Oxidative grinding preparation method and application of carbon group element simple material

A group element and elemental technology, applied in the field of oxidative grinding and preparation of carbon group element materials, can solve the problems affecting the efficiency and quality of batch preparation products, low capacity of battery anode materials, poor charge-discharge cycle performance, etc., and achieve excellent electrochemical performance. performance, excellent charge-discharge cycle performance, and the effect of reducing the energy consumption of ball milling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Single elemental silicon oxide material preparation method of grinding, comprising the steps of:

[0049] (1) Synthesis of precursors:

[0050] In an argon atmosphere glove box, in a 2: 1: Chemical Formula metered 1 obtained ratio of mixing metallic lithium, zinc, silicon simple substance mixture; mixture was sealed into the tantalum container, the tantalum container is placed in a vacuum environment to heating rate 200 ℃ / h heating to 600 ℃ incubated 3h, cooled to room temperature with the furnace; tantalum container is opened in an argon atmosphere glove box, the milled powder obtained by a solid phase reaction to the non-metallic luster; the powder after regrinding sealing the tantalum container, the tantalum metal is placed in a vacuum environment to / heating rate h, 200 ℃ heated to 770 deg.] C incubation for 4h, and the furnace was cooled to room temperature; under an inert gas atmosphere the tantalum container is opened, the solid phase reaction milled to obtain pow...

