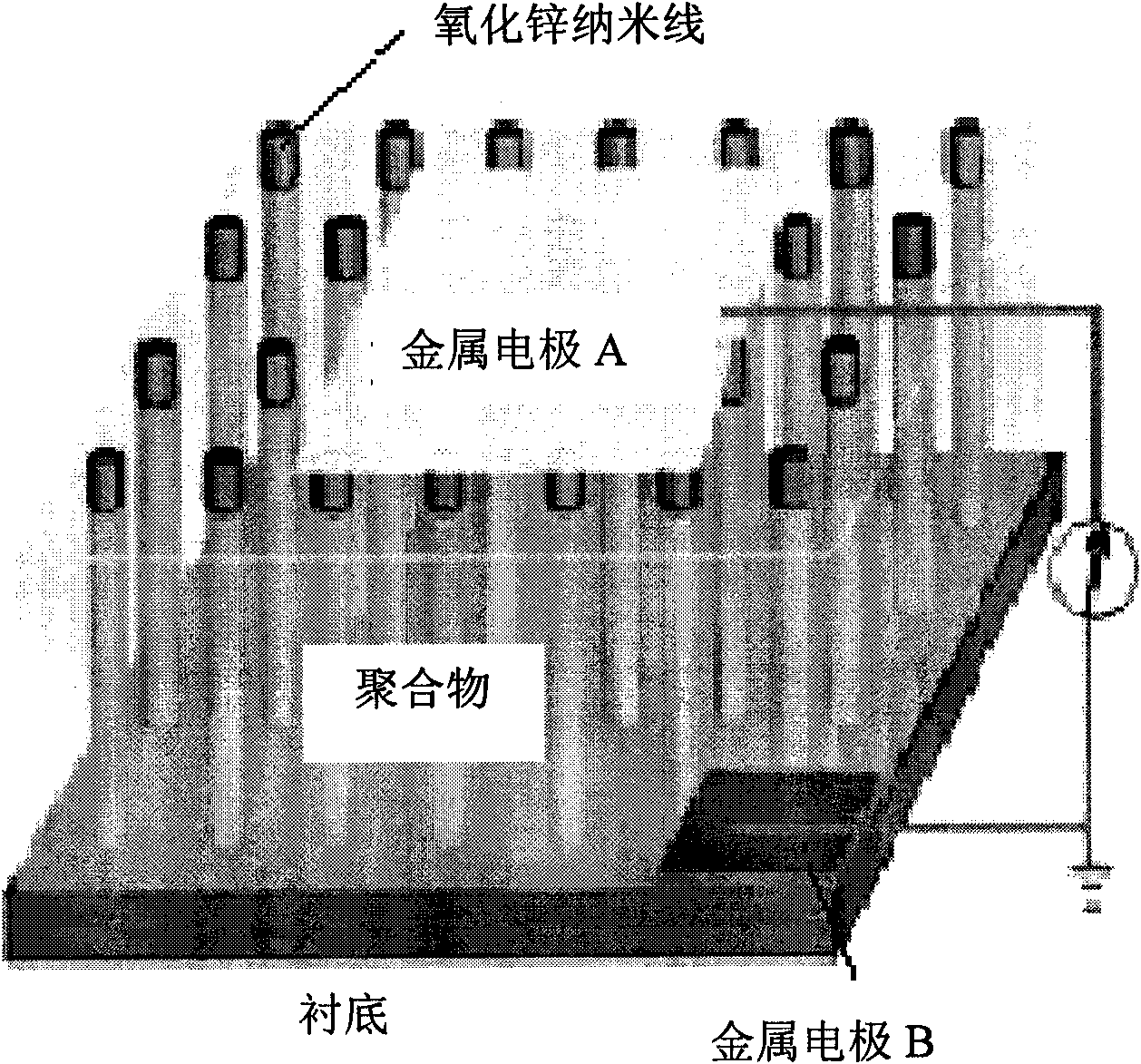

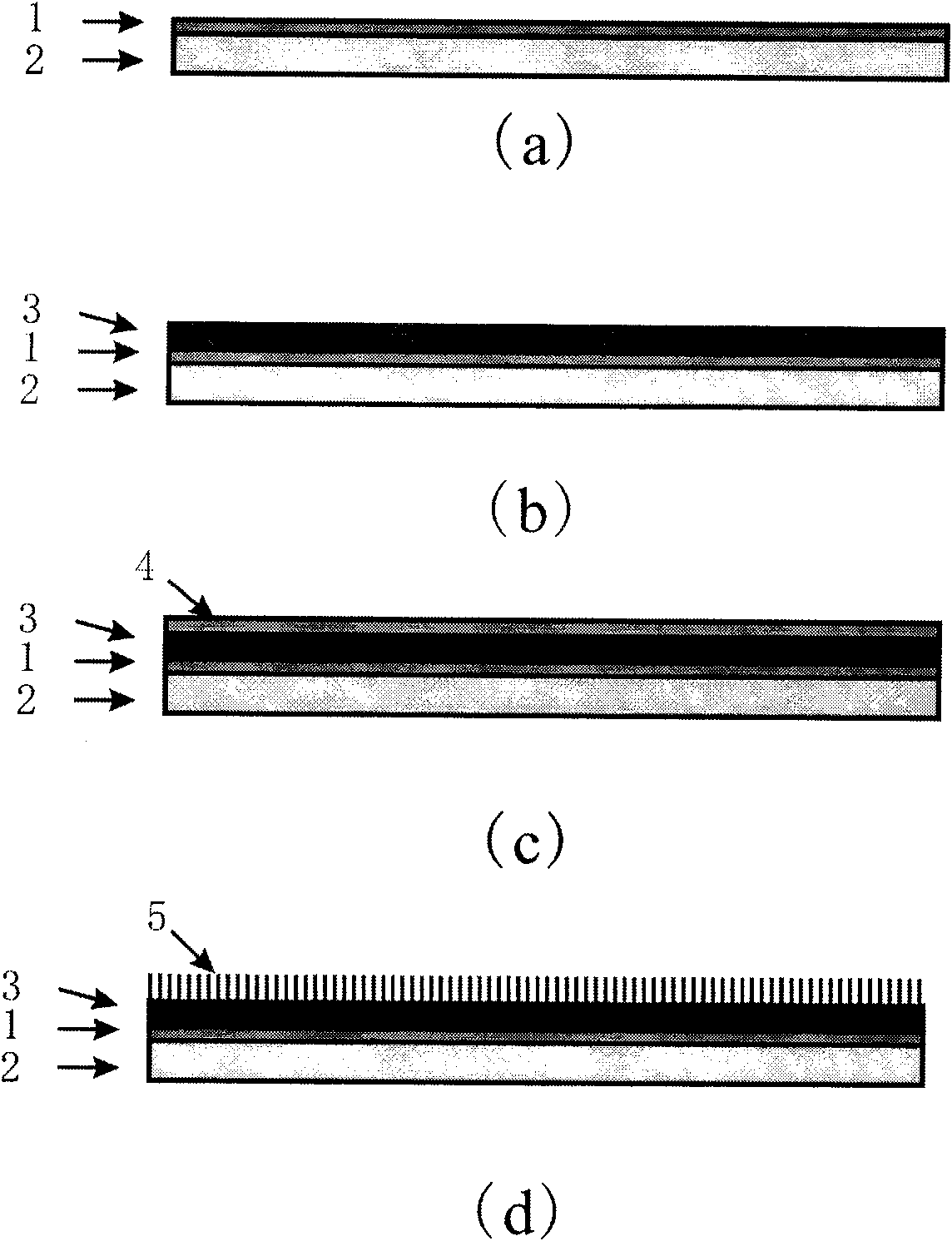

Zinc oxide nano wire/polymer nano composite energy converter and preparation method thereof

InactiveCN101656486AExpand the connotationAvoid Synthetic ProcessesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesNanogeneratorPolymer composites

The invention discloses a zinc oxide nano wire / polymer nano composite energy converter and a preparation method thereof. The oxide nano wire / polymer nano composite energy converter comprises a zinc oxide nano wire, a polymer, a substrate and two metal electrodes, wherein the polymer senses the change of an environment signal to produce shrinkage or expansion to drive the zinc oxide nano wire covered by the polymer to generate distortion, thereby producing electric signals to convert other energies in the environment into electric energy. The invention skillfully utilizes a zinc oxide nano wireand polymer composite structure to prepare a nano generator element, and enables the zinc oxide nano wire to convert heat energy, chemical energy and the like into electric energy in the environmentby means of the action of the polymer.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Semiconductor sensor and production method

InactiveCN101866975ALow priceGood repeatabilityFinal product manufactureSemiconductor devicesSemiconductor sensorNanometre

The invention discloses a sensor for ultraviolet detection and a production method thereof. The semiconductor sensor of the invention is integrated by two electrodes, and a zinc oxide nanowire positioned between the two electrodes in a parallel way. The production method of the semiconductor sensor of the invention comprises the following steps of: firstly growing a layer of zinc oxide nanowire array which is vertical to a substrate surface on a first substrate, then transferring the zinc oxide nanowire array onto the surface of a second substrate, placing an electrode pattern on a masking film plate onto a gluing surface, making the electrode pattern be vertical to the two ends of the oriented nanowire and cover the end parts of the nanowire so as to carry out exposing, developing and photoetching, then depositing at least one electric conduction metal-made electrode in an electrode area which is formed by photoetching in a physical method, then stripping the electrodes and the nanowire from the second substrate, connecting leads onto the electrodes, and finally obtaining the required device.

Owner:LANZHOU UNIVERSITY

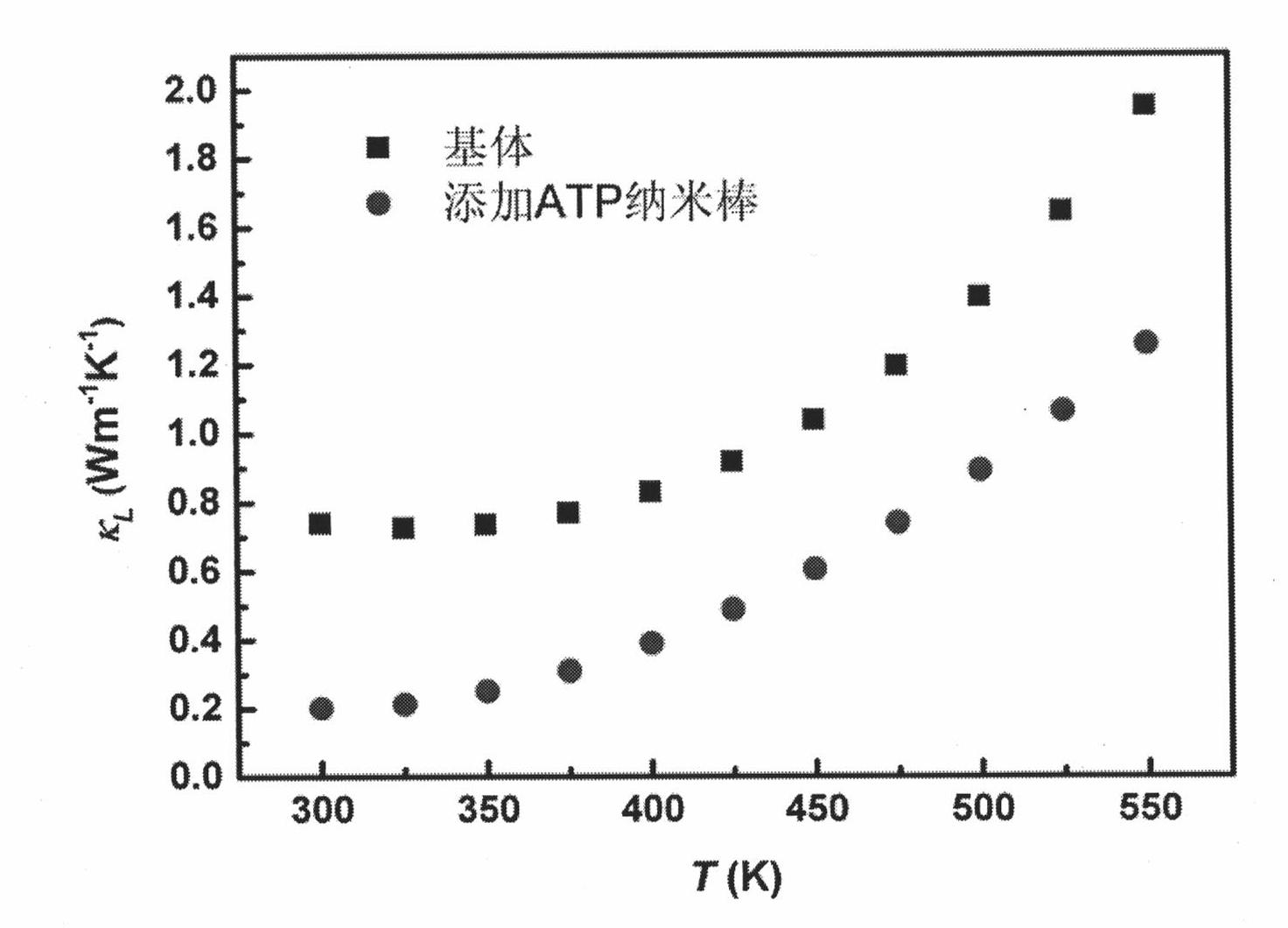

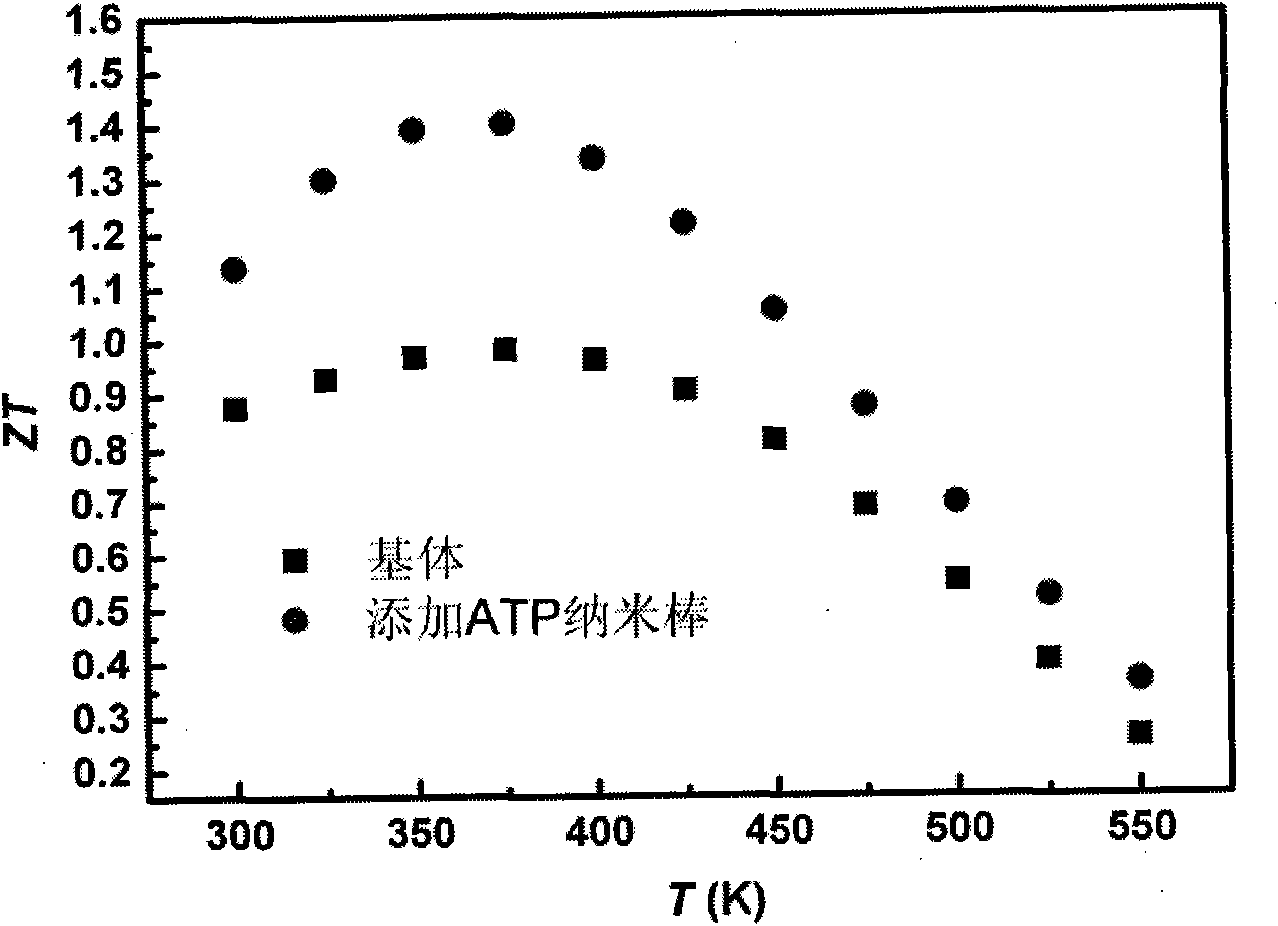

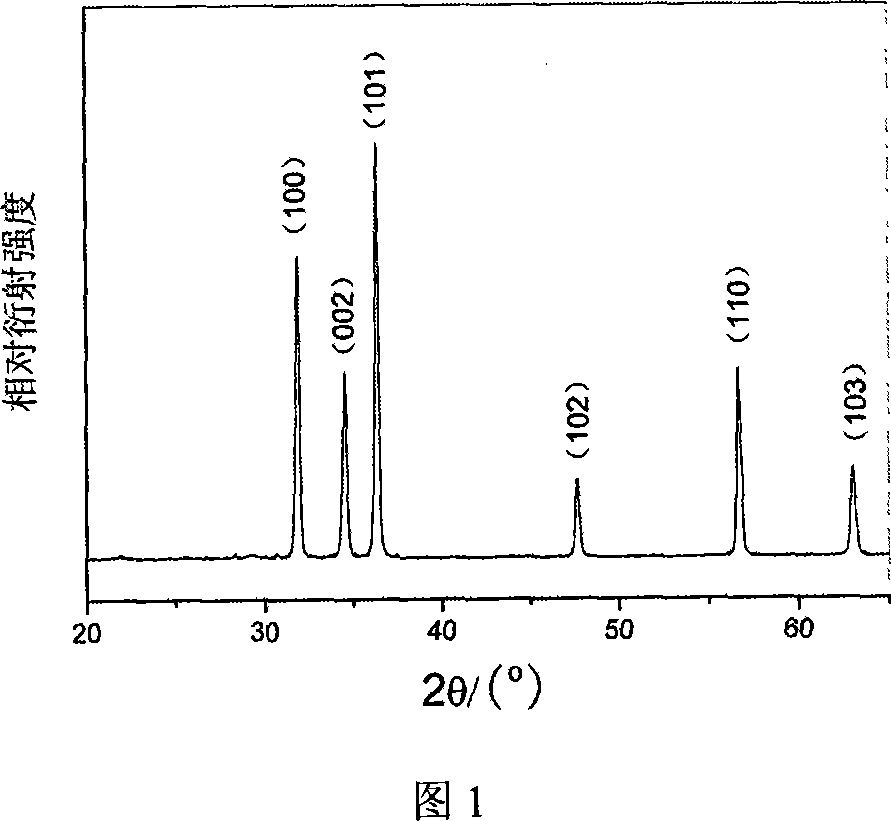

Nanophase doped bismuth telluride-based thermoelectric material and preparation method thereof

