Patents

Literature

316results about How to "Stable chemical structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

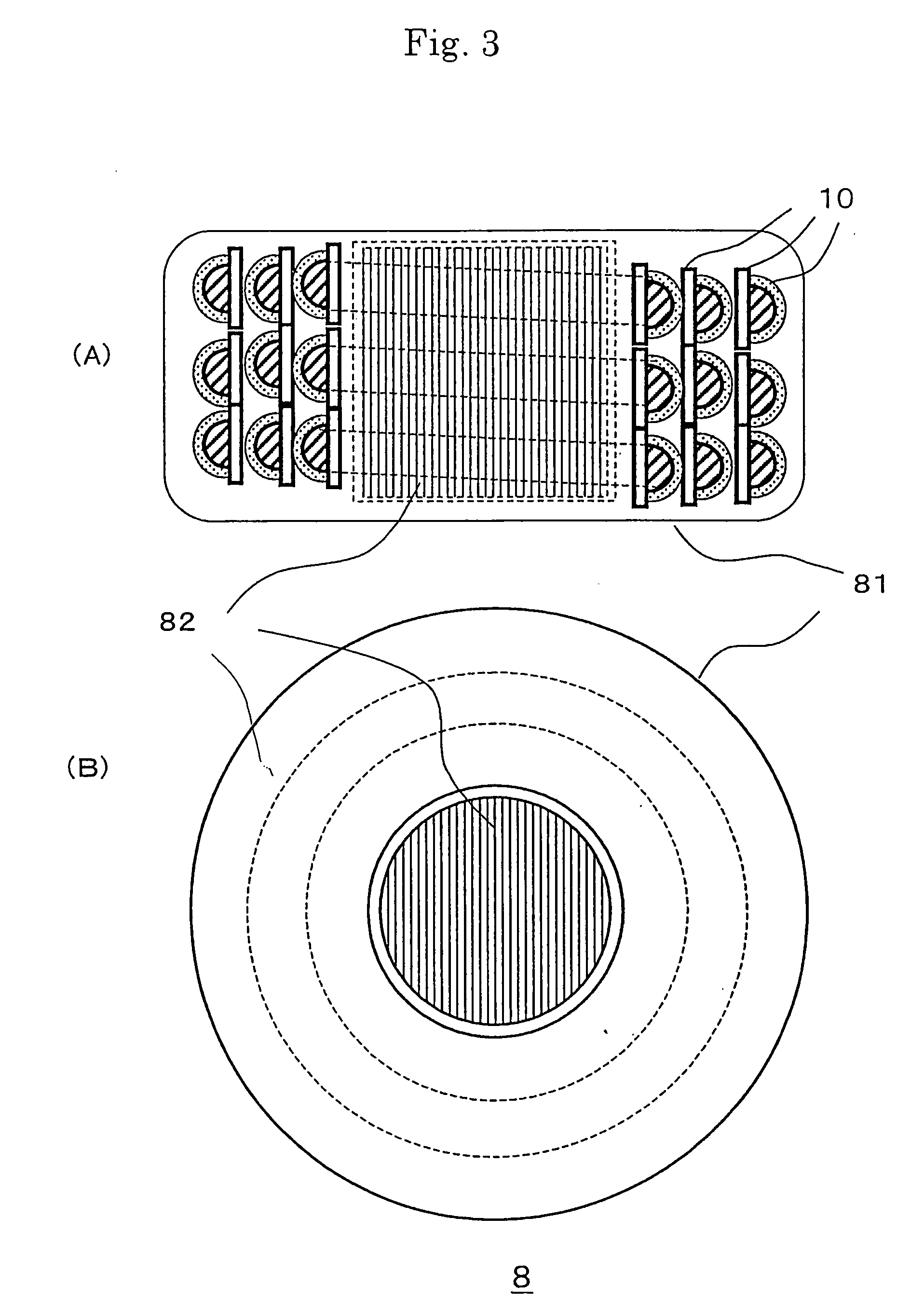

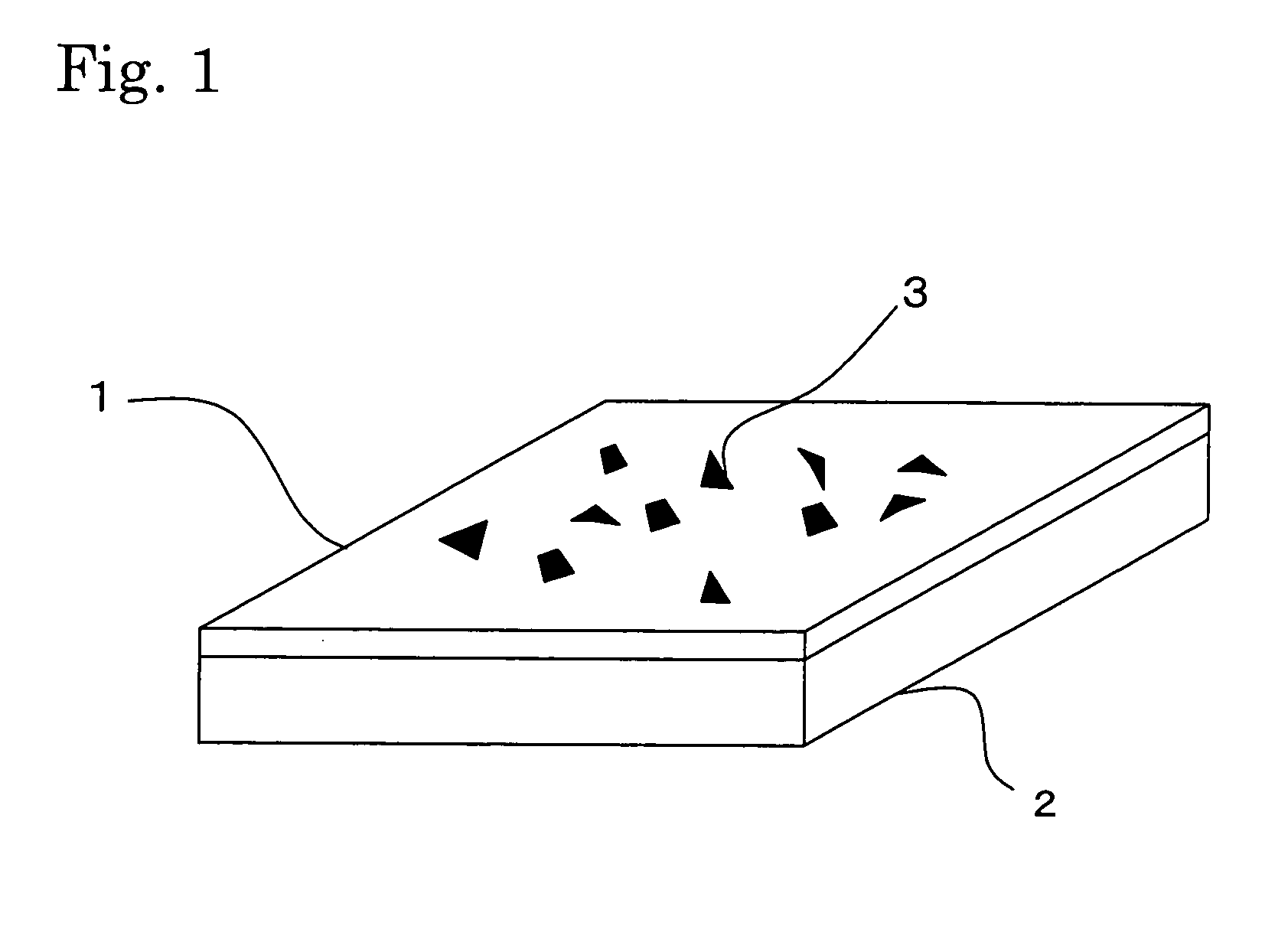

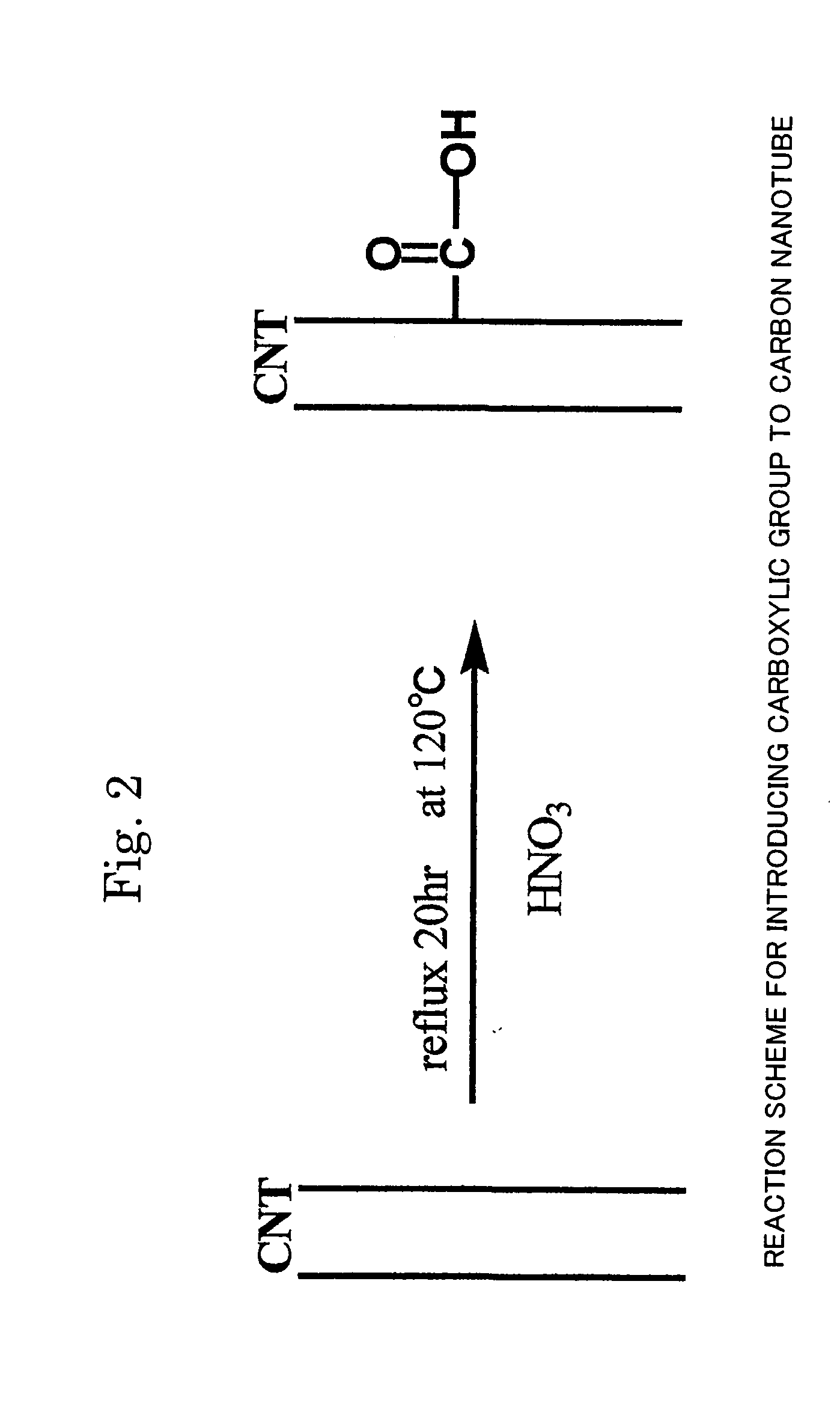

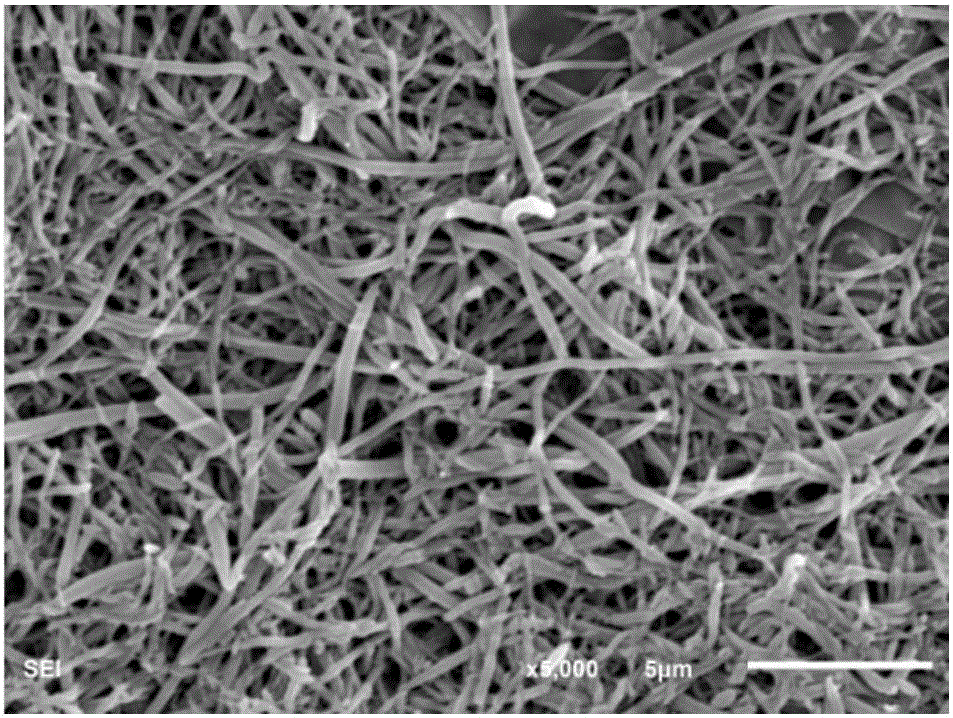

Carbon nanotube composite structure and method of manufacturing the same

InactiveUS20050069701A1Stable chemical structureReduce the binding forceMaterial nanotechnologyIndividual molecule manipulationCross-linkNetwork structure