Embodiment 2

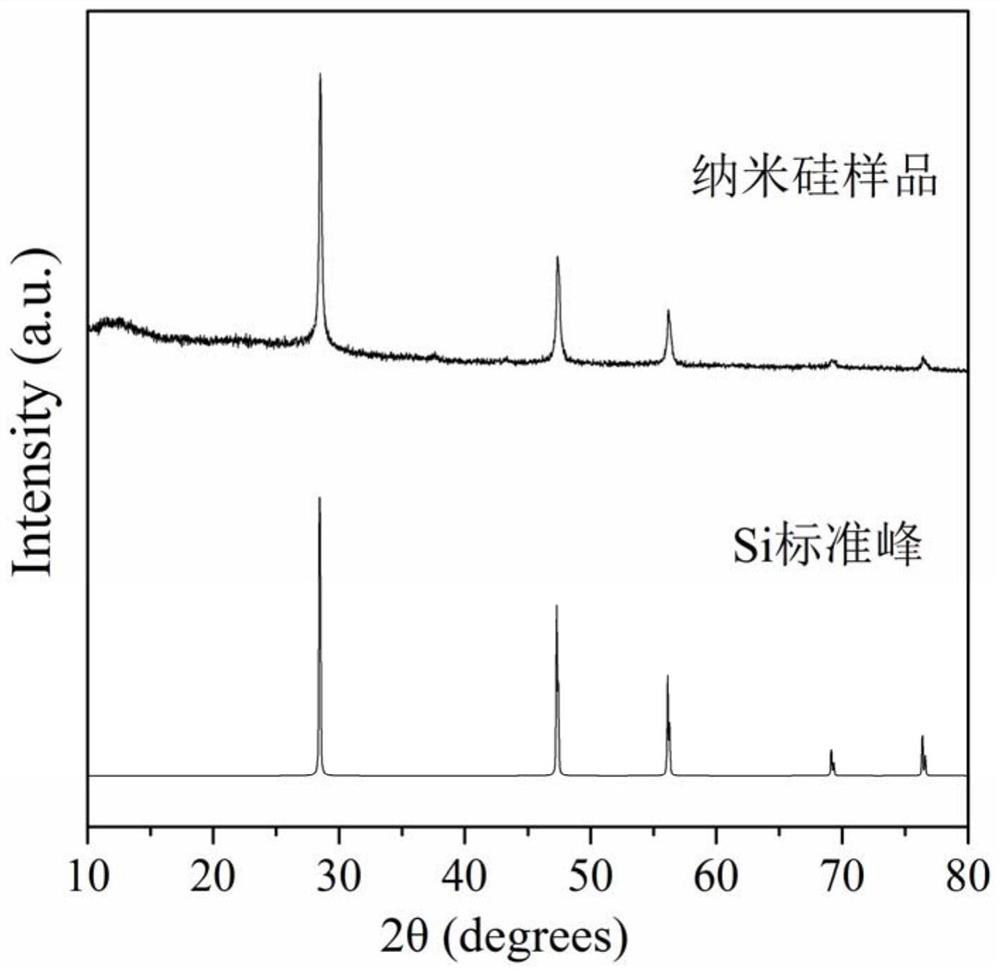

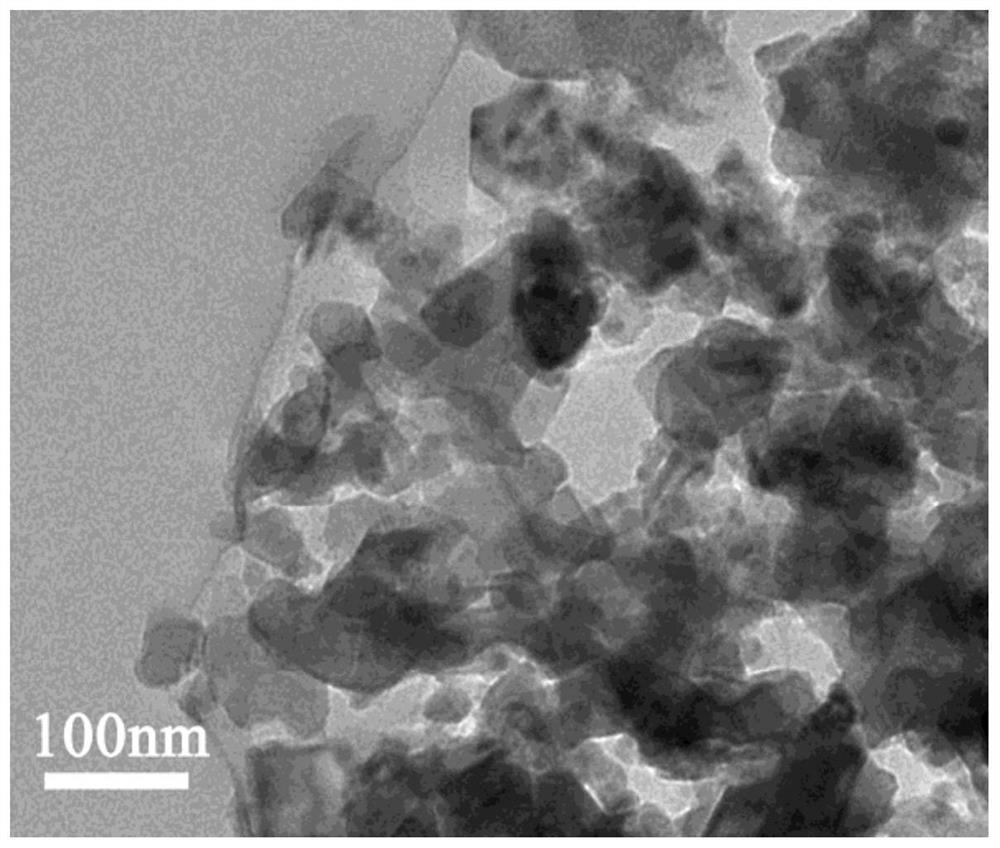

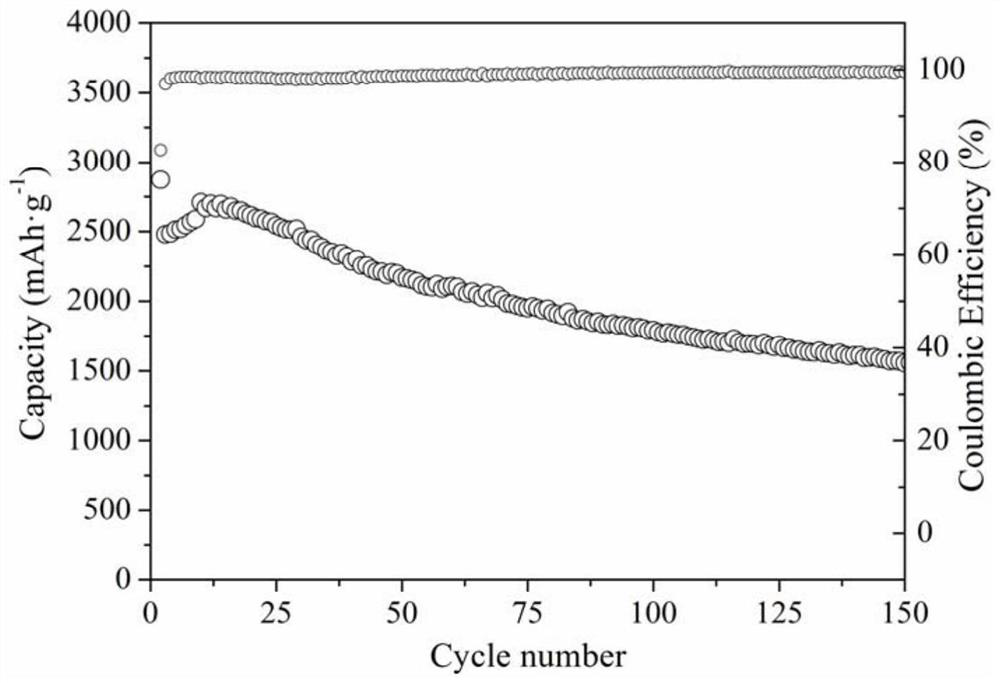

[0058] Nanometer silicon performance test

[0059] Preparation Example 1 nanometer silicon embodiment of the performance tests as an electrode material of a lithium battery. Nano-silicon, acetylene black, and a binder (sodium alginate) mass ratio of 6: 2: 2 ratio thoroughly mixed, the slurry viscosity adjusting solvent is added; the slurry with a doctor blade coated on a copper current collector; in vacuo an oven dried 100 ℃ vacuum 10H; 12mm in diameter was cut into a circular sheet battery anode; in a glove box for the lithium electrode sheet assembled coin half-cell electrolyte is 1.0mol LiPF6 / EC: DMC: DEC = 1: 1: 1Vol% with 10% FEC, 2% VC. The sealed battery was allowed to stand 24h, using Land (electric blue) Battery performance test battery system cycle performance test results as image 3 Indicated. Depend on image 3 Seen, the first ring nanometer silicon discharge capacity was 2870mAh · g -1 , The first lap coulombic efficiency was 82%, preferably the first charge-discharg...

Embodiment 3

[0061] As described in Example 1, except that: after completion of step (3), the samples in a vacuum of 10 -3 PA was heated at 3h, at 600 ℃ conditions, can be collected zinc metal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com