ActiveCN101994155ALower lattice thermal conductivityReduced lattice thermal conductivity κ

<sub>L</sub>Polycrystalline material growthBy zone-melting liquidsBismuth tellurideCarbon nanotube

The invention discloses a nanophase doped bismuth telluride-based thermoelectric material and a preparation method thereof. The bismuth telluride-based thermoelectric material is characterized in taking the bismuth telluride-based thermoelectric material containing a tellurium element, a bismuth element and a doped chemical element, as a matrix. The doped nanophase is a one-dimensional nanophase,and the weight of the one-dimensional nanophase accounts for 0.01-5 percent of the weight of the matrix. Attapulgite or a zinc oxide nanowire or a single-wall carbon nanotube or a multi-wall carbon nanotube is preferable to the one-dimensional nanophase. Compared with the prior art, in the bismuth telluride-based thermoelectric material, the lattice heat conductivity within the whole temperature zone range is reduced, thereby a ZT value is greatly improved and the thermoelectric performance of the bismuth telluride-based thermoelectric material is improved. The preparation method is simple and easy to implement, and compared with other methods of balling milling or liquid phase and the like, impurities are not easy to introduce in the preparation method so that the one-dimensional nanophase is evenly staggered and distributed in the matrix and the mechanical property of the material is effectively improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

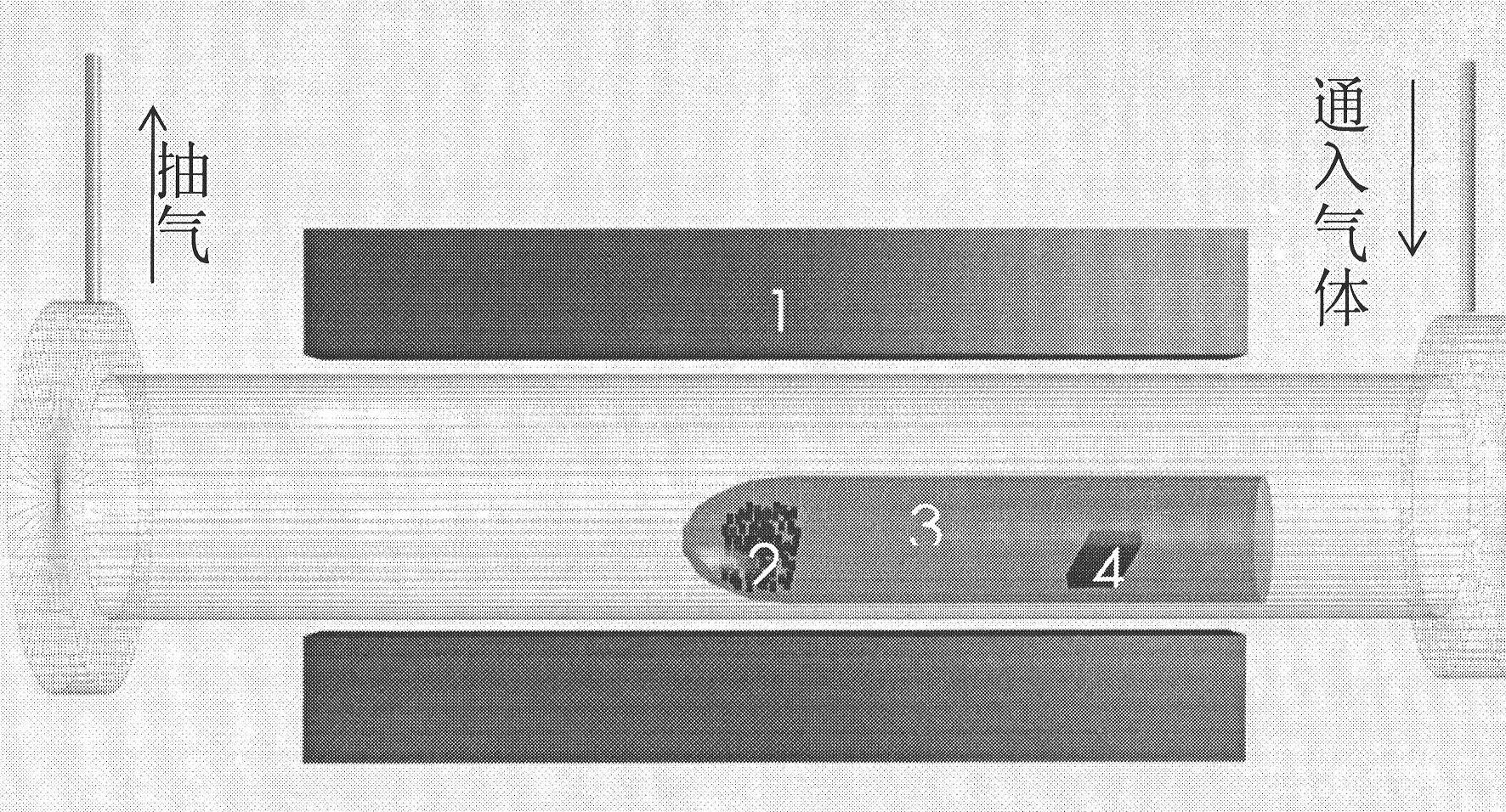

Preparation method of tin mixed with zinc oxide nanowire

InactiveCN101045553AHigh purityIncrease productionNanostructure manufactureZinc oxides/hydroxidesPowder mixtureCleansing Agents

A process for preparing the Sn doped zinc oxide nanowires includes such steps as flushing the Si substrate by detergent, proportionally mixing ZnO powder, SnO powder and C powder by ball grinding, putting said substrate and powder mixture in a ceramic crucible, loading it in a quartz tube of tubular furnace, filling the mixture of argon gas and O2, heating at 850-950 deg.C while reacting, and cooling.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of zinc oxide nanowire array/ foamy graphene composite material and application thereof

InactiveCN103558273AImprove bindingHigh sensitivityZinc oxides/hydroxidesGrapheneHydrothermal synthesisCvd graphene

A preparation method of a zinc oxide nanowire array / foamy graphene composite material and an application thereof relate to a preparation method of a composite material and an application thereof. The invention aims to solve technical problems of low sensitivity and high limit of detection when a present material is applied in L-dopa detection. The preparation method provided by the invention comprises: 1, a chemical vapor deposition method; and 2, a hydrothermal synthesis method. The zinc oxide nanowire array / foamy graphene composite material can be used as an electrode material to detect L-dopa. The preparation method is mainly used in preparation of the zinc oxide nanowire array / foamy graphene composite material.

Owner:HARBIN UNIV OF SCI & TECH

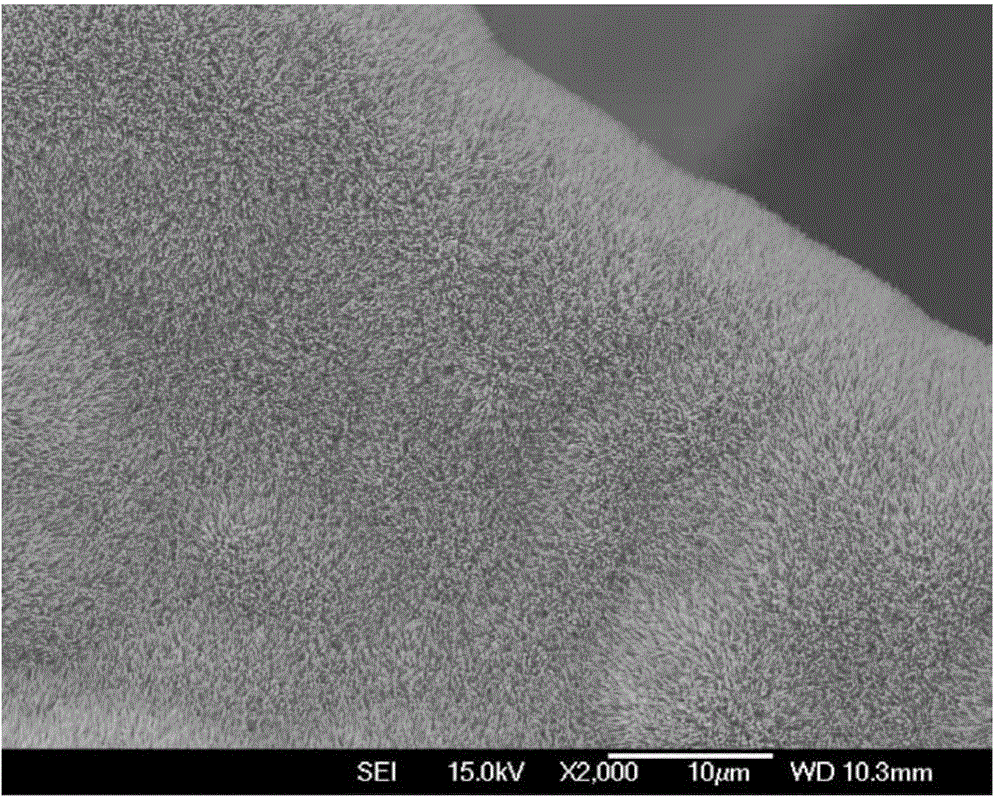

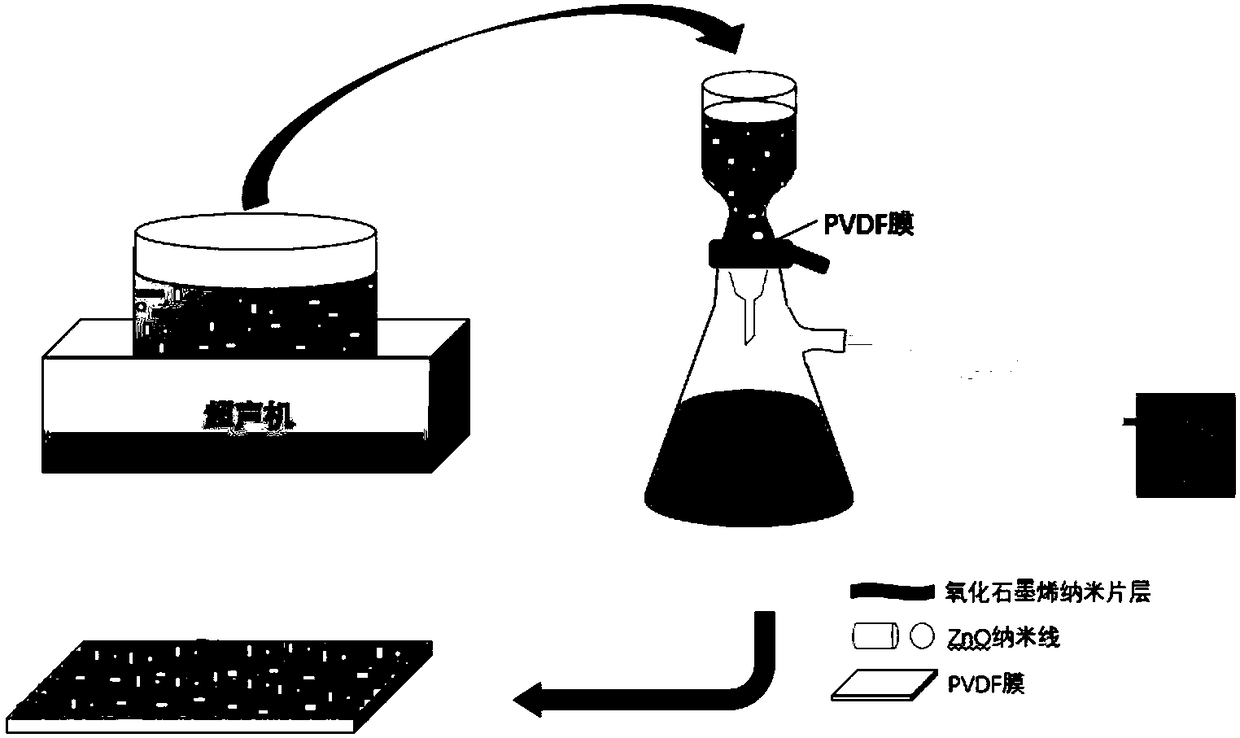

Antipollution self-cleaning GO/ZnO-PVDF film and preparation method thereof

ActiveCN108722206AEasy to operateMaterials are readily availableMembranesSemi-permeable membranesGrapheneZinc oxide nanowire

The invention discloses a preparation method of an antipollution self-cleaning GO / ZnO-PVDF film. The method comprises the following steps: adding graphene oxide nanosheet layer solid powder into deionized water, ultrasonically dispersing to form a homogenous graphene oxide dispersion solution; adding zinc oxide nanowire into the graphene oxide dispersion solution, performing ultrasonic treatment,so that the nano material is completely dispersed and uniformly mixed with the GO nanosheet layer; and suction filtering the nano material suspension onto a diaphragm by utilizing a vacuum suction filtering apparatus and adopting a PVDF filter film as a substrate film layer, and vacuum drying, thus obtaining the GO / ZnO-PVDF film. The prepared GO / ZnO-PVDF film has efficient self-cleaning performance, can rapidly degrade surface oily pollutants under the illumination of the ultraviolet rays, and is simple in operation and easy in industrialized production.