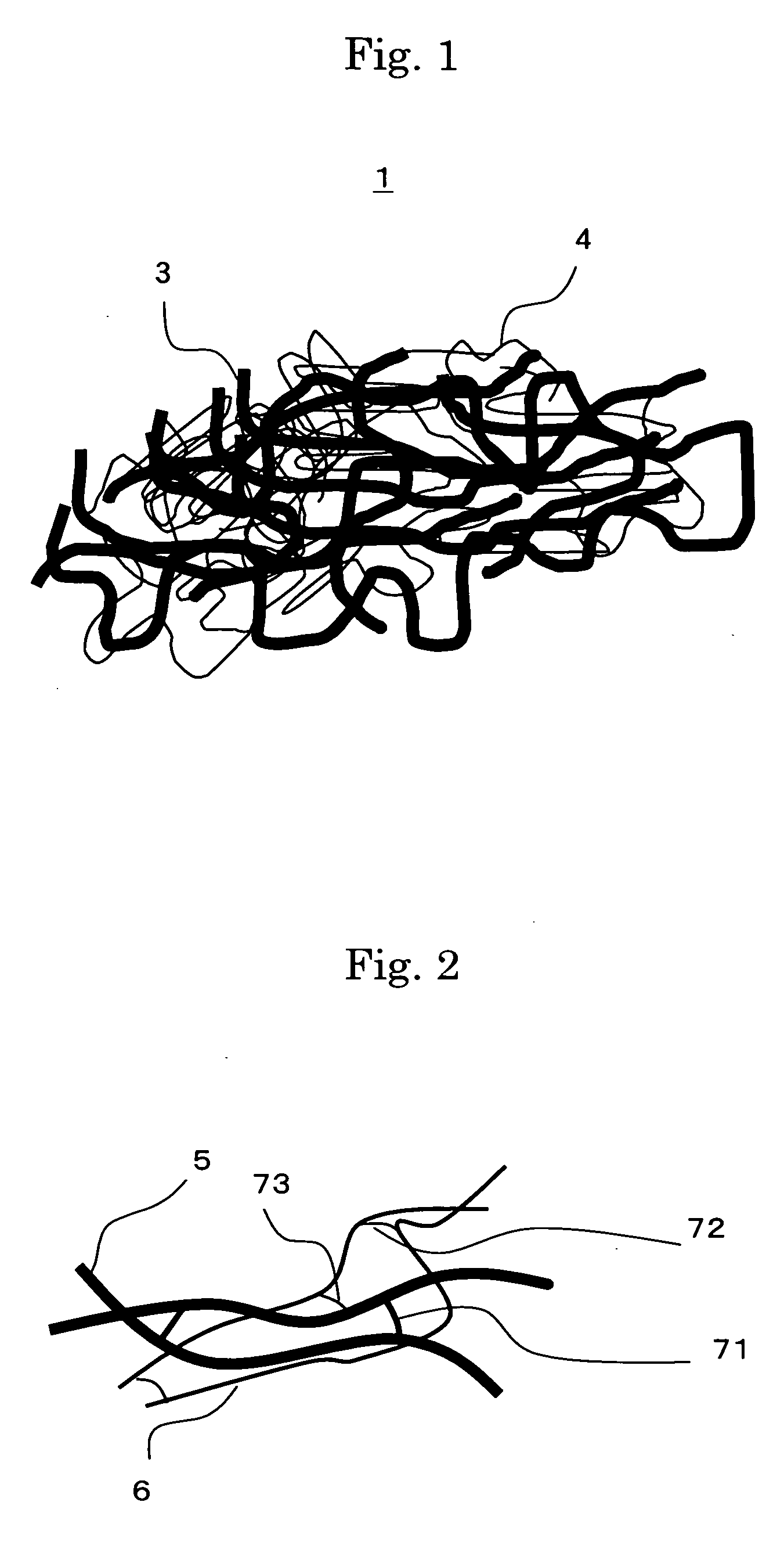

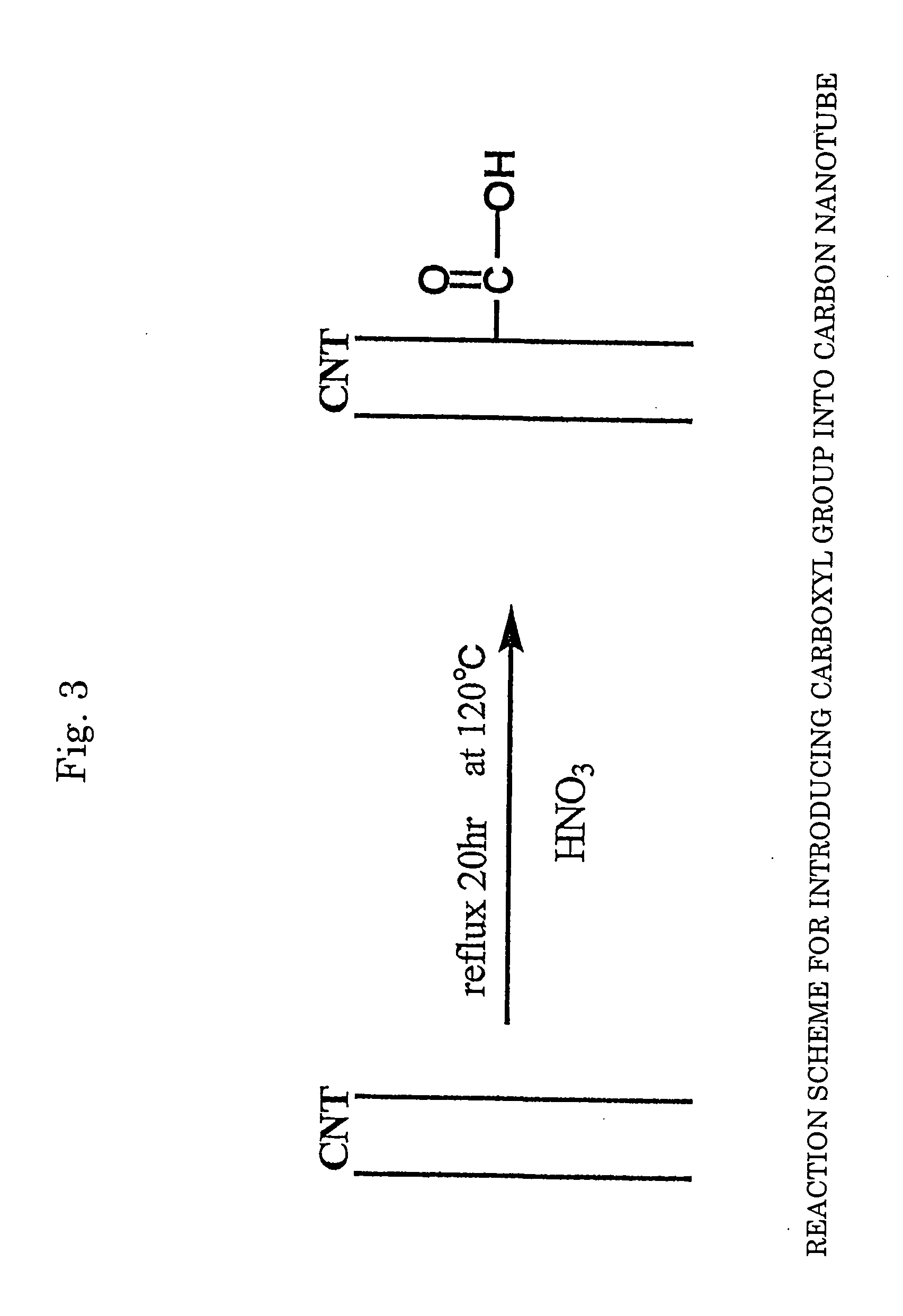

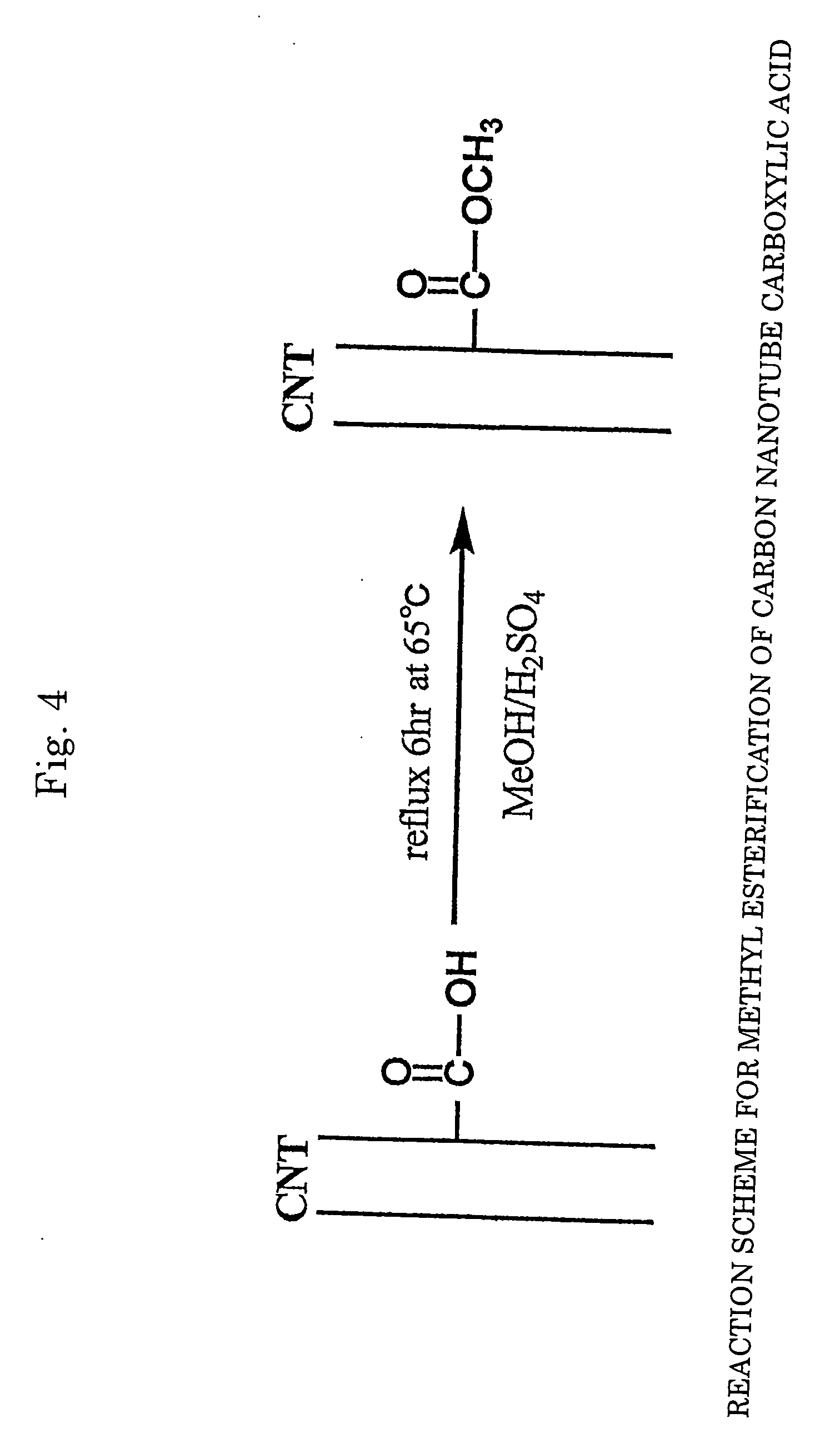

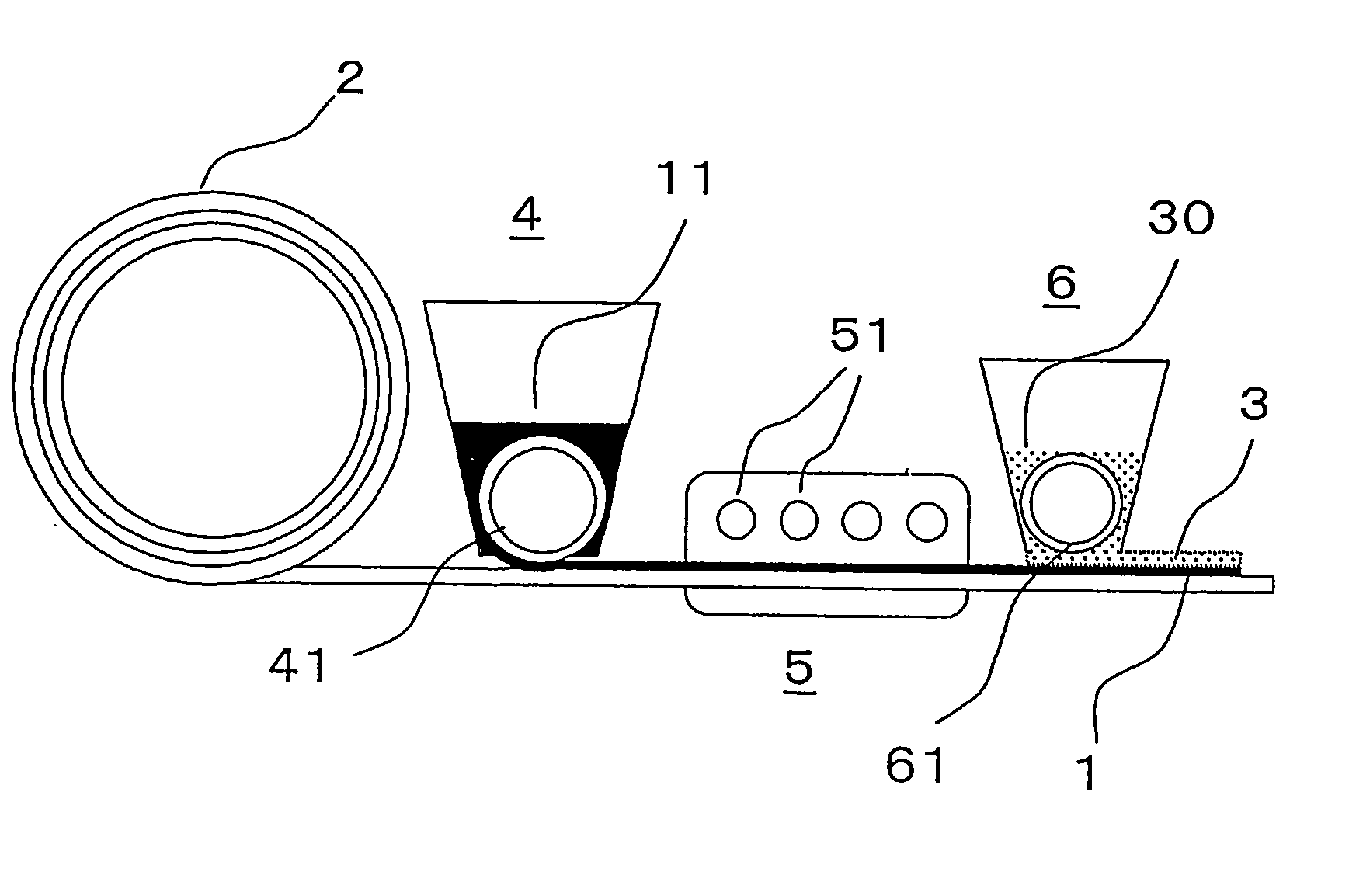

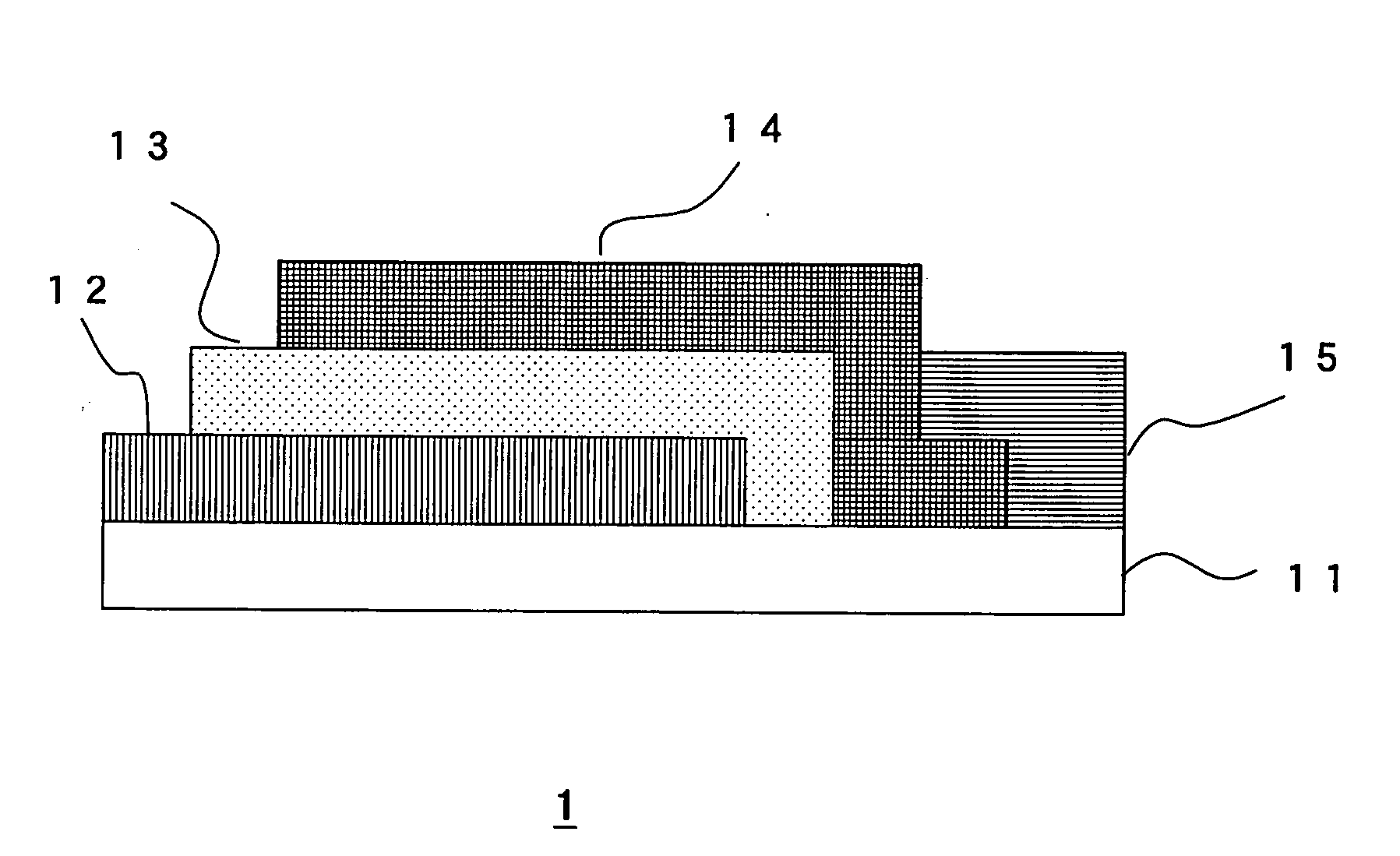

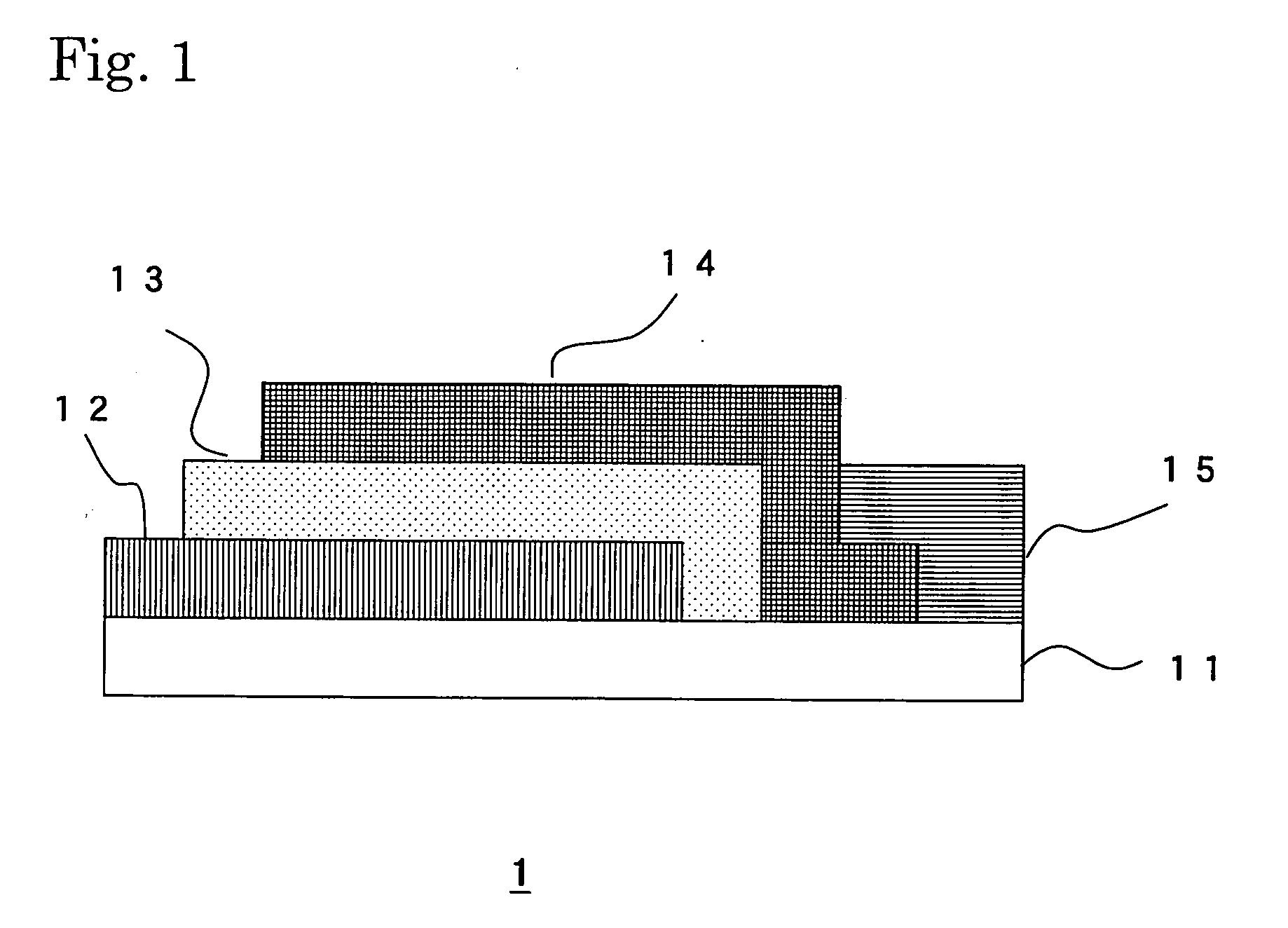

Provided are a carbon nanotube structure more excellent in electric conductivity, thermal conductivity, and mechanical strength, and a method of manufacturing the carbon nanotube structure. A carbon nanotube composite structure is characterized by including: a first carbon nanotube structure in which functional groups bonded to plural carbon nanotubes are chemically bonded and mutually cross-linked to construct a network structure; and a second carbon nanotube structure in which functional groups bonded to plural carbon nanotubes are chemically bonded and mutually cross-linked to construct a network structure, the second carbon nanotube structure being combined with the network structure of the first carbon nanotube structure.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Spray coating type fire-retardant antistatic polyurethane elastomer and preparation method thereof

ActiveCN103709362ALow viscosityImprove liquidityFireproof paintsPolyurea/polyurethane coatingsCarbon nanotubeSpray coating

The invention discloses a spray coating type fire-retardant antistatic polyurethane elastomer and a preparation method thereof. The spray coating type fire-retardant antistatic polyurethane elastomer comprises an A component and a B component, wherein the A component is composed of 40-60 parts of isocyanate and 40-60 parts of phosphorus-containing flame-retardant polyol, and the B component is composed of 0-30 parts of chain extender, 0-30 parts of polyether polyol, 10-75 parts of amine-terminated polyether, 0-30 parts of carbon nanotube slurry, 0-3 parts of pigment and 0-3 parts of assistant. The preparation method comprises the following steps: adding the phosphorus-containing flame-retardant polyol into a reaction kettle, heating up to 110 DEG C, vacuumizing for 3 hours, cooling to 30 DEG C, adding the isocyanate, heating up to 105 DEG C, and reacting for 3 hours to obtain a semi-prepolymer A component; sequentially adding the ingredients of the B component into a stirring tank, stirring uniformly, and grinding the mixture in a sand mill for 2.5 hours to prepare the B component; spray-coating the A component and the B component onto a surface through a high pressure spray coating machine, and quickly curing to form. According to the spray coating type fire-retardant antistatic polyurethane elastomer disclosed by the invention, film forming matters are stable, no fire retardant is separated out and the durability is good; a spray coating type fire-retardant antistatic material prepared by the preparation method disclosed by the invention has both fire resistance and anti-static function, so that the material is suitable for application on flame-retardant and explosion-proof occasions.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

