Patents

Literature

31results about How to "There are security risks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

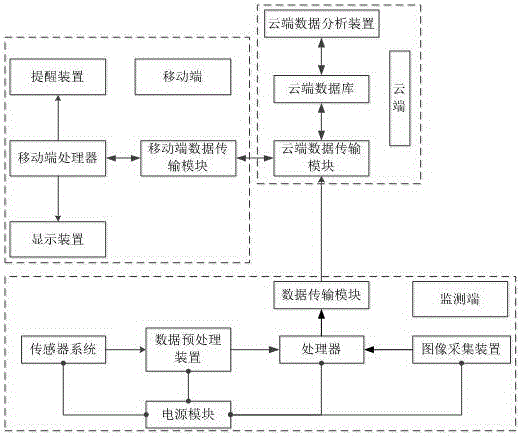

Mobile remote electric power monitoring system based on 4G network and monitoring method

ActiveCN105897925AAccurate monitoringTroubleshootingClosed circuit television systemsData switching networksData transmissionMobile end

The invention provides a mobile remote electric power monitoring system based on a 4G network and a monitoring method, and relates to the field of electric power. The system comprises a monitoring terminal, a cloud terminal and a mobile terminal. The monitoring terminal comprises a power supply module, a sensor system, a data preprocessing device, a processor, an image collection device and a data transmission module. The cloud terminal comprises a cloud terminal data transmission module, a cloud terminal database and a cloud terminal data analyzing device. The mobile terminal comprises a mobile terminal data transmission module, a mobile terminal processor, a display device and a reminding device. According to the system and the method, an improvement scheme is provided specific to the defects that according to the existing electric power monitoring system and monitoring method, the monitoring is not in real time, the monitoring results are inaccurate and the network transmission is unreliable. The scheme has the advantages of accurate monitoring, real time monitoring, reliable transmission and complete information.

Owner:湖南一二三智能科技有限公司

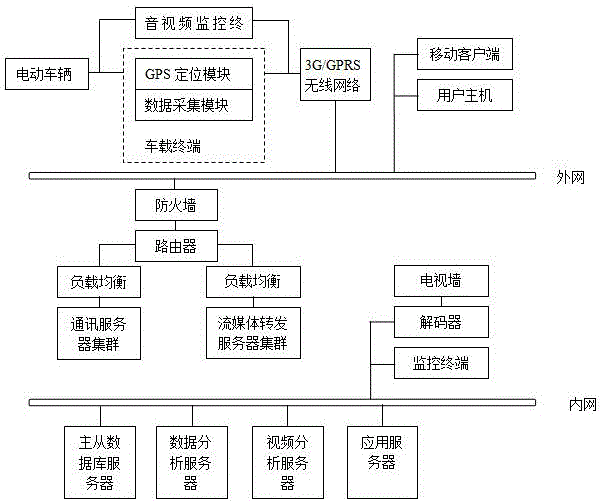

Electric automobile remote safety monitoring method

InactiveCN106488191AThere are security risksRemind in timeProgramme controlComputer controlMonitoring dataTroubleshooting

The invention discloses an electric automobile remote safety monitoring method. The method comprises the steps that 1), a vehicular terminal and an audio / video monitoring terminal collect vehicle information in real time and transmit the vehicle information to a remote monitoring center through a wireless network, wherein the information at least comprises vehicle body CAN bus data, GPS data and video data in front of a vehicle body; 2), after obtaining vehicle information data, the monitoring center carries out safety state analysis on vehicle operation data and the video data according to a preset strategy model, stores an analysis result in a database and sends the analysis result to a video analysis server through a message; and 3), the monitoring center establishes communication connection with a mobile terminal of a user and transmits a vehicle operation state and the analysis result to a mobile terminal application APP, and the user processes the vehicle according to the analysis result. According to the method, potential safety hazards are discovered and troubleshot timely, and the problem that a similar product is fuzzy in function positioning, high in monitoring data volume and difficult in potential safety hazard troubleshooting is improved.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

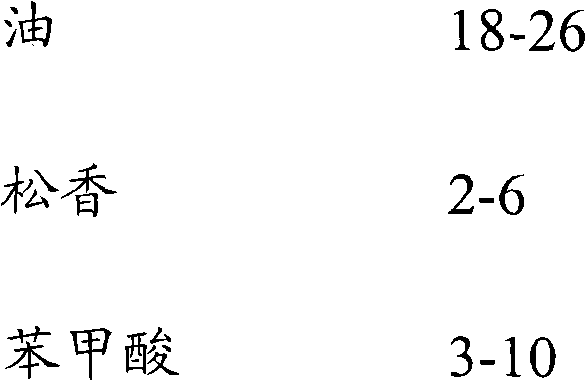

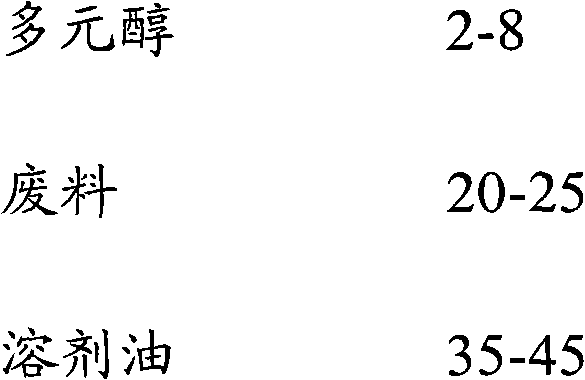

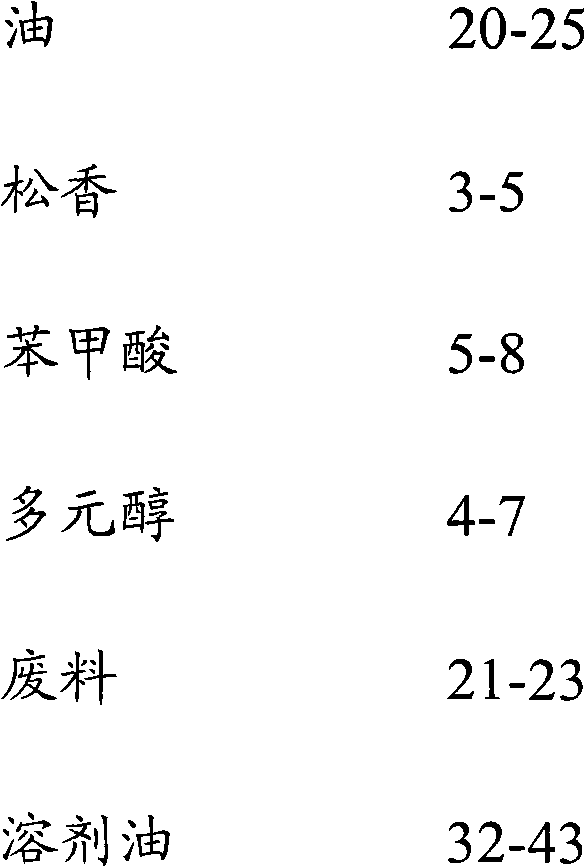

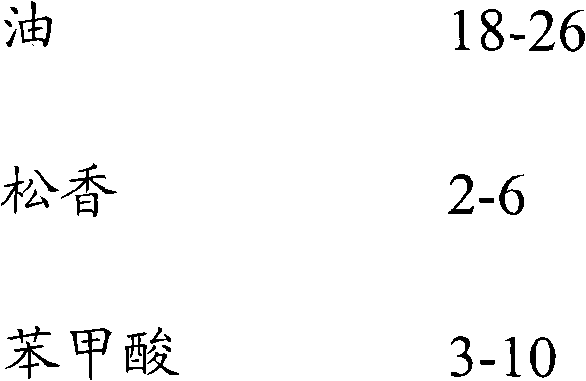

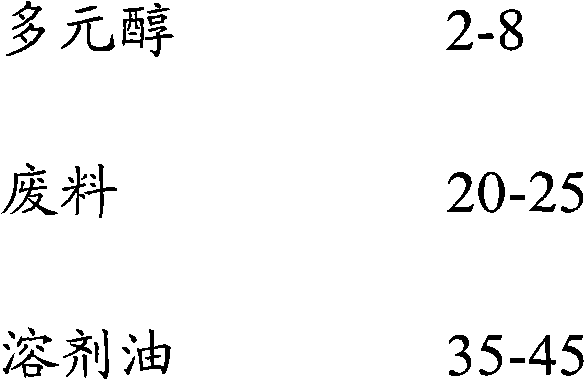

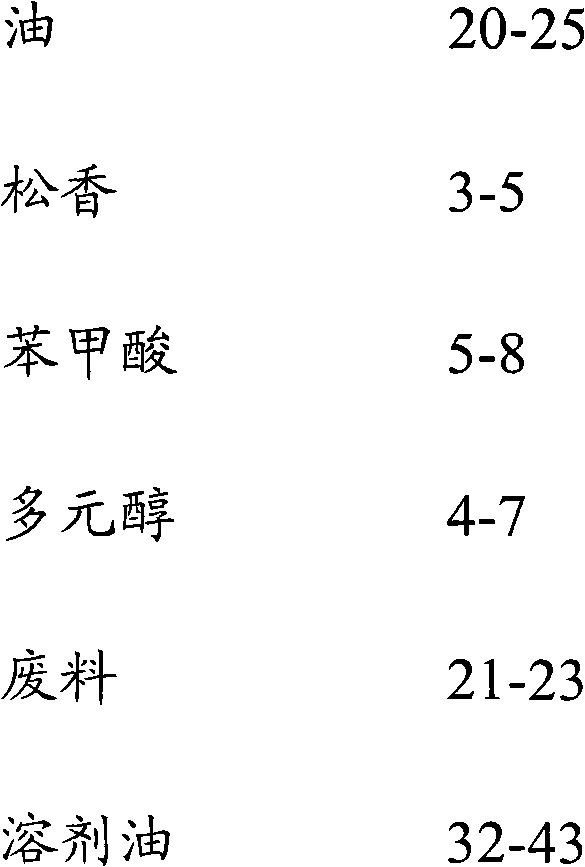

Liquid alkyd resin and preparation method thereof

InactiveCN102432851AAvoid pollutionWith technological innovationPlastic recyclingPolyester coatingsFiberBenzoic acid

The invention relates to liquid alkyd resin and a preparation method thereof. The liquid alkyd resin comprises the following raw materials: oil, rosin, benzoic acid, polyatomic alcohol, waste, solvent oil and the like. The preparation method comprises the following steps of: adopting recovered waste and old plastic and chemical-fiber industrial waste as main raw materials, adding all auxiliary materials, generating polyesterification reaction in a reaction kettle, then carrying out dilution, and finally carrying out filtering to prepare a finished liquid alkyd resin product. In the invention, the waste plastic is utilized for preparing the liquid alkyd resin, the wastes become valuables, the technical process is simple and is easy to operate, the mode for utilizing heat-conducting oil for heating is safer and more energy-saving, and the application range is wide.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

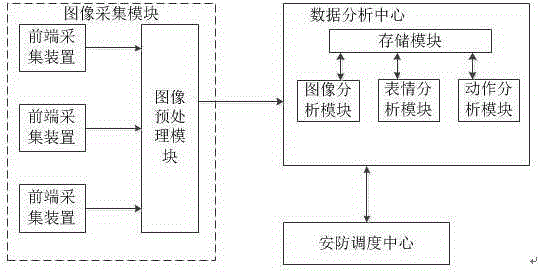

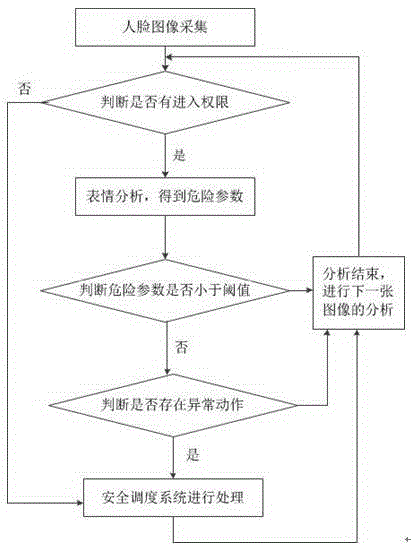

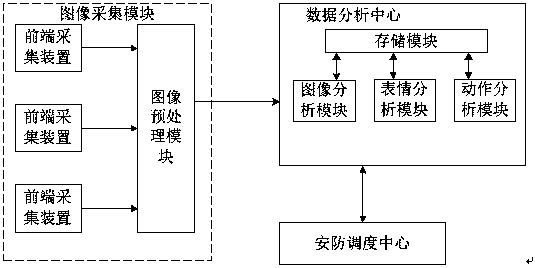

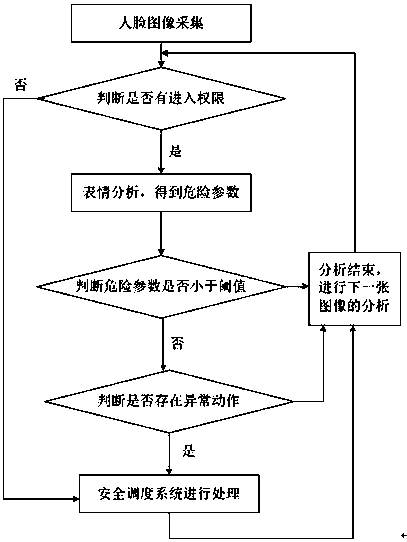

Identity identification system and method based on image and somatosensory analysis

ActiveCN105335727AEnsure safety and stabilityEnsure safetyAcquiring/recognising facial featuresAbnormal expressionSomatosensory system

The invention discloses an identity identification system and a method based on image and somatosensory analysis. The system comprises a data acquisition module, a data analysis center and a security dispatching center connected in sequence, wherein the data acquisition module is used for acquiring face images and body actions in a security area; the data analysis center is used for analyzing the face images, expressions and the body actions; and the security dispatching center is used for carrying out security dispatching according to a result obtained through analysis of the data analysis center. According to the identity identification system and the method based on image and somatosensory analysis, whether a person in the security area enters illegally is judged through the face image, and security dispatching measures are taken; expression analysis is carried out on a legally-entering person; and when an abnormal expression is analyzed and obtained, a body action is further analyzed, and a more accurate basis is provided for judgment of hidden safety dangers.

Owner:CHENGDU WISDOM SHULIAN INFORMATION TECH CO LTD

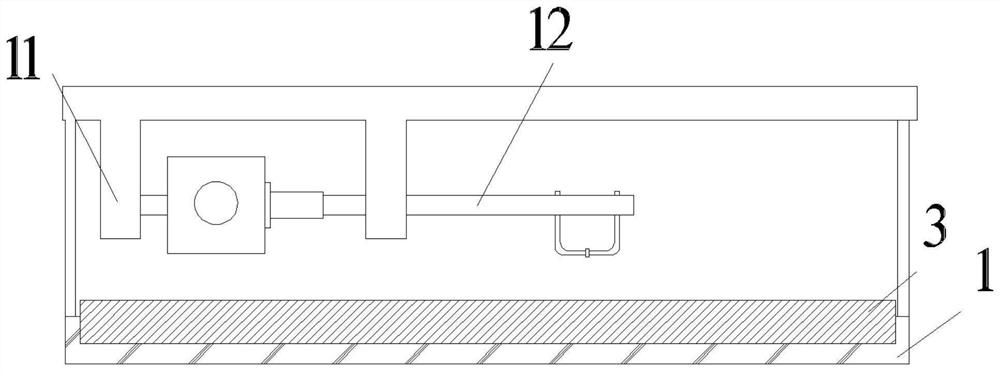

High-efficiency loading method and system capable of automatically identifying goods

The invention relates to a high-efficiency loading method and system capable of automatically identifying goods. The method comprises the following steps: 1) defining goods identification codes and goods parameters corresponding to the identification codes; presetting truck compartment size and total loading weight; 2) identifying the goods identification codes and reading the goods parameters corresponding to the goods identification codes from a database by a goods identification code reading device; 3) calculating a total number of loaded pieces according to the goods parameters and the total loading weight; 4) creating a goods stacking model in a truck compartment according to the total number of loaded pieces, the truck compartment size and the goods parameters; 5) stacking the goods into goods stacks in a relay station according to the stacking model by grip equipment; 6) transporting the goods stacks to the truck compartment from the transfer station by transportation equipment. According to the method and the system, the stacking model is automatically determined by automatically identifying the goods and the goods can be quickly and orderly loaded.

Owner:FUJIAN ZHENGDE INTELLIGENT DEVICE

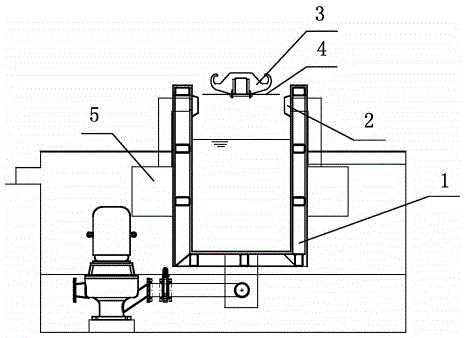

Pickling tank

The invention relates to a pickling tank. The pickling tank is characterized by comprising a groove body and a hook. The groove body is provided with a notch. An opening of the notch is upward. A groove cover is arranged on the hook. The side walls of the groove body are provided with exhaust openings. The groove cover is detachably connected to the hook through a fastening component. The outer walls of the groove body are provided with acid mist recycle chambers. The acid mist recycle chambers are connected with the exhaust openings through pipelines. According to the pickling tank, due to the fact that the groove cover is installed on the hook, after a bar is lifted to the groove body through the hook by a worker, the hook does not need to be moved away, the groove cover arranged on the hook can have a protective effect, and the potential safety hazard can be reduced. Meanwhile, the groove cover also has a drainage effect, and acid mist is guided to the portion nearby the side wall of the groove body, so that the acid mist can be fully sucked away by the exhaust openings. The condition that due to the fact that a workshop is polluted by the acid mist, the physical health of the worker is harmed is avoided.