Owner:TONGJI UNIV

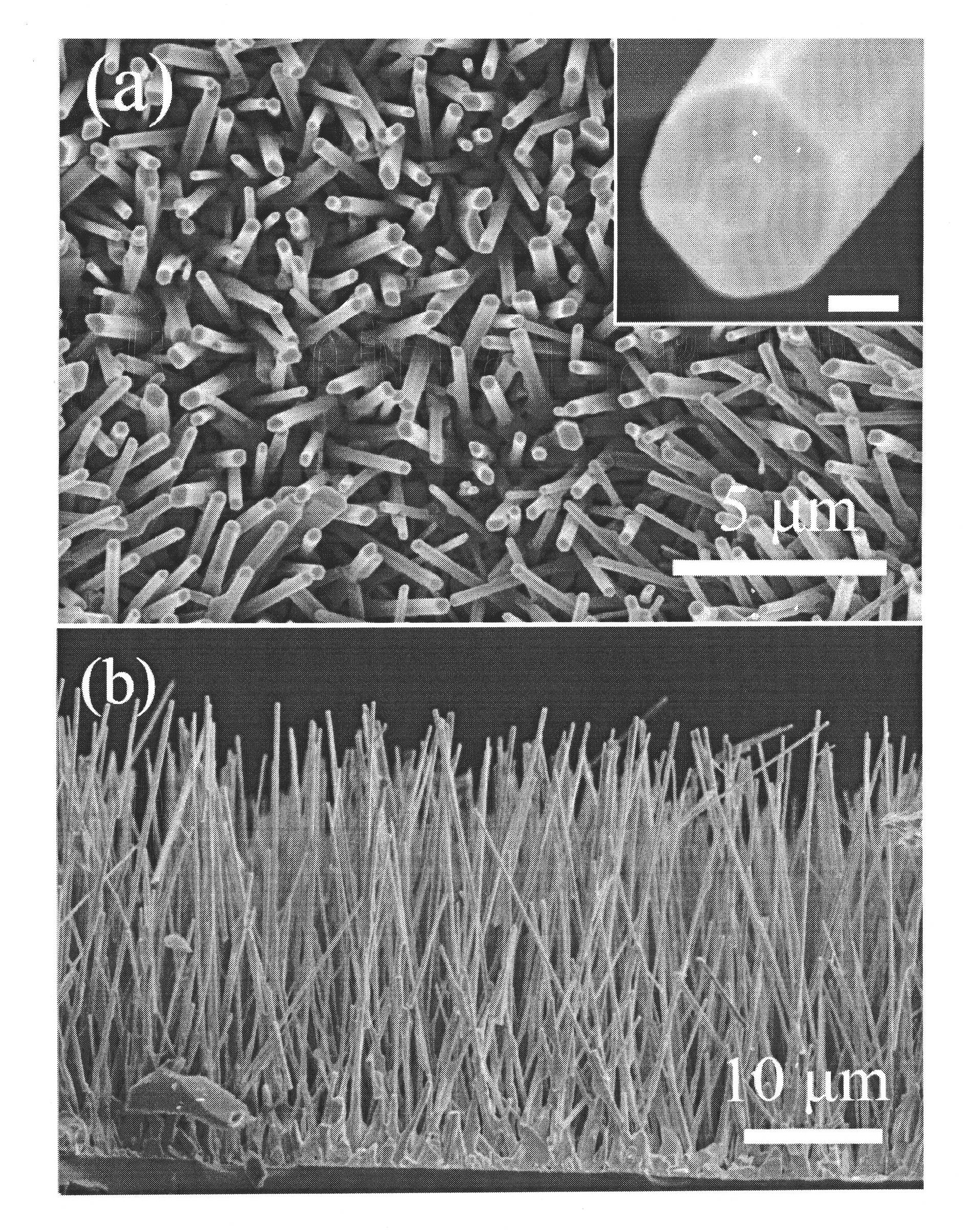

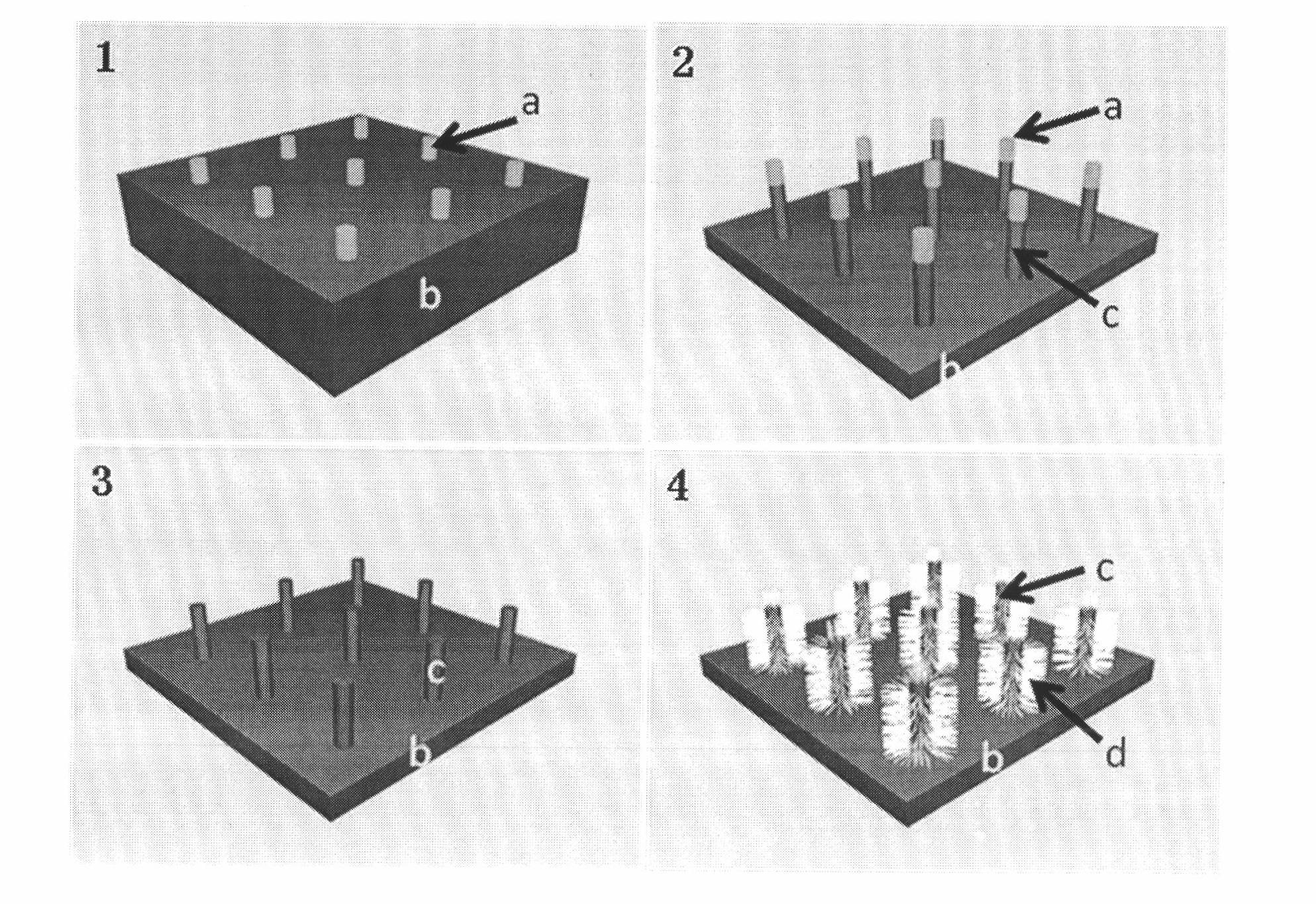

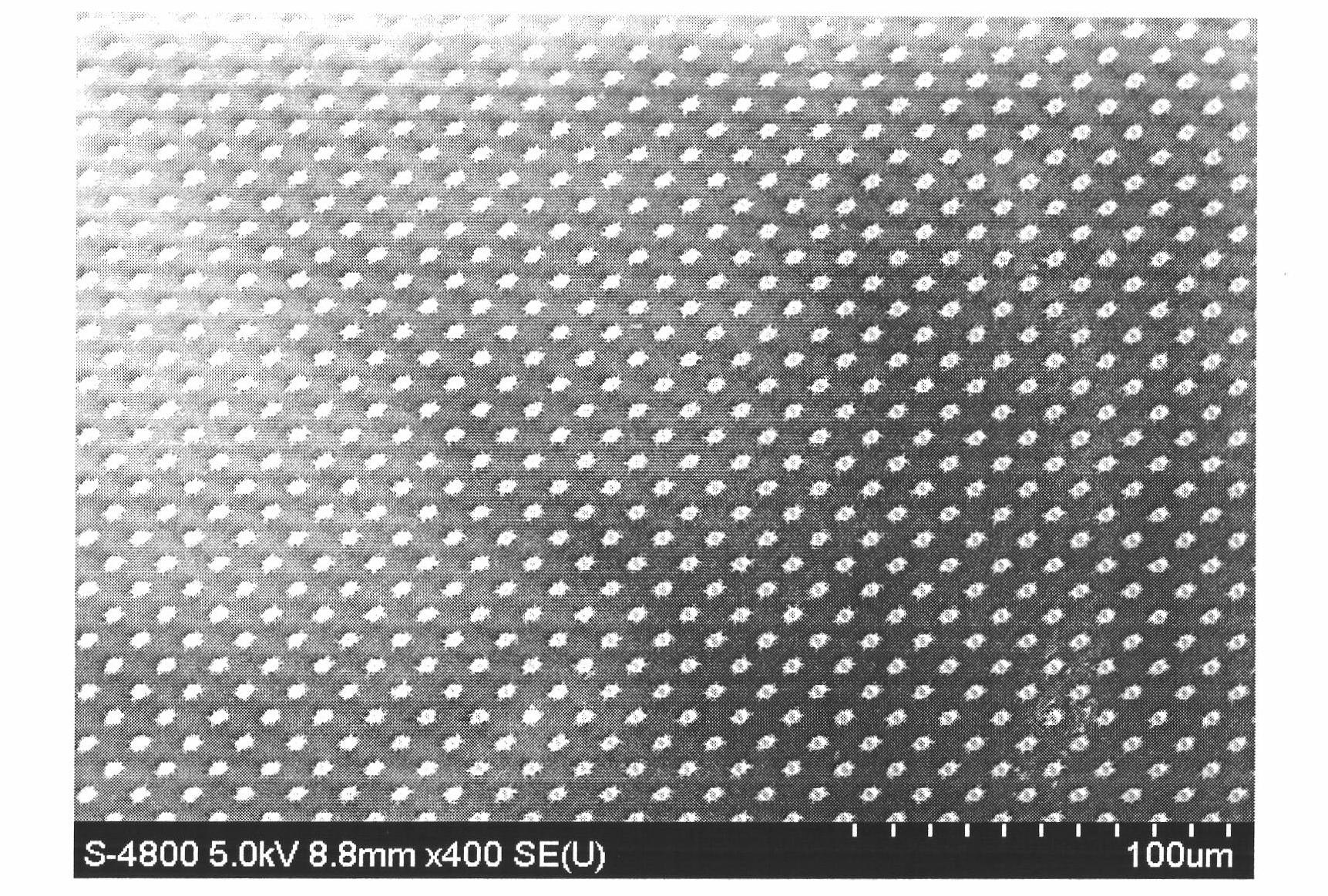

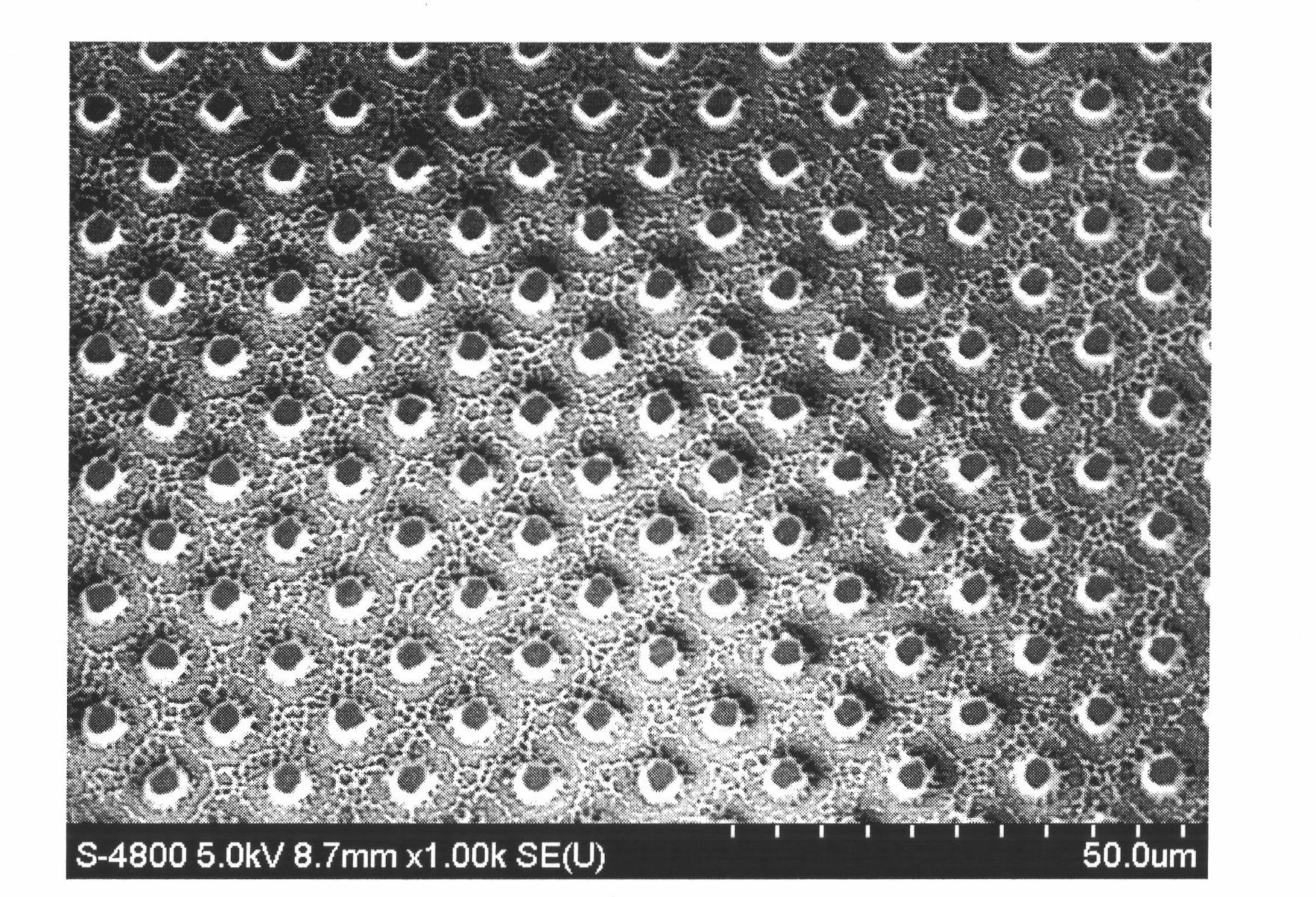

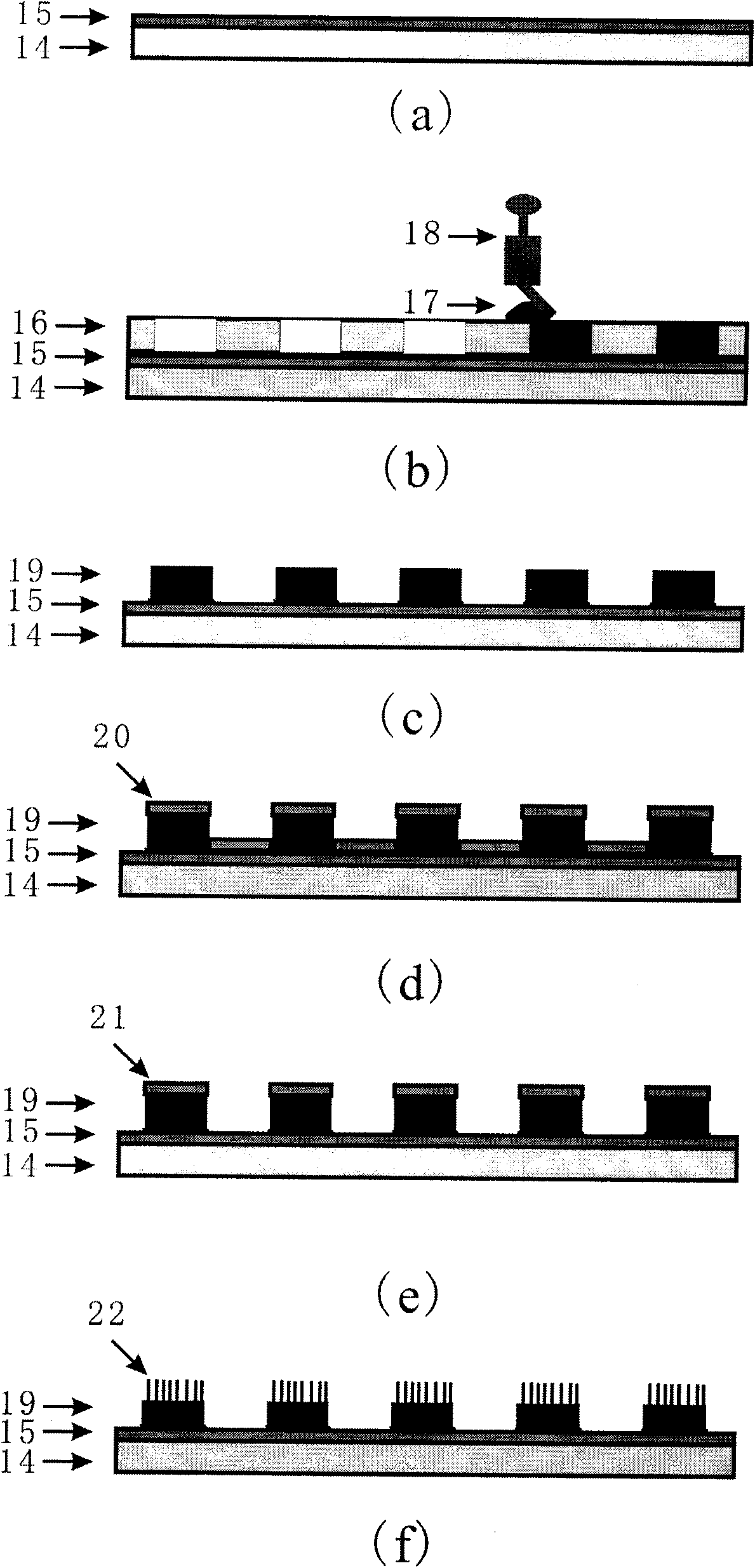

Preparation method of super-hydrophobic surface

InactiveCN102553812AGood mechanical propertiesNot easy to damagePolycrystalline material growthFrom normal temperature solutionsProtein secondary structureOptoelectronics

The invention discloses a method for preparing a super-hydrophobic surface on a surface of a random high molecular material, particularly a high molecular membrane material. The method comprises preparing a cylindrical array first stage structure on the surface of a random high molecular substrate by using a method of surface etching, wherein the cylindrical array is made of a material same as the material of the substrate; further depositing a zinc oxide seeding layer on the surface of the cylindrical array first stage structure; afterwards putting the substrate into a growth liquid in a growing zinc oxide nano-line array, then a second stage structure of the growing zinc oxide nano-line array grows from the surface of the first stage structure; dipping the high molecular substrate prepared with the first and the second stage structures into a solution with hydrophobic substances; after the surfaces of the first and second stage structures of the high molecular substrate are materialized together with the hydrophobic substances, taking out the high molecular substrate, and drying to obtain the desired super-hydrophobic surface.