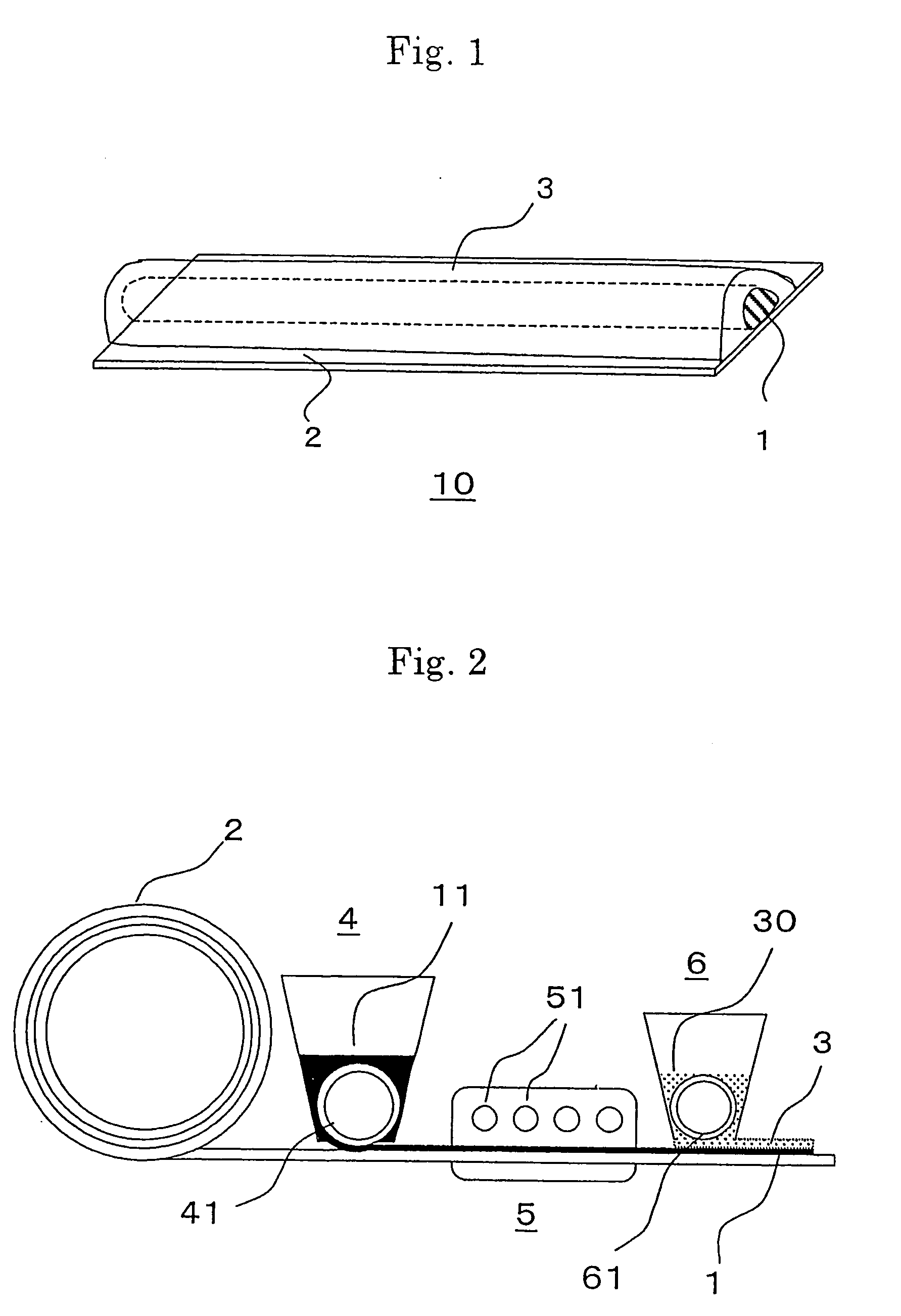

Wire, method of manufacturing the wire, and electromagnet using the wire

InactiveUS20050064647A1Stable chemical structureLow possibilityMaterial nanotechnologySingle bars/rods/wires/strips conductorsCarbon nanotubeMaterials science

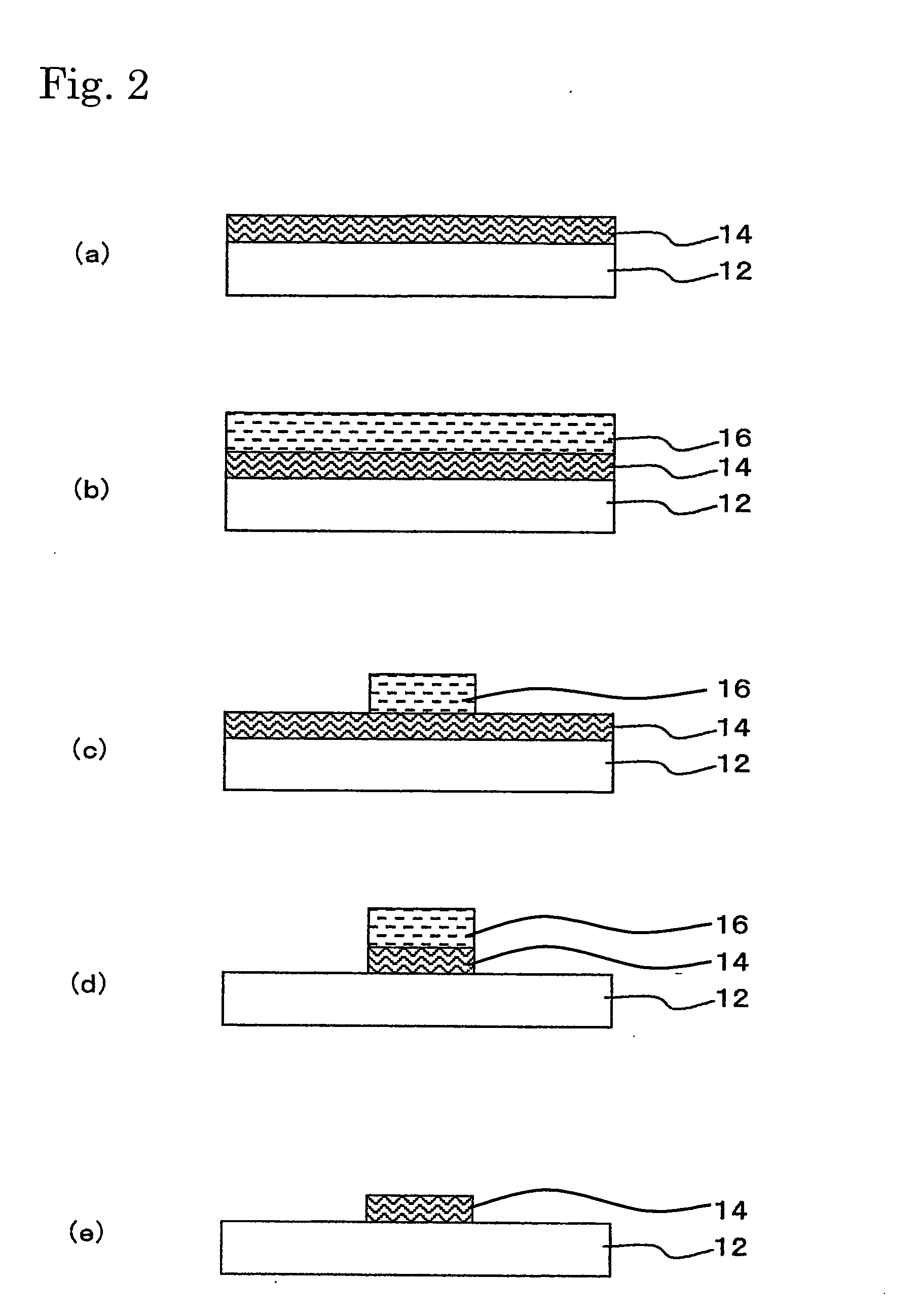

To provide a wire excellent in electrical characteristics or in mechanical characteristics. A wire is constructed at least by a carbon nanotube structure layer (1) in which plural carbon nanotubes mutually cross-link to configure a mesh structure on the surface of a substrate (2). A method of manufacturing the wire includes: an applying step of applying to the surface of the substrate (2) a liquid solution containing a carbon nanotube having a functional group; and a step of curing the liquid solution after the application. An electromagnet scarcely causing a loss is formed using the wire.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Water swelling polyurethane elastomer sealing product material and preparation method

ActiveCN101565602AStable physical and chemical propertiesStable physical and chemical properties (hardnessOther chemical processesPolyurethane elastomerPolyol

The invention relates to a water swelling polyurethane elastomer sealing product material and a preparation method. The material is prepared from the following three components (A), (B) and (C) through polymerization reaction of two steps, the elastomer material has water swelling property, and a main chain structure of material molecules absorbs water, wherein the (A) is hydrophilic polyether type polymer1polyol; the (B) is polyisocyanates; and the (C) is low-molecular polyol and amino chain-extended crosslinker. The molar ratio of the (B) to the (A) in an isocyanate end capping reaction is 1.3 to 2.8; and the molar ratio of a product of the isocyanate end capping reaction of the (A) and the (B) to the (C) in a chain-extended crosslinking reaction is 0.75 to 1.05. In the preparation method for the material, the reaction of the two steps is a reaction process of liquid polymerization, and the production of a product is an elastomer casting-molding process. The material has the characteristics of small mass variation rate and stable physical performance after the material absorbs the water repeatedly to swell, and permanent compression deformation and small stress relaxation.

Owner:NORTHWEST RUBBER & PLASTIC RES & DESIGN INST CO LTD

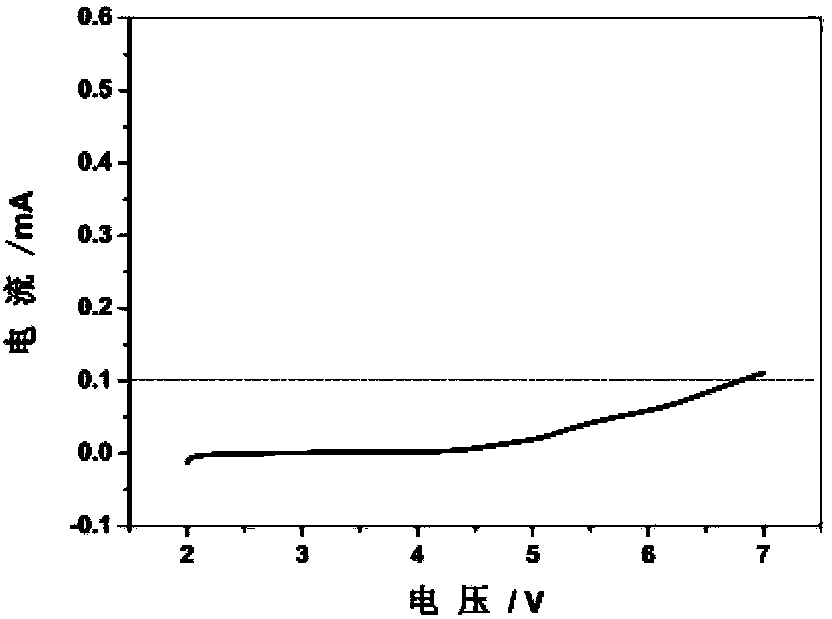

All-solid-state polyelectrolyte film, its preparation and application method

InactiveCN103367799AImprove thermal stabilityAchieve conductionSecondary cellsSolid state electrolytePolymer science

The invention provides an all-solid-state polyelectrolyte film based on polyvinyl formal or its homolog and a preparation method thereof. Through stepwise reaction of polyvinyl formal or its homolog and boric acid, oxalic acid, and a lithium salt in an organic solvent system, the solid-state polyelectrolyte film with polyvinyl acetal as a main chain and a lithium mono(oxalato)borate structure grafted on a polymer molecular chain can be formed. With low cost and simple operation, the all-solid-state polyelectrolyte film prepared by the invention can realize large-scale production, and has ideal ionic conductivity, electrochemical stability window and mechanical properties. Therefore, the all-solid-state polyelectrolyte film can be used as all-solid-state electrolyte in polymer lithium ion batteries to improve the safety performance of the lithium ion batteries.

Owner:浙江爱科新材料有限公司

Capacitor and method of manufacturing the same

InactiveUS20050083635A1Stable chemical structureReduce the binding forceMaterial nanotechnologyThin/thick film capacitorCross-linkCarbon nanotube

Owner:FUJIFILM BUSINESS INNOVATION CORP

Preparation method for novel graphene polyion liquid composite material

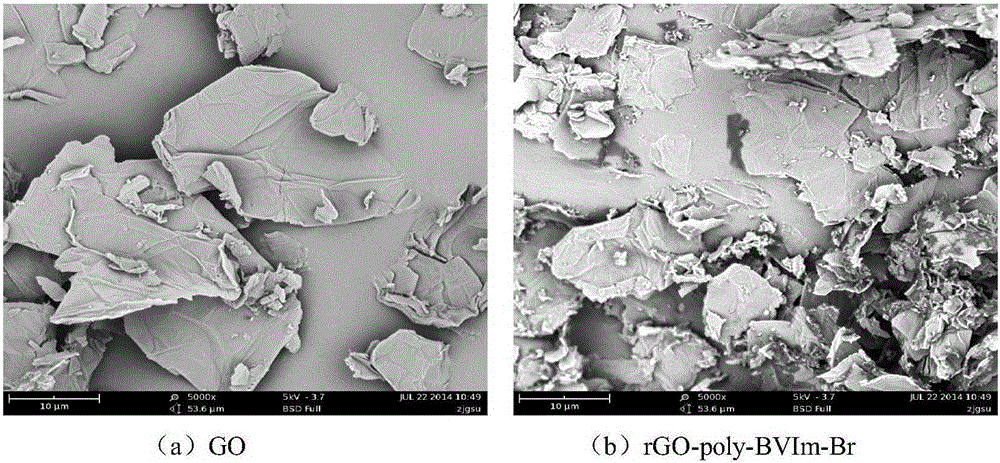

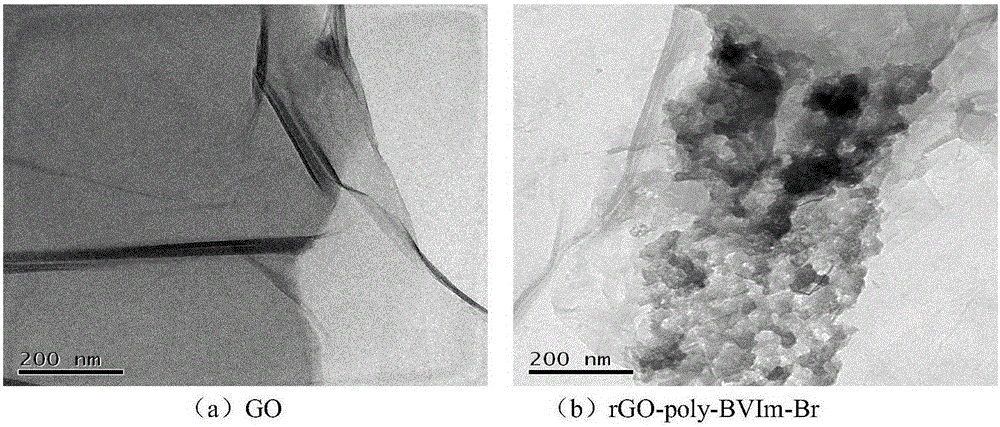

ActiveCN105289503AReduce the adsorption rateHigh adsorption rateOther chemical processes2-methylpropeneSupercapacitor

The invention provides a preparation method for a novel graphene polyion liquid composite material. The method comprises the following steps of 1, preparing graphene oxide; 2, preparing ionic liquid 1-[(2-methylacryloyl)-ethyl-3-(MEBIm-Br); 3, using the 1-[(2-methylacryloyl)-ethyl-3-(MEBIm-Br) as imidazole ionic liquid to obtain the novel graphene polyion liquid composite material (rGO-poly-MEBOm-B and rGO-poly-MEBIm-Br). The obtained novel graphene polyion liquid composite material not only can be applied to the aspects of biological sensors, super-capacitors and the like and but also has the good performance on the aspects of adsorbing and separating pollutants.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Gas decomposing unit, electrode for a fuel cell, and method of manufacturing the gas decomposing unit

InactiveUS20050090388A1Stable chemical structureLengthMaterial nanotechnologyGas treatmentCross-linkFuel cells

Provided are a gas decomposing unit and an electrode for a fuel cell capable of stably supporting a gas decomposing catalyst. A gas decomposing unit and an electrode for a fuel cell each including: a carbon nanotube structure having a mesh structure in which functional groups bonded to plural carbon nanotubes are chemically bonded to mutually cross-link the plural carbon nanotubes; and a gas decomposing catalyst supported on the carbon nanotube structure. A method of manufacturing a gas decomposing unit characterized by including: an applying step of applying, to the surface of a substrate, a solution containing plural carbon nanotubes to which functional groups are bonded; a cross-linking step of chemically bonding the functional groups to build a mesh structure in which the plural carbon nanotubes mutually cross-link; and a supporting step of forming the carbon nanotube structure supporting a gas decomposing catalyst.

Owner:FUJIFILM BUSINESS INNOVATION CORP

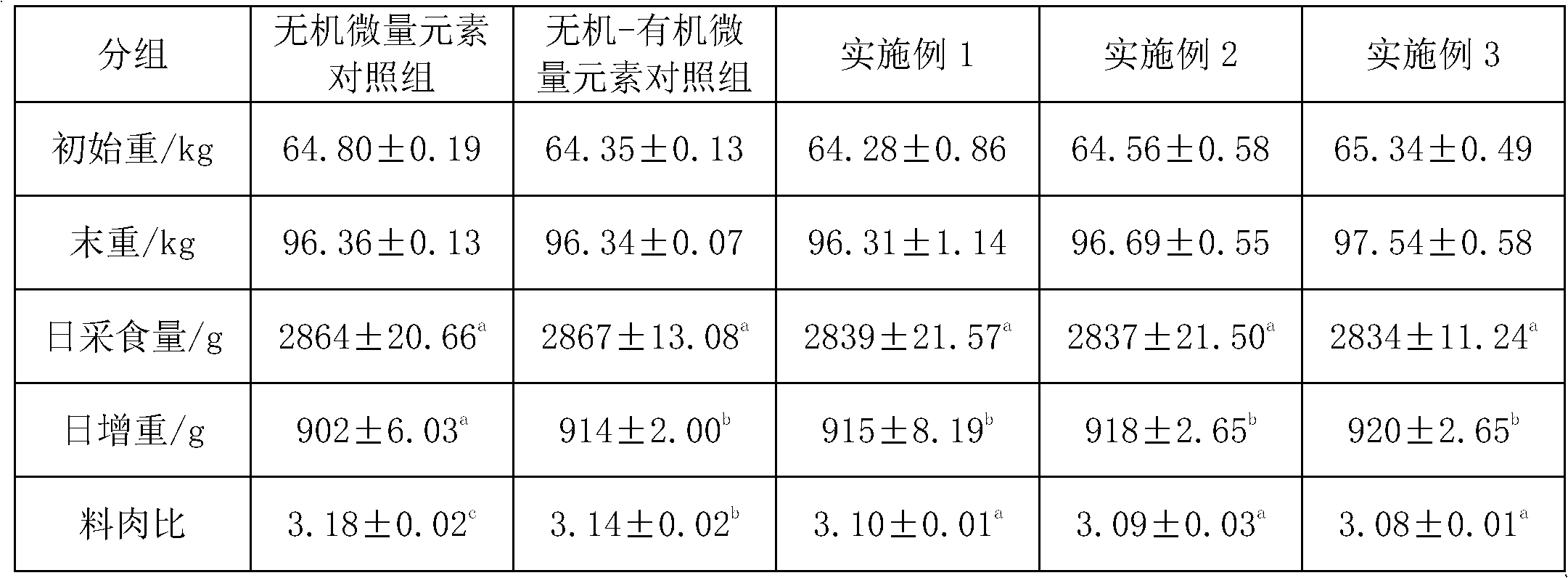

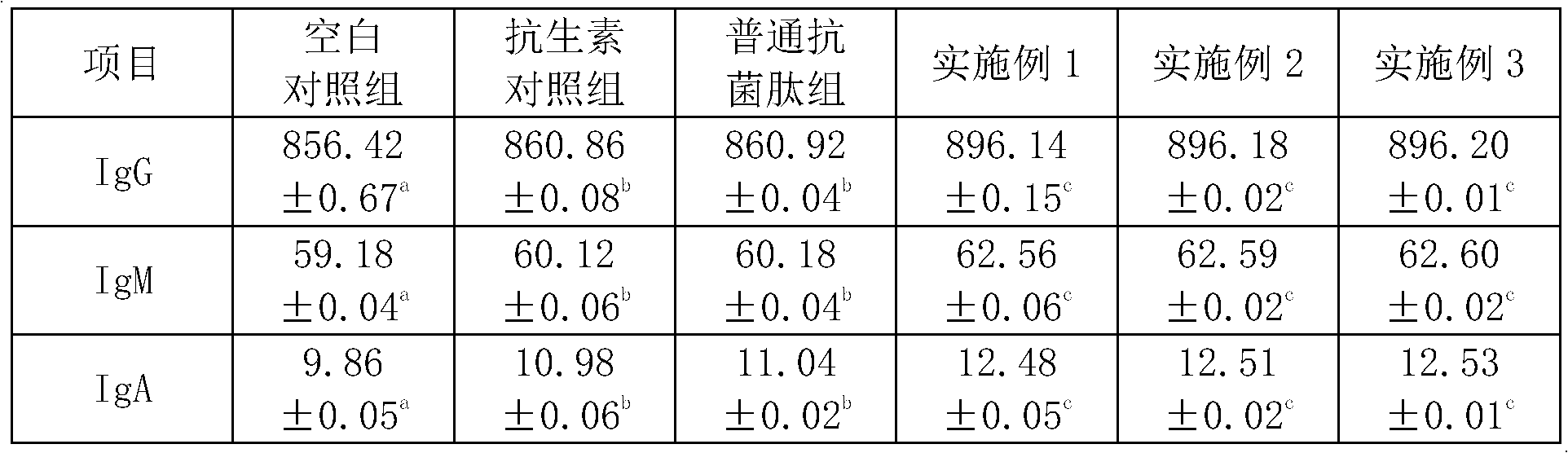

Composite premix for pigs

ActiveCN102726618AImprove immunityImprove survival rateAnimal feeding stuffPig farmsEcological environment

The invention discloses a composite premix for pigs and belongs to the technical field of feeds. The composite premix for pigs comprises a carrier, mineral matters, composite vitamin, amino acid, an anti-oxidant, phytase, antibacterial peptide and phytosterol. The mineral matters comprise trace element mineral matter and constant element mineral matter. The composite premix for pigs contains no antibiotic but antibacterial peptide and phytosterol. The trace elements adopted in the invention are mainly organic trace elements. Weighed according to a ratio, components of the composite premix forpigs can perform a synergistic effect, so as to avoid the antagonistic effect, raise utilization rate of additives such as trace elements for live pigs, save limited resources of inorganic mineral feeds, substantially improve the ecological environment around a pig farm, simultaneously reduce deposition of the trace elements in pigs, raise the quality of pork and guarantee the health of consumers.