Owner:ZHEJIANG SUNRAY COPPER IND

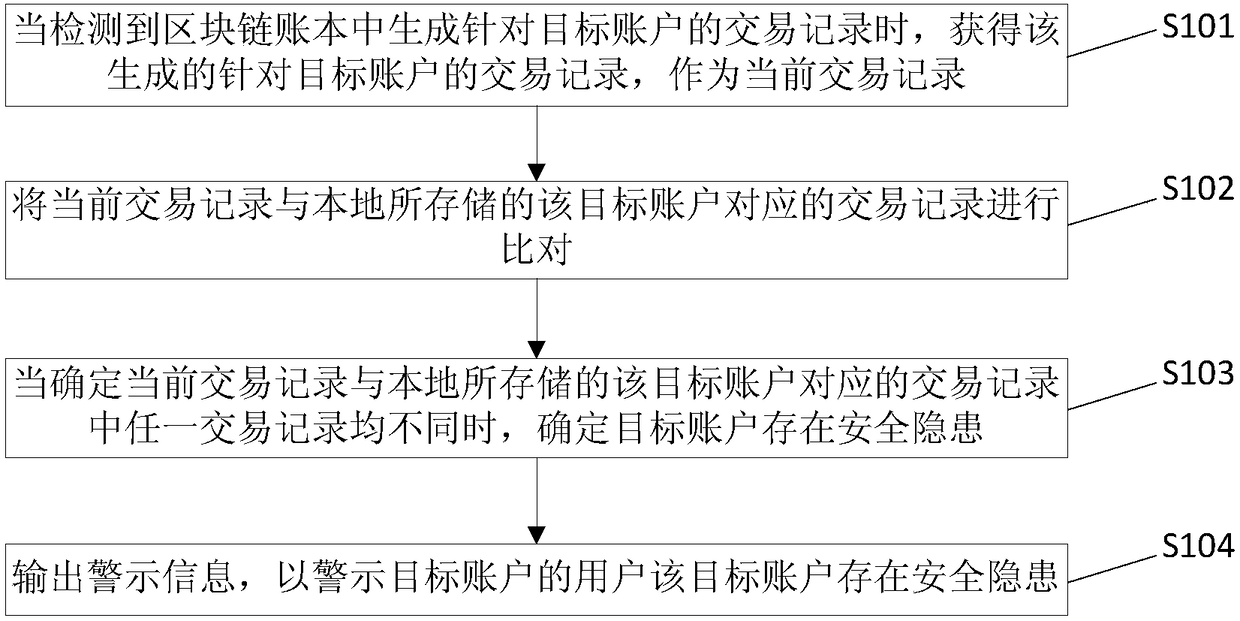

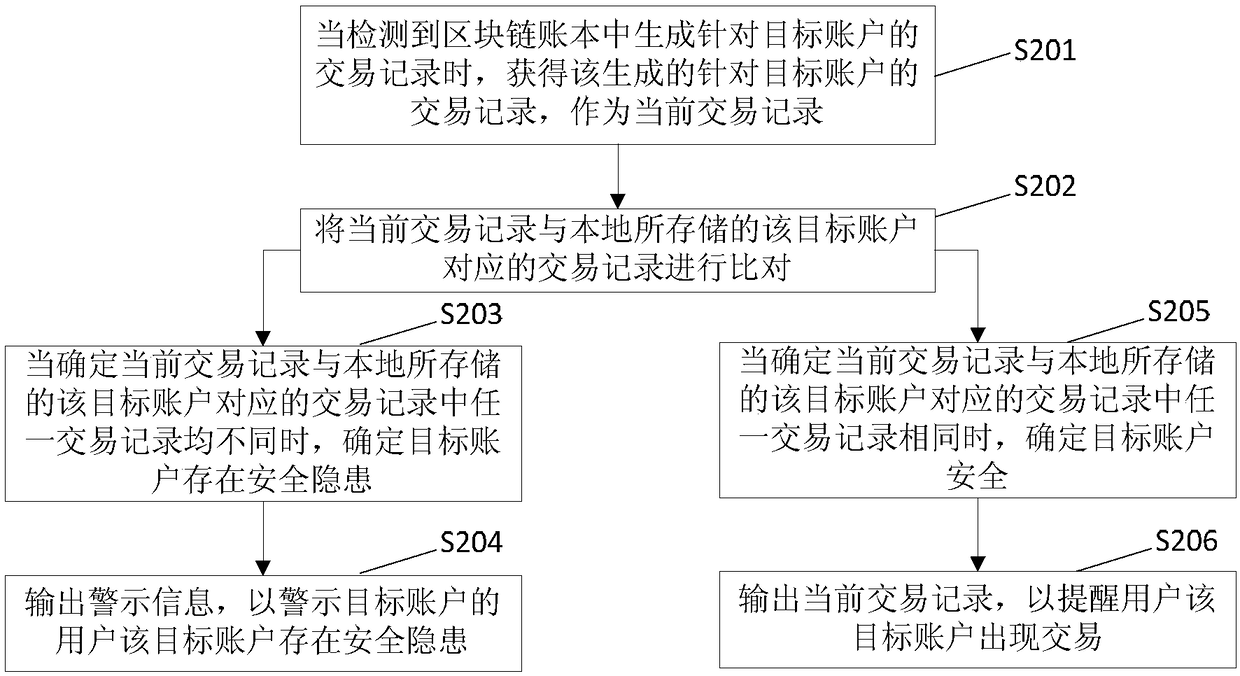

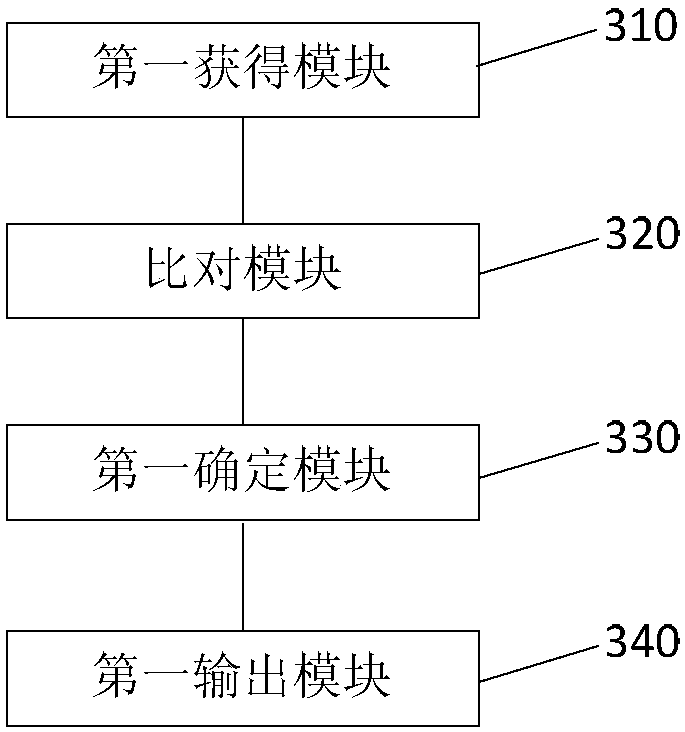

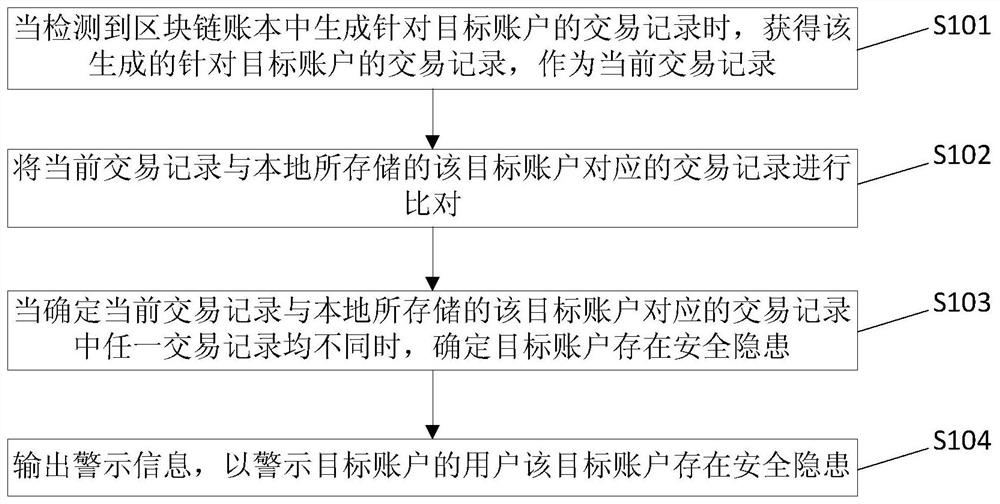

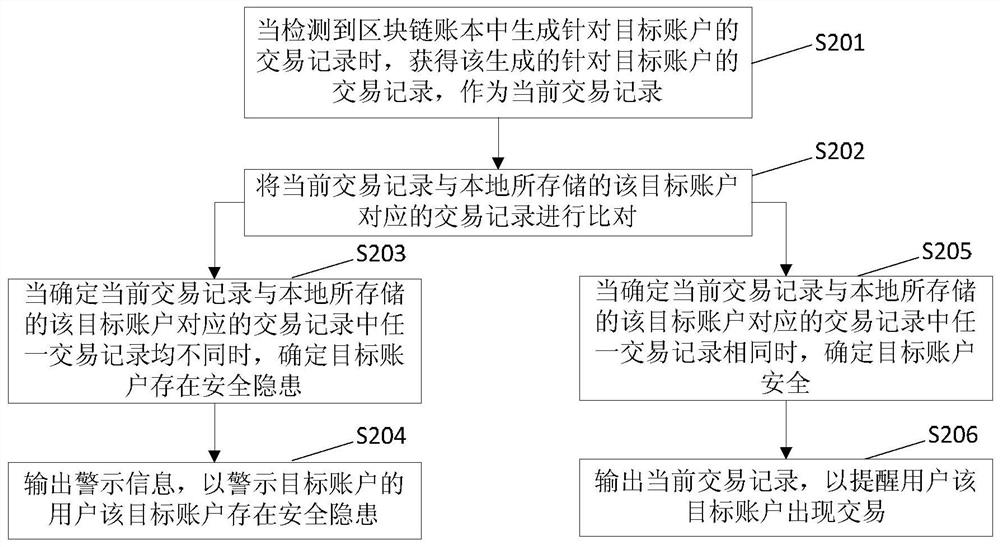

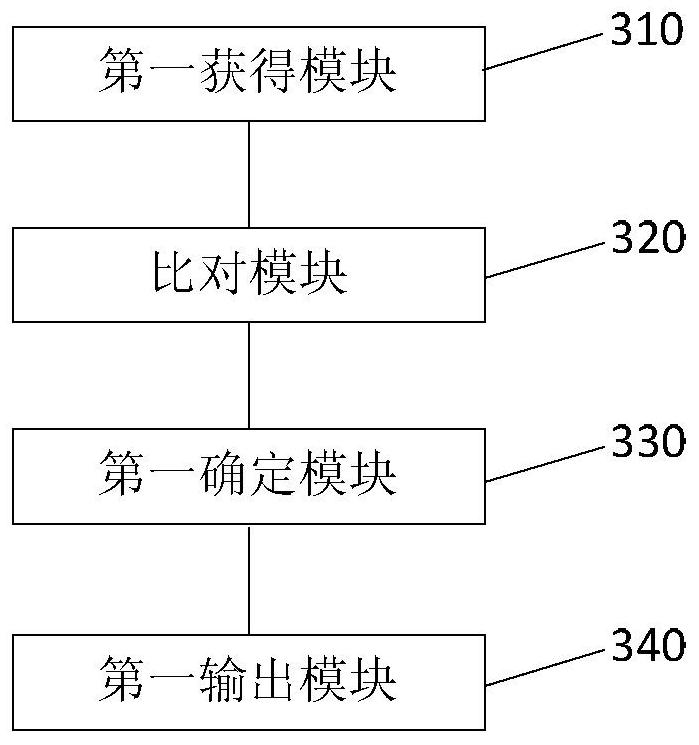

Information reminding method and device and electronic equipment

ActiveCN108280358ARealize identificationThere are security risksFinanceCryptography processingElectric equipmentDatabase

The embodiment of the invention provides an information reminding method and device and electronic equipment. The method comprises the steps that when it is detected that transaction records for a target account are generated in a block chain account book, the generated transaction records for the target account are obtained and used as current transaction records; the current transaction recordsare compared with locally-stored transaction records corresponding to the target account; when it is determined that the current transaction records are different from any transaction record in the locally-stored transaction records corresponding to the target account, it is determined that hidden security dangers exist in the target account; alarm information is output to warn that hidden security dangers exist in a user target account of the target account. The legality of an asset transaction is identified, and then the account security is identified.

Owner:KINGSOFT

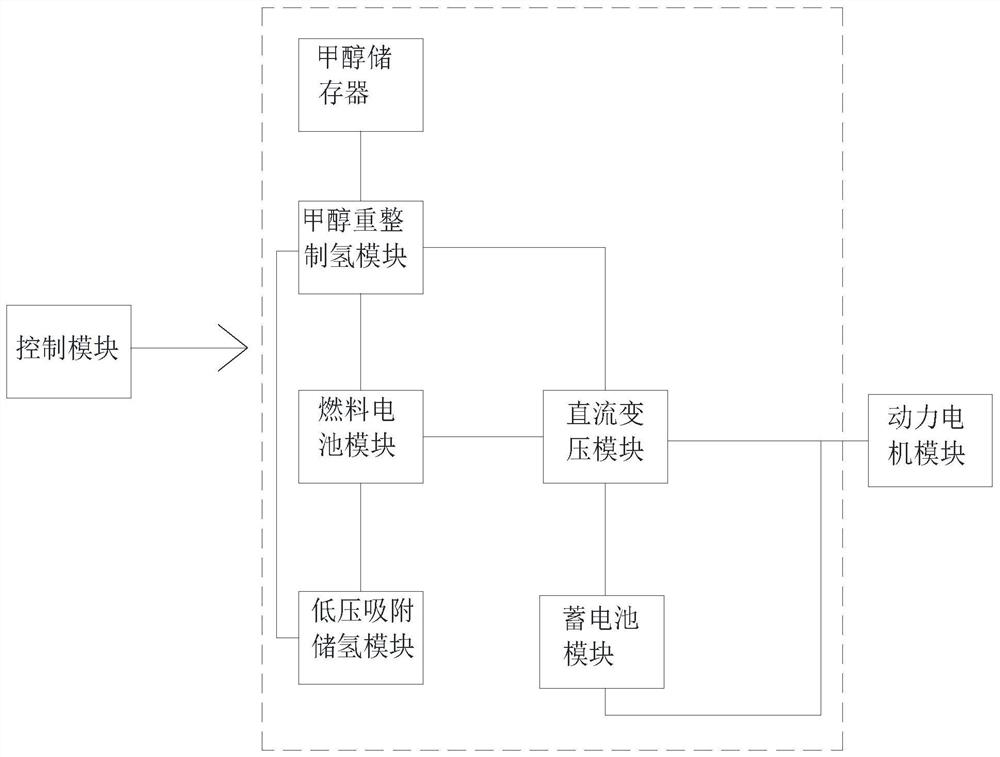

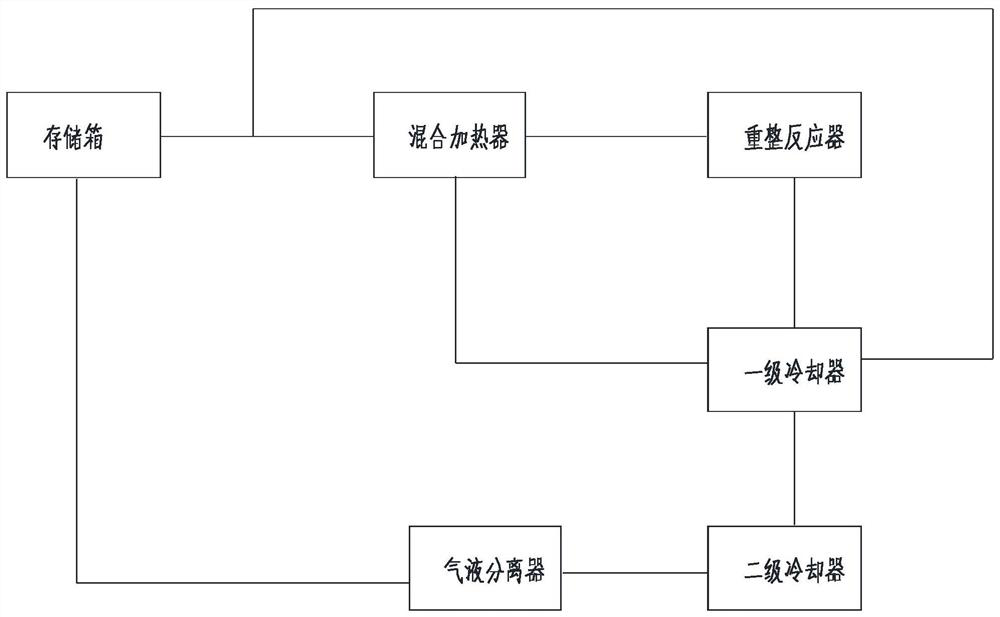

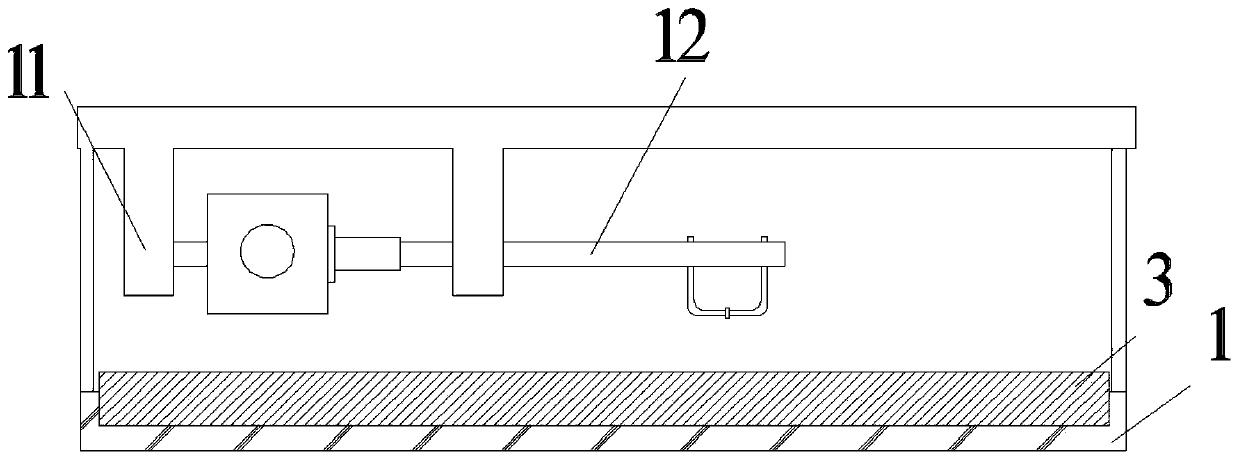

Modularized hydrogen energy ship electric transmission power system and method

PendingCN113386936AHigh difficultyThere are security risksHydrogenPropulsion based emission reductionMethanol waterFuel cells

The invention discloses a modularized hydrogen energy ship electric transmission power system and method. The system is provided with a methanol reforming hydrogen production module, a fuel cell module, a power motor module and a low-pressure adsorption hydrogen storage module, the first feeding end of the fuel cell module is connected with the methanol reforming hydrogen production module, the second feeding end of the fuel cell module is connected with the low-pressure adsorption hydrogen storage module, and the feeding end of the low-pressure adsorption hydrogen storage module is connected with the methanol reforming hydrogen production module; and the output end of the fuel cell module is connected with the direct current transformation module, and the output end of the direct current transformation module is connected with the power motor module. Existing high-pressure hydrogen storage is generally 70 MPa, a fuel cell has potential safety hazards, and low-pressure adsorption storage is adopted in the method, so that the method is safe and reliable; and methanol water reforming hydrogen production heating needs about 10 minutes, when the ship is started, the low-pressure adsorption hydrogen storage module is used for providing hydrogen, meanwhile, the storage battery module provides supplementary electric power, and the requirement for high-power power in the initial starting stage of the ship is met.

