Method for growing nanometer zinc oxide structure through low-temperature heating of zinc and catalyst and application thereof

A technology of zinc oxide nanometer and zinc oxide nanowire, which is applied in the direction of zinc oxide/zinc hydroxide, discharge tube, electrical components, etc., can solve the problems in the field of unapplied cold cathode, etc., and achieve the effect of good field emission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

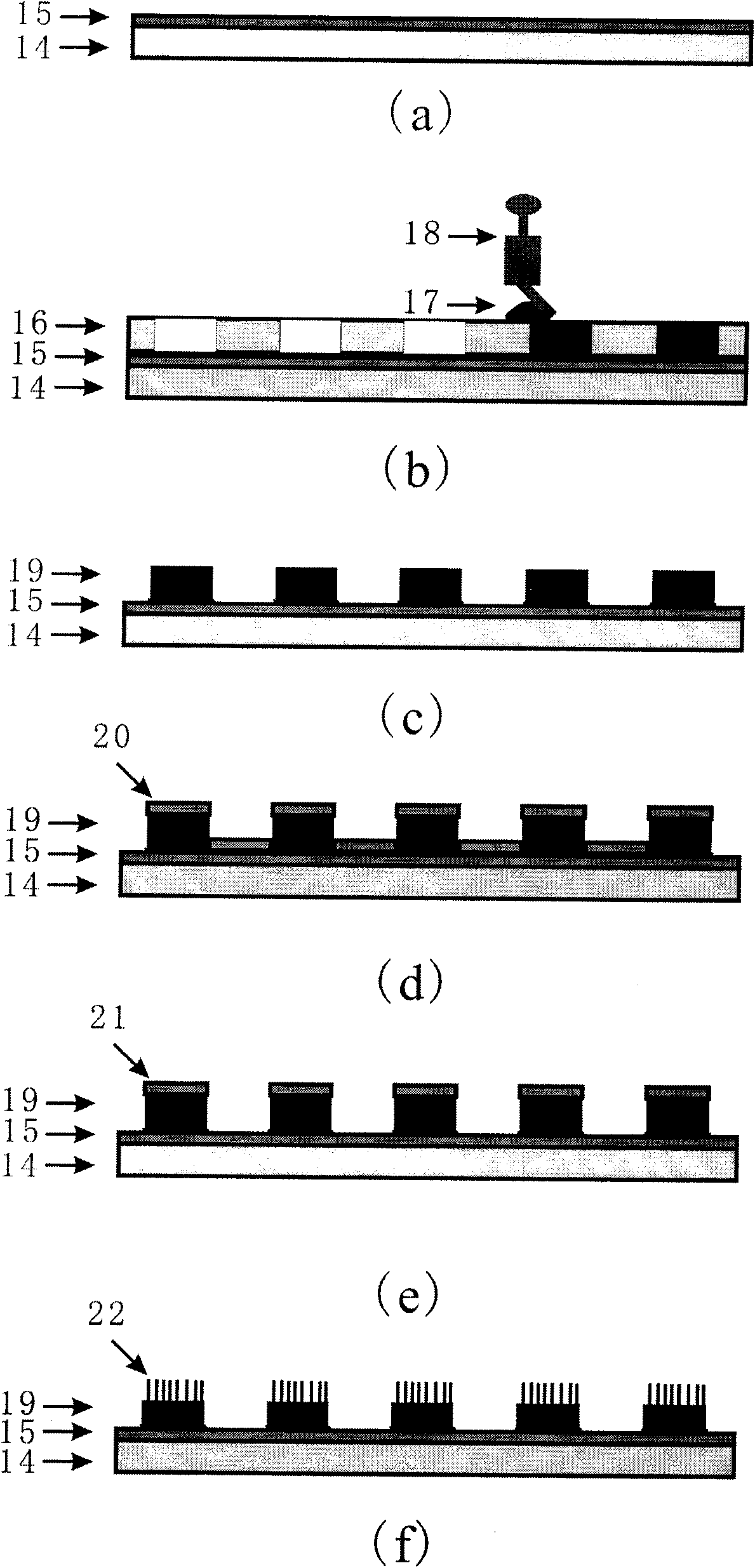

[0045] This example shows the process of localized preparation of ZnO nanowire cold cathode electron source array on ITO glass.