Owner:CHENGDU CENTURY INVESTMENT

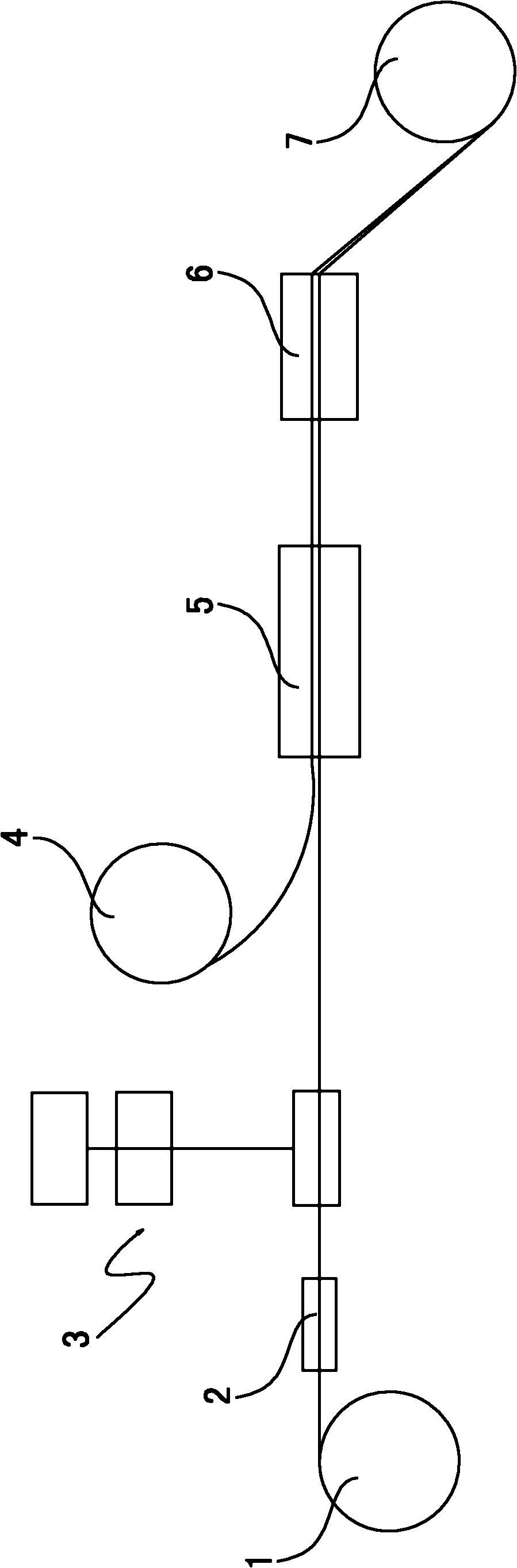

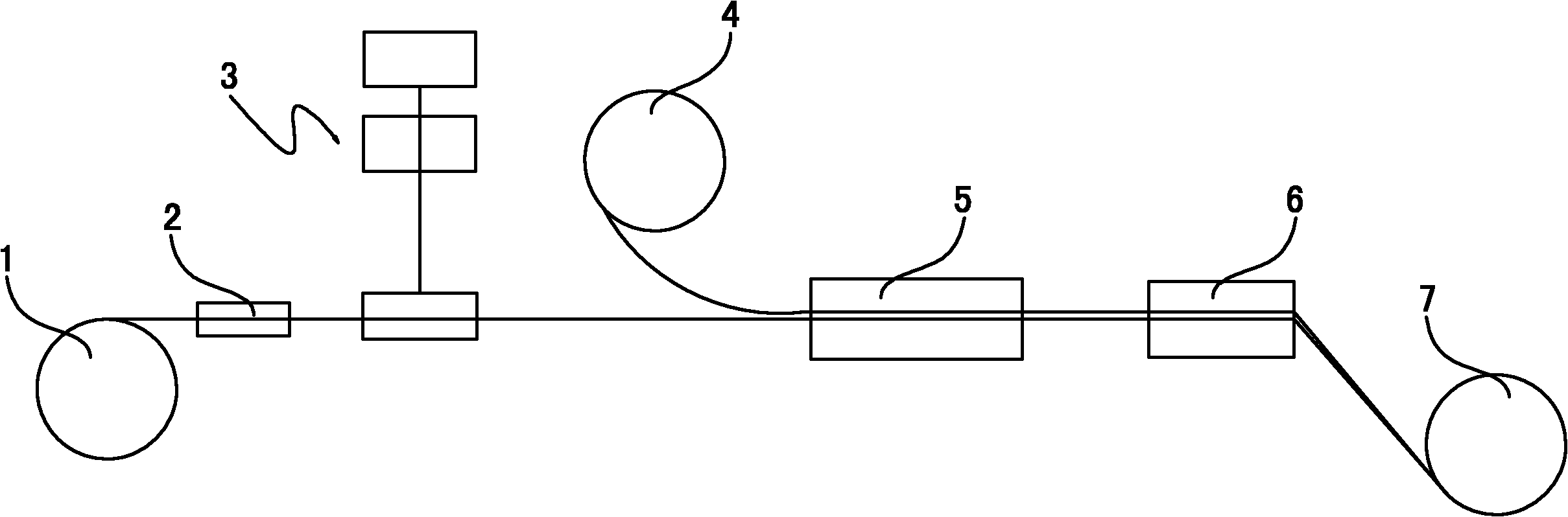

A kind of ultrasonic heat-sealing film for preparing aircraft inner wall insulation sealing bag and preparation method thereof

ActiveCN102267264AImprove performanceImprove permeabilitySynthetic resin layered productsLaminationAviationGlass fiber

The invention discloses an ultrasonic sealing film for preparing thermal-isolating, soundproof, fire-retardant, moistureproof, shock-resistant and high-strength insulating sealable bags on the inside walls of aircrafts, and a preparation method thereof. According to the ultrasonic sealing film for preparing insulating sealable bags and the preparation method thereof, the thickness of a substrate of the film is 0.008-0.05 mm, the coating weight of an ultrasonic sealing polyurethane adhesive is 5-35g / m<2>, a reinforcing fiber web is composed of polyamide fibers by way of weaving, and the proportion of the polyamide fibers is 0.006-0.035 ounces / cubic Zhang, the adhesive coating mode refers to one of comma blade coating, bar coating, web coating, extrusion coating and slot coating, the drying temperature is 80-110 DEG C, and the coating speed is 15-55 m / min. The prepared ultrasonic sealing film is subjected to press fit by using an ultrasonic seam-sealed machine. Therefore, the sealable bag (in a shell of an aircraft) prepared by press fit, and can meet the requirements of American FAA (federal aviation administration) after being filled with glass fiber felts; and the peel strength of the press-fitted sealable bags is more than 400g / cm<2>400.

Owner:太仓斯迪克新材料科技有限公司

Full-color three-dimensional self-luminous road line paint and preparation method thereof

InactiveCN104629568AStable chemical structureImprove water resistanceLuminescent paintsRadiation-absorbing paintsAcrylic resinFriction force

The invention discloses a full-color three-dimensional self-luminous road line paint and a preparation method thereof. The full-color three-dimensional self-luminous road line paint comprises the following components in parts by mass: 20-40 parts of acrylic resin, 0-20 parts of titanium dioxide, 0.1-10 parts of an additive, 10-20 parts of an extender pigment, 10-30 parts of an organic solvent and 20-60 parts of a luminous carrier, wherein the additive is a mixture of a dispersant, a flatting agent, a plasticizer, an anti-settling agent and a defoaming agent at any ratio. The preparation method comprises the following steps: preparing a mother solution by stirring the acrylic resin, the organic solvent and the anti-settling agent at a high speed; respectively adding the titanium dioxide, the extender pigment and the dispersant into the mother liquid and uniformly dispersing by stirring by a medium speed to obtain a predispersoid; grinding the predispersoid, subsequently adding the luminous carrier, the flattening agent, the plasticizer and the defoaming agent and uniformly stirring to obtain the full-color three-dimensional self-luminous road line paint. The method is simple; the prepared paint is safe and nontoxic, has the capabilities of repeatedly absorbing light, storing light and emitting light, and is extremely high in light radiation resistance, high in ageing resistance and good in adhesive force and hardness friction force resistance; a coating formed by the paint is good in water resistance, alkali resistance and weather resistance.

Owner:SHAANXI CENTURY TRAFFIC ENG

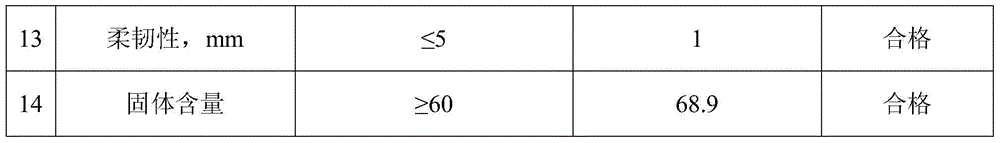

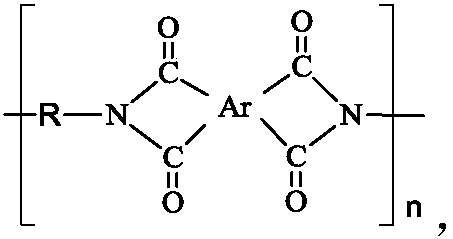

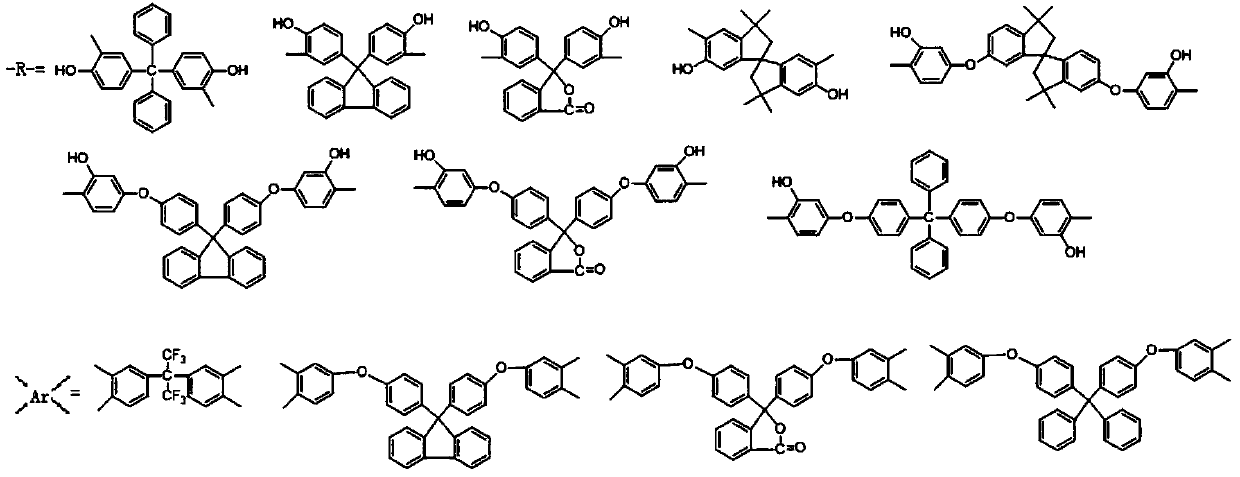

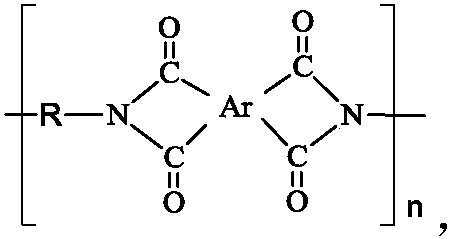

Preparation method of high-throughput graphene oxide/polyimide mixed matrix membrane material

ActiveCN107551835AImprove throughputHigh selectivitySemi-permeable membranesChemical structureRearrangement reaction

The invention relates to a preparation method of high-throughput graphene oxide / polyimide mixed matrix membrane material. The high-throughput graphene oxide / polyimide mixed matrix membrane material isprepared by the steps of introducing graphene oxide into a polyimide matrix subjected to thermotropic rearrangement reaction through an in-situ method to prepare a composite material membrane, and processing the composite material membrane for at least 0.1h under inert atmosphere. The prepared mixed matrix gas separation membrane material has the characteristics of excellent seepage separation performance and stable chemical structure and can solve the inadequate problems of limited separation performance, poor anti-plasticizing capability, poor temperature tolerance and the like of the existing polymer separation membrane material.

Owner:UNIV OF SCI & TECH LIAONING +1

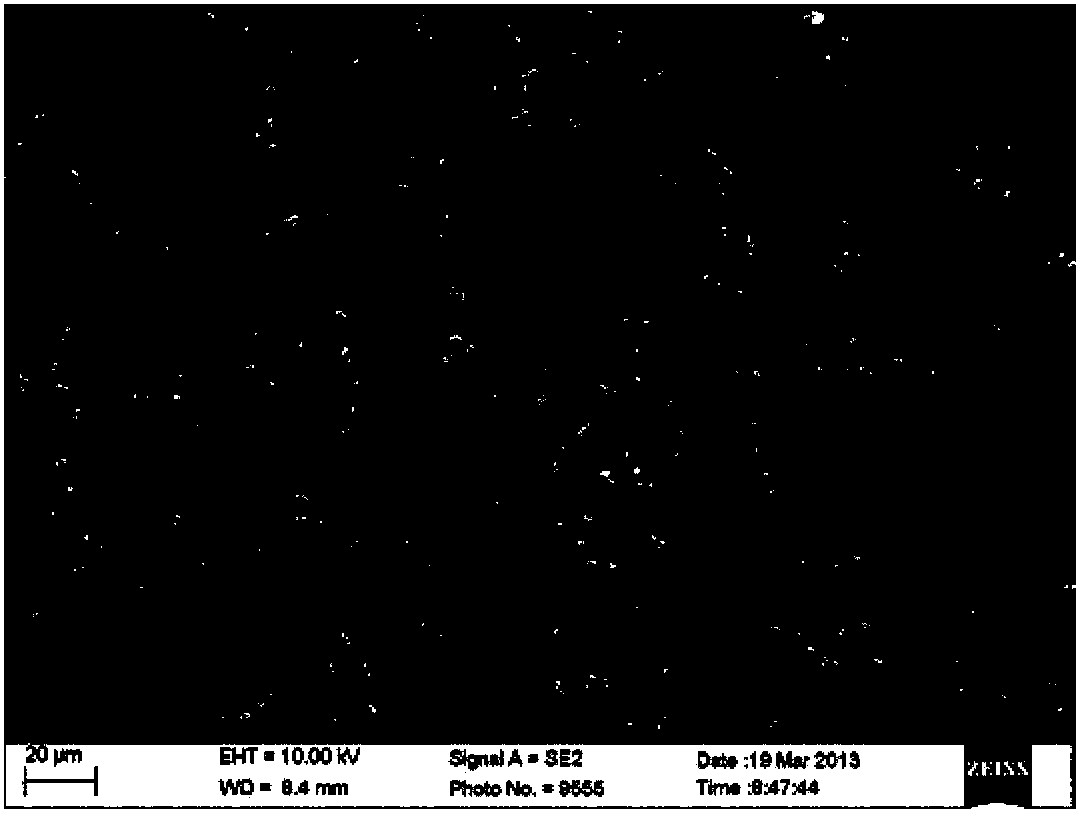

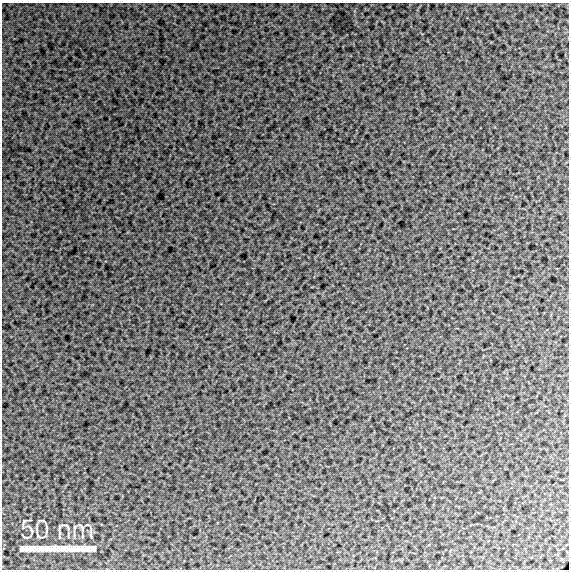

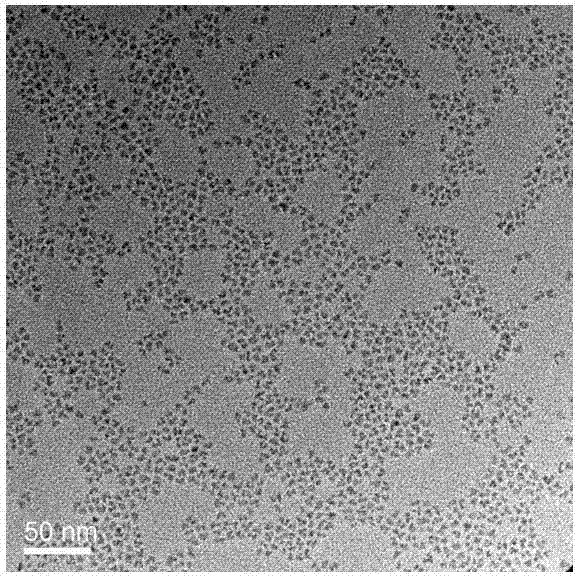

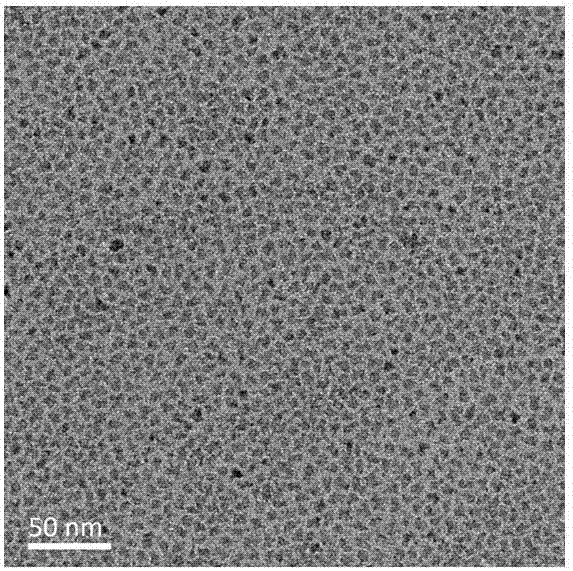

Surface modifier for preparing water-solubility and high biocompatibility metal nano particles and preparation and use method thereof

The invention discloses a surface modifier used for preparing water-soluble and metallic nano-particles with high biocompatibility, a preparation method and a usage method used for the metallic nano-particle. The surface modifier is a small molecular compound and consists of three parts: a functional group A which is used for being combined with the metal nano-particle, a middle spacing arm B and an end phosphorylcholine function group C. The surface modifier can be used for water-soluble or oil-soluble metallic nano-particle, forms stable single-molecular protection layer on the surface of the nano-particle, improves the water-solubility, stability, anticoagulant activity and biocompatibility of the nano-particle. The surface modifier can be used for the fields of drug releasing, gene delivery, biomolecule diagnosis, biomolecule separation, biological sensor, etc.