Owner:张纵

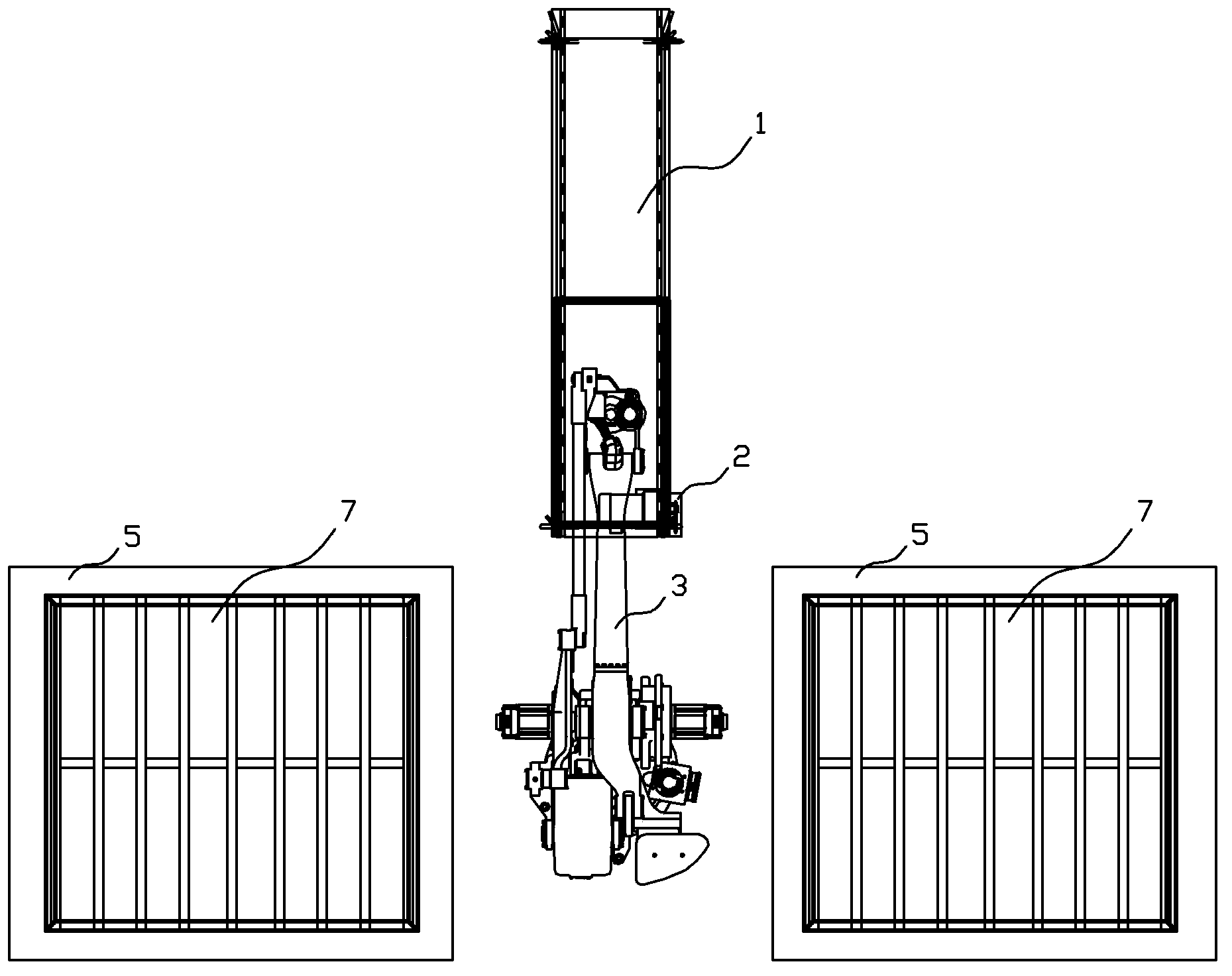

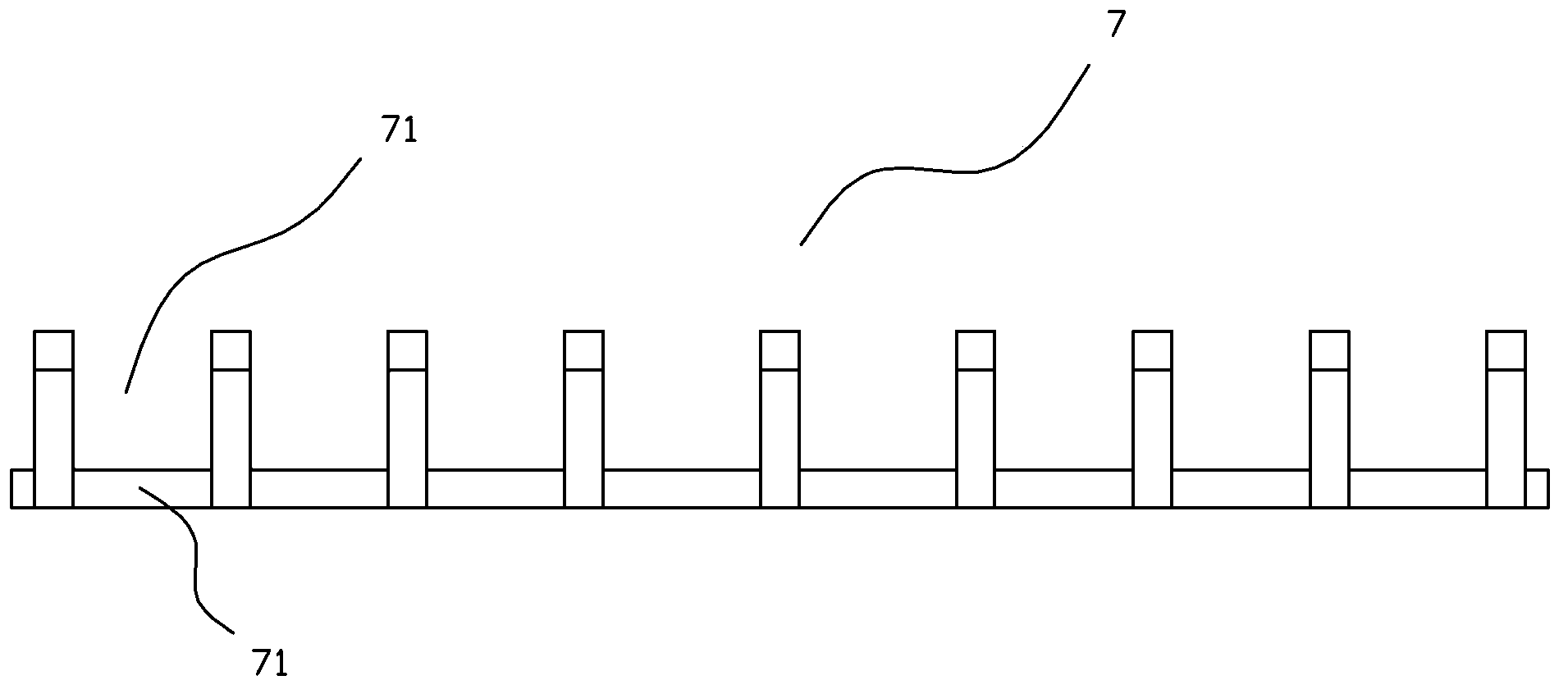

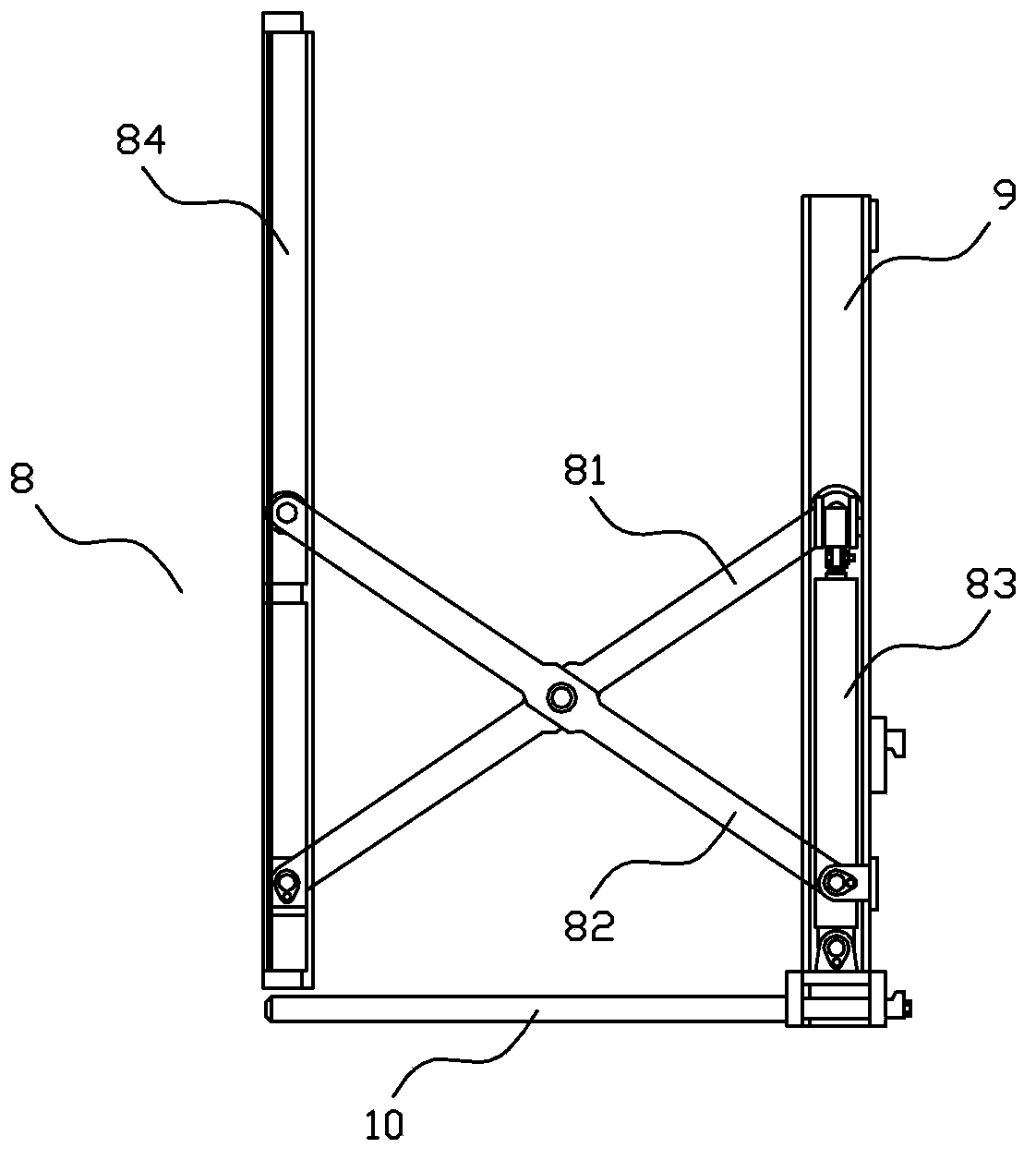

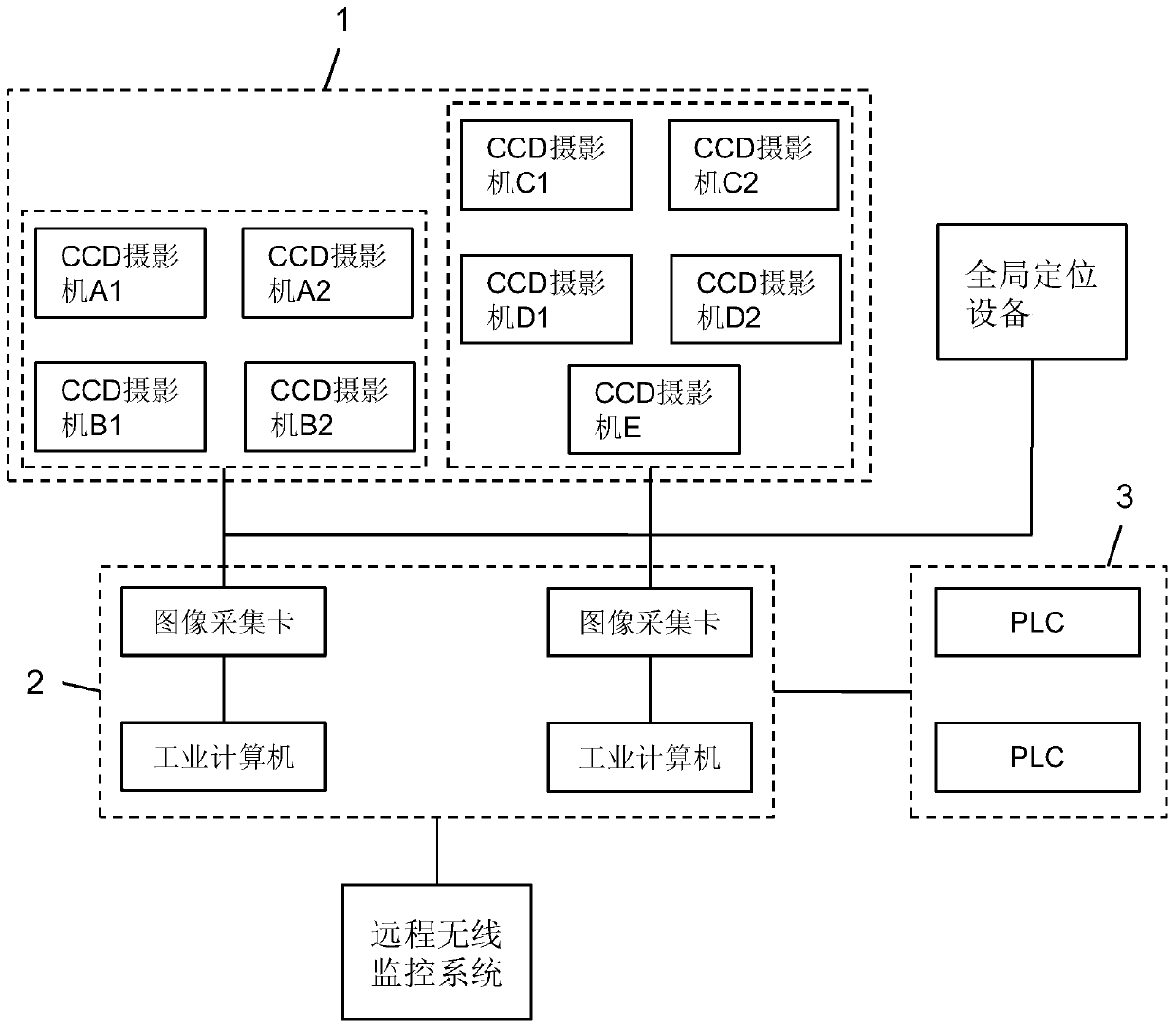

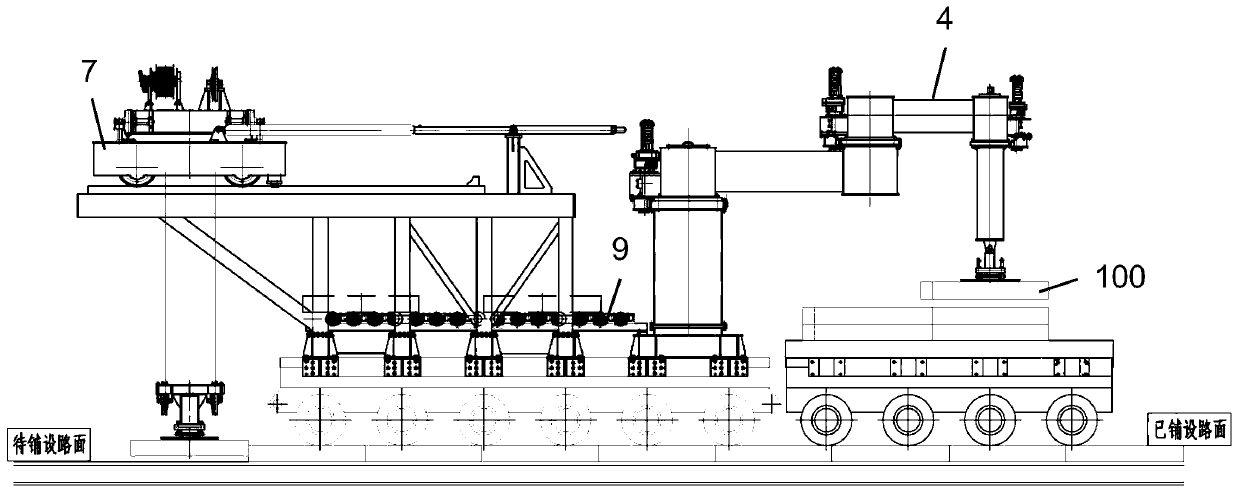

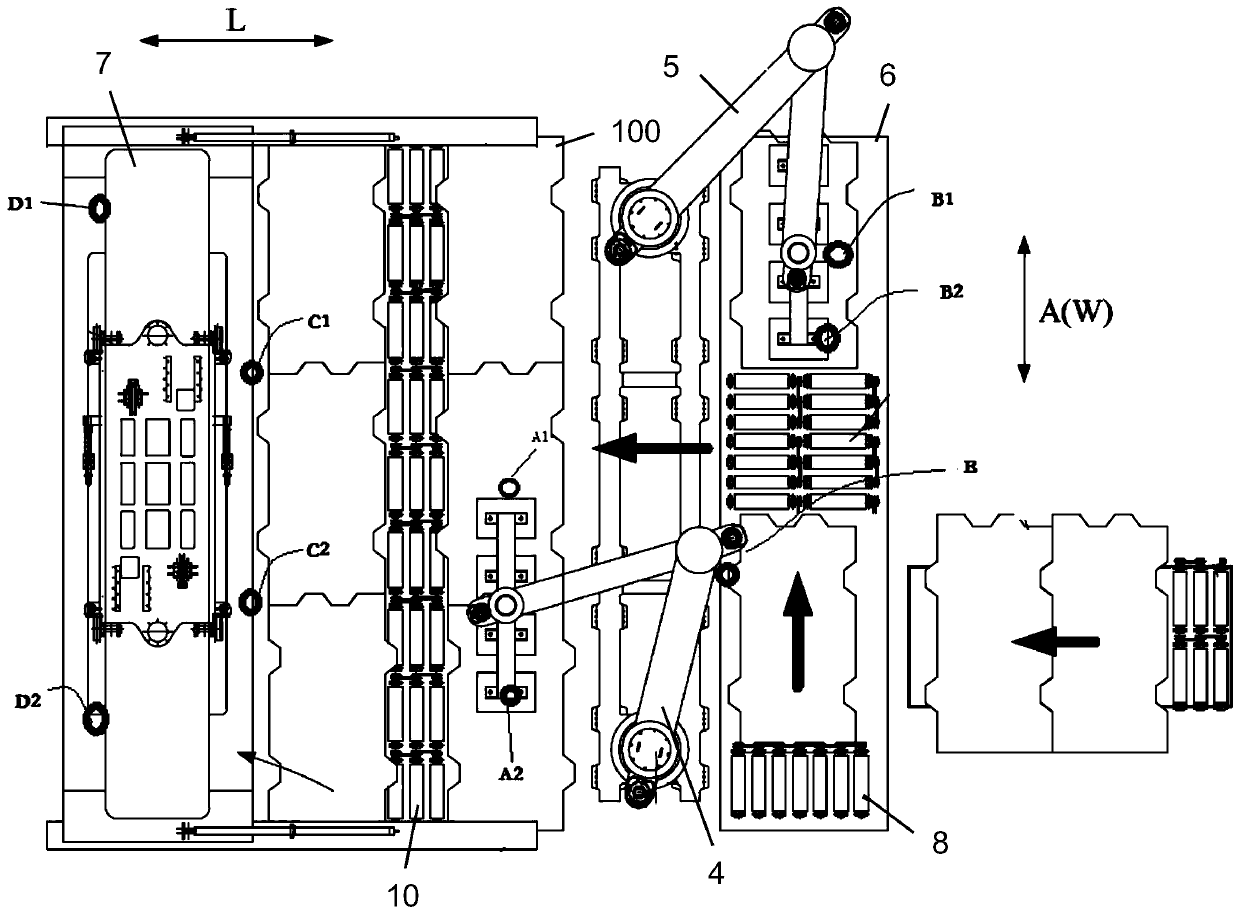

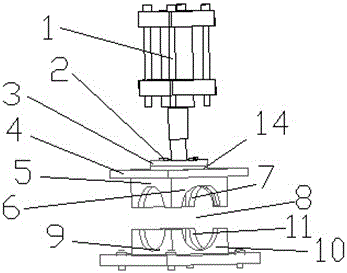

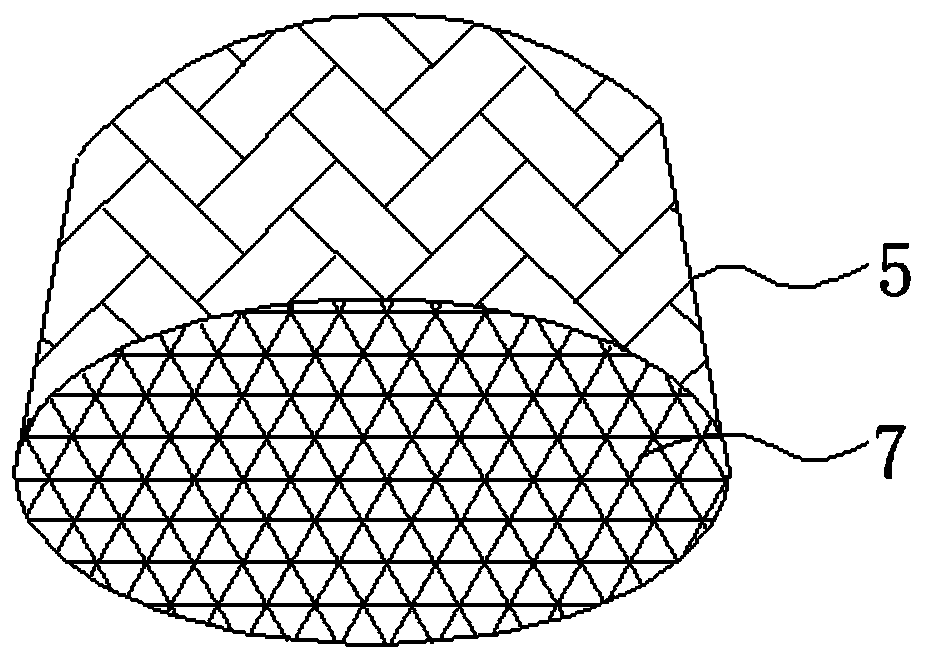

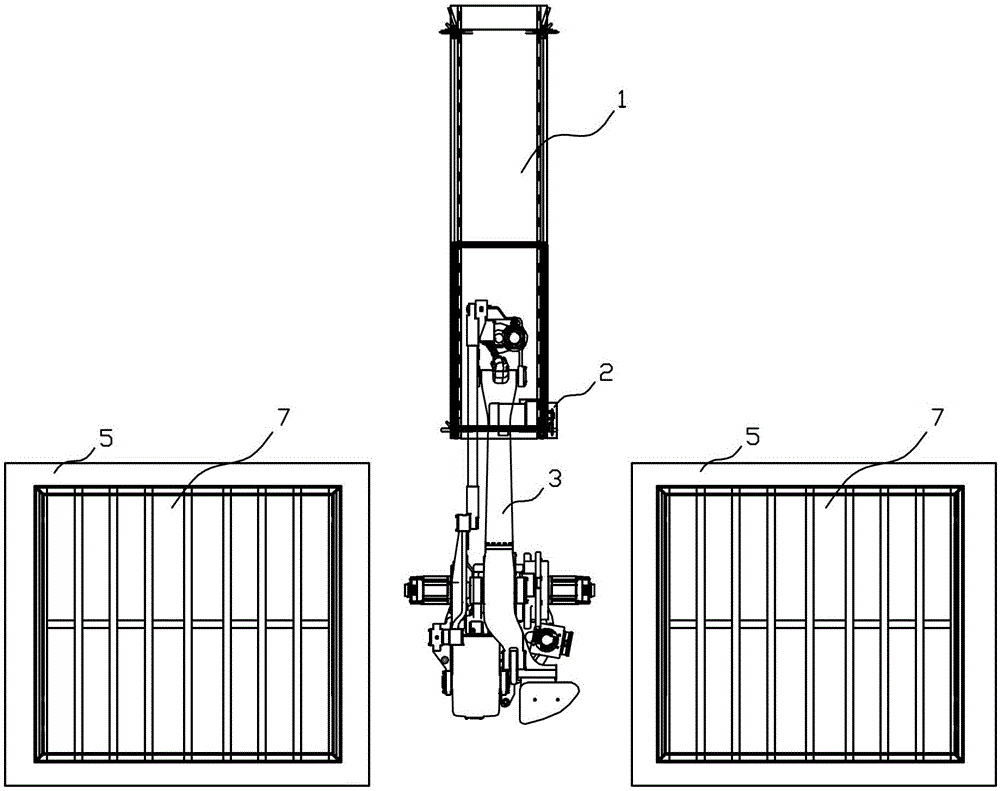

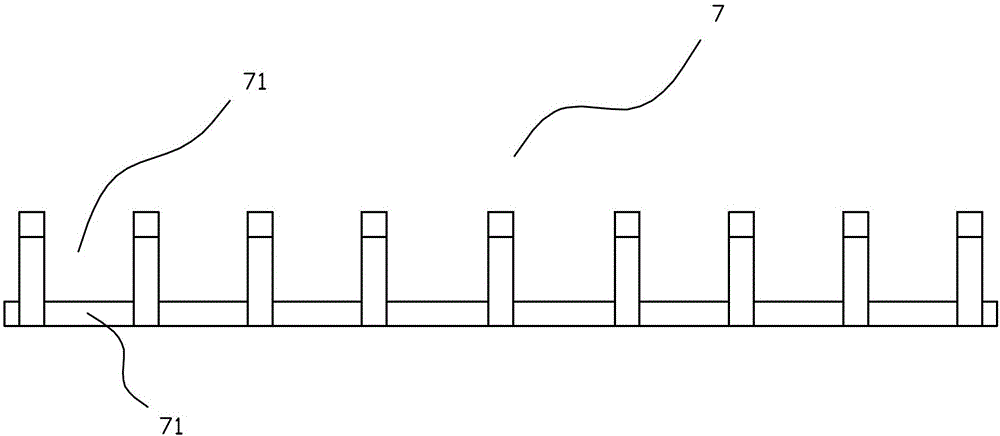

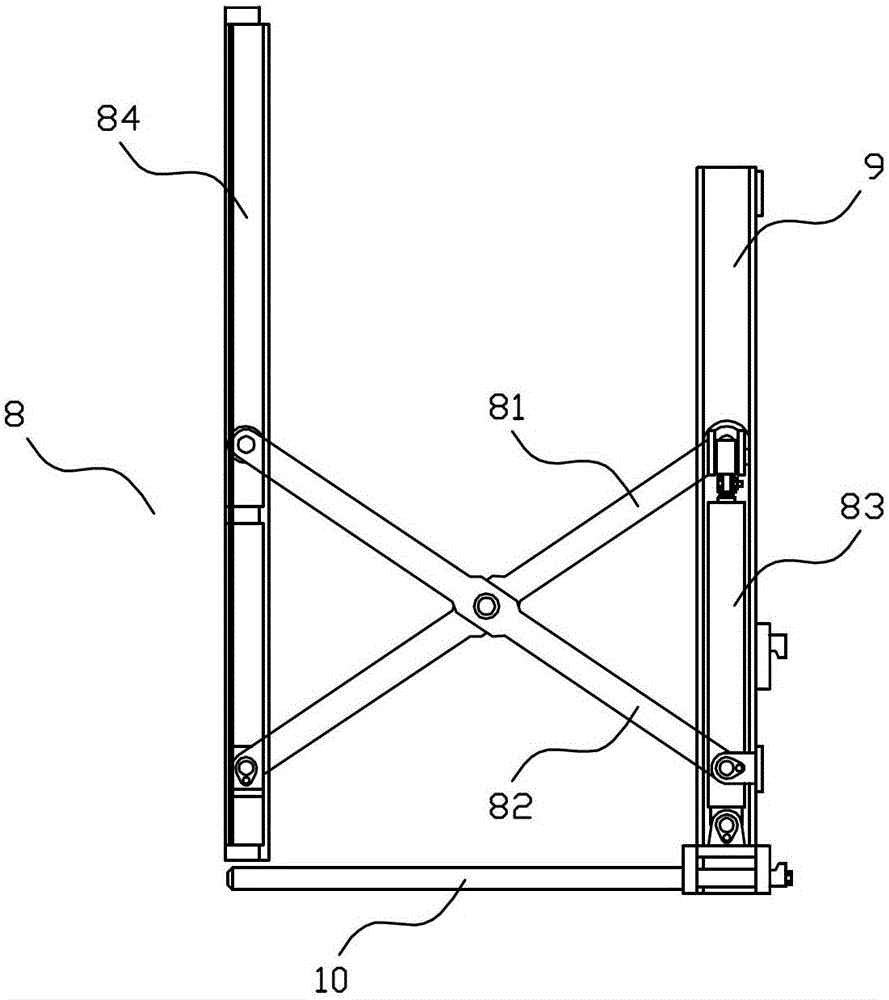

Automatic control system and automatic laying method of assembly type road and prefabricated pavement slab

InactiveCN111335118AReduce location requirementsReduced accuracy requirementsSingle unit pavingsGripping headsAutomatic controlControl system

The invention discloses an assembly type road automatic control system. The assembly type road automatic control system comprises a paver, a visual positioning unit arranged on the paver, a visual analysis unit connected with the visual positioning unit and a paver control unit connected with the visual analysis unit. The paver comprises a mechanical arm, a prefabricated plate preparation area arranged at the front channel position of the mechanical arm and a portal lifting appliance arranged at the rear channel position of the mechanical arm. A roller way is arranged on the precast slab preparation area, and an assembling area is arranged below the gantry lifting appliance; and the visual positioning units are respectively arranged on the mechanical arm, the prefabricated slab preparationarea, the assembly area and the gantry lifting appliance. It should be pointed out that for ordinary technicians in the field, on the premise of not breaking away from the conception of the invention, a plurality of deformations and improvements can also be made. These belong to the scope of protection of the invention.

