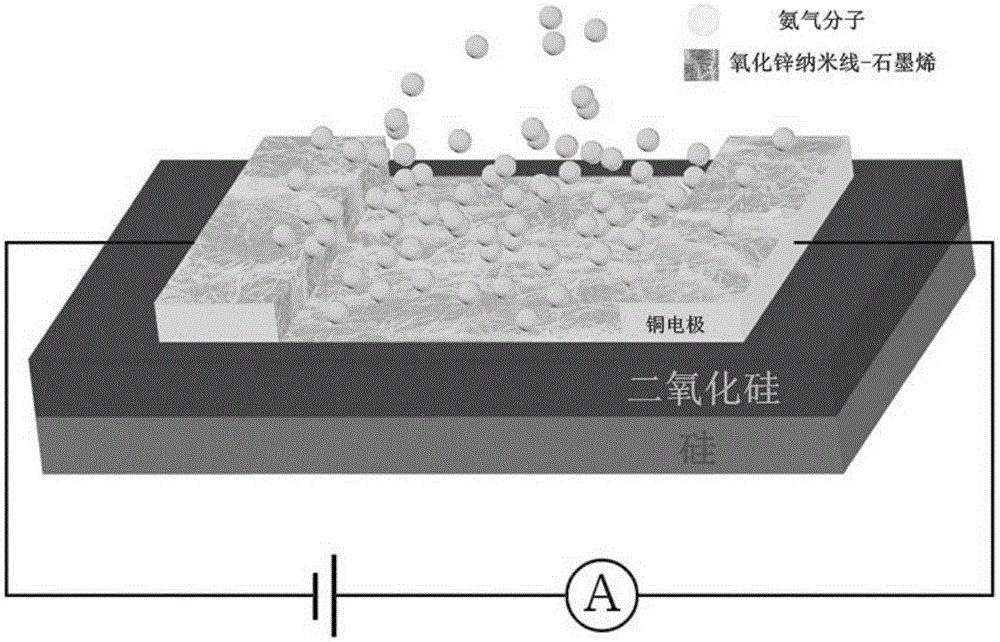

Zinc oxide nanowire-graphene gas sensor and preparation method thereof

A zinc oxide nanowire, gas sensor technology, applied in the direction of material resistance, can solve the problems of poor selectivity and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