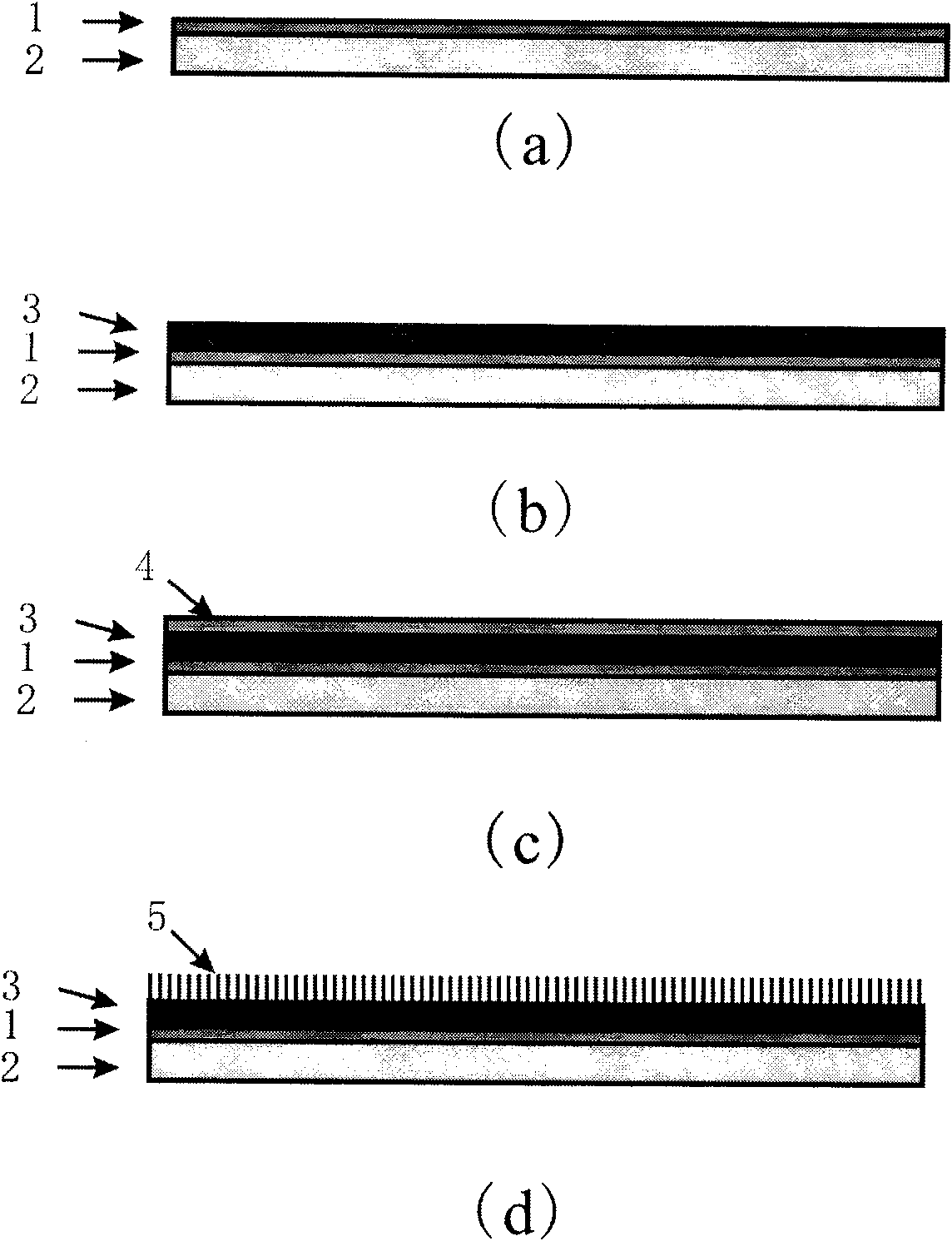

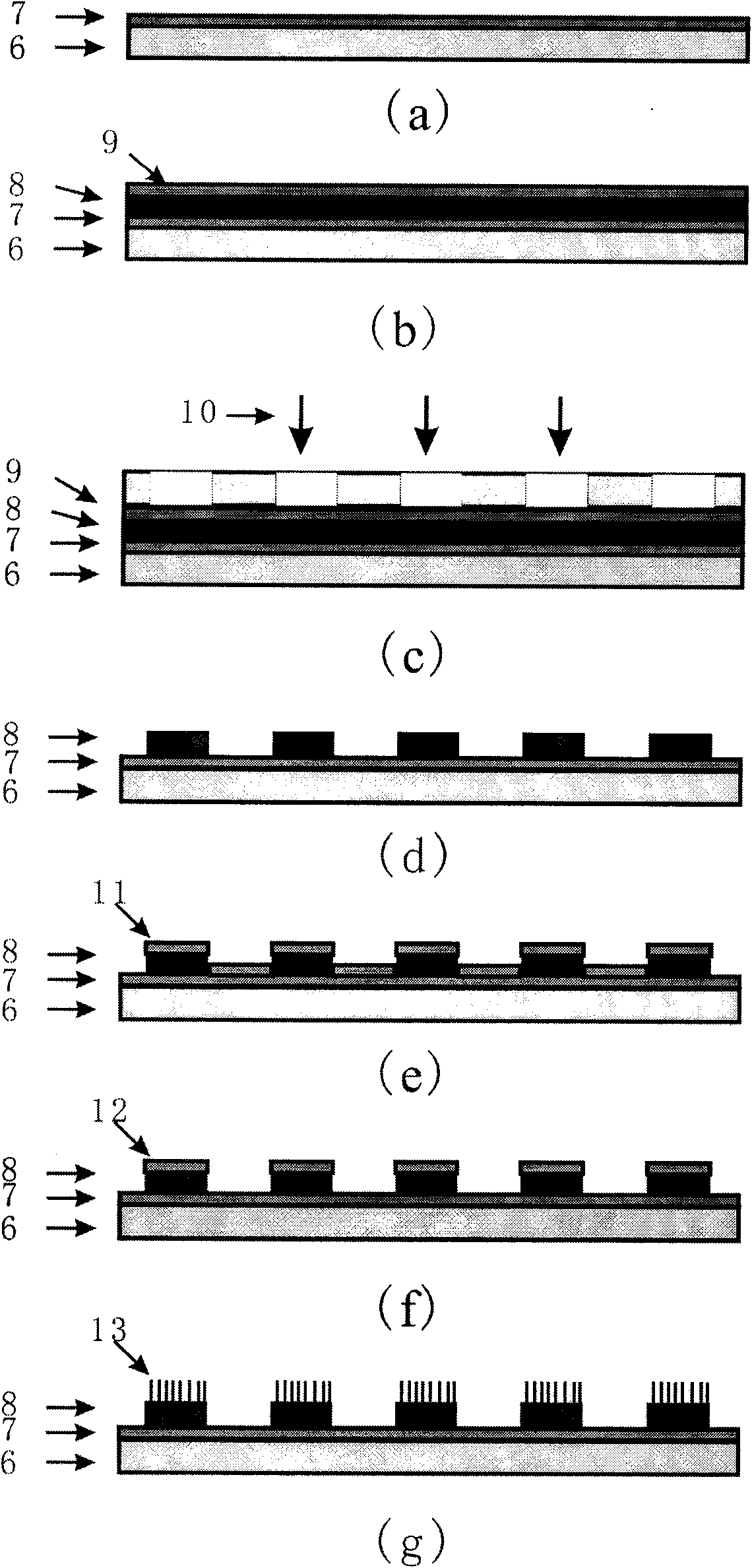

[0046] First, the ITO glass substrate was ultrasonically cleaned with acetone and alcohol for 15 minutes, and then dried. Attached figure 1 The localized preparation procedure is shown. First, a zinc particle array is prepared on the surface of the substrate by screen printing, with a thickness of about 15-20 microns, and then, a catalyst gold film is prepared by direct current sputtering, and the thickness is 5 nanometers. The prepared zinc particle array was put into a heating furnace, the temperature was raised to 500°C at a rate of 3°C / min, kept for 1 hour, and then cooled naturally.

[0047] The crystal structure of the prepared zinc oxide nanowire arrays was measured by X-ray diffraction (XRD), and the morphology and morphology of the prepared zinc oxide nanowire arrays were observed by optical microscopy, scanning electron microscopy (SEM) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com