Owner:SHANGHAI ZHENHUA HEAVY IND +1

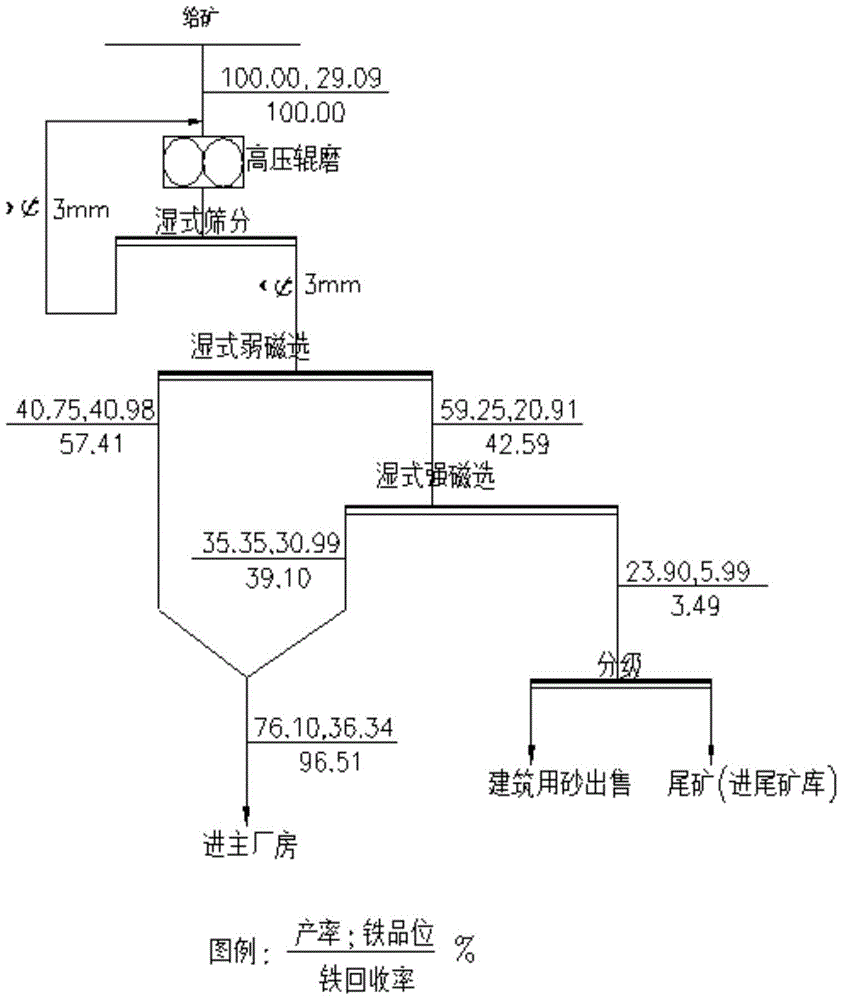

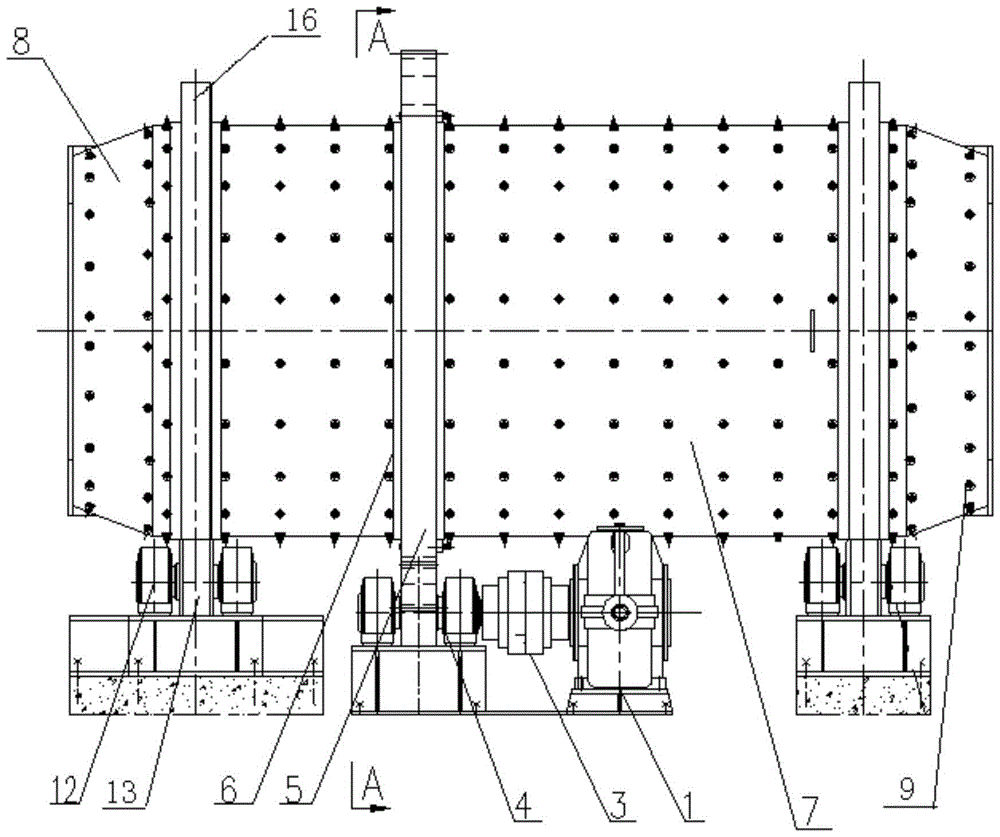

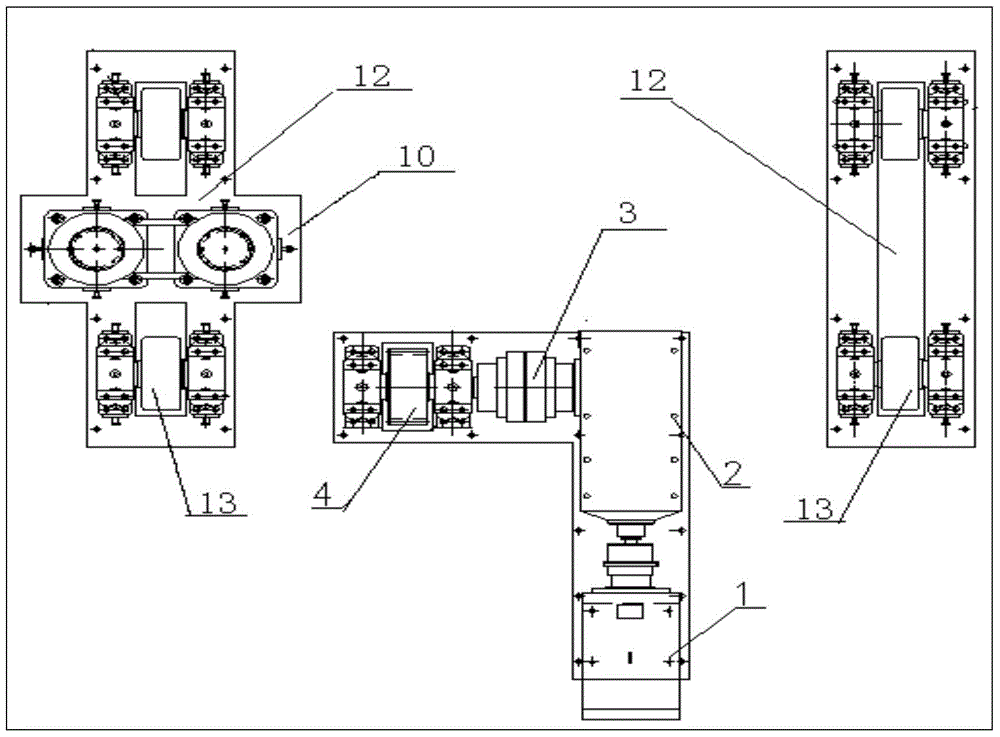

A new process and production system for composite lean iron ore pre-selection

ActiveCN104722394BImprove grindabilityIt has the effect of saving energy and reducing consumptionSievingScreeningHigh intensityAssembly line

The invention discloses a novel composite lean iron ore pre-concentration technology and a production system thereof, and belongs to the technical field of ore concentration. The novel composite lean iron ore pre-concentration technology includes the steps that composite lean iron ore is crushed; the crushed products are smashed to be phi 3 mm through a high-pressure roller milling screen fully-closed superfine crushing technology; a wet low-intensity magnetic separation and wet high-intensity magnetic separation combined technology is carried out; concentrate of a low-intensity magnetic separation machine and concentration of a high-intensity magnetic separation machine are mixed and then later ball milling grading starts; tailings of the high-intensity magnetic separation machine enters a linear vibration screen II for dehydration. The production system of the novel composite lean iron ore pre-concentration technology comprises a high-pressure roller grinding machine, a wet efficient beating machine, a linear vibration screen I, the low-intensity magnetic separation machine, the high-intensity magnetic separation machine and the linear vibration screen II which are sequentially distributed on a production assembly line according to the process sequence. By means of the technology and the system, a large amount of qualified tailings can be abandoned before the composite lean iron ore is ground, the grinding amount is lowered, and the aims that more tailing is crushed, little tailing is ground and the tailing is abandoned earlier are achieved.

Owner:ANHUI MASTEEL ENG & TECH GRP

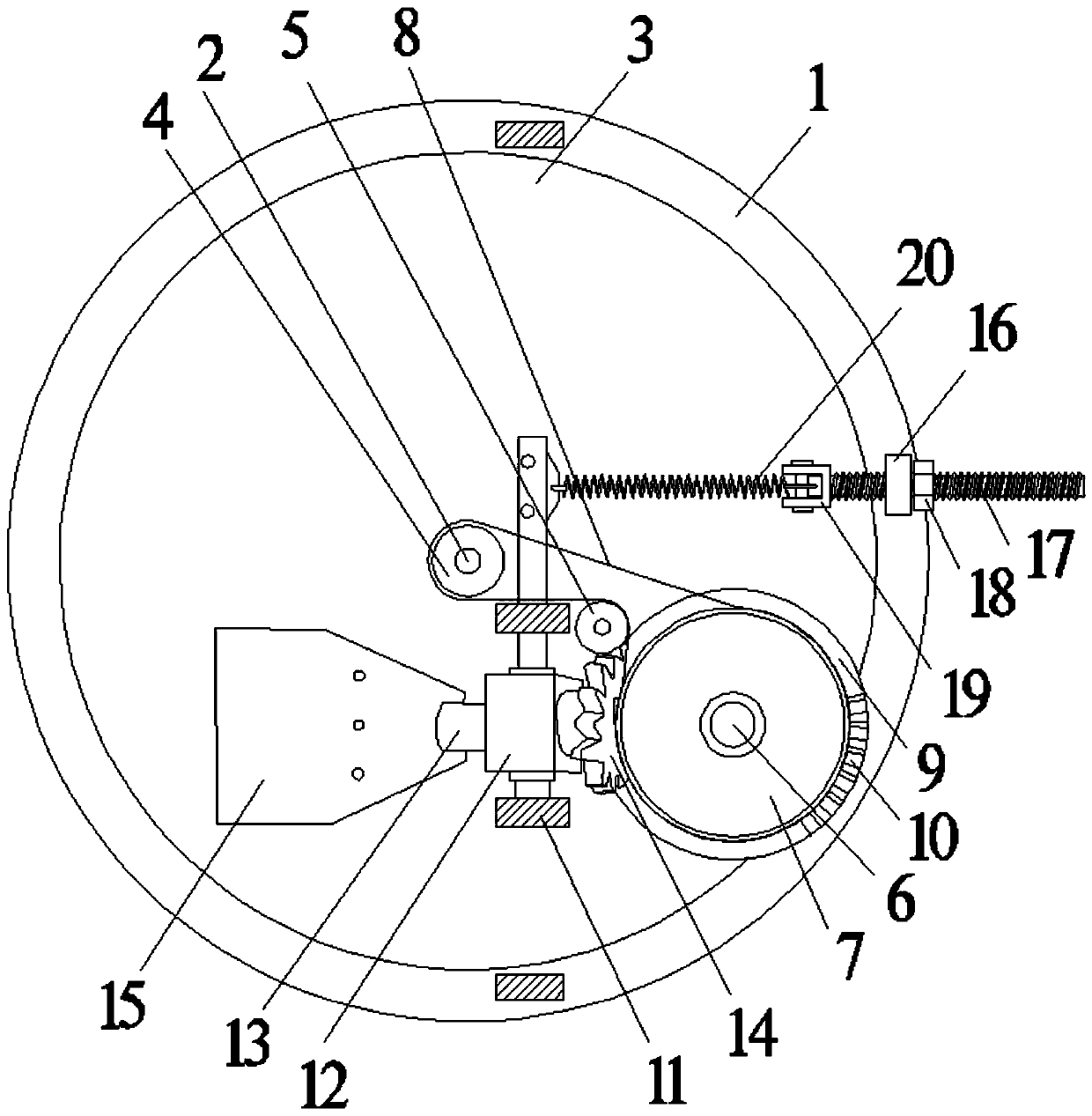

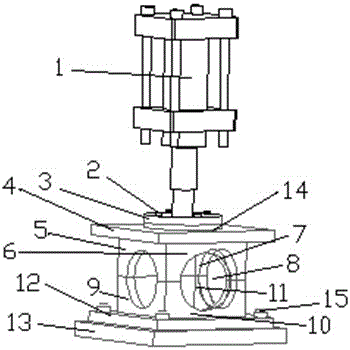

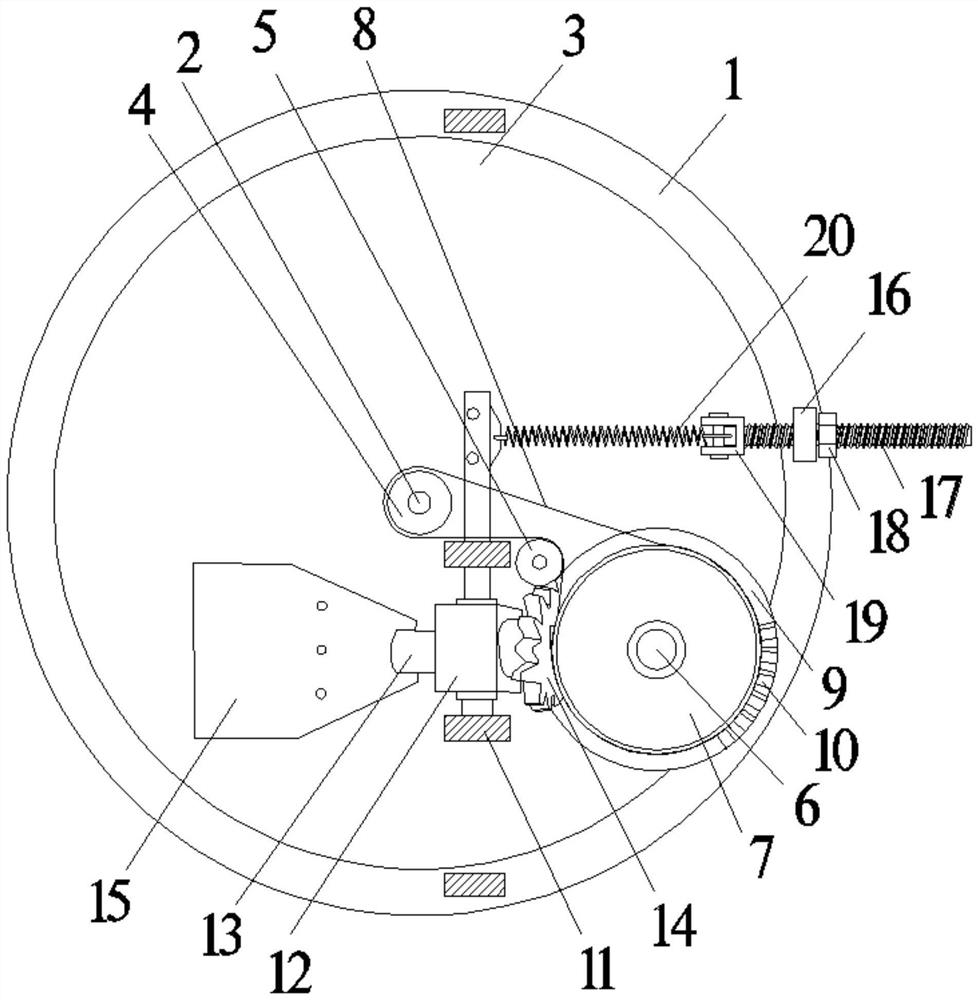

Mechanical equipment capable of automatic overturning and polishing of part

ActiveCN111546153ASave human effortImprove efficiencyGrinding drivesGrinding work supportsGear wheelPolishing

The invention relates to the technical field of mechanical automation, and discloses mechanical equipment capable of automatic overturning and polishing of a part. The equipment comprises a chassis, wherein a power shaft is rotationally mounted in the center of the chassis; the outer wall of the center of the power shaft is fixedly sleeved by a polishing disc; the outer wall of the upper part of the power shaft is fixedly sleeved by a first belt wheel; a second belt wheel is rotationally clamped in the chassis on the lower right side of the first belt wheel; and a rotating shaft is rotationally clamped in the chassis on the lower right side of the second belt wheel. The mechanical equipment capable of the automatic overturning and polishing of the part has the advantages that the polishingof the part and position adjustment and control during mounting of a new part can be achieved through a clamp, a rotating seat, a screw, a nut, a connecting seat and a pressure spring, so that the structure is simple, the cost is low, and the safety is high; and the polishing and the overturning functions can be simultaneously fulfilled by a single power source through the chassis, the power shaft, a support frame, a spoon-shaped frame, a strut and a gear, so that manpower consumption is avoided, high efficiency, safety and practicality as well as low energy consumption are achieved, and popularization is further facilitated.

Owner:威海铭天体育用品有限公司

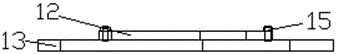

Three-head groove machining die for three-way pipe fitting

The invention provides a three-head groove machining die for a three-way pipe fitting. A bottom die plate and an upper die plate are manufactured through iron plates according to the center height of a groove working platform of a three-head groove machine, and the three-head groove machining die for the three-way pipe fitting is formed through welding according to the center distance of a three-way pipe fitting straight pipe and a supporting opening. A disc is welded to the die upper die plate of the die. The disc is subjected to drilling and tapping and used for being connected with the oil top of the three-head groove machine. Three pressing piece baffles are welded by the upper die plate according to the center distance of the three-way pipe fitting straight pipe and the supporting opening. Three baffles are welded by a bottom die body according to the center distance of the three-way pipe fitting straight pipe and the supporting opening, and the bottom die body is fixed to the machining platform of the three-way groove machine through bolts. During welding of the bottom die body and an upper die body, according to the center distance of the three-way pipe fitting straight pipe and the supporting opening, the distance between the plates is equal, and the upper die baffles and the lower die baffles are vertically welded. The three-head groove machining die is easy to manufacture and high in practicability, groove machining is conducted by three openings at the same time, piece pressing is firm, the machining speed is high, and the production efficiency and the product quality are improved greatly.

