a security machine

A technology of security inspection machine and linkage mechanism, which is applied in the direction of conveyors, instruments, nuclear radiation exploration, etc., and can solve the problems of increasing use cost, affecting use, and reducing the use efficiency of security inspection machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

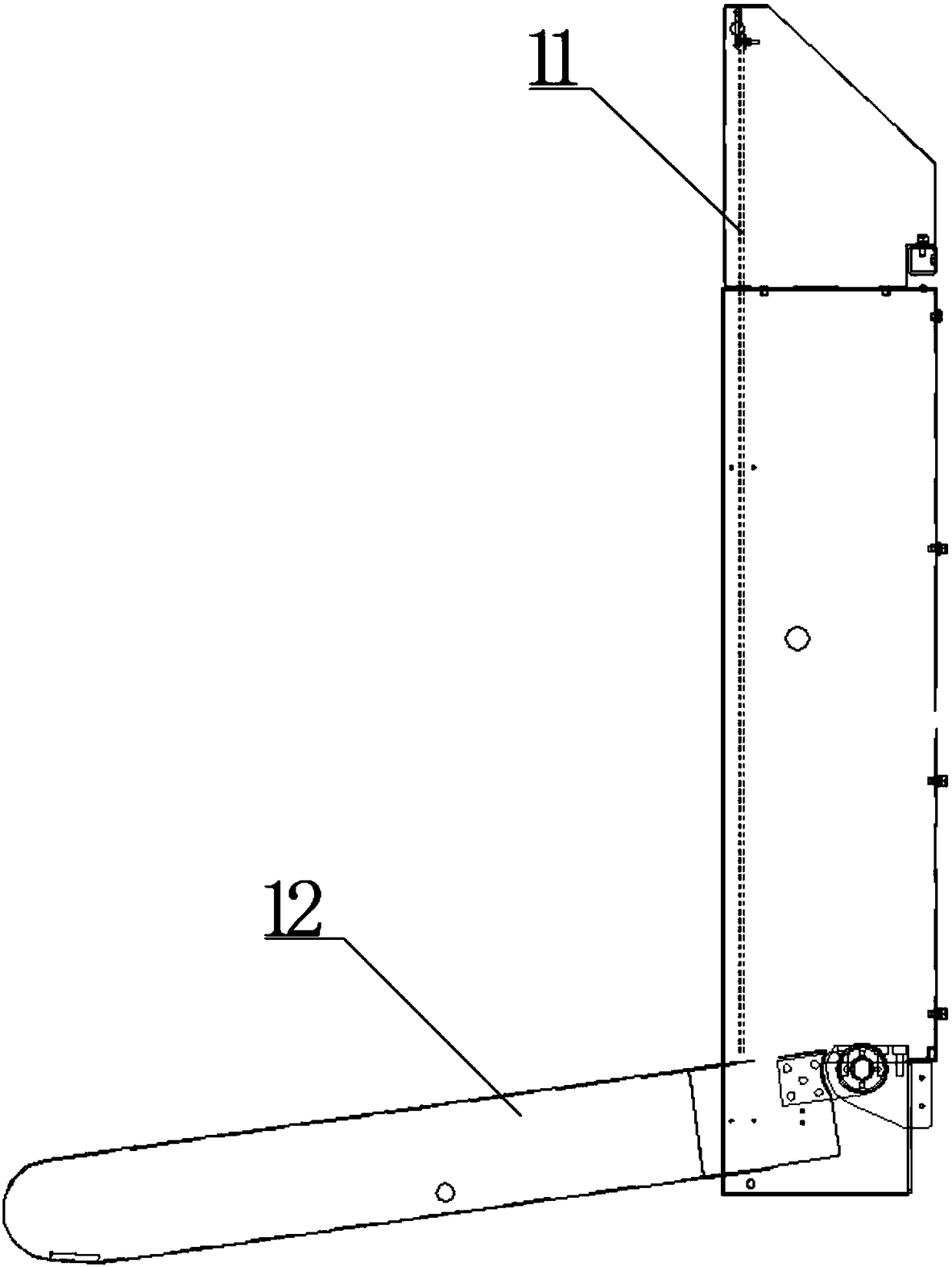

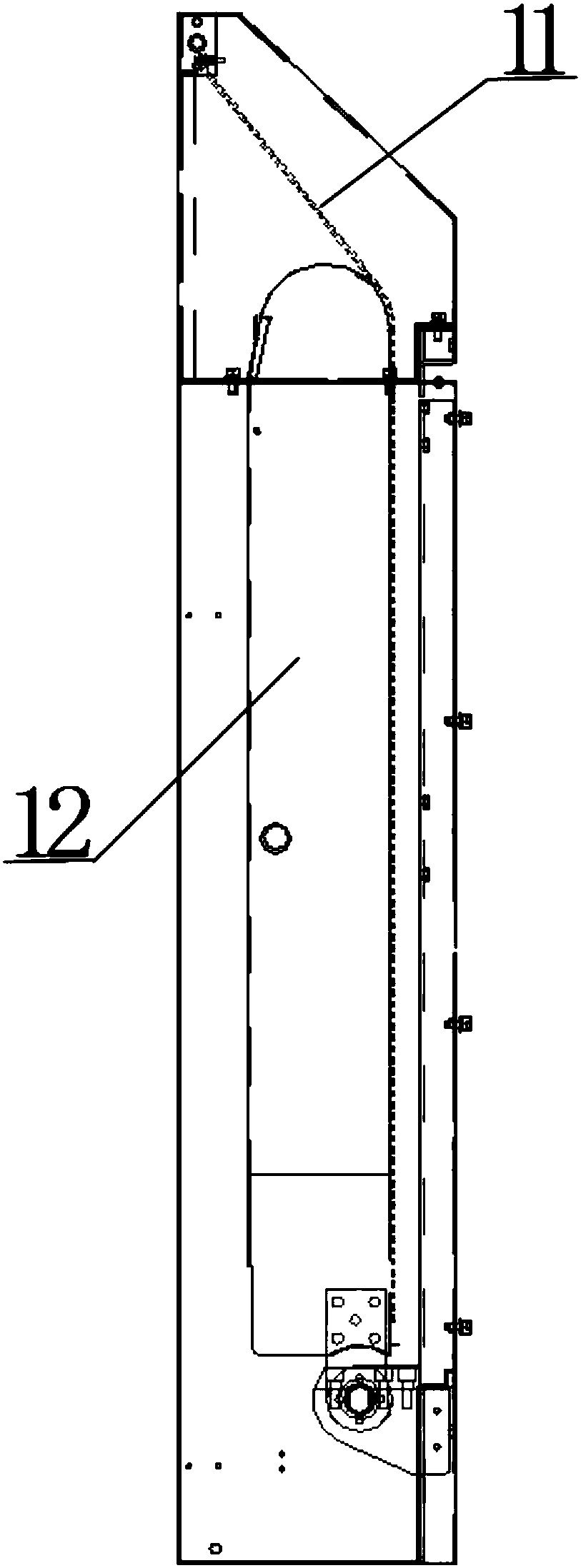

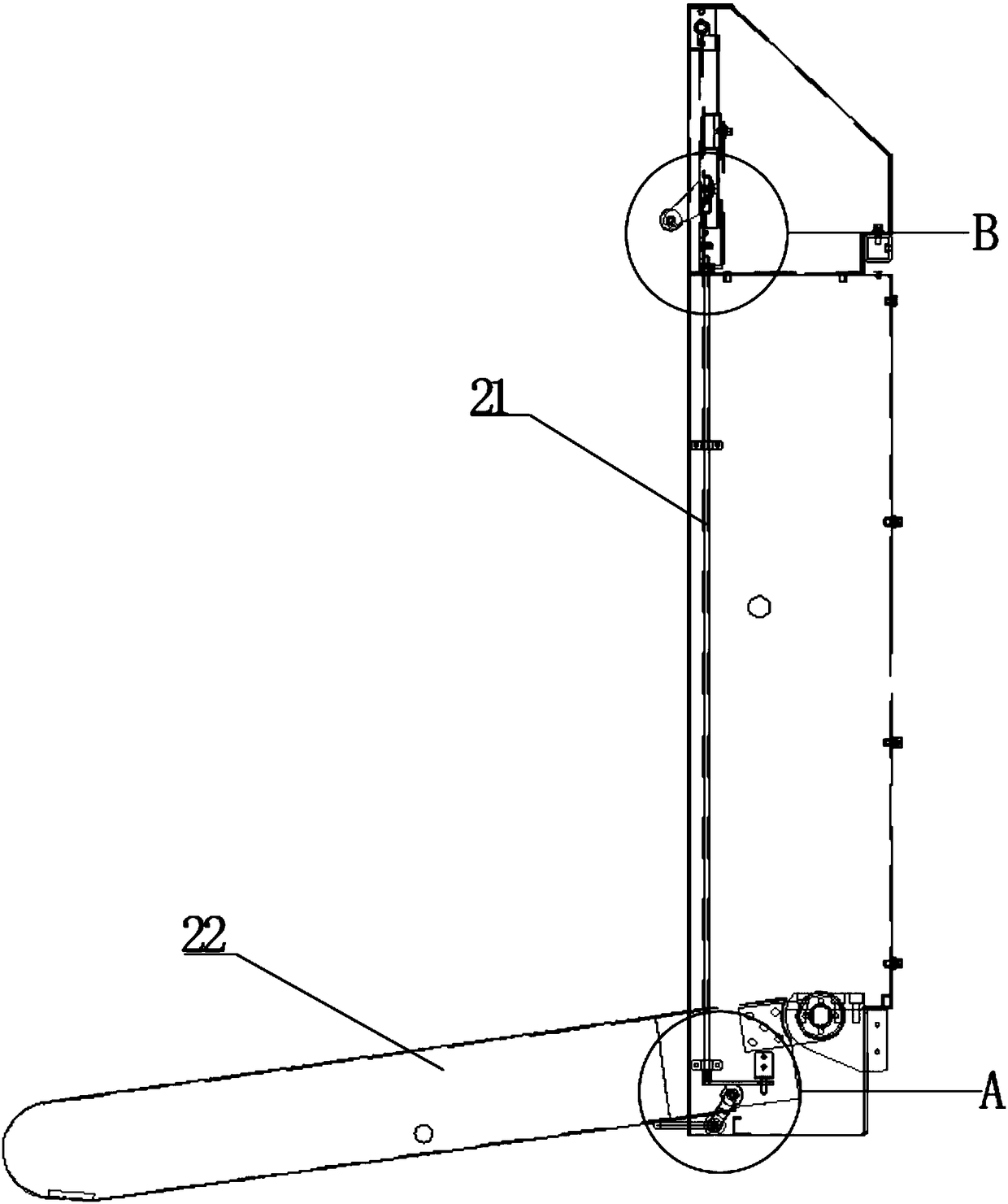

[0040] refer to figure 1 with figure 2 The current security inspection machine includes a shielding curtain 11 and a conveyor belt 12. The conveyor belt 12 can rotate between a working position that plays a role in transmission and a retracted position that is stored in the channel of the security inspection machine. The shielding curtain 11 is clamped and fixed by a steel plate and then hung on the Above the entrance of the security inspection machine. Wherein, it can be understood that the security inspection machine channel includes two channel openings, which are respectively used as the entrance and the exit of the security inspection machine channel. leakage.

[0041]Taking the vehicle-mounted security inspection machine as an example, the conveyor belt 12 is in the working position when it is parked and used. At this time, the shielding curtain 11 naturally droops under its own gravity and is in a vertical state, covering the channel opening of the security inspectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com