Owner:LANZHOU UNIVERSITY

Method for growing nanometer zinc oxide structure through low-temperature heating of zinc and catalyst and application thereof

The invention provides a method for growing a nanometer zinc oxide structure through the low-temperature heating of zinc and a catalyst and application thereof. The method comprises the following steps (1) cleaning an underlayer to remove impurities on the underlayer; (2) depositing a zinc layer on the underlayer; if the positioning growth is needed, preparing the zinc layer on the surface of the underlayer by a screen printing method, a spin-coating photolithography method or other positioning deposition methods in a positioning mode; (3) preparing a catalyst layer on the zinc layer; and (4) heating the underlayer to a temperature of more than 250 DEG C in an oxygenous atmosphere at a speed of temperature rise of between 2 and 50 DEG C per minute; and keeping the underlayer for 10 minutes to 5 hours at the set temperature; and finally cooling the underlayer. As the zinc and the catalyst can be accurately positioned and placed in advance, the method is conveniently applied to the accurate positioning preparation of a zinc oxide nanowire and a nanometer sharp needle array. As the temperature can be lower than 650 DEG C, the preparation can be carried out on glass and other underlayers to realize the zinc oxide nanowire and the nanometer sharp needle array with low-cost preparation and large-dimension accurate positioning.

Owner:SUN YAT SEN UNIV

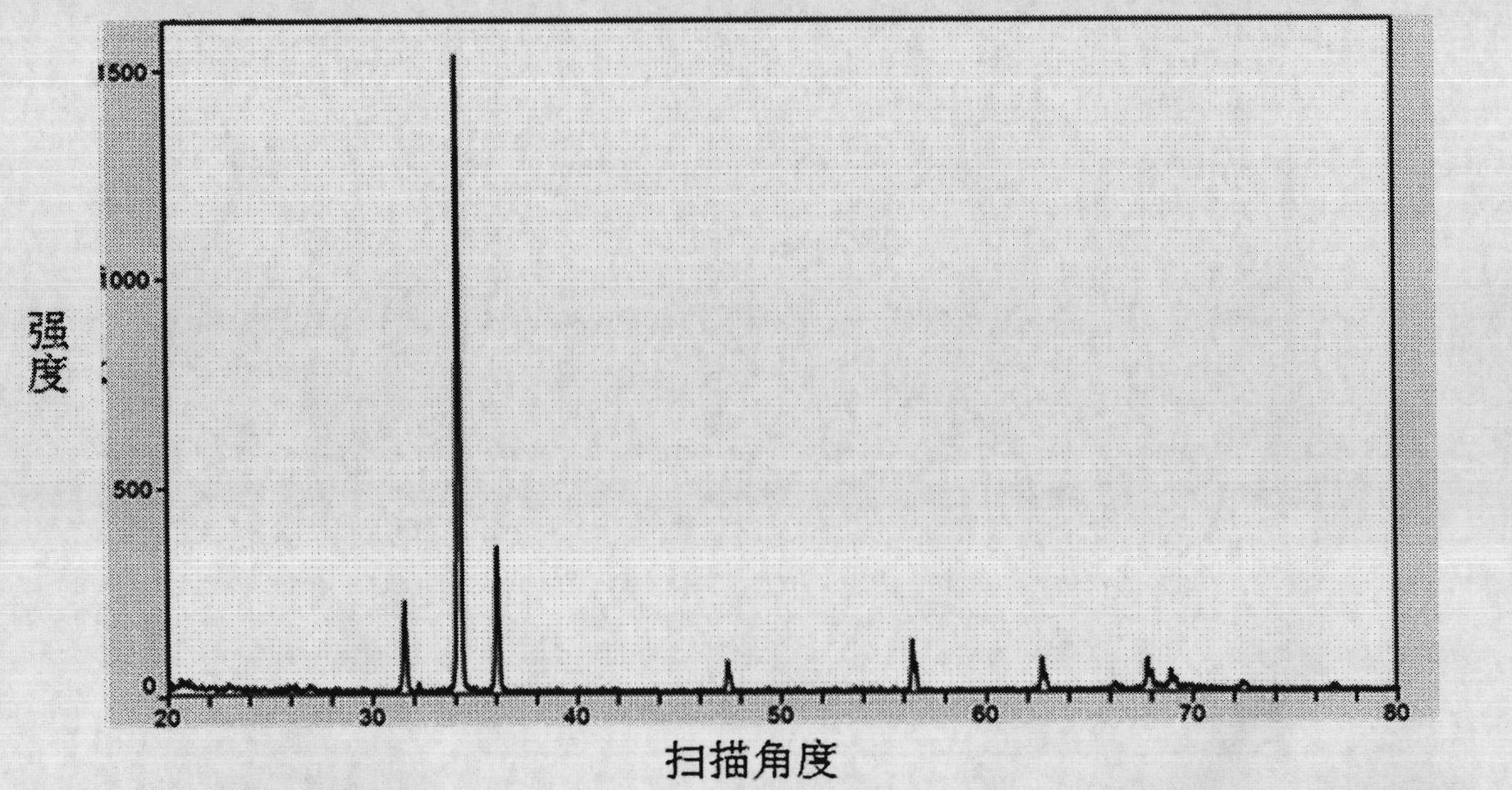

An ethanol sensor based on a zinc oxide nanometer structure and a preparing method thereof

ActiveCN104698041AHigh sensitivityShort response timeMaterial resistanceEthanol absorptionResponsivity

An ethanol sensor based on a zinc oxide nanometer structure and a preparing method thereof are provided. The ethanol sensor comprises two electrode groups forming an interdigitated electrode and a zinc oxide nanometer film on at least one side surface of the interdigitated electrode. The zinc oxide nanometer film is formed by zinc oxide nanowires having a hexagonal wurtzite crystal phase. The two electrode groups of the interdigitated electrode are not conducted and form signal output ends of the ethanol sensor. The ethanol sensor can sense resistance reduction on the zinc oxide surface caused by ethanol absorption. The responsivity of the ethanol sensor is in approximate linear variation with the concentration of added ethanol gas in the environment.

Owner:纳米新能源生命科技(唐山)有限责任公司

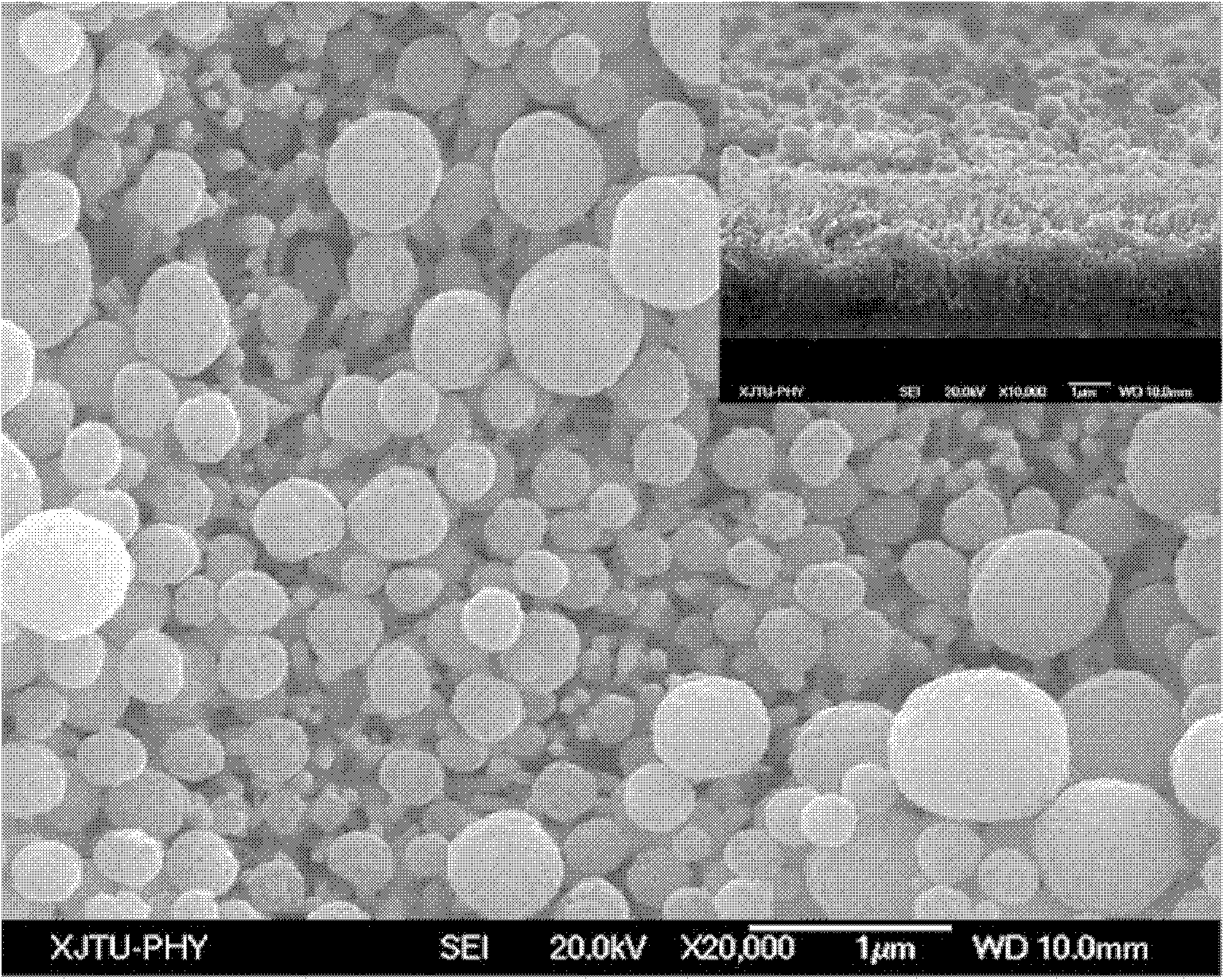

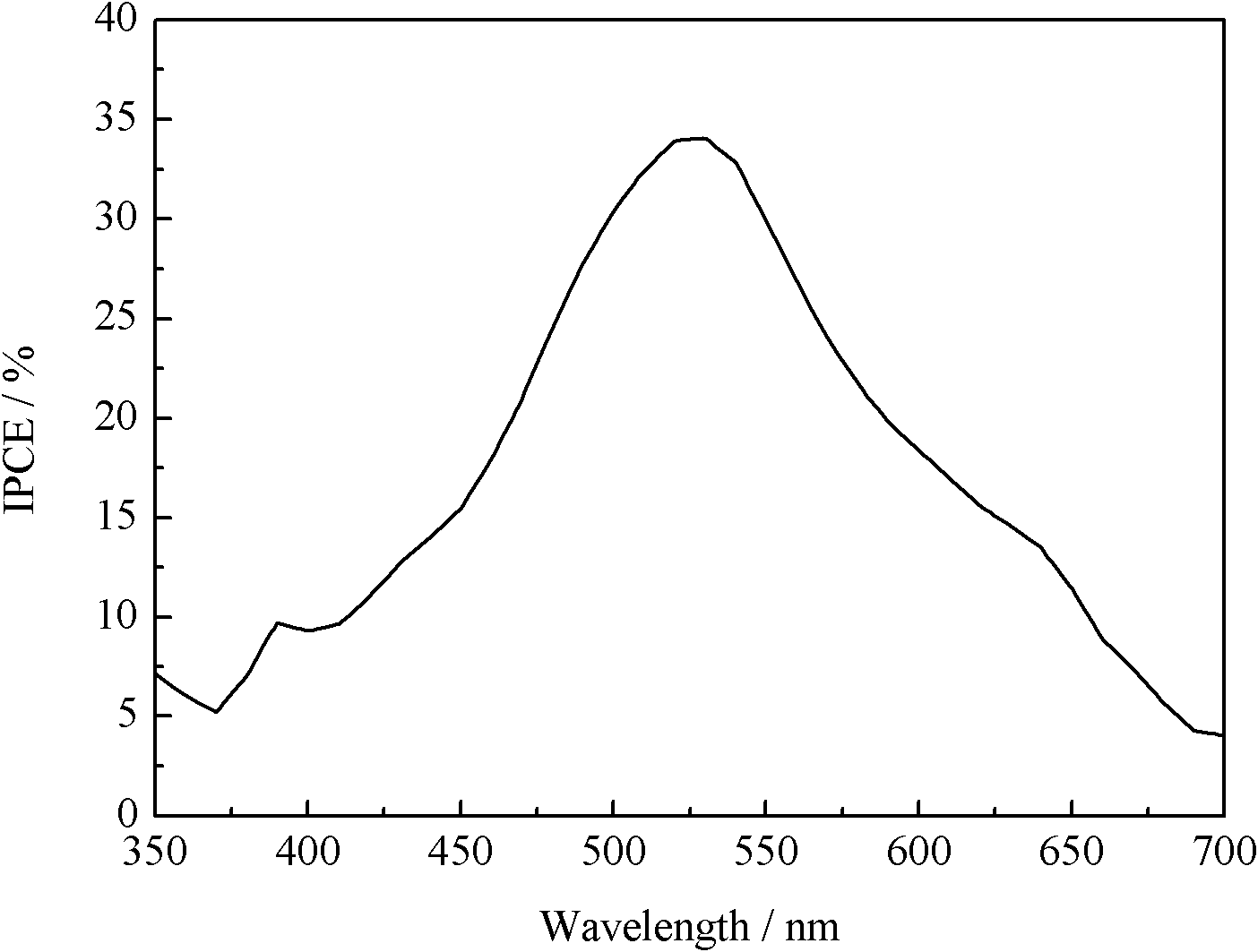

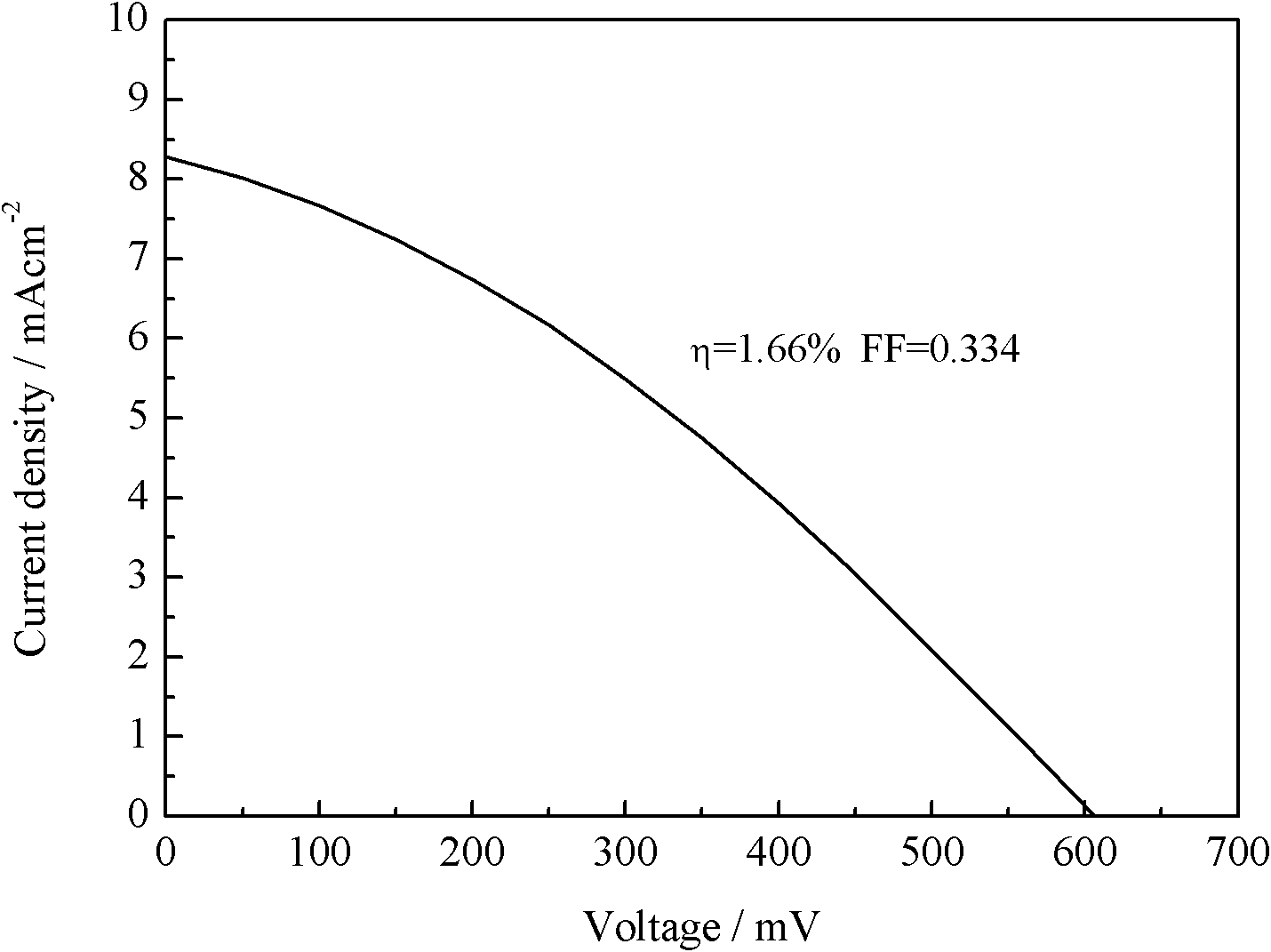

Method for preparing dye-sensitized solar cell compound light anode with zinc oxide nanometer structure

InactiveCN101800130ALower synthesis costSimple process requirementsLight-sensitive devicesFinal product manufactureDye absorptionMicrosphere

The invention relates to a method for preparing a dye-sensitized solar cell compound light anode with a zinc oxide nanometer structure, which adopts a one-dimensional zinc oxide nanowire array as an electronic transport layer, and a layer of multi-dispersed system zinc oxide microspheres is coated on the electronic transport layer and is used as a dye absorption and light scattering layer. The method comprises the following steps of: firstly, depositing a zinc oxide film on a FTO glass sheet by utilizing the sol-gel technology; secondly, growing a zinc oxide nanowire array on the zinc oxide film by adopting the hydrothermal self-assembly growth technology; and finally, coating a layer of multi-dispersed system zinc oxide microspheres grown by collochemistry self-assembly on the zinc oxide nanowire array to prepare the compound light anode with the zinc oxide nanometer structure, which has the advantages of low cost, simple process requirement, good repeatability, capability of performing large-scale preparation and high specific surface and light scattering properties.