Owner:青岛昌辉管业有限公司

Cylinder temperature sensor with protection structure

InactiveCN111307317AReasonable structureImprove insulation effectThermometer detailsThermometers using electric/magnetic elementsPhysicsOrganosilicon

The invention discloses a cylinder temperature sensor with a protection structure. The sensor comprises a shell, a connecting rod, a hollow pipe and a protective block, a preformed groove is formed inthe shell. An organic silicon high-temperature-resistant layer is arranged on the side wall of the bottom end in the preformed groove; a thermistor is mounted at the bottom end of the interior of thepreformed groove; a first wiring pin is mounted on one side of the top end of the thermistor; a second wiring pin is mounted on the other side of the top end of the thermistor; a first inserting partis arranged on one side of the upper portion of the thermistor, the bottom end of the first inserting part is connected with the top end of a first wiring pin, a second inserting part is arranged onthe other side of the upper portion of the thermistor, the bottom end of the second inserting part is connected with the top end of a second wiring pin, and a hollow pipe is installed in the middle ofthe bottom end of the shell. By uniformly arranging the organic silicon high-temperature-resistant layer on the side wall of the bottom end in the preformed groove, the high-temperature-resistant capacity is improved. Meanwhile, temperature leakage is prevented, and the accuracy of a detection result is improved.

Owner:江苏伟正电气科技有限公司

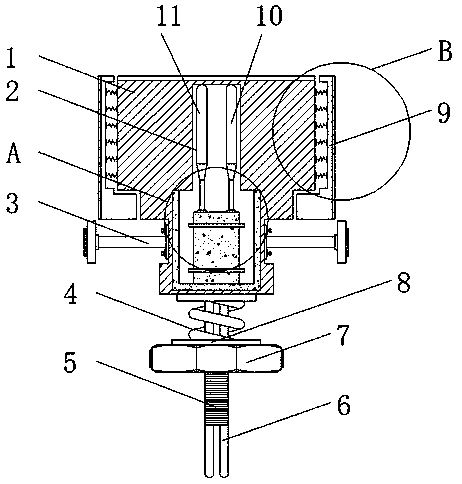

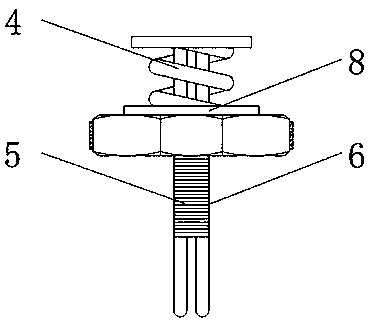

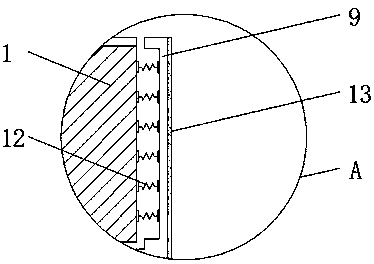

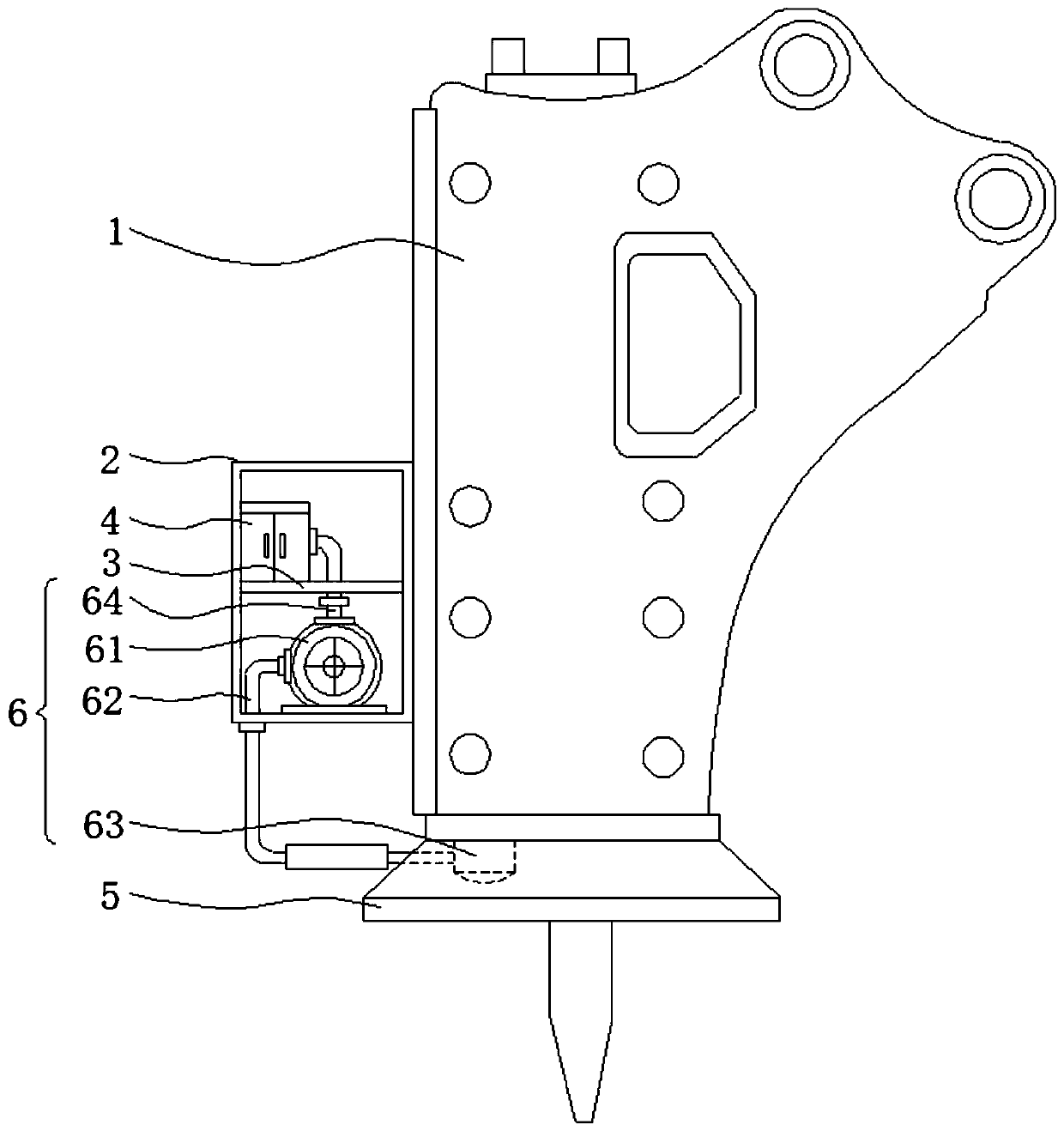

Hydraulic breaking hammer

InactiveCN110984277AThere are security risksAvoid pollutionDispersed particle separationSoil-shifting machines/dredgersActivated carbonDust control

The invention provides a hydraulic breaking hammer. The hydraulic breaking hammer comprises a breaking hammer body, a control box, a protective cover, and a dust removal assembly, wherein one side ofthe control box is fixed to one side of the breaking hammer body, a fixing plate is fixedly connected between the two sides of the inner wall of the control box, a collecting box is fixedly connectedto the top of the fixing plate, the top of the protective cover is arranged at the bottom of the breaking hammer body, and the dust removal assembly is located inside the control box. According to thehydraulic breaking hammer, dust can be well treated, a suction pump is started, a dust suction head on the suction pump can rapidly suck the dust generated in the crushing process, a large amount ofdust is avoided, the environment is prevented from being polluted, and the body health of workers is prevented from being damaged; and an activated carbon plate can be replaced, so that the situationthat the dust suction rate of the activated carbon plate is influenced due to blockage caused by long-time use is avoided, and then the practicability of the hydraulic breaking hammer is further improved.

Owner:HENGYANG CITY LINKEN HYDRAULIC EQUIP

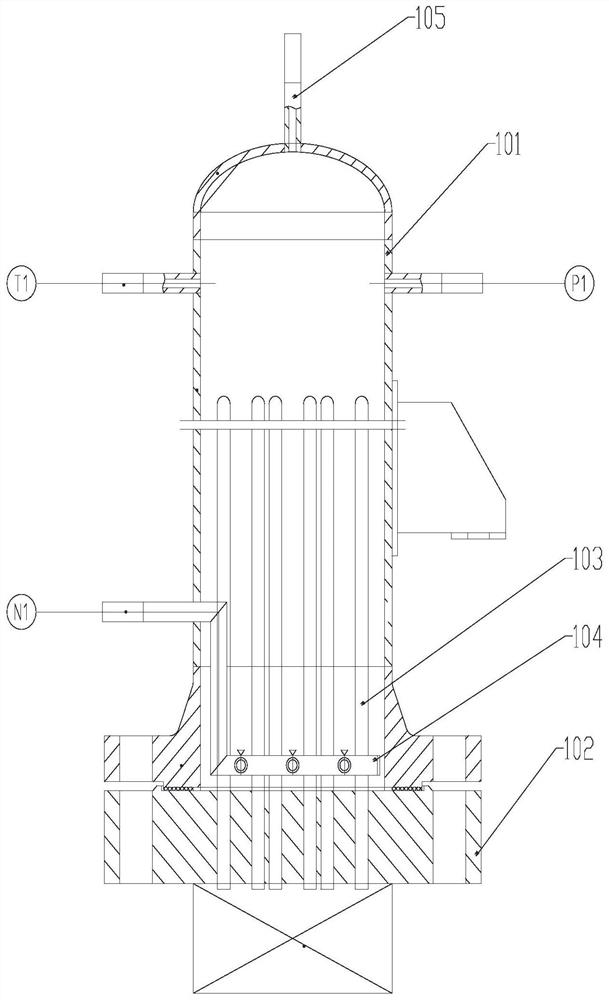

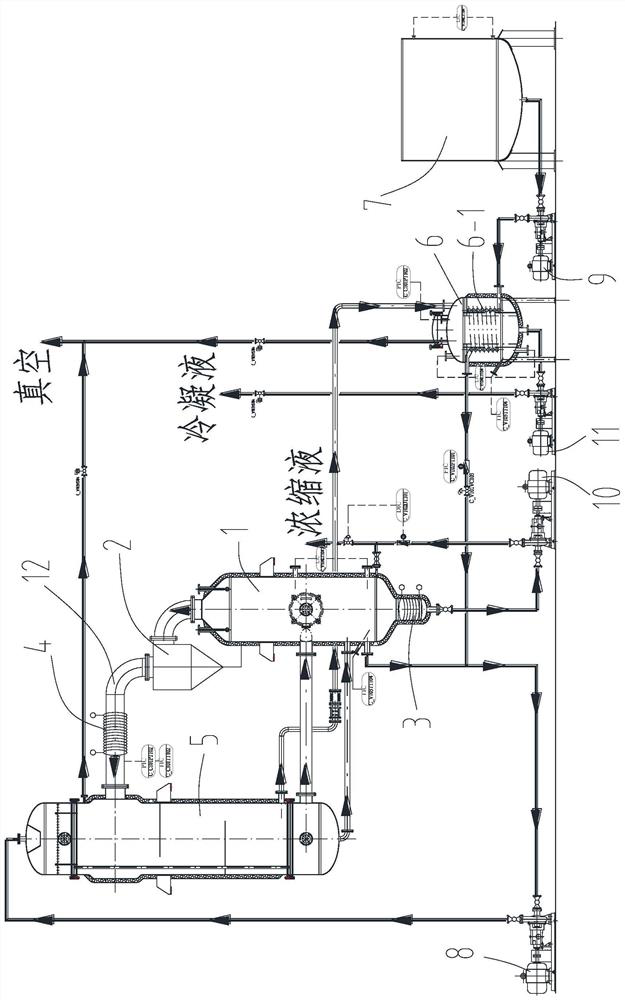

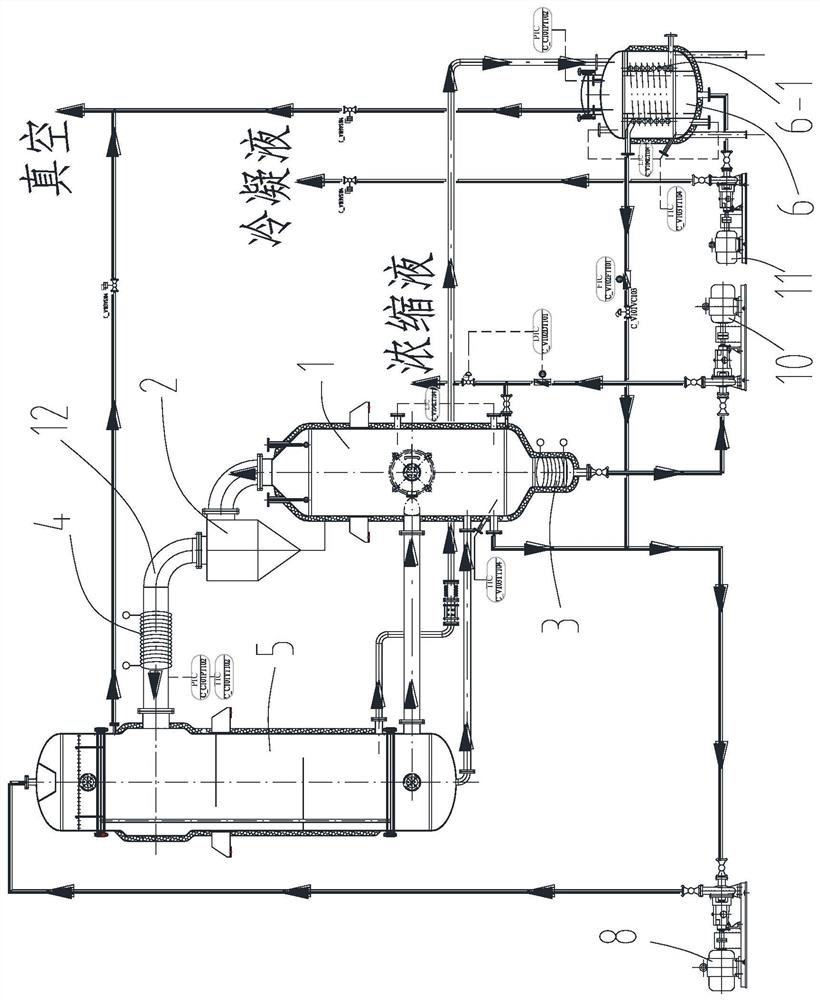

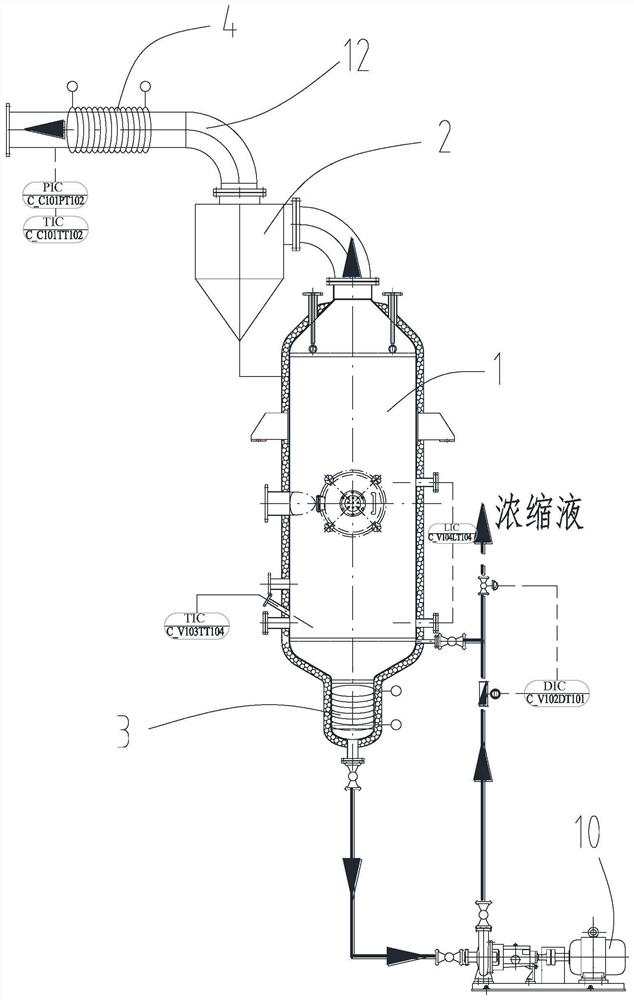

Electromagnetic induction evaporation concentrator

PendingCN111821706ALow costReduce energy consumptionSeawater treatmentEvaporator accessoriesOrganic solventEngineering