Owner:ZHEJIANG UNIV

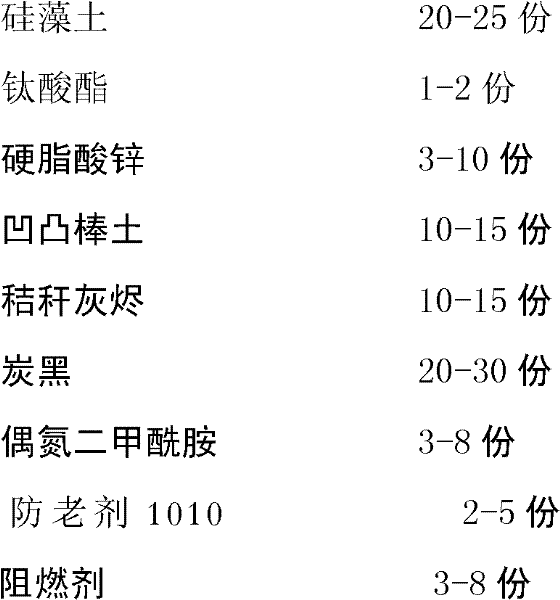

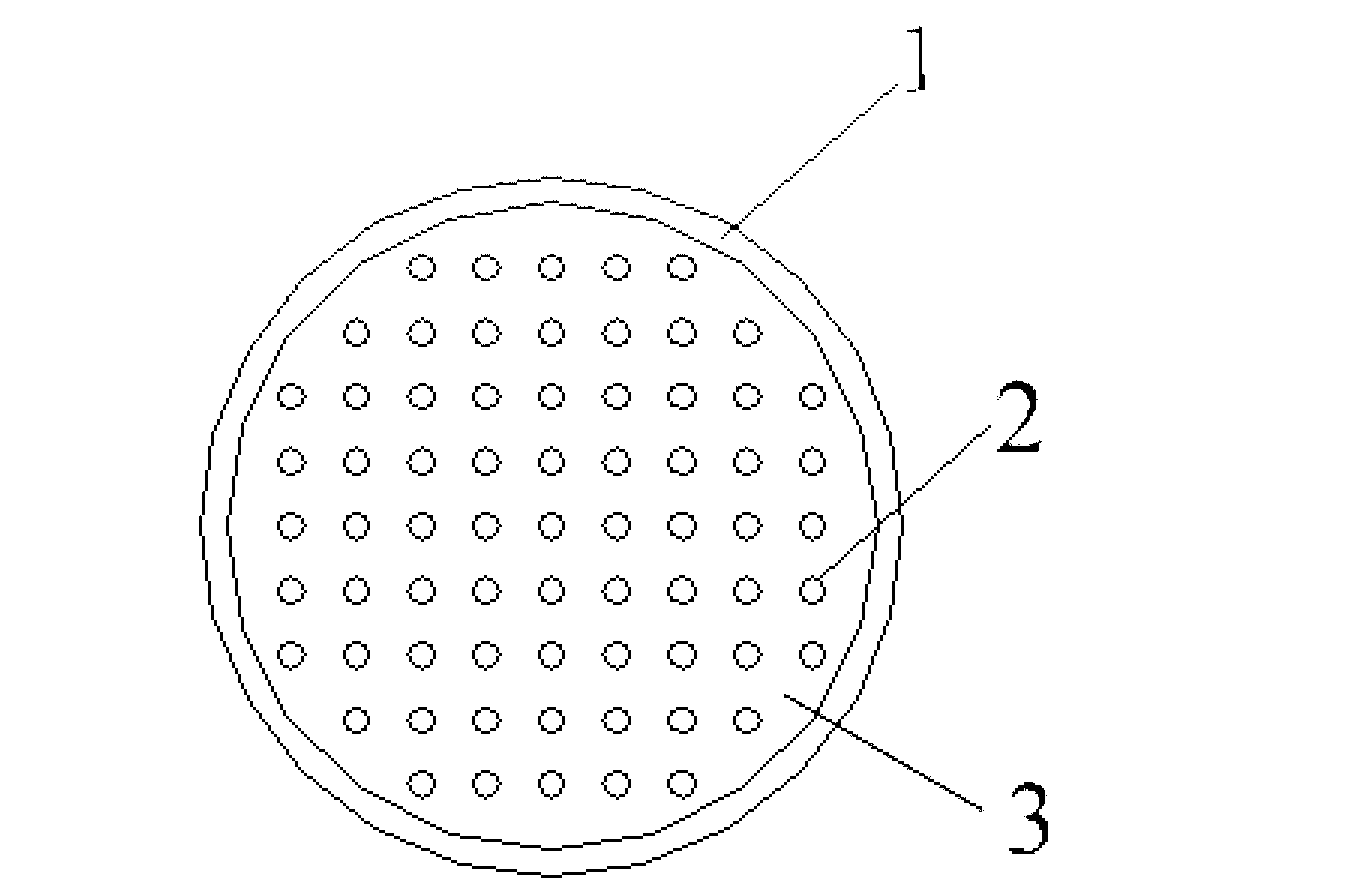

Flame-retardant cable filler and preparation method thereof

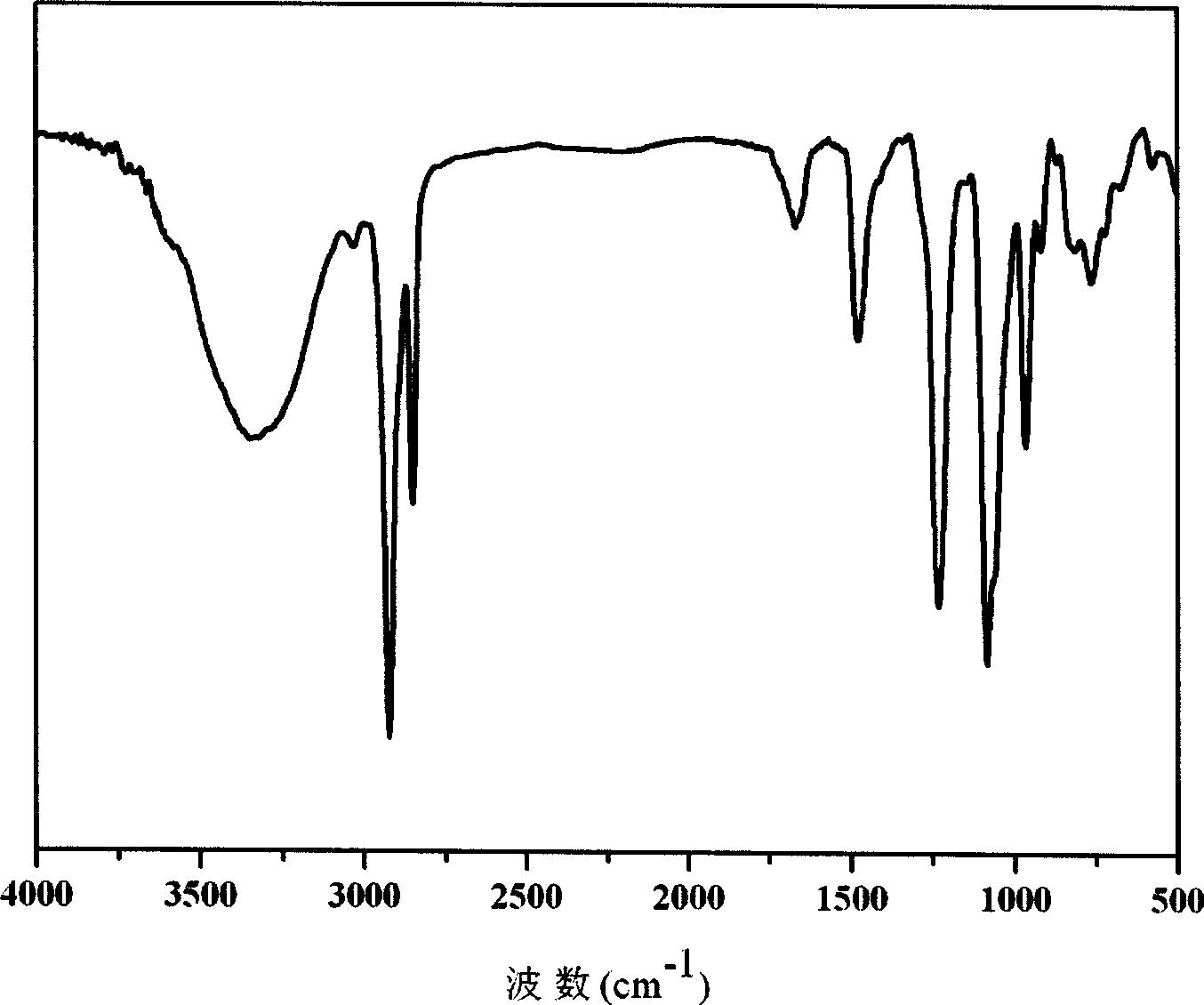

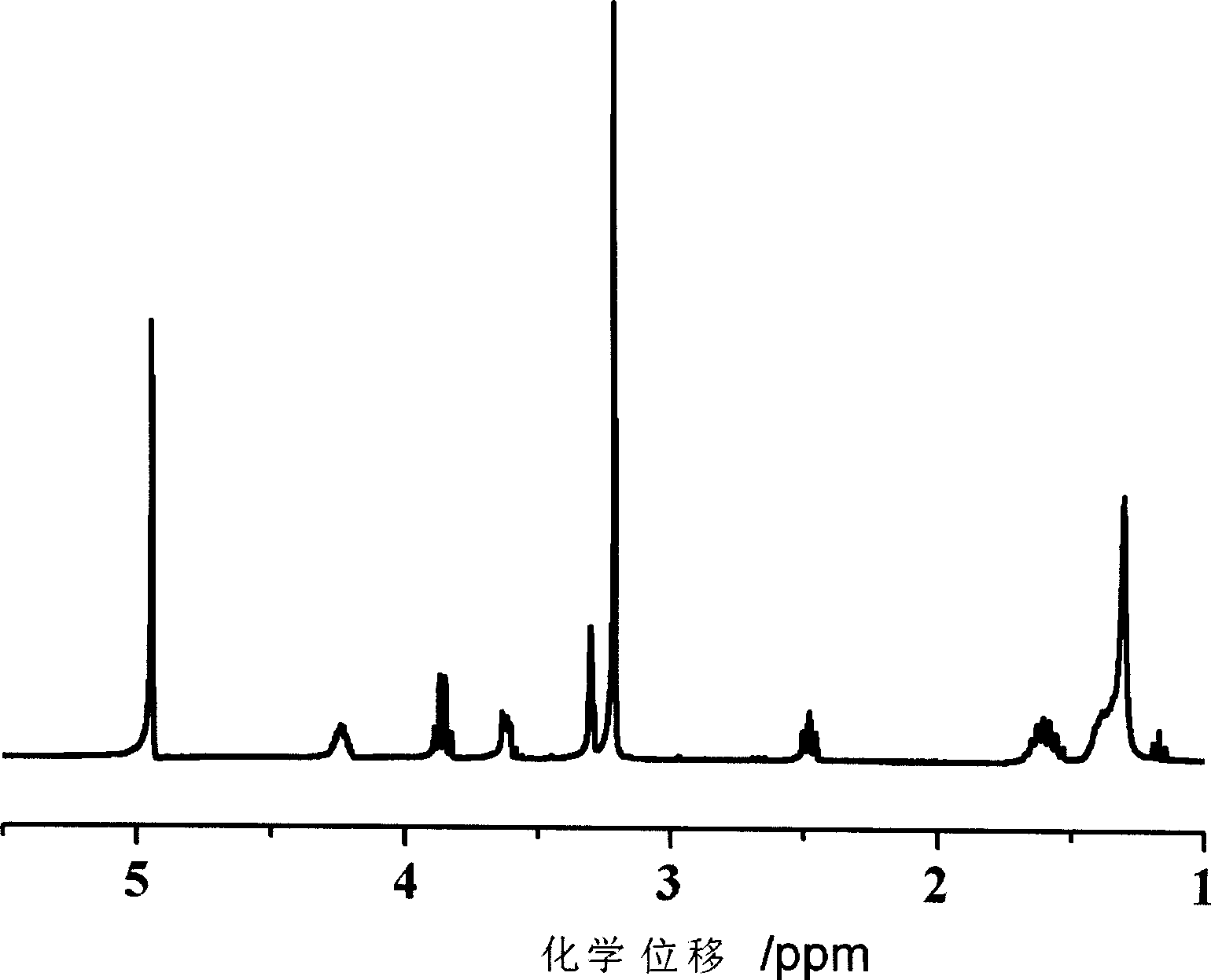

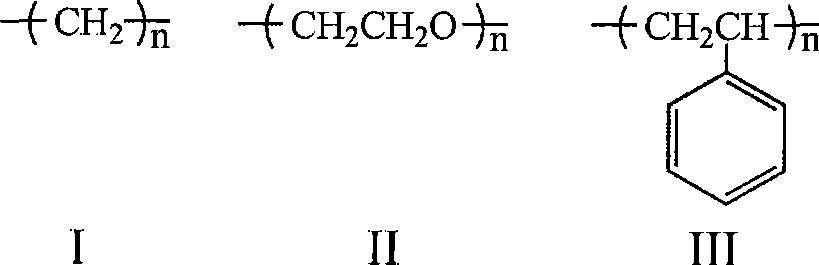

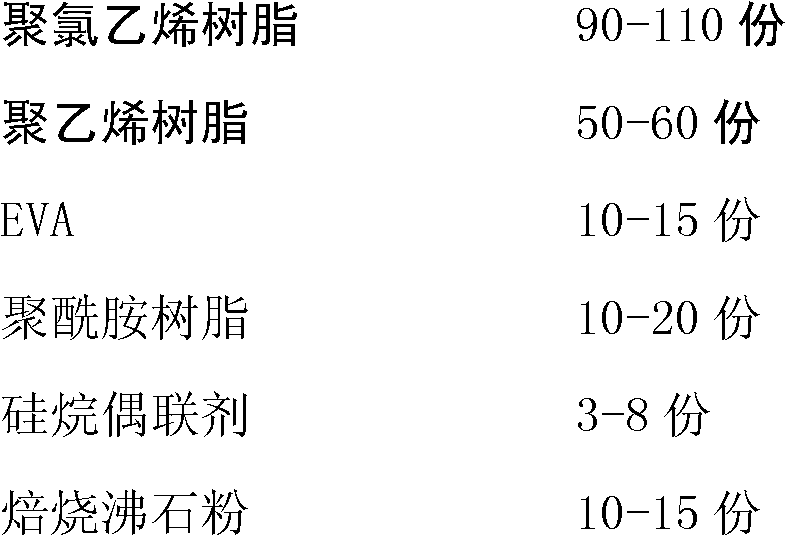

InactiveCN102504436AStable chemical structureGood gelPower cablesChemical structurePolyvinyl chloride

The invention discloses flame-retardant cable filler and a preparation method of the flame-retardant cable filler. The flame-retardant cable filler is prepared by the following main raw materials according to a certain mixing proportion: polyvinyl chloride resin, polyvinyl resin, EVA (ethylene), polyamide resin, silane coupling agents, roasted zeolite powders, diatomite, titanate, zinc stearate, attapulgite, straw ashes, carbon black, azodicarbonamide, an age resister 1010 and a fire retardant. The fame-retardant cable filler has a stable chemical structure, can not be decomposed by microorganism easily, is good in gel property and high in swelling capability, and the electrical property of the cable is improved, the service life of the cable is prolonged, and the resources are saved.

Owner:池州灵芝化建材料科技有限公司

Selenium-rich medicinal herb feed additive

InactiveCN102972627ANo cross resistanceImprove immunityFood processingAnimal feeding stuffMedicinal herbsBiotechnology

The invention relates to a selenium-rich medicinal herb feed additive. The additive is characterized by comprising the following components: polygonum multiflorum, sophora flavescens, cyrtomium rhizome, coptis, pine needle, epimedium, kudzuvine leaf, sweet wormwood, honeysuckle and cibotium barometz. The selenium rich medicinal herb feed additive is a feed additive prepared by using Hubei Enshi selenium rich medicinal herbs as raw materials; the medicinal herbs are medicaments and natural products and contain multiple minerals and vitamins, so the additive has an effective effect of a feed additive and can become a unique feed additive; various animals freely eat the medicinal herbs in field; and the additive can promote the growth of the animals, prevent and treat diseases, enhance the disease resistance of the animals and condition the physiological functions of the animals.