Owner:XI AN JIAOTONG UNIV

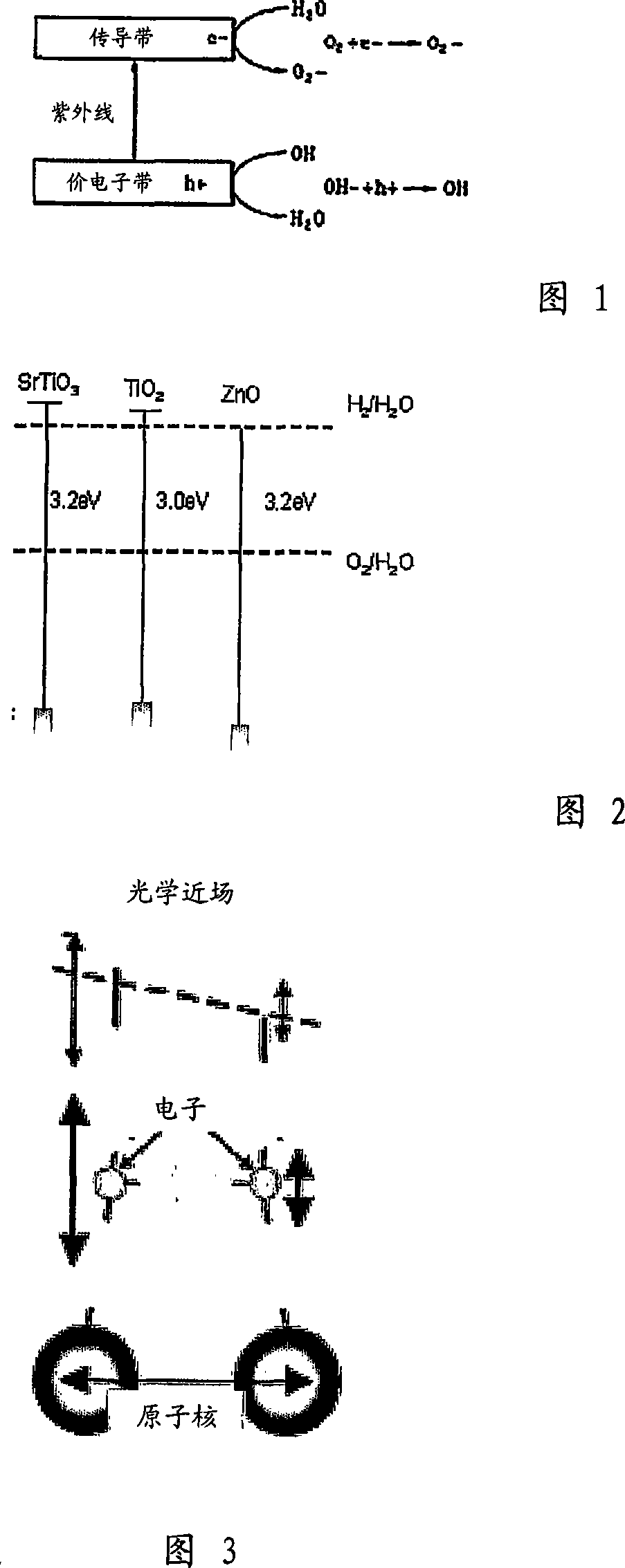

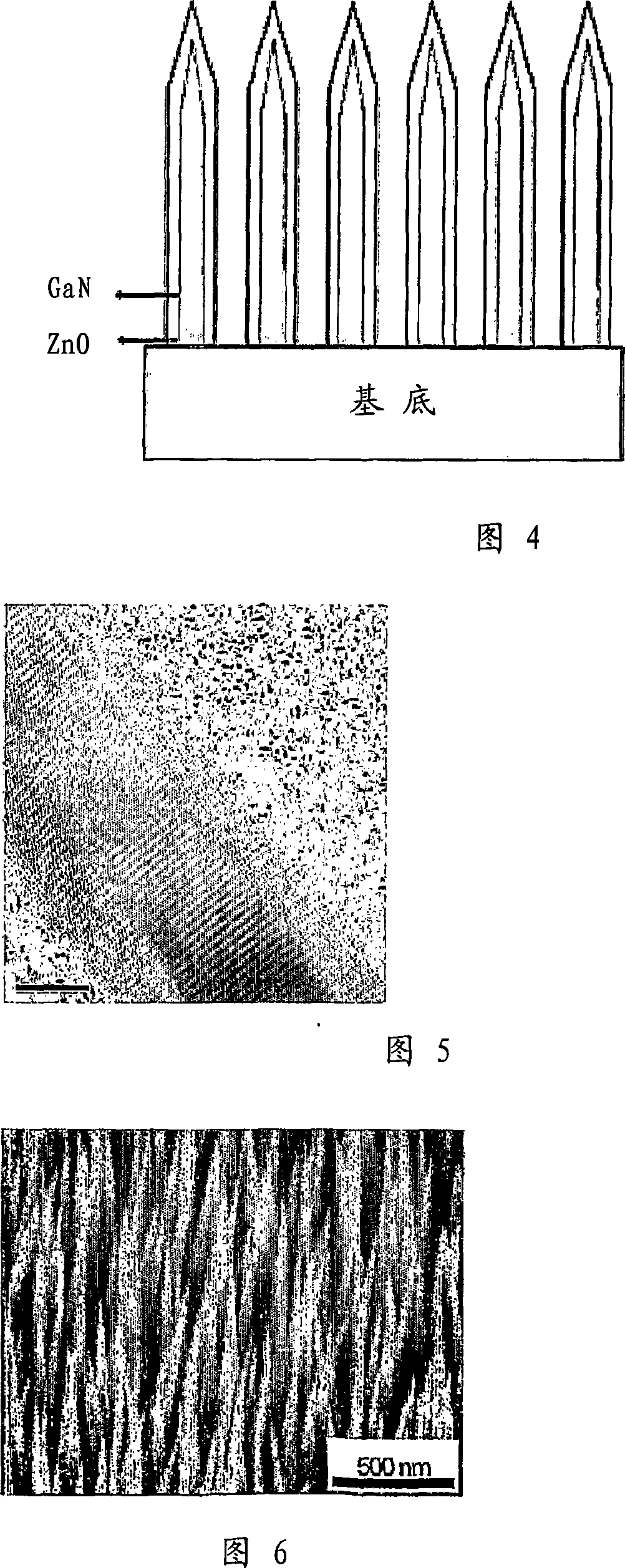

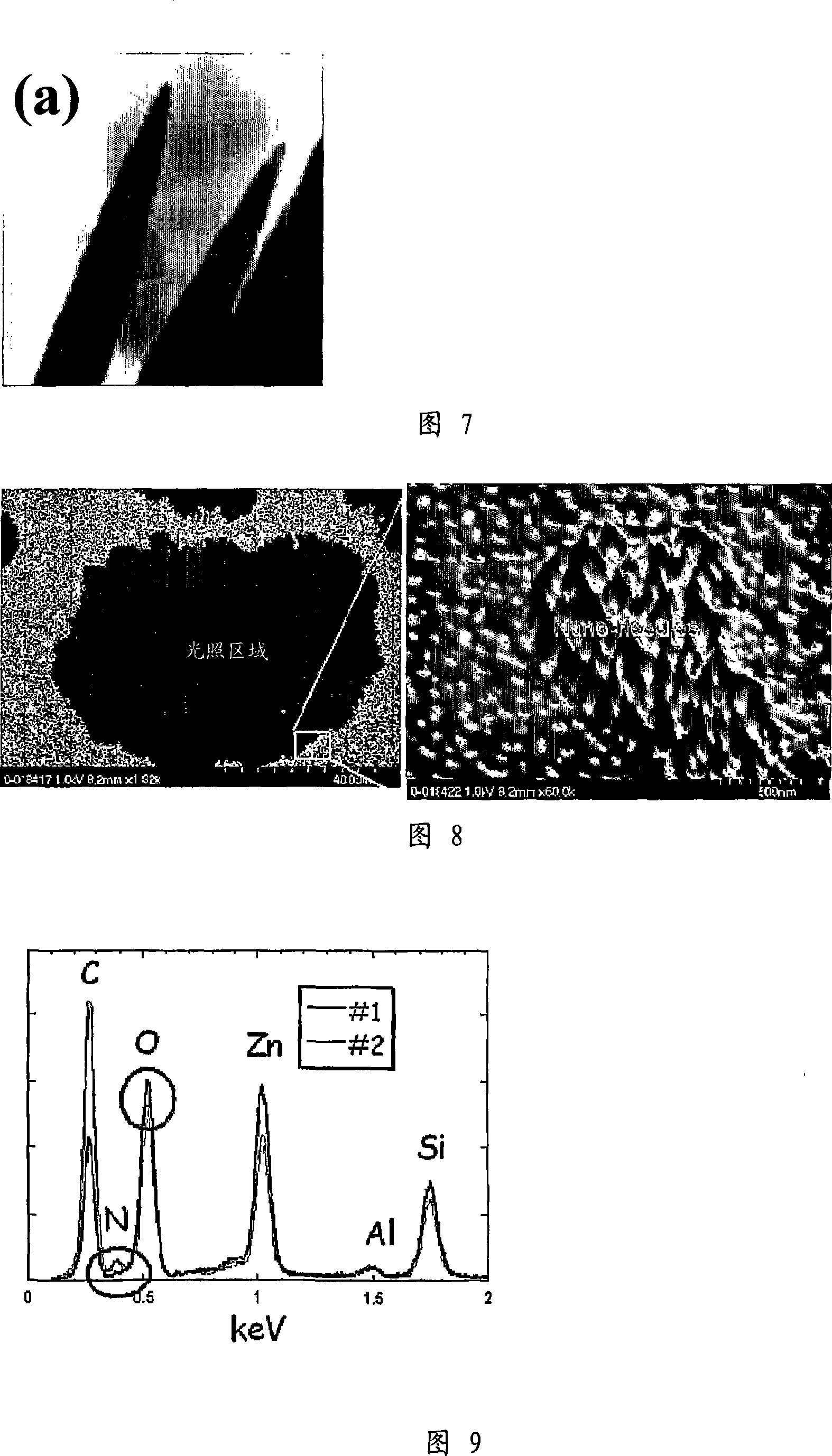

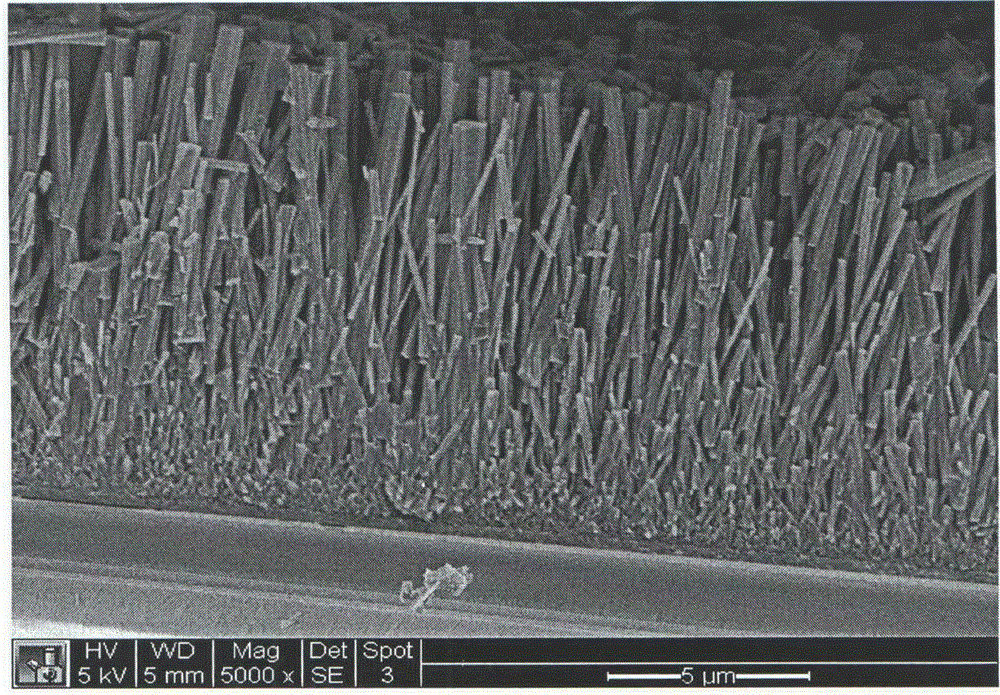

Near-field photocatalyst containing zinc bloom nanometer line

InactiveCN101252988ALow costSimplify production stepsNanostructure manufactureMetal/metal-oxides/metal-hydroxide catalystsOvervoltagePlatinum

Disclosed is a near-field photocatalyst using a ZnO (ZnO) nanowire. The photocatalyst is advantageous in that low-priced zinc is used instead of titanium, conventionally used as a photocatalyst to reduce expenses, and that it is possible to obtain overvoltage which is sufficient to generate hydrogen using an optical near field formed around an end of a ZnO nanowire without the application of additional extenal voltage, thus the use of a costly electrode, such as platinum, is avoided and a process is simplified.

Owner:POHANG UNIV OF SCI & TECH +1

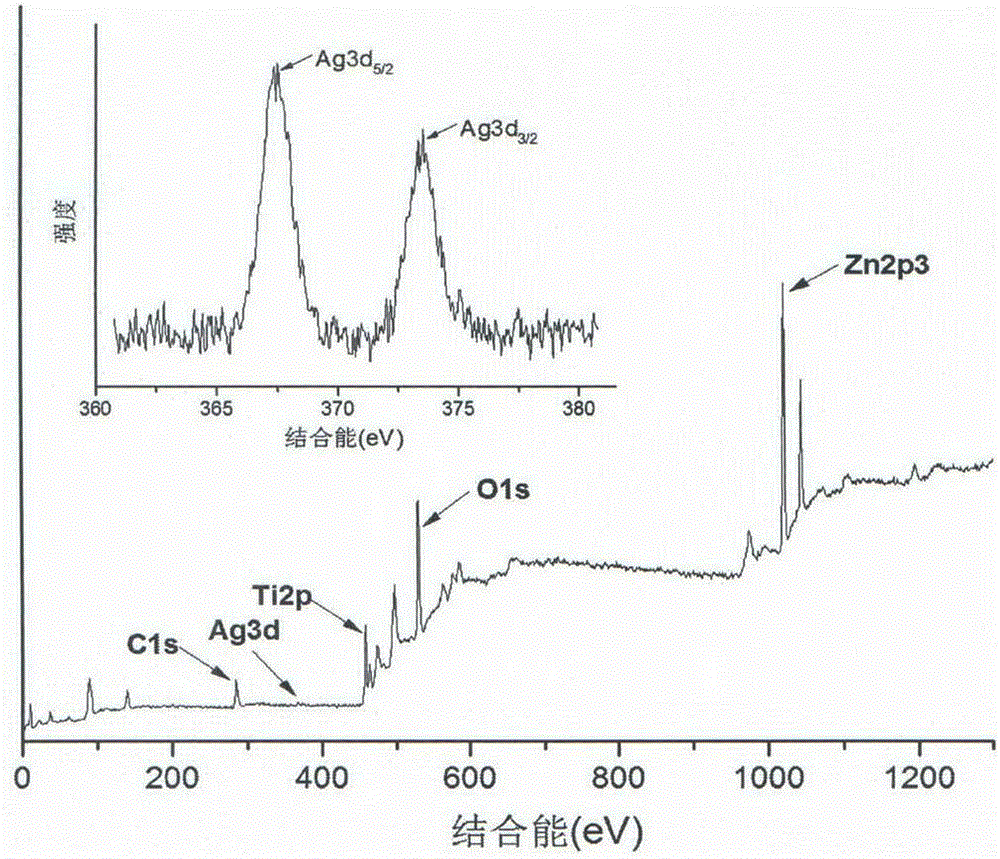

ZnO nano-wire array synergistically modified by nano-Ag and TiO2 and preparation method of zinc oxide nano-wire array

InactiveCN105336501ALarge specific surface areaImprove adsorption capacityLight-sensitive devicesPhotovoltaic energy generationElectronic transmissionSolar cell

The invention relates to a ZnO nano-wire array synergistically modified by nano-Ag and TiO2 and a preparation method of the zinc oxide nano-wire array. The structure of the array is as follows: a ZnO nano-wire is taken as an inner core, nano-Ag is loaded on the surface of the ZnO nano-wire, a TiO2 film is modified at the outermost part of the nano-Ag, wherein the length of the ZnO nano-wire array is 10mum, the thickness of the TiO2 film is 5-10nm. The preparation method comprises the following steps: the ZnO nano-wire array is prepared by a hydro-thermal method, AgNO3 solution is taken as a precursor, nano-Ag is loaded on the surface of the ZnO nano-wire array by an illumination reduction method, then the ZnO nano-wire array is put into mixed solution of Ammonium hexafluorotitanate and boric acid, and the TiO2 film is formed on the surface of the array by an immersion method. The structure has the main purpose that the ZnO nano-wire modified by Ag inside a nanocable can be taken as an expressway for electronic transmission, and the light absorption is enhanced by utilizing the Ag surface plasmon resonance effect. The preparation method has the advantages that the cost is low, the process is controllable, and the repeatability is good, therefore, the preparation method can be applied to photo anode materials of a solar cell and can be also utilized in the photocatalysis field.