Owner:上海贵江机电技术有限公司

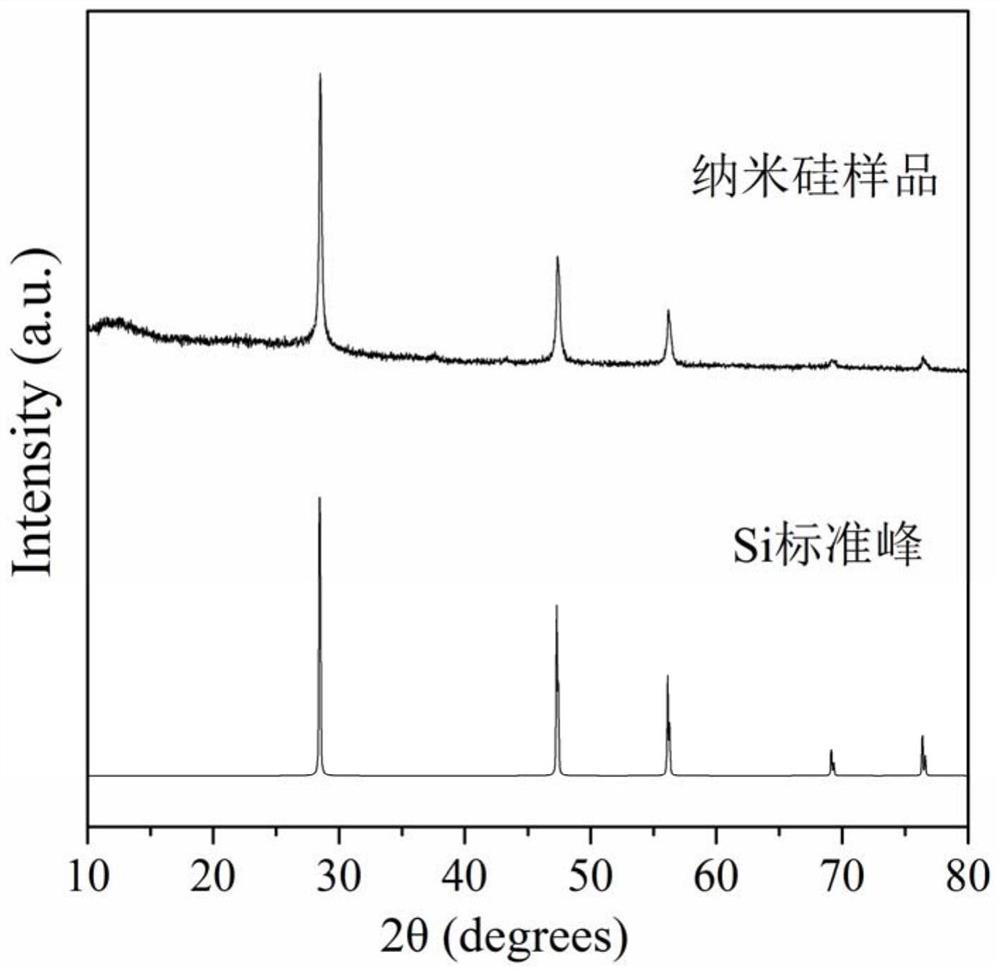

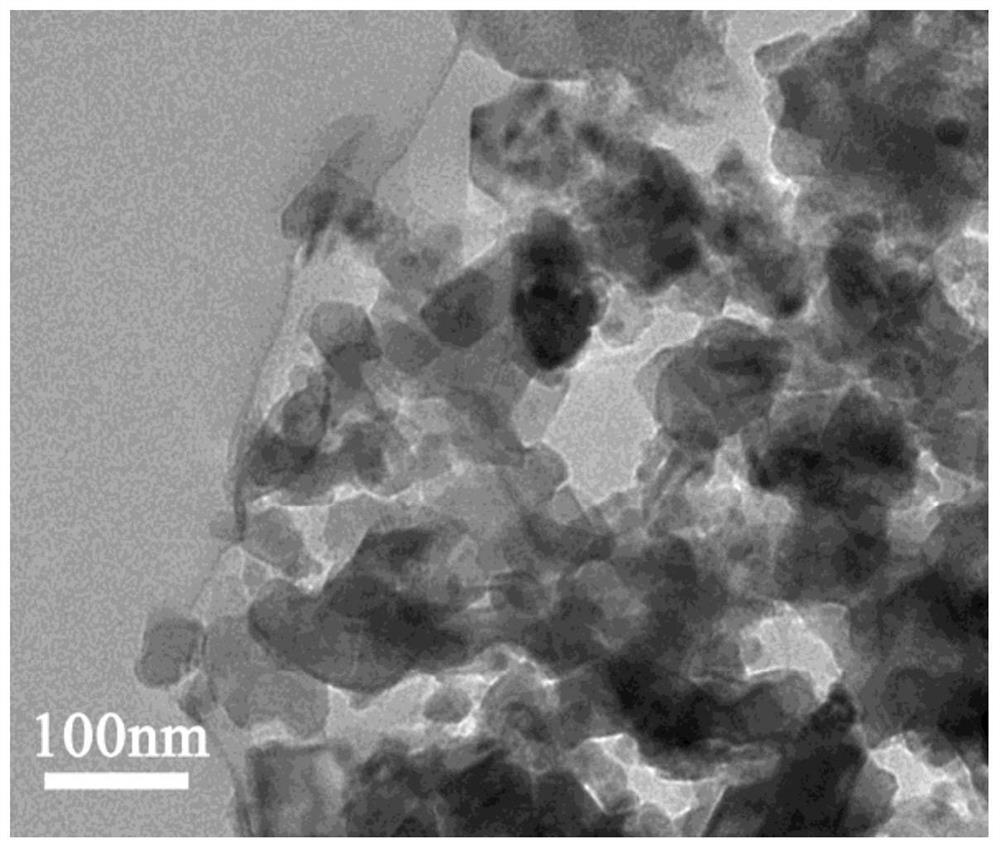

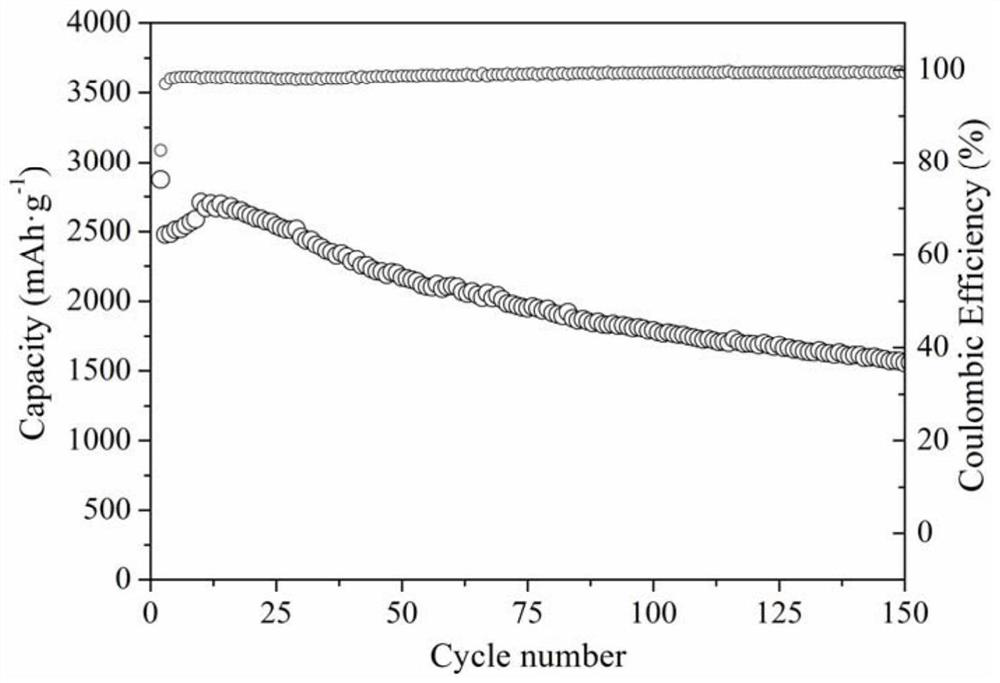

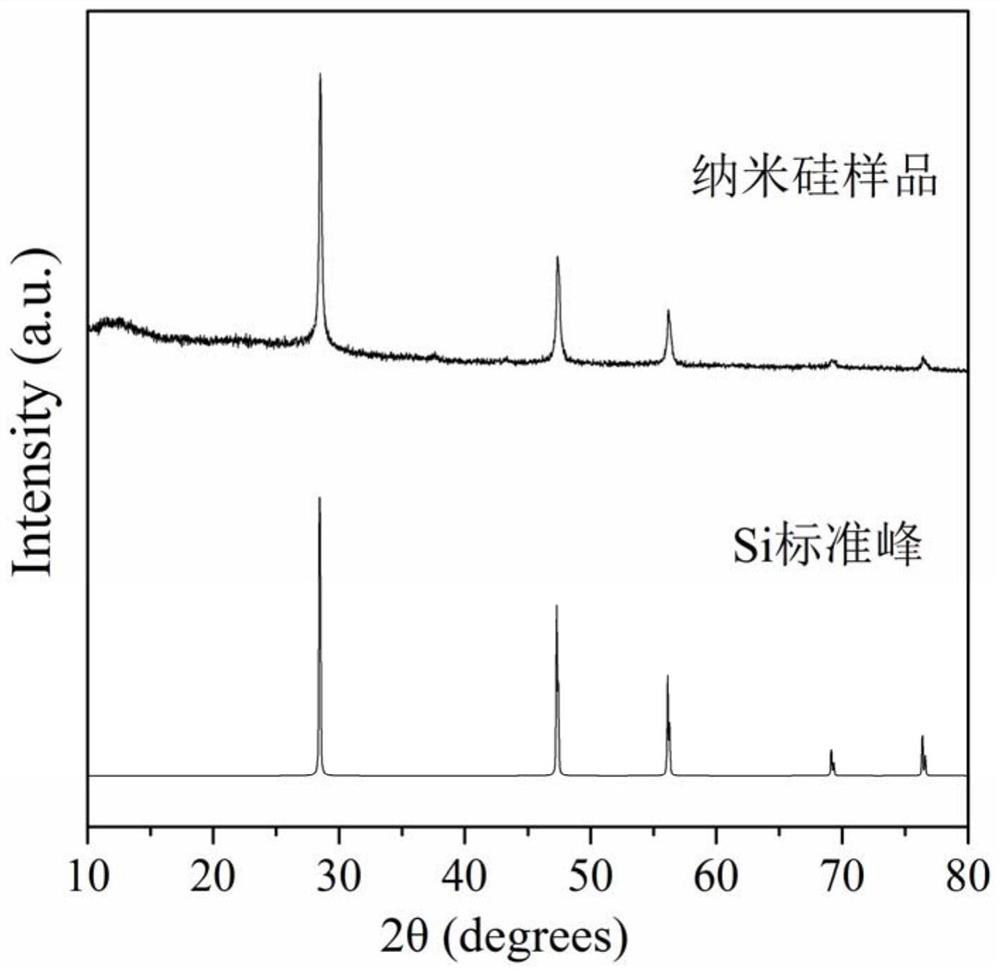

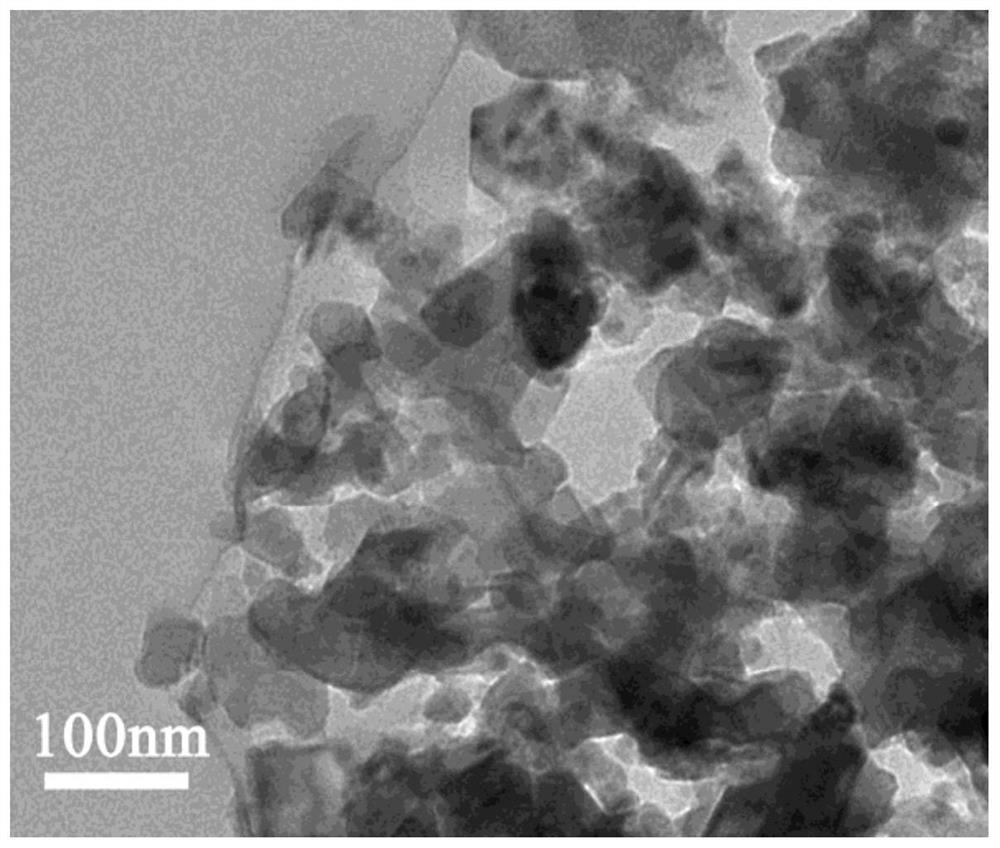

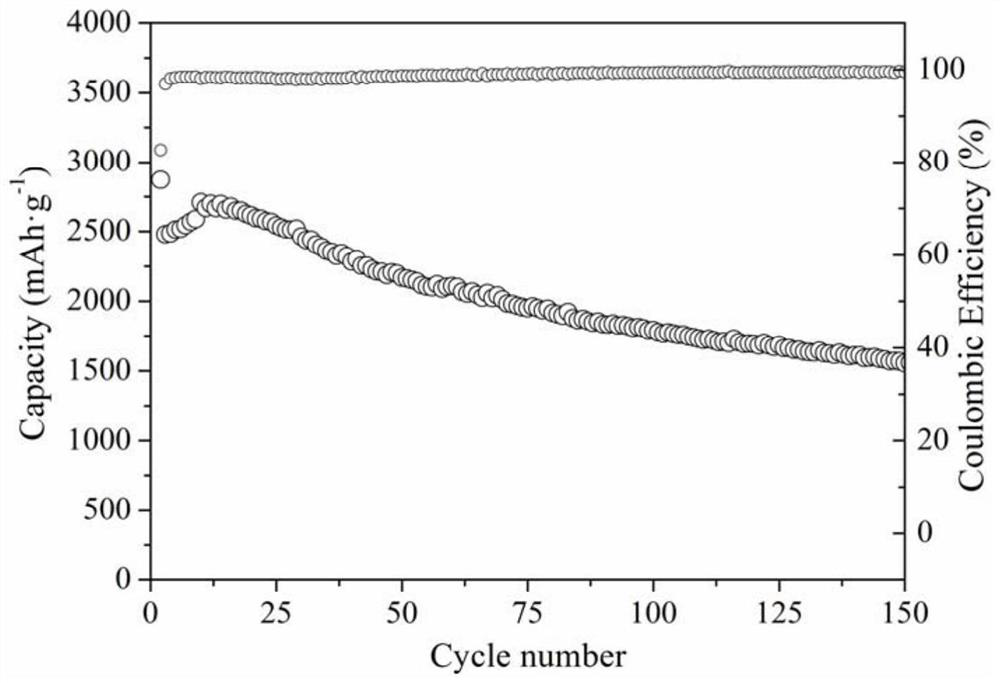

Oxidation grinding preparation method and application of carbon group element elementary substance material

ActiveCN112038616ALow efficiencyHigh energy consumptionMaterial nanotechnologySiliconAlkaline earth metalElectrochemistry

The invention relates to an oxidation grinding preparation method and application of a carbon group element elementary substance material. The method comprises the following steps: mixing an intermetallic compound and an inorganic oxidant, and grinding and decomposing the intermetallic compound under vacuum or inert gas conditions to obtain the corresponding carbon group element elementary substance material. According to the method, an intermetallic compound is used as a reducing agent, and a proper inorganic solid or gas oxidizing agent is selected to be mixed and then ground, wherein the reaction is mild, pollution is avoided, and compared with direct use of active alkali metal or alkaline-earth metal, the method is obviously high in safety and higher in synthesis efficiency, and ball milling energy consumption is greatly reduced. The carbon group element elementary substance prepared by the method has excellent electrochemical performance, and shows relatively high lithium ion battery capacity and excellent charge-discharge cycle performance.

Owner:SHANDONG UNIV

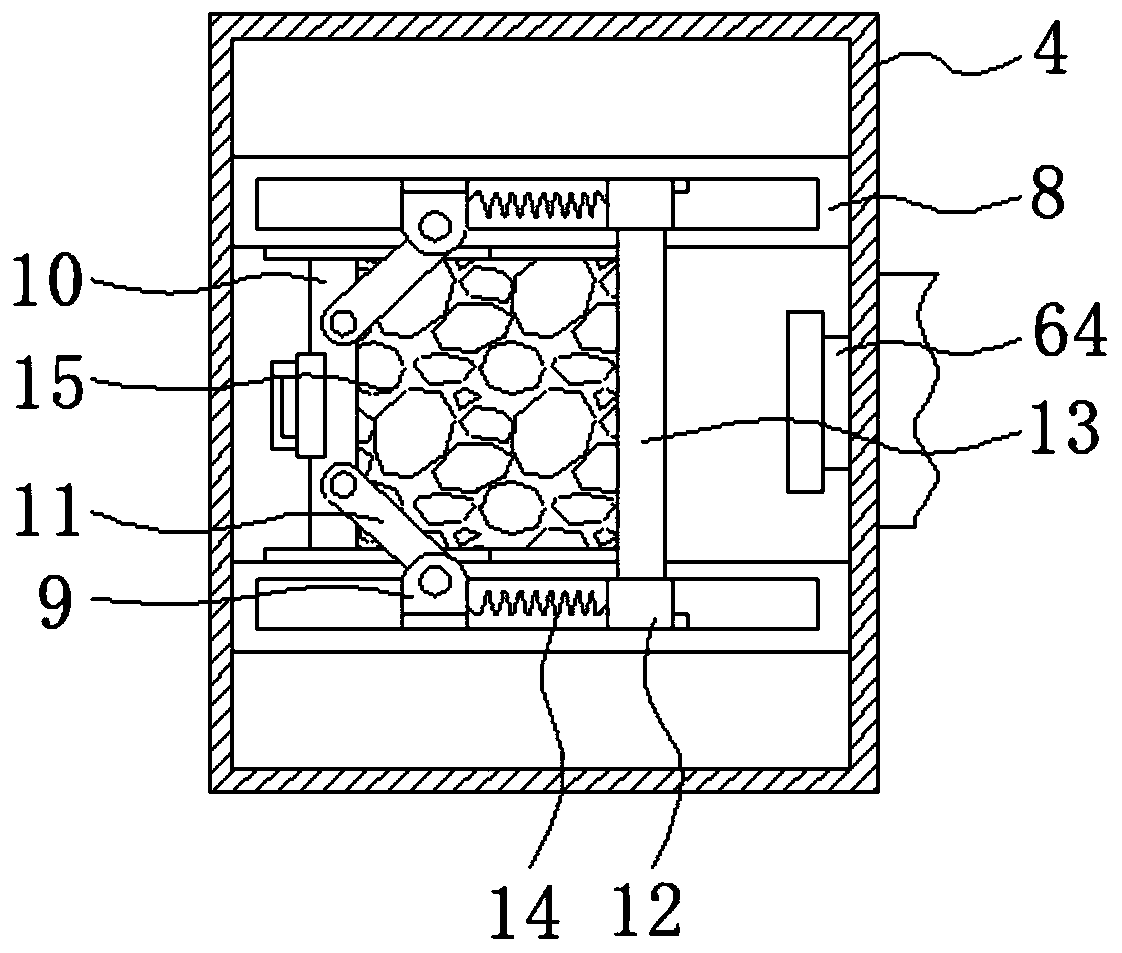

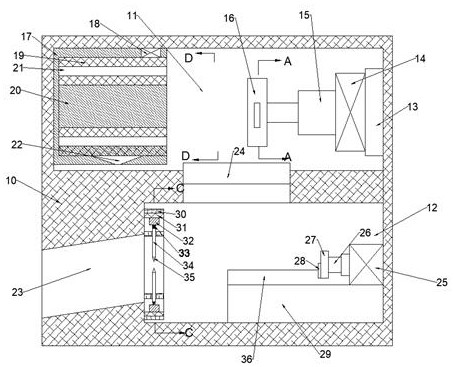

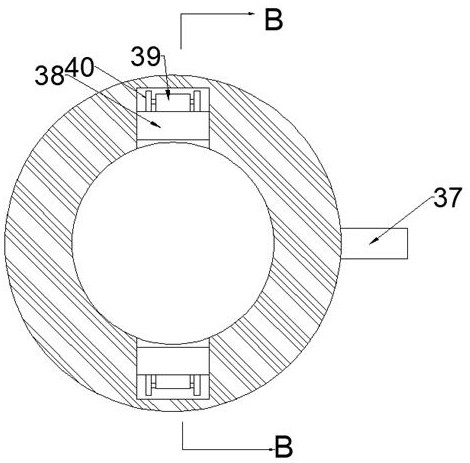

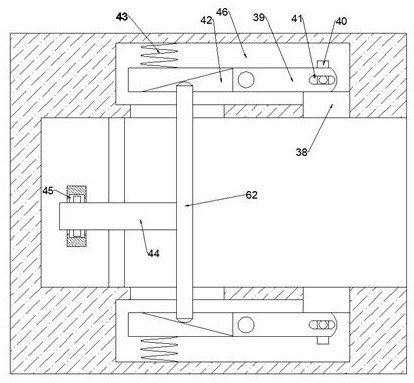

Spring processing and detecting device in shock absorber

InactiveCN111791134AExtended use timeThere are security risksMachine part testingGrinding drivesElectric machineShock absorber

The invention discloses a spring processing and detecting device in a shock absorber. The spring processing and detecting device comprises a working box, a cleaning chamber and a detecting chamber arearranged in the working box, a front-back electric guide rail is fixedly installed on the right wall face of an inner cavity of the cleaning chamber, a rotating motor is installed on the left end face of the front-back electric guide rail, and a left-right electric telescopic rod is installed on the left end face of the rotating motor; a clamping block is arranged at the left end face of the left-right electric telescopic rod, after a spring is placed at a designated position, rust on the surface of the spring can be automatically removed; after the rust on the surface is removed, spring cracks are detected; after the spring is used for a long time, the potential safety hazards are prevented; and meanwhile, the spring processing and detecting device is high in crack detection efficiency,careful in detection and capable of judging tiny cracks or sunken parts.

Owner:QINGDAO JUNPING DAMPING TECH CO LTD

Method for simultaneous production of methyl ethyl ketone and cyclohexane

InactiveCN103030539BImprove efficiencyExtended service lifeOrganic compound preparationHydrocarbon by hydrogenationBenzeneAmyl methyl ketone

Owner:NANJING COLLEGE OF CHEM TECH

A mechanical device for automatically turning and grinding parts

ActiveCN111546153BLow efficiencyThere are security risksGrinding drivesGrinding work supportsGear wheelMechanical equipment

Owner:威海铭天体育用品有限公司

Liquid alkyd resin and preparation method thereof

The invention relates to liquid alkyd resin and a preparation method thereof. The liquid alkyd resin comprises the following raw materials: oil, rosin, benzoic acid, polyatomic alcohol, waste, solvent oil and the like. The preparation method comprises the following steps of: adopting recovered waste and old plastic and chemical-fiber industrial waste as main raw materials, adding all auxiliary materials, generating polyesterification reaction in a reaction kettle, then carrying out dilution, and finally carrying out filtering to prepare a finished liquid alkyd resin product. In the invention, the waste plastic is utilized for preparing the liquid alkyd resin, the wastes become valuables, the technical process is simple and is easy to operate, the mode for utilizing heat-conducting oil for heating is safer and more energy-saving, and the application range is wide.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

An efficient loading method and system for automatically identifying goods

The invention relates to a high-efficiency loading method and system capable of automatically identifying goods. The method comprises the following steps: 1) defining goods identification codes and goods parameters corresponding to the identification codes; presetting truck compartment size and total loading weight; 2) identifying the goods identification codes and reading the goods parameters corresponding to the goods identification codes from a database by a goods identification code reading device; 3) calculating a total number of loaded pieces according to the goods parameters and the total loading weight; 4) creating a goods stacking model in a truck compartment according to the total number of loaded pieces, the truck compartment size and the goods parameters; 5) stacking the goods into goods stacks in a relay station according to the stacking model by grip equipment; 6) transporting the goods stacks to the truck compartment from the transfer station by transportation equipment. According to the method and the system, the stacking model is automatically determined by automatically identifying the goods and the goods can be quickly and orderly loaded.

