Liquid alkyd resin and preparation method thereof

An alkyd resin, liquid technology, applied in the field of liquid alkyd resin and its preparation, can solve the problems of high production cost, increased production cycle, potential safety hazards, etc., and achieves the effects of simple production process, easy operation, and pollution avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

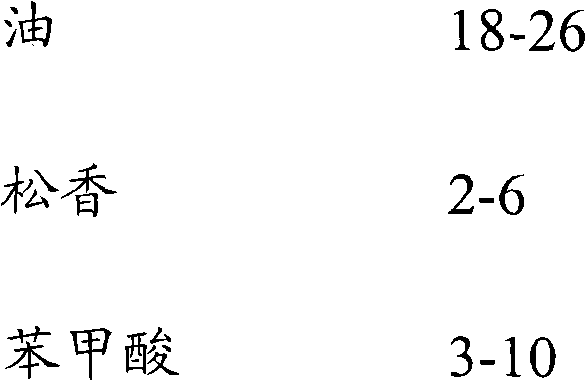

[0046] Embodiment one: making alkyd resin comprises following raw material by weight parts, makes alkyd resin finished product by polyesterification reaction:

[0047]

Embodiment 2

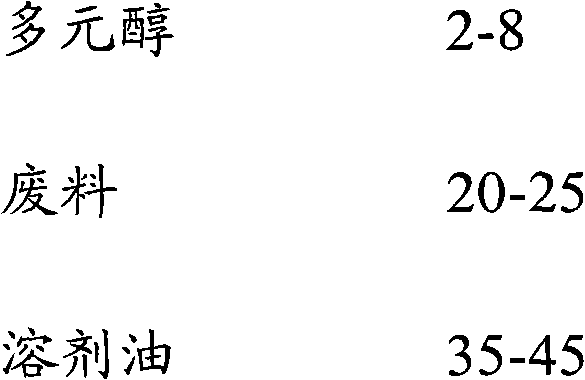

[0048] Embodiment two: making alkyd resin comprises following raw material by weight parts, makes alkyd resin finished product by polyesterification reaction:

[0049]

Embodiment 3

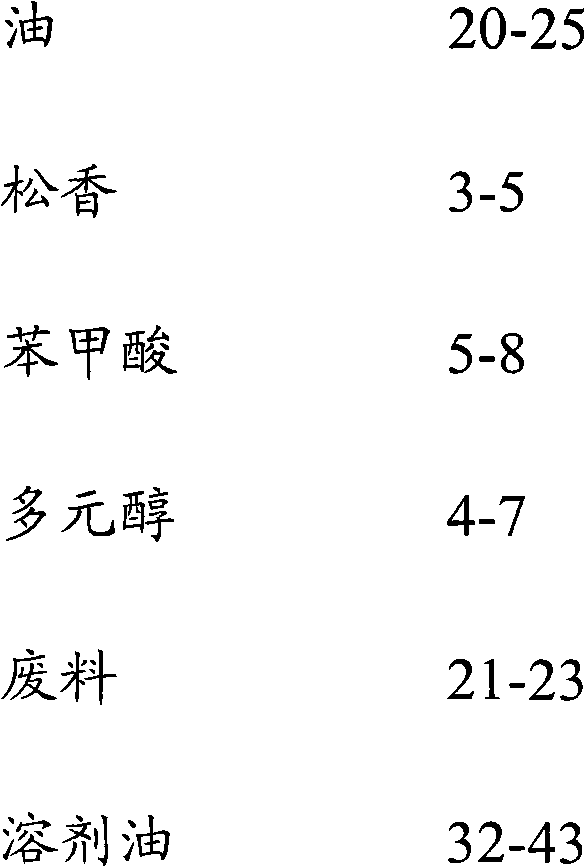

[0050] Embodiment three: making alkyd resin comprises following raw material by weight, makes alkyd resin finished product by polyesterification reaction:

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com