Owner:SHIHEZI UNIVERSITY

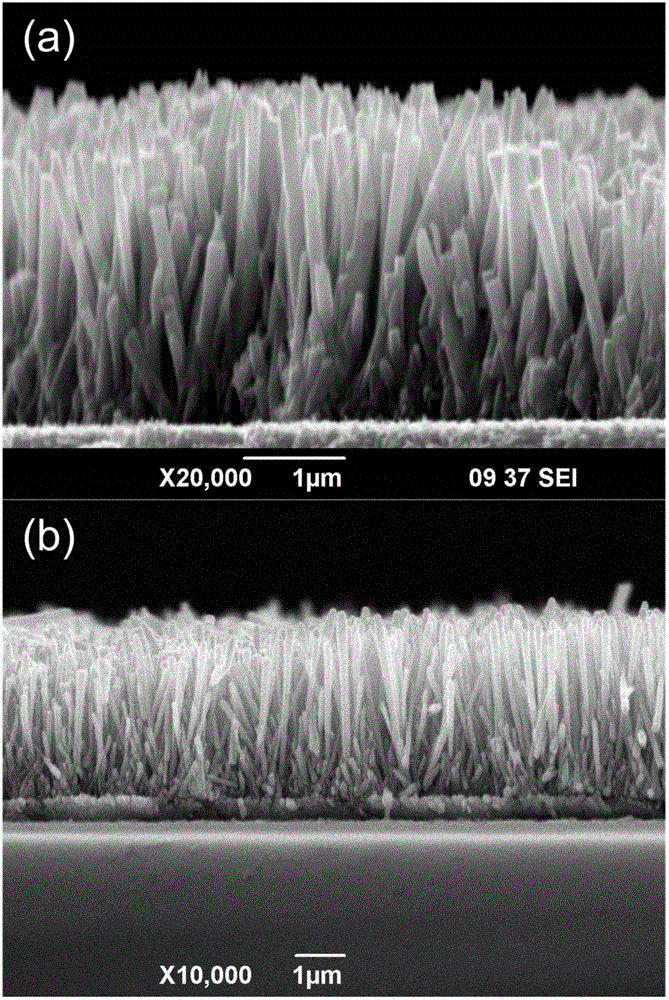

Preparation method of composite nanowire array with one-dimensional ZnO(zinc oxide)-TiO2(titanium dioxide) core-shell structure

InactiveCN102723208AImprove efficiencyLow environmental requirementsLight-sensitive devicesPhotovoltaic energy generationAtomic layer depositionZno nanowires

A preparation method of a composite nanowire array with a one-dimensional ZnO(zinc oxide)-TiO2(titanium dioxide) core-shell structure. In the whole preparation process, a wet chemistry method is adopted. The preparation method comprises the following steps: at first, a ZnO seed layer is prepared on conductive glass in a sol-gel method, then a ZnO nanowire array is grown on the seed layer in a liquid-phase deposition method, and next a TiO2 shell layer is prepared on a ZnO nanowire array in a circulating adsorption reaction method, so as to obtain the composite nanowire array with the one-dimensional ZnO-TiO2 core-shell structure. The preparation method has the advantages that (1) compared with the other methods (such as a chemical meteorology deposition method, an atom layer deposition method and a magnetron sputtering method), the preparation method has a simple process, does not require complex equipment and severe environments, and is low in cost; (2) the preparation method can control the diameter and the length of the ZnO nanowire and the thickness of the TiO2 shell layer conveniently; and (3) the preparation method can be combined with a photoanode preparation method of a quantum dot dye-sensitized solar cell conveniently to facilitate the research of the cell performance.

Owner:XI AN JIAOTONG UNIV

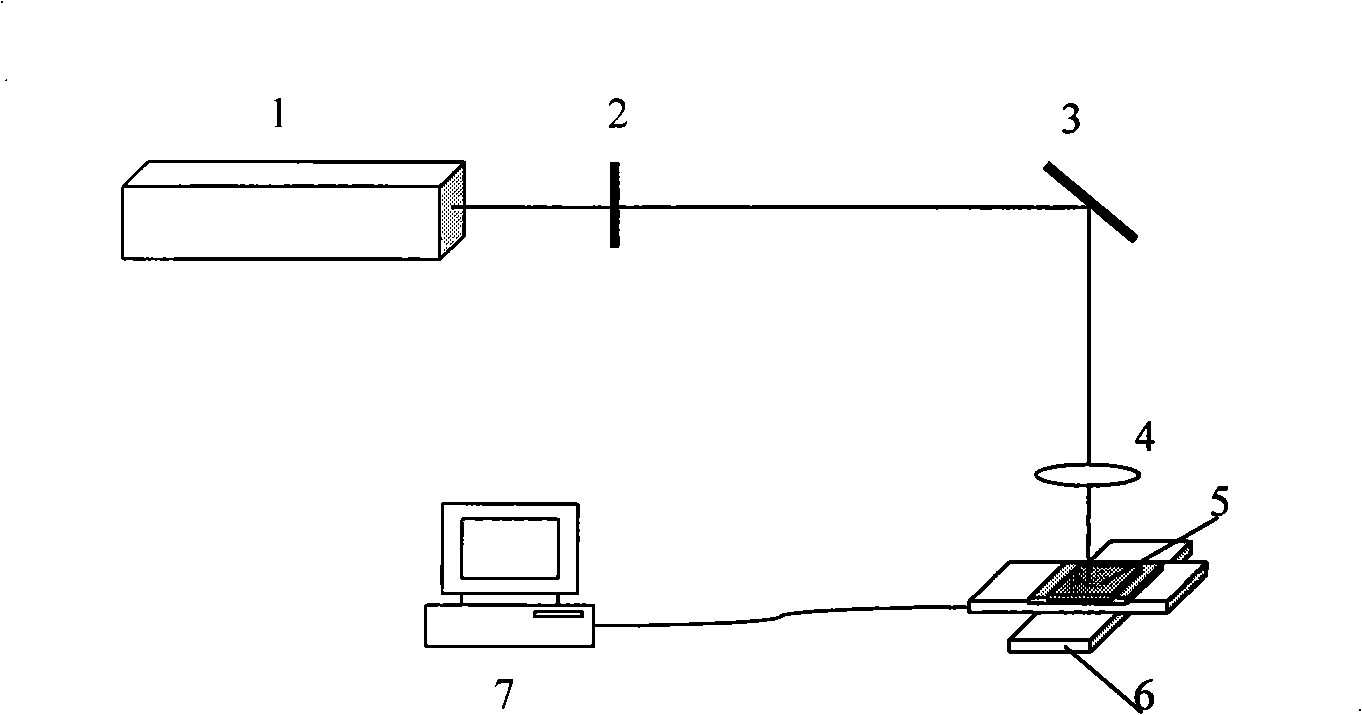

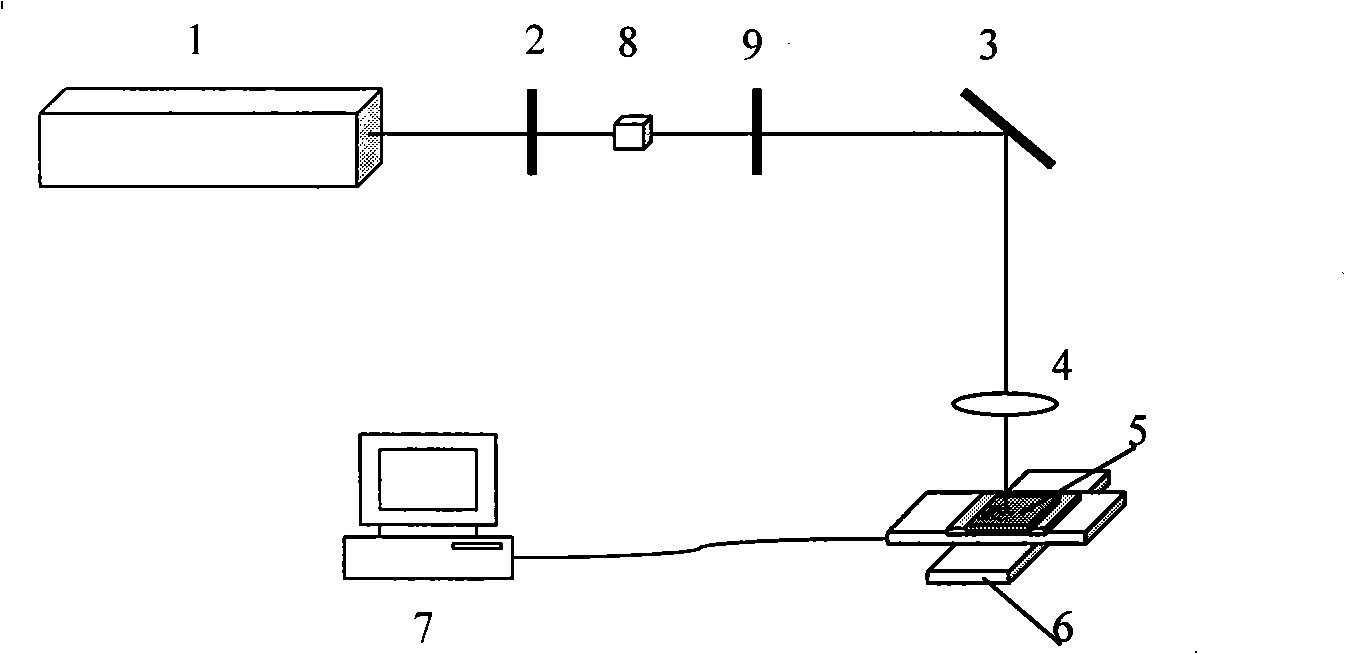

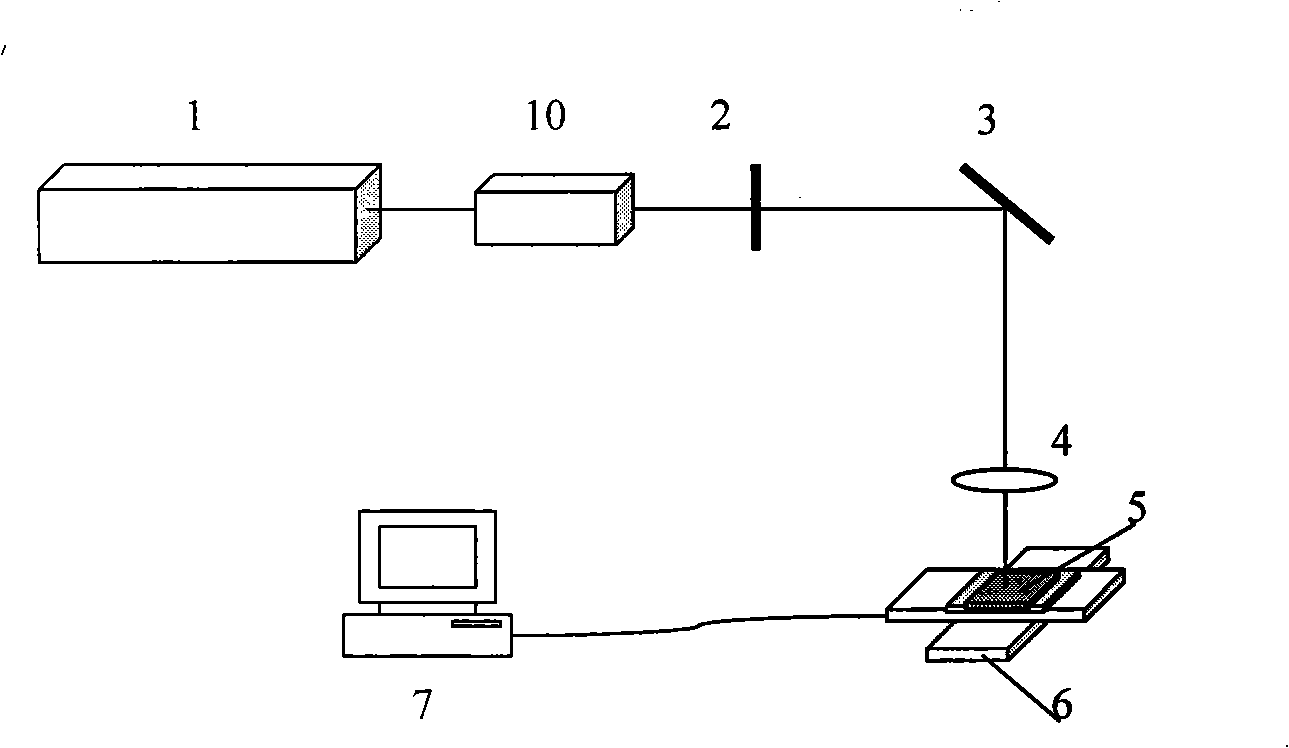

Process for preparing zinc oxide nanometer wire array by femtosecond laser and device thereof

InactiveCN101311358AImprove uniformityReduce consumptionPolycrystalline material growthSingle crystal growth detailsMaterials preparationOptoelectronics

The invention discloses a method for preparing a zinc oxide nanowires array by femtosecond laser and a device thereof, which belongs to technical fields of micro nanophase material preparation and femtosecond laser micro processing, relates to a periodical nanometer microstructure of zinc oxide material, and particularly provides a method for preparing a periodical nanowires array on the target of the zinc oxide by means of a femtosecond laser radiation field. When the zinc oxide nanowires array is prepared, zinc oxide target material is first fixed on a two-dimensional accurate displacement station, and then a bunch of light femtosecond laser is focalized by a lens to act on the zinc oxide target material; by a coordinated scan of femtosecond induction and the two-dimensional accurate displacement station, the zinc oxide periodical nanowires array is generated. The method for preparing the zinc oxide nanowires array by the femtosecond laser and the device thereof have the advantages that the preparation efficiency is high; the application scope is wide; the zinc oxide nanowires array processed and obtained is neatly and evenly arrayed.