Owner:FUJIAN ZHENGDE INTELLIGENT DEVICE

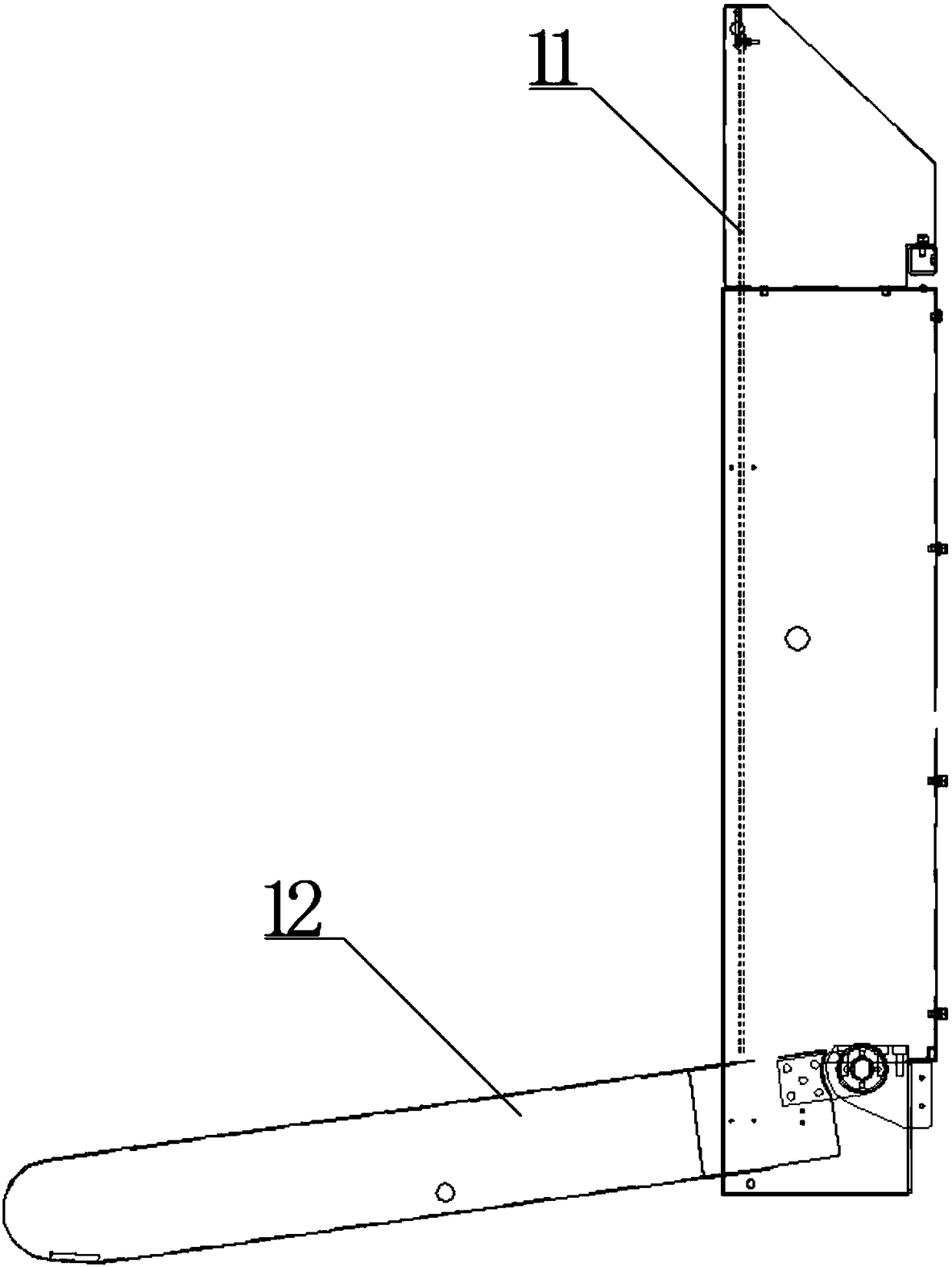

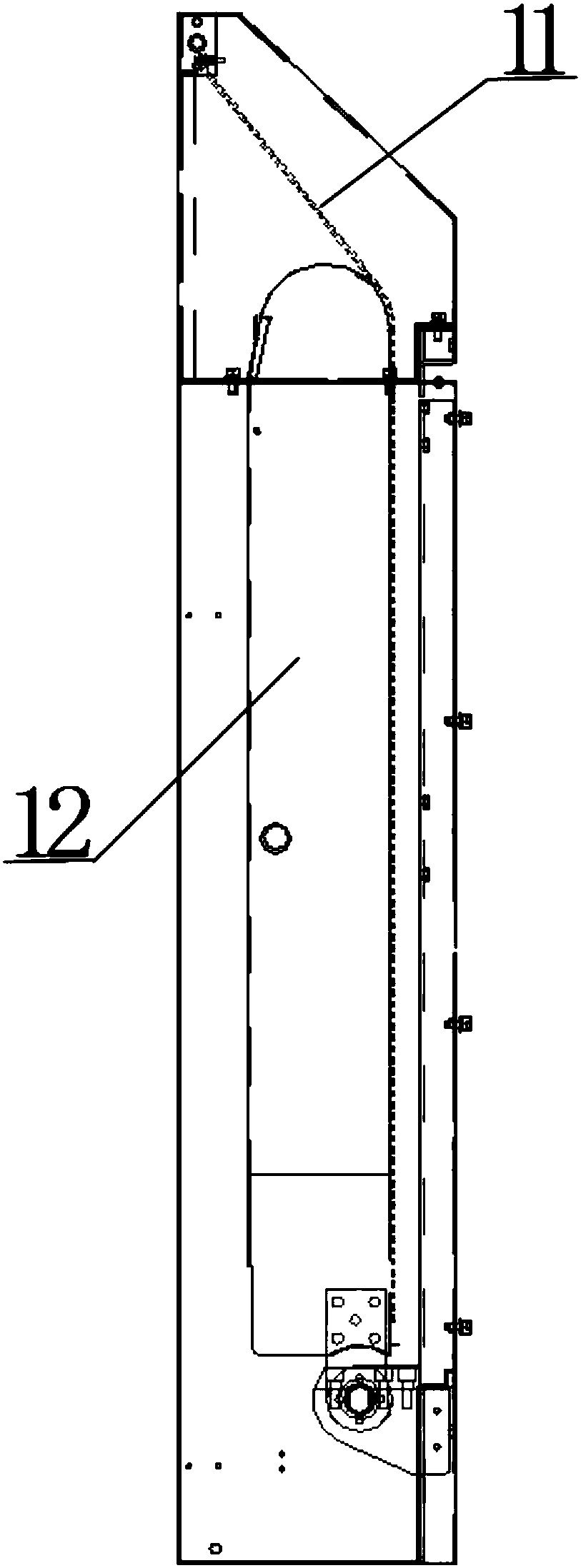

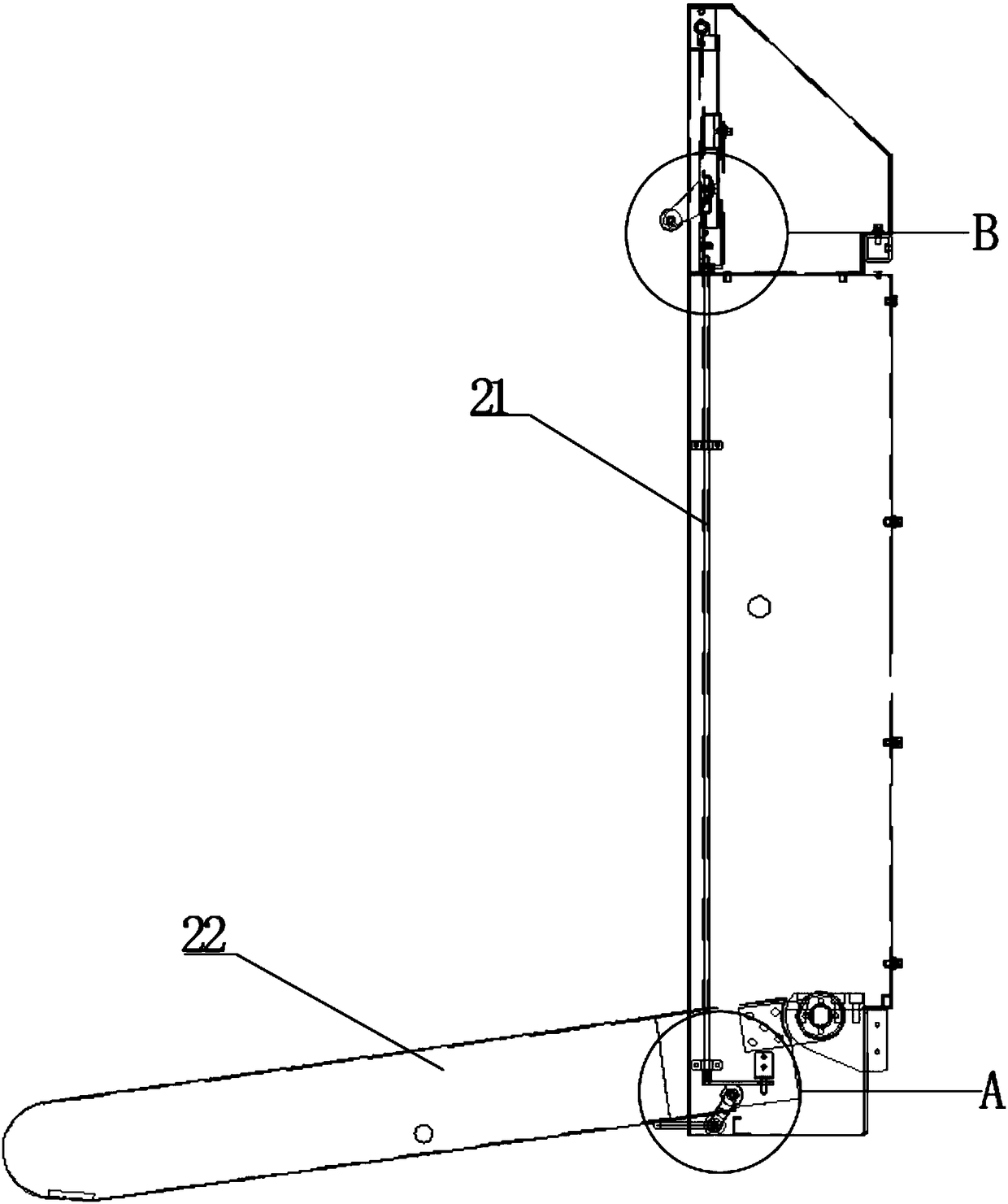

a security machine

ActiveCN106429221BImprove efficiencyEasy to useConveyorsNuclear radiation detectionEngineeringMechanical engineering

The invention relates to the technical field of security inspection, in particular to a security inspection machine. The security inspection machine comprises a baffle capable of rotating between a vertical position and an inclination position. A shielding curtain is connected to the baffle vertically as a whole when the baffle is located in the vertical position and the inclination position. A conveying belt pushes the baffle to rotate from the vertical position to the inclination position when rotating from a work position to a put-away position. The shielding curtain is spaced to the conveying belt all the time in the rotation process of the baffle. Thus, the shielding curtain is always kept vertical and cannot be pushed by the put-away conveying belt to be bent, the shielding curtain cannot be deformed when the conveying belt is put away no matter how long the security inspection machine is placed, safety hidden hazards do not exist, use efficiency of the security inspection machine is improved, and use cost is reduced. Besides, the length of the shielding curtain can be arranged to be equal to the height of an internal channel of the security inspection machine, a user can accurately judge the height of the internal channel of the security inspection machine according to the length of the shielding curtain, and the security inspection machine is convenient to use.

Owner:NUCTECH CO LTD

Oxidative grinding preparation method and application of carbon group element simple material

ActiveCN112038616BLow efficiencyHigh energy consumptionMaterial nanotechnologySiliconAlkaline earth metalElectrochemistry

The present invention relates to an oxidation grinding preparation method and application of carbon group element simple material. The method is to mix an intermetallic compound with an inorganic oxidizing agent, grind and decompose the above intermetallic compound under vacuum or inert gas conditions, and obtain the corresponding carbon group element simple substance Material. The method of the present invention uses intermetallic compounds as reducing agents, selects appropriate inorganic solids or gas oxidants and grinds them after mixing. The reaction is mild and pollution-free. Compared with the direct use of active alkali metals or alkaline earth metals, it is obviously safer and more efficient. High synthesis efficiency greatly reduces the energy consumption of ball milling. The simple substance of the carbon group element prepared by the invention has excellent electrochemical properties, and exhibits higher lithium ion battery capacity and excellent charge-discharge cycle performance.

Owner:SHANDONG UNIV

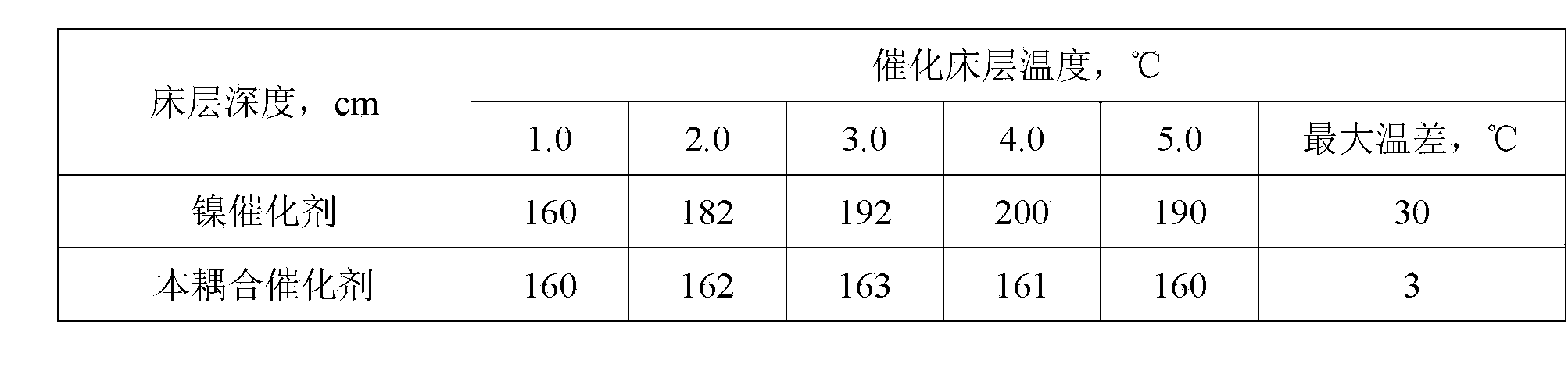

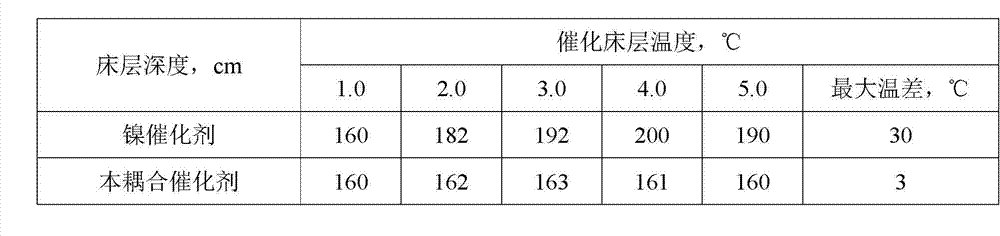

Method for simultaneous production of methyl ethyl ketone and cyclohexane

InactiveCN103030539AImprove efficiencyExtended service lifeOrganic compound preparationHydrocarbon by hydrogenationBenzeneAmyl methyl ketone

The invention relates to a method for a simultaneous production of methyl ethyl ketone and cyclohexane in the same reactor. The method is characterized by taking a mixture of sec-butyl alcohol and benzene (a mol ratio is controlled to be not lower than 4, preferably 4-10) as a raw material, vaporizing, treating by a two-stage catalytic reactor containing a nickel-copper catalyst, and rectifying and separating. Conditions of two stages of reactions are as follows: conditions of the first stage of reaction is as follows: reaction temperature is 150-250 DEG C, reaction pressure is not greater than 0.5MPa, the mol ratio of sec-butyl alcohol and benzene is not lower than 4, and the space velocity of the mixing material liquid is 0.5-2.5; and the conditions of the second stage of reaction is as follows: reaction temperature is 180-250 DEG C, and reaction pressure is not greater than 1.0MPa; and yields are respectively as follows: the yield of the cyclohexane is not lower than 98.5%, and the yield of ethyl ketone is not lower than 97.0%.

Owner:NANJING COLLEGE OF CHEM TECH

Information reminder method, device and electronic device

ActiveCN108280358BThere are security risksRealize identificationFinanceCryptography processingEngineeringFinancial transaction

An embodiment of the present invention provides an information reminder method, device, and electronic equipment, the method comprising: when detecting that a transaction record for a target account is generated in a blockchain ledger, obtaining the generated transaction record for the target account , as the current transaction record; compare the current transaction record with the transaction record corresponding to the target account stored locally; when it is determined that any transaction record in the current transaction record and the transaction record corresponding to the target account stored locally At the same time, it is determined that there is a security risk in the target account; and a warning message is output to warn the user of the target account that the target account has a security risk. In order to realize the identification of the legality of asset transactions, and then realize the identification of account security.

Owner:BEIJING KINGSOFT INTERNET SECURITY SOFTWARE CO LTD

Identity authentication system and method based on image and somatosensory analysis

ActiveCN105335727BEnsure safety and stabilityEnsure safetyAcquiring/recognising facial featuresHuman bodyAnalysis center

The invention discloses an identity authentication system and method based on image and somatosensory analysis. The system includes a sequentially connected data acquisition module, a data analysis center, and a security dispatch center; Face images and human body movements are collected; the data analysis center is used to analyze face images, expressions and human body movements; the security dispatch center is used to perform security dispatch according to the results analyzed by the data analysis center. The invention provides an identity authentication system and method based on image and somatosensory analysis, which can judge whether people in the security area enter illegally through face images, and take security scheduling measures; Analysis; further analysis of human body movements when the expression is abnormal can provide a more accurate basis for judging potential safety hazards.

Owner:CHENGDU WISDOM SHULIAN INFORMATION TECH CO LTD

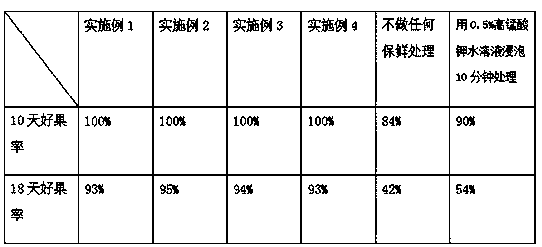

A kind of preservation method of pitaya

InactiveCN105613725BExtended shelf lifeIncrease fruit weightFruit and vegetables preservationPreservation methodsHorticulture

Owner:广西绿希望农业发展有限公司

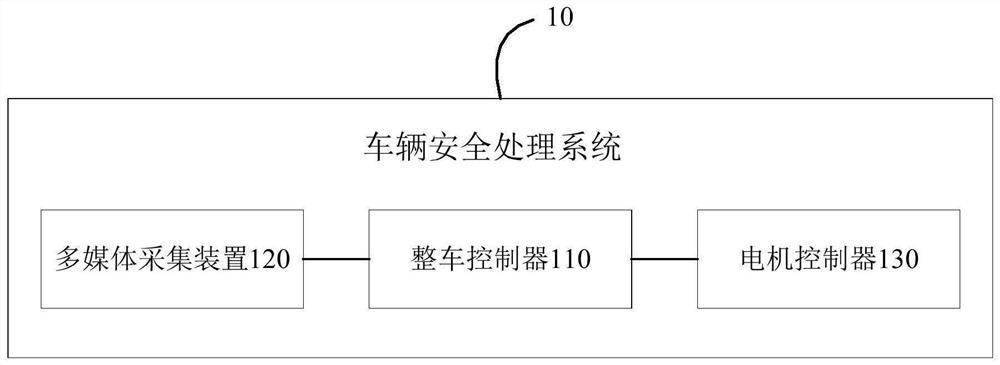

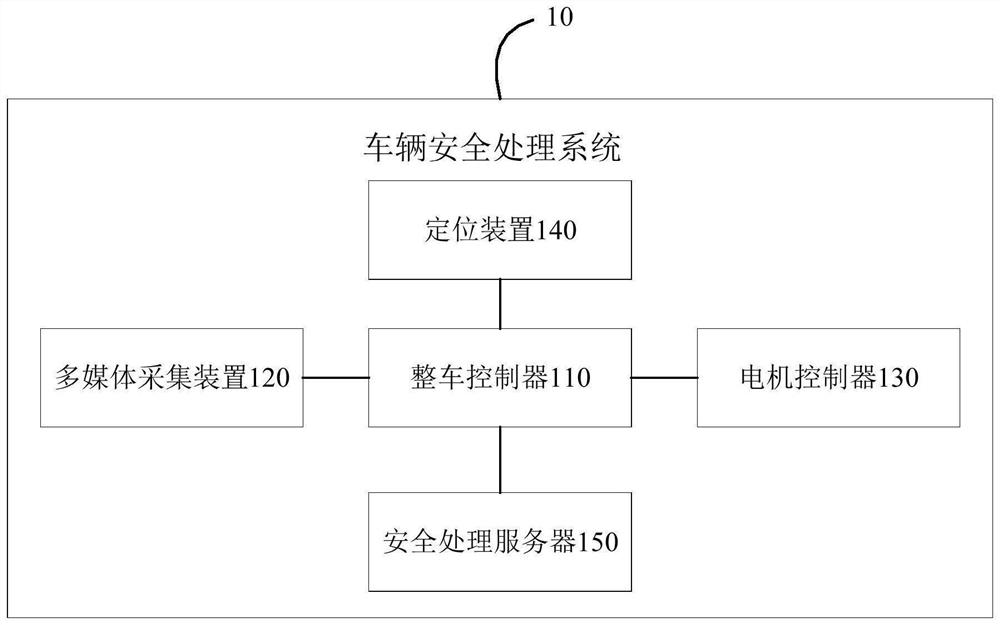

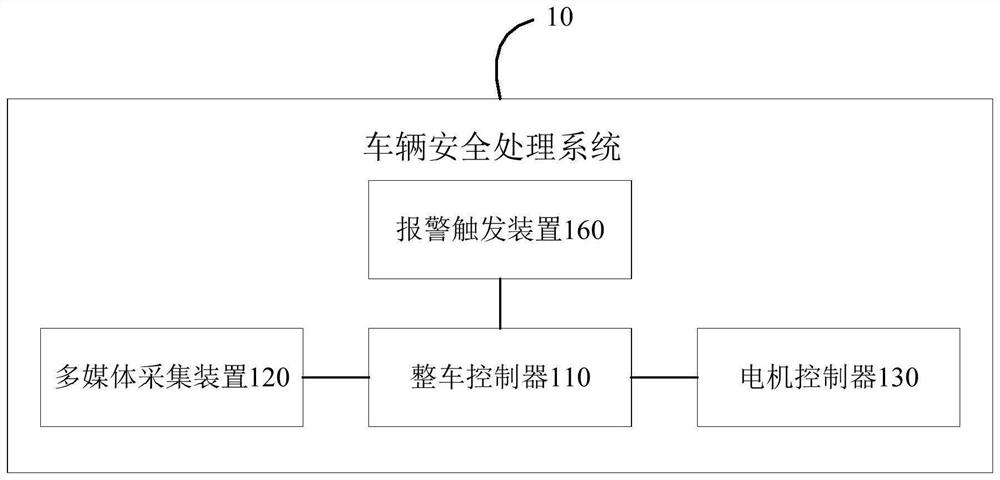

Vehicle safety processing system and method and vehicle

InactiveCN112092638AEnsure personal safetyAvoid traffic accidentsSpeed controllerElectric energy managementElectric machineryMotor controller

The invention provides a vehicle safety processing system and method and a vehicle. The system comprises a vehicle control unit, a multimedia acquisition device and a motor controller; the multimediaacquisition device is used for acquiring multimedia information in a set safety detection area of the vehicle; the vehicle control unit is used for analyzing the multimedia information acquired by themultimedia acquisition device so as to determine whether the vehicle has potential safety hazards or not at present, and sending a braking instruction to the motor controller when determining that the vehicle has potential safety hazards at present; and the motor controller is used for controlling the vehicle to brake according to the brake instruction. By means of the system, when it is detectedthat the vehicle has potential safety hazards, the vehicle can be controlled to be braked, the vehicle can stop running within a short time, and the technical problems that in the prior art, the vehicle cannot be controlled, and the vehicle cannot be braked quickly are solved.