Owner:HUBEI UNIV FOR NATITIES

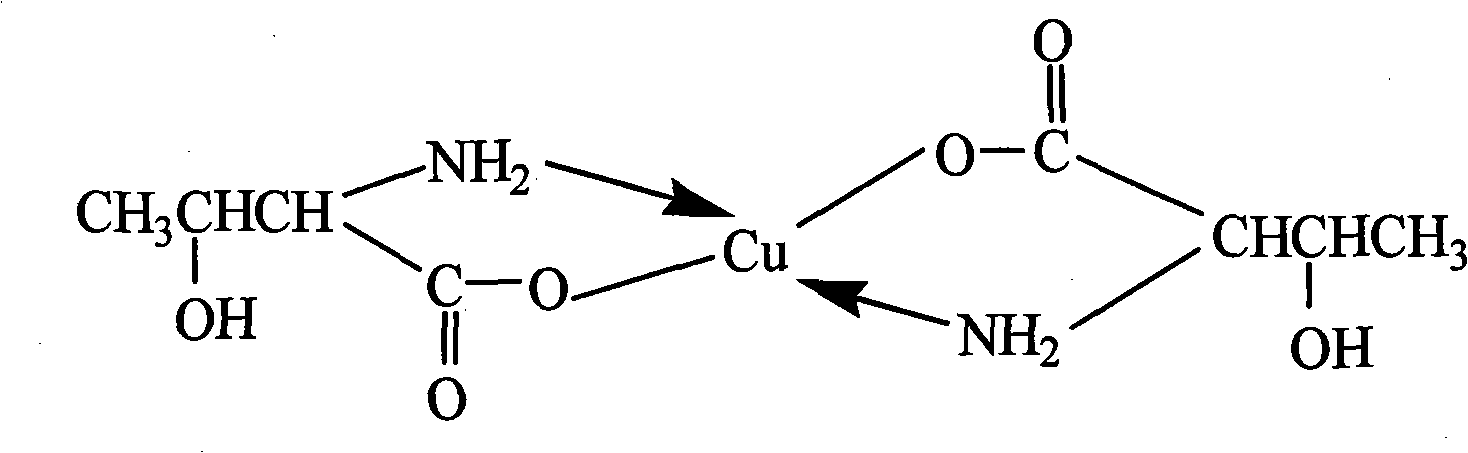

Method for preparing DL-threonine chelated copper serving as feed additive

InactiveCN101838214AHigh yieldRaw materials are easy to getOrganic compound preparationAnimal feeding stuffGlycineFood additive

The invention discloses a method for preparing DL-threonine chelated copper serving as a feed additive. The invention adopts a technical scheme of taking aminoacetic acid as raw material, allowing aminoacetic acid to react with basic copper carbonate to form glycine chelated copper and allowing glycine chelated copper to react with acetaldehyde to form DL-threonine chelated copper. Compared with the conventional method for preparing threonine chelated copper, the method of the invention has the following outstanding advantages that: 1) as threonine and threonine chelated copper are prepared from aminoacetic acid, the method is readily available in raw material, needs no threonine and is low in cost; 2) as the feed additive amino-acid chelated copper does not need separation, and DL-threonine copper is directly utilized, so over 50 percent of cost is reduced; and 3) the preparation of the DL-threonine chelated copper is performed at normal temperature under normal pressure and is short in reaction route, little in equipment investment and convenient for industrial production.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

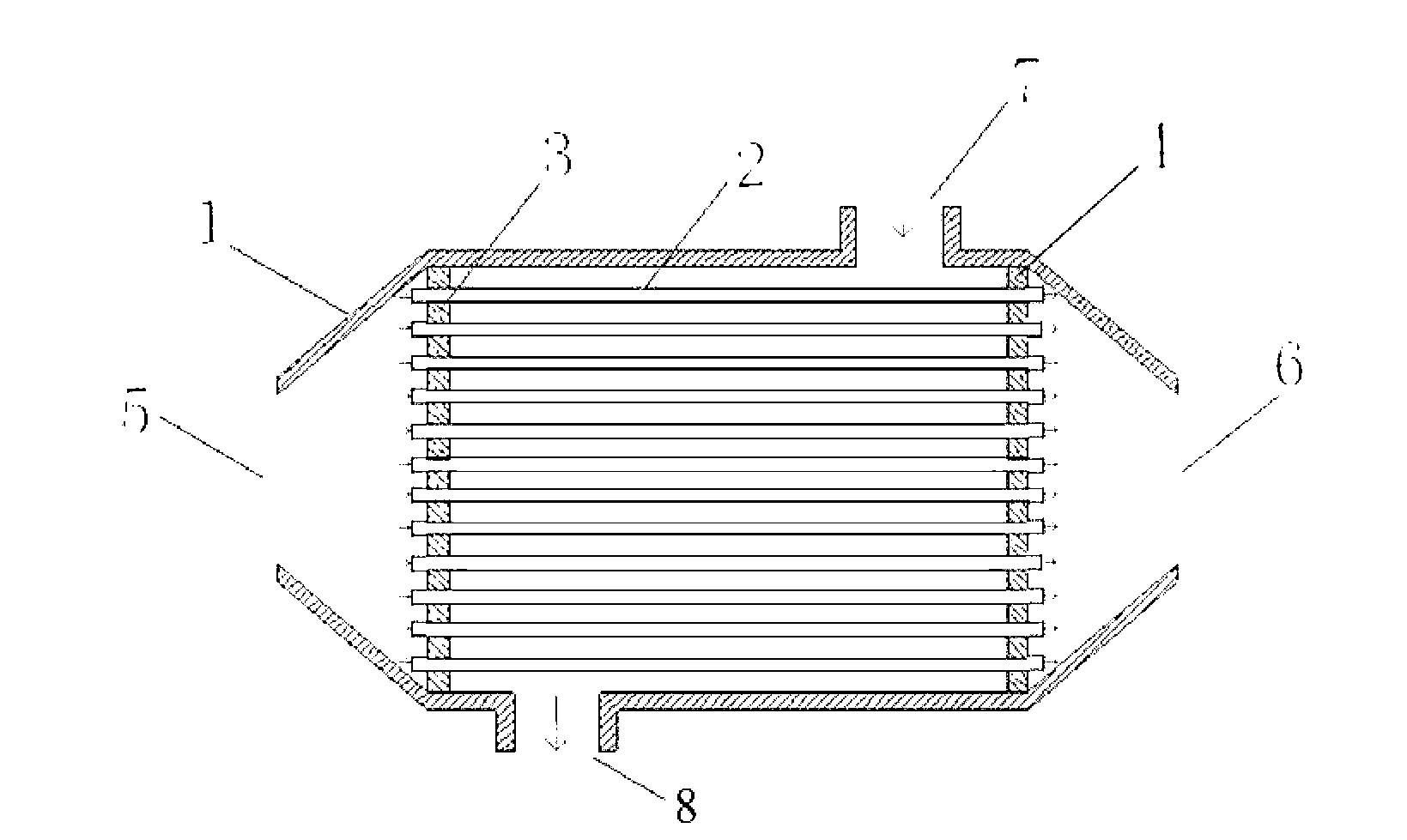

Membrane humidifier for fuel cells

The invention discloses a membrane humidifier for fuel cells, which comprises a cylindrical shell, humidification tubes, a first baffle and a second baffle plate, wherein each humidification tube adopts a two-layer structure; the outer layer of the humidification tube is an aramid paper tube; the inner layer of the humidification tube is a stainless-steel screen stencil; and the two ends of the humidification tube are respectively fixed on the first baffle and the second baffle plate and are sealed in the cylindrical shell, so as to form a tube side and a shell side. The invention further discloses a fuel cell device comprising the membrane humidifier. According to the membrane humidifier for fuel cells, two different gases are conveyed to the tube side and the shell side, and humidity exchange and temperature exchange are carried out through the tube walls of the humidification tubes, so that inlet air of the fuel cells can be humidified and heated effectively and the performance of the fuel cells can be played better; and the membrane humidifier is simple in preparation technology, excellent in performance, lower in cost and long in service life.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of supported catalyst for synthesizing chloroaniline through catalytic hydrogenation of chloronitrobenzene

InactiveCN109939713AThe production process is not bigSimple processOrganic compound preparationCatalyst activation/preparationAsymmetric hydrogenationAniline

The invention relates to a preparation method of a supported catalyst for synthesizing chloroaniline through catalytic hydrogenation of chloronitrobenzene and particularly relates to a preparation method of a nitrogen-doped carbon material supported noble metal catalyst applied to the synthesis of chloroaniline through catalytic hydrogenation. The catalyst has the advantages of high catalytic activity, dechloridation inhibition capacity, long service life and the like, and the prepared chloroaniline product is high in purity.

Owner:JIANGSU YANGNONG CHEM GROUP +2

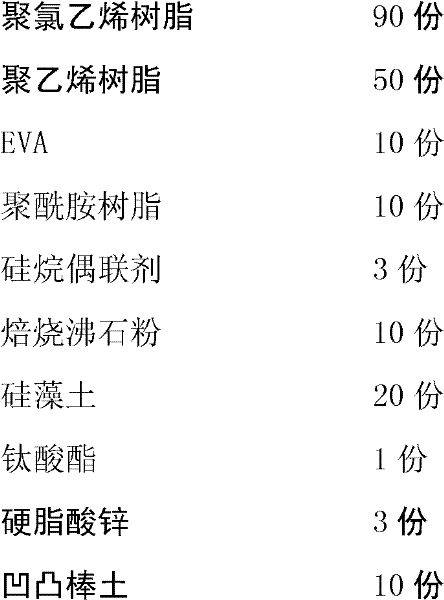

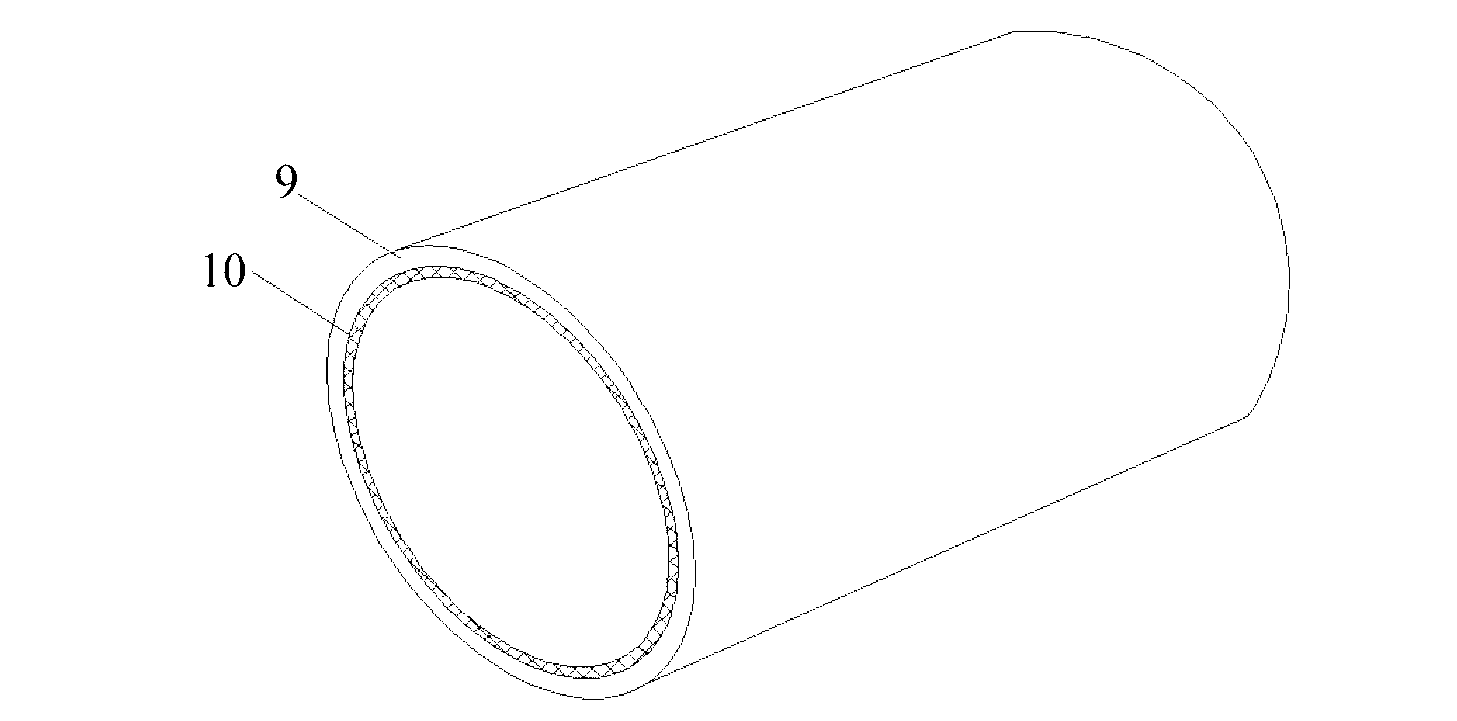

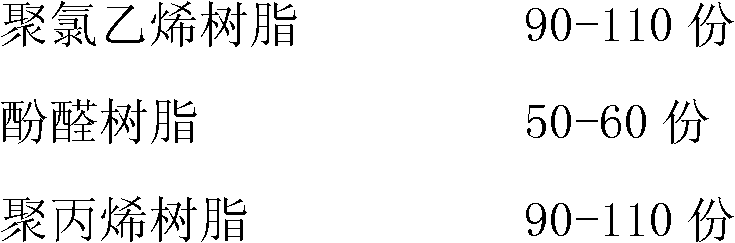

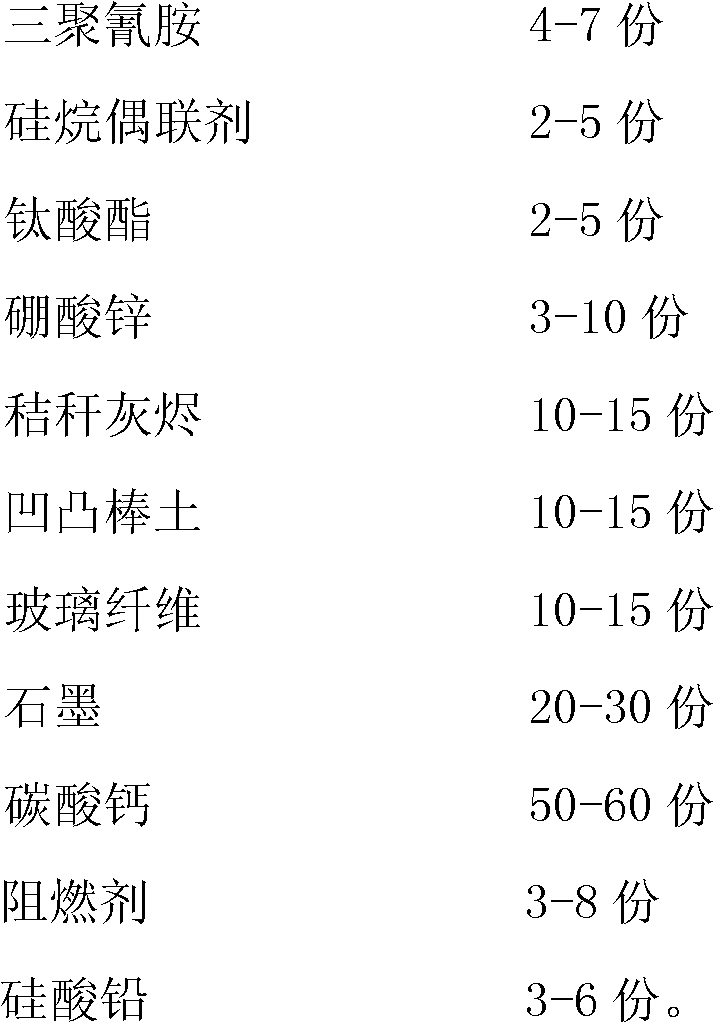

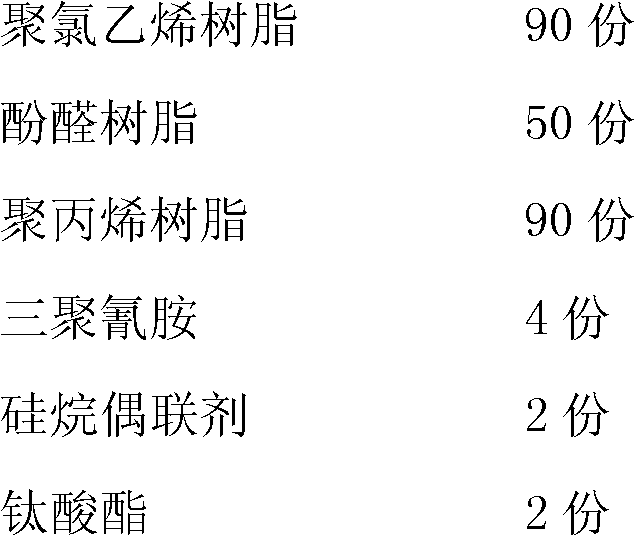

Modified cable filler and preparation method thereof

ActiveCN102585398AStable chemical structureGood gelInsulated cablesInsulated conductorsChemical structurePolymer science

The invention discloses a modified cable filler and a preparation method thereof. The modified cable filler is prepared by mixing raw materials such as polyvinyl chloride (PVC) resin, phenolic resin, polypropylene resin, melamine, a silane coupling agent, titanate, zinc borate, straw ash, attapulgite, glass fibers, graphite, calcium carbonate, a flame retardant and lead silicate in a certain ratio. The modified cable filler has a stable chemical structure and high gel performance and swelling capacity and is not decomposed by microorganisms, the electrical performance of a cable is improved, the service life of the cable is prolonged, and resources are saved.

Owner:安徽塞帕斯电缆材料有限公司

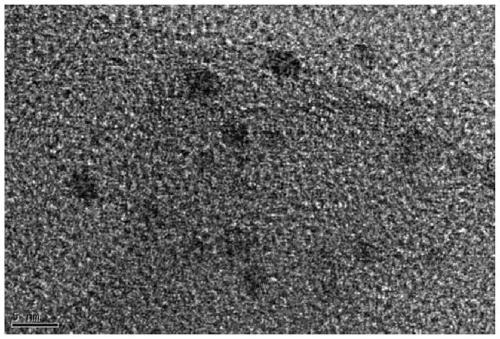

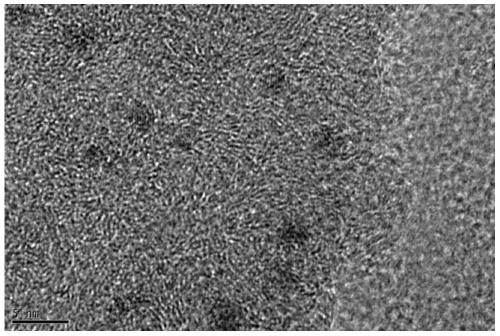

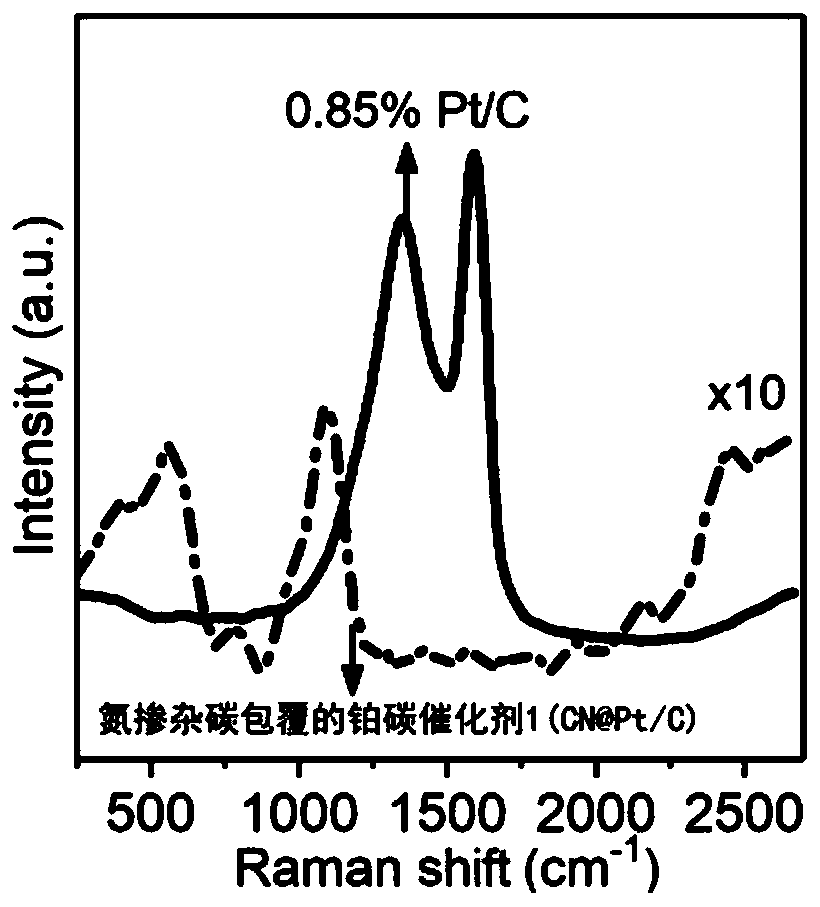

Nitrogen-doped carbon-coated catalyst as well as preparation method and application thereof

ActiveCN111151284ASimple preparation processStable hydrogenation activityMolecular sieve catalystsOrganic compound preparationCarbon layerPtru catalyst

The invention discloses a nitrogen-doped carbon-coated catalyst as well as a preparation method and application thereof. The invention provides a nitrogen-doped carbon-coated catalyst for preparing halogenated arylamine through catalytic hydrogenation of halogenated nitroaromatic hydrocarbons; the nitrogen-doped carbon-coated catalyst comprises a supported metal catalyst and a coating layer, the supported metal catalyst comprises a carrier and a metal active component, the coating layer is a nitrogen-doped carbon layer, and the thickness of the nitrogen-doped carbon layer is 0.1 nm-10 nm. Themetal active component is G-M, G is one or more of noble metals Pt, Pd, Rh or Ru, and M comprises at least one of metals Fe, Co, Ni, Sn and Mo. The catalyst provided by the invention is applied to preparation of halogenated arylamine through catalytic hydrogenation of halogenated nitroaromatic hydrocarbon; the conversion rate of the halogenated nitrobenzene is as high as 100%, the nitrogen-doped carbon-coated catalyst is quite high in activity and excellent in stability, high-purity halogenated arylamine can be obtained, the selectivity can reach 99.7% or above, dehalogenation is smaller than0.3%, and dehalogenation is effectively inhibited; a dechlorination inhibitor does not need to be added into a reaction system, so that the cost is reduced, the complexity of the reaction system is reduced, and side reactions possibly introduced are reduced.