Owner:XI AN JIAOTONG UNIV

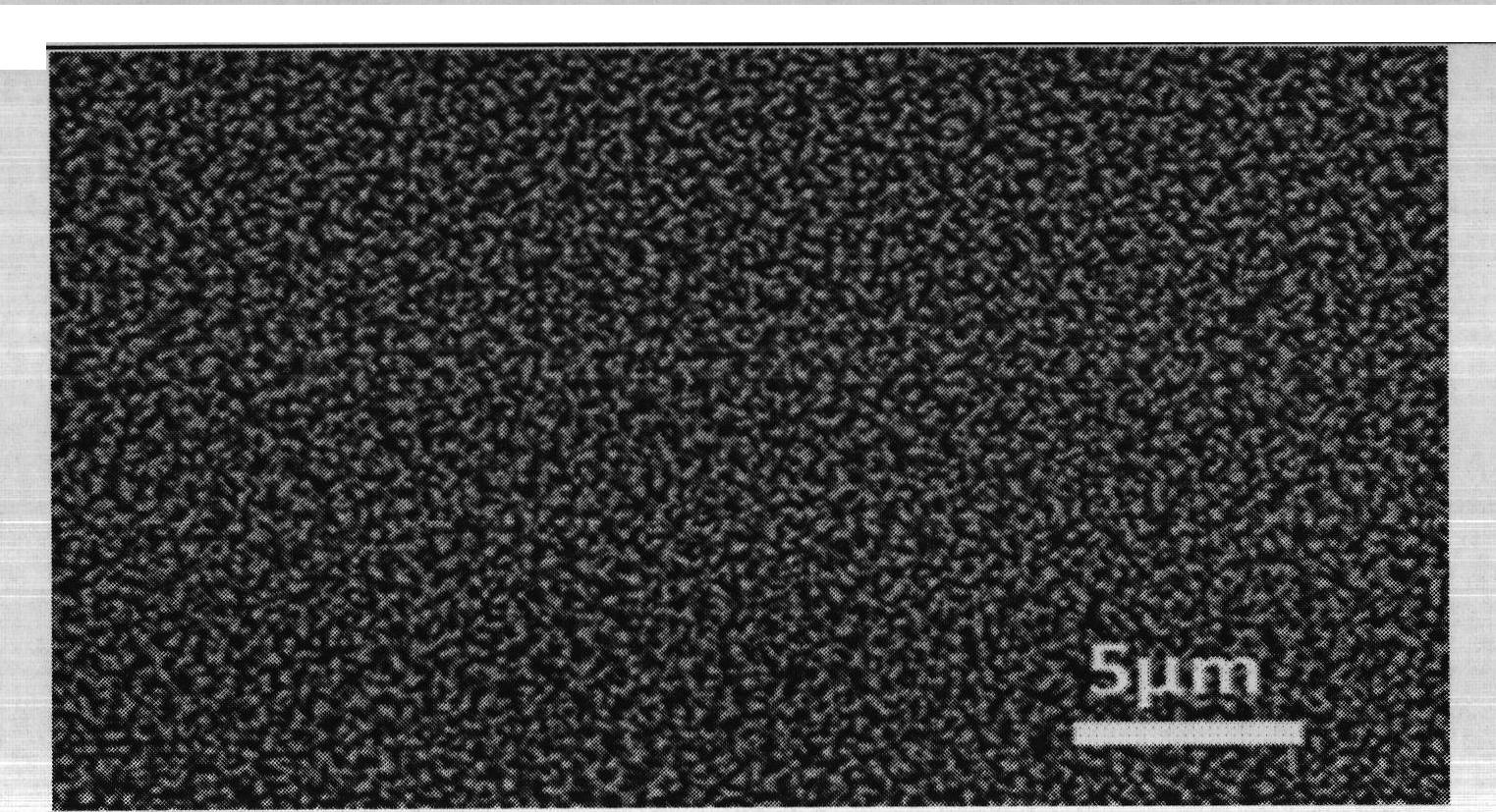

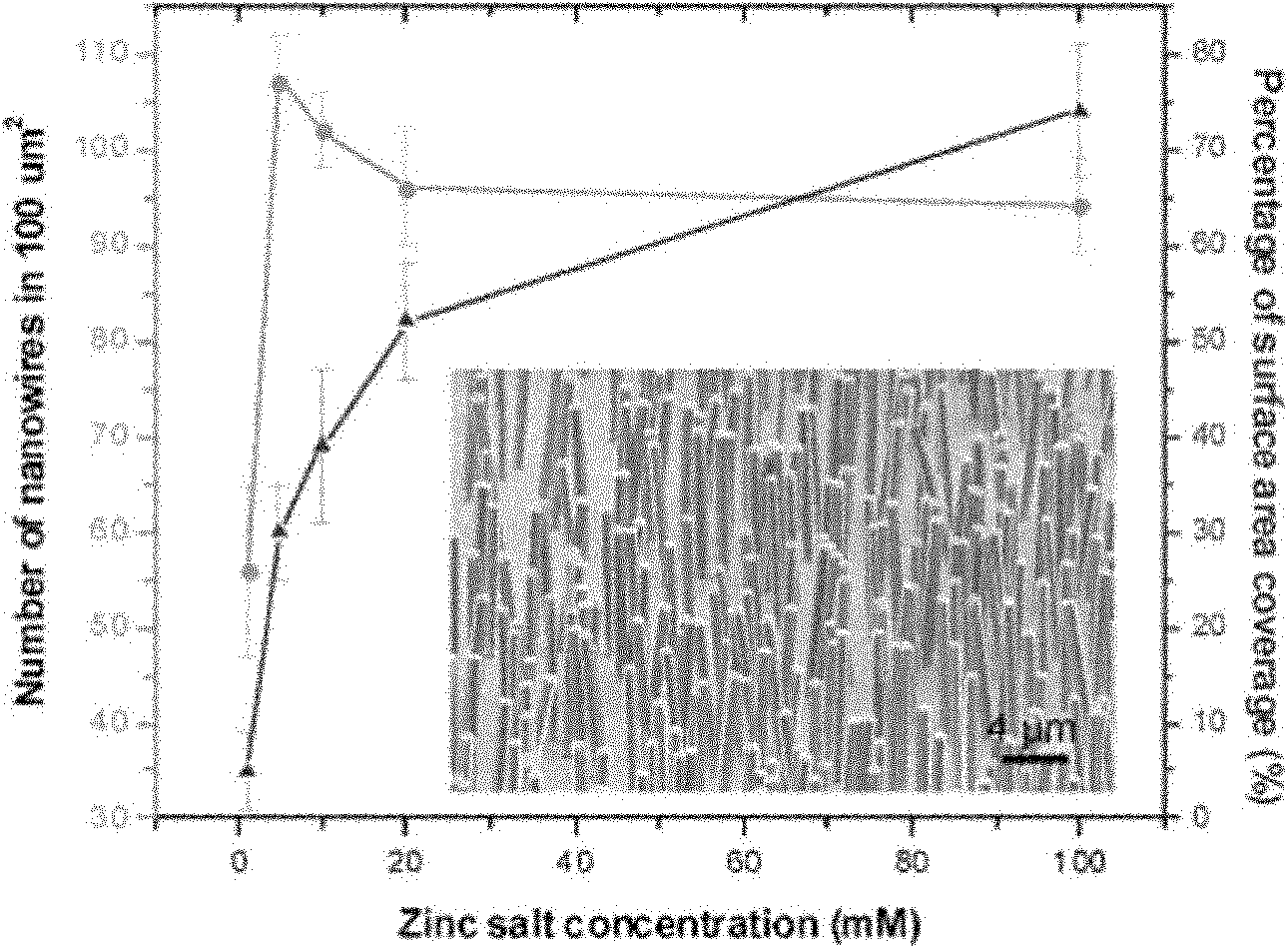

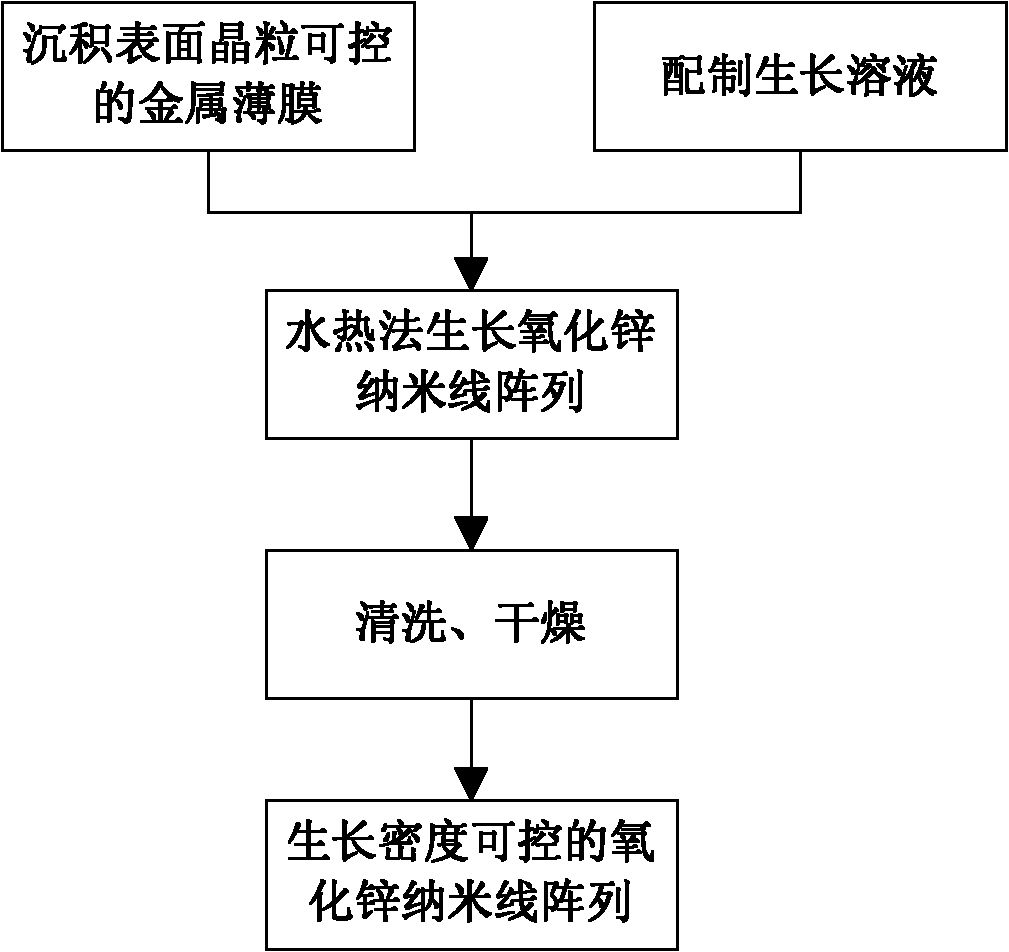

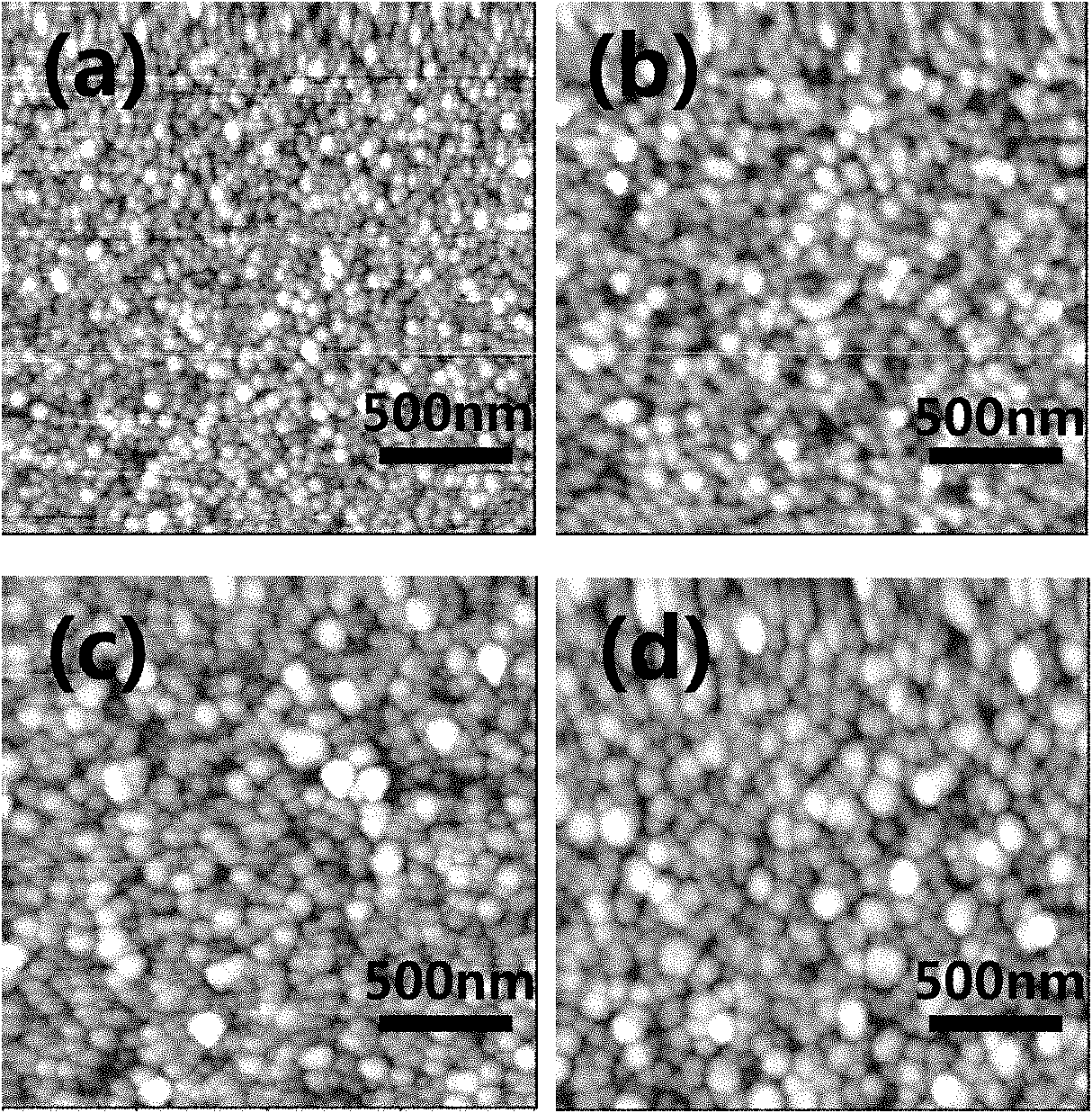

Preparation method of zinc oxide nano linear array

ActiveCN102092774AEasy accessControl growth densityZinc oxides/hydroxidesNanotechnologyVolumetric Mass DensityZinc nitrate

The invention discloses a preparation method of a zinc oxide nano linear array, belonging to the technical field of materials. The preparation method comprises the steps of: firstly, depositing a layer of metal film with controllable surface crystal grain radius on the surface of a substrate by adopting a film depositing process; then, floating the metal film on the surface of a growth solution prepared from a zinc nitrate solution and hexamethylene tetramine, which are equal in lolar weight, by adopting a mode that the surface of the metal film faces downwards; and standing under the condition with the temperature of 60-90 DEG C for growing of the zinc oxide nano linear array. By controlling the sizes of the surface crystal grains of the metal film, the zinc oxide nano linear arrays with different growth densities can be acquired conveniently. Compared with the conventional hydro-thermal method for controlling the growth density of the zinc oxide nano linear array by using a growth solution, the preparation method is easier to realize the control of the growth density of the zinc oxide nano linear array, and the zinc oxide nano linear array with higher requirements on the density precision can be prepared at low temperature in a large area without addition of extra steps or cost.