Owner:BYD CO LTD

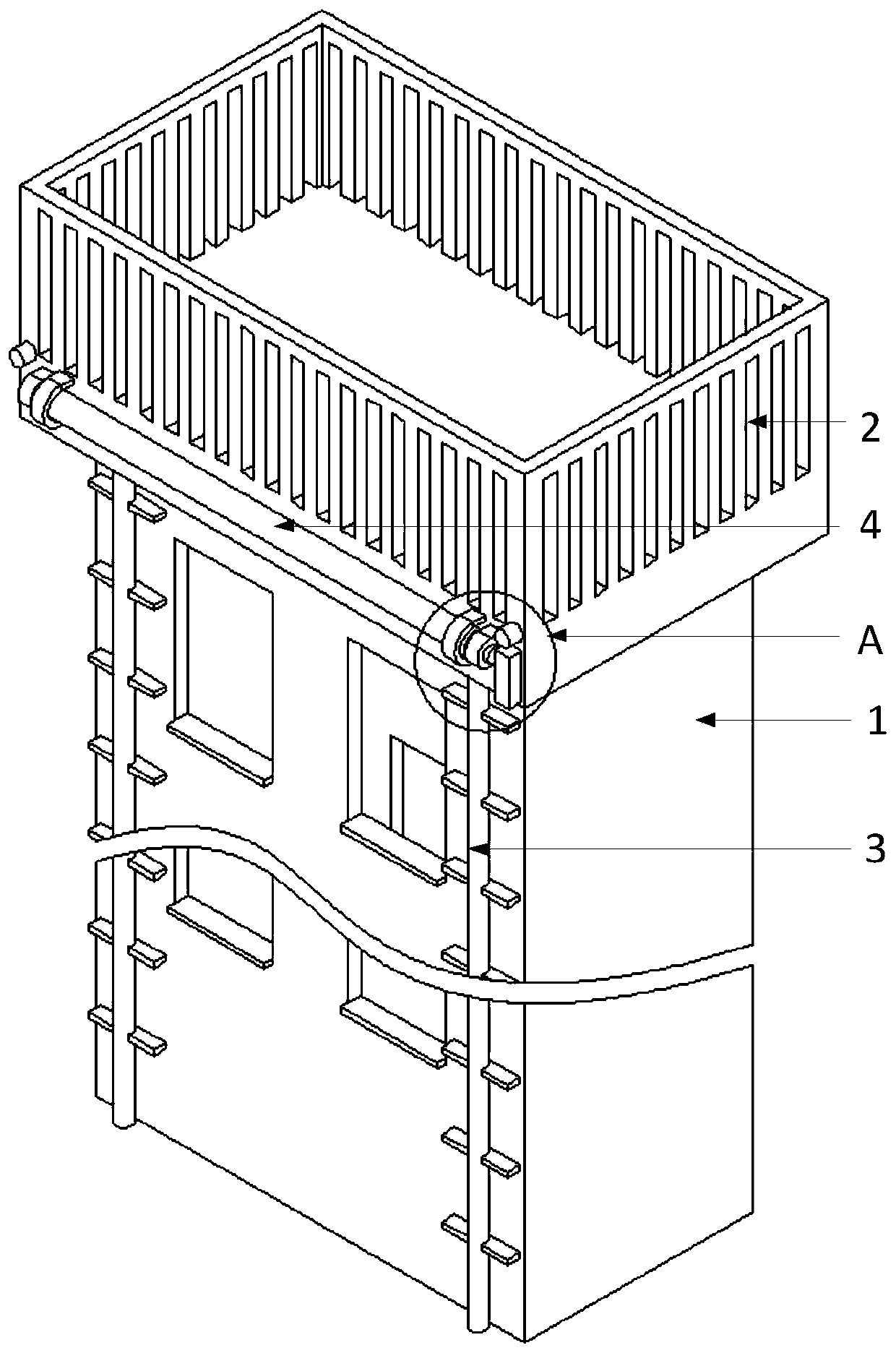

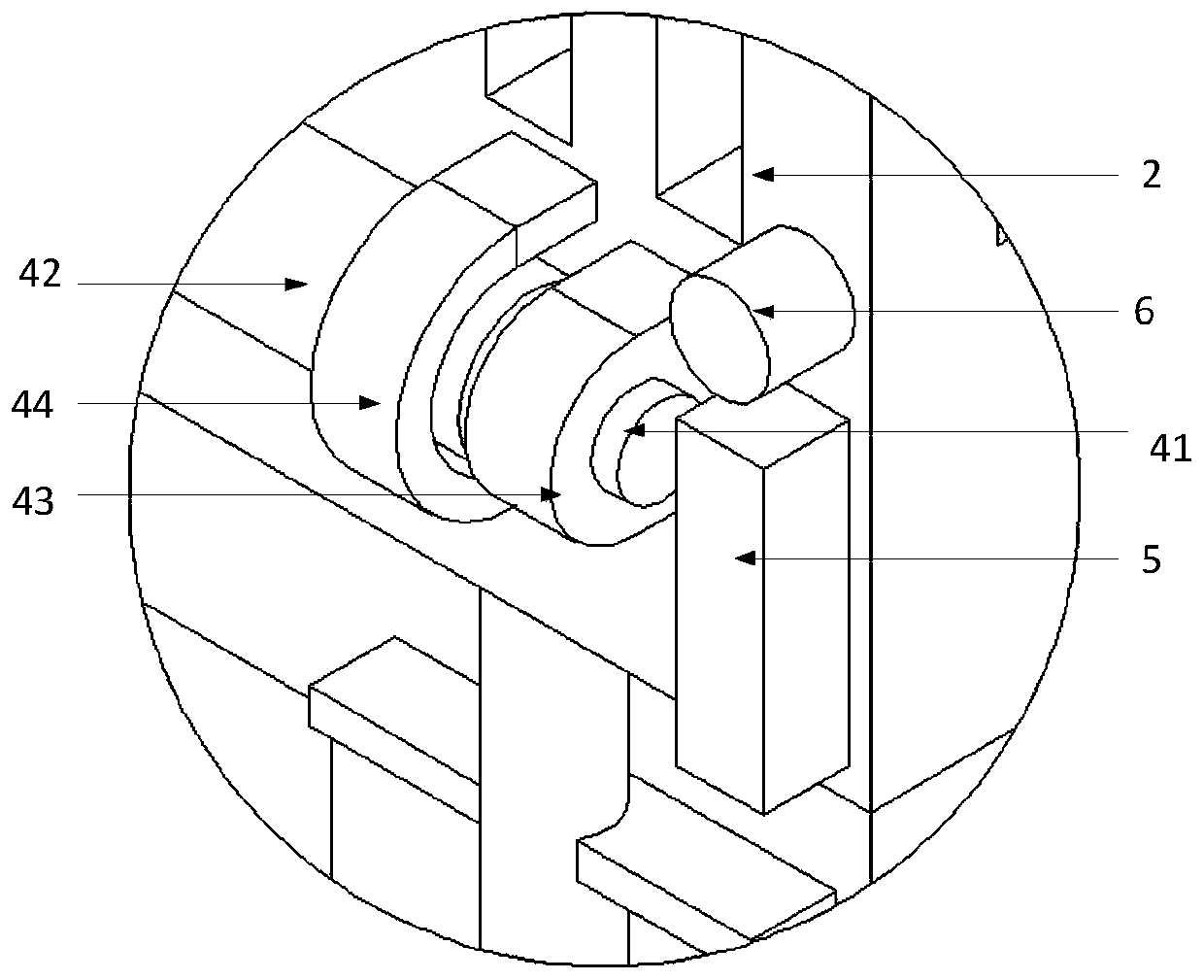

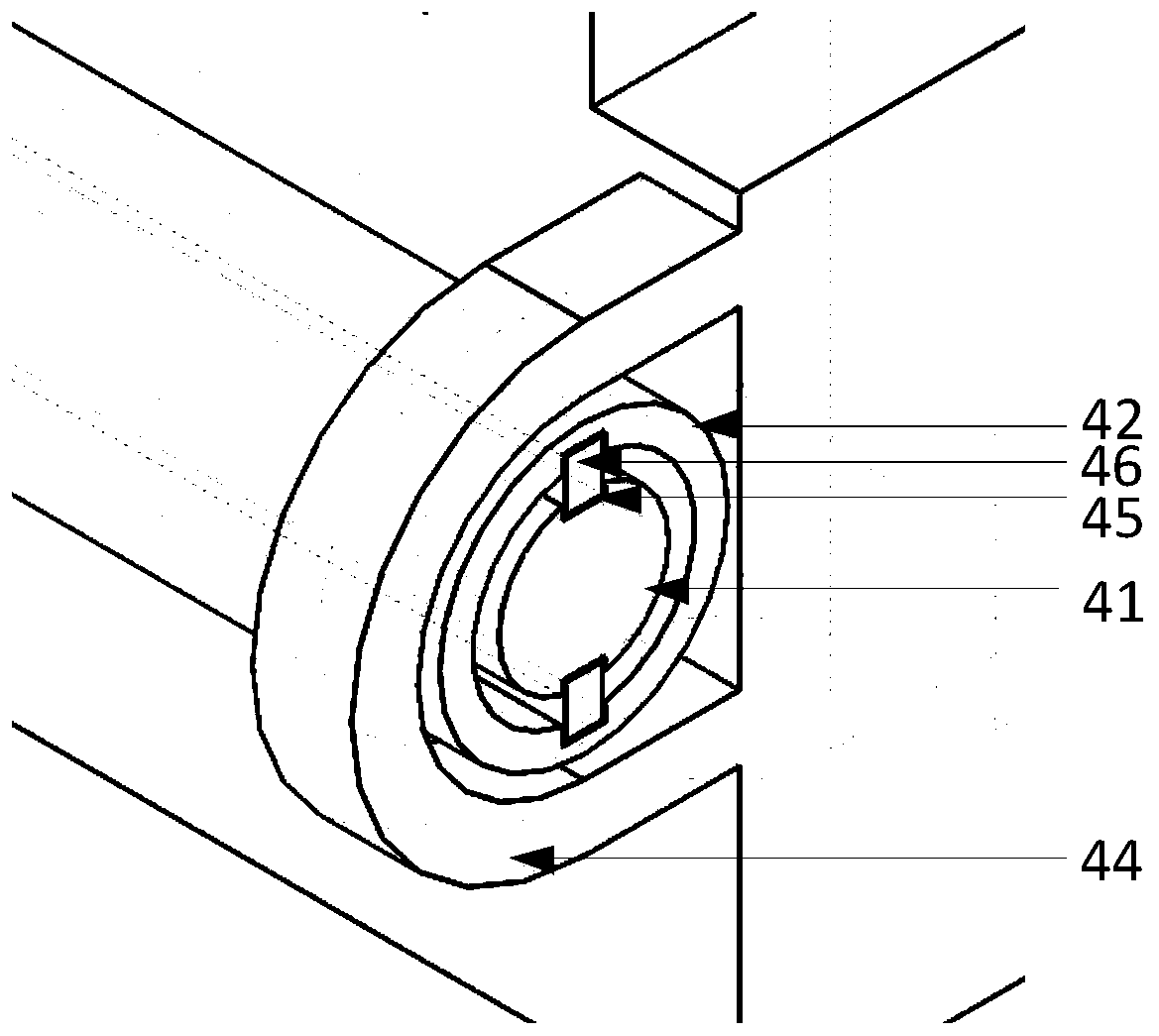

Rock climbing protection bar

PendingCN111249700ATake care of personal safetyImprove securitySport apparatusTowerMechanical engineering

The invention provides a rock climbing protection bar. The rock climbing protection bar comprises a tower main body, a tower platform, a climbing ladder and a rod body assembly, wherein the tower platform is arranged at the top of the tower main body, and the rod body assembly is horizontally arranged on the front side of the tower platform; the rod body assembly comprises an inner rod and an outer rod; first-stage brackets are arranged at the two ends of the inner rod correspondingly, and the inner rod is fixed to the tower platform through the first-stage brackets; the outer rod is of a hollow structure and sleeves the inner rod; the two ends of the outer rod are located on the inner side of the first-stage bracket; secondary-stage brackets are respectively arranged on the outer sides ofthe two ends of the outer rod and are fixedly connected with the tower platform; grooves are correspondingly formed in the upper end and the lower end of the outer surface of the inner rod and the upper end and the lower end of the inner surface of the outer rod and filled with limiting pins; pressure sensors are arranged between the limiting pins and the outer rod; the rod body assembly furthercomprises a control box and an alarm; and a microprocessor, a sampling circuit and a battery module are arranged in the control box. The rock climbing protection bar has the advantages of dual protection and excellent safety.

Owner:苏州诲爱系统科技有限公司

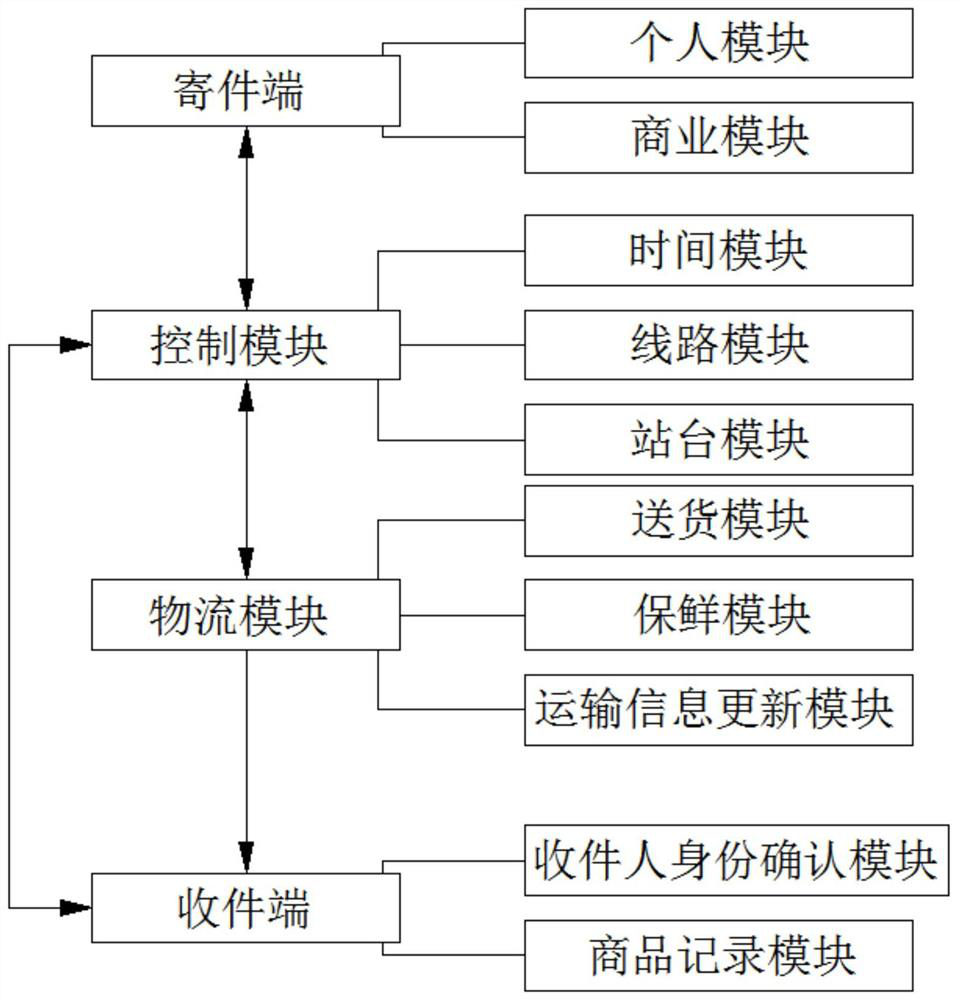

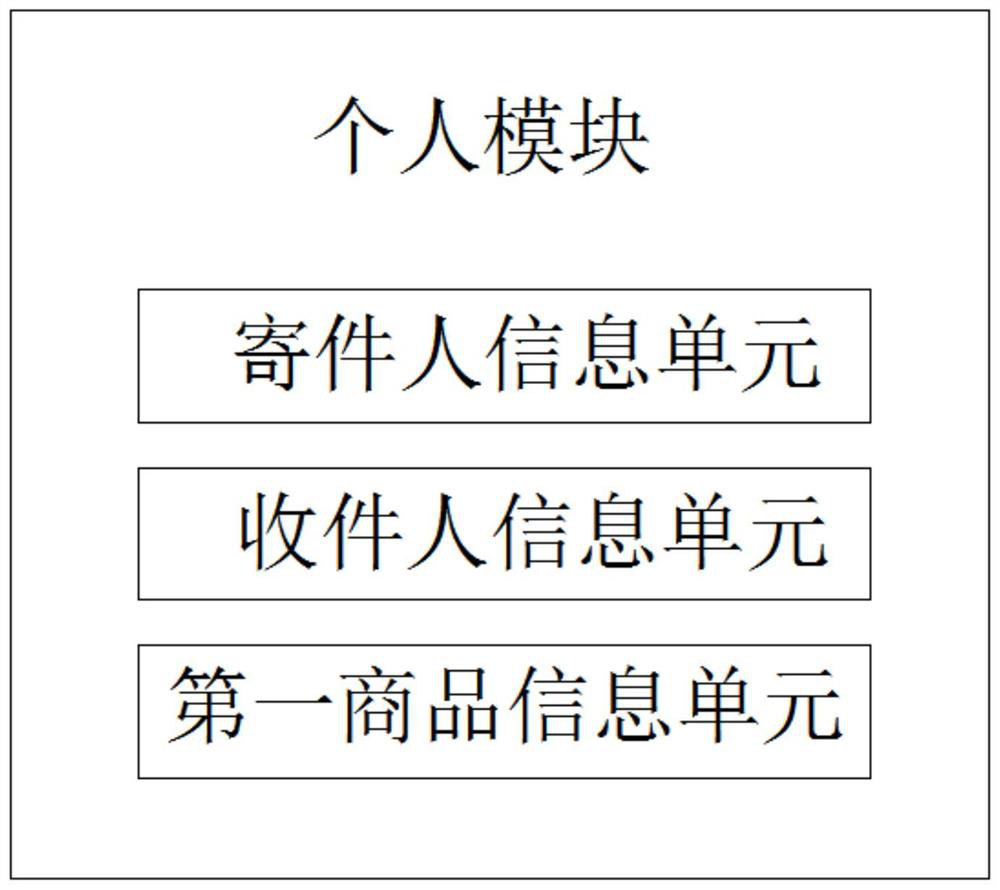

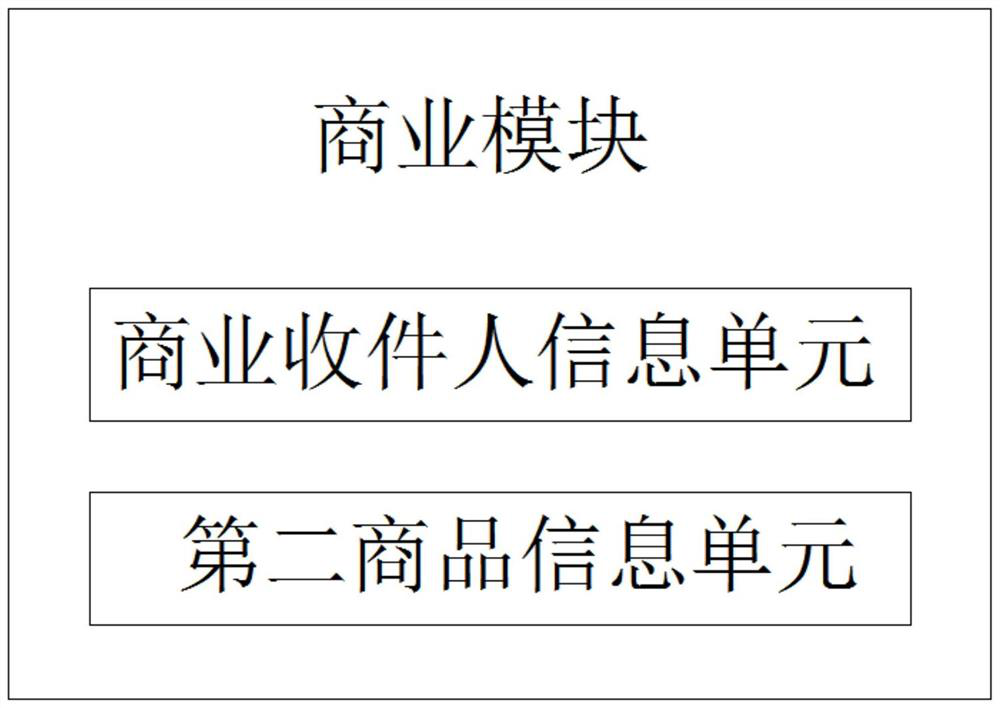

Intelligent fresh-keeping storage logistics system

PendingCN111861321ASave on shippingShorten the timeApparatus for meter-controlled dispensingLogisticsTransit lineEngineering

The invention provides an intelligent fresh-keeping storage logistics system. The intelligent fresh-keeping storage logistics system comprises: a sending terminal which is used for registering information of commodities by individuals and businesses and storing the commodities at sending positions by the individuals and the businesses; a control module which is used for recording time required bybus driving, recording a bus driving route and recording bus driving station conditions; and a logistics module which is used for storing the commodities and updating the transportation information intime. According to the intelligent fresh-keeping storage logistics system, an existing public transportation network is fully utilized to carry out goods conveying, the freight can be greatly reduced, a large amount of time consumed by passengers for bus line operation is effectively saved, the logistics cost is saved, convenience is brought to citizens, urban traffic pressure is reduced, traveling is reduced, goods can be taken only through operation of passwords or two-dimensional codes and mobile phone APPs during goods taking, and the goods safety is guaranteed.

Owner:练军荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com