Owner:XIAMEN UNIV

Transfer printing PP glue and preparation method thereof

InactiveCN104342068AEasy to makeOperational securityAldehyde/ketone condensation polymer adhesivesPolymer scienceOrganic solvent

The invention relates to a transfer printing PP glue and a preparation method thereof. The transfer printing PP glue is prepared from the following raw materials by weight part: 5-40 of chlorinated polypropylene resin, 0-40 of polyolefin adhesion promotion resin, 0-20 of EVA resin, 0-20 of phenolic resin, 0.1-5 of an anti-adhesive additive, and 60-90 of an organic solvent. The preparation method includes: when the raw materials are not 0 at the same time, under room temperature and atmosphere pressure, conducting stirring mixing for 40-120min at a stirring speed of 2000-10000 rpm, thus obtaining the transfer printing PP glue. Compared with the prior art, the preparation method provided by the invention is simple and is safe to operate. The prepared glue has the advantages of good stability, no denaturation after long-term placement, and is good drying property, good leveling property, easy gravure coating, and excellent adhesion to PP substrates and a variety of ink layers and coatings.

Owner:RESPLENDENT SHANGHAI SPECIALDECAL CO LTD

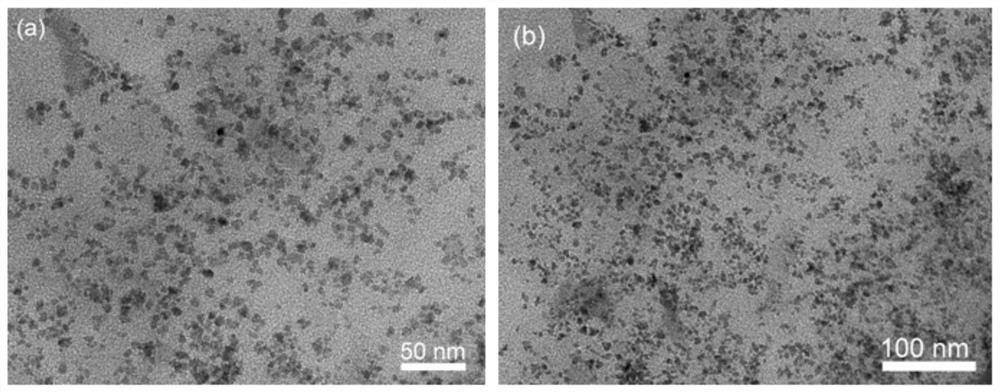

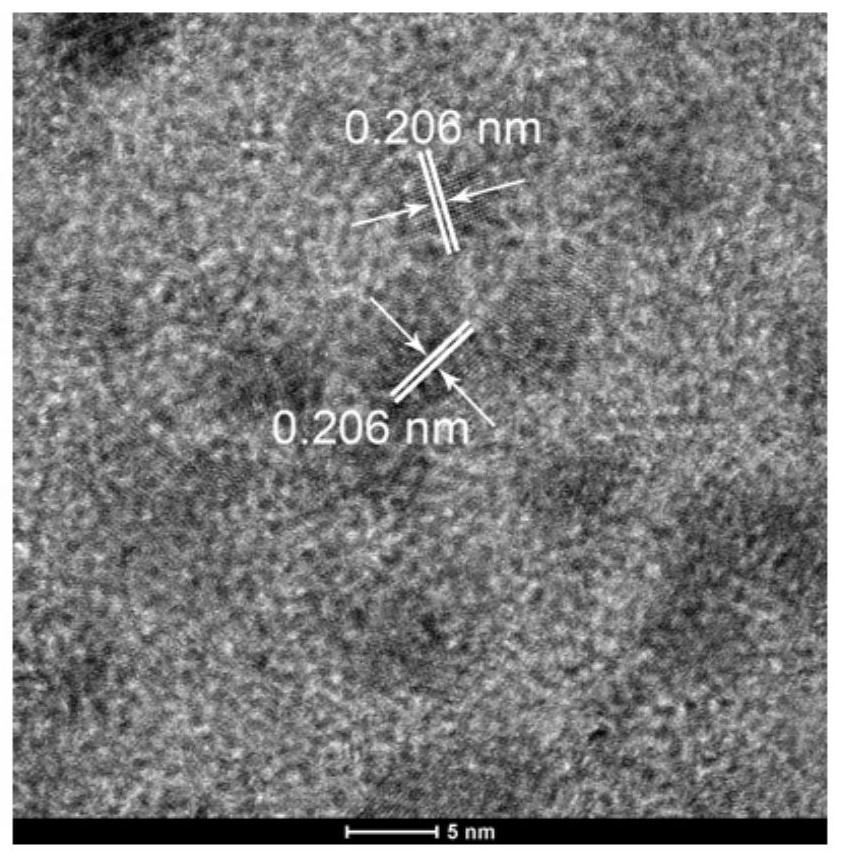

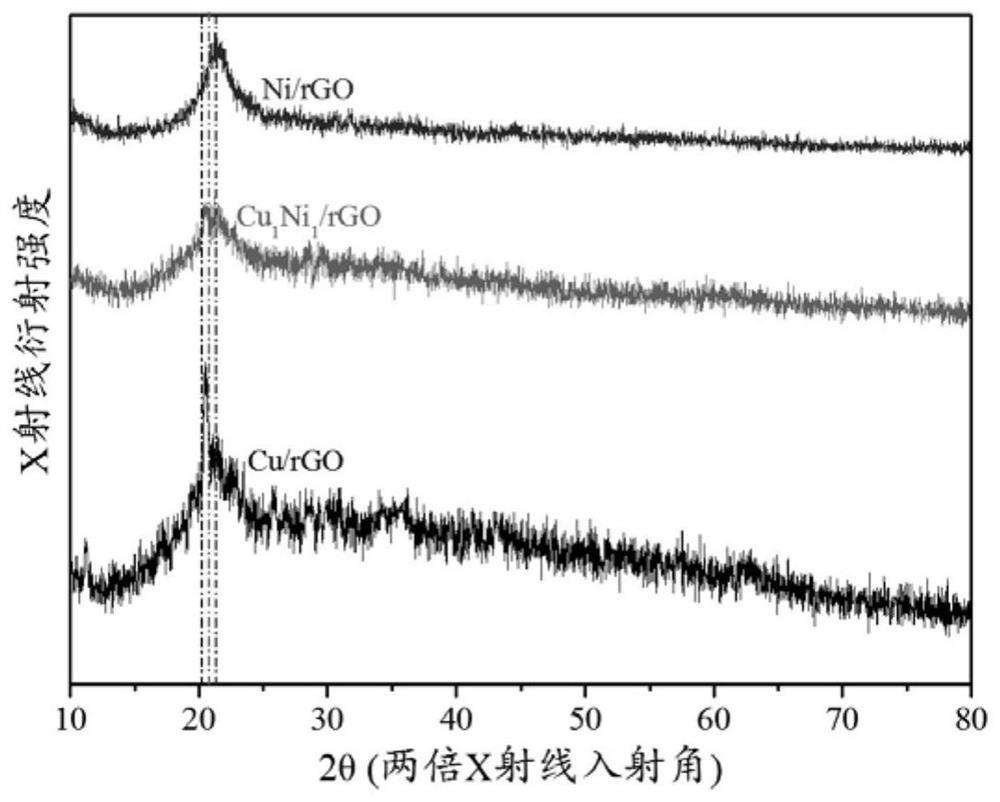

Preparation method of supported CuNi bimetallic catalyst and application of supported CuNi bimetallic catalyst in reduction reaction

ActiveCN111659400AMultiple controllabilityModulation of catalytic activityOrganic compound preparationCatalyst activation/preparationPtru catalystCopper acetylacetonate

The invention belongs to the technical field of catalyst preparation, and particularly relates to a preparation method and application of a supported CuNi bimetallic Cu1Ni1 / rGO catalyst. The preparation method of the catalyst comprises the following steps: (1) mixing copper acetylacetonate, nickel acetylacetonate, ferric trichloride, ascorbic acid and oleylamine; (2) adding graphene oxide into deionized water; (3) adding a graphene oxide aqueous solution obtained in step (2) into a material obtained in step (1), and uniformly mixing; (4) heating a material obtained in step (3) to react, stirring, cooling and standing; and (5) centrifuging a reaction solution obtained in step (4), and removing impurities to obtain the supported bimetallic catalyst. The catalyst disclosed by the invention ishigh in catalytic activity, stable in chemical structure and relatively good in conductivity; the raw materials are rich in source, and the catalyst preparation cost is reduced; and the cyclic utilization rate is high.

Owner:HUANGSHAN UNIV

Natural keratin composite fertilizer and method for preparing same

ActiveCN101514122AWell developed root systemGood qualityAnimal corpse fertilisersClimate change adaptationInorganic compoundBiology

The invention relates to a natural keratin composite fertilizer and a method for preparing the same. The paddy seedling raising farming fertilizer at present has unqualified product quality and cannot be applied widely. The natural keratin composite fertilizer comprises the following components in portion by weight: 75 to 85 portions of natural keratin raw material, 12 to 20 portions of sulphate inorganic compound, and 2 to 4 portions of complexing agent. The natural keratin composite fertilizer is applied to paddy seedling raising farming fertilizer and the method for preparing the same.

Owner:黑龙江省大地丰农业科技开发有限公司

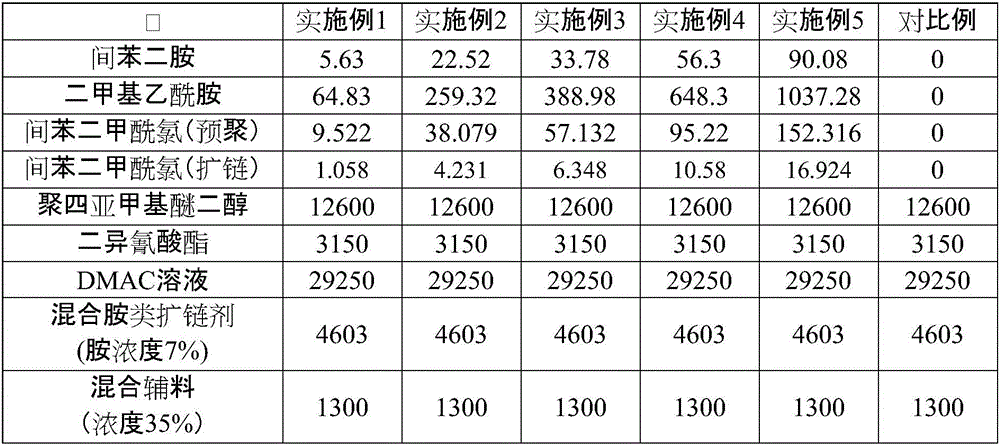

Heat-resistant spandex fiber and preparation method thereof

ActiveCN106592008AIncrease elasticityImprove heat resistanceMonocomponent synthetic polymer artificial filamentArtifical filament manufacturePolymer scienceAramid

The invention discloses a preparation method of heat-resistant spandex fiber. The preparation method is characterized in that a spinning solution for production of m-aramid fiber is added to a spinning solution for production of spandex. The method comprises four steps including preparation of the spandex spinning solution, preparation of the m-aramid fiber spinning solution, mixing of the spandex spinning solution and the m-aramid fiber spinning solution and dry spinning. The novel heat-resistant spandex fiber prepared through spinning after a few m-aramid fiber spinning solutions are added to the spandex spinning solution and mixed uniformly not only keeps original high elasticity, but also has more excellent heat resistance than conventional spandex fiber under the action of the m-aramid fiber spinning solution.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

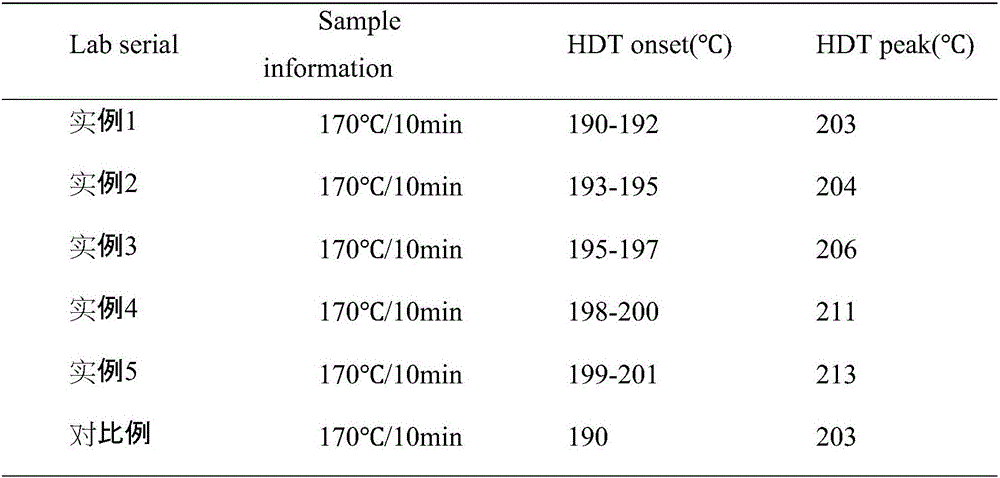

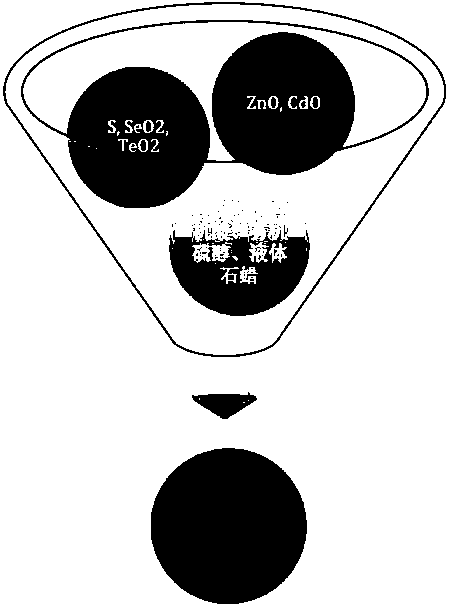

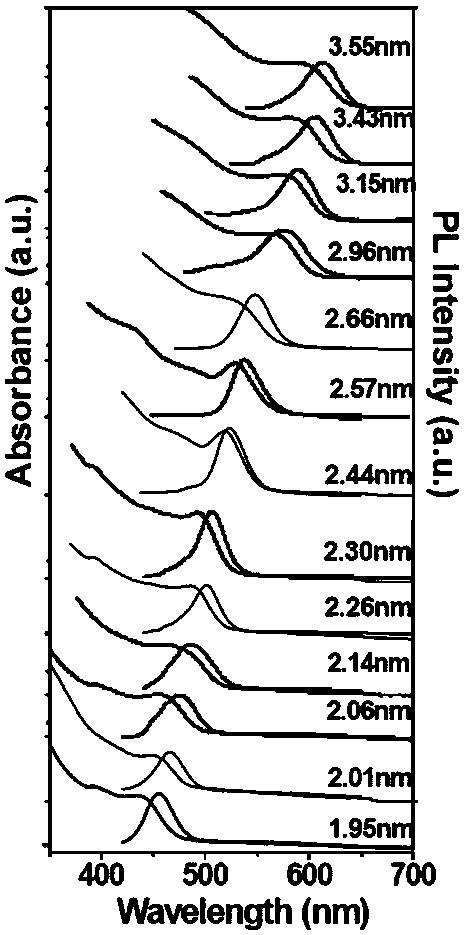

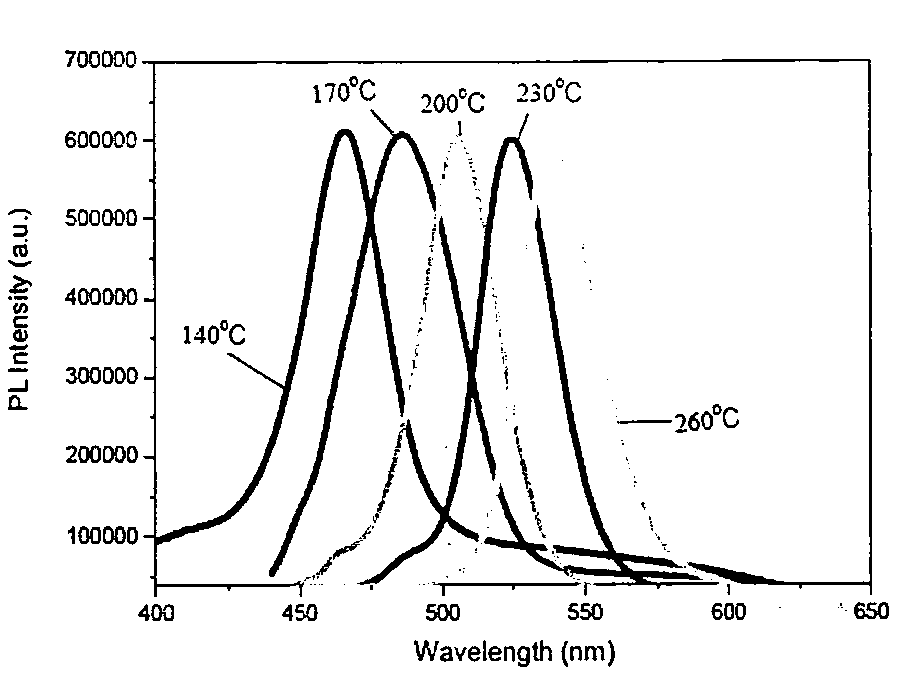

Efficient light-emitting sulfur selenium tellurium zinc cadmium/zinc sulfide quinary alloy core-shell structure quantum dot material and preparation method

ActiveCN107794044ALow priceStable chemical structureMaterial nanotechnologyNanoopticsQuantum yieldTe element

The invention discloses an efficient light-emitting sulfur selenium tellurium zinc cadmium / zinc sulfide quinary alloy core-shell structure quantum dot material and a preparation method. Liquid paraffin serves as a solvent, powdered sulfur serves as a sulfur source, selenium oxide powder serves as a selenium source, tellurium oxide serves as a tellurium powder source, zinc oxide serves as a zinc source, cadmium oxide serves as a cadmium source, liquid organic amine, liquid organic acid and liquid mercaptan serve as stabilizers, and heating reaction is performed in inert gas atmosphere to prepare an inner core of a sulfur selenium zinc cadmium telluride quinary alloy core. The liquid organic amine serves as a solvent, alkyl sulfhydryl serves as a sulfur source, zinc fatty acid serves as a zinc source, and heating reaction is performed in the inert gas atmosphere to grow a zinc sulfide shell. ZnCdSSeTe / ZnS quinary alloy core-shell structure quantum dots with adjustable light-emitting peakpositions, uniform shapes and sizes and high fluorescence quantum yield are controllably prepared by low-cost reaction raw materials and reaction solvents.

