Preparation method for novel graphene polyion liquid composite material

A technology of polyionic liquid and composite material, applied in the field of preparation of graphene polyionic liquid composite material, can solve the problems of few reports of graphene polyionic liquid composite material and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of graphene oxide

[0038] Slowly add 5g of graphite powder into a 1000mL large beaker containing 115mL of concentrated sulfuric acid under stirring, keep the temperature below 5°C, then slowly add a mixture of 2.5g of sodium nitrate and 15g of potassium permanganate, and react at low temperature for 15min. In a constant temperature water bath at about 35°C, keep stirring for 30 minutes, slowly add 230mL of warm water to raise the temperature to 98°C, and maintain this temperature for 15 minutes. After that, dilute to 700mL with warm water, pour 50mL of 30% hydrogen peroxide, filter while hot, wash the filter cake with 5% hydrochloric acid until there is no sulfate ion in the filtrate, dry in vacuum for 24h to obtain GO seal.

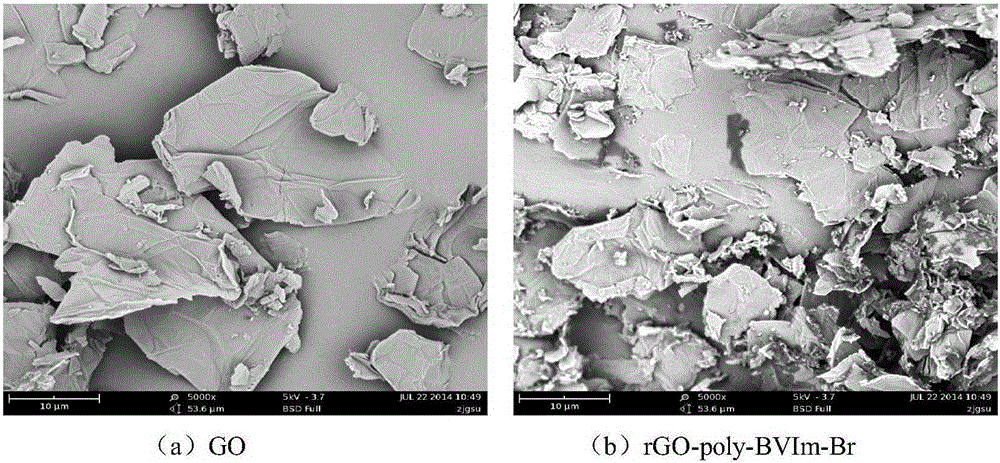

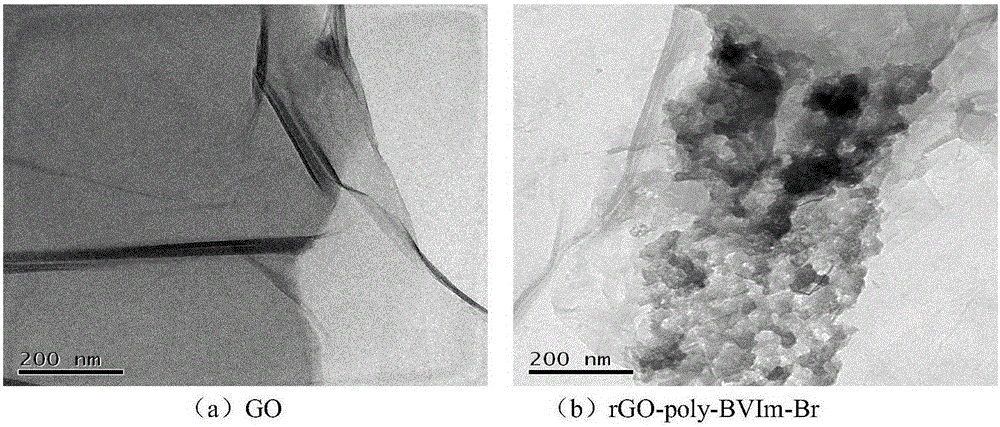

[0039] (2) Preparation of graphene polyionic liquid composite (rGO-poly-BVIm-Br)

[0040] a.0.5gGO ultrasonic dispersion in 130mL volume ratio DMF / H 2 In the mixed solution of O=9:1, ultrasonically disperse for 30min, add 0.3gNa...

Embodiment 2

[0048] (1) Preparation of graphene oxide

[0049] With the step (1) in the embodiment 1.

[0050] (2) Preparation of ionic liquid MEBIm-Br

[0051] a. Place a 500mL three-necked flask in an ice-water bath, and feed high-purity nitrogen into the three-necked flask. Weigh 39.37g (0.315mol) of 2-bromoethanol and dissolve it in 50mL of dichloromethane, mix well and add to a three-necked flask. Weigh 33.39g of triethylamine, dissolve it in 50mL of dichloromethane, and then slowly add it into the flask. Then weigh 31.36g (0.3mol) of methacryloyl chloride, and dissolve it in 50mL of dichloromethane, mix well and slowly add to the three-necked flask. After the liquid in the flask was mixed evenly, it was stirred at room temperature for 18 hours and filtered. The filtrate was washed 4 times with deionized water, separated with a separatory funnel, and the obtained organic layer was washed with anhydrous MgSO 4 Dry and vacuum filter to obtain pure light yellow liquid 2-bromoethyl m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com