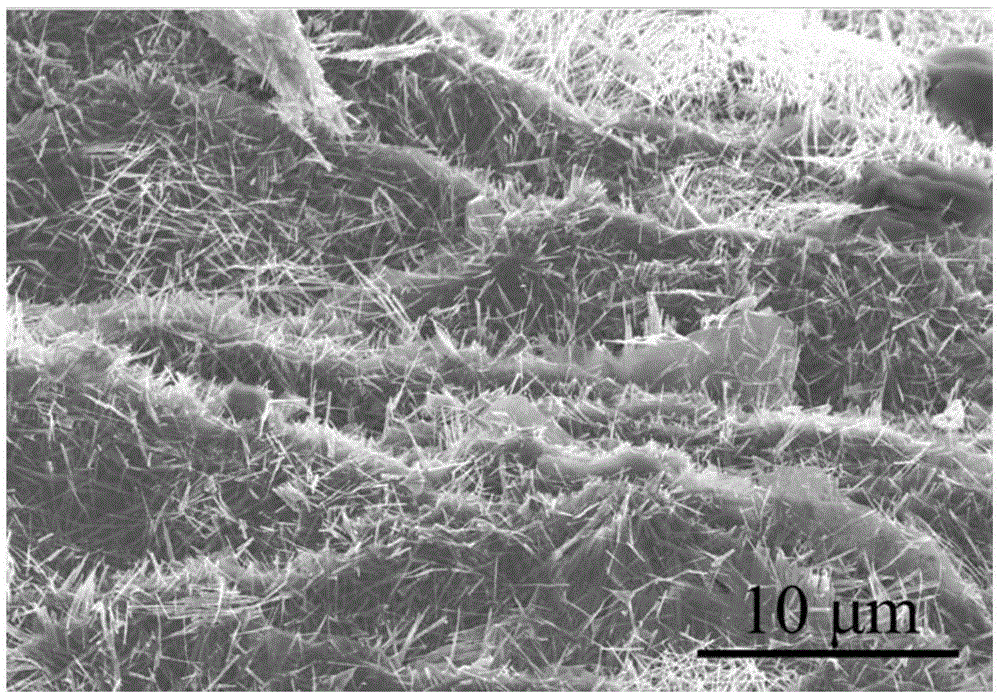

[0028] Dissolve 0.1 g of zinc oxide nanowires and 0.1 g of polyvinylpyrrolidone in 30 ml of deionized water, and sonicate for 15 minutes to obtain the first solution. 0.3 g of graphene was dissolved in 30 ml of deionized water, and the second solution was obtained by ultrasonication for 15 min. The two solutions were mixed and stirred for 1 h, centrifuged for 3 times and then dried in a vacuum oven at 50° C. for 24 h to obtain a zinc oxide nanowire-graphene oxide composite material.

[0029] The obtained zinc oxide nanowire-graphene oxide composite material was annealed under argon protection, the annealing temperature was 300° C., and the annealing time was 30 min, to obtain the zinc oxide nanowire-graphene composite material. The powder of the composite material was added to deionized water at a concentration of 1 mg / L, and ultrasonically treated at 40KHz for 10 minutes, so that the composite material was uniformly dispersed in the deionized water, thereby obtaining a disper...

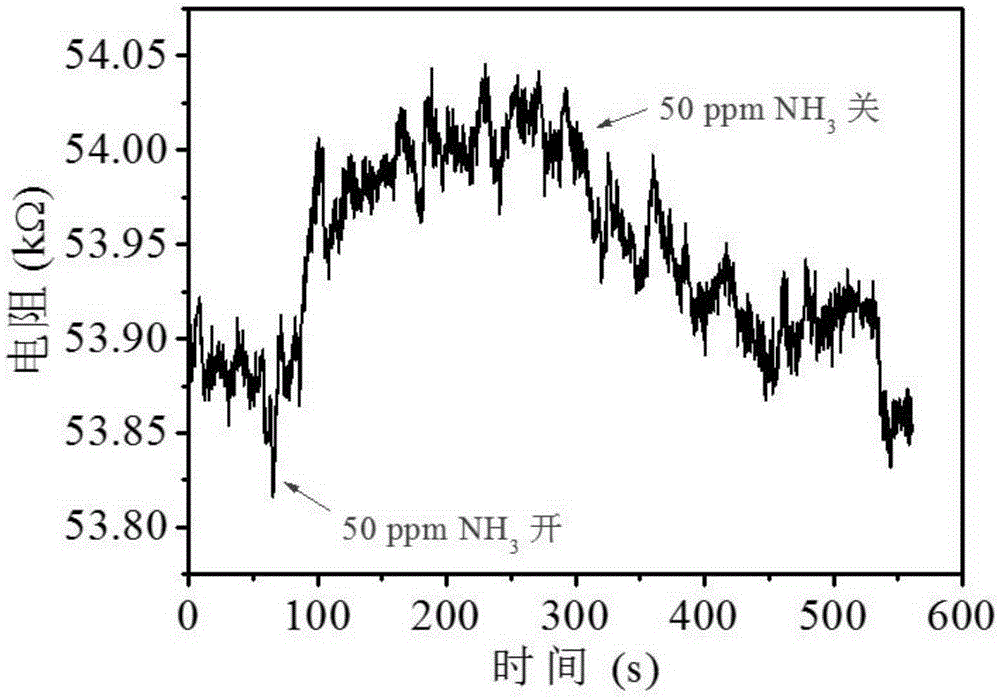

Embodiment 2

[0036] The steps are as in Example 1, the mass percentage of zinc oxide nanowires in the zinc oxide nanowire-graphene composite material is reduced from 25% to 10%, and the response value of the gas sensor to 50ppm concentration ammonia is reduced to 6.2%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com