Owner:苏州帝格欣新材料科技有限公司

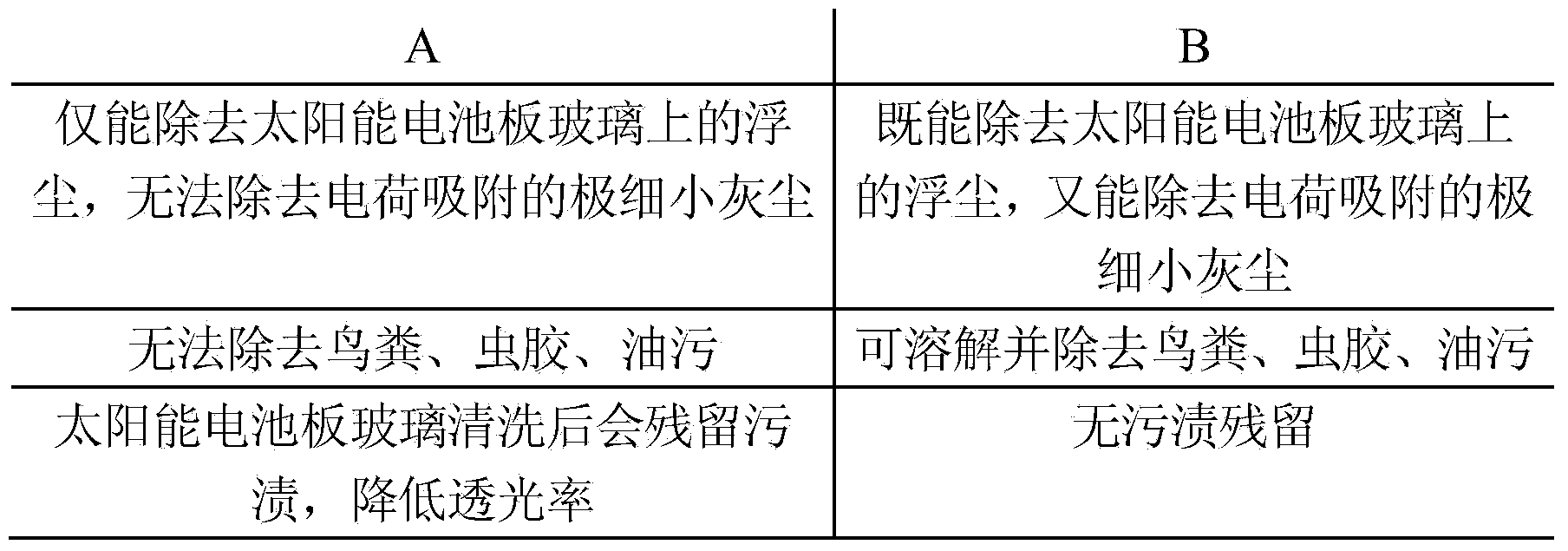

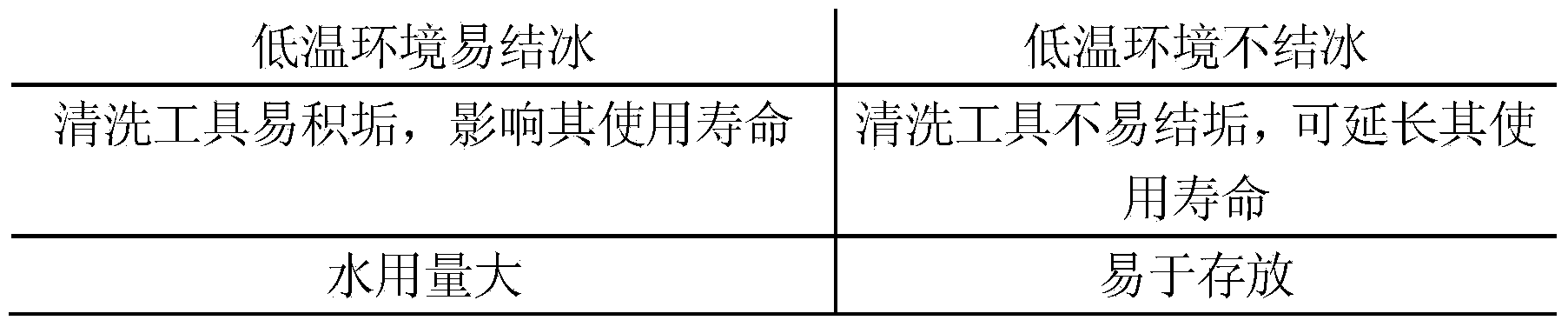

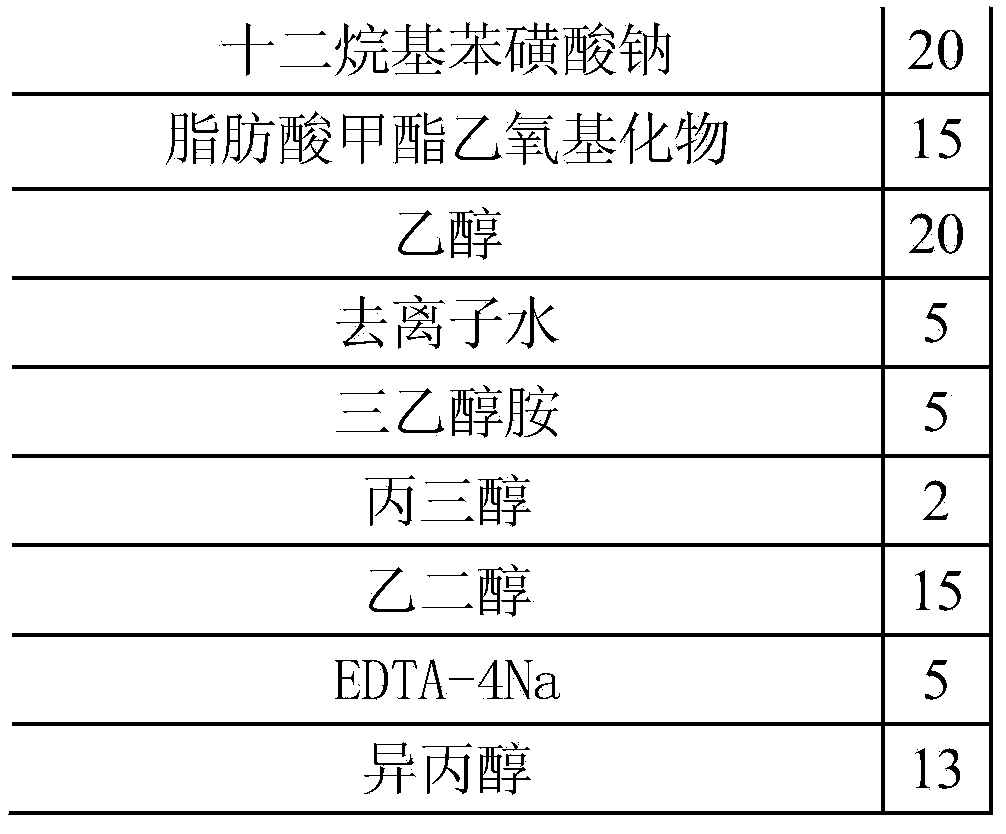

Cleaning agent for solar panel

InactiveCN103773638AWide temperature adaptabilityStable chemical structureSurface-active non-soap compounds and soap mixture detergentsEngineeringSurface-active agents

The invention relates to a cleaning agent for a solar panel. The cleaning agent comprises the following components by mass percent: 10 to 30 percent of surface active agent, 10 to 30 percent of solvent, 0.5 to 5 percent of electrostatic resisting agent, 10 to 30 percent of antifreezing agent, 2 to 5 percent of softening agent and 5 to 20 percent of oil removing agent. The solar panel is conventionally cleaned manually and rinsed mechanically at present, and the traditional way for cleaning the solar panel has the weaknesses such as high labor cost, large workload, high risk, complexity in operation, halfway cleaning, short washing period and the like. The cleaning agent for the solar panel is strong in decontamination capacity, anti-electrostatic, wide in environmental applicability, good in stability, low-foam, nondestructive for the glass surface, free from peculiar smell, toxic-free, corrosiveless, inflammable, unexplosive and free from polluting the environment.

Owner:WUHAN ZHUOCHENG PHOTOVOLTAIC NEW ENERGY CO LTD

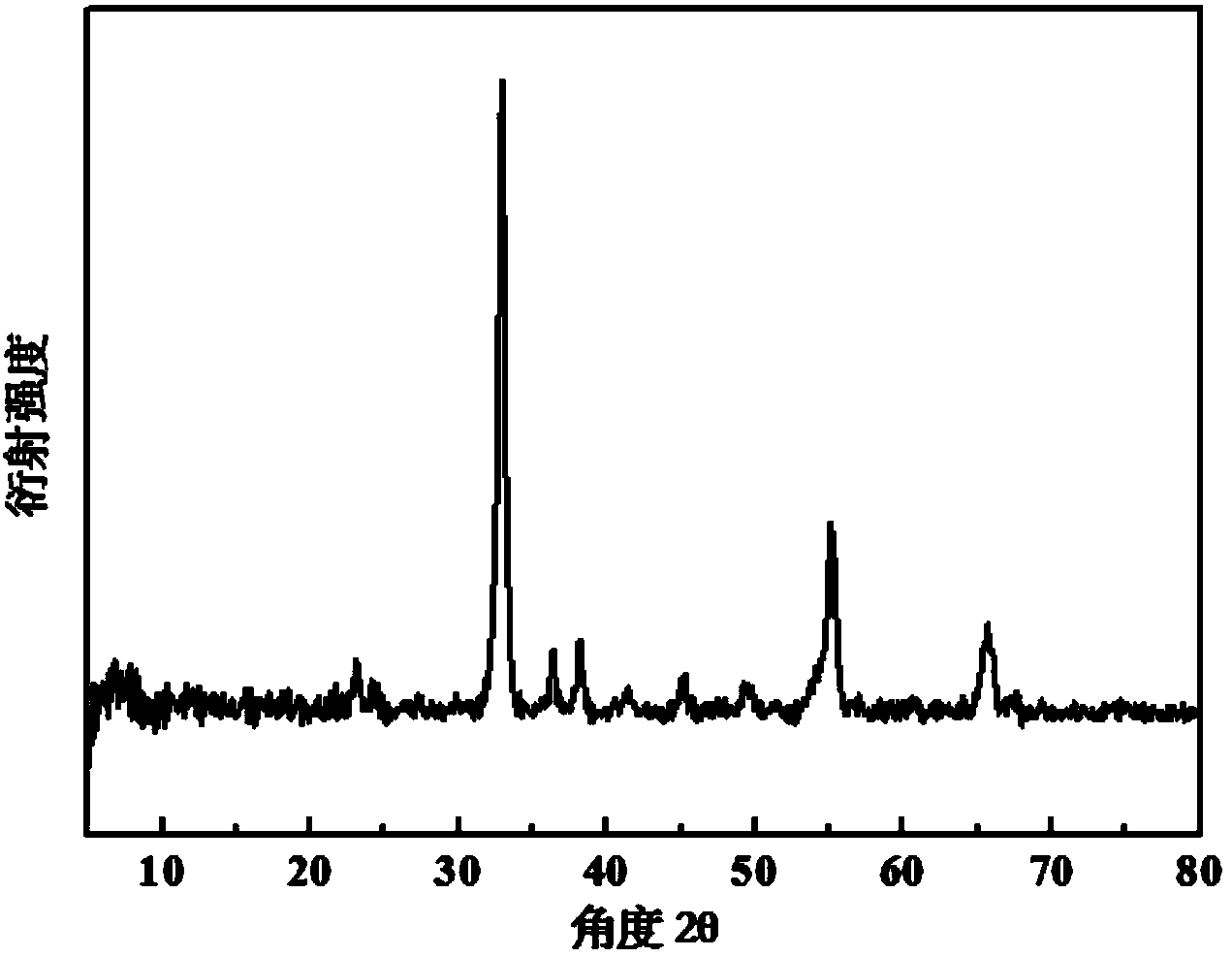

Preparation method of core-shell structure vanadium trioxide microspheres

InactiveCN103633309AWide variety of sourcesIncrease abundanceCell electrodesNanotechnologyChemical structureMicrosphere

The invention relates to a preparation method of vanadium trioxide microspheres, particularly a preparation method of core-shell structure vanadium trioxide microspheres. The method aims to solve the problems of high cost, complex steps and poor safety in the existing vanadium trioxide synthesis method, and the problems of small specific area, nonuniform shape and size, large particle size and poor stability in the product. The method comprises the following steps: 1. adding ammonium metavanadate into a solvent; 2. keeping the temperature at 180-220 DEG C for 8-15 hours; 3. washing the solid product, and drying; and 4. calcining. The method is simple and easy to implement and low in raw material cost; and the prepared material has the advantages of large specific area, high surface roughness, small particle size, uniform shape and size, stable chemical structure, high safety and the like. The method is used for preparing vanadium trioxide microspheres.

Owner:HEILONGJIANG UNIV

Method for preparing tetrahedral light-emitting indium phosphide/zinc sulfide core-casing quantum dots

ActiveCN107312534ALow priceStable chemical structureLuminescent compositionsChemical structureQuantum yield

The invention discloses a method for preparing tetrahedral light-emitting indium phosphide / zinc sulfide core-casing quantum dots. The method comprises the following steps: preparing high-boiling point tris(dialiphatic amido) phosphine, preparing InP quantum dot cores, preparing InP / ZnS core-casing quantum dots and separating the InP / ZnS core-casing quantum dots. Through the use of the high-boiling point tris(dialiphatic amido) phosphine as a phosphorus source, the price is low, the chemical structure is stable, the reaction is mild and safe, and gas is not produced. All reaction precursors are common chemical reagents and low in toxin and safe to store and use. The luminescent color of the InP / ZnS core-casing quantum dots can be precisely controlled simultaneously by the reaction temperature, the ratio of indium halide to the tris(dialiphatic amido) phosphine, the type of the halide and the reaction time, and high fluorescence quantum yield can be ensured.

Owner:南京紫同纳米科技有限公司

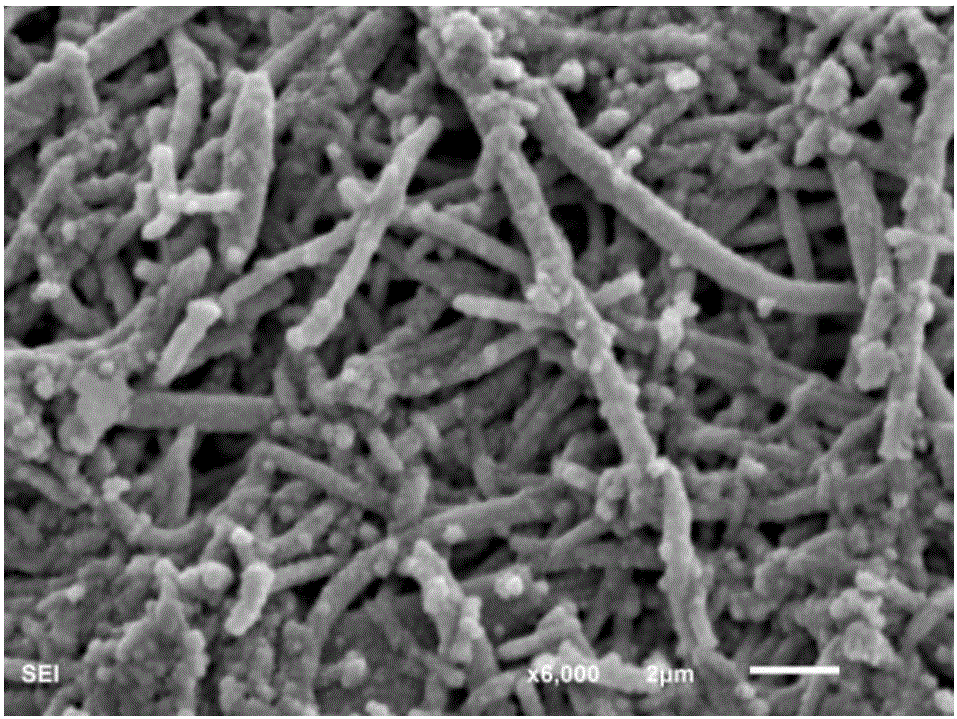

Nickel nanofiber membrane for membrane catalysis and preparation method of nickel nanofiber membrane

ActiveCN105148996APhysically and chemically stableReliable specific surface areaOrganic-compounds/hydrides/coordination-complexes catalystsFibre typesSolventChemistry

The invention relates to a nickel nanofiber membrane for membrane catalysis. The nickel nanofiber membrane is composed of a thermoplastic polymer nanofiber membrane and a nickel nano membrane deposited on the thermoplastic polymer nanofiber surface and comprises components in mass of 14%-75% of the thermoplastic polymer nanofiber membrane and 25%-86% of the nickel nano membrane. A preparation process adopts the method that thermoplastic polymers and cellulose acetate butyrate are subjected to blending melt spinning in proportion, thermoplastic polymer nanofibers are prepared through solvent extraction and dispersed and coated to the surface of a smooth substrate, and the thermoplastic polymer nanofiber membrane is taken down after drying. The nanofiber membrane is placed into a nickel bath with a certain formula for chemical nickel-plating after allergy and activating treatment and dried after taken out to obtain the nickel nanofiber membrane for membrane catalysis. The process is simple, the cost is low, and large scale preparation is easy to implement. The nickel nanofiber membrane for membrane catalysis has the characteristics that the porosity is high, the pore diameter is controllable, the flux is large, the catalytic activity is high, and separation is easy.

Owner:佛山市维晨科技有限公司 +1

High-protein dry type dog food for adult dogs and preparation method thereof

PendingCN106721345AComprehensive and balanced nutritionEasy to feedFood processingAnimal feeding stuffWheat germAntioxidant

The invention discloses high-protein dry type dog food for adult dogs. The high-protein dry type dog food for the adult dogs is prepared from the following components in percentage by mass: 13 to 15 percent of meat, 10 to 12 percent of fruits, 10 to 12 percent of vegetables, 3 to 4 percent of purple sweet potatoes, 3 to 4 percent of potatoes, 3 to 4 percent of salmon, 6 to 8 percent of bone meal, 2 to 3 percent of shrimp meal, 7 to 9 percent of corn flour, 2 to 3 percent of oat bran, 1 to 2 percent of wheat germ flour, 5 to 6 percent of beef tallow, 4 to 5 percent of eggs, 1 to 2 percent of seaweed meal, 1 to 2 percent of NP-2002 plasma protein powder, 1 to 2 percent of hydrolyzed wheat protein powder, 1 to 2 percent of nanometer pearl layer powder, and the balance of antioxidant, se-enriched yeast and milk. The high-protein dry type dog food for the adult dogs provided by the invention is overall and balanced in nutrition, convenient to feed, good in palatability and high in digestibility; the adult dogs fed by the dog food are fast in growth speed, fast in reaction speed, lively and healthy, lustrous in eyes, shiny in color and lustre of fur, and enhanced in disease resistance.

Owner:合肥寻宠记宠物食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com