Owner:INST OF ELECTRONICS & INFORMATION ENG OF UESTC IN GUANGDONG

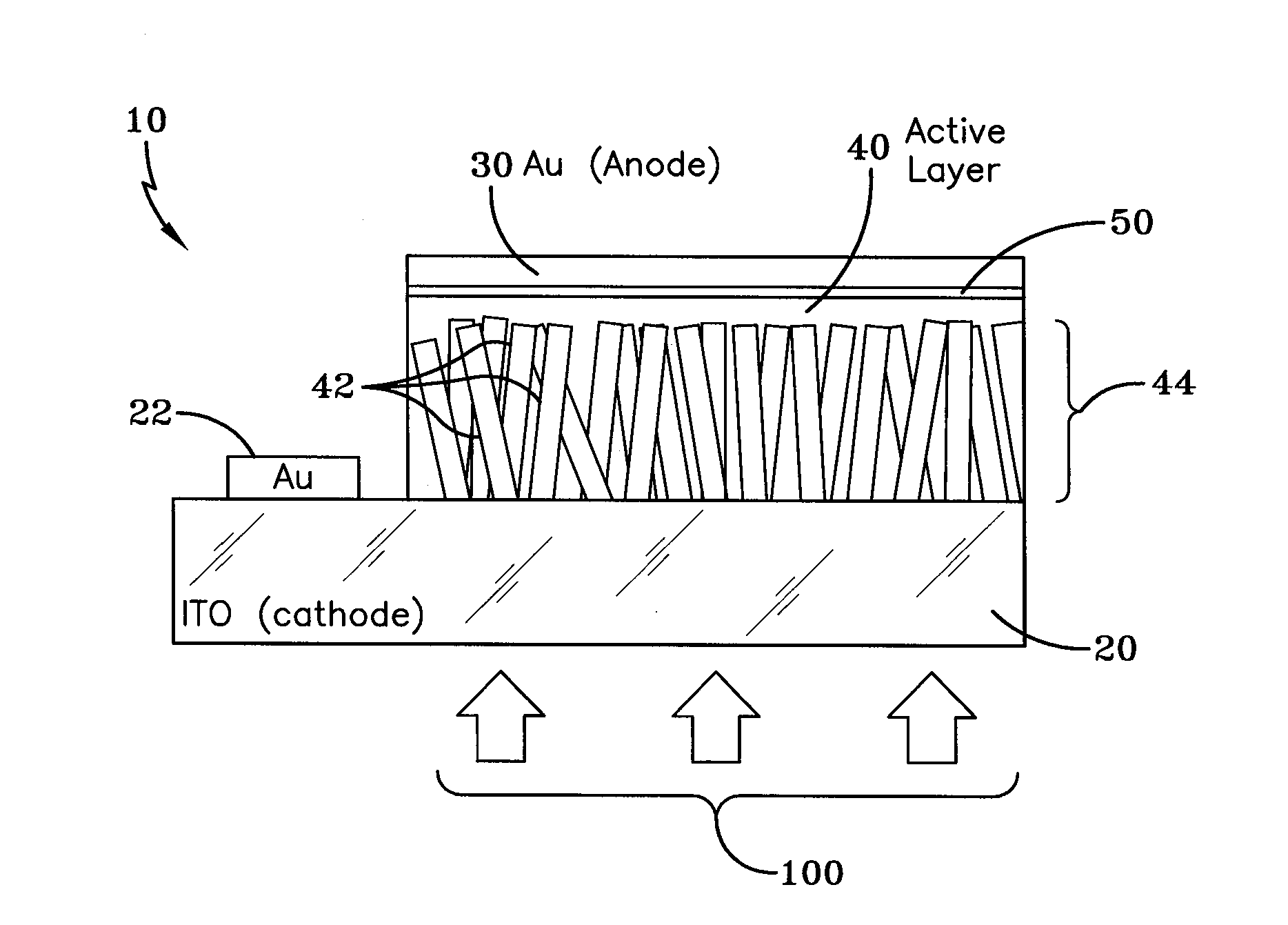

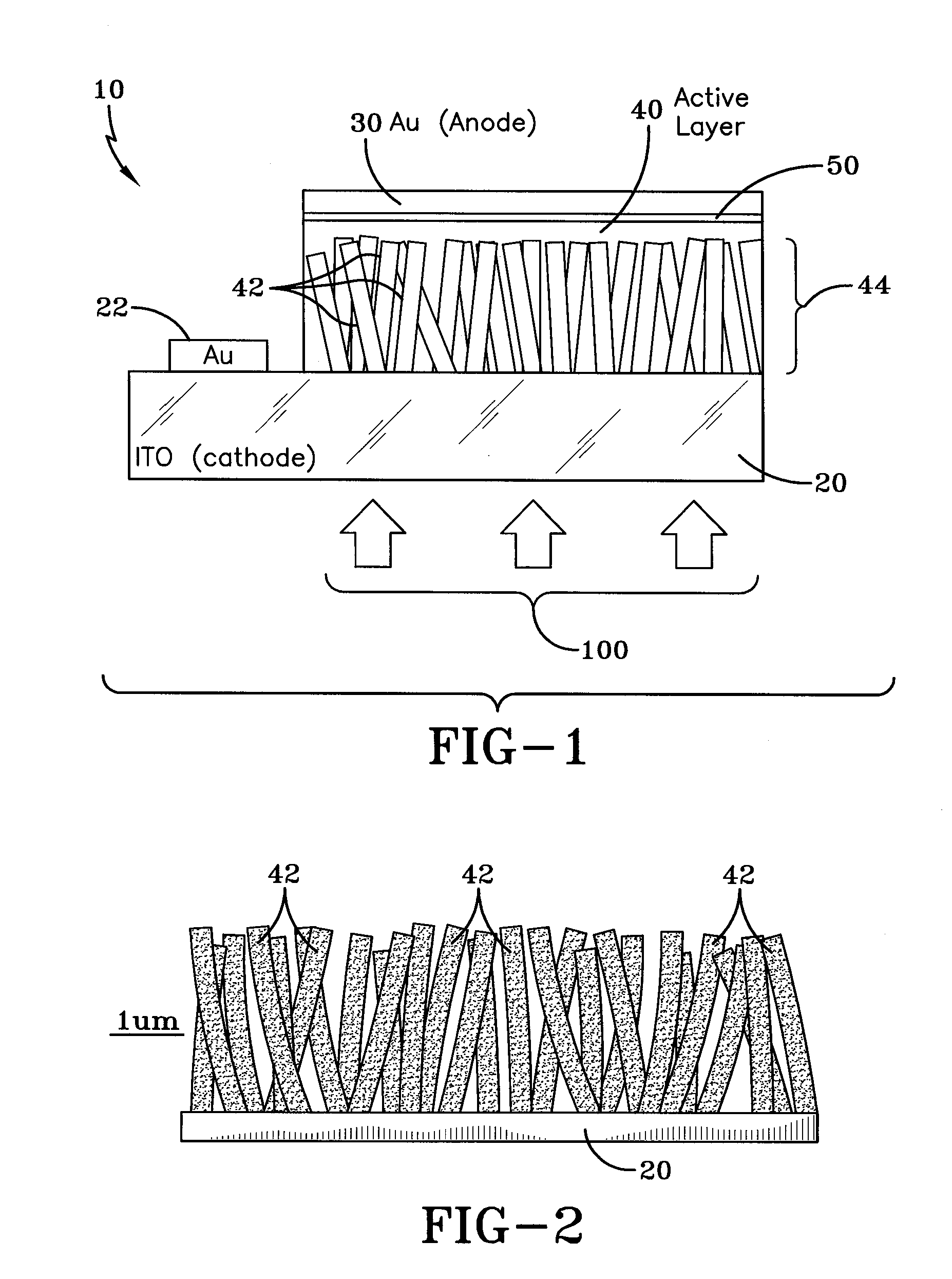

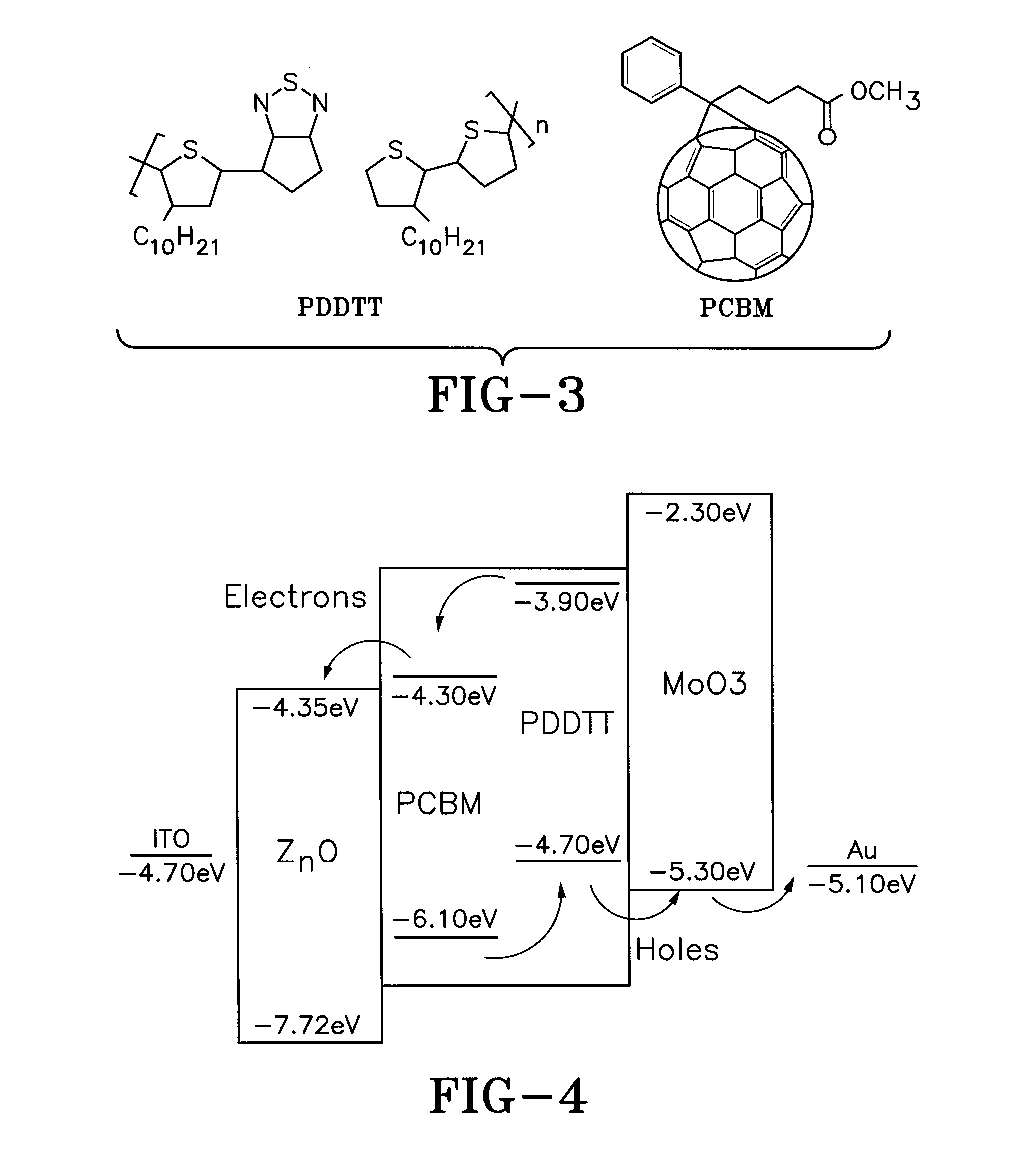

Broadband Polymer Photodetectors Using Zinc Oxide Nanowire as an Electron-Transporting Layer

InactiveUS20130248822A1Increase surface areaEfficient extractionSolid-state devicesSemiconductor/solid-state device manufacturingSpectral responsePhotodetector

A polymer photodetector has an inverted device structure that includes an indium-tin-oxide (ITO) cathode that is separated from an anode by an active layer. The active layer is formed as a composite of conjugated polymers, such as PDDTT and PCBM. IN addition, a cathode buffer layer formed as an matrix of ZnO nanowires is disposed upon the ITO cathode, while a MoO3 anode buffer layer is disposed between a high work-function metal anode and the active layer. During operation of the photodetector, the ZnO nanowires allows the effective extraction of electrons and the effective blocking of holes from the active layer to the cathode. Thus, allowing the polymer photodetector to achieve a spectral response and detectivity that is similar to that of inorganic photodetectors.

Owner:THE UNIVERSITY OF AKRON

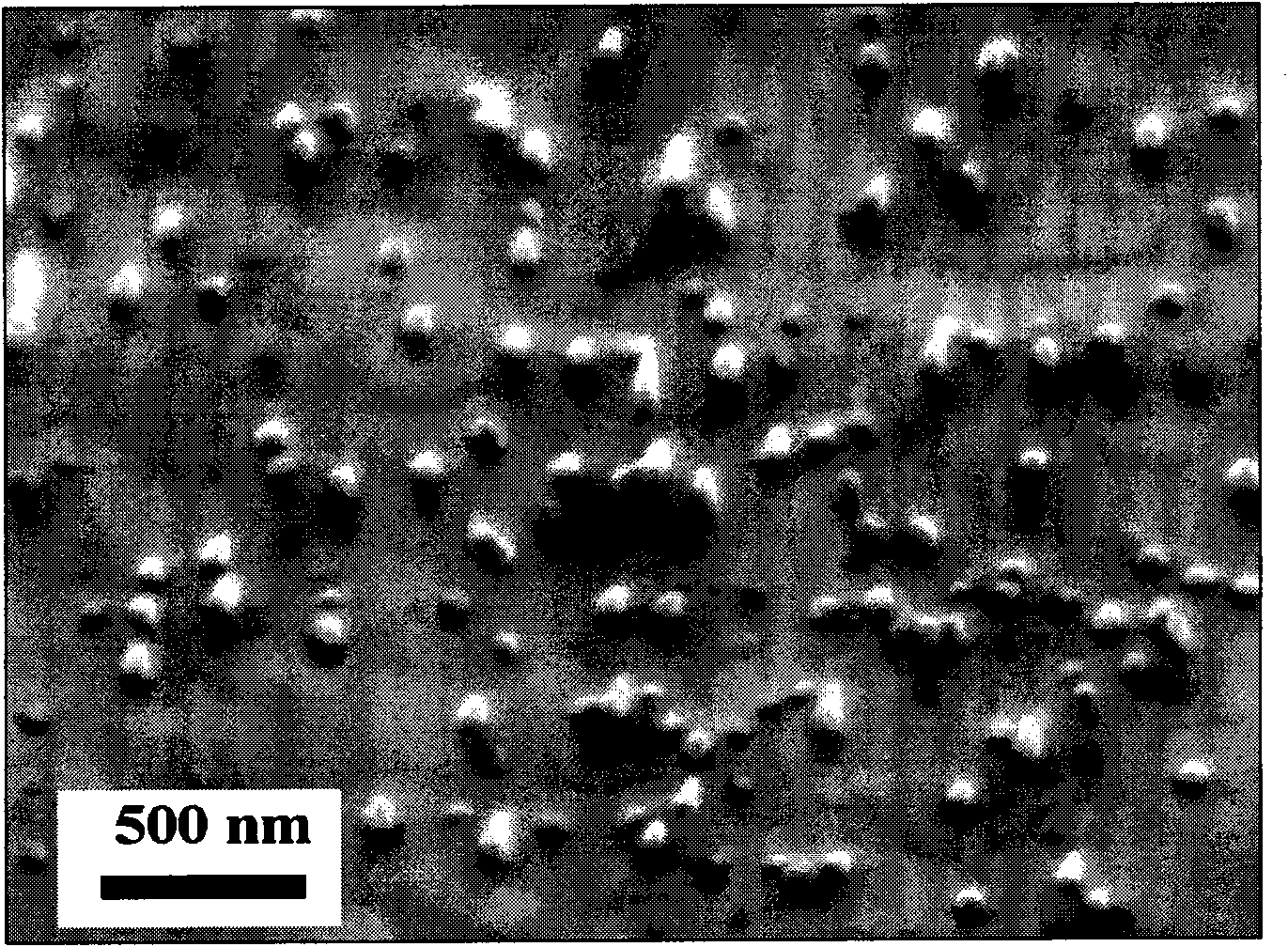

Ultra-fine zinc oxide nonometer line and its preparation method

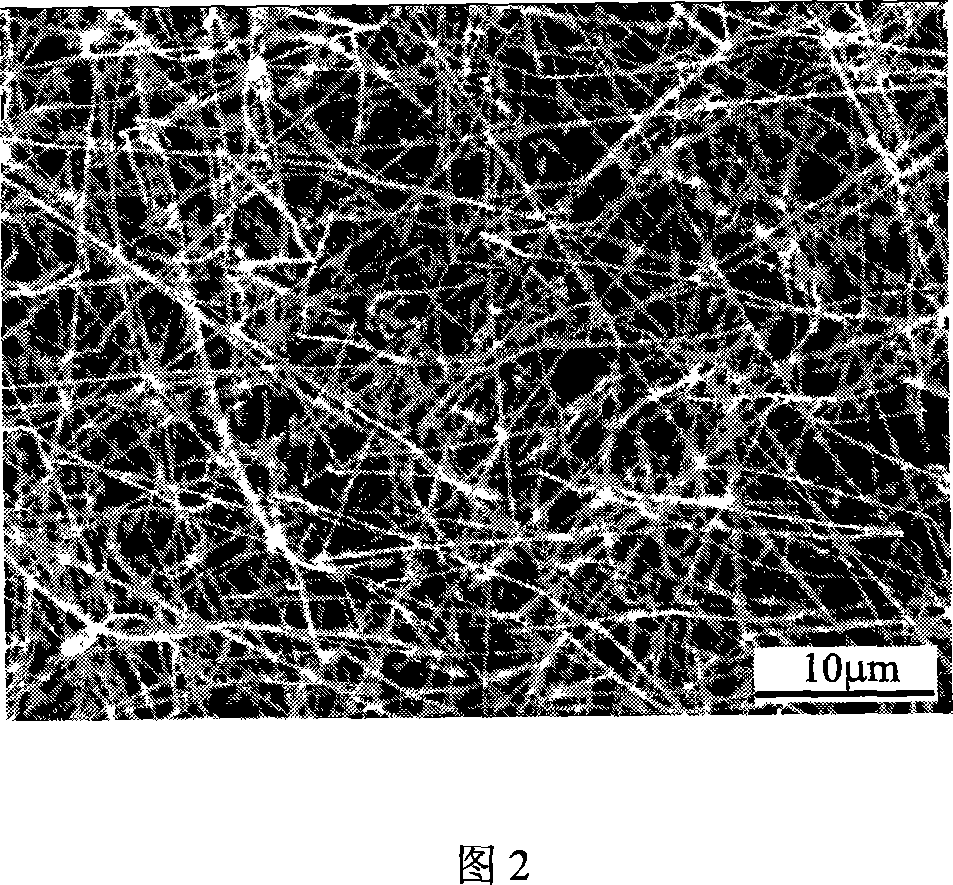

InactiveCN1800029AHigh field emission currentSimple and easy operation processZinc oxides/hydroxidesZno nanowiresOxide

The invention discloses an ultra-fine unoriented zinc oxide nanometer wire and making method in the semiconductor nanometer material technique domain, which comprises the following steps: cleaning n-typed heavy silicon piece in the acetone and alcohol for 25-30 min by ultrasound; deposing a 0.5-2 nm thickness layer of gold plating catalyst film on the silicon piece through electronic beam evaporation method; taking the silicon piece with gold plating film as the receiving substrate and high-pure zinc powder as the evaporation source; putting the substrate and evaporation source on the glass; placing the glass in the pipe-typed furnace; charging high-pure Ar2 in the vacuumed pipe-typed furnace as the protecting atmosphere; heating the temperature at 460-540 deg.c at the speed of 10-20 deg.c per min; reacting for 100-150 min; reducing the reactant temperature to the room temperature protected by Ar2. The invention realizes the controllability and low cost synthesis of nanometer ZnO, which avoids the shielding effect due to array.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of branched zinc oxide nanowire array film

InactiveCN102503171AGood value for moneyLarge specific surface areaZinc oxides/hydroxidesDecorative surface effectsPhotoluminescencePrice ratio

The invention discloses a preparation method of a branched zinc oxide nanowire array film. The preparation method comprises the following steps of: cleaning a conductive substrate with acetone, ethanol and deionized water for later use, and preparing a zinc oxide nanowire array on the surface of the cleaned conductive substrate through a hydro-thermal reaction: cleaning the conductive substrate, and putting into a reaction solution in a reaction kettle; dissolving the reaction solution which consists of a zinc salt, polyethyleneimine, hexamethylene tetramine and ammonia water into a certain amount of water, putting into a high-pressure kettle, heating to 50-200 DEG C, reacting for 1-24 hours, and naturally cooling to the room temperature; and vulcanizing and calcining a growing zinc oxide nanowire (rod) array, and performing secondary hydro-thermal treatment to obtain a branched zinc oxide nanowire (rod) array film. Due to the generation of a branched structure, the specific surface area of a zinc oxide nanowire (rod) can be increased effectively. The zinc oxide nanowire array film prepared with the method can be applied in various fields of dye-sensitized solar cells, photoluminescence, electron field emission and the like. The preparation method is simple and convenient and has a high performance price ratio.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com